Patents

Literature

100results about How to "Stacking Accurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

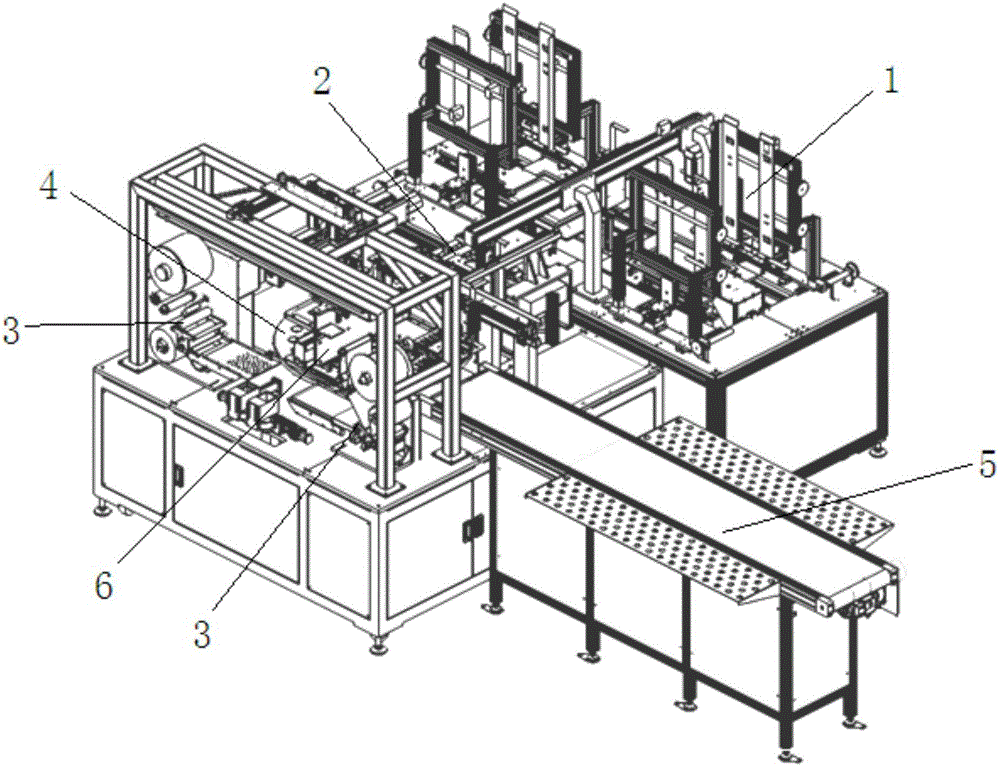

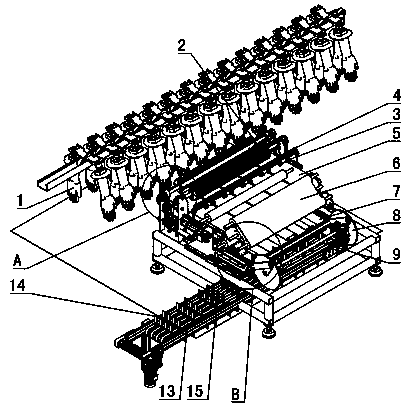

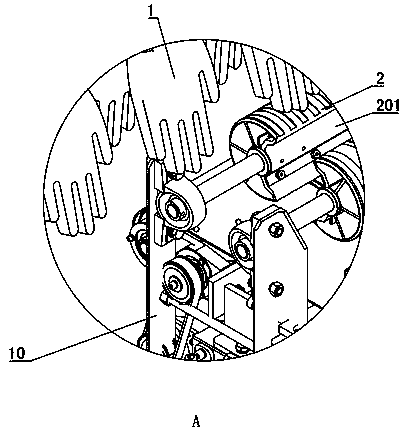

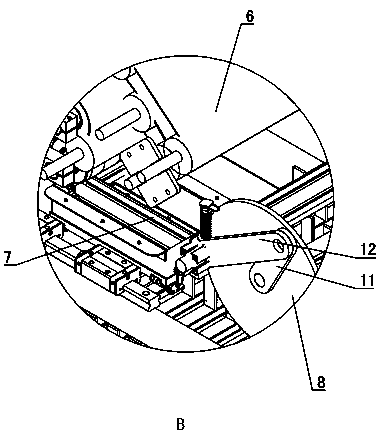

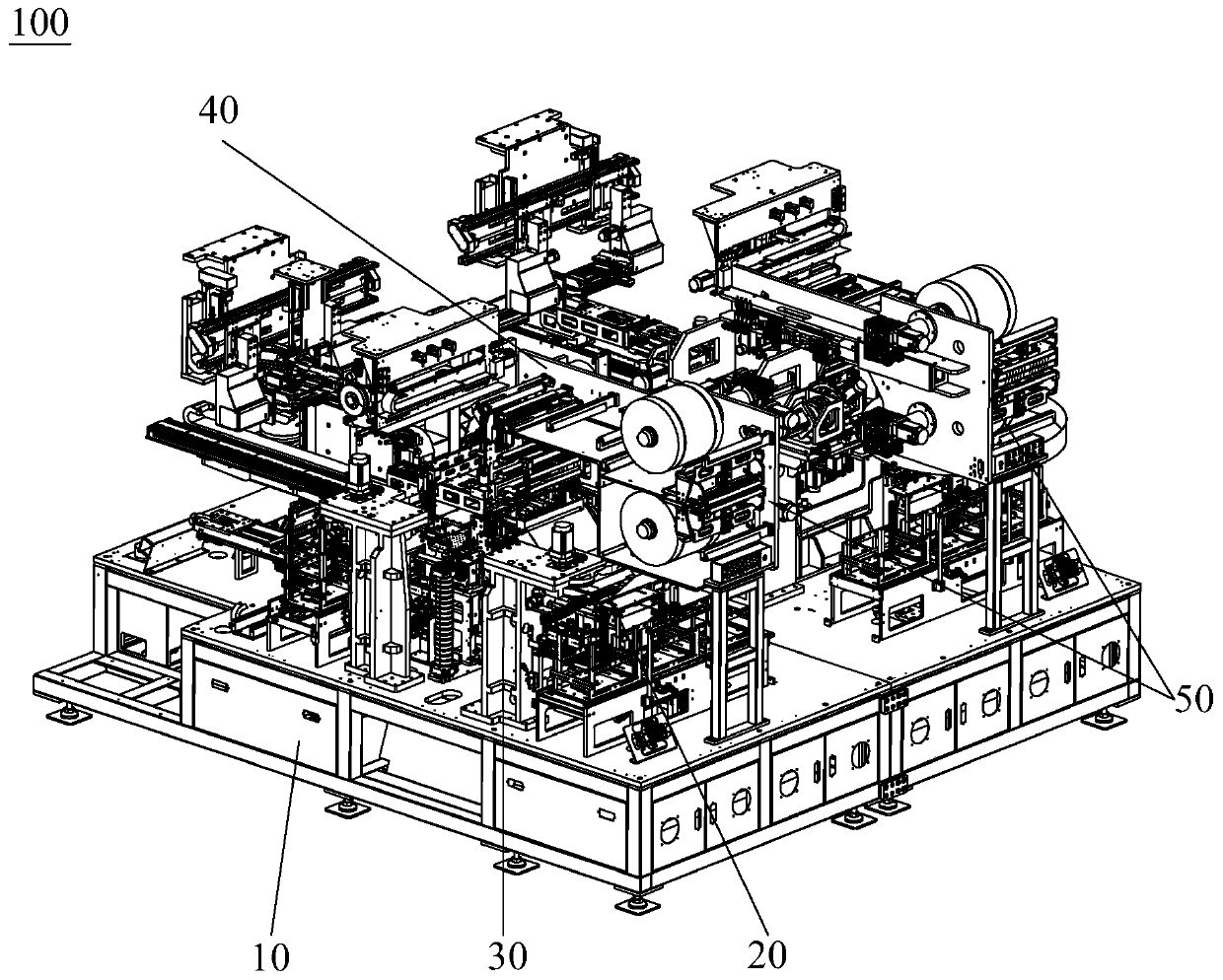

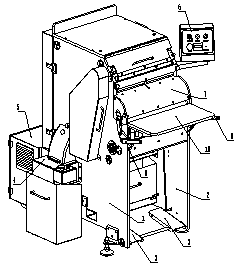

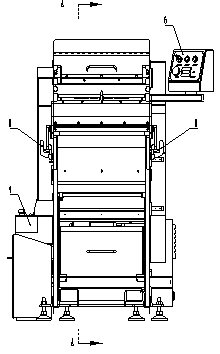

Automatic film sticking machine

ActiveCN106428746AFast and effective film applicationImprove the efficiency of automatic film applicationPackagingEngineeringElectrical and Electronics engineering

The invention discloses an automatic film sticking machine. The machine comprises an automatic feeding mechanism, a pre-positioning mechanism, a film sticking automatic stripping mechanism, a film sticking station conversion mechanism, an automatic film sticking mechanism and a finished product output mechanism; according to the automatic feeding mechanism, an element to be subject to film sticking is taken out and conveyed to the pre-positioning mechanism, the pre-positioning mechanism carries out position pre-adjustment on the element to be subject to film sticking, the element to be subject to film sticking and position pre-adjustment is placed on the film sticking station conversion mechanism, the automatic film sticking mechanism enables a sticking film stripped from the film sticking automatic stripping mechanism to be pasted and covered on the element to be subject to film sticking on the film sticking station conversion mechanism, and the element subject to film sticking is output through the finished product output mechanism for quality inspection. The automatic film sticking machine can be suitable for single-layer or multi-layer rapid effective film sticking, full-automatic feeding, cleaning, sticking film stripping, sticking film absorbing and film sticking are achieved, time and labor are saved, the automatic film sticking efficiency is improved, the film sticking yield is high, and the good application prospect is achieved.

Owner:JIANGSU BVM INTELLIGENT TECH

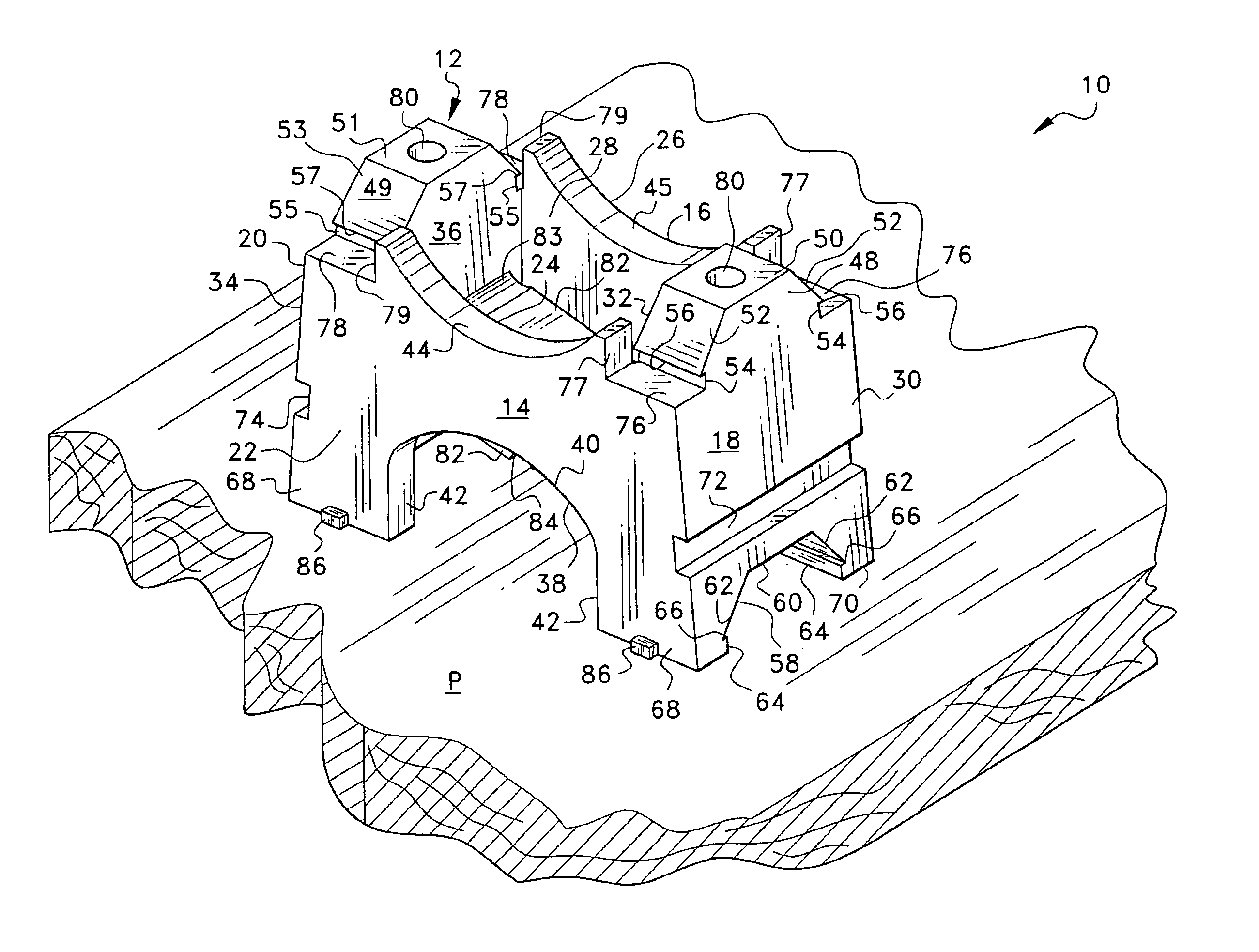

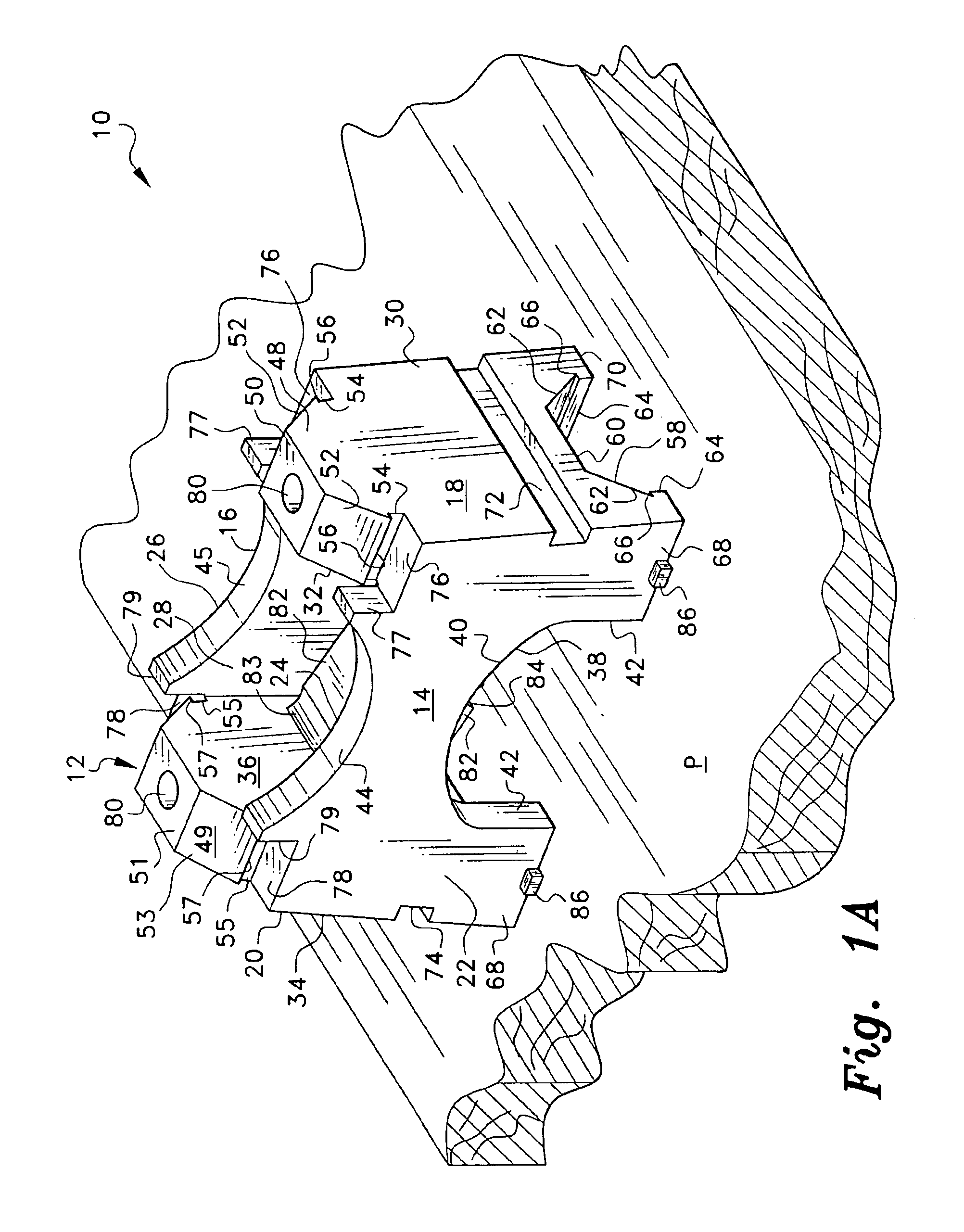

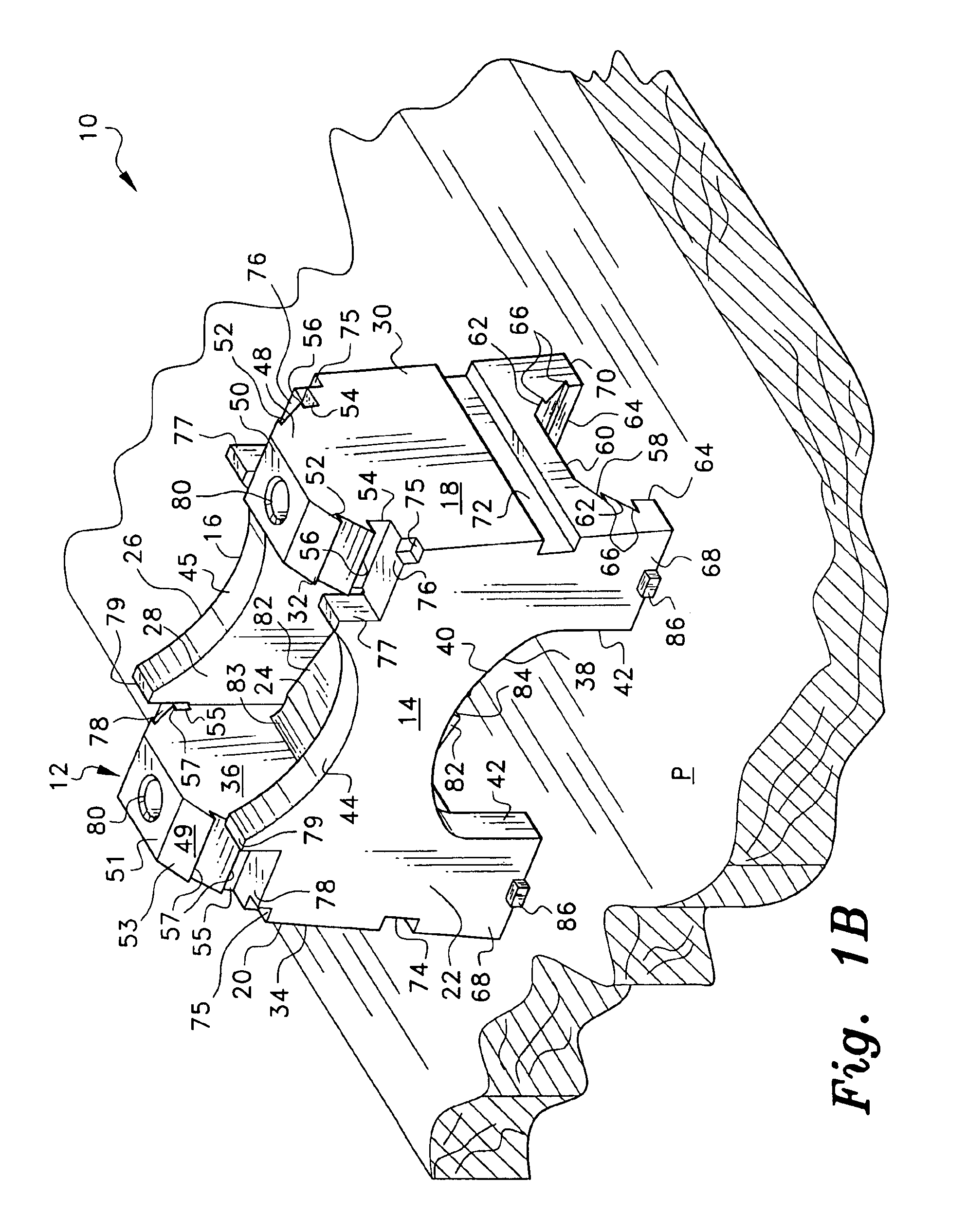

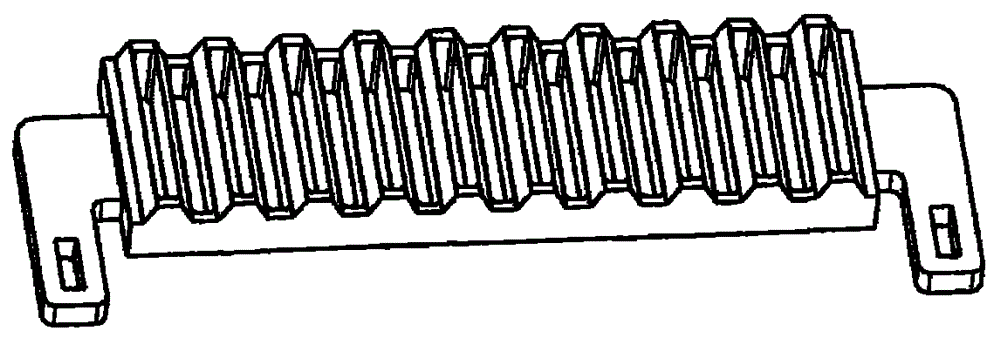

Cable to frame fastener system

A fastener system for securing cable, conduits, pipes, etc., to frames. The fasteners are stackable such that multiple cable may be individually secured in a co-linear route above the wood frame. The system comprises of identical plastic securing blocks, each in the form of a bridge that provides for cables to be nested together, one atop the other. The first or bottom securing block may be nailed or stapled to the wood frame, and the additional fasteners are designed to snap together in a stacked fashion. Several of the plastic securing blocks may be molded together to form a magazine which may be used in an application tool or by hand.

Owner:BRANDZEL MICHAEL +1

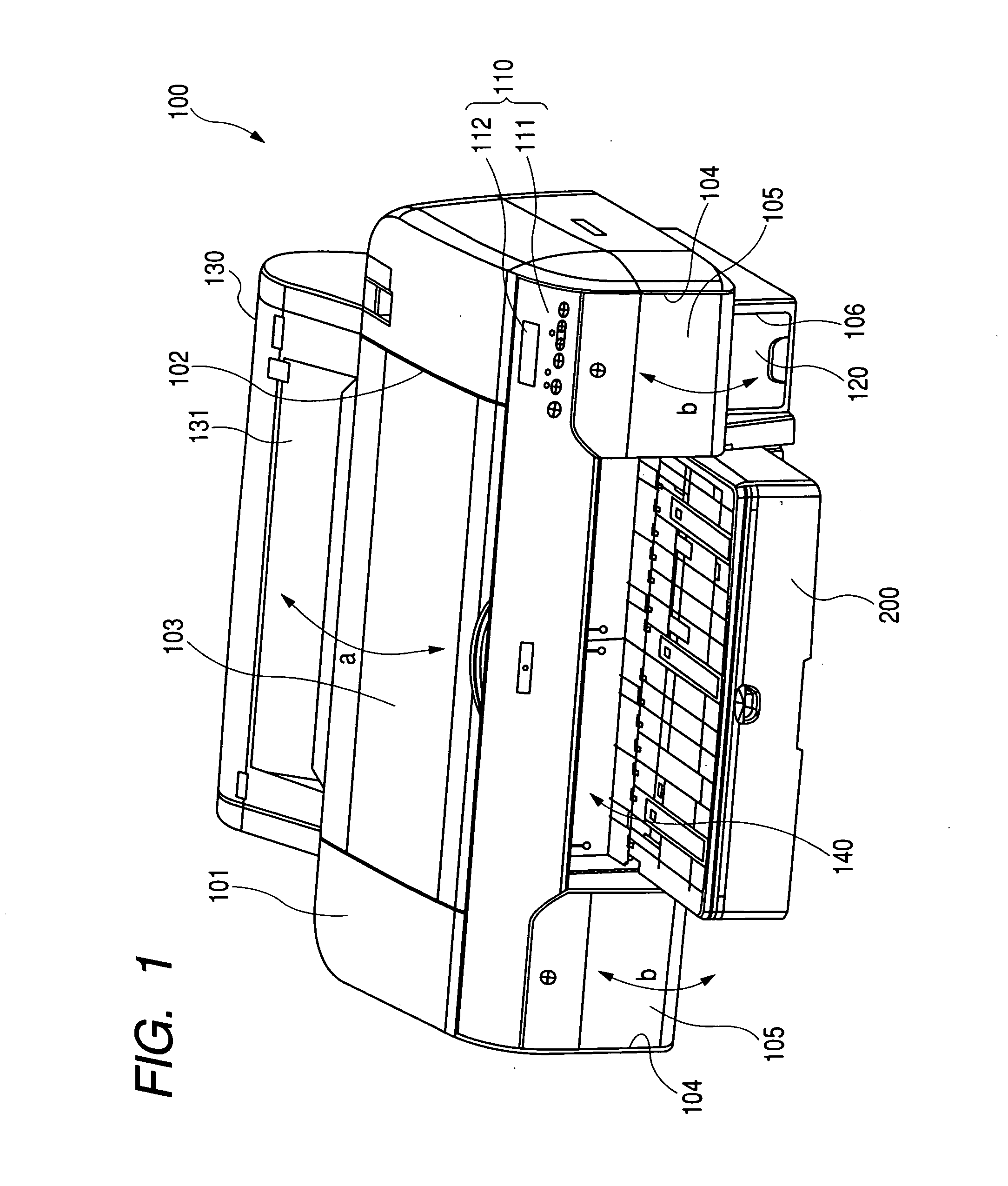

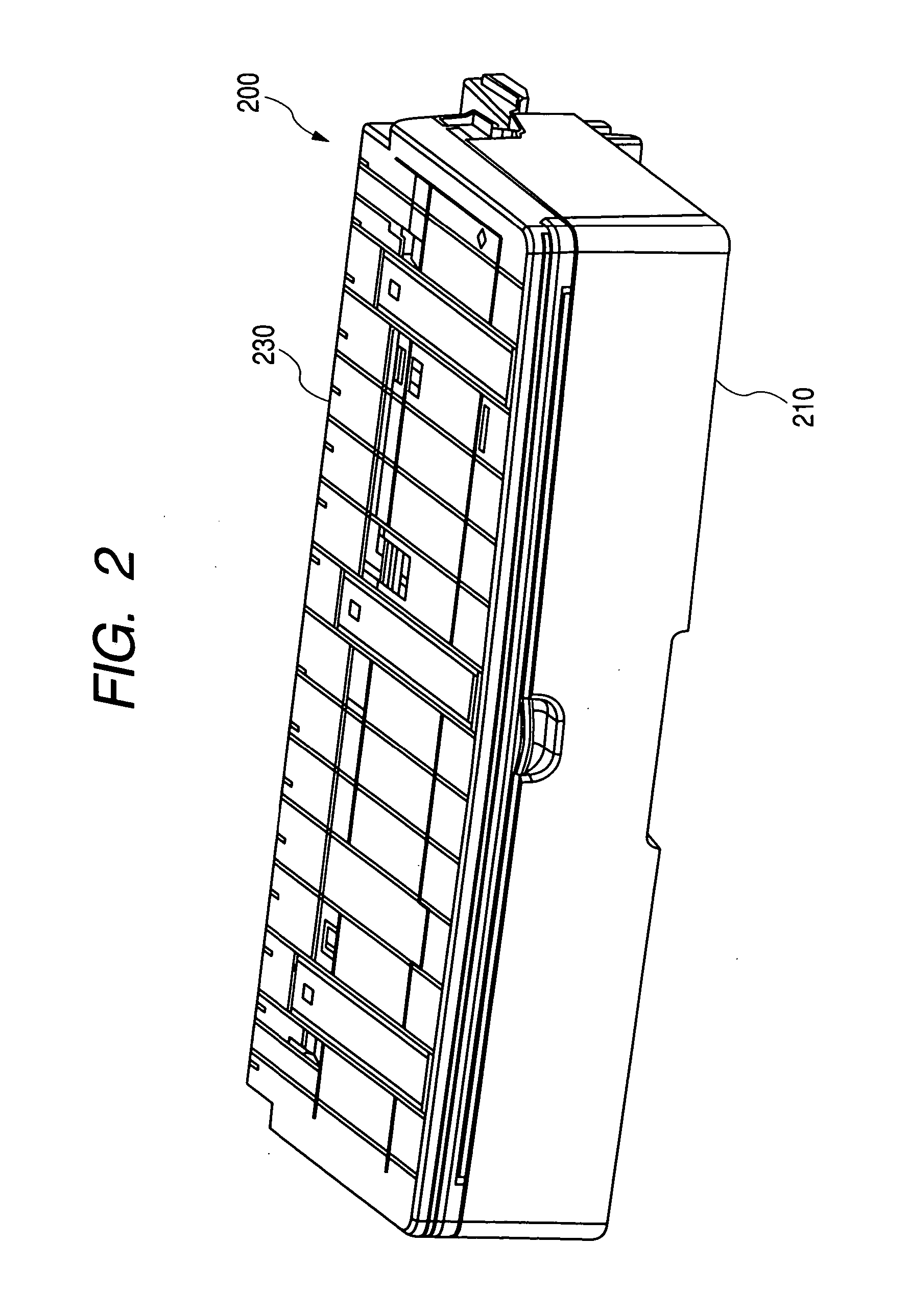

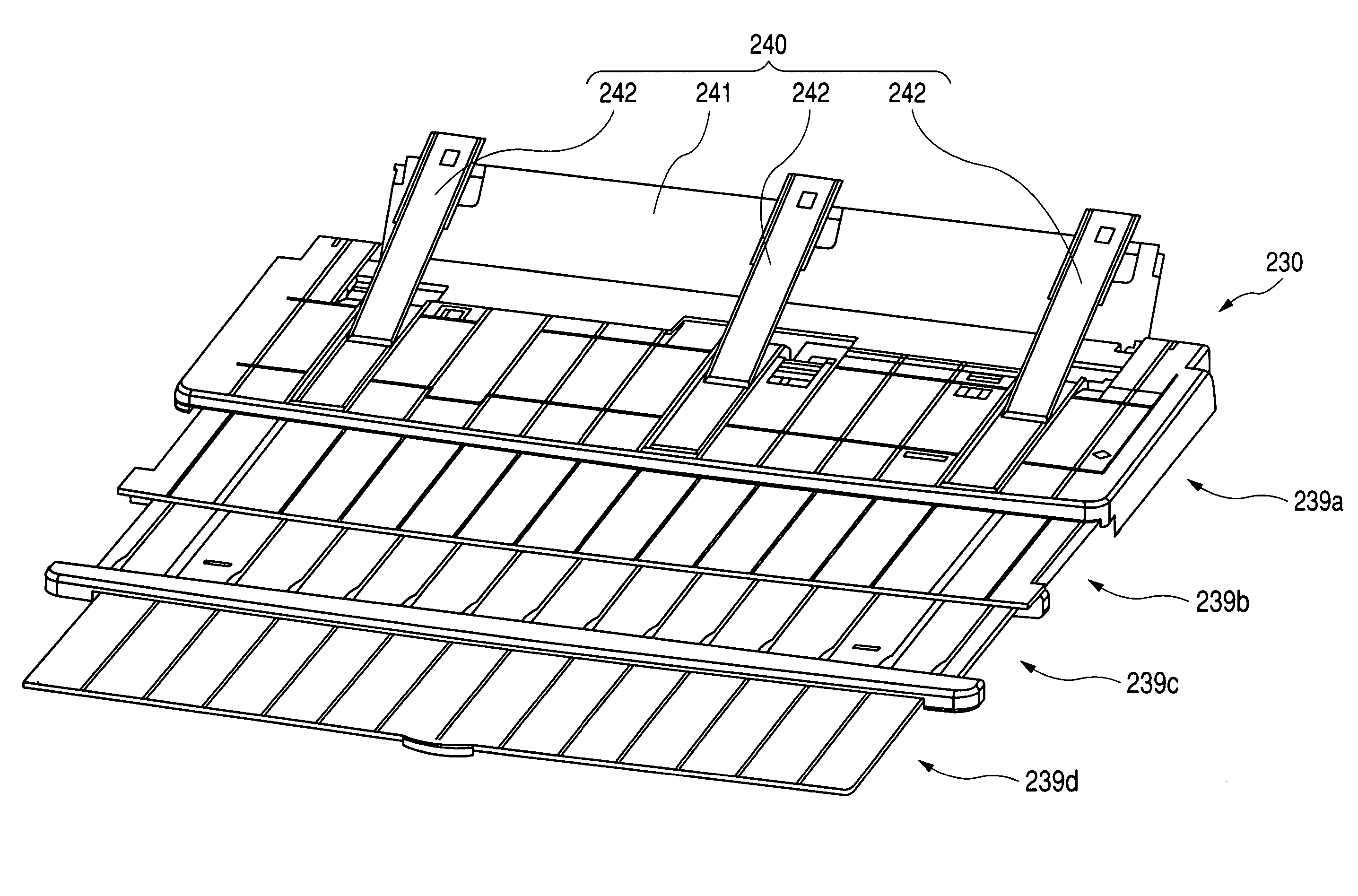

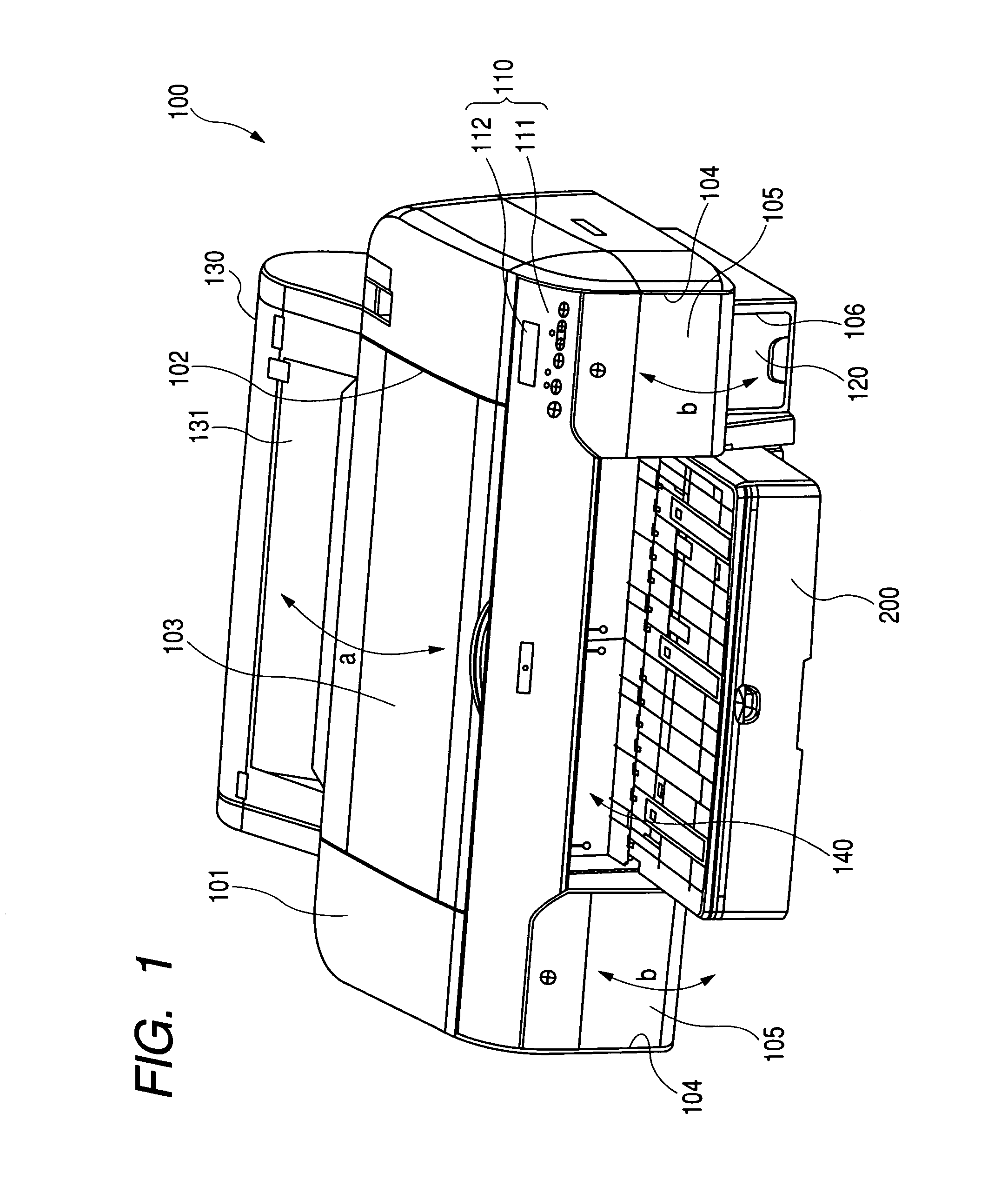

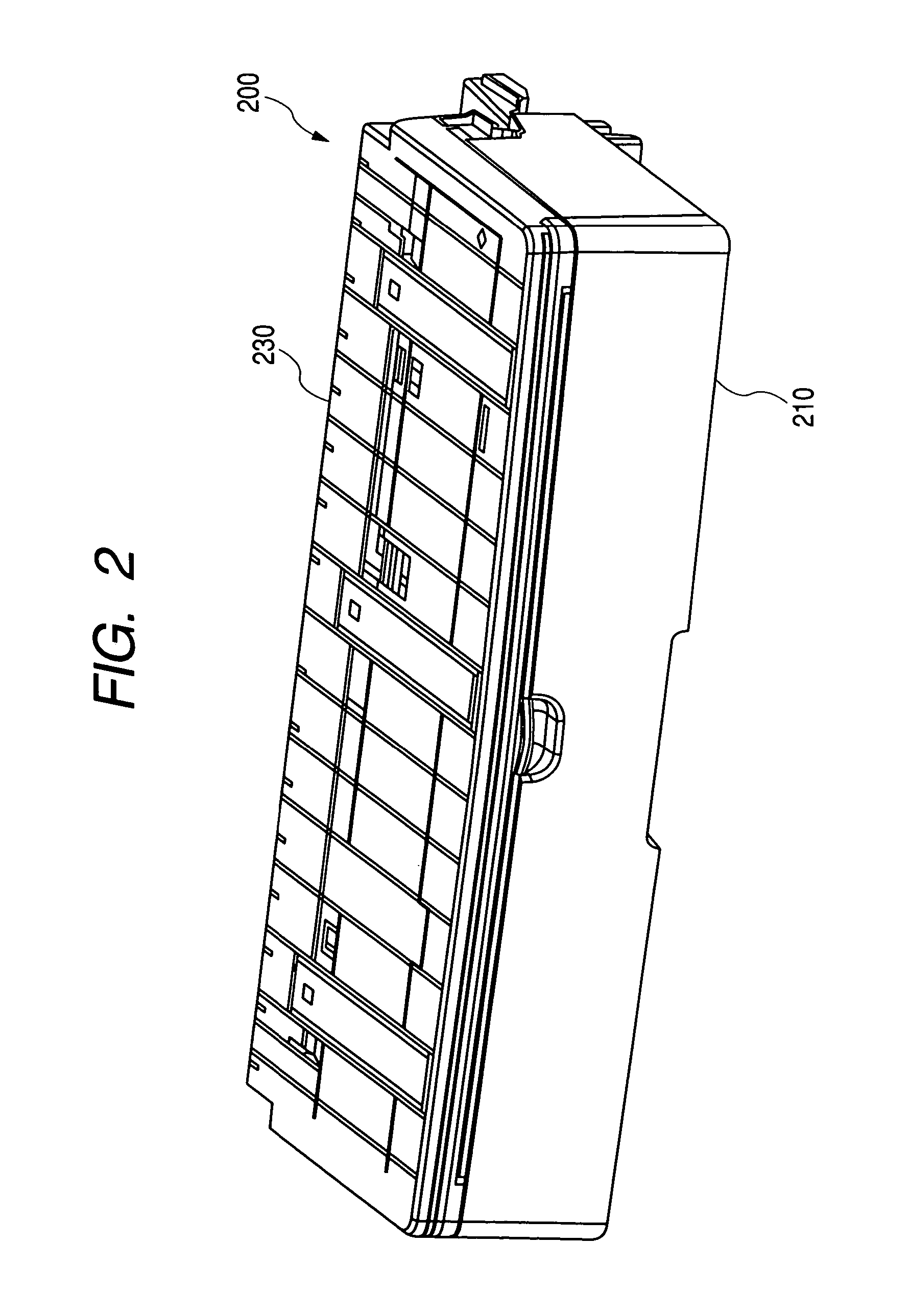

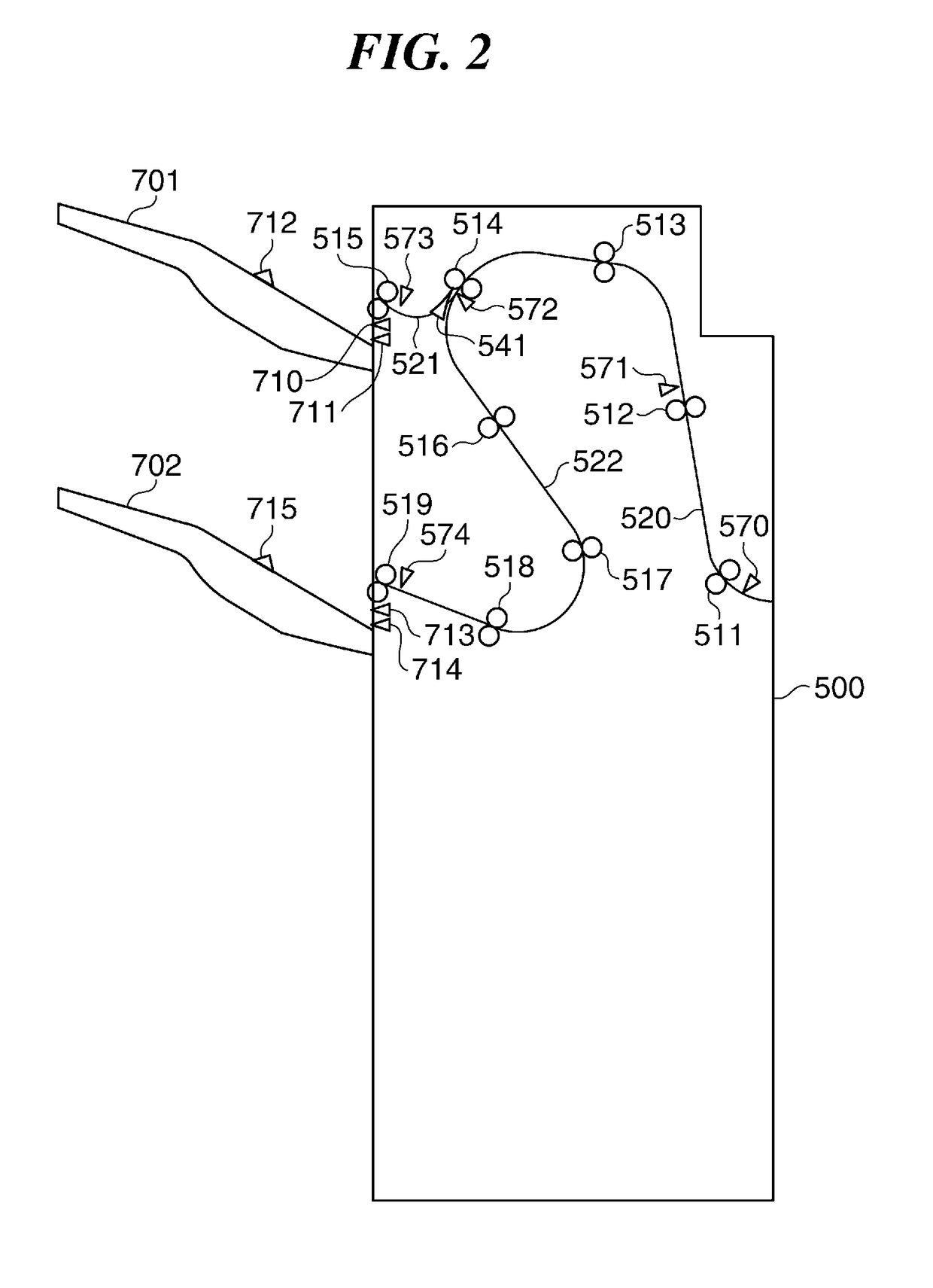

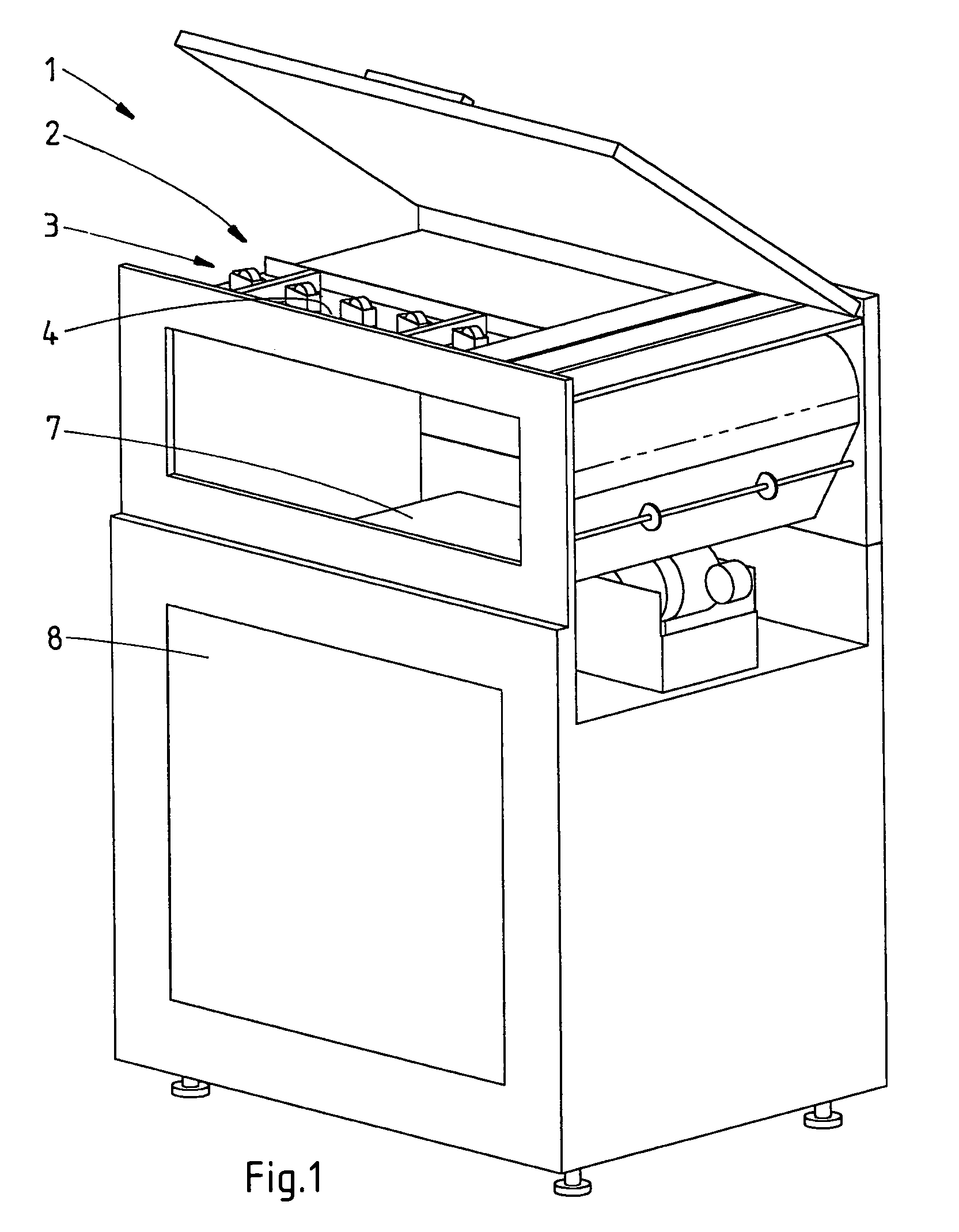

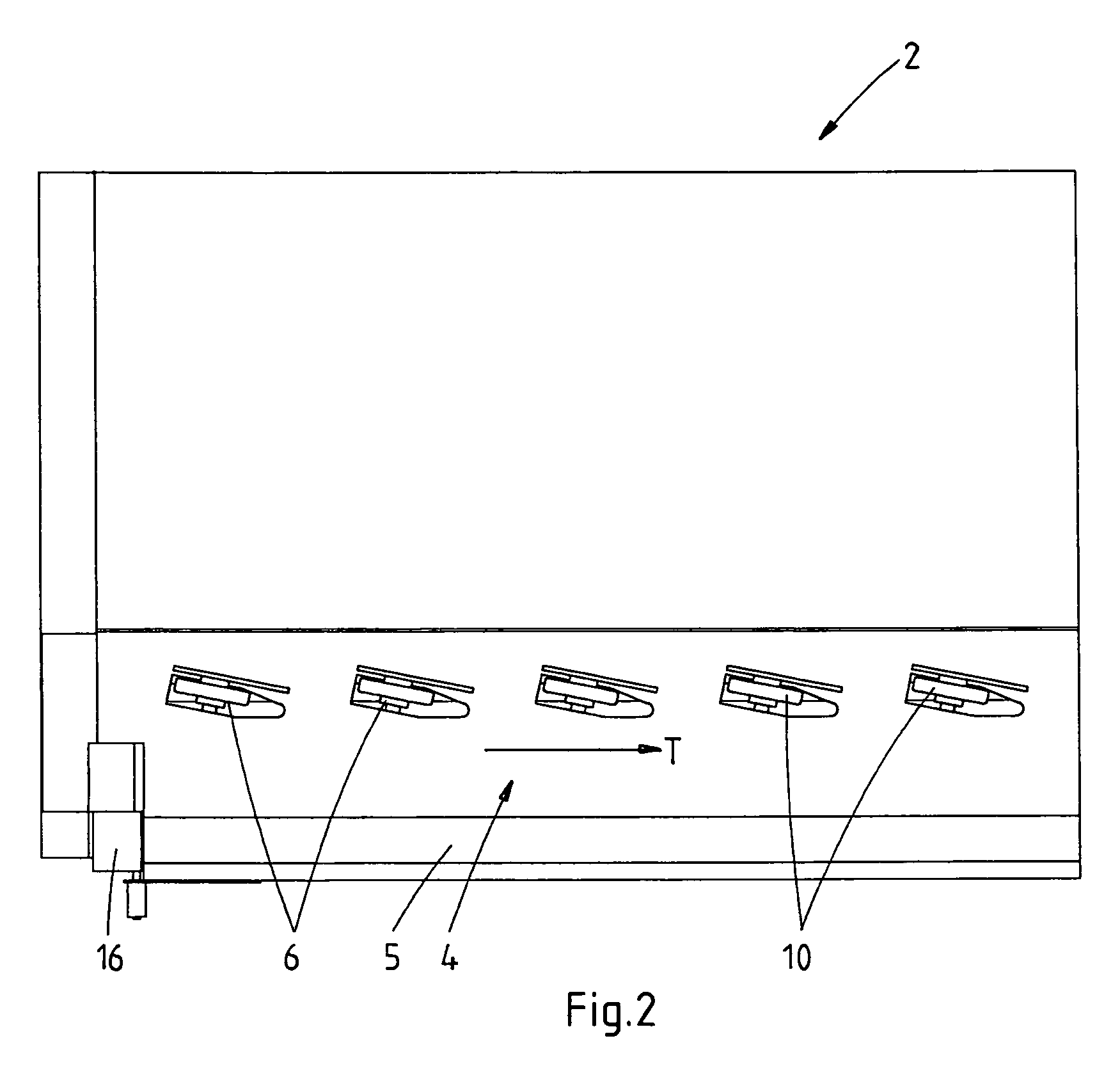

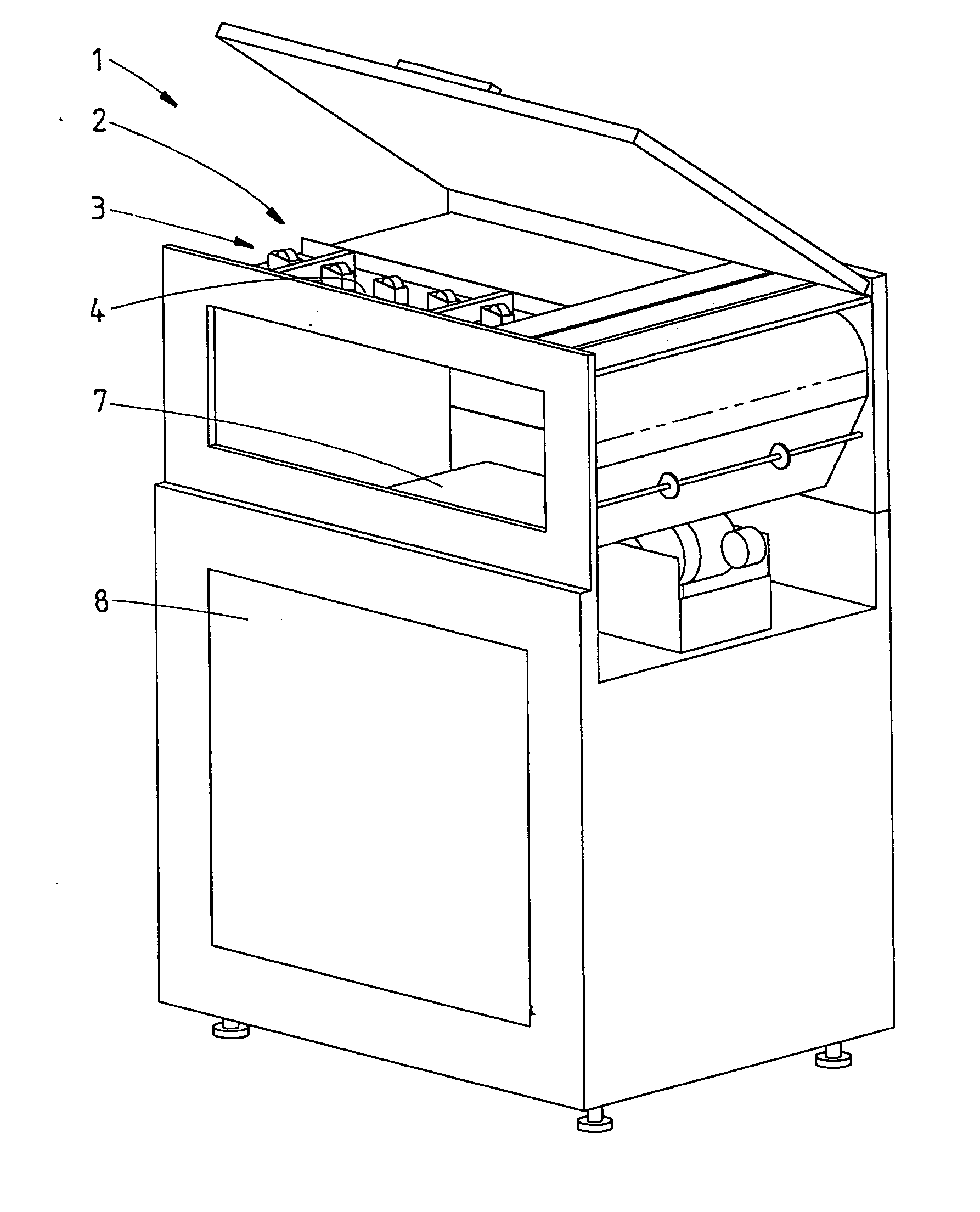

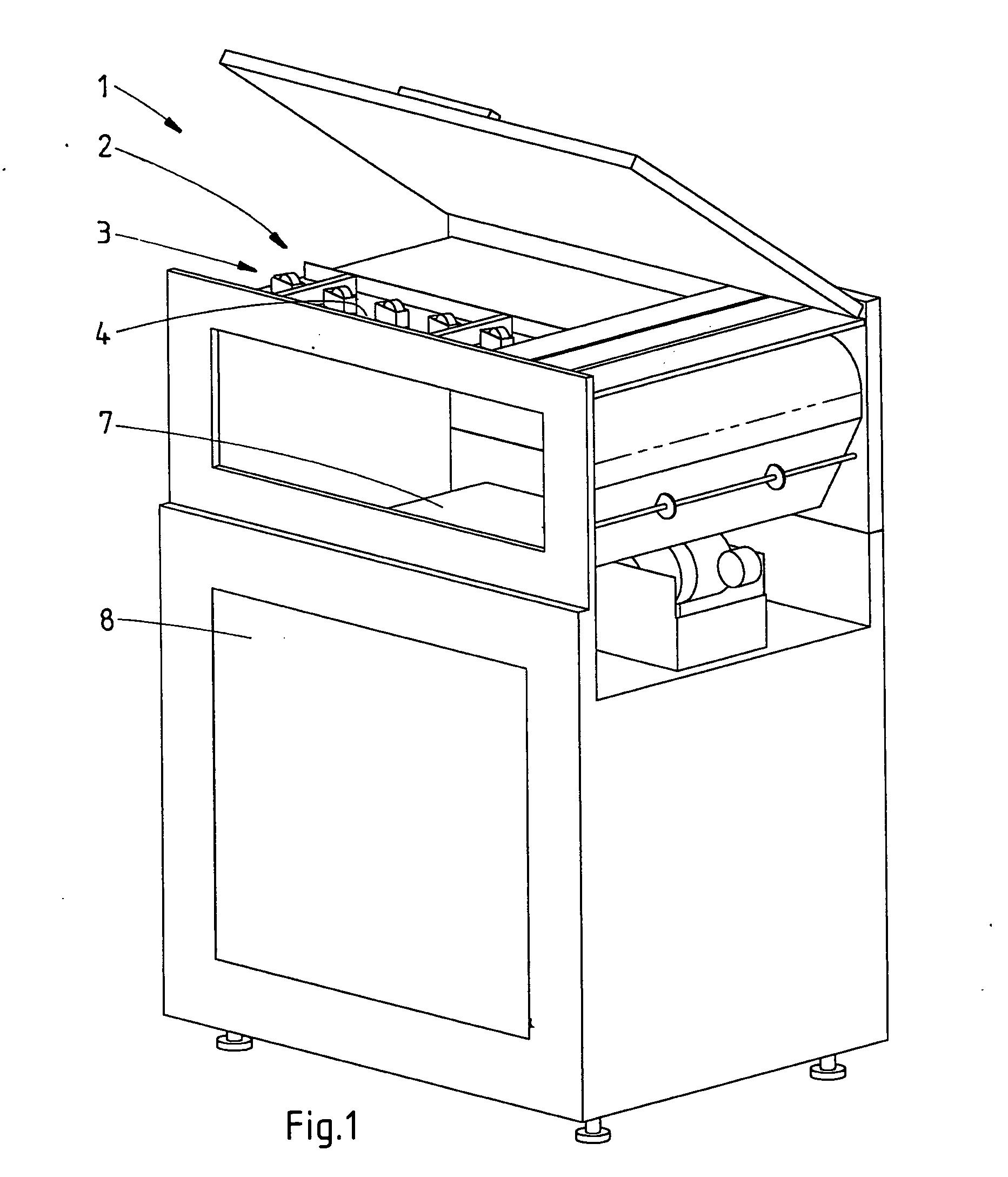

Tray and recording apparatus

InactiveUS20050052517A1Difficult to stackStacking AccurateFunction indicatorsPile receiversEngineeringRecording media

A discharge tray includes a guide portion that is retractable or extendable, relative to medium stacking portions, in consonance with the form of the recording media that are to be discharged. When the recording media that are to be discharged have a predetermined form, the guide portion at the medium stacking portion is prepared so as to guide a recording medium from a discharge portion to the medium stacking portion. With this arrangement, when recording media are so formed that arranging them on the medium stacking portion is difficult, the recording media can be guided from the discharge portion to the medium stacking portion, where they can be stacked accurately.

Owner:SEIKO EPSON CORP

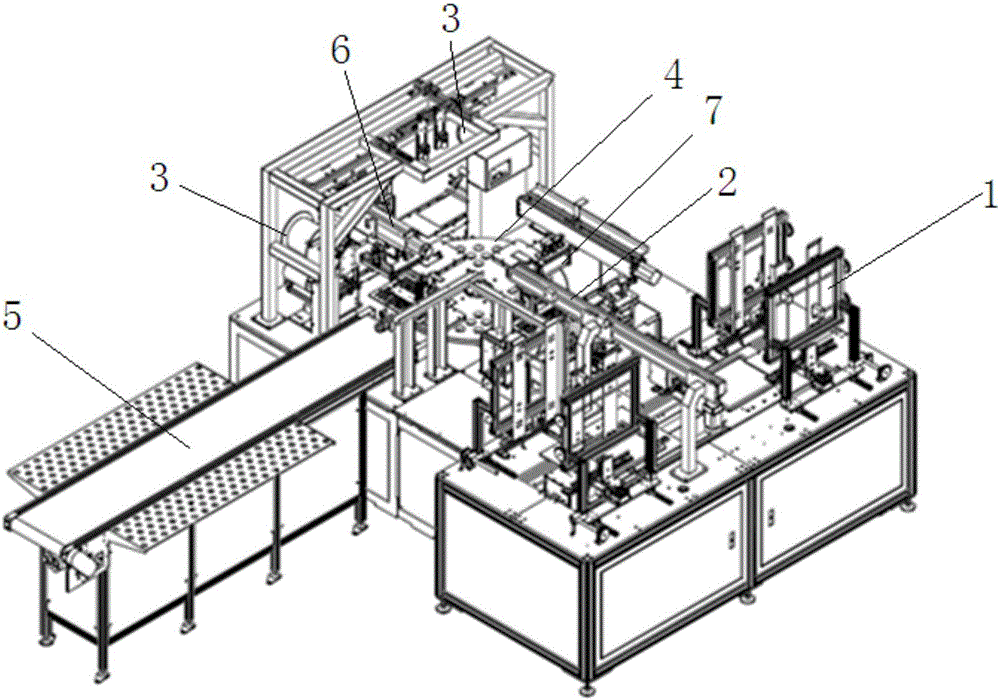

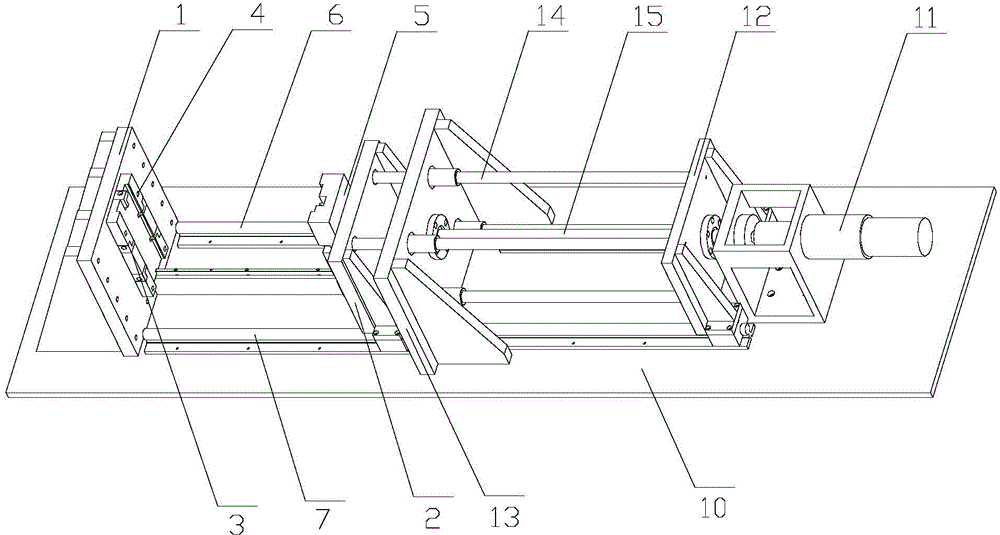

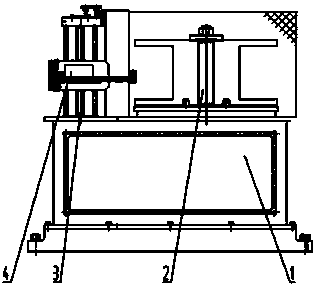

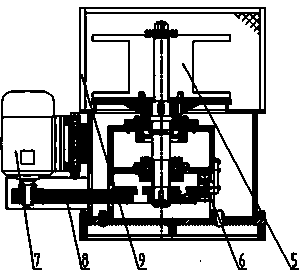

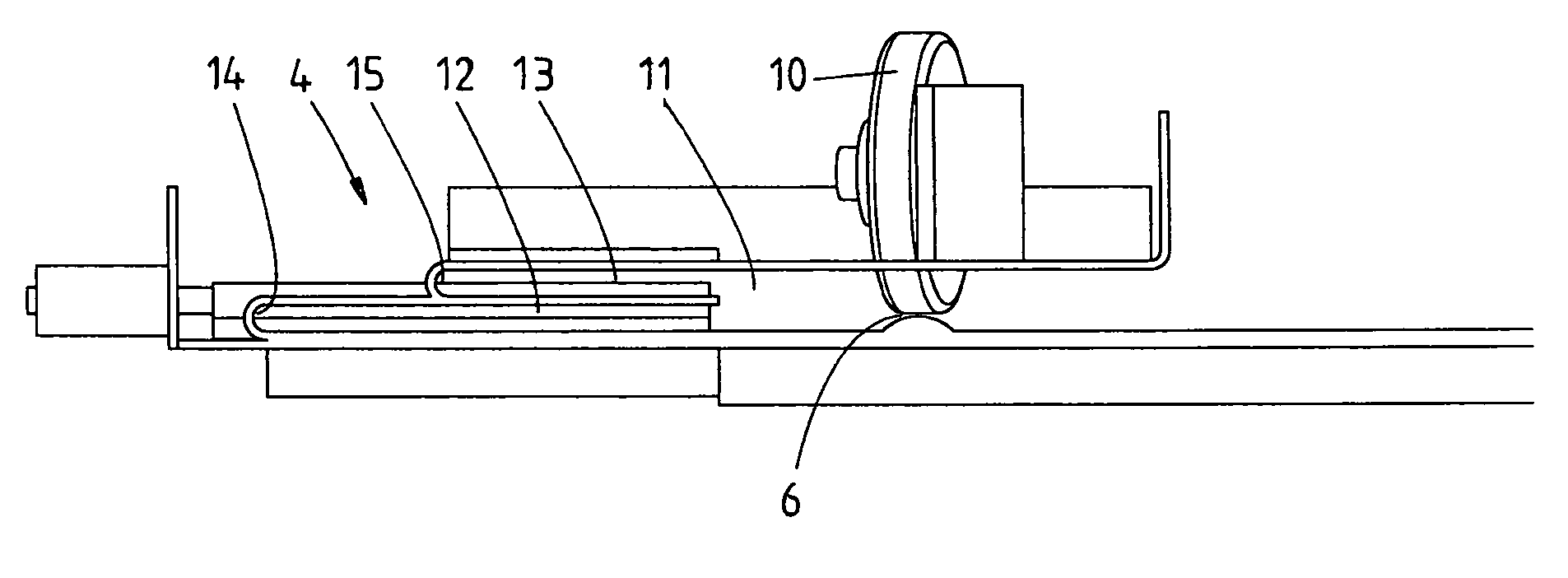

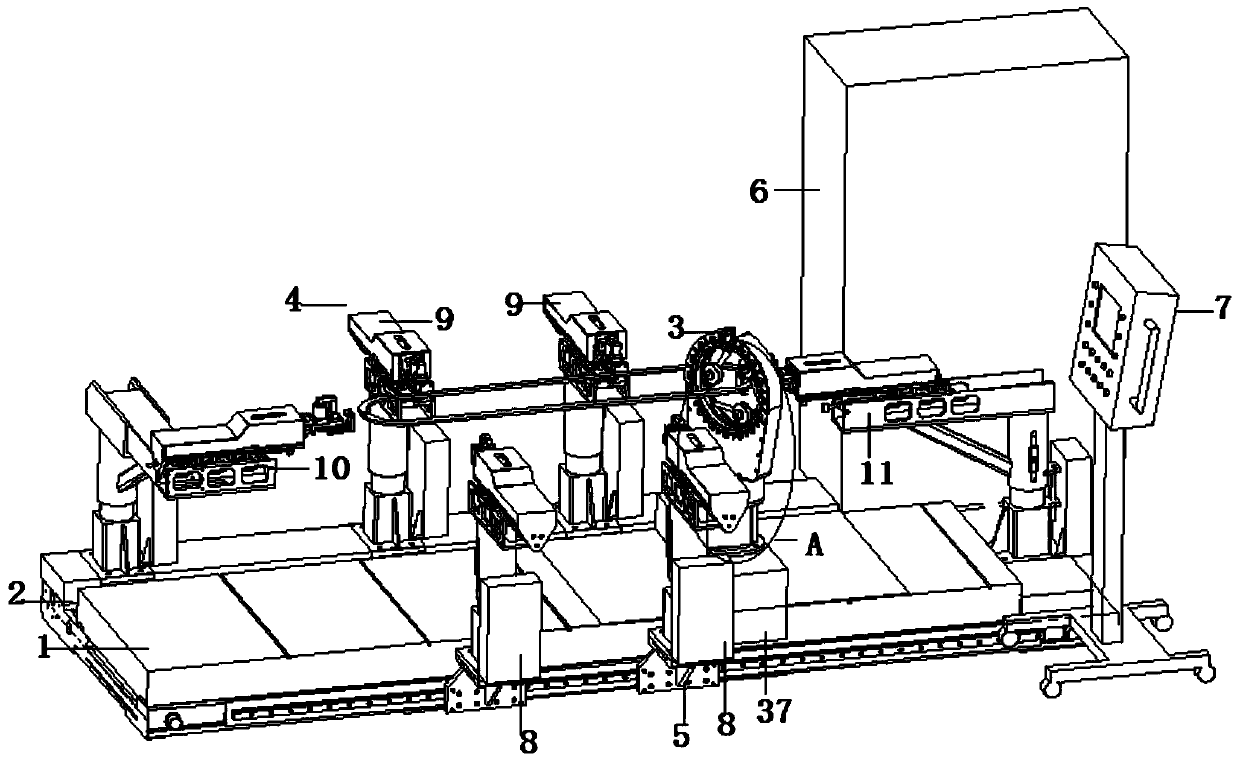

Device and method for horizontally loading fuel cell stacks

The invention discloses a device for horizontally loading fuel cell stacks. The device comprises a driving device, a stack pressing device and a horizontal base, wherein the stack pressing device consists of a first pressing plate and a second pressing plate and is arranged on the horizontal base, the opposite surfaces of the first pressing plate and the second pressing plate are parallel mutually and are perpendicular to the horizontal base, and templates for fixing end plates on two ends of a fuel cell are respectively arranged on the opposite surfaces of the first pressing plate and the second pressing plate; a plurality of positioning holes are correspondingly formed in the two templates and used for mounting external positioning rods of the fuel cell stacks; the second pressing plate is driven under the control of a control system to horizontally move to the first pressing plate, and a stack assembly inserted between the two templates can be pressed tightly. The first pressing plate and the second pressing plate are perpendicularly arranged on the horizontal base, so that the fuel cell stacks can be horizontally loaded, and two ends of the stack assembly are stressed evenly so as not to cause performance difference from two ends of the stack.

Owner:江苏氢电新能源有限公司

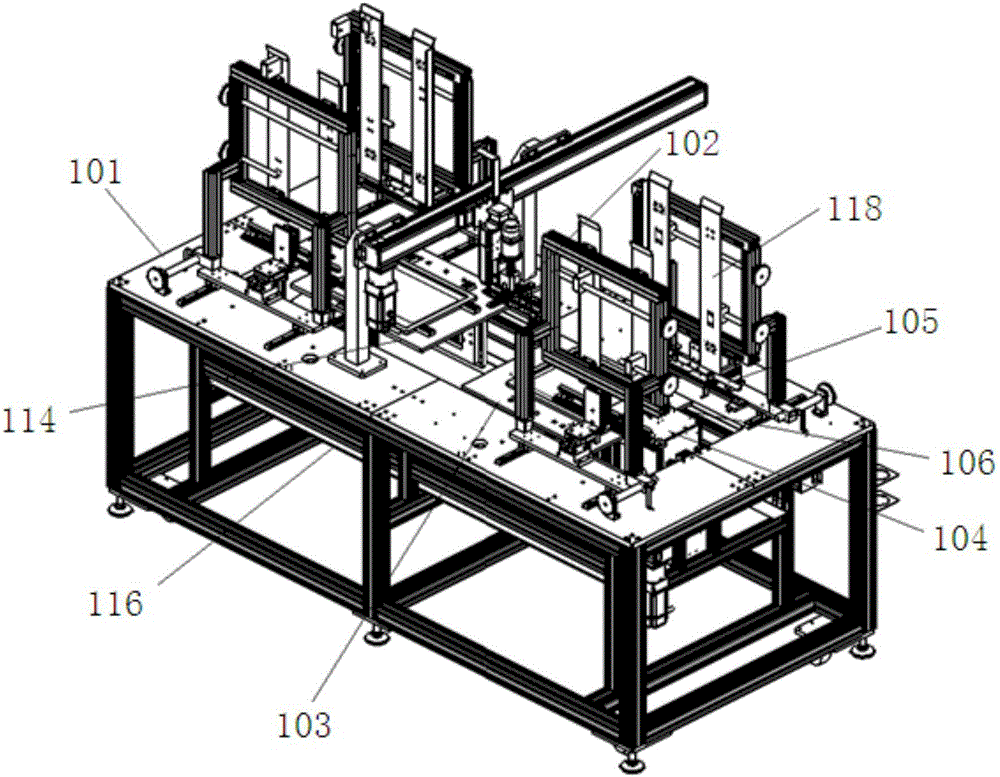

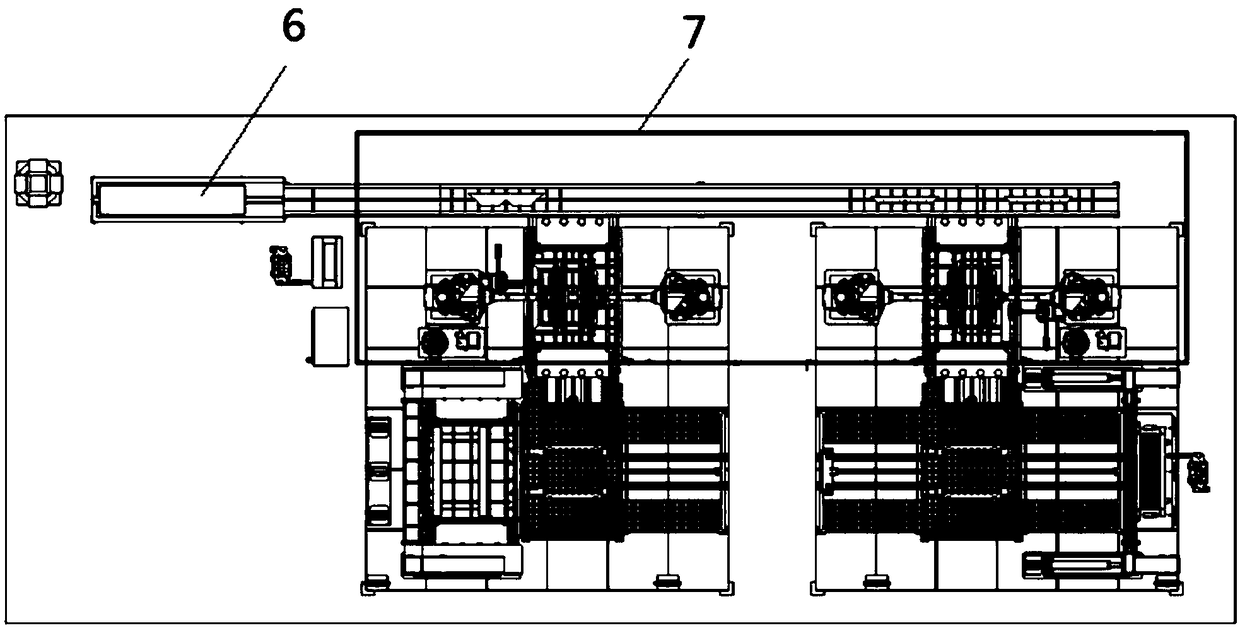

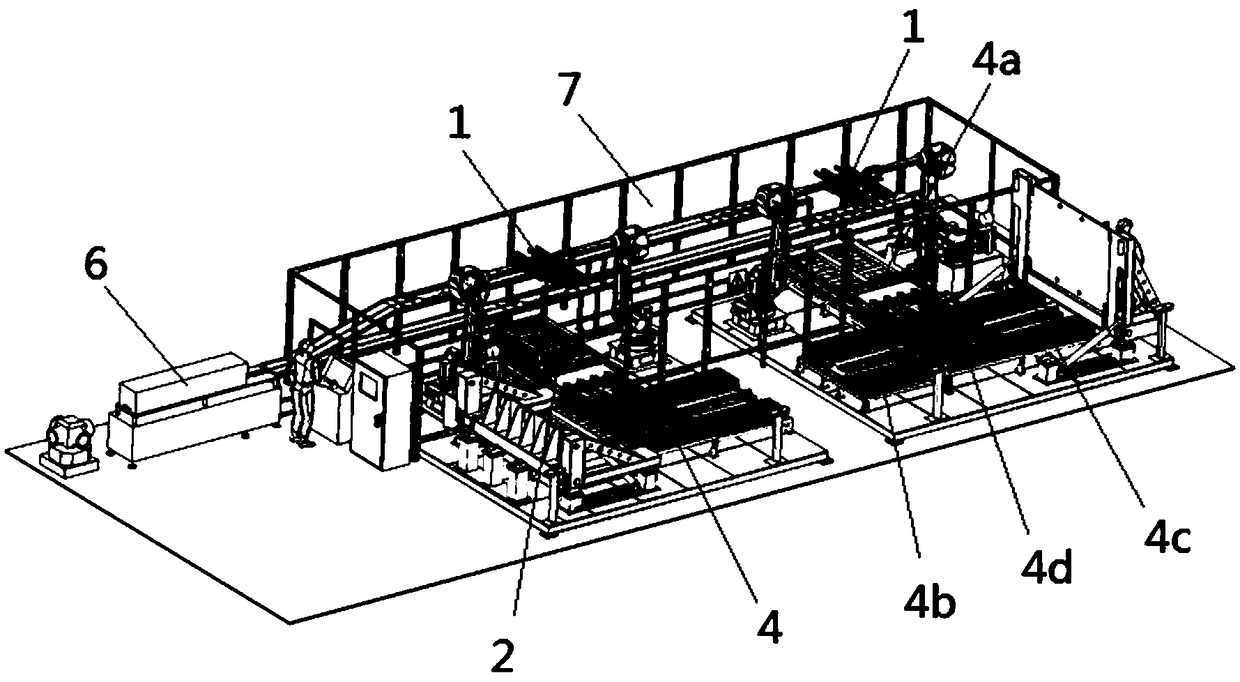

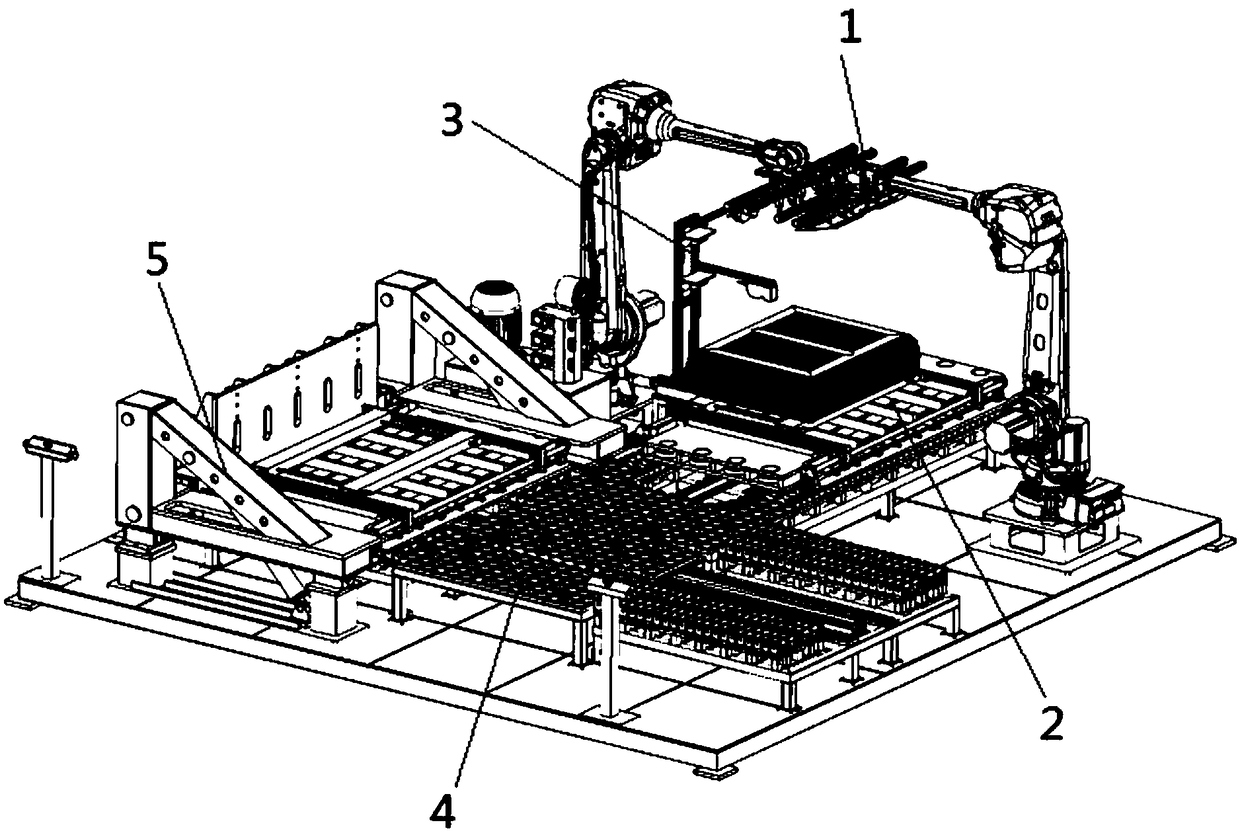

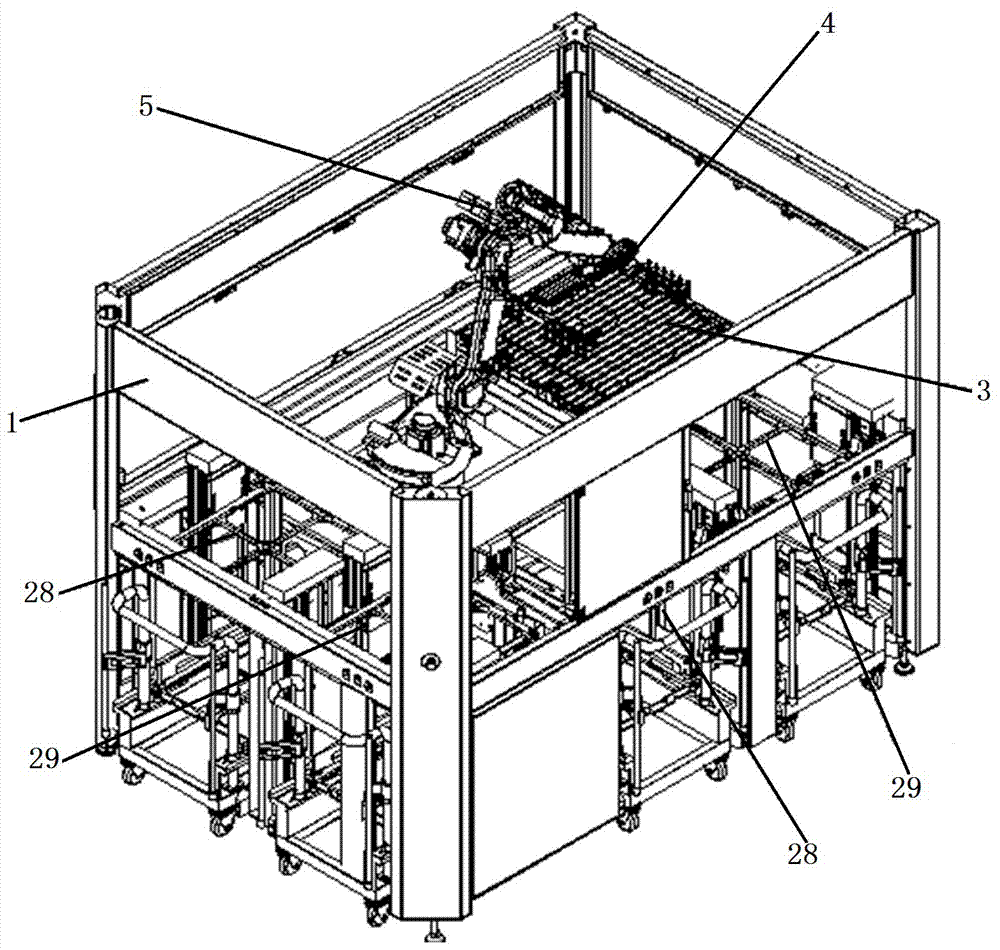

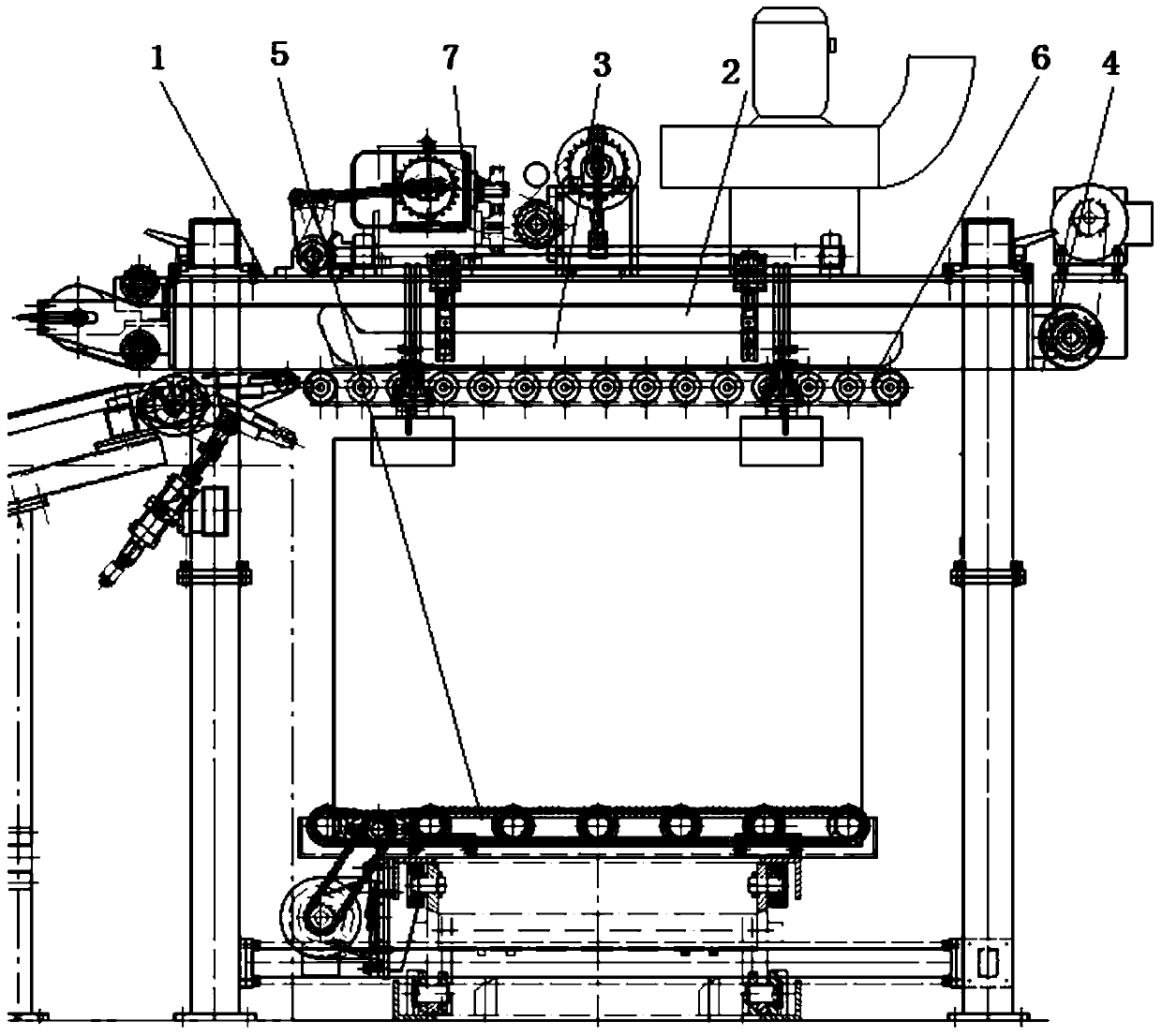

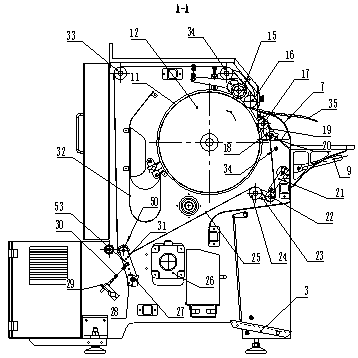

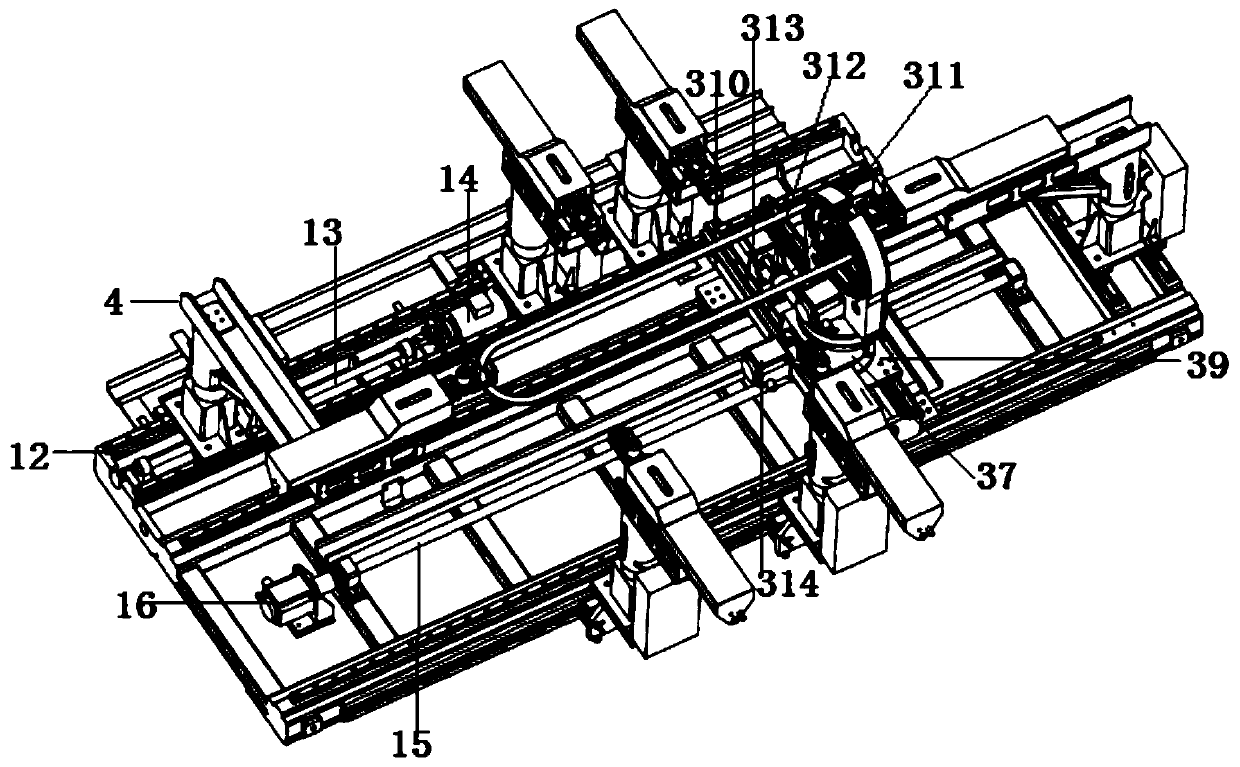

High-speed lamination automation system of transformer core

ActiveCN109378204AQuick stackStacking AccurateInductances/transformers/magnets manufactureTransformerMeasuring instrument

The invention discloses a high-speed lamination automation system of a transformer core, which comprises an automatic lamination workstation, wherein the automatic lamination workstation comprises a lamination manipulator, a lamination table, a high-speed profile measuring instrument, a sliding table and a 90 degree turnover machine. The sliding table is divided into an automatic lamination area,a core upper clamp and base mounting area, and a core lower clamp mounting and finished products pick-up area; when the lamination table slides to the area, the lamination manipulator is used for automatically grabbing silicon steel sheets and placing the silicon steel sheets on the lamination table for an automatic lamination, and the high-speed profile measuring instrument is used for measuringa thickness of the core on the lamination table and can horizontally rotate and abdicate after a measurement; when the lamination table slides to the core lower clamp mounting and the finished products pick-up area, the 90 degree turnover machine drives the lamination table and the core to perform a 90 degree turnover together until the lamination table and the core stand up, and meanwhile, afterthe core is transported away, the core lower clamp mounting of the next core can be carried out. By the adoption of the high-speed lamination automation system of the transformer core, a rapid and accurate stacking of the silicon steel sheets is achieved; safety and reliability are achieved; high precision is achieved; and the production efficiency is obviously improved.

Owner:摩西智能工业股份有限公司

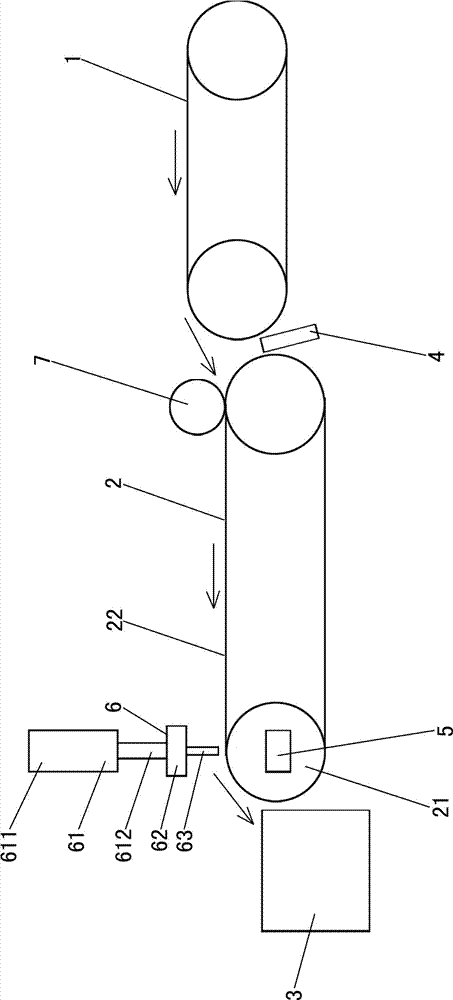

Automatic high-speed conveyer system of EPS (Expandable Polystyrene) cup printing machine

InactiveCN101823361AWidely used valueIncrease productivityRotary pressesProgrammable logic controllerPolystyrene

The invention relates to a cup and bowl printing machine, in particular to an automatic high-speed conveyer system of an EPS (Expandable Polystyrene) cup printing machine, mainly comprising an automatic high-speed cup separating device, an automatic high-speed cup receiving and sending device, an automatic high-speed cup stacking and conveying device, an automatic high-speed cup counting and pushing device and a PLC (Programmable Logic Controller) controller, wherein the automatic high-speed cup separating device separates conveyed cups to be printed, which are sleeved and stacked into a whole strip, into single cups and conveys the cups into a mould of a eight-graduation turntable of a stepper graduator for printing; the printed cups are conveyed to the automatic high-speed cup stacking device through the automatic high-speed cup receiving and sending device; the automatic high-speed cup stacking device sleeves and stacks the cups into a whole cup strip and pushes the cup strip to the automatic high-speed cup counting and pushing device; and after counting, the cups are pushed to a cup receiving groove. The whole process is controlled by the PLC controller to realize the automation of the whole printing process, and the production efficiency is greatly improved.

Owner:GUANGDONG LONGXING PACKAGING IND

Presswork counting and stacking method

The invention provides a presswork counting and stacking method. A counting sensor is arranged between a fast-speed conveying belt and a slow-speed conveying belt; the counting sensor generates a presswork counting signal and conveys the presswork counting signal to a control device; an encoder is arranged on a belt wheel of the slow-speed conveying belt; a presswork stopping mechanism is arranged above the slow-speed conveying belt; when the accumulated value of the presswork counting signal which is transmitted to the control device by a timing sensor is equal to the pre-set value of the presswork quantity, the control device starts to count pulses to the encoder; when the pulse counting numerical value of the encoder is equal to the encoder pulse pre-set value, the presswork stopping mechanism moves and stops a presswork at the back side; a presswork at the front side is moved to a stacking mechanism to finish the counting and stacking process; and the presswork stopping mechanism is reset. According to the presswork counting and stacking method, the transmission speed of the presswork can be slowed through the slow-speed conveying belt, and the impact force on the presswork is reduced so as to be good for sequentially stacking the presswork; and the encoder and the presswork stopping mechanism are arranged, so that the accurate counting on the presswork can be realized.

Owner:YANBIAN CHANGBAISHAN PRINTING

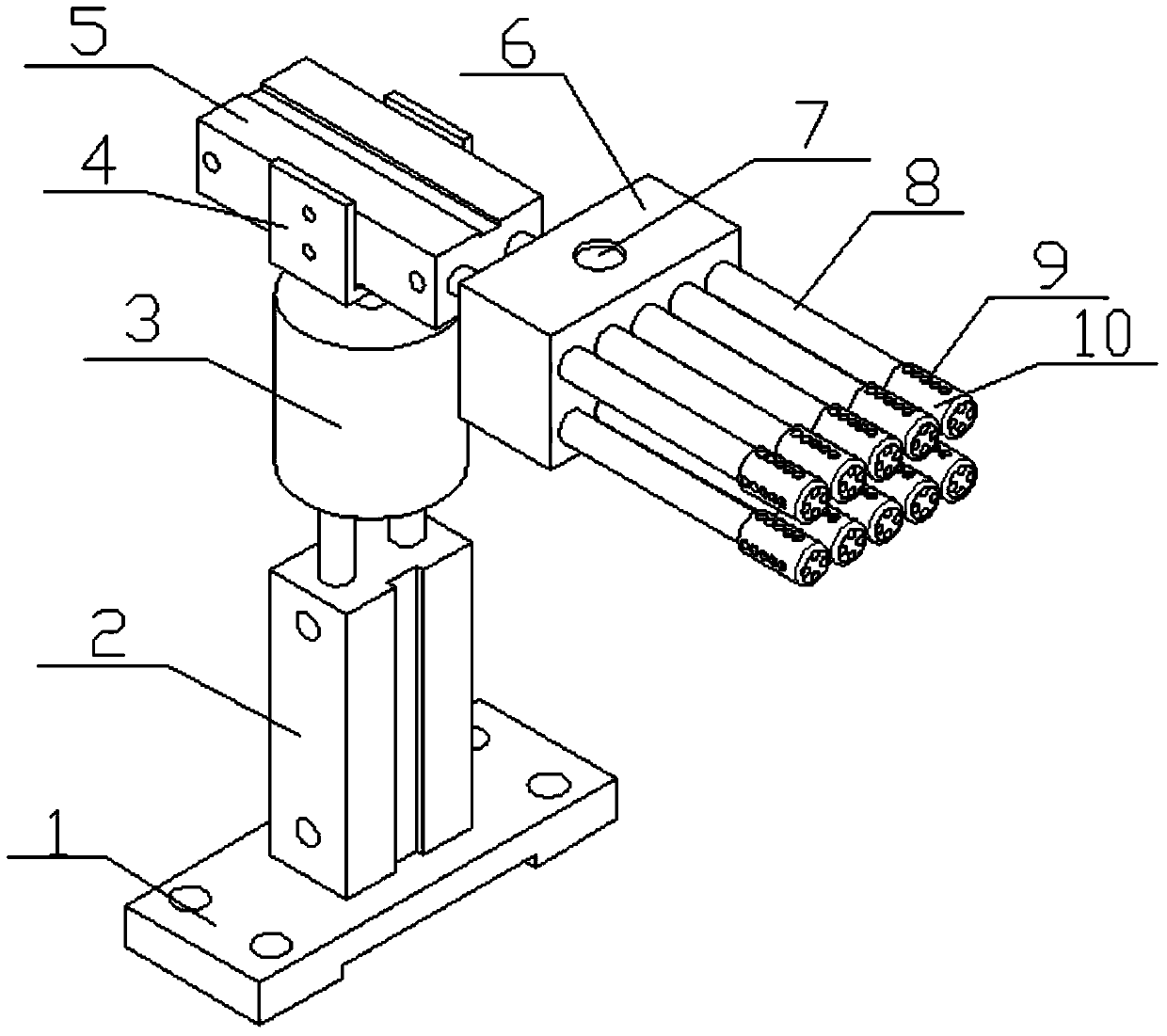

Test tube cleaning device

InactiveCN104043626AAchieve scrubbingAchieve ejectionHollow article cleaningWater storage tankEngineering

The invention relates to the field of experiment equipment, in particular to a test tube cleaning device. The test tube cleaning device comprises a base, a first air cylinder, a stepping motor, an air cylinder fixing frame, a second air cylinder, a water storage tank, water injecting ports, a brush rod, water spraying ports and a brush head, wherein the first air cylinder and the base are fixed together in a welding mode, the first air cylinder is installed on the upper portion of base, the stepping motor is installed above a piston rod of the first air cylinder, the second air cylinder is installed above a rotary shaft of the stepping motor, the water storage tank is installed at one end of a piston rod of the second air cylinder, the water injecting ports are formed in the upper surface of the water storage tank, the brush rod is installed on the lateral surface of the water storage tank, the brush head is installed at one end of the brush rod, and the water spraying ports are in the periphery of the brush head. The test tube cleaning device can assist in cleaning test tubes.

Owner:张伟

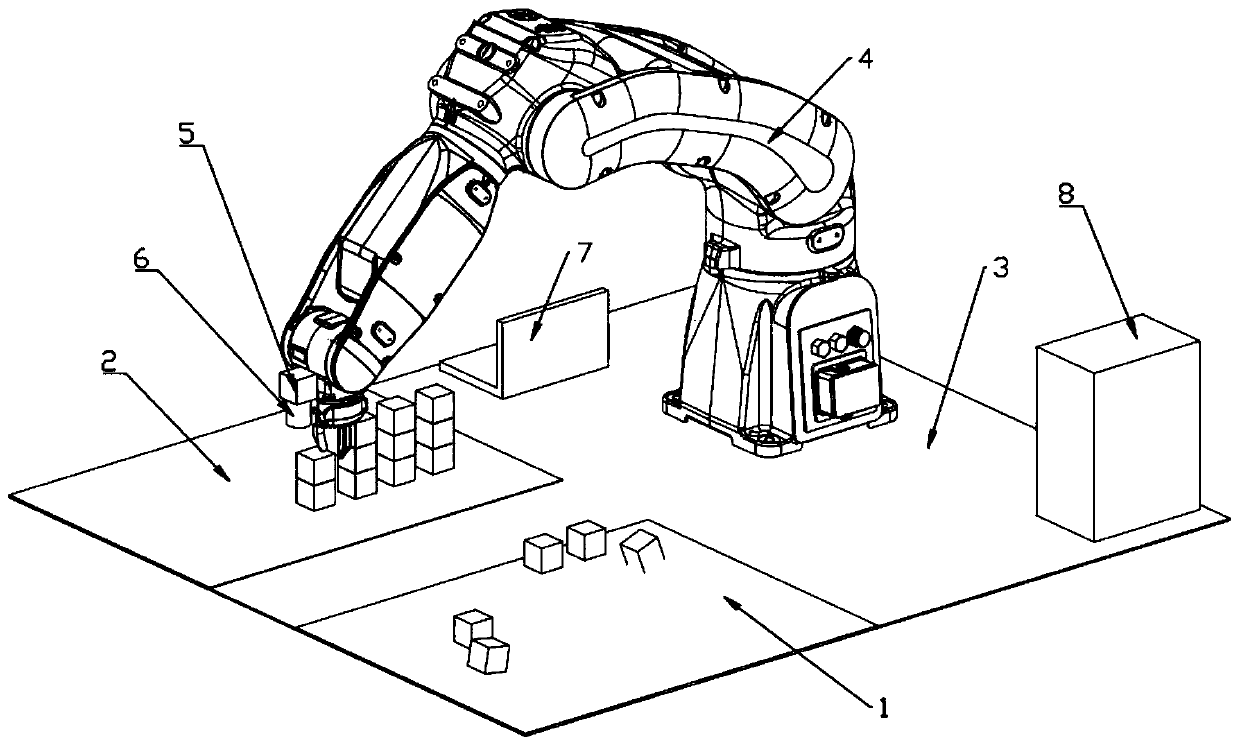

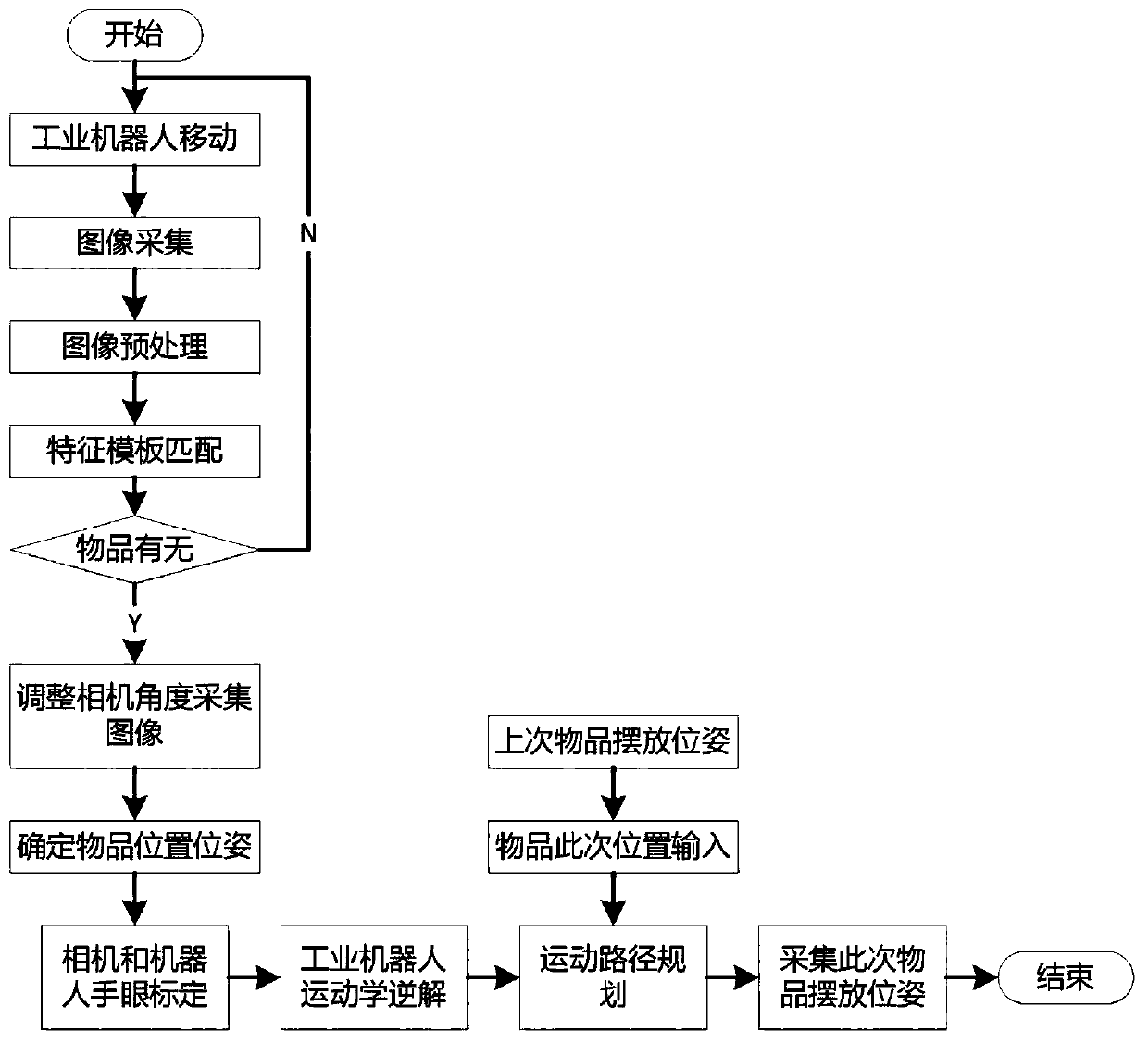

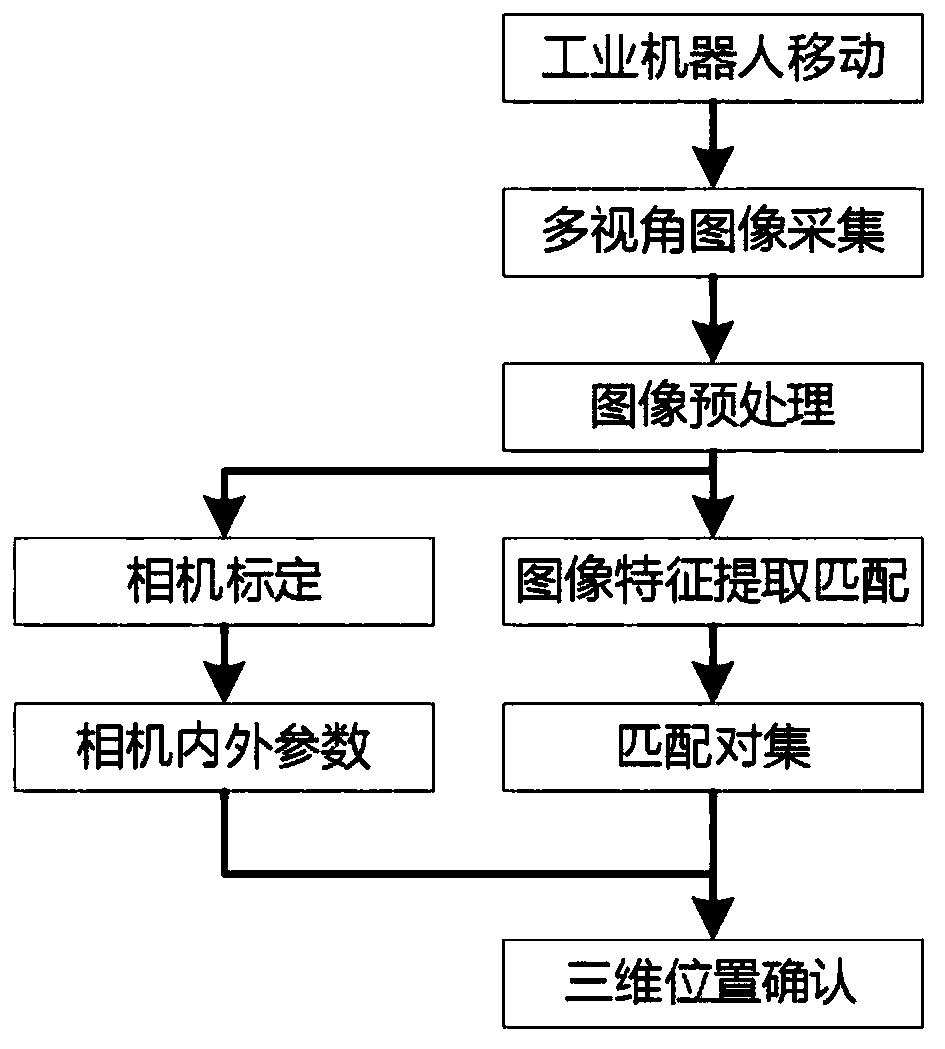

Industrial robot sorting method based on active vision

InactiveCN110666805AAccurate captureStacking AccurateProgramme-controlled manipulatorSortingInformation controlIndustrial robotics

The invention discloses an industrial robot sorting method based on active vision. The industrial robot sorting method based on active vision is capable of accurately grabbing and stacking materials.An industrial robot drives a CCD industrial camera to carry out material search and matching in a material placement area, and obtain the position information of target materials; the industrial robotadjusts a shooting angle of the CCD industrial camera, enables the CCD industrial camera to shoot the image information of the target materials from different angles, carry out three-dimensional calibration, and then confirm the position information and the attitude information of the target materials; the industrial robot is controlled to grab the target materials according to the position information and the attitude information of the target materials; when the first target material is placed, the industrial robot is controlled to place the target material at initial stacking coordinates,and acquire the position information and the attitude information of the target material; and when the subsequent target materials are placed, the industrial robot is controlled to stack the subsequent target materials on the previous target material according to the position information and the attitude information of the previous target material until stacking for all the target materials is completed.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

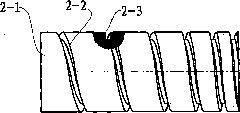

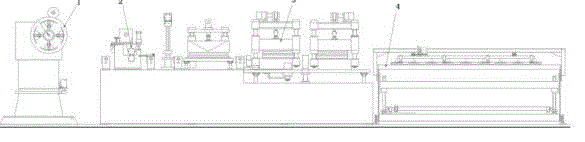

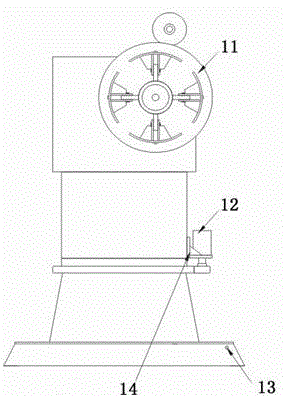

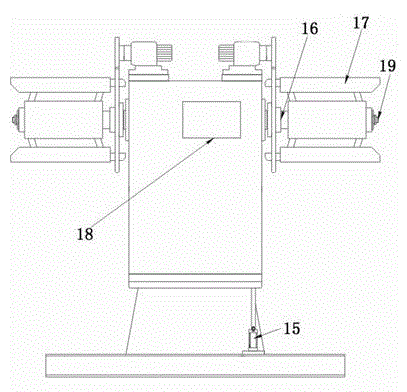

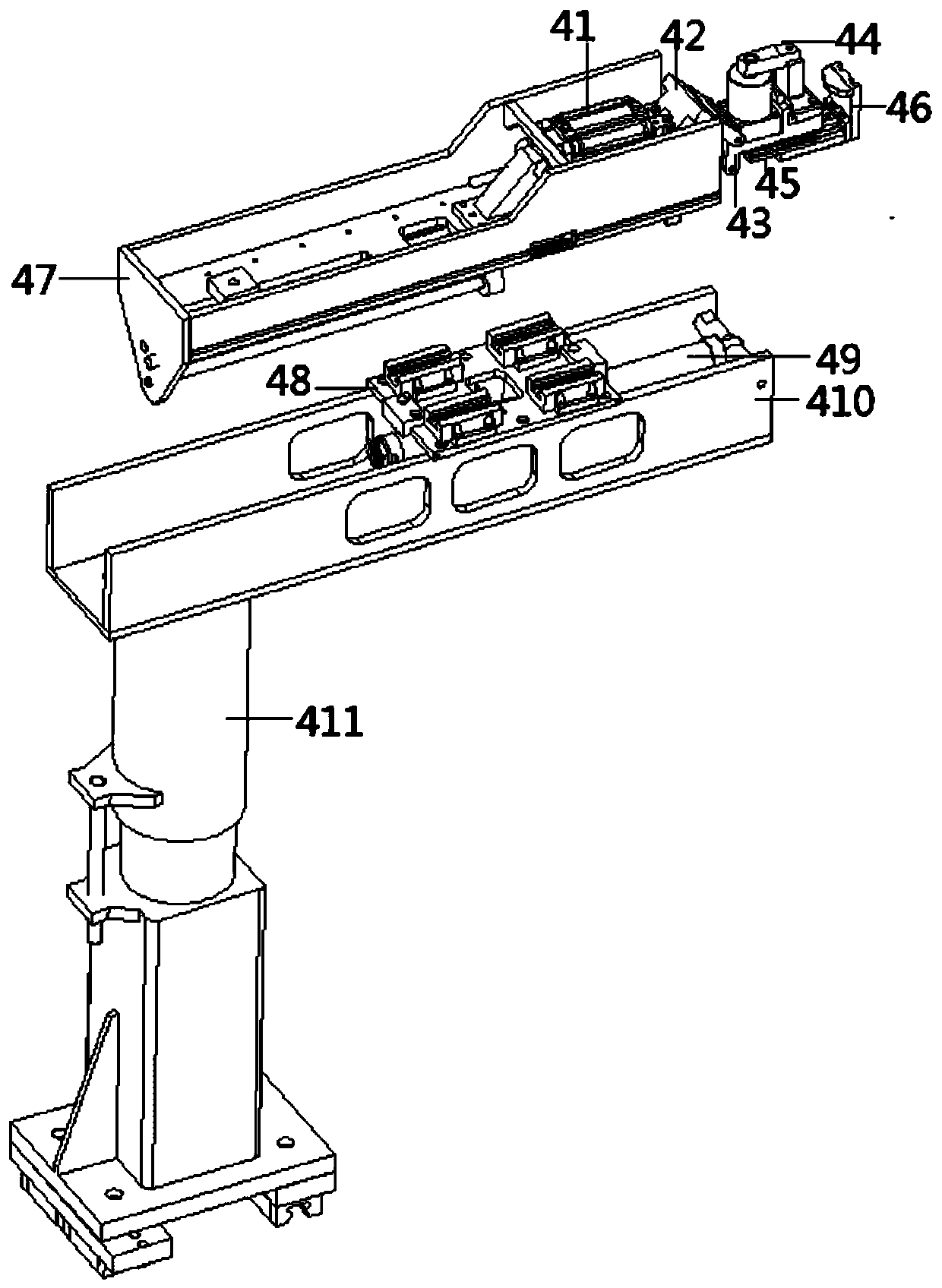

Efficient silicon steel sheet cross line shearing device

InactiveCN104801626AImprove work efficiencyReduce the possibility of looseningMetal-working feeding devicesPositioning devicesMagnetElectric machine

The invention relates to steel sheet machining equipment, and specifically relates to a silicon steel sheet cross line shearing device. The silicon steel sheet cross line shearing device comprises a winding device (1), a feed device (2), a shearing device (3) and a discharge device (4), wherein the winding device comprises at least two winding shafts (11), a hydraulic motor (12), a photoelectric inductive switch (13), a photoelectric proximity switch (14) and an air cylinder (15). Each winding shaft (11) comprises a winding shaft body (16), a press plate (17), a hydraulic cylinder (18) and a hydraulic cylinder pull rod (19). The discharge device (4) comprises a magnet suction disk (41), an air cylinder (42), a servo motor (43) and a photoelectric inductive switch (44). The efficient silicon steel sheet cross line shearing device has the advantages of finishing the integrated full-automatic design of the whole machining line shearing and discharging, accordingly saving a plenty of labor cost, and increasing the efficiency and the stability of machining the lines.

Owner:上海祯驰电气设备有限公司

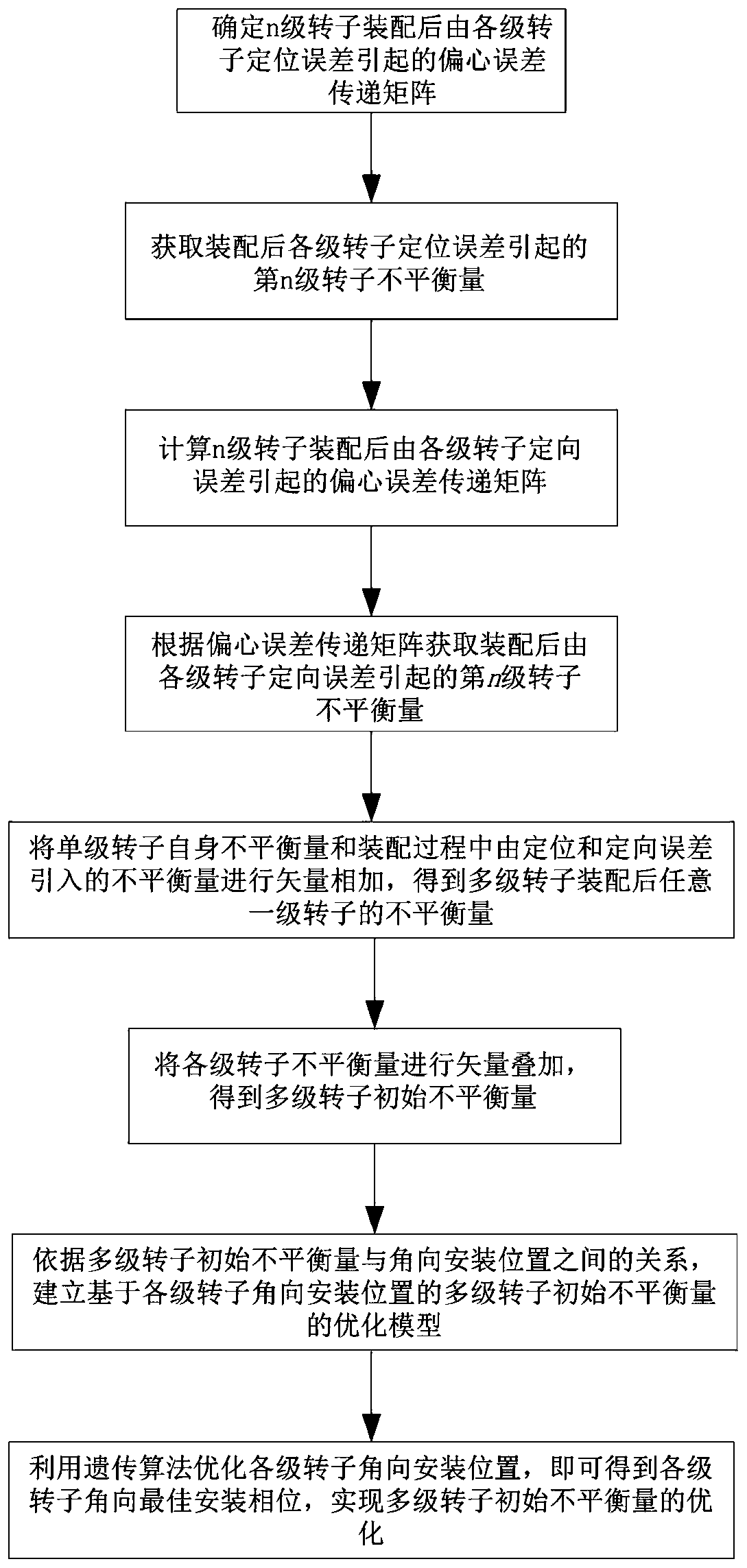

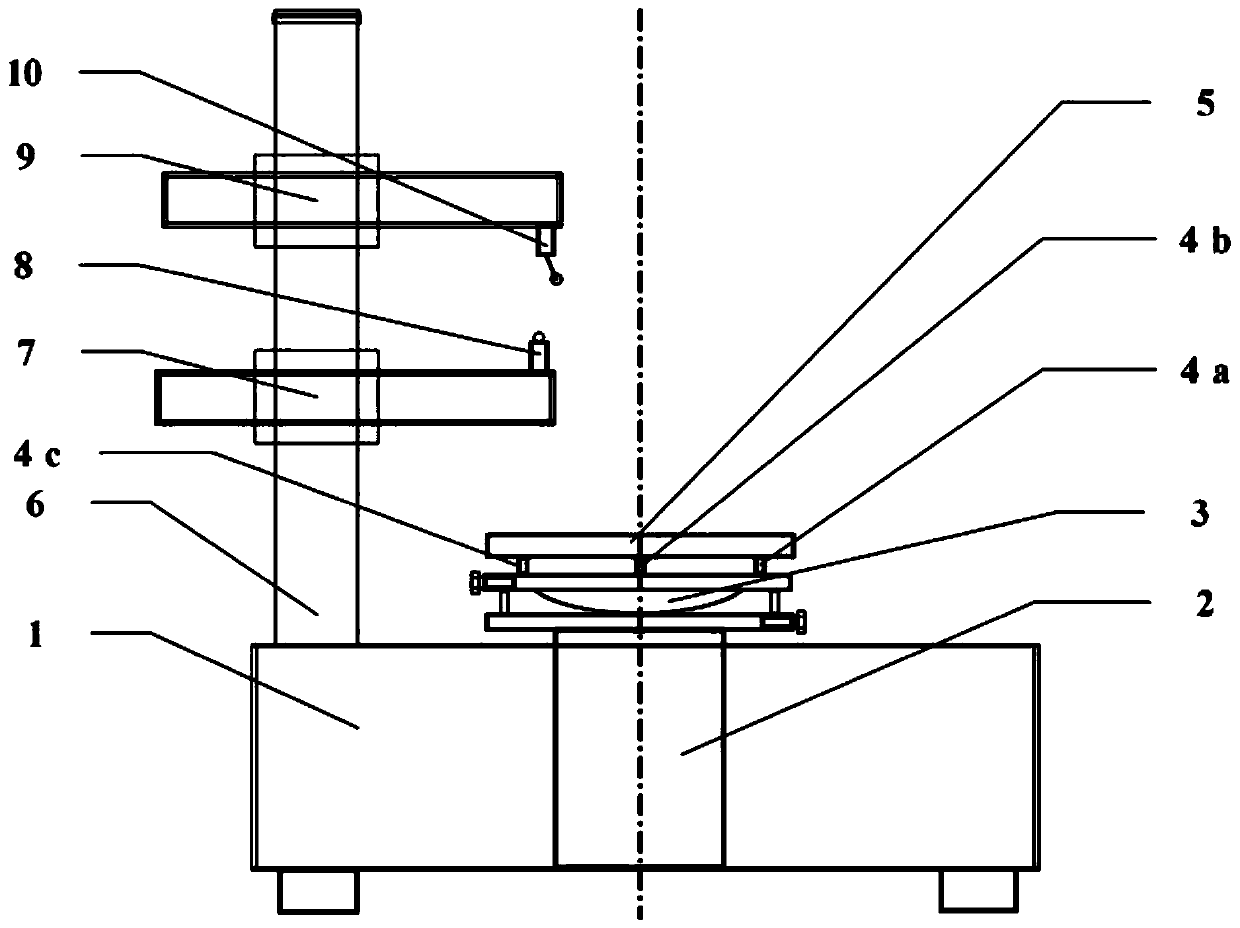

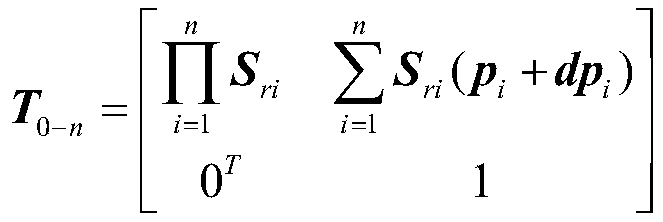

Convolutional neural network-based step-by-step stacking method and device for initial unbalance of multistage parts of large high-speed rotary equipment

ActiveCN109871947AInitial unbalance optimizationImprove efficiencyGenetic modelsStatic/dynamic balance measurementTransfer matrixControl theory

The invention provides a convolutional neural network-based step-by-step stacking method and device for initial unbalance of multistage parts of large high-speed rotary equipment, and belongs to the technical field of mechanical assembly. The method comprises the following steps: firstly, respectively obtaining eccentric error transfer matrixes caused by rotor positioning errors of all stages after n stages of rotors are assembled; after assembly, acquiring the n-th-stage rotor unbalance amount caused by the rotor positioning error of each stage; after the n stages of rotors are assembled, acquiring an eccentric error transfer matrix caused by rotor orientation errors of all stages and an nth stage of rotor unbalance caused by rotor orientation errors of all stages, then acquiring the unbalance of any stage of rotor after the multistage rotors are assembled in a vector addition mode, and establishing an optimization model according to the unbalance. The device comprises a base, an airfloatation shaft system and an aligning and inclination adjusting workbench which are a precision force sensor, a static balance measuring platform, a stand column, a lower transverse measuring rod, alower telescopic inductance sensor, an upper transverse measuring rod and an upper lever type inductance sensor respectively.

Owner:HARBIN INST OF TECH

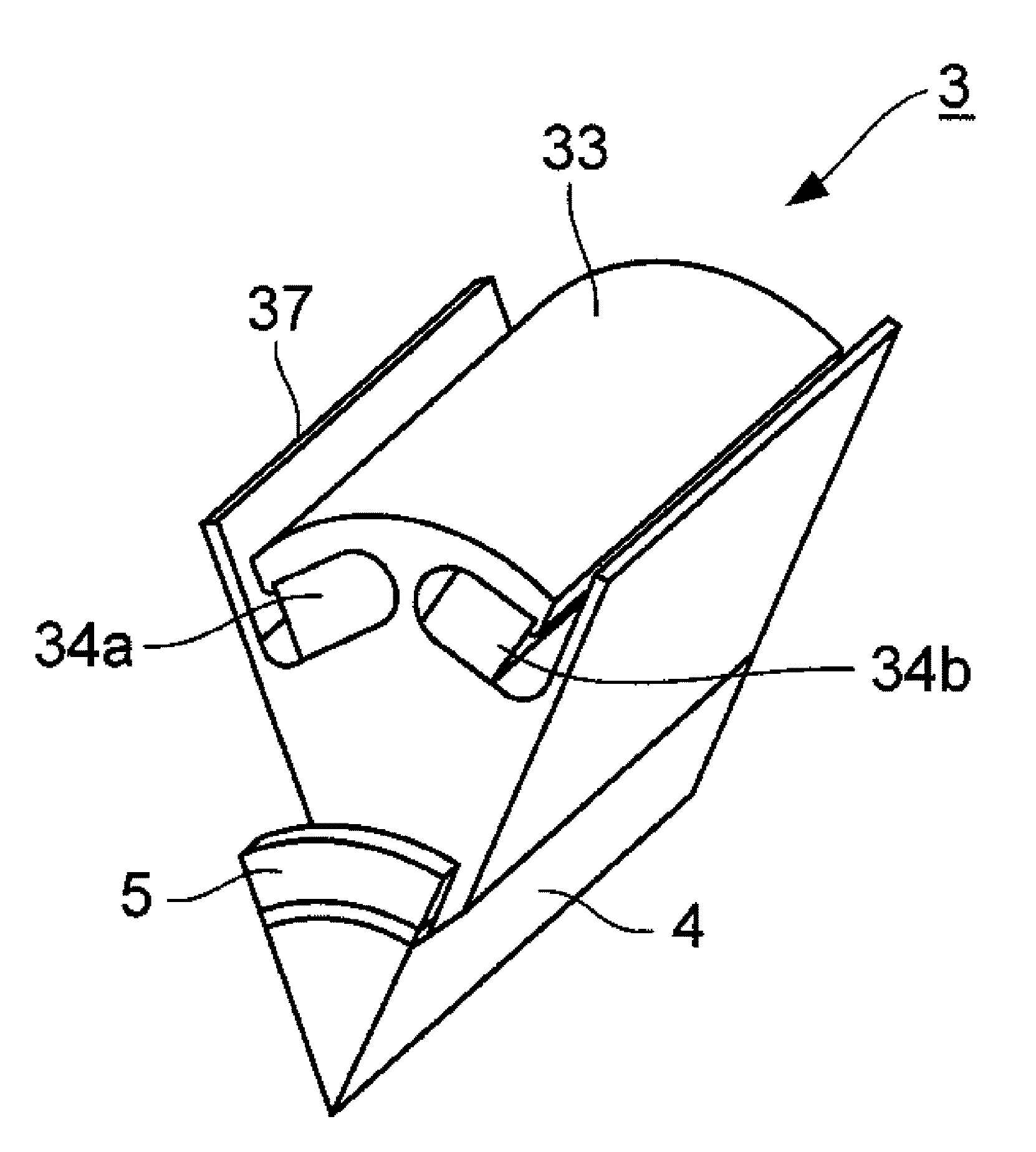

Tray and recording apparatus

InactiveUS7448617B2Difficult to stackStacking AccurateFunction indicatorsPile receiversRecording mediaElectrical and Electronics engineering

A discharge tray includes a guide portion that is retractable or extendable, relative to medium stacking portions, in consonance with the form of the recording media that are to be discharged. When the recording media that are to be discharged have a predetermined form, the guide portion at the medium stacking portion is prepared so as to guide a recording medium from a discharge portion to the medium stacking portion. With this arrangement, when recording media are so formed that arranging them on the medium stacking portion is difficult, the recording media can be guided from the discharge portion to the medium stacking portion, where they can be stacked accurately.

Owner:SEIKO EPSON CORP

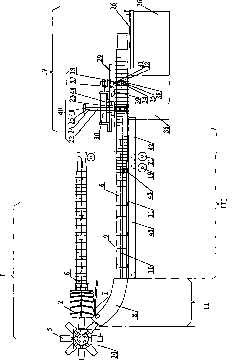

Method and device for rolling steel wire through large vertical spool

InactiveCN104016189AEliminate 90° torsion phenomenonEnsure cleaning rod performanceFilament handlingMotor driveEngineering

The invention provides a method and device for rolling a steel wire through a large vertical spool. A spindle device is installed on a machine frame and fixedly connected with the detachable spool. A straightener is fixed to a vertical moving frame of a wire arranging device, a motor is fixed to the side face of the machine frame, a braking device is arranged on the spindle device, and a safety protection device is installed on the machine frame. A winding method includes the steps that a door on the safety protection device is opened, the assembled detachable spool is installed on the spindle device in a lifting mode, the spool is tightly locked through a nut and a taper sleeve, after the steel wire is wound on the spool by three to five circles through a wheel of the straightener on the wire arranging device and the wire arranging distance is well adjusted, a power supply is started, and the motor drives the spool on the spindle to rotate so as to achieve wire winding. According to the method and device for rolling the steel wire through the large vertical spool, the phenomenon that a steel wire is twisted in the winding process is avoided, wire arrangement is tight and smooth, meanwhile large flexible packaging stacking is achieved, stacking fields and investment of the spool are saved, and the cost is lowered.

Owner:GUIZHOU WIRE ROPE

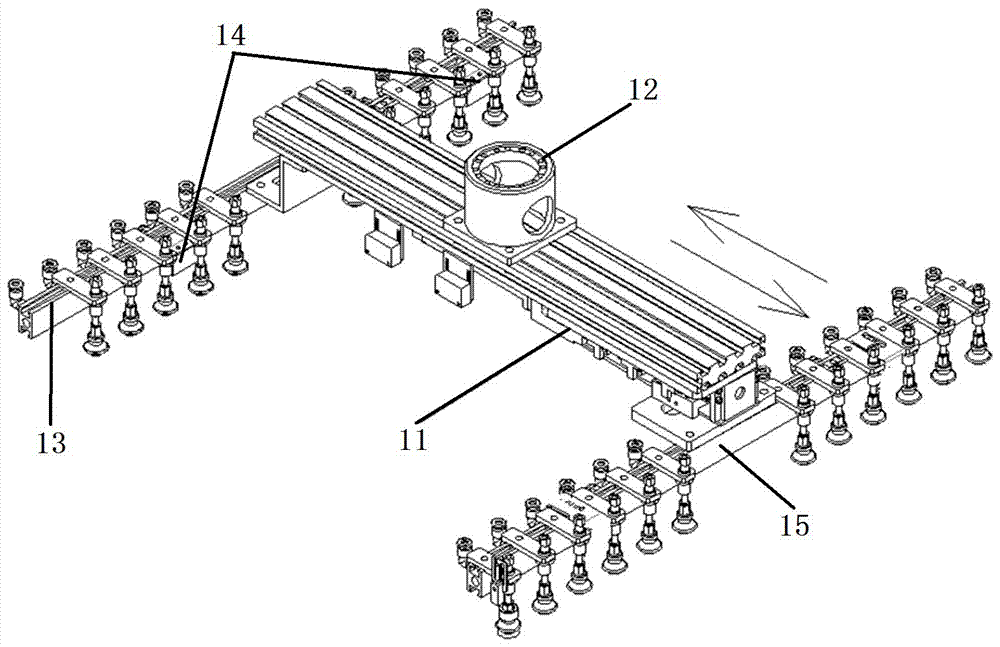

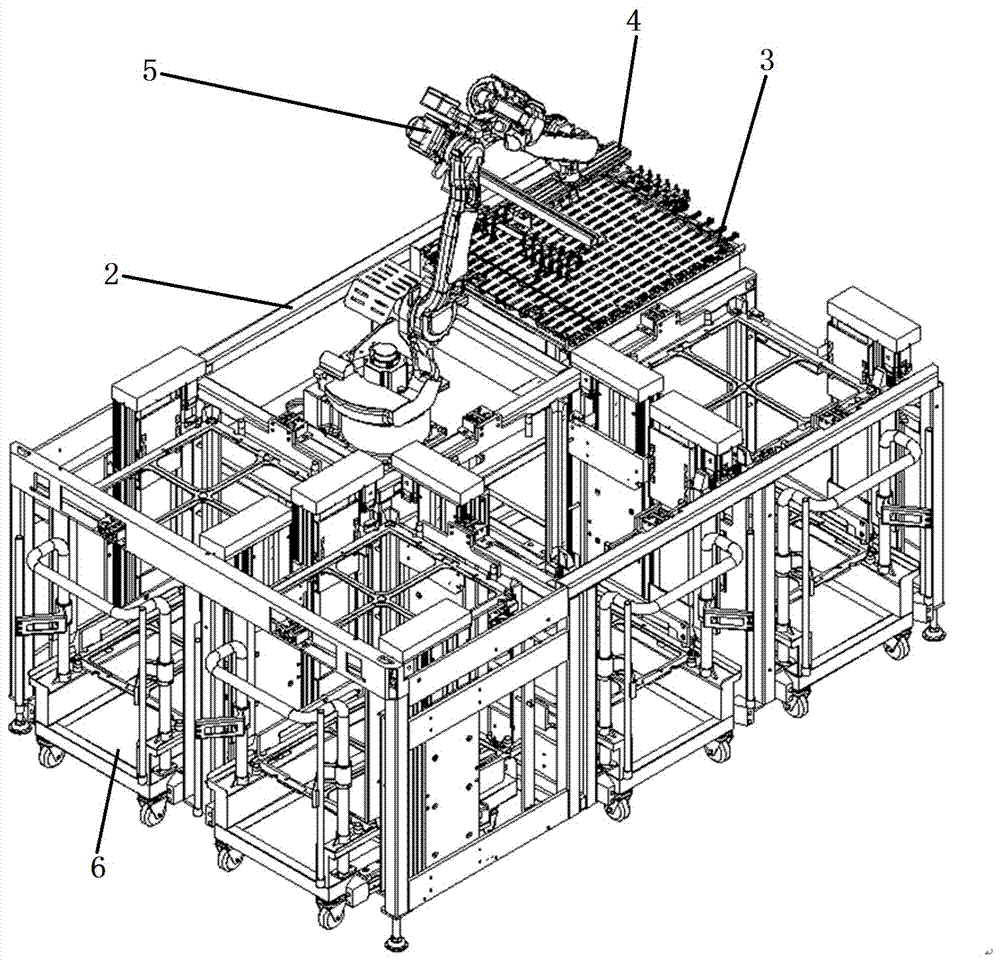

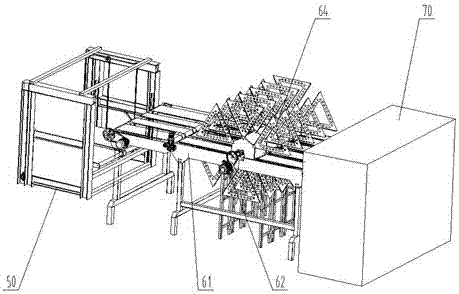

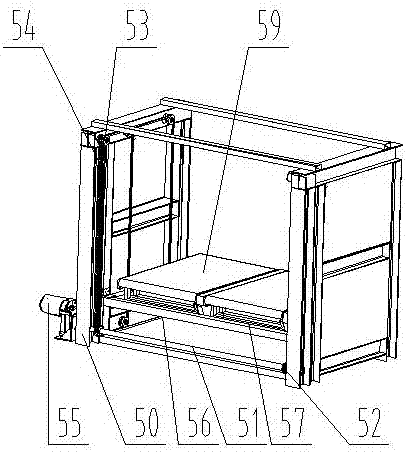

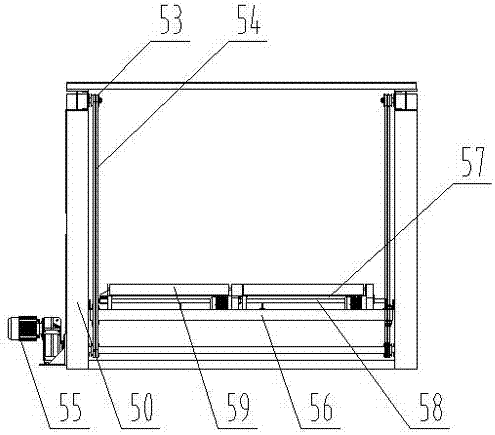

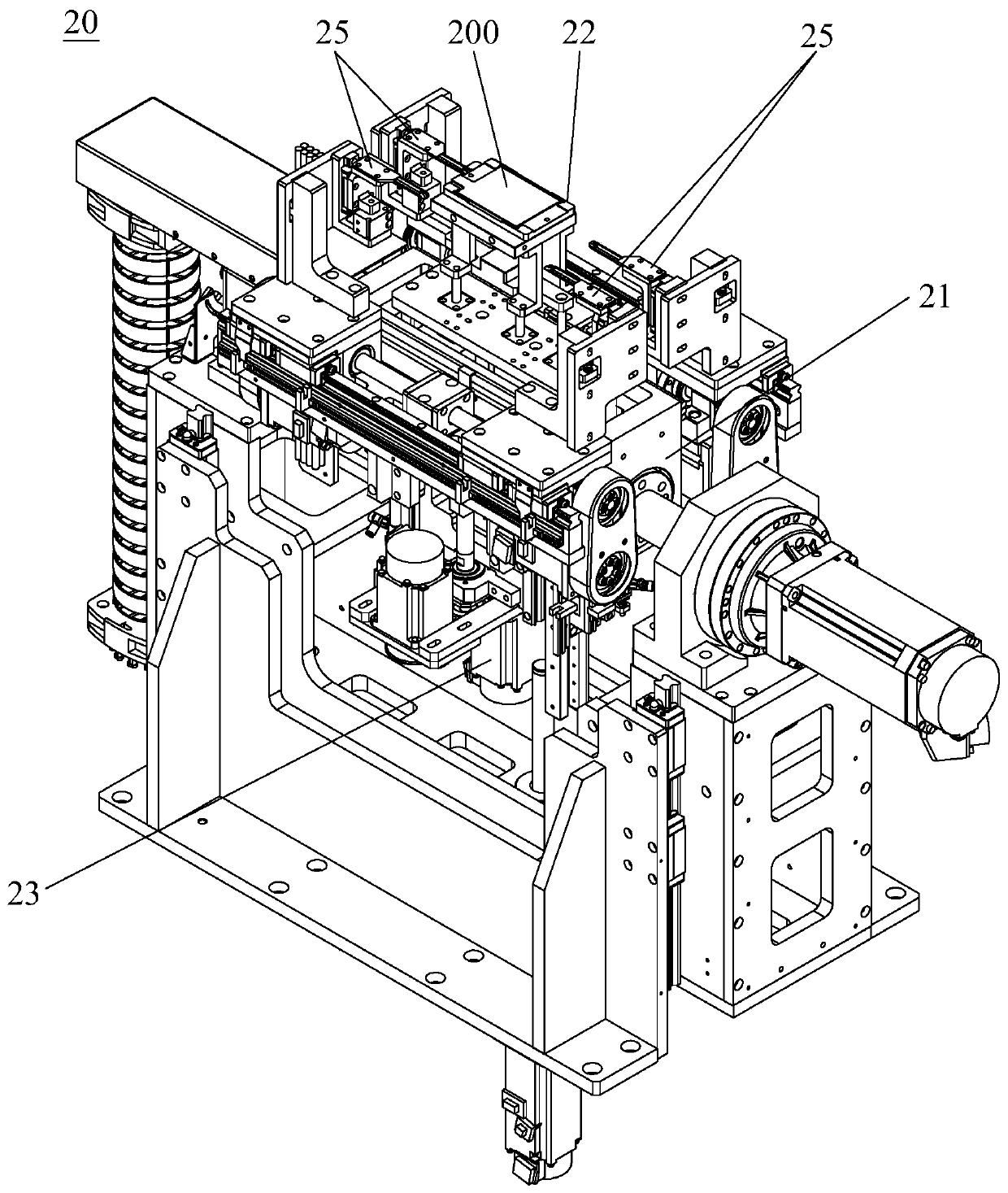

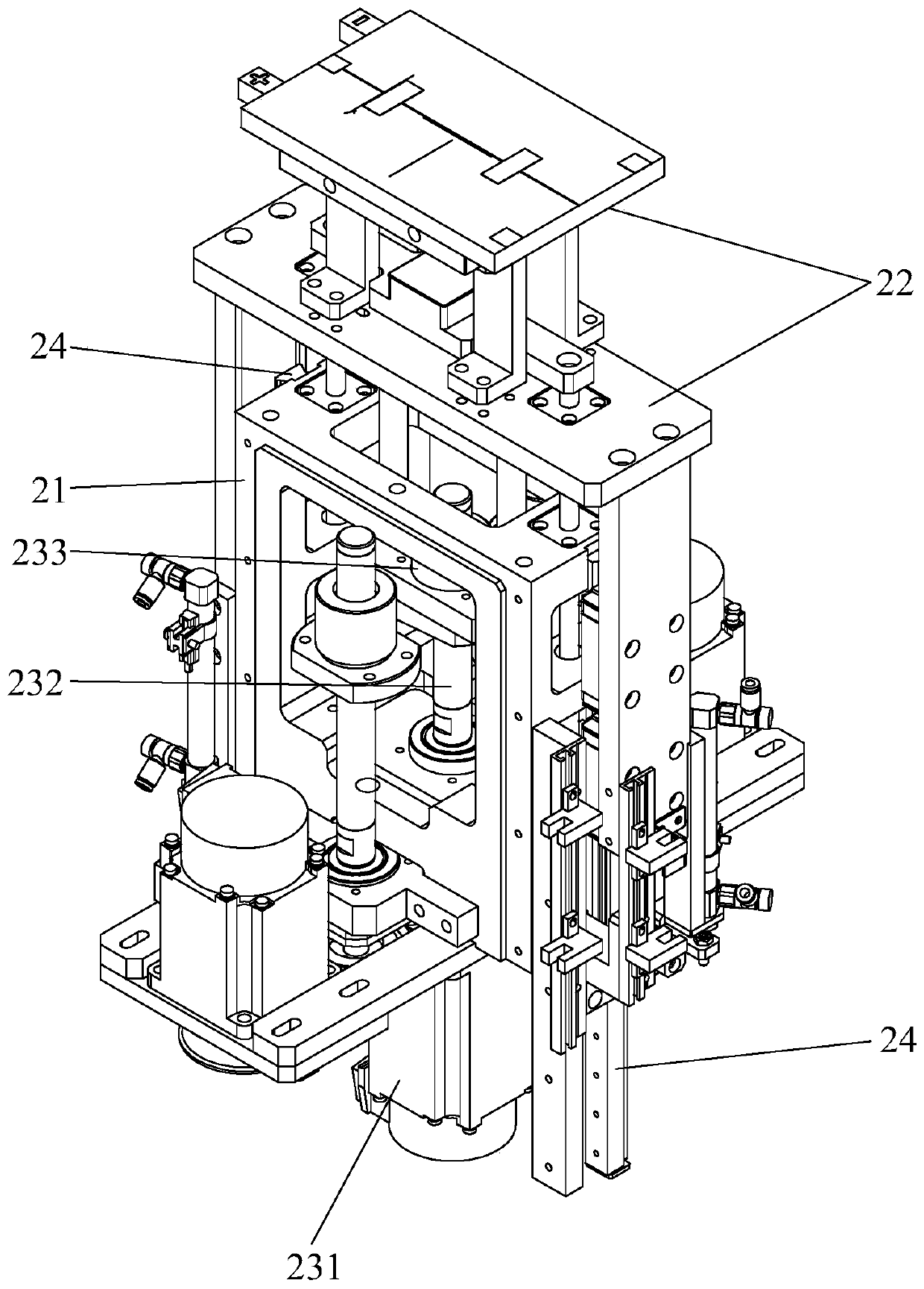

Tray and PCB automatic storing and putting equipment

PendingCN107380958AExact alignmentStacking AccurateConveyorsControl devices for conveyorsProcess engineeringMachine

The invention relates to the field of circuit board automation equipment, in particular to Tray and PCB automatic storing and putting equipment. The Tray and PCB automatic storing and putting equipment mainly comprises an outer frame, a robot, an attraction plant, a conveying platform, a cart and two containing stations, and has the functions of Tray and PCB attraction, Tray aligning lifting, PCB positioning and the like. The Tray and PCB automatic storing and putting equipment solves the problem that in a traditional plate storing and putting machine, plate storing and putting operation cannot be achieved under the working condition that a Tray serves as a carrier, the Tray and PCB automatic plate storing and putting operation is achieved, station switching and using can be achieved, and the continuous production aim is achieved.

Owner:SHANGHAI KAISER ELECTRONICS

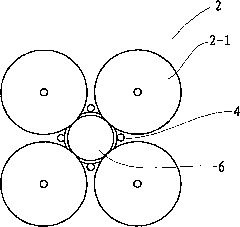

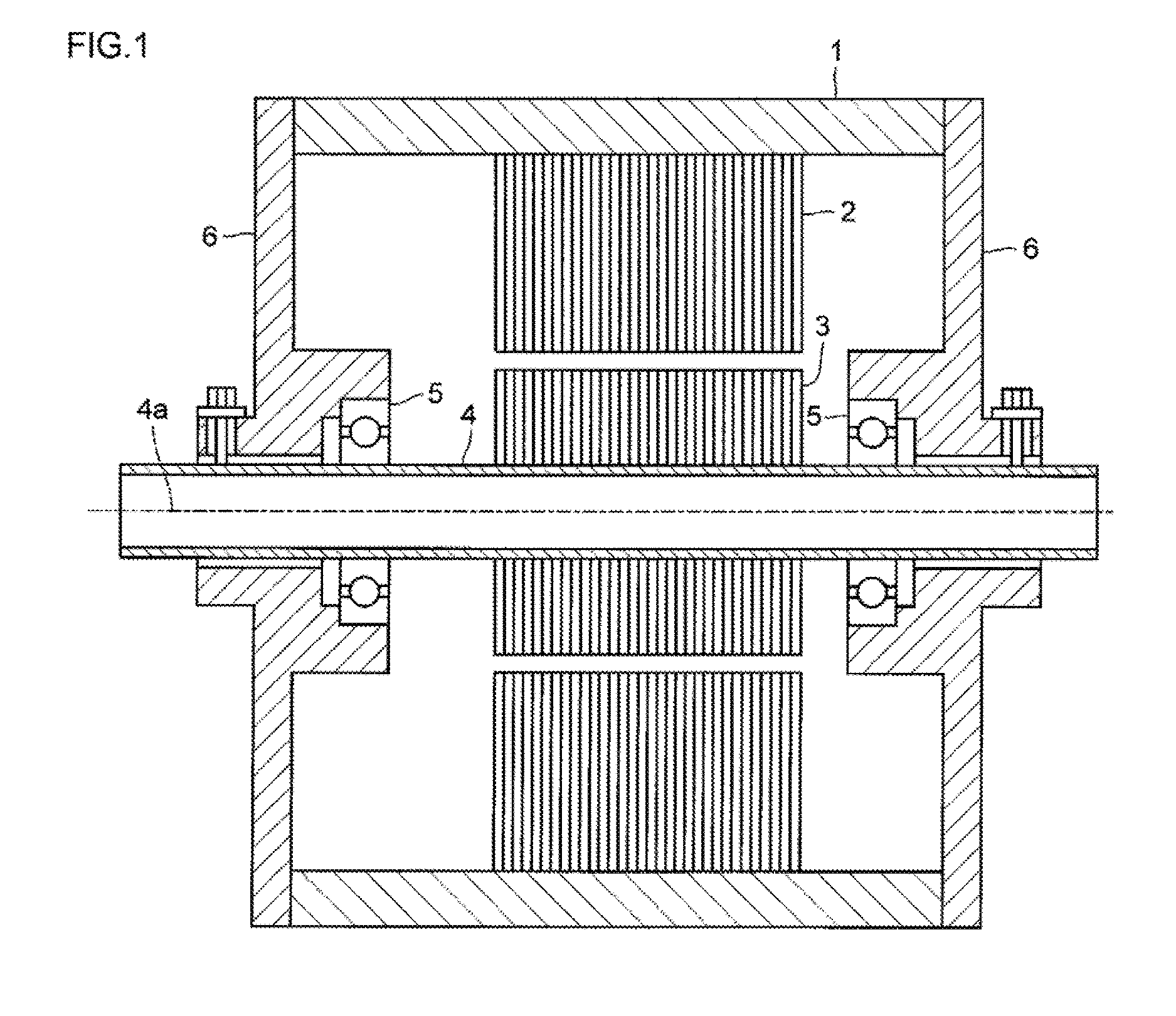

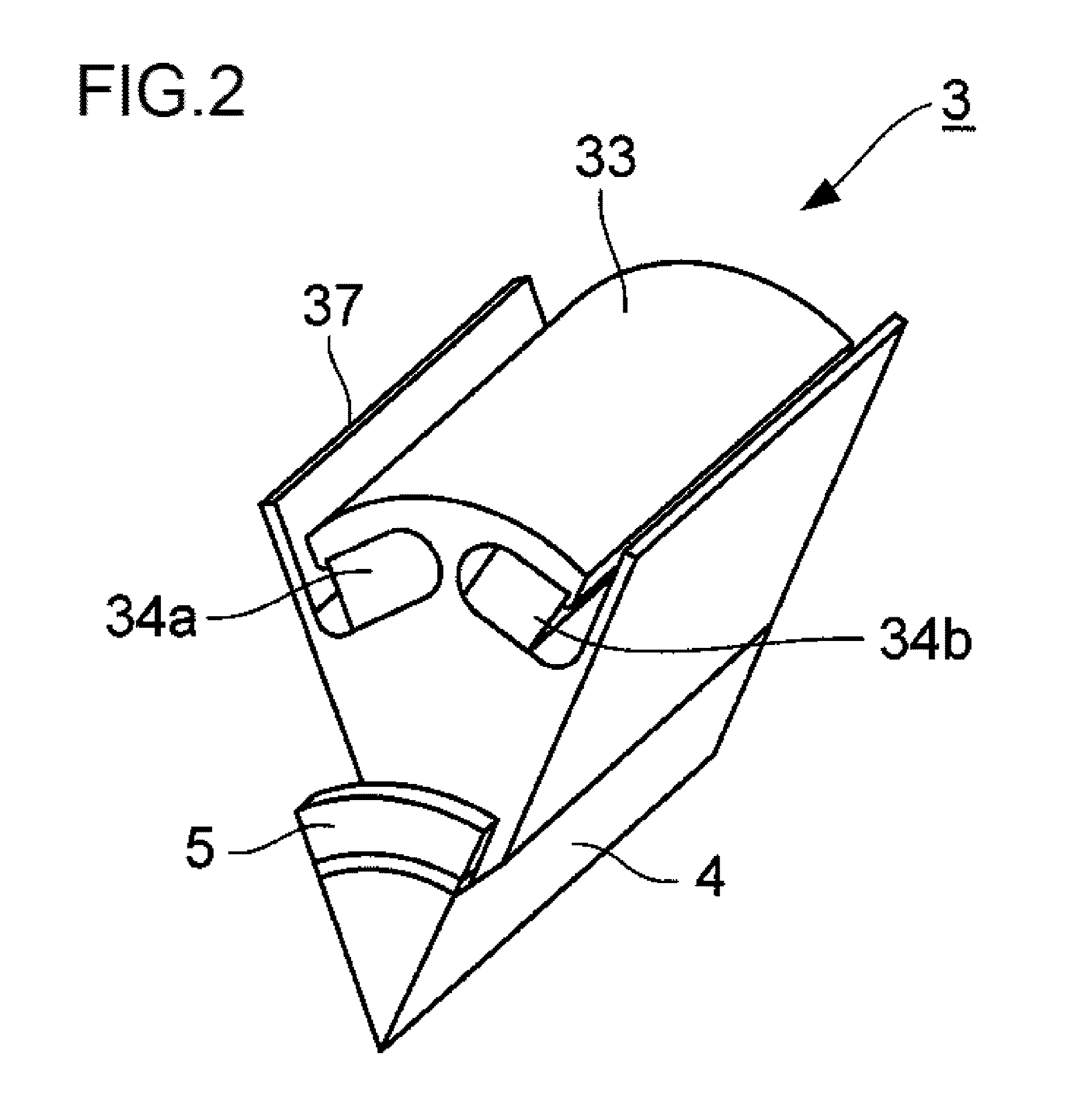

Permanent magnet embedded rotating electrical machine

InactiveUS20170063211A1Reduce leakage fluxHigh strengthMagnetic circuit rotating partsManufacturing stator/rotor bodiesEngineeringMagnet

A permanent magnet embedded rotating electrical machine such that permanent magnets of a multiple of poles are embedded in an interior of a rotor of which one pole is configured by two permanent magnets has a rotor such that an outer periphery of the rotor and a magnet embedding hole housing the permanent magnet communicate. Magnet embedding holes are arrayed so as to form an inverted V-shape. An auxiliary process, which is a V-shape process, a boss process, a pinhole process, or a bolt hole process, is performed in a region between an inscribed circle of the magnet embedding hole and the outer periphery of the rotor in each rotor steel plate configuring the rotor.

Owner:FUJI ELECTRIC CO LTD

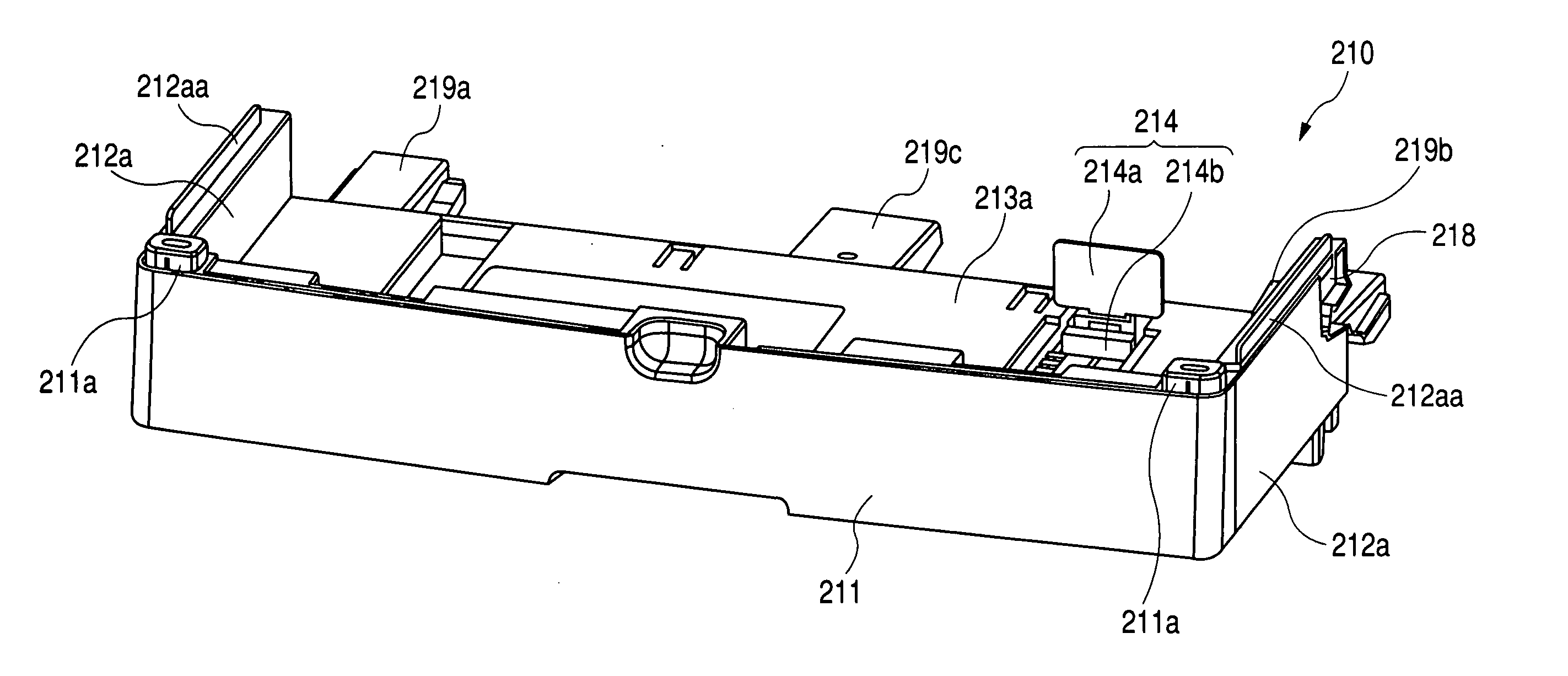

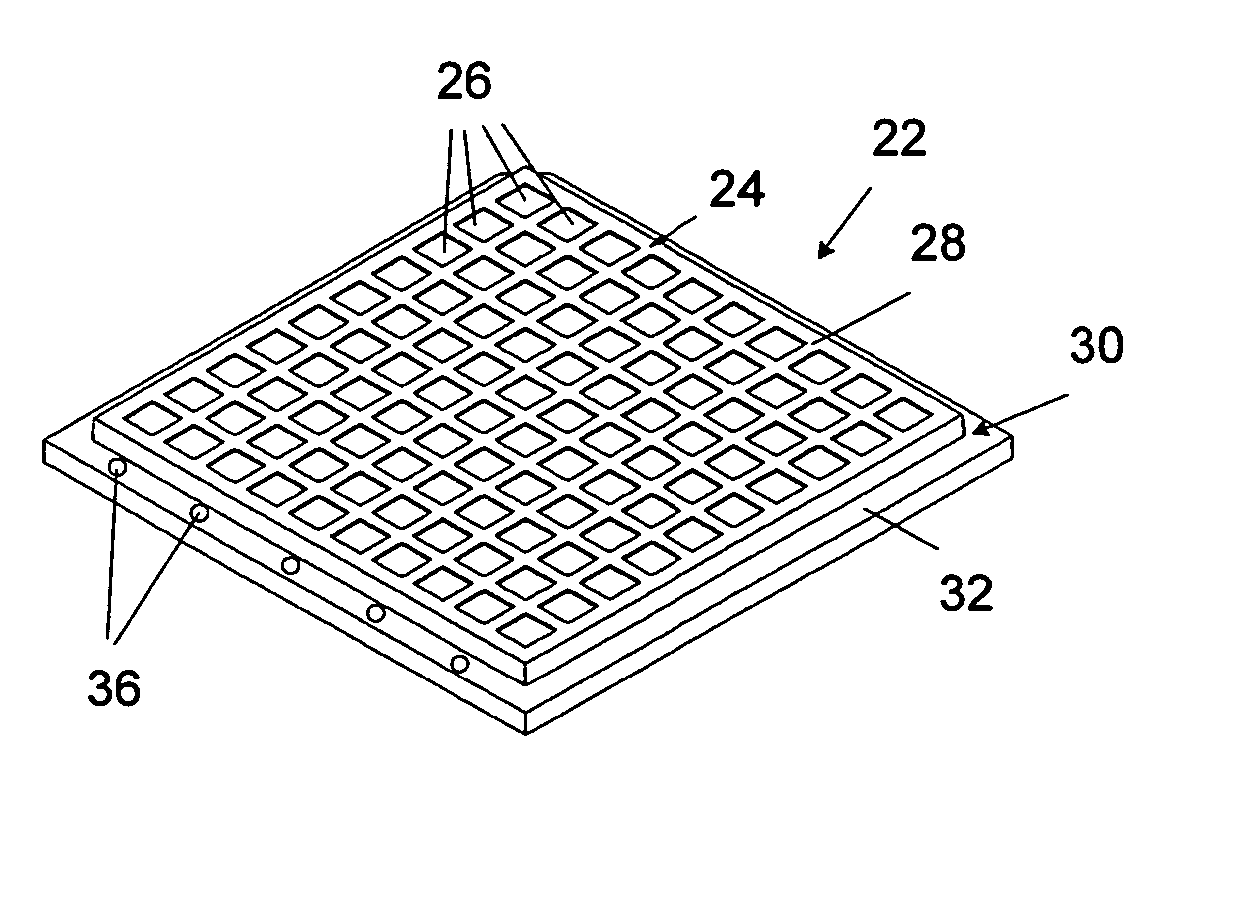

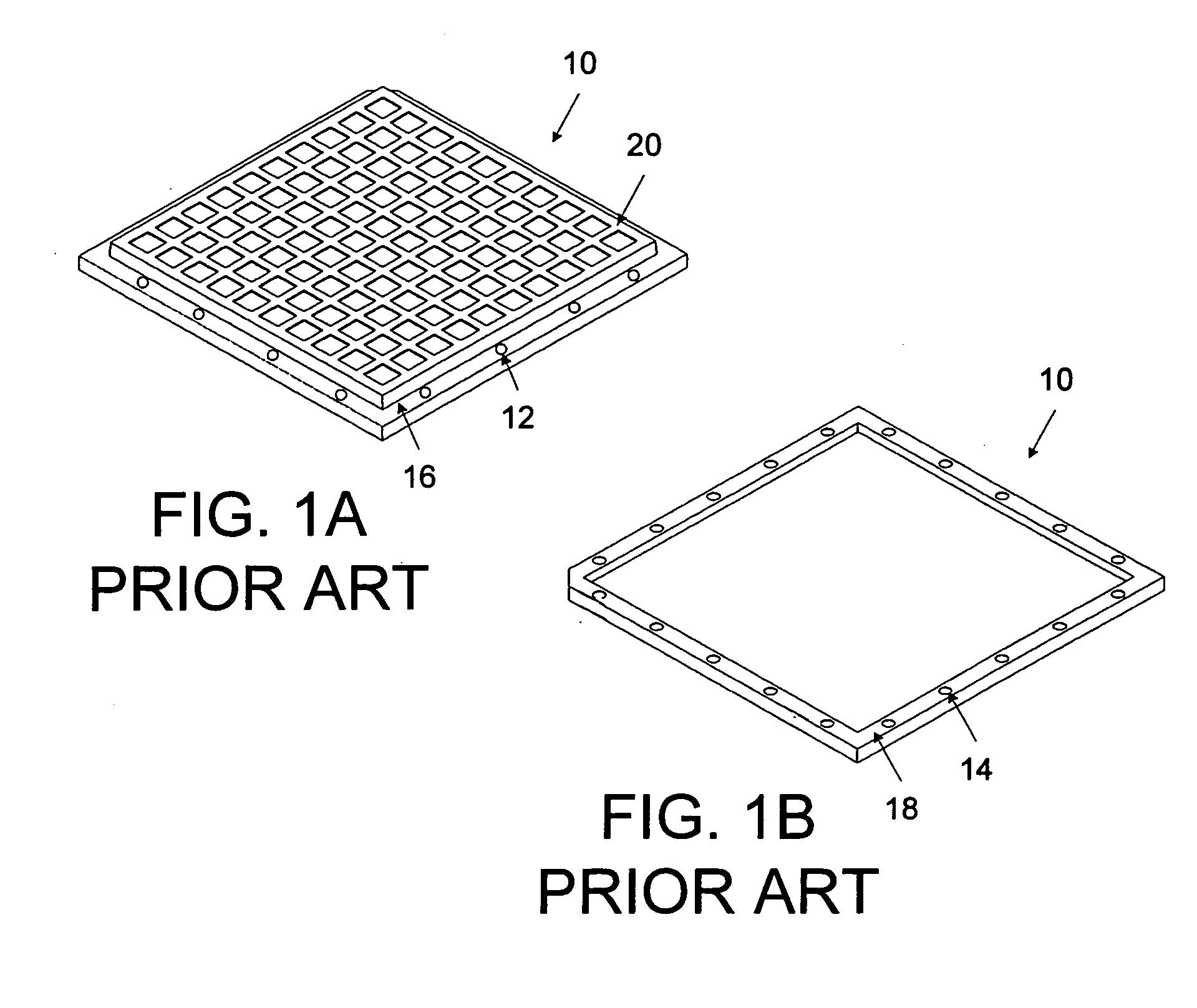

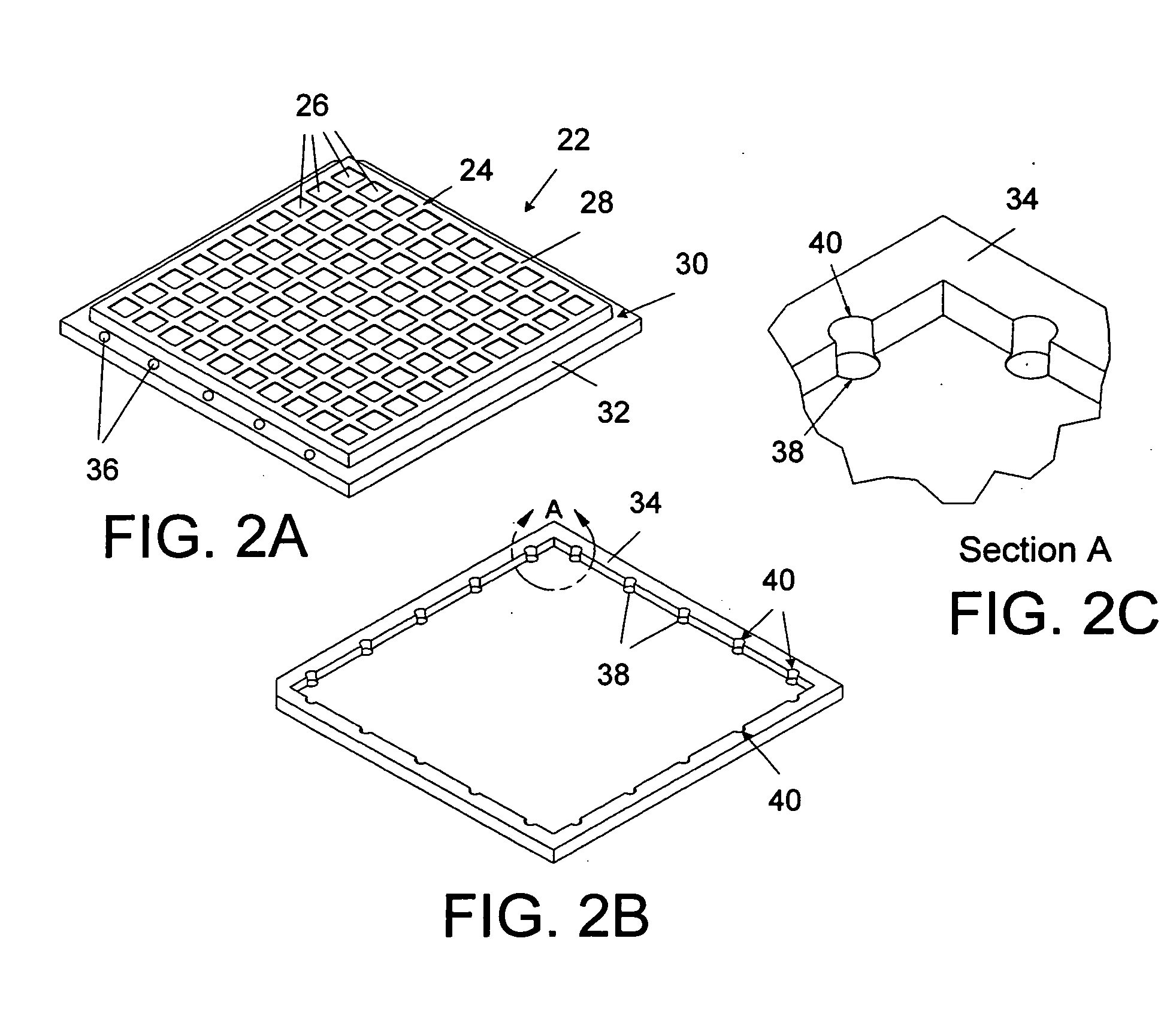

Tray with flat bottom reference surface

InactiveUS20050077205A1Improved reference surfaceStacking AccurateSemiconductor/solid-state device manufacturingOther accessoriesEngineeringReference surface

A molded component tray includes a component housing portion having a plurality of component pockets. The tray has a flange around the component housing portion defining a perimeter of the tray. A flange top surface in one embodiment is below the component housing top surface. A flange bottom surface includes recessed areas positioned in alignment with mold ejector pins which may contact the flange bottom surface, and alternatively in alignment with mold ejector pin marks on the flange top surface. The depth of the recesses is greater than the height burrs left by the ejector pins, thereby leaving the tray bottom surface free of burrs caused by ejector pins. Alternatively, when one tray is stacked on top of another, the recesses in the bottom of an upper tray can be positioned to allow clearance for ejector pin marks on the top of the flange of a lower tray.

Owner:PEAK PLASTIC & METAL PRODS INT

Glove stacking and counting machine

PendingCN108313378ANeatly stackedAccurate quantityPackaging automatic controlReciprocating motionEngineering

The invention discloses a glove stacking and counting machine and belongs to the technical field of glove production equipment. The glove stacking and counting machine is characterized in that the glove stacking and counting machine comprises a transferring conveying belt (5), a stacking bin (7) and a clamping conveying mechanism (6), wherein the stacking bin (7) is arranged at the output end of the transferring conveying belt (5), and the clamping conveying mechanism (6) is arranged between the transferring conveying belt (5) and the stacking bin (7); the stacking bin (7) is arranged at the lower side of the output end of the clamping conveying mechanism (6) in a sliding manner; the stacking bin (7) is connected with a power mechanism, wherein the stacking bin (7) is pushed by the power mechanism to perform reciprocating motion; the motion direction of the stacking bin (7) is parallel with the conveying direction of the transferring conveying belt (5); and a glove detection module isarranged at the side of the transferring conveying belt (5). By means of the transferring conveying belt of the glove stacking and counting machine, gloves taken off a hand mold can be conveyed to theclamping conveying mechanism; the clamping conveying mechanism clamp the gloves and is matched with the stacking bin, so that the gloves are gradually and flatly put into the stacking bin from one side; the stacking bin performs reciprocating motion; and it is guaranteed that the gloves are stacked orderly in the stacking bin.

Owner:淄博荣琦自动化科技有限公司

Counting conveying stacking system for corrugated paper

PendingCN106892294AReasonable structural designEasy to operateArticle deliveryStack machineDrive shaft

A counting conveying stacking system for corrugated paper comprises a corrugated board counting machine, a turning over conveying mechanism and a staggering and stacking machine; the turning over conveying mechanism comprises a corrugated paper conveyor and a turning over mechanism, the corrugated board counting machine comprises a paper separating rack, a chain plate lifting mechanism, a paper pushing mechanism and a paper separating baffle device, the chain plate lifting mechanism comprises a chain plate conveyor, a lifting control electric motor and a transmission shaft, a pair of rollers are respectively arranged on the two sides of the chain plate conveyor, and four upright columns of the paper separating rack are respectively provided with chutes matched with the rollers for use. The invention provides the counting conveying stacking system for corrugated paper which is reasonable in structural design, the corrugated board counting machine can realize automated and precise separate piling, and the counting conveying stacking system has the advantages of simple operation, high precision, safety and efficiency, capability of saving labor, and the like, can realize conveying, turning over and staggering and stacking of corrugated boards, is high in degree of automation and has well practical value.

Owner:武汉京山轻机智能装备有限公司

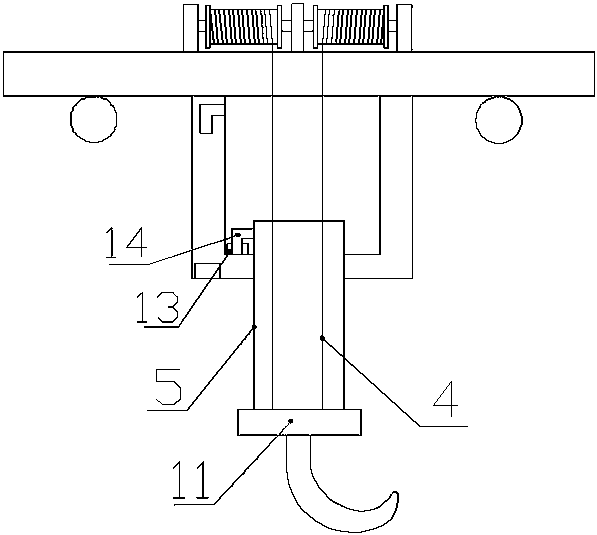

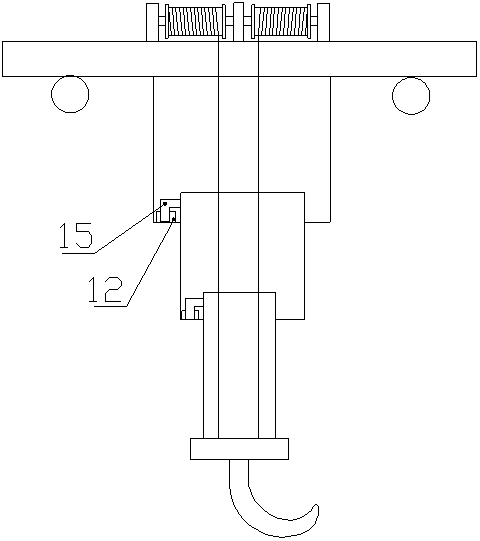

Roll-weakening device of crane

PendingCN108439213AAvoid swingingSwing doesn't happenWinding mechanismsLoad-engaging elementsEngineeringReducer

The invention discloses a roll-weakening device of a crane. The roll-weakening device comprises a trolley, wherein the middle part of the lower end of the trolley is welded with an outer barrel; a middle barrel is connected in the outer barrel in a sleeving mode; an inner barrel is connected in the middle barrel in the sleeving mode; a groove A is formed in the left side of the lower end in the outer barrel; the upper part of the left side surface of the middle barrel is fixedly connected with a bulge A matched with the groove A; a groove B is formed in the left side of the lower end in the middle barrel; the upper part of the left side surface of the inner barrel is fixedly connected with a bulge B matched with the groove B; a motor, a speed reducer and a winding drum mechanism are mounted at the upper end of the trolley; the output shaft of the motor is connected with a high-speed shaft of the speed reducer through a shaft coupler; the winding drum mechanism is composed of winding drums which are symmetrically arranged at the two sides of the speed reducer; the two ends of each winding drum are separately mounted on the trolley through bearing bases; steel wire ropes are mountedon the winding drums; the inner barrel and the lower ends of the steel wire ropes are fixedly connected with a fixed plate; and the lower end of the fixed plate is fixedly connected with a hanger. Theroll-weakening device has the advantages of being simple and convenient to operate, capable of reducing hanger swing, and being good in roll-weakening effect, high in stability and high in safety.

Owner:HENAN ZHONGYUAN HOIST MACHINERY

Anti-toppling stacker robot

InactiveCN109437056AReduce stacking robots and item damageImprove stabilitySafety devices for lifting equipmentsEngineeringStacker

The invention relates to the field of robots, in particular to an anti-toppling stacker robot. According to the technical scheme, the anti-toppling stacker robot comprises a robot main body; a material bearing lifting mechanism is installed on the robot main body, and a material bearing plate is connected to the material bearing lifting mechanism; the robot main body is further connected with an anti-toppling lifting mechanism; one end of a supporting rod is connected to the anti-toppling lifting mechanism, the other end of the supporting rod is connected with one end of a spring, and the other end of the spring is connected with a supporting barrel; and the spring and the supporting rod are both arranged in the supporting barrel in a sleeved mode, and the supporting barrel is connected with a rolling wheel. The anti-toppling stacker robot provided by the invention can avoid toppling through the self reliable support when toppling to a certain extent, and the problem that an existing stacking robot is prone to rollover in the moving process is solved.

Owner:蒲培忠

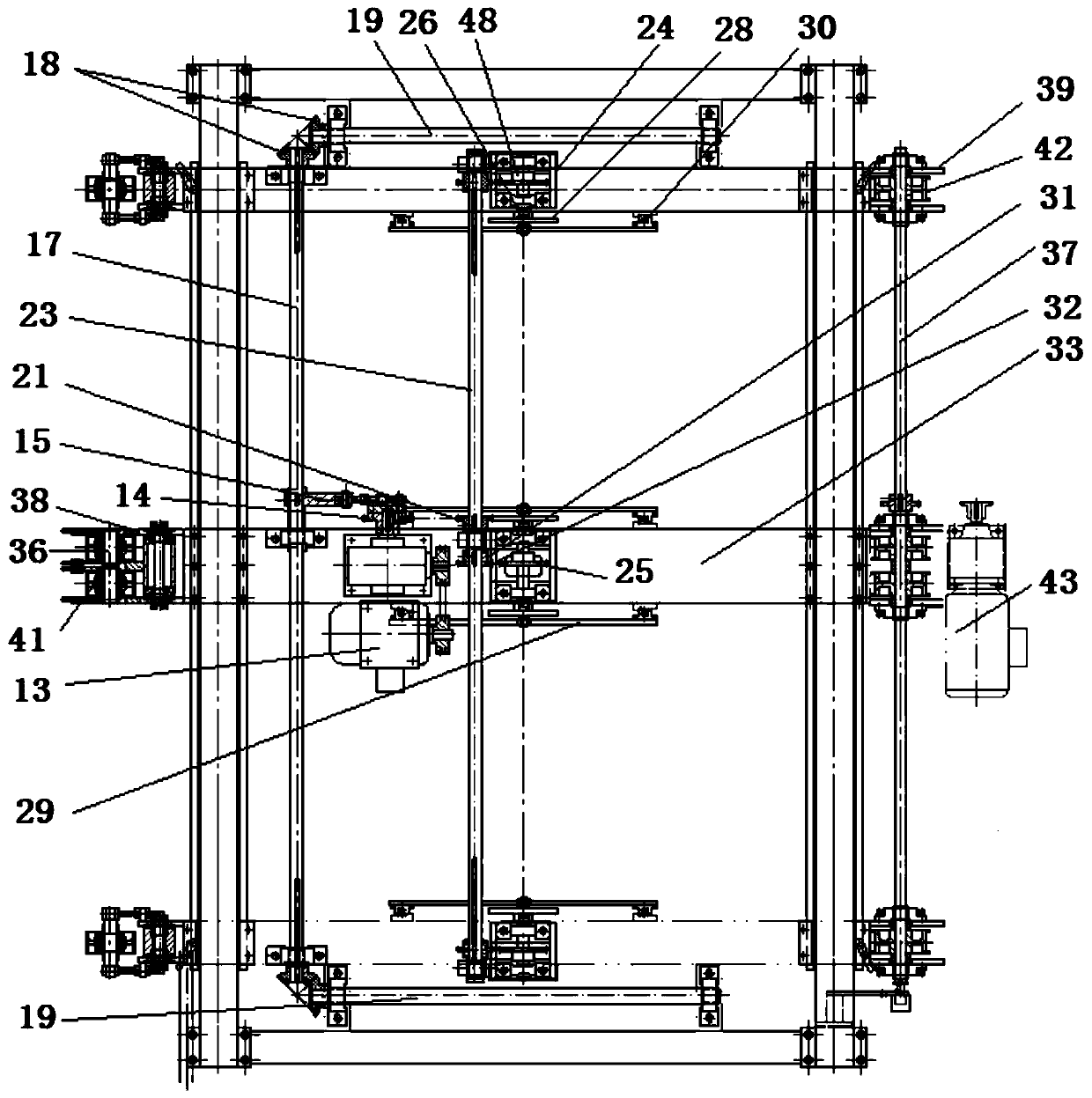

Combined-layer laminated plate automatic stacking device

PendingCN111153153ANo damageNovel structureControl devices for conveyorsStacking articlesSingle plateStructural engineering

The invention discloses a combined-layer laminated plate automatic stacking device. The combined-layer laminated plate automatic stacking device comprises a rack, an adsorbing mechanism, a falling mechanism, a conveying mechanism, a plate receiving mechanism and a control device, and is characterized in that clamping and conveying mechanisms are arranged on the two sides of the rack in a mirror image mode, and a clamping and falling driving device is arranged at the upper end of the rack. The clamping and falling driving device automatically controls the clamping and conveying mechanisms and the conveying mechanism to automatically clamp and convey combined-layer single plates, automatically fall and automatically center, the working efficiency is significantly improved, and the combined-layer laminated plate automatic stacking device has the advantages of the novel structure, automatic single plate combined-layer stacking, automatic centering, unbroken plates, accurate stacking, the time-saving and labor-saving effect, the high working efficiency and the like.

Owner:SHANDONG BAISHENGYUAN GRP

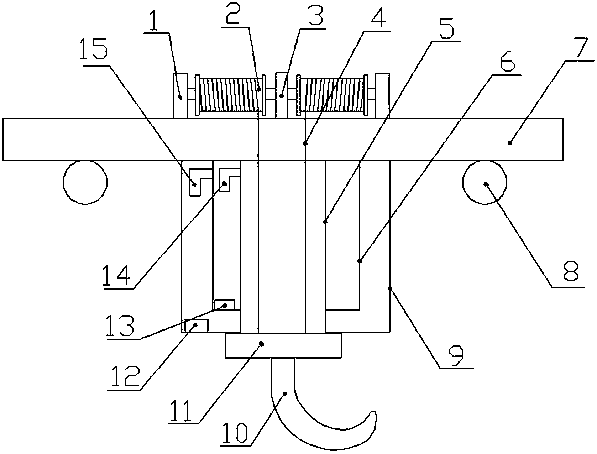

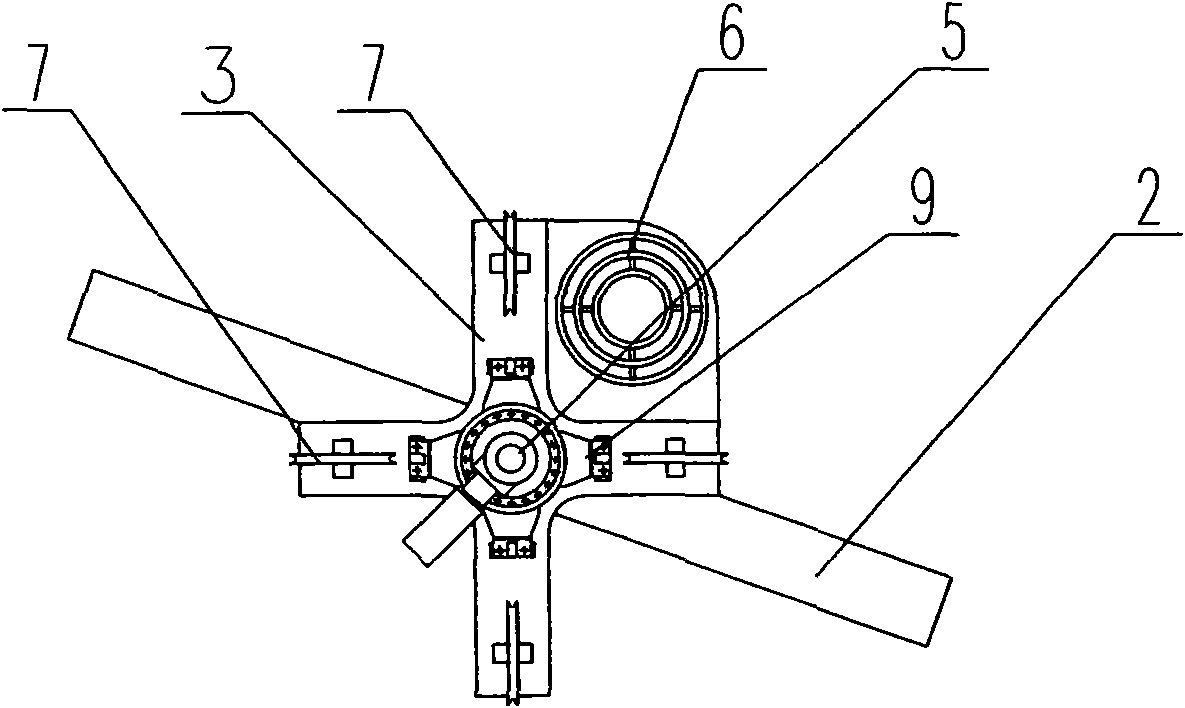

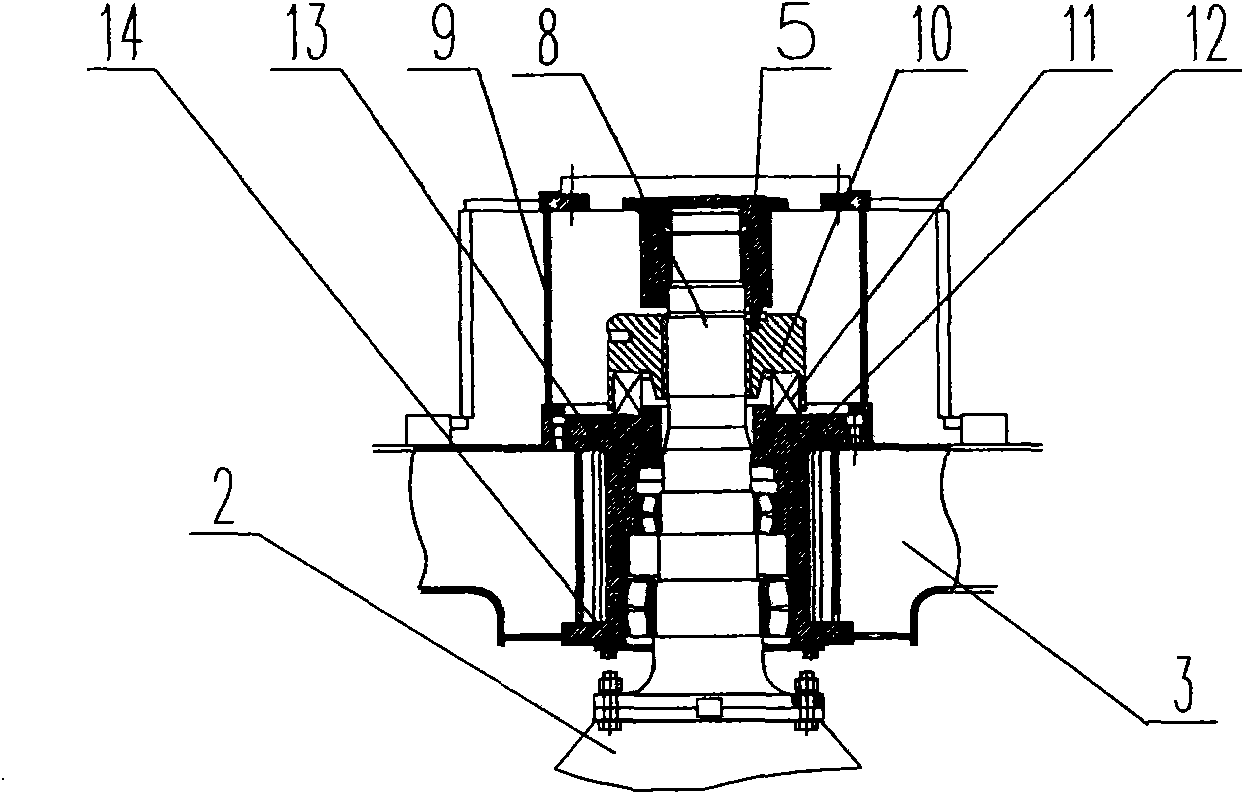

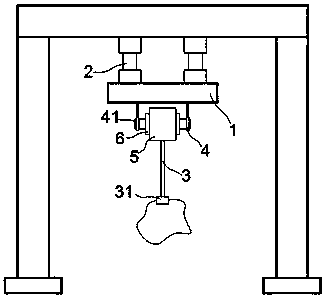

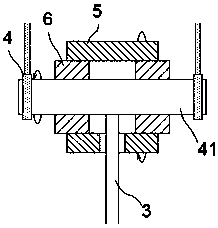

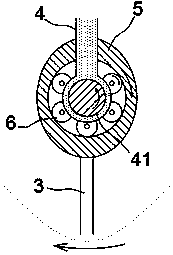

Rotary lifting appliance of electromagnetic plate crane

The invention discloses a rotary lifting appliance of an electromagnetic plate crane and relates to the electromagnetic plate crane. By the rotary lifting appliance, the problems of complex structure, unreasonable structure design and poor sealing performance of the existing rotary lifting appliance are solved. A cross beam connected with a driving mechanism of the rotary lifting appliance is arranged above an electromagnetic suspended beam. A motor drives a speed reducer. An internal spline of an output shaft of the speed reducer is matched with an external spline of a rotating shaft to drive the rotating shaft to rotate. A flange at the lower end of the rotating shaft is connected with a flange at the end part of the electromagnetic suspended beam through a bolt. Screw threads at the upper part of the rotating shaft are connected with a lifting hook nut. A thrust bearing is arranged between the lifting hook nut and a bearing support which is sleeved on the rotating shaft and is connected with the cross beam. The lower end of the bearing support is provided with a sealing flange and is matched with the rotating shaft. A positioning bearing is also arranged between the bearing support and the rotating shaft.

Owner:TAIYUAN HEAVY IND

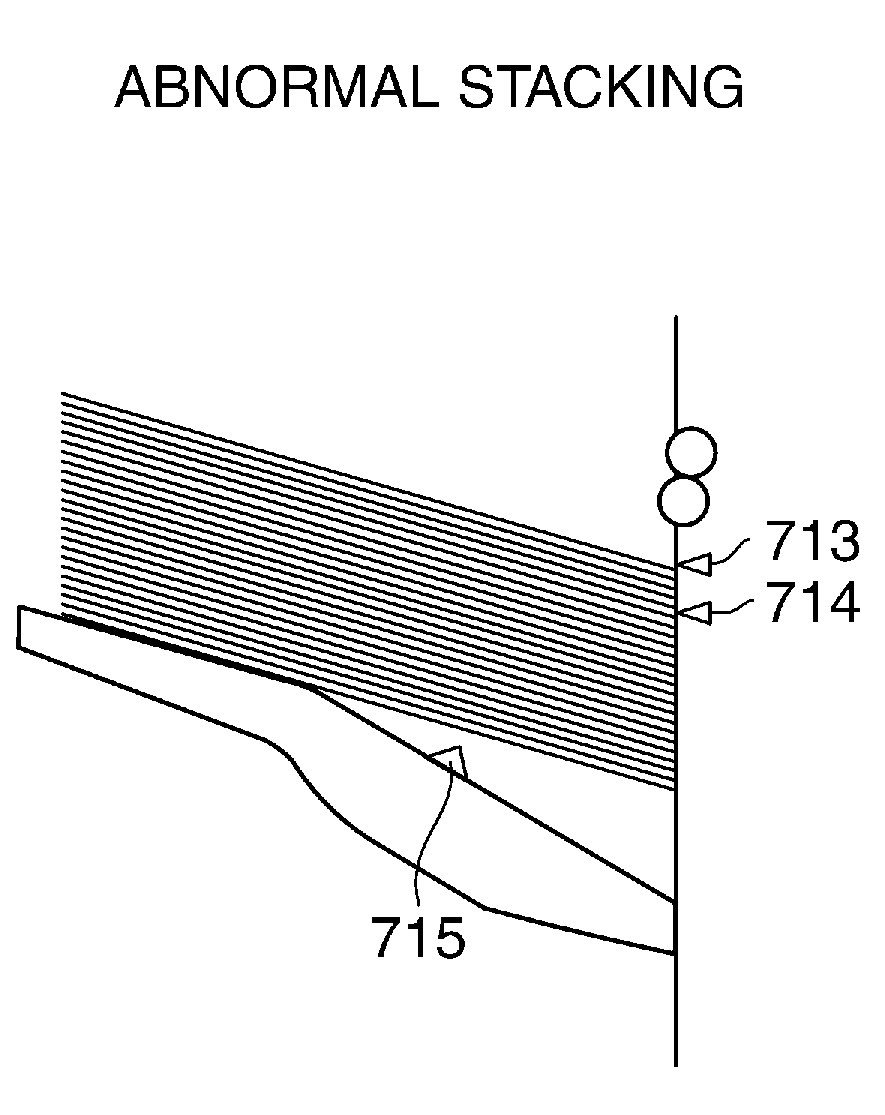

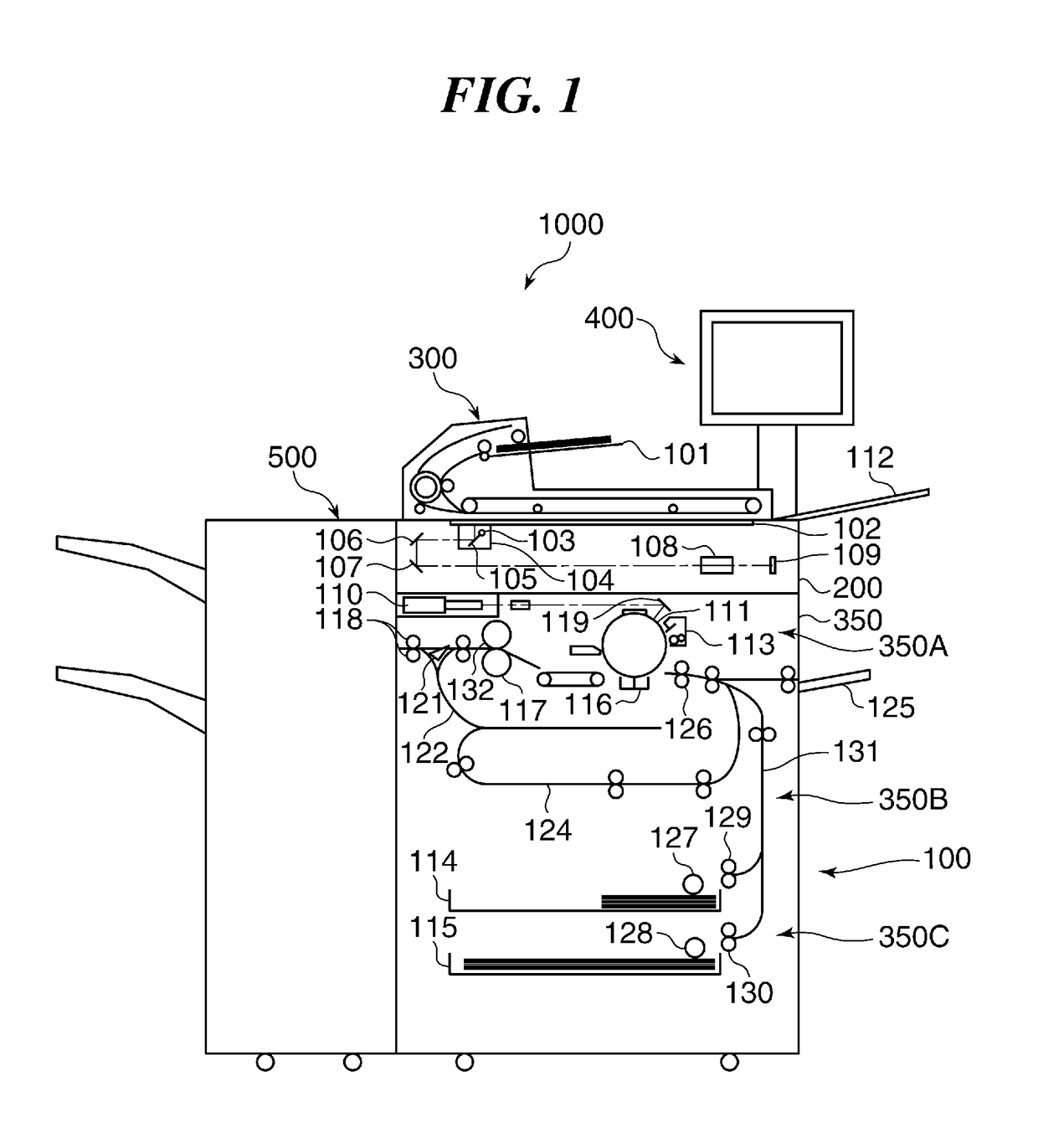

Sheet processing apparatus including stacking tray on which sheets are stacked, and image forming system

ActiveUS9708149B2Avoid stackingStacking AccurateFunction indicatorsPile receiversStack overflowPaper sheet

A sheet processing apparatus capable of properly stacking sheets by detecting abnormality of a sheet stacking state during a sheet stacking operation to thereby prevent stack overflow. In the sheet processing apparatus, a conveyed sheet is stacked on a stacking tray. A sheet presence sensor detects a sheet on a sheet stacking surface of the stacking tray. A sheet height reduction sensor detects sheets within a predetermined distance downward from the uppermost surface of sheets stacked on the stacking tray. When the sheet presence sensor detects no sheet, and the sheet height reduction sensor detects a sheet during an operation for discharging a plurality of sheets onto the stacking tray, it is determined that an abnormal stacking state has occurred, and conveyance of a sheet is stopped.

Owner:CANON KK

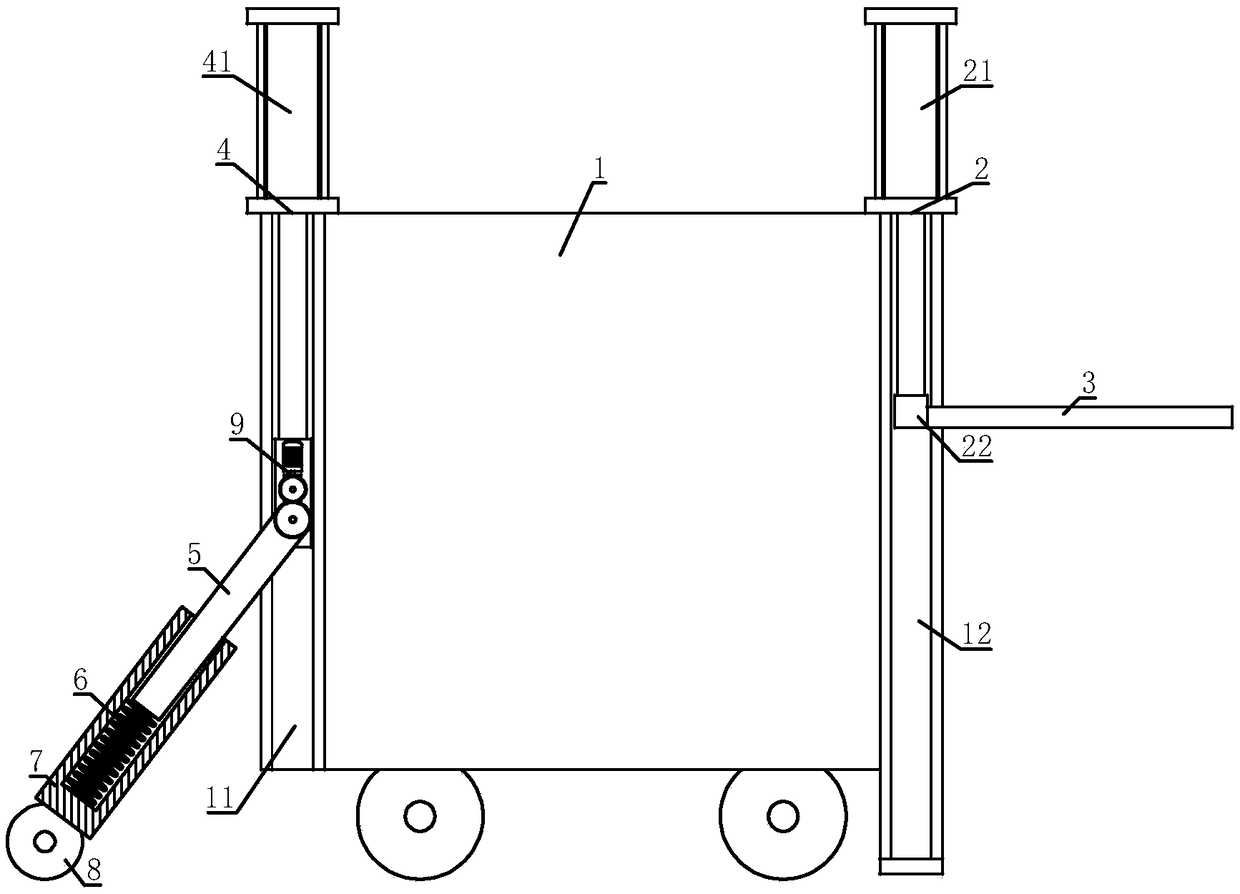

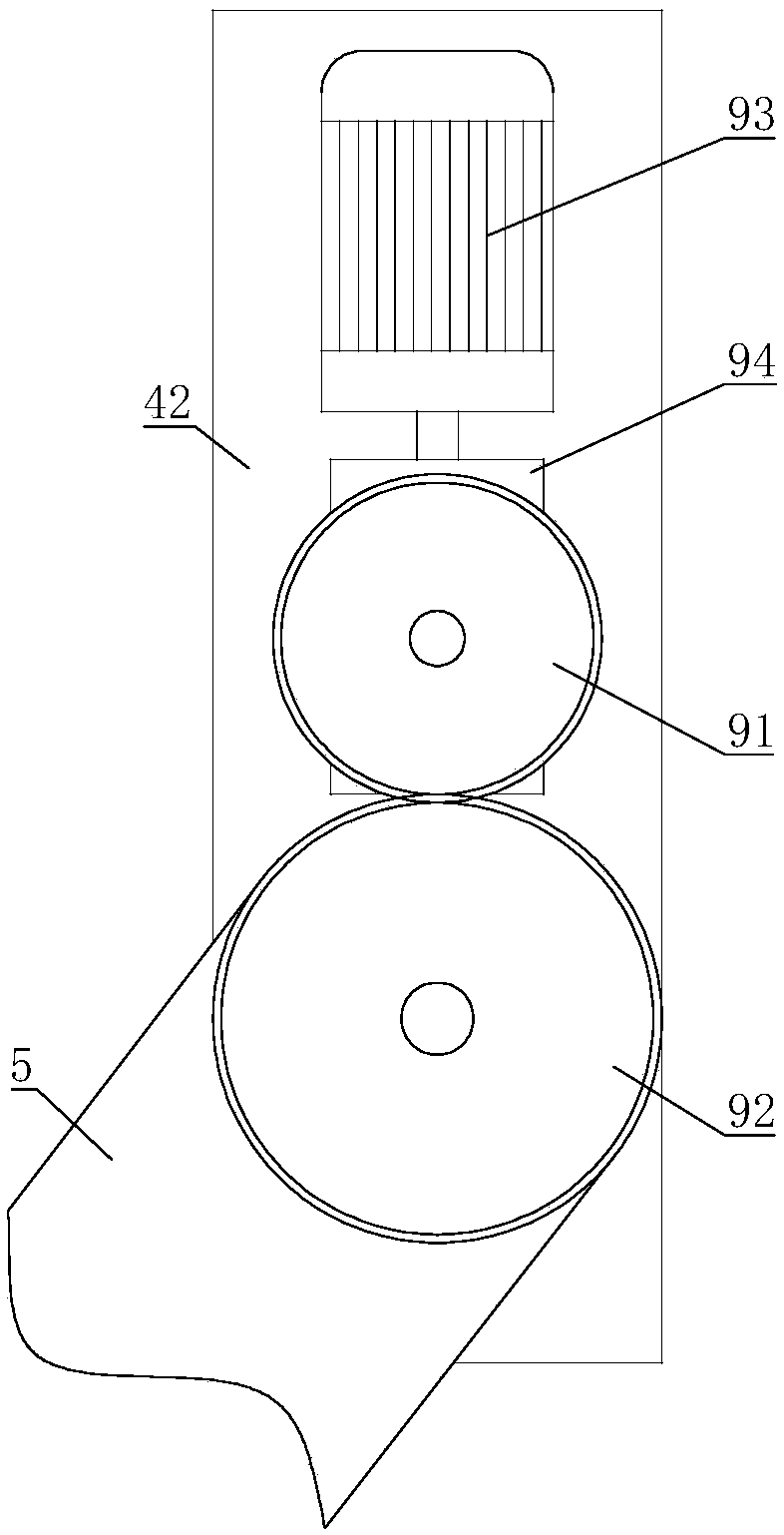

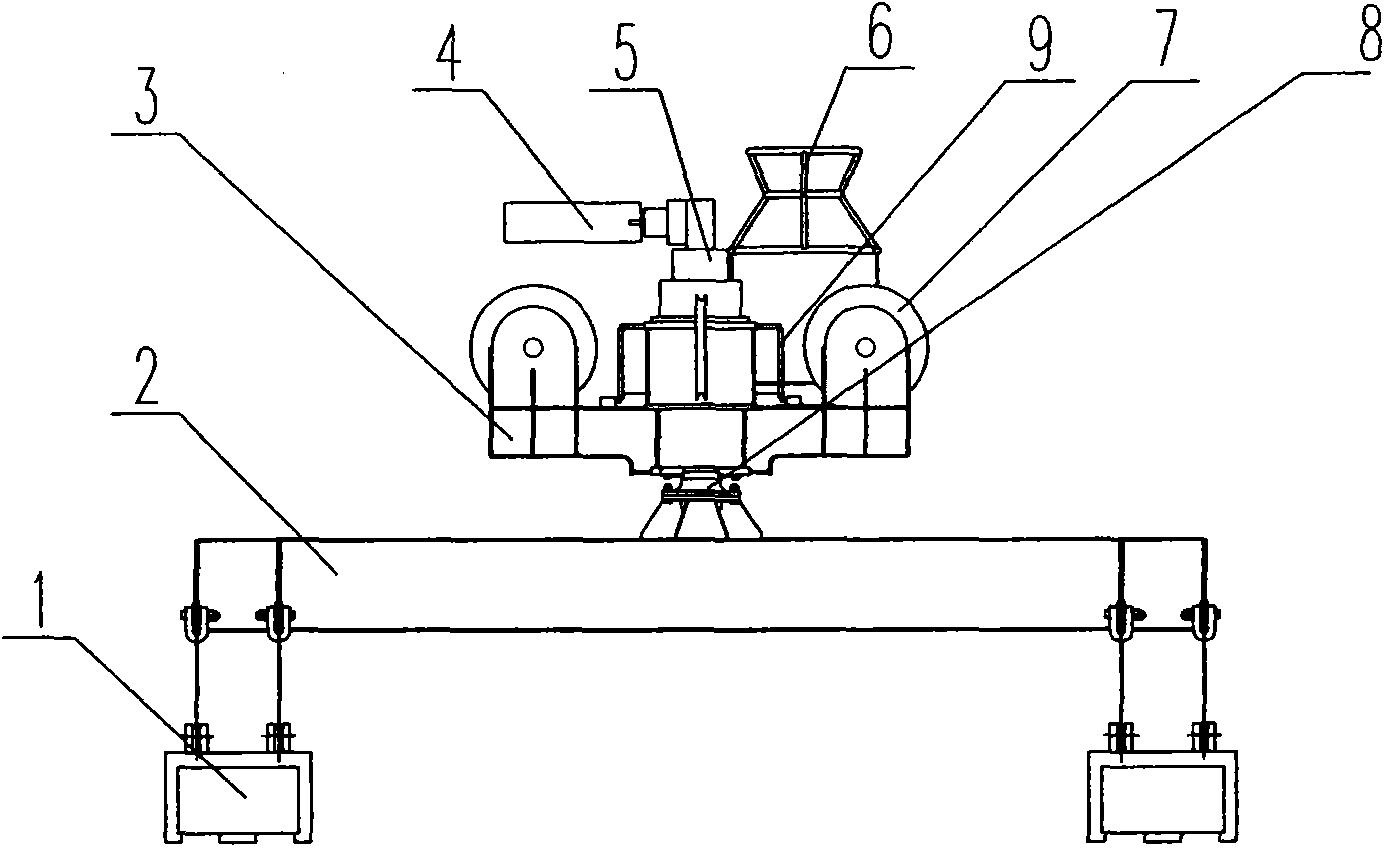

Anti-shaking device for crane

InactiveCN107601281AStacking AccurateReduce swingTrolley cranesLoad-engaging elementsEngineeringAcceleration Unit

The invention relates to an anti-shaking device for a crane. The anti-shaking device comprises a supporting frame, a main beam, an operation trolley, lifting mechanisms, a sling and a lifting hook arranged at the lower part of the sling; the anti-shaking device is arranged at the lower part of the operation trolley, and comprises supporting rings, wherein a horizontal central shaft is arranged inthe supporting rings in a sleeved mode, and the central shaft can freely rotate around the axis of the central shaft; an anti-shaking cylinder is coaxially arranged outside the central shaft in a sleeving mode, and the anti-shaking cylinder is meshed with the central shaft through an acceleration gear set; the sling penetrates through the cylinder wall of the anti-shaking cylinder, and then is fixedly arranged on the shaft surface of the central shaft; and when the lifting hook is located right below the central shaft, the sling is in a vertical straight line shape. According to the anti-shaking device, the swing amplitude in the suspension process of weights can be effectively relieved, so that rapid stability recovery of cargoes is promoted, operators can safely and accurately land the weights conveniently, stacking stability and accuracy are guaranteed, and carrying efficiency is effectively improved.

Owner:丁向峰

Sheet registry device

InactiveUS7490829B2Stacking AccurateEliminate needRegistering devicesFunction indicatorsEngineeringSheet material

Owner:OCE TECH

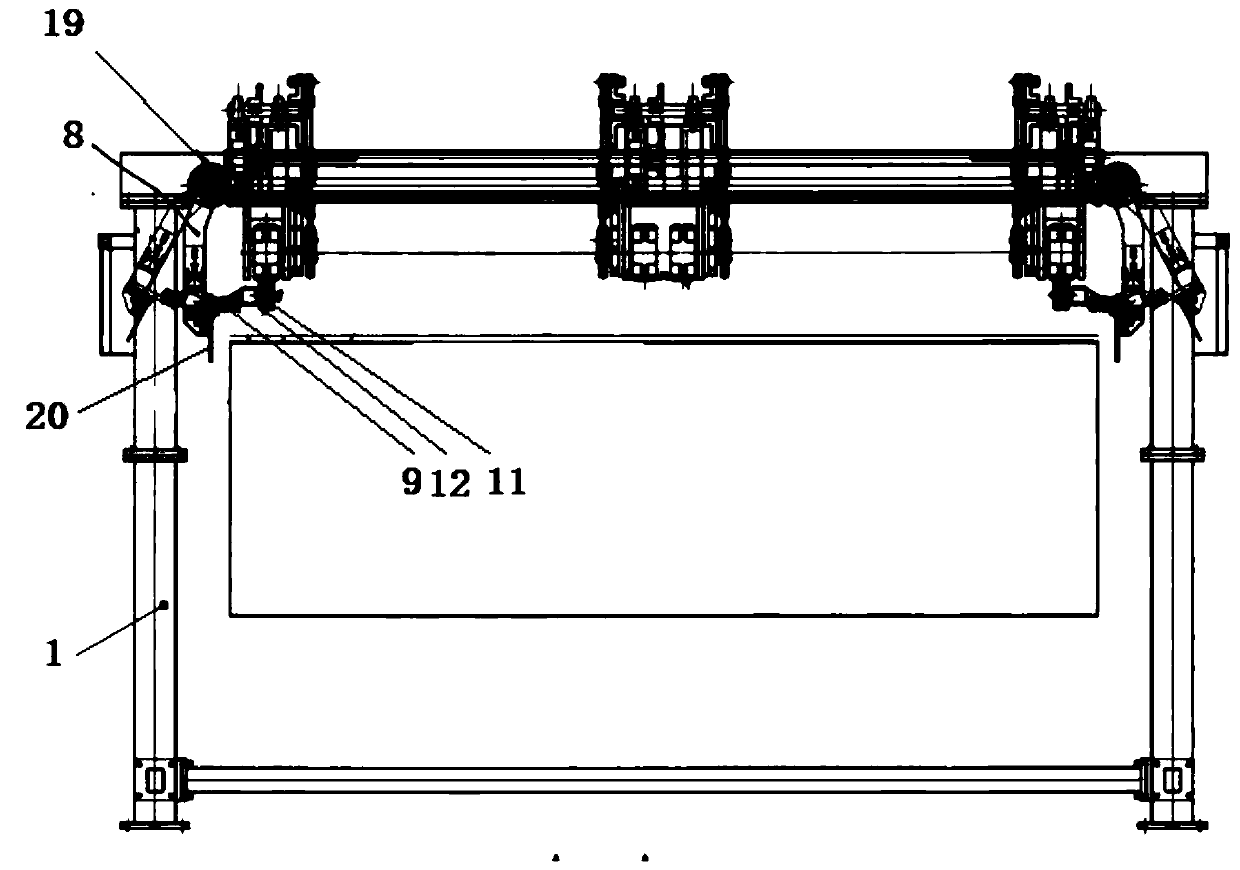

High-precision stacking machine

PendingCN110010974APrecise feeding positionStacking AccurateFinal product manufactureElectrolyte accumulators manufactureStack machineMechanical engineering

The invention discloses a high-precision stacking machine, comprising a frame, a stacking table for stacking battery pole pieces, and a pick-and-place mechanism for clamping the battery pole pieces and placing the same on the stacking table. The pick-and-place mechanism and the stacking table are all disposed on the frame. The stacking table comprises a rack fixed to the frame, a worktable for stacking the battery pole pieces, and a driving device connected to the worktable. The worktable, after receiving the battery pole pieces placed by the pick-and-place mechanism every time, is driven by the driving device to move a preset distance downwards in the height direction of the frame. The worktable downwards moves the preset distance so that the pick-and-place mechanism discharges the battery pole pieces at the same height relative to the frame every time. Thus, the pick-and-place mechanism can achieve an accurate discharging position and ensures accurate stacking between the battery pole pieces. In addition, the stacking efficiency of the high-precision stacking machine is also increased due to the reduced path of the pick-and-place mechanism.

Owner:DONGGUAN CHAOHONG AUTOMATION EQUIP CO LTD

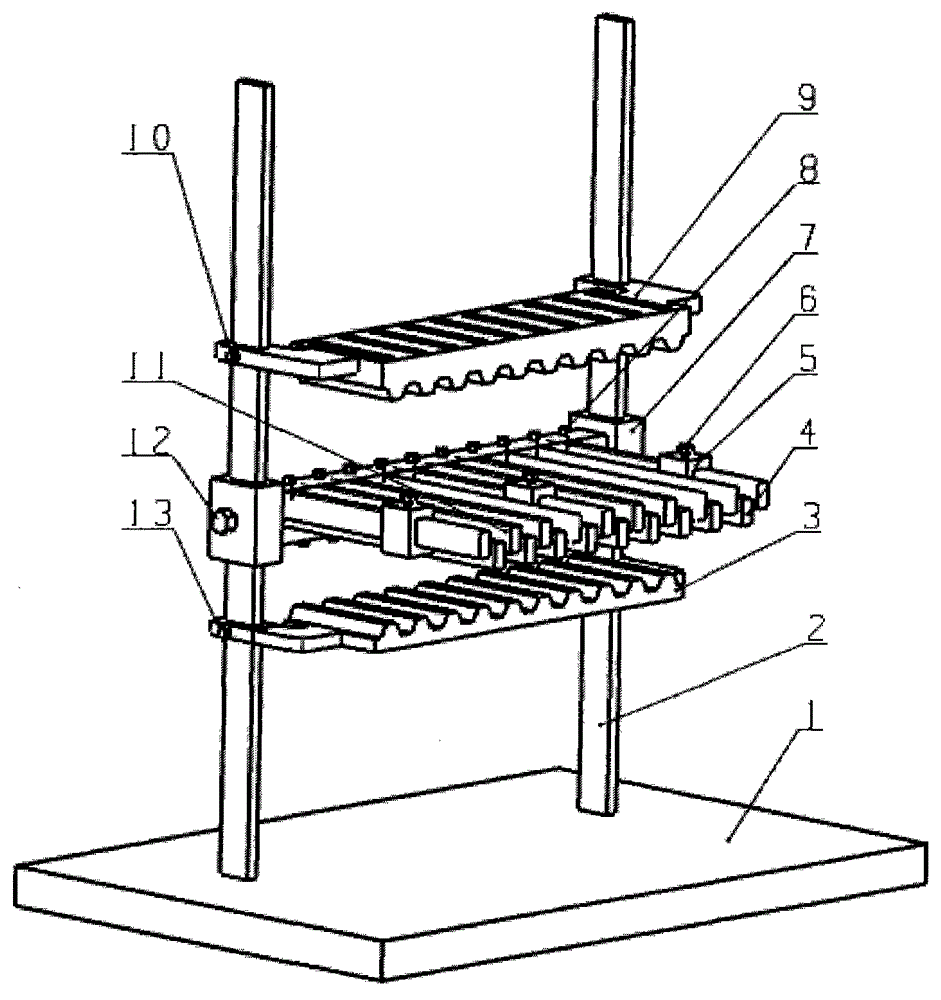

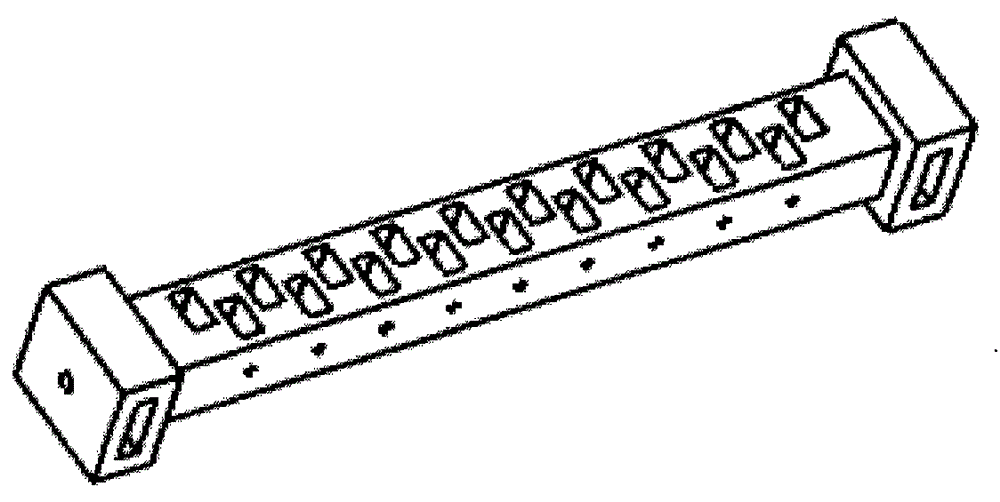

High-temperature alloy honeycomb core and corrugated board stacking method and device

ActiveCN103552360AGuaranteed shape accuracyFit tightlyLamination ancillary operationsLaminationHoneycombStructural engineering

The invention belongs to the field of a honeycomb core machining technology, and particularly relates to a high-temperature alloy honeycomb core and semi-regular-hexagon corrugated board stacking method and device. Press plates are used for pressing and locating, and locating mandrils and support mandrils are used for locating and supporting, so that high-temperature alloy honeycomb cores and semi-regular-hexagon corrugated boards can be accurately stacked, located and supported, the deformation of the corrugated boards and the honeycomb cores can be greatly reduced during stacking spot welding, and the shape accuracy of the honeycomb cores is guaranteed; the press plates, limiting plates and rising location blocks can be flexibly adjusted up and down along support rods according to the stacking height of the honeycomb cores; limiting blocks can move along the locating mandrils and the support mandrils, and can be flexibly adjusted and located according to the corrugated boards with different widths; the numbers of the locating mandrils and the support mandrils as well as the lengths of the press plates and the limiting plates can be designed according to the whole length of the required honeycomb core; the stacking method and the stacking device are high in efficiency, high in accuracy, low in cost and short in process, thus being suitable for industrial large-scale production.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

Sheet registering device

InactiveUS20070108699A1Productive and reliable mannerEasy to useRegistering devicesFunction indicatorsEngineeringSheet material

A sheet processing device wherein sheets are deposited in a staggered configuration relative to one another, which includes a paper path, a first and second sheet edge guide fitted substantially parallel to one another in the feed-through direction, and a transportation device arranged to convey a sheet through the paper path in the feed-through direction and the lateral direction, where the first and second sheet edge guides are arranged statically relative to the paper path and in a staggered configuration relative to one another in the lateral direction, and a switchable control mechanism is fitted to adopt a first and second configuration, allowing a sheet edge to be conveyed into respective first and second sheet edge guides during operation.

Owner:OCE TECH

Cigar wrapper and binder stem removing device

InactiveCN108142981AEfficient cullingEfficient stackingTobacco preparationTobacco treatmentMechanical engineeringDouble edge

Provided is an intelligent tobacco leaf stem removing device. The device can realize modes of stem removing, stacking, tobacco stem smashing, flexibly controlling and the like. Each cloth belt is formed into a closed driving belt by winding a large roller and each small roller, and the contact surface formed by the large roller and the driving belTS can complete the conveying, spreading and stacking of tobacco leaf pieces. A circular double-edged hob is arranged in the middle of the large roller, each hob blade and the corresponding rotary butcher's knife and chopping block form two pairs of rotary rolling cutters, and the rolling cutters complete the cutting of leaf stems. Wall plates at the two sides provide support, fixation and connection for the large roller, small rollers and other functional parTS. A set of manual connecting rod mechanisms is arranged on an operation table, the opening and closing of a machine head are completed, and at the same time, the relaxation and tensionof the cloth belt are completed. A separate tension spring mechanism is arranged on each driving cloth belt, the cloth belt tension is kept when the machine head is closed, and the tension spring is unloaded to keep the cloth belt loose when the machine head is opened.

Owner:XIANGYANG SHENGUAN MECHANICAL & ELECTRICAL TECH CO LTD

Runway type coil numerical control taping machine

PendingCN110611408AHigh degree of automationEasy to operateApplying solid insulationElectrical and Electronics engineeringTape head

The invention discloses a runway type coil numerical control taping machine which comprises a base, a telescopic platform is arranged on the base along the periphery, a taping head is mounted on the telescopic platform, the taping head can move along the telescopic platform, an air cylinder clamping device is arranged on the periphery of the telescopic platform, the air cylinder clamping device isfixed to the base through an air cylinder locking handle, an electrical cabinet and an operation box are arranged on two sides of the base, the electrical cabinet is electrically connected with the operation box, the operation box is electrically connected with the air cylinder clamping device, and the taping head is electrically connected with the electrical cabinet and the operation box. The runway type coil numerical control taping machine has the advantages of a high automation degree of a taping mode, simple operation, tight tape shape, uniform binding tightness, accurate lapping, attractive appearance and good practicability.

Owner:上海闵行机械工程技术研究所有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com