Cigar wrapper and binder stem removing device

A technology for cigars and wrappers, which is applied in the fields of tobacco, tobacco preparation, and tobacco processing, and can solve problems that restrict the development of the industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] specific implementation plan

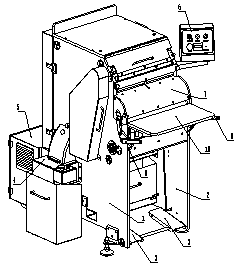

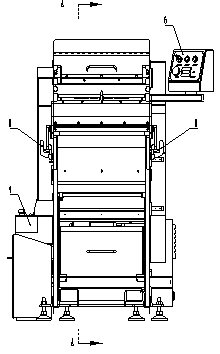

[0020] figure 1 , figure 2 It is the appearance layout diagram of the device, including left wallboard 1 right wallboard 2, reversible machine head 7, electric control box 5, stem crushing device 7, cantilevered console 6, operation table 10, linkage mechanism 8, pedals Mechanism 3 and the invisible large roller, small roller, cutter, stem row and other mechanisms are formed.

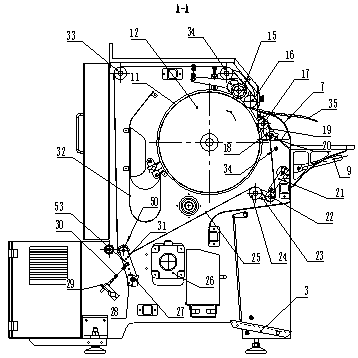

[0021] exist figure 2 , image 3 Among them, the main drive motor 26 drives the large drum 12 to rotate in the M direction. The annular hob 11 and the rotary knife 15 that are fixedly connected in the middle of the large drum 12 form a shearing edge. The cloth belt 25 wrapped on the surface of the large drum 12 forms a closed endless transmission belt through the upper feed roller 16, roller 34, roller 33, roller 50, roller 24, roller 22, and lower discharge roller 17, and the material 35 passes through the feed roller 16. The material 35 is sent into the la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com