Patents

Literature

32results about How to "Stacked flat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

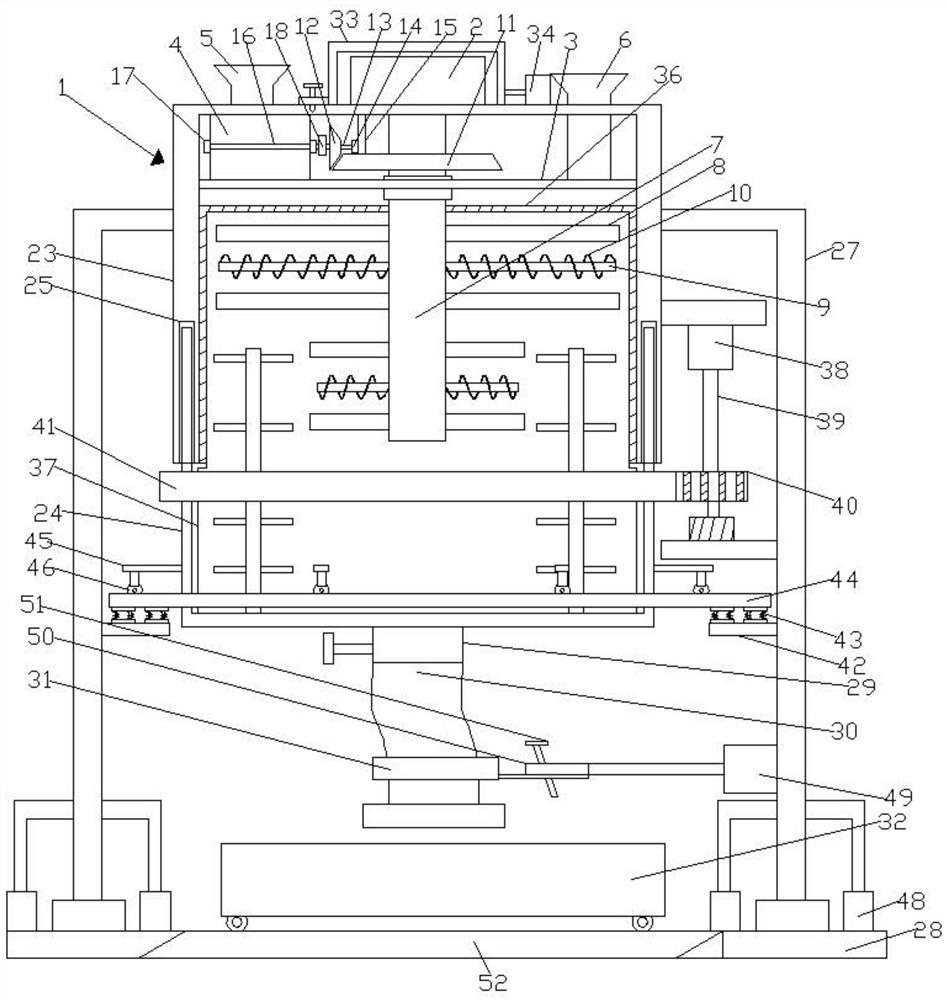

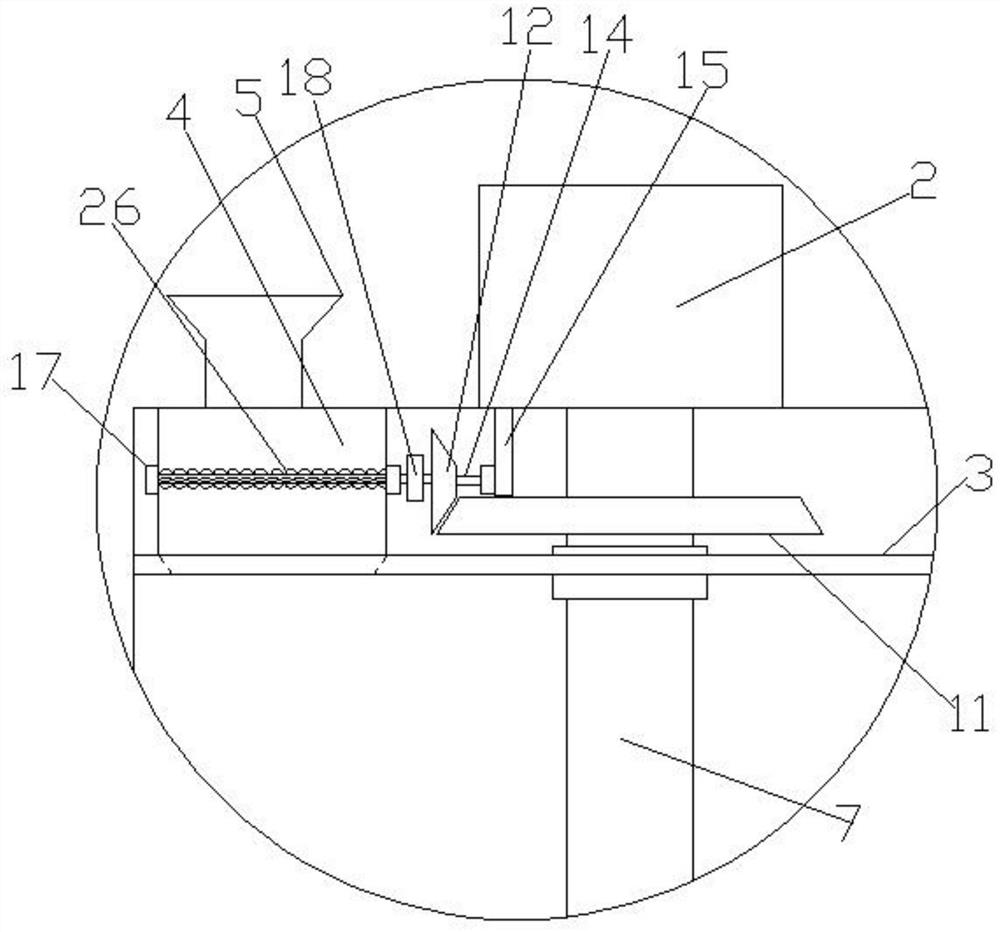

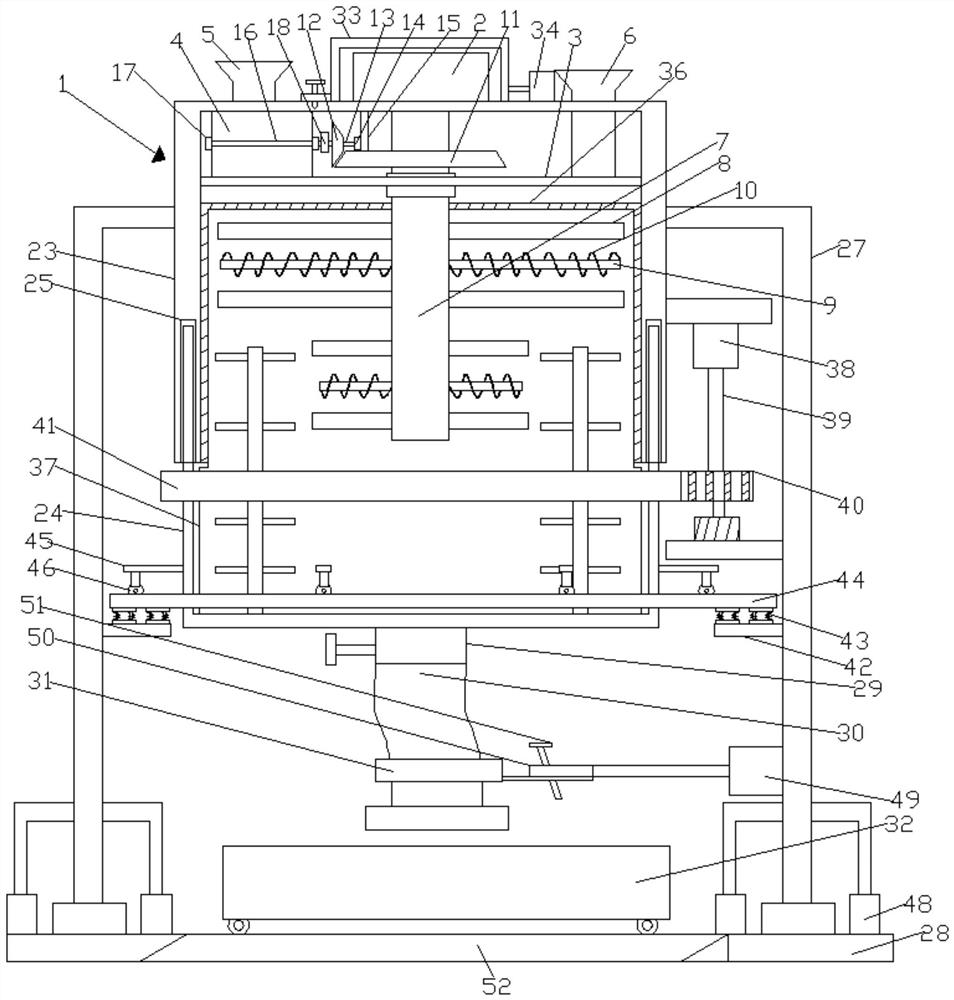

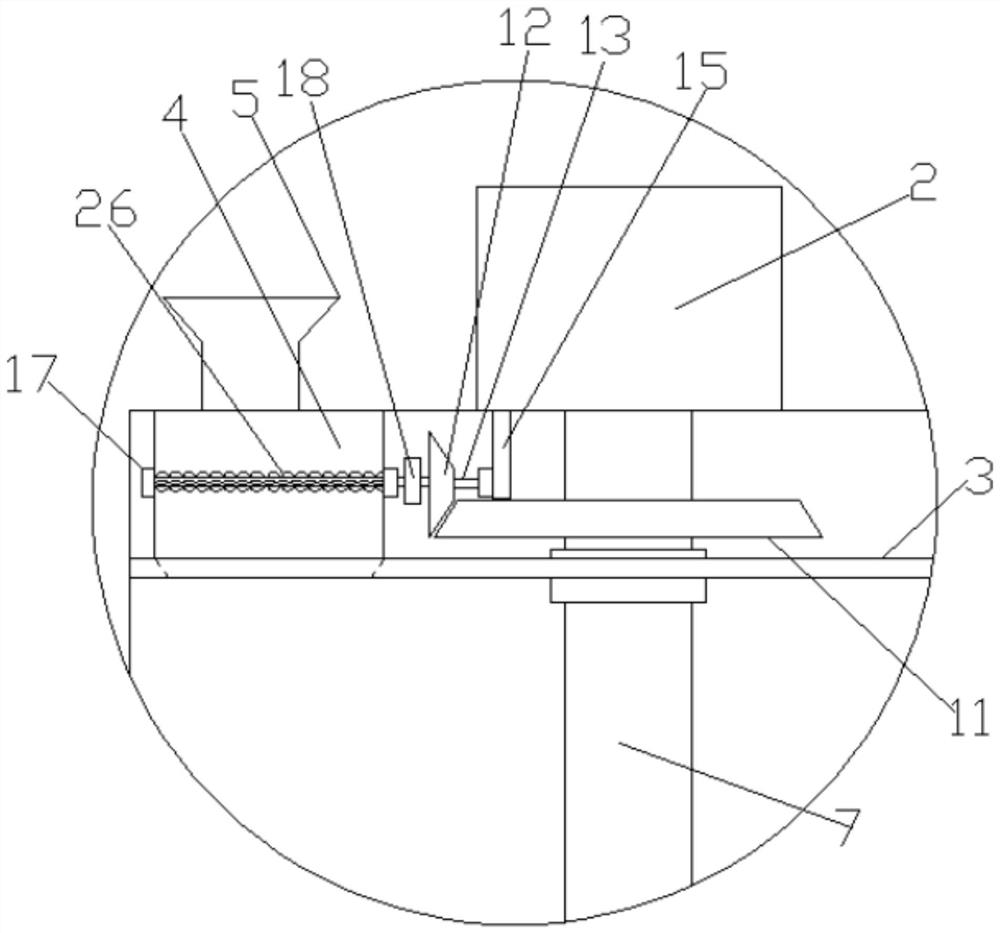

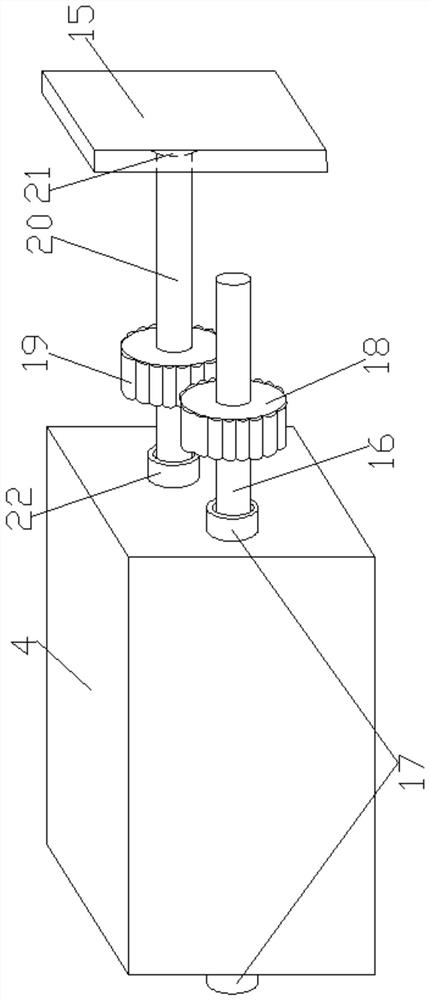

Plate production line

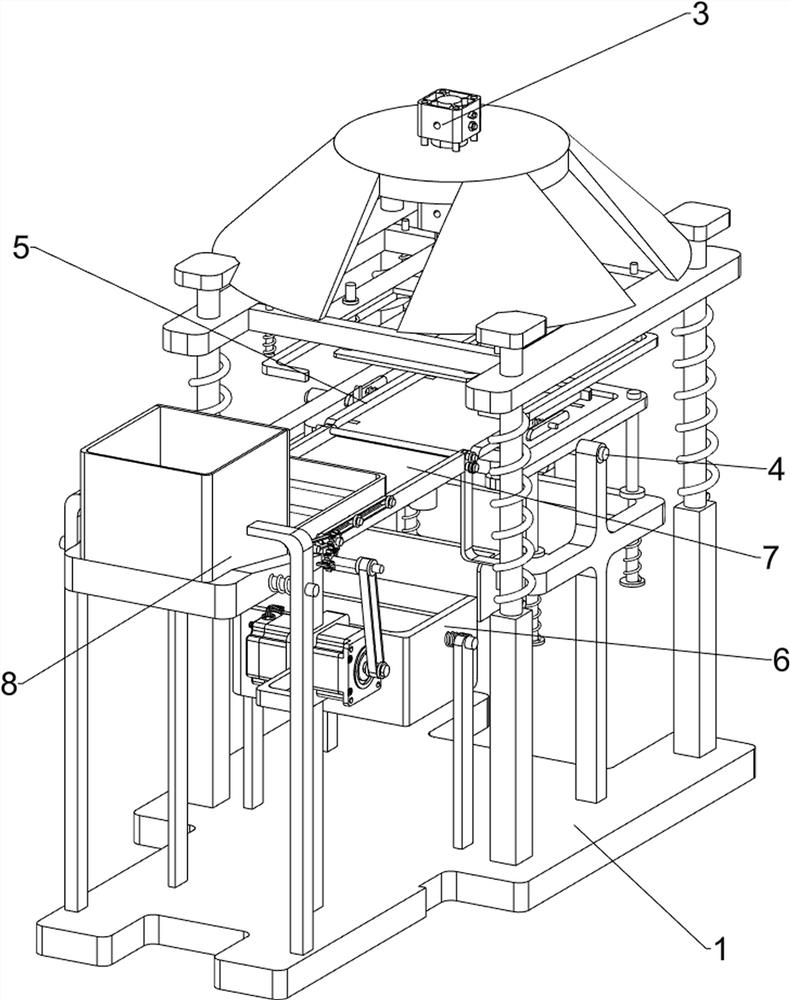

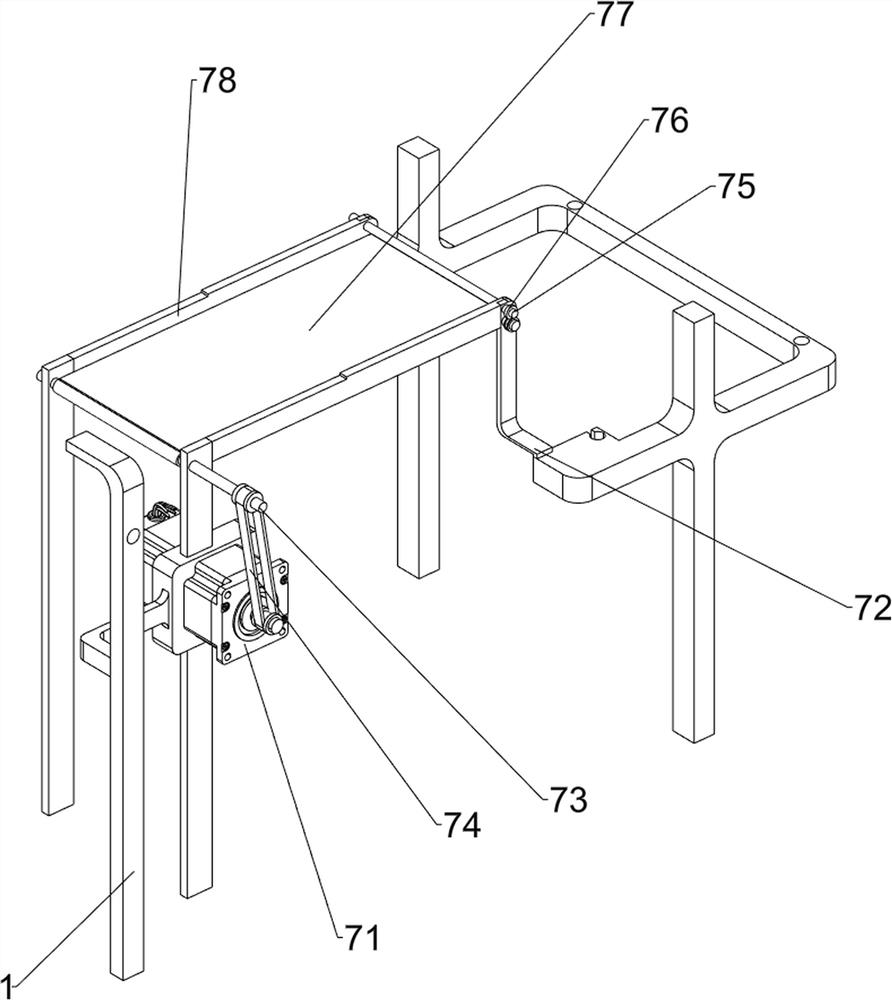

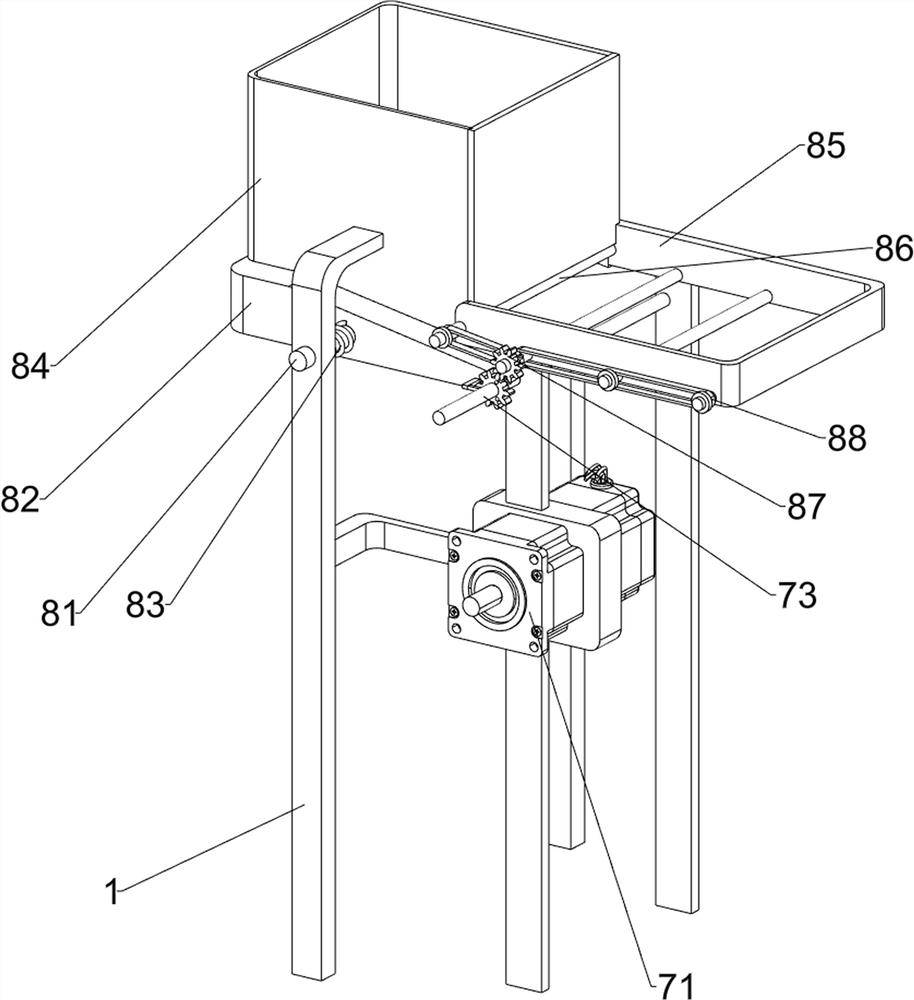

PendingCN111153102AQuality improvementIngenious designConveyorsStacking articlesPalletizerEngineering

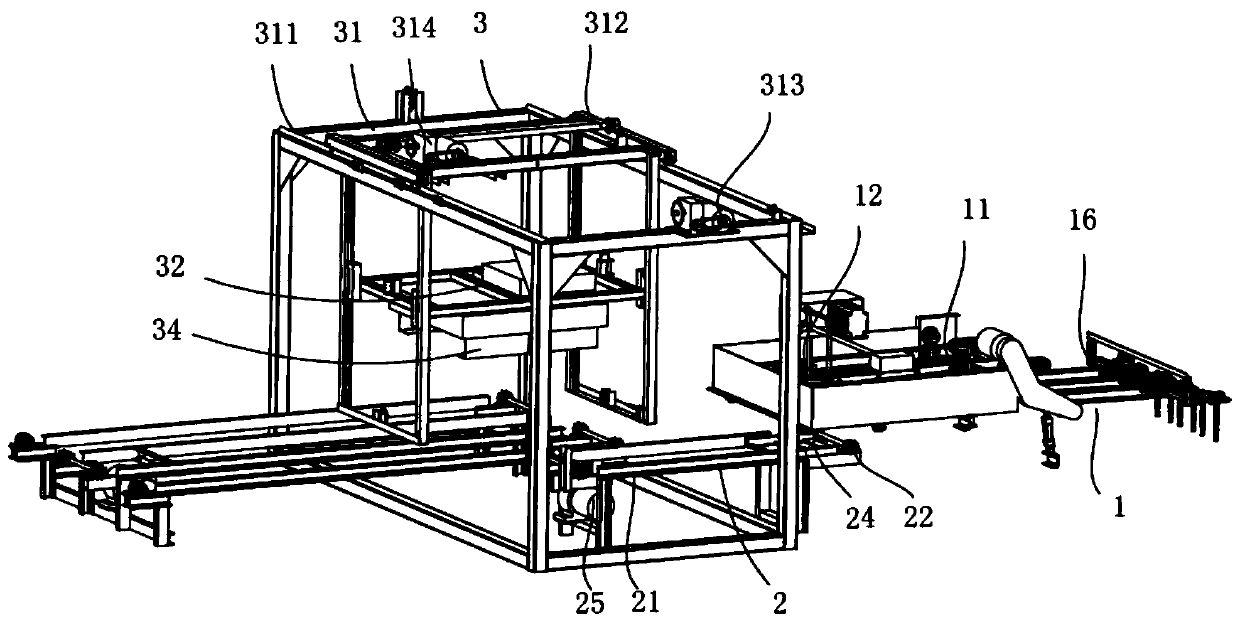

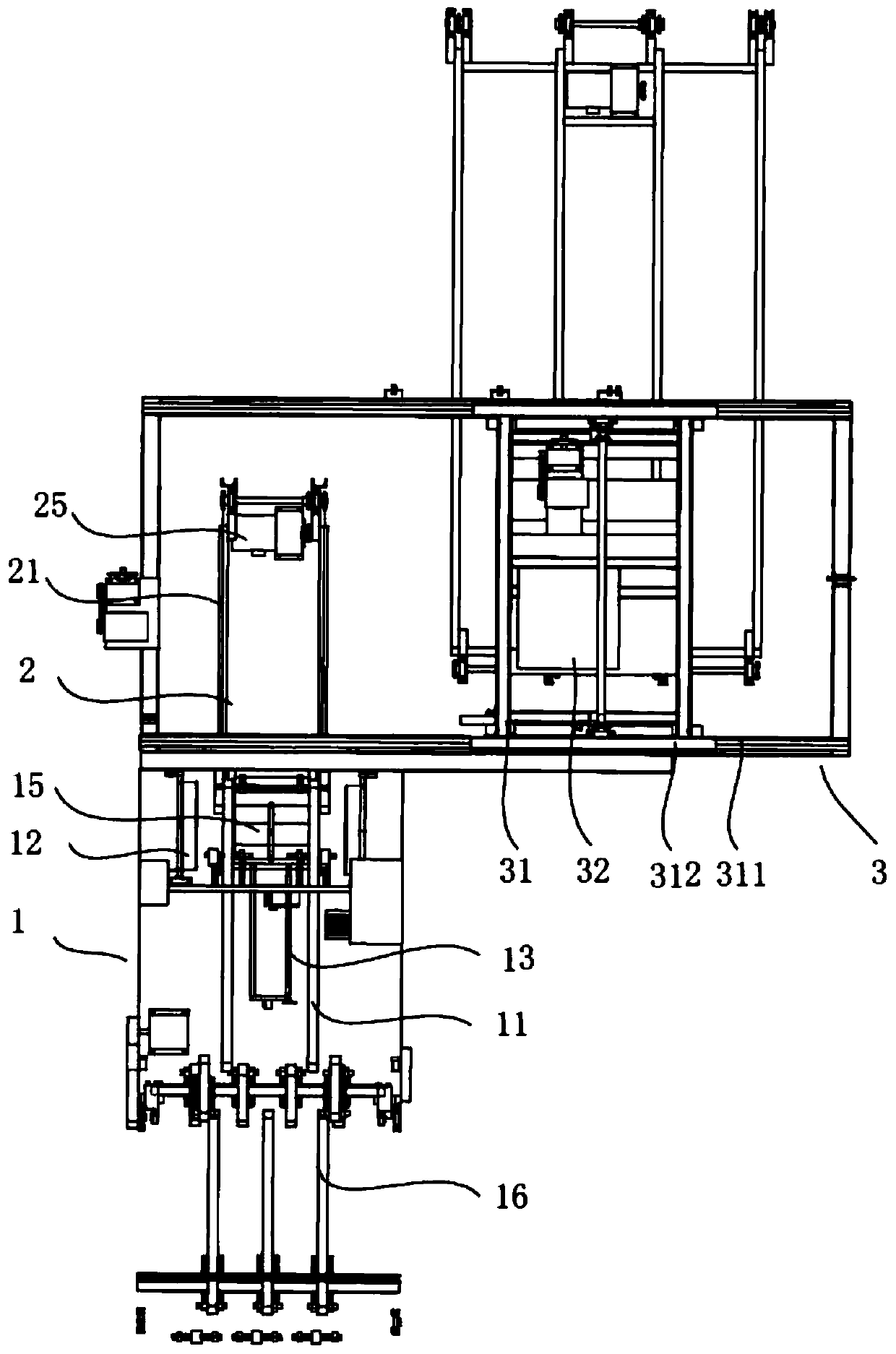

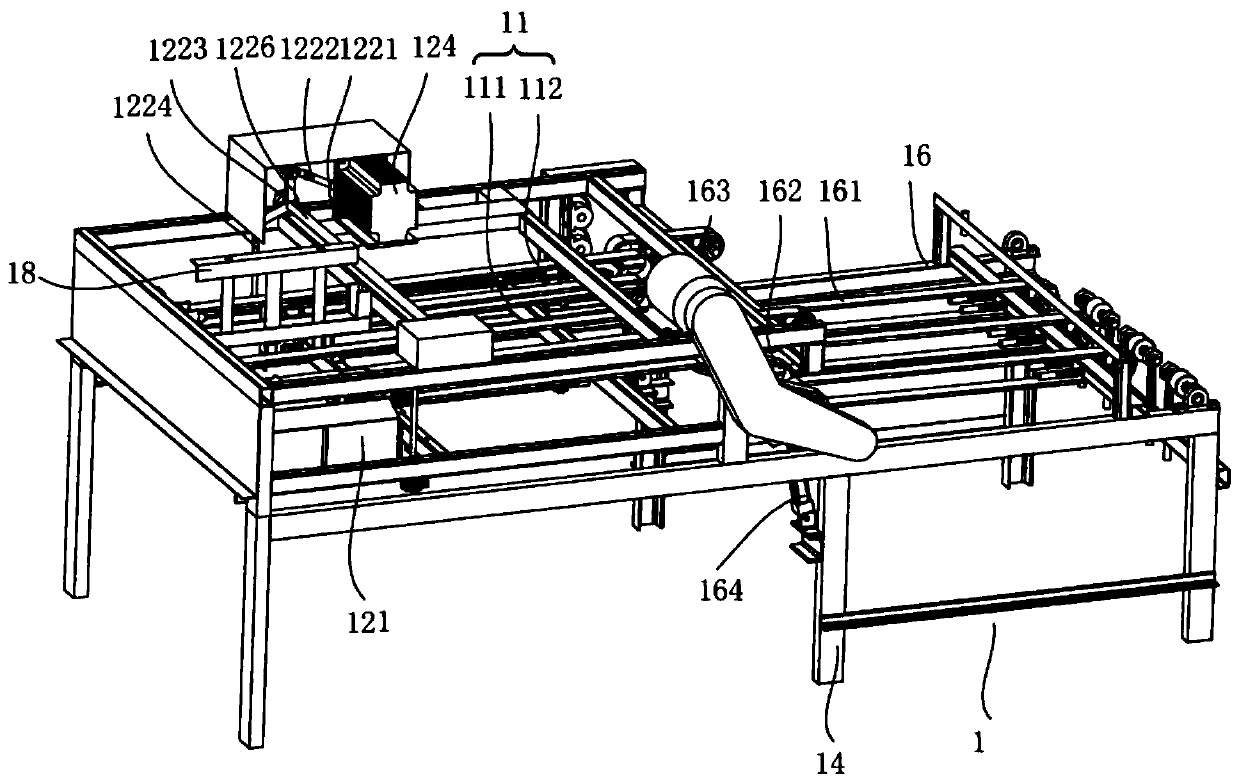

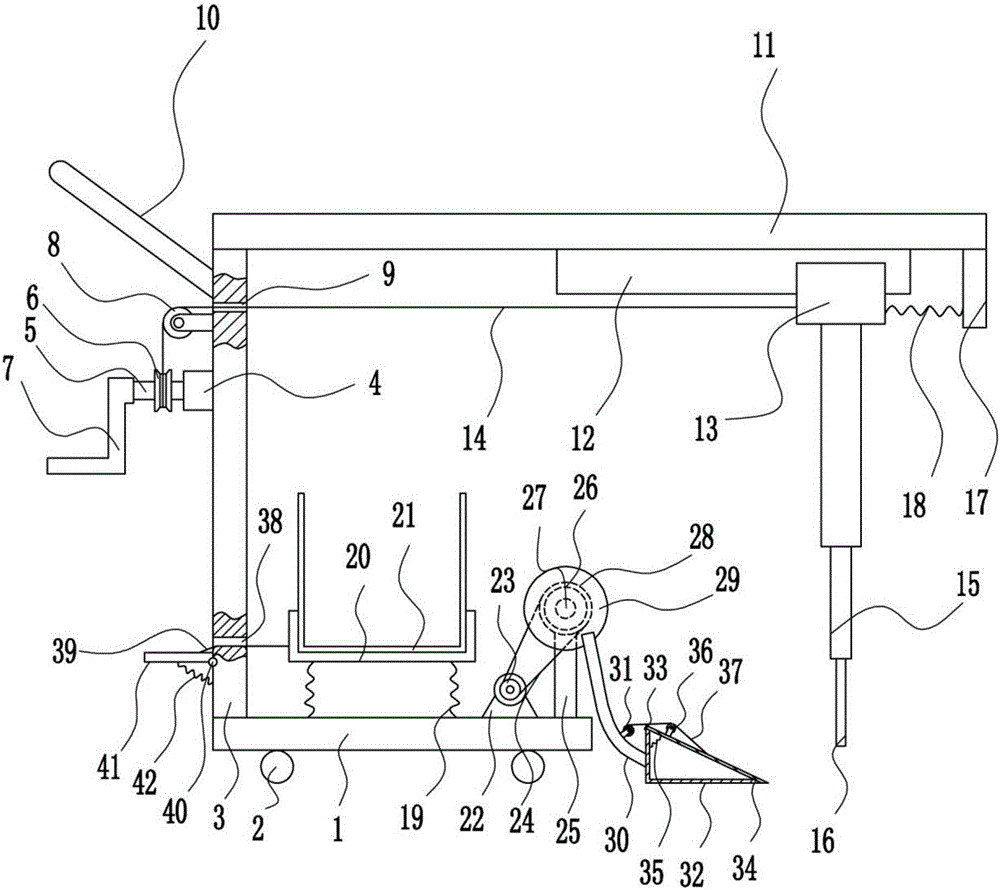

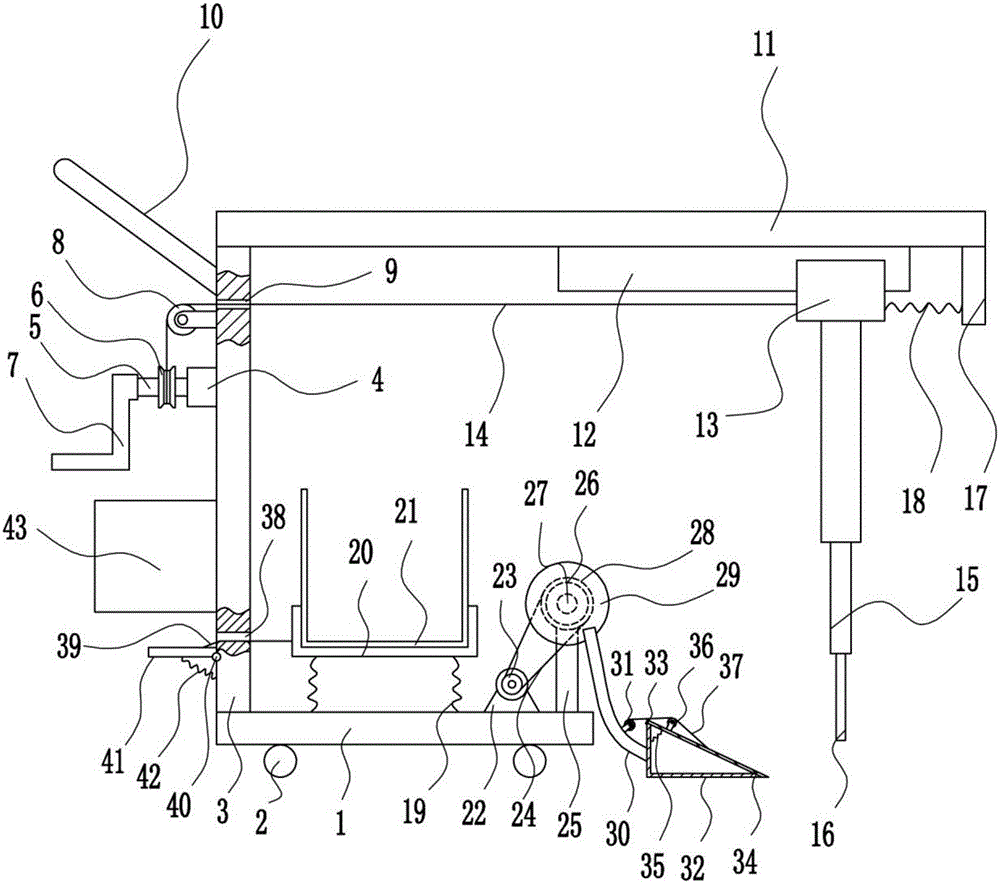

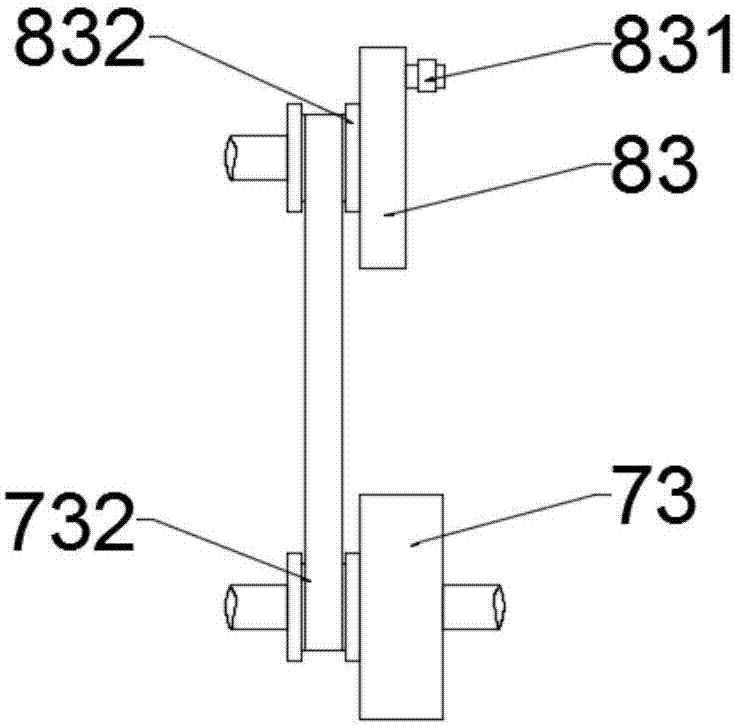

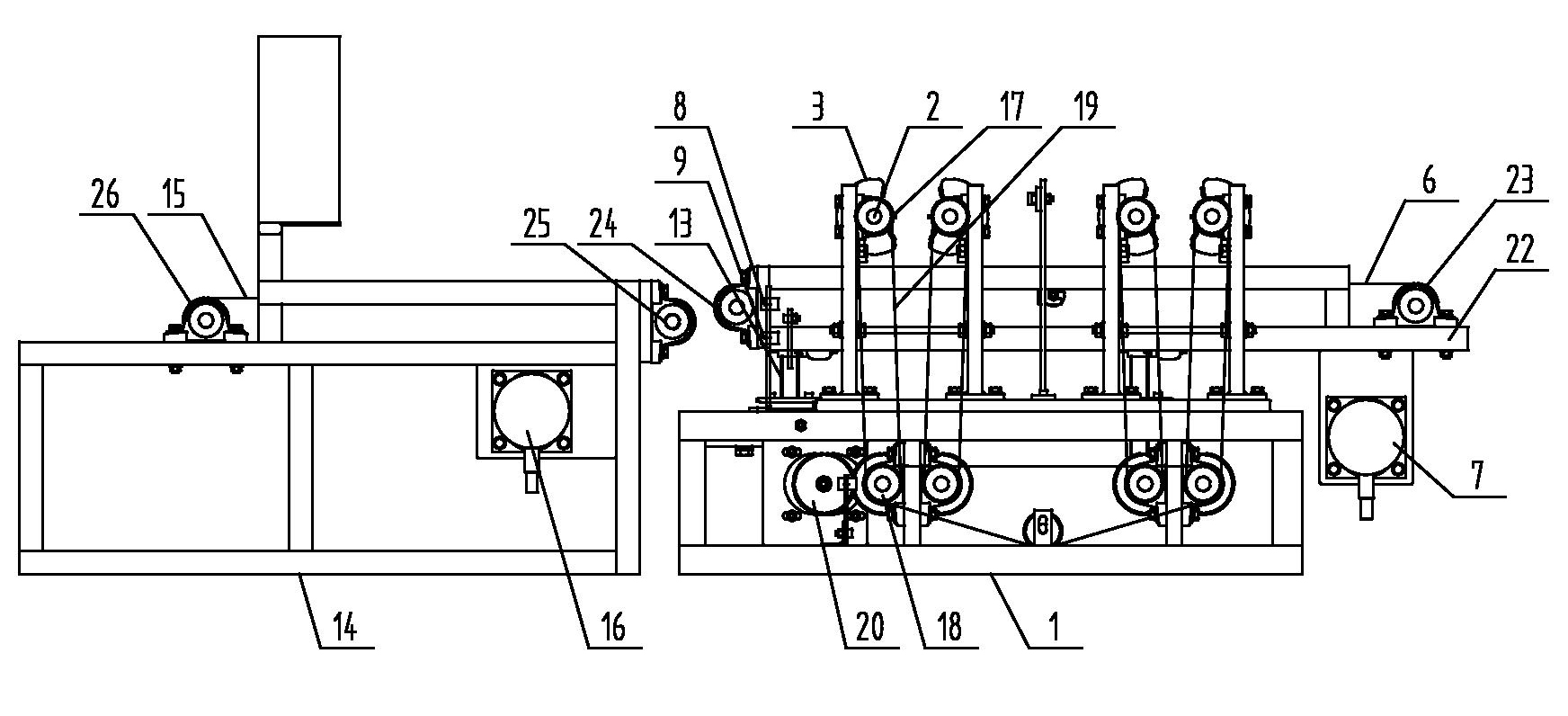

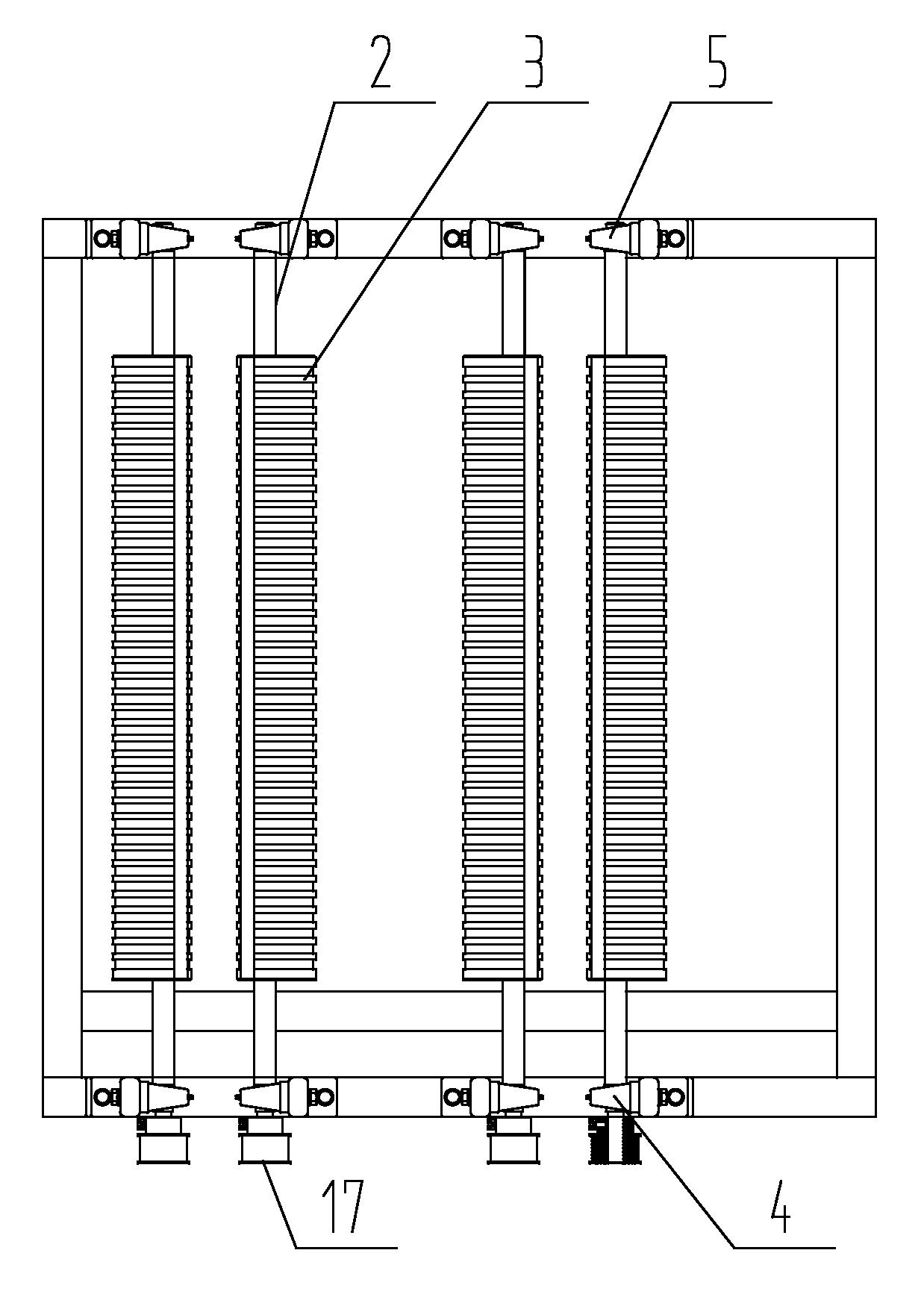

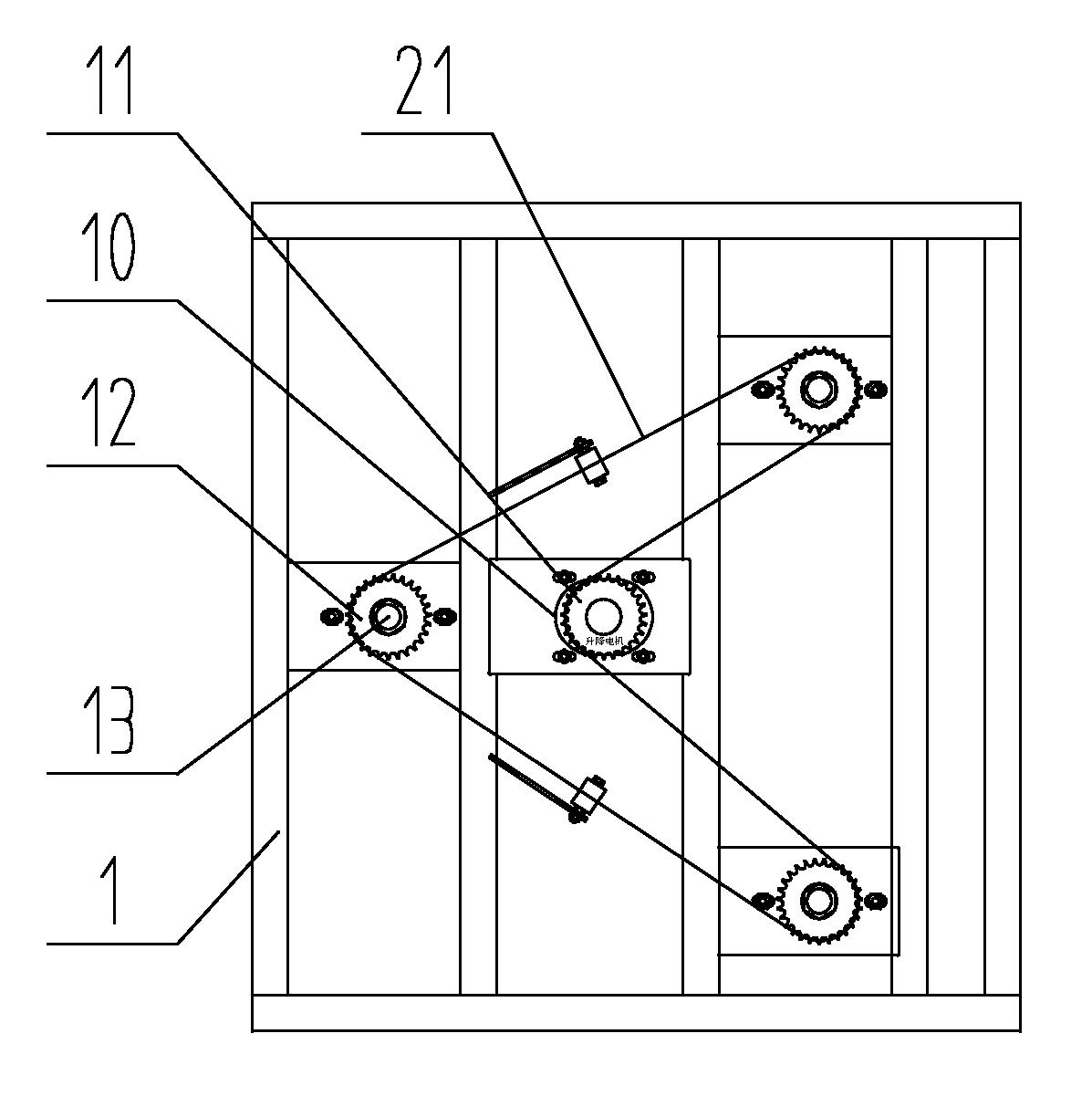

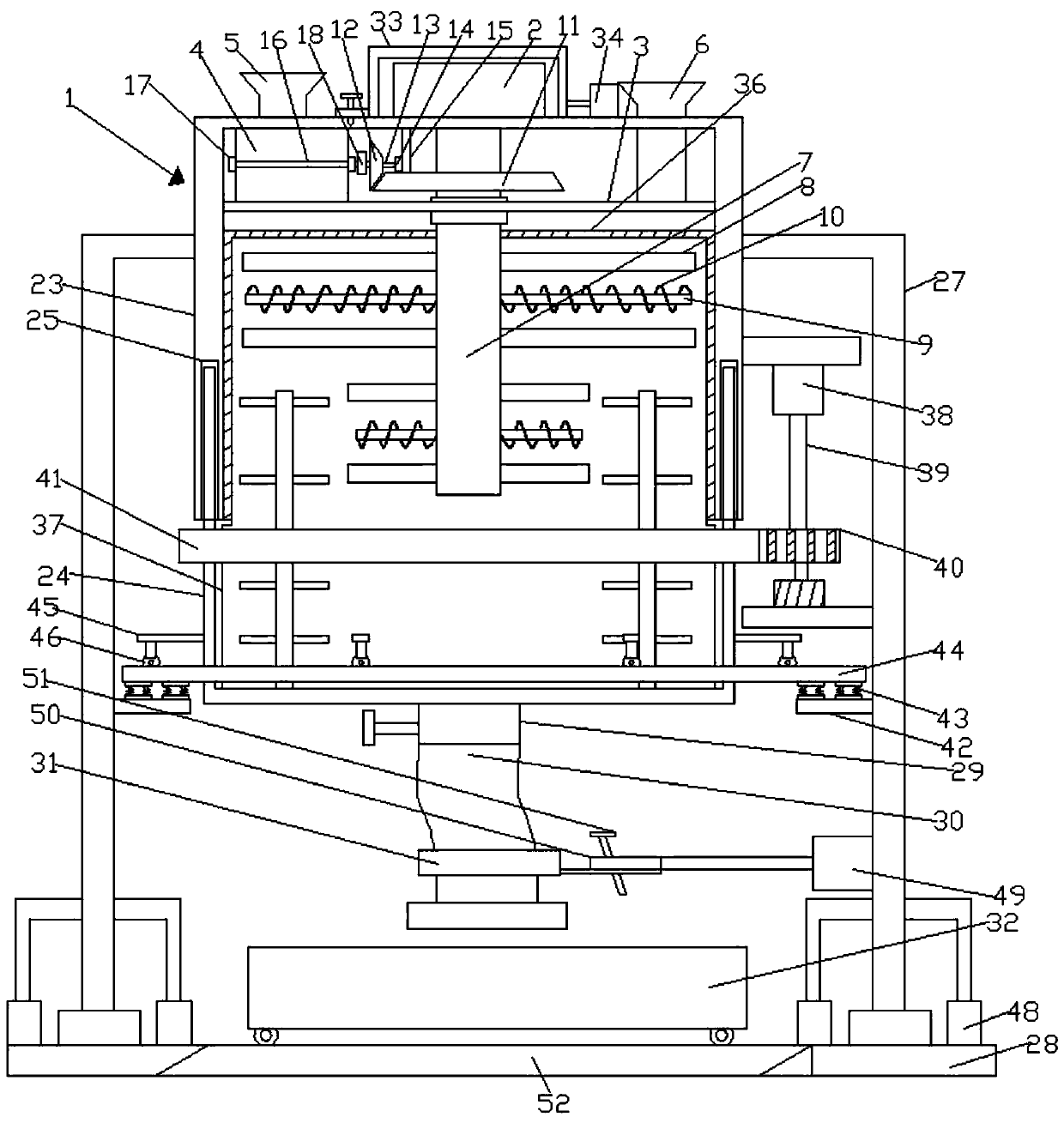

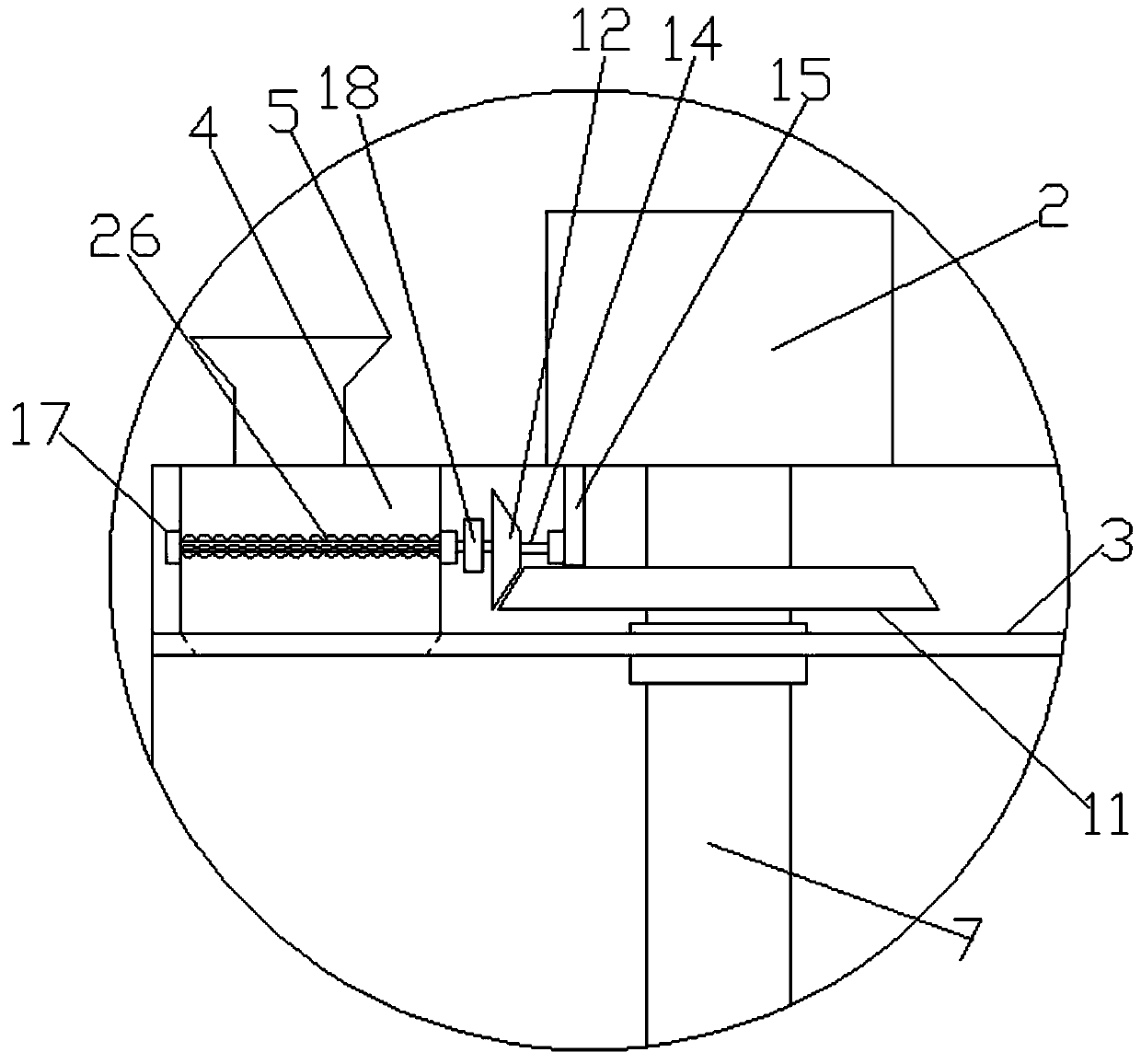

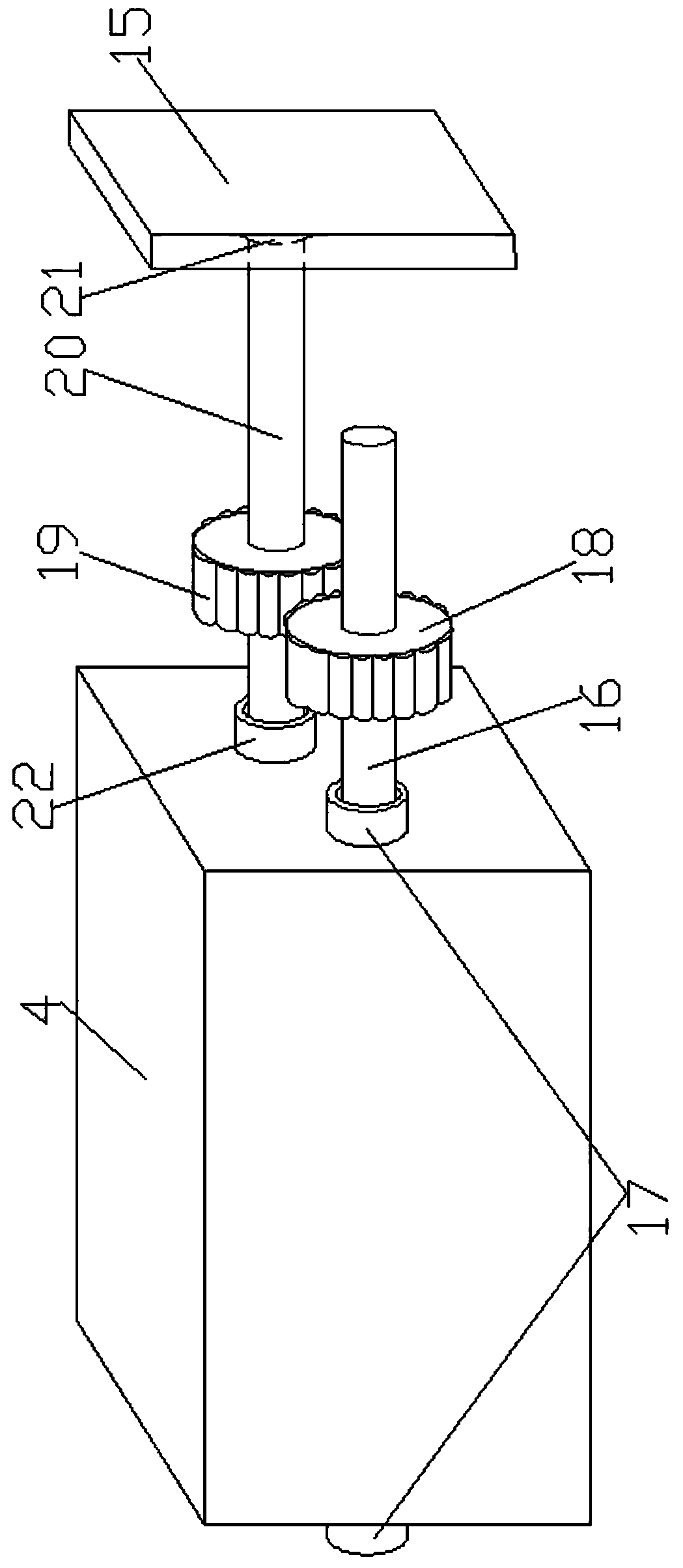

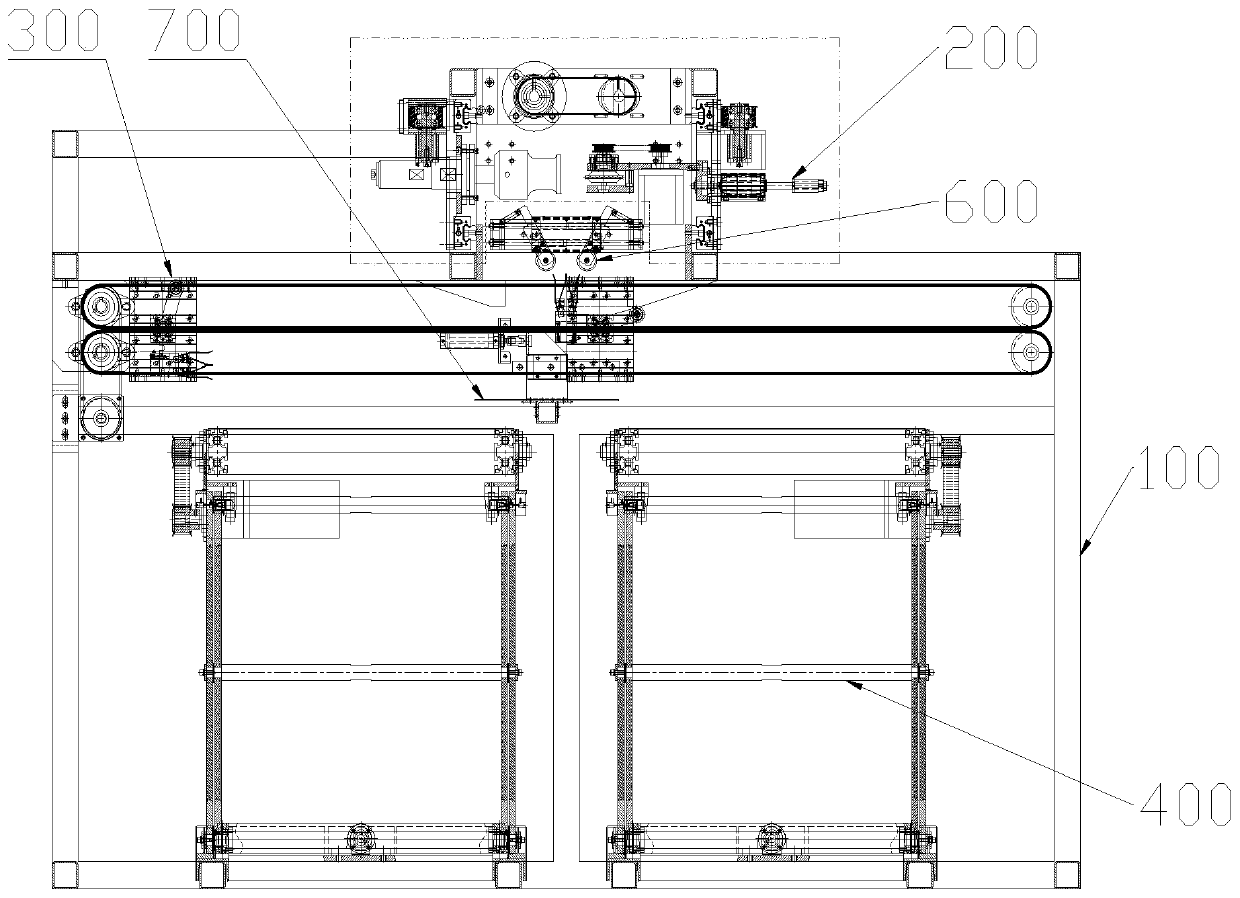

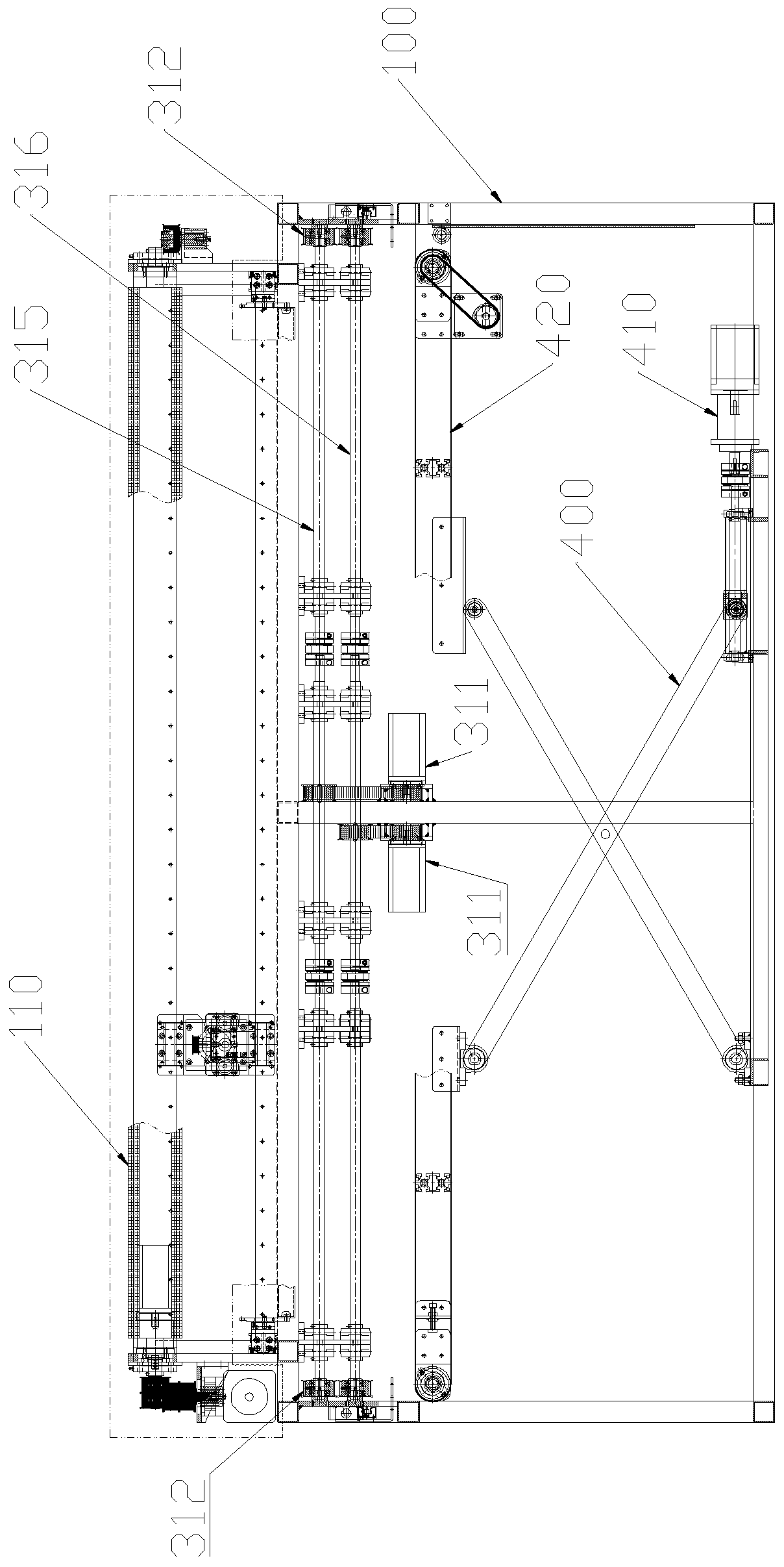

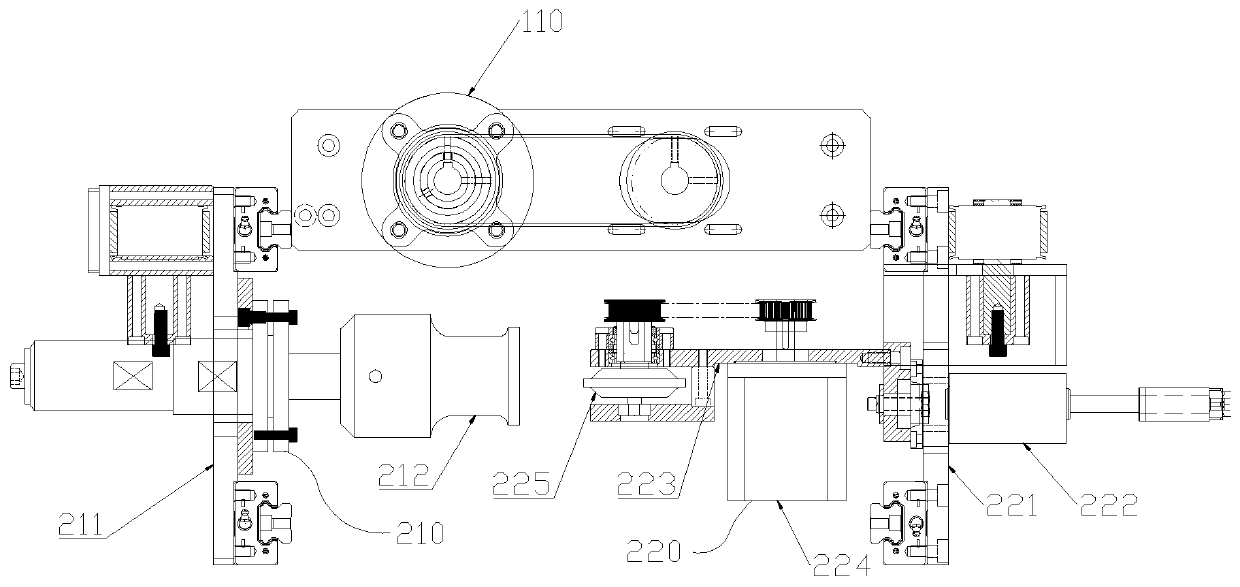

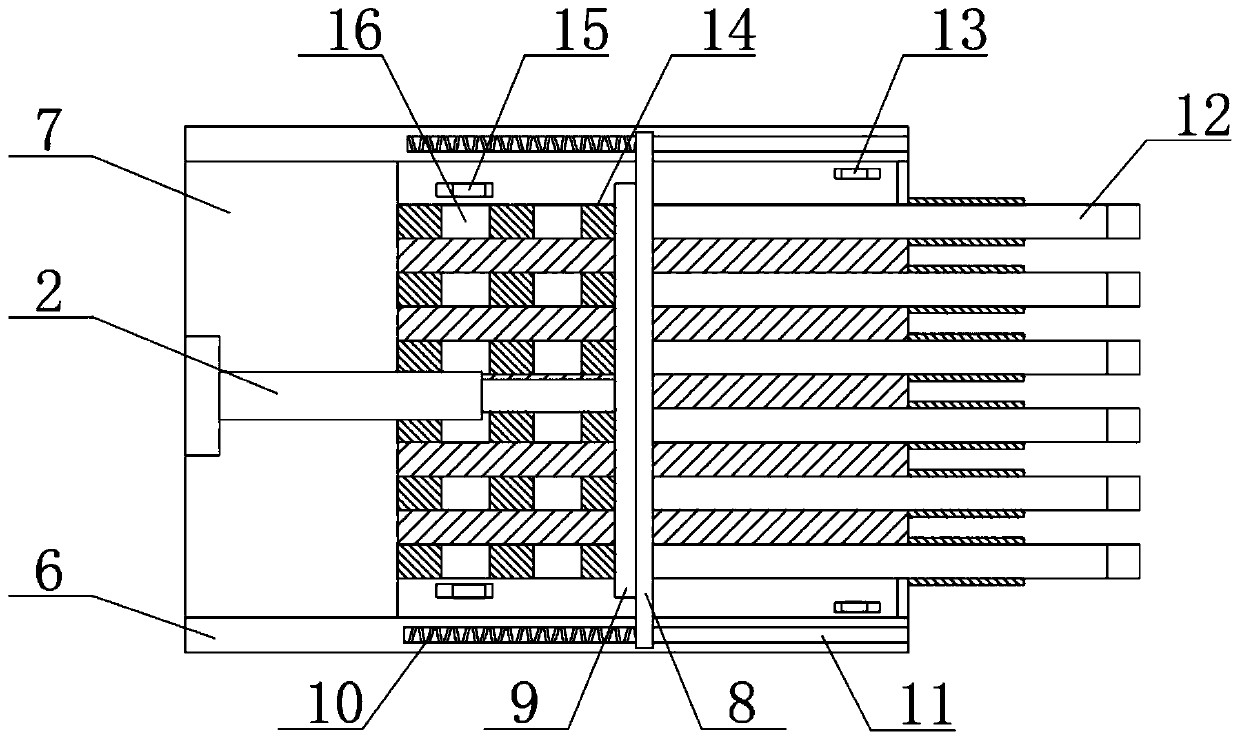

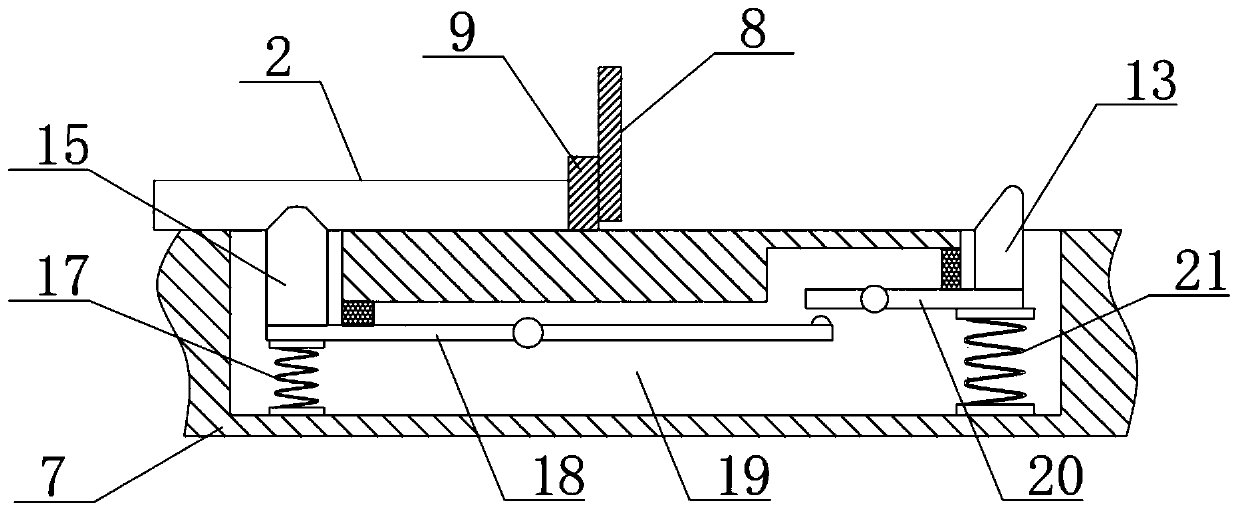

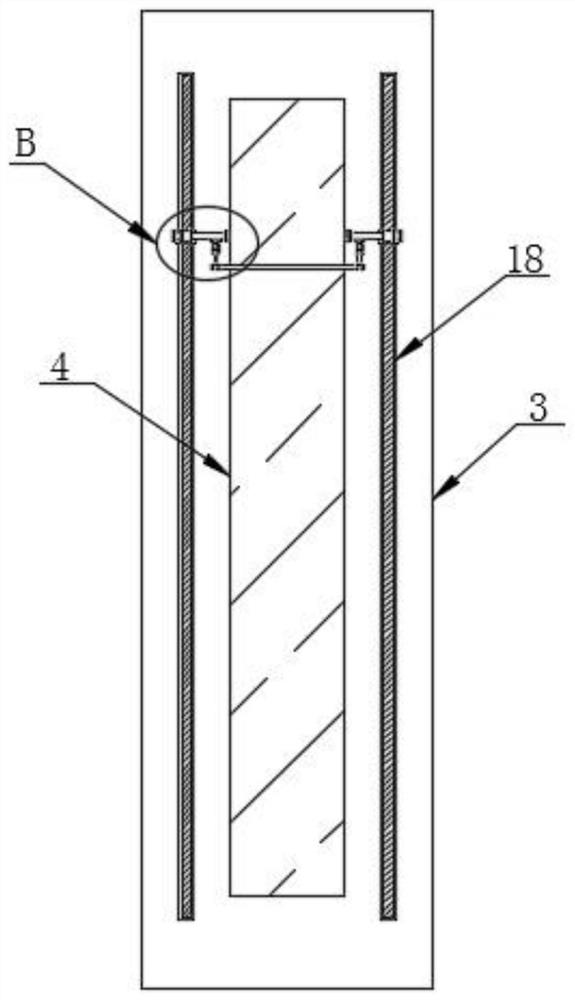

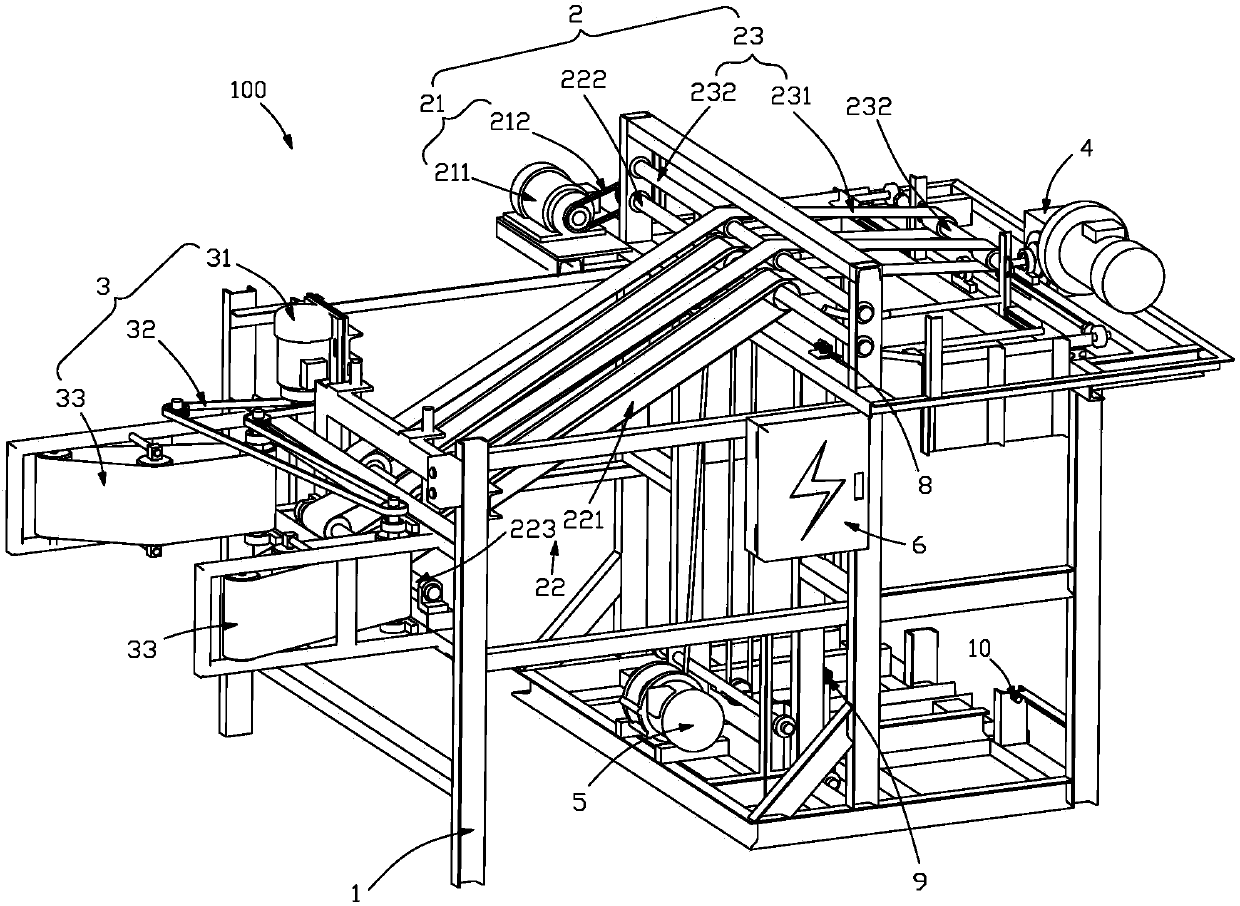

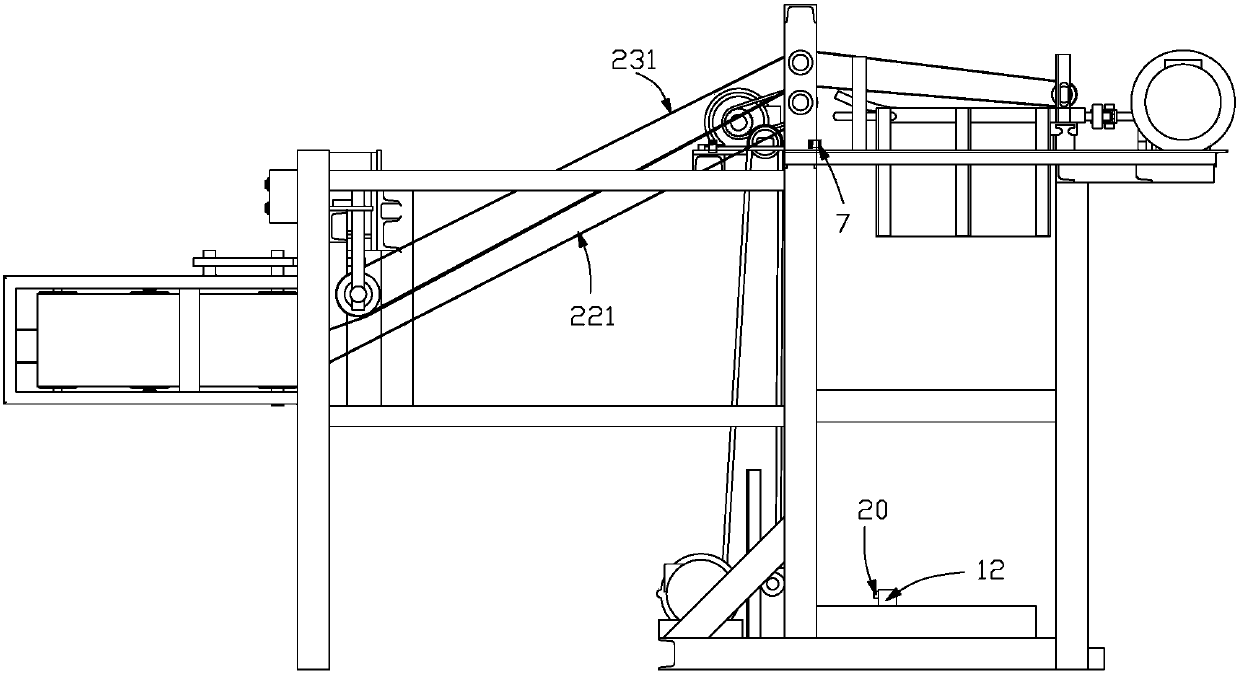

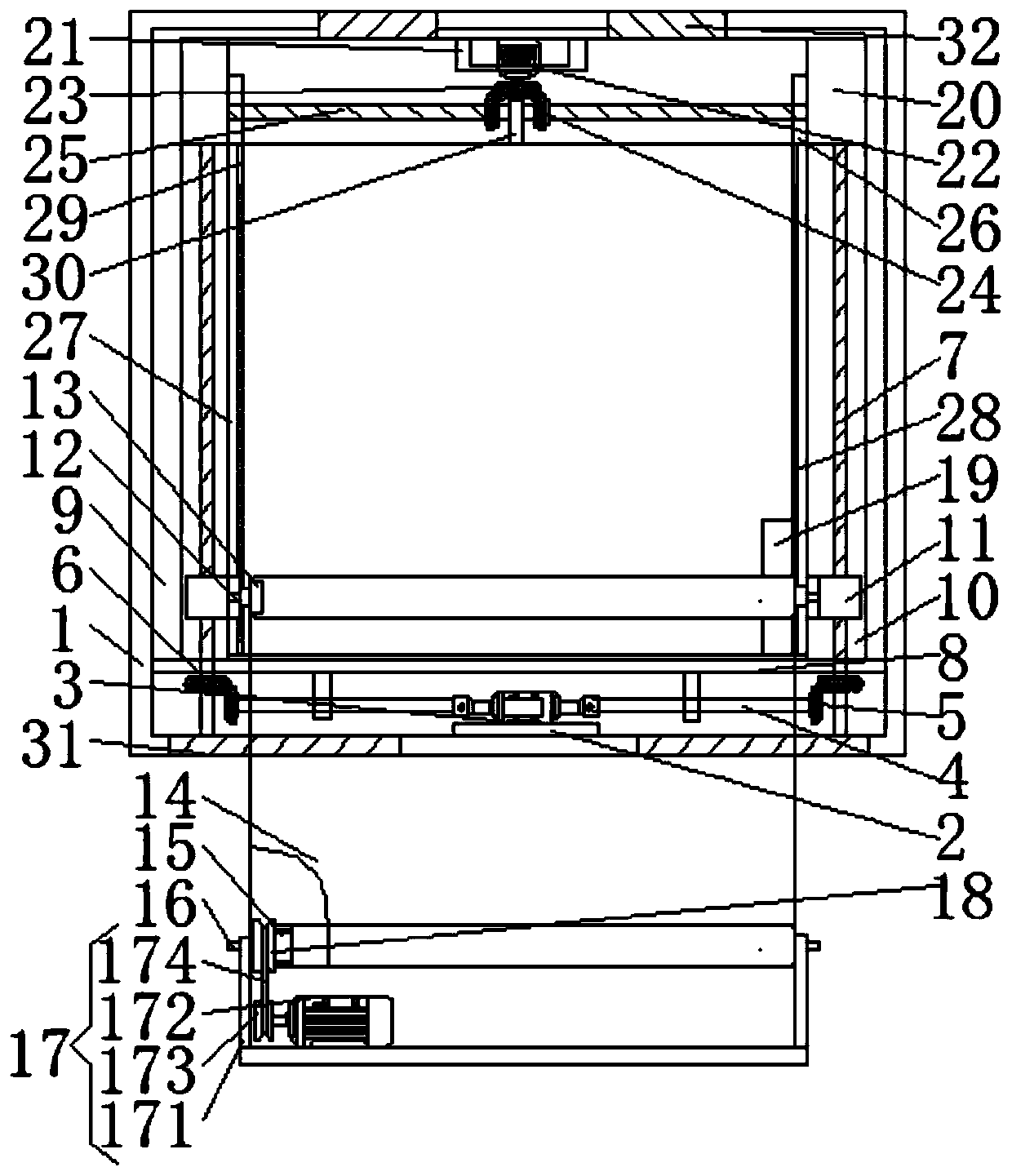

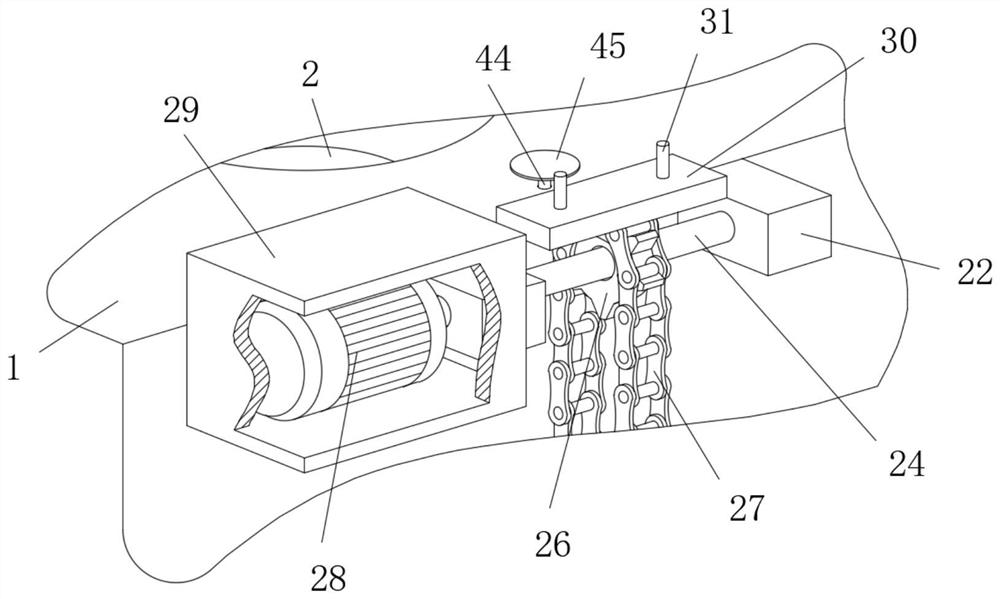

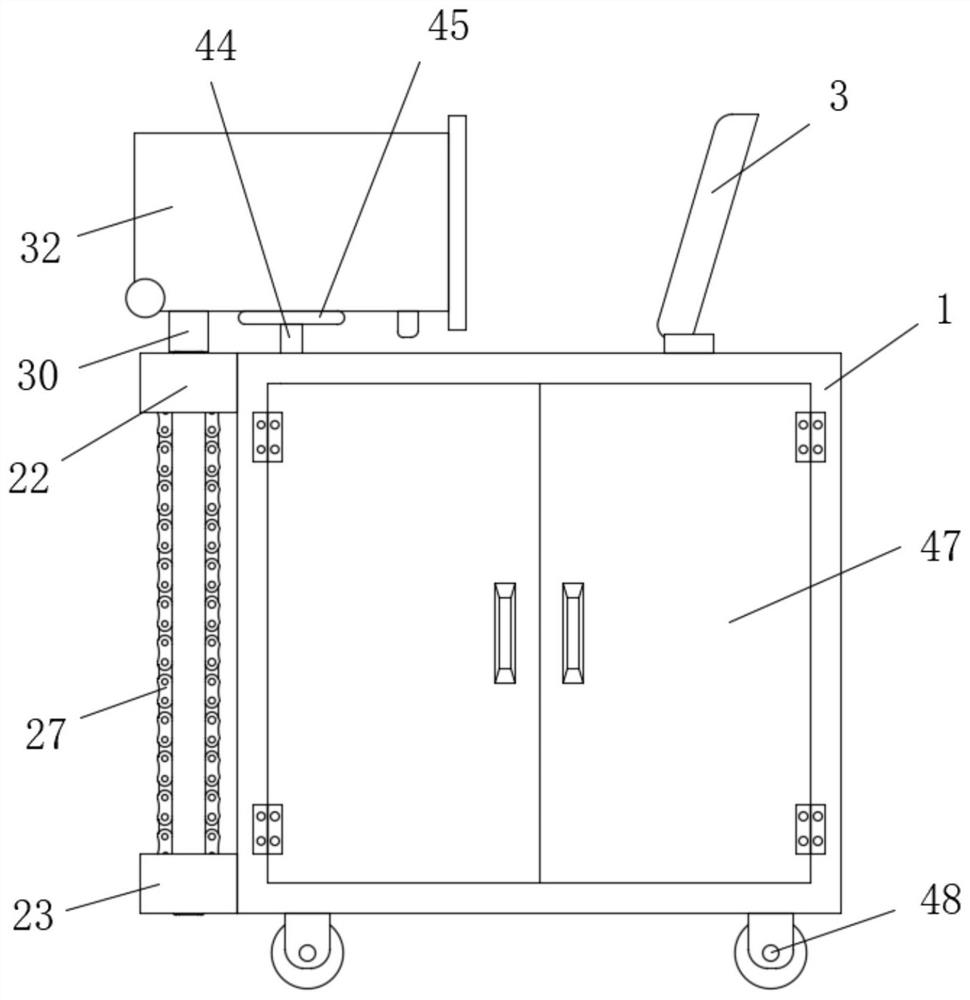

The invention discloses a plate production line. The plate production line comprises a plate palletizer, a stacking machine and a transfer machine connected between the plate palletizer and the stacking machine. The plate palletizer comprises a clamping and conveying device, a plate receiving device and a plate collection device arranged at the output end of the clamping and conveying device. Receiving guide plates capable of being opened and closed oppositely are arranged on the two sides, located at the output end of the clamping and conveying device, of the plate receiving device. The two receiving guide plates can be matched with each other to adjust the positions of the two side of plates in the conveying direction and guide the plates to be stacked on the plate collection device frombottom to top. The stacking machine comprises a moving device, a rotating device and a clamping device. The output end of the moving device can drive the rotating device to realize space displacement. The clamping device is rotatably mounted on the rotating device. The clamping device comprises a driving connecting rod assembly and at least one pair of clamping and supporting mechanisms capable of being opened and closed oppositely. The plate production line provided by the invention can stack up the warping plates one by one and stably clamp and stack plate piles.

Owner:广西腾森自动化设备有限公司

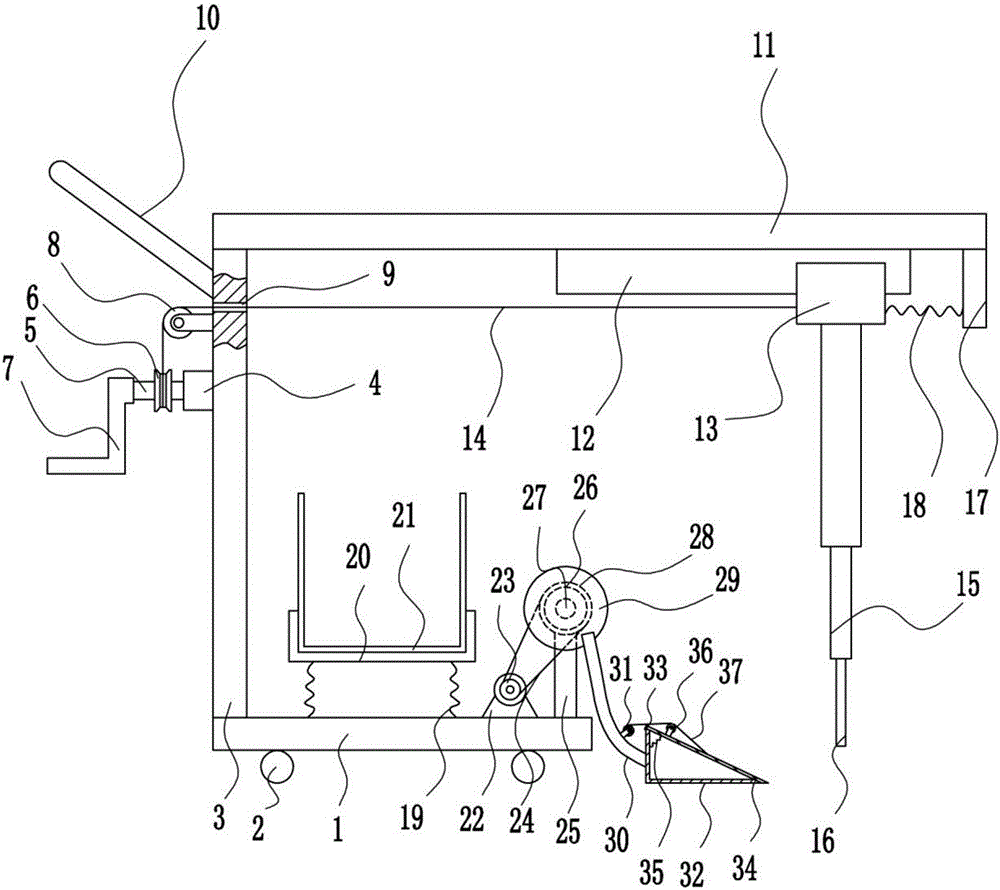

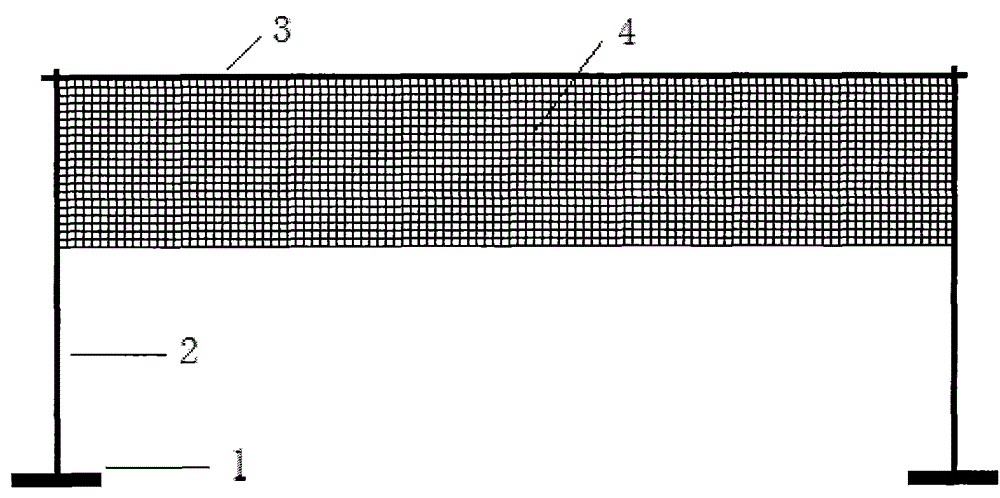

Shuttlecock collecting device for badminton training ground

The invention relates to a shuttlecock collecting device, in particular to a shuttlecock collecting device for a badminton training ground. The shuttlecock collecting device for the badminton training ground is high in collecting speed and small in working intensity. In order to achieve the technical purposes, the shuttlecock collecting device for the badminton training ground comprises a bottom plate, wheels, a supporting frame, a first bearing block, a first rotary shaft, a winding wheel, a rocking handle, a first fixed pulley, a push handle, a top plate, a sliding rail, a sliding block, a first pull line and the like. The supporting frame is welded to the left end of the top of the base plate, the upper portion of the left side of the supporting frame is connected with the first bearing block in a screw connection mode, and a bearing in the first bearing block is connected with the first rotary shaft in an interference connection mode. Through cooperation of a collecting hopper and a push plate, shuttlecocks are firstly swept into the collecting hopper, and the shuttlecocks in the collecting hopper are poured into the collecting frame by controlling rotation of a rotary motor.

Owner:HUNAN NORMAL UNIVERSITY

Efficient and easy-unloading feed mixing device

The invention discloses a high-efficiency and easy-to-cut feed mixing device, which includes a base, a mixing cylinder, an inner cylinder, a mixing drive mechanism, a lifting device and a material receiving frame; a chassis is fixed on the top right side of the base, and A support frame is provided; the mixing cylinder is rotated and set in the support frame, and the outer bottom of the mixing cylinder is connected with a discharge pipe; the inner cylinder is relatively static and is set at the center of the inner cavity of the mixing cylinder, and the inner cylinder is provided with a helical blade, which is driven by mixing. The mechanism drives the mixing cylinder and the spiral blade to rotate; the support frame rotates and connects to the chassis, and its tilt is controlled by the lifting device; the top left side of the base is movable with a material receiving frame; the left side of the material receiving frame is also equipped with an auxiliary unloading mechanism. The feed mixing device of the invention can effectively prevent the feed from sinking to the bottom, has good feed mixing effect, and is easy to feed; meanwhile, it has a reasonable structure and convenient operation, and is worthy of popularization and use.

Owner:桐乡市搏腾贸易有限公司

Counting machine

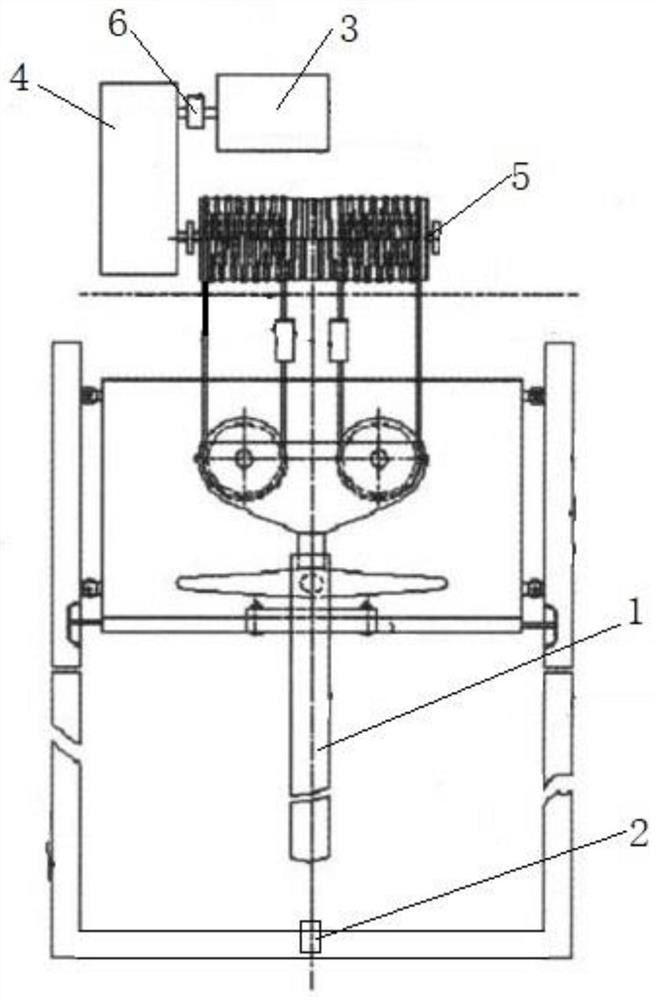

The invention relates to a counting machine which comprises a rack, wherein the rack is provided with at least one group of fetching mechanisms; each fetching mechanism comprises two mutually parallel rotary shafts arranged in the rack; each rotary shaft is respectively connected with a rotary driving device arranged on the rack; the driving device drives the two rotary shafts to rotate inwards in opposite directions; the two rotary shafts are respectively provided with a plurality of cams which are arrayed; the cams on the two rotary shafts are mutually symmetrically arranged; two ends of each rotary shaft are respectively provided with a counting sensor; a platform is arranged below the fetching mechanism; a conveying belt is arranged in the platform; the conveying belt is driven by a conveying motor arranged on the platform; and the rack is also provided with an up-and-down movement driving device which can drive the platform to move up and down along the vertical direction. The counting machine has the advantages of simple structure and long service life, and is convenient to use. Because the cam mechanism is adopted and the cams rotate to fetch gloves, the gloves can be stably fetched, and no gloves are missed. Because compressed air is not required, the cost is low.

Owner:ZHANGJIAGANG PIONEER AUTOMATION MACHINERY EQUIP

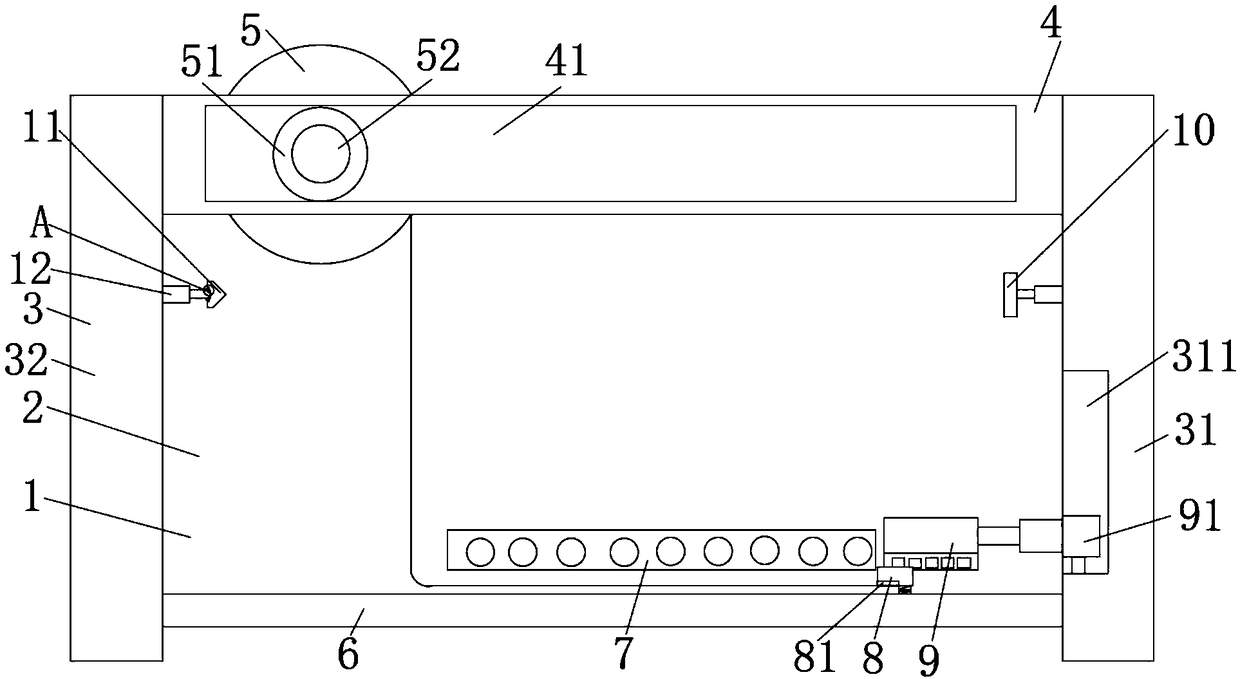

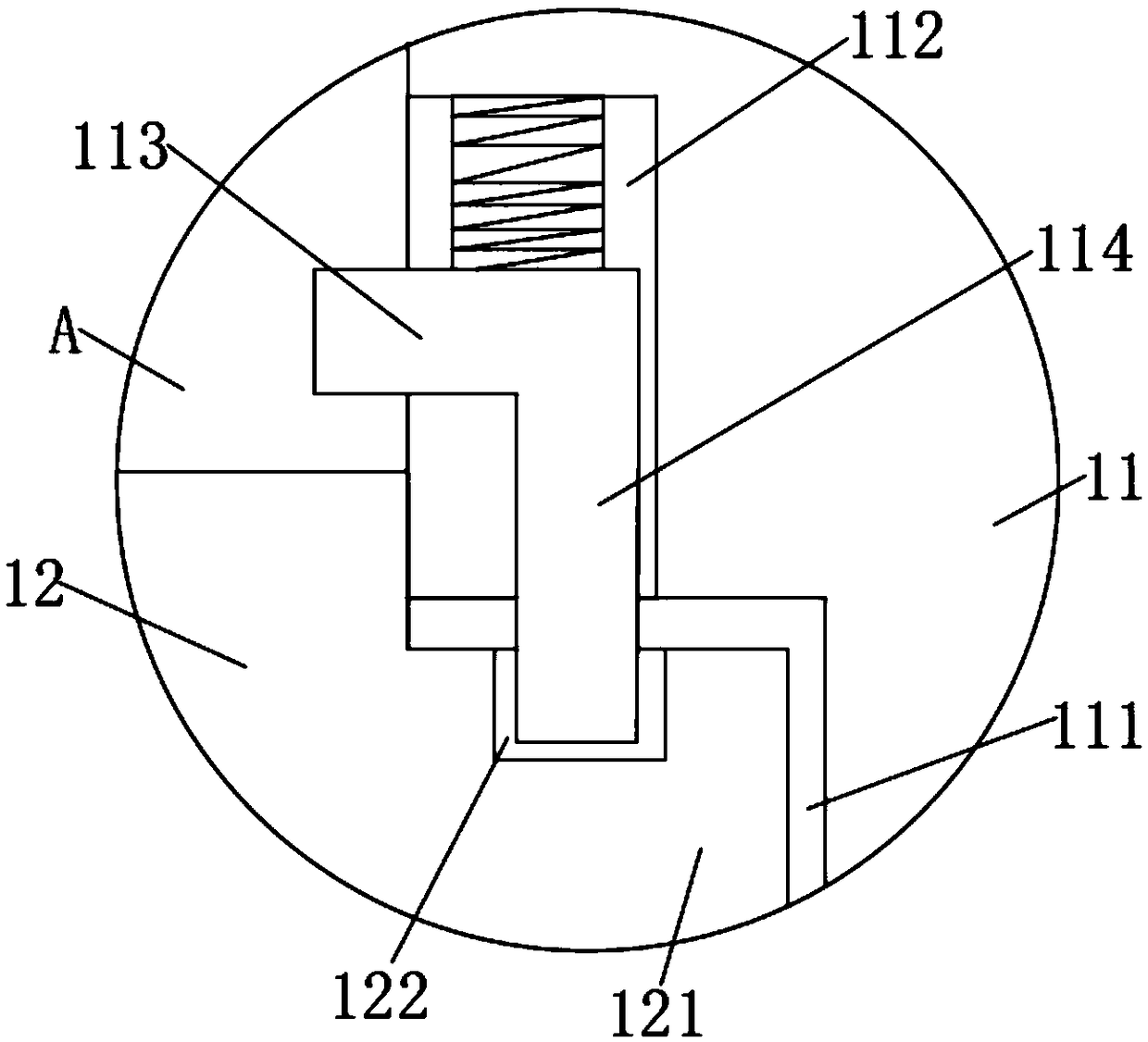

Full-automatic efficient positioning printing machine for production

InactiveCN112406284AGood effectImprove printing effectRegistering devicesRotary pressesPrinting pressIndustrial engineering

The invention relates to a positioning printing machine, in particular to a full-automatic efficient positioning printing machine for production. The full-automatic efficient positioning printing machine for production integrates automatic feeding, precise positioning and automatic discharging. The full-automatic efficient positioning printing machine for production comprises a bottom plate, and apressing mechanism is arranged on the bottom plate; and a pressure bearing mechanism arranged on the bottom plate, wherein the pressure bearing mechanism is connected with the pressing mechanism andlocated below the pressing mechanism. A rubbing plate is driven by a mounting plate to move downwards, a printing material can be rubbed when the rubbing plate touches paper, in order to achieve a better and clearer printing effect, an air cylinder continues to extend to enable a fixing plate to continue to slide along a first sliding rod and a second sliding rod, and the effect that the rubbing plate efficiently prints the paper and other materials is achieved.

Owner:钟源

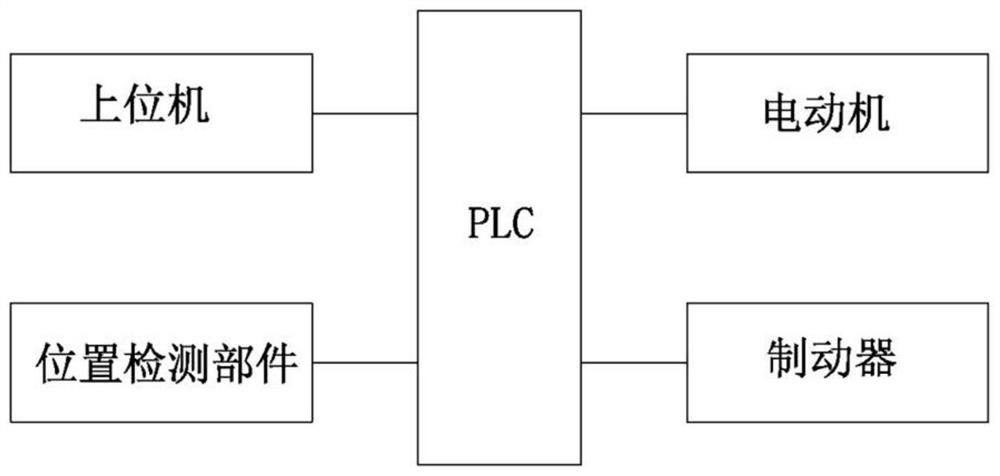

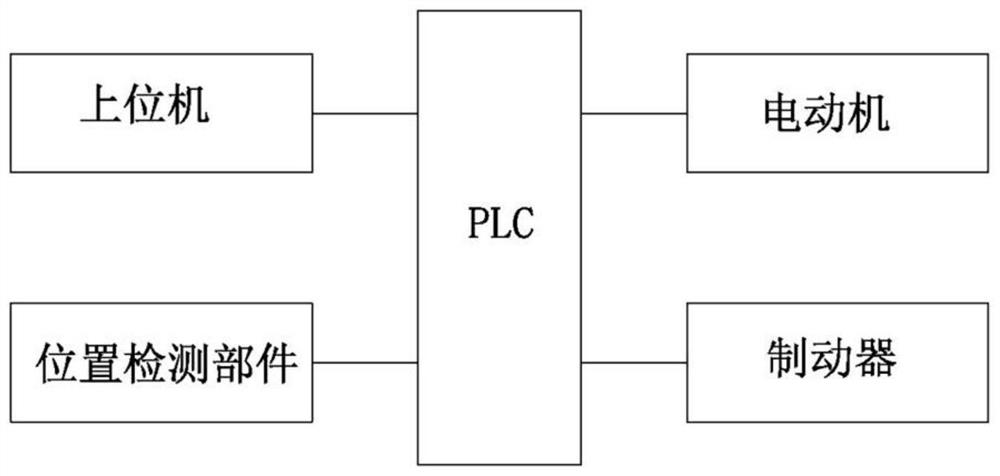

Automatic slag splashing control method and system for converter

ActiveCN112981033AHigh viscosityHigh melting pointManufacturing convertersProcess efficiency improvementSlagControl system

The invention discloses an automatic slag splashing control method and system for a converter, and belongs to the technical field of converter slag splashing furnace protection. The control method comprises the steps that firstly, final slag conditions are classified according to the end point oxygen content, the end point carbon content and the residual manganese yield range in molten steel; secondly, according to different final slag conditions, slag adjusting materials with the corresponding weights are selectively added into the converter to adjust the viscosity of the slag, and the content of magnesium oxide in the final slag is made to be 10%-15%; and thirdly, corresponding slag splashing gun position curves are selected according to different final slag conditions, and the control system is used for carrying out automatic slag splashing operation. The automatic slag splashing control method and system have the beneficial effects that the slag adjusting materials with corresponding weights are added according to the different final slag conditions for slag adjusting, the corresponding slag splashing gun positions are automatically selected, the automatic slag splashing operation is completed, and the slag splashing operation is standardized. The labor intensity of workers is lowered, the slag splashing time is shortened, the nitrogen consumption is reduced, and the furnace profile can be more stable to maintain.

Owner:新余钢铁股份有限公司

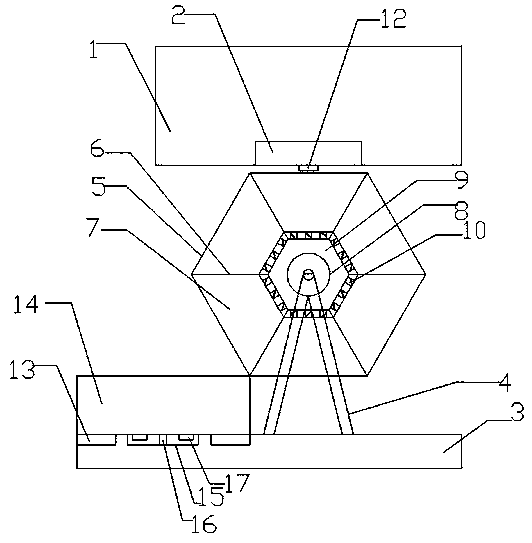

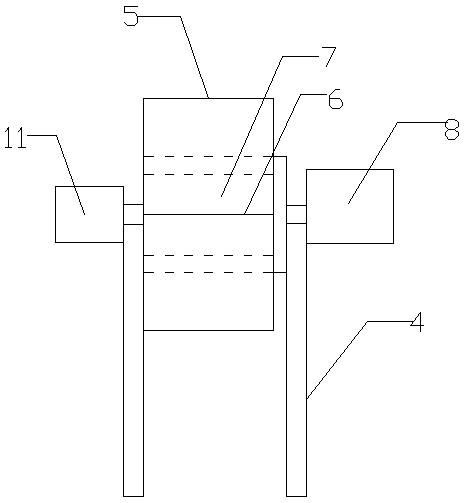

Air conditioner injection molding part injection molding blanking device

The invention provides an air conditioner injection molding part injection molding blanking device. The air conditioner injection molding part injection molding blanking device comprises an injectionmolding machine, wherein an injection mold is arranged at the lower side of the injection molding machine, a base is arranged below the injection molding machine, a support is arranged in the middle of the base, the upper end of the support is rotationally connected with a hexagonal turntable, six material receiving grooves are formed in the turntable in a separated mode through partition plates,the front side of the turntable rotates through a servo rotating motor connected with the turntable, a cooling chamber is arranged in the middle of the turntable, ventilation holes are arranged amongthe cooling chamber and the material receiving grooves, a cooling fan is arranged on the rear side of the turntable, and a blowing opening of the cooling fan is connected with the cooling chamber. Themultiple material receiving grooves are formed by separating the turntable to separate and discharge injection molding pieces, and the injection molding pieces are cooled by the cooling fan to be collected in a centralized mode, so that deformation caused by extrusion when the injection molding pieces are collected is reduced, and the injection molding quality of the injection molding pieces is effectively improved.

Owner:WUHU LANBO PLASTIC

Storage device for food processing

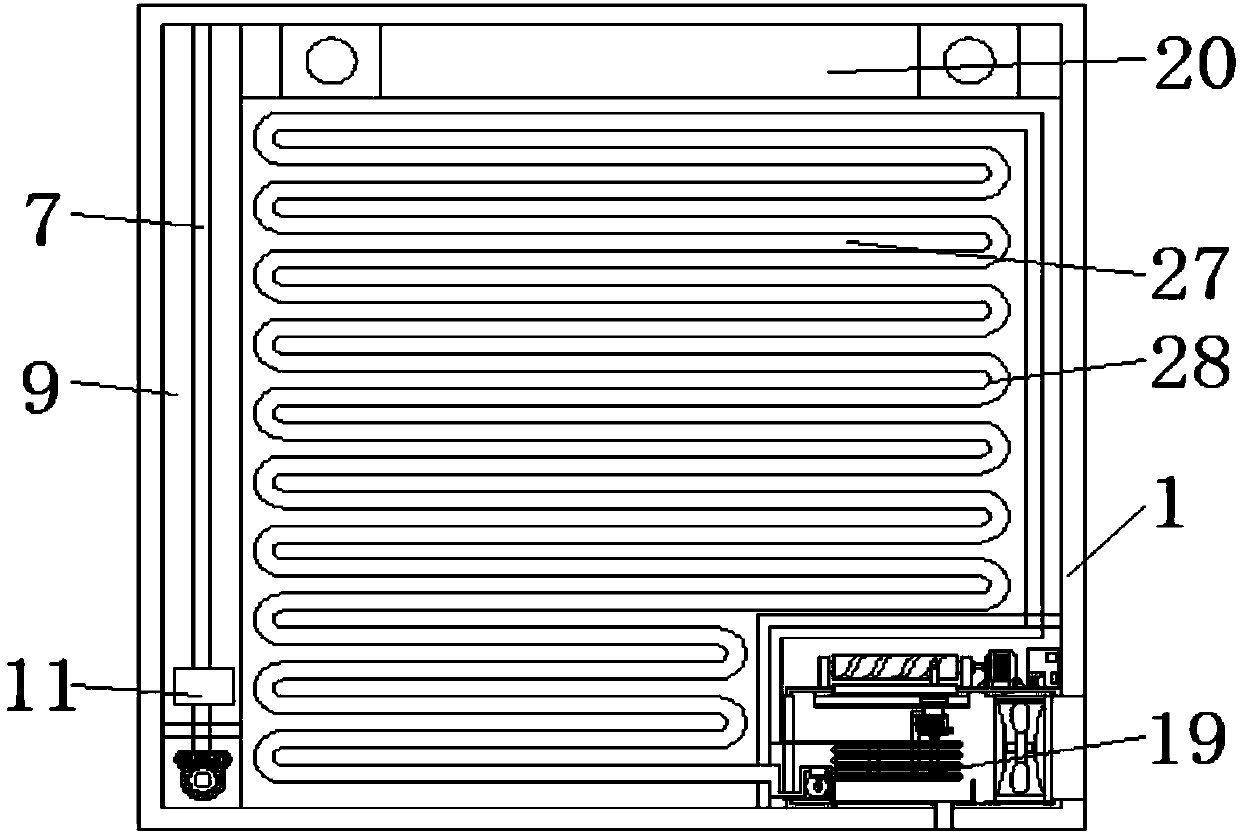

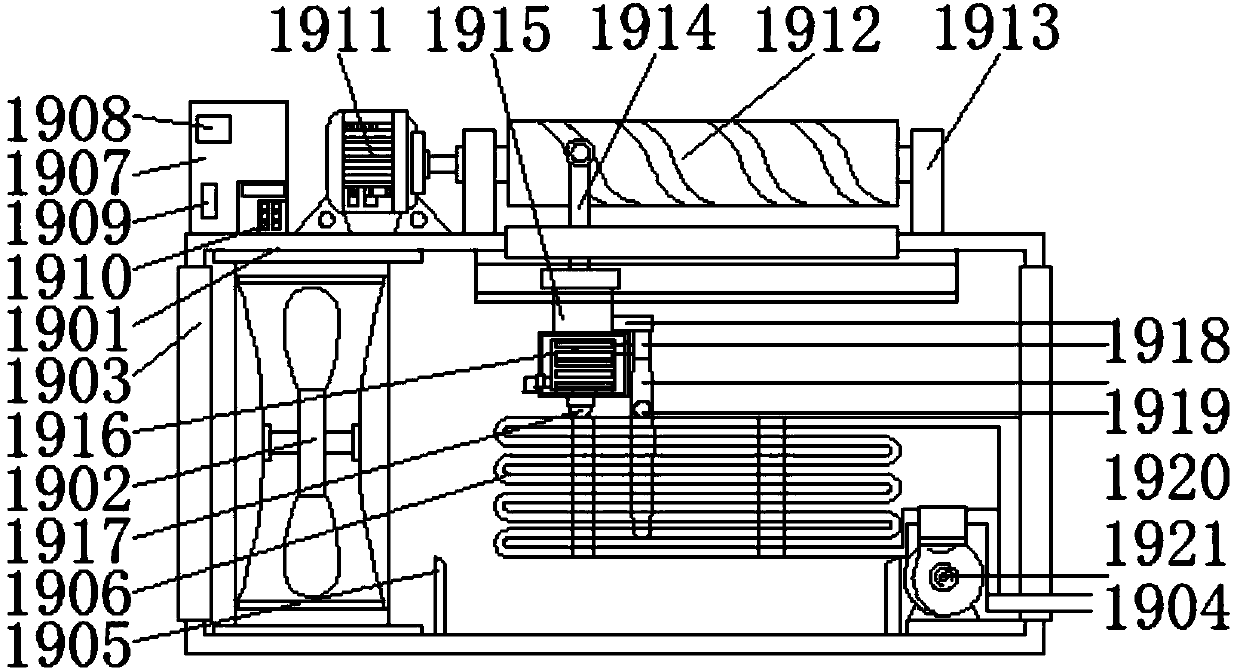

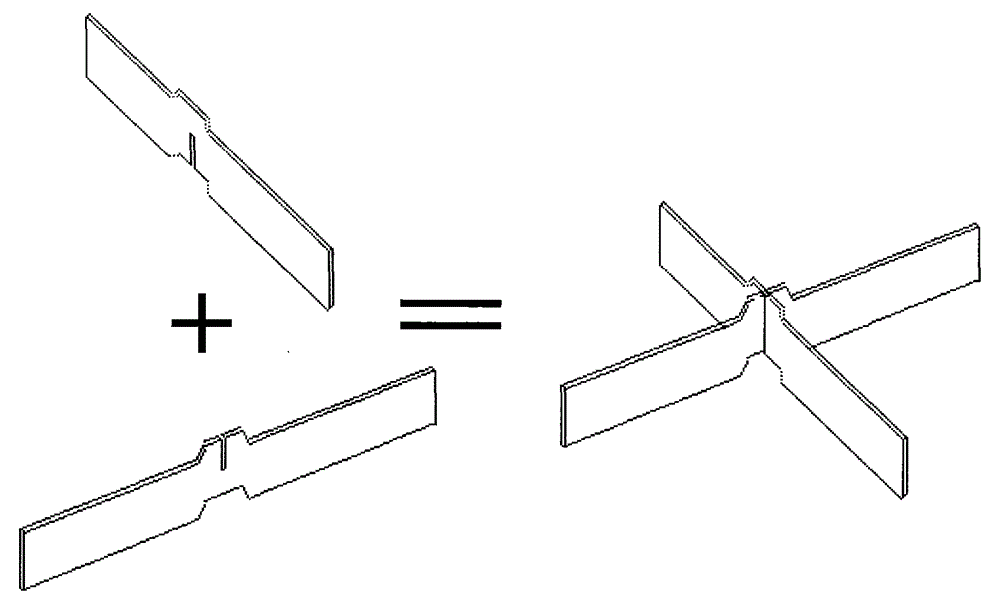

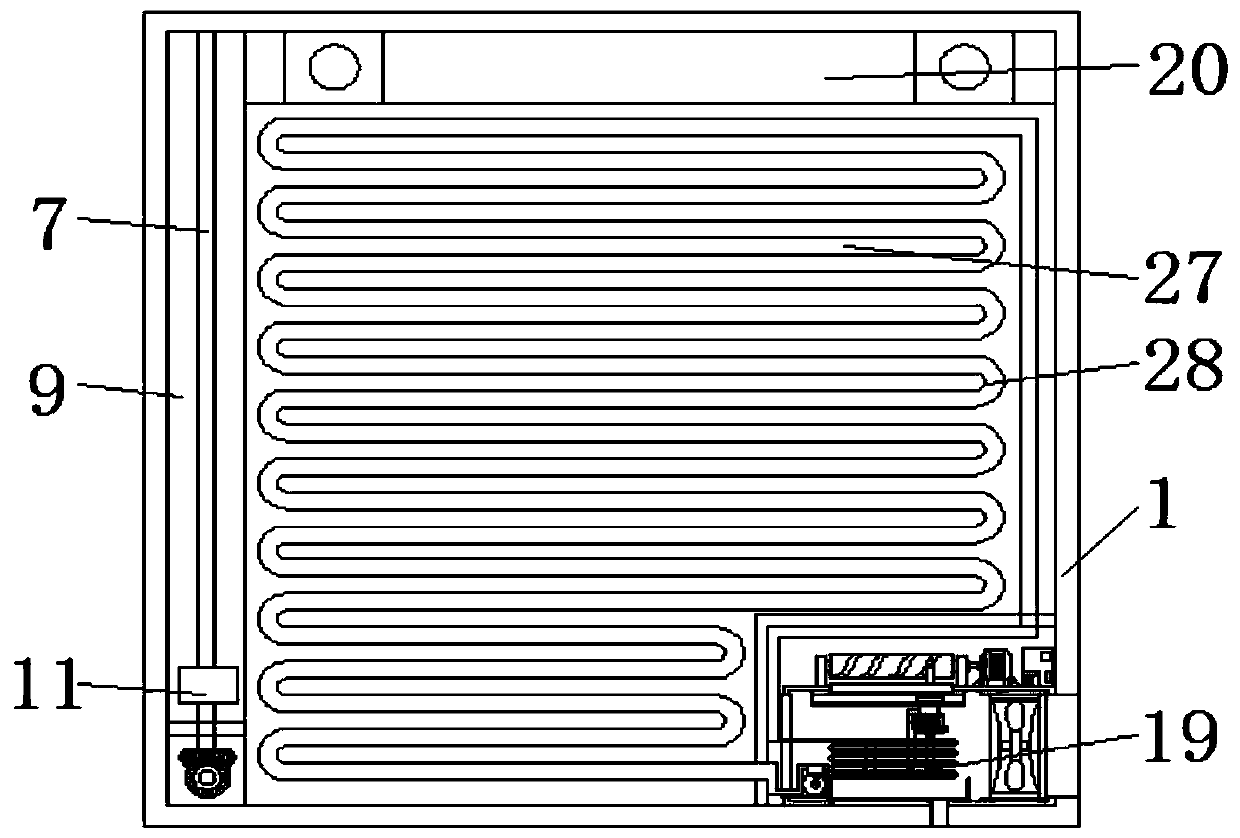

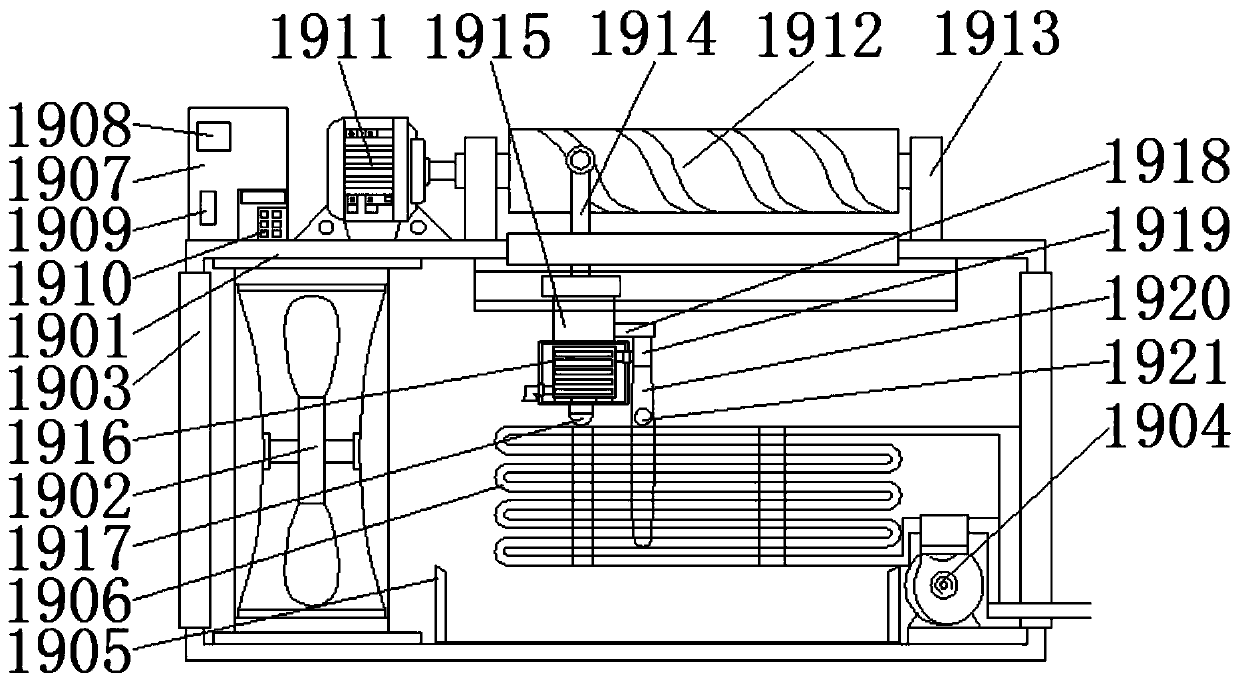

ActiveCN107747839AStacked flatImprove efficiencyLighting and heating apparatusDomestic refrigeratorsEngineeringFood processing

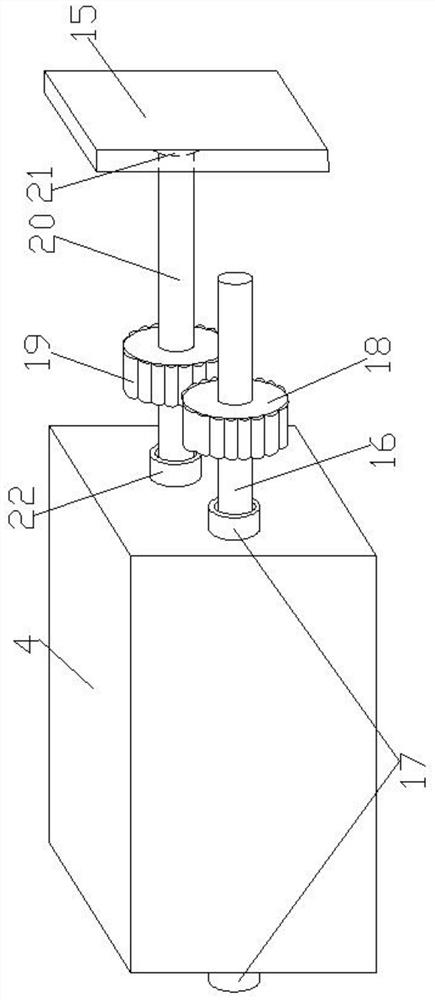

A storage device for foodstuff comprises a box body. The outer surfaces of threaded rods are both connected with threaded sliding blocks through threads. The middle positions of the sides, close to each other, of the threaded sliding blocks are rotationally connected with a first rotating shaft. The outer surface of the first rotating shaft is fixedly connected with a first gear. The outer surfaceof the first gear is in engaged transmission with a second gear through a conveyor belt. The side, close to the back face, of the bottom of an inner cavity of the box body is fixedly connected with adehumidifying and cooling device. The outer surface of a roller lead screw is connected with sliding blocks through threads, the sides, far away from the top of the inner cavity of the box body, of the sliding blocks are fixedly connected with fastening plates, and the sides, close to each other, of the fastening plates are provided with heat conduction pipes. The invention relates to the technical field of foodstuff. By means of the storage device for foodstuff, automatic feeding and automatic layering can be achieved, foodstuffs are stacked tidily, smashing or other current situations cannot occur, the efficiency is improved, and the product quality is guaranteed. The temperature and the humidity can be automatically adjusted to meet the different requirements of the different types offoodstuffs, and the food safety is guaranteed.

Owner:JIANGSU JIUSIXIANG FOOD TECH

Portable ball net rack

Owner:缪国平

Cigar wrapper and binder stem removing device

InactiveCN108142981AEfficient cullingEfficient stackingTobacco preparationTobacco treatmentMechanical engineeringDouble edge

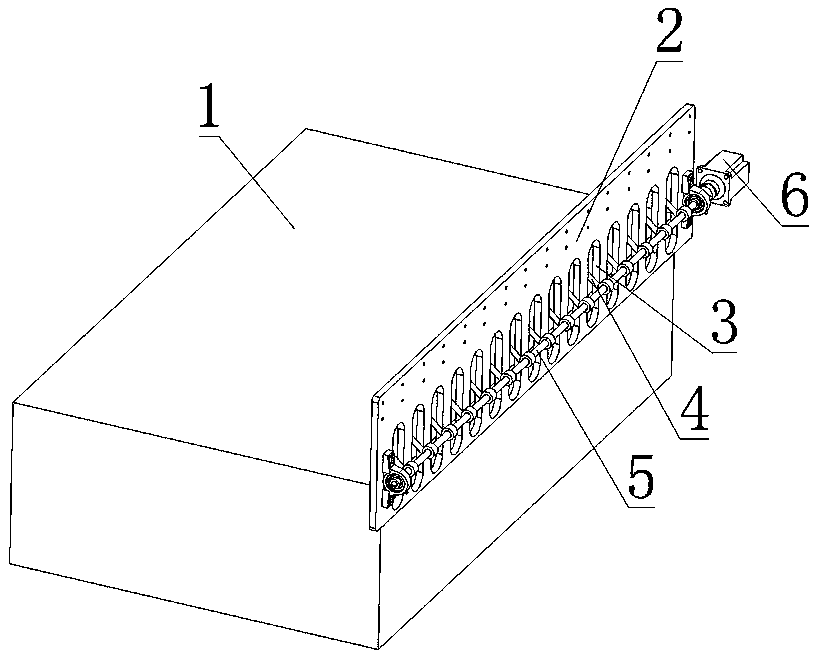

Provided is an intelligent tobacco leaf stem removing device. The device can realize modes of stem removing, stacking, tobacco stem smashing, flexibly controlling and the like. Each cloth belt is formed into a closed driving belt by winding a large roller and each small roller, and the contact surface formed by the large roller and the driving belTS can complete the conveying, spreading and stacking of tobacco leaf pieces. A circular double-edged hob is arranged in the middle of the large roller, each hob blade and the corresponding rotary butcher's knife and chopping block form two pairs of rotary rolling cutters, and the rolling cutters complete the cutting of leaf stems. Wall plates at the two sides provide support, fixation and connection for the large roller, small rollers and other functional parTS. A set of manual connecting rod mechanisms is arranged on an operation table, the opening and closing of a machine head are completed, and at the same time, the relaxation and tensionof the cloth belt are completed. A separate tension spring mechanism is arranged on each driving cloth belt, the cloth belt tension is kept when the machine head is closed, and the tension spring is unloaded to keep the cloth belt loose when the machine head is opened.

Owner:XIANGYANG SHENGUAN MECHANICAL & ELECTRICAL TECH CO LTD

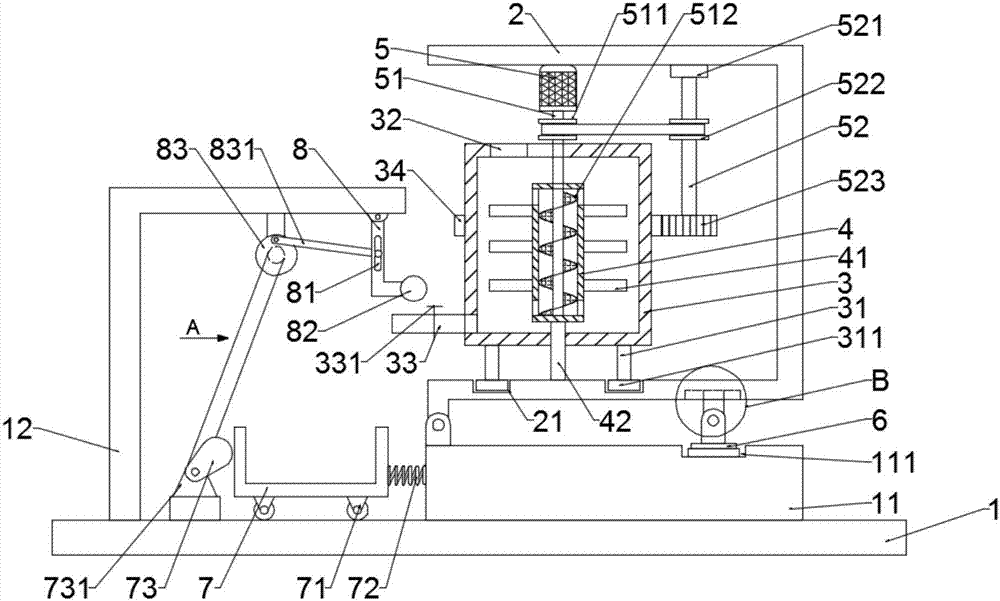

Feed mixing production device for green ecological livestock breeding

PendingCN111545120AQuality improvementImprove finished product qualityFeeding-stuffTransportation and packagingElectric machineryAnimal science

The invention discloses a feed mixing production device for green ecological livestock breeding. The device comprises a working bin; a motor is fixedly arranged in the center of the top end of the outer wall of the working bin; a noise reduction and heat dissipation mechanism is arranged on the motor; a partition plate is fixedly arranged at the top in the working bin; a crushing bin is fixedly arranged at the top end of the partition plate; the bottom end of the crushing bin is open; and the bottom end of the crushing bin penetrates through the partition plate and is communicated with the interior of the working bin. The rotating directions of vertical rods and auxiliary stirring plates are opposite to the rotating directions of stirring plates and connecting rods, therefore, the feed inthe working bin is stirred and mixed in a disordered manner, and the stirring effect of the feed can be improved; the feed is discharged through a discharge port and a hose after being stirred, so that the feed is discharged into a receiving frame; and the hose is driven to move through a moving mechanism in a discharging process, so that the feed is scattered in a reciprocating manner, and the feed in the receiving frame is stacked more smoothly.

Owner:华廷卿 +1

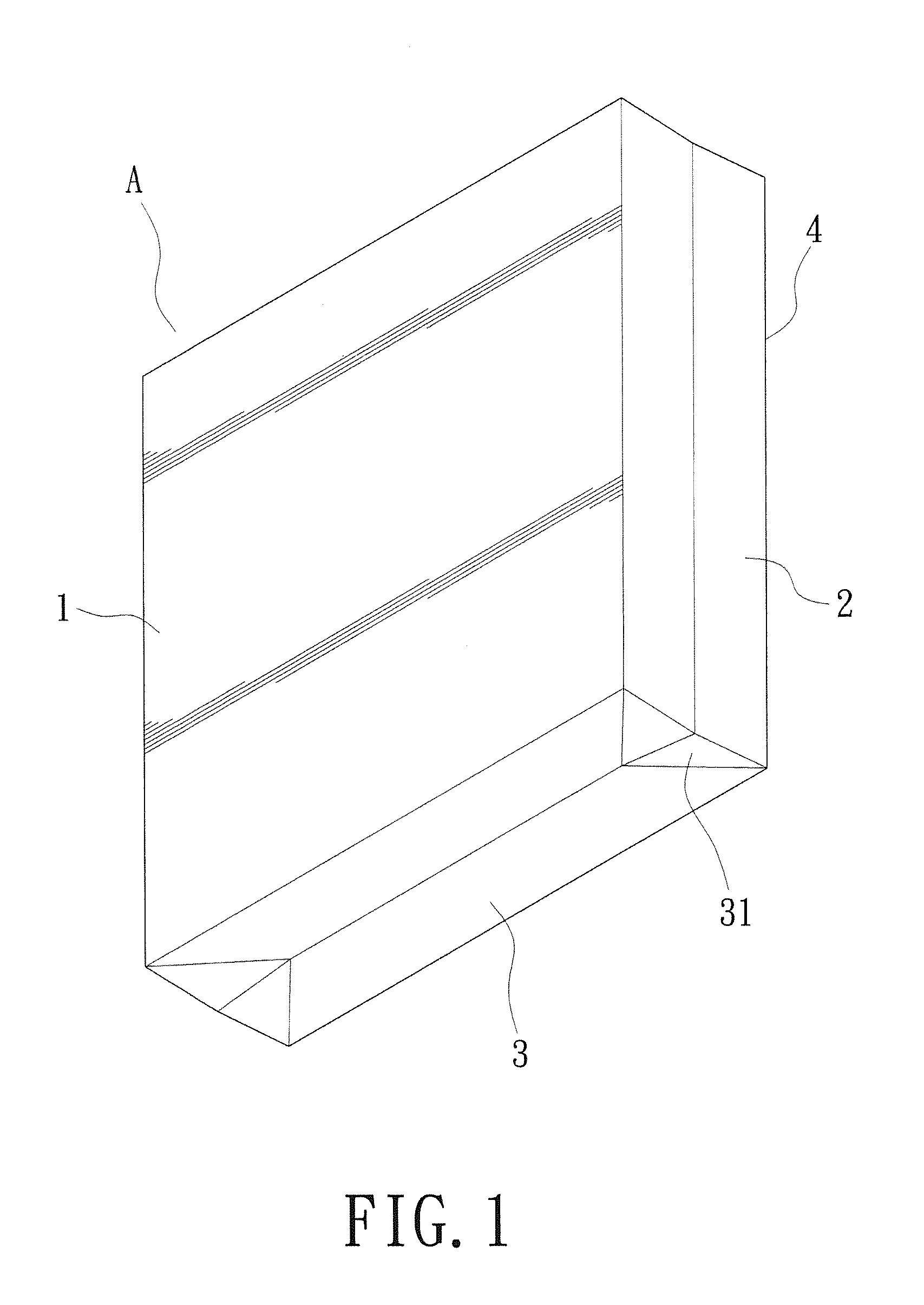

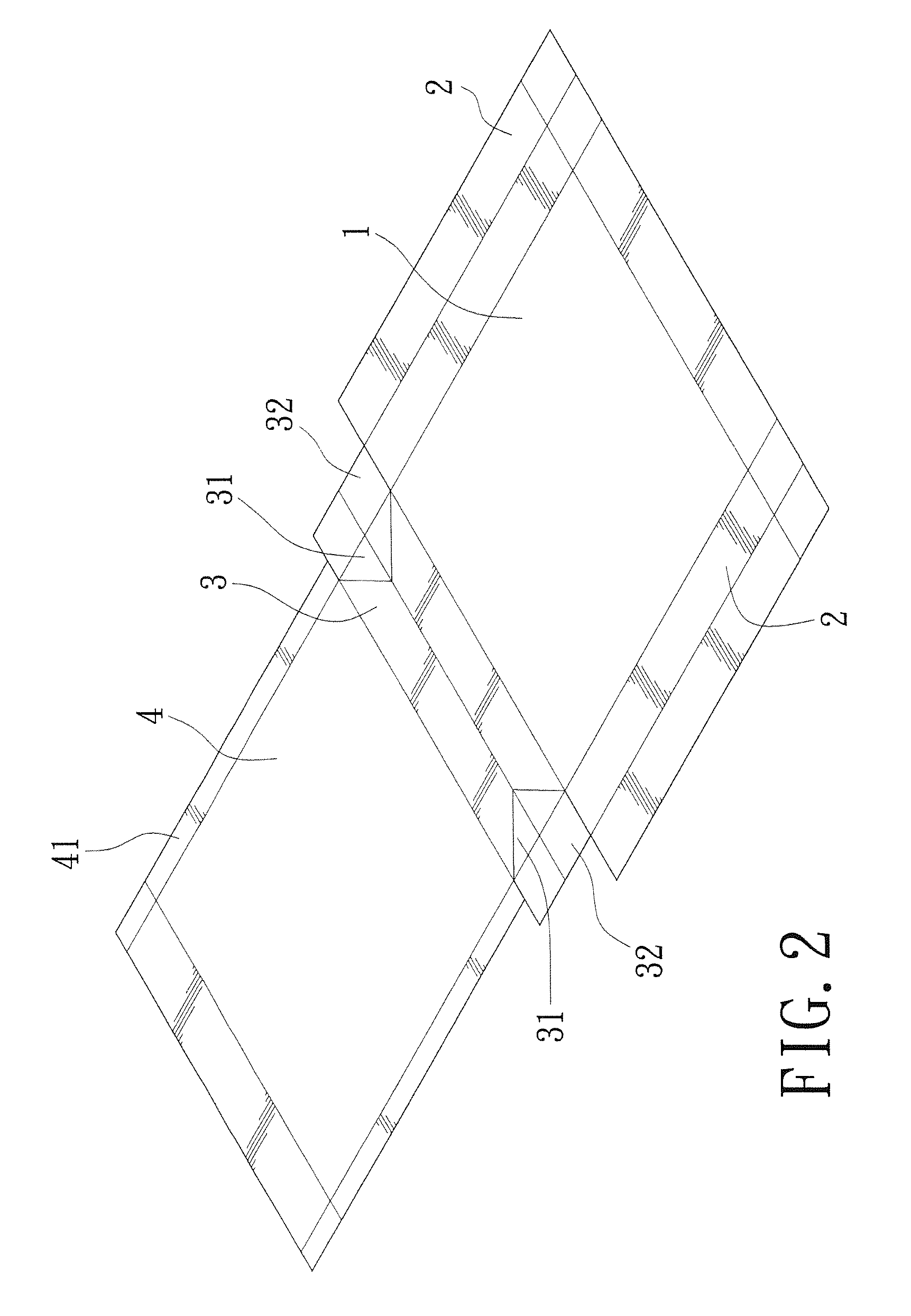

Bag structure

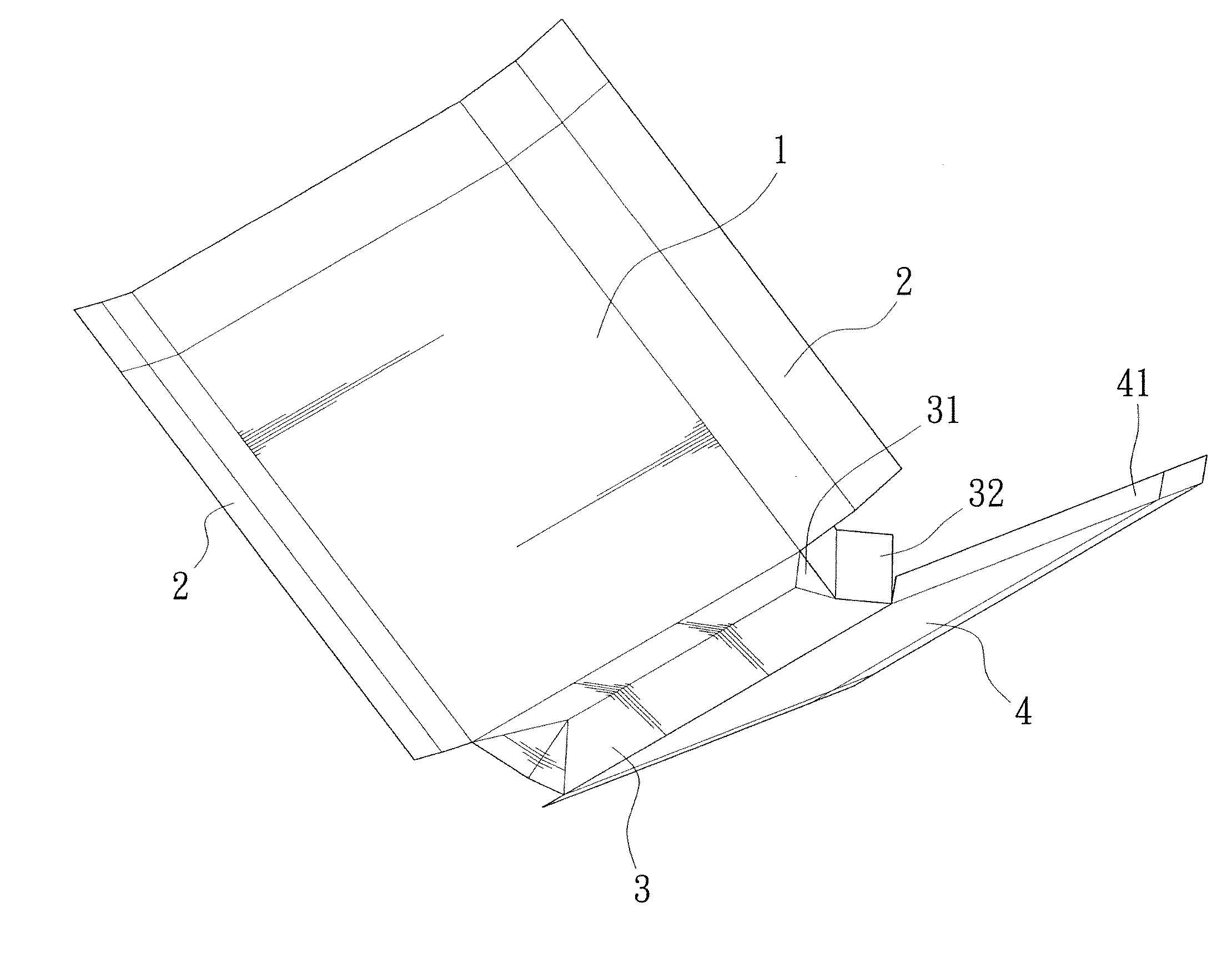

InactiveUS20160090212A1Attractive appearanceStrong and stable structureBagsSacksEngineeringFront panel

The present invention is related to a bag structure. The bag structure comprises a front panel, two lateral panels, a bottom panel, and a rear panel, and all panels join together to form the bag. Two lateral edges of the bottom panel have an extension flap for joining to the lateral panel, respectively, and a valley fold portion is between the bottom panel and the extension flap. After the bag structure is folded, the bag structure has a one-piece bottom and the flat front and rear panels, thereby having attractive appearance and strong structure and being flat when stacked.

Owner:LIN TING CHU +1

Feed mixing production device used for livestock breeding

ActiveCN111632710AQuality improvementImprove finished product qualityRotating receptacle mixersFeeding-stuffAnimal scienceCrop livestock

The invention discloses a feed mixing production device used for livestock breeding. A sound eliminating and heat dissipating mechanism is arranged on a motor. The bottom end of a smashing bin penetrates a partition plate and communicates with the interior of a work bin. Universal sliding wheels are fixed to the bottom ends of connecting rods. A round sliding groove is formed in the top of a roundsliding plate, and the universal sliding wheels are matched with the round sliding groove. Branch rods are fixed to the two sides of the bottom of the supporting rod, and second shock absorbers are fixed to the bottom ends of the branch rods and the bottom end of the supporting rod. The feed mixing production device has the beneficial effects that the rotating direction of a vertical rod and an auxiliary stirring plate and the rotating direction of a stirring plate and a connection rod are arranged in an opposite rotating manner, thus, it is ensured that feed in the work bin is stirred and mixed in a form disturbing manner, and the feed stirring effect is improved; after stirring is completed, a discharging opening and a soft pipe are used for discharging, and therefore the feed is discharged into a feed receiving frame; and in the discharging process, a moving mechanism is arranged for driving the soft pipe to move, and therefore reciprocating feed scattering is achieved, and the feed in the material receiving frame can be stacked more flatly.

Owner:华廷卿 +1

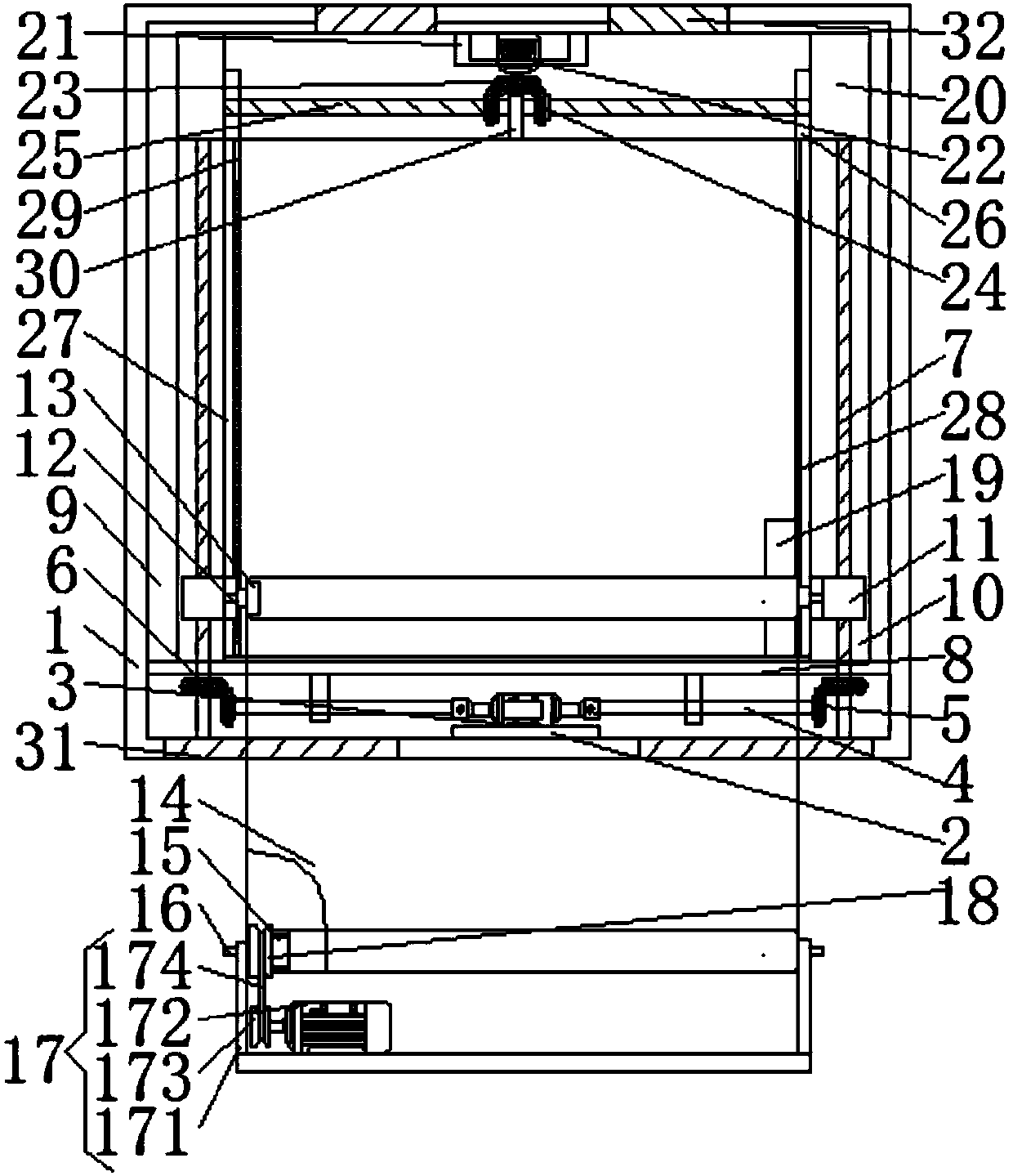

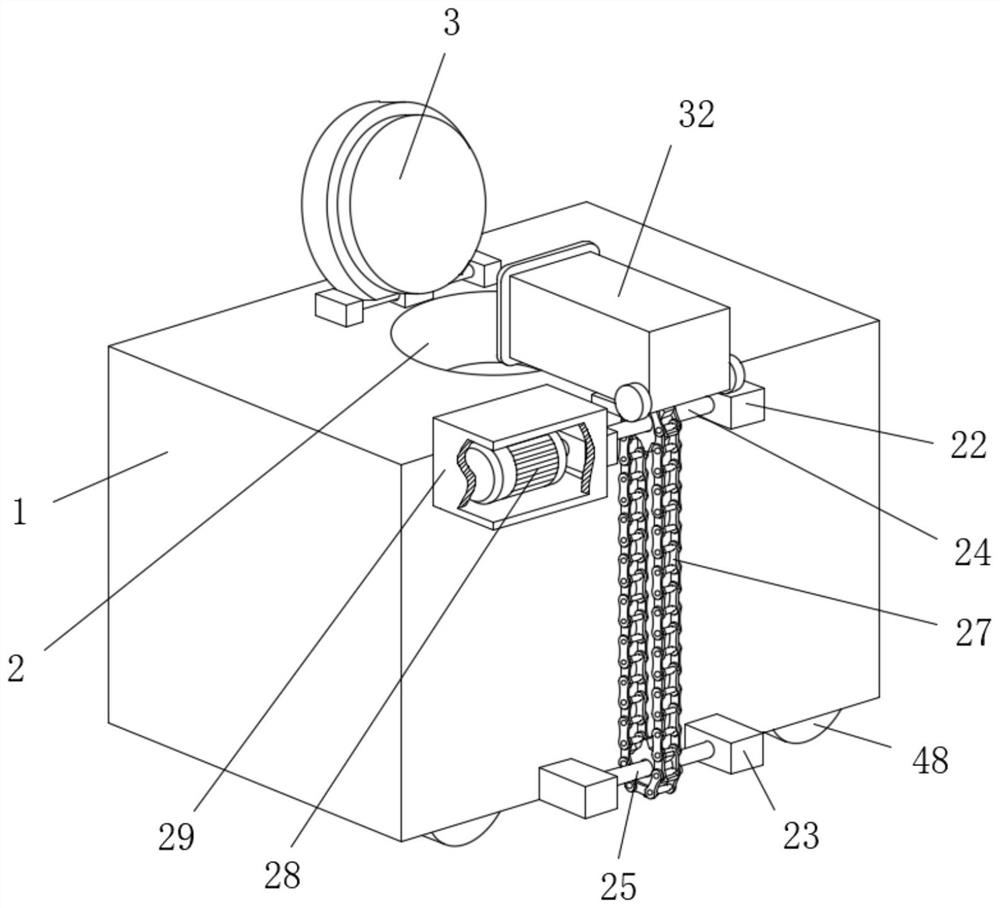

Novel automatic stacking and packing machine

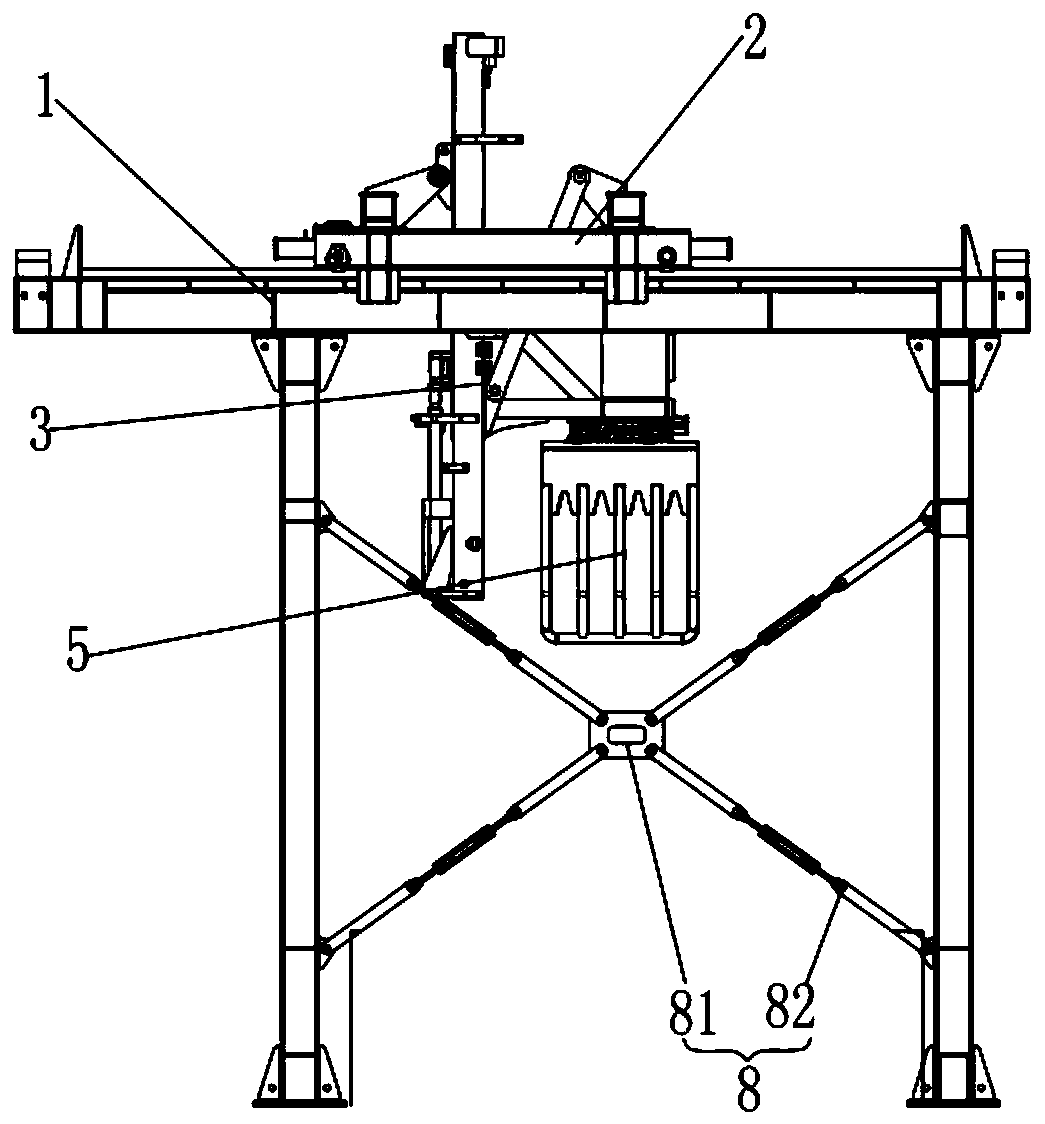

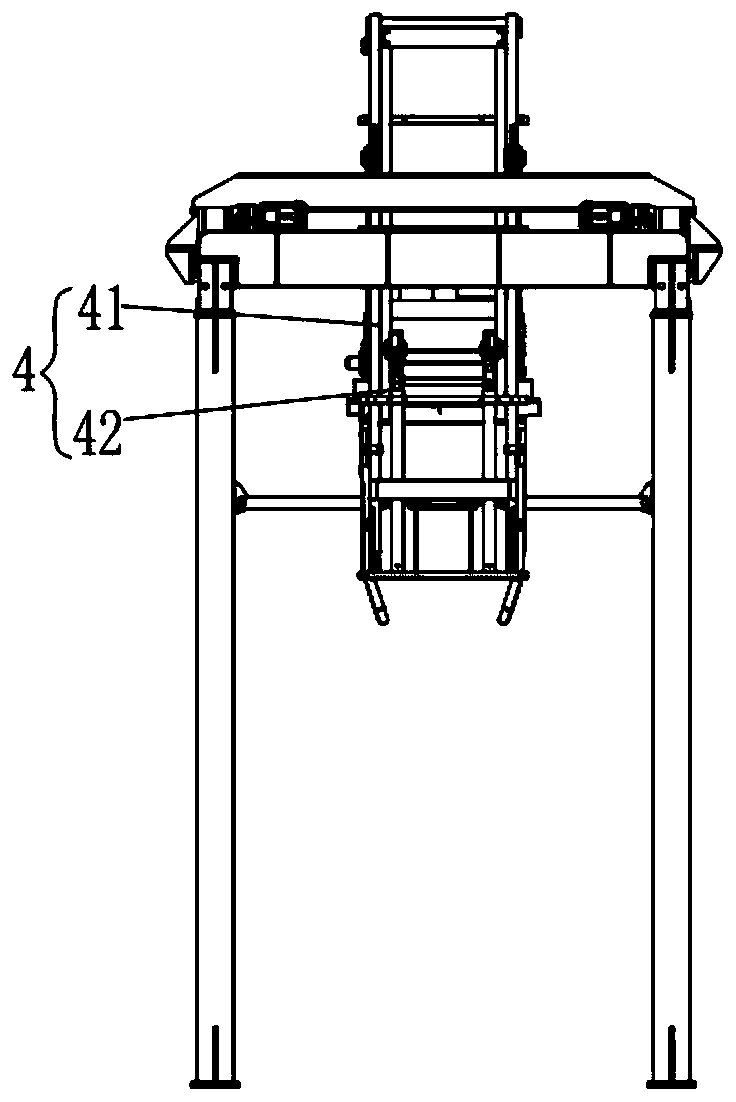

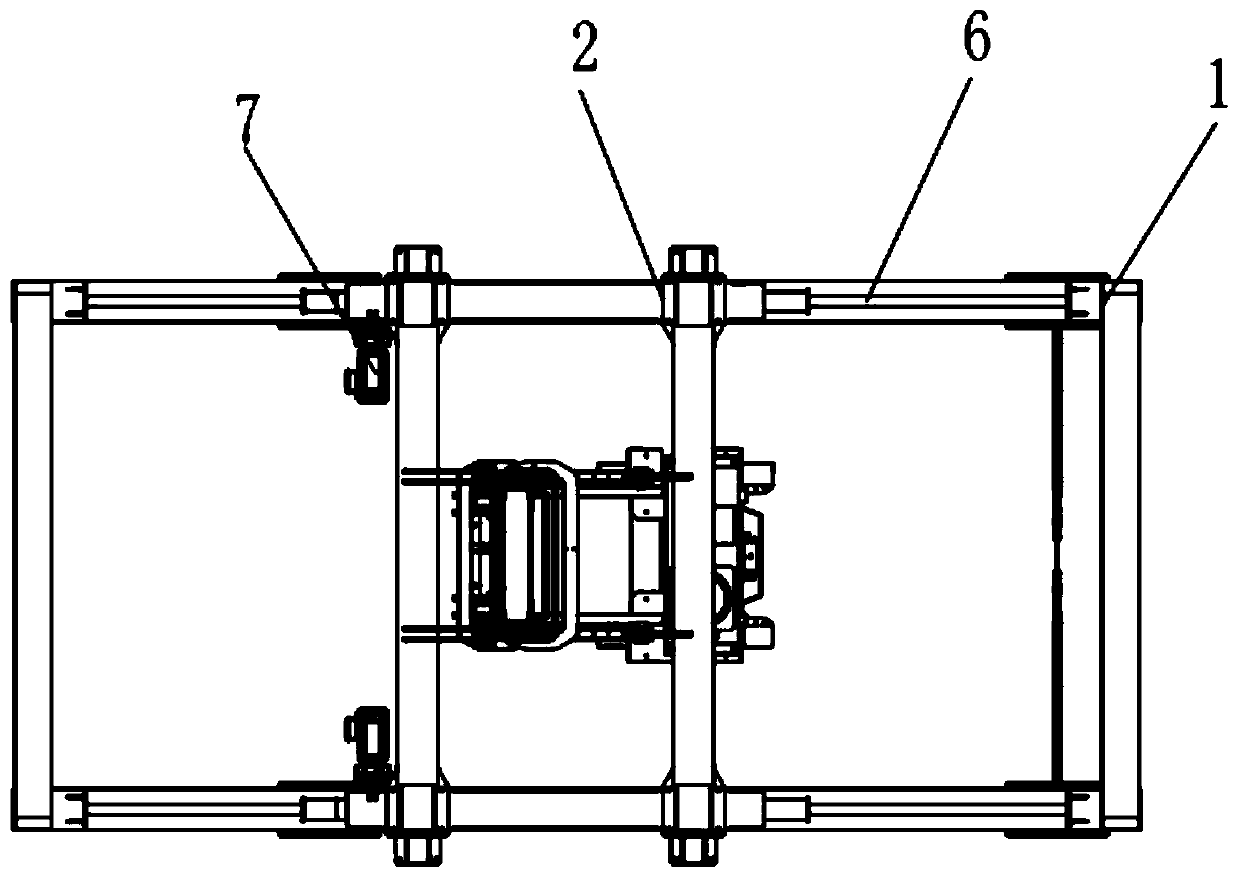

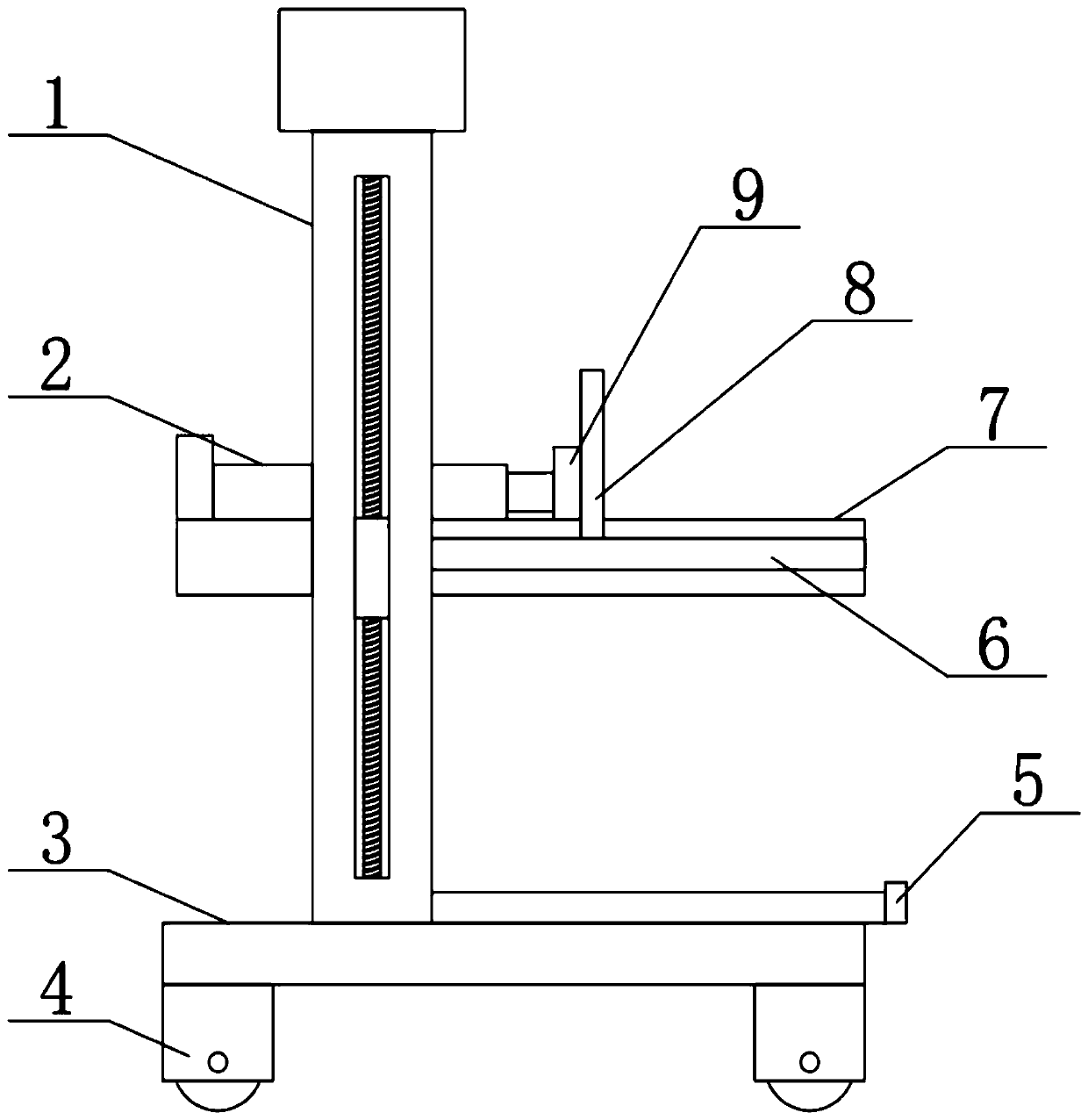

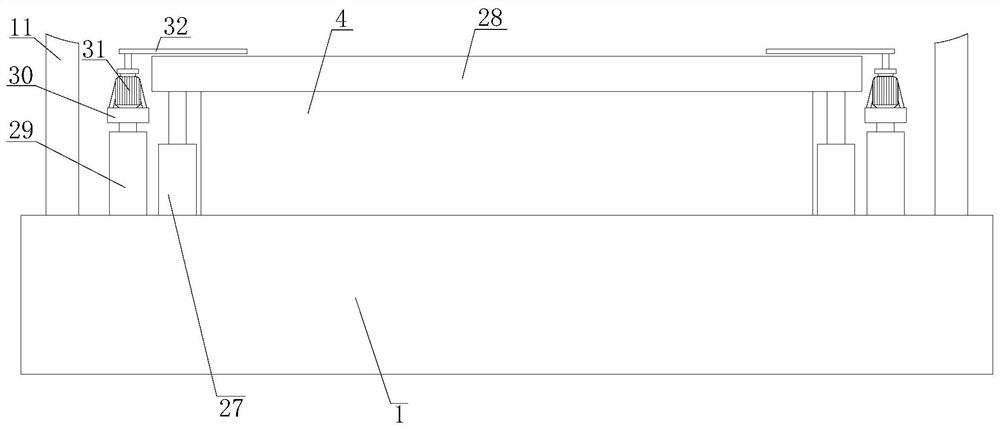

PendingCN111186775AAchieve grippingAchieve placementTrolley cranesTrolleysVehicle frameClassical mechanics

The invention discloses a novel automatic stacking and packing machine. The novel automatic stacking and packing machine comprises a truss, a transverse frame is arranged at the upper end of the trussin a sliding mode, a material taking mechanism is arranged on the transverse frame, wherein the material taking mechanism comprises a material taking frame, jacking devices arranged on the two sidesof the material taking frame and a clamping arm device arranged at the lower ends of the jacking devices, the clamping arm device comprises a clamping arm frame, a lateral movement driving device arranged on the clamping arm frame and a clamping arm group arranged at the lower end of the clamping arm frame, the jacking devices can drive the clamping arm group to move up and down, and the lateral movement driving device can drive the clamping arm group for opening and clamping and lateral movement. The transverse frame moves transversely on the truss to drive the clamping arm group to move transversely to a position corresponding to an object, then the clamping arm group is driven to move up and down through jacking driving devices, the clamping arm group is driven to clamp and place the object through the lateral movement driving device, the whole stacking process is automatically controlled by a sensor and a controller, compared with manual work, the efficiency is higher, and stackingis flatter.

Owner:LONGHE INTELLIGENT EQUIP MFG CO LTD

Towel cloth transverse cutting machine

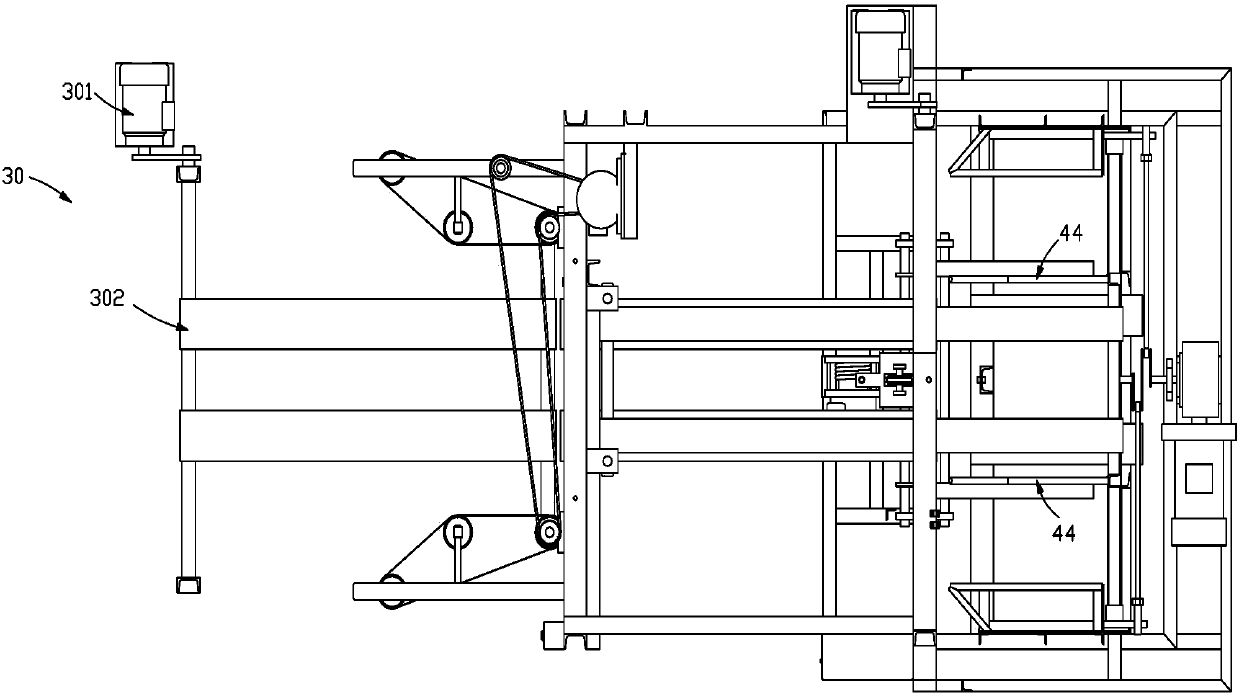

PendingCN111483001AGuaranteed production efficiencyReduce manufacturing costSevering textilesMetal working apparatusEngineeringMechanical engineering

The invention provides a towel cloth transverse cutting machine. The towel cloth transverse cutting machine comprises a cutting mechanism, a grabbing mechanism and a lifting mechanism; the cutting mechanism is for transversely cutting a towel cloth and comprises an ultrasonic vibrator assembly, a circular knife assembly, and a transverse cutting synchronous driving mechanism; the transverse cutting synchronous driving mechanism drives the ultrasonic vibrator assembly and the circular knife assembly to move back and forth synchronously to realize transverse cutting of the towel cloth; the grabbing mechanism is for grabbing the towel cloth and moving the cloth towards the left side or the right side of a rack; the grabbing mechanism comprises a cloth clamping assembly, a following boss and acloth clamping driving mechanism; the cloth clamping driving mechanism can drive the cloth clamping assembly to move left and right along the lateral direction of the rack; and the following boss isprovided with a wedge-shaped reversing wall. A splint of the cloth clamping assembly clamps the towel cloth and the cloth clamping driving mechanism can drive a follower to slide through the reversingwall and overturn the splint; and a lifting driving device can intermittently lower a cloth piling counter top for piling up the towel cloth after cutting. The towel cloth transverse cutting machinecan realize direct transverse cutting of a whole roll of towel cloth and automatic piling of towels, the degree of automation is high, and the production efficiency is high.

Owner:常熟寿胜自动化机械有限公司

Intelligent wax printing cloth stacker with adjusting function

InactiveCN110894003AAvoid inertia dumpingPrevent back movementStacking articlesStructural engineeringStacker

The invention discloses an intelligent wax printing cloth stacker with an adjusting function. The stacker comprises stacker supports, a bottom plate, moving wheels and a carrying plate, the stacker supports are arranged at the two sides of the upper end face of the bottom plate, the moving wheels are arranged at the four corners of the lower end face of the bottom plate, the carrying plate is arranged between the two stacker supports, and an electric telescopic arm is arranged at one side of the upper end face of the carrying plate; a designed baffle plate can prevent cloth from inertial toppling when the electric telescopic arm pushes a fixed plate and can avoid the cloth from returning by following the carrying plate, so that the cloth is stacked smoothly in a flatter way, the baffle plate can be automatically adjusted and reset in the contraction process of the electric telescopic arm, the automatic degree is high, and operation is convenient; by means of first and second compression springs, a dialing block and a limiting block can be adjusted and reset automatically; and arc angles reduce wearing between the cloth and a sliding rod.

Owner:HUANGSHI ZHONGTIAN MACHINERY MFG

Cloth stacking device for garment production

InactiveCN108867003ANeatly stackedStacked flatMechanical cleaningPressure cleaningPulp and paper industrySteam engine

The invention discloses a cloth stacking device for garment production, and relates to the technical field of garment production. The device comprises a stacking device body, and the stacking device body comprises an operation box, a support rod, a cross beam, a discharge roller, a workbench, a blower, a fixed clamp, a steam engine, a cutting board, and a cutter. One side of the inner wall of theoperation box is fixedly connected with the rear side of one end of the support rod, and the upper end of the operation box is fixedly connected with the lower end of the cross beam. According to theinvention, on the one hand, the discharge roller can roll back and forth so as to quickly and effectively stack the cloth in a neat manner; on the other hand, the steam engine can iron and press the surface of the cloth after the discharge roller can roll back and forth to stack two cloth layers, thereby enabling the cloth to be stacked more flatly. In addition, the steam engine can move up and down, so the cloth at the uppermost end still can be ironed when the cloth is put at a very high place. Moreover, the steam engine is driven by a telescoping rod to move, so the steam engine does not stay on the surface of the stacked cloth for too long, thereby avoiding the damages to the cloth.

Owner:湖州南童魔服饰有限公司

High-efficiency reducing furnace electrode repairing method

InactiveCN110923692ASolve production inefficienciesImprove cleanlinessPressure inorganic powder coatingMachiningBonding strength

The invention discloses a reducing furnace electrode repairing method. The reducing furnace electrode repairing method comprises the following steps that firstly, cleaning and grinding treatment is conducted on the surface of a to-be-repaired area on a reducing furnace electrode; secondly, inert gas is used for loading to-be-sprayed particles, and after heating is conducted to 200-800 DEG C, the to-be-sprayed particles are sprayed to the surface of the to-be-repaired area; and thirdly, mechanical machining is conducted on a reducing furnace electrode surface coating according to the actual usage size, and a repaired reducing furnace electrode is obtained. According to the reducing furnace electrode repairing method, a repairing body can be dense, and the bonding strength between the repairing body and an electrode base body material is high; based on the electrode component shape, the electrode material deposition precision can be optimized by controlling the nozzle size, spraying parameters, tracks and the like, and the subsequent machining amount is reduced; the thickness and the shape of the repairing body are not limited, and the reducing furnace electrode repairing method canbe used for repairing of electrodes different in damage degree; applicable materials are wide, a base body and the coating can be repaired at the same time, and efficiency is high; and the spraying process is simple, heat treatment is not needed, cost is low, and the production efficiency is high.

Owner:GUANGDONG INST OF NEW MATERIALS

Garbage monitoring device and system based on Internet of Things

ActiveCN113382082AImprove incineration efficiencyStacked flatGlass recyclingRefuse transferringComputer hardwareThe Internet

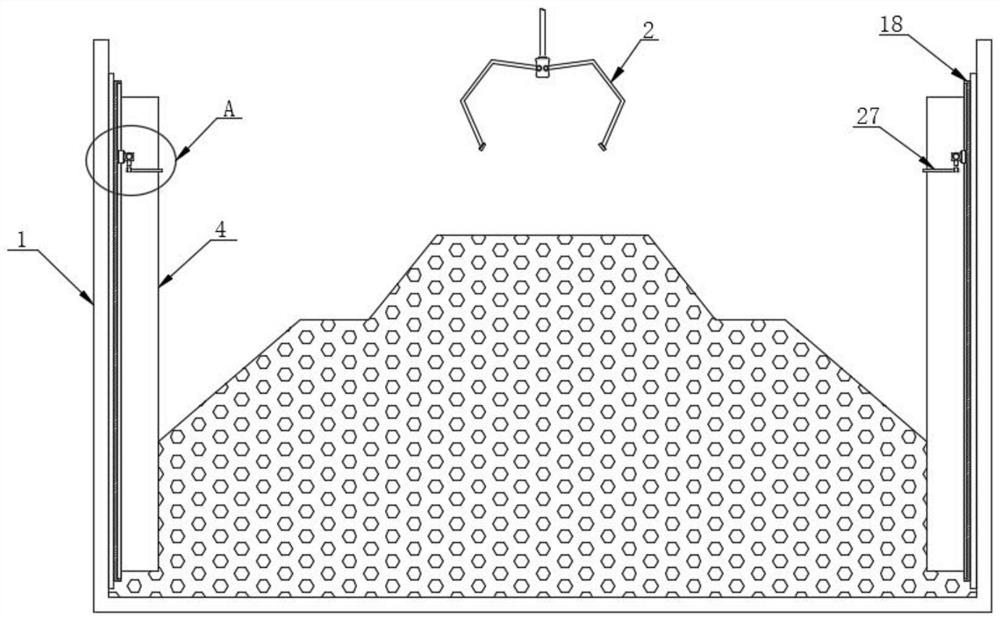

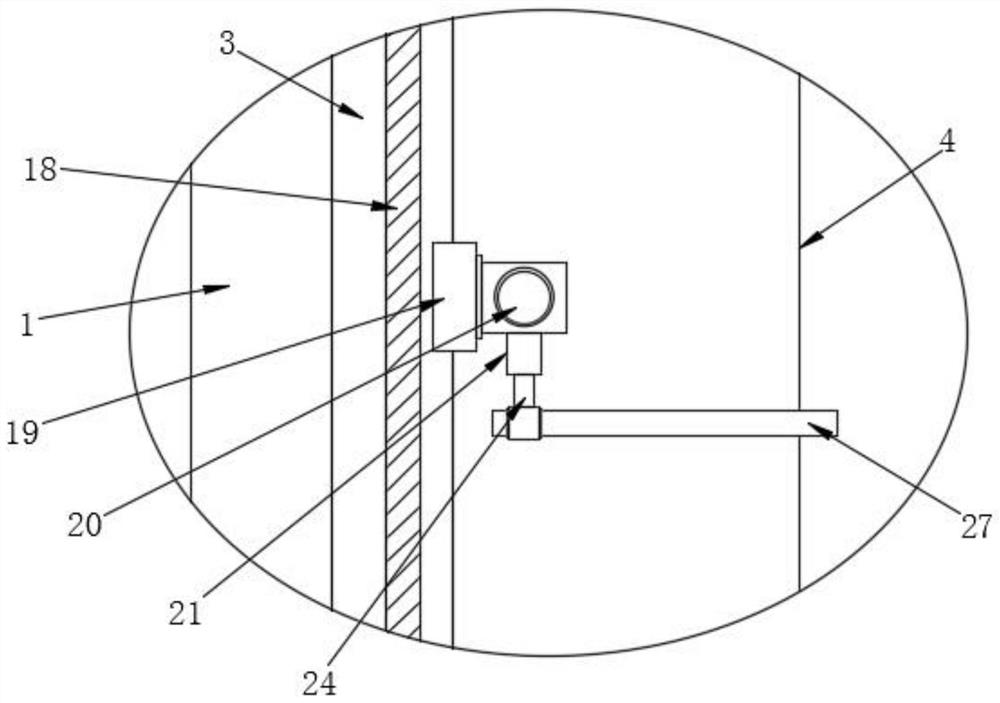

The invention discloses a garbage monitoring device and system based on the Internet of Things, the garbage monitoring device comprises a garbage filling pool and a mechanical claw, the two sides of an inner cavity of the garbage filling pool are fixedly connected with base plates, the opposite sides of the two base plates are fixedly connected with glass frames, and the front parts of the sides, close to the base plates, of inner cavities of the glass frames are fixedly connected with meshing plates; and the invention relates to the technical field of monitoring systems. According to the garbage monitoring device and system based on the Internet of Things, glass frames are installed on the two sides of the interior of the filling pool, image scanners are installed in the glass frames, and then a motor and a meshing plate are used for driving the image scanners to move up and down; and through the arrangement of the structure, images of the two scanners can be synthesized into a real-time three-dimensional model, the mechanical claw grabs accumulated garbage in real time and adjusts the area through communication of the Internet of Things, the garbage is accumulated more flatly, and collapse and splashing are avoided.

Owner:陕西中科启元信息技术有限公司

Integrated automatic cat litter basin

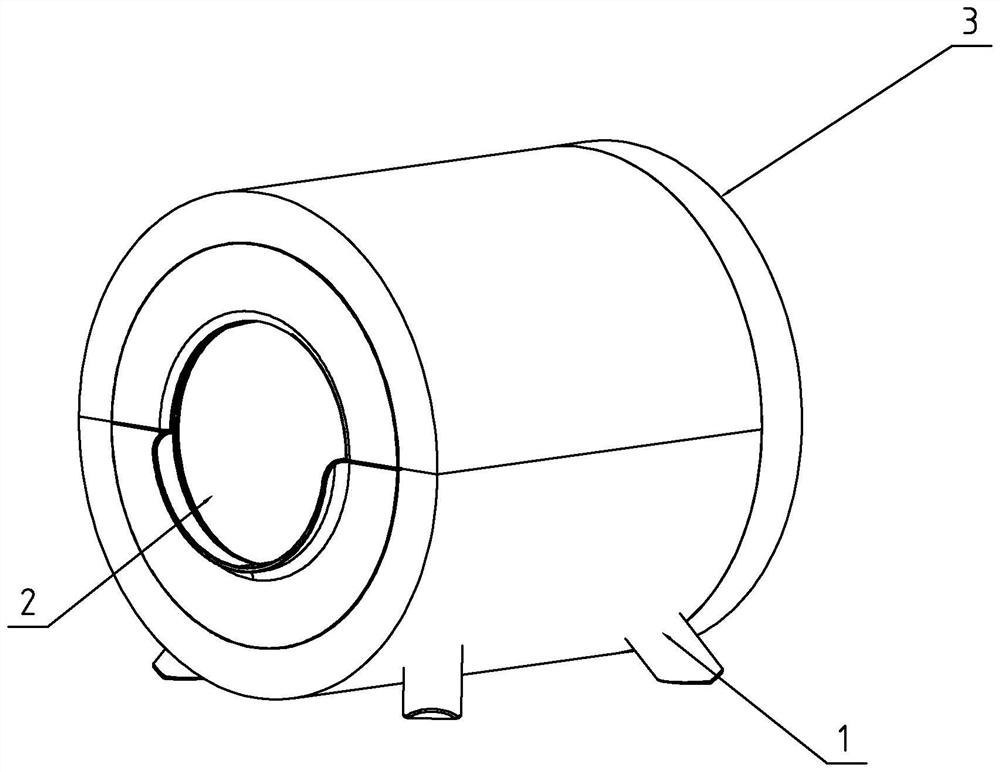

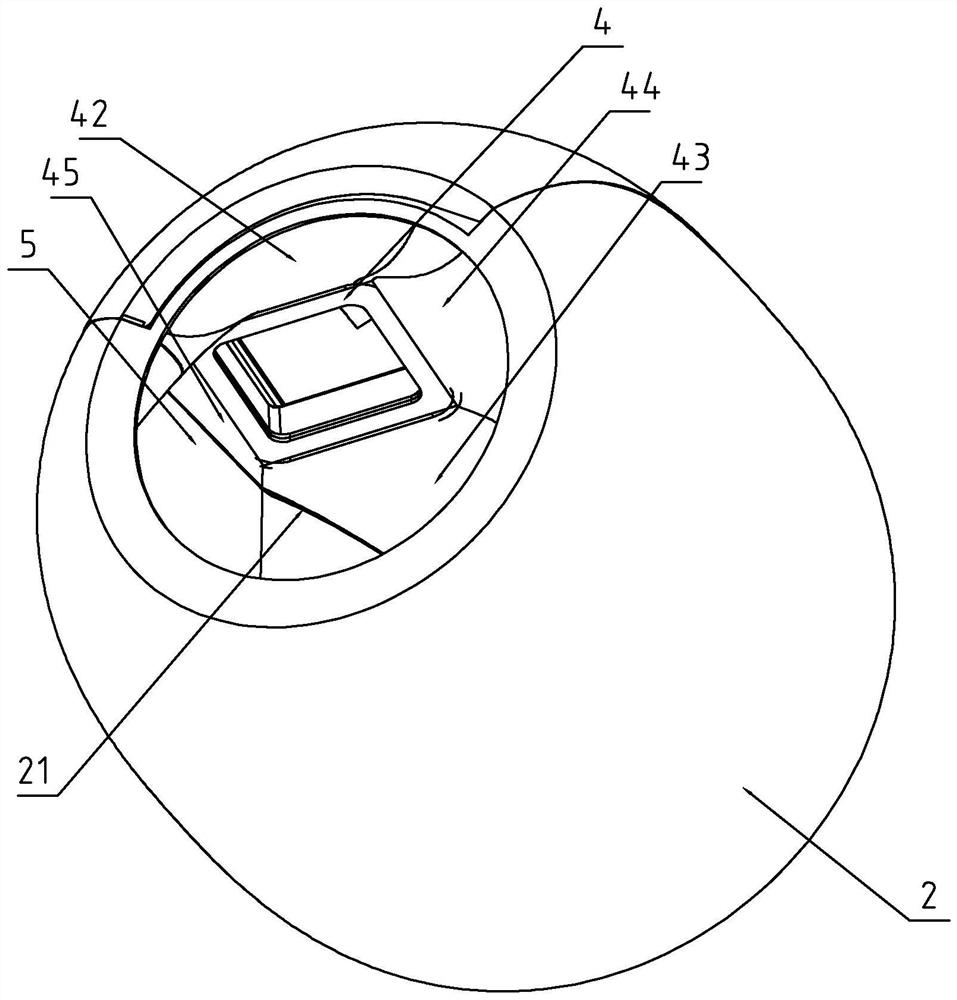

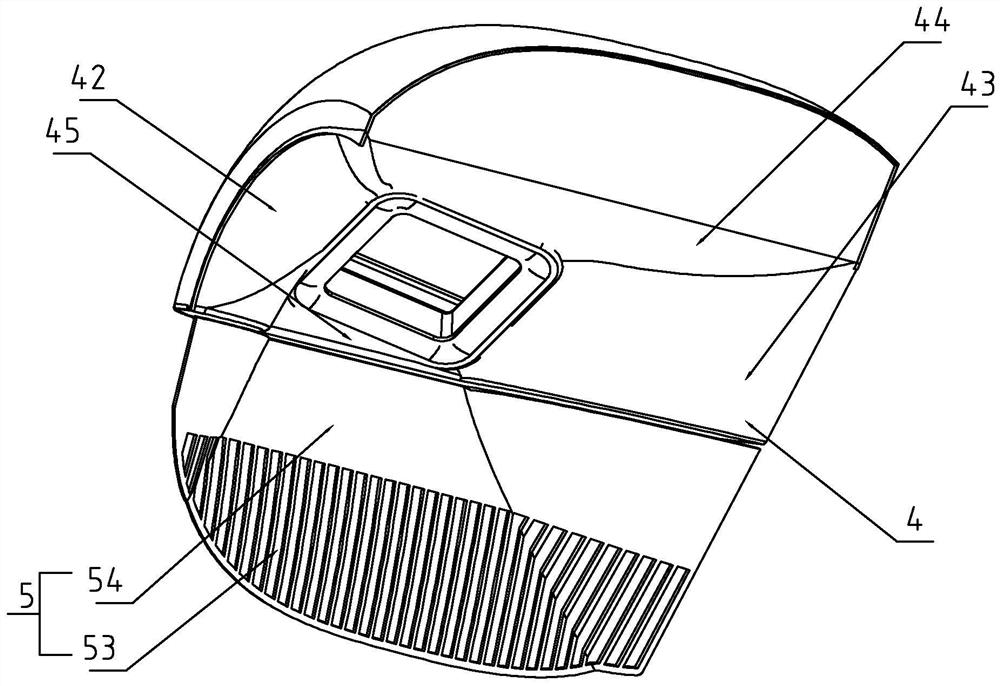

ActiveCN114532234AChange the detached styleImprove volume utilizationWaste collection and transferAnimal housingAgricultural scienceLitter

According to the technical scheme, the integrated automatic cat litter basin is characterized in that the integrated automatic cat litter basin comprises an installation frame, an operation bin arranged in a barrel-shaped structure and a driving part used for driving the operation bin to rotate, the operation bin is installed on the installation frame, and an operation cavity is formed in the operation bin; an inner arc plate is arranged in the operation bin, the operation cavity is divided into a treatment cavity and a garbage cavity by the inner arc plate, and a communication opening for communicating the treatment cavity with the garbage cavity is formed in the inner arc plate; a sieve plate body is arranged in the cat cavity, the treatment cavity is divided into the cat cavity and the cat litter cavity by the sieve plate body, and the integrated automatic cat litter basin can guarantee complete functions of equipment while saving the occupied area all the time.

Owner:上海乔吉梦科技有限公司

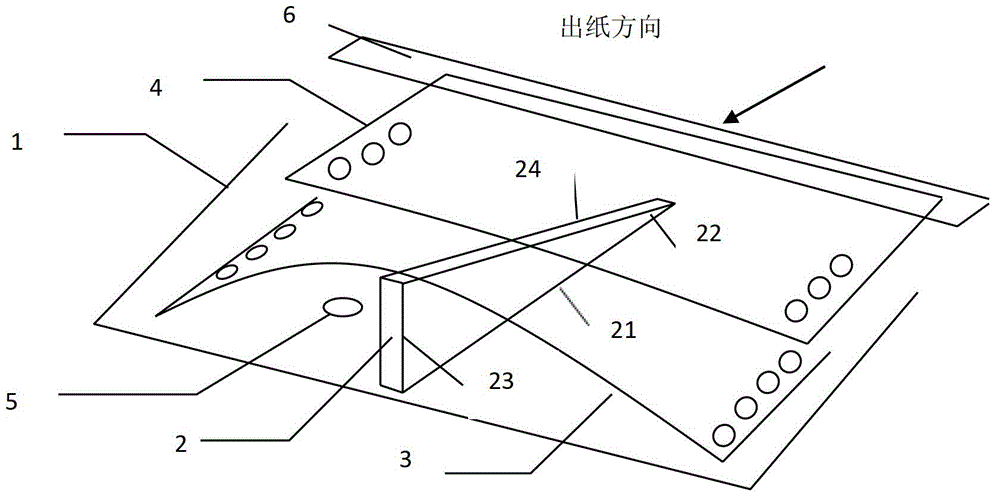

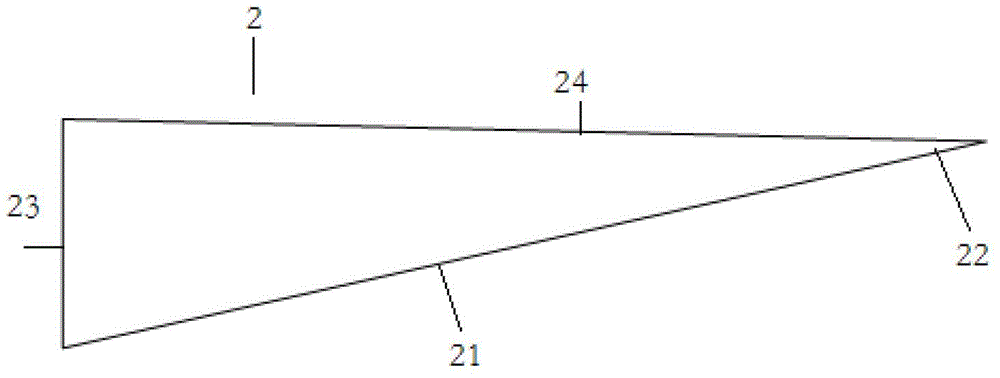

Paper-out bracket of printer

ActiveCN102729649BPaper output will not affectEasy accessOther printing apparatusAcute anglePulp and paper industry

The invention provides a paper-out bracket of a printer and is characterized in that the paper-out bracket (2) is triangular, a first side (21) of the paper-out bracket (2) is combined with a baseplate (1), wherein the baseplate (1) is arranged at the extending position of a paper outlet (6) of the printer, a second side (24) is combined with printing paper (4) at the position of the paper outlet (6), an angle (22) between the first side (21) and the second side is an acute angle, and the paper out bracket (2) extends from a place near the paper outlet (6) towards the direction far away from the paper outlet (6). The paper-out bracket of the printer can pile up the paper neatly.

Owner:GUANGDONG KAMFU TECH CO LTD

Cutting device for air column bag production

InactiveCN112677565AAvoid Shaking DisplacementEasy to processBag making operationsPaper-makingMechanical engineeringPhysics

The invention relates to the technical field of air column bag cutting, and discloses a cutting device for an air column bag production. The device comprises a base, a limiting roller and a clamping roller are fixedly connected to the top of the base, a cutting table is fixedly connected to the top of the base, a cutting groove is formed in the top of the cutting table, two air cylinders are symmetrically and fixedly connected to the top of the base, a top plate is fixedly connected between the output ends of the two air cylinders, two telescopic mechanisms are symmetrically and fixedly connected to the bottom of the top plate, and a pressing plate is fixedly connected between the bottom ends of the two telescopic mechanisms. The problems that after air column bags are cut through existing cutting equipment, the air column bags cannot be stacked together in order and need to be manually arranged by workers, and due to the fact that the air column bags are very soft and prone to deformation when not inflated, manual stacking and arranging become extremely troublesome, the stacking and arranging efficiency is extremely low, and the stacking and tidying effect is poor are solved.

Owner:魏群

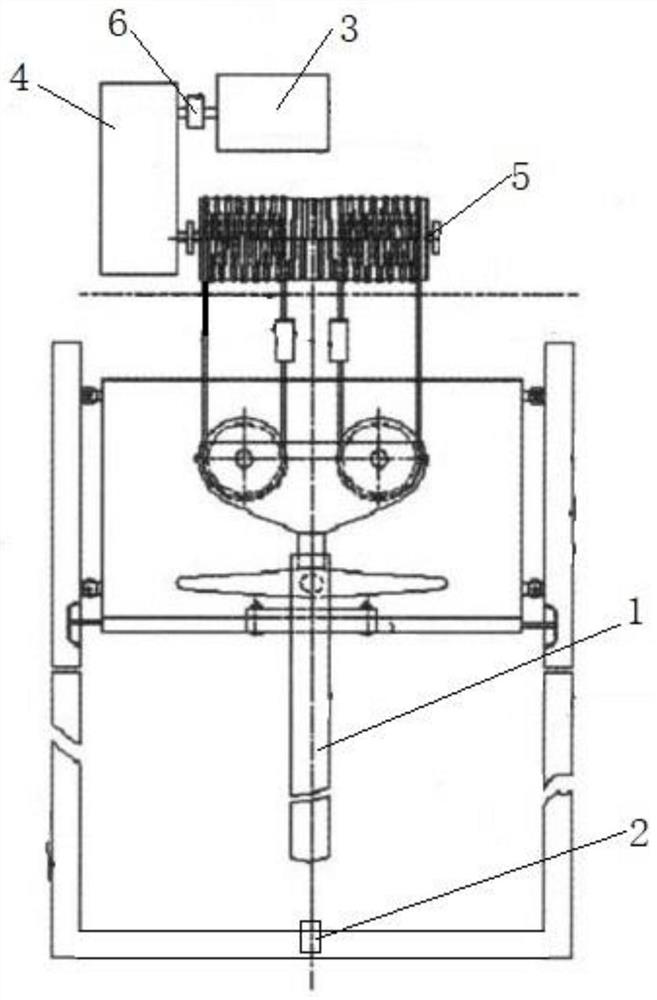

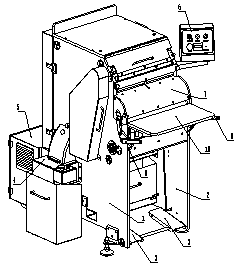

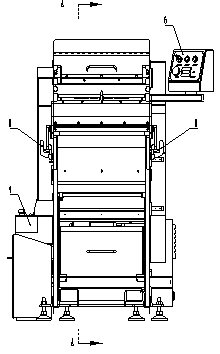

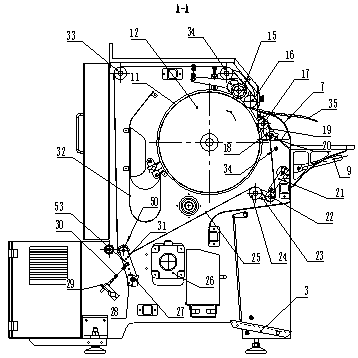

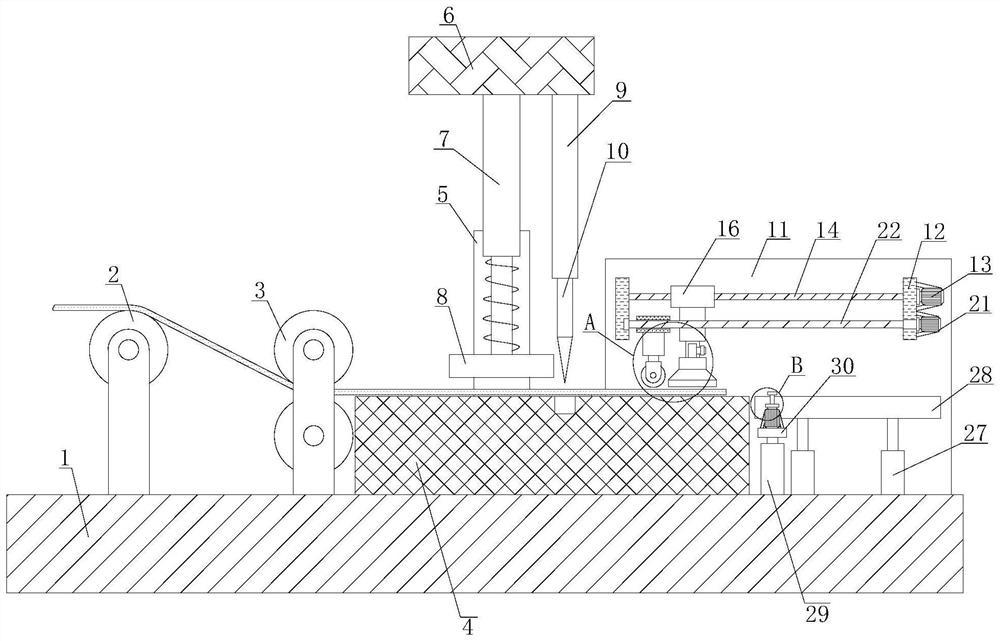

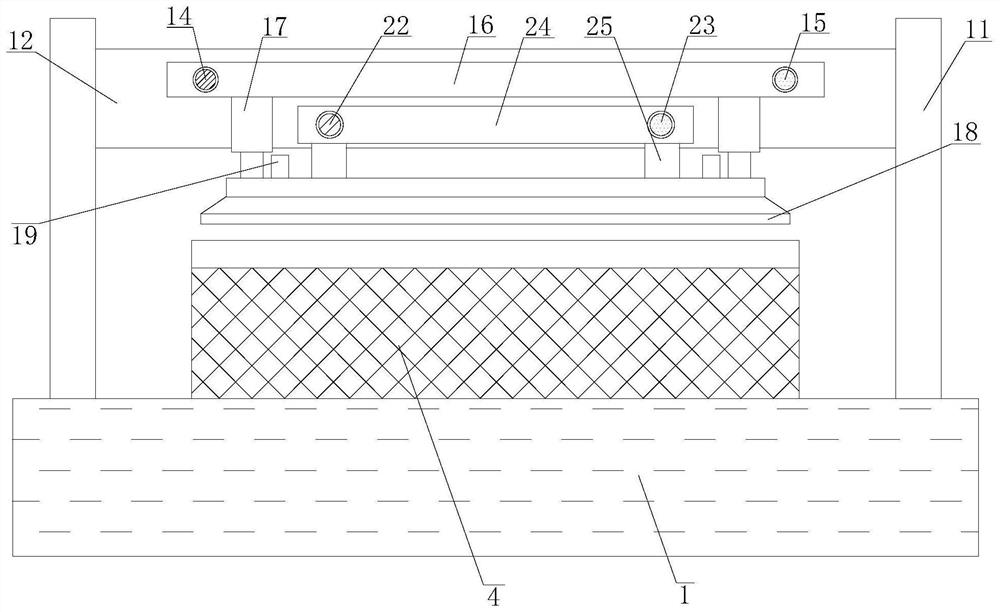

An automatic skinning machine

ActiveCN105858238BRealize automatic transportationHigh degree of automationConveyorsStacking articlesEngineeringWood processing

The invention provides an automatic veneer collecting machine, and belongs to the field of wood processing devices. The automatic veneer collecting machine comprises a rack and a transportation device, wherein the transportation device is mounted on the rack, comprises a first driving component and a first conveying belt component, and further comprises a second conveying belt component; the first driving component is connected with the first conveying belt component; the first conveying belt component is obliquely arranged; the higher end of the first conveying belt component is an outlet end; the first conveying belt component comprises first conveying belts; the second conveying belt component comprises second conveying belts; the second conveying belts transport veneer in the transportation direction of the first conveying belt component; the lower surfaces of one ends of the second conveying belts are in contact with the upper surfaces of the first conveying belts; and the other ends of the second conveying belts extend towards the outer sides of output ends of the first conveying belts, and are downwards obliquely arranged relative to the output ends. According to the automatic veneer collecting machine, integration and automation of wood plate collecting and stacking can be achieved, the automatic veneer collecting machine is applicable to a rotary cutting machine with high rotation speed, the integral structure is simple, the operation is easy and convenient, and relatively good practicability and market prospect are achieved.

Owner:广西腾森自动化设备有限公司

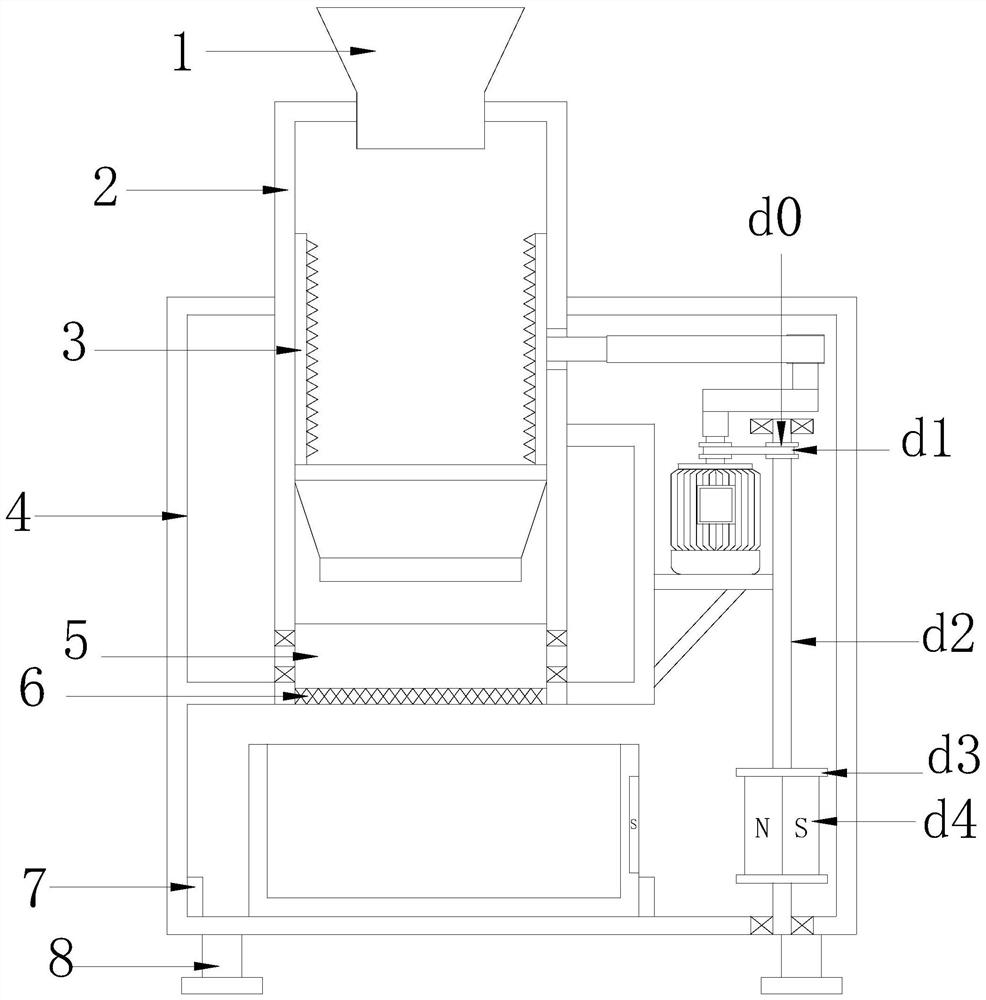

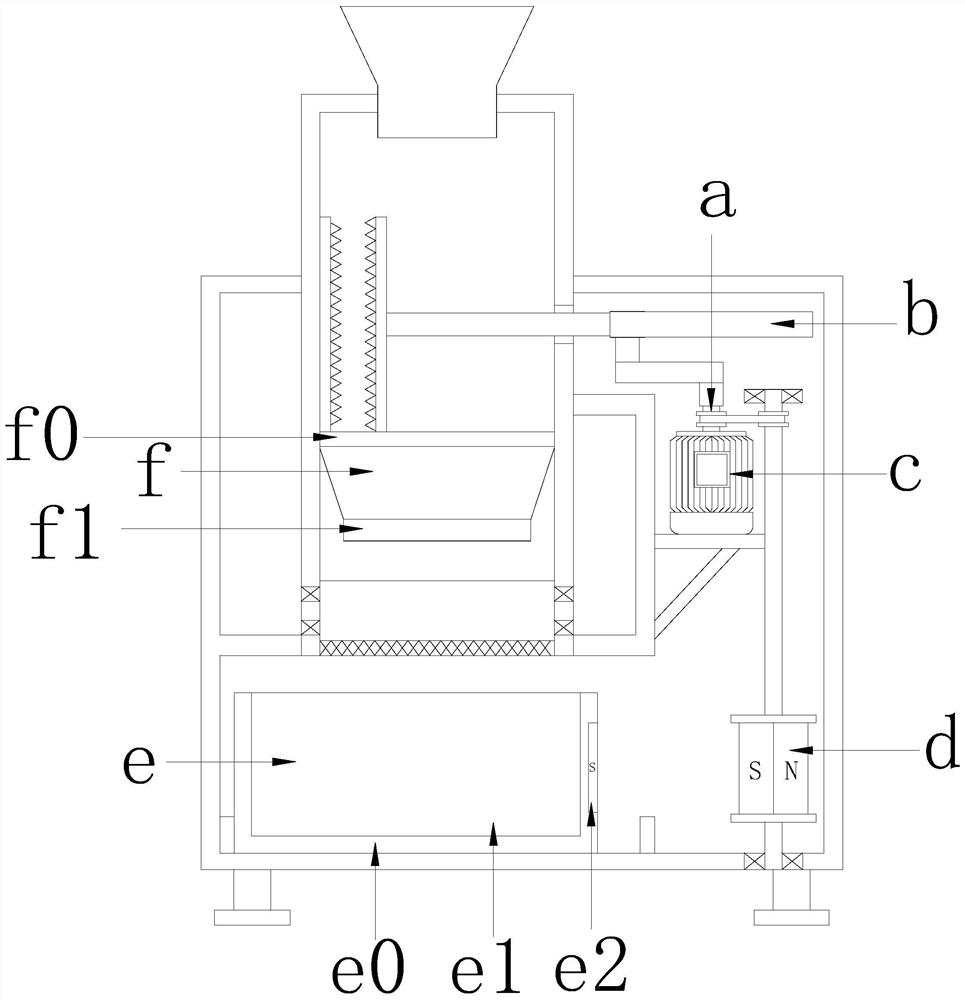

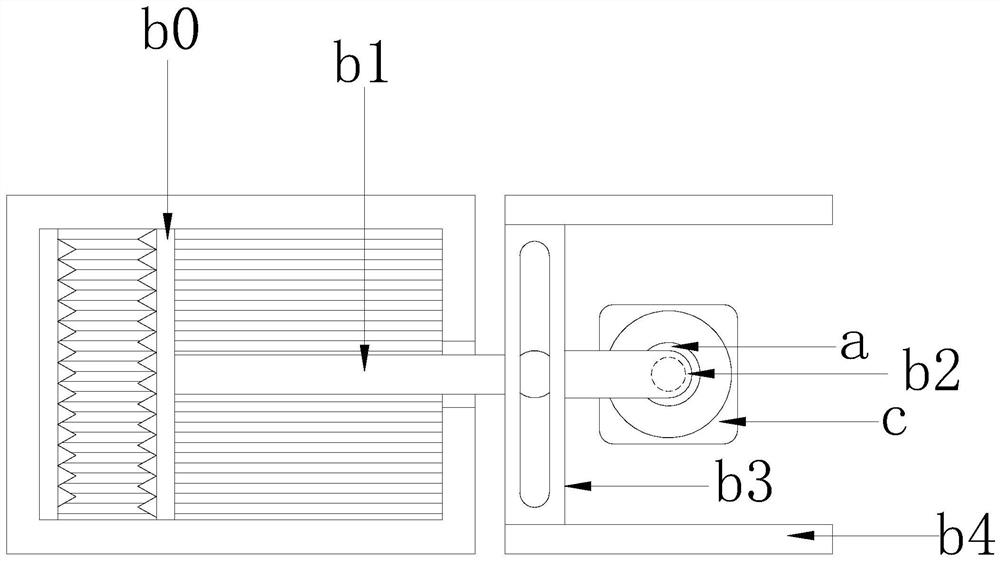

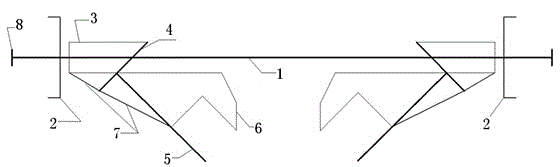

A high-efficiency extrusion deblocking grinding equipment for damp cement

ActiveCN109926129BSqueeze and deblock thoroughlyHigh deblocking efficiencySievingScreeningStructural engineeringMechanical engineering

The invention discloses a special efficient extruding deblocking grinding device for cement affected with damp. The special efficient extruding deblocking grinding device for the cement affected withdamp structurally comprises a feeding hopper, a deblocking box for cement affected with damp, a fixed pressure receiving plate, a machine body, a grinding roller, a filter screen, a buffering block and anti-slip supporting feet; and the anti-slip supporting feet are perpendicularly connected to the four corner portions of the bottom face of the machine body. Compared with the prior art, the special efficient extruding deblocking grinding device for the cement affected with damp has the beneficial effects that due to the combined arrangement of parts such as a reciprocating deblocking mechanism, a cement collecting frame and a cement screening bucket, during both reciprocating type extruding deblocking on cement block mass and reciprocating type shaking of the collecting frame, cement is stacked flatly; no springs are adopted during fast falling of cement after being decompressed, thus it is avoided that due to long-time back and forth compressing restoration of the springs, the springslose elasticity and are frequently replaced, the maintaining cost is low, and the cement deblocking efficiency is high; and knocking is not needed during fast falling of the cement and flat stackingof the cement, noise pollution generated due to knocking can be avoided, and it can also be avoided that due to long-time knocking on the device, damage is caused.

Owner:温州承玥机械设备有限公司

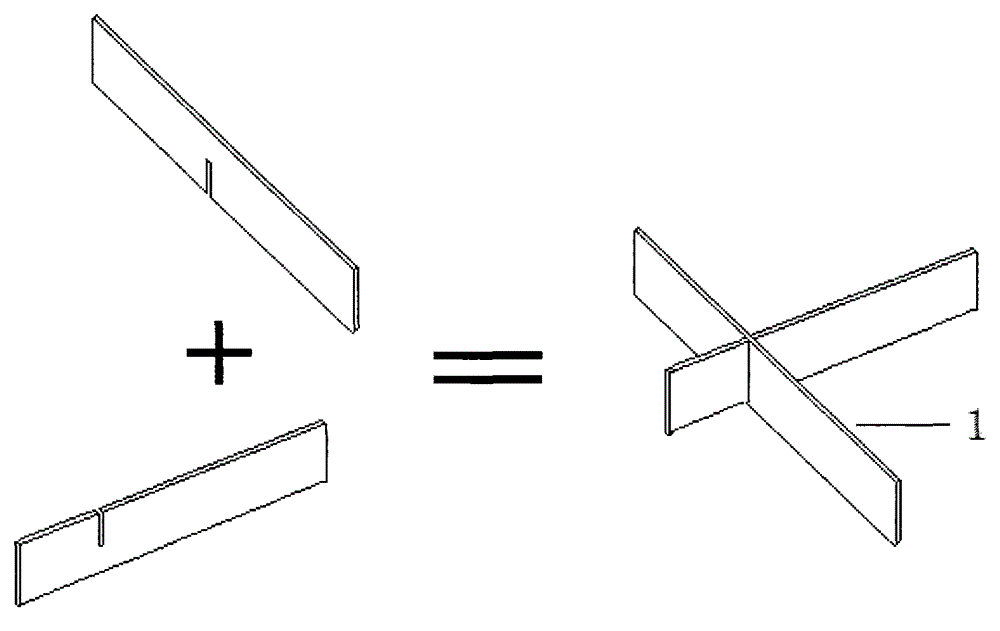

Conical lock for integrated template

ActiveCN104895320AStacked flatImprove quality and efficiencyForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksEngineeringStructural engineering

The invention discloses a conical lock for an integrated template. The conical lock comprises a lock rod, two wing lock nuts and two conical clamps; the two mobile wing lock nuts are in threaded connection with two ends of the lock rod respectively; each conical clamp comprises a lock tube, a supporting plate, a clamping plate and a lock jaw; the lock tubes sleeve the lock rod in a penetrating mode; one end of each lock tube is close to the corresponding wing lock nut and is limited through the wing lock nut; the other end of each lock tube is connected with the corresponding supporting plate; each supporting plate is connected with the clamping plate in a welding mode; each clamping plate is connected with the corresponding lock jaw in a welding mode; a bayonet which is formed by each clamping plate and the corresponding lock jaw is of a rectangular U-shaped structure which is matched with a frame of the template to be reinforced. According to the conical lock for the integrated template, the U-shaped clamps are designed, a 45 degree of cone and the U-shaped clamps are welded into a whole, and accordingly the clamping connection is achieved, the fastening connection of a screw is achieved, and the purpose of external corner reinforcement is achieved and the external corner does not need to be welded to be connected with a steel plate, the back edge is neat and free of concave and convex node, the template is stacked flat, the damage to a panel of the template is not produced, the conveying is safe and reliable, and accordingly the conduction quality and the detachment and installation efficiency of the steel template are effectively improved, and the market prospects are broad.

Owner:中南建设(南通)建筑产业有限公司

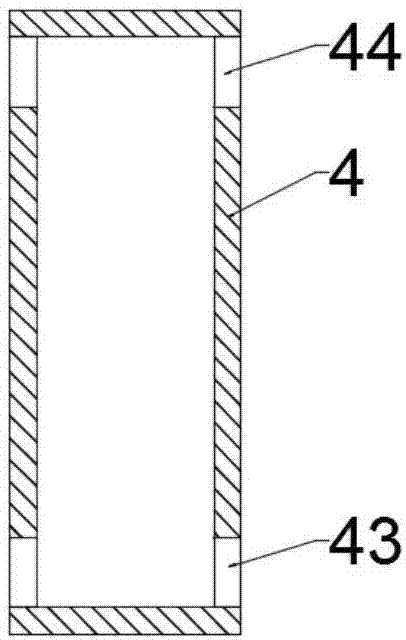

Storage device for food processing

ActiveCN107747839BStacked flatNo crushingLighting and heating apparatusDomestic refrigeratorsFood safetyGear wheel

Owner:重庆泰和熹食品有限公司

A garbage transport device

ActiveCN112193658BEasy to separateRealize the effect of separate collectionRefuse receptaclesLiquid wasteElectric machine

Owner:兴力洁道路保洁集团有限公司

Paper flattening mechanism

The invention discloses a paper flattening mechanism which comprises a paper baffle plate (2). The paper flattening mechanism is characterized in that a flexible paper flapping sheet (4) is arranged close to the paper baffle plate (2), the flexible paper flapping sheet (4) is connected with a driving mechanism, and the driving mechanism can drive the flexible paper flapping sheet (4) to rotate. The flexible paper flapping sheet (4) is arranged on a rotating rod (5), and the rotating rod (5) is in transmission connection with a driving motor (6). The paper baffle plate (2) is provided with a long strip hole (3) through which the flexible paper flapping sheet (4) penetrates. The paper flattening mechanism is simple in structure and reasonable in design, can flap one end, close to the paper baffle plate, of paper, prevents the paper from warping, and further ensures the smoothness of paper stacking.

Owner:ZHEJIANG DAYUAN MACHINERY

A converter automatic slag splash control method and system

ActiveCN112981033BHigh viscosityHigh melting pointManufacturing convertersProcess efficiency improvementSlagControl system

A converter automatic slag splash control method and system, belonging to the technical field of converter slag splash protection, wherein the control method includes 1) classifying the final slag status according to the end point oxygen content, end point carbon content and residual manganese yield range in molten steel ; 2) According to different final slag conditions, choose to add corresponding weight slag adjusting material to the converter to adjust the viscosity of the slag, so that the content of final slag magnesium oxide is 10% to 15%; 3) according to different final slag Select the corresponding slag splashing gun position curve according to the situation and use the above-mentioned control system to perform automatic slag splashing operation. The slag splashing gun position completes the automatic slag splashing operation, standardizes the slag splashing operation, reduces the labor intensity of workers, shortens the slag splashing time, saves the amount of nitrogen gas, and makes the maintenance of the furnace more stable.

Owner:新余钢铁股份有限公司

Feed Mixing Plant for Animal Husbandry

ActiveCN111632710BQuality improvementImprove finished product qualityRotating receptacle mixersFeeding-stuffAnimal scienceElectric machinery

The invention discloses a feed mixing production device for animal husbandry. The motor is provided with a sound-absorbing and heat-dissipating mechanism. There is a universal pulley, and a circular chute is opened on the top of the circular slide, and the universal pulley matches the circular chute, and the two sides of the bottom of the support rod are fixed with sub-rods, and the sub-rods and the bottom end of the support rod are fixedly provided with a second shock absorber. Beneficial effects: the direction of rotation of the vertical bar and the auxiliary stirring plate is opposite to the direction of rotation of the stirring plate and the connecting rod, so that the feed inside the working chamber is ensured to be stirred and mixed in a disturbed form, thereby improving the stirring effect of the feed, and the stirring is completed Finally, it is discharged through the discharge port and the hose, so as to be discharged into the material receiving frame. During the discharge process, the set moving mechanism drives the hose to move, so as to realize reciprocating spreading, so that the feed in the material receiving frame Stacks more evenly.

Owner:华廷卿 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com