Paper flattening mechanism

A flat paper and paper technology, applied in the field of paper delivery equipment, can solve the problems affecting the flatness and stability of the paper, and the paper is not flat enough to achieve the effect of improving the flatness and stability, simple structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

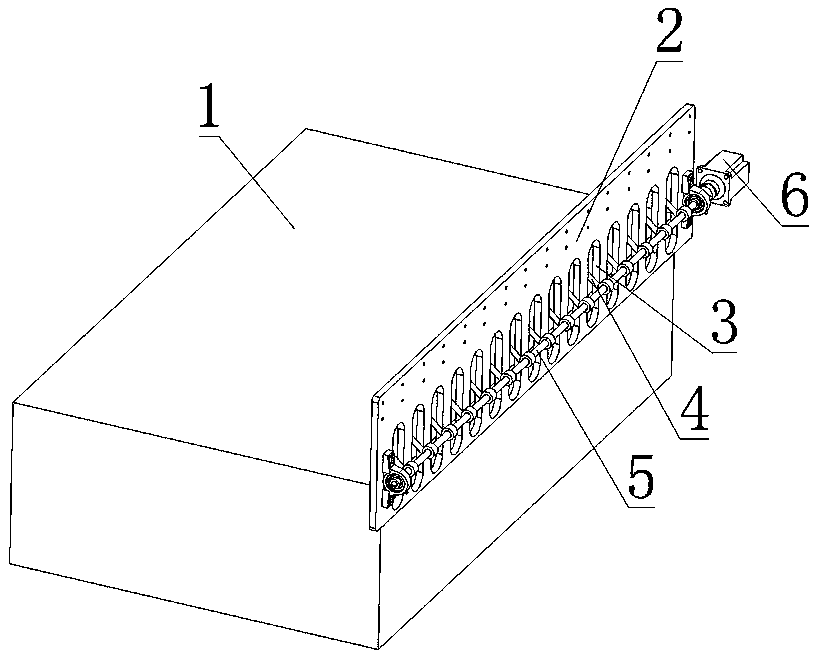

[0011] As shown in the figure, the paper flat paper mechanism disclosed by the present invention includes a paper stopper 2, and a flexible paper sheet 4 is arranged near the paper stopper 2, and the flexible paper sheet 4 is connected with a driving mechanism, and the driving mechanism can drive the flexible paper sheet 4 to rotate. Specifically, the driving mechanism includes a driving motor 6, the flexible pad 4 is arranged on the rotating rod 5, and the rotating rod 5 is connected to the driving motor 6, and the rotating rod 5 is driven to rotate by controlling the driving motor 6 to drive the flexible pad. The blade 4 swings to slap the end of the paper 1 close to the paper stopper 2. It can slap the end of the paper 1 in contact with the paper stopper 2 to ensure that the paper does not warp and is stacked together smoothly, effectively improving the stability of the paper stack. Flatness, of course, the rotating rod 5 can also be connected with a common power source suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com