Ink composition for 3D ink-jet printing, ink kit and preparation method thereof

An inkjet printing and composition technology, applied in the field of printing, can solve the problems of high energy consumption and complex use of the composition, and achieve the effects of simple curing process, simple composition, excellent printing effect and operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

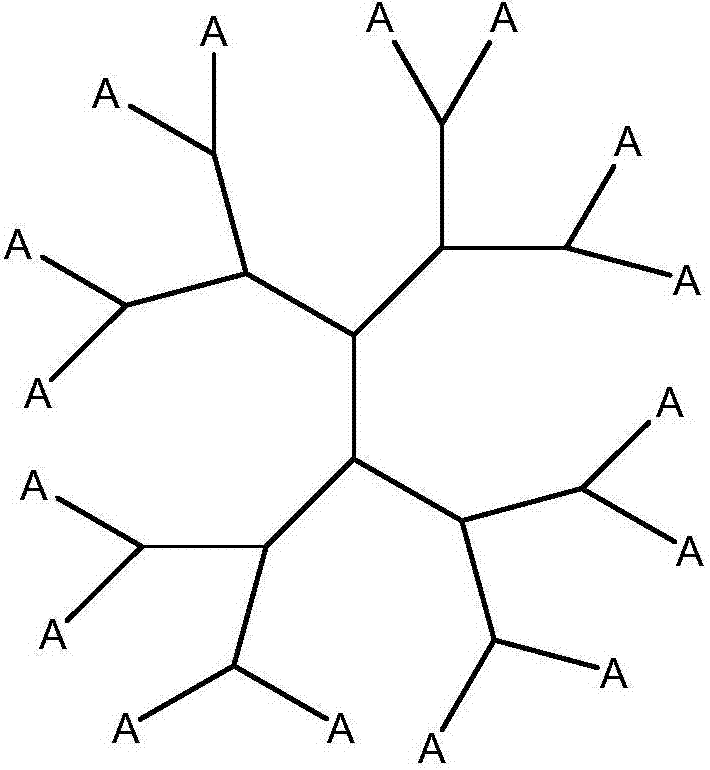

Image

Examples

Embodiment 1

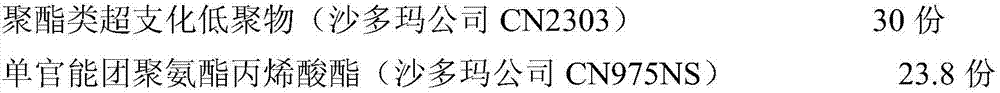

[0051] The ink composition of the present embodiment comprises the following components in parts by weight:

[0052]

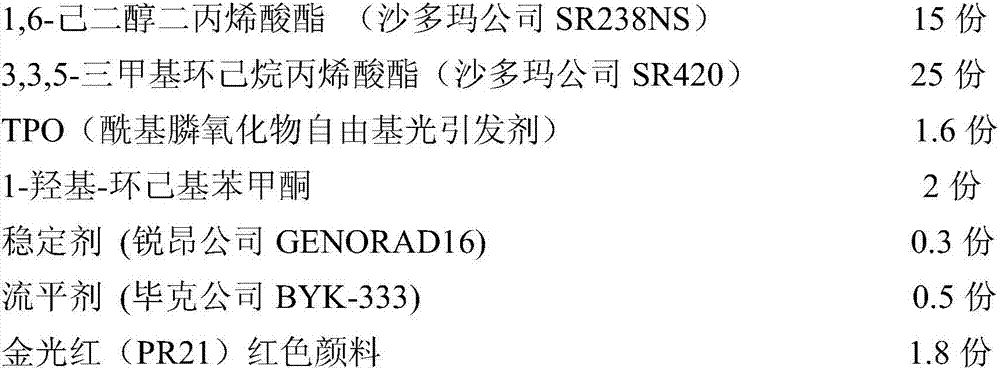

[0053]

[0054] Preparation:

[0055] (1) Weigh 30 parts of polyester hyperbranched oligomer CN2302, 23.8 parts of monofunctional urethane acrylate CN975S, 15 parts of 1,6-hexanediol diacrylate SR238NS, 25 parts of 3,3,5-trimethyl Cyclohexane acrylate SR420, 0.3 parts of GENORAD16, 0.5g BYK-333 were placed in a glass container, stirred with a stirrer until all materials were mixed evenly, and the first mixture was generated; 1.6 parts of photoinitiator TPO, 184 2 part into the first mixture, then continue to stir until the UV photoinitiator is completely dissolved to obtain the second mixture, and finally add 1.8 parts of golden red (PR21) red pigment to the second mixture and transfer it to VFF-230 intelligent dispersion sand mill Carry out high-speed shear dispersion in the machine until the mixture is uniform to obtain the third mixture;

[0056] (2...

Embodiment 2

[0065]

[0066] Preparation:

[0067] The preparation method of the ink composition in this example is basically the same as that of Example 1, except that the degassing time under reduced pressure is adjusted to 2 hours, and finally a yellow ink composition for 3D inkjet printing is obtained.

[0068] According to the same test method as in Example 1, the performance test of the ink composition in this example was carried out, and the test results are shown in Table 1.

Embodiment 3

[0070]

[0071] Preparation:

[0072] The preparation method of the ink composition in this example is basically the same as that of Example 1, except that the degassing time under reduced pressure is adjusted to 3 hours, and finally a blue ink composition for 3D inkjet printing is obtained.

[0073] According to the same test method as in Example 1, the performance test of the ink composition in this example was carried out, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com