Patents

Literature

530results about How to "Fast shaping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

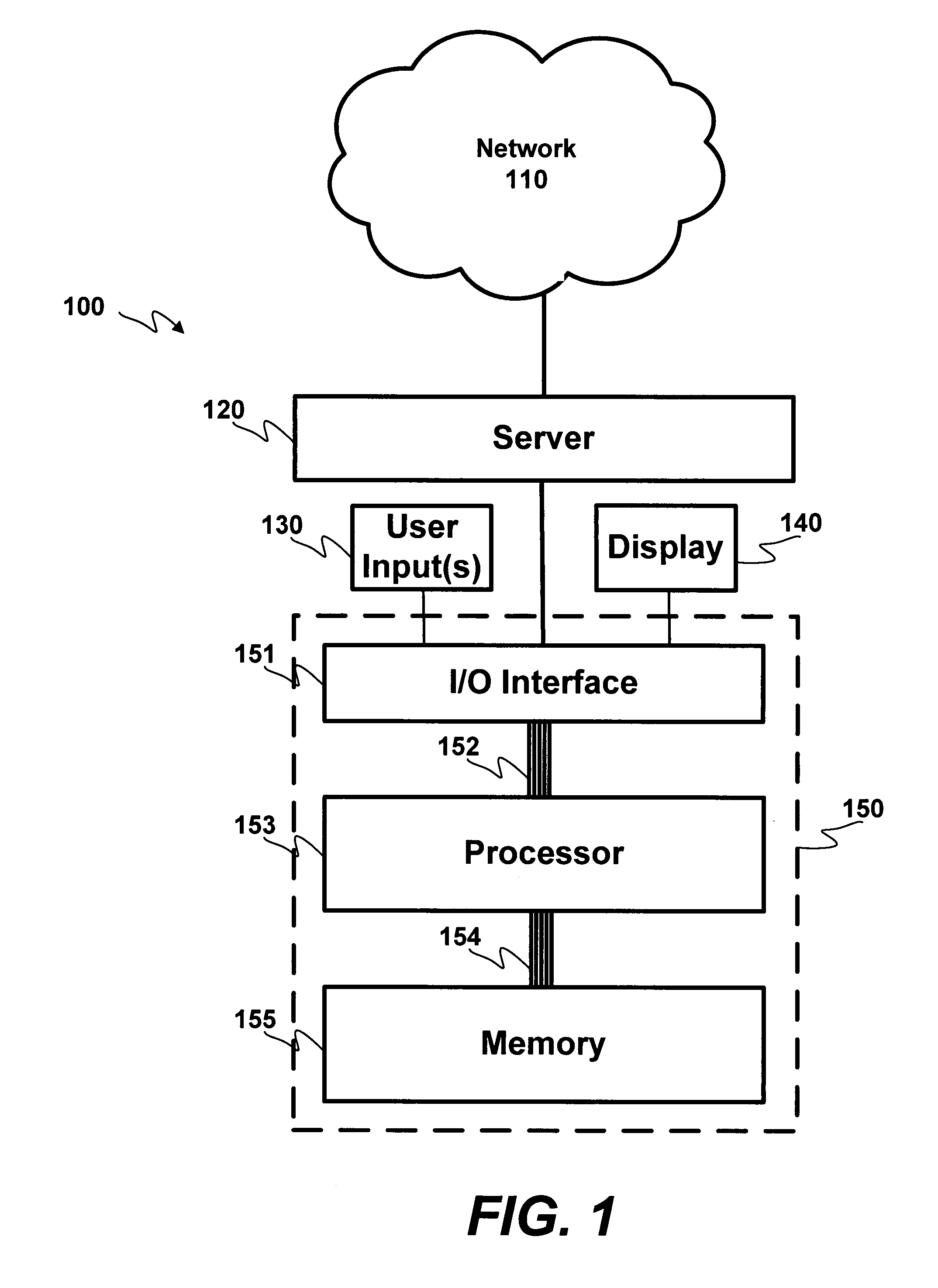

Content delivery network by-pass system

InactiveUS20030174648A1Increase capacityIncrease in sizeError preventionTransmission systemsWeb sitePeering

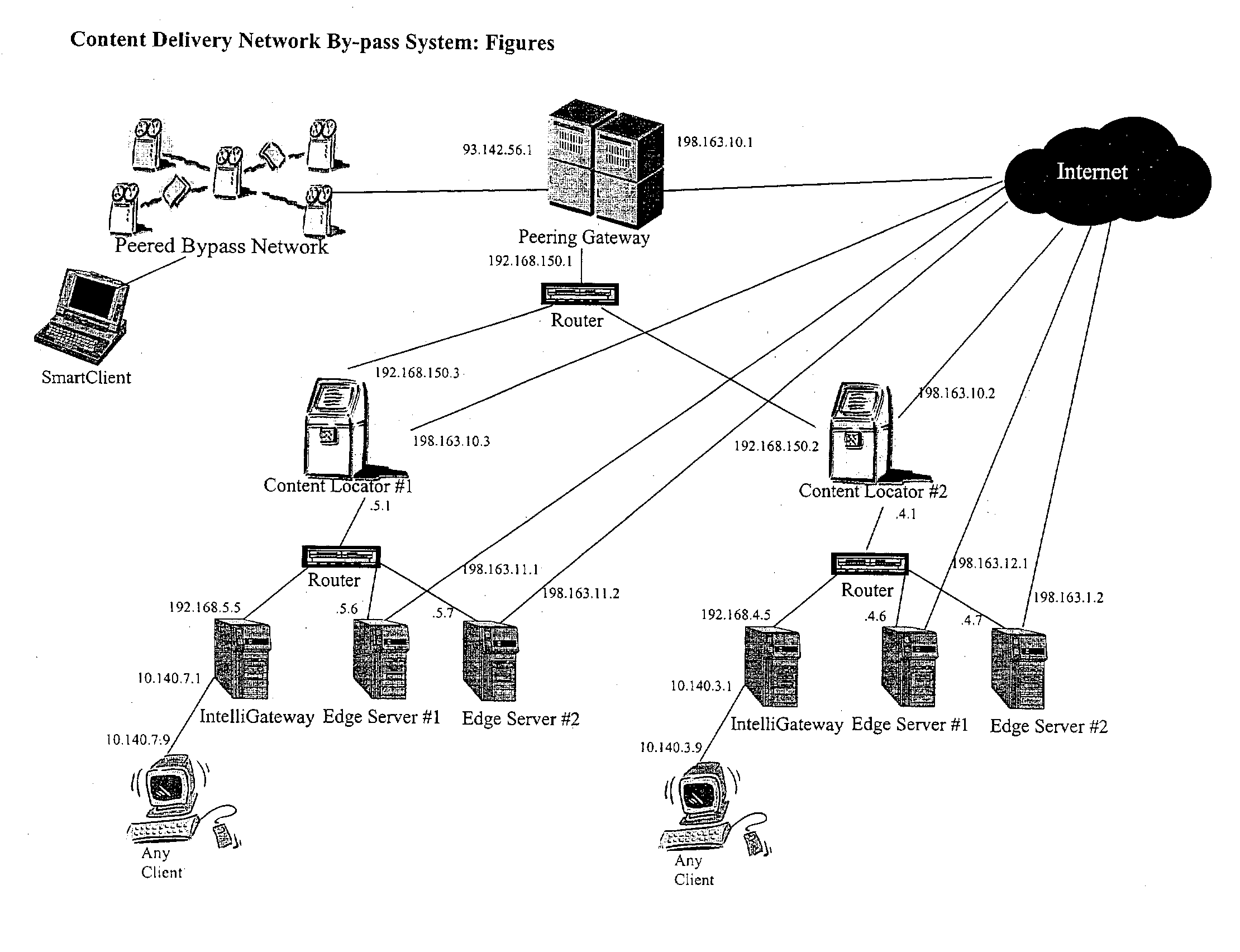

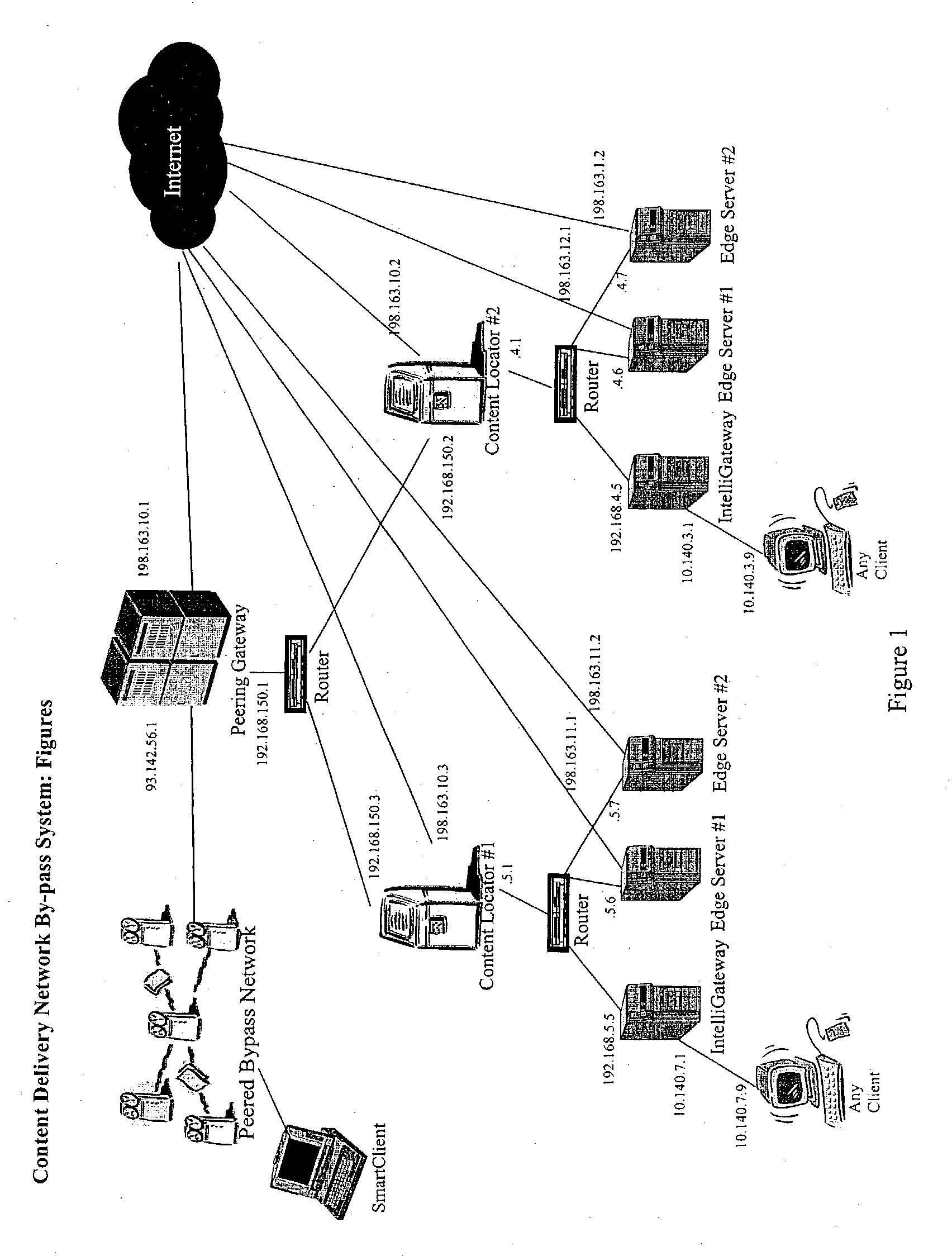

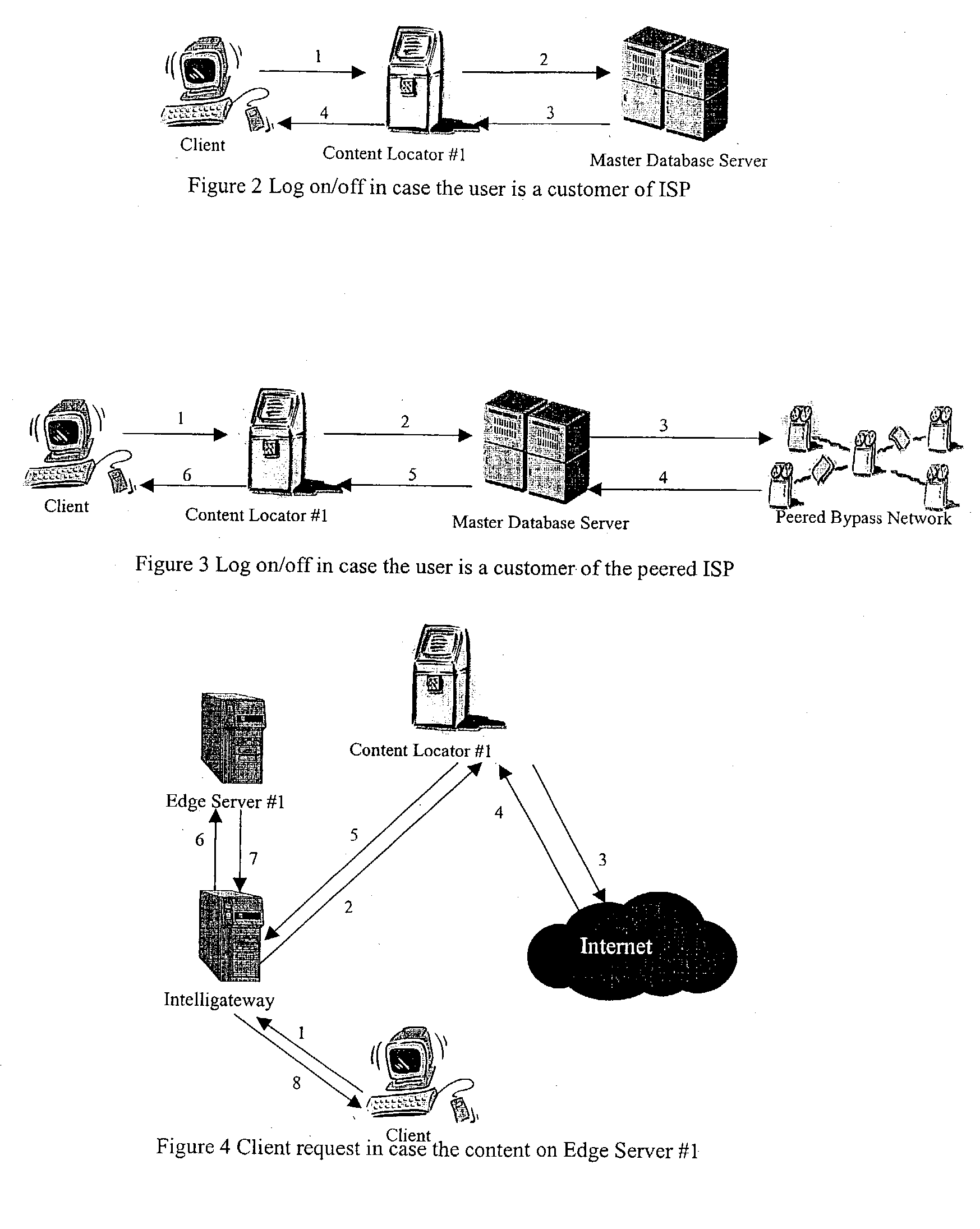

The bypass network is designed to provide fast access and high quality streaming media services anywhere anytime. There are five major components including Peering Gateway, Content Locator, Edge Server, Gateway and Client. The whole bypass network is divided into number of self-managed sub-networks, which are referred as local networks in this document. Each local network contains Edge Servers, gateways, and a Content Locator. The Edge Servers serve as cache storage and streaming servers for the local network. The gateways provide a connection point for the client computers. Each local network is managed by a Content Locator. The Content Locator handles all client requests by communicating with the Peering Gateway and actual web sites, and makes the content available on local Edge Servers. The Content Locator also balances the load on each Edge Server by monitoring the workload on them. One embodiment is designed for home users whose home machine does not move around frequently. A second embodiment is designed for business users who travel around very often where the laptops would self-configure as a client of the network.

Owner:TELECOMM RES LAB

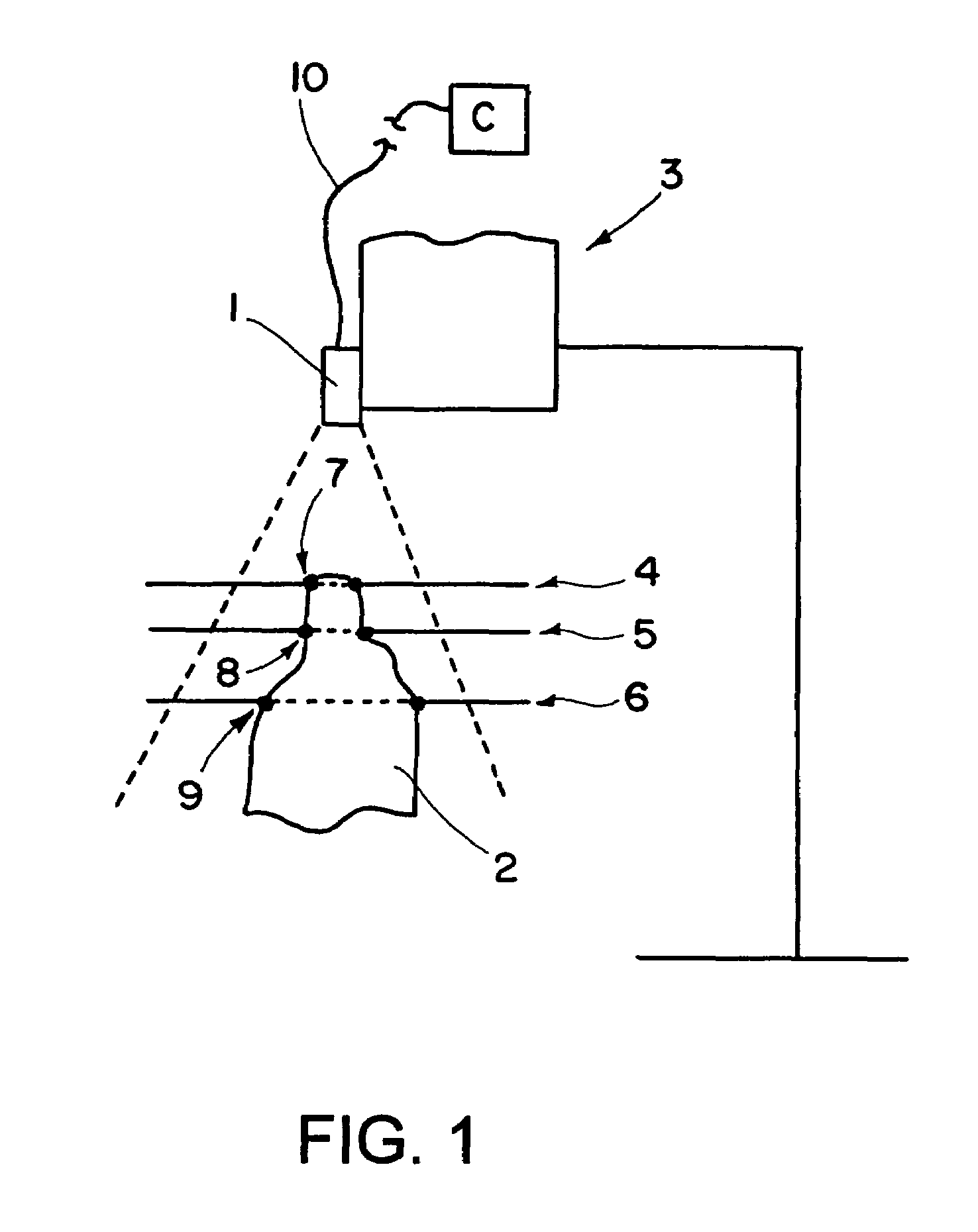

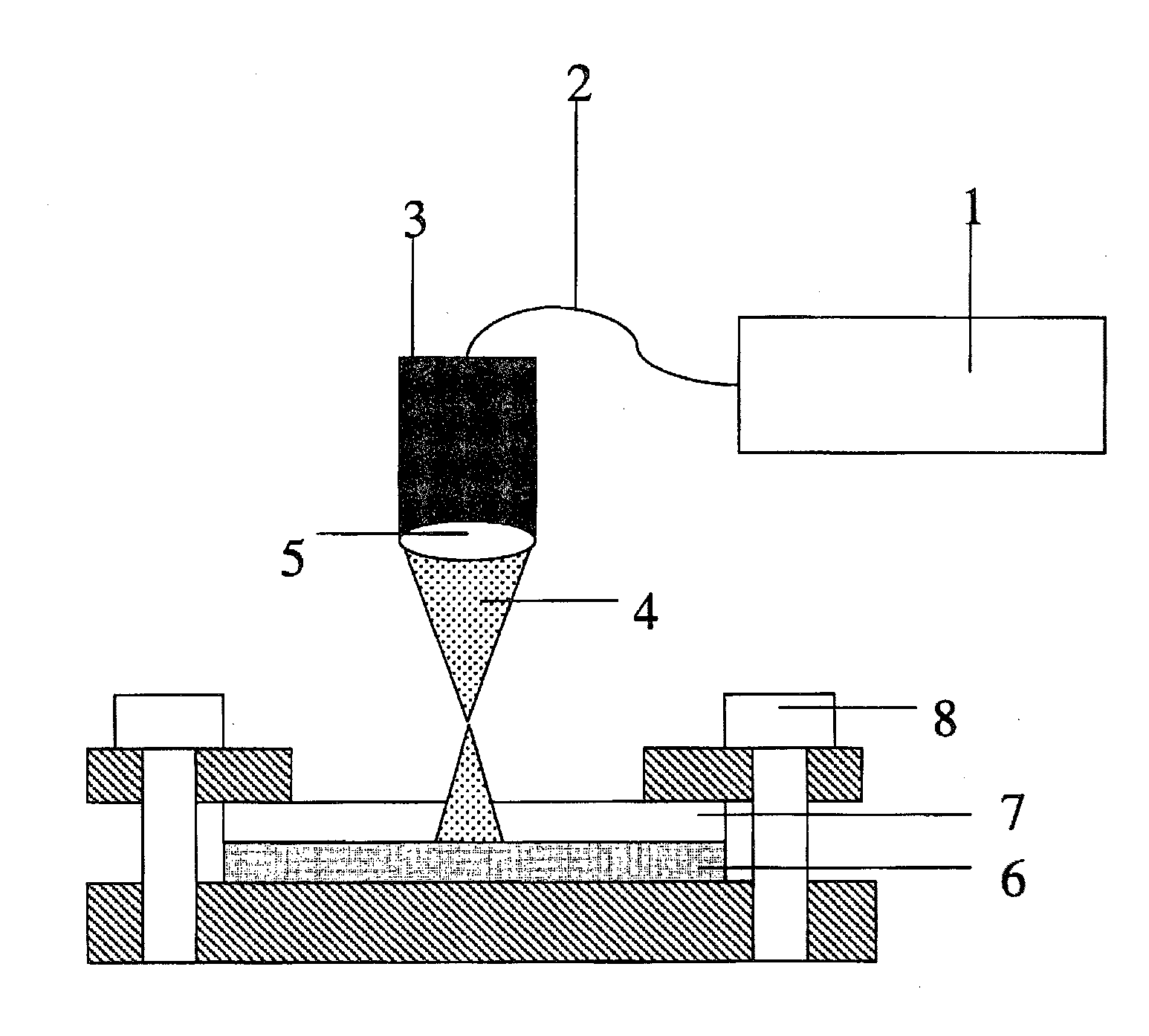

Three-dimensional shape detection by means of camera images

InactiveUS6947582B1Fast shapingSurgeryCharacter and pattern recognitionThree dimensional shapeAnalyser

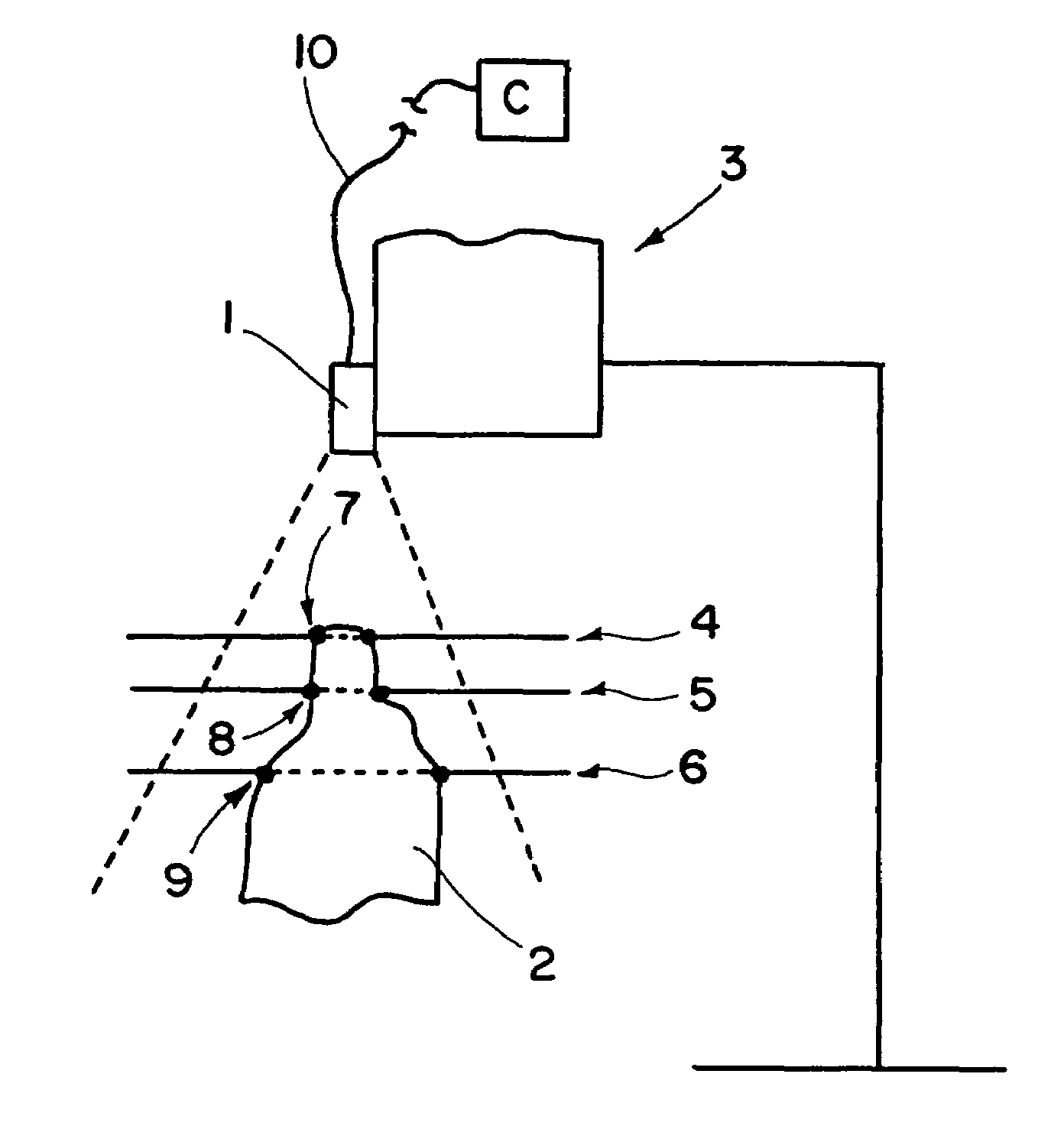

A method of detecting the shape of an object comprises the following steps: a) producing a camera image of the object; b) mapping an outline of the object, which appears sharp in the camera image, in a first plane by means of an analyzer connected to the camera; c) altering the focusing distance of the camera; d) mapping a sharp outline of the object in a second plane by means of the analyzer; e) repeating steps b) to d) until a sufficient number of outlines has been mapped so that the three-dimensional shape of the object can be established. Also disclosed is an apparatus for implementing the method.

Owner:BRAINLAB

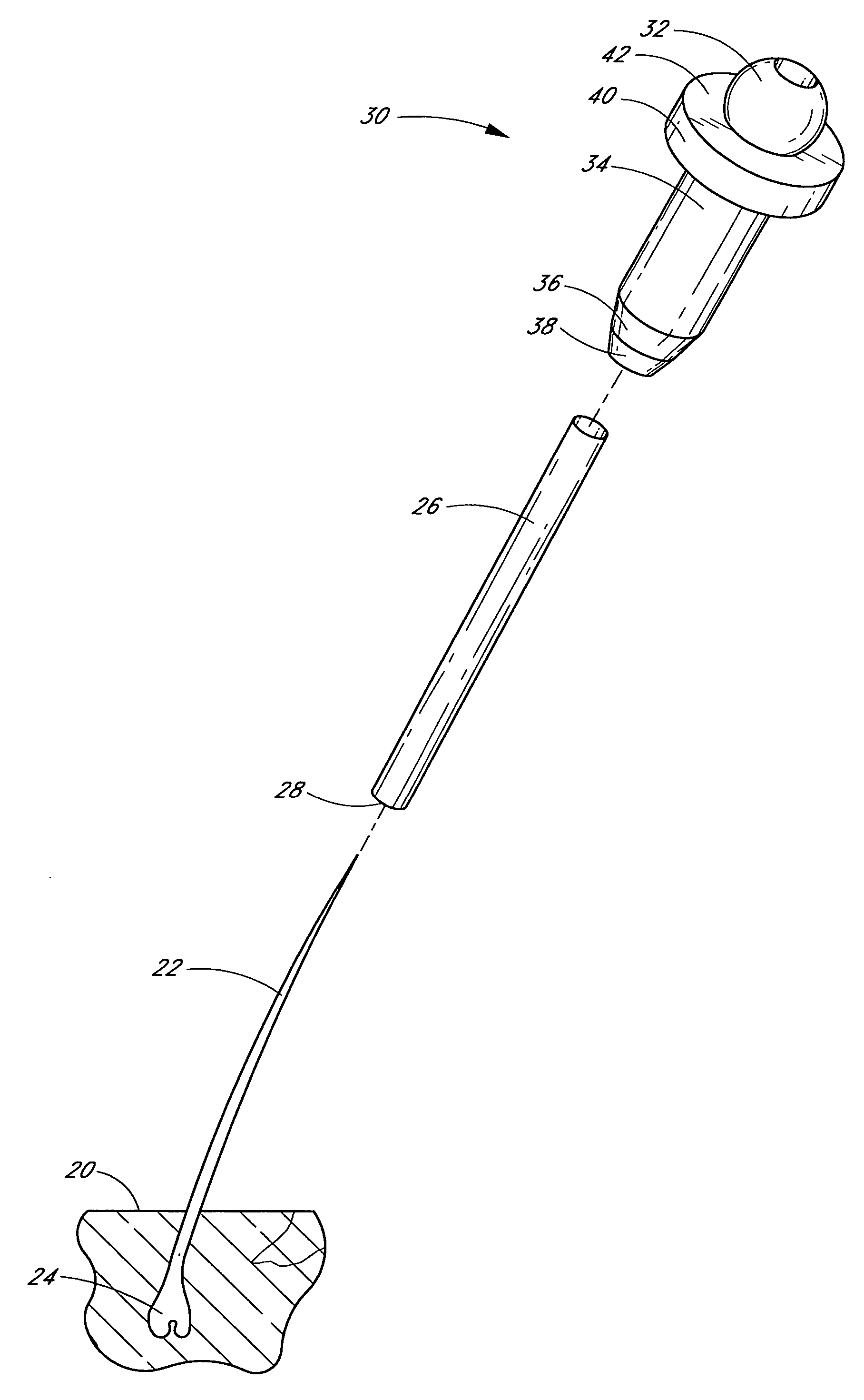

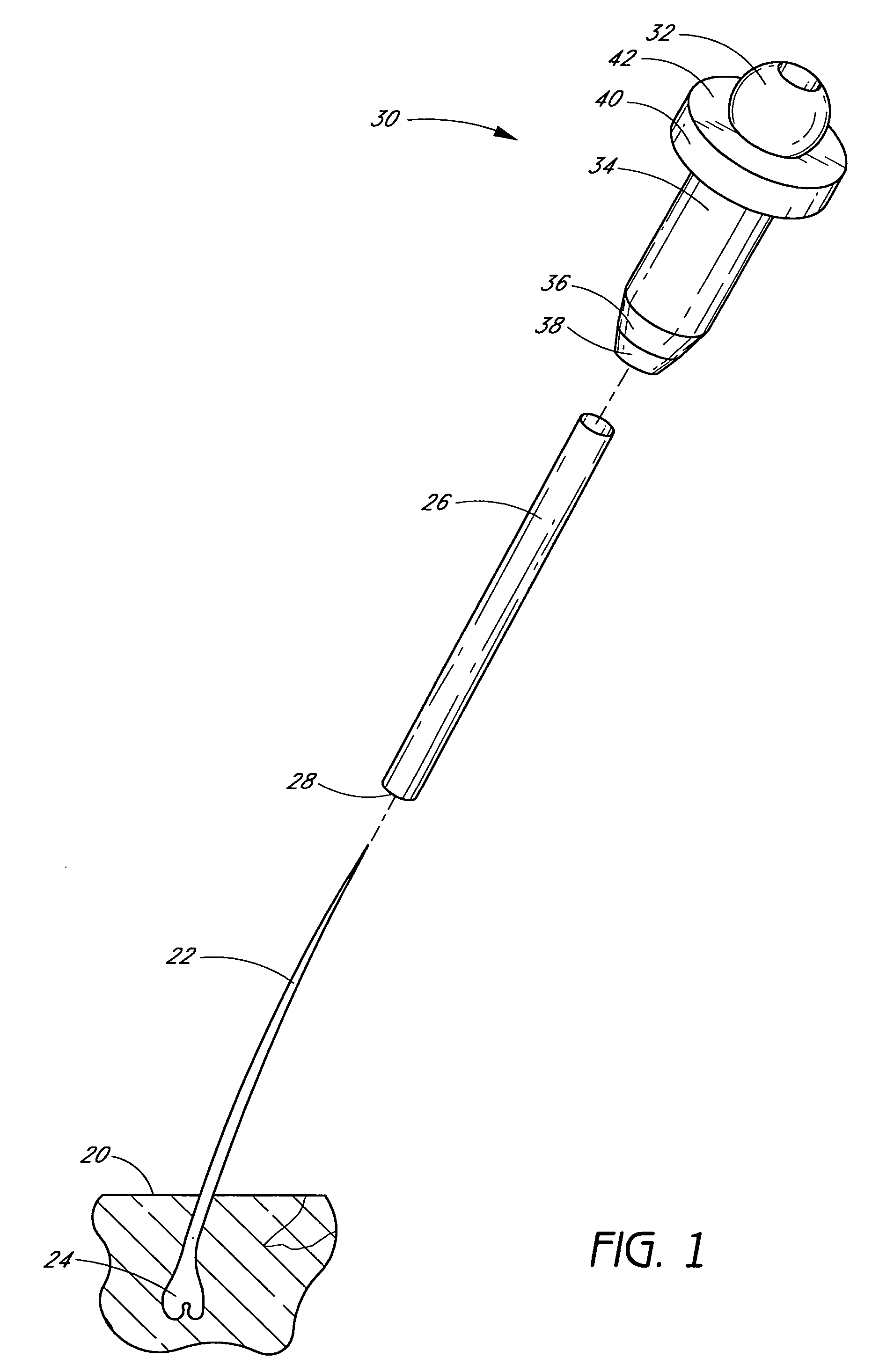

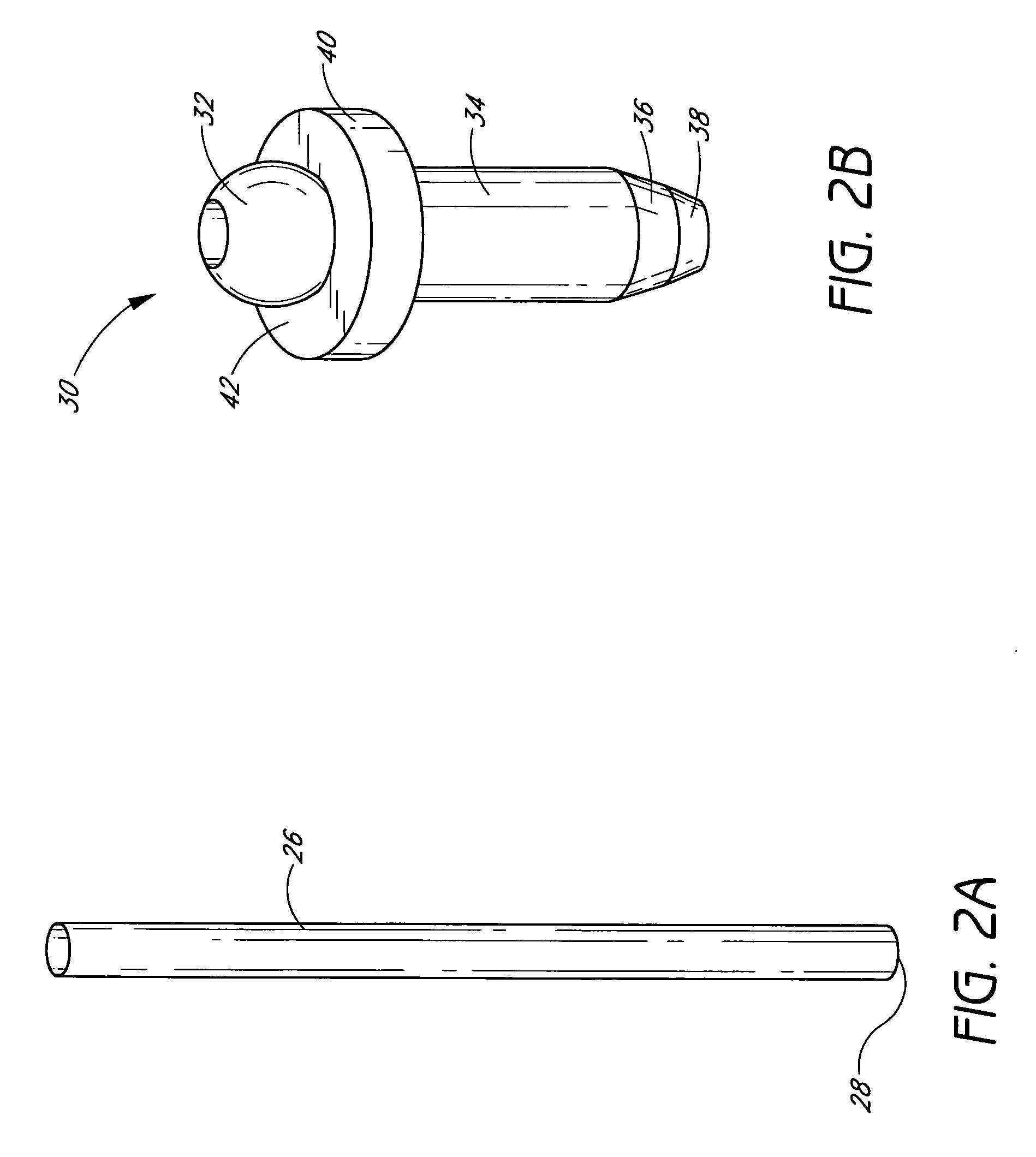

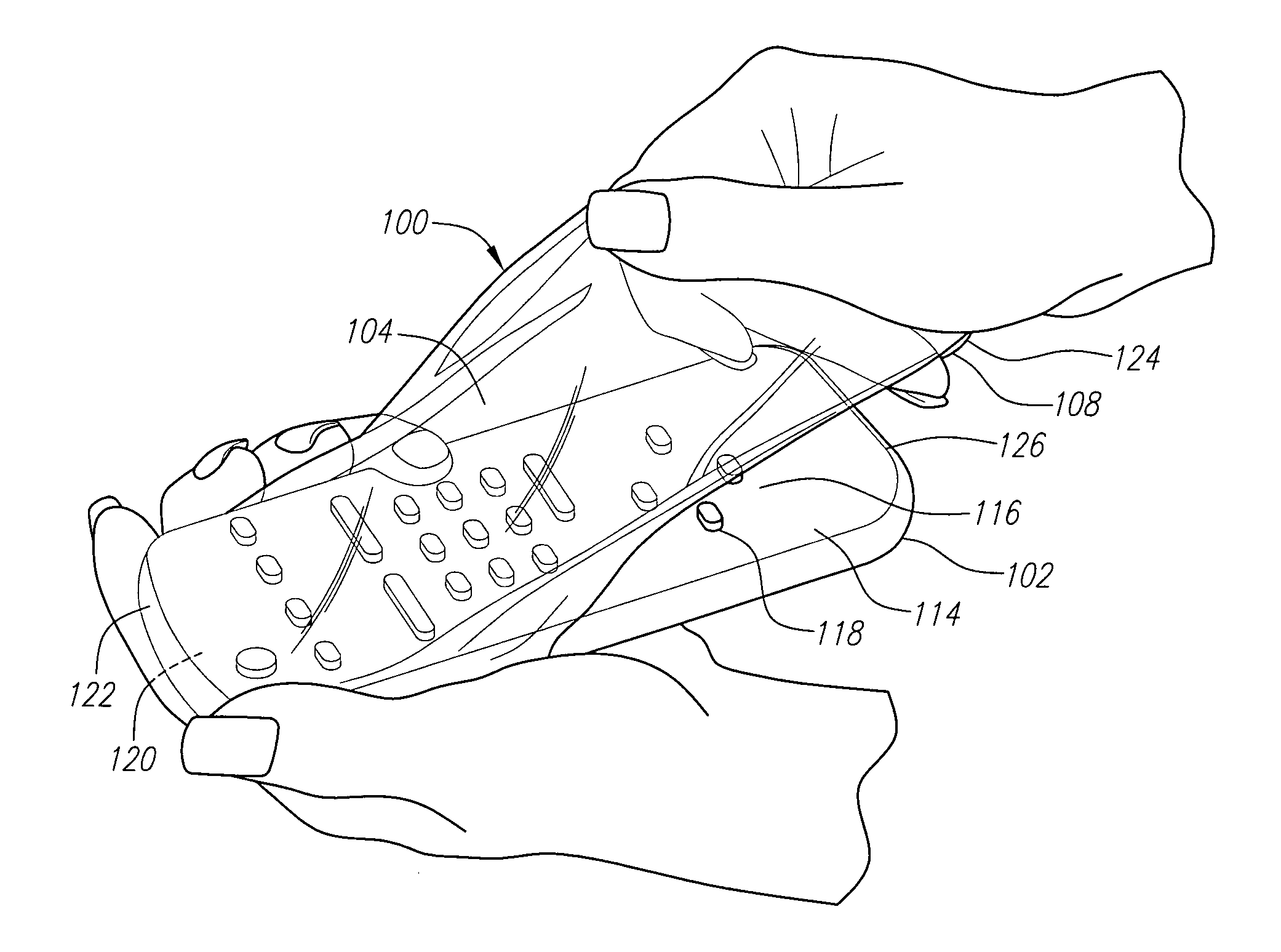

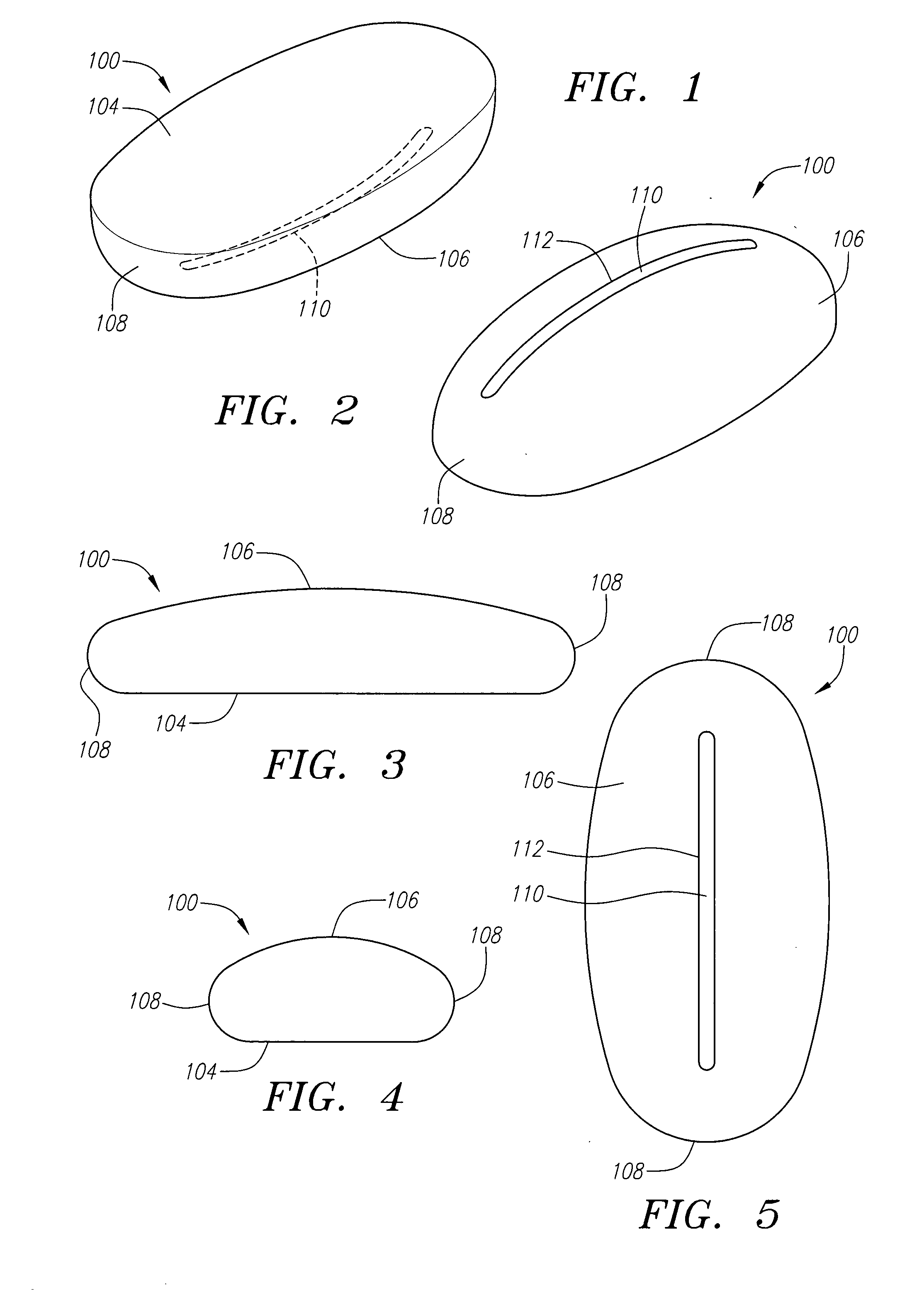

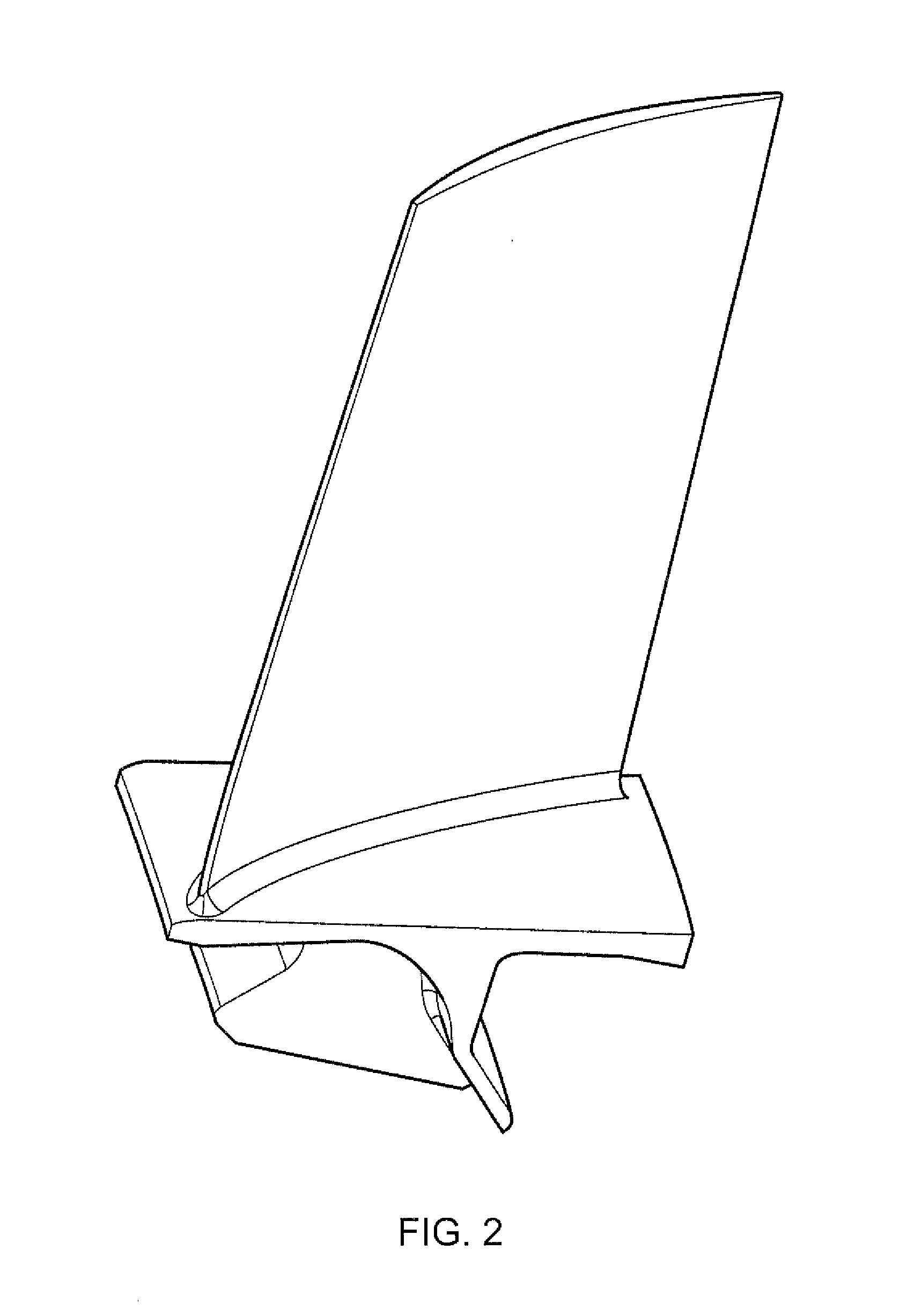

Follicular transplantation device and method

InactiveUS20060161179A1Accurate locationAccurate removalSkin implantsDiagnosticsDilatorHair follicle

A hair transplantation device can include a generally tubular guide configured to locate a hair follicle bulb by sliding over a hair shaft down to an upper surface of a hair follicle. The guide can have a blunt distal end configured not to transect the hair follicle bulb. The hair transplantation device also includes an outer tubular member sized and configured to be advanced around the guide. The outer tubular member has a dilator and a harvester. The device can be used in a follicle transplantation method in which the guide locates a hair follicle bulb, and the outer tubular member is slid over the guide. Once the outer tubular member is aligned with the guide, the harvesting portion is advanced, cutting dermal tissue surrounding the hair follicle. The outer tubular member is then withdrawn with the hair follicle, relocated in a recipient area, and the hair follicle implanted.

Owner:KACHENMEISTER ROBERT M

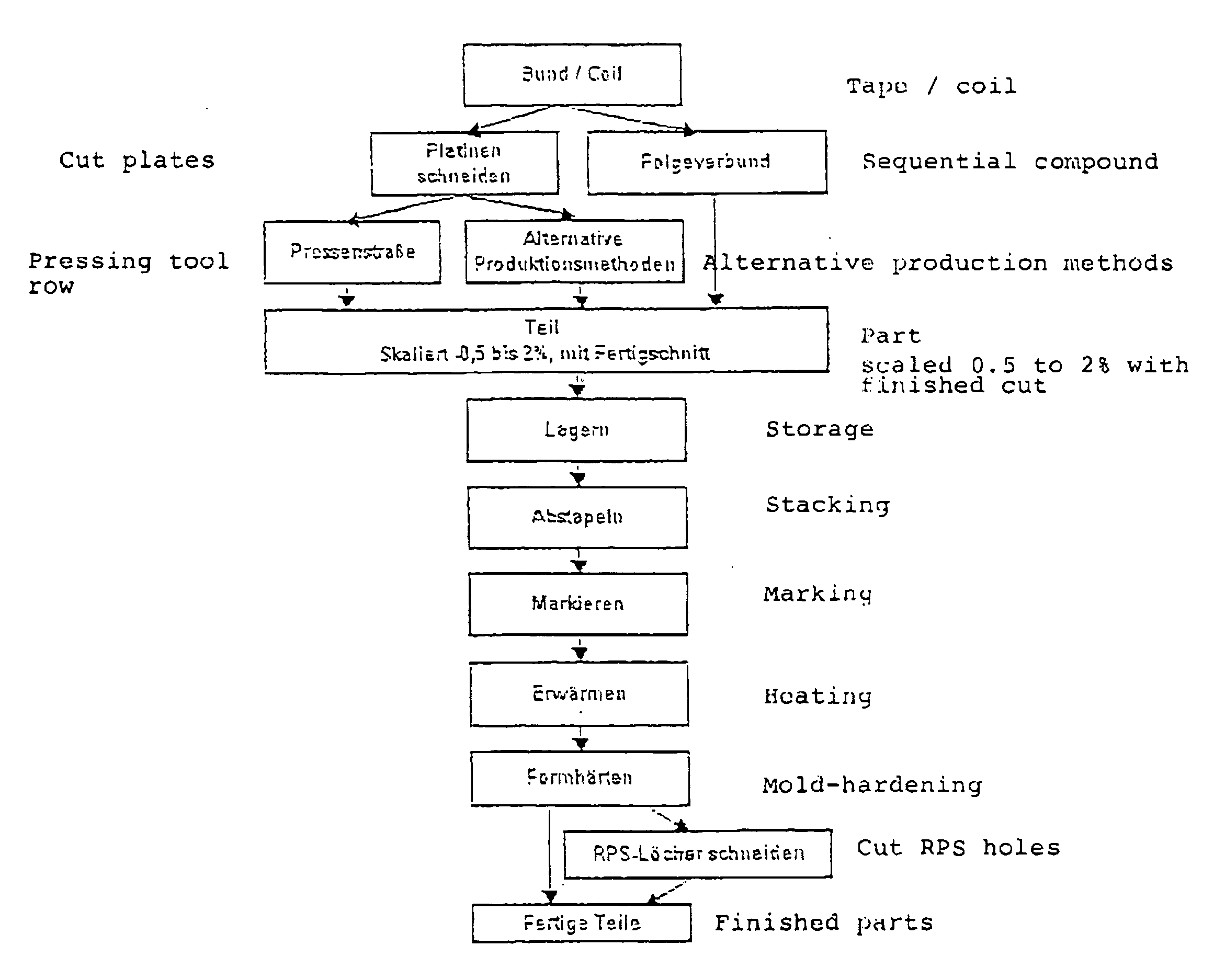

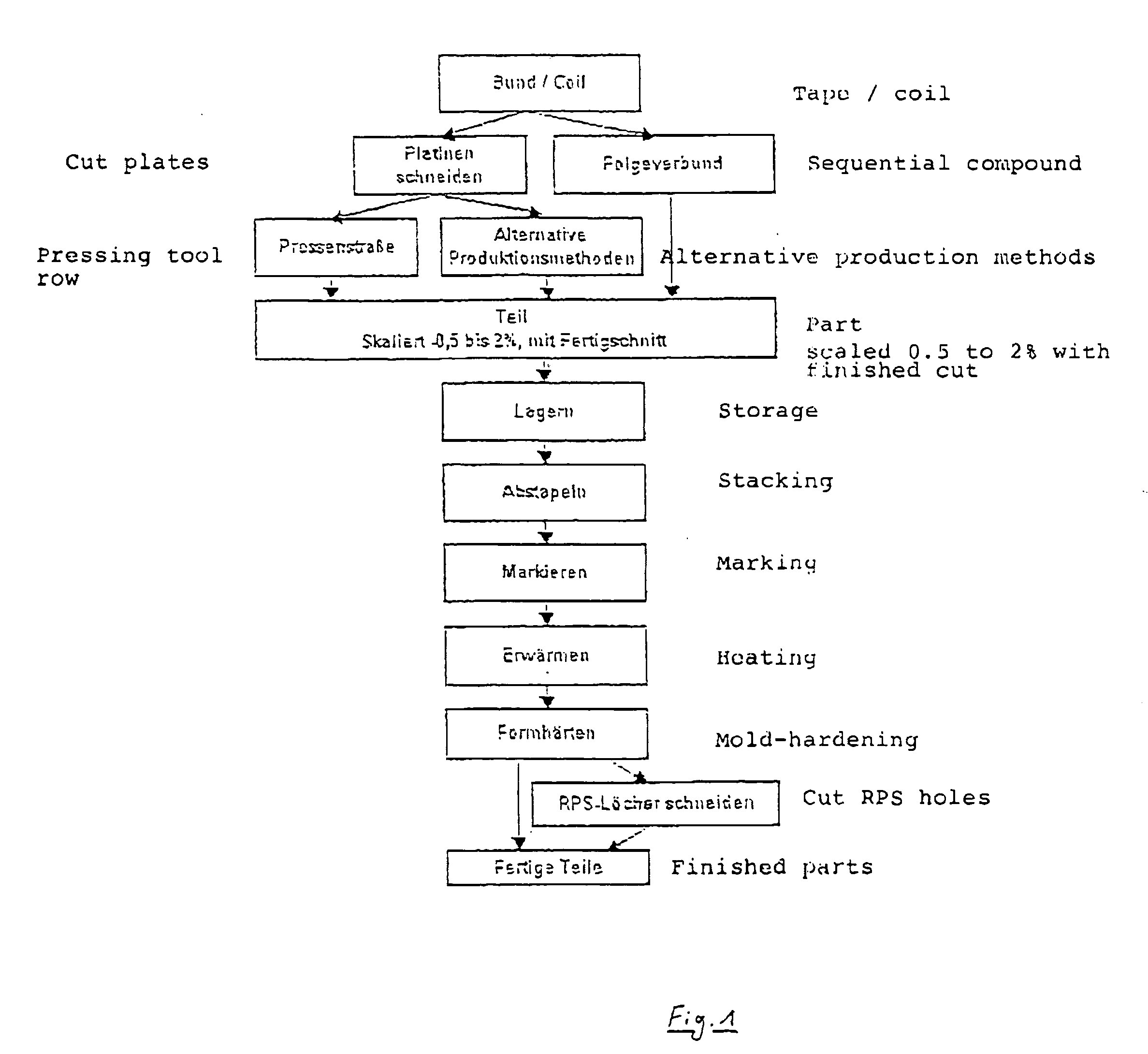

Method for producing hardened parts from sheet steel

ActiveUS20070000117A1Fast coolingEasy to integrateHot-dipping/immersion processesMetal rolling stand detailsPunchingSheet steel

The invention relates to a method for producing hardened structural parts from sheet steel. The method includes shaping at least one shaped part made of sheet steel provided with a cathodic corrosion protection coating, performing any required final trim of the shaped part and possibly any required punching, or the creation of a perforation pattern, subsequently heating the shaped part, at least over partial areas, under the admission of atmospheric oxygen to a temperature which permits austenizing of the steel material, and thereafter transferring the structural part to a mold-hardening tool and performing mold-hardening in the mold-hardening tool, wherein the structural part is cooled by the contact with and pressing by the mold-hardening tool and is hardened thereby.

Owner:VOESTALPINE STAHL GMBH

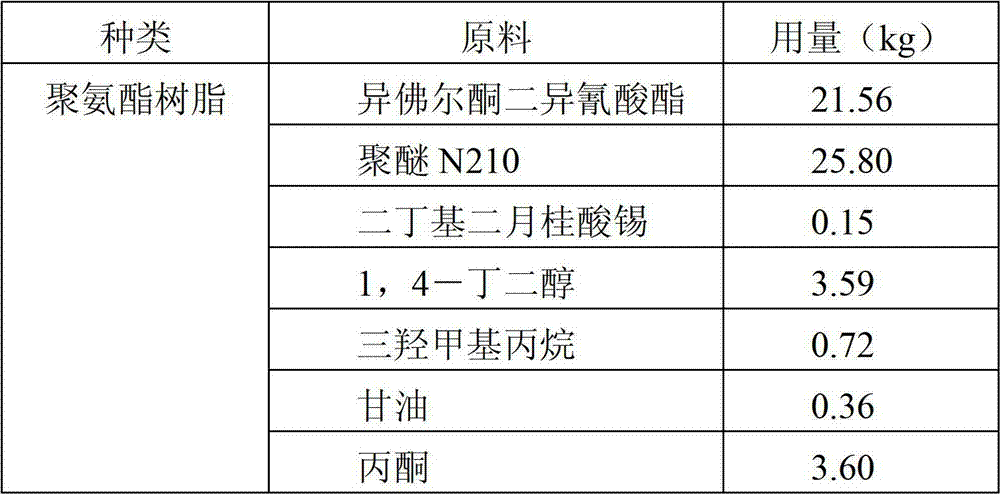

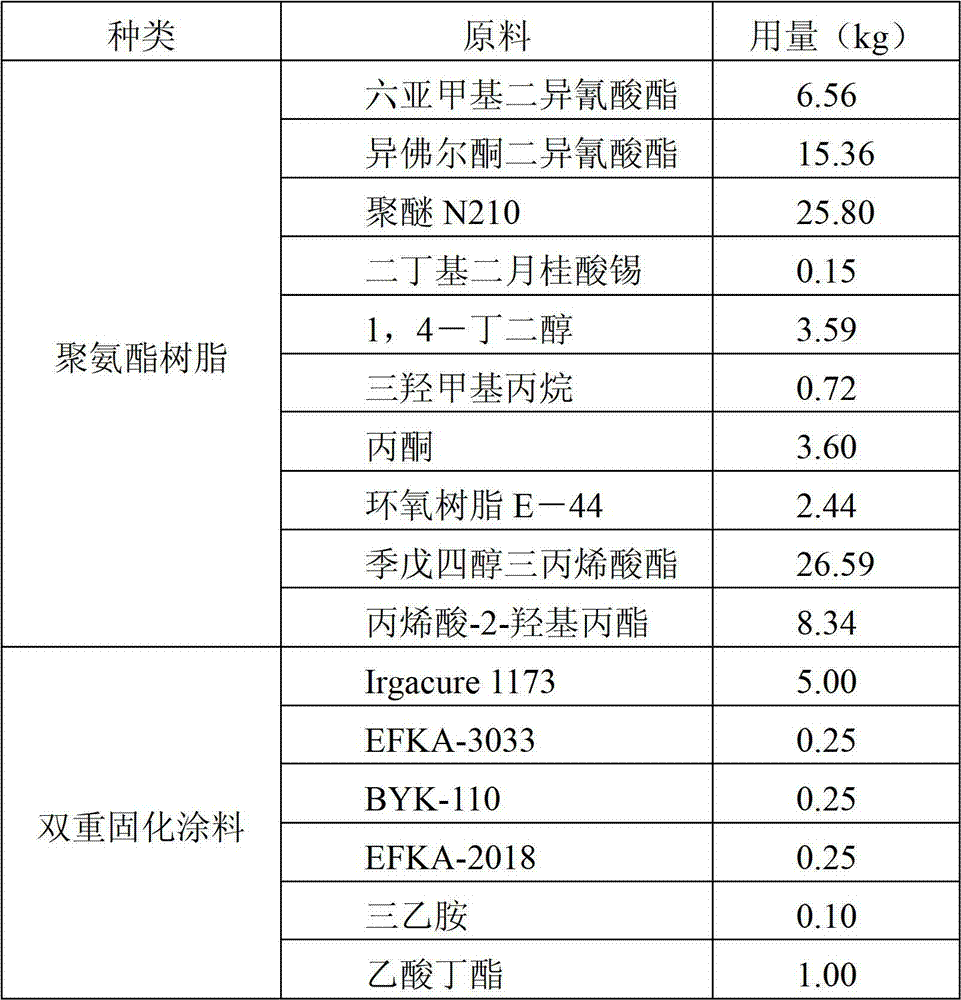

Humidity and ultraviolet dual-cured polyurethane woodware coating and preparation method thereof

The invention discloses humidity and ultraviolet dual-cured polyurethane woodware coating and a preparation method thereof. A synthesis method includes synthesizing initial polyurethane polymer I, polyurethane pre-polymer II, polyurethane pre-polymer III, polyurethane acrylate oligomer and ultraviolet cured woodware coating. The humidity and ultraviolet dual-cured polyurethane woodware coating is mainly prepared by aliphatic diisocyanate, dihydric alcohol pre-polymer, polyhydroxy acid, epoxy resin and hydroxy acrylic ester and the like, and by adding auxiliaries such as photoinitiators, flatting agents, defoamers, substrate wetting agents and catalysts, the ultraviolet cured woodware coating is prepared. The ultraviolet cured woodware coating can form films and be cured under irradiation of ultraviolet, also can be cured by humidity in the air within 5 hours at the room temperature, and has the advantages of high solid, NCO (isocyanate) group content and adhesion force, fine resistance to chemical corrosion, high film coating hardness and fine storage stability and the like, can be used for irregular coating surfaces, hone finished UV (ultraviolet) paint and UV colored paint and the like where cannot be irradiated by the ultraviolet.

Owner:广州常圣新材料科技有限公司

Aluminum alloy section production process for IT (information technology) industry

Owner:CHENGDU SUNSHINE ALUMINUM

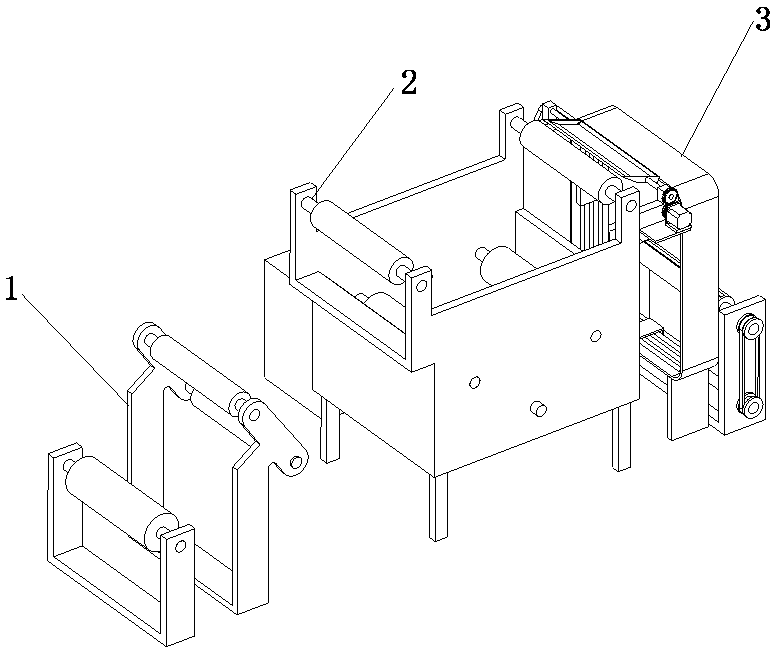

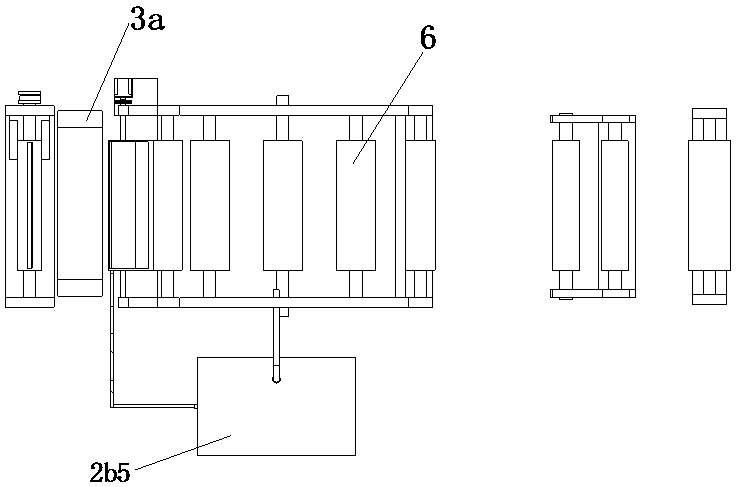

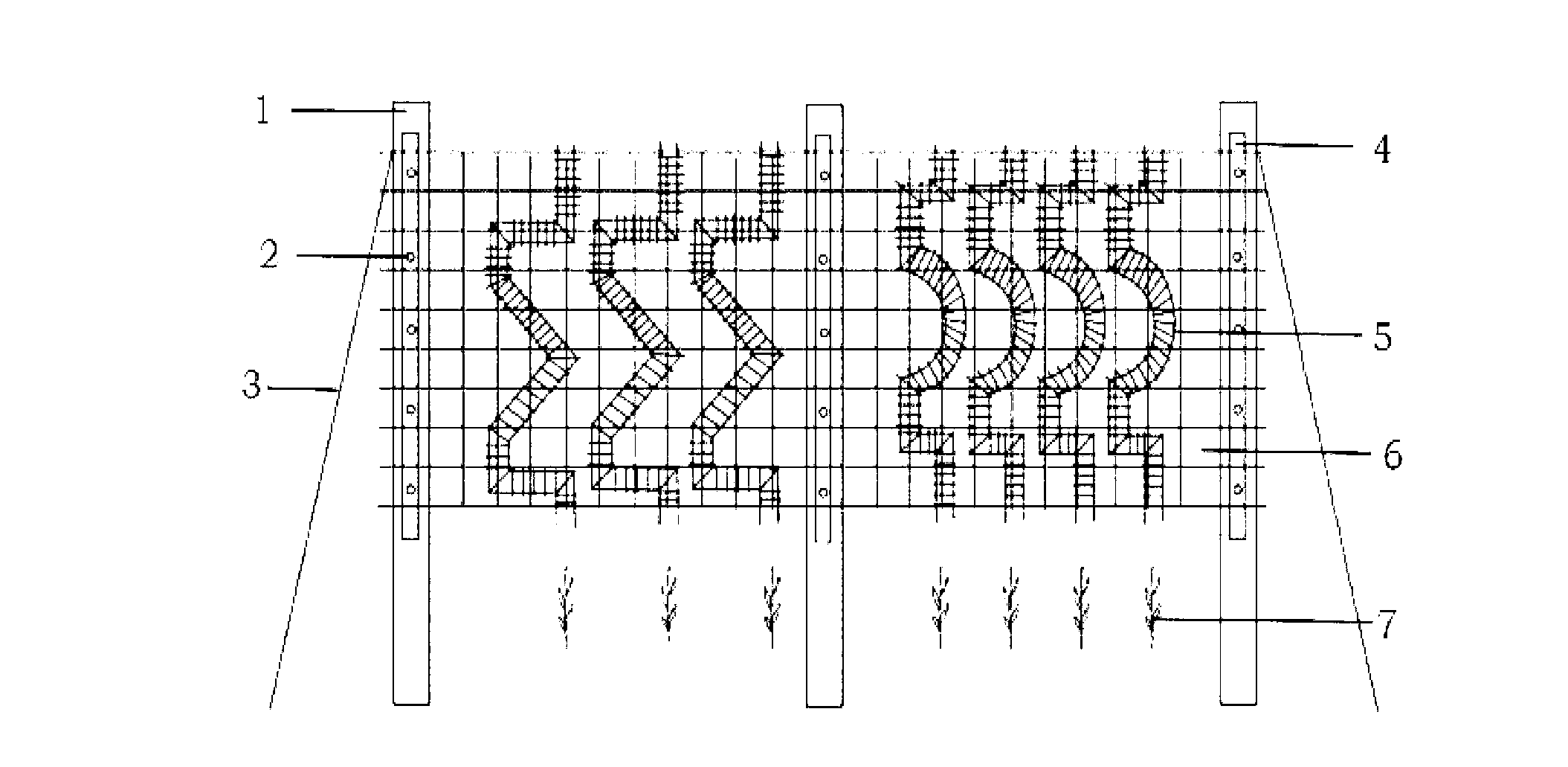

Method for producing steel mesh reinforced plastic composite pipes and its self-contained equipment

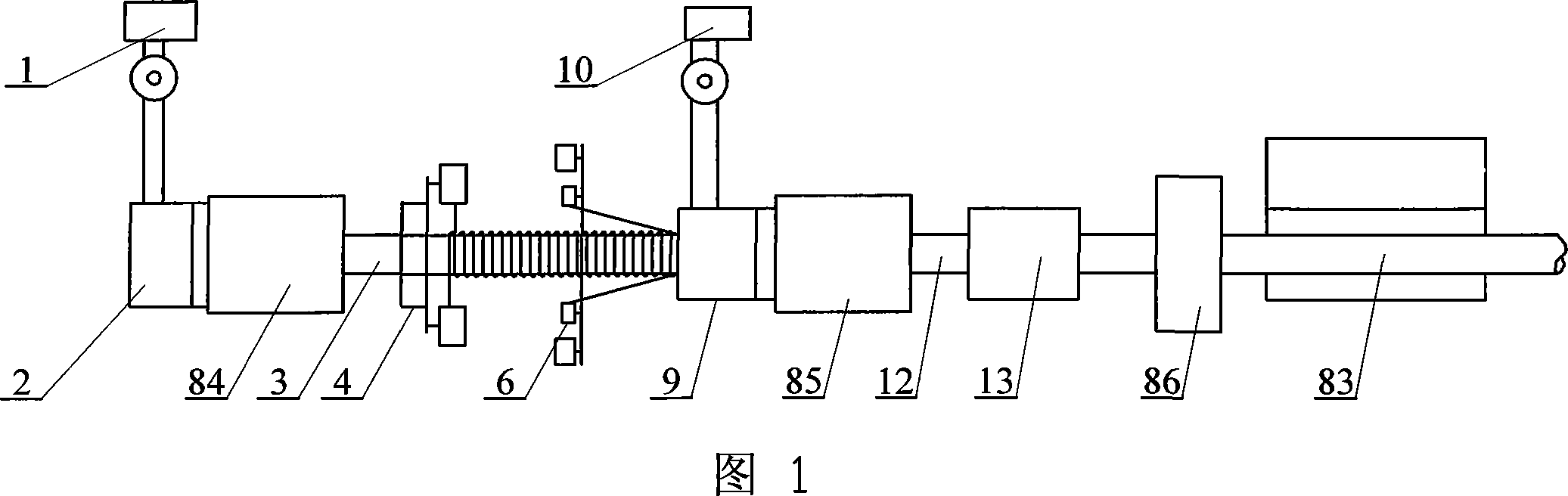

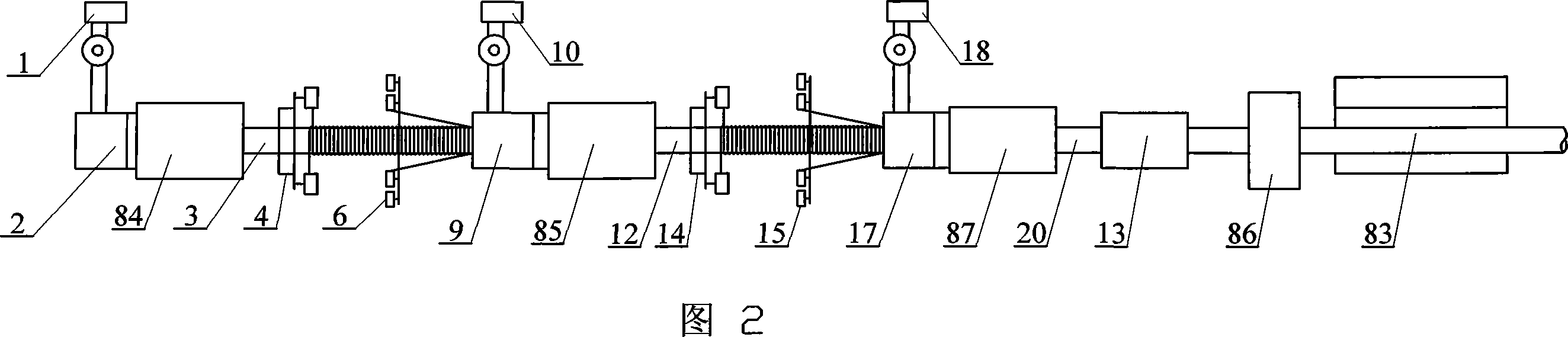

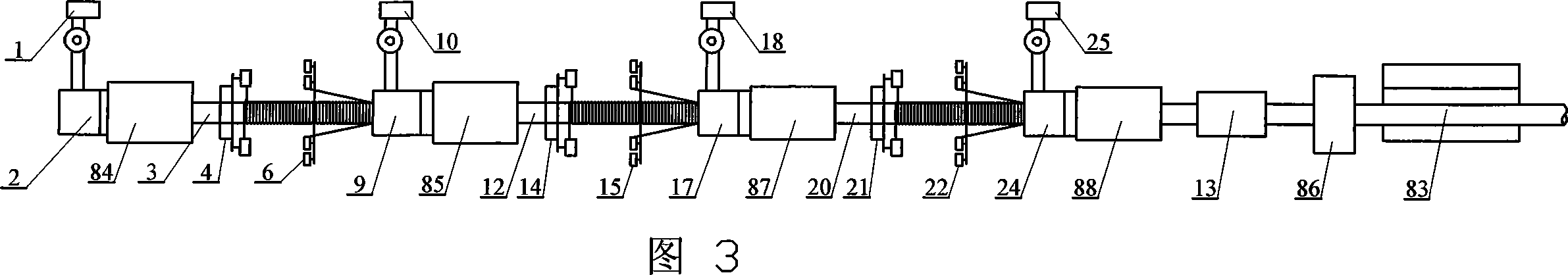

InactiveCN101077613AFast shapingEasy to shapeTubular articlesPlastic forming machineProcess configuration

The present invention is process and apparatus for producing steel net reinforced plastic composite pipe as one kind of steel structure reinforced plastic composite pipe. The process includes: extruding hot molten plastic into the inner plastic forming machine and cooling to obtain the inner plastic pipe blank layer, winding steel wire and arranging longitudinal wire onto the inner plastic pipe blank layer to form steel net, setting inside the first plastic pipe forming machine and extruding hot molten plastic into the first plastic pipe forming machine to form the composite plastic blank comprising one inner plastic pipe blank layer, one steel net layer and one outer plastic coating layer, and cutting to obtain the steel net reinforced plastic composite pipe. The equipment includes also one cooling water tank.

Owner:李富春

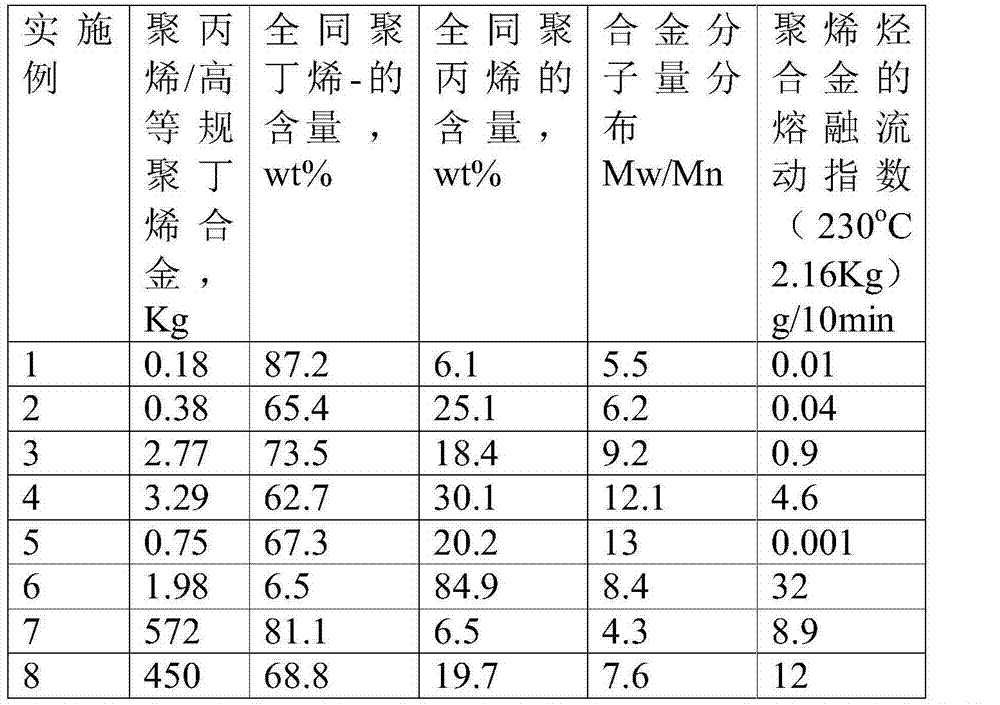

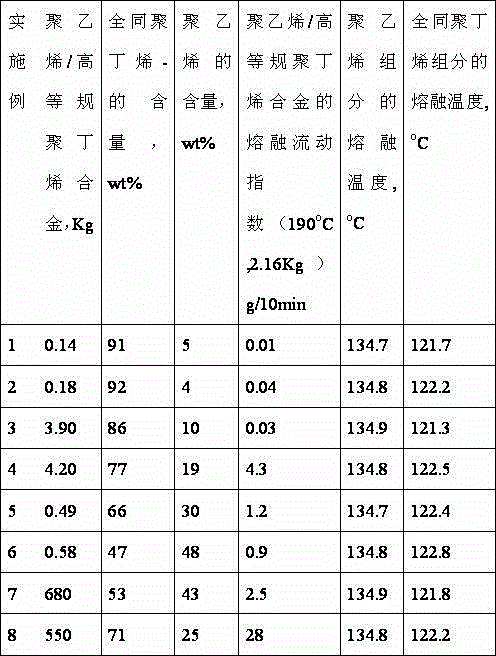

High isotactic polypropylene alloy material and preparation method thereof

The invention discloses a high isotactic polypropylene alloy material and a preparation method thereof. The material contains 5-98.9 parts by weight of polybutylene, 1-80 parts by weight of polypropylene and 0.1-15 parts by weight of propylene-butene copolymer; the isotacticity of the high isotactic polypropylene is larger than 85%, and the smelting point of the high isotatic polypropylene is 115-129 DEG C; the isotacticity of the high isotactic polypropylene is larger than 85%, and the smelting point of the high isotactic polypropylene is 155-169 DEG C; the propylene-butene copolymer contains a random copolymer and a segmented copolymer of propylene-butene. The preparation method uses a titanium / vanadium supported catalyst and adopts a multistage sequential polymerization manner and specifically comprises the steps of carrying out propylene polymerization or butane-1 polymerization, then initiating butane-1 polymerization or propylene polymerization, and respectively carrying out propylene polymerization or butane-1 polymerization, and so on to synthesize the high isotactic polypropylene alloy material. The material is a powdery or spherical product, and has the advantages of excellent impact resistance, thermal creep resistance and low shrinking percentage of polybutylene, high modulus, high surface hardness and fast setting of polypropylene, and the like.

Owner:QINGDAO UNIV OF SCI & TECH +1

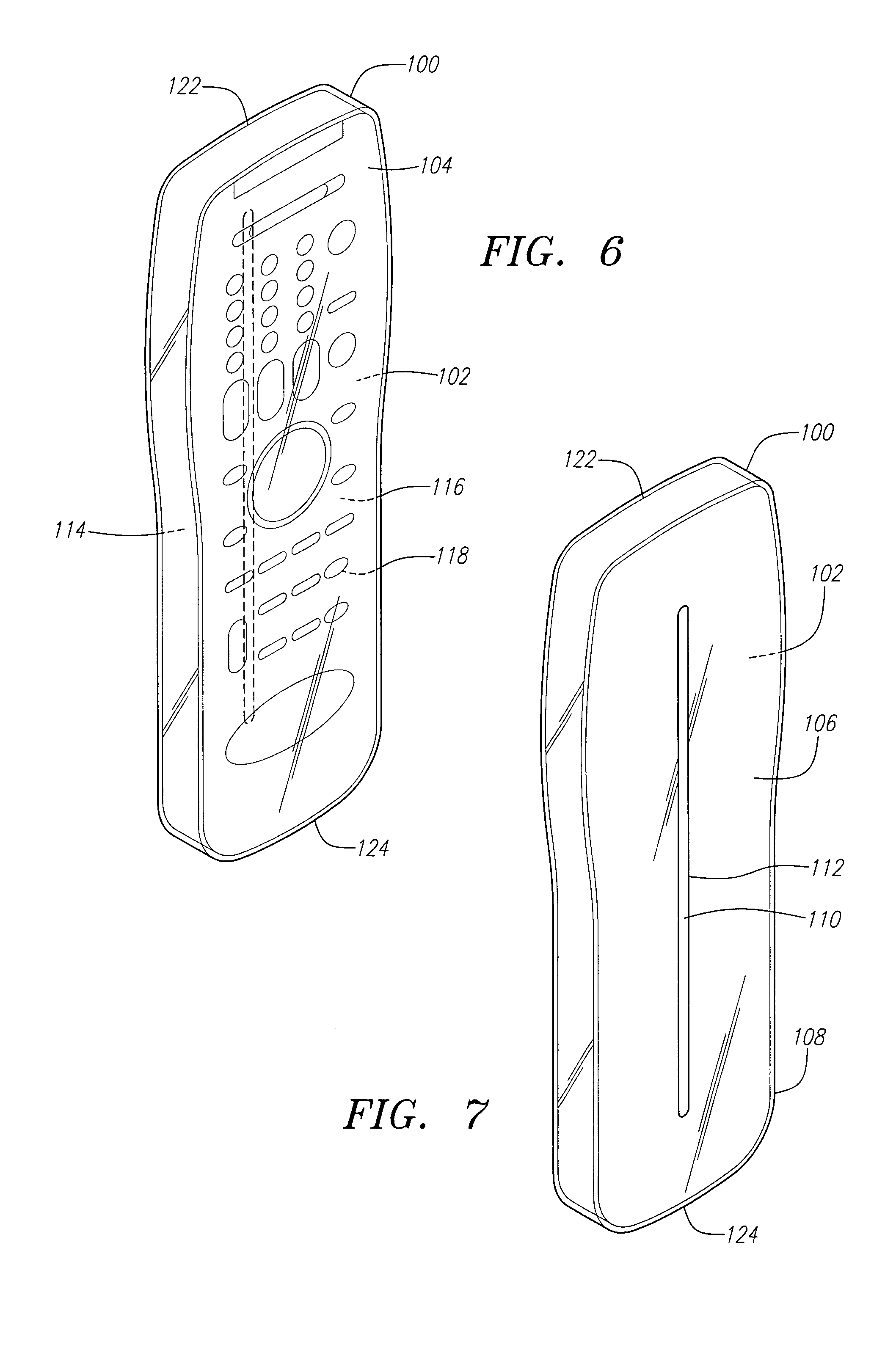

Cover for remote control device

InactiveUS20050098456A1Minimizing transferEasy to captureOther accessoriesElectric switchesRemote controlEngineering

A cover for use with a remote control device comprising a front member which exhibits a continuous flat surface and a rear member having a curved surface. The rear member is integrally formed with the front member at a plurality of rounded surfaces for forming an enclosure. An orifice is formed in the curved surface of the rear member for enabling a remote control device to be inserted into and removed from the enclosure. The rounded surfaces designed into the cover facilitate the closing of the orifice for enclosing the remote control device. The front member, rear member and rounded surfaces are each comprised of a flexible, stretchable and transparent material for conforming to the shape of the remote control device and for providing a sanitation barrier.

Owner:HODGES RICHARD P

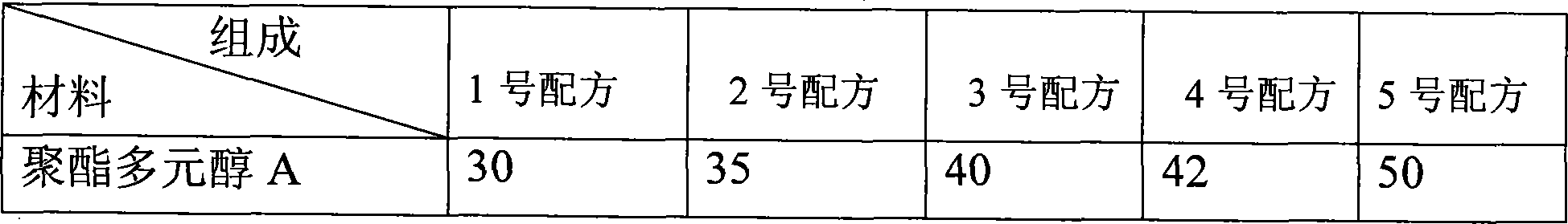

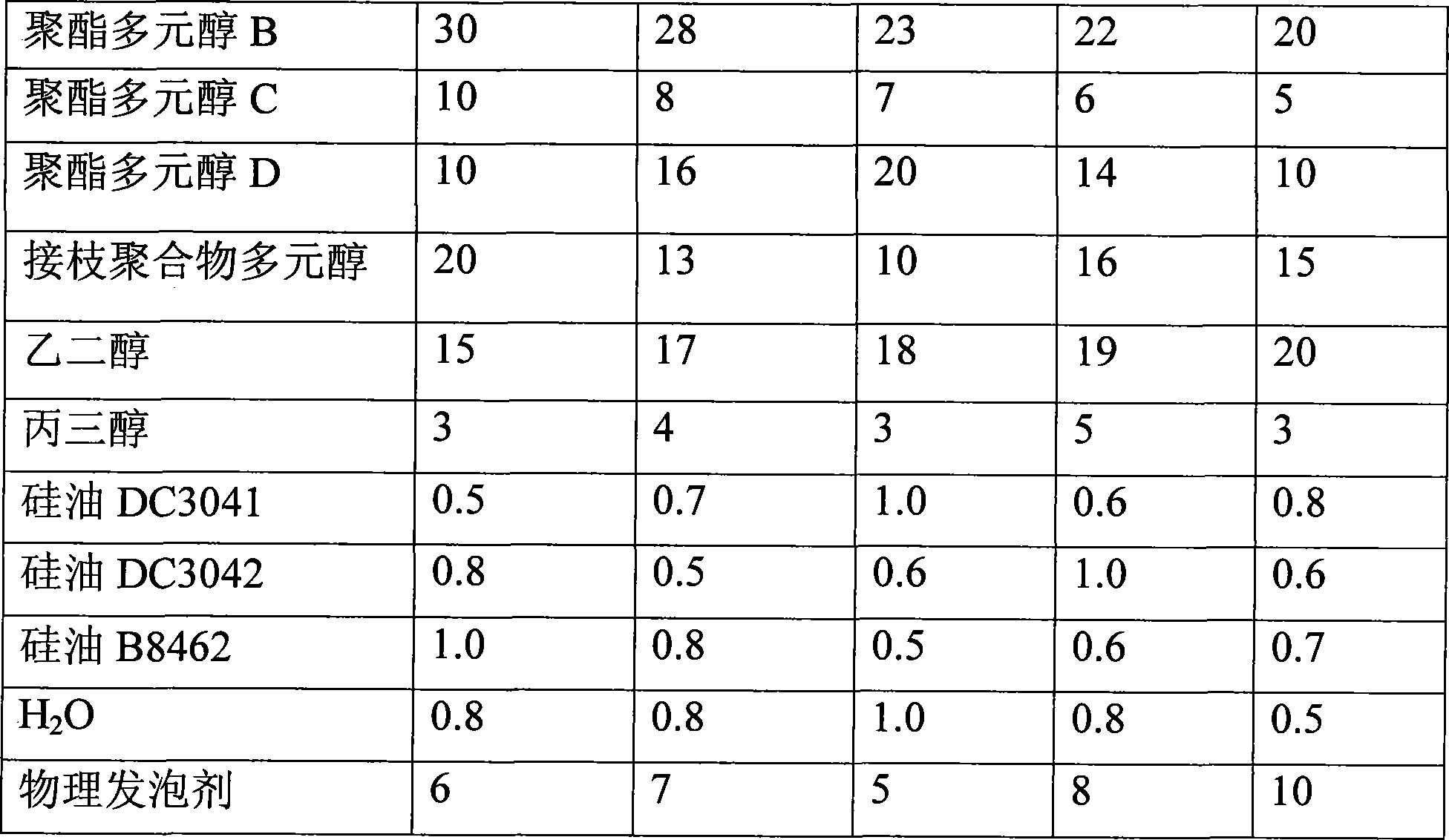

Polyester type ultra-low density polyurethane resin for shoes

The present invention is the recipe of three component polyurethane resin for insole. The polyurethane resin includes one component A of active hydrogen-containing mixture comprising long chain polyol polymer, chain expanding agent, cross-linking agent, surfactant, foaming agent and other assistants; one component B comprising polyester or polyether modified MDI pre-polymer; and one component C or catalyst component of glycol solution of triethylidene diamine. The polyurethane resin has density as low as 0.25-0.30 g / cu cm, capacity of making the product firm and good in appearance, and other advantages.

Owner:无锡双象新材料有限公司

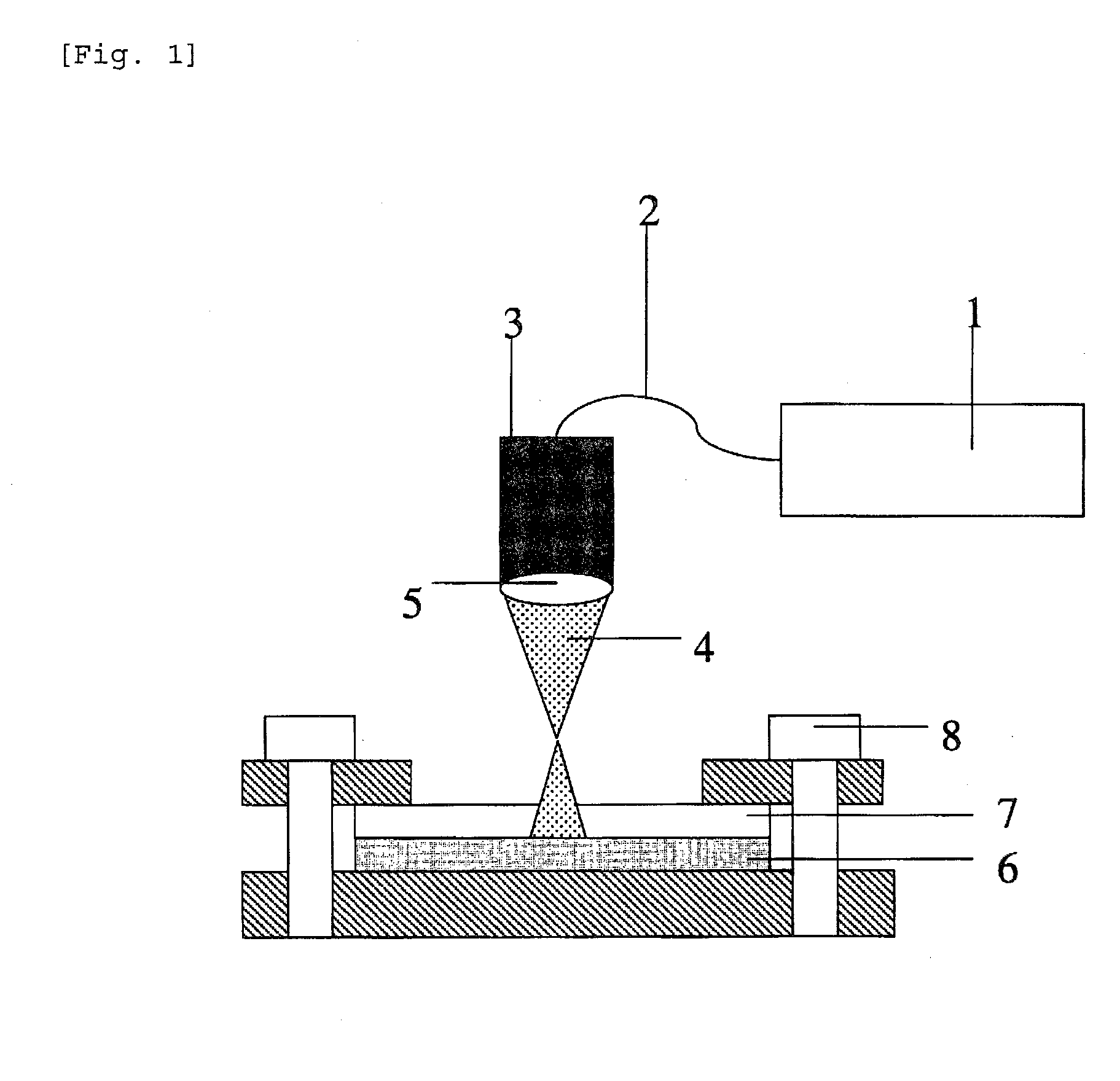

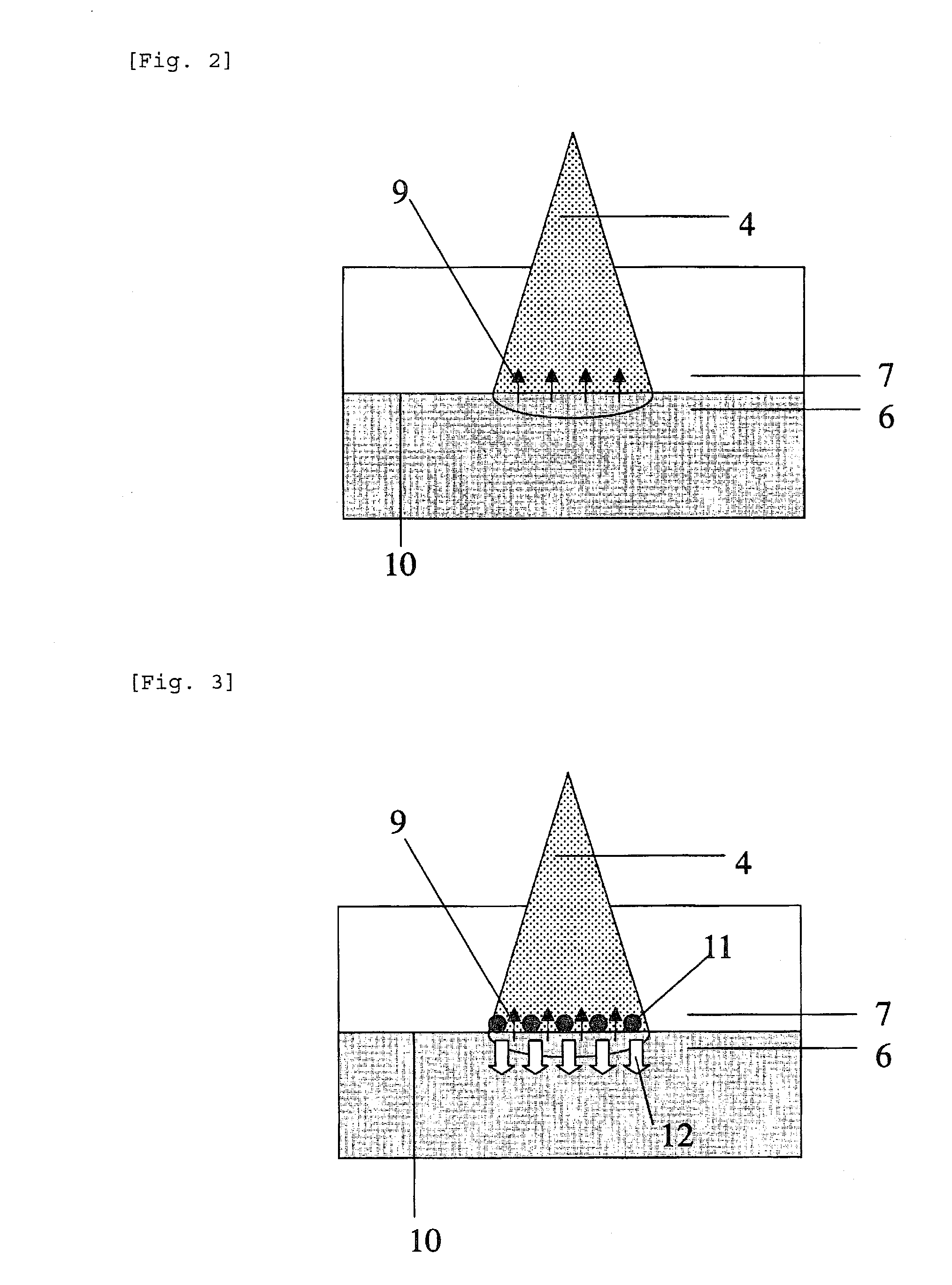

Method for metal-resin joining and a metal-resin composite, a method for glass-resin joining and a glass-resin composite, and a method for ceramic-resin joining and a ceramic-resin composite

InactiveUS20090252978A1Small jointPrecise and fine jointLamination ancillary operationsLaminationMetallic materialsLaser light

The present invention provides a method for joining a metallic material, a glass material or a ceramic material, and a resin material, that have no limitation in their field of application and that can form a strong joint by an easy method. The method for joining a metallic material, a glass material or a ceramic material, and a resin material is characterized in that joining is effected by heating a portion to be joined, in such a state that the metallic material, glass material or ceramic material is coupled with the resin material, to a temperature at which bubbles (preferably the sphere equivalent diameter from 0.01 mm to 5.0 mm) are generated in the resin material at the portion to be joined. As a heating source for heating the portion to be joined, a laser light source is used, especially.

Owner:OSAKA UNIV

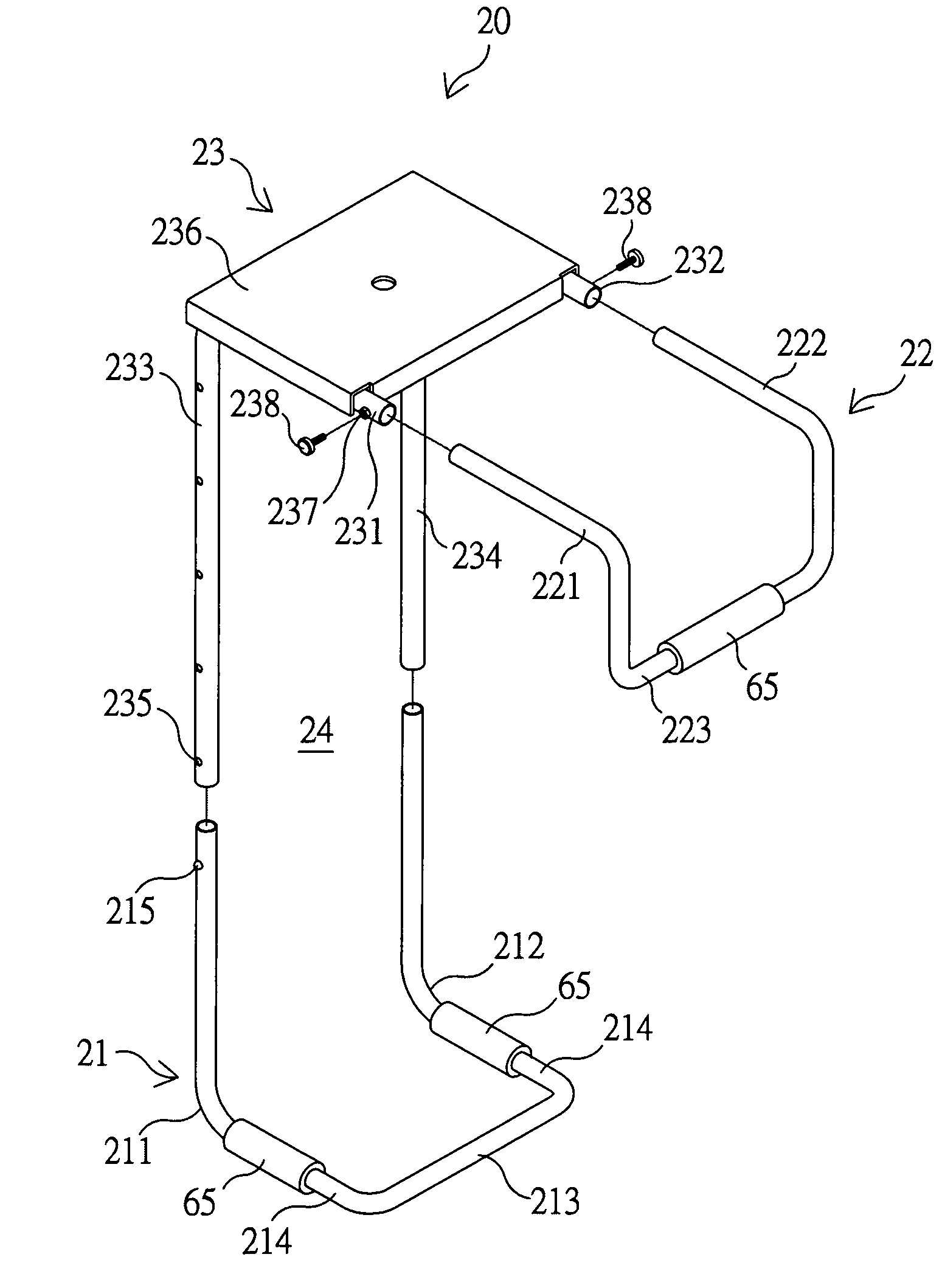

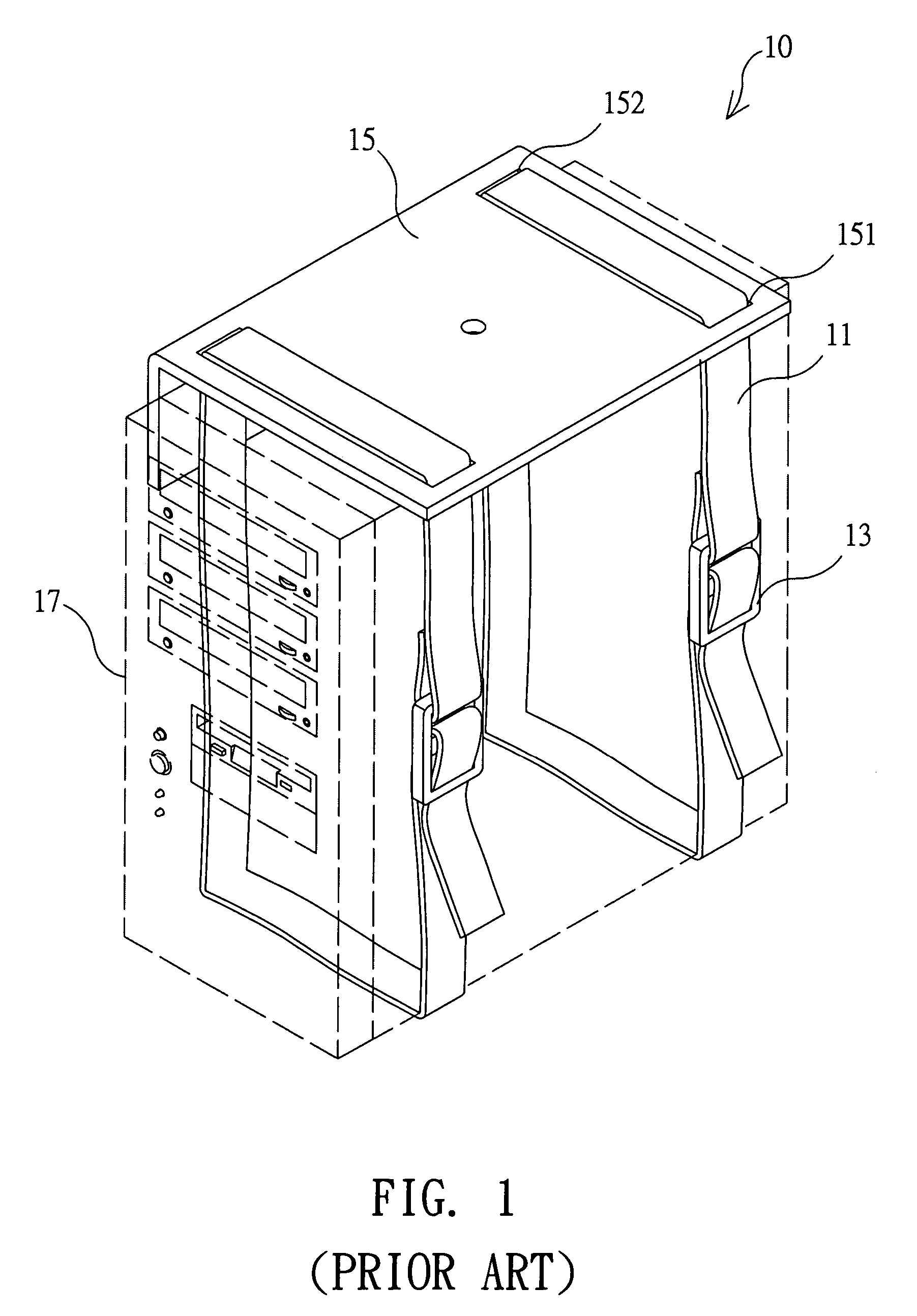

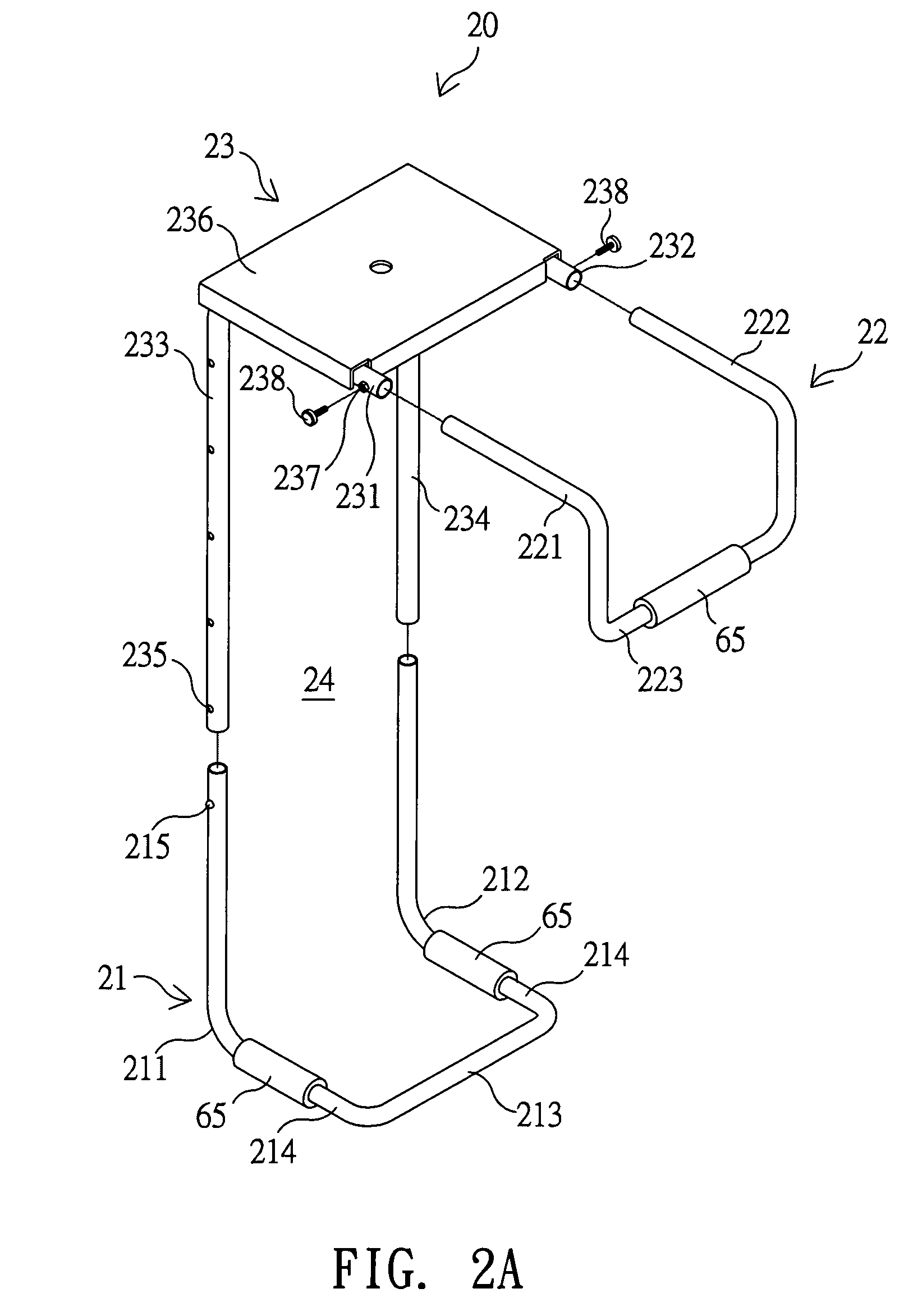

General computer host mounting shelf

ActiveUS7172166B2Rapid localizationFast shapingCurtain suspension devicesRod connectionsGeneral purpose computerEngineering

Owner:SALLAS INDAL

Lightweight high-elasticity EVA shoe sole and preparation method thereof

ActiveCN104804297ARaise the crystallization temperatureIncrease temperatureSolesCross-linkPolyolefin

The invention relates to the technical field of high-molecular compounds, and provides a lightweight high-elasticity EVA shoe sole and a preparation method thereof. The lightweight high-elasticity EVA shoe sole is prepared by the steps of performing internal mixing, open milling and pelleting on the materials of EVA, polyolefin segmented copolymer, ethylene propylene diene monomer, chlorinated polyethylene, a foaming agent, a cross-linking agent, zinc stearate, stearic acid, an abrasion-resistant agent and talcum powder, so as to obtain lightweight high-elasticity pellets, and performing injection molding at one time to obtain the lightweight high-elasticity EVA shoe sole. The lightweight high-elasticity EVA shoe sole provided by the invention has the characteristics that the resilience is high, the dimensional stability is high, the compression deformation rate is low, the surface is not easy to wrinkle, the weight is light, the comprehensive performance is good, the product percent of pass is high, and in addition, the EVA shoe sole is lighter in weight and is particularly suitable for production of top-grade EVA sport shoes and casual shoes.

Owner:MAOTAI FUJIAN SOLES CO LTD

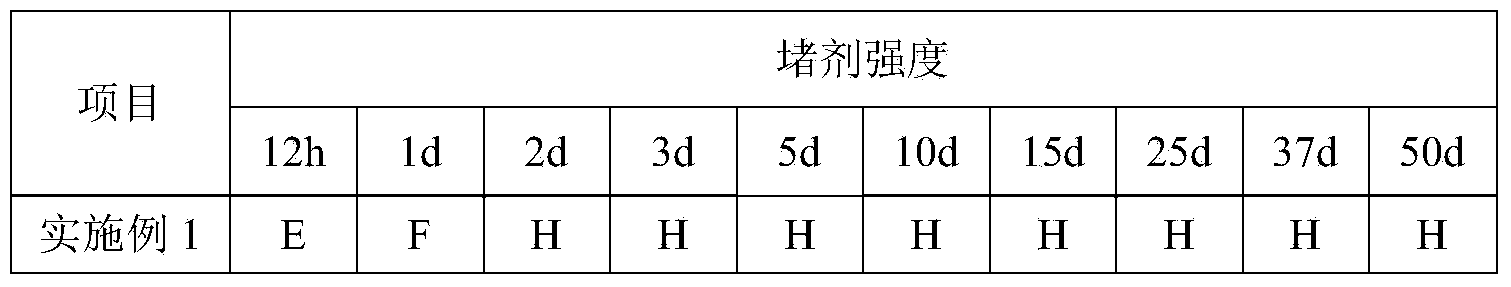

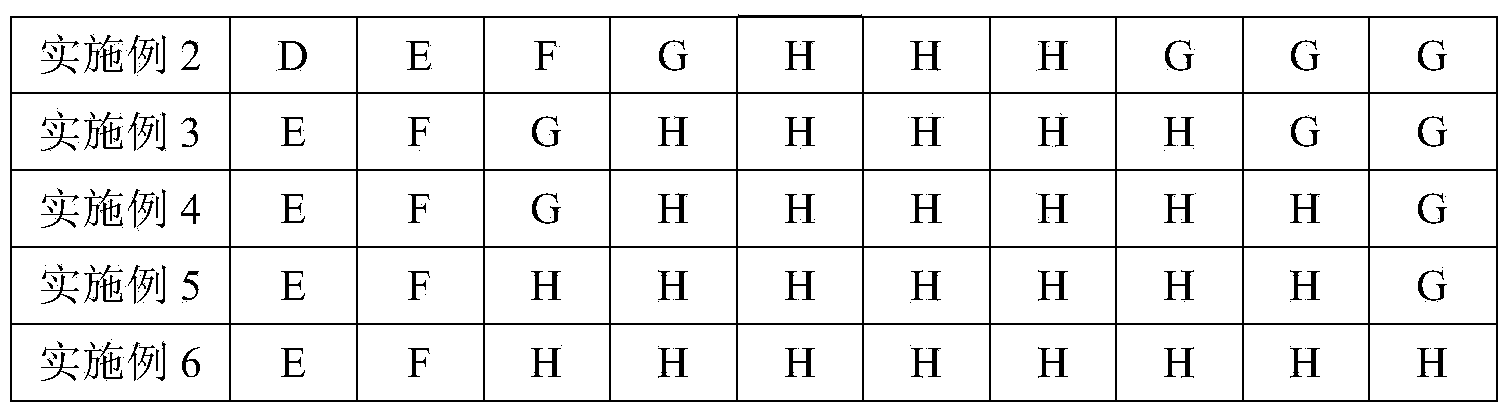

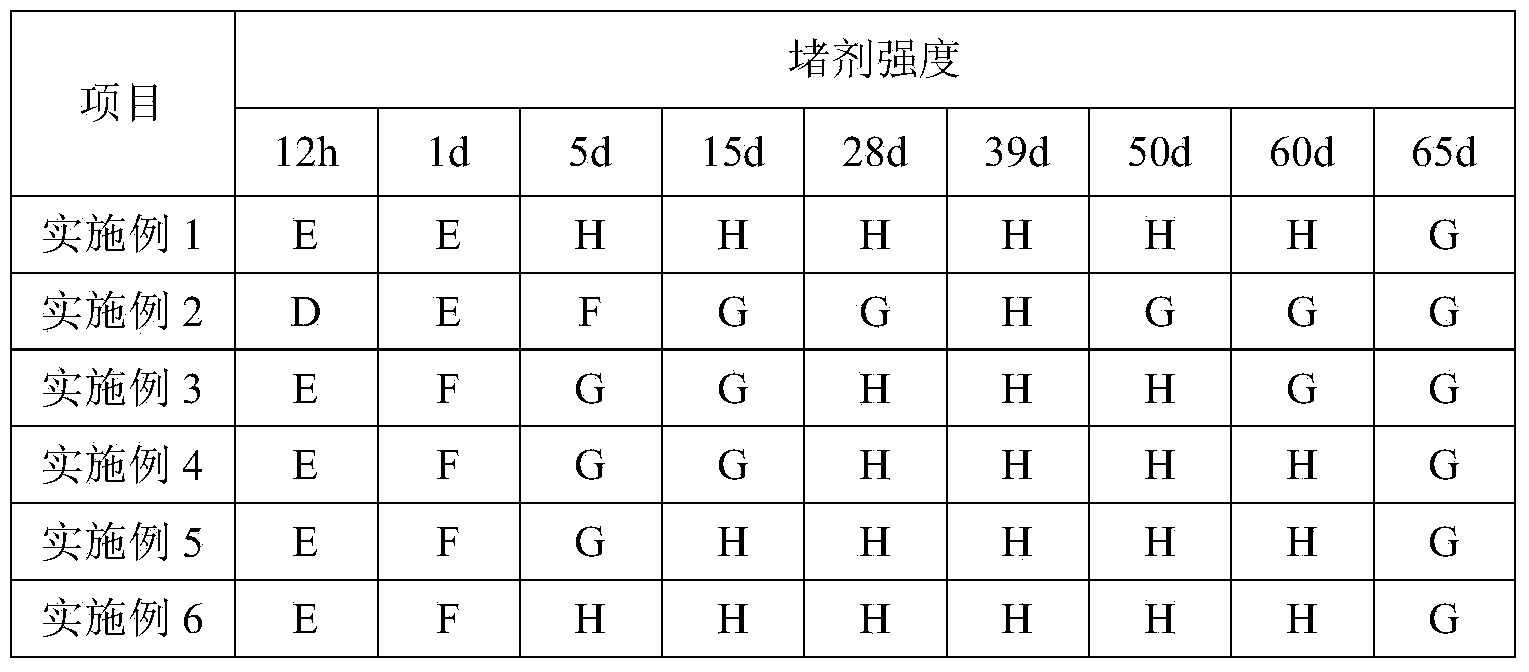

High-temperature resistant secondary cross-linked gel profile control agent and preparation method thereof

InactiveCN104357032AImprove gelationImprove seal strengthDrilling compositionCross-linkSalt resistance

The invention discloses a high-temperature resistant secondary cross-linked gel profile control agent and a preparation method thereof, and belongs to the technical field of oilfield chemistry. The profile control agent has good gelling property and high plugging strength and can resist high temperature of 150 DEG C, and the gelling strength and the gelling time can be adjusted. The high-temperature resistant secondary cross-linked gel profile control agent is mainly characterized by the secondary composite crosslinking process, that is, a plugging agent reacts with a first crosslinking agent under the ground condition to form flowable gel similar to weak gel so as to reduce filter loss of the plugging agent in oil deposit during the construction process and reduce the risk of blocking a low-permeability oil flow channel by the plugging agent; and a second crosslinking agent has a second crosslinking reaction under the high-temperature condition of an oil layer to form high-strength gel so as to effectively plug a high-permeability steam flowing channel, and accordingly, steam suction is controlled, and the sweep efficiency is improved. Gelling of the high-temperature resistant secondary cross-linked gel profile control agent is characterized in that micromolecules are inserted into organic macromolecular materials HPAM, and micromolecules and macromolecules mutually permeate, so that a gel system easily performs sizing; and meanwhile, temperature resistance, salt resistance, shear resistance and ageing resistance are enhanced, and the system performance can be well played.

Owner:CHINA PETROLEUM & CHEM CORP +1

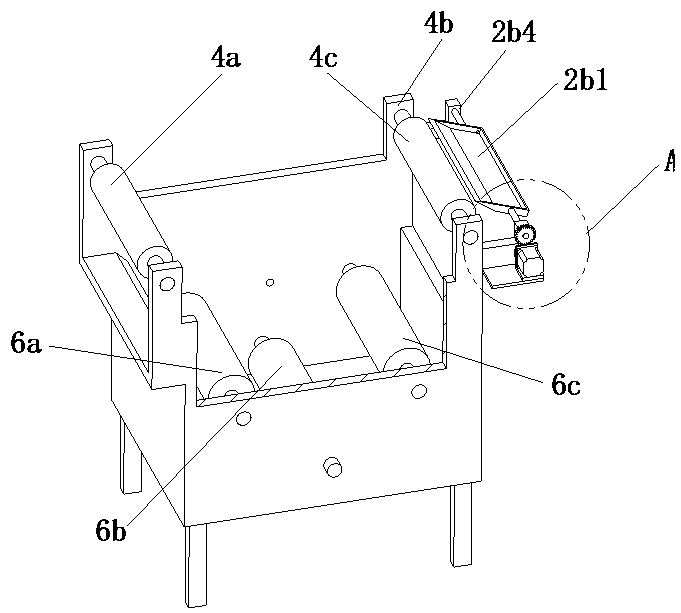

Sizing device of textile fabric

InactiveCN108265428ASimple structureReduce labor intensityTextile treatment containersTextile treatment machine arrangementsSlurry coatingEngineering

The invention provides a sizing device of a textile fabric. The sizing device comprises a feeding mechanism, a slurry coating mechanism and a drying and discharging mechanism, wherein the slurry coating mechanism is located between the feeding mechanism and the drying and discharging mechanism; the slurry coating mechanism comprises a slurry box, a slurry coating assembly, a slurry scraping assembly and a first material guide assembly; the drying and discharging mechanism comprises a drying assembly and a discharging assembly; the slurry scraping assembly comprises a material guide box and twoL-shaped mounting plates; the material guide box is located between the two L-shaped mounting plates; the material guide box and each L-shaped mounting plate are connected through a rotary rod; a slurry scraping plate is arranged at one end, close to the slurry coating assembly, of the material guide box. The sizing device provided by the invention has the beneficial effects that the slurry coating mechanism is simple in structure and can be used for automatically carrying out slurry coating work on the fabric, so that a lot of labor intensity of workers is reduced; the slurry scraping assembly can be used for scraping off slurry dreg on the fabric and preventing the slurry dreg from falling off in a fabric conveying process; the drying assembly can be used for carrying out drying work onthe fabric so that the fabric can be rapidly shaped.

Owner:安聪聪

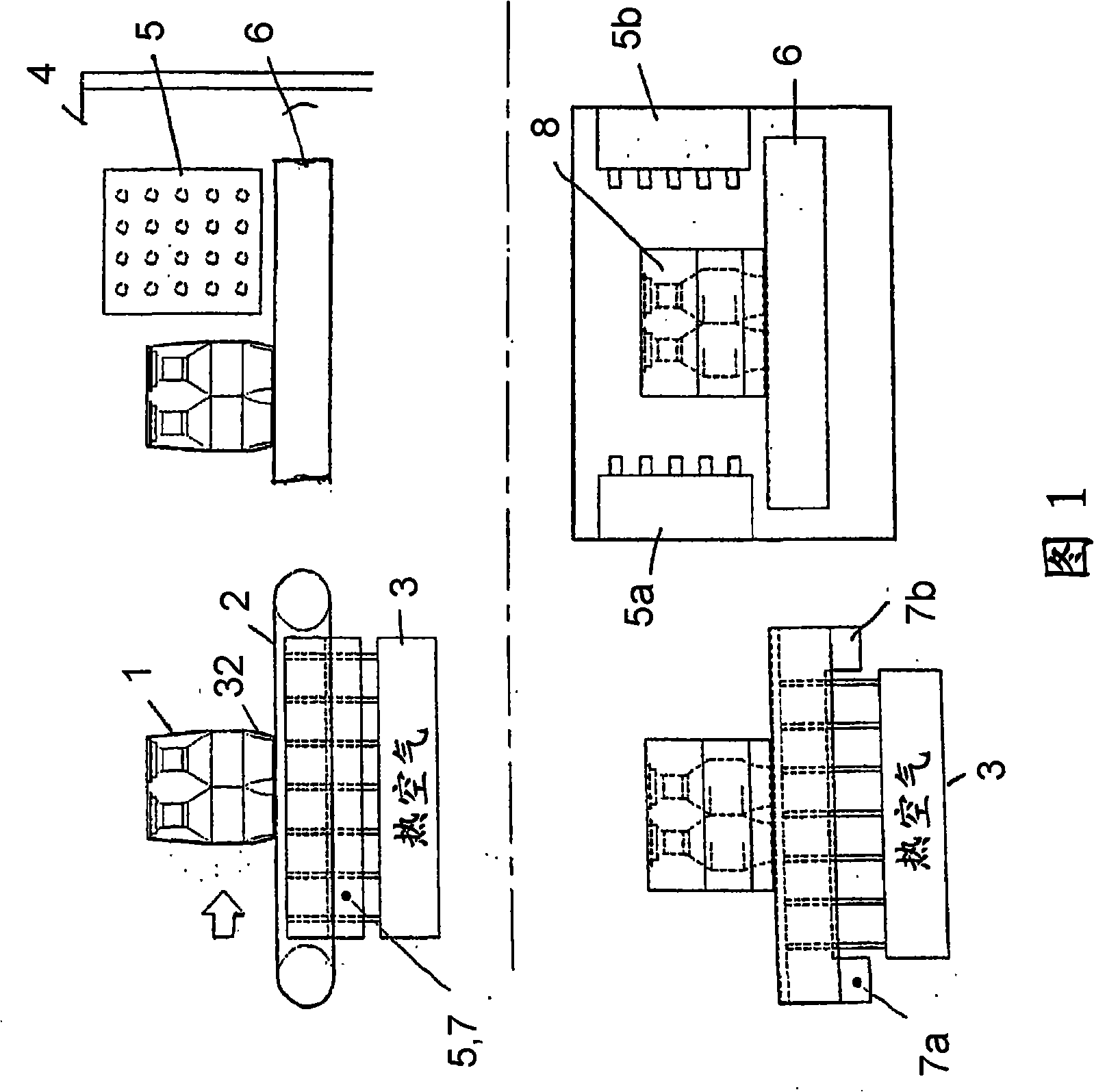

Shrinking process for producing solid, transportable and printable containers and device for carrying out said shrinking process

ActiveCN101356094AReduced energy outputFast shapingWrappers shrinkageContainers with multiple articlesWaddingProduct gas

The invention relates to a shrinking process for producing solid, transportable and printable containers, especially bottle containers with a height / width ratio of > 1 and containing heat-sensitive filling substances. The shrinking process comprises the steps of covering the containers to be packaged with a film in such a manner as to produce an overlapping section of the film ends on the bottom surface, heating them by heat transfer or convection, thereby fusing together the free ends in the area of overlap, and then finally heating the containers in a shrinking oven, the container so produced being stabilized by the shrinking process. The incoming hot air is first locally limited to the bottom surface of the container in order to form a peripheral shell in the area of the bottle bottoms and the shape of the container is stabilized while the container is continuously transported during stabilization. The hot air directed onto the bottom area of the container in a bundle of discretely distributed gas jets is discharged and returned after a locally limited heat transfer with the film. More hot gas is directed laterally onto the continuously transported container at an increased lateral blow speed in order to complete the shrinking process.

Owner:KHS GMBH

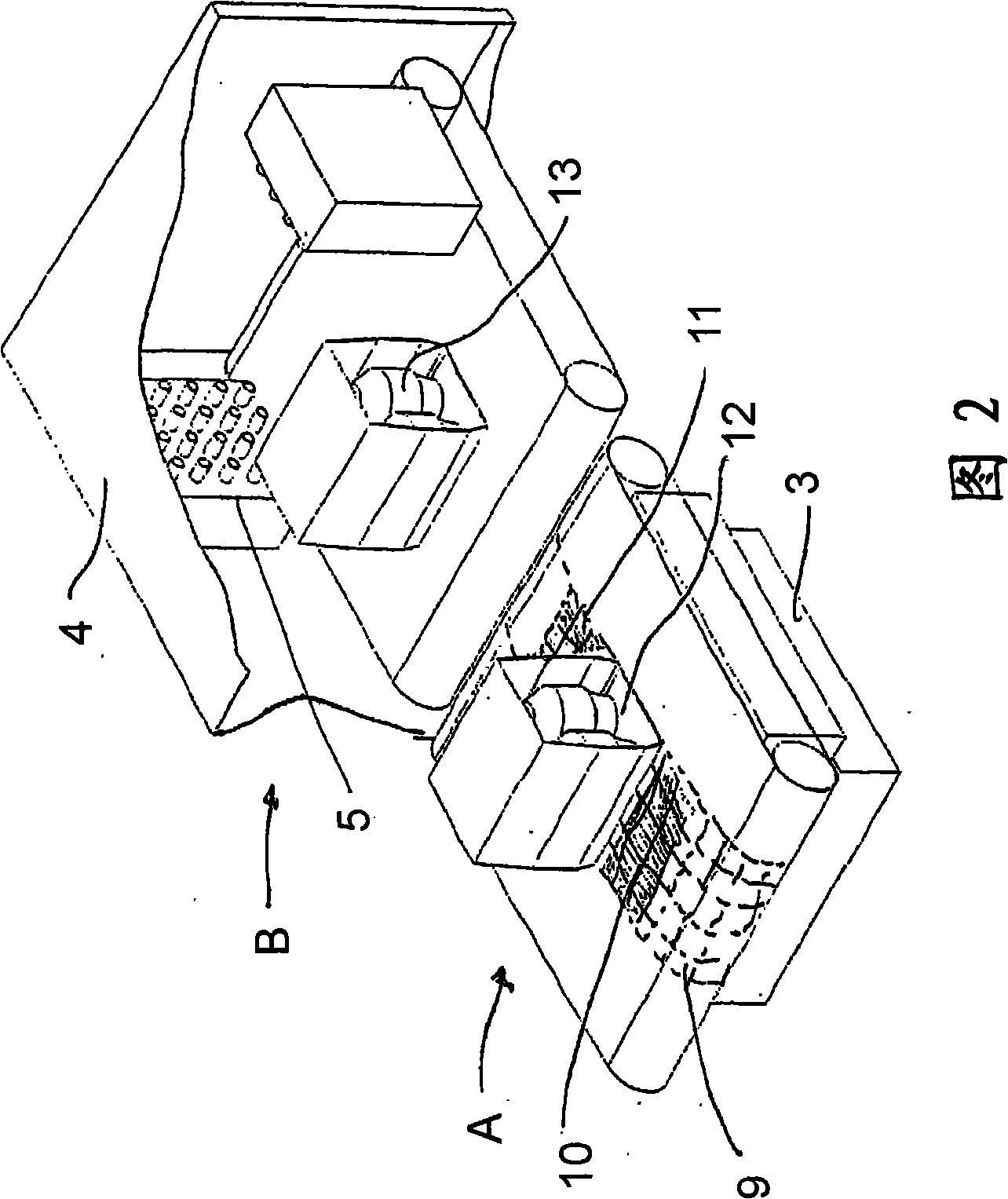

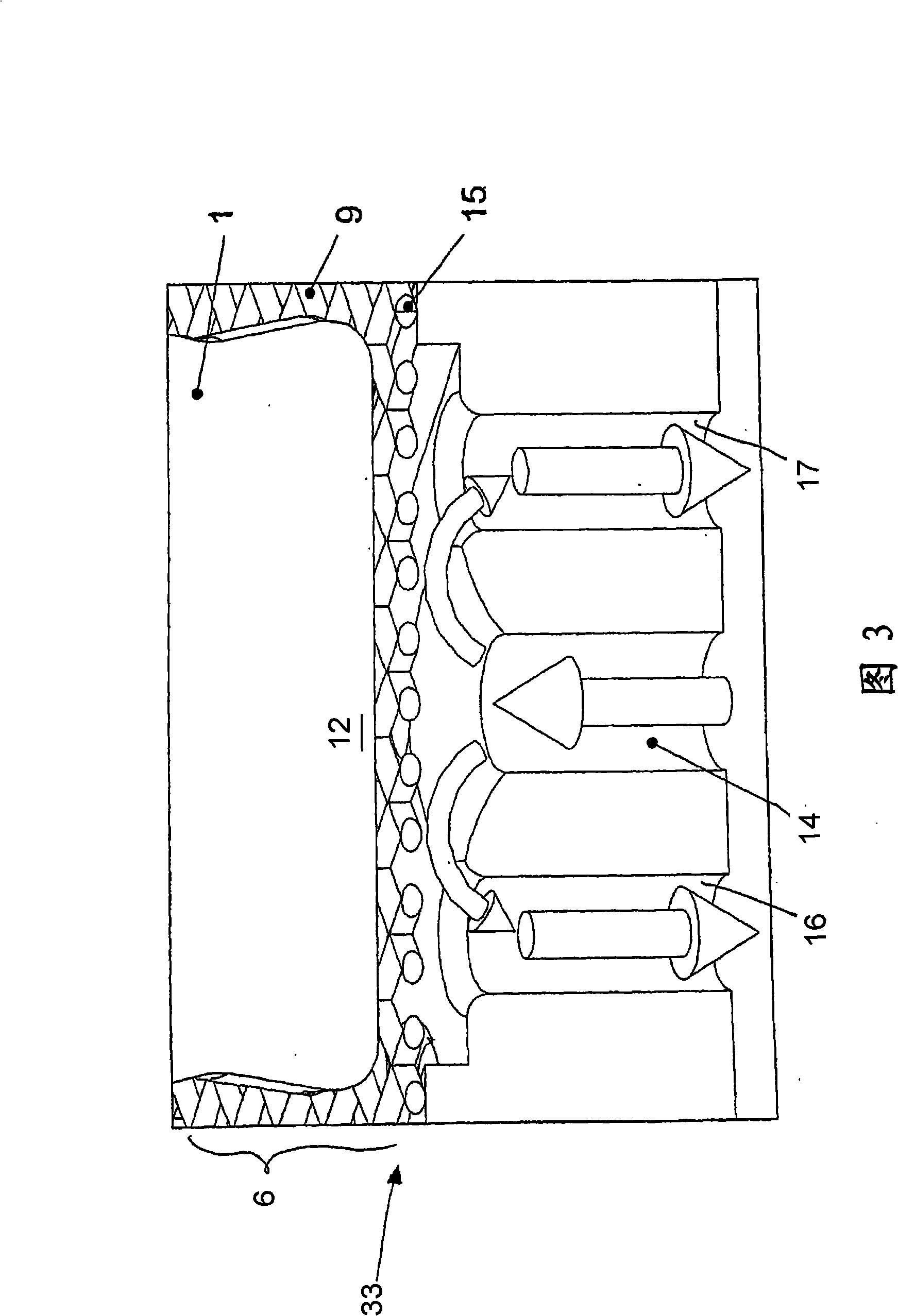

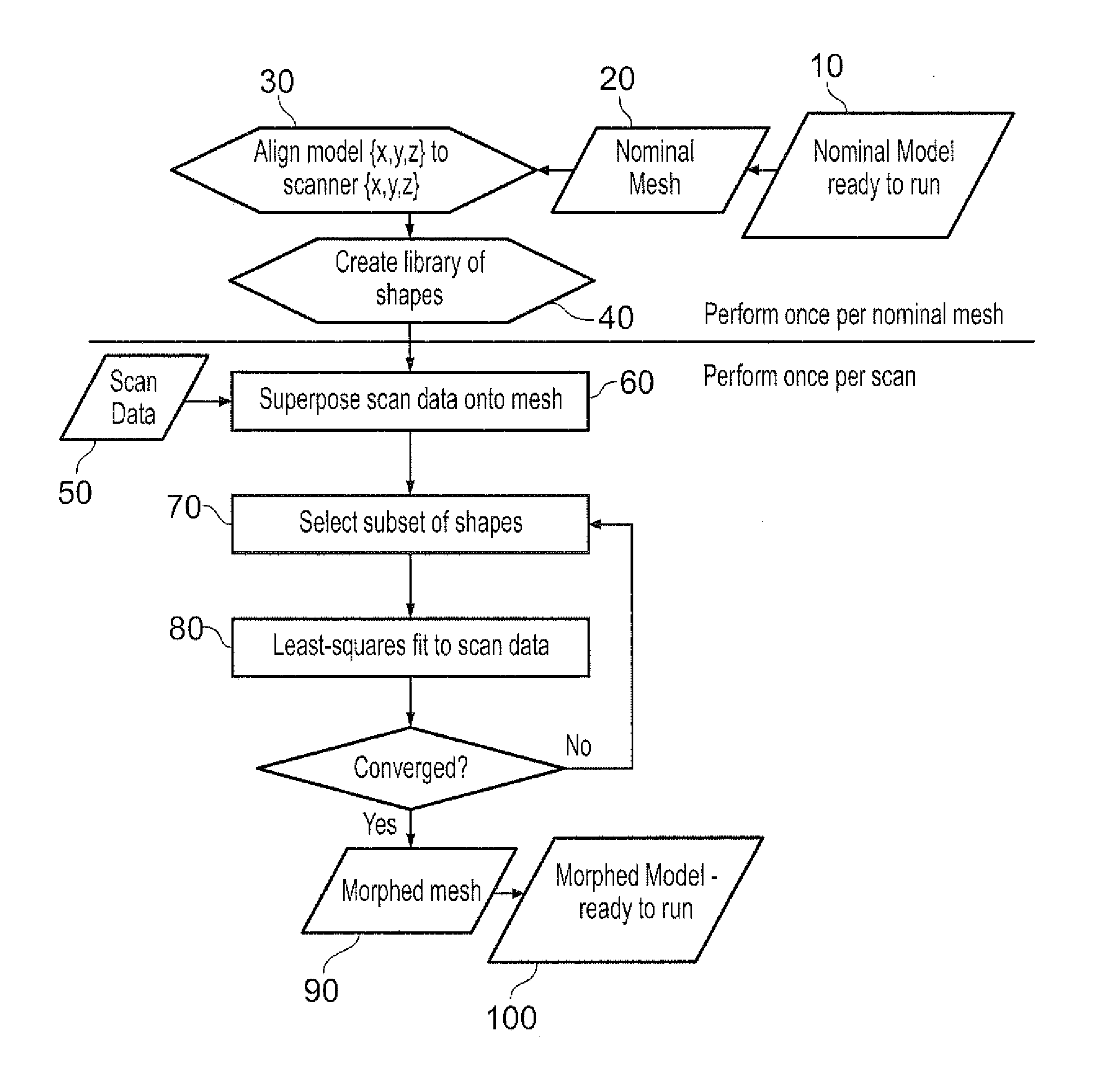

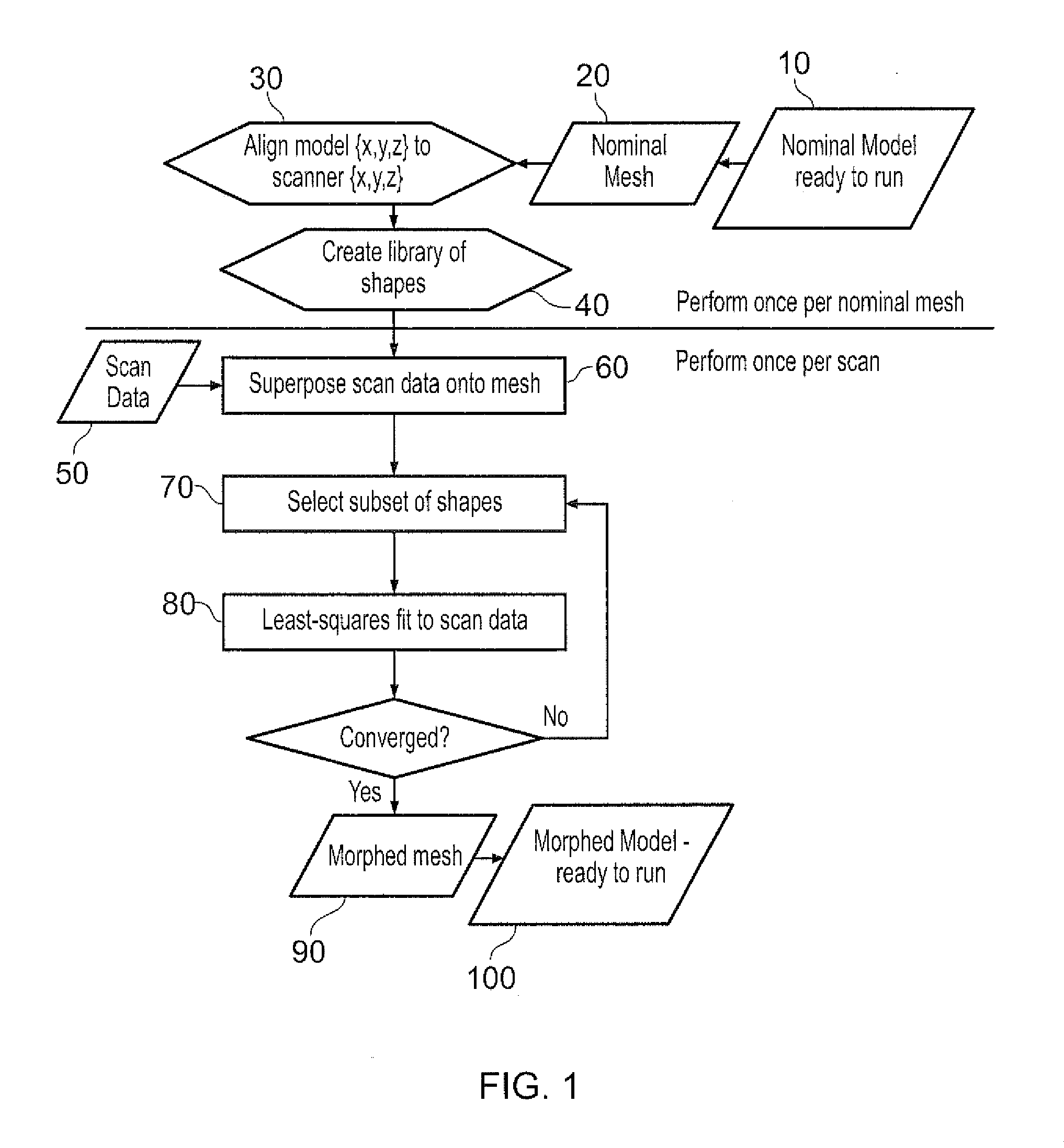

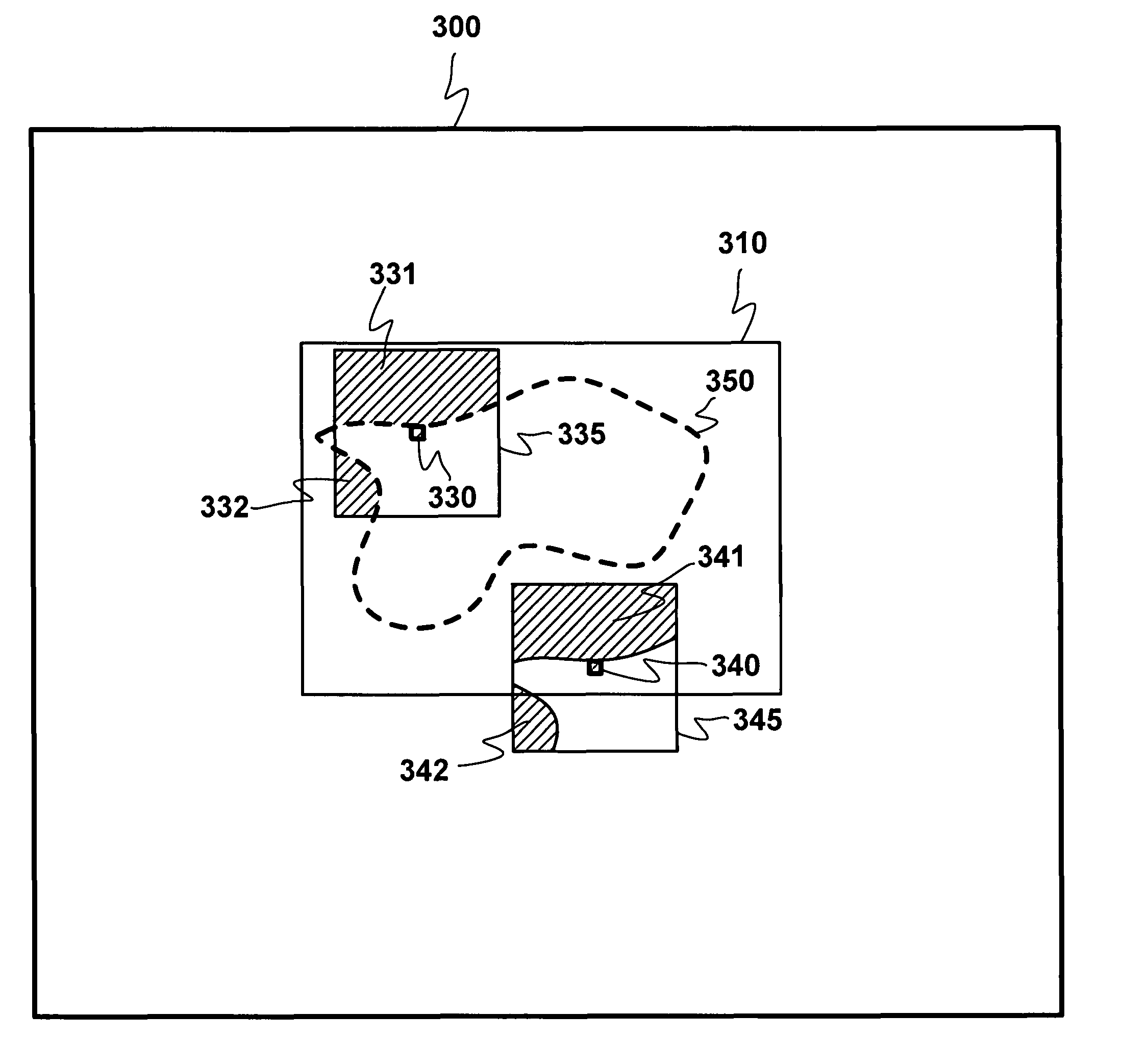

Finite element mesh customisation

ActiveUS20150339851A1Increase the curvatureFast shapingDesign optimisation/simulationSpecial data processing applicationsComputer visionComputer science

Method of providing the generic finite element mesh; providing a library of displacement shapes of generic mesh, each displacement shape being applicable to the generic mesh to generate altered mesh; providing a set of scanned data points which map the surface of the actual component, each scanned data point defining the spatial position of a respective location on the surface of the actual component; superposing the scanned data points on the surface of generic mesh; projecting scanned data points onto respective proximal surface locations of generic mesh to form a set of near data points, each near data point defining the spatial position of respective location on the surface of the generic mesh; determining a combination of the displacement shapes; and applying the combination of displacement shapes to the generic mesh to generate a customised finite element mesh for the actual component.

Owner:ROLLS ROYCE PLC

Low-density timber-imitation polyurethane resin for shoes

ActiveCN101177473AGood liquidityWide range of foamingDomestic footwearDomestic articlesDiaminePrepolymer

The invention relates to a novel resin for polyurethane shoes; wherein, A component is a polyester polyol with hydroxyl (OH) group, and the main components are polyester polyol, chain extendor, cross linker, surface-active material, foaming agent and other addition agent. B component is a prepolymer with isocyanate (NCO) group. C component is glycol solution with triethylene diamine. The invention adopts five kinds of polyester polyol, wherein, two kinds are foaming agent and three kinds are silicon oil; the density of the product is low up to 0.25 to 0.30g / m<3>; the Shaw A hardness of the product is over 90 DEG C.

Owner:无锡双象新材料有限公司

Production process of 6A02T6 container sections

Owner:CHENGDU SUNSHINE ALUMINUM

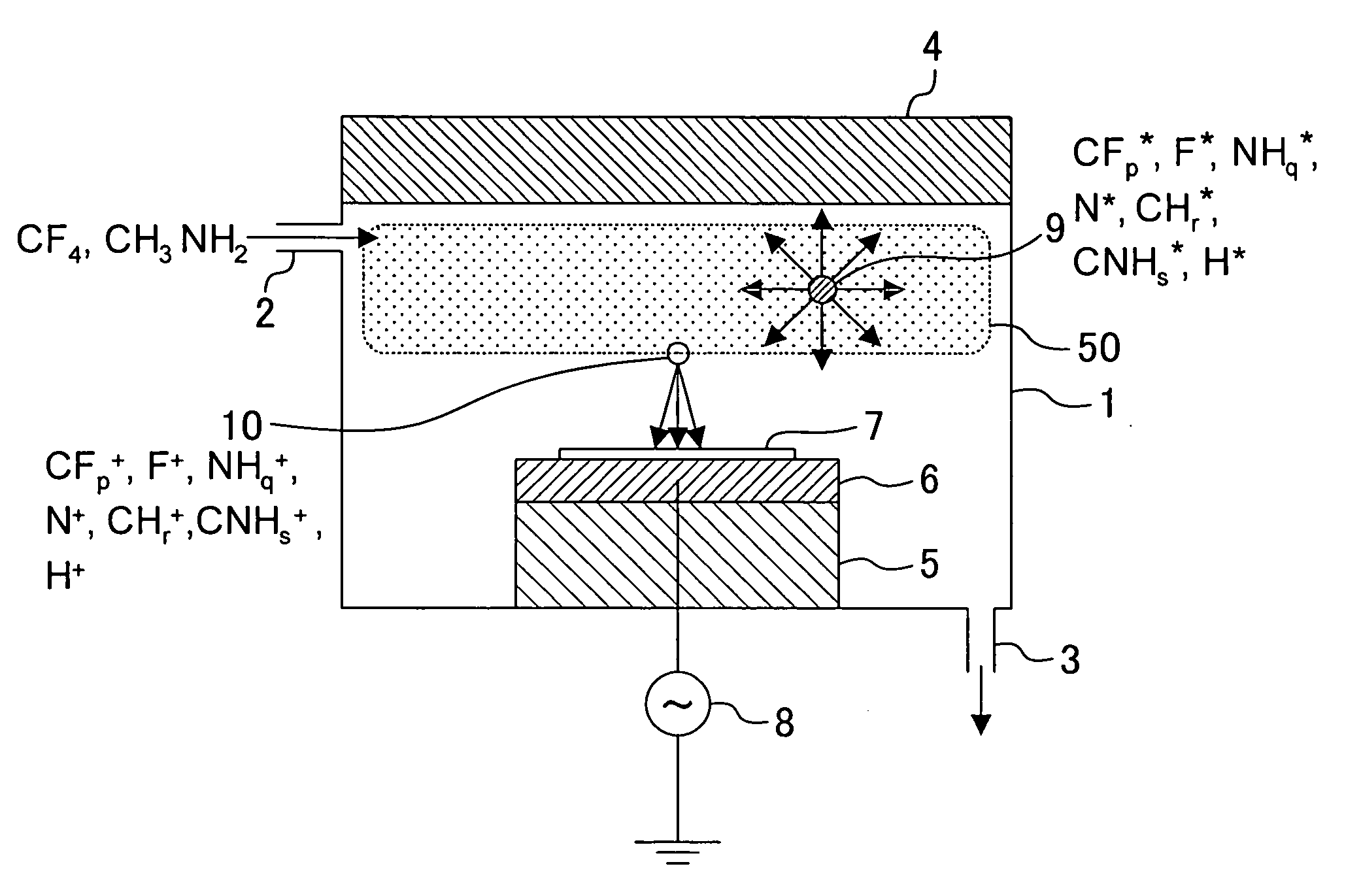

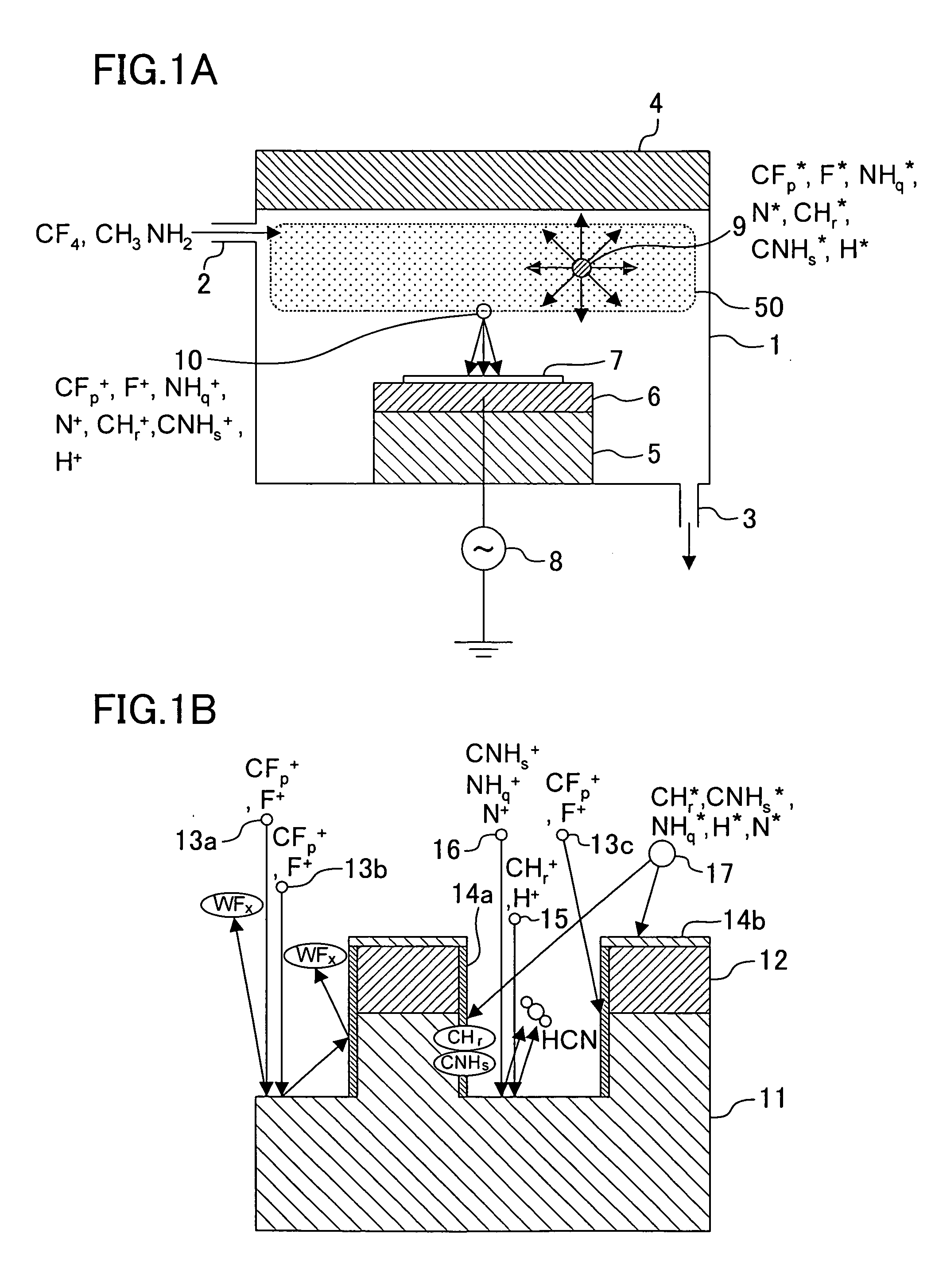

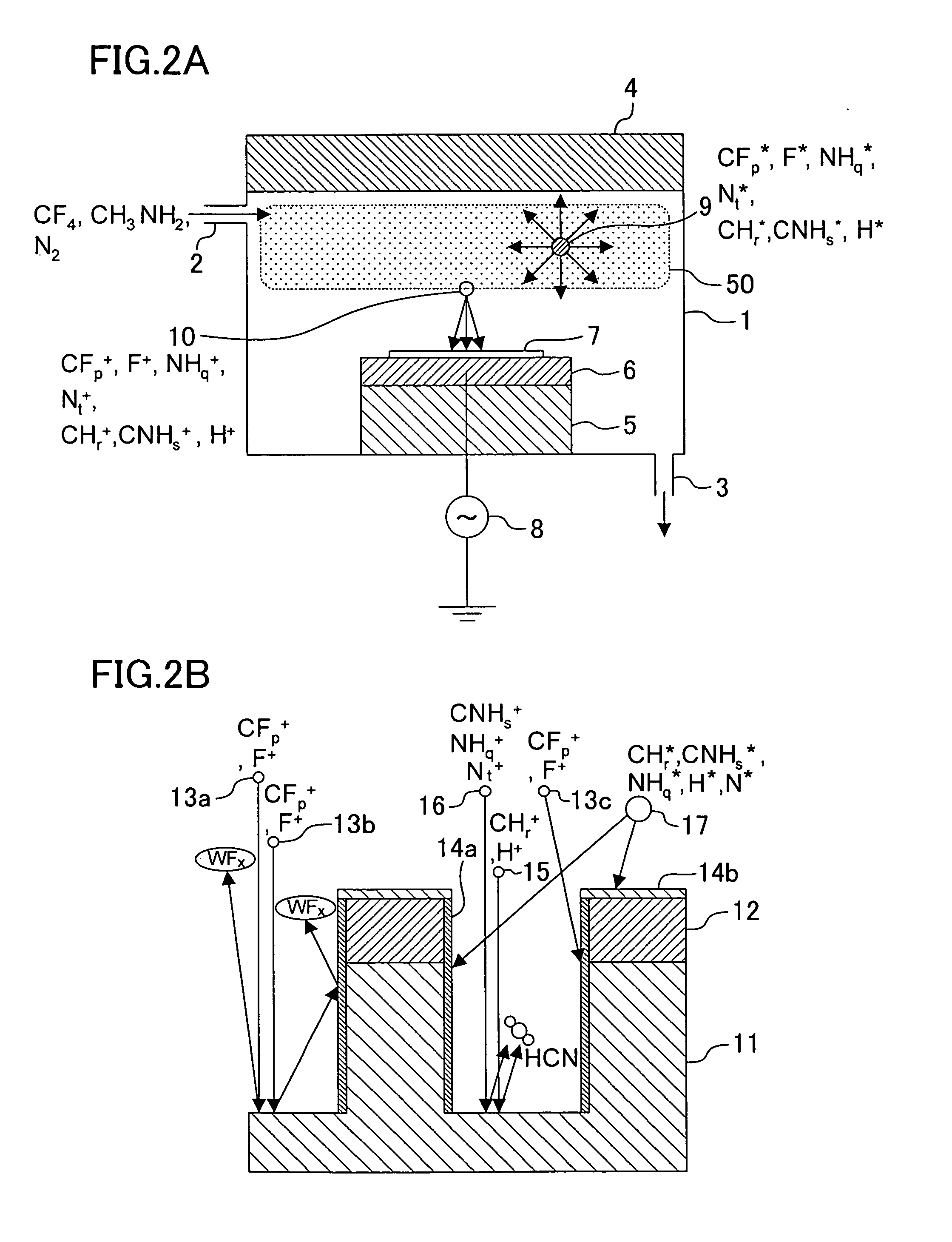

Dry etching method, fine structure formation method, mold and mold fabrication method

InactiveUS20070187359A1Efficient removalImprove etching efficiencyDecorative surface effectsOptical light guidesFine structureHydrogen atom

Owner:PANASONIC CORP

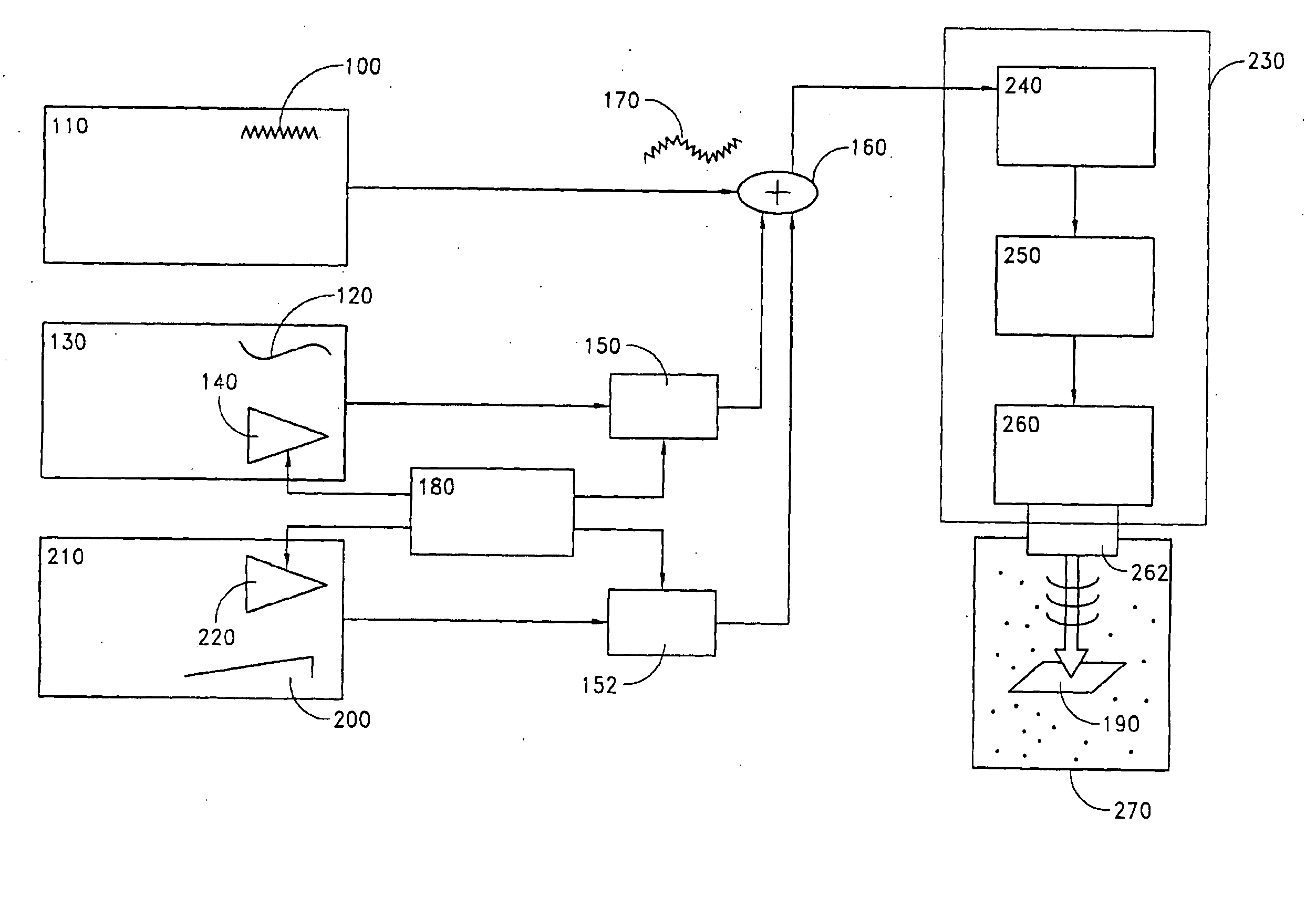

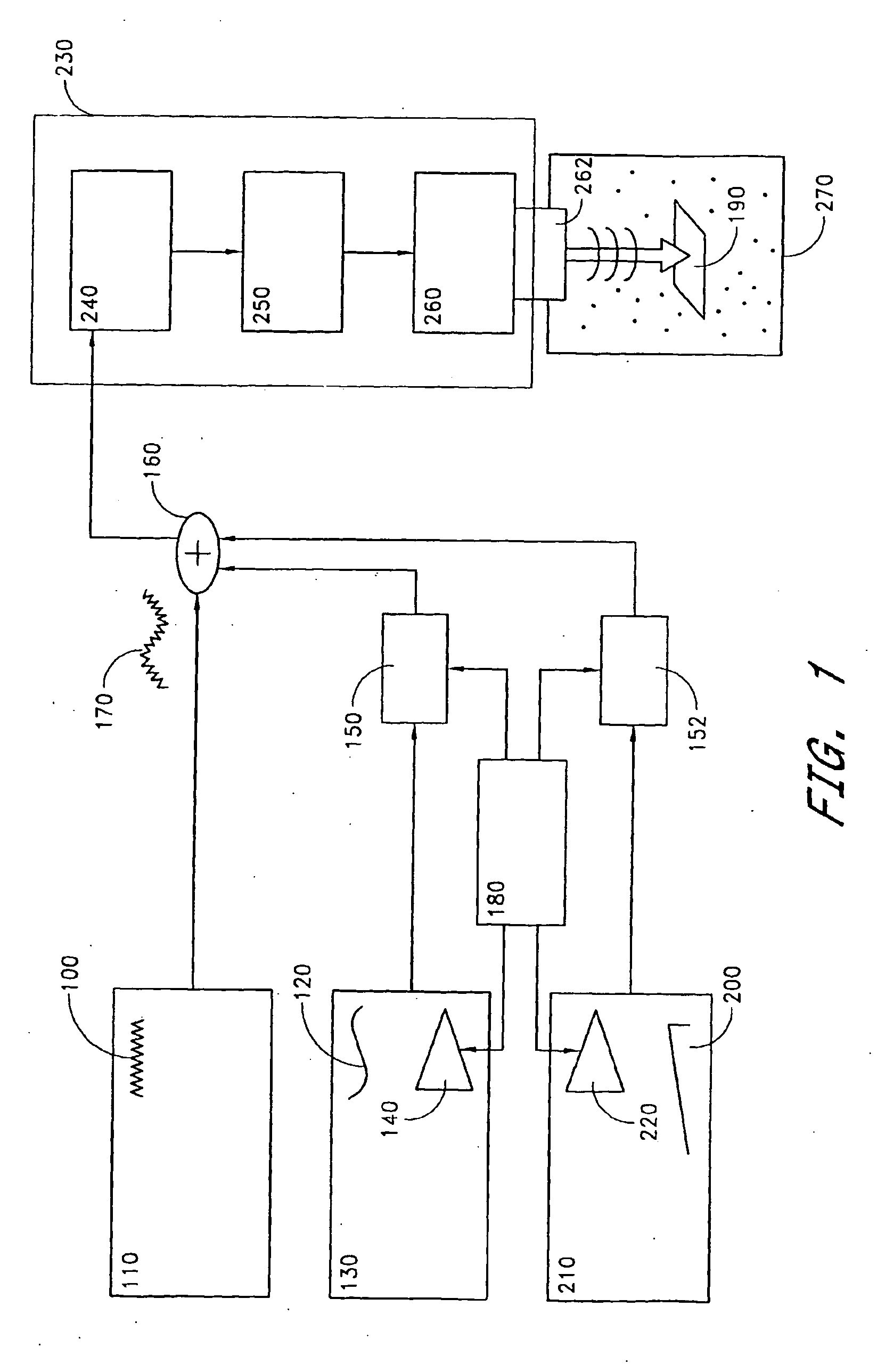

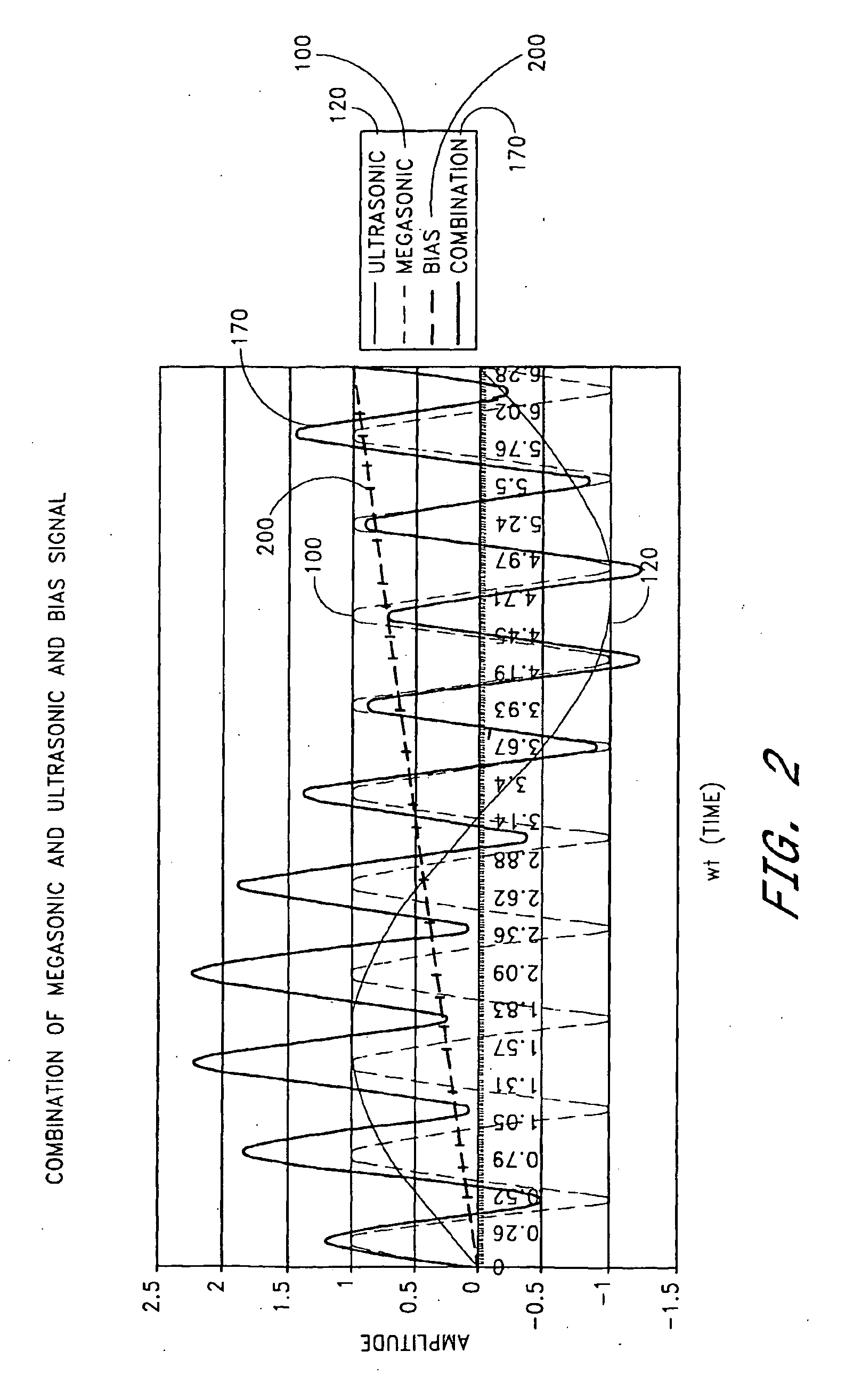

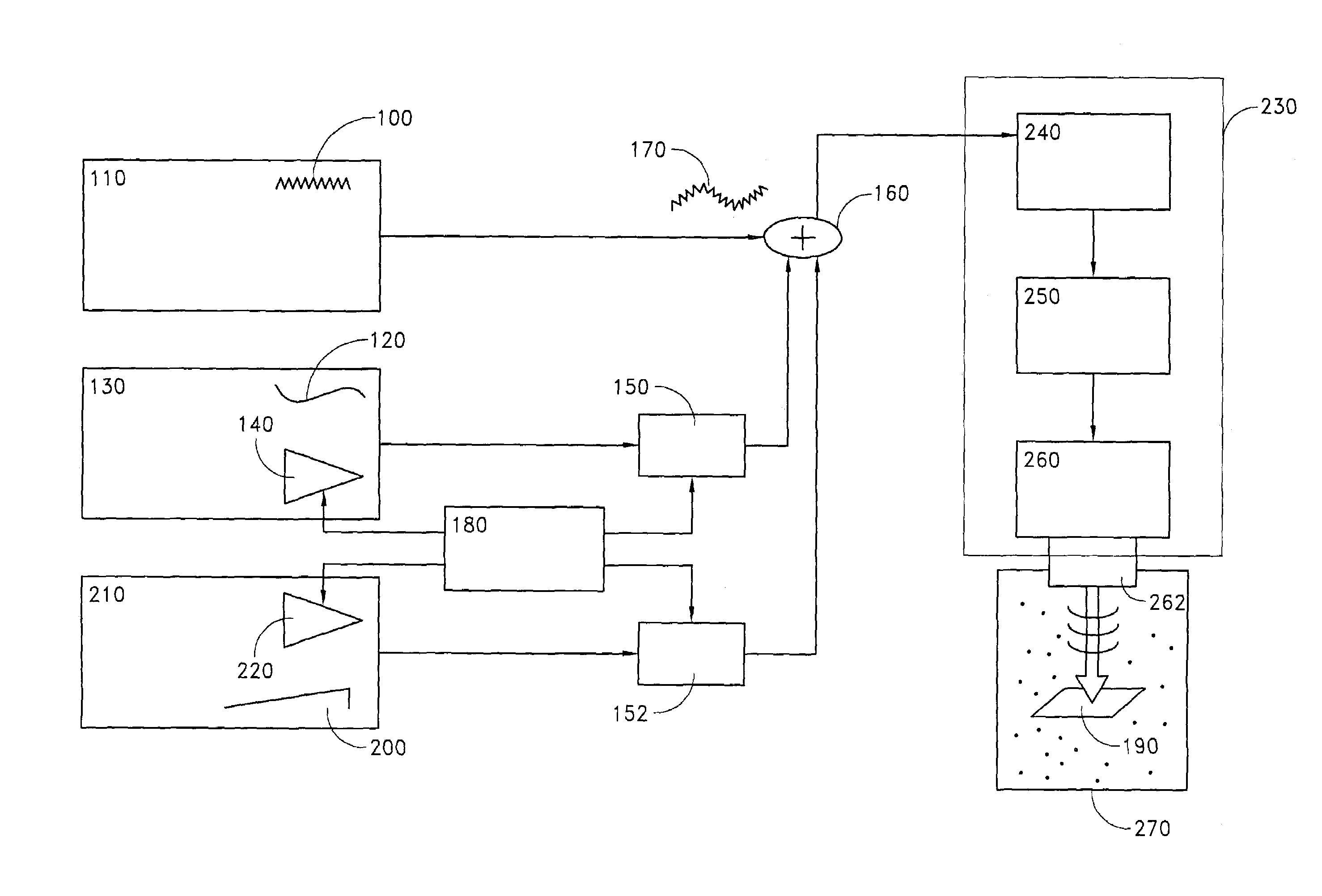

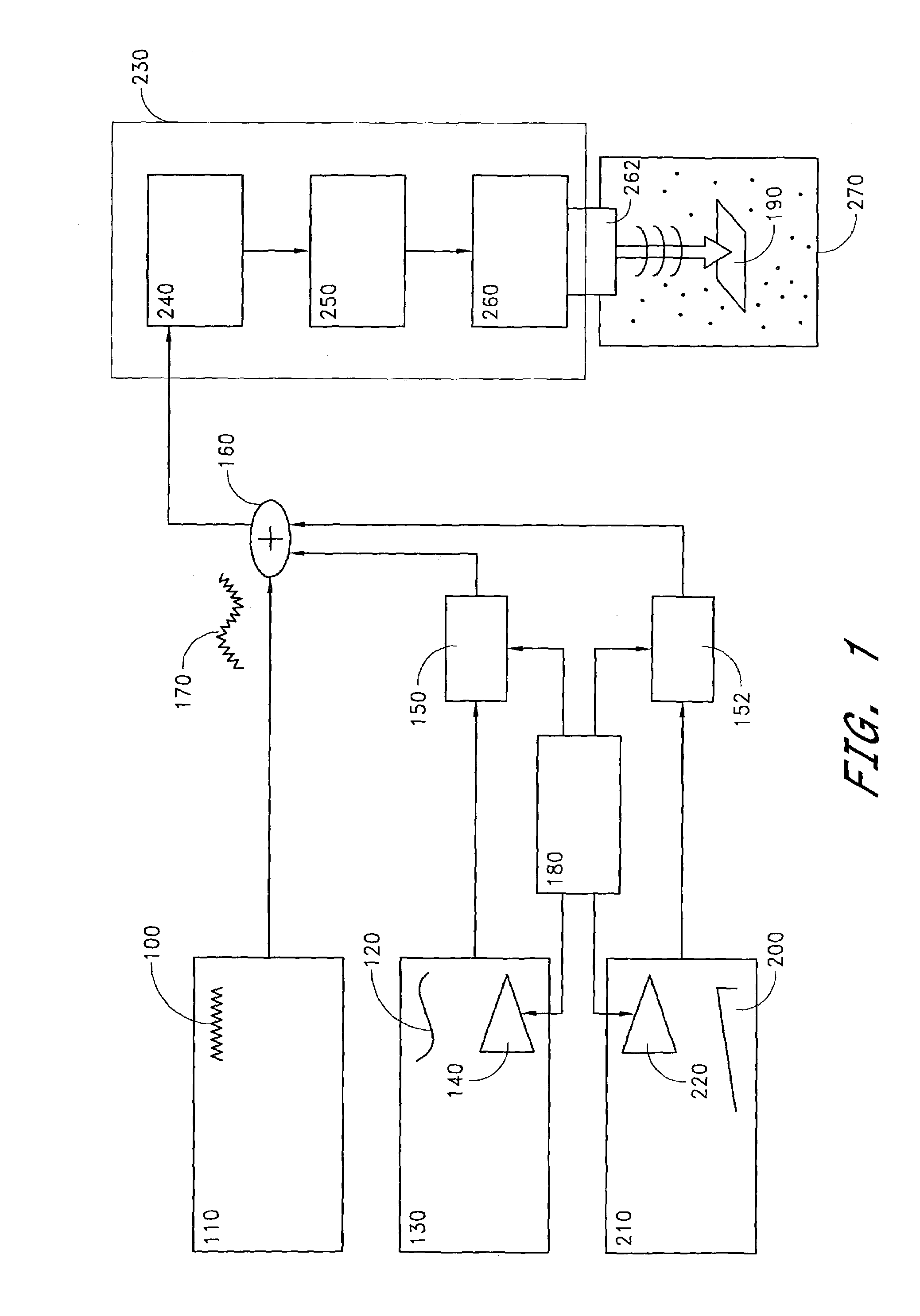

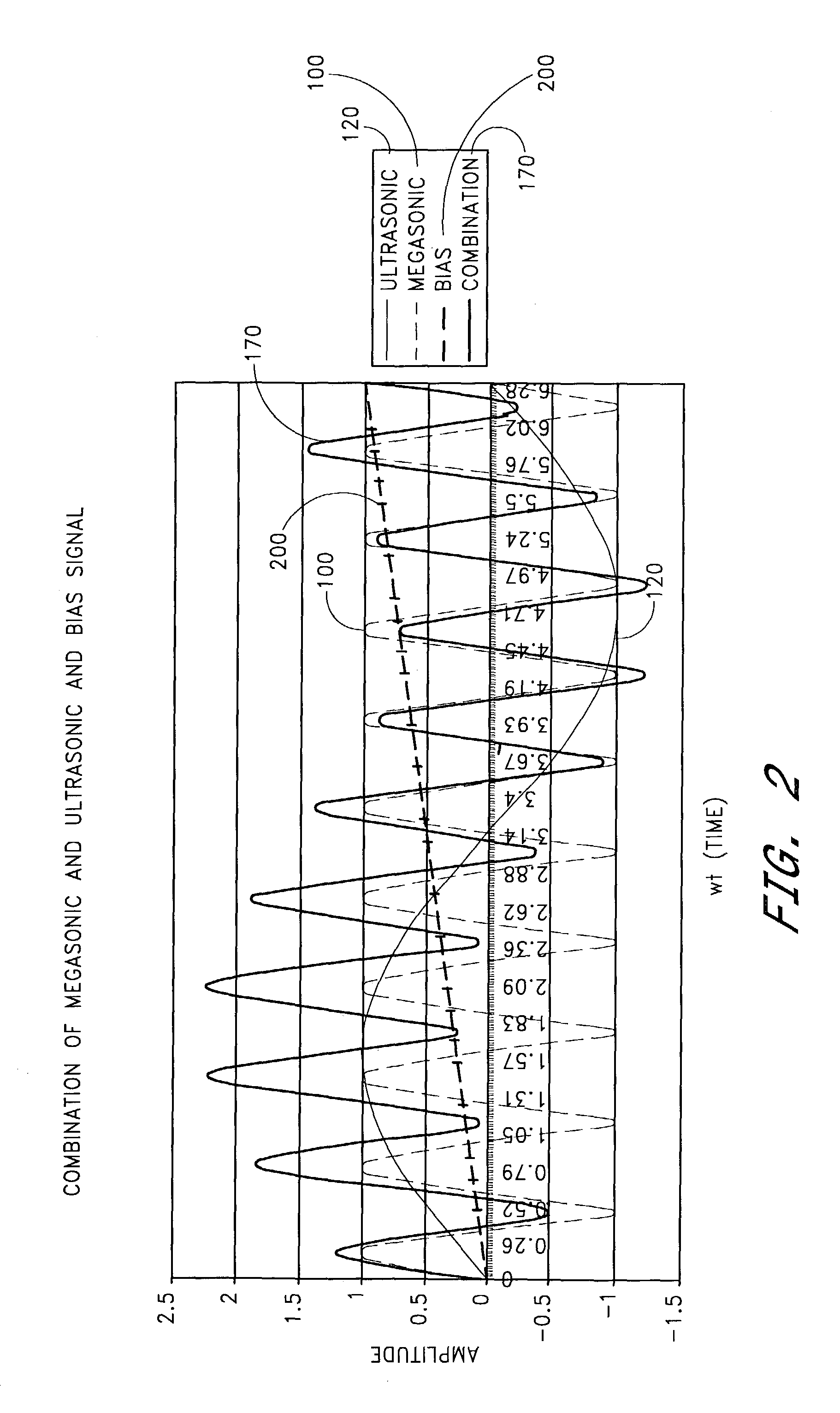

Megasonic cleaning system with buffered cavitation method

InactiveUS20060260641A1Effectively buffering micro bubble growthFast shapingElectrostatic cleaningCleaning using liquidsCavitationMicro bubble

An acoustic energy cleaning system and method which fosters micro-bubble formation for effective cleaning while buffering micro-bubble growth which would otherwise damage the wafer. In one embodiment, the invention includes combining a first frequency signal and a second frequency signal having a positive amplitude bias component so as to form a combined signal. The combined signal, which has a positive amplitude offset, is applied to a transducer system that converts the combined signal into acoustic waves. The acoustic waves can be applied to the object to be cleaned in a cleaning fluid.

Owner:AKRION TECH +1

Modifying agent for building expansion material

The invention relates to an additive used in the construction industry, in particular to an additive for a lightweight member in a cast-in-place hollow building roof, which comprises the following components by weight percentage in modifying agent: 5.4 to 34.6 percent of early strength agent, 3.3 to 39.6 percent of diffusion agent, 5.4 to 28.8 percent of water-reducing agent, 2.7 to 21.6 percent of suspending agent, 3.8 to 27.4 percent of foaming agent, and 1.1 to 25.9 percent of foam stabilizer. The modifying agent adopting the proposal improves strength of a member greatly, and the member is quickly molded; the cement foaming agent in the additive has strong dispersion property and does not generate phenomenon such as caking and flocculation, shrinkage, bleeding and deposition during production of foam concrete; the foam concrete has stable air holes, and can be reacted with cement to generate cement solid foam concrete which has low water absorption rate; and the air holes are separately closed, and do not absorb water or store water. The added early strength agent can accelerate settling time of the cement concrete, can meet the characteristics of the concrete such as large fluidity, delayed coagulation, early strength and no backward shrinkage on later strength, has good durability, improves construction efficiency, and can improve the strength of the concrete by more than 40 percent in two days. By using the materials for the modifying agent added according to a proportion, the additive has the advantages of light weight, heat preservation, thermal insulation, large strength, quick formation and the like, is tighter and firmer to joint with other building materials, and can be completely used in the building roof.

Owner:HUNAN BDF ENERGY SAVING TECH

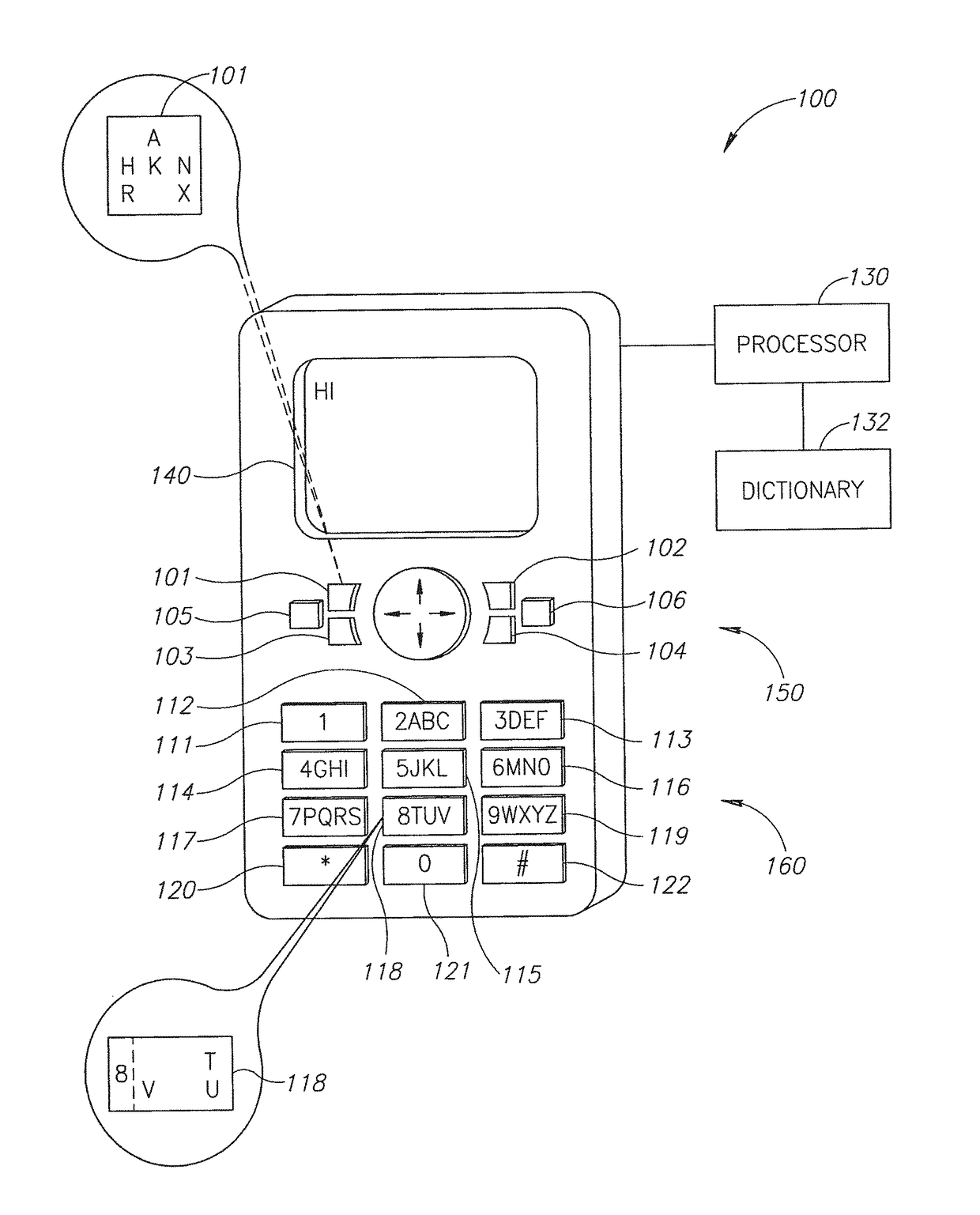

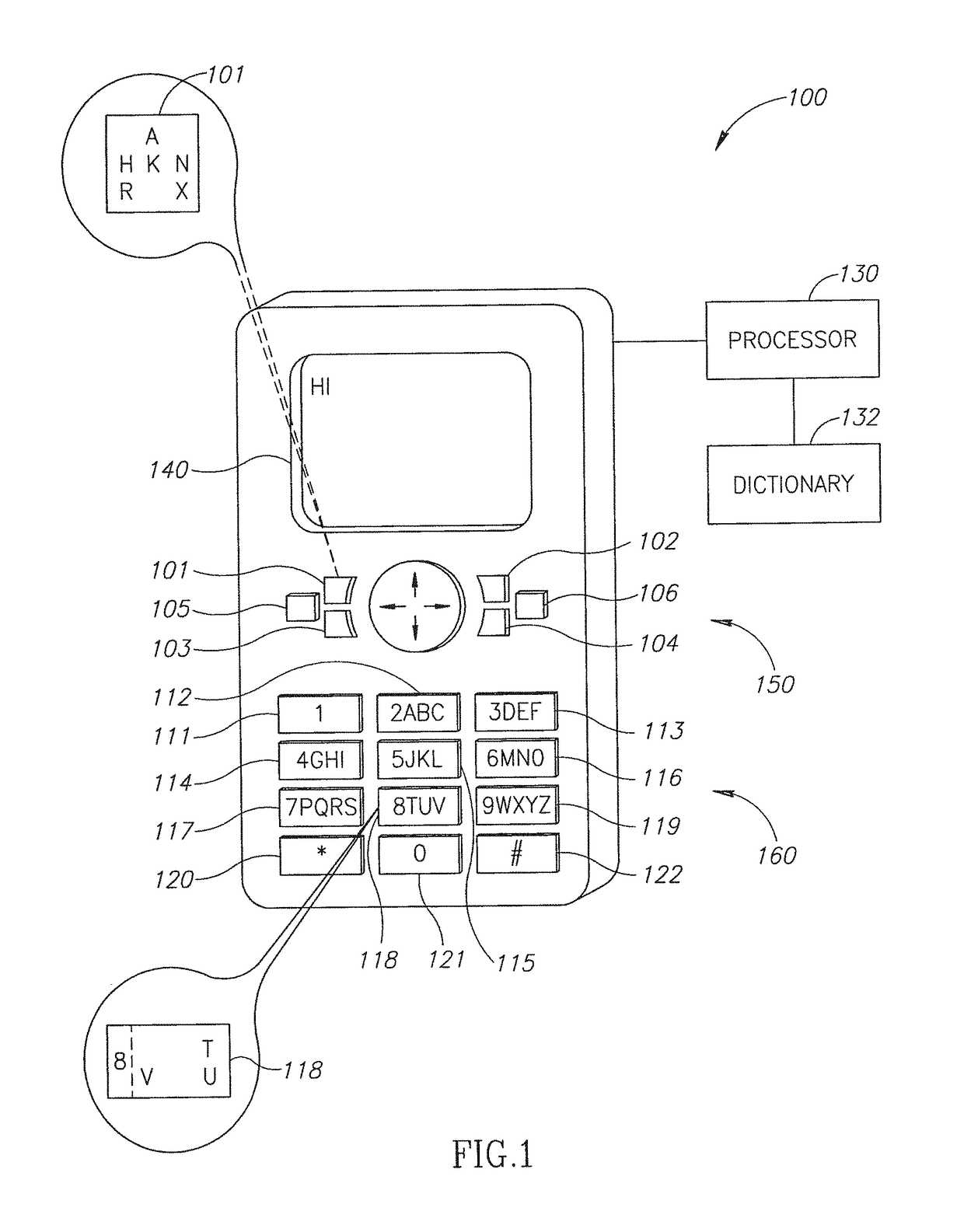

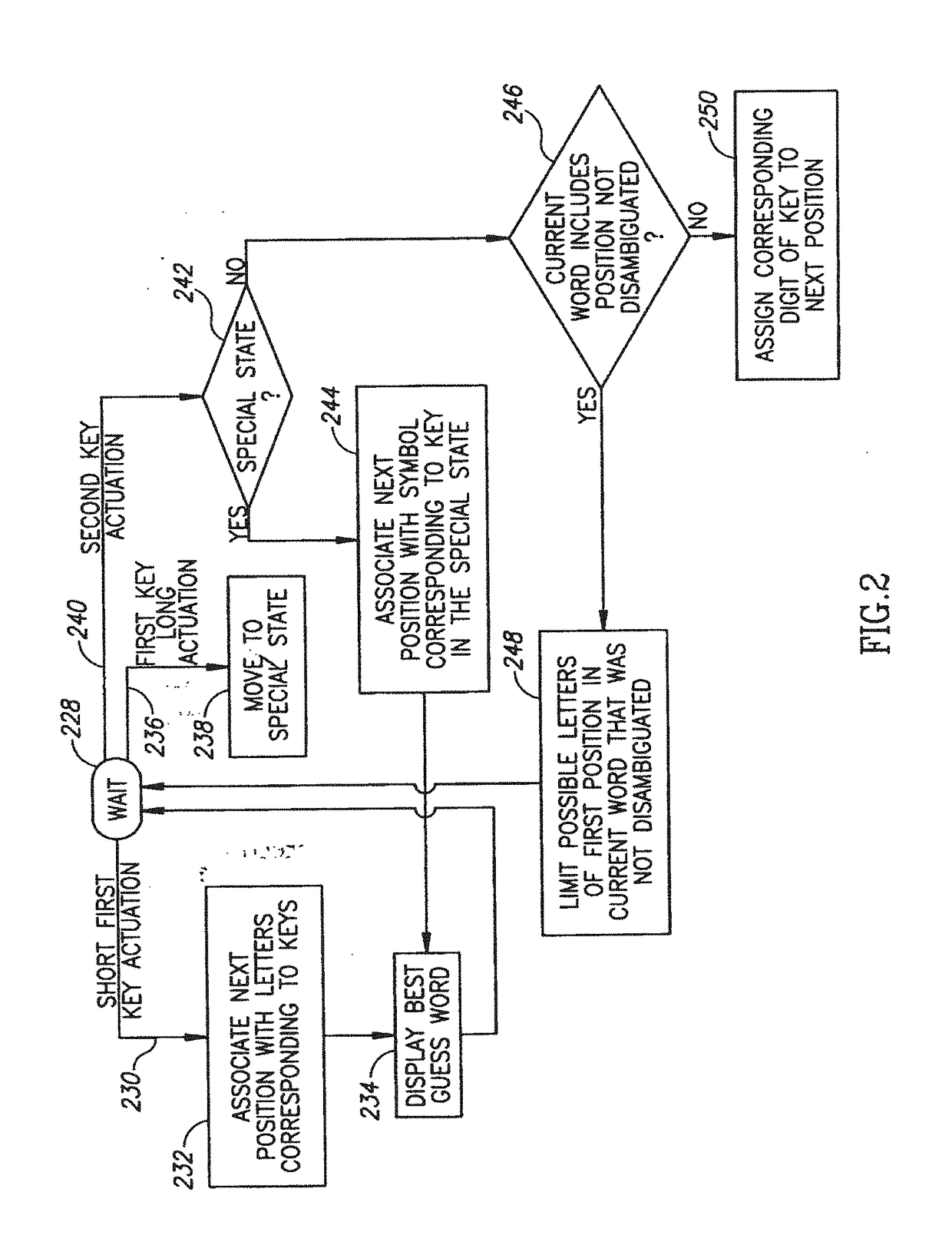

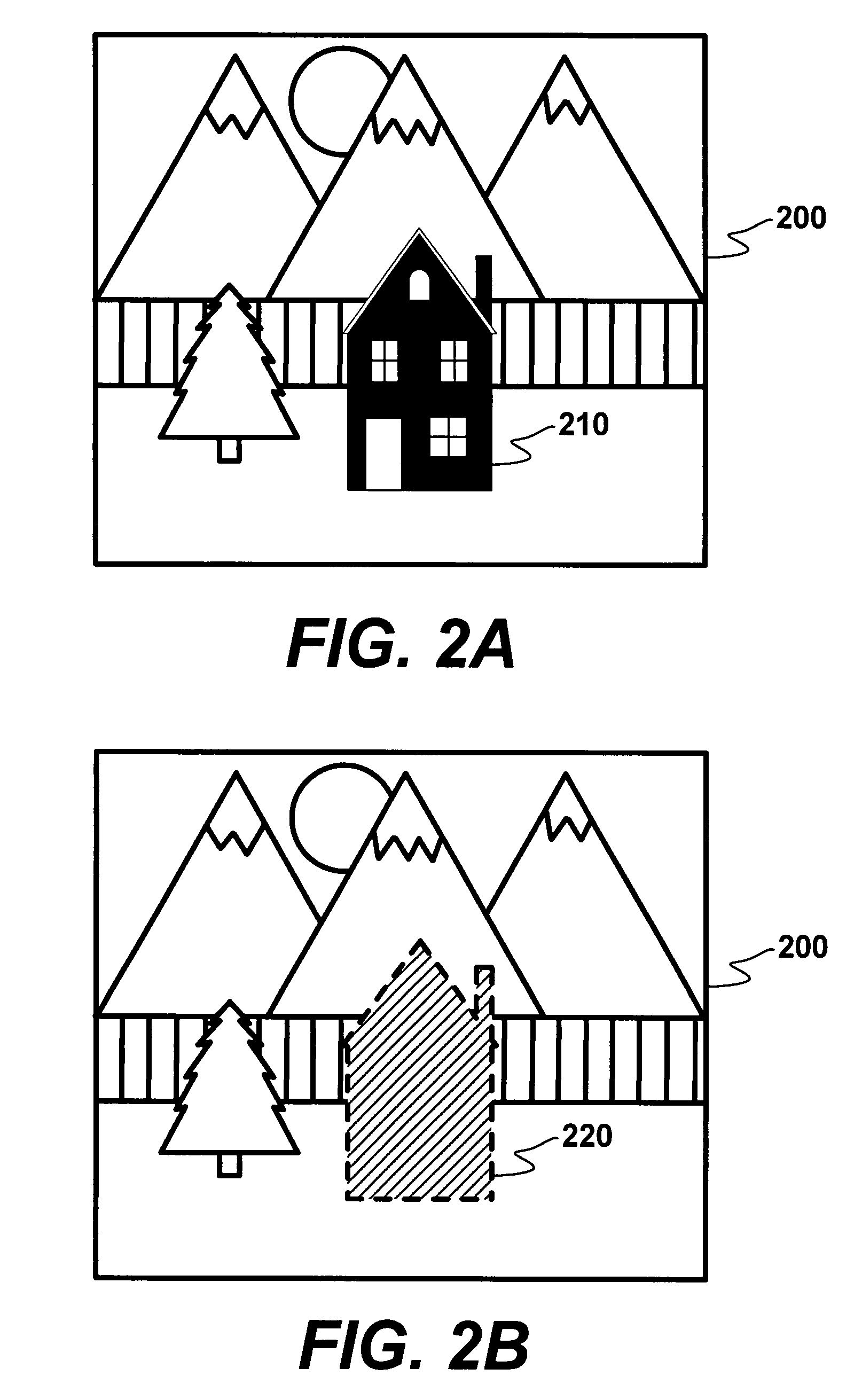

Features ofa data entry system

PendingUS20170228123A1Fast shapingSimple taskDetails for portable computersInput/output processes for data processingHuman–computer interactionData entry

A data entry system, having an input interface adapted to identify a plurality of user interactions. The system includes a processor adapted to associate user interactions identified by the input interface with a plurality of letters of the alphabet, such that all the letters of the alphabet are assigned to at most eight user interactions. Most of the letters are assigned to specific user interactions according to one or more features of their shape in their printed form, such that most of the letters assigned to each user interaction have the same shape feature.

Owner:GHASSABIAN BENJAMIN FIROOZ

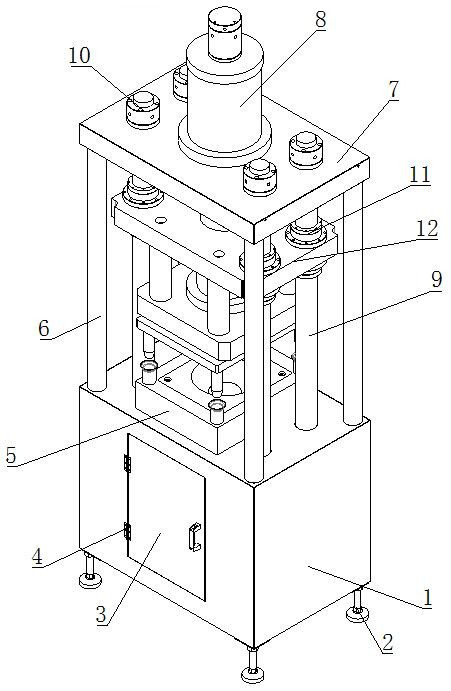

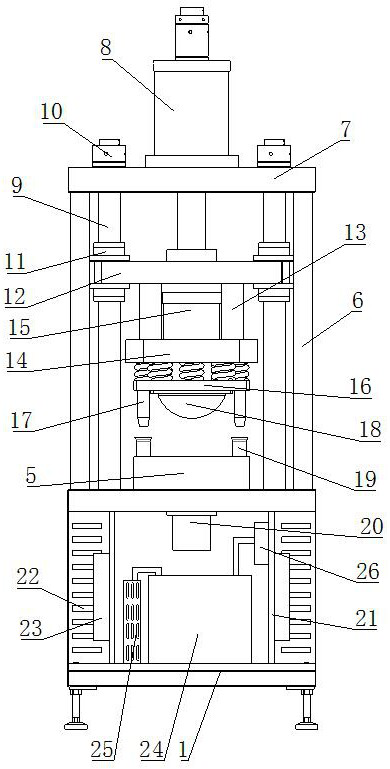

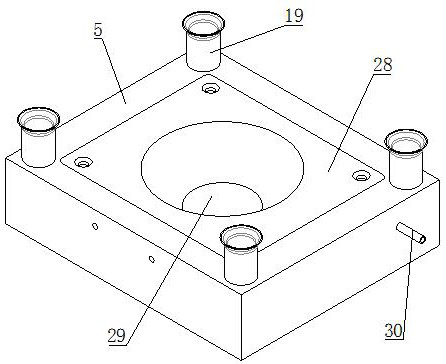

Injection mold and injection molding process thereof

PendingCN111873302AIncrease production typeReduce manufacturing costInjection molding processEngineering

The invention discloses an injection mold and an injection molding process thereof. A lower mold base is fixedly arranged in the center of the upper end of an injection molding bottom cabinet, a mounting groove matched with an injection molding lower mold is formed in the lower mold base, and the injection molding lower mold is detachably mounted on the lower mold base through bolts; and vertically upward supporting columns are fixedly connected to the four corners of the upper end of the injection molding bottom cabinet correspondingly, a top plate is fixedly connected to the upper ends of the supporting columns, and a vertically downward first driving hydraulic cylinder is fixedly installed at the center position of the upper end of the top plate. According to the injection mold, the upper surface and the lower surface of an injection molding part are cooled at the same time, uniform cooling of the upper surface and the lower surface of the injection molding part is guaranteed, the forming quality of the injection molding part is guaranteed while rapid cooling and shaping of the injection molding part are improved, the injection molding part obtained after injection molding is completed is ejected out of a female mold on the injection molding lower mold through a demolding ejection plate, rapid demolding of the injection molding part is achieved, and the injection molding part machining efficiency is improved.

Owner:金华观瑞科技有限公司

Apparatus and methods for image restoration

InactiveUS8073277B2Fast shapingTelevision system detailsImage enhancementImage restorationComputer vision

Owner:SOUTHERN MISSISSIPPI THE UNIV OF

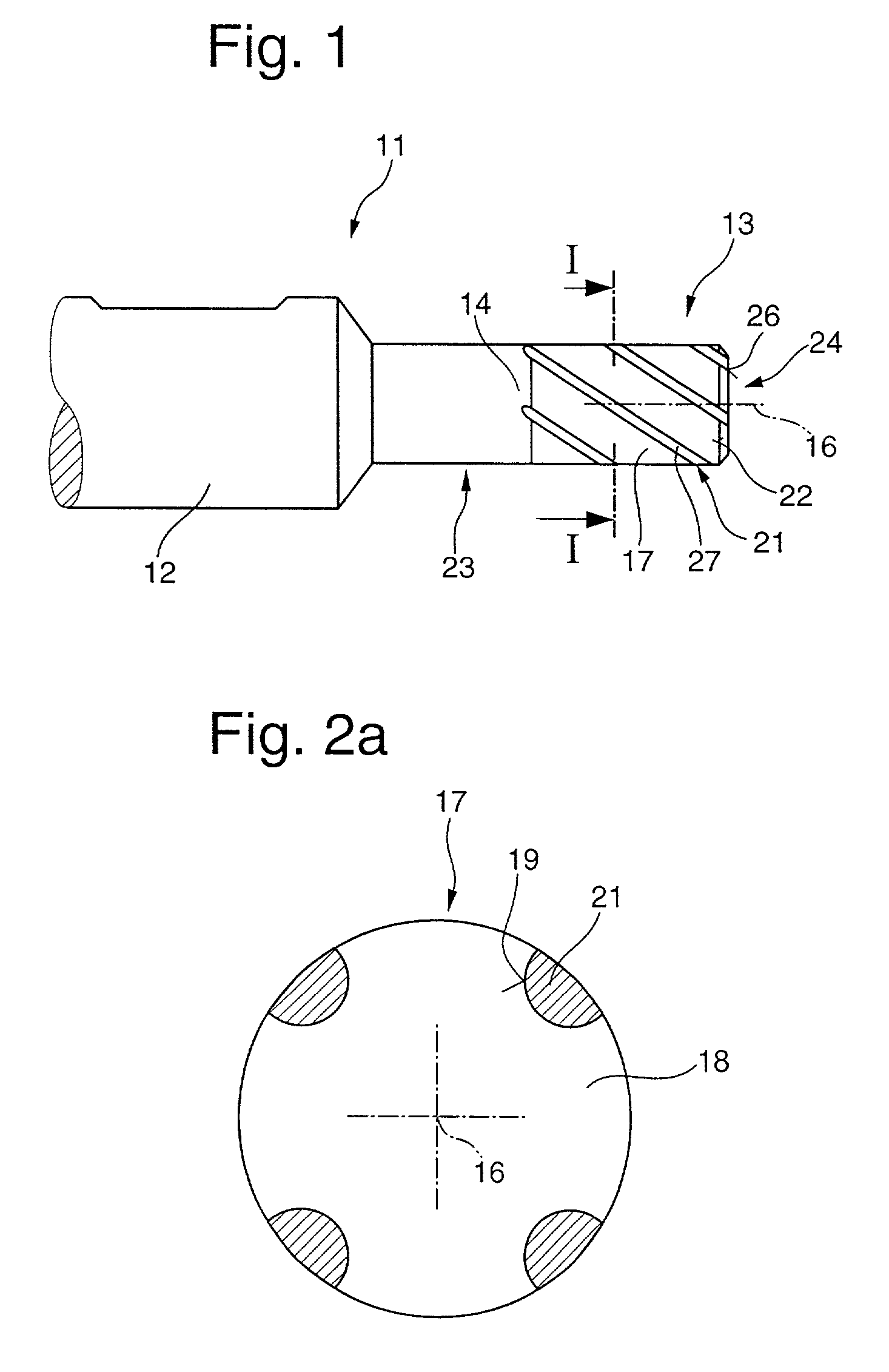

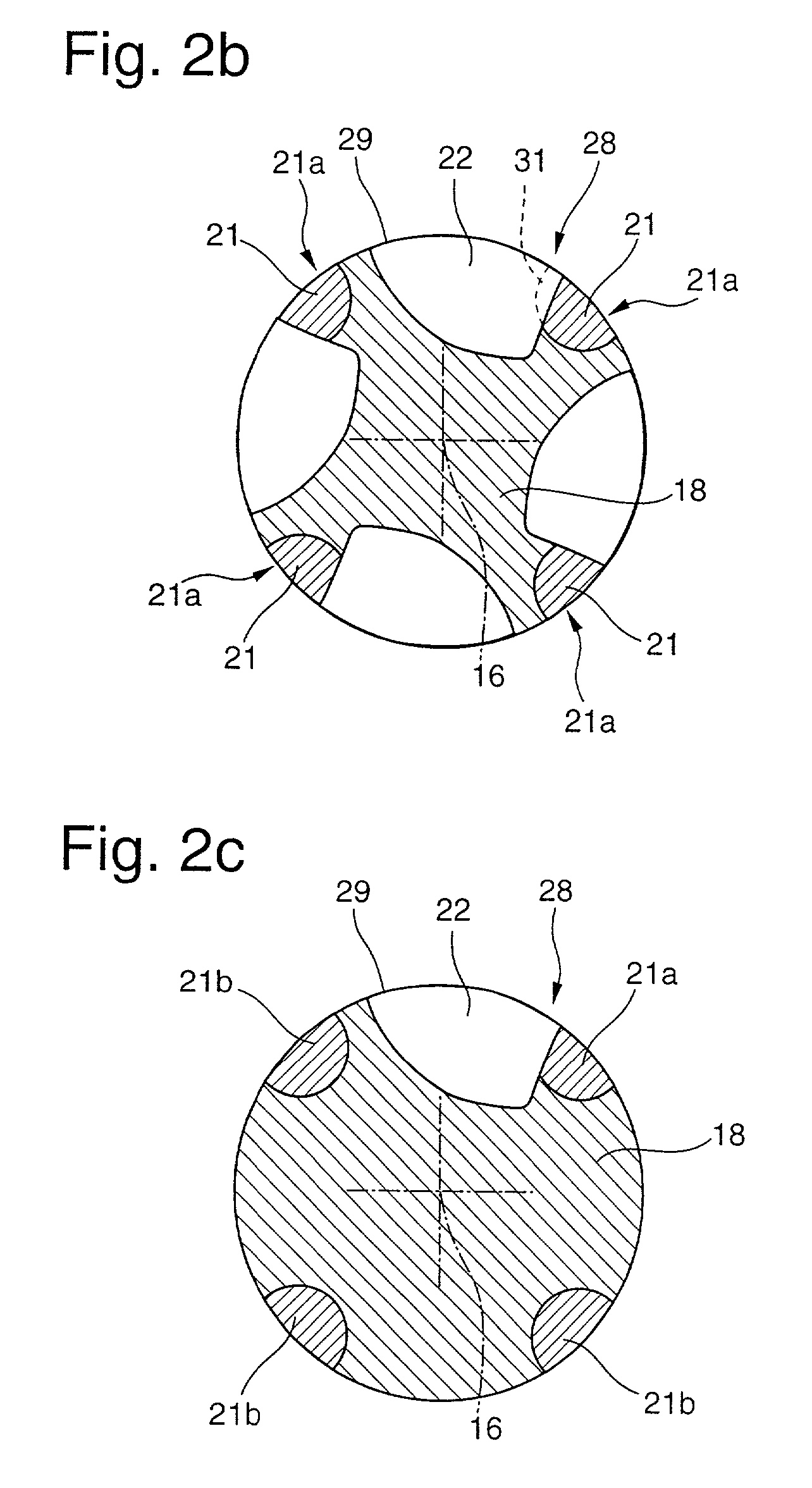

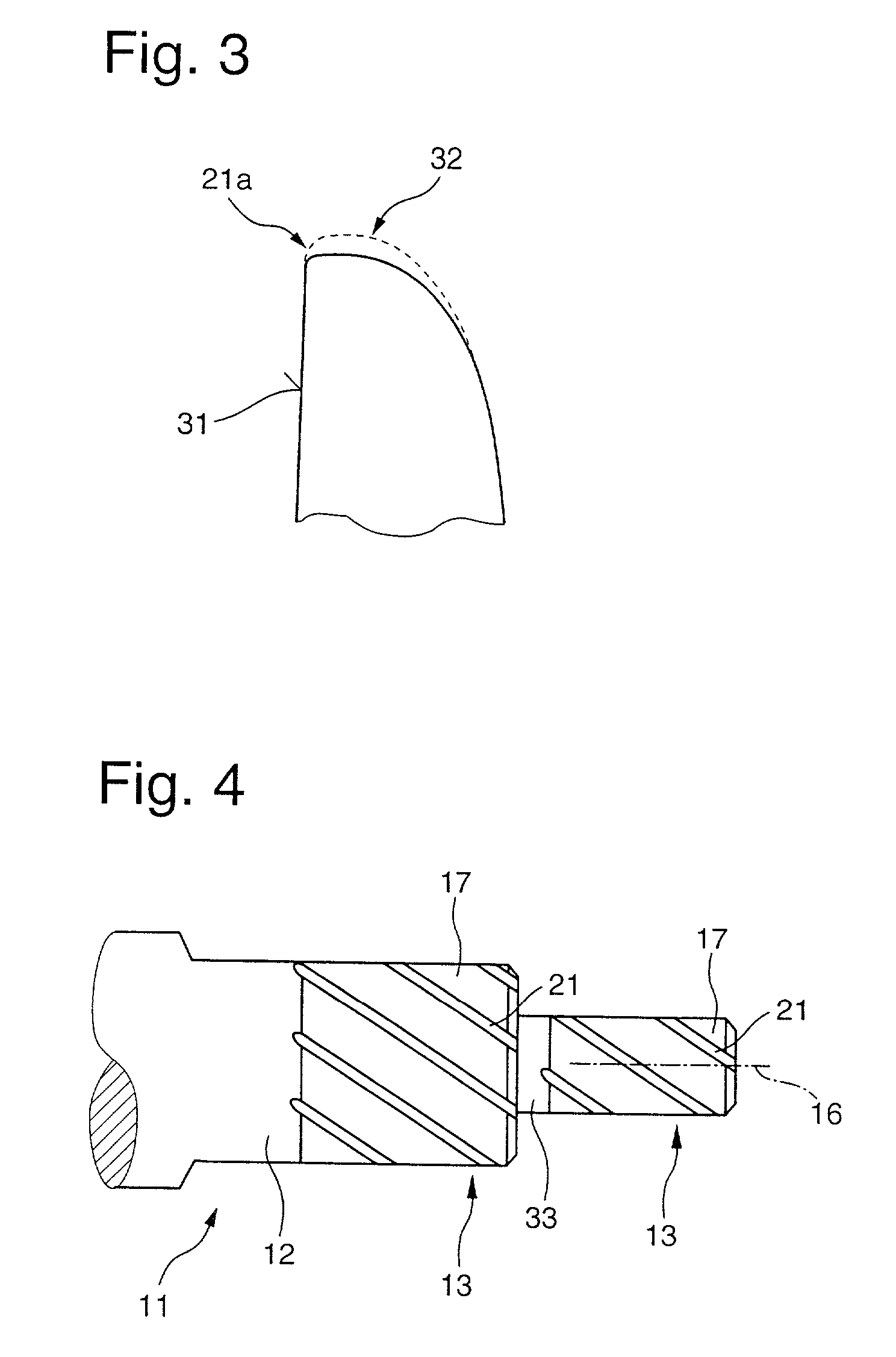

Reaming tool and process for its production

InactiveUS20010024602A1Cost-favorable manufactureCost-favorable productionWood turning toolsTransportation and packagingEngineeringHardness

A multi or single cutter reaming tool has a shaft and a shaped head with at least one cutter. The shaped head is produced from a blank having a base body of a base material on its envelope surface with at least one rectilinear or helical groove-shaped recess running around it, into which high hardness cutting material is sintered. The high hardness cutting material includes at least one cutter having cutting surfaces formed by the introduction of a chip groove by a grinding wheel into the base body and movement of the grinding wheel toward the high hardness cutting material.

Owner:BECK GMBH & CO AUGUST

Megasonic cleaning system with buffered cavitation method

ActiveUS7104268B2Fast sizingLess likelihoodPiezoelectric/electrostriction/magnetostriction machinesElectrostatic cleaningMicro bubbleEngineering

A wafer cleaning method and system including a combined high frequency signal, a low frequency signal, and in one embodiment a biased voltage signal, allows cleaning particles and impurities off of fine-structured wafers, through application of an acoustic field to the wafer through a cleaning liquid which fosters micro-bubble formation for effective cleaning while buffering micro-bubble growth which would otherwise damage the wafer.

Owner:NAURA AKRION INC

Method for shaping scaling ladder type plastic-dipped metal rack tree

ActiveCN103009907AEasy to operateEasy to shapeSpecial ornamental structuresRetention periodEngineering

The invention discloses a method for shaping a scaling ladder type plastic-dipped metal rack tree. The method mainly comprises the following steps of: (1) designing special parameters of a tree shape, destructing a certain quantity of single plants according to corresponding parameters, and manufacturing a tree cultivation shape technical pattern of the corresponding single plants; (2) manufacturing and mounting a scaling ladder type plastic-dipped metal rack and a supporting frame, so as to manufacture a tree cultivation template; (3) planting shaped nursery stocks in a nursery cultivation field below the scaling ladder type plastic-dipped metal rack; (4) when a tree grows to an oriented tree cultivation height, binding tree twigs on the tree cultivation template in an oriented manner; and (5) carrying out shaped nursery stock management, mainly including bud fixing, bud picking, binding and unbundling, and thickening cultivation. The method provided by the invention has the advantages of simpleness in operation, good shaping effect and long shaping retention period; the ornamental value is improved, and the watch time is prolonged; the scaling ladder type plastic-dipped metal rack and the supporting frame are durable, and can be continuously shaped for many years, so that the requirement of a shaping length can be met; the polarized shaping can be realized; the trees are prevented from being damaged; and the standard scale production can be realized by accurately shaping according to the pattern.

Owner:TONGREN MANTANGHONG AGRI TECH

Natural mung bean and pea vermicelli

ActiveCN104106762AImprove elasticityLow sliver breakage rateFood freezingLactobacillusLactobacillus plantarumFood additive

The invention discloses a mung bean and pea vermicelli. The mung bean and pea vermicelli is prepared by using mung bean starch and pea starch as raw materials through a preparation method. The preparation method comprises the following steps: adding drinking water accounting for 15-35% of the sum of the dry weights of the mung bean starch and the pea starch to the mung bean starch and the pea starch, and mixing to obtain a slurry; adding a Lactobacillus plantarum liquid accounting for 0.1-6.0% of the weight of the starch slurry to the starch slurry, and fermenting; adding the mung bean starch and the pea starch to the fermented starch slurry, and mixing with 75-80DEG C drinking water to make a dough; stirring the dough under vacuum conditions to remove air in the dough, putting the dough in a vermicelli falling device to make vermicelli, and slaking and shaping the vermicelli in 90-95DEG C water; and cooling and ageing the completely slaked vermicelli, and drying to obtain the required vermicelli. The vermicelli has the advantages of no food additives, good elasticity and toughness, low broken rate and high production efficiency.

Owner:SICHUAN BAZHONG FEIXIA IND CO LTD

Polyolefin alloy material and preparation method thereof

The invention discloses a polyolefin alloy material and a preparation method thereof, belongs to the field of polyolefin materials and in particular relates to a polyethylene / highly isotactic polybutene alloy material and a preparation method thereof. According to the polyethylene / highly isotactic polybutene alloy material disclosed by the invention, the mass content of polybutene is 10-98.9 percent (the isotacticity is more than 85 percent), the mass content of polyethylene is 1-80 percent, and the mass content of a butane-ethylene copolymer is 0.1-10 percent. By utilizing the supported titanium and / or vanadium catalyst, the polyethylene / highly isotactic polybutene alloy material is synthesized by virtue of two-section polymerization, and the obtained polybutene alloy is a powdery or spherical product with a core-shell structure, has the advantages of excellent impact resistance, thermal creep resistance and low shrinkage rate of polybutene-1 and high modulus, high surface hardness and quick setting property of polyethylene, is used for manufacturing pipes and pipe fittings and performing toughening modification on polypropylene, or can serve as a universal polyolefin material and is a novel polyolefin material.

Owner:QINGDAO UNIV OF SCI & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com