Method for producing steel mesh reinforced plastic composite pipes and its self-contained equipment

A technology of reinforced plastics and production methods, which is applied in the direction of tubular objects, other household appliances, household appliances, etc., and can solve the problems of complex steel wire reinforced plastic-steel composite pipe process, reduction of steel wire tensile strength, large amount of steel and plastic materials, etc., Achieve the effect of satisfying the hot melt bonding process, reducing raw material consumption, and promoting cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

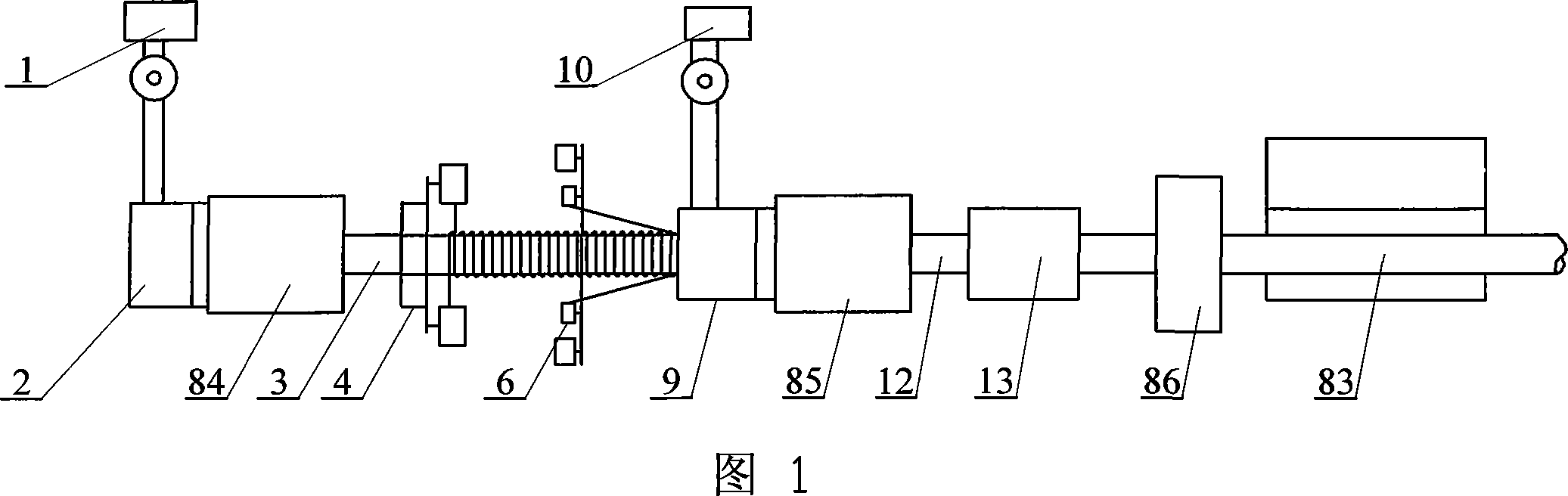

[0007] Specific embodiment one: illustrate this embodiment in conjunction with Fig. 1, the production method of the manufacture steel mesh reinforced plastic composite pipe of this embodiment is completed by the following steps; After the inner plastic tube forming machine 2 is formed, the inner layer plastic tube blank 3 is cooled and shaped by the first vacuum cooling water tank 84; b, the outer wall of the inner layer plastic tube blank 3 is firstly wound horizontally by the first horizontal winding machine 4 steel, and then through the first longitudinal winding machine 6, the steel wires are longitudinally arranged to form the first layer of steel mesh, and the first layer of steel mesh and the inner plastic pipe blank 3 are sent into the first plastic pipe forming machine 9, and the first layer of steel mesh is used to form the first layer of steel mesh. The waste heat of the plastic pipe forming machine 9 heats the outer surface of the inner plastic pipe blank 3 to melt,...

specific Embodiment approach 2

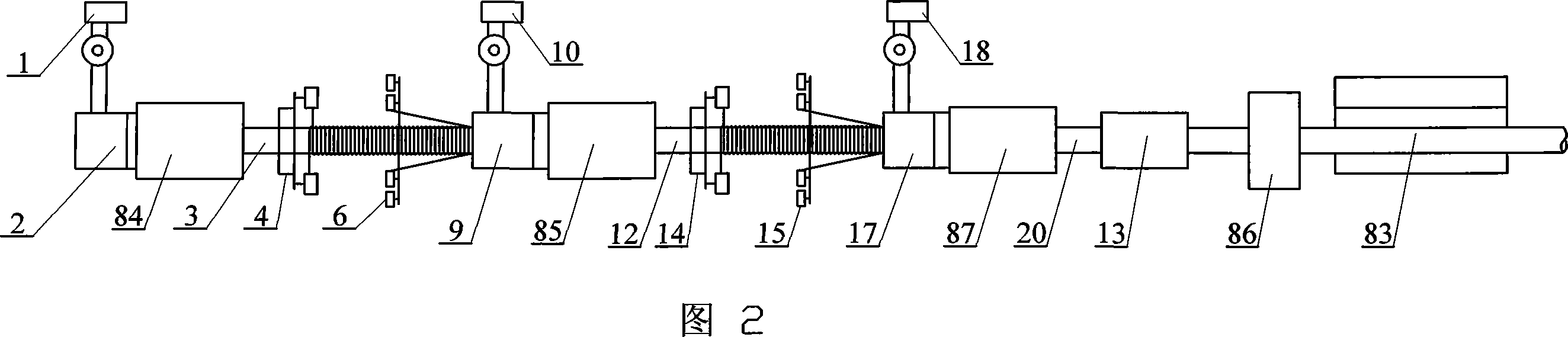

[0008] Specific embodiment two: this embodiment is described in conjunction with Fig. 2, the difference between this embodiment and specific embodiment one is: this embodiment also adds b1 step between b and c steps, and described b1 step is: On the outer wall of the plastic composite tube blank 12 with a steel mesh structure, the steel material is continuously and horizontally wound by the second horizontal winding machine 14, and then the steel wires are longitudinally arranged by the second longitudinal winding machine 15 to form a second layer of steel mesh, with a layer of steel mesh. The plastic composite tube blank 12 with the net structure enters the second plastic tube forming machine 17 with the second layer of steel mesh, and the plastic composite tube blank 12 with one layer of steel mesh structure is heated by the waste heat of the second plastic tube forming machine 17. The outer surface is heated to melt, and the melting temperature is 120°C to 180°C. At the same...

specific Embodiment approach 3

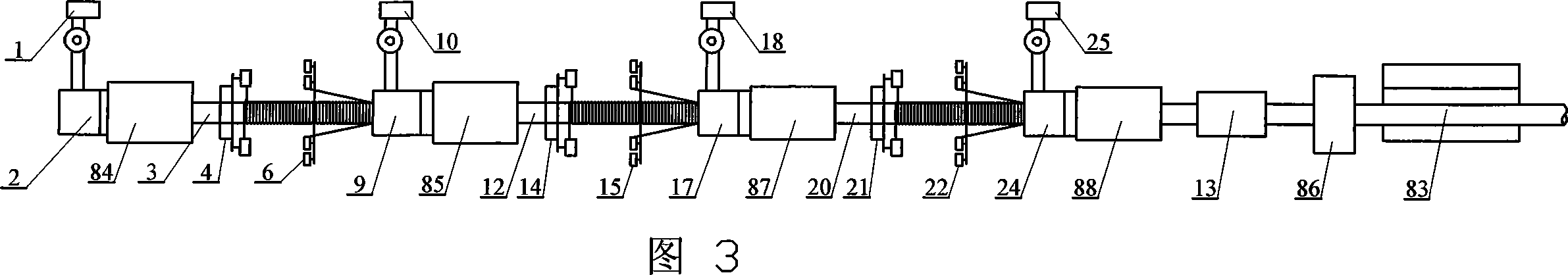

[0009] Specific embodiment three: This embodiment is described in conjunction with FIG. 3 . The difference between this embodiment and specific embodiment one is: this embodiment also adds a b2 step between b1 and c steps, and the b2 step is: On the outer wall of the plastic composite tube blank 20 of the two-layer steel mesh structure, the steel material is continuously and horizontally wound by the third horizontal winding machine 21, and then the steel wires are longitudinally arranged by the third vertical winding machine 22 to form a third layer of steel mesh, with two The plastic composite pipe blank 20 of layer steel mesh structure enters in the third plastic pipe forming machine 24 with the third layer of steel mesh, and utilizes the waste heat of the third plastic pipe forming machine 24 to heat the plastic composite pipe with two layers of steel mesh structure. The outer surface of the billet 20 is heated to melt, and the melting temperature is 120°C to 180°C. At the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com