High-temperature resistant secondary cross-linked gel profile control agent and preparation method thereof

A secondary cross-linking and high-temperature-resistant technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of reduced efficiency and oil increase, the need for moving string operations, and limited foam strength, etc. Achieve the effects of reducing filtration loss, little change in strength and stability, and controlling steam absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

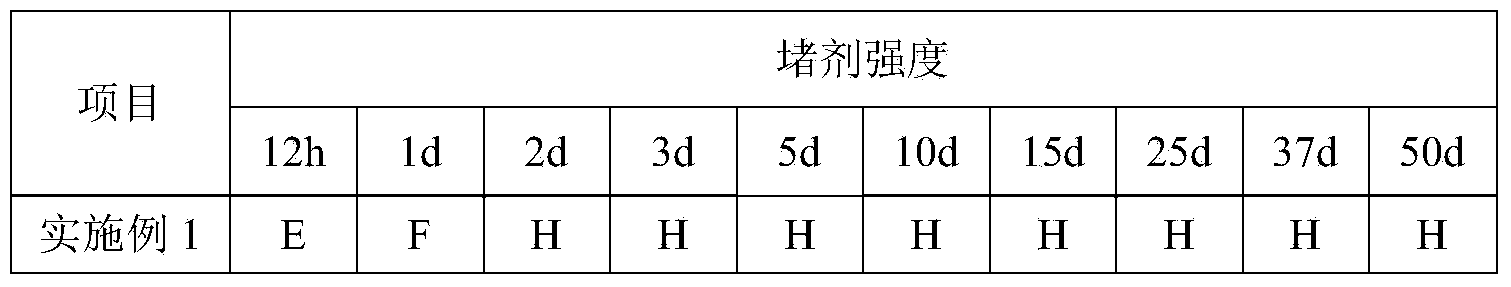

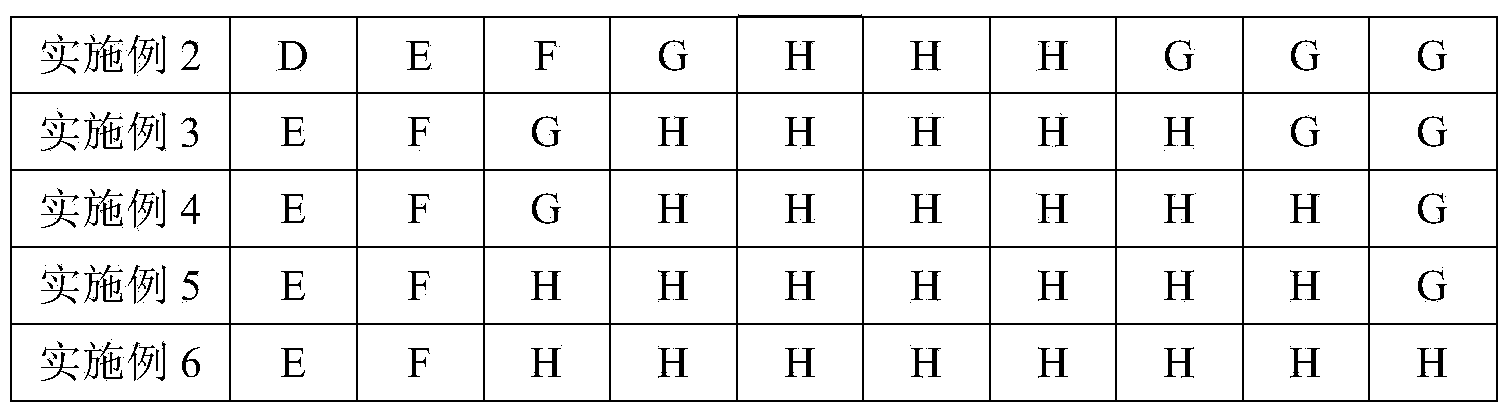

Examples

Embodiment 1

[0020] In this example, the high-temperature-resistant secondary cross-linked gel profile control agent consists of the following components: 12 kg of partially hydrolyzed polyacrylamide (molecular weight 25 million, degree of hydrolysis 25%), 0.1 kg of chromium acetate (effective solid content > 95%) ), 26kg phenol and hexamethylenetetramine synthetic liquid (the mass ratio of phenol and hexamethylenetetramine in the synthetic liquid is 1:5, relative density 1.04, effective solid content> 90%), 0.3kg resorcinol Phenol (effective solid content > 95%), 10kg of sodium soil (effective solid content > 90%) and 1 cubic meter of water.

[0021] The preparation method of the high-temperature-resistant secondary cross-linked gel profile control agent in this example includes the following steps: adding partially hydrolyzed polyacrylamide into water at a temperature of 55°C and fully dissolving it; then adding chromium acetate, phenol and hexamethylene Synthetic solution of base tetram...

Embodiment 2

[0023] In this embodiment, the high temperature resistant secondary cross-linked gel profile control agent is composed of the following components: 8kg partially hydrolyzed polyacrylamide (molecular weight 25 million, degree of hydrolysis 23%), 0.05kg chromium acetate (effective solid content > 95%) ), 26kg phenol and hexamethylenetetramine synthesis liquid (the mass ratio of phenol and hexamethylenetetramine in the synthesis liquid is 1:5, relative density 1.04, effective solid content > 90%), 0.2kg resorcinol Phenol (effective solid content > 95%), 8 kg of sodium soil (effective solid content > 90%) and 1 cubic meter of water.

[0024] The preparation method of the high-temperature-resistant secondary cross-linked gel profile control agent in this example includes the following steps: adding partially hydrolyzed polyacrylamide into water at a temperature of 50°C and fully dissolving it; then adding chromium acetate, phenol and hexamethylene Synthetic solution of base tetrami...

Embodiment 3

[0026] In this example, the high temperature resistant secondary cross-linked gel profile control agent consists of the following components: 9kg partially hydrolyzed polyacrylamide (molecular weight 25 million, degree of hydrolysis 23%), 0.07kg chromium acetate (effective solid content > 95%) ), 27kg phenol and hexamethylenetetramine synthetic liquid (the mass ratio of phenol and hexamethylenetetramine in the synthetic liquid is 1:5, relative density 1.04, effective solid content > 90%), 0.24kg resorcinol Phenol (effective solid content > 95%), 8.5kg sodium soil (effective solid content > 90%) and 1 cubic meter of water.

[0027] The preparation method of the high-temperature-resistant secondary cross-linked gel profile control agent in this example includes the following steps: adding partially hydrolyzed polyacrylamide into water at a temperature of 50°C and fully dissolving it; then adding chromium acetate, phenol and hexamethylene Synthetic solution of base tetramine, res...

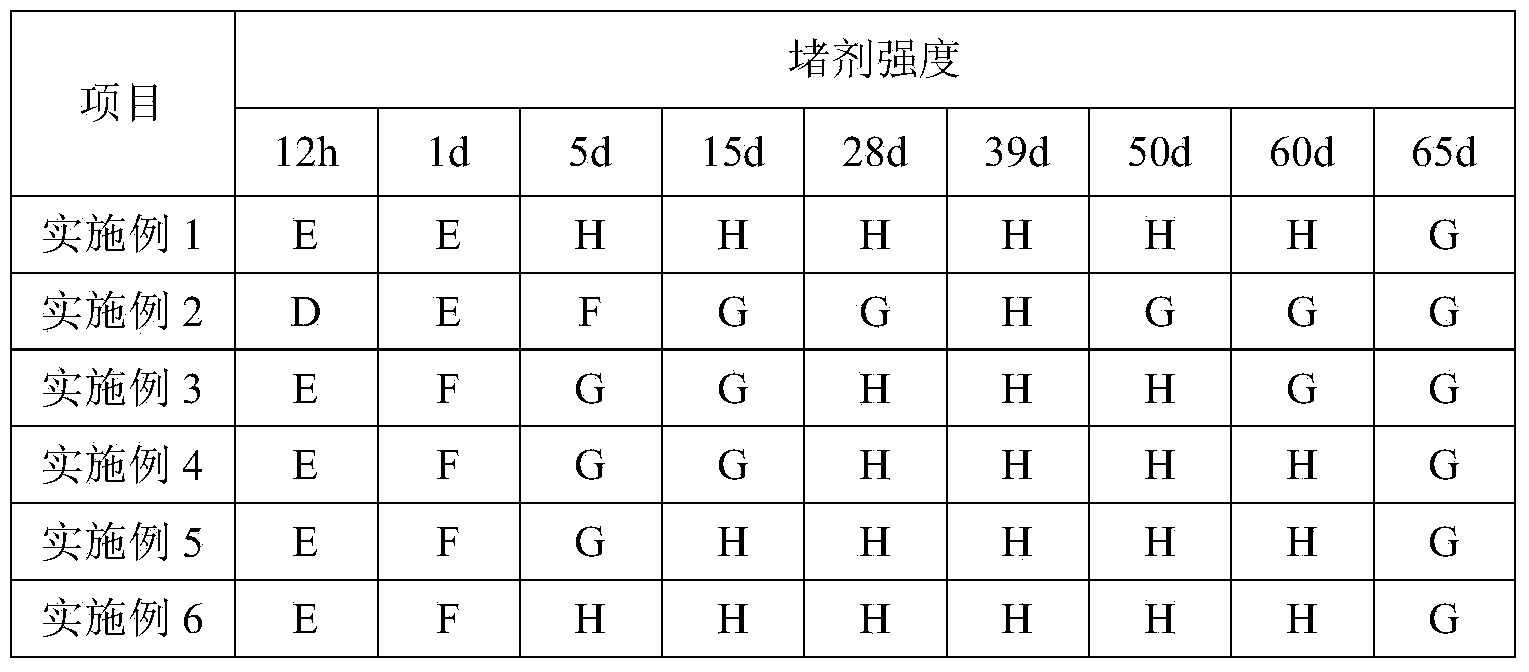

PUM

| Property | Measurement | Unit |

|---|---|---|

| sealing strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com