Low-density timber-imitation polyurethane resin for shoes

A polyurethane shoe and low-density technology, which is applied in the field of shoe resin, can solve the problems of broken products due to poor strength, easy shrinkage and deformation of products, and narrow foaming range. wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

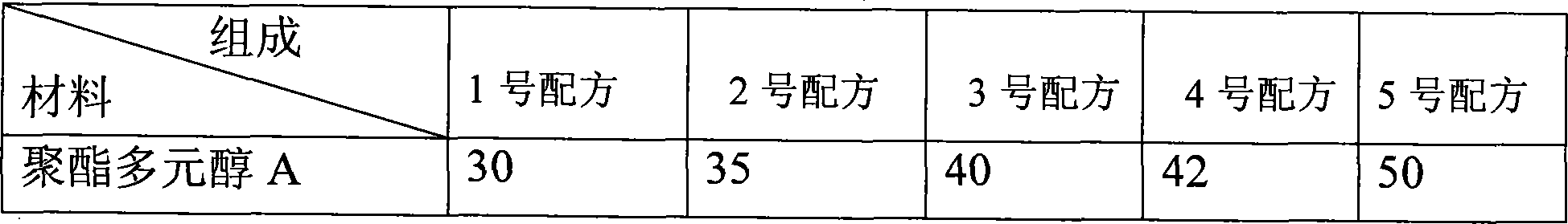

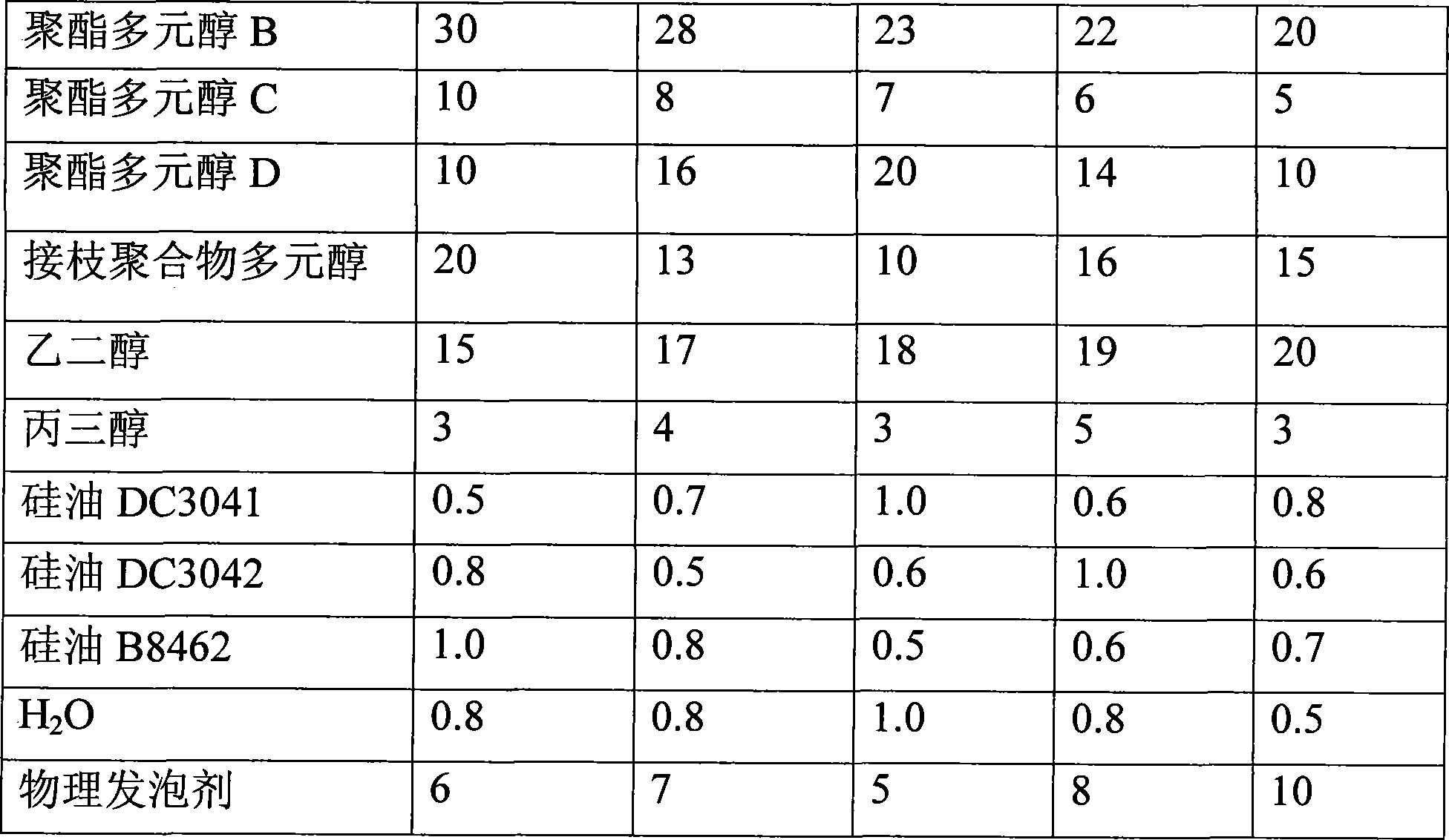

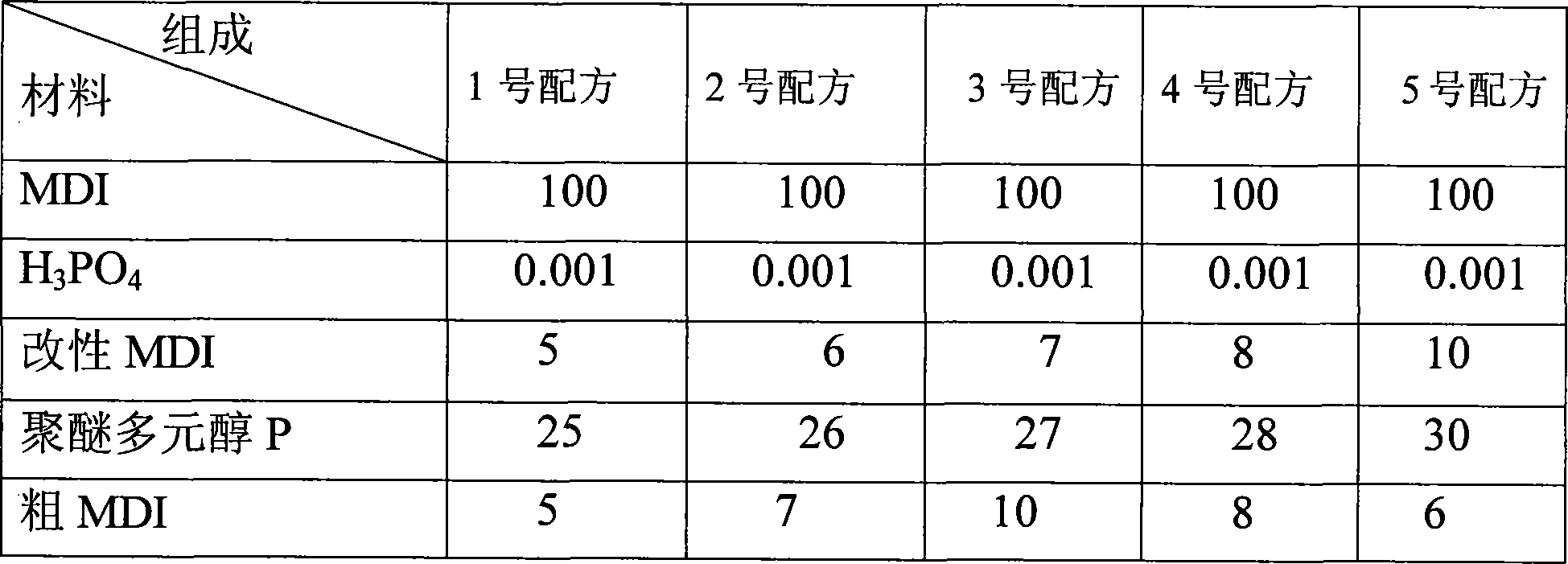

Method used

Image

Examples

Embodiment Construction

[0036] The present invention mainly belongs to three-component polyurethane shoe resin, A component is polyester polyol containing hydroxyl (OH) group, B component is a prepolymer containing isocyanate (NCO) group, C component It is an ethylene glycol solution containing triethylenediamine. When used, add component C to component A, mix well first, and use it as a component, and then chemically react with component B. After high-speed stirring with a foaming machine for low-pressure shoes, it is injected into the mold for one-time injection molding.

[0037] The molding processing condition of the low-density wood-like polyurethane shoe resin is to add component C to component A to form a mixed component of component A.

[0038] (1) For manual foaming, weigh 100 parts of component A and 145-155 parts of component B, and pour it into the mold cavity for foaming under the strong stirring of 2500r / min.

[0039] (2) Mechanical operation: the mixed components are added to the mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com