High-efficiency water-reducing agent

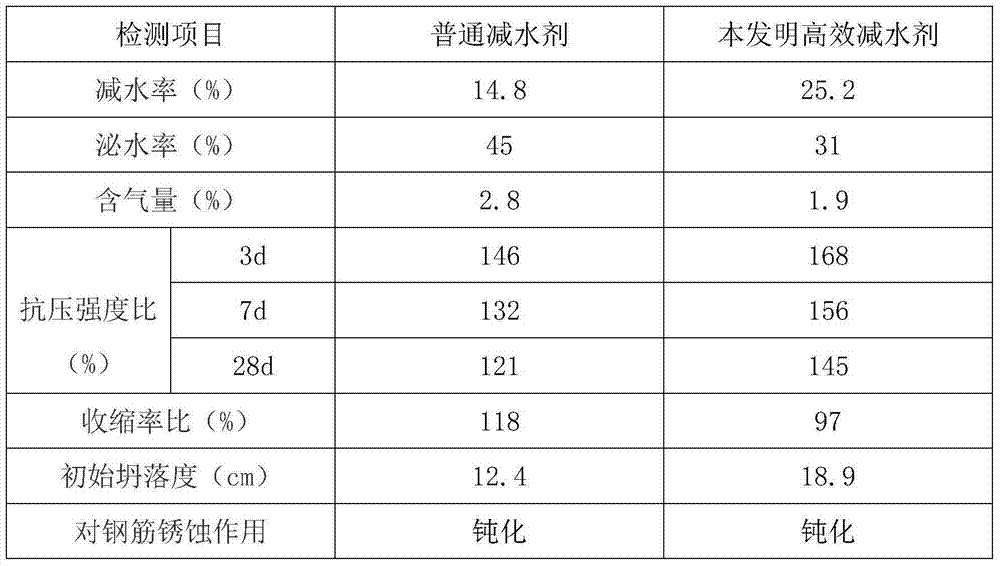

A high-efficiency water-reducing agent and additive technology, applied in the field of concrete admixtures, can solve problems such as low water-reducing rate, low strength, and poor fluidity, and achieve the effects of high water-reducing rate, increased strength, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] A high-efficiency water reducer, which is made by mixing the following raw materials by weight (kg): β-naphthalene sulfonate formaldehyde condensate 55, polyethylene glycol monomethyl ether methacrylate 25, calcium lignosulfonate 20, Ethylene oxide-propylene oxide copolymer 12, trehalose 2-4, silicone powder 2, shale ash 6, sodium bisulfite 3.5, polyethylene oxide 8, aluminum tripolyphosphate 12, cocoamide diethanolamine 2.5, barium dinonyl naphthalene sulfonate 1.5, urotropine 2.5, additive 4;

[0011] The auxiliary agent is made of the following raw materials by weight (kg): 10-15 magnesite, 3-6 magnesium humate, 2-4 ammonium benzoate, 6-12 sodium α-olefin sulfonate, inositol Hexaphosphate 1.5-2.5, Isobutylene Triethoxysilane 3-5, Polyferric Chloride 5-10, Germanium Stone Powder 12-18, Titanium Dioxide 5-10, Myristyl Glucoside 1-2, Polyamide Wax 4 -6, lithium magnesium silicate 2-3, tea saponin 1.5-2.5;

[0012] Mix the above-mentioned magnesite, germanite powder, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com