Hyperbranched polymer, hyperbranched polycarboxylic acid-series super plasticizer and preparation method thereof

A technology of hyperbranched polymers and polycarboxylic acids, which is applied in the preparation of sulfonates, organic chemistry, etc., can solve the problems of complex synthesis process, high cost, and difficulty in realizing industrialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0095] The invention provides a kind of preparation method with the hyperbranched polymer of formula (I) structure, comprises the following steps:

[0096] Alkenylamine and 2-acrylamido-2-sodium methylpropanesulfonate undergo an addition reaction to obtain a hyperbranched polymer having a structure of formula (I);

[0097] The alkenylamine is allylamine, acrylamide, diallylamine, 9-octadecenylamine or chloroenylamine.

[0098] Firstly, alkenylamine and sodium 2-acrylamido-2-methylpropanesulfonate are dissolved in an organic solvent to obtain a mixed solution of alkenylamine and sodium 2-acrylamido-2-methylpropanesulfonate. The alkenylamine is allylamine, acrylamide, diallylamine, 9-octadecenylamine or chloroenylamine, preferably allylamine, diallylamine, more preferably allyl amine. Wherein the molar ratio of alkenylamine to 2-acrylamido-2-methylpropanesulfonate sodium is 1: (1~5), preferably 1: (1.2~4); more preferably 1: (1.5 ~3); the organic solvent is preferably an alco...

Embodiment 1

[0225] Dissolve 1 mol of allylamine and 2 mol of sodium 2-acrylamido-2-methylpropanesulfonate in 1 mL of methanol, react the resulting mixed solution at 25°C for 1 hour, and then raise the temperature of the reaction system to 80°C React for 5 hours. After the reaction is completed, the obtained reaction solution is evaporated under reduced pressure to remove methanol to obtain hyperbranched polymer powder.

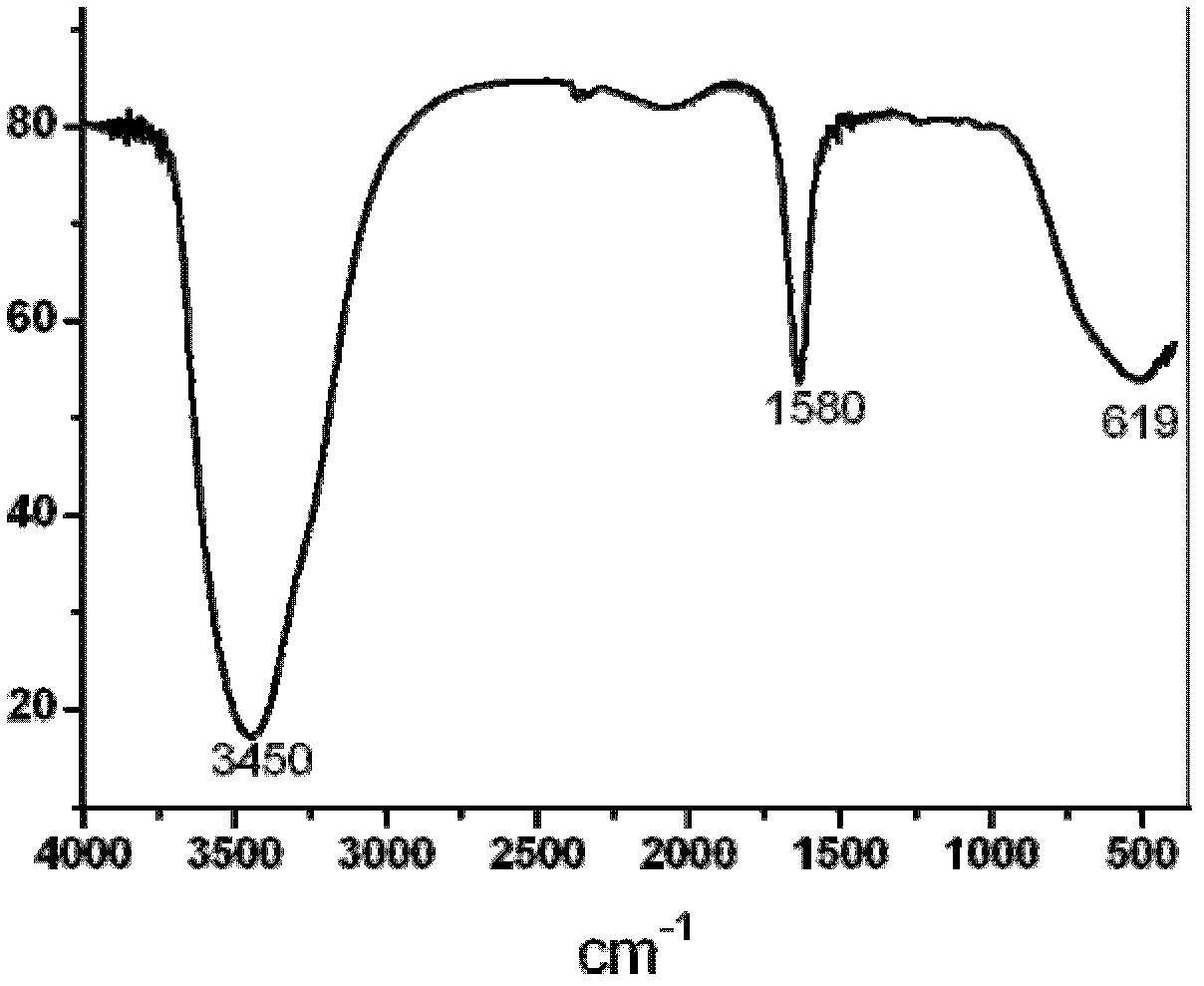

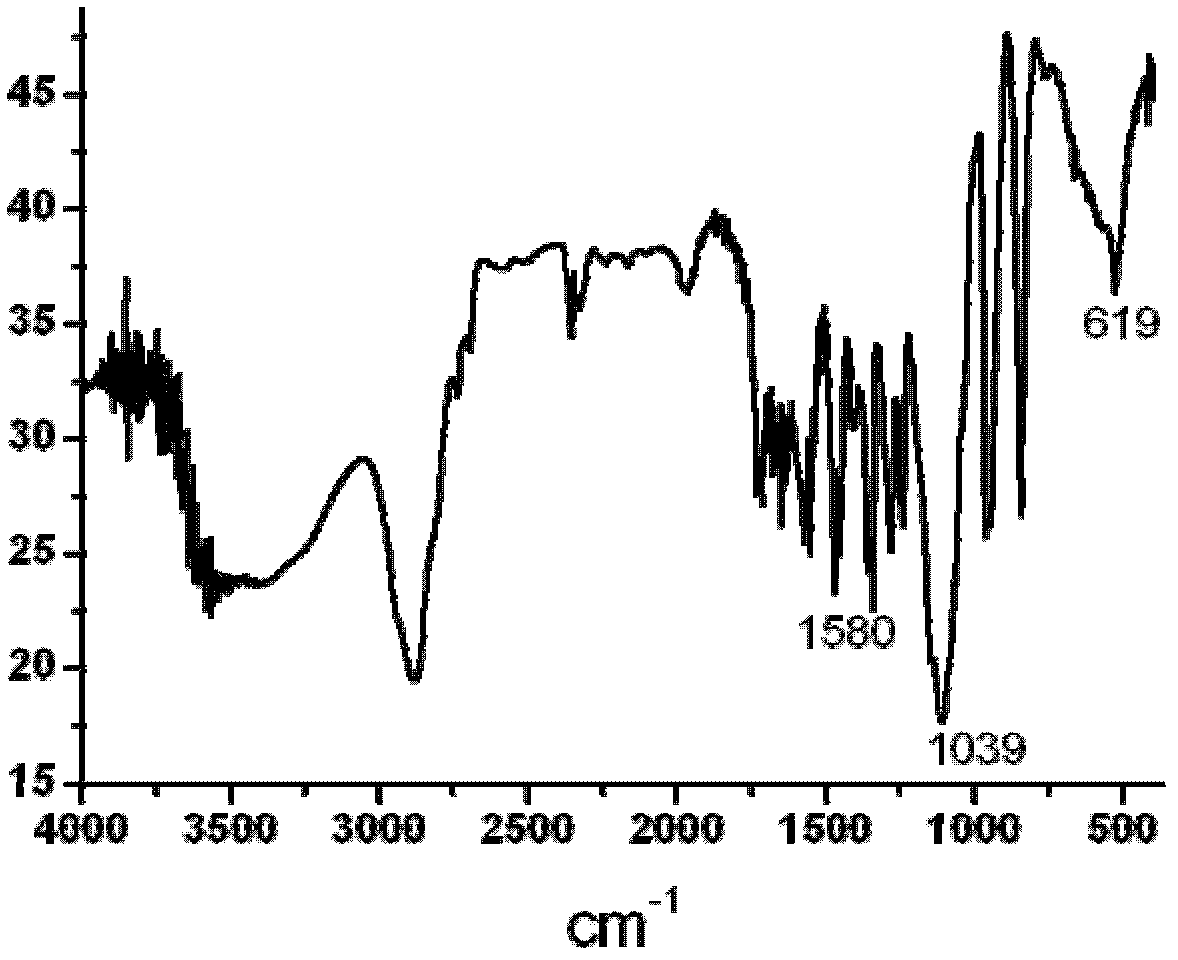

[0226] Will obtain hyperbranched polymer powder to carry out infrared test, the result is as follows figure 1 shown. figure 1 For the infrared spectrogram of the hyperbranched polymer prepared by the embodiment of the present invention 1, in figure 1 Medium, 1580cm -1 is the characteristic vibration of the amide group, 619cm -1 Be the characteristic vibration of sulfonic acid group, illustrate that allylamine and 2-acrylamido-2-sodium methyl propane sulfonate have undergone addition reaction, and the hyperbranched polymer powder that obtains has formula (I) structure. ...

Embodiment 2

[0228] Dissolve 1 mol of allylamine and 2 mol of methyl acrylate with 2 mL of methanol, react the resulting mixed solution at 25°C for 12 hours, then evaporate the obtained reaction solution under reduced pressure, remove methanol, and obtain the first intermediate product; Add 2.5 mol of ethylenediamine and 1 mL of methanol to an intermediate product, react the reaction system at 25°C for 12 hours, then gradually raise the temperature to 80°C for 5 hours, evaporate the obtained reaction solution under reduced pressure, and remove methanol to obtain the first The second intermediate product; the obtained second intermediate product and 4mol 2-acrylamido-2-methylpropanesulfonate were dissolved in 2 mL of methanol, and the resulting mixed solution was reacted at 70°C for 5 hours to obtain a hyperbranched polymer .

[0229] The obtained hyperbranched polymer is carried out infrared test, the result is as follows figure 2 mentioned. figure 2 Be the infrared spectrogram of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com