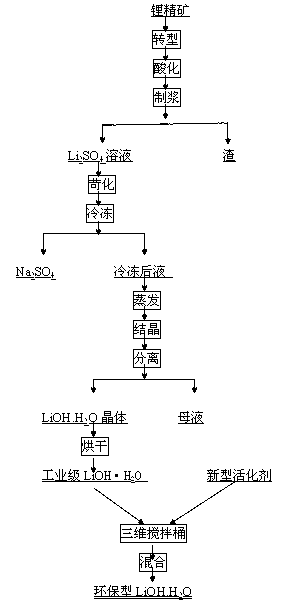

Method for directly producing environment-friendly lithium hydroxide monohydrate from spodumene

A spodumene, environmentally friendly technology, applied in the direction of lithium oxide; / hydroxide, etc., can solve problems such as damage, and achieve the effect of good fluidity and crystal enlargement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0033] Example 1:

[0034] The 200 mesh spodumene powder is calcined under high temperature conditions for 30 minutes, among which: Li in the spodumene 2 The content of O is greater than 5%; the roasted spodumene is ball milled to a particle size greater than 200 mesh by a ball mill; the concentrated sulfuric acid with a concentration of 98% is mixed with the ball-milled spodumene powder uniformly, and the reaction temperature is controlled at 250°C ; Make a slurry of acidified ore and water, add double fly powder and adjust the pH to 5.5, then add quicklime or lime slurry to adjust the pH to 13.5, then stir and react for 20 minutes; separate the liquid and slag in the disc filter, The slag is washed with water for 1-6 times and drained to make bricks. First, NaOH is added to the liquid separated in step (5) and the mother liquor separated in step (9) is stirred evenly; sent to the freezing tank to cool to 0 degrees for precipitation Sodium sulfate crystals, separated by a separa...

Example Embodiment

[0036] Example 2:

[0037] Spodumene is transformed into industrial grade LiOH·H through traditional process transformation, acidification, leaching, freezing, evaporation, drying and other processes 2 O. Take 500 kg of industrial grade LiOH·H 2 Put O into the three-dimensional mixer, press the new activator and LiOH·H 2 The mass ratio of O is 0.8:100, and a new activator is added. The activator is composed of 70% C12 linear alkanes, 20% 2,5-dinonylheptane and 10% cyclopentane. . And the three-dimensional mixer is sealed, the mixing speed is 120 rpm, and the time is half an hour. Finally get environmentally friendly LiOH·H 2 O, the environmentally friendly LiOH·H obtained 2 O passes through a 320-mesh sample sieve, and the dust under the sieve (by mass percentage) is less than 0.5%.

Example Embodiment

[0038] Example 3:

[0039] Spodumene is transformed into industrial grade LiOH·H through traditional process transformation, acidification, leaching, freezing, evaporation, drying and other processes 2 O. Take 500 kg of industrial grade LiOH·H 2 Put O into the three-dimensional mixer, press the new activator and LiOH·H 2 The ratio of O is 0.5:100 and the new activator is added. The activator is in accordance with the ratio of 75% C15 linear alkanes, 20% 2,5-dimethyl-3-propyl octane and 5% cyclohexane. consist of. And the three-dimensional mixer is sealed, the revolution of the three-dimensional mixer is 50 revolutions per minute, and the time is half an hour. Finally get environmentally friendly LiOH·H 2 O, the environmentally friendly LiOH·H obtained 2 O passes through a 320-mesh sample sieve, and the dust under the sieve (calculated by mass percentage) is 0.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com