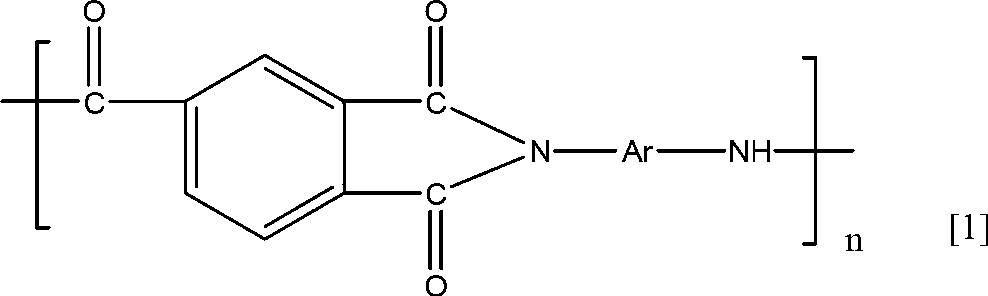

Preparation method of polyamide-imide copolymer

A technology of polyamide-imide copolymer and trimellitic anhydride acid chloride, which is applied in the field of preparation of polyamide-imide, can solve the problems of product performance damage, plasticizer migration, etc., achieve short reaction time, high temperature retention rate, and easy Processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

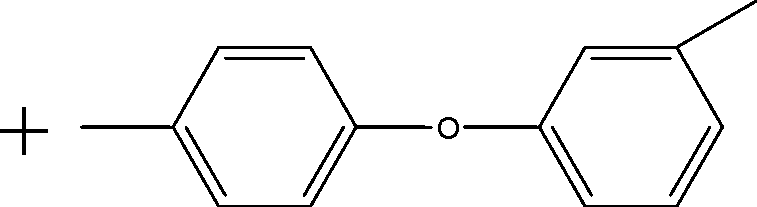

Embodiment 1

[0029] Add 660 g of N-methylpyrrolidone to a 3-liter reactor equipped with a stirrer, temperature regulator, dropping funnel and cooler, followed by 100 g (0.5 mol) of 4,4'-diaminodiphenyl ether, 100 g (0.5 mol) 3,4'-diaminodiphenyl ether and 10.8g m-phenylenediamine, stirred and dissolved at 10°C, then added 211g (1.1mol) trimellitic anhydride acid chloride (TMAc), where TMAc was divided into 10 batches, each Add 21.1g, add once every 10 minutes, react for 3 hours after the addition of the material, then add 2.3g of hydroxyphthalic anhydride, stir for 1.5 hours, the reaction is over, add 1600ml of deionized water, stir to precipitate the polymer, filter, Wash with water, filter, dry and imidize at 250°C for 2 hours, in N-methylpyrrolidone at 30°C, the concentration is 0.5g / dl, the measured intrinsic viscosity is 0.65dl / g, Tg: 275°C.

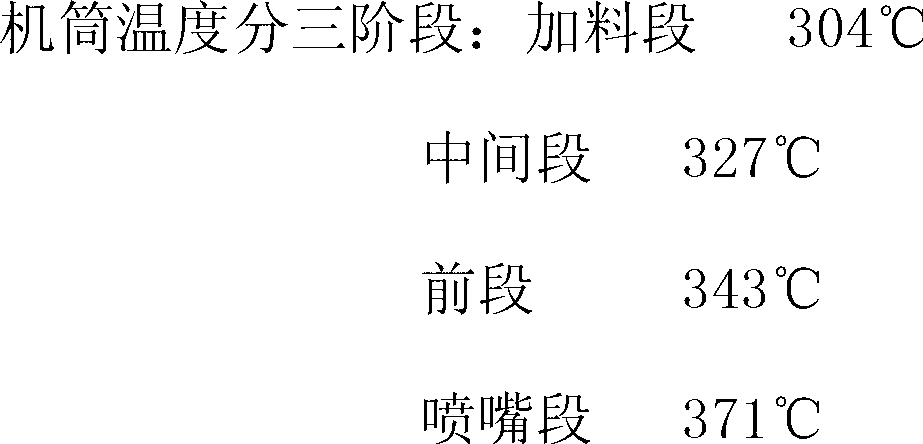

[0030] Injection molding according to injection conditions, drying at 150°C for 5 hours, moisture content is 0.05%.

[0031] Injection tempera...

Embodiment 2

[0036] In addition to adding 120g (0.6mol) 4,4'-diaminodiphenyl ether, 80g (0.4mol) 3,4'-diaminodiphenyl ether, the polymerization reaction temperature is 5°C, and adding 0.9g of end-capping agent hexahydrophthalic anhydride, The capping reaction was performed for 1 hour, and the dry imidization was carried out at 230° C. for 2 hours. Other formulations and operating steps were the same as in Example 1. Results: the intrinsic viscosity is 1.0dl / g, the Tg is 285°C, and the performance index of the injection sample is the same as that of Example 1.

Embodiment 3

[0038] Except that the polymerization reaction temperature is 25°C, 1g of capping agent 1-methylhexahydrophthalic anhydride is added, the capping reaction is 2 hours, and the imidization reaction is 2 hours at 220°C, other formulations and operating steps are the same as in Example 1. Results: The intrinsic viscosity is 0.72dl / g, Tg: 260°C. The performance index of the injection sample is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Tg | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com