Patents

Literature

1014 results about "Cycloalkane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In organic chemistry, the cycloalkanes (also called naphthenes, but distinct from naphthalene) are the monocyclic saturated hydrocarbons. In other words, a cycloalkane consists only of hydrogen and carbon atoms arranged in a structure containing a single ring (possibly with side chains), and all of the carbon-carbon bonds are single. Cycloalkanes are named analogously to their normal alkane counterparts of the same carbon count: cyclopropane, cyclobutane, cyclopentane, cyclohexane, etc. The larger cycloalkanes, with more than 20 carbon atoms are typically called cycloparaffins.

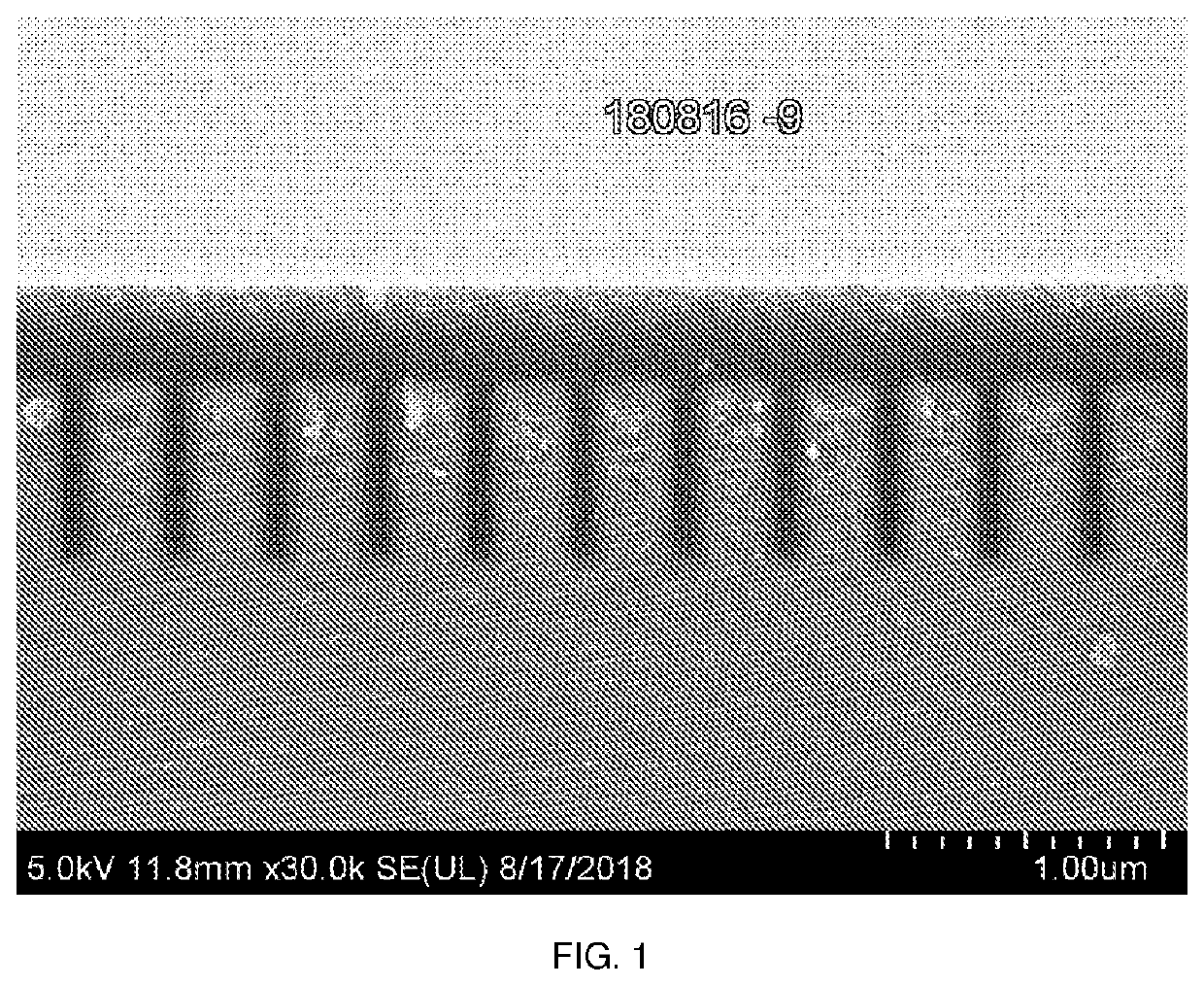

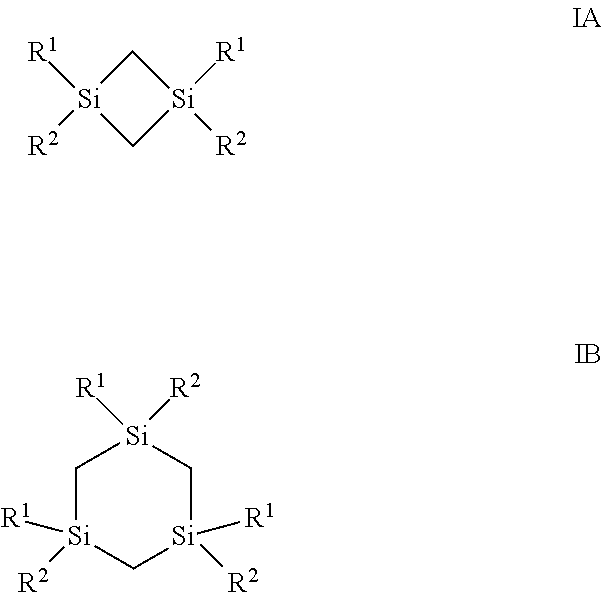

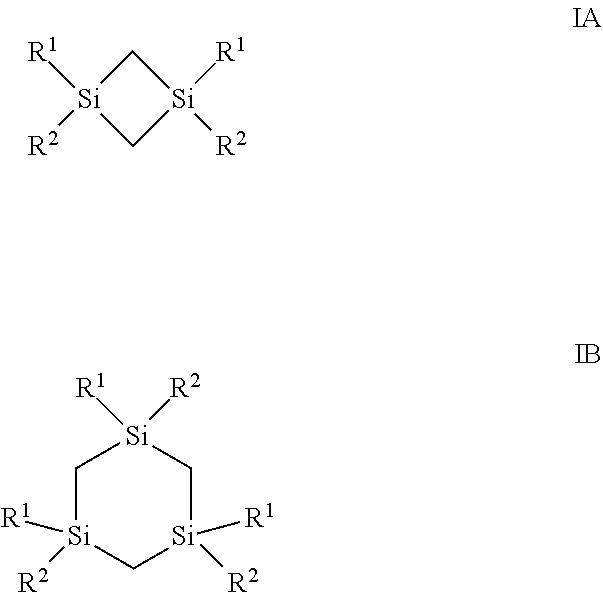

Compositions and methods for depositing silicon-containing films

PendingUS20200270749A1Group 4/14 element organic compoundsSemiconductor/solid-state device manufacturingDielectric membranePhysical chemistry

Described herein are compositions and methods of forming a dielectric film comprising silicon and carbon onto at least a surface of a substrate, the method comprising introducing into a reactor at least one silacycloalkane precursor selected from the group consisting of compounds represented by the structure of Formula IA and compounds represented by the structure of Formula IB: as defined herein.

Owner:VERSUM MATERIALS US LLC

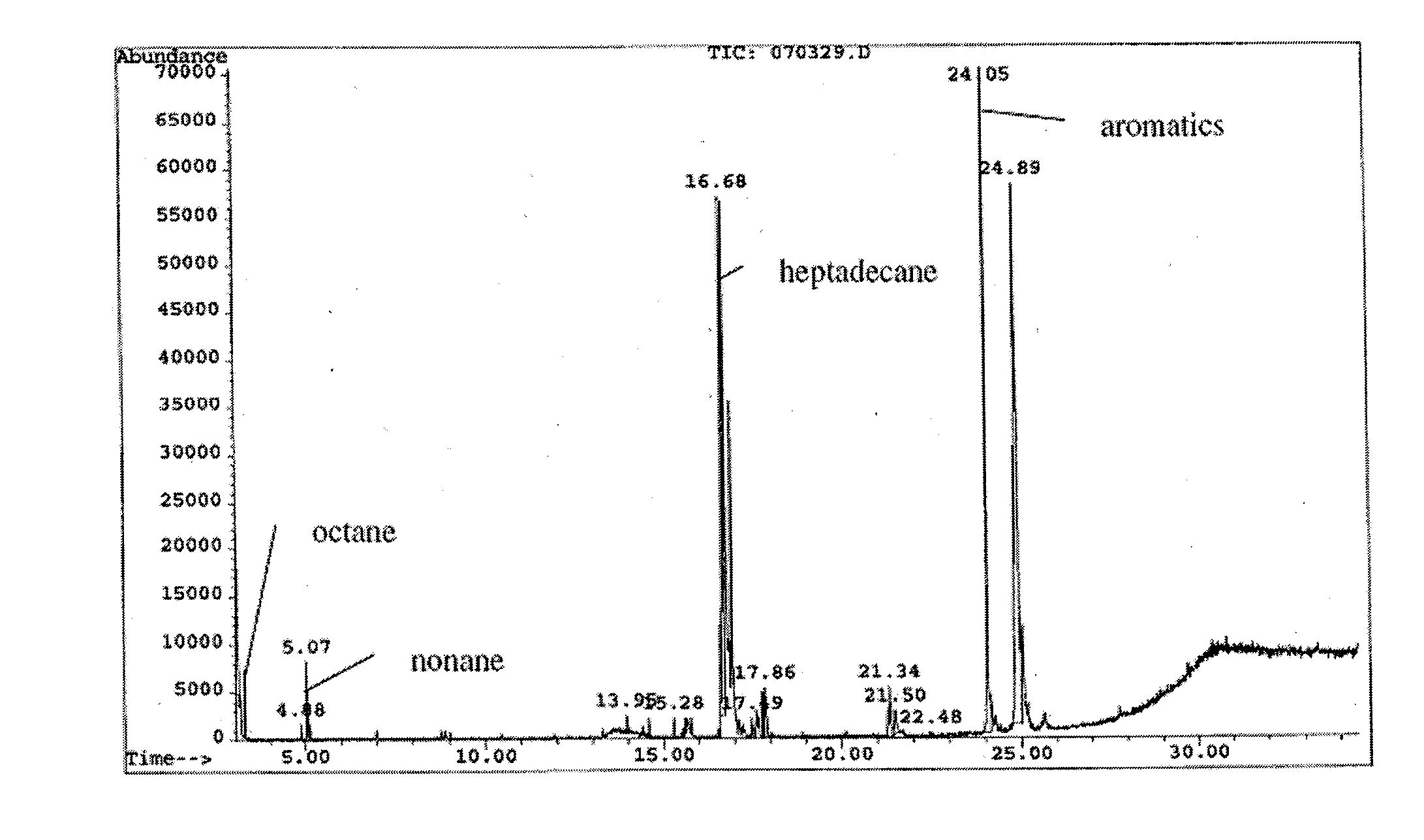

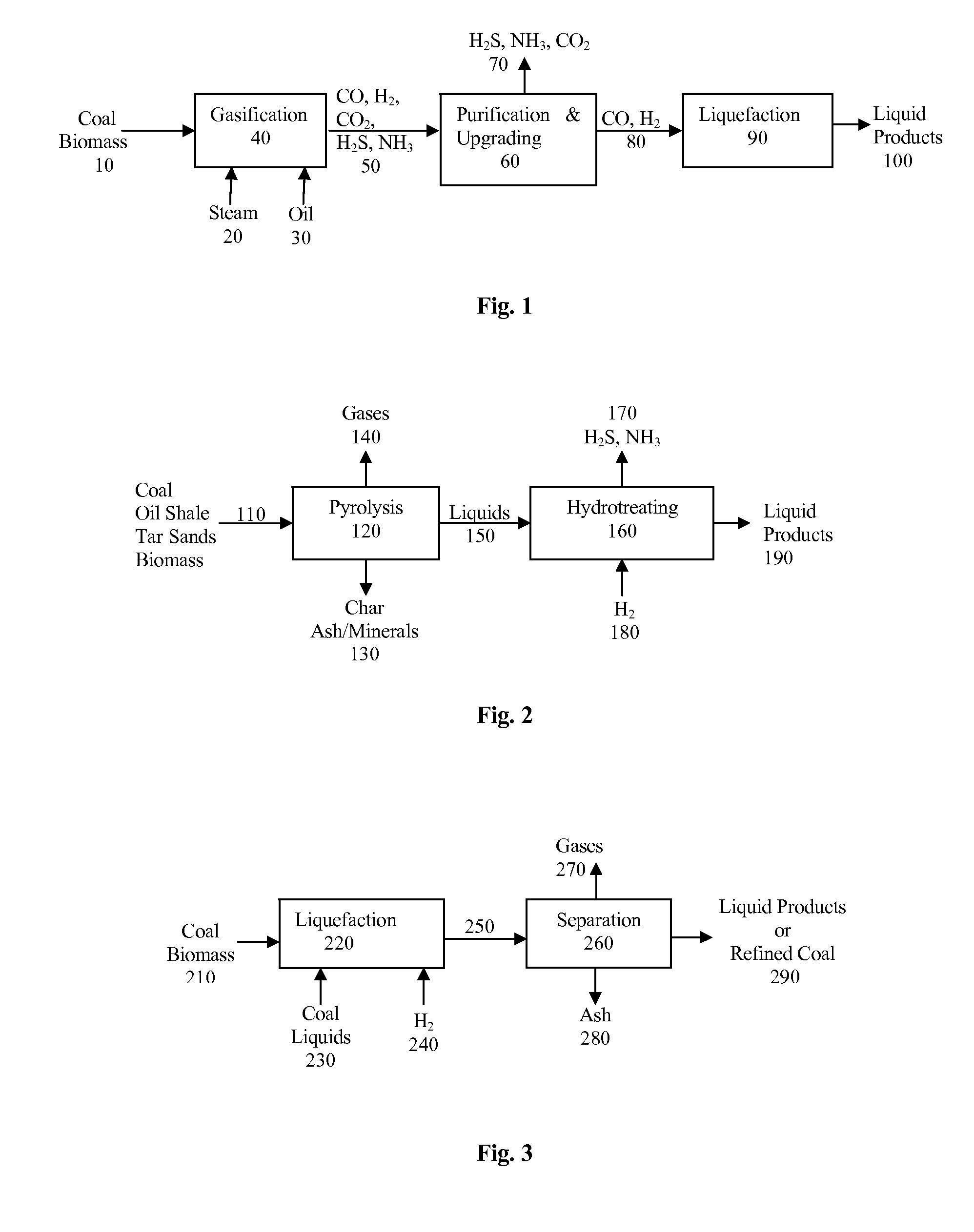

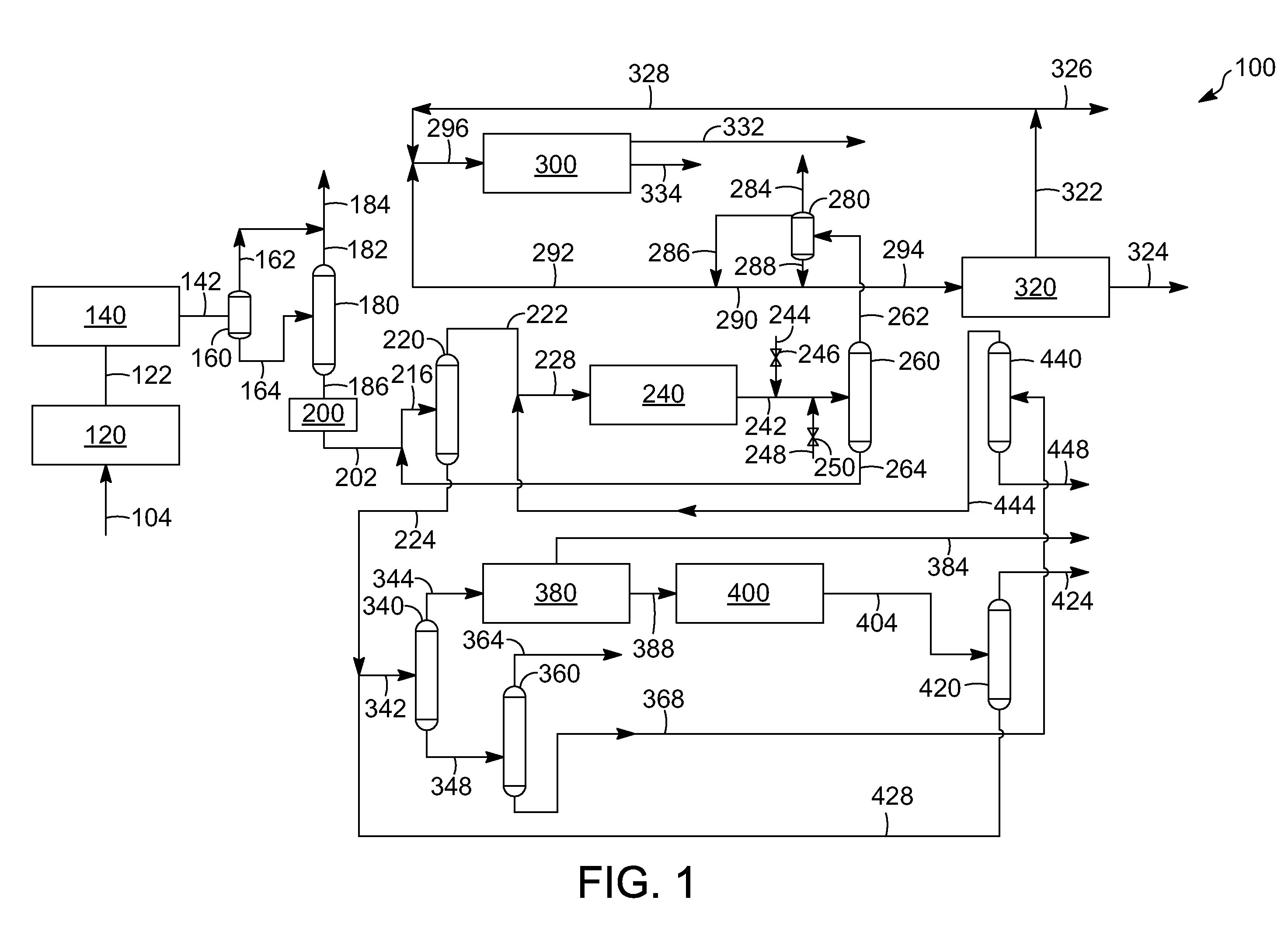

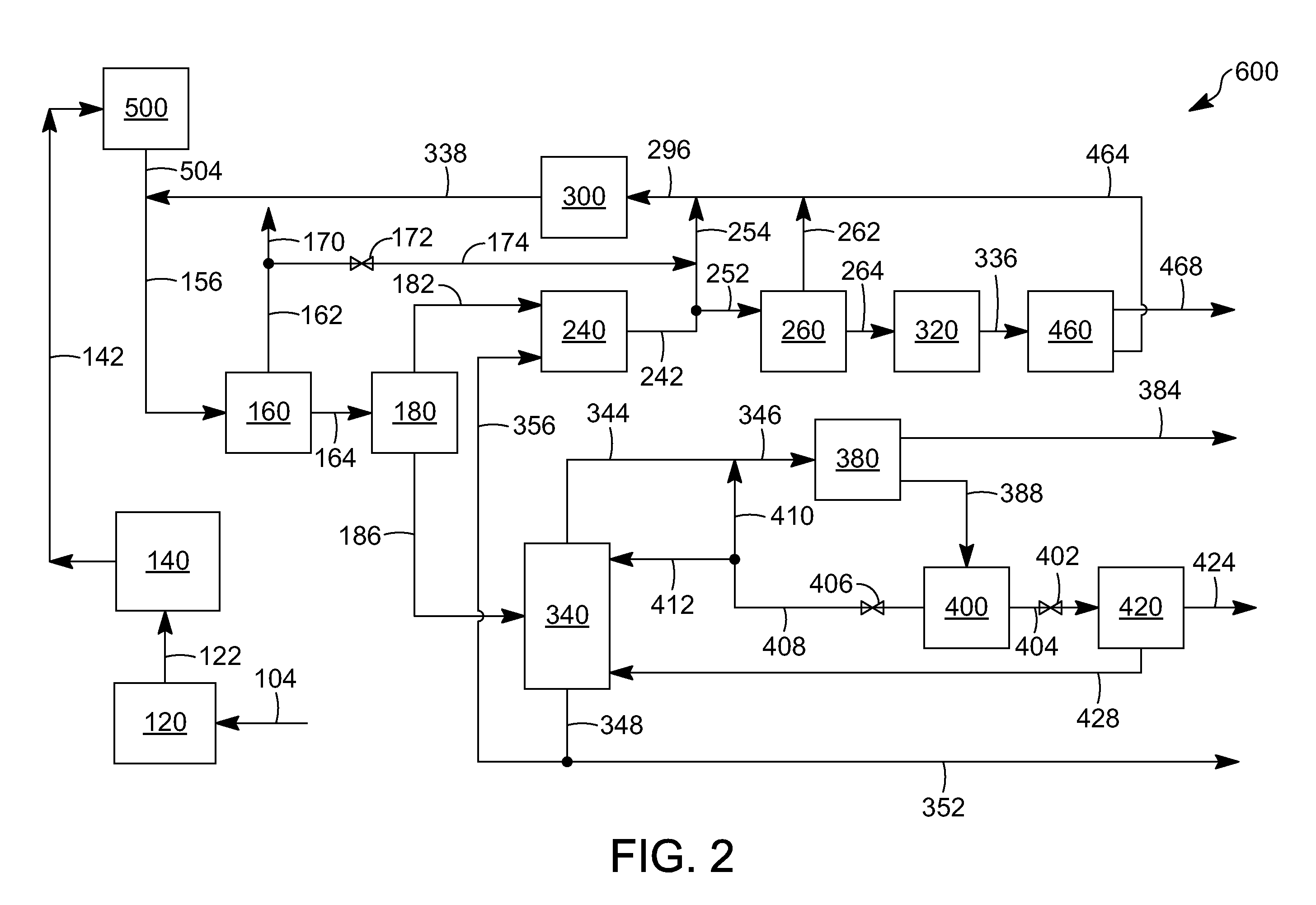

Process for conversion of biomass to fuel

ActiveUS20090069610A1Meet growth needsEasy to processFatty acid esterificationRefining to change hydrocarbon structural skeletonAlkaneChain length

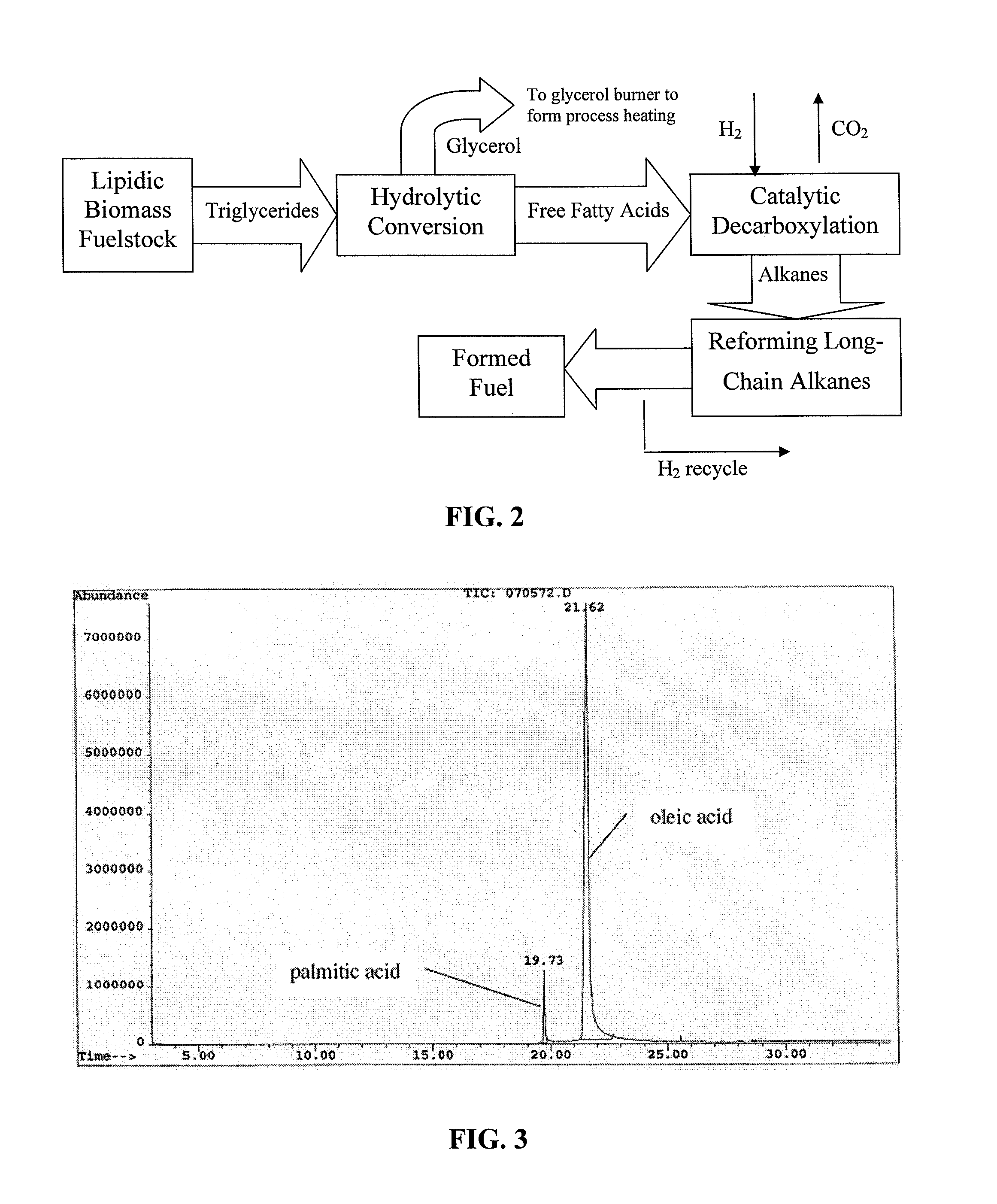

The present invention is directed to processes for the direct conversion of lipidic biomass fuelstock to combustible fuels. In particular, the invention provides a process for the direct conversion of animal fats to transportations fuels suitable as replacement for petroleum-derived transportation fuels. In one embodiment, the method comprises the steps of hydrolyzing a lipidic biomass to form free fatty acids, catalytically deoxygenating the free fatty acids to form n-alkanes, and reforming at least a portion of the n-alkanes into a mixture of compounds in the correct chain length, conformations, and ratio to be useful transportation fuels. Particularly, the product prepared according to the invention comprises mixtures of hydrocarbon compounds selected from the group consisting of n-alkanes, isoalkanes, aromatics, cycloalkanes, and combinations thereof.

Owner:NORTH CAROLINA STATE UNIV

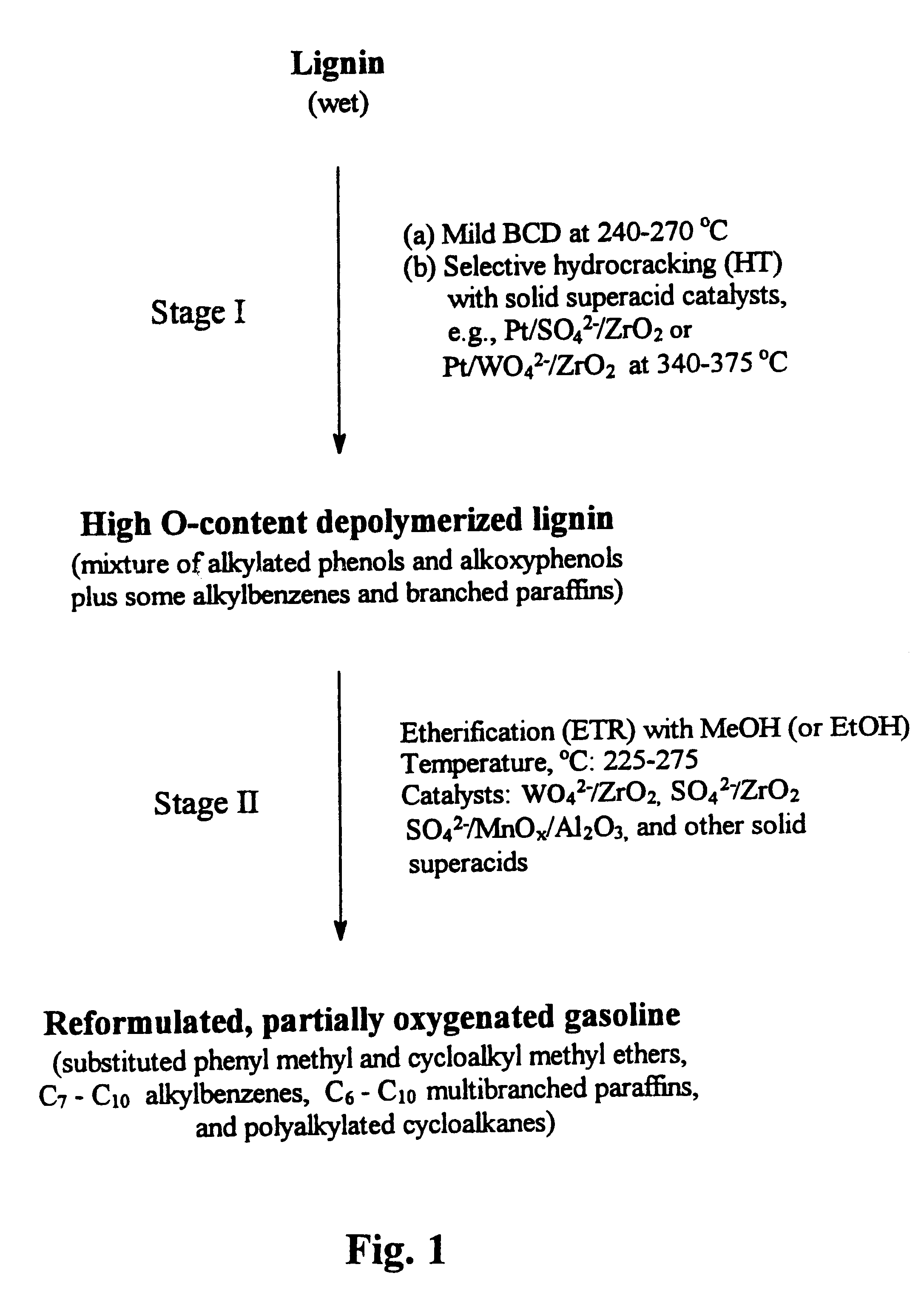

Process for conversion of lignin to reformulated, partially oxygenated gasoline

InactiveUS6172272B1Short reaction timeMaintain good propertiesOrganic compound preparationHydrocarbon from oxygen organic compoundsDepolymerizationMethyl group

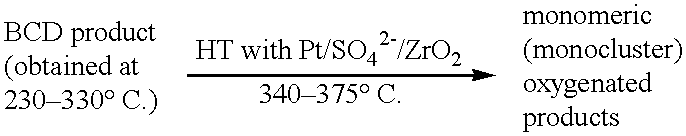

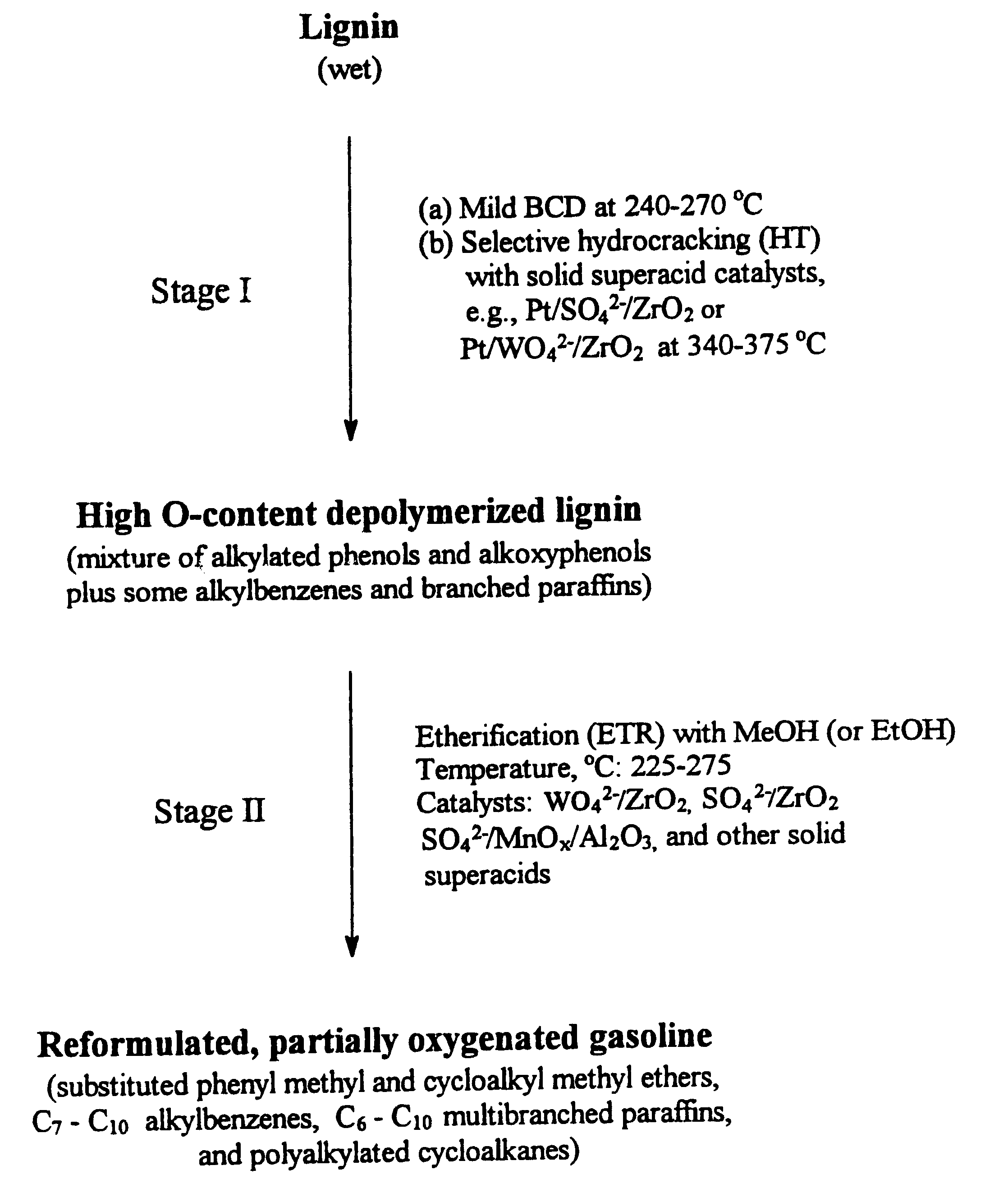

A high-yield process for converting lignin into reformulated, partially oxygenated gasoline compositions of high quality is provided. The process is a two-stage catalytic reaction process that produces a reformulated, partially oxygenated gasoline product with a controlled amount of aromatics. In the first stage of the process, a lignin feed material is subjected to a base-catalyzed depolymerization reaction, followed by a selective hydrocracking reaction which utilizes a superacid catalyst to produce a high oxygen-content depolymerized lignin product mainly composed of alkylated phenols, alkylated alkoxyphenols, and alkylbenzenes. In the second stage of the process, the depolymerized lignin product is subjected to an exhaustive etherification reaction, optionally followed by a partial ring hydrogenation reaction, to produce a reformulated, partially oxygenated / etherified gasoline product, which includes a mixture of substituted phenyl / methyl ethers, cycloalkyl methyl ethers, C7-C10 alkylbenzenes, C6-C10 branched and multibranched paraffins, and alkylated and polyalkylated cycloalkanes.

Owner:ALLIANCE FOR SUSTAINABLE ENERGY +1

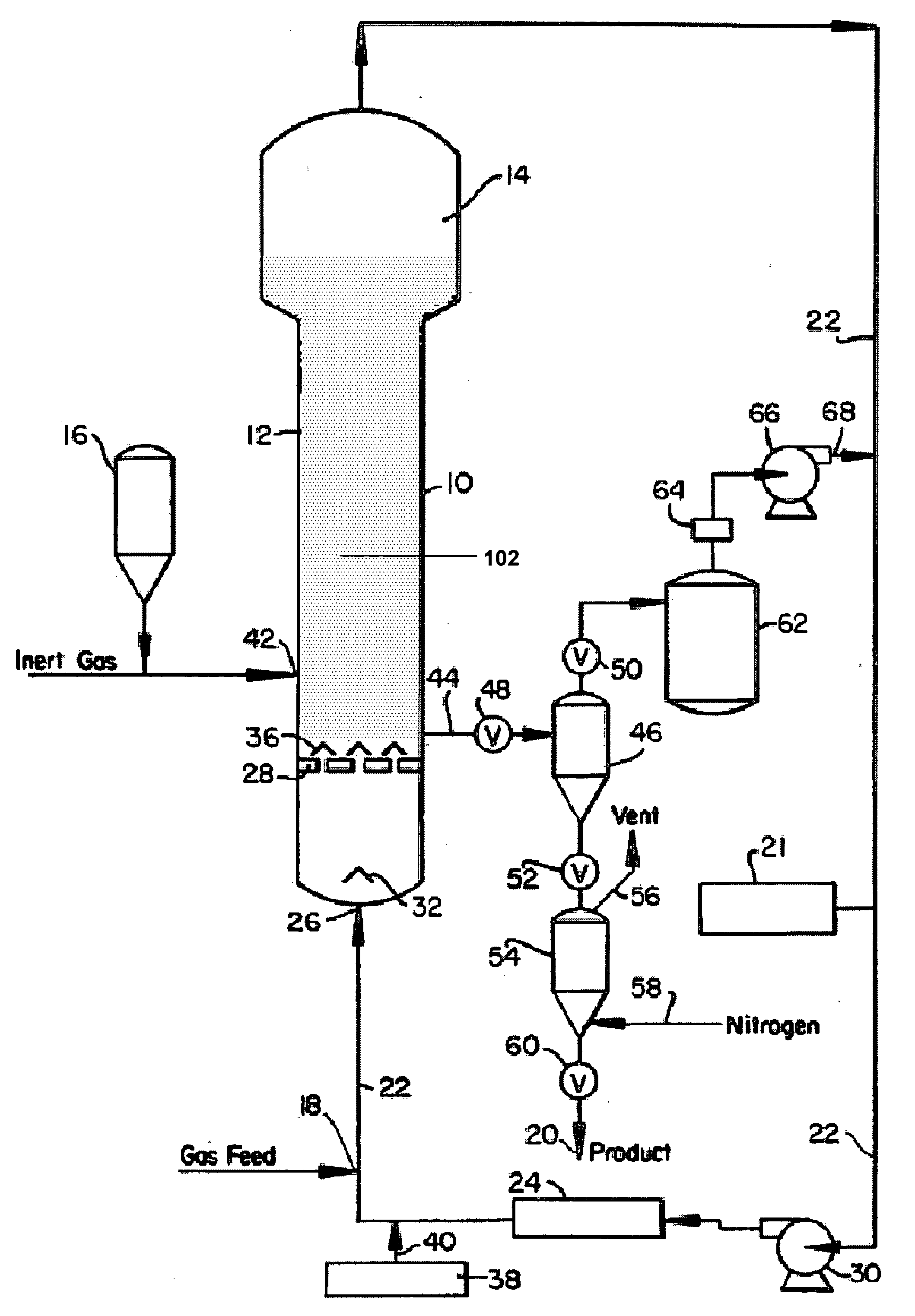

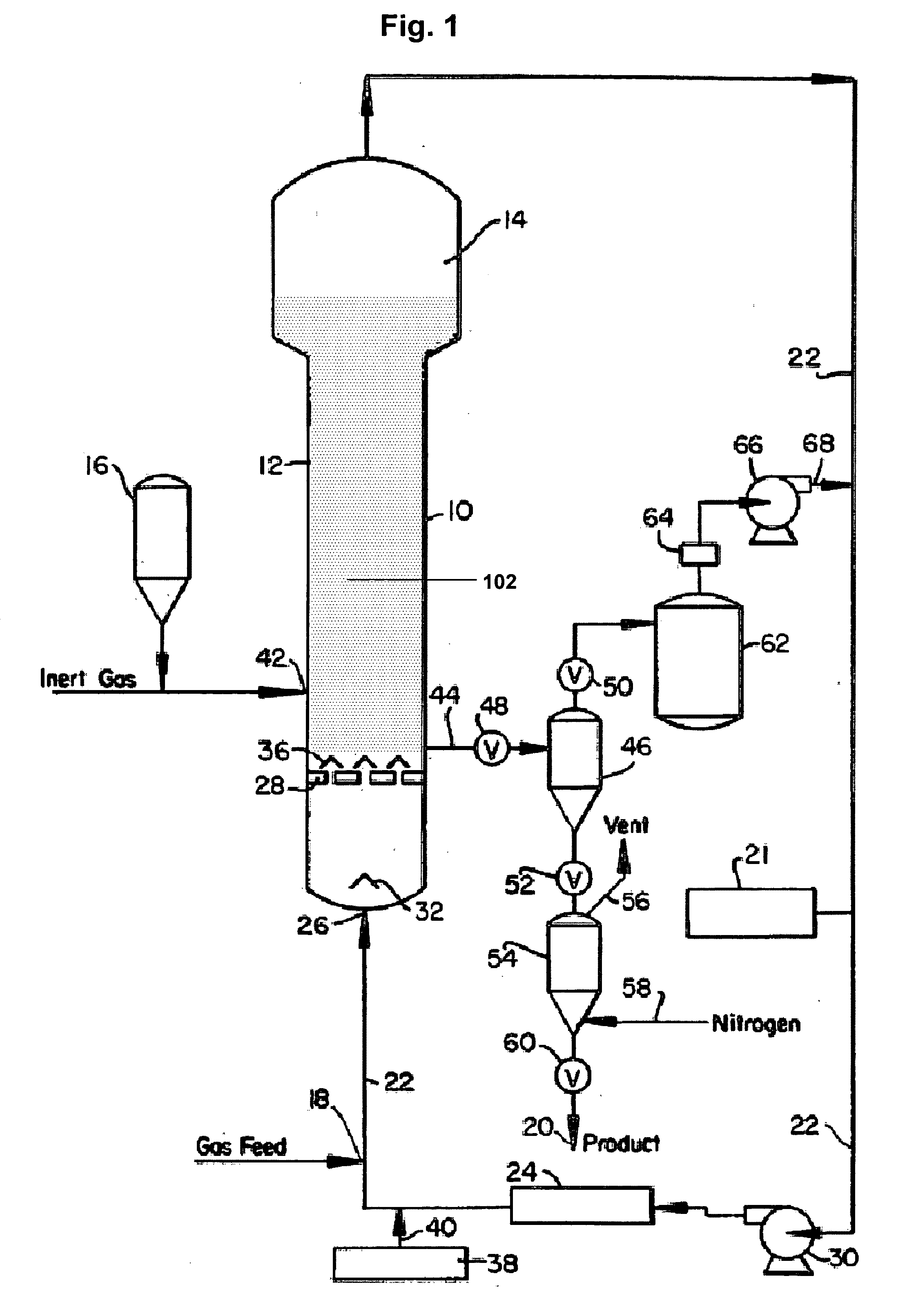

Condensing mode operation of gas-phase polymerization reactor

A continuous gas fluidized bed polymerization process for the production of a polymer from a monomer including continuously passing a gaseous stream comprising the monomer through a fluidized bed reactor in the presence of a catalyst under reactive conditions; withdrawing a polymeric product and a stream comprising unreacted monomer gases; cooling said stream comprising unreacted monomer gases to form a mixture comprising a gas phase and a liquid phase and reintroducing said mixture into said reactor with sufficient additional monomer to replace that monomer polymerized and withdrawn as the product, wherein said liquid phase is vaporized, and wherein the stream comprises an induced condensing agent selected from the group consisting of alkanes, cycloalkanes, and mixtures thereof, the induced condensing agent having a normal boiling point less than 25° C.

Owner:UNIVATION TECH LLC

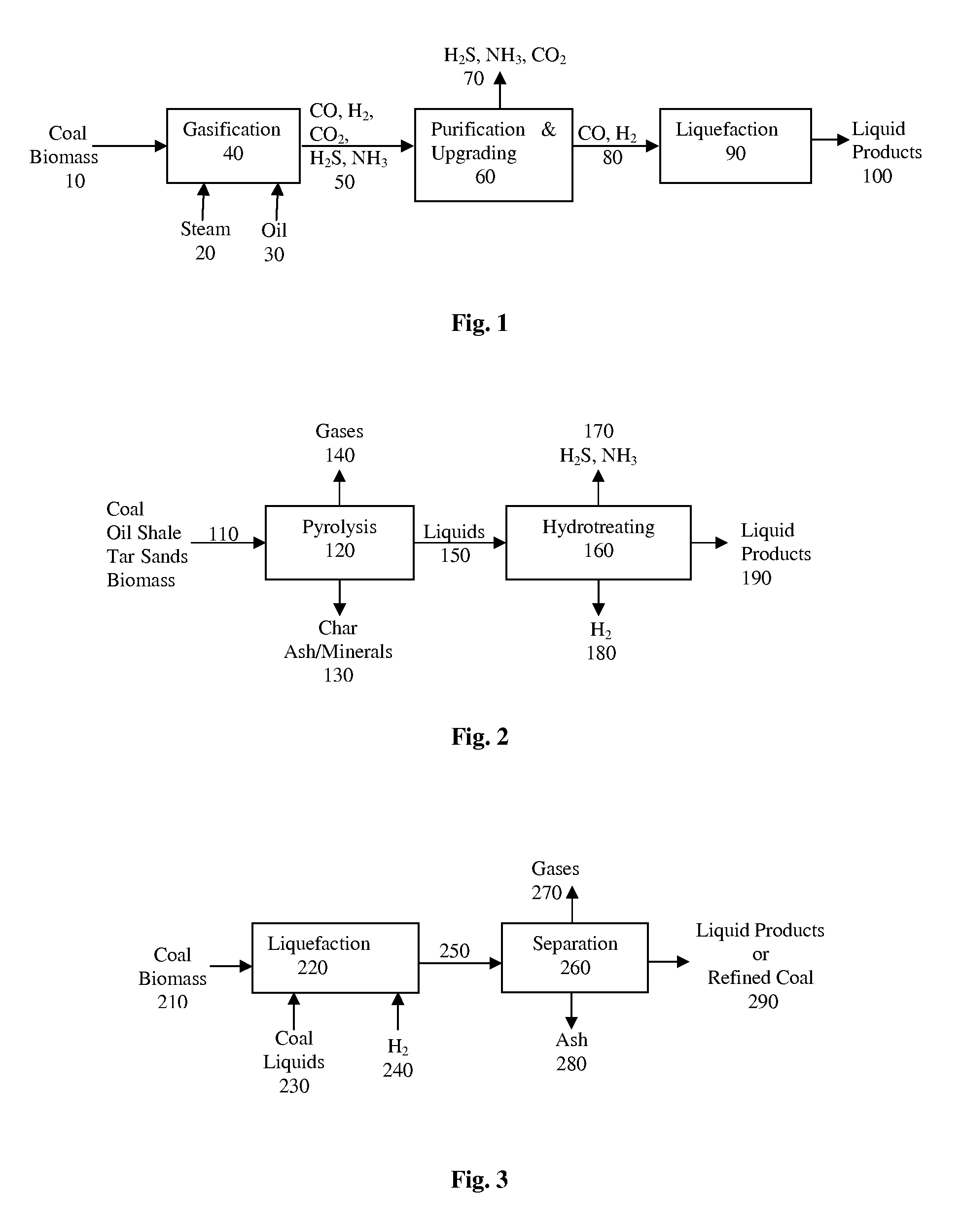

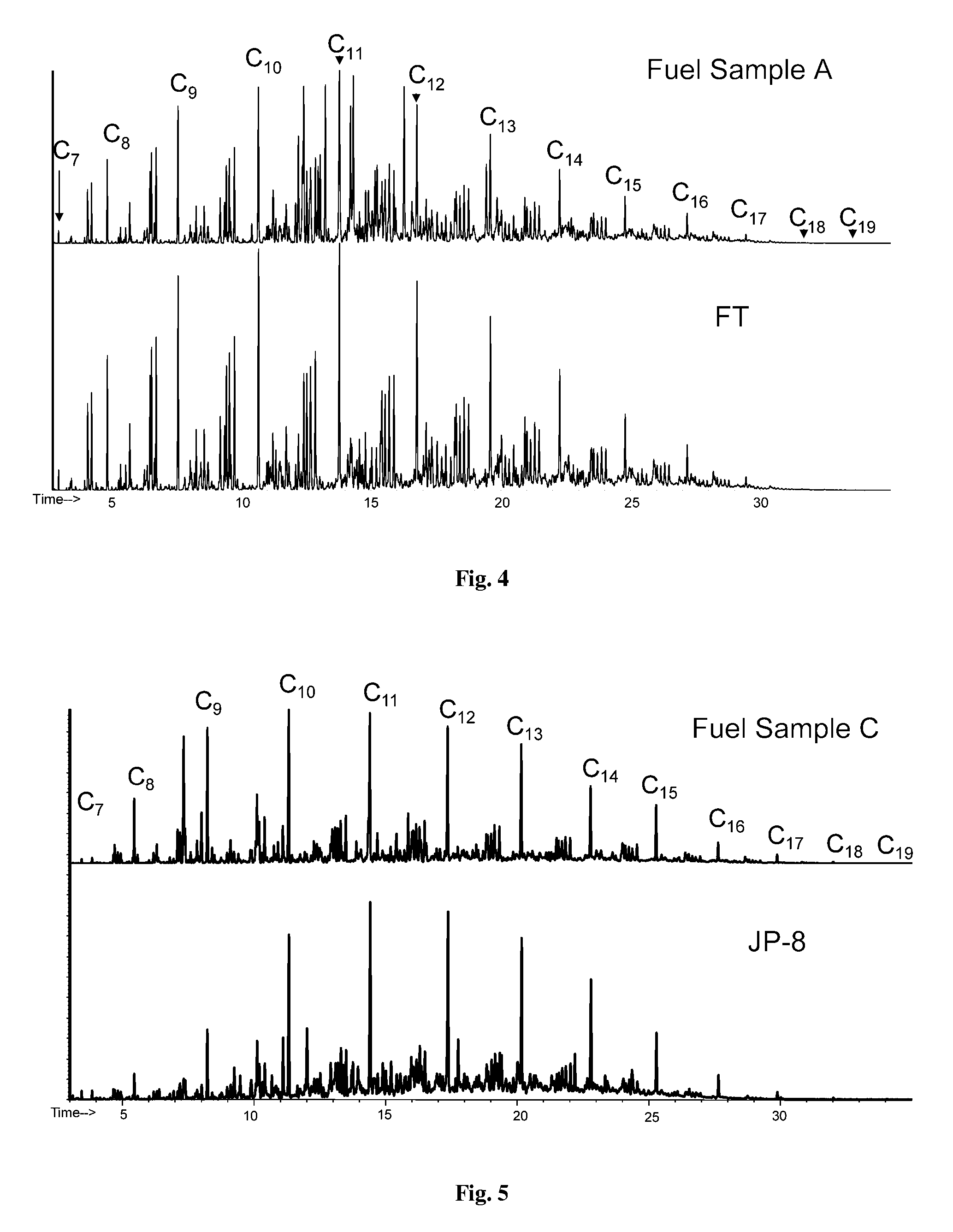

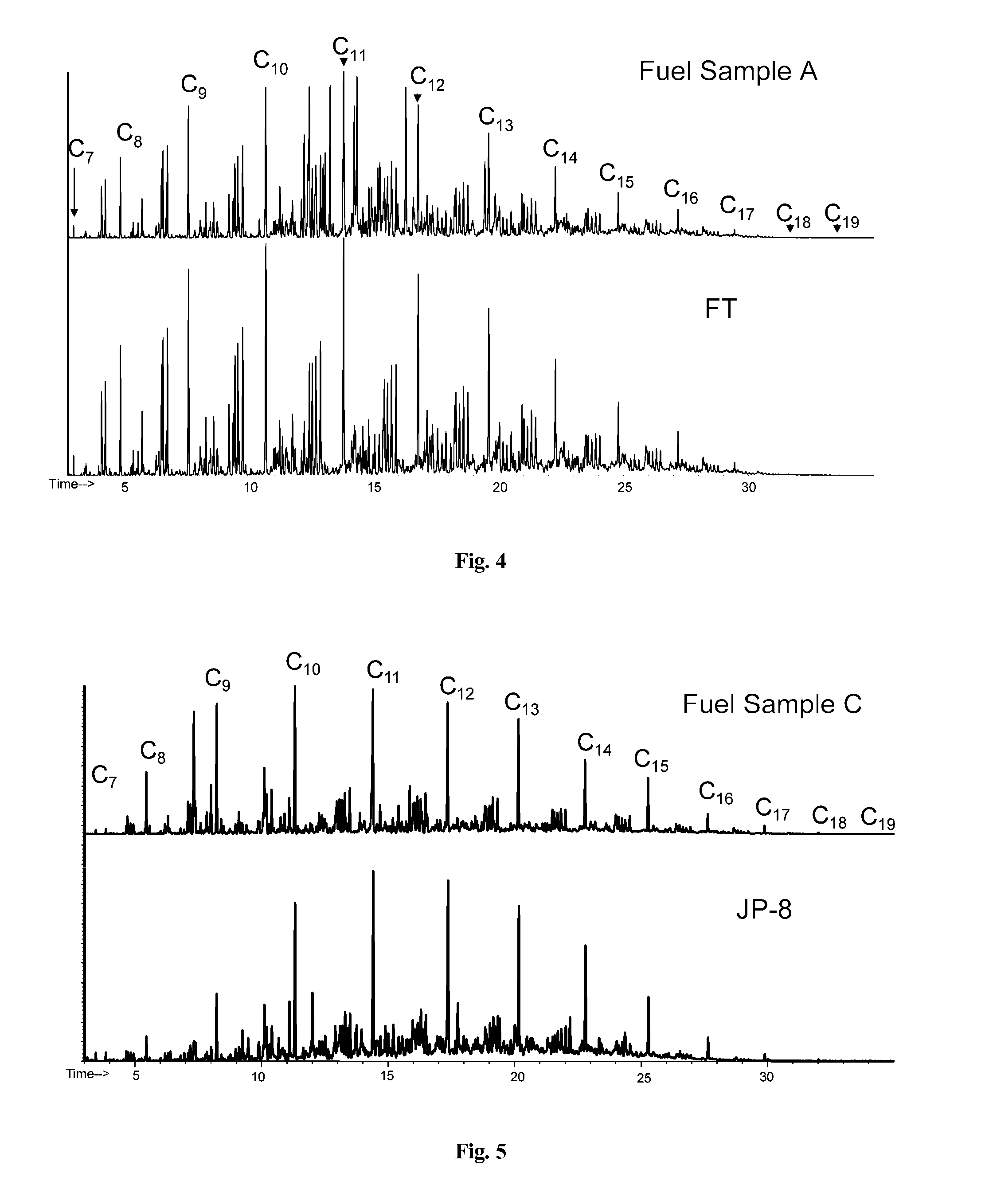

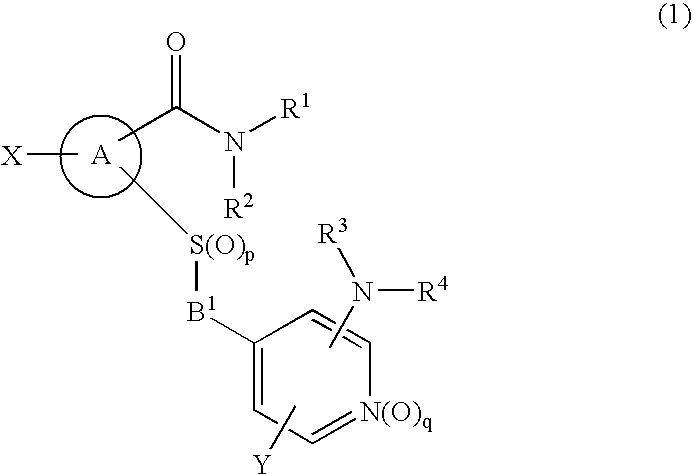

Aviation-grade kerosene from independently produced blendstocks

InactiveUS20090000185A1Liquid carbonaceous fuelsLiquid hydrocarbon mixture productionKeroseneParaffin oils

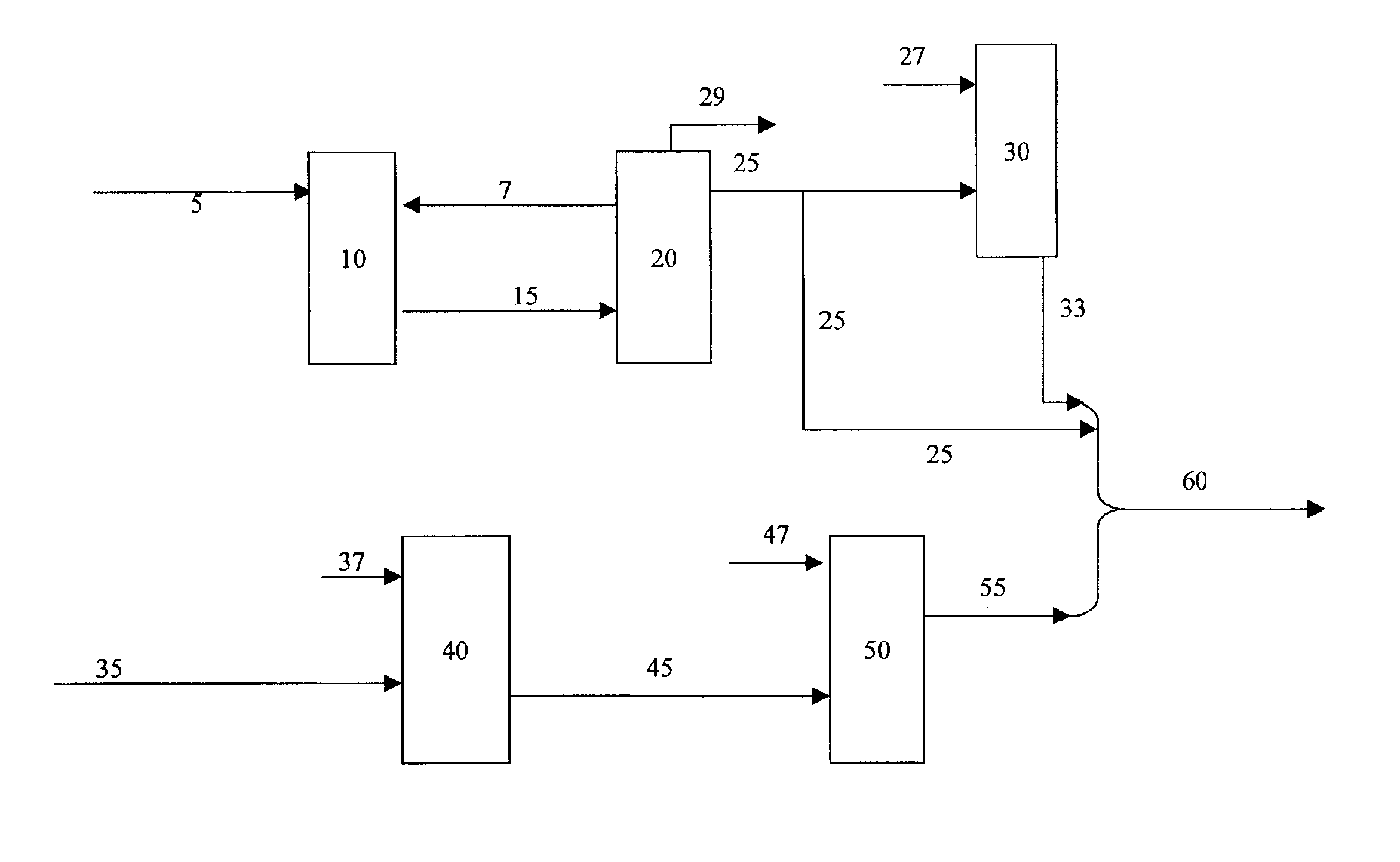

Aviation-grade kerosene comprising a first blendstock derived from non-petroleum feedstock and comprising primarily hydrocarbons selected from the group consisting of isoparaffins and normal paraffins, and a second blendstock comprising primarily hydrocarbons selected from the group consisting of cycloalkanes and aromatics.A method for the production of aviation-grade kerosene comprising producing a first blendstock from at least one non-petroleum feedstock, the first blendstock comprising primarily hydrocarbons selected from the group consisting of isoparaffins and normal paraffins; producing a second blendstock comprising primarily hydrocarbons selected from the group consisting of cycloalkanes and aromatics; and blending at least a portion of the first blendstock with at least a portion of the second blendstock to produce aviation-grade kerosene.

Owner:ENERGY & ENVIRONMENTAL RES CENT FOUNDATIO

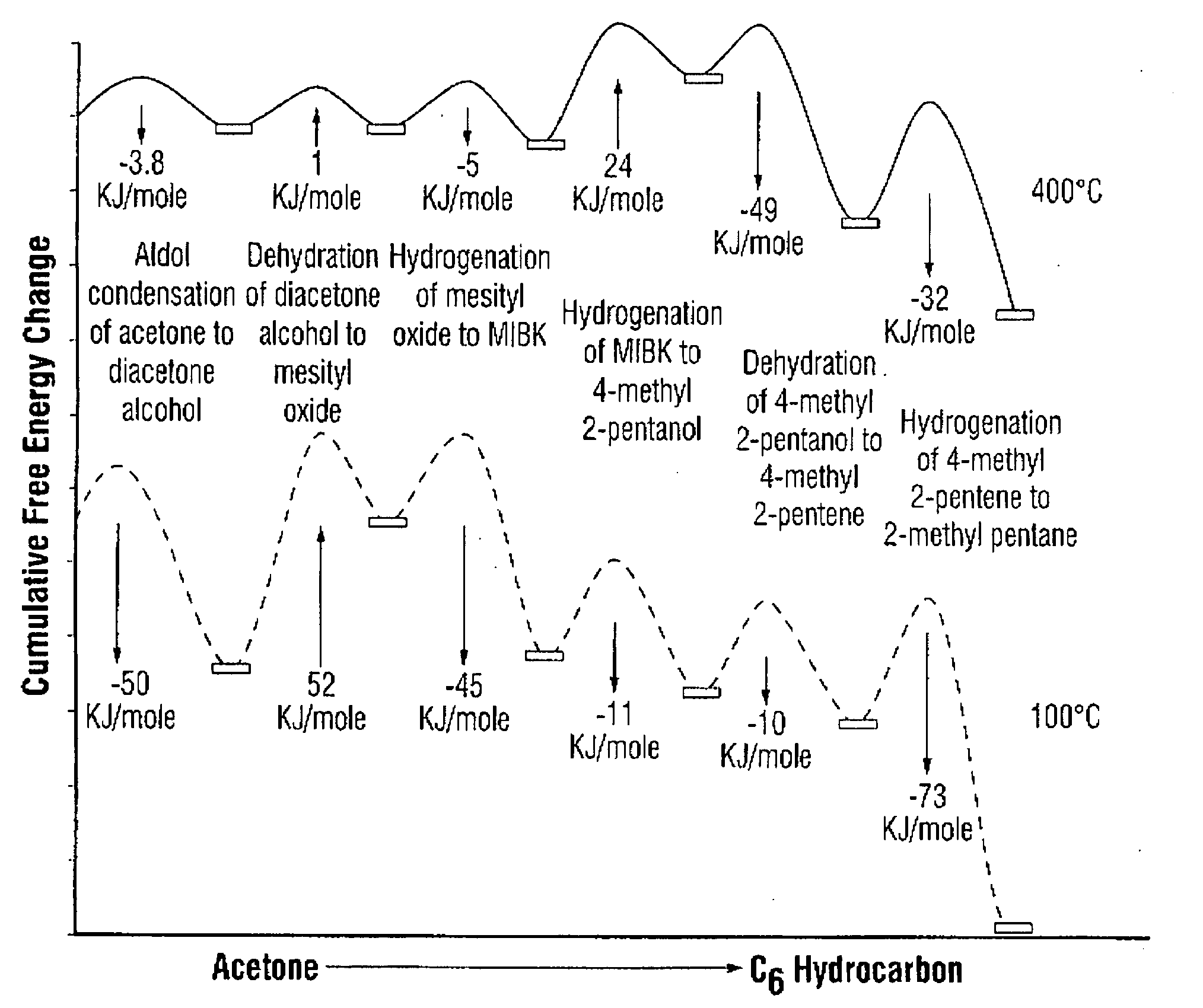

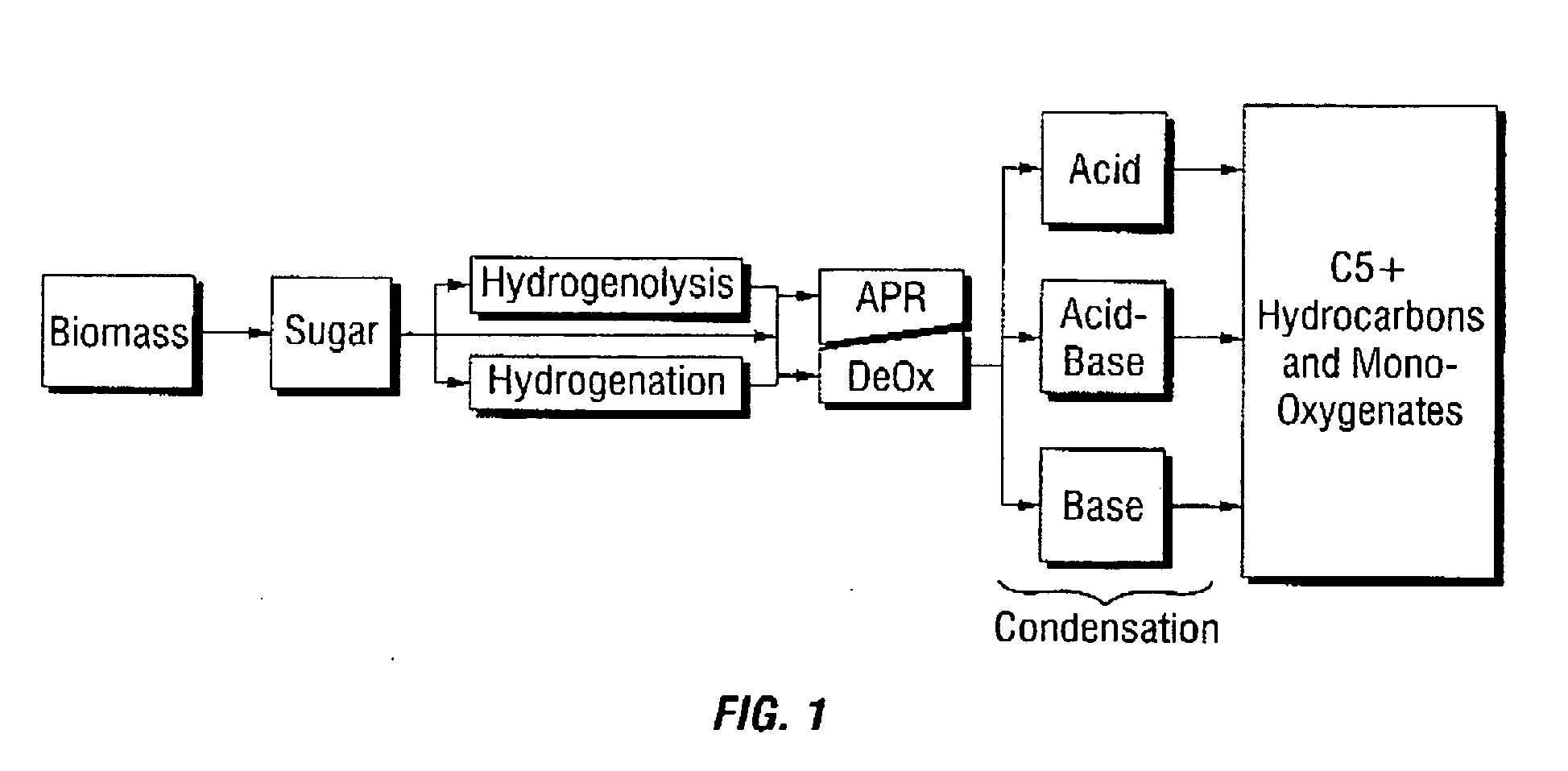

Liquid fuel compositions

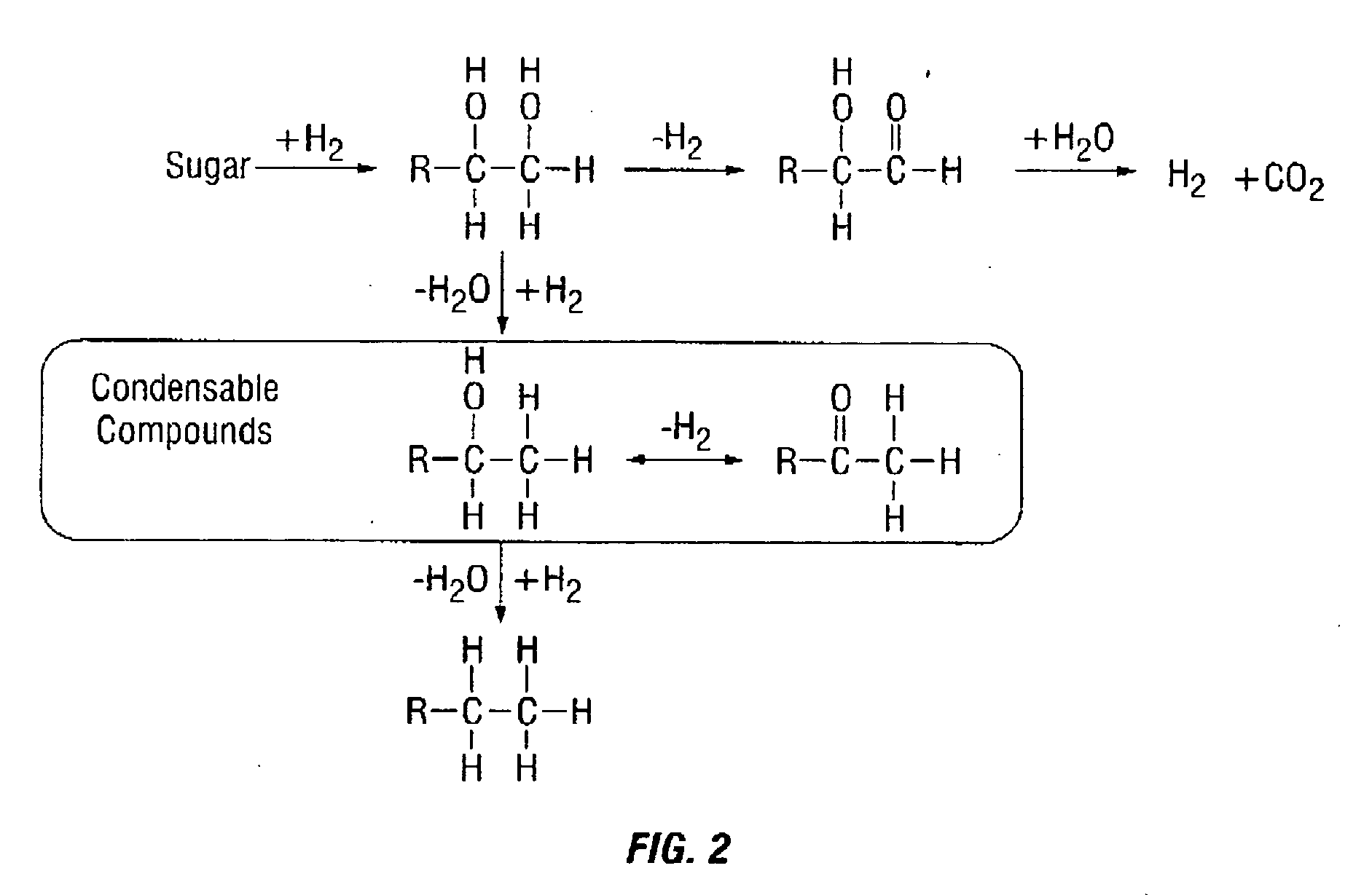

The present invention provides a liquid fuel composition comprising a distillation fraction of a component having at least one C4+ compound derived from a water-soluble oxygenated hydrocarbon prepared by a method comprising:providing water and a water-soluble oxygenated hydrocarbon comprising a C1+O1+ hydrocarbon in an aqueous liquid phase and / or a vapor phase;providing H2;catalytically reacting in the liquid and / or vapor phase the oxygenated hydrocarbon with the H2 in the presence of a deoxygenation catalyst at a deoxygenation temperature and deoxygenation pressure to produce an oxygenate comprising a C1+O1-3 hydrocarbon in a reaction stream; andcatalytically reacting in the liquid and / or vapor phase the oxygenate in the presence of a condensation catalyst at a condensation temperature and condensation pressure to produce the C4+ compound,wherein the C4+ compound comprises a member selected from the group consisting of C4+ alcohol, C4+ ketone, C4+ alkane, C4+ alkene, C5+ cycloalkane, C5+ cycloalkene, aryl, fused aryl, and a mixture thereof;wherein the liquid fuel composition is selected from:a gasoline composition having an initial boiling point in the range of from 15° C. to 70° C. (IP123), a final boiling point of at most 230° C. (IP123), a RON in the range of from 85 to 110 (ASTM D2699) and a MON in the range of from 75 to 100 (ASTM D2700);a diesel fuel composition having an initial boiling point in the range of from 130° C. to 230° C. (IP123), a final boiling point of at most 410° C. (IP123) and a cetane number in the range of from 35 to 120 (ASTM D613); anda kerosene composition having an initial boiling point in the range of from 80 to 150° C., a final boiling point in the range of from 200 to 320° C. and a viscosity at −20° C. in the range of from 0.8 to 10 mm2 / s (ASTM D445).

Owner:SHELL USA INC

Method of Converting Triglycerides to Biofuels

ActiveUS20080071125A1Improve chemical and physical and combustion qualityImprove thermal stabilityFatty acid chemical modificationBiofuelsIsomerizationPtru catalyst

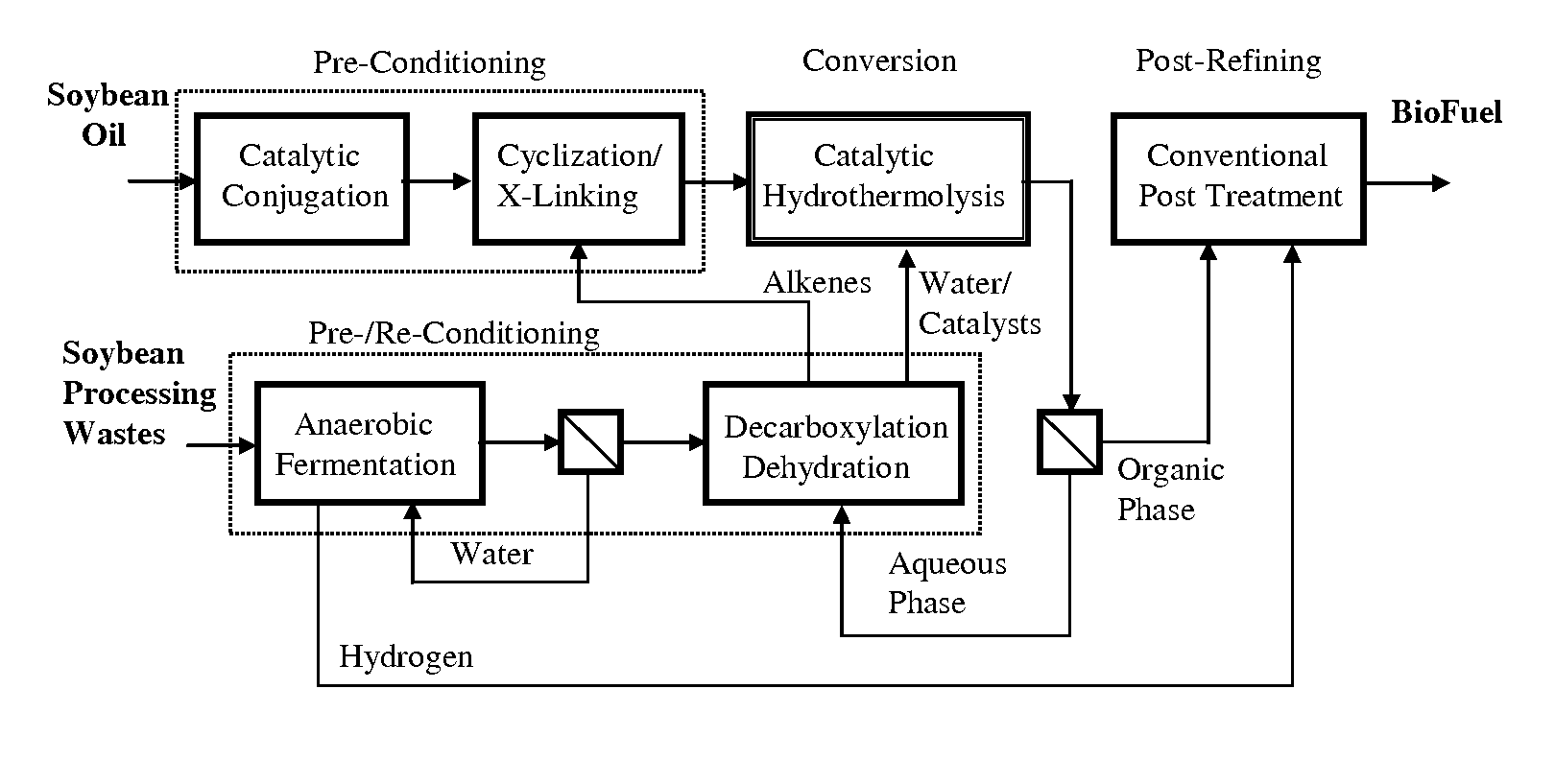

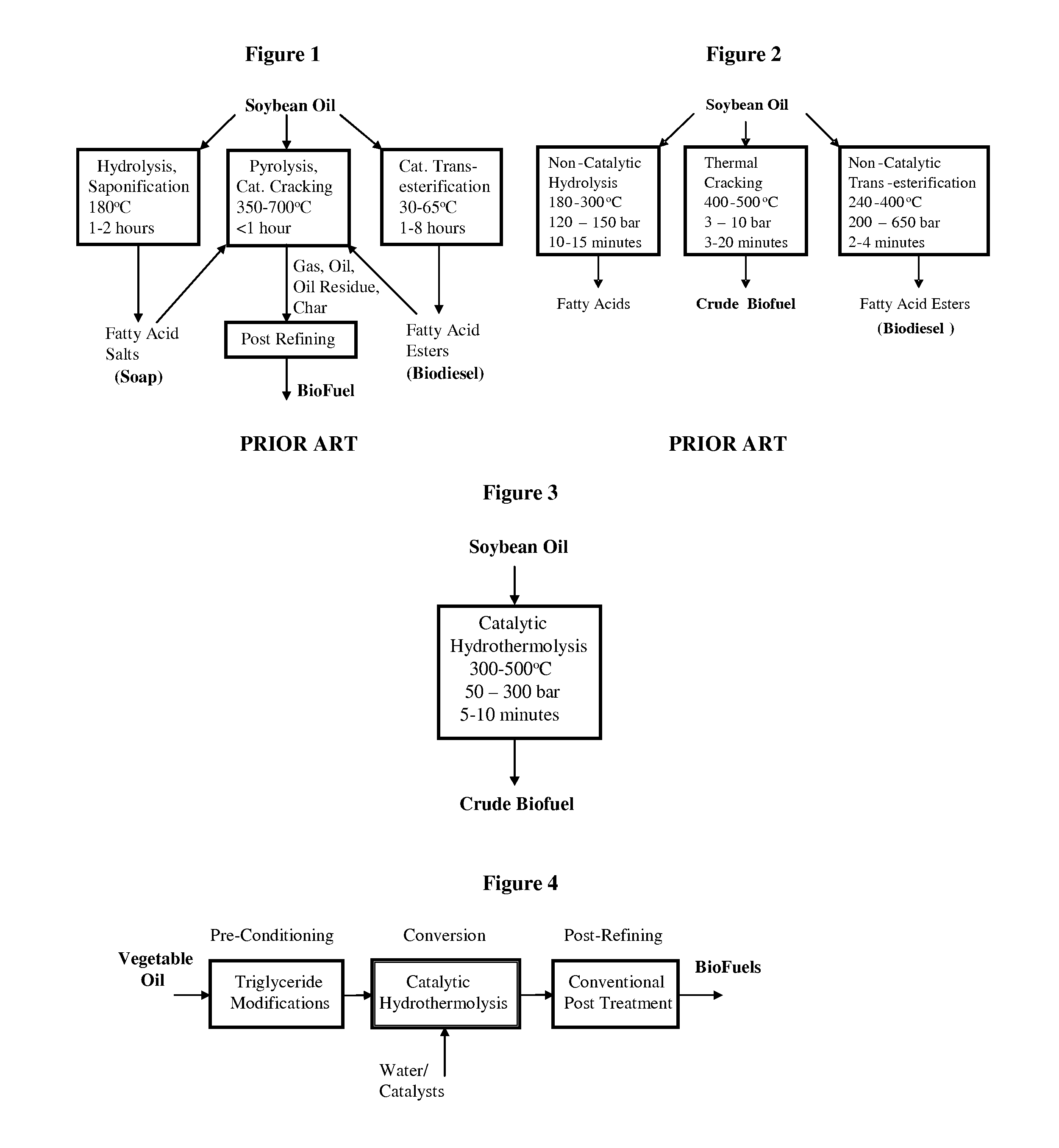

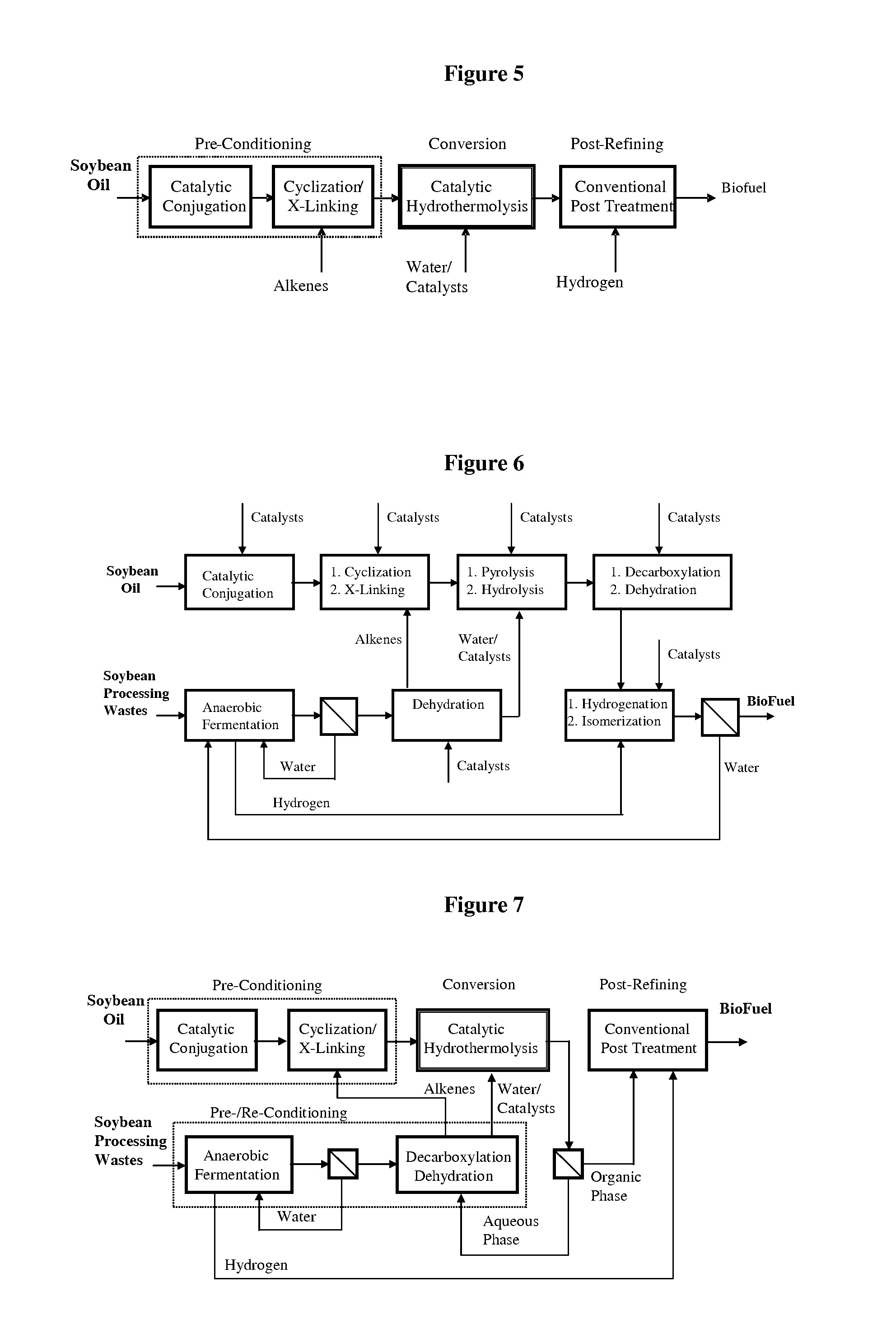

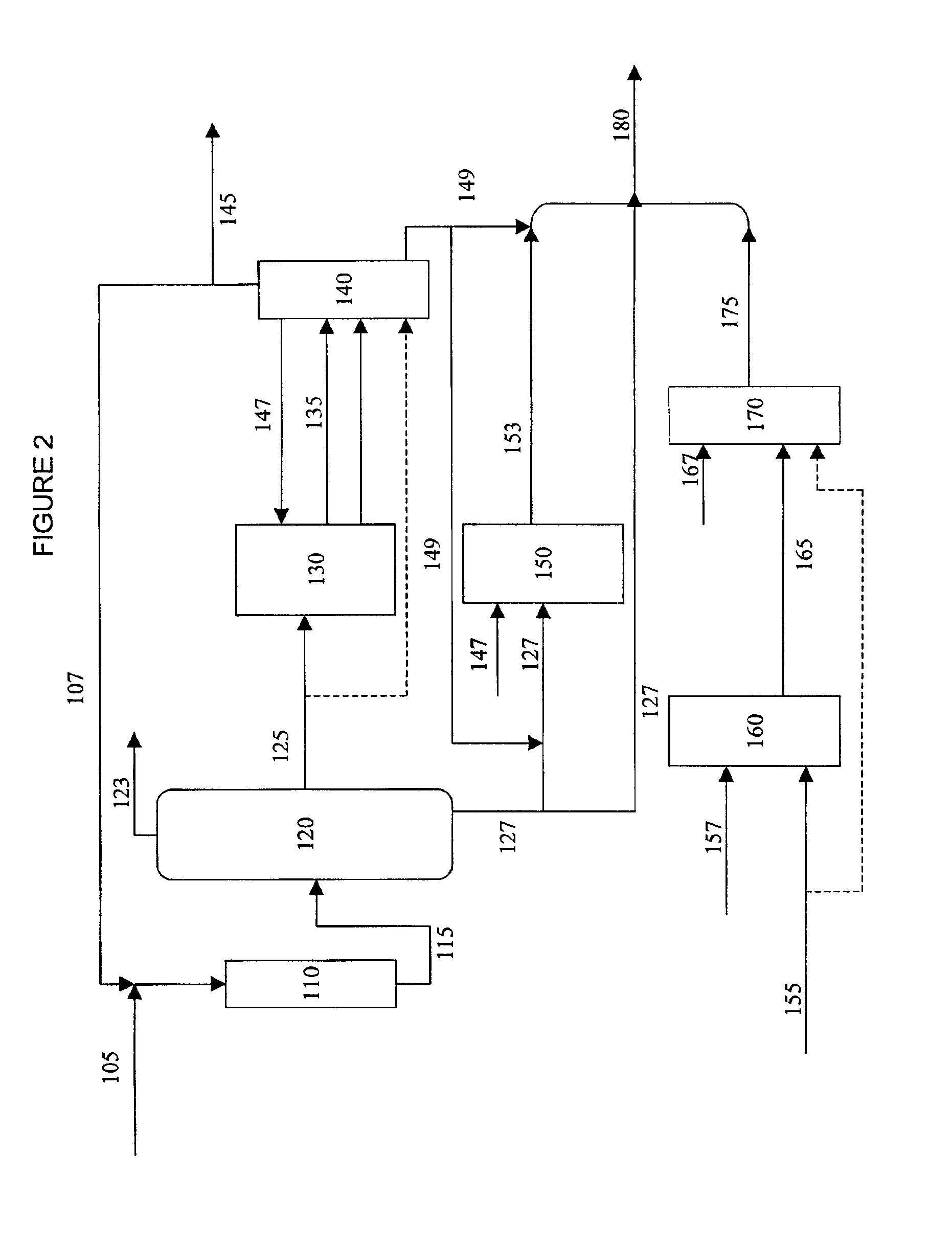

A triglyceride-to-fuel conversion process including the steps of (a) preconditioning unsaturated triglycerides by catalytic conjugation, cyclization, and cross-link steps; (b) contacting the modified triglycerides with hot-compressed water containing a catalyst, wherein cracking, hydrolysis, decarboxylation, dehydration, aromatization, or isomerization, or any combination thereof, of the modified triglycerides produce a crude hydrocarbon oil and an aqueous phase containing glycerol and lower molecular weight molecules, and (c) refining the crude hydrocarbon oil to produce various grades of biofuels. A triglyceride-to-fuel conversion process further including the steps of (a) carrying out anaerobic fermentation and decarboxylation / dehydration, wherein the anaerobic fermentation produces hydrogen, volatile acids, and alcohols from fermentable feedstocks, and the decarboxylation / dehydration produces alkenes from the volatile acids and alcohols, respectively; (b) feeding the alkenes to the cyclization process; (c) feeding the hydrogen to the post refining process; and (d) recycling the aqueous phase containing glycerol to the decarboxylation / dehydration process. A biofuel composition including straight-chain, branched and cyclo paraffins, and aromatics. The paraffins are derived from conversion of triglycerides. The aromatics are derived from conversion of either triglycerides, petroleum, or coal.

Owner:APPLIED RES ASSOCS INC

Distillate fuel blends from Fischer Tropsch products with improved seal swell properties

InactiveUS6890423B2Hydrocarbon by isomerisationCatalytic naphtha reformingPolymer scienceEngineering

The invention provides distillate fuel blend components with improved seal swell and lubricity properties obtained from Fischer Tropsch products. The blends contain a highly paraffinic distillate fuel component and distillate-boiling alkylcycloparaffins and / or distillate-boiling alkylaromatics. The invention further provides processes for obtaining such blends using the products of Fischer Tropsch processes. Finally, the invention provides methods for improving seal swell and lubricity properties for distillate fuels.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

Hydrocracking catalyst and preparation method thereof

ActiveCN103100417AHigh selectivityLarge freezing pointMolecular sieve catalystsHydrocarbon oil crackingAlkaneMolecular sieve

The invention discloses a hydrocracking catalyst and a preparation method thereof. The hydrocracking catalyst comprises: a carrier composed of a modified beta molecular sieve, a modified Y type molecular sieve and alumina, and hydrogenation active metal components. Specifically, the modified beta molecular sieve is prepared by: subjecting a crystallized beta molecular sieve slurry directly to ammonium exchange and a template agent removal treatment, then first conducting a hydrothermal treatment, and performing an aluminum salt solution treatment, under the condition of maintaining a high beta molecular sieve crystallinity, removing part of non-framework aluminum uniformly, thus obtaining the beta molecular sieve with the characteristics of high Si / Al ratio, large specific surface area, appropriate acidity and acid distribution, and reasonable structure, etc. The modified beta molecular sieve especially has a suitable cracking effect and a very good isomerization effect on long-chain alkane and the long side chain alkyl of aromatic hydrocarbon and cyclane, and has a synergistic effect with the Y type molecular sieve, so that the hydrocracking catalyst can have very high catalytic activity and middle distillate selectivity. And the condensation point of diesel fraction is substantially reduced, and the product properties of middle distillate are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

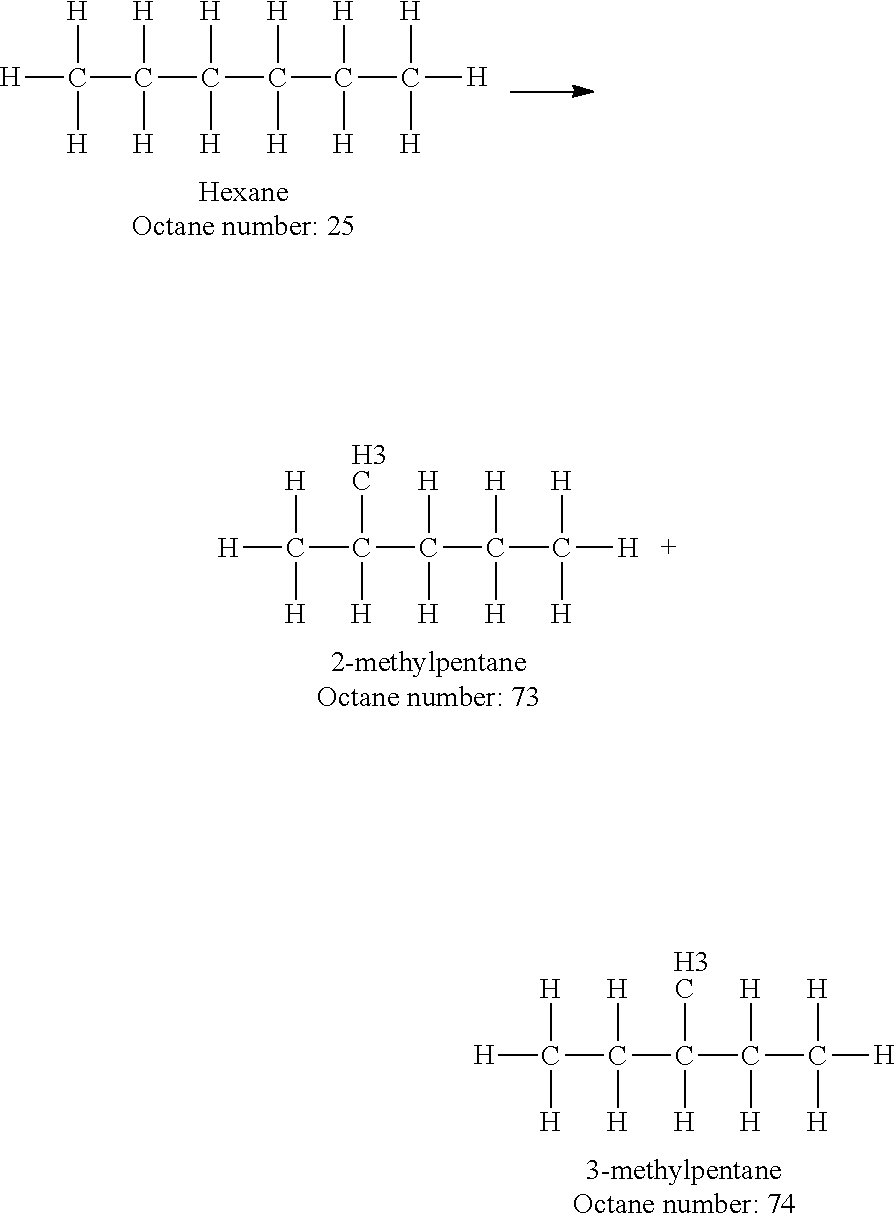

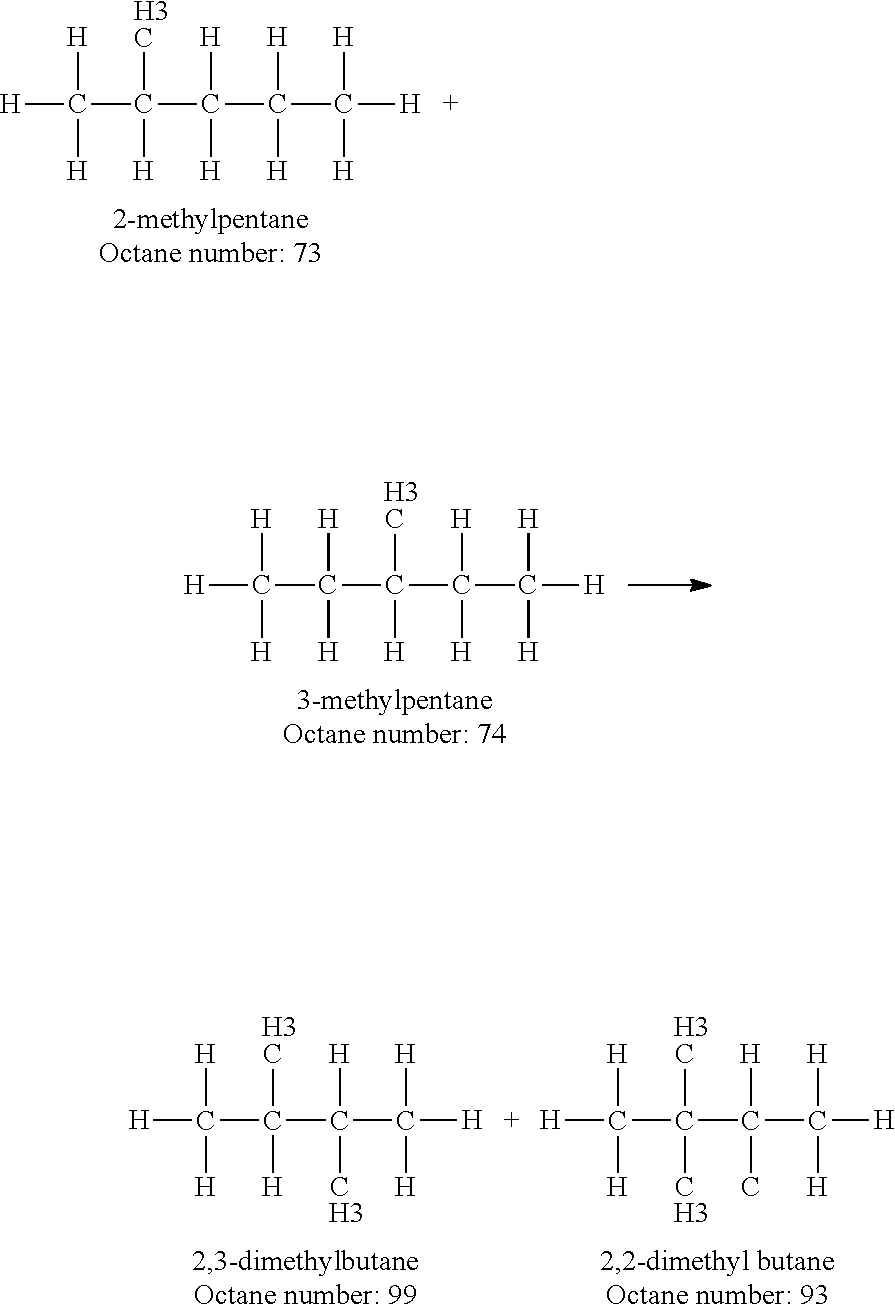

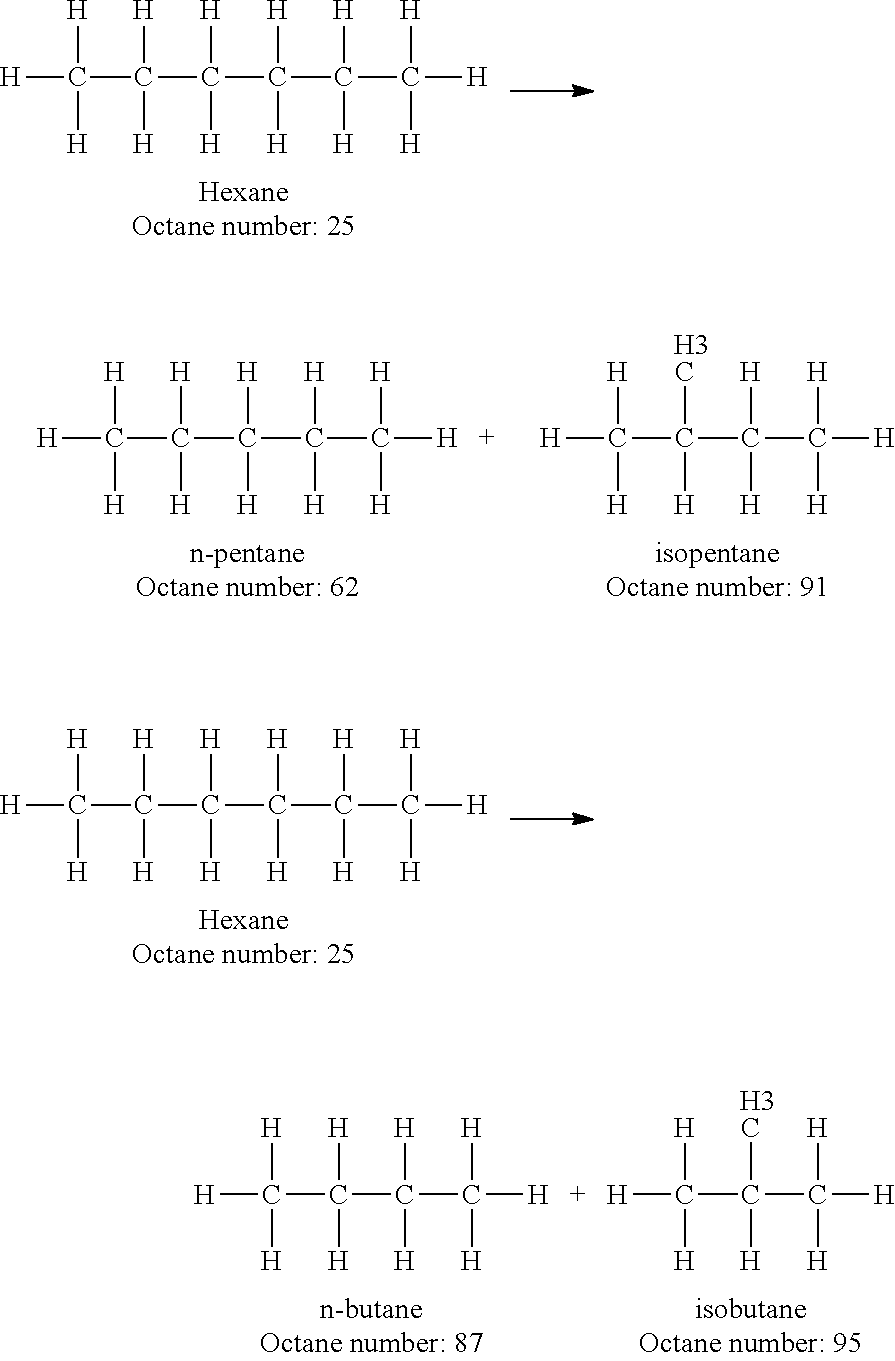

High octane number gasolines and their production using a process associating hydro-isomerization and separation

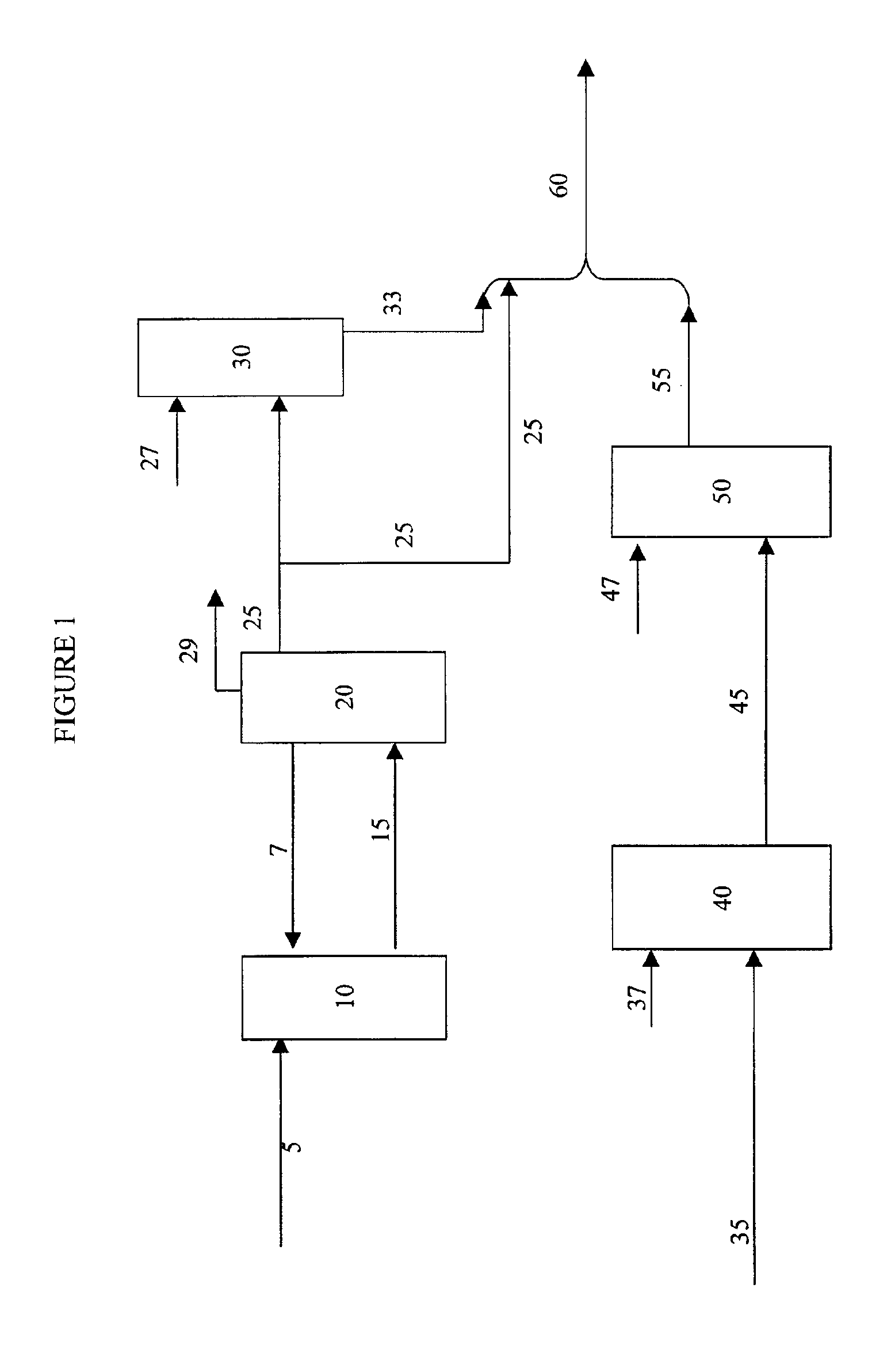

InactiveUS6338791B1Minimize cracksReduce the amount requiredRefining to change hydrocarbon structural skeletonHydrocarbon by hydrogenationCyclic alkaneIsomerization

The invention provides a high octane number gasoline pool comprises at least 2% of di-branched paraffins containing 7 carbon atoms, and a process for producing this gasoline pool by hydro-isomerizing a feed constituted by a C5 to C8 cut which comprises at least one hydro-isomerization section and at least one separation section, in which the hydro-isomerization section and at least one separation section, in which the hydro-isomerization section comprises at least one reactor. The separation section comprises at least one unit and produces at least two streams: a first stream which is rich in di- and tri-branched paraffins, and possibly in naphthenes and aromatic compounds which is sent to the gasoline pool; and in a first version of the process, a second stream is produced which is rich in straight-chain and mono-branched paraffins which is recycled to the inlet of the hydro-isomerization section, while in a second version of the process, a second flux is produced which is rich in straight-chain paraffins which is recycled to the inlet of a first hydro-isomerization section and a third stream is produced which is rich in mono-branched paraffins which is recycled to the inlet of a second hydroisomerization section.

Owner:INST FR DU PETROLE

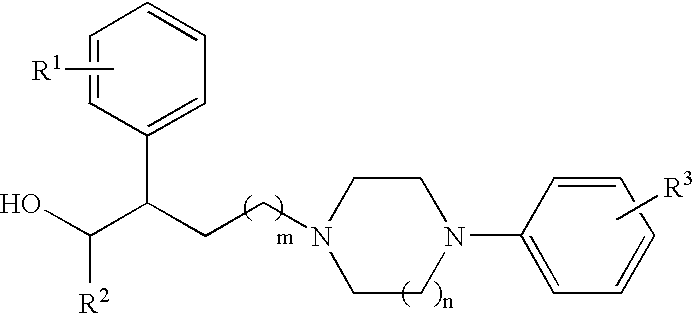

N,N-disubstituted diazocycloalkanes

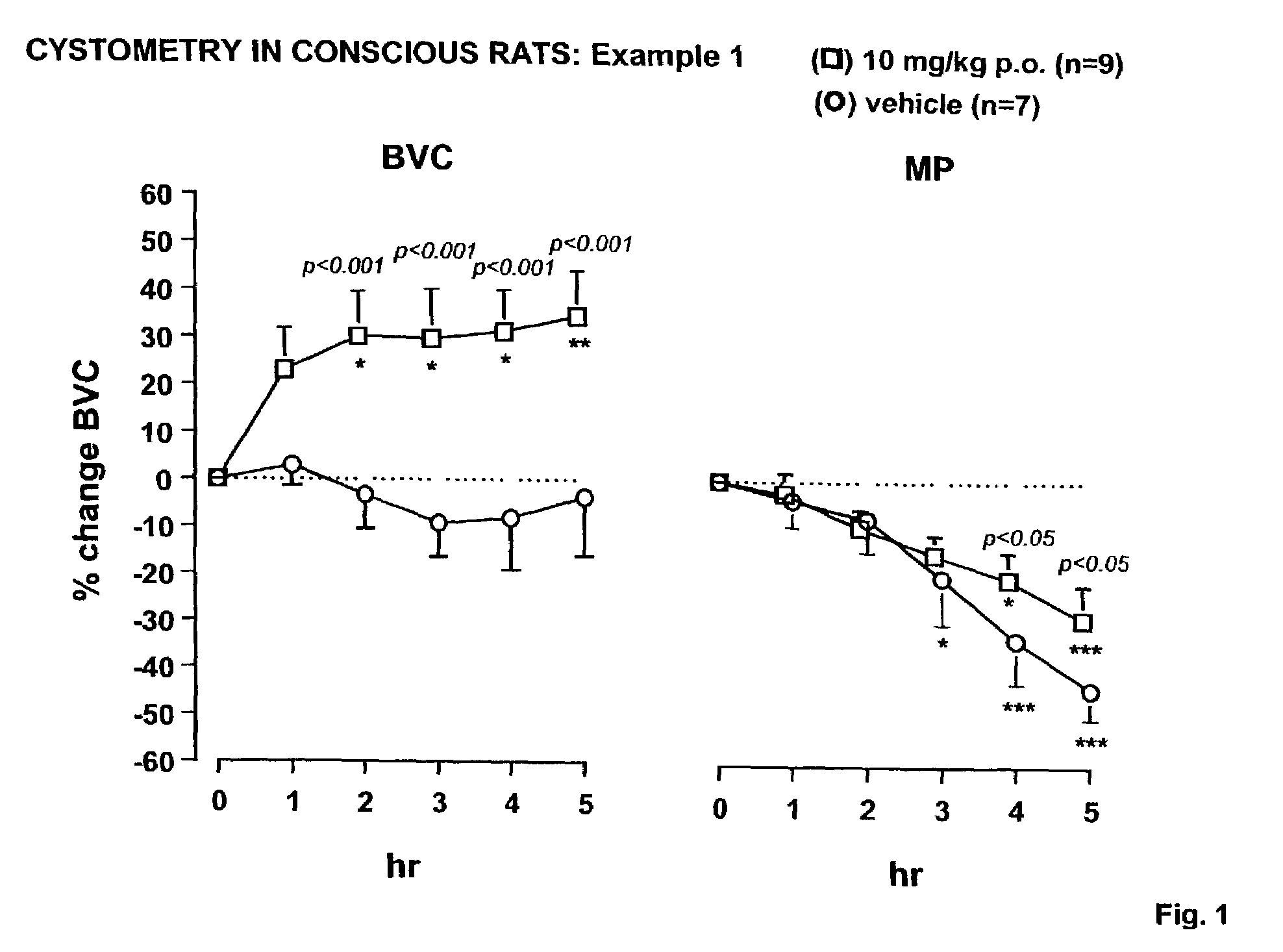

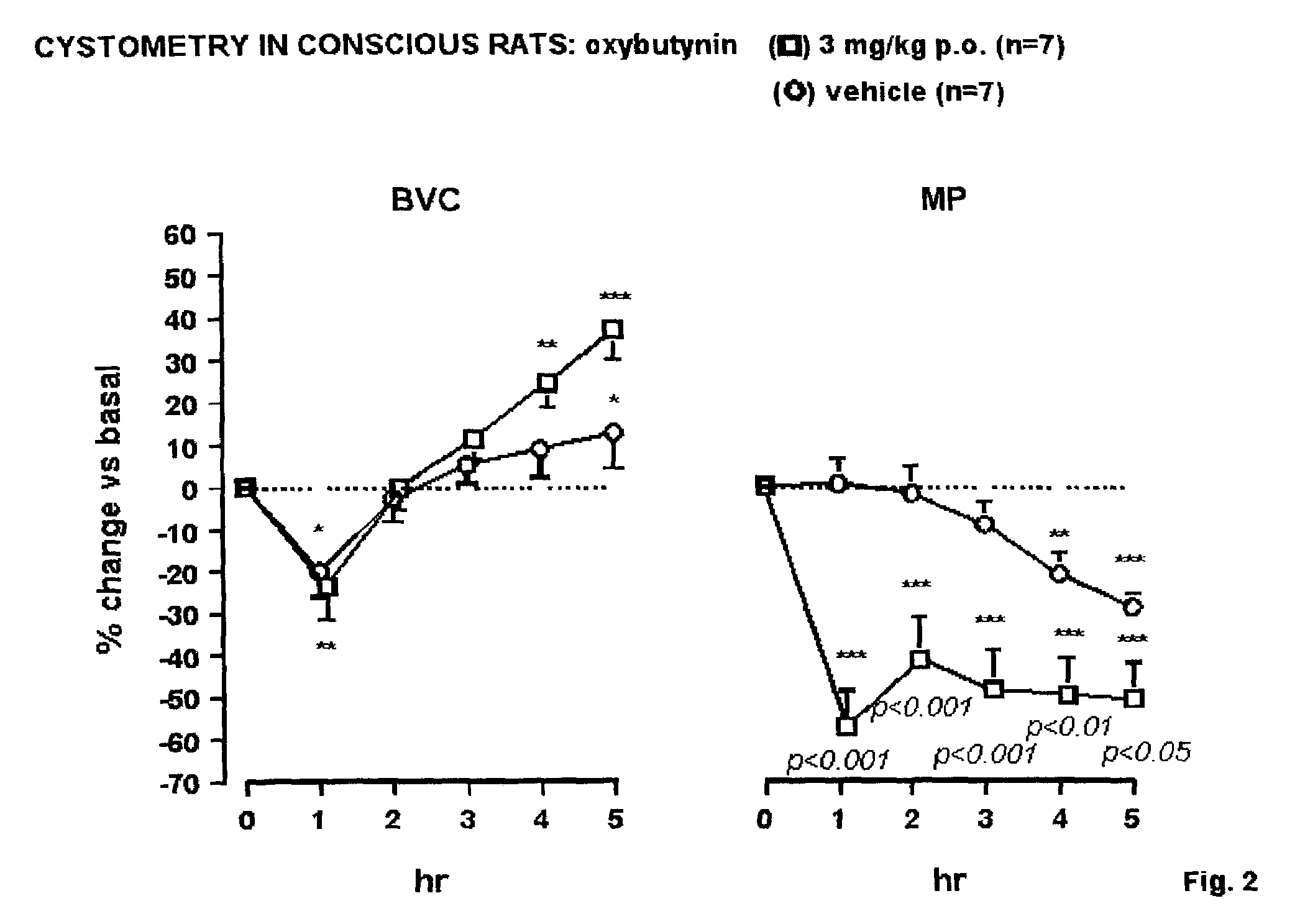

N,N-Disubstituted diazocycloalkanes of the formula I(R1=halogen, R2=(C3–C8)-cycloalkyl, R3=(C1–C4)-alkoxy or (C1–C4)-haloalkoxy group, m is 1 or 2 and n is 1 or 2, have affinity for serotonergic receptors. These compounds and their enantiomers, diastereoisomers, N-oxides, polymorphs, solvates and pharmaceutically acceptable salts are useful in the treatment of patients with neuromuscular dysfunction of the lower urinary tract and diseases related to 5-HT1A receptor.

Owner:RECORDATI SA

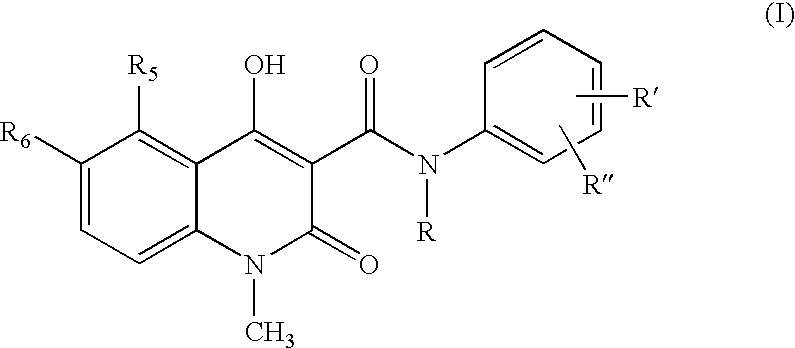

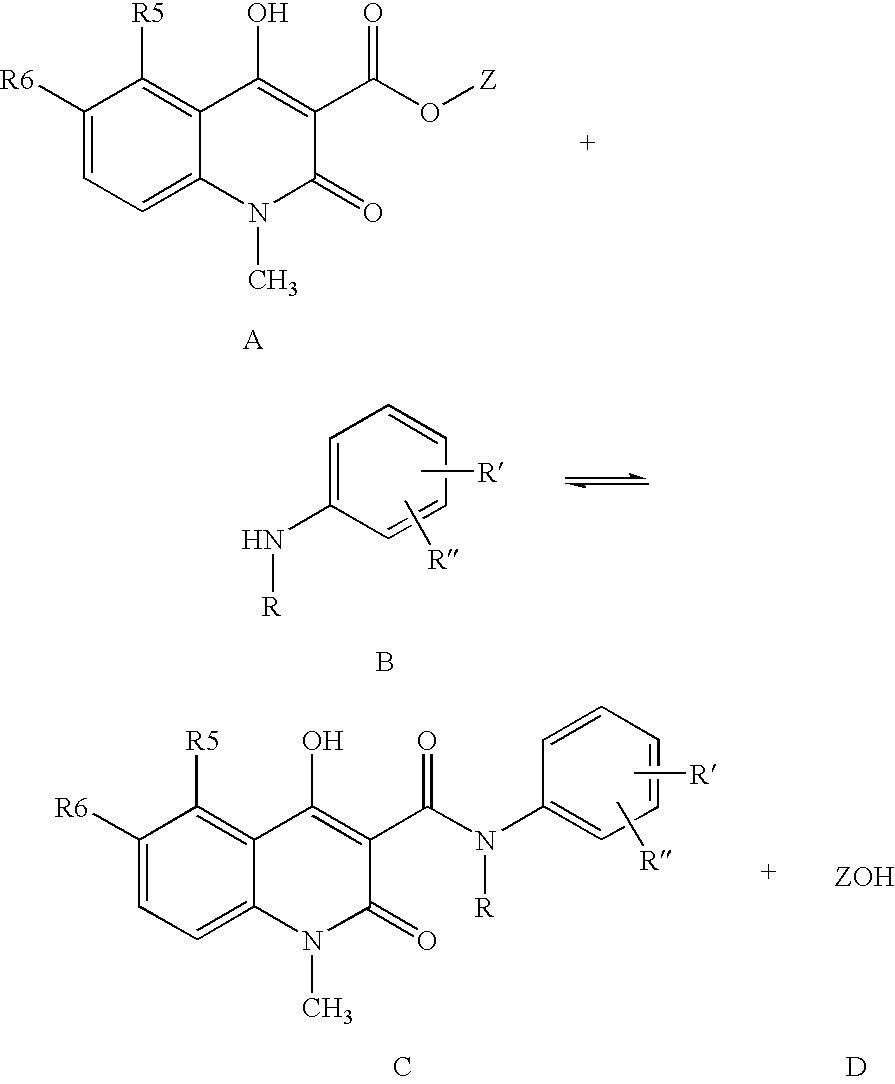

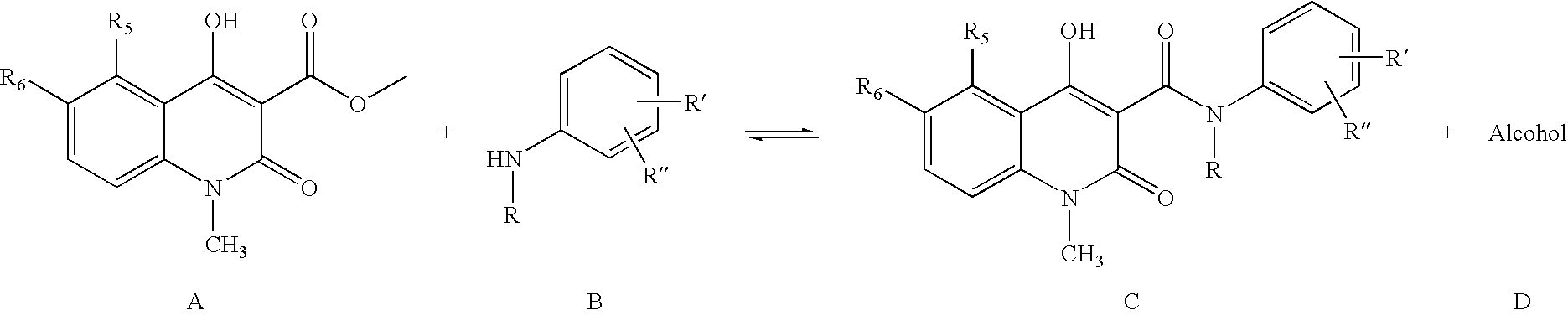

Process for the manufacture of quinoline derivatives

Owner:ACTIVE BIOTECH AB

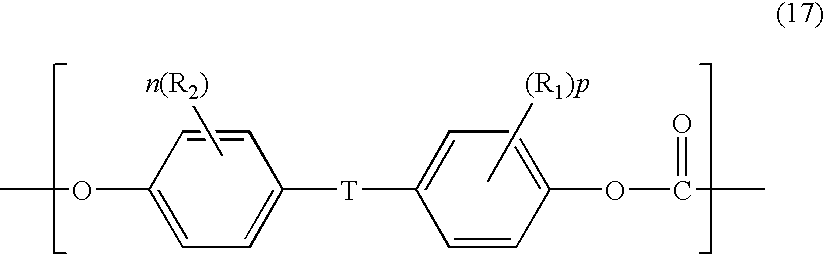

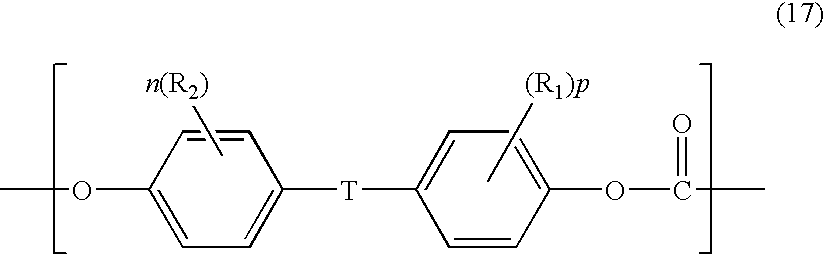

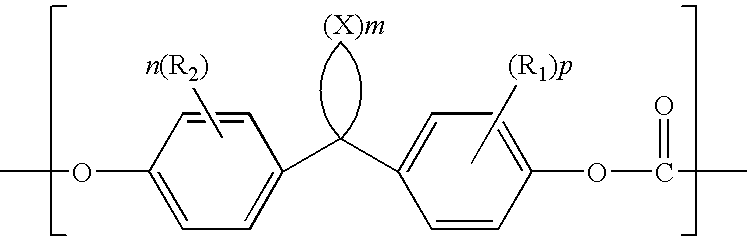

Flame retardant and chemical resistant thermoplastic polycarbonate compositions

A flame retardant thermoplastic composition comprising in combination a polycarbonate component comprising an aromatic polycarbonate and a polycarbonate homopolymer or copolymer comprising repeat carbonate units having the following structure:wherein R1 and R2 are independently at each occurrence a C1-C4 alkyl, n and p are each an integer having a value of 1 to 4, and T is selected from the group consisting of C5-C10 cycloalkanes attached to the aryl groups at one or two carbons, C1-C5 alkyl groups, C6-C13 aryl groups, and C7-C12 aryl alkyl groups; a polycarbonate-polysiloxane copolymer; an impact modifier; and a flame retardant. The compositions have excellent chemical resistance as well as an improved balance of physical properties such as impact strength and spiral flow, while at the same time maintaining their good flame performance.

Owner:SABIC INNOVATIVE PLASTICS IP BV

Paint stripping compositions

InactiveUS6479445B1Improve combination effectImprove efficacyChemical paints/ink removersDetergent solventsAlcoholPropylene carbonate

This invention concerns a composition useful as a paint remover, comprising: an organic carbonate, an alcohol, an activator, hydrogen peroxide, and water. The alcohol may be benzyl alcohol. The organic carbonate may be propylene carbonate, ethylene carbonate, or combination thereof. The activator may be an alkyl-substituted cycloalkane (naphthene), a soy oil, an alkyl soyate, or combination thereof.

Owner:HUNTSMAN PETROCHEMICAL LLC

Aviation-grade kerosene from independently produced blendstocks

Aviation-grade kerosene comprising a first blendstock derived from non-petroleum feedstock and comprising primarily hydrocarbons selected from the group consisting of isoparaffins and normal paraffins, and a second blendstock comprising primarily hydrocarbons selected from the group consisting of cycloalkanes and aromatics.

Owner:ENERGY & ENVIRONMENTAL RES CENT FOUNDATIO

Process for dehydrogenating organic compounds in the presence of a supported bimetallic catalyst with a strong interaction between a group VIII metal and tin

InactiveUS6600082B2Synergistic effectHydrocarbon by dehydrogenationHydrocarbon by hydrogenationPlatinumIsomeric shift

Owner:INST FR DU PETROLE

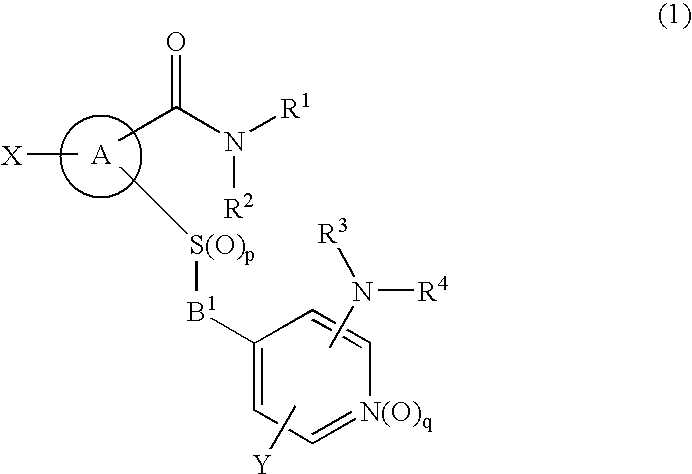

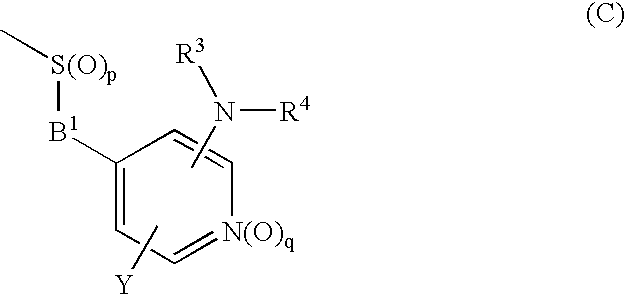

Novel cyclic compound having 4-pyridylalkylthio group having substituted or unsubstituted amino group introduced therein

InactiveUS20070149574A1Useful in therapyExcellent cell proliferation inhibitory effectBiocideSenses disorderDiseaseAryl

A novel cyclic compound having a 4-pyridylalkylthio group having an (un)substituted amino group introduced therein or a salt thereof. They are useful as a medicine. The cyclic compound is a compound represented by the following formula (1), which is useful for the treatment of diseases in which angiogenesis participates. In the following formula (1), ring A represents a benzene ring or a 5- or 6-membered aromatic heterocycle optionally fused with a cycloalkane ring; B represents alkylene; R1 and R2 each represents H, (substituted) aryl, (substituted) heterocyclic group, etc.; R3 and R4 each represents H, (substituted) alkyl, (substituted) cycloalkyl, -Z-R5, etc.; R5 represents (substituted) alkyl, (substituted) aryl, (substituted) heterocyclic group, etc.; X and Y each represents H, etc.; Z represents —CO—, —COO—, —CONR6—, —SO2—, etc.; R6 represents H, etc.; p is 0, 1, or 2; and q is 0 or 1.

Owner:SANTEN PHARMA CO LTD

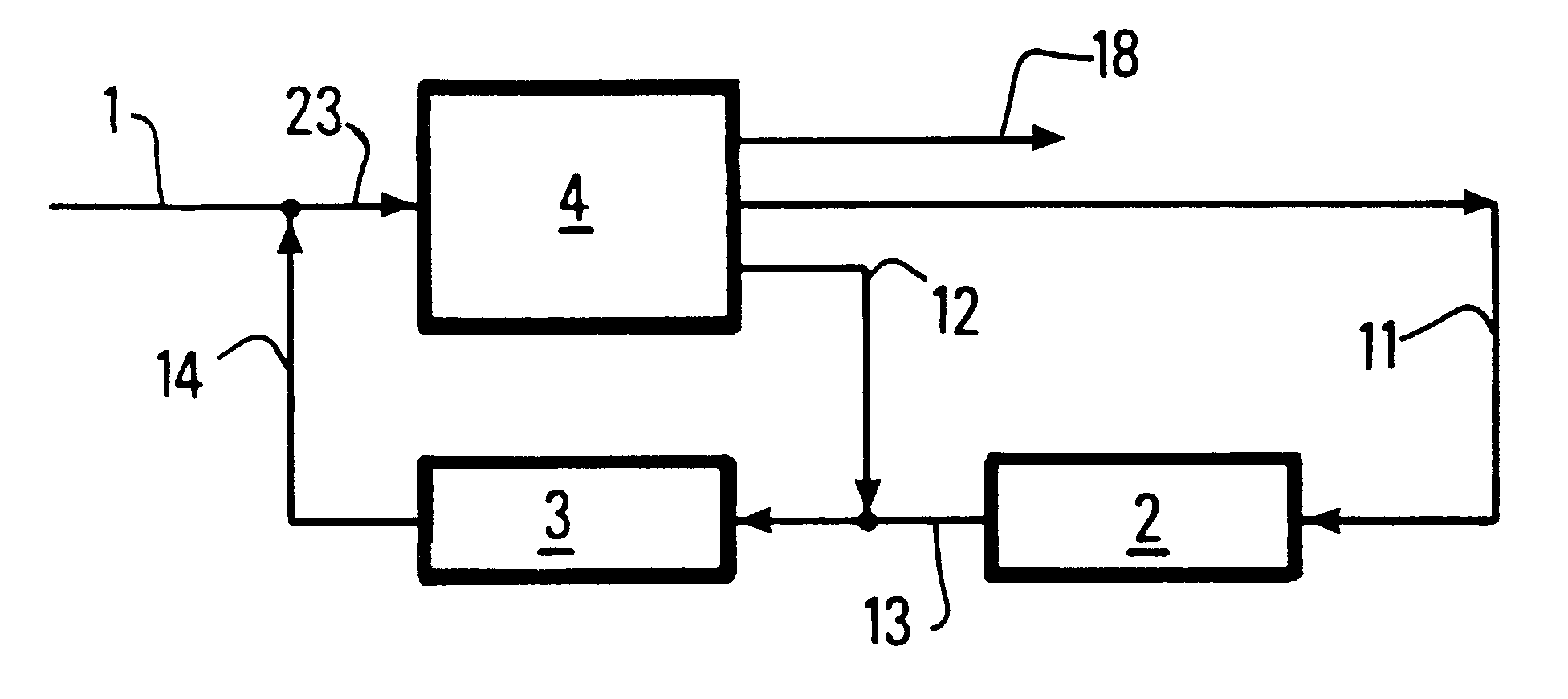

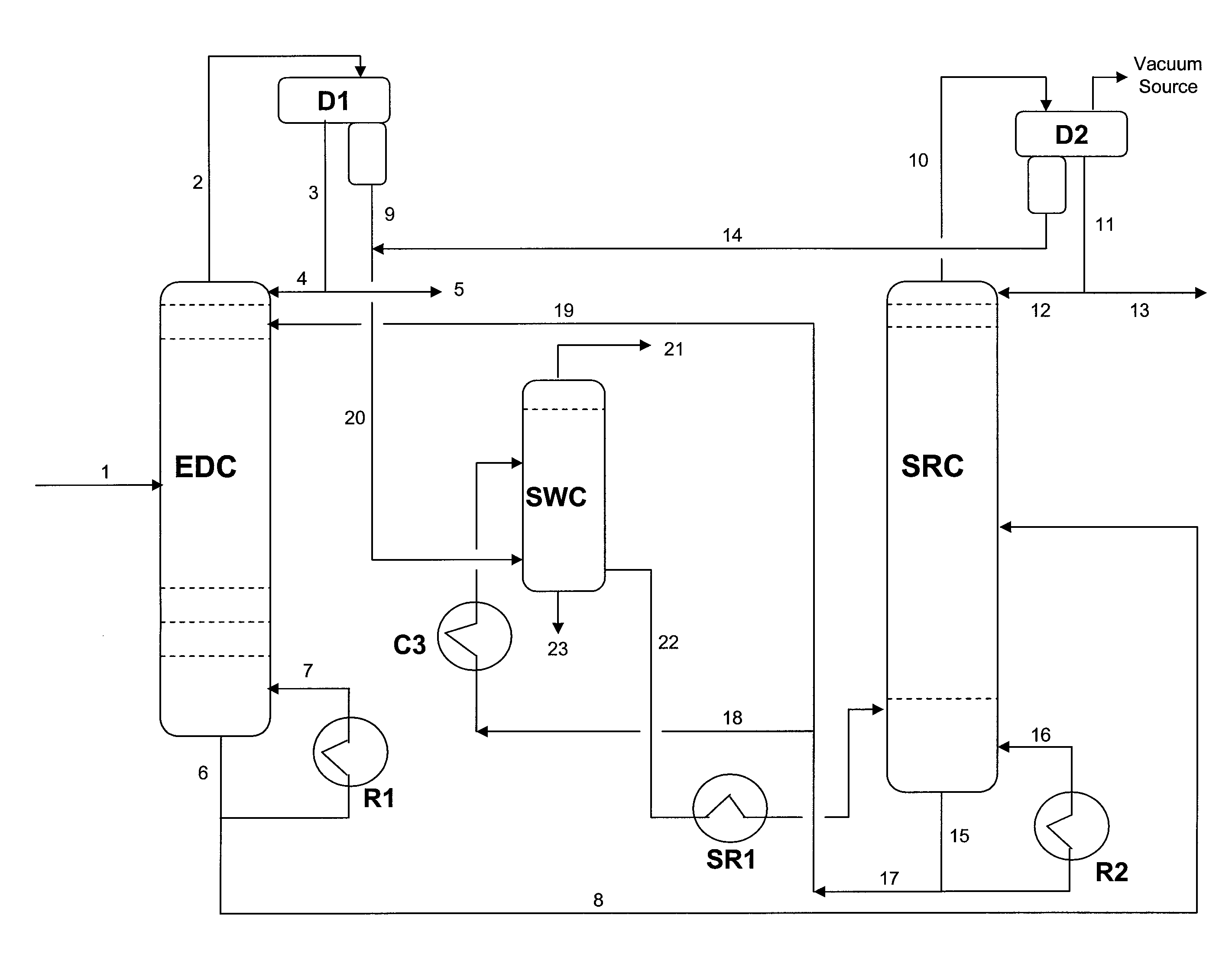

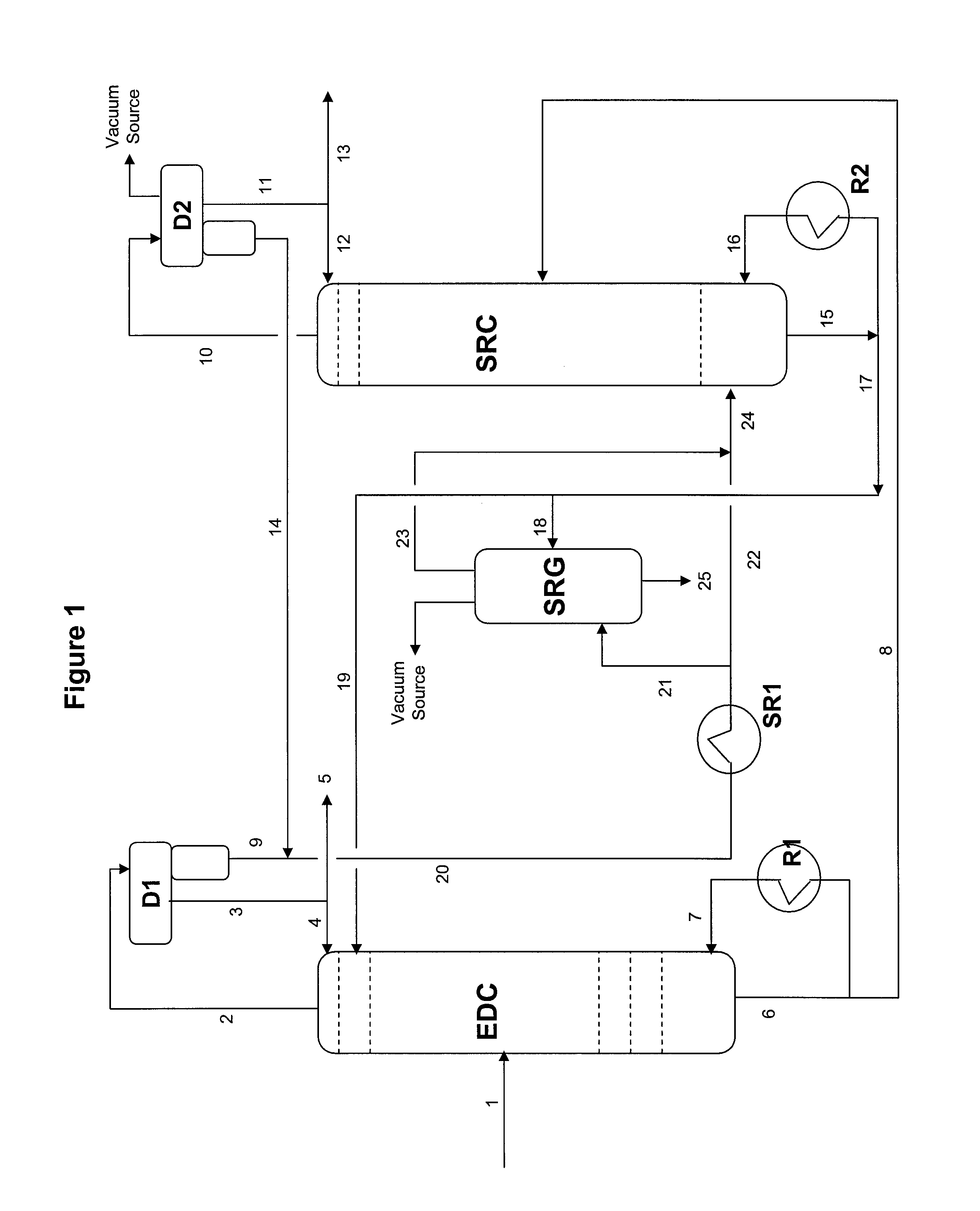

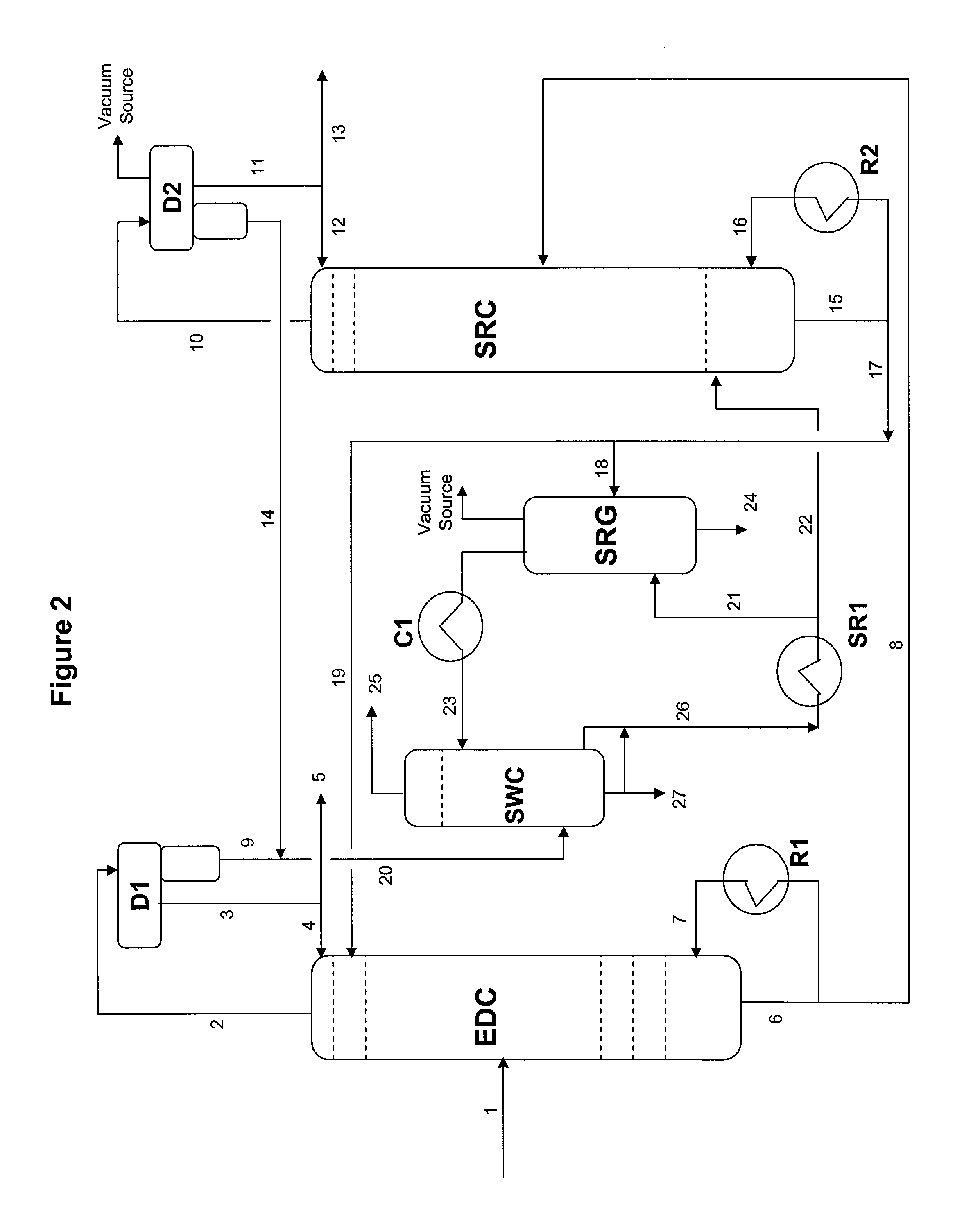

Extractive distillation process for recovering aromatics from petroleum streams

InactiveUS7666299B2Treatment with plural serial cracking stages onlyHydrocarbon oils refiningAlkaneExtractive distillation

A process for recovering polar hydrocarbons from non-polar hydrocarbons, such as aromatics from non-aromatics, naphthenes from paraffins and isoparaffins, or olefins from paraffins and isoparaffins, in feed mixtures containing at least a measurable amount of heavier hydrocarbons. This improved extractive distillation (ED) process recovers aromatic hydrocarbons including benzene, toluene, and xylenes from the C6-C8 petroleum streams containing a measurable amount of C9+ hydrocarbons. The ED process also recovers benzene and toluene from the C6-C7 petroleum streams containing a measurable amount of C8+ hydrocarbons. The ED solvent utilized to recover and purify the aromatic hydrocarbons from the petroleum stream with a heavier than intended feedstock of hydrocarbons is also regenerated and recovered.

Owner:AMT INT INC +1

Paint stripping compositions

InactiveUS20030119686A1Improve combination effectImprove efficacySurface-active detergent compositionsChemical paints/ink removersAlcoholPropylene carbonate

This invention concerns a composition useful as a paint remover, comprising: an organic carbonate, an alcohol, an activator, hydrogen peroxide, and water. The alcohol may be benzyl alcohol. The organic carbonate may be propylene carbonate, ethylene carbonate, or combination thereof. The activator may be an alkyl-substituted cycloalkane (naphthene), a soy oil, an alkyl soyate, or combination thereof.

Owner:HUNTSMAN PETROCHEMICAL LLC

Aromatic aklylating agent and an aromatic production apparatus

InactiveUS20110178354A1Increase the molar ratioIncrease valueHydrocarbonsHydrocarbon by hydrocarbon condensationAlkaneMethylating Agent

One exemplary embodiment can be a process using an aromatic methylating agent. Generally, the process includes reacting an effective amount of the aromatic methylating agent having at least one of an alkane, a cycloalkane, an alkane radical, and a cycloalkane radical with one or more aromatic compounds. As such, at least one of the one or more aromatic compounds may be converted to one or more higher methyl substituted aromatic compounds to provide a product having a greater mole ratio of methyl to phenyl than a feed.

Owner:UOP LLC

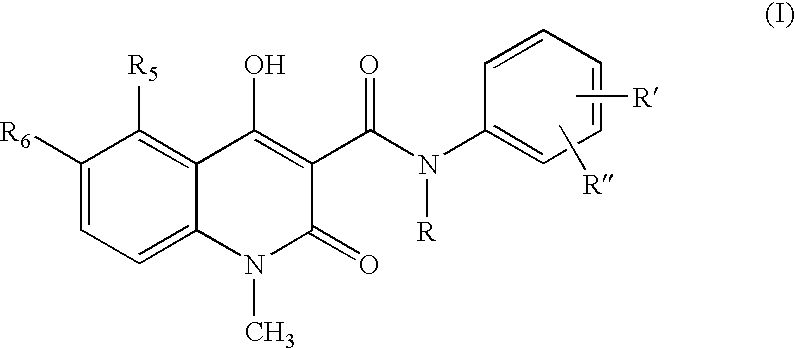

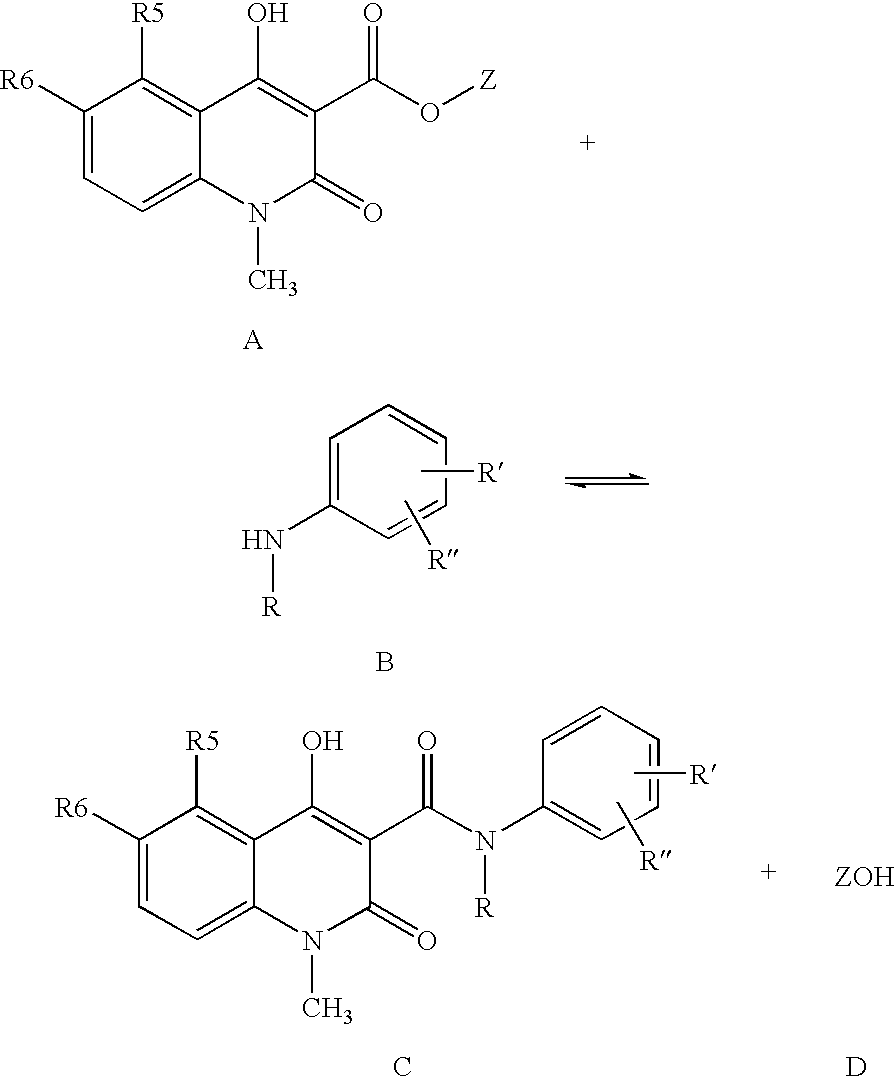

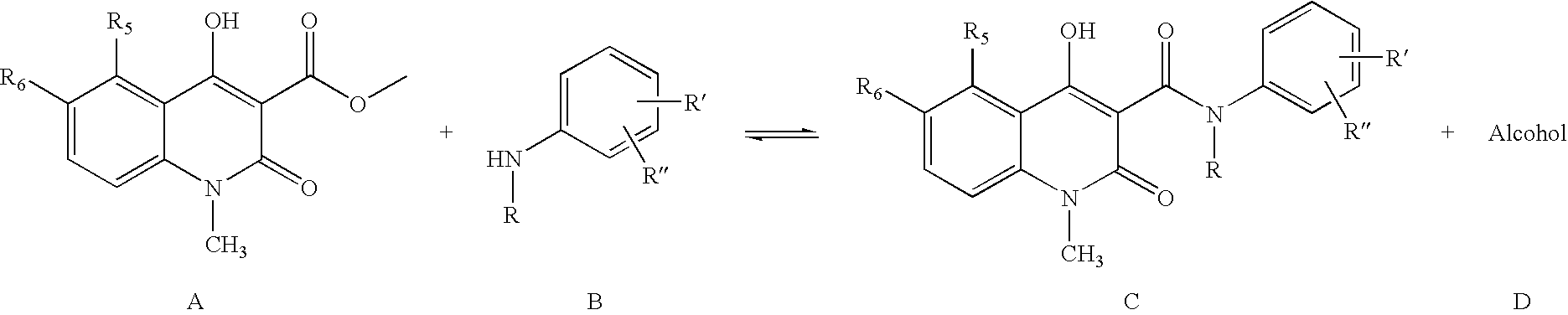

Process for the manufacture of quinoline derivatives

A process for the preparation of the compounds of general formula (I) wherein R is selected from methyl, ethyl, n-propyl, iso-propyl, n-butyl, iso-butyl, sec.-butyl and allyl; R5 is selected from methyl, ethyl, n-propyl, iso-propyl, methoxy, ethoxy, methylthio, ethylthio, n-propylthio, methylsulphinyl, ethylsulphinyl, fluoro, chloro, bromo, trifluoromethyl, and OCHxFy; wherein x=0−2, y=1−3 with the proviso that x+y=3; R6 is hydrogen; or R5 and R6 taken together are methylenedioxy; R′ is selected from hydrogen, methyl, methoxy, fluoro, chloro, bromo, trifluoromethyl, and OCHxFy, wherein x=0−2, y=1−3 with the proviso that x+y=3; R″ is selected from hydrogen, fluoro and chloro, with the proviso that R″ is selected from fluoro and chloro only when R′ is selected from fluoro and chloro; by reacting a quinoline-3-carboxylic acid ester derivative of formula A, where Z is methyl, with an aniline derivative of formula B according to the following reaction diagram, to give the compound of general formula (I), designated “C”, and an alcohol, designated “D”. in a solvent selected from straight or branched alkanes and cycloalkanes or mixtures thereof with a boiling point between 80 and 200° C.

Owner:ACTIVE BIOTECH AB

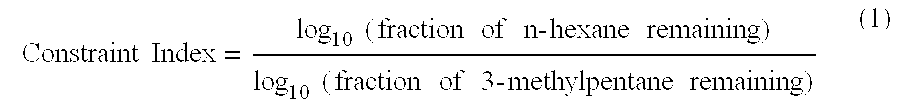

Increasing octane number of light naphtha using a germanium-zeolite catalyst

InactiveUS20110132804A1Boost octaneMolecular sieve catalystsHydrocarbon by hydrogenationAlkaneAlkaline earth metal

This invention relates to a process for the increasing the octane number of a naphtha hydrocarbon feed having a predominantly paraffin content with a germanium-containing zeolite catalyst. The catalyst is a non-acidic germanium zeolite on which a noble metal, such as platinum, has been deposited. The zeolite structure may be of MTW, MWW, MEL, TON, MRE, FER, MFI, BEA, MOR, LTL or MTT. The zeolite is made non-acidic by being base-exchanged with an alkali metal or alkaline earth metal, such as cesium, potassium, sodium, rubidium, barium, calcium, magnesium and mixtures thereof, to reduce acidity. The catalyst is sulfur tolerant. The hydrocarbon feed may contain sulfur up to 1000 ppm. The present invention could be applicable to a feedstream which is predominantly naphthenes and paraffins.

Owner:SAUDI BASIC IND CORP SA

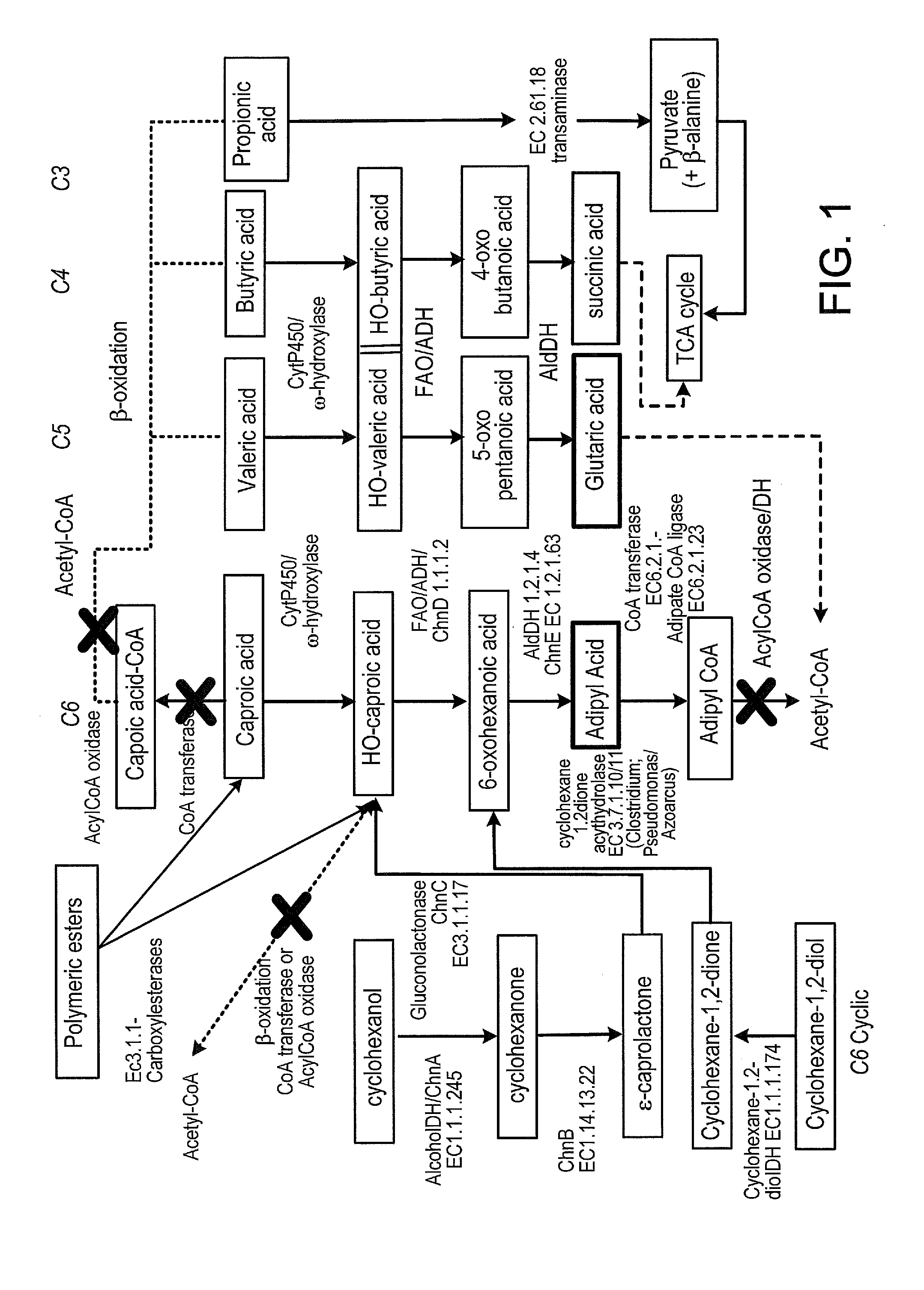

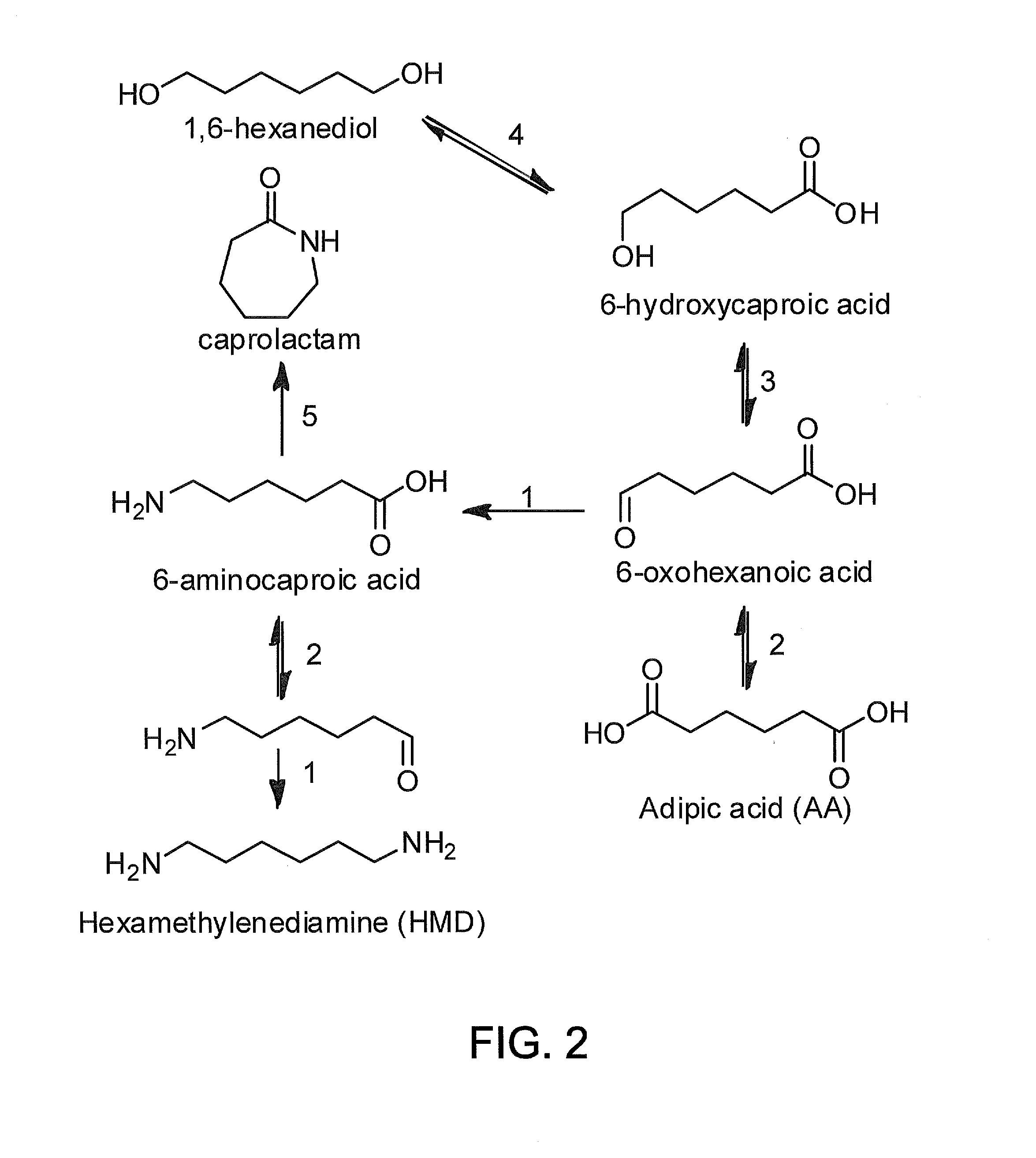

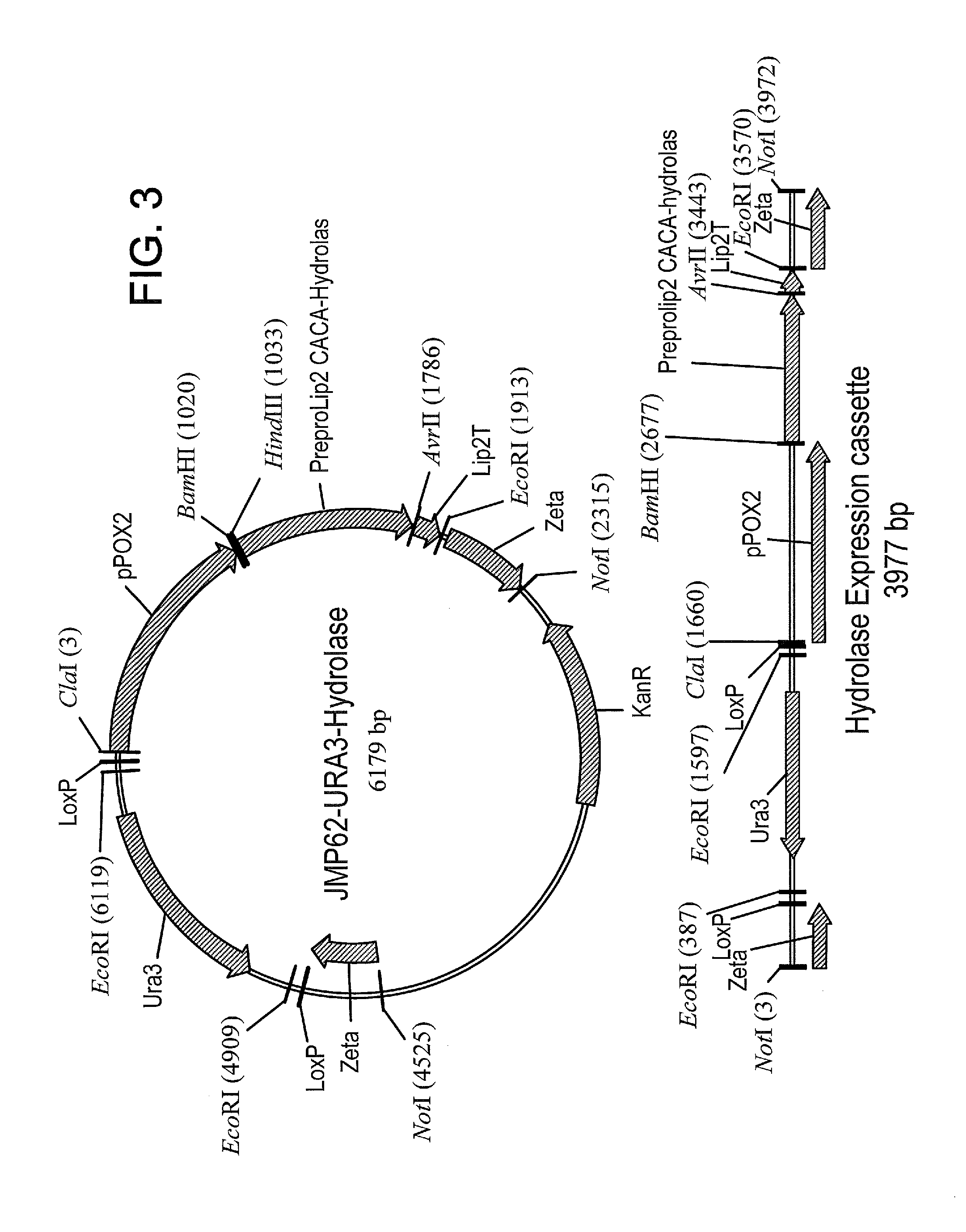

Methods of producing carboxylic acids

The invention relates to methods for enriching monomer content in a cycloalkane oxidation process mixed organic waste stream. In particular, the methods involve combining a biocatalyst with a mixed organic waste stream from a cycloalkane oxidation process, and enzymatically converting dimeric and / or oligomeric components of said waste stream into monomeric components. The methods may enrich the content of diacids, adipic acid, and / or other α,ω-difunctional C6 alkanes in the mixed organic waste stream. Additionally, the treated mixed organic waste streams may have improved burning efficiency.

Owner:INV NYLON CHEM AMERICAS LLC

Environmentally friendly base fluids and methods for making and using same

InactiveUS20120071367A1Reduce surface tensionReduce interfacial tensionProgramme controlFluid removalParaffin waxOxygen compound

Non-toxic, biodegradable base fluids are disclosed for use in making downhole fluids, where the base fluids include blends of paraffins, olefins, naphthenes, esters, and oxygenates, having low viscosities, having a pale-yellow color, having a flashpoint of >80° C. (175° F.) and have a pour point of about 19° F. Methods for making and using fluids include the base fluids of this invention are also disclosed

Owner:LUBRIZOL OILFIELD SOLUTIONS

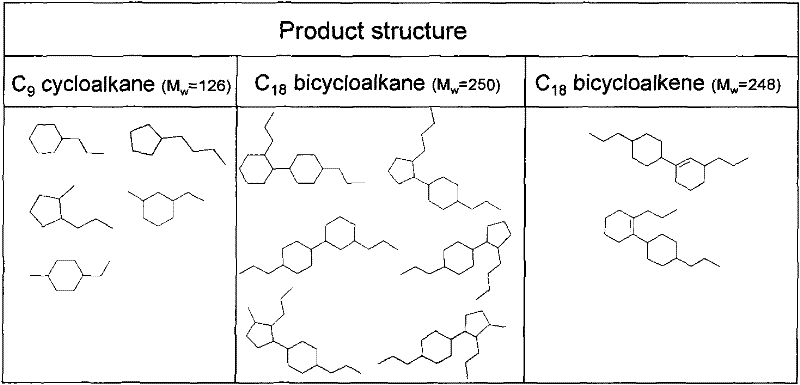

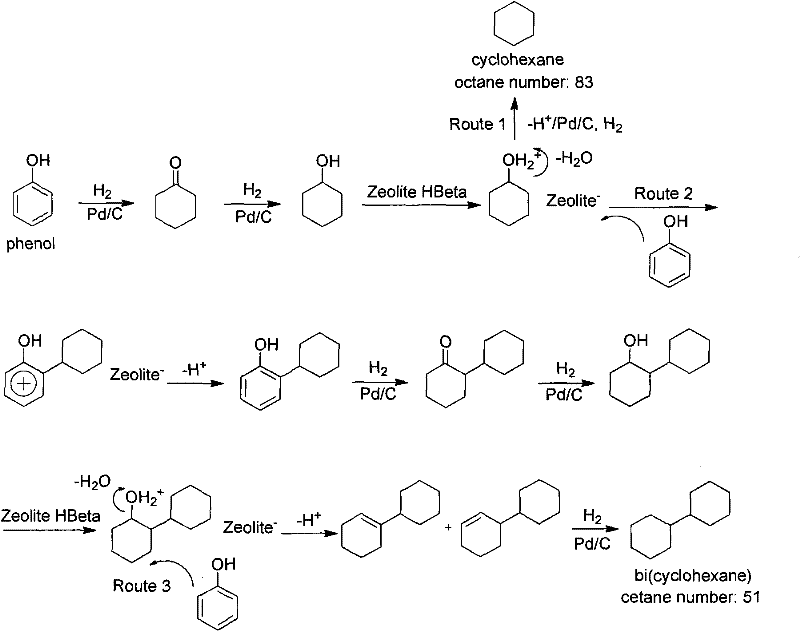

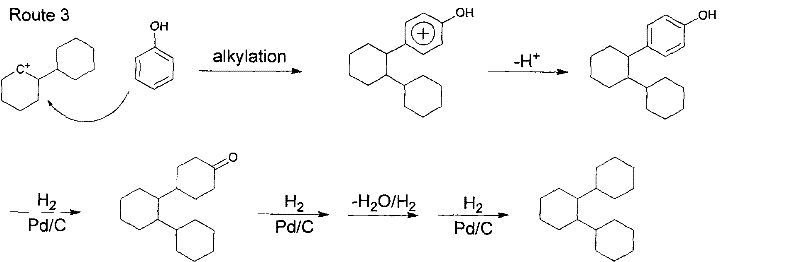

Method for preparing high-quality gasoline and diesel oil from lignin pyrolysis oil

InactiveCN102676202AWide variety of sourcesLow costLiquid hydrocarbon mixture productionBio-feedstockAlkaneGasoline fuel

The invention discloses a method for preparing high-quality gasoline and diesel oil from lignin pyrolysis oil, and belongs to the technical field of preparation of liquid fuel. The method comprises the steps of using lignin pyrolysis oil, crude biological oil, lignin, phenolic monomer and / or dipolymer derived from the lignin as materials, and converting the materials into C6-C9 gasoline and C10-C20 diesel oil hydrocarbon fuel with adjustable ratio under the catalytic action of Ni-based or Pd-based catalyst loaded on a molecular sieve, wherein the major ingredients of the obtained gasoline are C6-C9 cycloalkanes and aromatic hydrocarbons and belong to clean gasoline fuel with high octane value and high quality; while the major ingredients of the diesel oil are C12-C20 bicyclic alkanes, the cetane number is between 51-60, and the diesel oil does not contain polycyclic aromatic compound or sulphur or nitrogen and belongs to the clean high-quality diesel fuel. The method disclosed by the invention has the advantages of wide material source, low cost, clever reaction process, efficient coupling, simple and green process, easiness of industrialization, large product requirement, very broad application prospect and the like.

Owner:赵晨

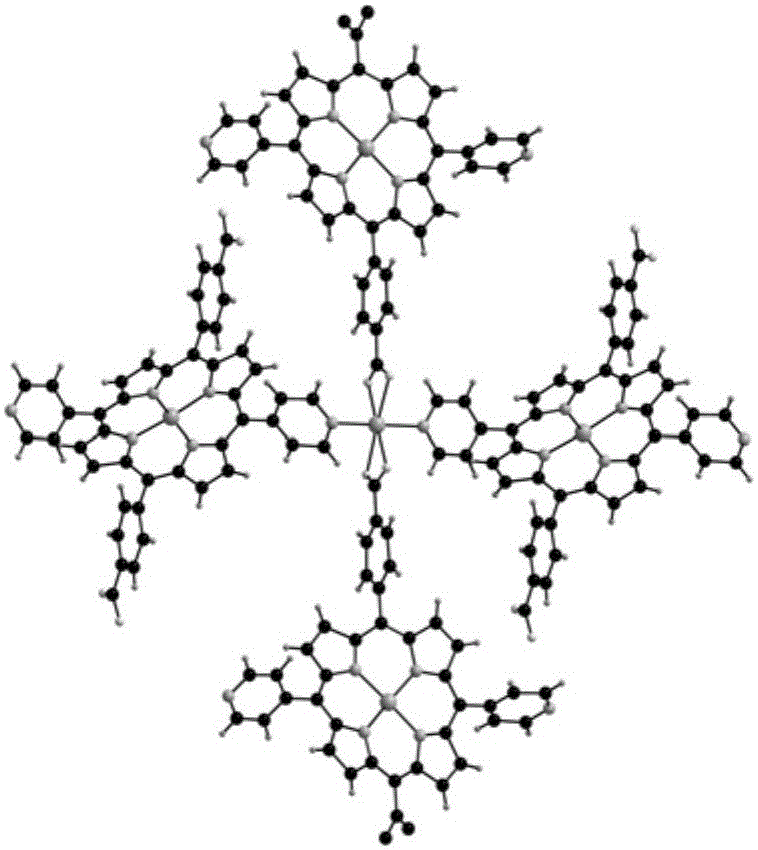

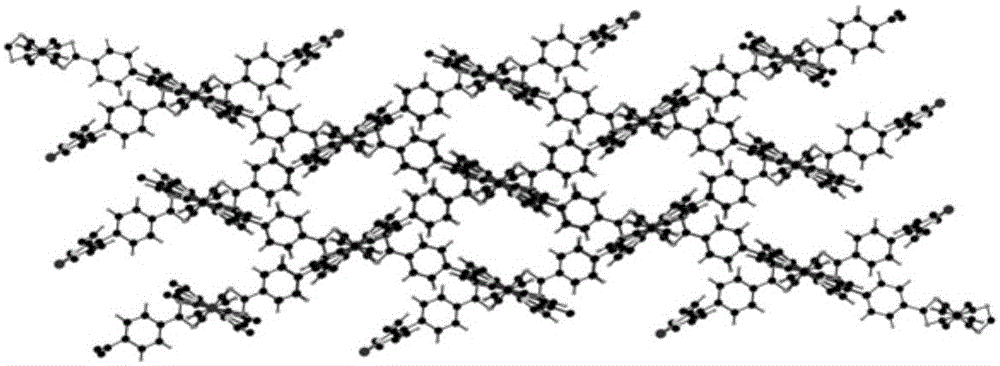

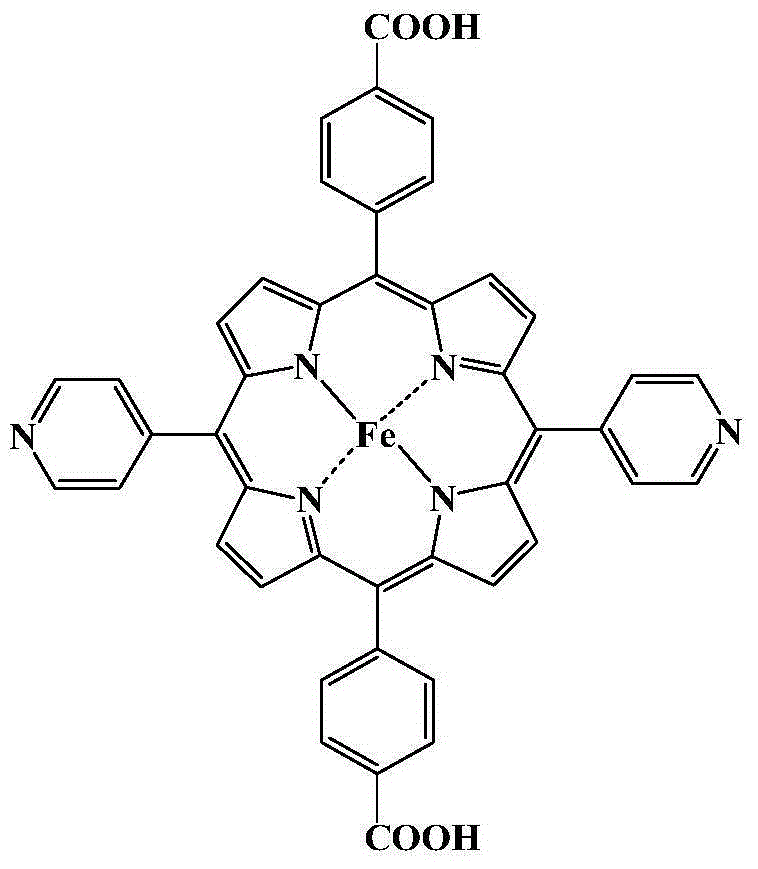

Metal organic framework material of Fe porphyrin ligand, preparation method therefor and application thereof

InactiveCN105061776ANovel structureImprove catalytic performancePreparation by oxidation reactionsOrganic-compounds/hydrides/coordination-complexes catalystsAcetic acidN dimethylformamide

The invention discloses a metal organic framework material of a Fe porphyrin ligand, a preparation method therefor and an application thereof, and belongs to the technical field of crystalline materials. A chemical formula of the Fe porphyrin ligand is FeL, wherein L is am organic ligand, namely 5, 15-bipyridine-10 and 20-dicarboxyphenyl ironporphyrin. In a closing condition, a crystal of the metal organic framework material is obtained by the organic ligand, namely 5, 15-bipyridine-10, 20-dicarboxyphenyl ironporphyrin and iron nitrate nonahydrate by virtue of thermal reaction in a solution of N,N-dimethylformamide and acetic acid. The metal organic framework material has an iron porphyrin catalytic property, and can be used for selective catalysis of cycloalkane.

Owner:BEIJING UNIV OF TECH

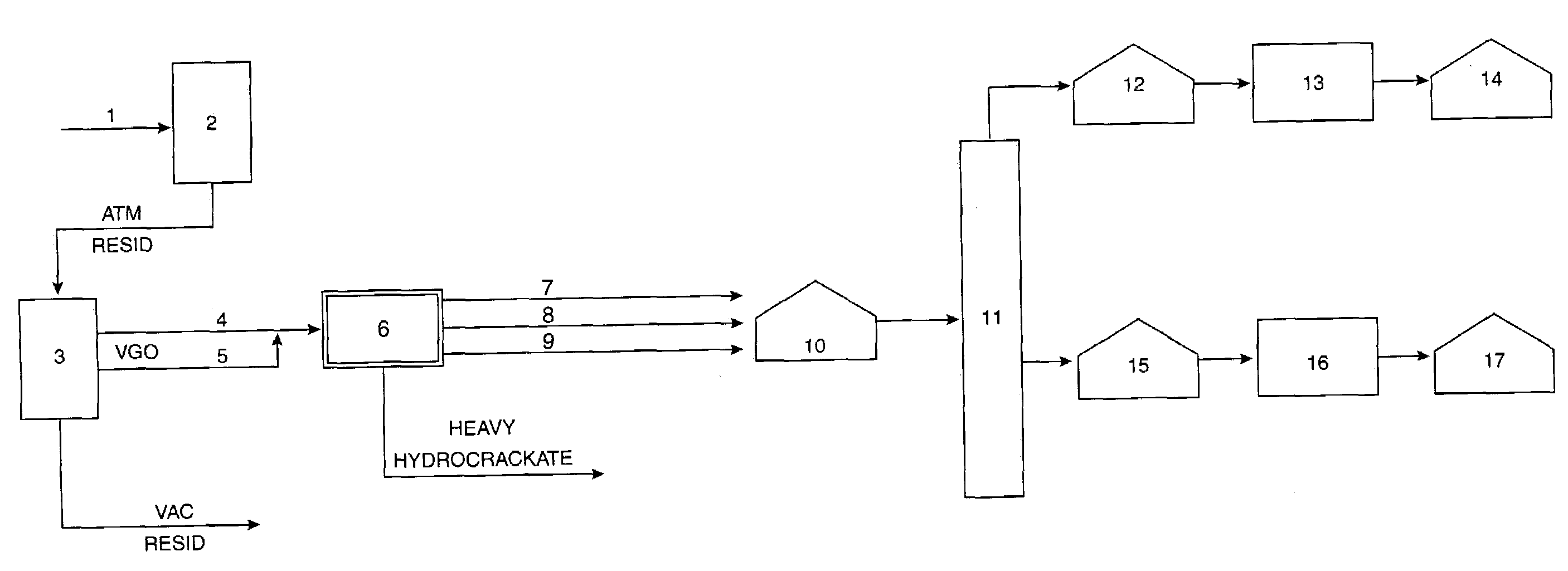

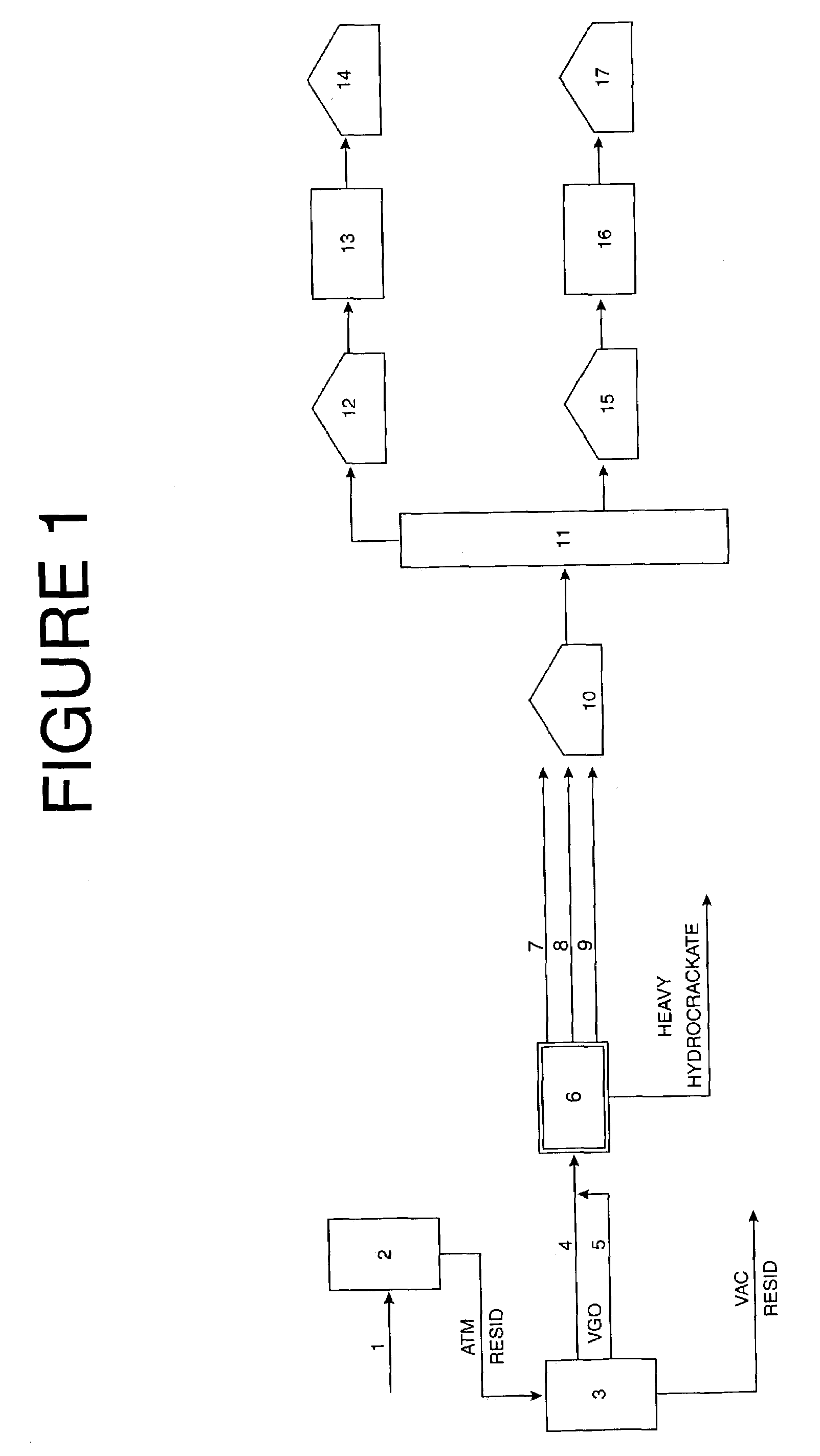

Process for the production of hydrocarbon fluids

ActiveUS7311814B2Low sulphur levelPoint become highSilicon organic compoundsPhysical/chemical process catalystsSolventMetal working

Hydrocarbon fluids are produced by hydrocracking a vacuum gas oil stream, fractionating and / or hydrogenating the hydrocracked vacuum gas oil. The fluids typically have ASTM D86 boiling point ranges within the range 100° C. to 400° C. the range being no more than 75° C., they also have a naphthenic content greater than 60%, the naphthenics containing polycyclic materials, an aromatic content below 2% and an aniline point below 100° C. The fluids are particularly useful as solvents, for printing inks, drilling fluids, metal working fluids and as silicone extenders.

Owner:EXXONMOBIL CHEM PAT INC +1

Noble metal containing low acidic hydrocracking catalysts

InactiveUS6362123B1Reduce acidityControl crackingMolecular sieve catalystsCatalyst activation/preparationMolecular sieveAlkane

A hydrocracking catalyst is provided that includes a crystalline molecular sieve material component having a faujasite structure and an alpha acidity of less than 1, preferably 0.3 or less, and a dispersed Group VIII noble metal component. The extremely low acidity allows selective hydrocracking of the aromatic and naphthenic species in a feedstock, while limiting the cracking of paraffins. The catalyst produces improved yields of products, such as diesel fuel, at high conversion rates and with high cetane values.

Owner:MOBIL OIL CORP

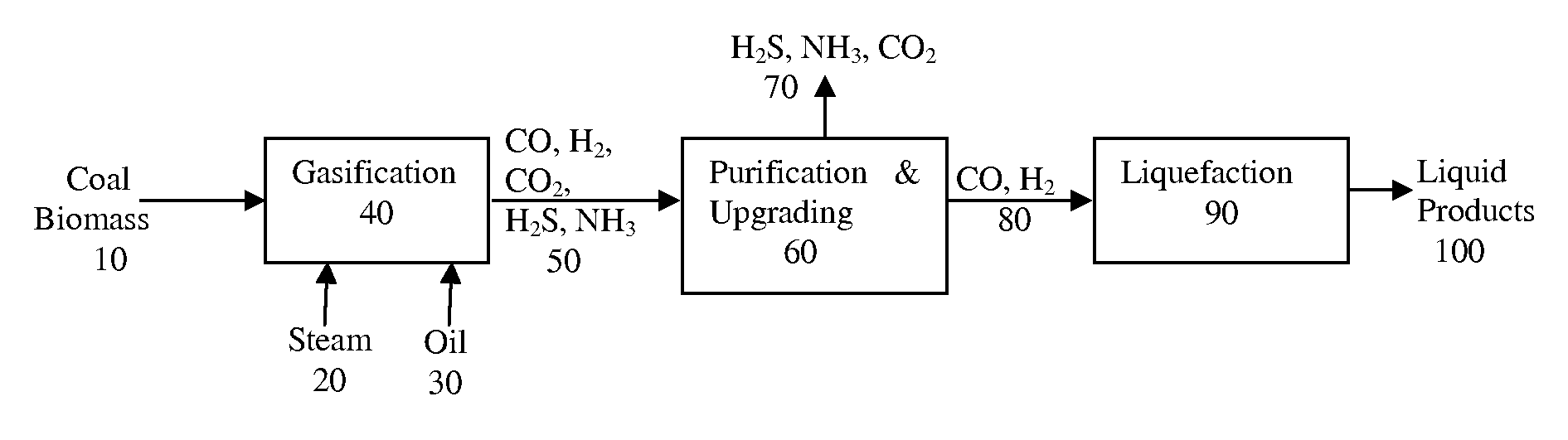

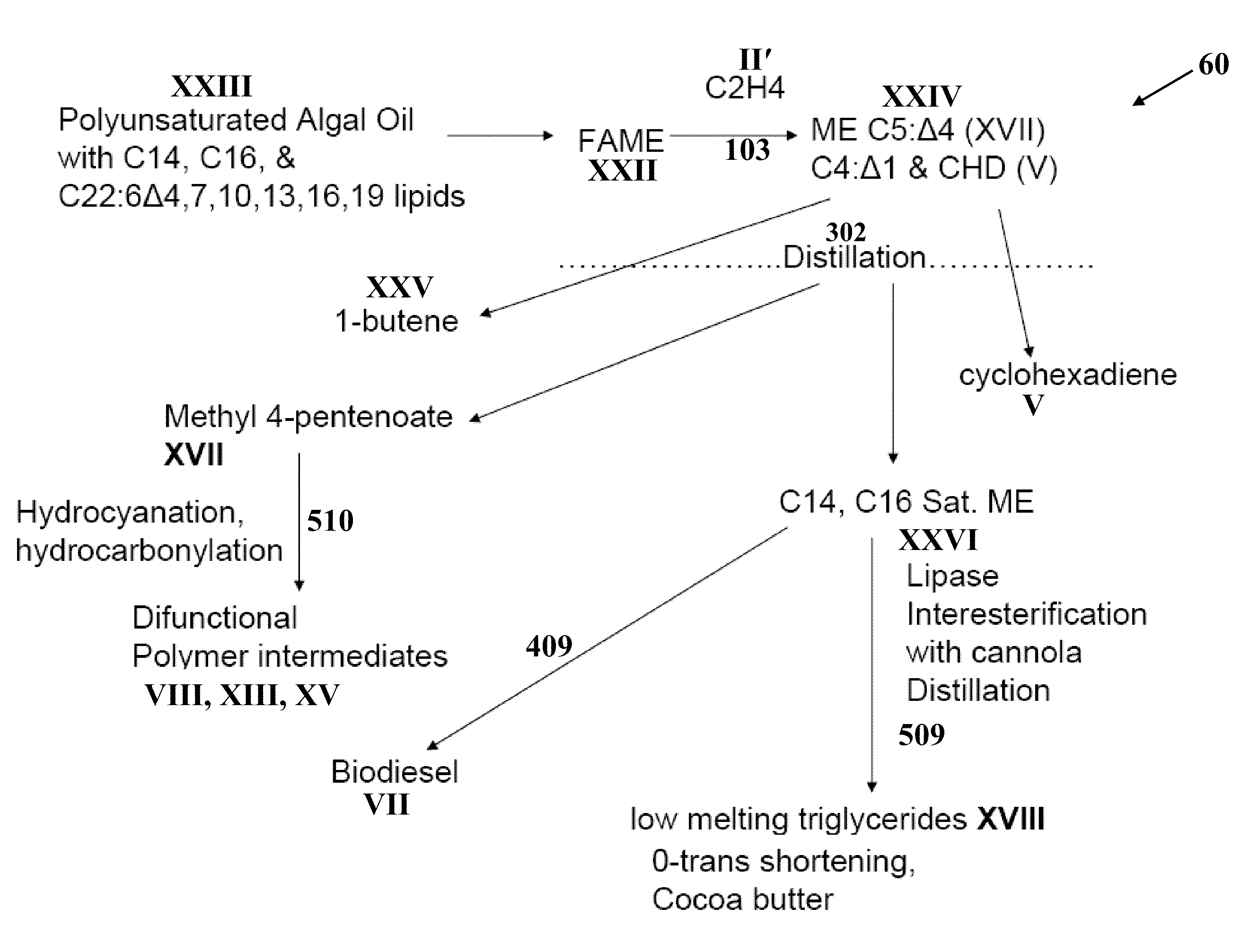

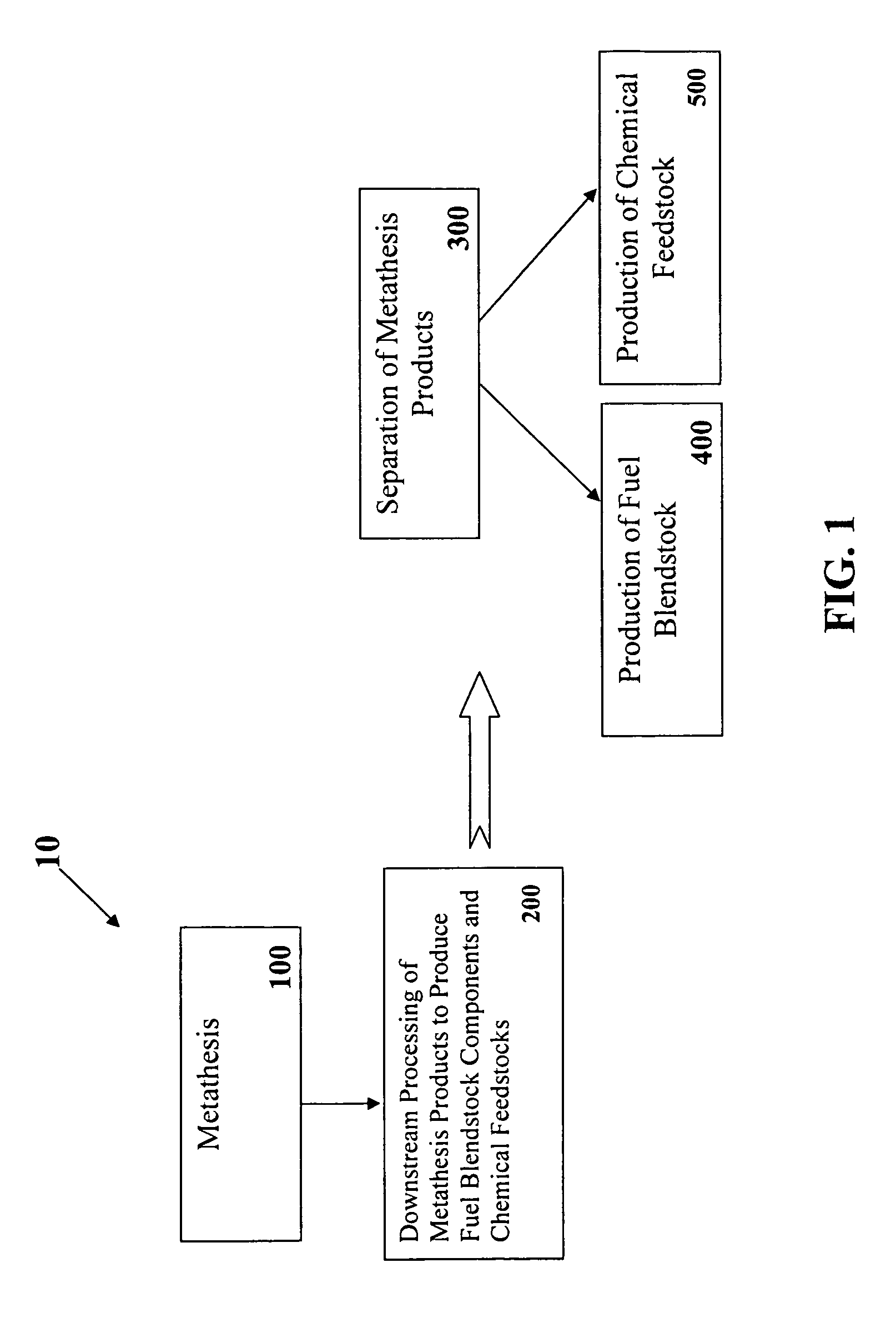

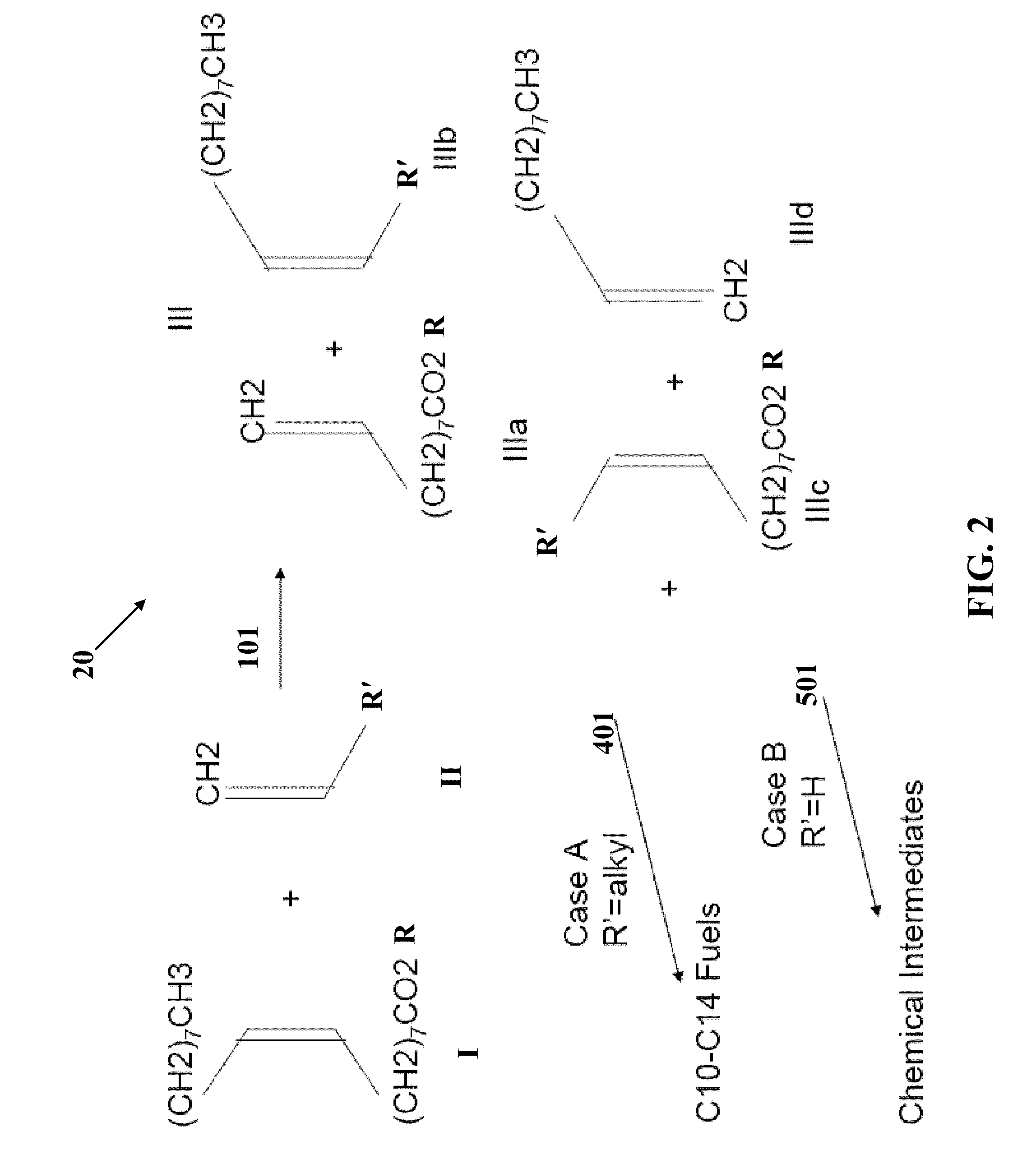

Chain-selective synthesis of fuel components and chemical feedstocks

ActiveUS8071799B2Low melting pointReadily apparentFatty acid esterificationPreparation by ester-hydroxy reactionTG - TriglycerideAlkene

A method comprising providing a starting composition comprising a polyunsaturated fatty acid, a polyunsaturated fatty ester, a carboxylate salt of a polyunsaturated fatty acid, a polyunsaturated triglyceride, or a mixture thereof; self-metathesizing the starting composition or cross-metathesizing the starting composition with at least one short-chain olefin in the presence of a metathesis catalyst to form self- / cross-metathesis products comprising: cyclohexadiene; at least one olefin; and one or more acid-, ester-, or salt-functionalized alkene; and reacting cyclohexadiene to produce at least one cycloalkane or cycloalkane derivatives. A method for producing cycloalkanes for jet fuel by providing a starting composition comprising at least one selected from the group consisting of algal and polyunsaturated vegetable oils, subjecting the starting composition to metathesis to produce metathesis product comprising at least one olefin, cyclohexadiene, and at least one acid-, ester-, or salt-functionalized alkene, and reacting the at least one olefin and cyclohexadiene to form cycloalkane(s).

Owner:ENERGY & ENVIRONMENTAL RES CENT FOUNDATIO

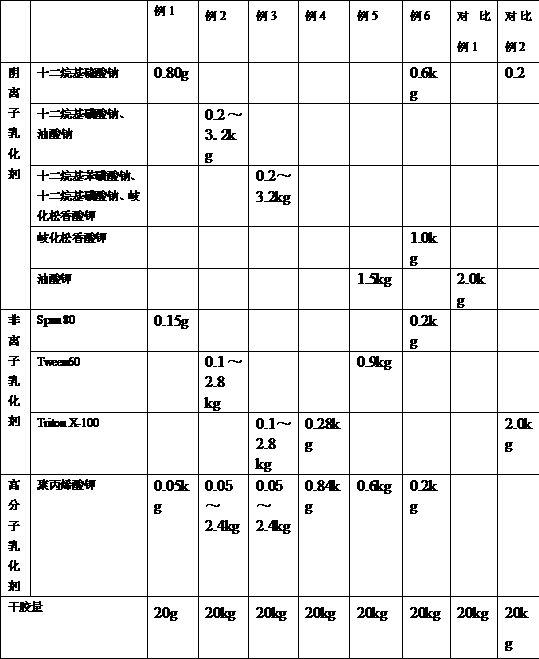

Production method of artificial latex

The invention discloses a production method of artificial latex. The method comprises the following steps of: dissolving a certain amount of isoprene rubber or butadiene rubber into cyclane or aliphatic hydrocarbon to prepare a rubber solution, dissolving a certain amount of anionic emulsifier, nonionic emulsifier and high molecular emulsifier into deionized water, and adjusting the pH value to 9-13 to obtain an emulsifier aqueous solution; mixing a certain amount of rubber solution and emulsifier aqueous solution, and stirring forcibly to form a macroscopic homogeneous pre-emulsified mixed solution; emulsifying an emulsifier emulsion with an emulsifying machine at the linear speed of 10m / s, emulsifying at the linear speed of 16m / s, standing, and filtering upper layer floating matters out; distilling the emulsified emulsion under the normal pressure, and distilling under reduced pressure after a part of solvents are removed till all solvents are removed; and after the temperature of latex to be diluted falls to the room temperature, and centrifuging under the condition of 8,000r / min with a centrifuge to obtain latex of which the solid content is 65-68 percent and the particle diameter is 400 nanometers.

Owner:盘锦信汇新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com