Aviation-grade kerosene from independently produced blendstocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

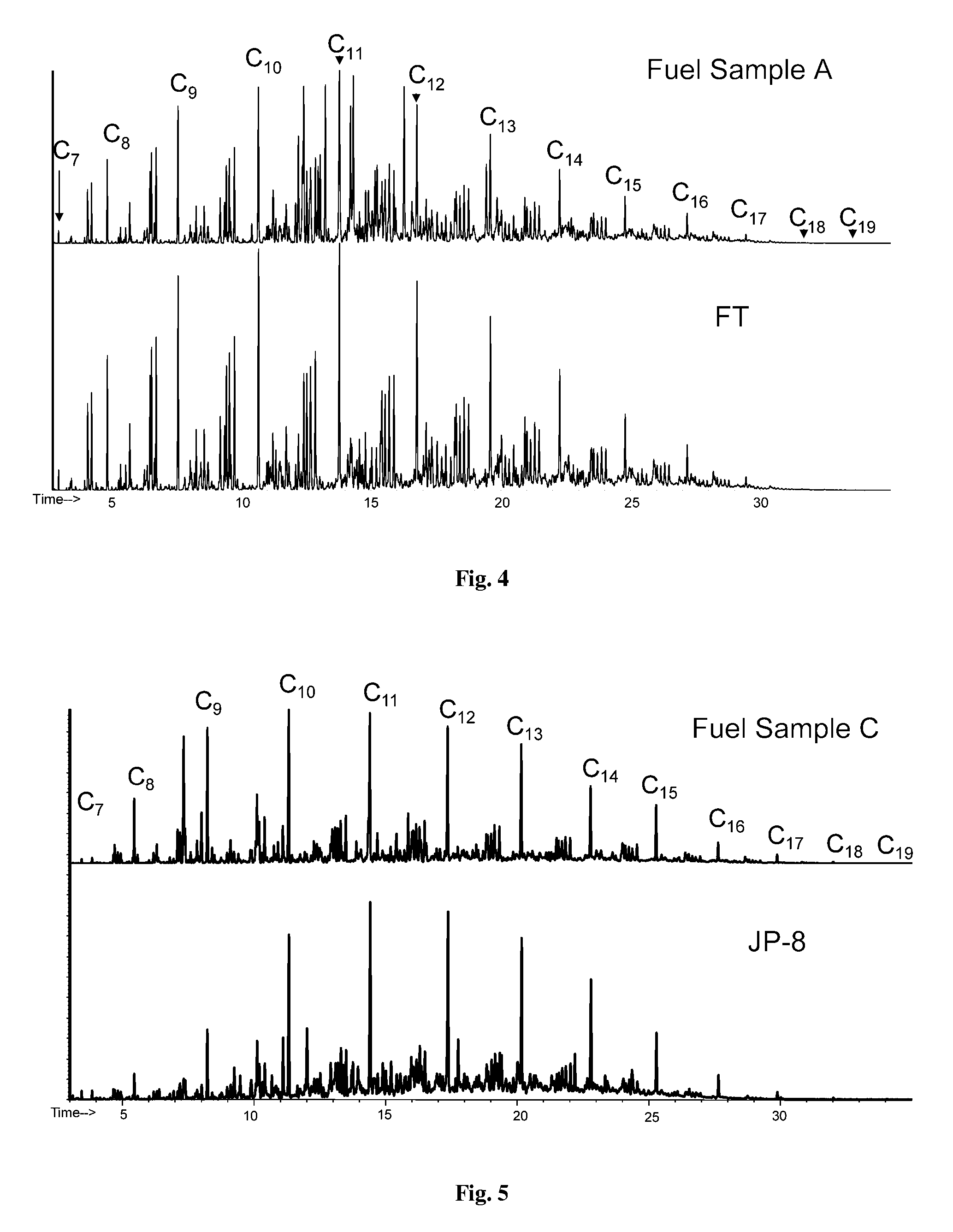

Fuel Sample A

[0061]A FT fuel produced from natural gas containing iso-paraffinic and normal paraffin hydrocarbons did not comply with density requirement of the JP-8 military specification (MIL-DTL-83133E). In this example, a mixture of aromatic hydrocarbon fluid containing aromatic hydrocarbons ranging in carbon chain length from 8-16, was blended to a concentration of 23% by weight with the FT fuel. A summary of results from Fuel Sample A compared to specification requirements outlined in MIL-DTL-83133E is provided in Table 4.

TABLE 4Results from Jet Fuel Specification Tests of Fuel Sample A ComprisingBlend of Aromatic Hydrocarbon and Fischer-Tropsch Derived FuelSpecification TestSample AMilitary SpecAcid Number, mg KOH / gm0.0030.015 maxAromatics, vol %19.425 vol % maxOlefins, vol %0.05 vol % maxSulfur, mass %0.00.30 maxHeat of Combustion, Btu / lb1850018400Distillation:10% recovered, ° C.172205 maxEndpoint, ° C.274300 maxResidue, vol %1.41.5 maxLoss, vol %0.41.5 maxFlash Point, ° C.4...

example 2

Fuel Sample B

[0063]The same FT fuel as used in Example 1 was blended at 82% wt. with 8% wt. of a mixed aromatic fluid and 10% wt. cycloparaffinic fluid. A summary of Fuel Sample B results from key specification parameters is provided in Table 5.

TABLE 5Results for Key Jet Fuel Specification Tests of Fuel Sample BComprising Blend of Aromatic and Cycloparaffin Hydrocarbonswith Fischer-Tropsch Derived FuelFreezeSpecificPoint,FlashHHV,Gravity° C.Point, ° C.MJ / kgMil Spec0.775-0.84−47>38C.>42.8Specificationvalue is a lowerheating valueSample B0.779−61.44846.1Lab analysisFT Fuel0.755−56.74846.6Lab analysis

[0064]As seen in the results in Table 5, the resulting fuel Sample B possessed a MIL-DTL-83133E specification compliant fuel with a density of 0.779 g / ml.

example 3

Fuel Sample C

[0065]Two hydrocarbon blendstocks, one consisting of normal- and iso-paraffinic hydrocarbon and the second consisting a mixture of aromatic and cycloparaffinic hydrocarbon, were produced exclusively from crop oil and blended to achieve a fuel sample complying with the requirements of MIL-DTL-83133E. In this example, neither fuel blendstock possessed, on its own, the physical characteristics required by the specification; however, through blending at a ratio of 44% normal and iso-paraffinic blendstock, and 66% aromatic and cycloparaffinic blendstock, the resulting fuel achieved the necessary characteristics. A summary of results from Fuel Sample C compared to specification parameters outlined in MIL-DTL-83133E is provided in Table 6. Data from gas chromatography of Sample C and a typical JP-8 fuel is provided in FIG. 5.

TABLE 6Results from Jet Fuel Specification Tests of Fuel Sample C Comprising aBlend of Two Discrete Hydrocarbon Blendstocks Produced from Crop OilSpecific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com