Patents

Literature

616 results about "Condensation point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In mathematics, a condensation point p of a subset S of a topological space, is any point p, such that every open neighborhood of p contains uncountably many points of S. Thus, "condensation point" is synonymous with "ℵ₁-accumulation point".

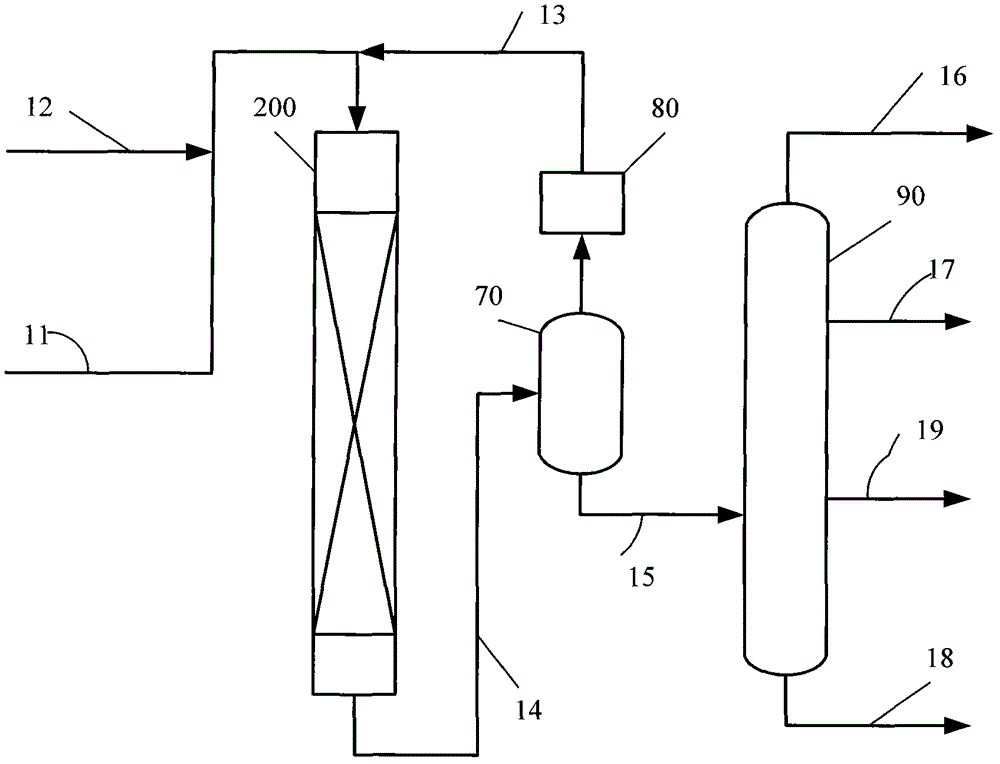

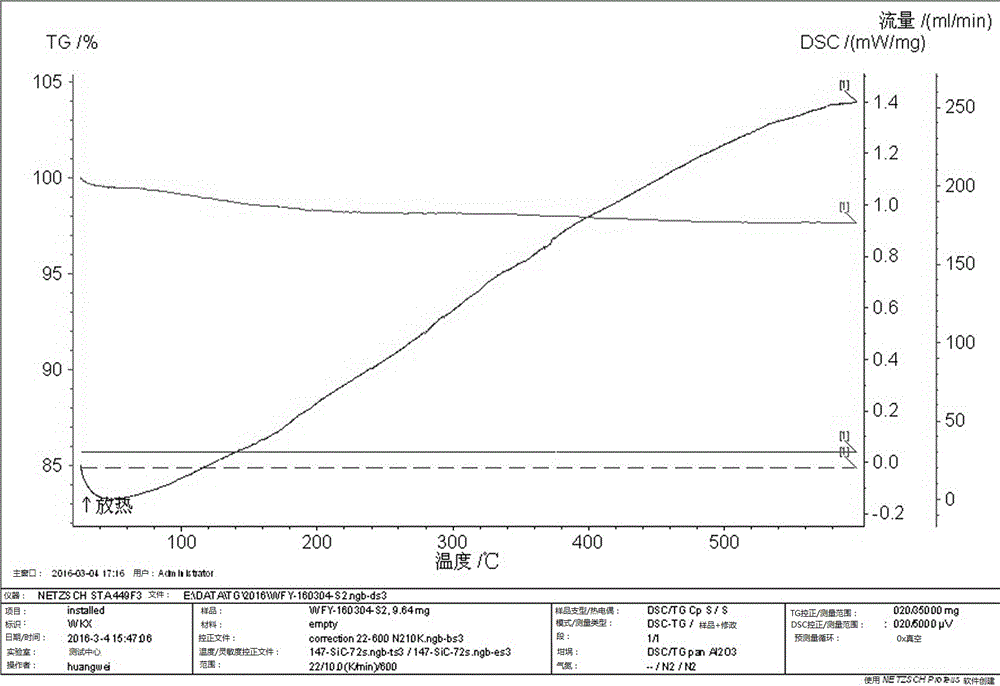

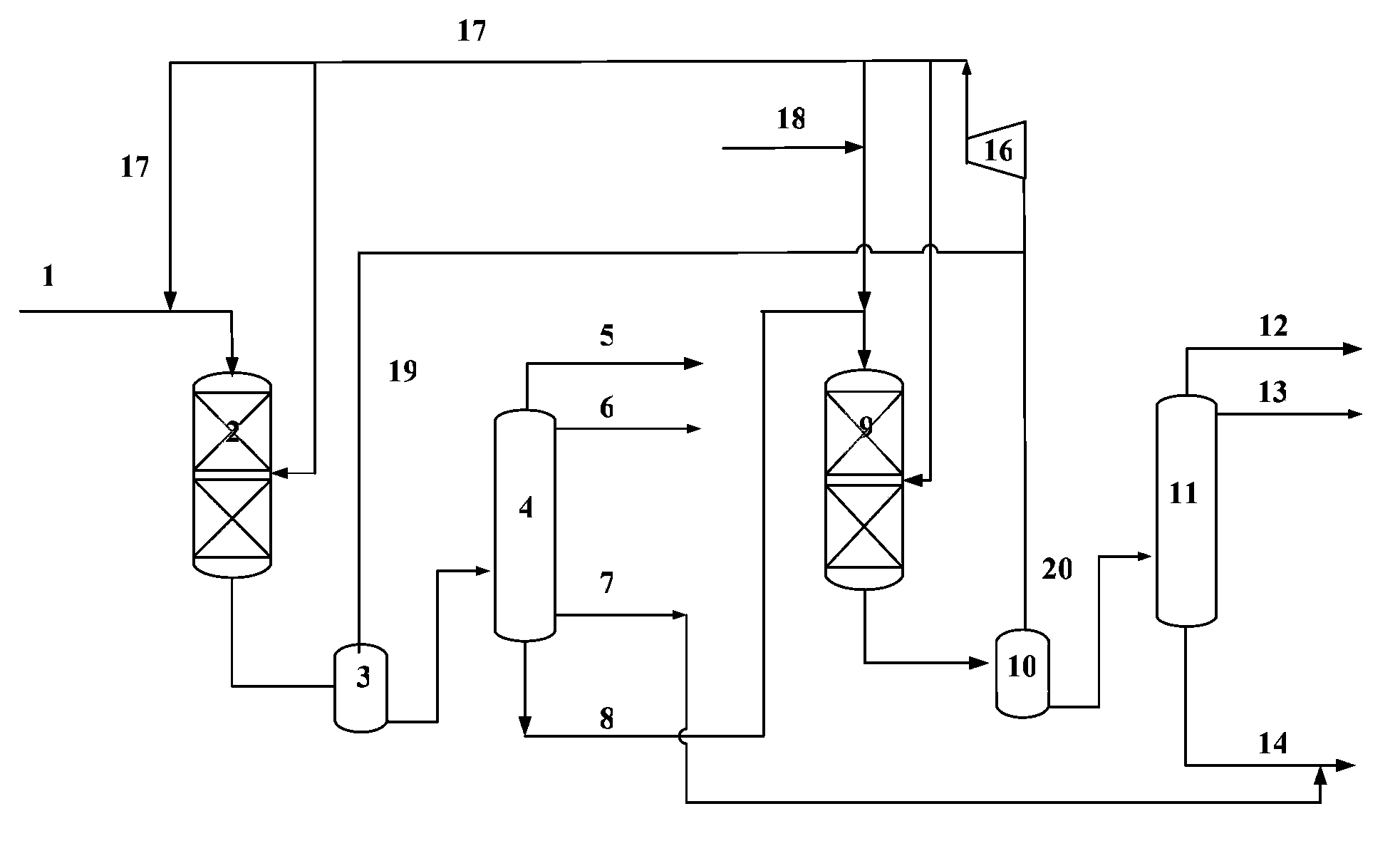

Method for processing ethylene tar

The invention discloses a method for processing ethylene tar, which selects an appropriate cutting point to fractionate the ethylene tar into a light fraction and a heavy fraction aiming at the characteristics of high content of arene, colloid and carbon residue in the ethylene tar. The light fraction passes through a hydrogenation protection reaction zone, a hydrofining reaction zone and a hydrocracking reaction zone sequentially to obtain a gasoline fraction and a diesel oil fraction; and the heavy fraction is used as a universal type carbon fiber asphalt stock. The method for processing the ethylene tar makes full use of the total fraction of the ethylene tar and increases the additional value of the ethylene tar. In addition, the method enables the arene after hydrostturation in the ethylene tar to open ring, crack moderately and / or isomerize by selecting two types of hydrocracking catalysts to perform grading loading so as to obtain the diesel oil fraction with condensation point less than -40 DEG C in high yield and obtain a side product high-octane gasoline fraction at the same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

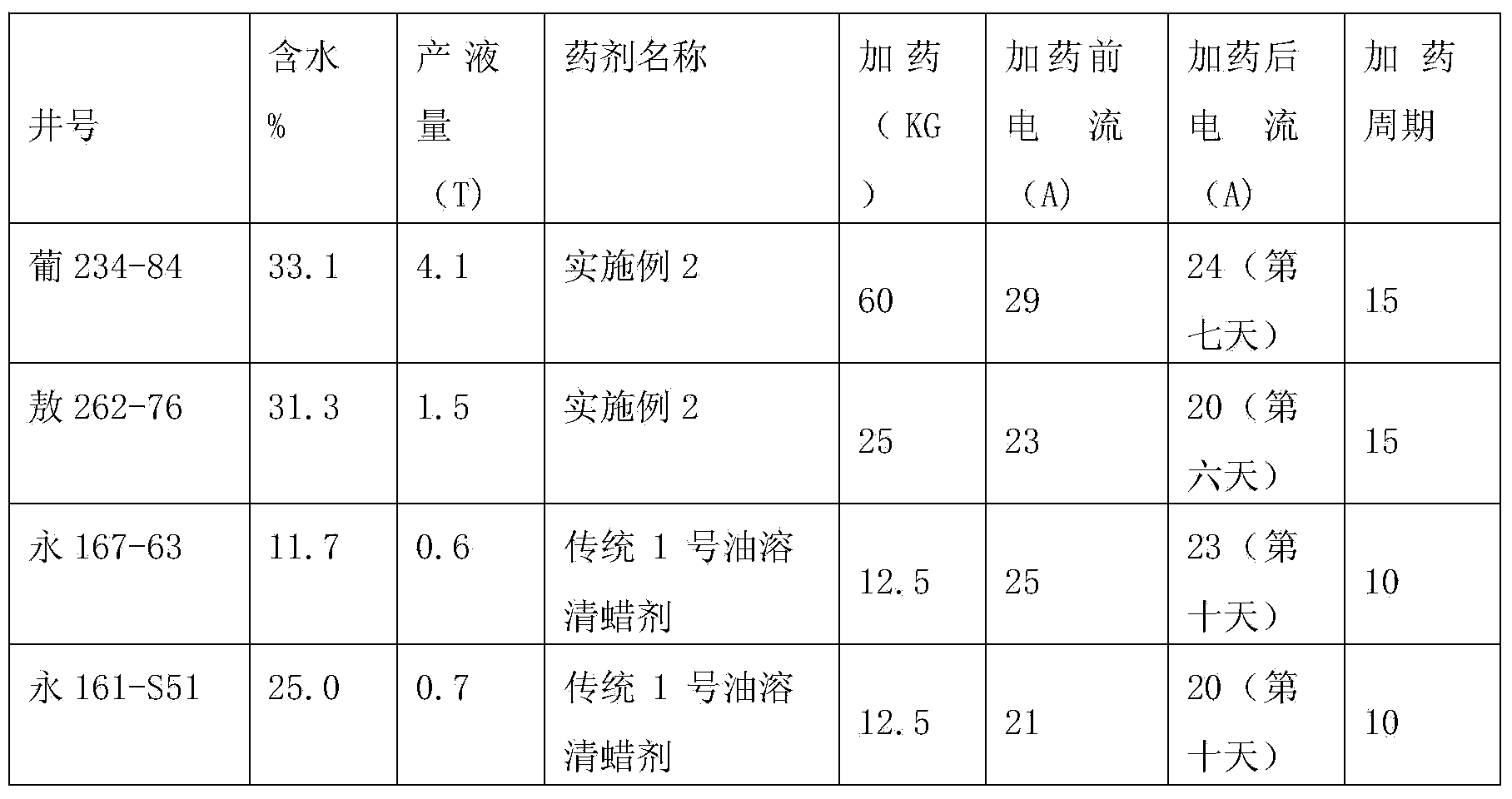

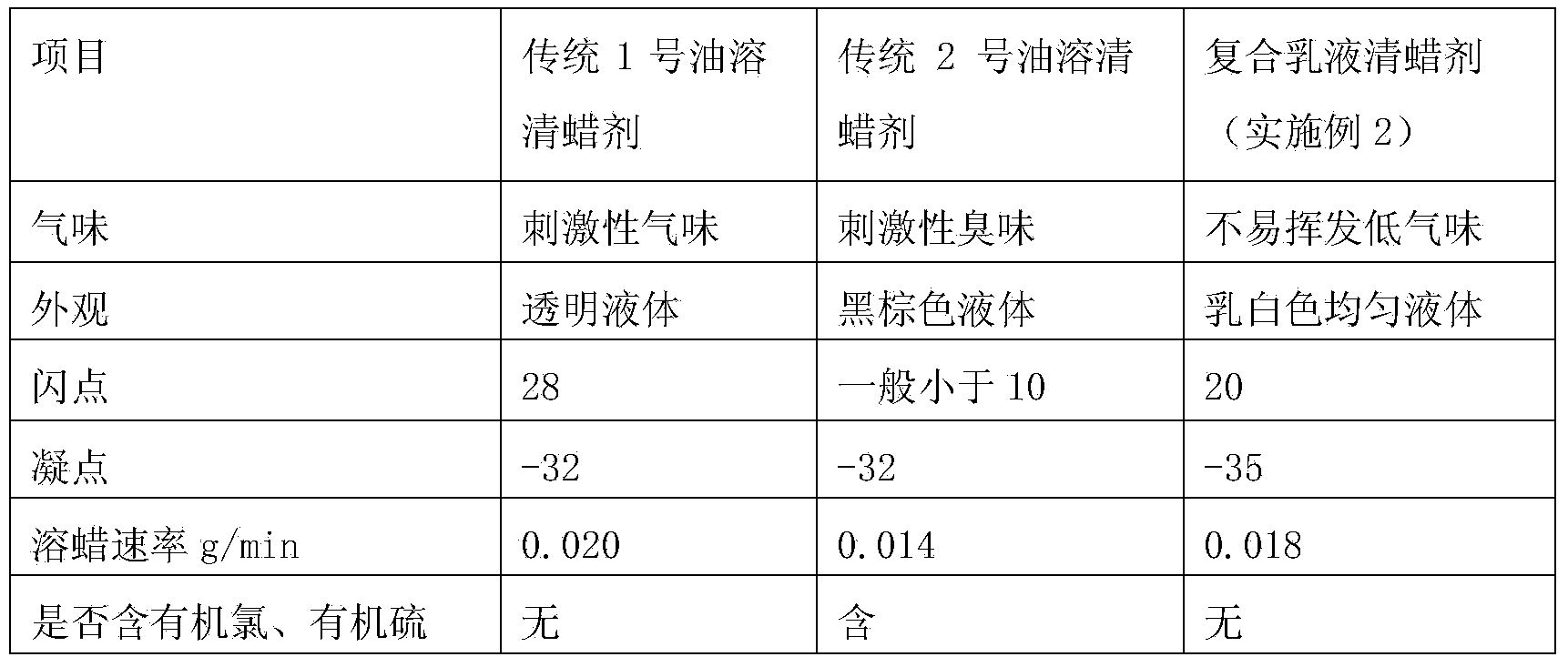

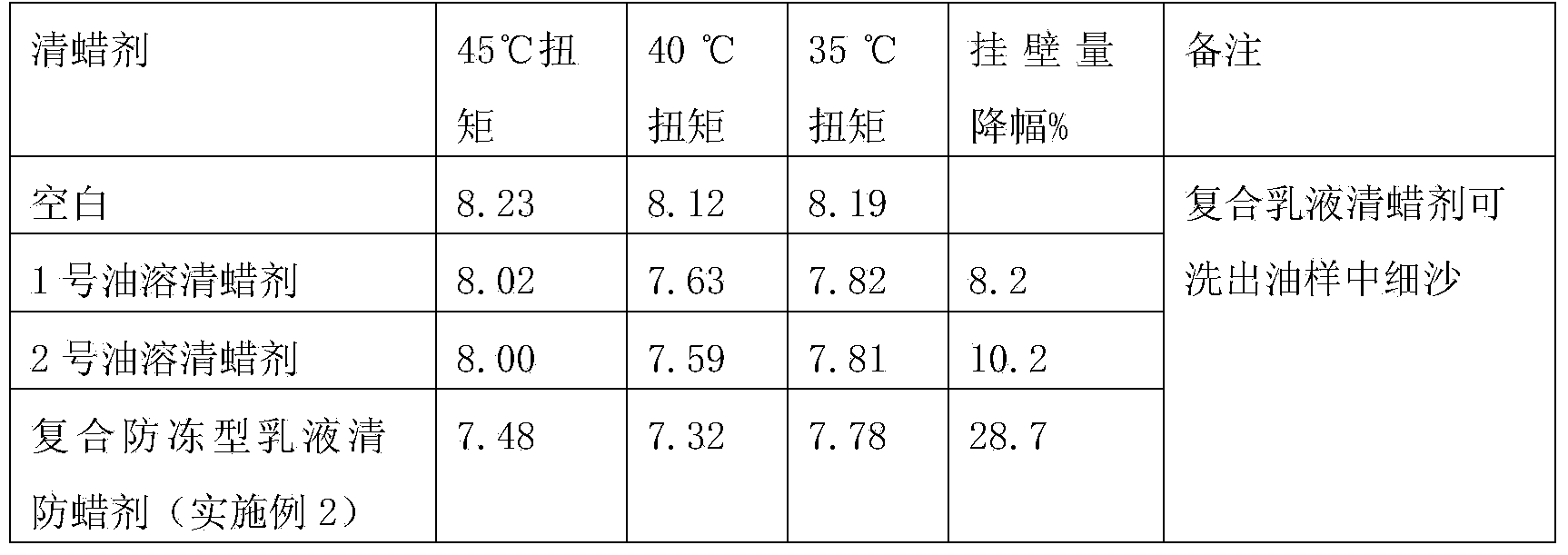

High-efficient environment-friendly composite antifreezing emulsion paraffin remover and inhibitor

InactiveCN103642477AEasy to separateIt has the function of washing oil, reducing viscosity and preventing waxDrilling compositionWaxOrganic solvent

The invention relates to a high-efficient environment-friendly composite antifreezing emulsion paraffin remover and inhibitor, which mainly solves problems of oil well large operation load caused by severe paraffin precipitation of high paraffin-containing oil wells at alpine regions, and compromising oil well yield caused by short hot washing period. The paraffin remover and inhibitor comprises a main agent of A agent system, and an auxiliary agent of B agent system, wherein the main agent of A agent system comprises the following component by weight: 1-3% of oil-soluble high-molecular polymer, 40-60% of aromatic hydrocarbon organic solvents, 10-20% of low carbon alcohol, 3-10% of composite emulsifiers, and 10-30% of water; the auxiliary agent of B agent system comprises the following component by weight: 7-15% of acid electrolytes, and 85-93% of water; the ratio of the main agent of A agent system to the auxiliary agent of B agent system is 100:0.8-1.2. The high-efficient environment-friendly composite antifreezing emulsion paraffin remover and inhibitor can effectively remove paraffin and inhibit paraffin, reaches the purposes of reducing oil well operation load and prolonging well washing period, has a low condensation point, and thus is especially suitable for winter paraffin removal at alpine regions.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

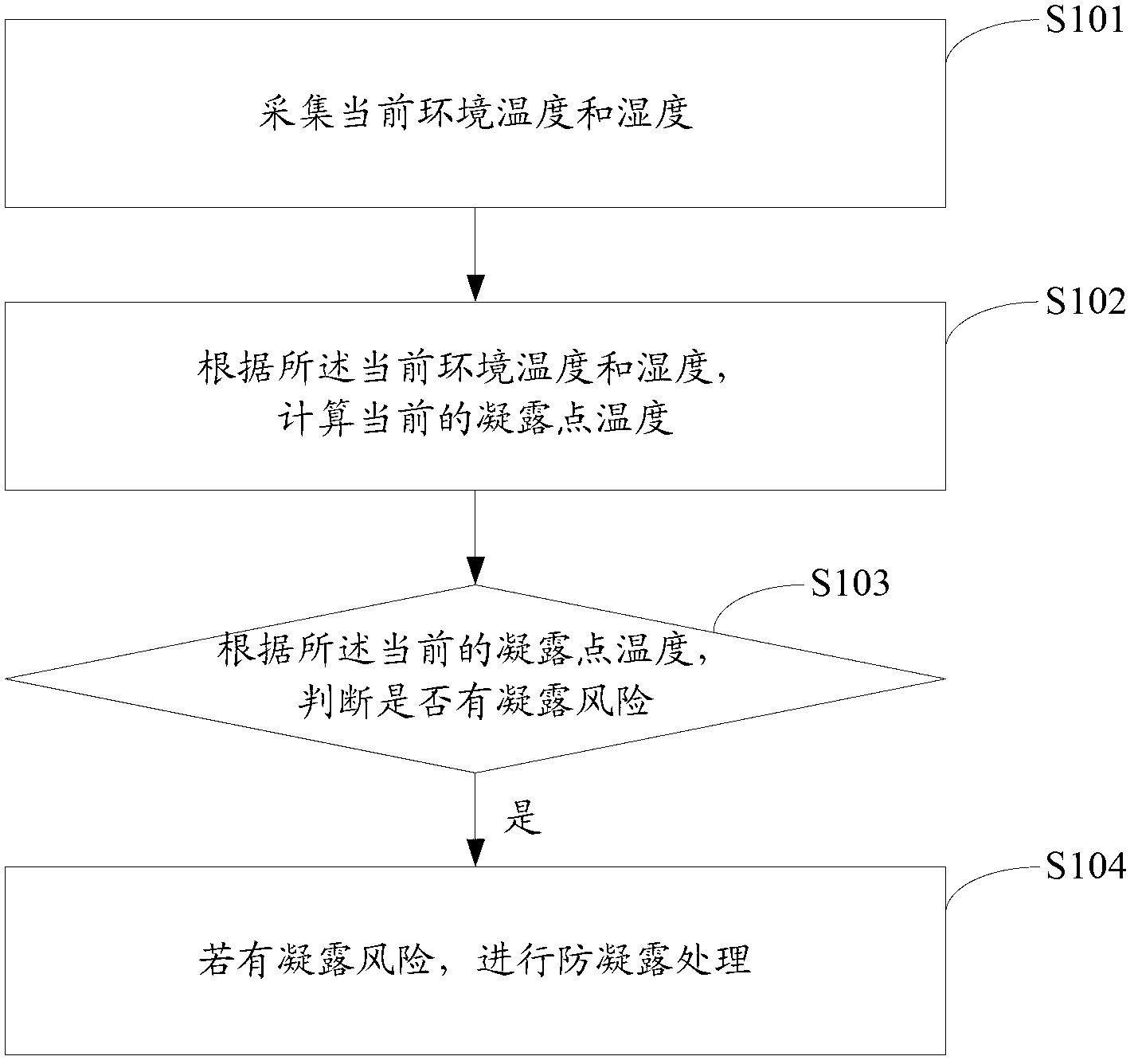

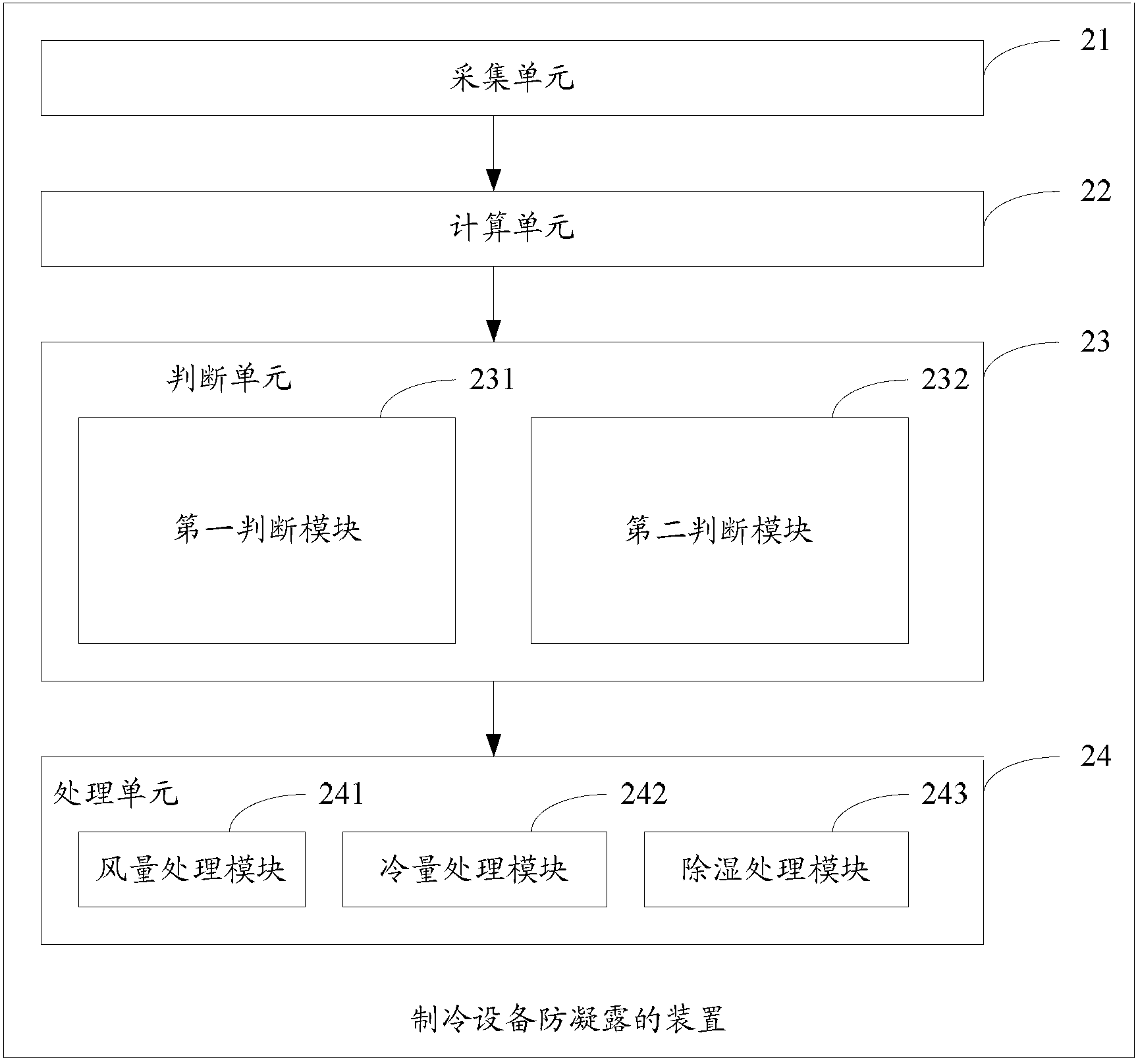

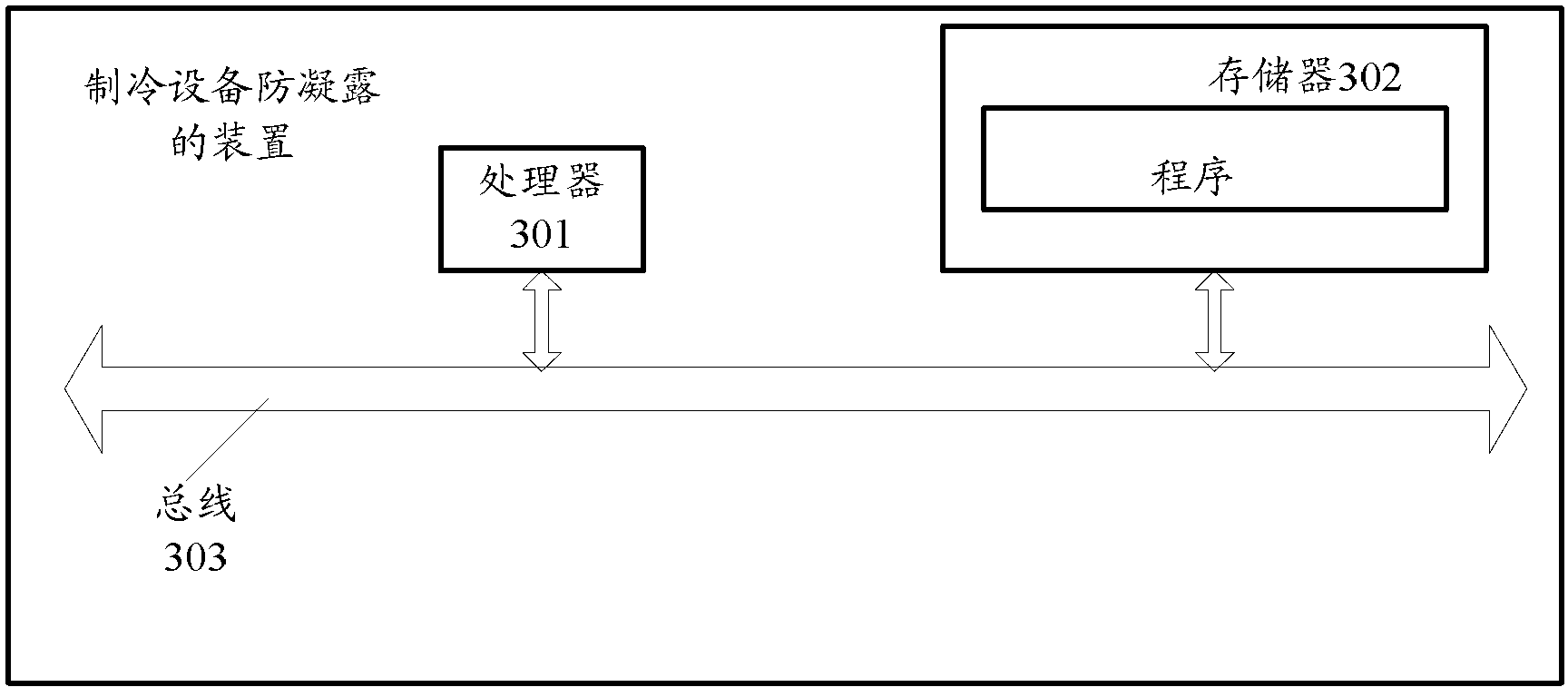

Method and device for preventing condensation of refrigerating device

InactiveCN103292448ASolve condensationCondensate preventionSpace heating and ventilation safety systemsEngineeringHumidity

The invention is applicable to the technical field of refrigerating and provides a method and device for preventing condensation of a refrigerating device. The method includes: calculating the current condensation point temperature according to the current environment temperature and humidity; judging whether condensation risks exist or not according to the current condensation point temperature; if so, performing condensation prevention. By the method, an air outlet of an air conditioner condensates easily in the prior art can be solved.

Owner:HUAWEI TECH CO LTD

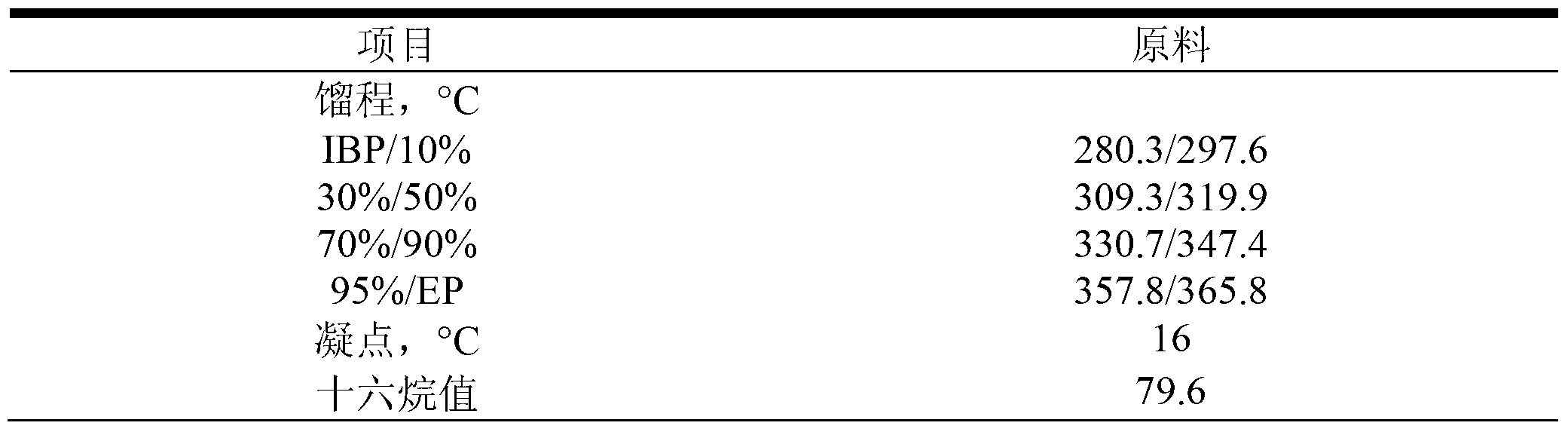

Hydro-cracking method for blending ethylene bottom oil

The invention discloses a hydro-cracking method for blending ethylene bottom oil, which is different from the method for processing the conventional ethylene bottom oil and comprises the following steps: blending an ethylene bottom oil light end into a conventional hydro-cracking raw material for hydro-cracking, in the presence of hydrogen, sequentially contacting the ethylene bottom oil light end with a hydro-guard catalyst, a hydro-refining catalyst, a hydro-residue carbon removing catalyst and a hydro-cracking catalyst; separating an effluent of hydro-cracking reaction to obtain light fuel oil. The method of the invention adopts a method of grading the hydrogenation catalyst, can process the ethylene bottom oil light end and produce diesel oil having a high cetane number and a low condensation point and a naphtha having high arene, and is not obviously changed in a BMCI value of tail oil and a smoke point of a jet fuel when compared with the conditions before blending the ethylene bottom oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

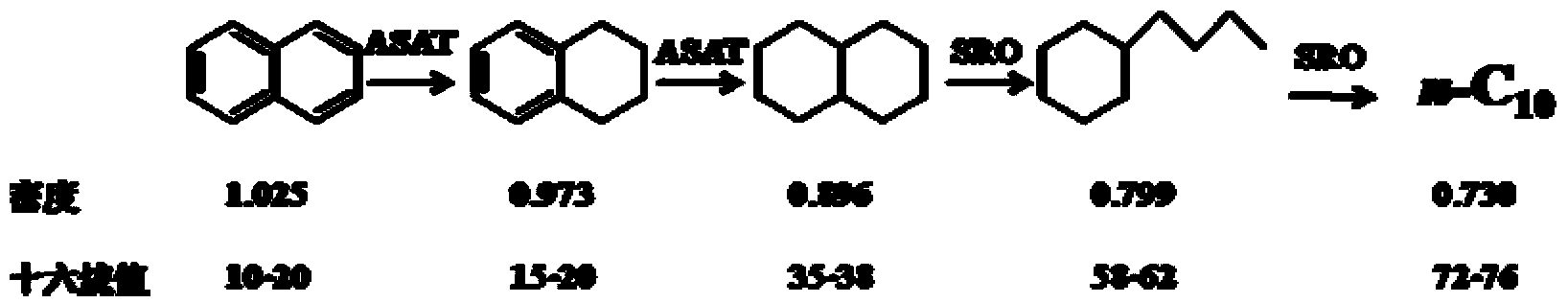

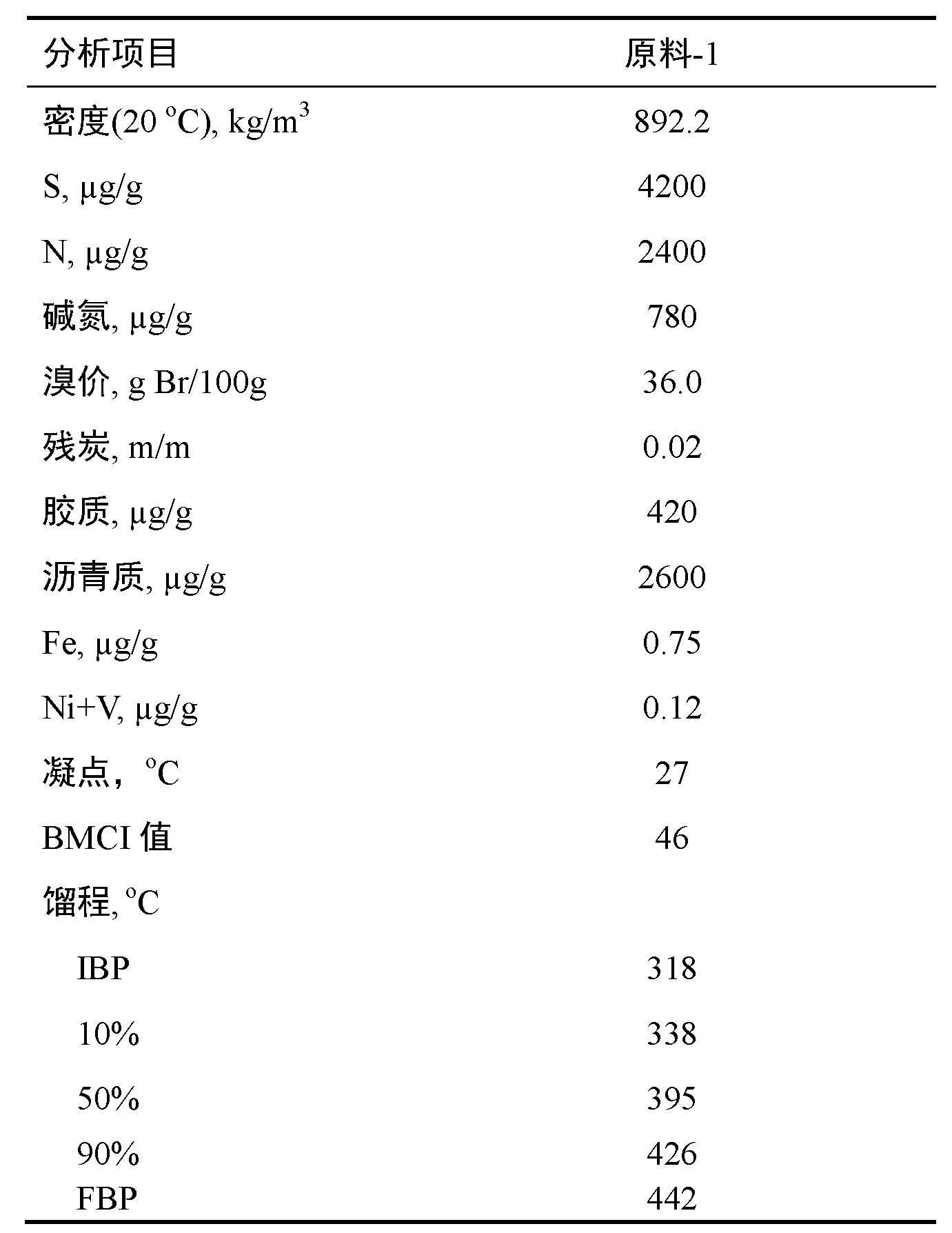

Catalyst used for hydrogenation ring opening reaction of polycyclic aromatic hydrocarbon, and preparation method and application thereof

InactiveCN104117386AAchieve conversion rateLower cold filter pointMolecular sieve catalystsHydrocarbon oils treatmentIsomerizationAcid strength

The invention relates to a catalyst used for hydrogenation ring opening of polycyclic aromatic hydrocarbon and advanced hydrogenation dearomatization and isomeric pour point depression of diesel oil, and a preparation method thereof. The catalyst is formed by using modified H-Beta molecular sieve with a high silica-alumina ratio and an inorganic oxide as a carrier, and precious metal Pt, Pd or Ir as an active component. The catalyst has a high metal dispersion ability, and has suitable acid kind, acid strength and pore structure. The catalyst can inhibit advanced cracking, and promotes the selective ring opening of aromatic hydrocarbon and product isomerization. The catalyst is suitable for advanced hydrogenation saturation of diesel oil with low sulfur and nitrogen content, selective ring opening and isomerization, can reduce the aromatic hydrocarbon content in the diesel oil, can improve the cetane number of oil products, and can reduce the condensation point of the diesel oil.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

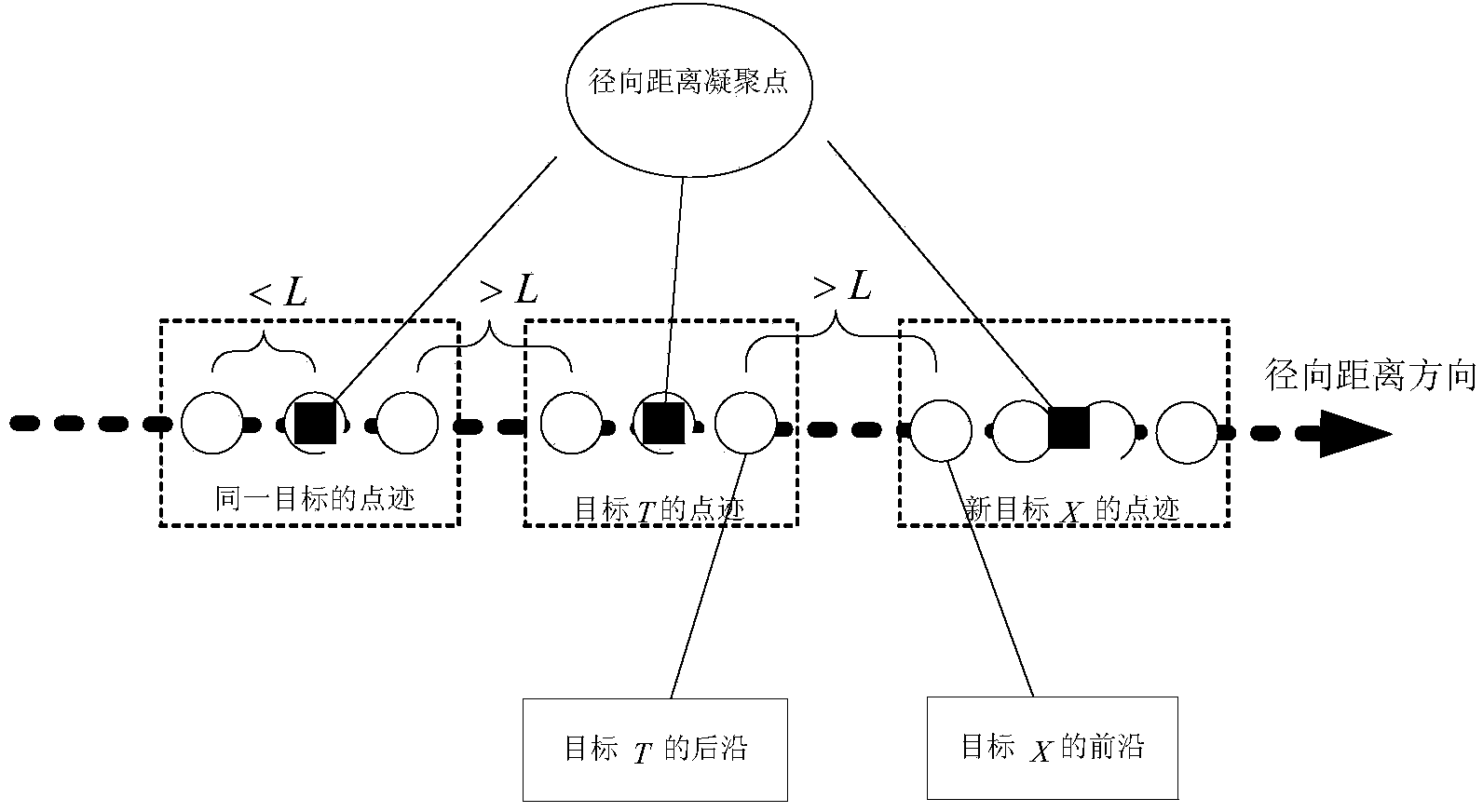

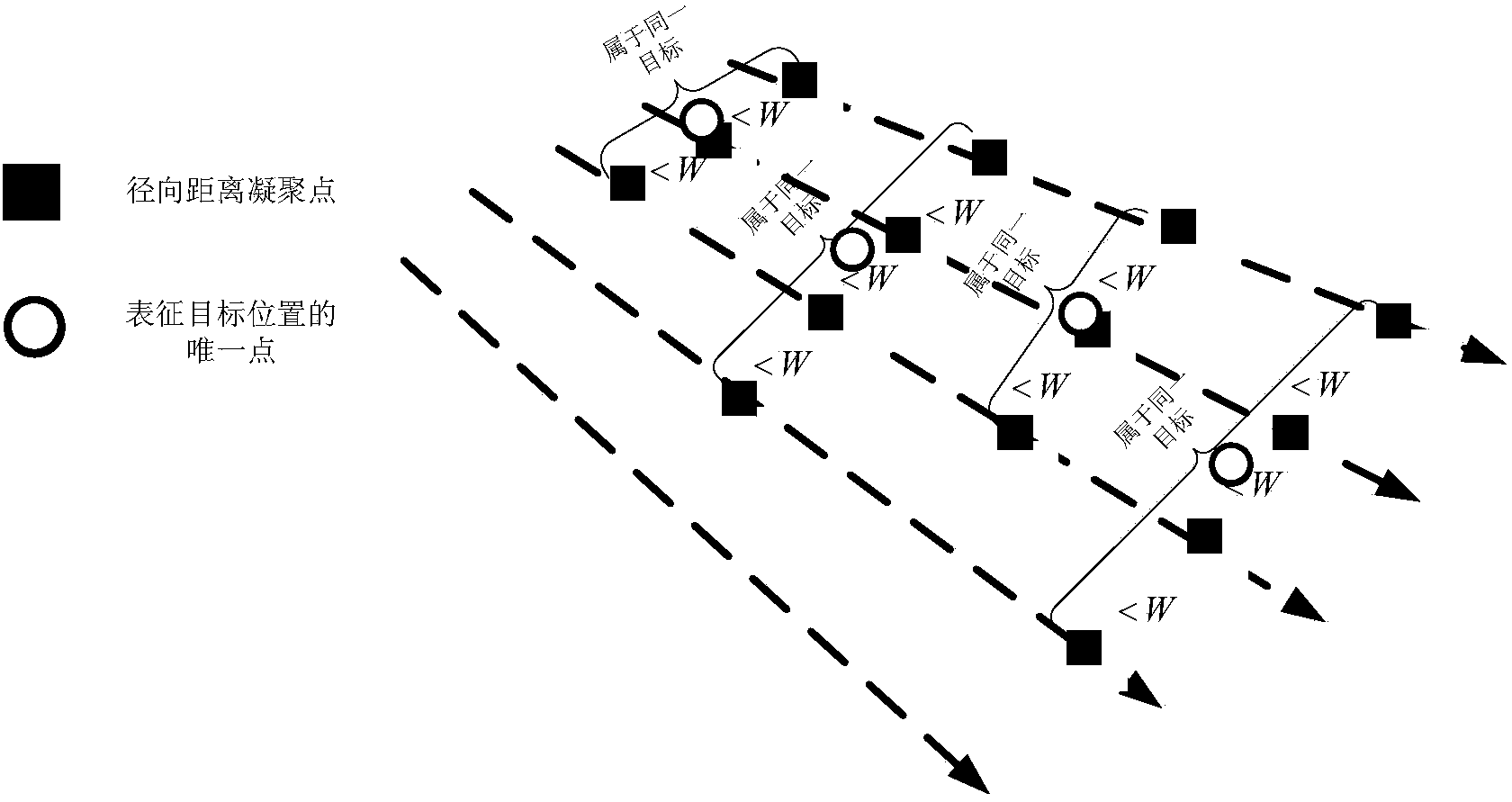

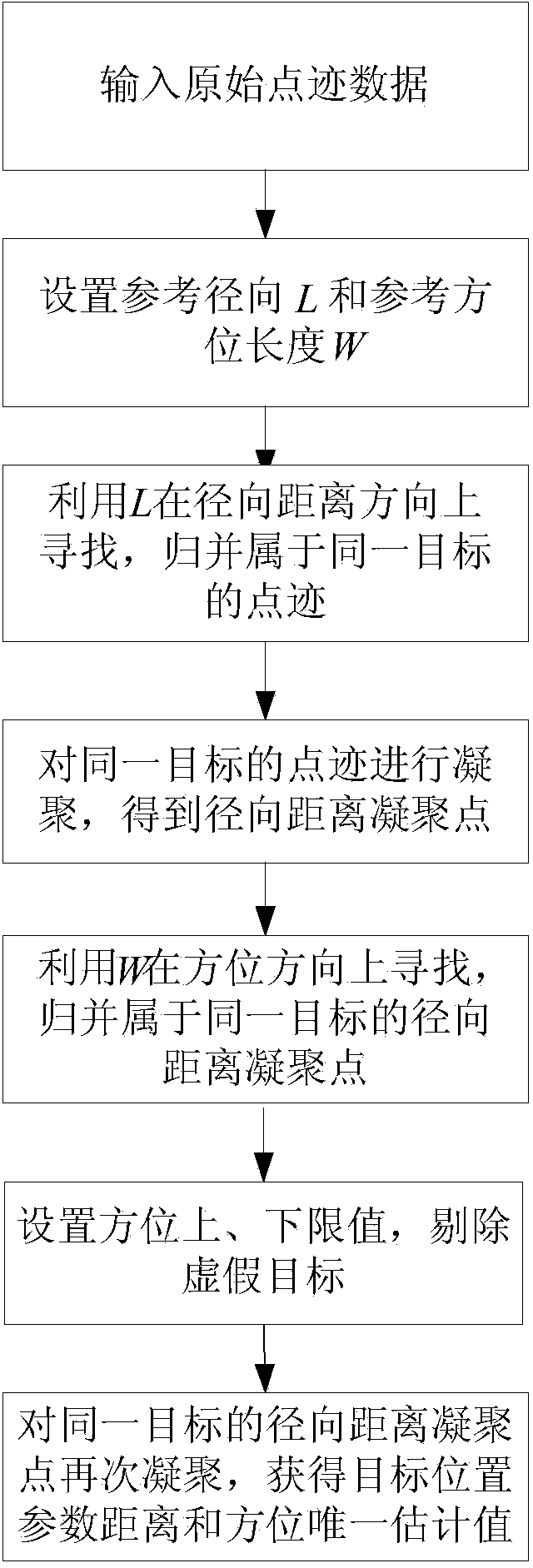

Method for processing original point trace condensation of broadband radar target

InactiveCN104166135AImprove effectivenessEasy to handleSpecial data processing applicationsRadio wave reradiation/reflectionRadarBroadband

The invention discloses a method for processing original point trace condensation of a broadband radar target. According to the method, a reference radial length L and a reference direction length W are set; the traces of points of the same target are merged in the radial distance direction; condensation is carried out on data of the traces, merged in the radial direction, of the points to obtain radial distance condensation points; the radial distance condensation points of the same target are merged on echo scanning lines in the adjacent directions; a background target is removed; sidelobe clutters are removed, direction condensation is carried out on the rest of the radial distance condensation points, and the direction parameter estimated value and the distance parameter estimated value of the same target are obtained. By means of the method, the radar original point trace data can be easily and quickly processed, the validity of point trace condensation and the accuracy of target parameter estimation are improved, and good essential data are provided for subsequent target tracing.

Owner:WUHAN ZHONGYUAN ELECTRONICS GRP

Air-conditioner defrosting method

InactiveCN104132404AEfficient removalDoes not affect normal heating operationLighting and heating apparatusAir conditioning systemsFrostUltrasonic sensor

The invention provides an air-conditioner defrosting method. The method comprises the following steps that a, an air-conditioner operates in a heating mode; b, a defrosting temperature sensor on a heat exchanger is used for measuring the temperature T of a coil pipe, when the T is lower than the temperature Tes of a condensation point, an outdoor unit enters in a defrosting mode; c, an outdoor fan stops rotating, an ultrasonic transducer on the heat exchanger is turned on, and a frost layer on the heat exchanger is vibrated to be float frost; d, the float frost is actively removed to enable the float frost to disengage from the heat exchanger; e, when the defrosting temperature sensor on the heat exchanger detects that the temperature T of the coil pipe is higher than the temperature Tes of the condensation point, the ultrasonic transducer stops operation, the float frost active removing operation is stopped, the outdoor fan rotates forwardly, and the defrosting process is ended. In the heating operation process, the ultrasonic transducer is used for vibrating the frost layer into the float frost capable of falling off easily, then the float frost is actively removed, the frost layer can be quickly and effectively removed, the air-conditioner continuous operates without stopping, the normal heating operation of the system is not influenced, and the system energy efficiency can be better improved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

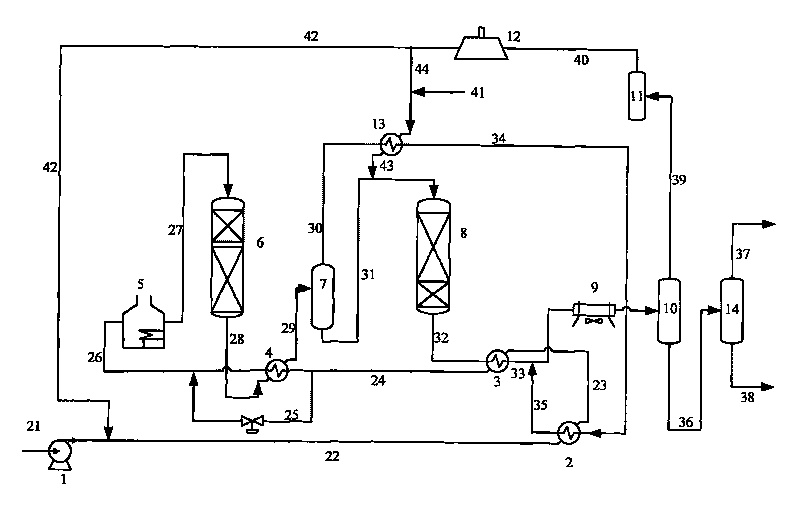

Method for preparing diesel oil component or jet fuel component by using animal and plant oil

ActiveCN103059901AHigh yieldHigh calorific valueLiquid hydrocarbon mixture productionBio-feedstockOil and greaseAlkane

The invention provides a method for preparing a diesel oil component or jet fuel component by using animal and plant oil. The method comprises the following steps of: (1) dividing the animal and plant oil into at least two parts, introducing the at least two parts of animal and plant oil to a plurality of catalyst beds of a first hydrogenation reactor, and enabling the at least two parts of animal and plant oil and a hydrodeoxygenation catalyst to contact and react to obtain n-alkanes with the carbon number of 8-24; (2) filling an isomerization catalyst in a second hydrogenation reactor, introducing a reaction product obtained in the step (1) to the second hydrogenation reactor, and reducing a condensation point after isomerization reaction to obtain a diesel oil component; or, (3) filling a selective cracking catalyst in the second hydrogenation reactor, introducing the reaction product obtained in the step (1) to the second hydrogenation reactor, and then, carrying out selective hydrocracking and isomerization to obtain a jet fuel blending component. The method provided by the invention is high in jet fuel yield; and the prepared jet fuel blending component is good in quality and can be mixed with the traditional petroleum-based jet fuel according to any proportion so as to be an excellent blending component.

Owner:CHINA PETROLEUM & CHEM CORP +1

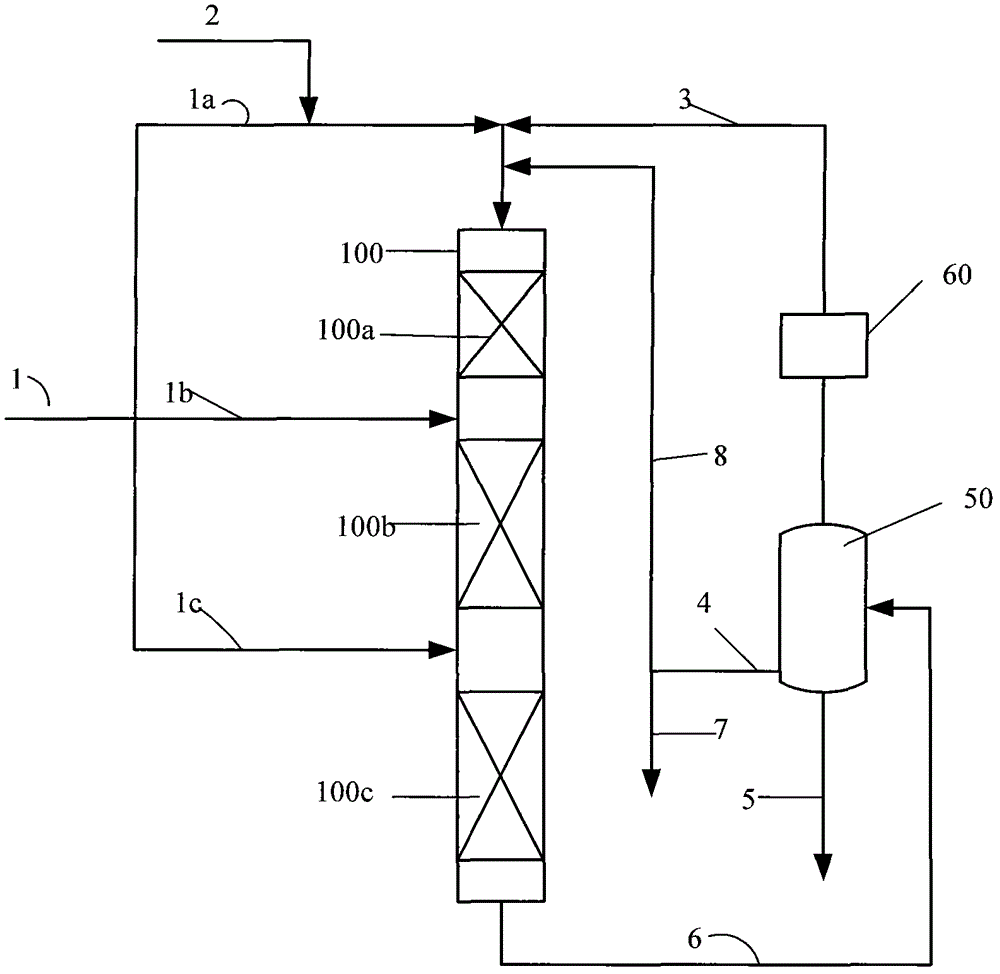

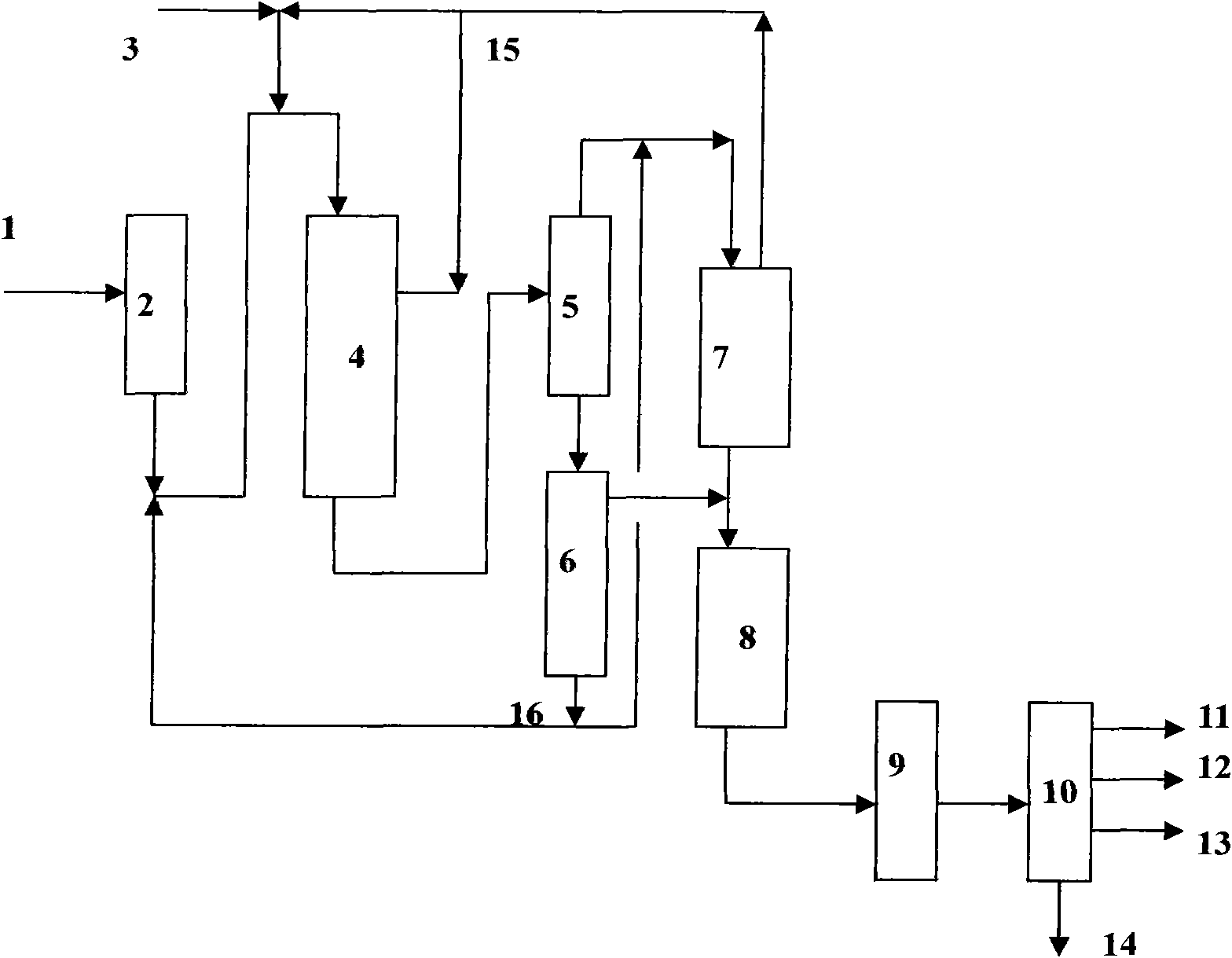

Hydrogenation method for reducing condensation point of diesel oil

ActiveCN101724459AAvoid crackingReduce sulfur contentTreatment with hydrotreatment processesHydrogenGas phase

The invention relates to a hydrogenation method for reducing the condensation point of diesel oil, comprising the following steps of: mixing diesel oil material and hydrogen for full fraction hydrogenation in a first hydrogenation area; flashing reaction effluences in a heat high-pressure separator; flashing the lighter components of the diesel oil out of the heat high-pressure separator, whereinliquid-phase material flows obtained by the heat high-pressure separator are the heavy components of the diesel oil; mixing the liquid-phase material flows with the hydrogen, and putting into second hydrogenation areas including a pour point depression reaction area and a post-refining area, for pour point depression reaction; mixing obtained gas-phase material flows of the heat high-pressure separator with reaction effluences of the second hydrogenation area, and putting into a sequential separation and fractionation system so as to obtain diesel oil products. The invention can enhance the yield coefficient of the diesel oil products with low pour point and also achieve the purpose of desulfurizing, denitriding and prolonging the service life period of a pour point depression catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydroisomerization/cracking catalyst, and preparation method and application thereof

ActiveCN103316710AExcellent isomerization performanceLowering the freezing pointMolecular sieve catalystsHydrocarbon oils treatmentAlkaneMolecular sieve

The invention discloses a hydroisomerization / cracking catalyst and a preparation method thereof. The catalyst is composed of an acidic isocraking carrier and a metal active component loaded on the acidic isocraking carrier; the acidic isocraking carrier is composed of a ZSM-22 molecular sieve and an amorphous oxide; and the mass ratio of the acidic isocraking carrier to the metal active component (by metal oxide and / or metal element) is 70-99.9:0.1-30. The preparation method of the catalyst comprises the following steps: 1, mixing the amorphous oxide with the ZSM-22 molecular sieve, carrying out adjusting and kneading molding by using an acid solution, and drying and roasting to obtain the acidic isocraking carrier; and 2, dipping the acidic isocraking carrier in an aqueous solution of a soluble salt of the active metal component, and drying and roasting to obtain the catalyst. The catalyst can crack high-melting-point long-chain normal paraffins into lightweight diesel oil during hydroisomerization, generates a small amount of gases and naphtha, and effectively reduces the condensation points of products.

Owner:SYNFUELS CHINA INNER MONGOLIA CO LTD

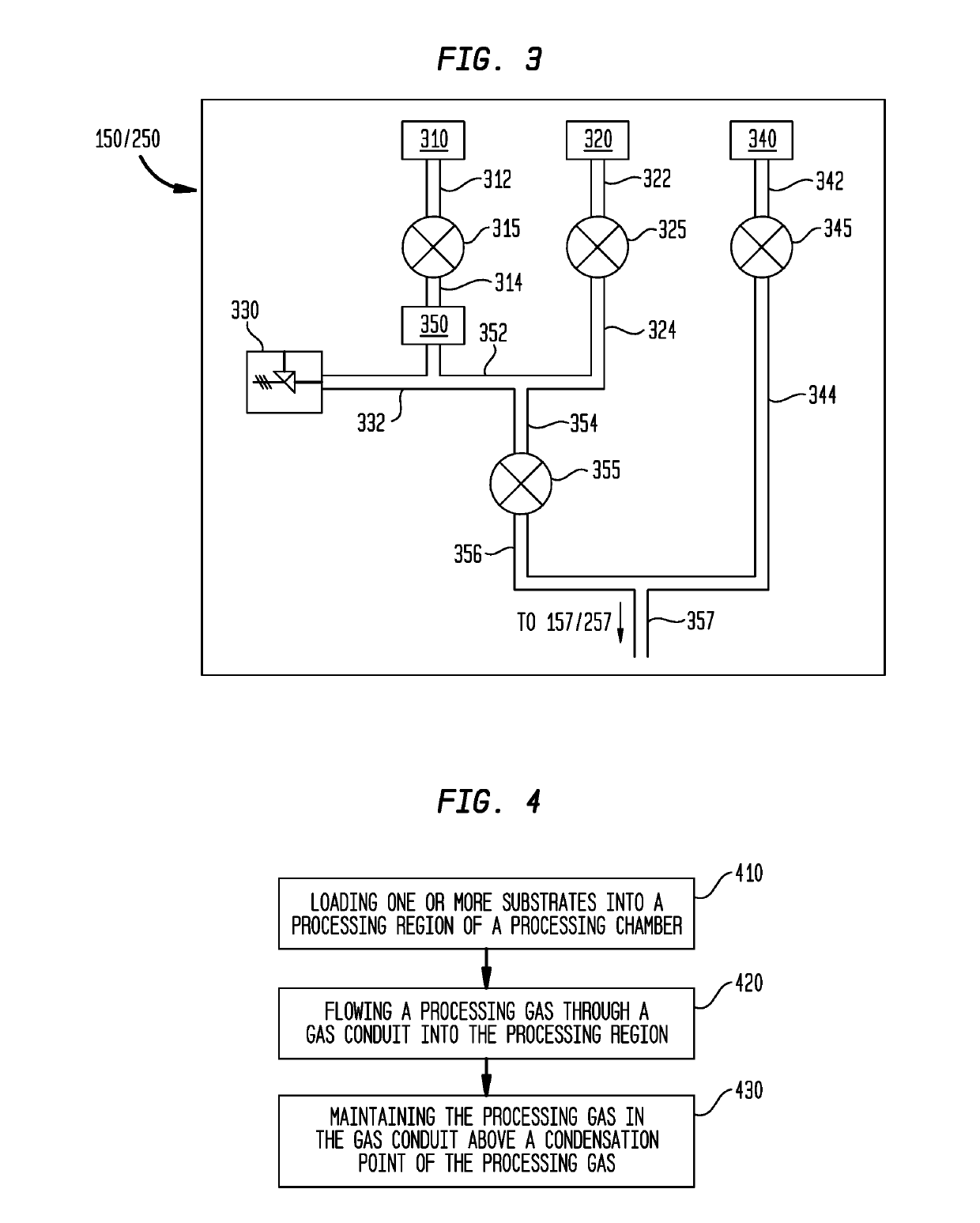

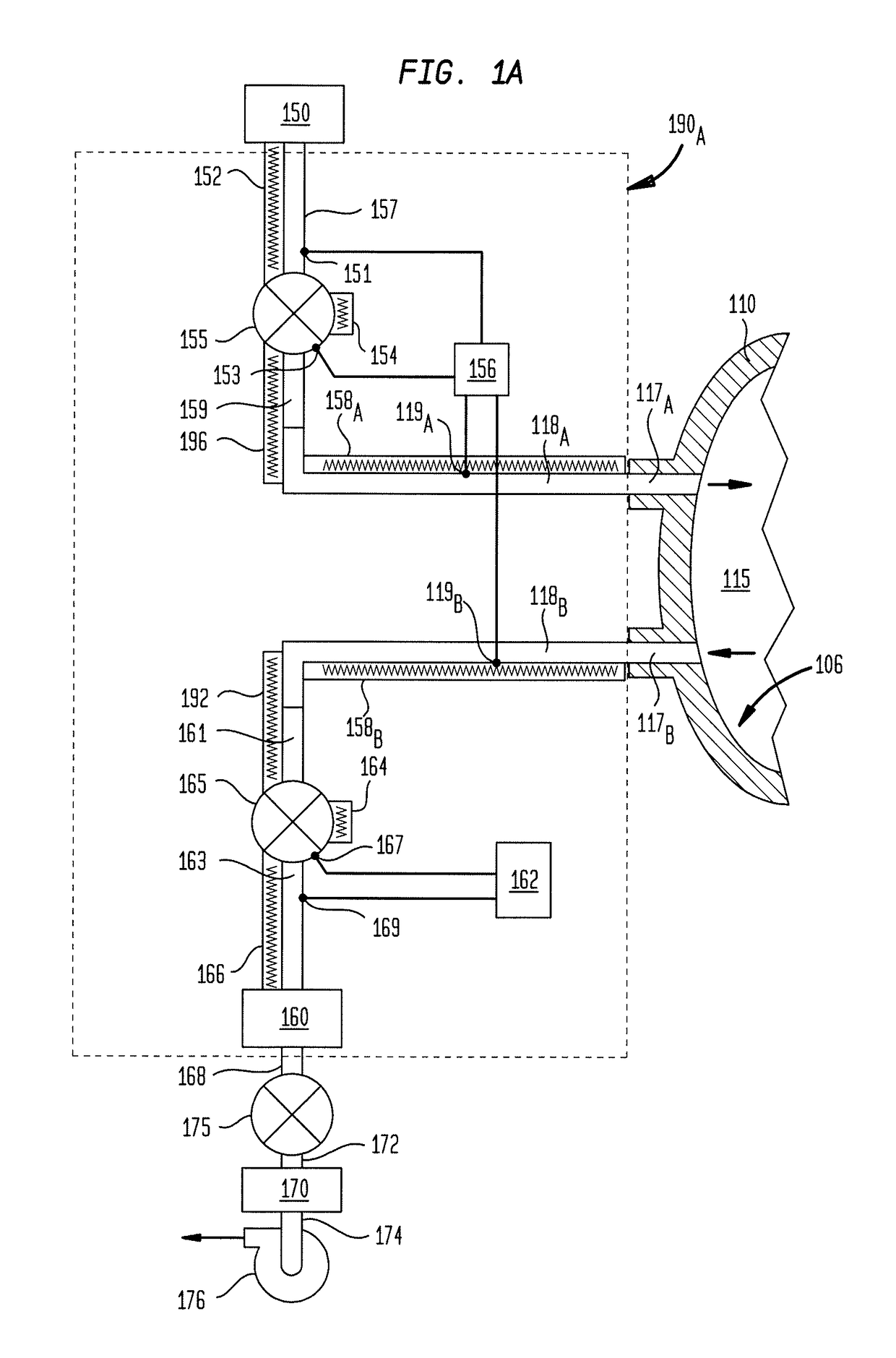

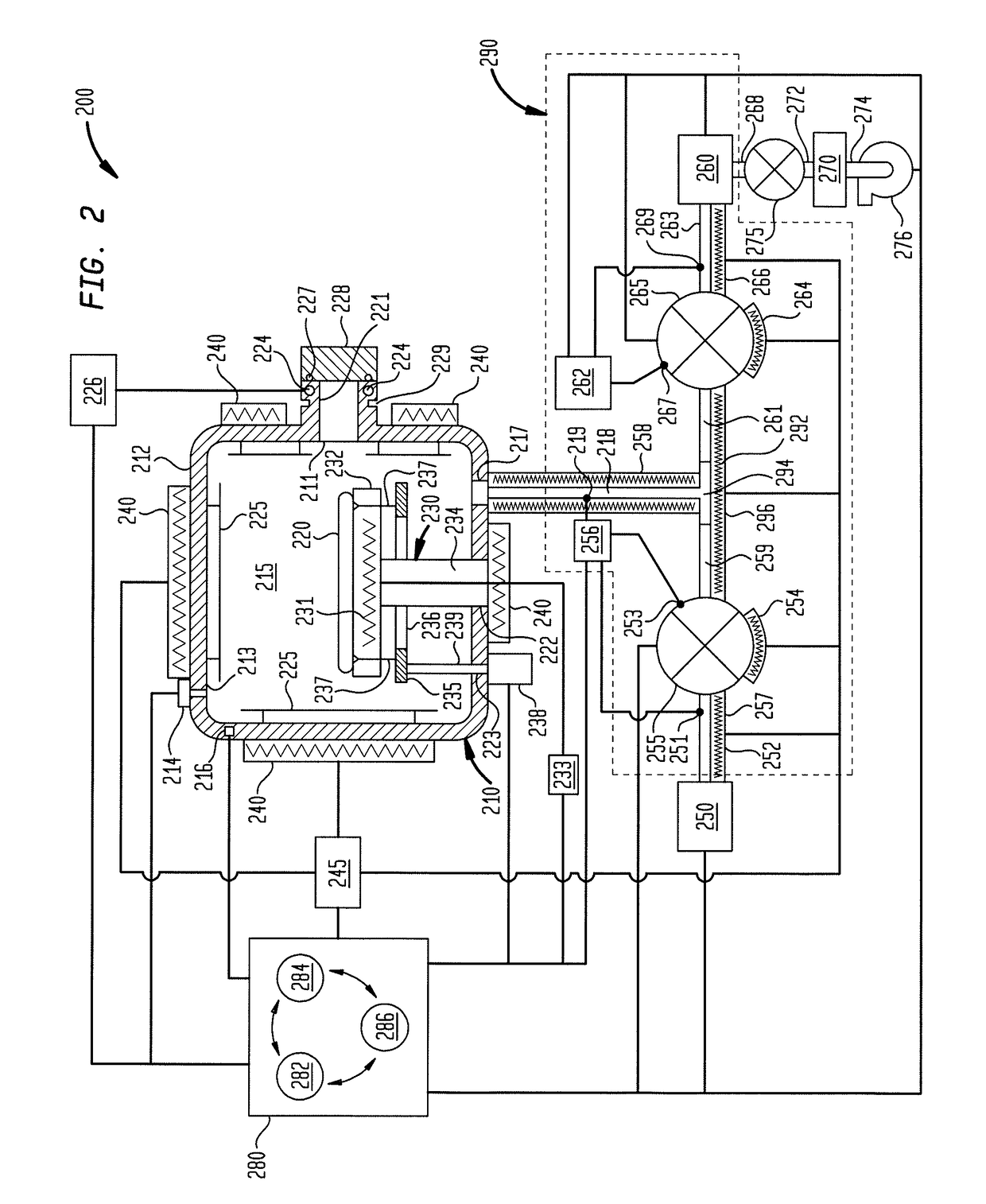

Quality improvement of films deposited on a substrate

InactiveUS20180350563A1Electric discharge tubesSemiconductor/solid-state device manufacturingCelsius DegreeEngineering

Embodiments of the disclosure generally relate to a method of processing a semiconductor substrate at a temperature less than 250 degrees Celsius. In one embodiment, the method includes loading the substrate with the deposited film into a pressure vessel, exposing the substrate to a processing gas comprising an oxidizer at a pressure greater than about 2 bars, and maintaining the pressure vessel at a temperature between a condensation point of the processing gas and about 250 degrees Celsius.

Owner:APPLIED MATERIALS INC

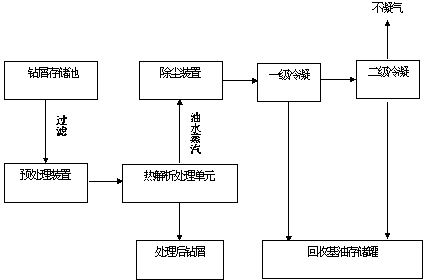

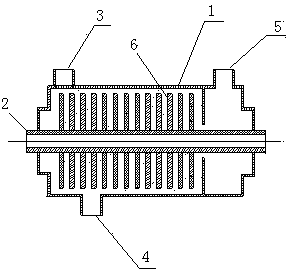

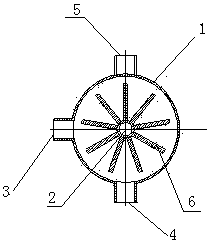

Oil-base drilling cuttings thermal analytical treatment method

ActiveCN104178200AReduce oil contentMeet emission requirementsLiquid hydrocarbon mixture productionAfter treatmentReaction temperature

The invention belongs to the technical field of environment protection of oil and gas fields and particularly provides an oil-base drilling cuttings thermal analytical treatment method. The method comprises the following main steps: conveying the oil-base drilling cuttings after pre-treatment to a processing unit; heating to raise the reaction temperature to the volatilization temperature of hydrocarbon in the components in the drilling cuttings; then, maintaining for a certain standing time till oil gas is completely volatilized; after treatment, storing the drilling cuttings by virtue of a discharge device for discharging; feeding the oil gas into a recovering and separating unit by virtue of an exhaust device; recovering components with different condensation points in different condensation recovery units; and maintaining the recovered oil unchanged for further preparing an oil-base drilling fluid. The method solves the defects and shortcomings of other methods well. By adopting the oil-base drilling cuttings thermal analytical treatment technology, the oil content of the drilling cuttings is low (less than 1%), so that the discharge requirement is satisfied. The method provided by the invention further achieves the purposes of treating the oil-base drilling cuttings and recycling resources while the problem of environmental pollution is solved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

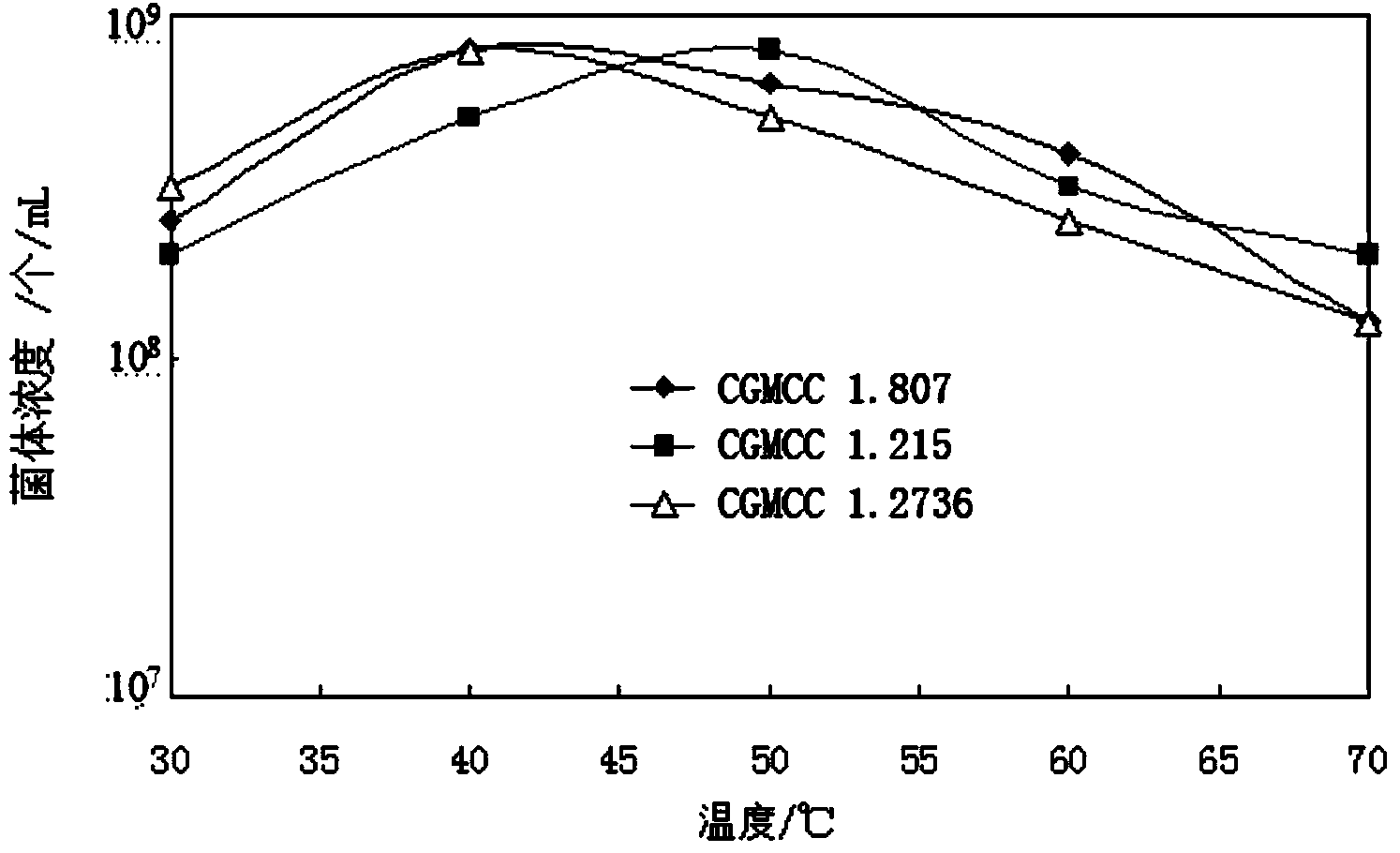

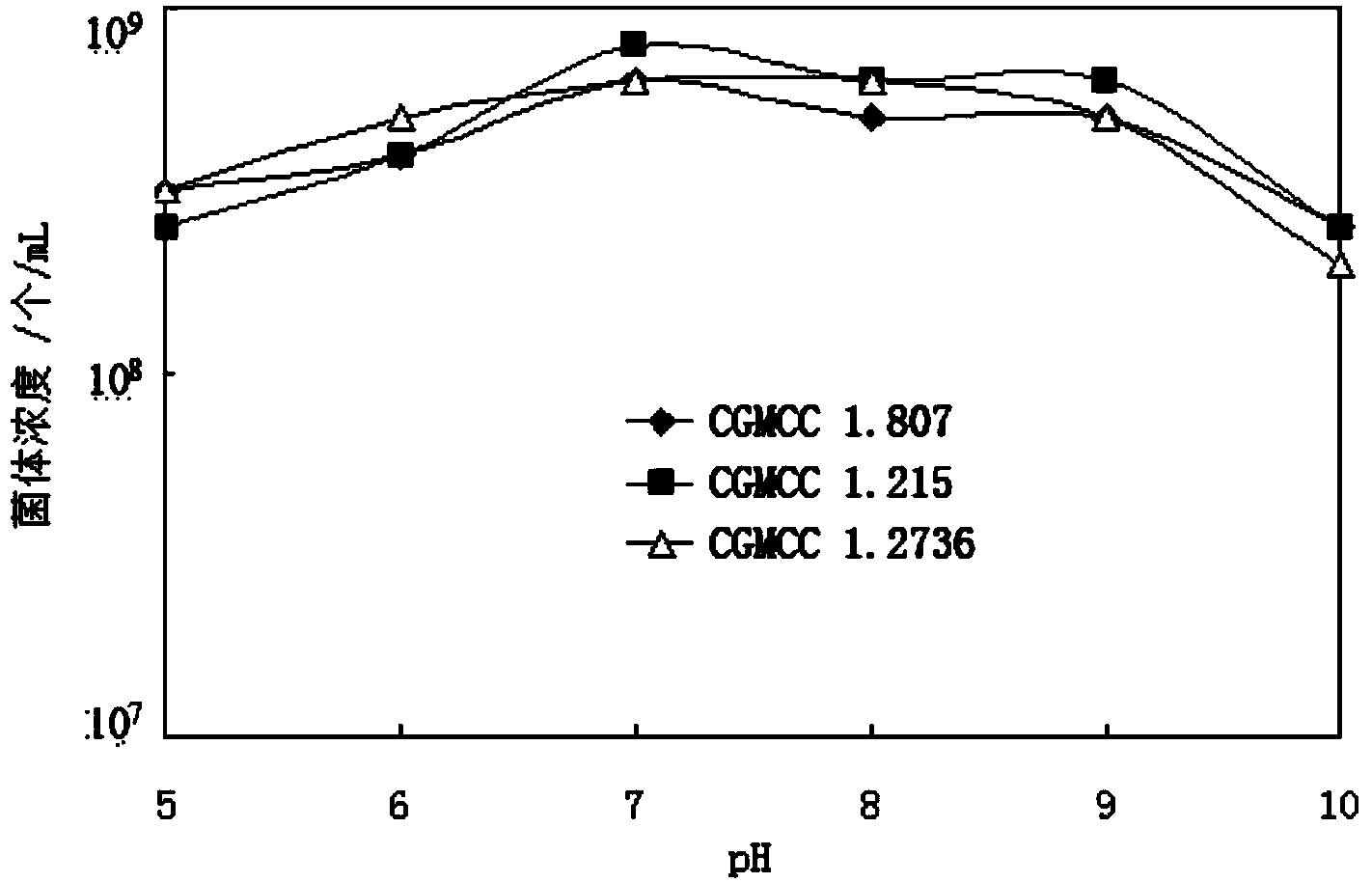

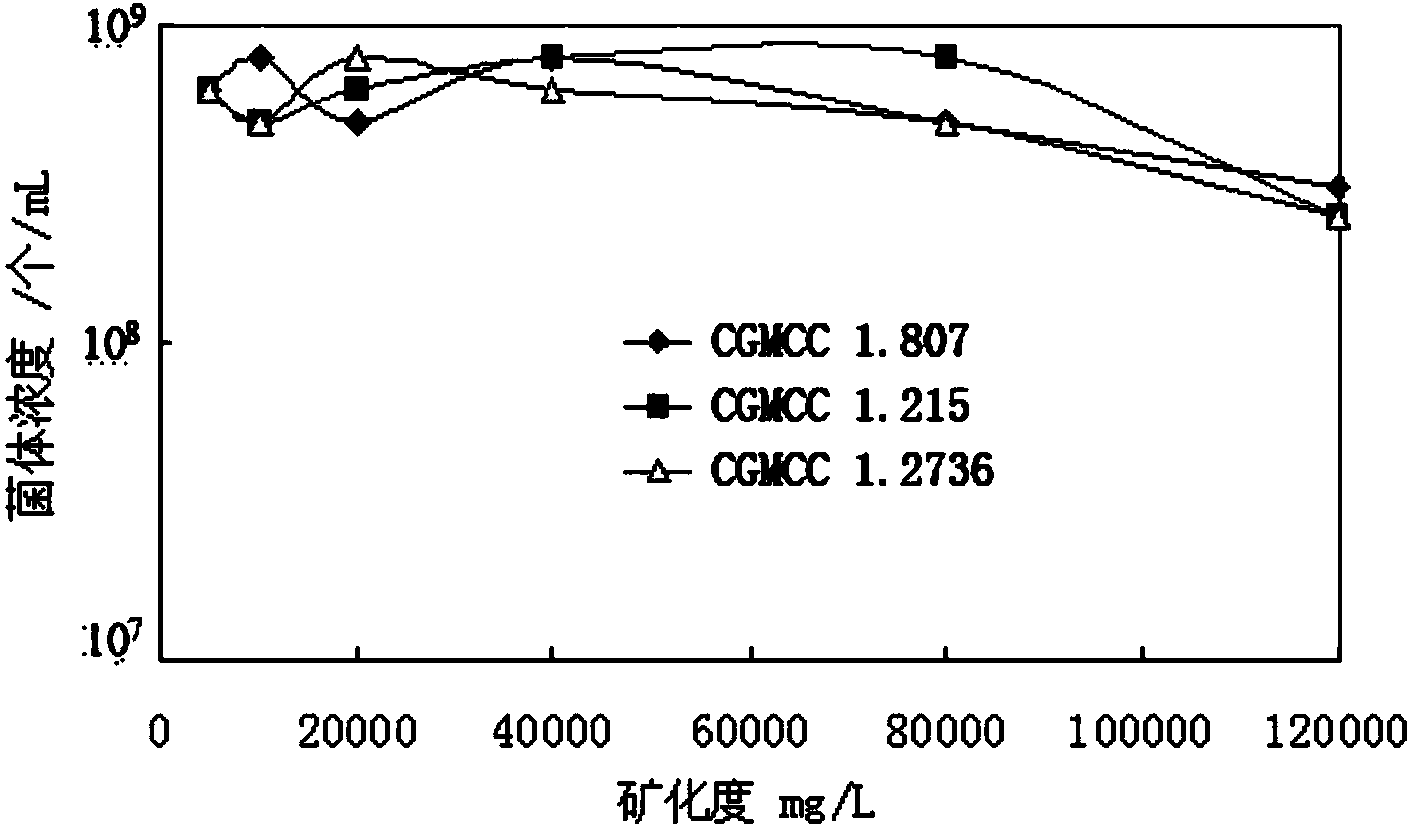

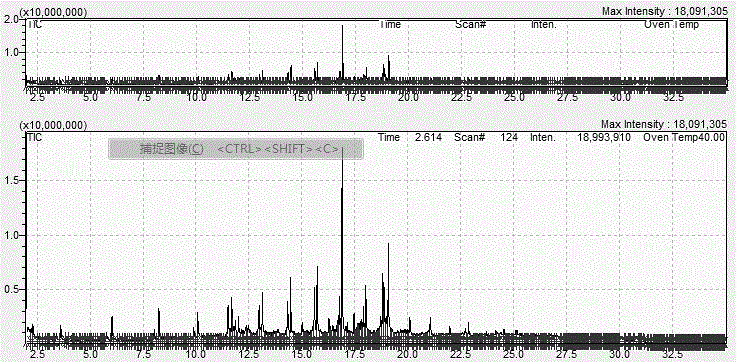

Slime reducing agent suitable for heavy oil wells with different mineralization and application

ActiveCN104109646ALow viscosityLowering the freezing pointBacteriaMicroorganism based processesBacillus licheniformisAureobasidium sp.

The invention discloses a slime reducing agent suitable for heavy oil wells with different mineralization and an application, which belongs to the oil field chemical technology field. The slime reducing agent is composed of Bacillus licheniformis, bacillus subtilis and bacillus thuringiensis, and is cultured for 24 hours under the condition that the temperature is 30-70 DEG C, pH value is 5-10, mineralization is 1000-120000mg / L, and the pressure is 0-30MPa, thalline concentration of each bacterial classification can reach 108-109 / Ml, and the breeding capability is strong. The slime reducing agent can degrade the crude oil heavy components, metabolize a biological surface active agent and biogas, so that crude oil viscosity is reduced, and then stable yield increase of the heavy oil wells can be ensured. According to the test, good yield increase effect can be achieved at on-site oil well under the condition that mineralization is 6000-83000mg / L, pH value is 7-8.6, and the temperature is 40-60 DEG C, daily oil production is increased by 24-83%, pump efficiency is increased by 4-10%, the crude oil viscosity is decreased by 50-65%, output liquid surface tension is decreased by 20%-30%, and the crude oil condensation point is decreased to 1-3 DEG C.

Owner:CHINA PETROLEUM & CHEM CORP +1

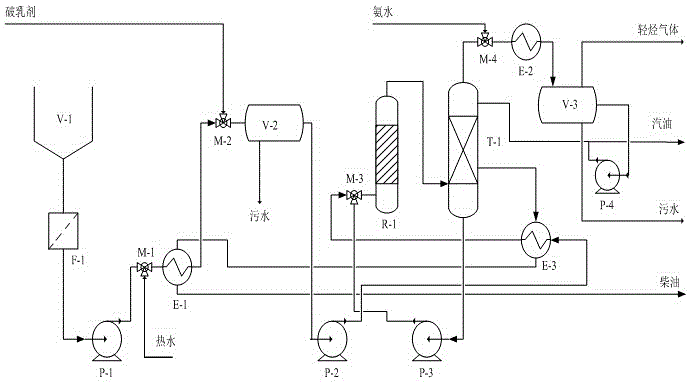

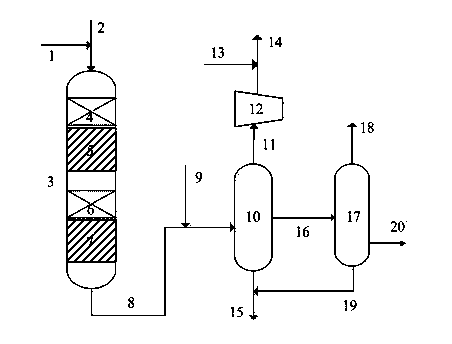

High value utilization method of gutter oil

InactiveCN105925381AImprove conversion rateReduce heat demand and supplyFatty acid chemical modificationMolecular sieve catalystsGasolineProcess engineering

The invention discloses a high value utilization method of gutter oil. The method comprises the following steps: purifying and preprocessing gutter oil, subjecting gutter oil to catalytic cracking, and separating and refining the products. The gutter oil is preprocessed in a clarifying tank, then filtered by a filter, washed by hot water, demulsified, desalted, dehydrated, and purified. Then, gutter oil exchanges heat with reaction products, and is delivered to a reactor to carry out catalytic cracking. The reaction products are separated by a separator, the waste heat is recycled, and fuel diesel oil, gasoline, and light hydrocarbon gas are obtained. The method has the following advantages: (1) the gutter oil is effectively converted into valuable resources such as diesel oil, gasoline, and the like, and the products have the advantages of high thermal efficiency, and low pollution environment; (2) the produced diesel oil has the advantages of good color value, high calorific value, low condensation point, and high flash point and meets related national and industrial standards; (3) the yield of liquid oil is high, the coking degree is low during the cracking process, the whole technology is compact, the efficiency is high, and the method can be applied to industry easily.

Owner:HUAIYIN TEACHERS COLLEGE

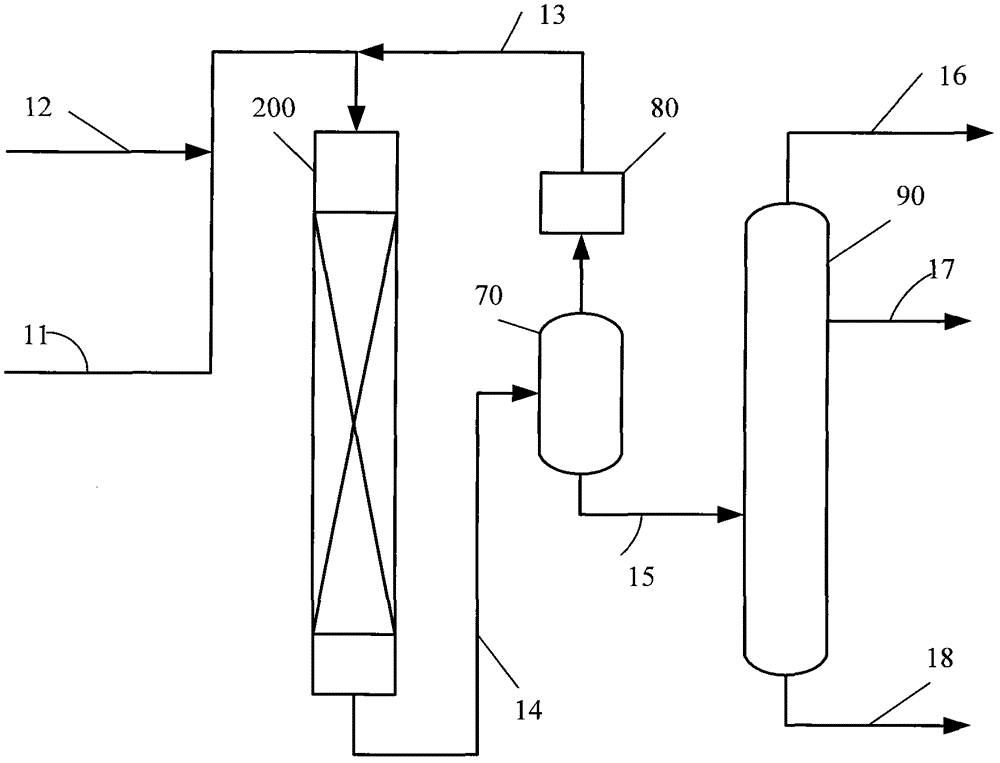

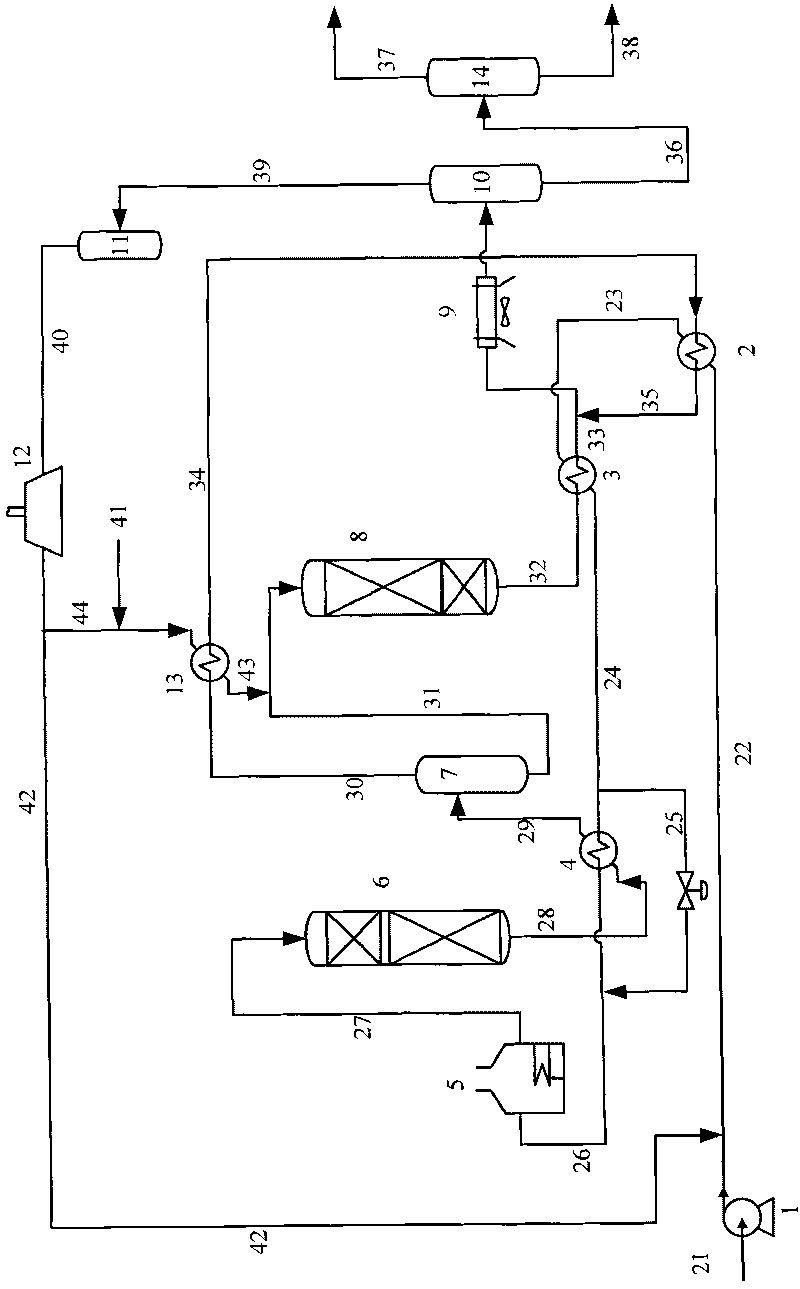

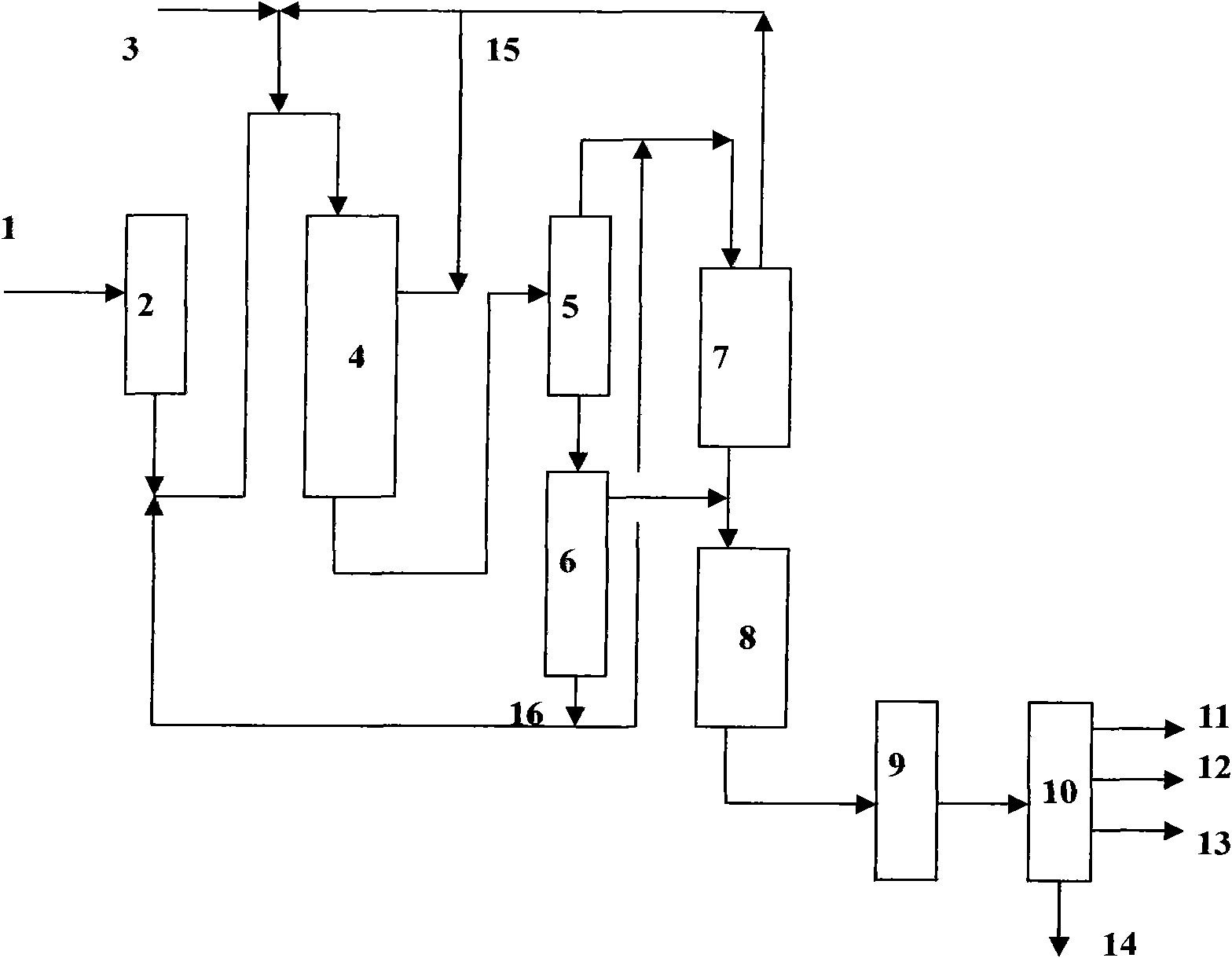

Hydrocracking method for blending ethylene tar

ActiveCN102234542AIncrease saturation rateHigh yieldTreatment with hydrotreatment processesChemistryLight crude oil

The invention discloses a hydrocracking method for blending ethylene tar, which comprises the following steps of: blending light fraction of ethylene tar into heavy distillate for hydrocracking, and contacting a hydrogenation protecting catalyst, a hydrogenation refining catalyst, a hydrogenation carbon residue removing catalyst and a hydrocracking catalyst in the presence of hydrogen to obtain hydrocracking crude oil, wherein partial hydrocracking crude oil is circulated and mixed with the light fraction and heavy distillate of the ethylene tar to enter a hydrocracking area, and the rest hydrocracking crude oil is future separated to obtain light fuel oil. By the method, the problem of high temperature rise of a hydrogenation reactor bed can be effectively solved; meanwhile, a method of grading the hydrogenation catalysts, the light fraction of the ethylene tar can be processed, and diesel with high cetane number and low condensation point and naphtha with high potential aromatic content can be produced; and compared with a state that the ethylene tar is not blended, the method has the advantage that the bureau of mines correlation index (BMCI) value of tail oil and the smoke point of jet fuel are not obviously changed.

Owner:CHINA PETROLEUM & CHEM CORP +1

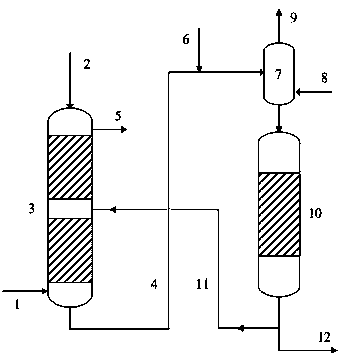

Animal and vegetable oil-catalytic diesel oil combined hydrogenation method

ActiveCN103773455ALowering the freezing pointSolve problems that cannot meet the needs of hydrogenation reactionsLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesVegetable oilHydrogen

The invention discloses an animal and vegetable oil-catalytic diesel oil combined hydrogenation method. The animal and vegetable oil-catalytic diesel oil combined hydrogenation method comprises following steps: countercurrent contact of animal and vegetable oil with hydrogen is carried out in a hydrogenation heterogeneous reactor, and hydrofinishing and condensation point reduction reaction are carried out; an obtained liquid effluent is mixed with catalytically cracked diesel oil, an obtained mixture is delivered into a hydrogen mixing tank for hydrogen mixing, and then is delivered into a liquid phase hydrogenation reactor for hydrofinishing; a part of obtained hydrofined diesel oil is cycled to a lower catalyst bed layer of the hydrogenation heterogeneous reactor. On the one hand, hydrogenation heterogeneous condensation point reduction of the animal and vegetable oil is capable of increasing hydrogen dissolving amount of the liquid phase hydrogenation reactor, and on the other hand condensation point of the animal and vegetable oil is reduced, the animal and vegetable oil is high in cetane value, and combined hydrogenation of the animal and vegetable oil with catalytic diesel oil is capable of solving a problem that the cetane value is too low. The animal and vegetable oil-catalytic diesel oil combined hydrogenation method is capable of widening raw material sources for refinery diesel oil production, and also providing a method for processing of low-quality catalytic diesel oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Diesel oil pour point depressant composition, its preparation method and application

ActiveCN102517104AGood dispersionImprove low temperature fluidityLiquid carbonaceous fuelsFuel additivesWaxOrganic solvent

The invention discloses a diesel oil pour point depressant composition and its preparation method. The diesel oil pour point depressant composition, i.e. a diesel oil pour point depressant composition formed by mixing acetic ester organic solvents with a pour point depressant, comprises the following raw materials by mass percent: 0-20% of methyl acetate, 0-20% of ethyl acetate, 0-10% of propyl acetate, 0-30% of butyl acetate, and 20-80% of the pour point depressant. The preparation method consists of: mixing all the raw materials and then conducting stirring in water bath at a constant temperature of 50DEG C for 20min, and controlling the rotation speed at 150r / min, thus obtaining the diesel oil pour point depressant composition. Adding of the obtained diesel oil pour point depressant composition into commercially available 0# diesel oil can make the cold filter plugging point of the diesel oil reduced by 5-11DEG C and the condensation point reduced by 6-10DEG C. The diesel oil pour point depressant composition provided in the invention enhances the dispersion effect of pour point depressants on wax crystals, and improves the low temperature fluidity of diesel oil.

Owner:SHANGHAI INST OF TECH

Method for removing sulfide from gasoline and diesel oil through extraction of ion liquid

InactiveCN1837332AEfficient removalPromote regenerationHydrocarbon oils refiningSource materialSulfide

The invention discloses a sulfide removal method in the petrol and diesel through ionic liquid extraction, which is characterized by the following: using ionic liquid as extractive solvent; proceeding extraction at atmosphere pressure, 5-6 deg.c; applying ionic liquid from alkylate hydrohalogenate, imidazolium or imidazolium alkylation, pyridine or pyridine alkylation, sulfonium or sulfonium alkylation as positive ionic source material; taking metal halide as ionic liquid of negative ionic source. The invention can improve desulfurizing effect without decreasing petrol octane value and diesel condensation point, which can meet the increasingly harsh environmetal standard.

Owner:BEIJING UNIV OF CHEM TECH

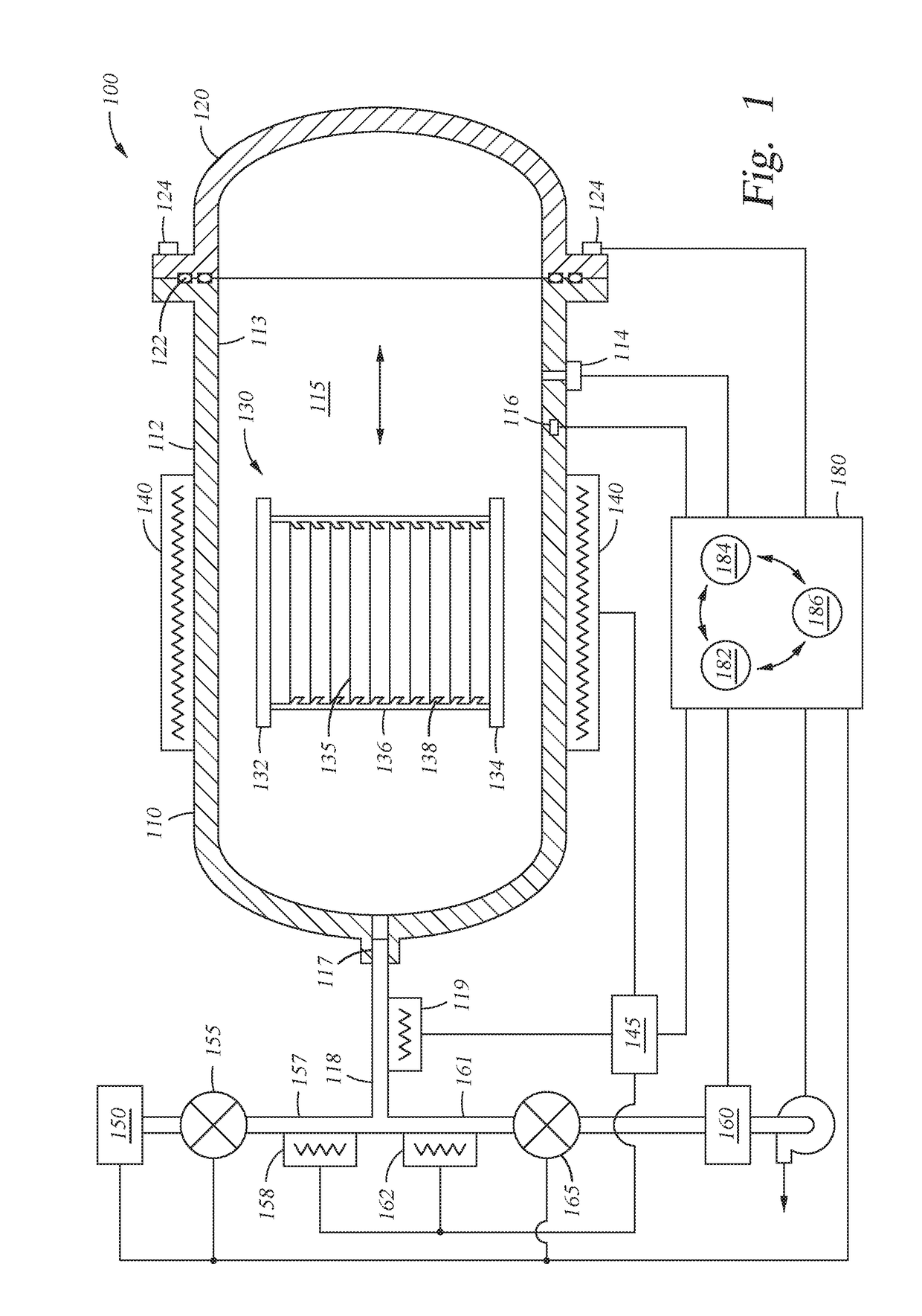

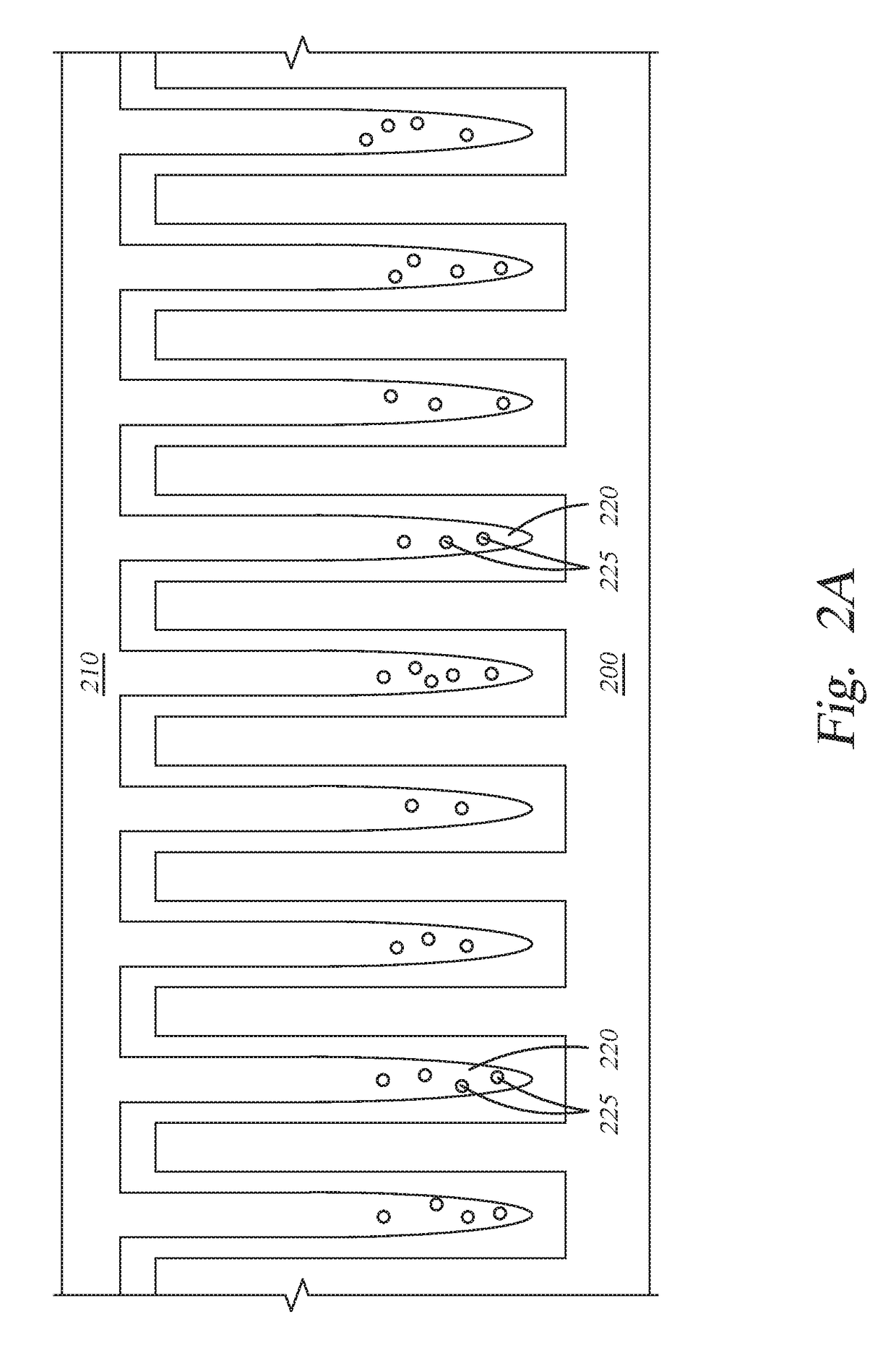

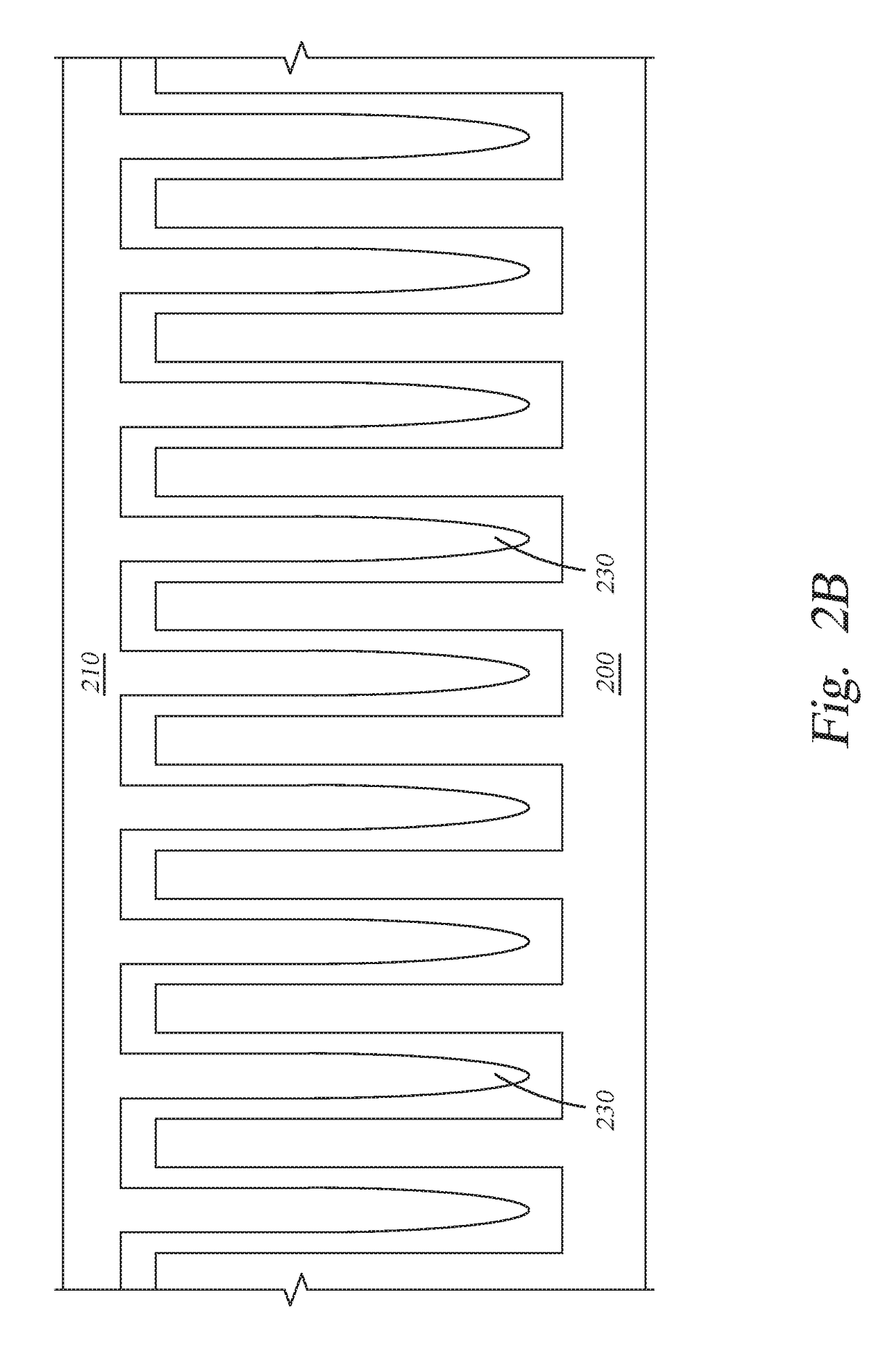

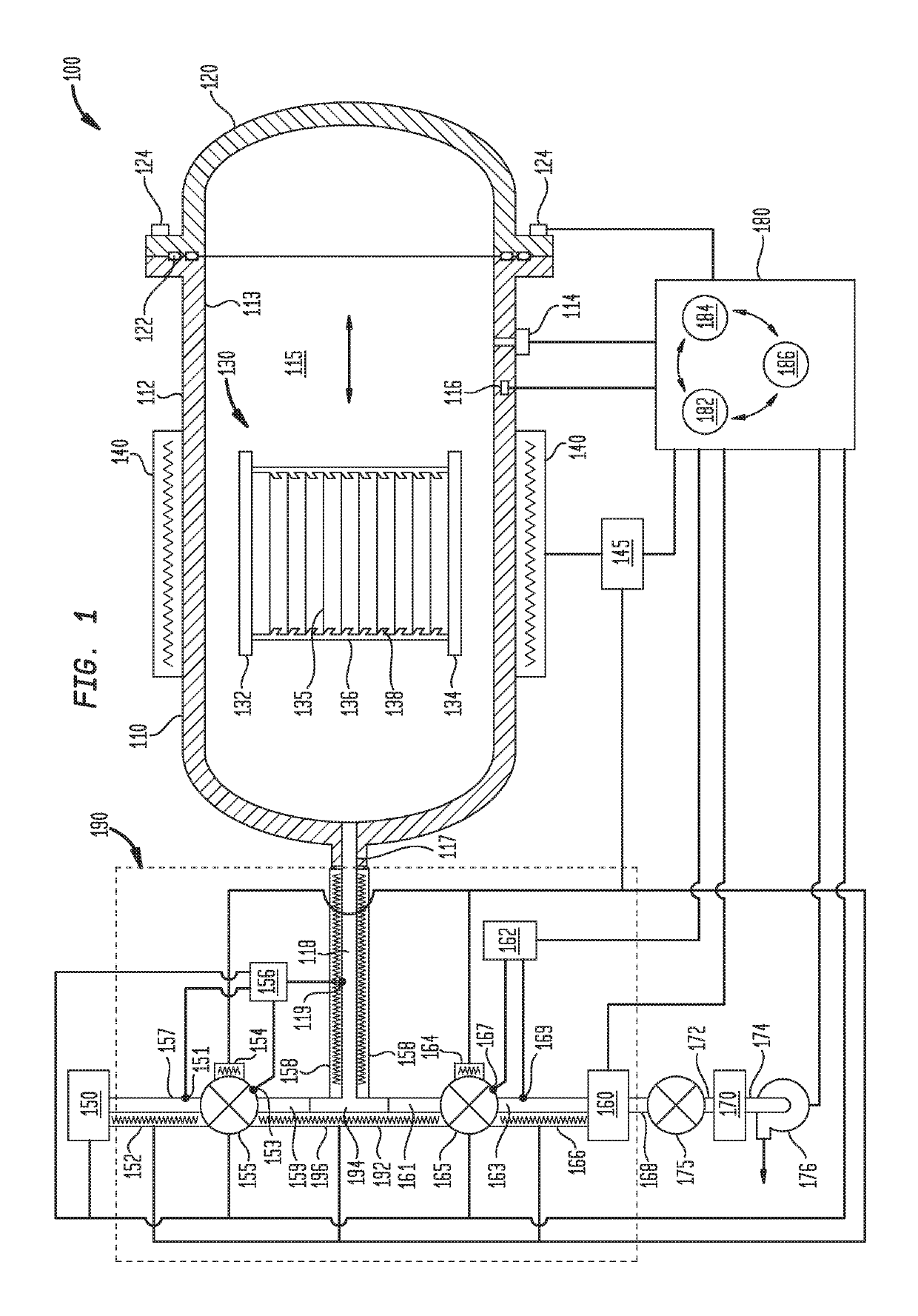

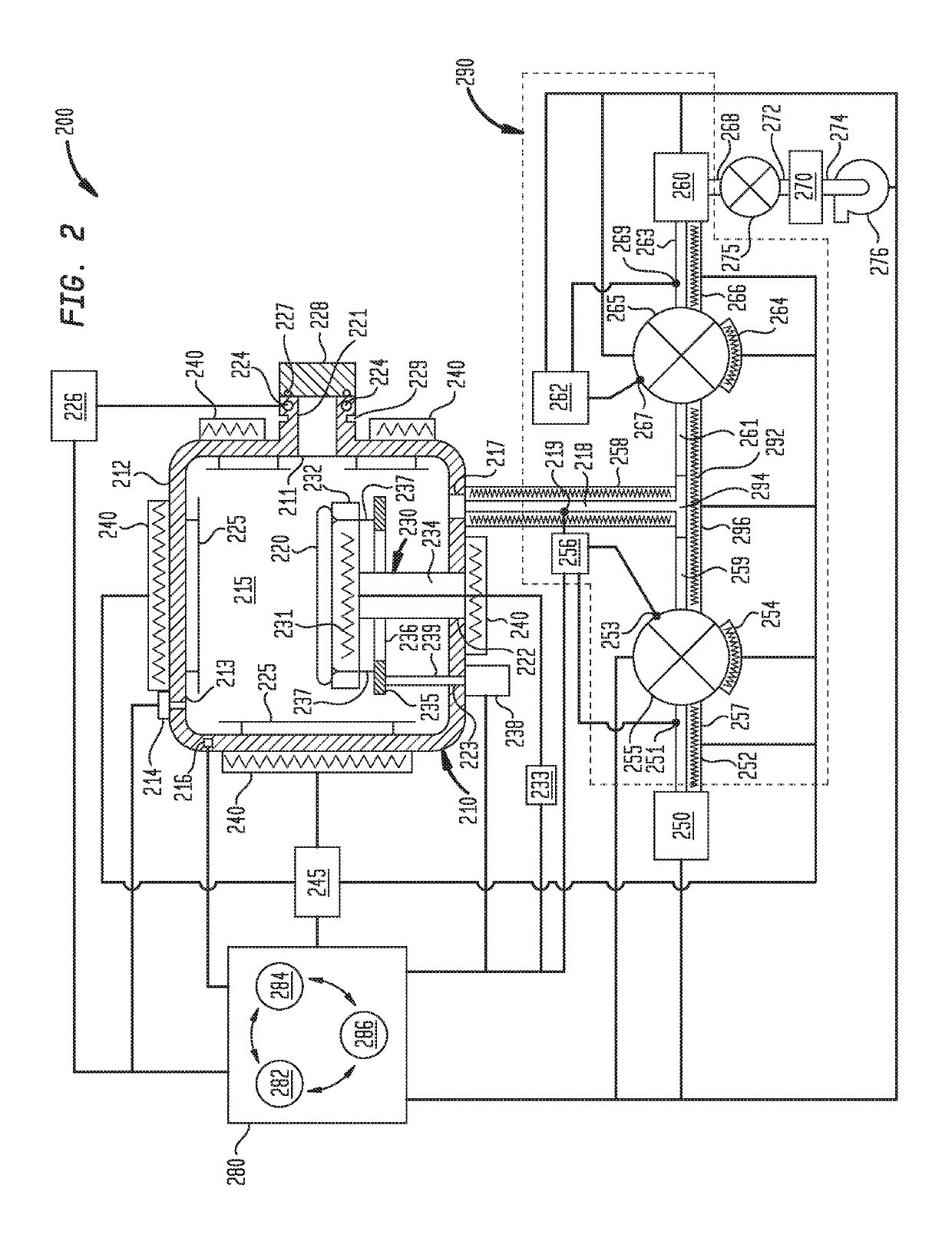

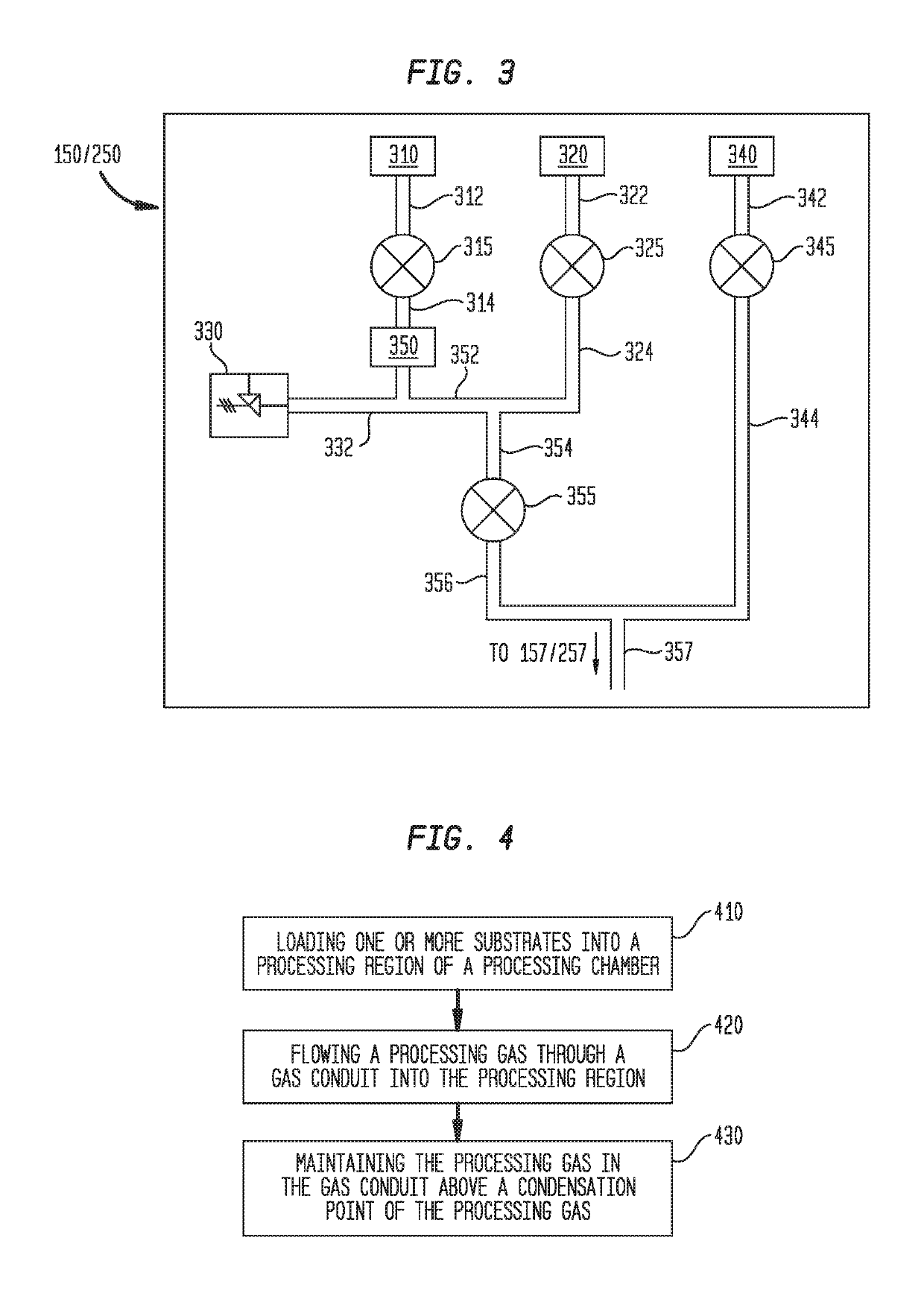

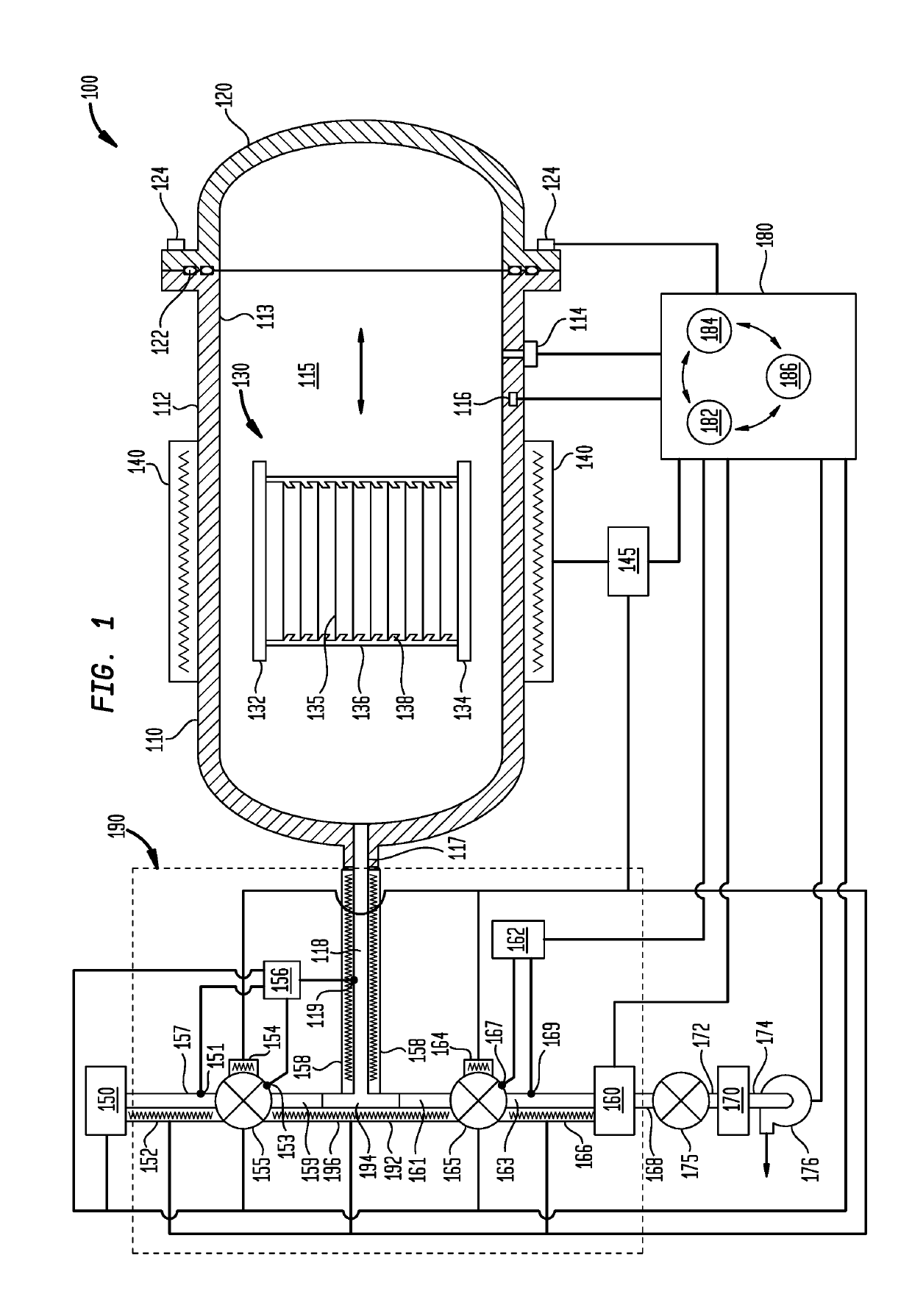

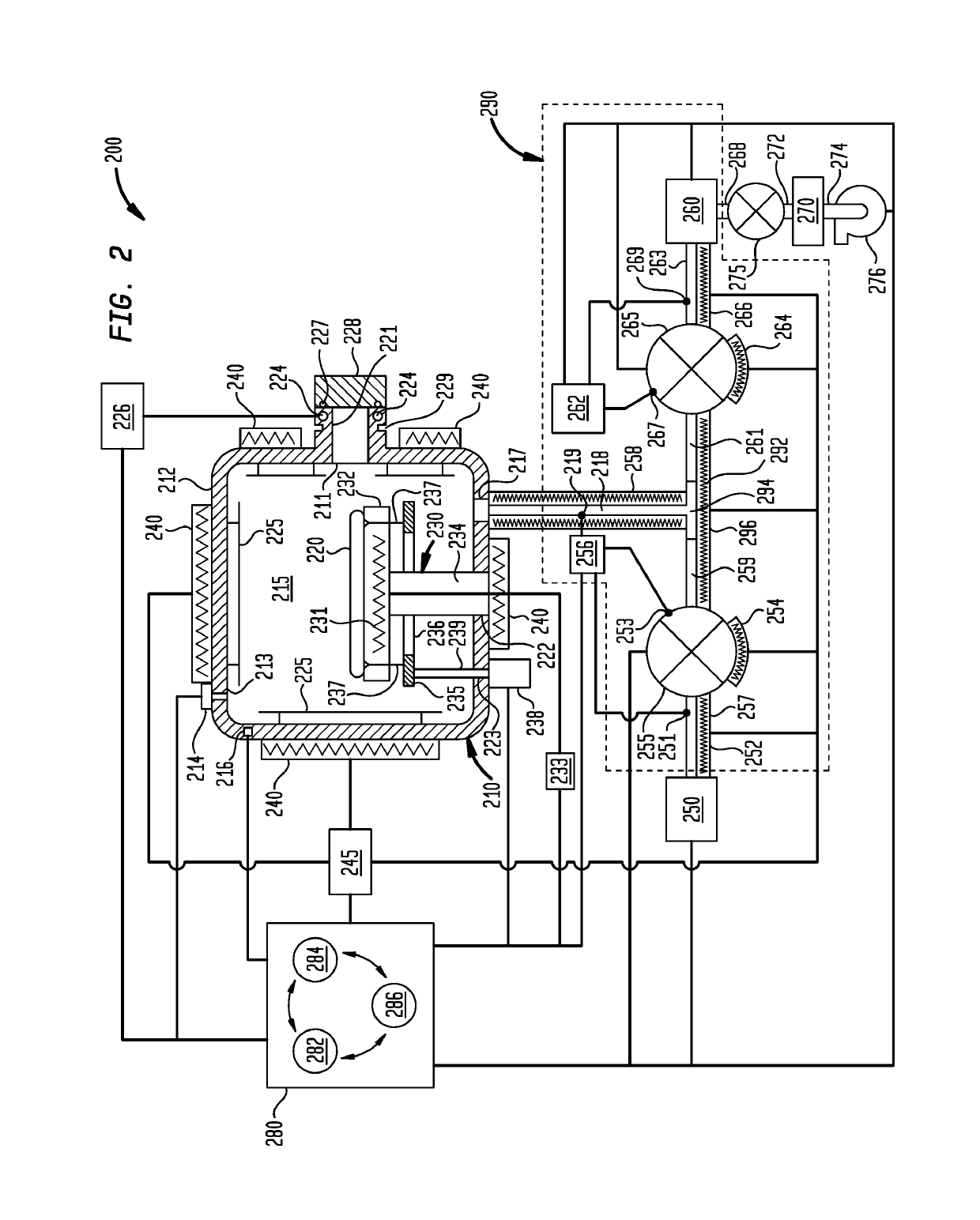

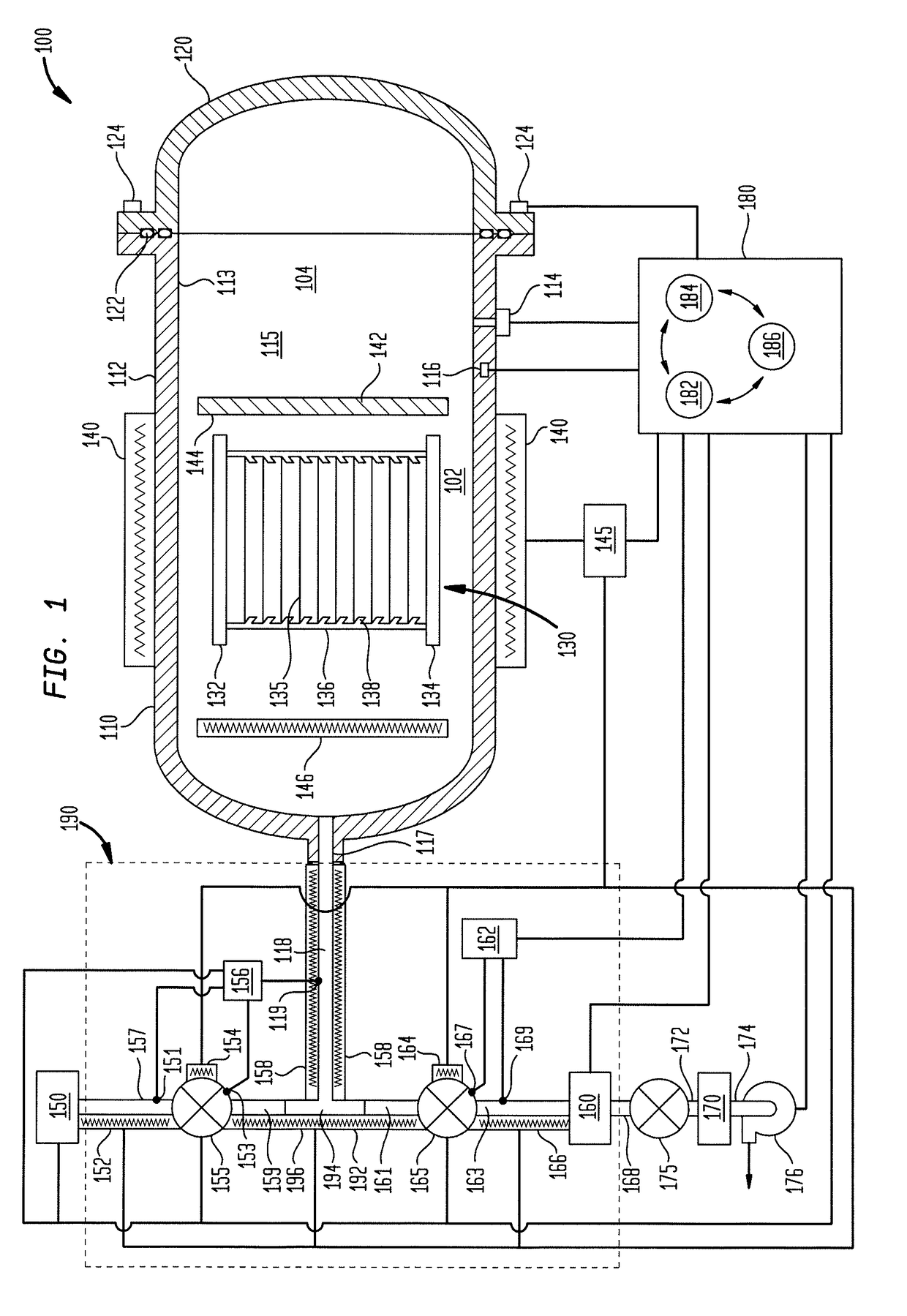

High pressure and high temperature anneal chamber

ActiveUS10276411B2Semiconductor/solid-state device manufacturingFurnace typesTemperature controlEngineering

Embodiments of the disclosure relate to an apparatus and method for annealing one or more semiconductor substrates. In one embodiment, a processing chamber is disclosed. The processing chamber includes a chamber body enclosing an internal volume, a substrate support disposed in the internal volume and configured to support a substrate during processing, a gas panel configured to provide a processing fluid into the internal volume, and a temperature-controlled fluid circuit configured to maintain the processing fluid at a temperature above a condensation point of the processing fluid. The temperature-controlled fluid circuit includes a gas conduit fluidly coupled to a port on the chamber body at a first end and to the gas panel at a second end.

Owner:APPLIED MATERIALS INC

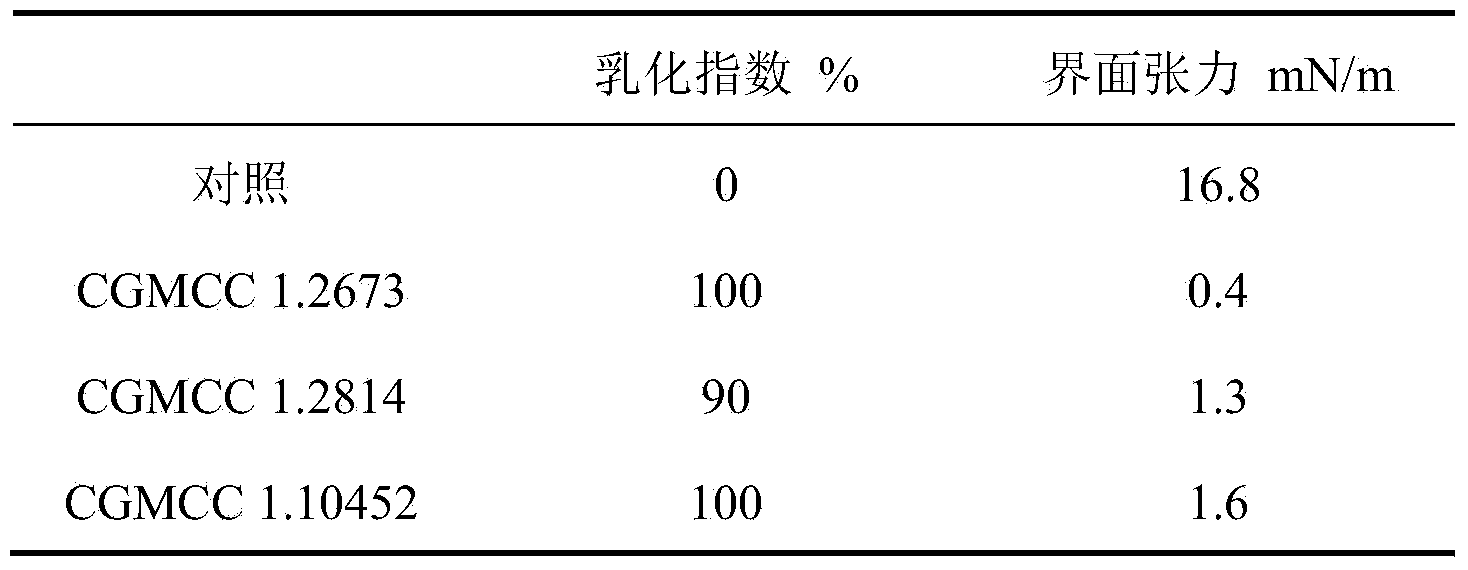

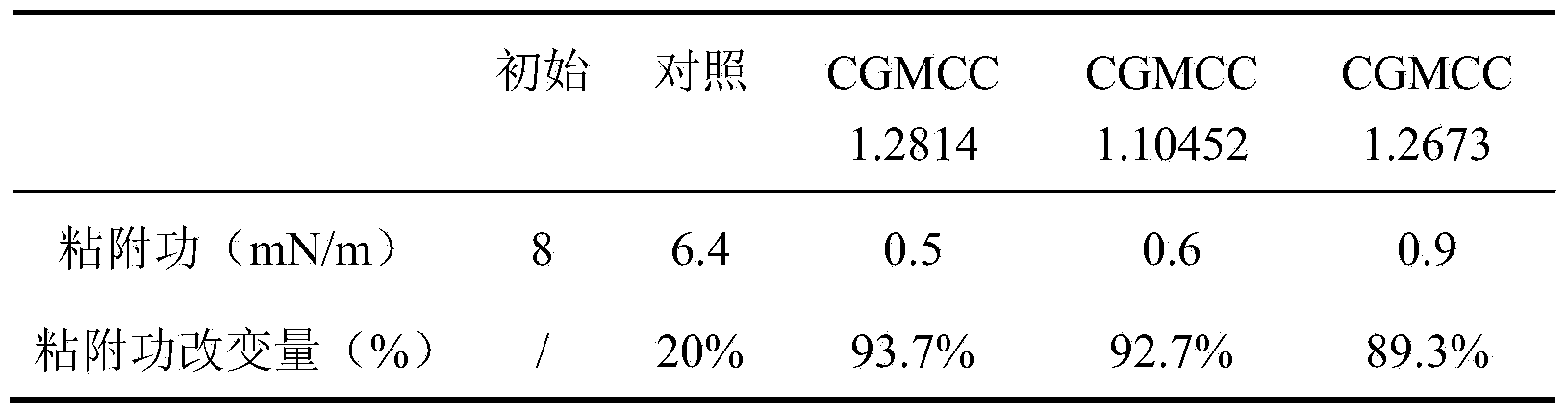

Strong emulsibility microbe wax cleaning and preventing bacterial agent and application thereof

ActiveCN104109516AStrong emulsifying abilityReduce interfacial tensionCleaning apparatusFluid removalInhibition zoneOil production

The invention discloses a strong emulsibility microbe wax cleaning and preventing bacterial agent and an application, which belongs to the oil field chemical technology field. The wax cleaning and preventing bacterial agent mainly comprises pseudomonas aeruginosa and geobacillus sp, has strong emulsification capability, and is capable of dispersing crude oil, promoting crude oil to flow, changing adherence force of borehole wall, preventing the accumulation of wax crystal on the borehole wall, and playing the paraffin inhibition and wax cleaning effects. By increasing the initial application amount of the bacteria liquid and prolong the well closing time, a stable paraffin inhibition zone can be formed due to adhesion of bacteria on borehole wall, near wellbore formation can be cleaned, and the paraffin inhibition and oil increase effects can be increased. After on-site enforcement, the well cleaning and chemical paraffin inhibition works can not be carried out in recent half year in the test wells, so that the wax cleaning and preventing bacterial agent has good paraffin inhibition effect in the well. The oil production is increased by about 30% daily, pump efficiency is increased about 10%, the surface tension of the output liquid is decreased to 20-25%, and the crude oil condensation point is decreased by 1-3 DEG C.

Owner:CHINA PETROLEUM & CHEM CORP +1

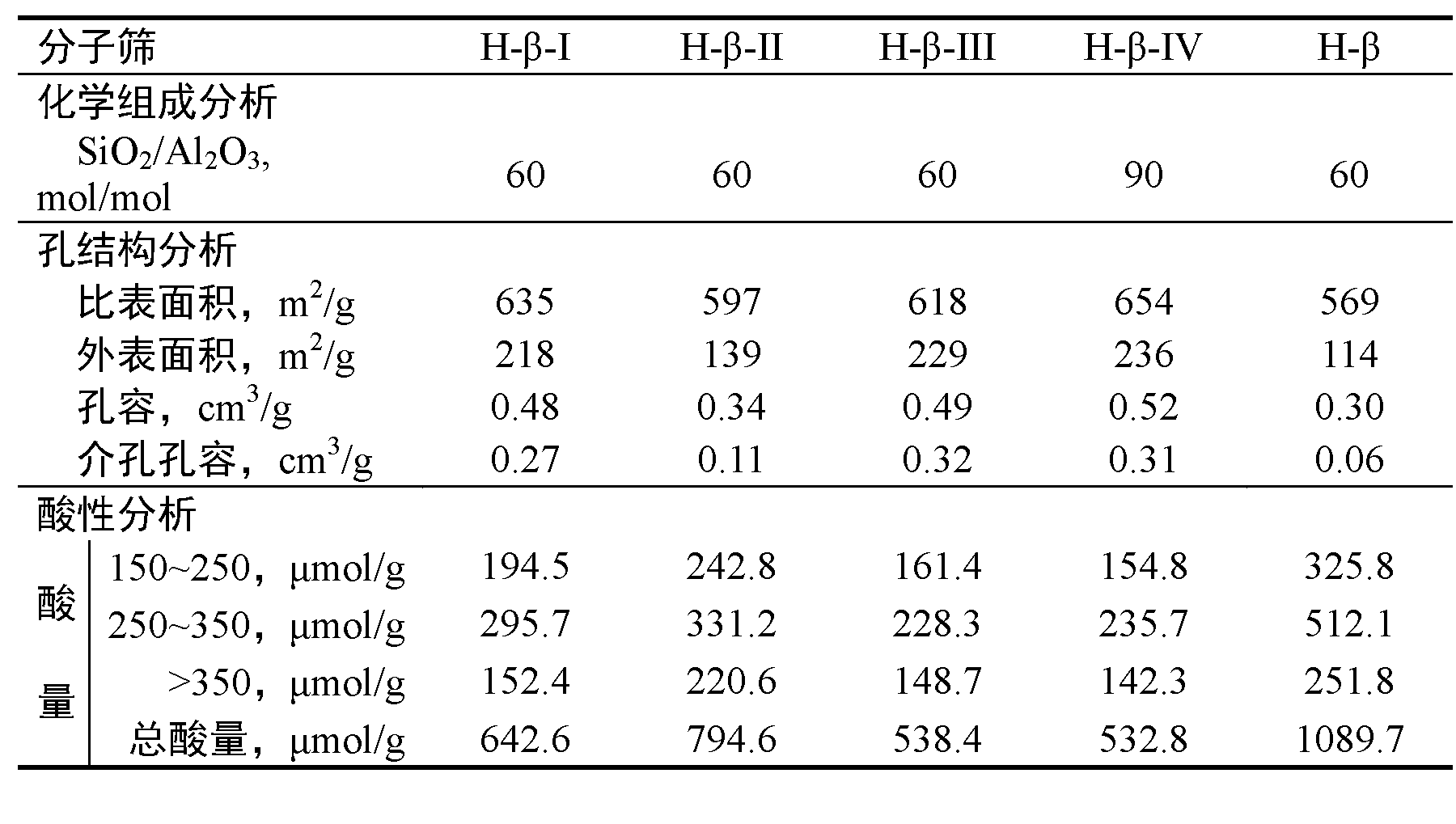

Preparation method for middle oil type hydrocracking catalyst carrier

ActiveCN102909082ASkeleton silicon aluminum ratio is highLarge specific surface areaCatalyst carriersMolecular sieve catalystsStrong acidsCrystallinity

The invention discloses a preparation method for a middle oil type hydrocracking catalyst carrier. The carrier is composed of a modified Y molecular sieve, a multi-pore beta molecular sieve, large-pore aluminum oxide, a binder and an extrusion assistant agent, wherein the Y molecular sieve is obtained by hydro-thermal treatment assisted by organic acid, high crystallinity and low cell parameter are maintained, and rich secondary pore canals and uniform medium and strong acid centers are contained; the multi-pore beta molecular sieve is synthesized by a soft template method, is high in specific surface area and high in pore volume and has abundant meso pores. The catalyst prepared by VI B and VIII group metal oxides on the hydrocracking catalyst carrier which is prepared by the method has the advantages of high hydrocracking activity, strong anti-nitrogen performance, good stability, high middle oil selectivity, low condensation point of diesel and the like.

Owner:CHINA NAT OFFSHORE OIL CORP +1

High pressure and high temperature anneal chamber

ActiveUS20190237345A1Semiconductor/solid-state device manufacturingFurnace typesTemperature controlEngineering

Owner:APPLIED MATERIALS INC

Methanol gasoline modified alcohol additive

InactiveCN101024788ASolve the problem of easy water absorptionDoes not reduce the use effectLiquid carbonaceous fuelsBenzoic acidZinc peroxide

The invention relates to a methanol gas oil modification alcohol additive that uses acetone, toluol, isobutyl alcohol, benzoic acid, ferrocene and zinc peroxide as raw material, and whisking equal in the volume under room temperature and normal pressure to gain the product. It adds 1-3% additive into methanol to gain modified mellow after whisking, and adding the mellow into naphtha or 90# diesel oil to gain the 90#, 93#, 97# and 98# methanol gas oil. The gas oil condensation point would be decreased by adjusting the methanol gas oil and the pollution would be sharply decreased. It has great social benefits and economic benefits.

Owner:北京福众金源环保科技有限公司

High pressure and high temperature anneal chamber

ActiveUS20190057879A1Semiconductor/solid-state device manufacturingTemperature controlBatch processing

Embodiments of the disclosure relate to an apparatus and method for annealing semiconductor substrates. In one embodiment, a batch processing chamber is disclosed. The batch processing chamber includes a chamber body enclosing a processing region, a gas panel configured to provide a processing fluid into the processing region, a condenser fluidly connected to the processing region and a temperature-controlled fluid circuit configured to maintain the processing fluid at a temperature above a condensation point of the processing fluid. The processing region is configured to retain a plurality of substrates during processing. The condenser is configured to condense the processing fluid into a liquid phase.

Owner:APPLIED MATERIALS INC

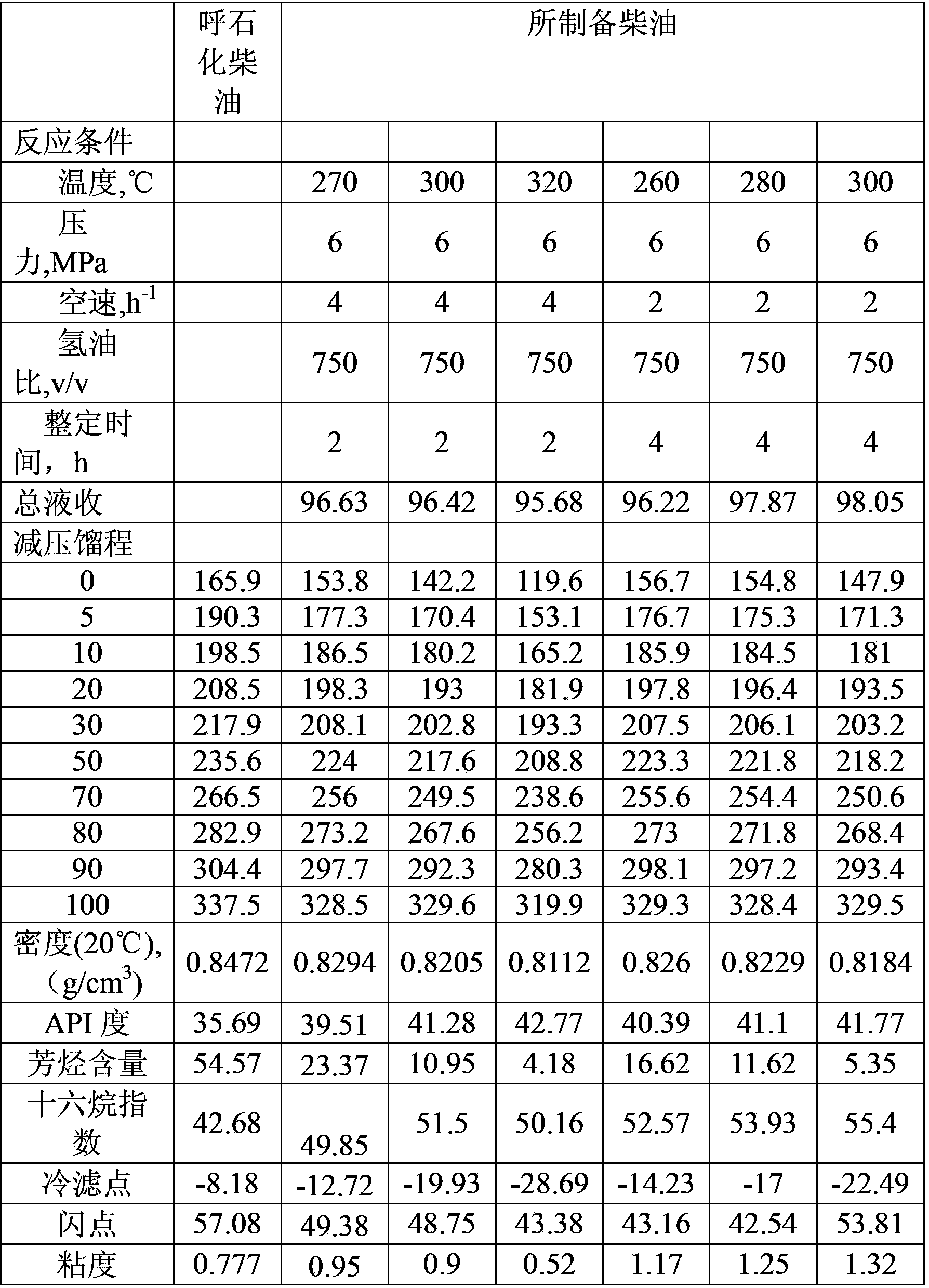

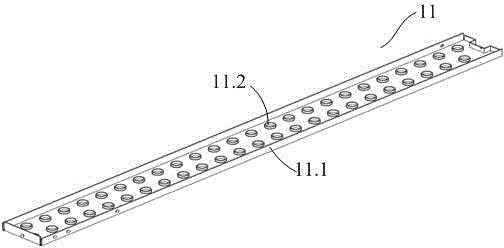

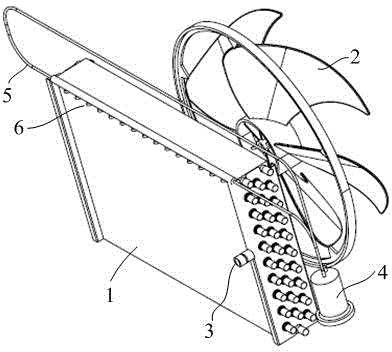

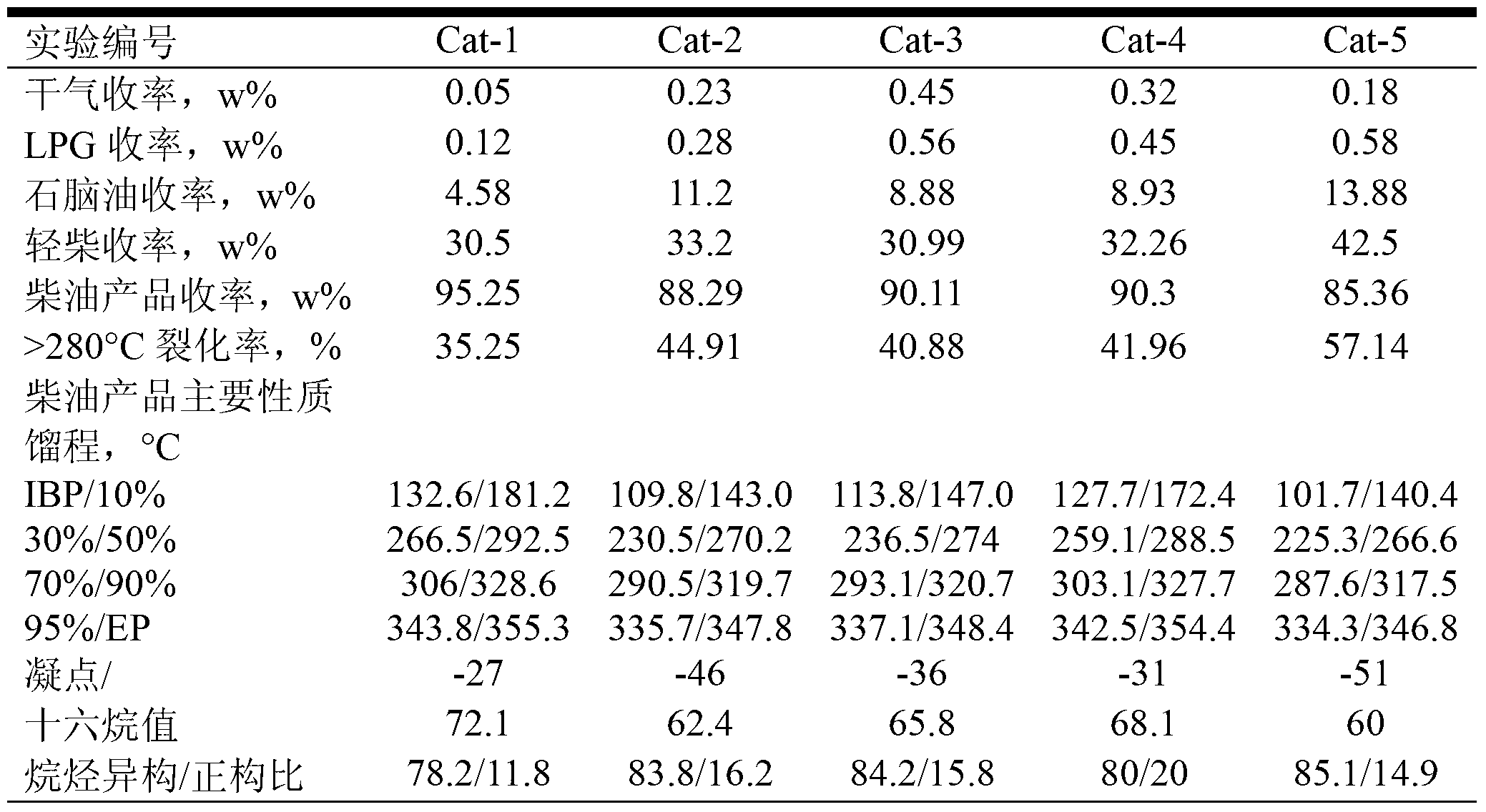

Method for producing diesel oil with low condensation point by catalyst gradation technology

ActiveCN103805257ALow yieldGuaranteed yieldTreatment with hydrotreatment processesHydrogenation reactionSulfur

The invention discloses a method for producing diesel oil with a low condensation point by catalyst gradation technology. The method comprises the following steps: mixing a diesel oil raw material with hydrogen, orderly passing through at least two hydrogenation reaction zones connected in series, wherein in the material flowing direction, each hydrogenation reaction zone orderly comprises a hydro-refining dewaxing catalyst composite bed layer filled with a mixture of a hydro-refining catalyst and a hydro-upgrading isodewaxing catalyst, and a hydrodewaxing catalyst bed layer; performing separation and fractionation of the reaction effluent from the last hydrogenation reaction zone to obtain the diesel oil product with a low condensation point. The method of the invention reasonably combines and utilizes the temperature increase of the hydro-refining and hydro-upgrading dewaxing process with the temperature decrease of the hydrodewaxing process, improves the diesel oil yield and the cetane value while producing diesel oil with a low condensation point and low sulfur, reduces the hot-spot temperature of the device, prolongs the running period, also reduces the cold hydrogen consumption or the combustion gas loss of a heating furnace, and saves operation cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

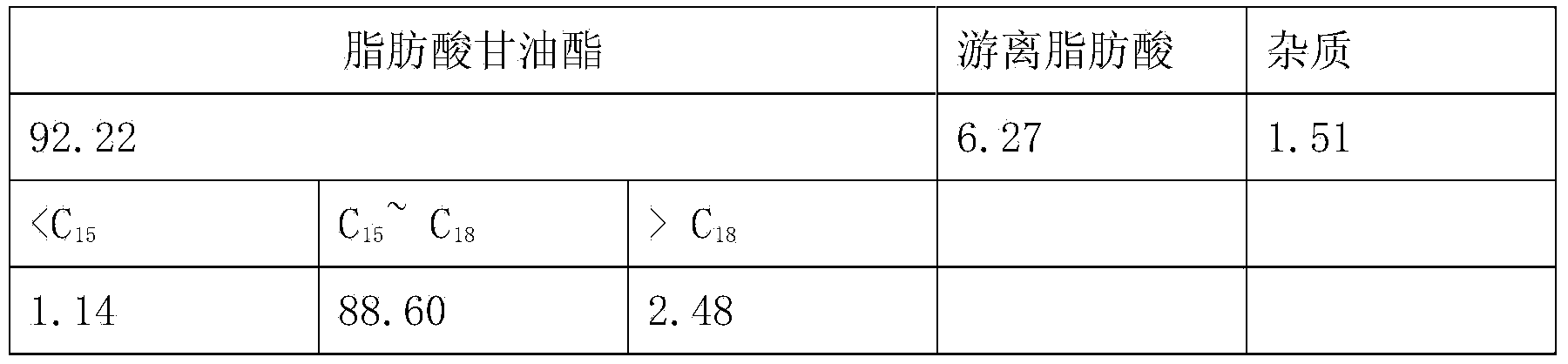

Method for producing second-generation biodiesel by hydrogenation production of illegal cooking oil

ActiveCN103756794AHigh activityHigh selectivityFatty acid hydrogenationPhysical/chemical process catalystsEnvironmental resistanceAlkane

The invention belongs to a chemical technology and the technical field of a renewable energy source, and relates to a method for producing second-generation biodiesel by hydrogenation production of illegal cooking oil. The method comprises the following steps: firstly, carrying out pretreatments such as filtering, dewatering and desalting, on the collected illegal cooking oil; respectively carrying out reaction, such as hydrodeoxygenation, hydrogenation decarboxylation and hydrogenation decarbonylation, in the presence of a transition metal phosphide catalyst so as to obtain the second-generation biodiesel. By adopting the method, the noble metal property and excellent hydrogenation performance of the transition metal phosphide are fully utilized, the illegal cooking oil is directly converted into oxygen-free fat alkanes, no byproduct for polluting the environment is generated, meanwhile, the method has the advantages of simple process, is clean and environmental, low in energy consumption and the like, the obtained diesel is high in cetane number and low in condensation point, has good economic and social benefits, and has important practical significance on growing fuel requirements.

Owner:NANJING KANG XIN CHENG BIOLOGICAL TECH CO LTD

Environment friendly energy-efficient heat conduction oil

ActiveCN103232837ALow viscosityLowering the freezing pointHeat-exchange elementsBase-materialsNon toxicityBoiling point

The environment friendly energy-efficient heat conduction oil of the present invention is composed of 90-95% of base oil and 10-5% of other additives. The invention has advantages of low viscosity, low condensation point, high boiling point, low volatility, low acid value, free of smell, non-toxicity, high viscosity index, high flash point, high initial boiling point, high specific heat capacity, low temperature flow performance, material compatibility of system, high tepid stability, antioxidation stability, anti-corrosivity, antirust performance, peace and quiet dispersion performance, high heat conduction coefficient, biodegradability, and other performances. The index of each performance accords with the usage requirement, and can satisfy the technology requirements of the GB23971-2009 heat conduction oil with L-QB, L-QC, L-QD quality grade specifications and the performance requirements of those with temperature grades: 280, 300, 310, 320, 330, 340 and 350.

Owner:GUANGXI UNIV

Hydrogenation method for reducing condensation point of diesel

ActiveCN103773488AHigh yieldHigh selectivityTreatment with hydrotreatment processesNaphthaPtru catalyst

A hydrogenation method for reducing the condensation point of diesel comprises the following steps: raw oil is in contact with a hydrofining catalyst in a first reaction area for reaction, effluents in the first reaction area are subjected to separation and fractionation to obtain gases, naphtha fractions, low-condensation-point diesel fractions I and high-condensation-point heavy diesel fractions; the obtained high-condensation-point heavy diesel fractions enter a second reaction area, and are in contact with a hydro-upgrading condensation point reducing catalyst to carry out an isocracking condensation point reducing reaction; effluents in the second reaction area are subjected to separation and fractionation to obtain low-condensation-point diesel fractions II; the low-condensation-point diesel fractions and the low-condensation-point diesel fractions II are mixed to obtain low-condensation-point diesel. According to the invention, the process selectivity is improved, so that the low-condensation-point diesel yield is improved remarkably. Through the adoption of the hydrogenation method, No.-10 to No.-50 low-condensation-point diesel can be produced flexibly, the cetane number is increased as compared with that of the raw material, the content of impurities such as sulfur and nitrogen is reduced greatly, and the Europe IV diesel standard and the Europe V diesel standard can be met.

Owner:CHINA PETROLEUM & CHEM CORP +1

Novel environmental protection and energy saving biological alcohol oil

InactiveCN102358853AHigh combustion valueAvoid situations where you mistakenly drink it for waterLiquid carbonaceous fuelsCombustionAlcohol

Relating to a biofuel, the invention provides novel environmental protection and energy saving biological alcohol oil, which is a biofuel with methanol as the main component. The novel environmental protection and energy saving biological alcohol oil of the invention is characterized by comprising, by weight percent: 75-95 parts of methanol, 0.2-1.0 part of an emulsifier, 0.01-0.5 part of ferrocene, and 5-25 parts of water. Characterized by complete combustion, high calorific value, stable performance, nonvolatility, low condensation point, difficult ignition, an ignition temperature higher than 200DEG C, no pressure, no explosion, and extinguishability by water in an accidental fire, the novel environmental protection and energy saving biological alcohol oil provided in the invention is nontoxic, odorless, smokeless and dust-free renewable green new energy, and has quality reaching the national primary standards of alcohol-based fuels.

Owner:刘一江

Diesel oil anti-wear agent and preparation method thereof

InactiveCN104130809AImprove the lubrication effectReduce wearLiquid carbonaceous fuelsCloud pointInjection pump

The invention discloses a diesel oil anti-wear agent. The diesel oil anti-wear agent is prepared from fatty acid, urea and ethanol in a mass ratio of 10: (4.8-5): 10 through purification of the fatty acid. The saturated fatty acid content of the diesel oil anti-wear agent disclosed by the invention is less than 2%, the yield of a product is more than 80%, the condensation point of the product is less than -12 DEG C, the cloud point of the product is less than -8 DEG C, the acid value of the product is 190, and the diesel oil anti-wear agent has good low-temperature stability, greatly improves the lubricity of diesel oil, reduces the wear degree of an oil injection pump, prolongs the service life of an engine, does not corrode metal and has good compatibility with diesel oil.

Owner:ANQING ZHONGCHUANG BIOENG

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com