Preparation method for middle oil type hydrocracking catalyst carrier

A catalyst carrier and hydrocracking technology, which is applied in the field of catalysis, can solve the problems of mass transfer and conversion of reactants that limit macromolecules, singleness, and low catalyst activity, and achieve the benefits of secondary cracking reactions, low freezing point, and excellent heterogeneity. The effect of texturing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment -1

[0028] Stir and mix 100 g NaY molecular sieve (Wenzhou) with 1000 g of 3% ammonium nitrate solution at 90 o Stir for 6 h at a constant temperature at C, filter with suction, wash with water three times, 120 o C drying 8 h, 520 o C roasting for 4 h, repeat the exchange operation three times; 550 o C hydrothermal treatment for 2 h, pressure 0.2 MPa; put 60 g of powder after hydrothermal treatment into a three-necked flask, then add 600 mL of 0.2 mol / L citric acid solution, at 90 o After mechanical stirring and reflux at C temperature for 4 h, the mixed turbid liquid was put into a polytetrafluoroethylene autoclave at 160 o After dynamic hydrothermal treatment at C temperature for 12 h, carry out suction filtration and separation, wash with water until neutral, and in 120 o C dried for 12 h to obtain the modified H-Y molecular sieve. The SiO of gained H-Y molecular sieve 2 / Al 2 o 3 =15.0, the unit cell parameter is 2.438, the pyridine infrared acid content is 0.423 mmol / g...

Embodiment -2

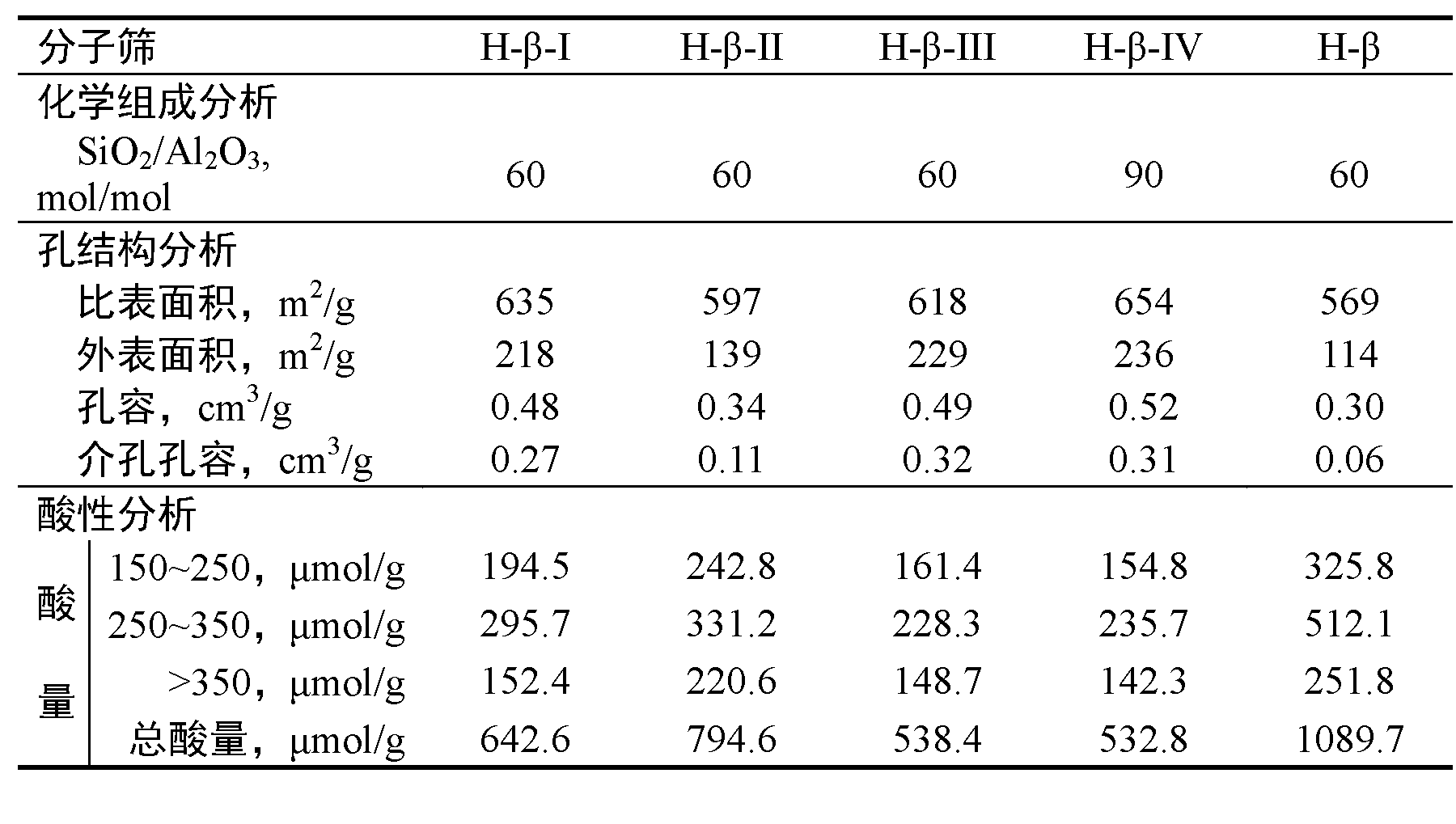

[0030] 0.75 g NaOH (analytically pure, NaOH ≥ 96wt.%) and 1.6 g NaAlO 2 (chemically pure, Al 2 o 3 , 41%) and 27.7 g TEAOH solution (industrial grade, 25wt%) were mixed evenly, and 77.2 g silica sol (industrial grade, SiO 2 ≥ 30wt.%), continue to stir for 2 h, add 20 g of hexadecyltrimethoxyorganosilicon quaternary ammonium salt (TPHAC) ethanol solution with a mass concentration of 10%, mix well to form a gel system, and the feeding of each reactant The molar ratio is: SiO 2 / Al 2 o 3 =60, SiO 2 / Na 2 O=43, SiO 2 / TEAOH=0.12,H 2 O / SiO 2 =3,TPHAC / SiO 2 =0.010, after continuing to stir for 2 h, put the resulting gel mixture into a polytetrafluoroethylene high-pressure reactor and adopt segmental dynamic crystallization, prior to 100 o After crystallization of C for 16 h, then with 10 o C / h heating rate to 155 o C degree, constant temperature crystallization for 72 h; the crystallized product was separated by filtration, and the solid product was washed with deioniz...

Embodiment -3

[0033] In Example 2, 20 g of mass concentration of hexadecyltrimethoxyorganosilicon quaternary ammonium salt (TPHAC) in ethanol was changed to 16 g of mass concentration of dodecyltrimethoxyorganosilicon quaternary ammonium salt of 10%. Ammonium salt (TPDAC) ethanol solution, molar ratio TPDAC / SiO 2 =0.010, the rest of the components and synthesis operating conditions are the same as in Example 2 to obtain a multi-stage porous H-β-II molecular sieve, whose physical and chemical properties are shown in Table-1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com