Patents

Literature

38results about How to "Reduce secondary cracking reactions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for hydrofining coking crude benzene

ActiveCN101519338AReduce lossesHigh retention rateDistillation purification/separationHydrocarbonsHydrogenExtractive distillation

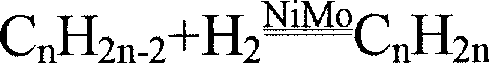

The invention discloses a process for hydrofining coking crude benzene, which consists of a raw-materialnits preseparating unit, a hydrofining unit, a predistillation unit, an extractive distillation, an aromatic-hydrocarbon refining unit and a xylene distillation unit, wherein supplementary hydrogen needed in reaction is supplied from the outside; a reaction part in the hydrofining unit adopts three-stage hydrogenation; and the temperature of second-stage hydrogenation and third-stage hydrogenation is 230 to 290 DEG C and 220 to 315 DEG C respectively. The process has the advantages that the temperature adopted in both the second-stage hydrogenation and the third-stage hydrogenation is greatly lower than the reaction temperature of the prior process; the process effectively reduces benzene transformed into cyclohexane, reduces the secondary cracking reaction of the cyclohexane, reduces the loss of aromatic compound, and improves the retention rate of aromatic hydrocarbon which can reach over 99.6 percent; meanwhile, the three-stage hydrogenation adopted in the reaction part prolongs the process of hydrogenation and ensures that sulfur-containing nitrogen-containing organic compounds can also be transformed into inorganic sulfur or inorganic nitrogen compounds at a lower temperature, so that the aim of purification is achieved; and the total content of both sulfur and total in a hydrofined product is less than 1 ppm.

Owner:中国寰球工程有限公司辽宁分公司

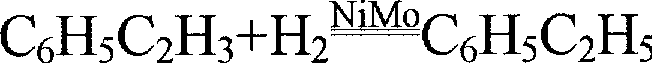

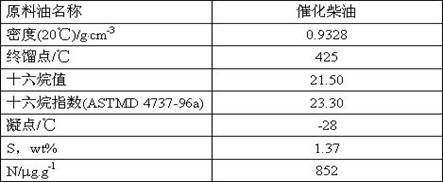

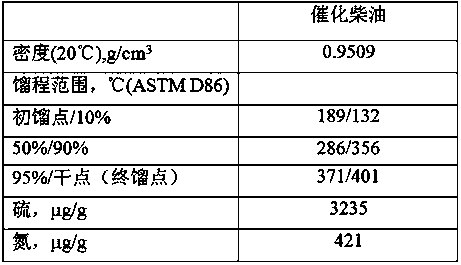

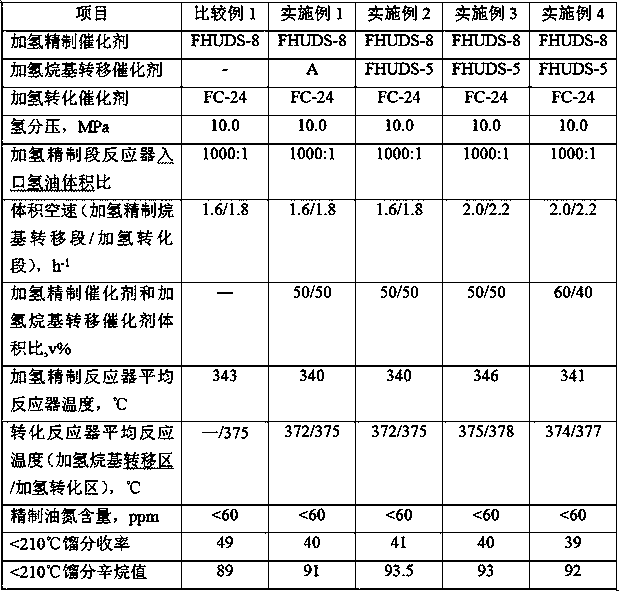

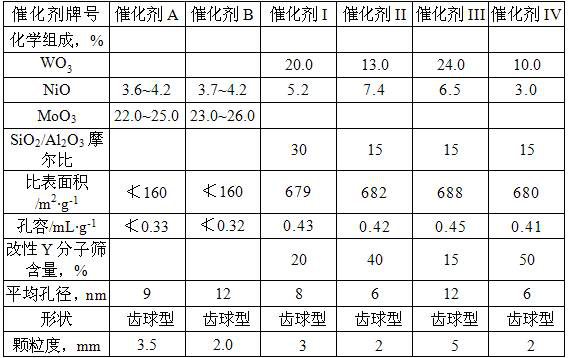

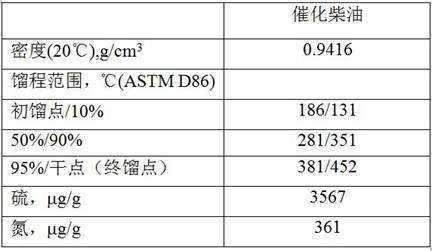

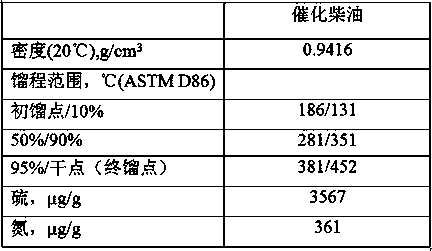

Catalytic cracking diesel oil hydro-upgrading catalyst and application thereof

InactiveCN103372457AReduce coking deactivation speedHigh acid strengthMolecular sieve catalystsHydrocarbon oils treatmentMolecular sieveAmorphous silicon

The invention relates to a catalytic cracking diesel oil hydro-upgrading catalyst and applications thereof. The catalyst is composed of VIII-group and VIB-group hydrogenation active metal components and a carrier containing a modified Y molecular sieve, amorphous silicon aluminum and alumina; the modified Y molecular sieve is prepared from a NaY molecular sieve by the steps of carrying out ammonium exchange twice, carrying out roasting one time and carrying out hydro-thermal treatment one time. The catalyst is used for carrying out hydro-upgrading on distillate or catalytic cracking diesel oil at a temperature of 160-380 DEG C. After inferior diesel distillate of which the sulfur content is higher than 1000 mu g / g, the nitrogen content is higher than 1000 mu g / g, the aromatics content is higher than 55v% is treated by using the catalyst, the desulfurization rate and the denitrification rate are both higher than 98%, the cetane number is increased by more than 10 units, and the yield of the diesel distillate is over 98wt%.

Owner:PETROCHINA CO LTD

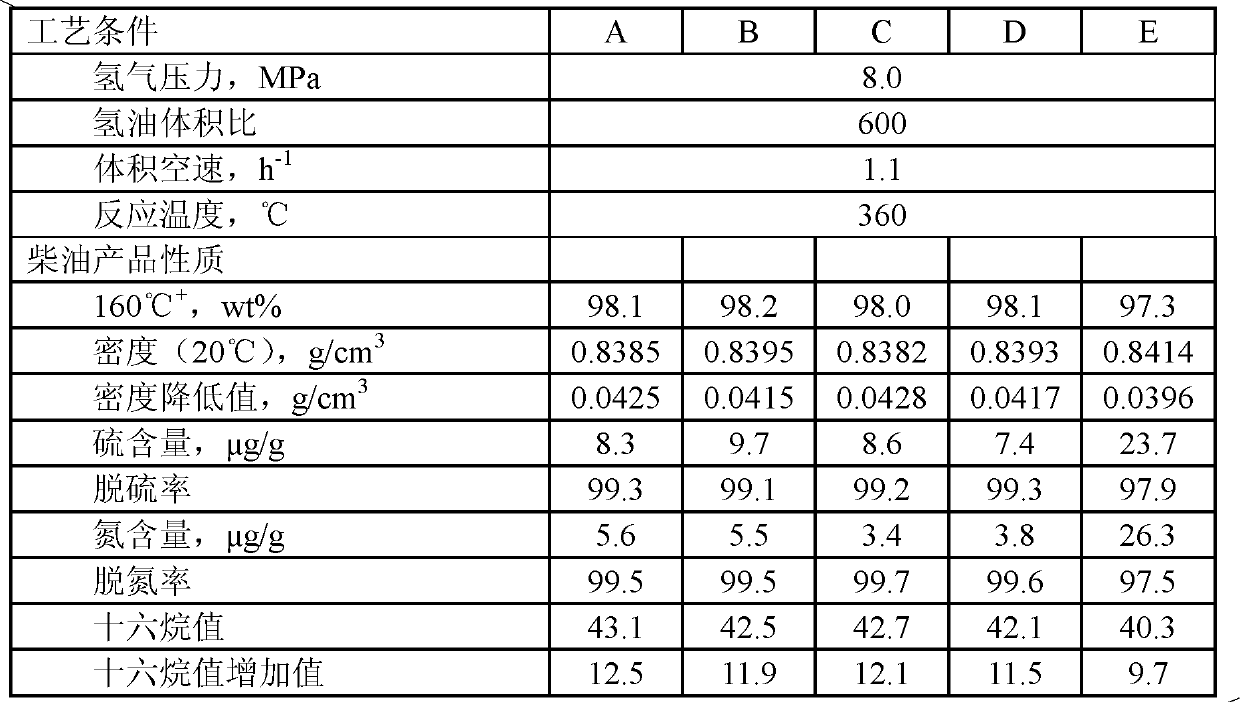

Method for hydro-dearomatization in catalytic cracking of diesel

InactiveCN102533315AReduce coking deactivation speedHigh acid strengthMolecular sieve catalystsRefining by aromatic hydrocarbon hydrogenationMolecular sieveCrystallinity

The invention relates to a method for hydro-dearomatization in catalytic cracking of diesel. According to the invention, Ni and W are adopted as hydrogenation active metal components of a catalyst and modified Y molecular sieve, modified Beta molecular sieve, amorphous silica-alumina and alumina are adopted as carriers of the catalyst, wherein the average crystal size of the modified Y molecular sieve is 100-400nm, the mole ratio of SiO2 / Al2O3 is 5-40:1; the relative crystallinity is greater than 90% and the specific surface area is 700-1000m<2> / g; the average crystal size of the modified Beta molecular sieve is 50-200nm, the mole ratio of SiO2 / Al2O3 is 50-200:1; the relative crystallinity is greater than 85% and the specific surface area is 700-900m<2> / g. When the method is adopted to process inferior diesel fraction, the desulfurization rate and the denitrification rate are up to more than 97.5%, the dearomatization rate is up to more than 55% and the diesel fraction yield is up to more than 98wt%.

Owner:PETROCHINA CO LTD

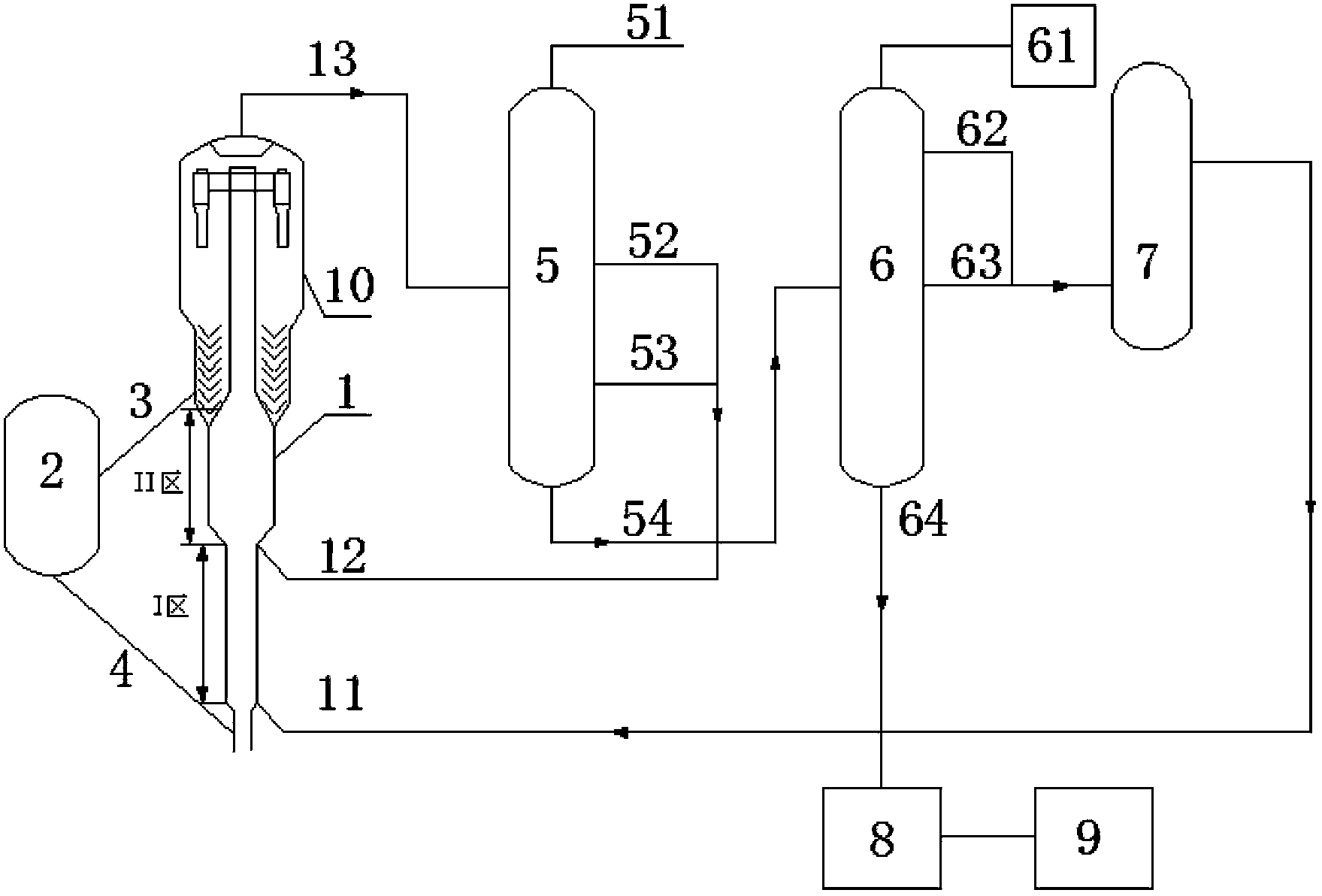

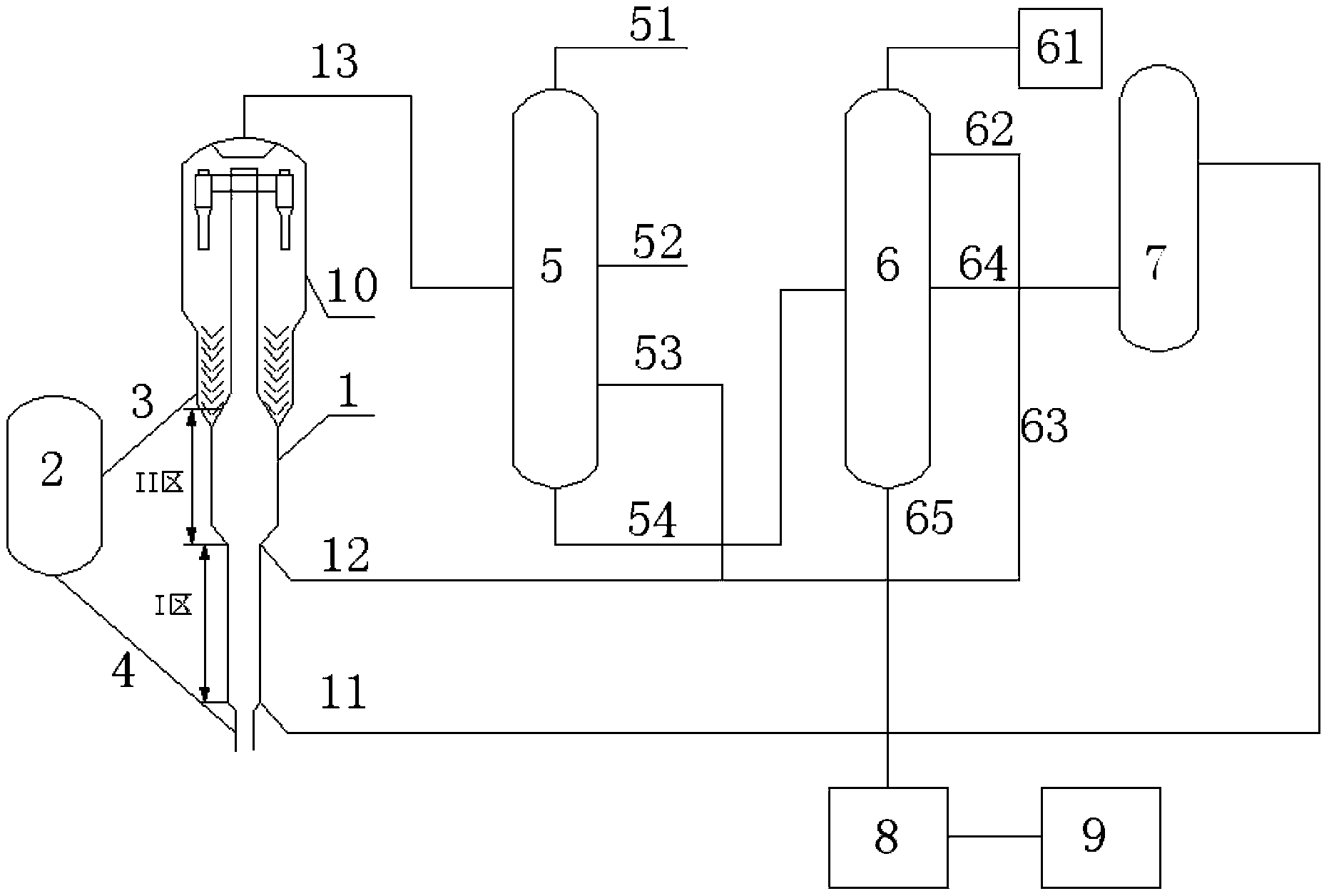

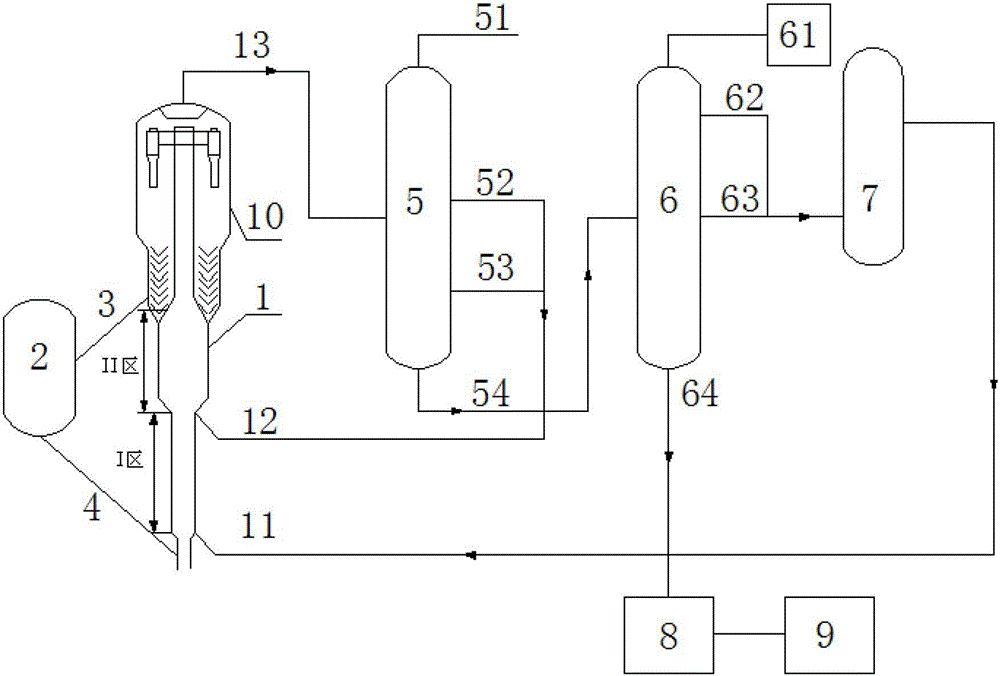

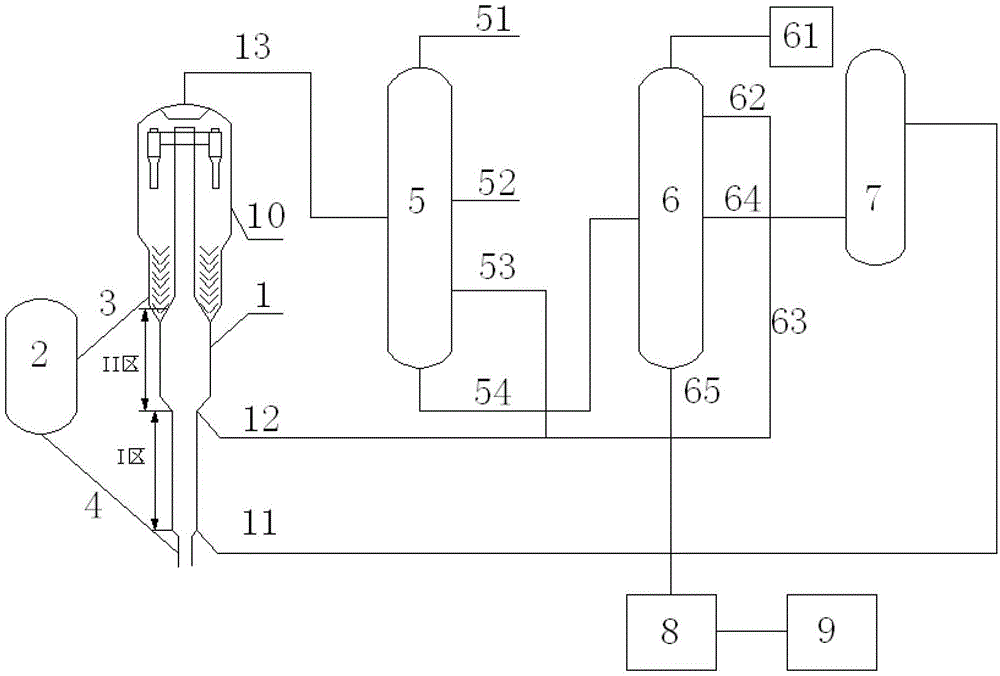

Low-grade heavy oil catalytic conversion process for increasing yield of low-carbon olefins and gasoline

ActiveCN103540359AReduce cokingReduced activityTreatment with hydrotreatment processesHigh carbonFuel oil

The invention relates to a low-grade heavy oil catalytic conversion process for increasing the yield of low-carbon olefins and gasoline. The process comprises the following steps: (1) low-grade heavy oil, namely raw oil, enters a first reaction zone (zone I) of a two-section riser, so as to be subjected to catalytic cracking reaction, and generated oil and gas enter a fractionating tower; (2) a top outlet material of the fractionating tower is a mixture of dry gas, liquefied gas and gasoline, a middle-part outlet material of the fractionating tower is diesel oil, a lower-part outlet material of the fractionating tower is catalyzing wax oil, a bottom outlet material of the fractionating tower is oil slurry, the catalyzing wax oil and the diesel oil enter a second reaction zone (zone II) of the two-section riser together, and the oil slurry enters a vacuum distillation tower; (3) a lower-carbon-residue light-distillate material of an upper-part outlet of the vacuum distillation tower and a higher-carbon-residue heavy-distillate material of a middle-part outlet of the vacuum distillation tower enter a hydrogenation device together, and ultrahigh-carbon-residue oil slurry at the bottom of the vacuum distillation tower enters a delayed coking device; (4) a low-carbon-residue easily-cracked material from the hydrogenation device enters the zone I of the riser and is subjected to reaction again. The process has the characteristics that the service life of the catalyst is prolonged, the yield of dry gases and coke is lowered, and meanwhile, the yield of low-carbon olefins and gasoline is increased.

Owner:PETROCHINA CO LTD

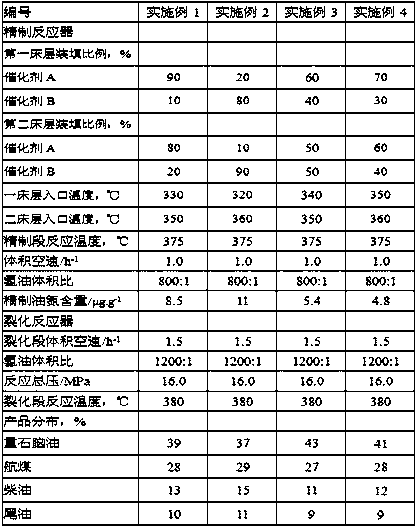

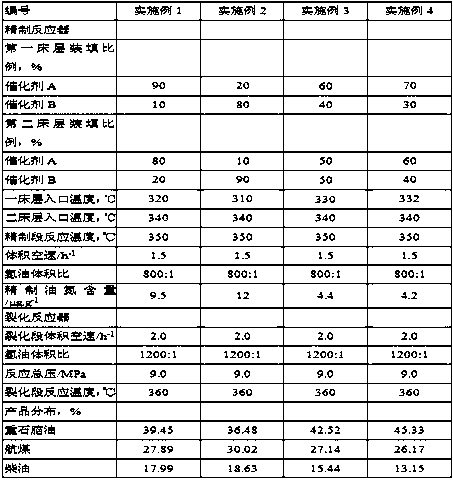

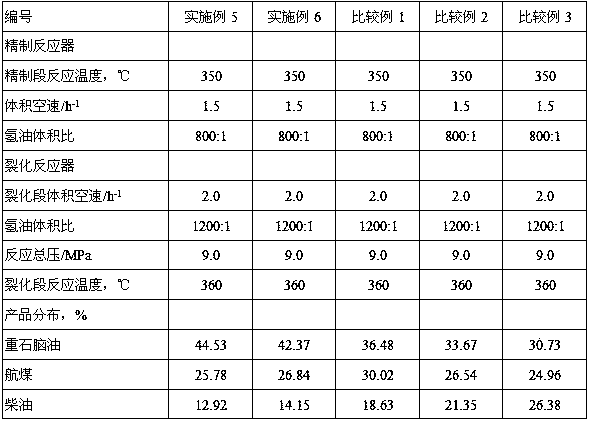

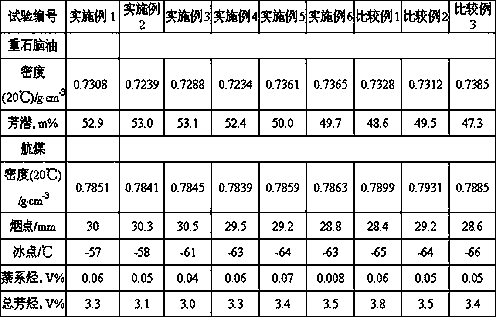

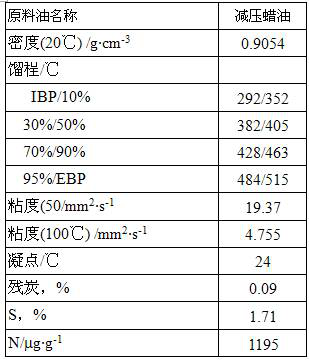

Wax oil hydrocracking method

ActiveCN110938466AExtended stayHigh molecular sieve contentTreatment with hydrotreatment processesHydrocarbon oils treatment productsMolecular sieveProcess engineering

The invention discloses a wax oil hydrocracking method, which comprises the following steps that (1) a wax oil raw material and hydrogen enters a hydrofining reactor in a mixed manner and are subjected to desulfurization, denitrification and aromatic hydrocarbon saturation reaction; (2) the effluent obtained in the step (1) enters a hydrocracking reactor, wherein the hydrocracking reactor comprises first to nth catalyst bed layers in a material direction, n is greater than or equal to 3, preferably 3 or 4, the first to (n-1)th catalyst bed layers are filled with a hydrocracking catalyst containing a modified Y molecular sieve, and the nth catalyst bed layer is filled with a hydroisomerization catalyst containing beta and / or ZSM-series molecular sieves and other molecular sieves with high isomerization performance; and (3) the effluent of the hydrocracking reactor is subjected to gas-liquid separation and liquid-phase fractionation to obtain naphtha, aviation kerosene, diesel oil and tail oil. According to the method, by using wax oil as a raw material, the yield of heavy naphtha with high aromatic potential is increased and the quality of aviation kerosene and diesel oil products is improved by setting a reasonable catalyst grading mode and modulating the catalyst composition and the structure in grading bed layers.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low-grade heavy oil catalytic conversion process for increasing yield of low-carbon olefins and diesel oil

ActiveCN103540356ALong catalyst lifeReduce dry gas and coke yieldsTreatment with hydrotreatment processesWaxChemistry

The invention relates to a low-grade heavy oil catalytic conversion process for increasing the yield of low-carbon olefins and diesel oil. The process comprises the following steps: (1) preheated low-grade heavy oil, namely raw oil, enters a zone I of a riser and is in high-temperature short-contact-time high-agent-oil ratio contact with a catalytic cracking catalyst, so as to be subjected to catalytic cracking reaction, and generated oil and gas enter a fractionating tower; (2) a top outlet material of the fractionating tower is a mixture of dry gas, liquefied gas and gasoline, a middle-part outlet material of the fractionating tower is diesel oil, a lower-part outlet material of the fractionating tower is catalyzing wax oil which is relatively difficult to crack, a bottom outlet material of the fractionating tower is oil slurry, the catalyzing wax oil enters a zone II of the riser, and the oil slurry enters a vacuum distillation tower; (3) an upper-part outlet material of the vacuum distillation tower enters the zone II of the riser and is subjected to reaction again, a middle-part outlet material of the vacuum distillation tower enters a hydrogenation device for hydrogenation, and oil slurry at the bottom of the vacuum distillation tower is subjected to treatment by an oil slurry filter and then enters a delayed coking device; (4) a low-carbon-residue easily-cracked material from the hydrogenation device enters the zone I of the riser and is subjected to reaction again. The process has the characteristics that the service life of the catalyst is prolonged, the yield of dry gases and coke is lowered, and meanwhile, the yield of low-carbon olefins and diesel oil is increased.

Owner:PETROCHINA CO LTD

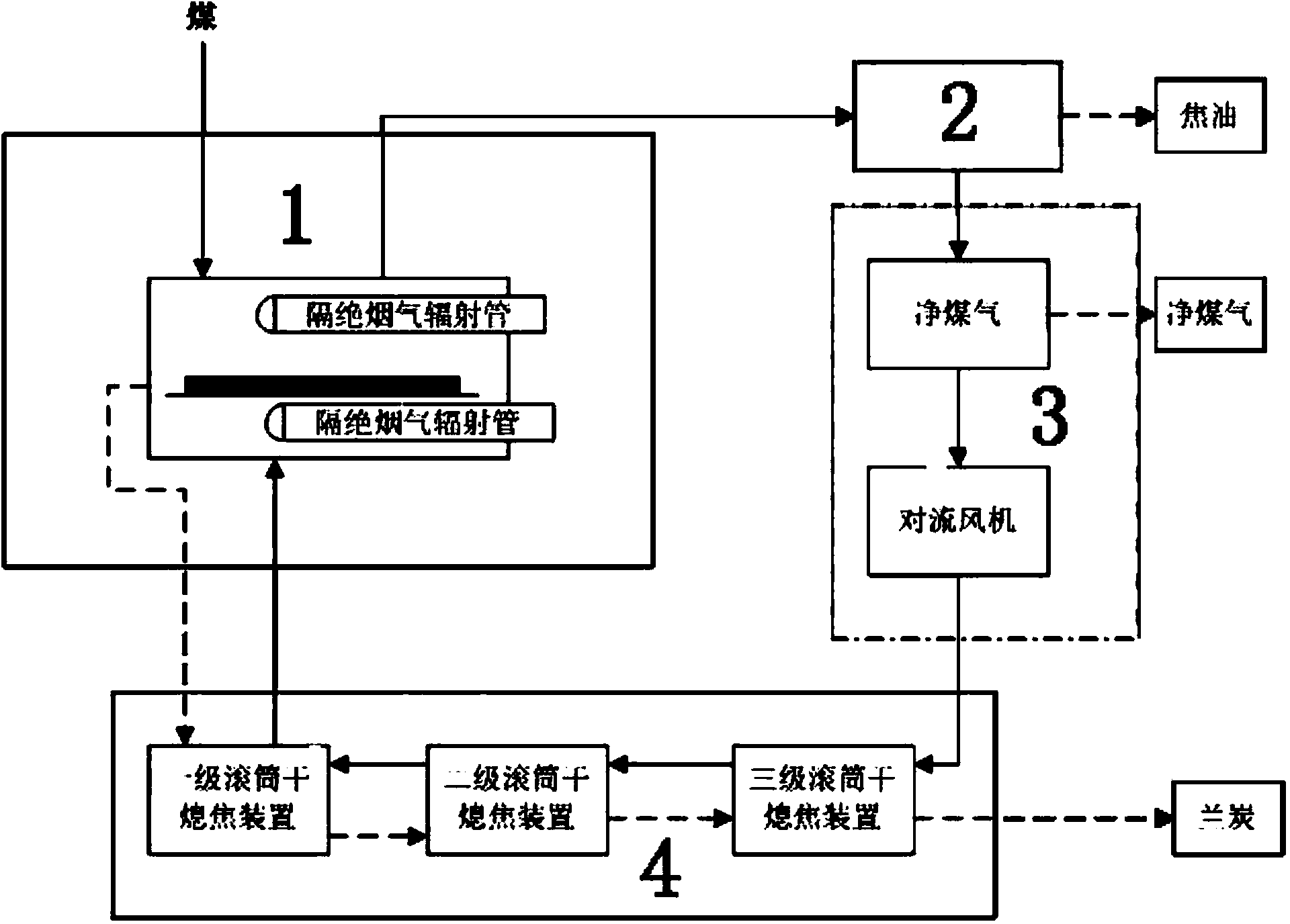

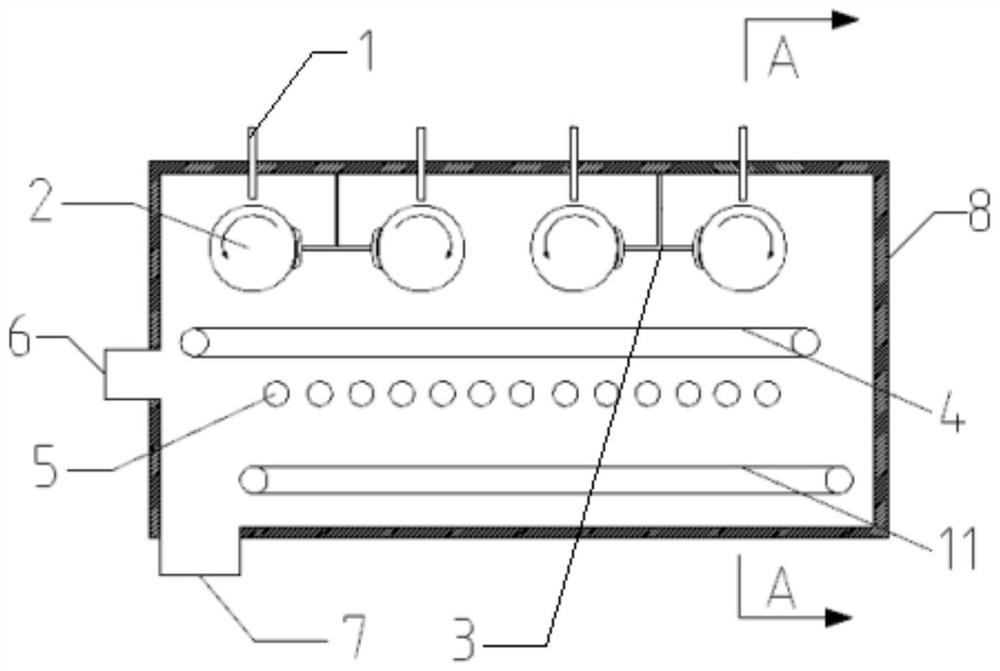

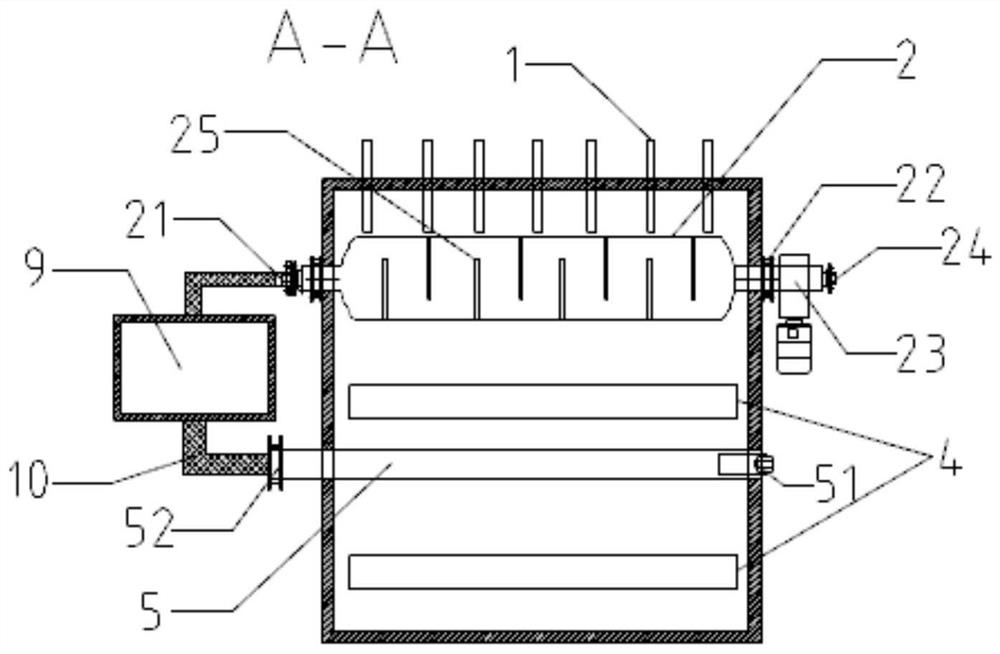

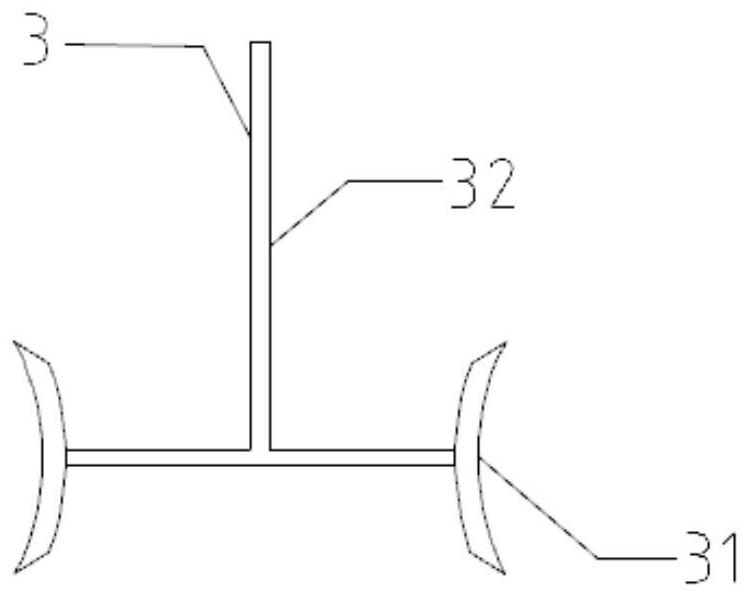

Coal low-temperature carbonization system and method

ActiveCN104178186AQuick take outShort staySpecial form destructive distillationTrappingCarbonization

The invention provides a coal low-temperature carbonization system and method. The system comprises a revolving bed carbonization unit, a raw gas washing unit, a tar trapping unit, a gas convection unit and a gas dry quenching unit, wherein the revolving bed carbonization unit is sequentially connected with the raw gas washing unit, tar trapping unit, gas convection unit and gas dry quenching unit. The system and method shorten the oil-gas retention time in the furnace, reduce the secondary cracking reaction and enhance the tar yield.

Owner:SHENWU TECH GRP CO LTD

One-stage tandem hydrocracking method

ActiveCN110938469AReduce flammabilityExtended stayTreatment with hydrotreatment processesHydrocarbon oils treatment productsMolecular sievePtru catalyst

The invention discloses a one-stage tandem hydrocracking method, which comprises the following steps that (1) a wax oil raw material and hydrogen are mixed, and the mixture enters a hydrofining reactor and is subjected to a desulfurization, denitrification and aromatic hydrocarbon saturation reaction; (2) the effluent obtained in the step (1) enters a hydrocracking reactor, wherein the hydrocracking reactor comprises first to nth catalyst bed layers along a material direction, n is greater than or equal to 3, and various catalyst bed layers are filled with hydrocracking catalysts with different contents of modified Y molecular sieves; and (3) the effluent of the hydrocracking reactor is subjected to gas-liquid separation, and the liquid phase is fractionated to obtain naphtha, aviation kerosene and diesel oil products. According to the invention, wax oil is used as a raw material, the yield of heavy naphtha with high aromatic potential is increased and the quality of aviation keroseneand diesel oil products is improved by setting a reasonable catalyst grading mode and modulating the catalyst composition and the catalyst structure in grading bed layers.

Owner:CHINA PETROLEUM & CHEM CORP +1

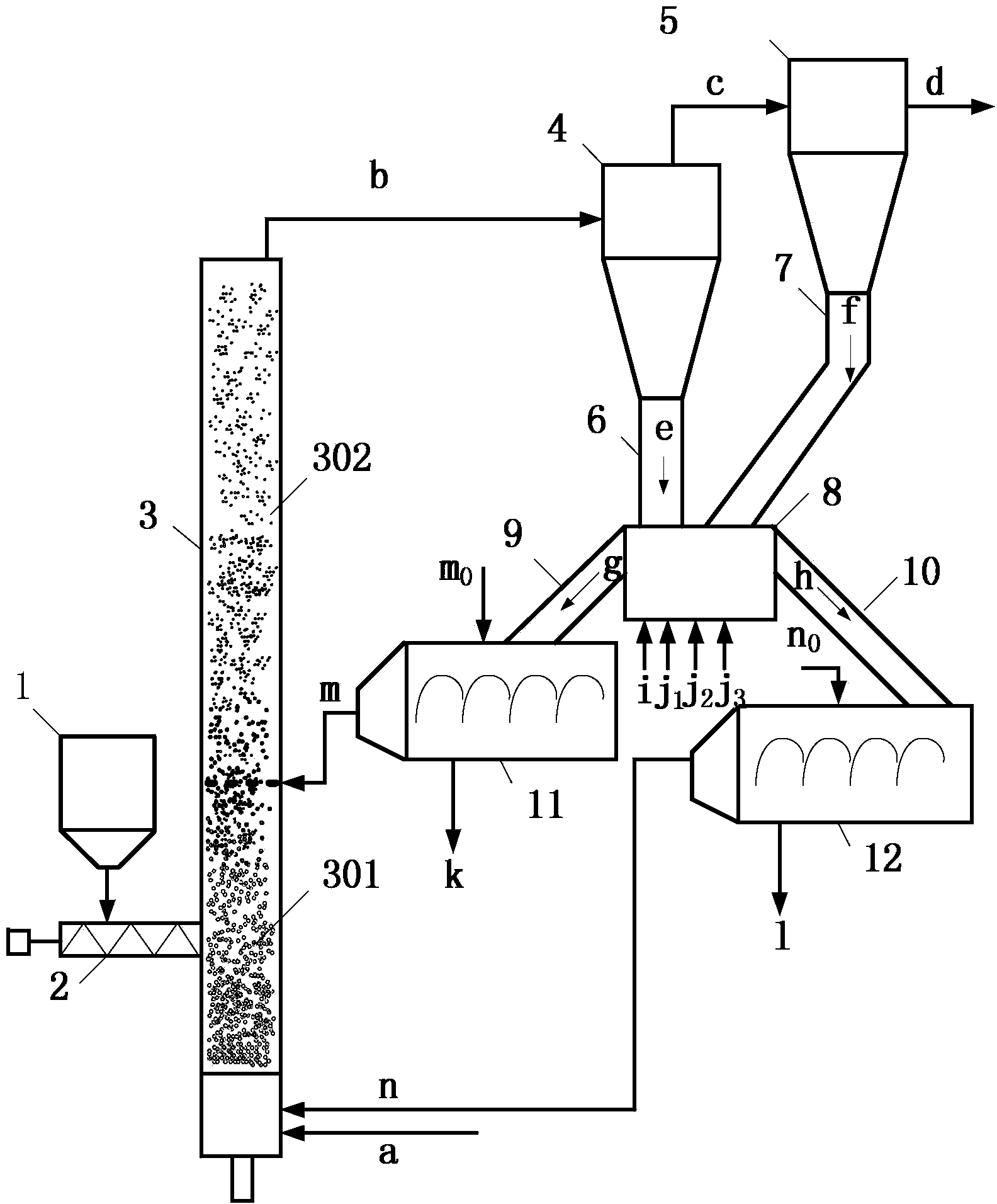

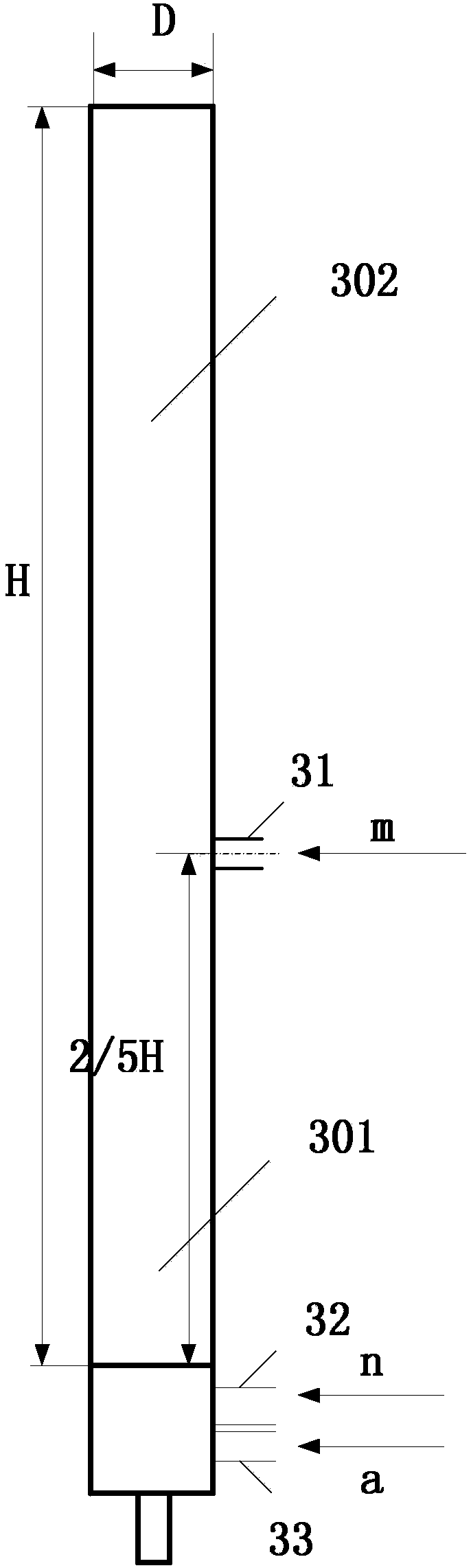

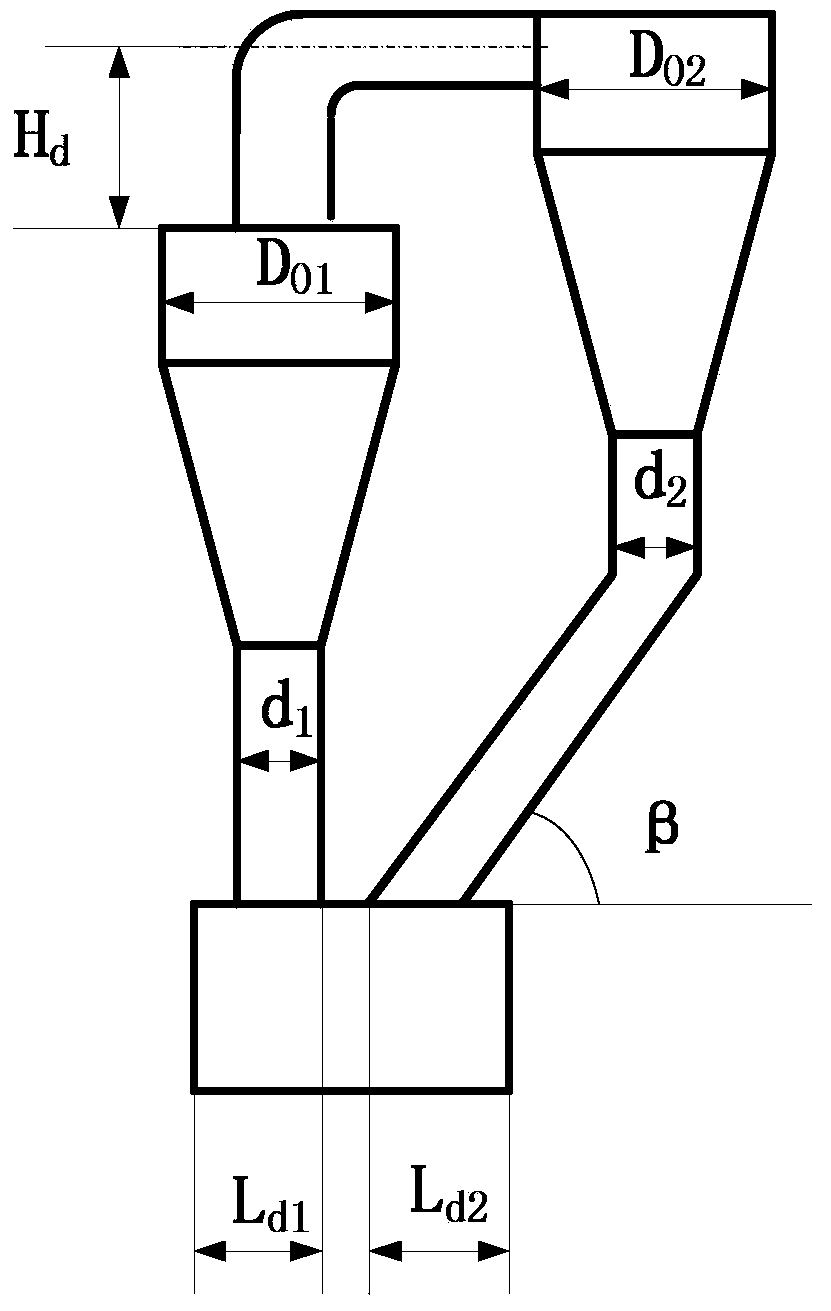

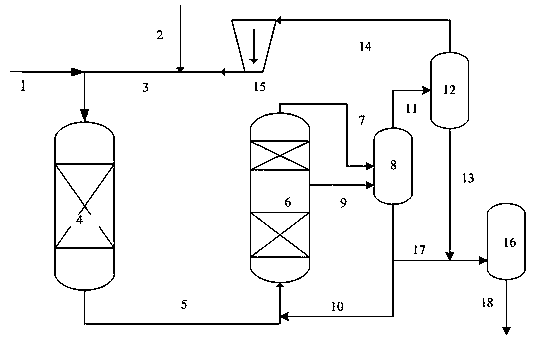

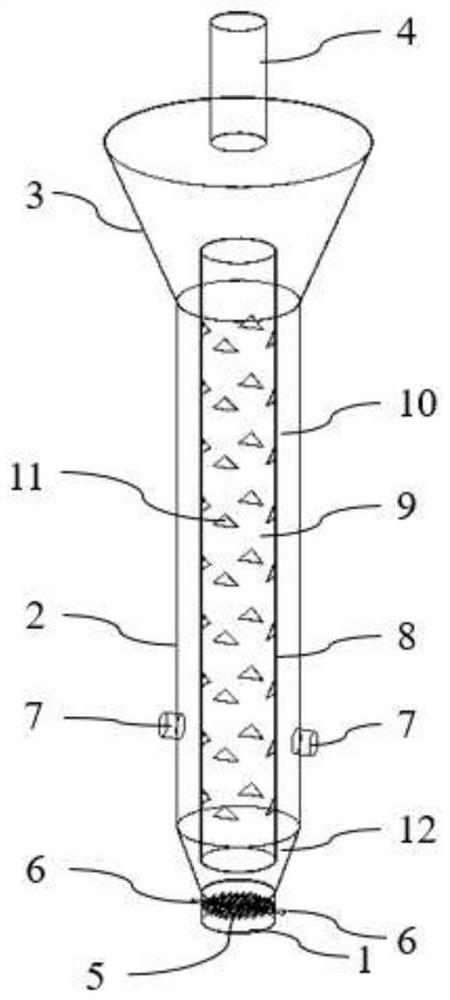

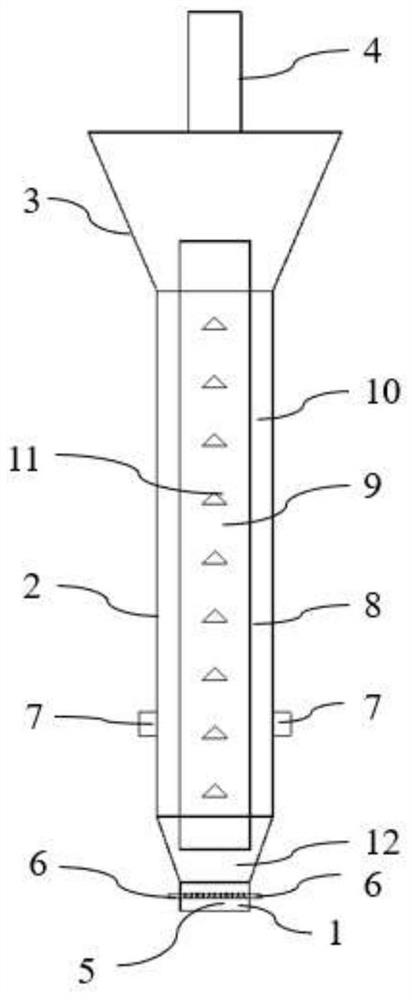

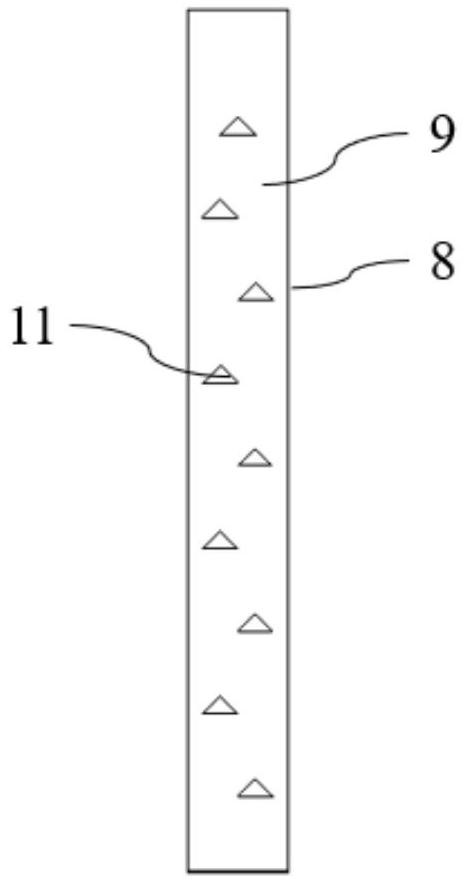

Fluidized bed grading differential temperature pyrolysis device and method for low heating value viscous solid fuel

InactiveCN103773403AGuaranteed dwell timeReduce secondary cracking reactionsDirect heating destructive distillationProcess engineeringCyclonic separation

The invention discloses a fluidized bed grading differential temperature pyrolysis device and a method for a low heating value viscous solid fuel. The device comprises a fluidized bed pyrolysis reactor (3), a two-stage efficient cyclone separator, a first-stage cyclone separator (4), a first-stage downcomer (6), a second-stage cyclone separator (5), a second-stage downcomer (7), a bi-inlet bidirectional pneumatic material reverting valve (8), a first cyclone burner (12) and a second cyclone burner (11). The method comprises following steps of pyrolyzing the solid fuel in the fluidized bed pyrolysis reactor, purifying the generated low temperature pyrolysis smoke (b) in the first-stage cyclone separator (4) and the second-stage cyclone separator (5) which are connected in series, and allowing the separated solid carbon residue to fall into the downcomer to enter the same pneumatic material reverting valve (8). The system is simple, and the pyrolysis temperature in the fluidized bed pyrolysis reactor can be controlled.

Owner:SOUTHEAST UNIV

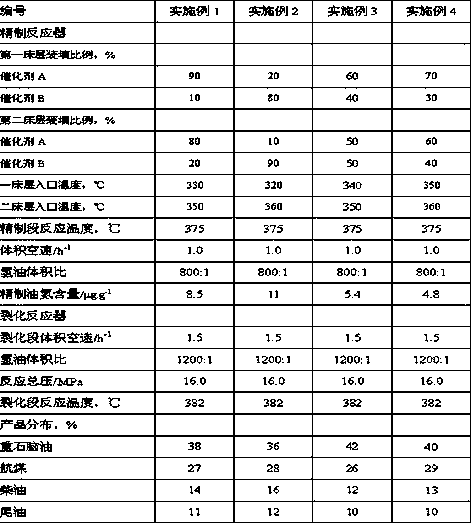

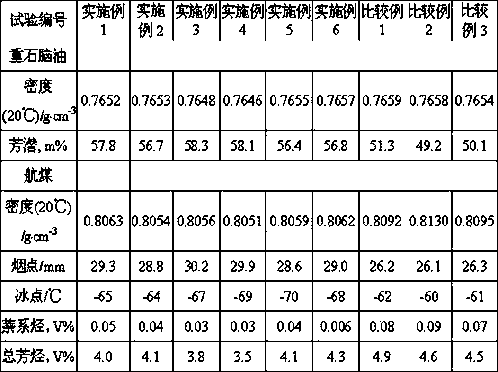

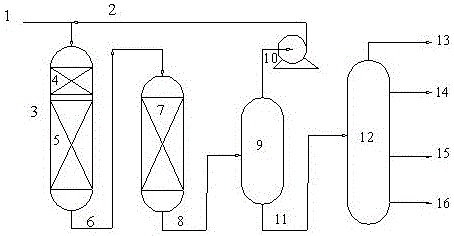

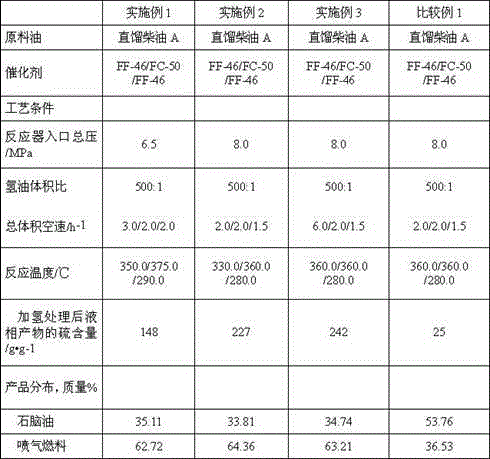

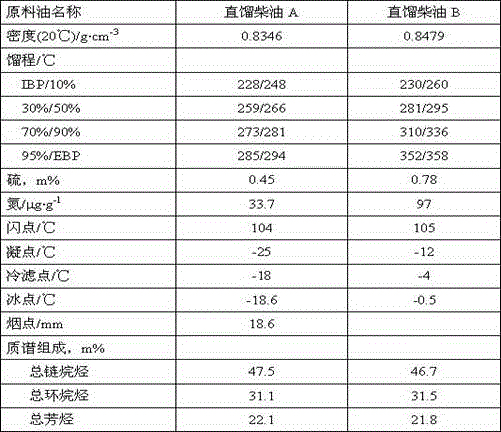

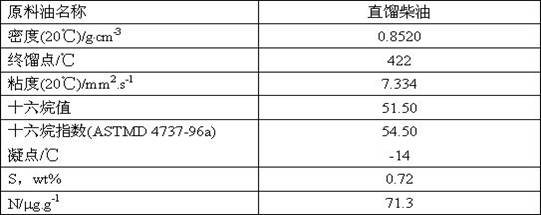

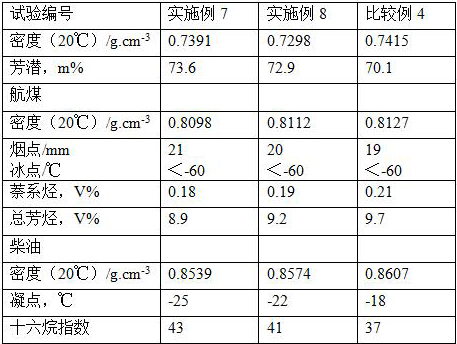

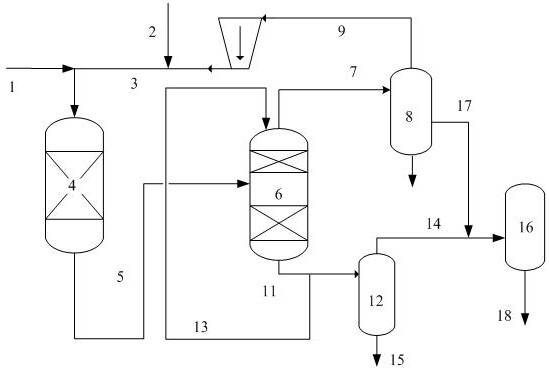

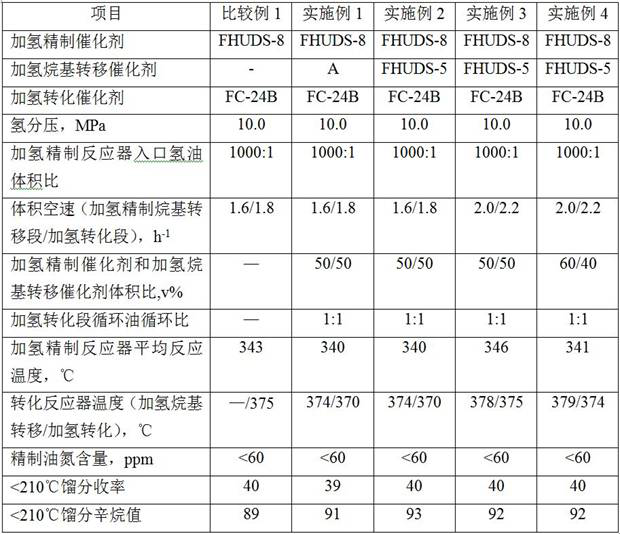

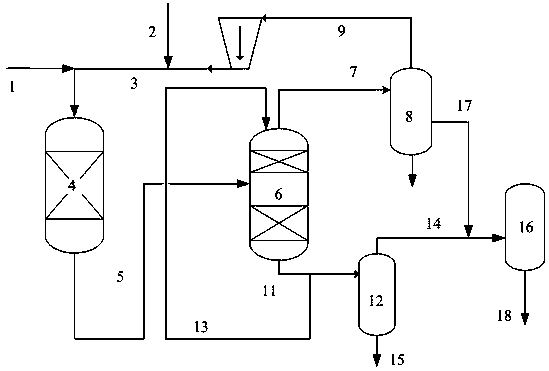

Method for producing jet fuel by straight-run diesel oil

ActiveCN107177374AHigh selectivityReduce secondary cracking reactionsTreatment with hydrotreatment processesChemistryNaphtha

The invention discloses a method for producing jet fuel by straight-run diesel oil. The method comprises the following steps: (1) mixing a straight-run diesel oil raw material with hydrogen gas; enabling a mixture to enter a hydrogenation treatment reaction region; carrying out hydrogenation and desulfurization reaction and hydrogenation and denitrification reaction under a condition of relatively low temperature and / or a large volume space velocity; (2) enabling refined straight-run diesel oil obtained by step (1) to enter a hydrocracking reaction region and be in contact with a hydrocracking catalyst; carrying out hydrocracking reaction; (3) enabling a full-fraction hydrocracking product obtained by step (2) into a hydrogenation refining reaction region and carrying out aromatic hydrogenation saturation reaction; (4) enabling a refined full-fraction product obtained by step (3) to enter a separation and fractionation system, so as to obtain naphtha and jet fuel products and the like. Compared with the prior art, the method disclosed by the invention can be used for producing the straight-run diesel oil into the jet fuel at maximum and the additional value of the product is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Oil sludge treatment method

ActiveCN111377579AHigh yieldReduce secondary cracking reactionsSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesCombustionCoke

The invention discloses an oil sludge treatment method which comprises the following steps: the oil sludge enters a drying unit to be dried and dehydrated, and dehydrated oil sludge and a gas-phase material are obtained after dehydration treatment; the dehydrated oil sludge enters a pyrolytic reaction unit to be subjected to a pyrolytic reaction, and pyrolysis gas, oil and coke are obtained afterthe reaction; heat exchange on the gas-phase material is performed to obtain non-condensable gas and condensed water; pyrolysis gas and non-condensable gas enter the combustion unit to be in contact with oxygen-containing atmosphere for a combustion reaction, and hot smoke generated by the reaction serves as a heat source to provide heating heat for the drying unit and the pyrolytic reaction unit.According to the oil sludge reduction, harmlessness and resourceful treatment method, reduction and resourceful utilization of the oil sludge are achieved to the maximum extent, meanwhile, high-valueoil products are recycled, and secondary pollution is avoided in the whole treatment process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking method

ActiveCN110938468ASmall average pore sizeExtended stayTreatment with hydrotreatment processesHydrocarbon oils treatment productsMolecular sievePtru catalyst

The invention discloses a hydrocracking method, which comprises the following steps: (1) mixing a diesel oil raw material and hydrogen, feeding the mixture into a hydrofining reactor, and carrying outa desulfurization, denitrification and aromatic hydrocarbon saturation reaction; and (2) feeding the effluent obtained in the step (1) into a hydrocracking reactor, wherein the hydrocracking reactorcomprises first to nth catalyst bed layers in a material direction, n is greater than or equal to 3, preferably n is 3 or 4, the first to (n-1)th catalyst bed layers are filled with a hydrocracking catalyst containing a modified Y molecular sieve, and the nth catalyst bed layer is filled with a hydroisomerization catalyst containing a beta or ZSM molecular sieve and other molecular sieves with strong isomerization performance. According to the method, diesel oil is used as a raw material, and through reasonable combination of hydrocracking catalysts with different functions, the yield of heavynaphtha with high aromatic potential is increased, and the low-temperature fluidity of aviation kerosene and diesel oil products is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Crude benzol hydrogenation refining process

InactiveCN106348998AReduce lossesHigh retention rateDistillation purification/separationHydrocarbonsThree stageExtractive distillation

The invention disclosed a crude benzol hydrogenation refining process. The crude benzol hydrogenation refining process comprises a raw material predissociation unit, a hydrofining unit, a predistillation unit, an unit of extractive distillation, an aromatic hydrocarbon refining unit and a xylene distillation unit, wherein the hydrofining unit comprises a reaction part and a steady part. The reaction part adopts a three stage hydrogenation. The first stage hydrogenation is the pre hydrofining reaction, while the second stage and the third stage hydrogenation are the main hydrofining reactions. The extractive unit distillation comprises an extractive distillation tower, a stripping tower and a liquid-liquid separation tank. When benzene is produced through the crude benzol hydrogenation refining process, the aromatic compound has the advantages of small loss, high retention rate of arene and high quality products.

Owner:SICHUAN DAXING ENERGY

A Catalytic Conversion Process for Inferior Heavy Oil with High Yield of Low-carbon Olefins and Gasoline

ActiveCN103540359BReduce cokingReduced activityTreatment with hydrotreatment processesHigh carbonSlurry

The invention relates to a low-grade heavy oil catalytic conversion process for increasing the yield of low-carbon olefins and gasoline. The process comprises the following steps: (1) low-grade heavy oil, namely raw oil, enters a first reaction zone (zone I) of a two-section riser, so as to be subjected to catalytic cracking reaction, and generated oil and gas enter a fractionating tower; (2) a top outlet material of the fractionating tower is a mixture of dry gas, liquefied gas and gasoline, a middle-part outlet material of the fractionating tower is diesel oil, a lower-part outlet material of the fractionating tower is catalyzing wax oil, a bottom outlet material of the fractionating tower is oil slurry, the catalyzing wax oil and the diesel oil enter a second reaction zone (zone II) of the two-section riser together, and the oil slurry enters a vacuum distillation tower; (3) a lower-carbon-residue light-distillate material of an upper-part outlet of the vacuum distillation tower and a higher-carbon-residue heavy-distillate material of a middle-part outlet of the vacuum distillation tower enter a hydrogenation device together, and ultrahigh-carbon-residue oil slurry at the bottom of the vacuum distillation tower enters a delayed coking device; (4) a low-carbon-residue easily-cracked material from the hydrogenation device enters the zone I of the riser and is subjected to reaction again. The process has the characteristics that the service life of the catalyst is prolonged, the yield of dry gases and coke is lowered, and meanwhile, the yield of low-carbon olefins and gasoline is increased.

Owner:PETROCHINA CO LTD

Hydrocracking method

ActiveCN110938468BSmall average pore sizeExtended stayTreatment with hydrotreatment processesHydrocarbon oils treatment productsMolecular sieveNaphtha

The invention discloses a hydrocracking method, which includes the following contents: (1) Diesel feedstock is mixed with hydrogen and first enters a hydrorefining reactor for desulfurization, denitrogenation and aromatics saturation reaction; (2) Step (1) effluent enters Hydrocracking reactor, along the material direction, the hydrocracking reactor includes the 1st to nth catalyst beds, wherein n≥3, preferably n is 3 or 4, wherein, the 1st to n-1th catalyst beds are filled A hydrocracking catalyst containing a modified Y molecular sieve; the nth catalyst bed is filled with a hydroisomerization catalyst containing molecular sieves such as β or ZSM with strong isomerization performance. The method uses diesel oil as a raw material, increases the production of heavy naphtha with high aromatic potential, and improves the low-temperature fluidity of jet fuel and diesel products through a reasonable combination of hydrocracking catalysts with different functions.

Owner:CHINA PETROLEUM & CHEM CORP +1

Slurry organic solid waste pyrolysis device and method

ActiveCN111518577BEvenly heatedQuick releaseSludge treatment by pyrolysisByproduct vaporizationCokeProcess engineering

The invention discloses a slurry-like organic solid waste pyrolysis device and method. The device comprises a casing, a feeding port is arranged on the top of the casing, and a heating roller is rotatably installed below the feeding port; There is a coke cleaner; the upper chain plate and the lower chain plate are arranged horizontally under the heating drum, and the output end of the upper chain plate corresponds to the input end of the lower chain plate; a row is installed between the upper chain plate and the lower chain plate Heating pipes arranged horizontally; an air outlet and a pyrolytic charcoal outlet are arranged on the casing, and the pyrolytic charcoal outlet is located at the bottom of the casing and corresponds to the output end of the lower chain plate. The above device is used to pyrolyze the slurry organic solid waste. The beneficial effect of the present invention is that the pulpy organic solid waste can be dehydrated, oil evaporated, and primary pyrolyzed to make the pulpy material into a solid state, and then undergo high-temperature pyrolysis through high-temperature heating of chain plates and heating pipes to realize pulpy waste. The high-efficiency pyrolysis of materials effectively solves the technical difficulties faced by conventional pyrolysis devices.

Owner:湖南华仁宏顺科技有限公司

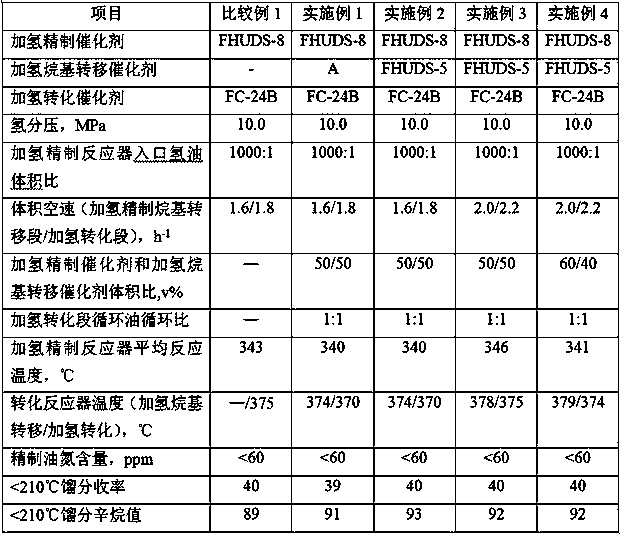

Method for producing high-octane fuel

ActiveCN111378496ASolve problems such as relatively large consumptionPromote generationTreatment with hydrotreatment processesHydrocarbon oils treatment productsPtru catalystGasoline

The invention discloses a method for producing high-octane gasoline. An aromatic hydrocarbon-containing raw material enters a hydrofining reaction zone for a hydrofining reaction, and an obtained effluent and a circulation product enter a hydro-conversion reactor together from the bottom of the reactor and firstly pass through an alkyl transfer catalyst bed; gas-liquid separation is carried out onthe obtained transalkylation effluent in the middle of a reactor, and gas is extracted out of the reactor; the obtained liquid phase passes through a hydro-conversion catalyst bed upwards, and a hydro-conversion reaction is carried out; and a hydro-conversion product and a gas phase extracted from the middle part of the reactor are subjected to separation and fractionating to obtain a gasoline fraction and a diesel fraction. According to the method, gasoline octane number loss caused by excessive hydrogenation can be avoided, meanwhile, good diesel oil blending components are obtained, investment can be better reduced, and the treatment capacity of the device is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

One-stage serial hydrocracking process

ActiveCN110938469BReduce flammabilityExtended stayTreatment with hydrotreatment processesHydrocarbon oils treatment productsWaxTransition stage

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for producing high-octane fuels from raw materials containing aromatics

ActiveCN111378497BSolve problems such as relatively large consumptionSolve the problem of controlling the depth of hydrogenationTreatment with hydrotreatment processesHydrocarbon oils treatment productsPtru catalystChemistry

The invention discloses a method for producing high-octane gasoline from raw materials containing aromatic hydrocarbons. The aromatics-containing raw material enters the hydrorefining reaction zone for hydrorefining reaction, and the resulting effluent enters the hydroconversion reactor from the middle of the reactor, where it undergoes gas-liquid separation; the resulting gas passes upward through the hydroconversion catalyst bed, and reacts The circulating oil entering from the top of the reactor is contacted to carry out hydroconversion reaction and saturated hydrogen dissolution; the separated liquid phase passes downward through the bed of hydrogenation transalkylation catalyst to eliminate the steric hindrance effect in condensed ring aromatics, and the obtained effluent One part is used as product and the other part is recycled back to the top of the hydroconversion reactor. The method of the invention can avoid the loss of gasoline octane number caused by excessive hydrogenation, obtain better blending components of diesel oil at the same time, can better reduce investment, and increase the processing capacity of the device.

Owner:CHINA PETROLEUM & CHEM CORP +1

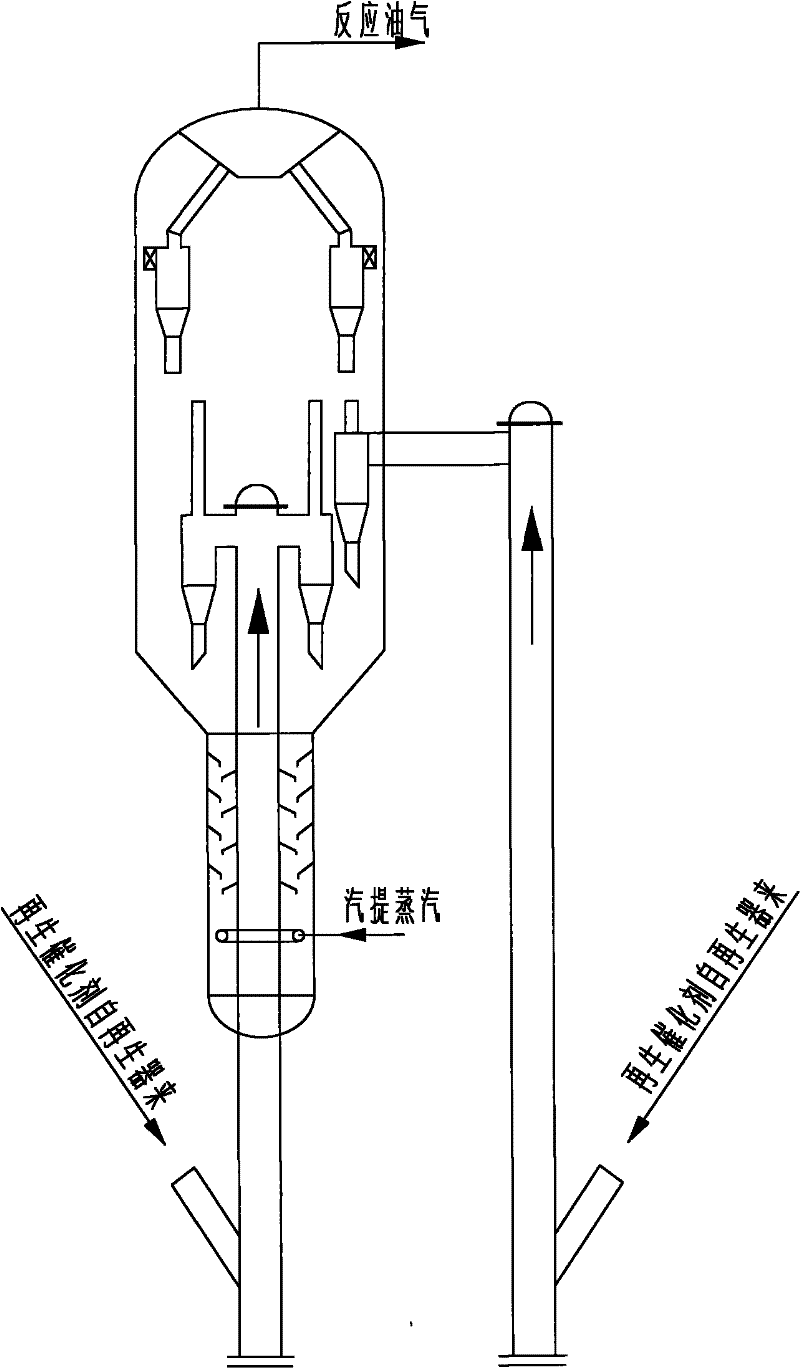

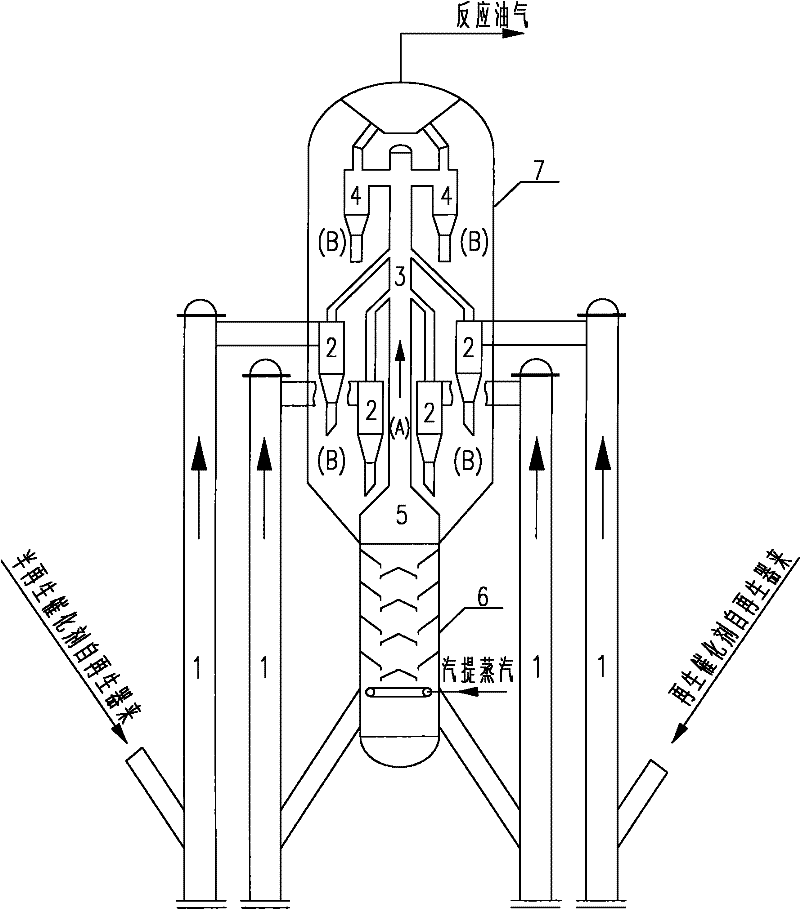

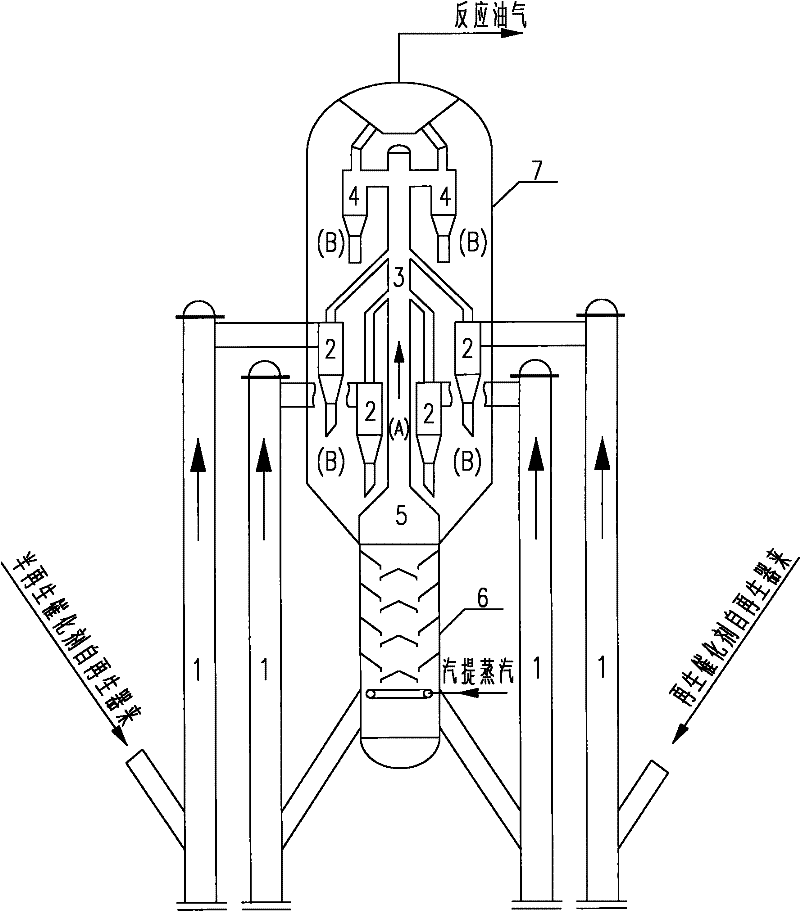

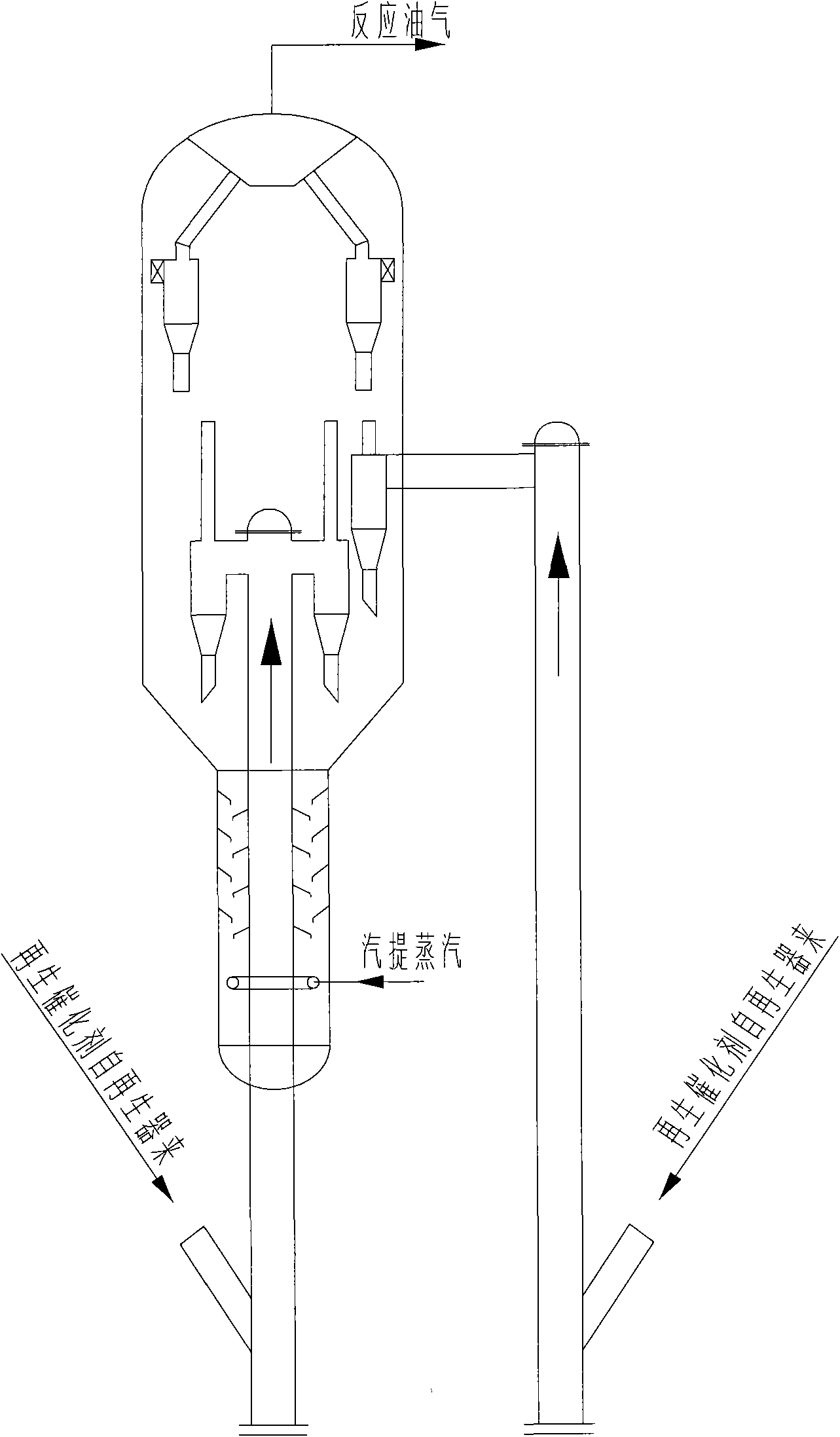

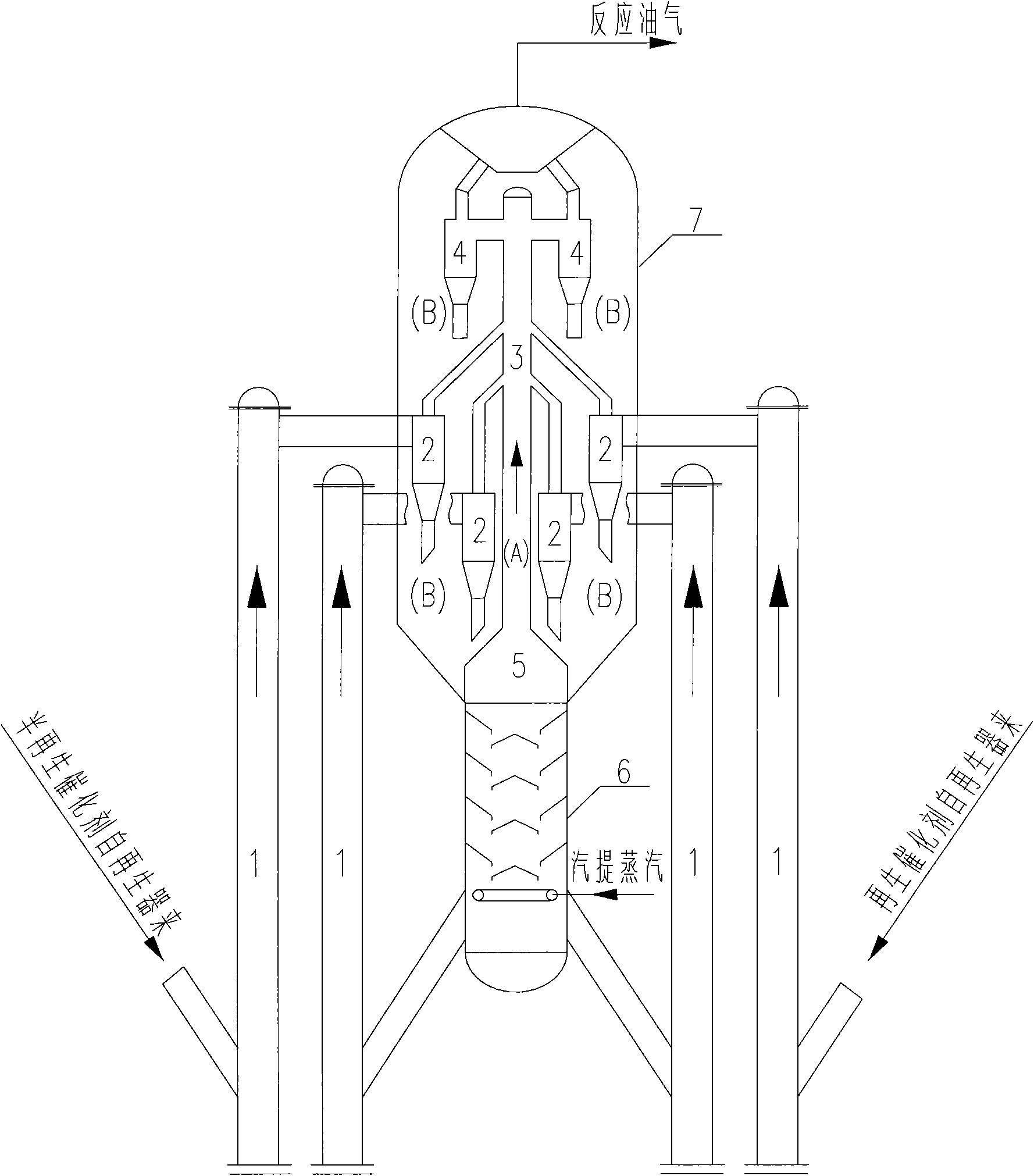

Closed type rough cyclone quick separation system carrying multiple-riser reactor for catalytic cracking process and catalytic cracking method thereof

ActiveCN102240528AEasy to separateSimple reaction conditionsCatalytic crackingReversed direction vortexCycloneCoke rate

The invention relates to a closed type rough cyclone quick separation system carrying multiple-riser reactor for catalytic cracking process and a catalytic cracking method thereof. The reactor provided by the invention comprises risers, a stripping stage, a reacting-settler, rough cyclone separators disposed inside the reacting-settler and cyclone separators disposed on the top of the reacting-settler, wherein outlet ascension pipes of the rough cyclone separators are connected with inlets of the top cyclone separators through an oil gas collecting pipe. As a plurality of independent risers are arranged in the invention, feedstocks of different traits respectively undergo cracking reaction under each appropriate environment according to the requirements of device production schemes and product quality, so as to raise the yield of a target product. As a novel close type rough cyclone quick separation system is adopted on the outlets of the risers in the system, the staying time of cracked oil gas inside a settler is effectively shortened, the coke rate is reduced, and the yield of the target product is raised, therefore guaranteeing the device to operate safely for long periods of time.

Owner:CHINA PETROCHEMICAL CORP +1

A Catalytic Conversion Process for Inferior Heavy Oil with High Yield of Low-carbon Olefins and Diesel Oil

ActiveCN103540356BReduce cokingReduced activityTreatment with hydrotreatment processesSlurryFuel oil

Owner:PETROCHINA CO LTD

A kind of hydrocracking catalyst and its preparation method and application

ActiveCN112717982BGuarantee capacityReduce overcrackingMolecular sieve catalystsCatalyst activation/preparationAlkanePtru catalyst

The invention discloses a hydrocracking catalyst and a preparation method and application thereof. The method includes the following steps: (1) forming modified Y molecular sieve, amorphous silica-alumina and / or alumina, drying and calcining to obtain the catalyst carrier; the sodium content in the modified Y molecular sieve is 1 to 8 wt%; (2) the catalyst carrier prepared in step (1) by saturated impregnation with a non-polar organic solvent, and then dried to the non-polar catalyst carrier in the catalyst carrier The content of the organic solvent is 20-90% of the saturated adsorption capacity of the catalyst carrier. (3) The material obtained in step (2) is subjected to ammonium salt ion exchange, drying and calcination treatment; (4) active metal is introduced into the material obtained in step (3), and the final catalyst is obtained by drying and calcining. The catalyst prepared by the method can reduce the cracking of high value-added lubricating oil base oil to generate other low-value products, especially the excessive cracking of straight-chain paraffin high viscosity index components in the lubricating base oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst and preparation method thereof

ActiveCN109926093AHigh content of acidic components on the outer surfaceIncreased acidity of the outer surfaceOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon oil crackingAlkaneLiquid state

The invention discloses a hydrocracking catalyst and a preparation method thereof, wherein the hydrocracking catalyst comprises an acidic component, a hydrogenation metal component, an auxiliary agentand a carrier, the acidic component is a heteropoly acid ammonium salt, the hydrogenation metal component is one or a plurality of materials selected from Group VIB metals and / or Group VIII metals, Pis an auxiliary agent, and the carrier is an alumina and silica composite carrier. The invention further provides a preparation method of the hydrocracking catalyst. According to the present invention, the catalyst obtained by the method exhibits high reactivity and high liquid-state hydrocarbon selectivity in the hydrocracking reactions of long chain alkanes.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of hydrocracking catalyst and its preparation method

ActiveCN109926094BHigh content of acidic components on the outer surfaceIncreased acidity of the outer surfaceOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon oil crackingAlkanePtru catalyst

The invention discloses a hydrocracking catalyst and a preparation method thereof. The hydrocracking catalyst comprises an acidic component, a hydrogenation metal component, an auxiliary agent and a carrier, and the acidic component is ammonium salt of a heteropolyacid. The preparation method of the hydrocracking catalyst includes preparing a catalyst precursor, modifying the precursor to prepare a carrier, and supporting acid components and hydrogenation metal components. The catalyst obtained by the method of the invention exhibits higher reactivity and liquid hydrocarbon selectivity when used in the hydrocracking reaction of long-chain alkanes.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of sludge treatment method

ActiveCN111377579BHigh yieldReduce secondary cracking reactionsSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesFiberCombustion

The invention discloses an oil sludge treatment method. The treatment method comprises the following steps: oil sludge enters a drying unit for drying and dehydration, and after dehydration treatment, dewatered oil sludge and gas-phase materials are obtained; the dewatered oil sludge enters a pyrolysis reaction unit for pyrolysis reaction, and cracked gas is obtained after the reaction. , oil and coke; the gas-phase material obtains non-condensable gas and condensed water after heat exchange; the cracked gas and non-condensable gas enter the combustion unit, contact with the oxygen-containing atmosphere for combustion reaction, and use the hot flue gas generated by the reaction as the heat source as the drying unit And the pyrolysis reaction unit provides heating heat. The invention provides a sludge reduction, harmless and resourceful treatment method, which realizes the maximum reduction and resource utilization of sludge, and at the same time recovers high-value oil products without causing secondary pollution in the whole processing process.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-selectivity hydrocracking catalyst and preparation method thereof

ActiveCN109926073AEnhanced Surface AcidityReduce acidityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon oil crackingAlkaneLiquid state

The invention discloses a high-selectivity hydrocracking catalyst and a preparation method thereof, wherein the catalyst comprises an acidic component, a hydrogenation metal component, an auxiliary agent and a carrier, the acidic component is a heteropolyacid ammonium salt, the hydrogenation metal component is one or a plurality of materials selected from Group VIB metals and / or Group VIII metals,and P is an auxiliary agent. The preparation method comprises: preparing and modifying a catalyst precursor, and loading an acidic component. According to the present invention, the catalyst obtainedby the method exhibits good reactivity and high liquid-state hydrocarbon selectivity in the hydrocracking reactions of long-chain alkanes.

Owner:CHINA PETROLEUM & CHEM CORP +1

Closed type rough cyclone quick separation system carrying multiple-riser reactor for catalytic cracking process and catalytic cracking method thereof

ActiveCN102240528BAchieve stabilitySatisfy the cracking reactionCatalytic crackingTreatment with plural parallel cracking stages onlyCycloneProcess engineering

The invention relates to a closed type rough cyclone quick separation system carrying multiple-riser reactor for catalytic cracking process and a catalytic cracking method thereof. The reactor provided by the invention comprises risers, a stripping stage, a reacting-settler, rough cyclone separators disposed inside the reacting-settler and cyclone separators disposed on the top of the reacting-settler, wherein outlet ascension pipes of the rough cyclone separators are connected with inlets of the top cyclone separators through an oil gas collecting pipe. As a plurality of independent risers are arranged in the invention, feedstocks of different traits respectively undergo cracking reaction under each appropriate environment according to the requirements of device production schemes and product quality, so as to raise the yield of a target product. As a novel close type rough cyclone quick separation system is adopted on the outlets of the risers in the system, the staying time of cracked oil gas inside a settler is effectively shortened, the coke rate is reduced, and the yield of the target product is raised, therefore guaranteeing the device to operate safely for long periods of time.

Owner:CHINA PETROCHEMICAL CORP +1

A kind of hydrocracking catalyst and preparation method thereof

ActiveCN109926093BHigh content of acidic components on the outer surfaceIncreased acidity of the outer surfaceOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon oil crackingAlkanePtru catalyst

The invention discloses a hydrocracking catalyst and a preparation method thereof. The hydrocracking catalyst includes an acidic component, a hydrogenation metal component, an auxiliary agent and a carrier. The acidic component is a heteropolyacid ammonium salt, a hydrogenation metal The components are one or more of Group VIB metals and / or Group VIII metals, P is an auxiliary agent, and the carrier is a composite carrier of alumina and silicon dioxide. A method for preparing the above hydrocracking catalyst is also provided. The catalyst obtained by the method of the invention exhibits higher reactivity and liquid hydrocarbon selectivity when used in the hydrocracking reaction of long-chain alkanes.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing high-octane fuel from aromatic hydrocarbon-containing raw material

ActiveCN111378497ASolve problems such as relatively large consumptionSolve the problem of controlling the depth of hydrogenationTreatment with hydrotreatment processesHydrocarbon oils treatment productsPolycyclic aromatic hydrocarbonPtru catalyst

The invention discloses a method for producing high-octane gasoline from an aromatic hydrocarbon-containing raw material. The aromatic hydrocarbon-containing raw material enters a hydrofining reactionzone for a hydrofining reaction, an obtained effluent enters a hydro-conversion reactor from the middle of the reactor, and gas-liquid separation is carried out in the hydro-conversion reactor; the obtained gas passes upwards through a hydro-conversion catalyst bed to make contact with circulating oil entering from the top of the reactor so as to carry out hydro-conversion reaction and carry outsaturated hydrogen dissolution; a separated liquid phase passes downwards through a hydrogenation transalkylation catalyst bed to eliminate the steric hindrance effect in the polycyclic aromatic hydrocarbon, one part of the obtained effluent is used as a product, and the other part of the effluent is recycled back to the top of the hydro-conversion reactor. By the method, gasoline octane number loss caused by excessive hydrogenation can be avoided, meanwhile, good diesel oil blending components are obtained, investment can be better reduced, and the treatment capacity of the device is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Biomass pyrolysis reactor and working method thereof

PendingCN111676036AWell mixedAchieve directional flowBiofuelsSpecial form destructive distillationProcess engineeringEnvironmental engineering

The invention discloses a biomass pyrolysis reactor and a working method thereof. The biomass pyrolysis reactor comprises a pyrolysis product conveying section, a reactant and product separation section, a circulation pyrolysis reaction section and a hot carrier gas inlet section, which are sequentially arranged from top to bottom. The pyrolysis product conveying section is used for quickly leading a pyrolysis oil gas product out of the biomass pyrolysis reactor; the reactant and product separation section is used for reducing the apparent gas velocity and efficiently and quickly separating apyrolysis product from incompletely reacted biomass; the circulation pyrolysis reaction section is provided with a guide cylinder, a guide area, an annular space area, a biomass feeding port and a return section and used for overall ordered circulation of biomass and hot carrier gas, that is, the hot carrier gas and large-particle biomass directionally flow in the circulation pyrolysis reaction section, and multiple times of circulation are formed. The flowing environment of biomass and hot carrier gas is effectively improved, the mixing and heat exchange behaviors of biomass and hot carrier gas are ensured, the sufficient pyrolysis of biomass is realized, the secondary pyrolysis reaction of pyrolysis oil gas is weakened, and the yield of pyrolysis oil gas is increased.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com