Patents

Literature

40results about How to "Improve nitrogen tolerance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrocracking catalyst, and preparation method and application thereof

ActiveCN102909048AHigh activityImprove nitrogen toleranceMolecular sieve catalystsHydrocarbon oil crackingMolecular sievePtru catalyst

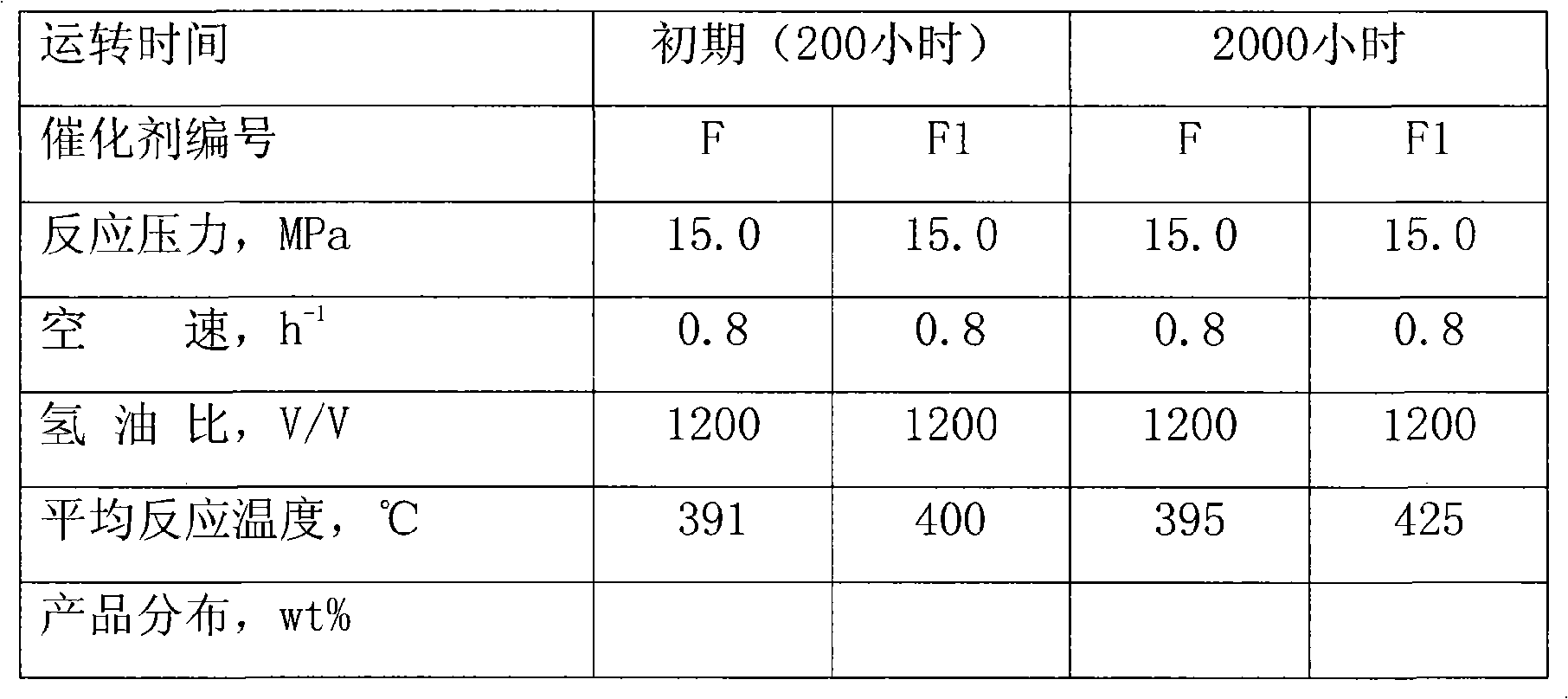

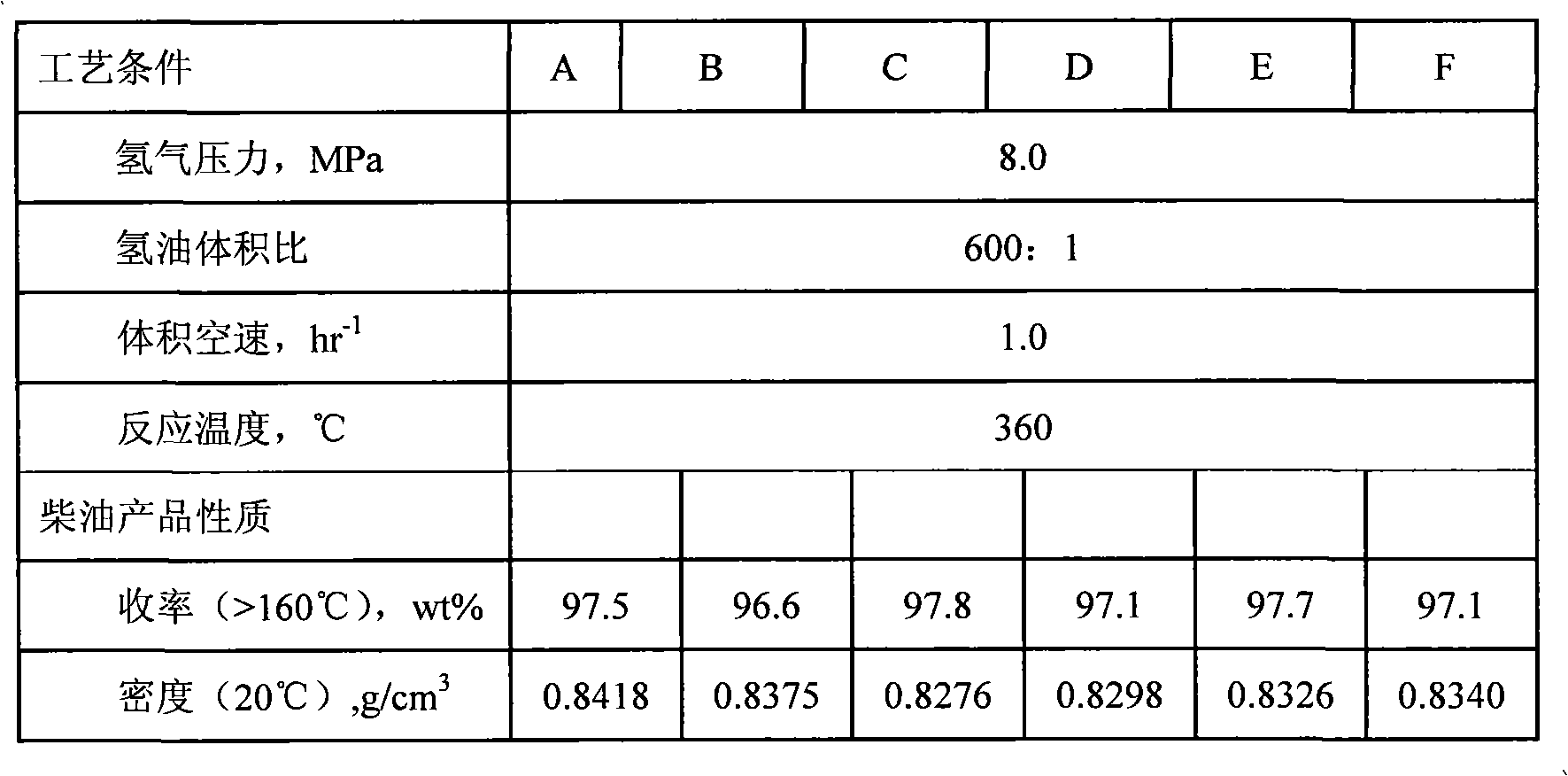

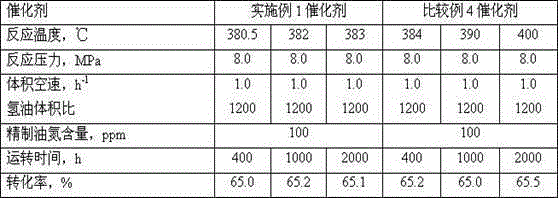

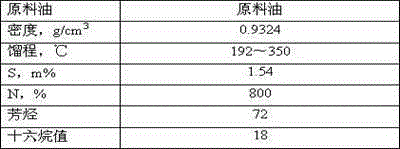

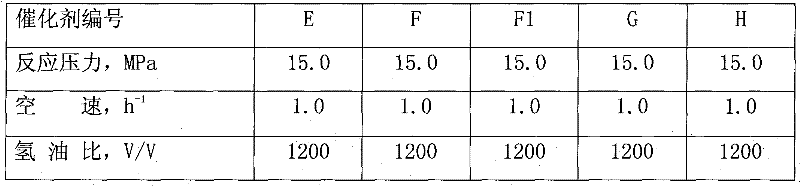

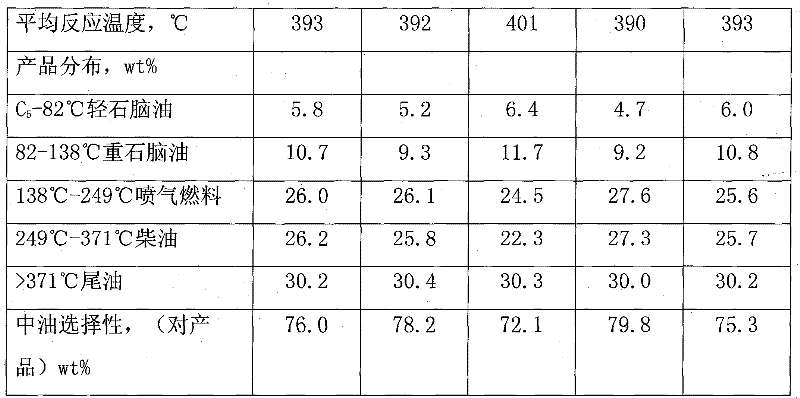

The invention describes a hydrocracking catalyst, and a preparation method and an application thereof. The hydrocracking catalyst comprises an acid component and an active metal component compound, wherein the acid component comprises at least one molecular sieve; the active metal component compound comprises a compound of Mo and / or W in a VIB group and a compound of Ni and / Co in a VIII group; and in a hydrocracking reaction state, the active metal component compound in the hydrocracking catalyst is in a metal phosphatizing state. The catalyst has excellent usage performance, good catalyst activity and high selectivity for medium oil under the condition of high nitrogen content in raw oil, is suitable for hydrocracking processes for increasing jet fuels and clean diesel oil, has stronger adaptability for nitrogen, and can reduce burden of a refining catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for producing high-performance catalyst for hydrocracking

ActiveCN101402048AImprove nitrogen toleranceExtended service lifeMolecular sieve catalystsHydrocarbon oil crackingPolymer scienceRare earth

The invention relates to a method for preparing a high-performance hydrocracking catalyst, which comprises the following steps: preparing amorphous aluminium-silicon into a paste material of which the pH value is between 3.0 and 5.5, evenly mixing Y zeolite solid powder of modified rare earth with the paste material of the amorphous aluminium-silicon, and then drying and dehydrating the mixture to prepare a moldable paste so as to prepare a catalyst carrier through molding, drying, and calcining, and finally obtaining the final hydrocracking catalyst by loading hydrogenation metal components through an impregnation method. The hydrocracking catalyst prepared by the method has the advantages of high activity and middle oil selectivity, and strong nitrogen resisting performance and water resistance, thus the hydrocracking catalyst can be used in the process of an unrefined single-stage hydrocracking, which not only can be used for processing heavy oil fraction of oil, but also can be used for processing heavy raw materials of other sources, such as the heavy distillate of coal liquefaction oil.

Owner:胜帮科技股份有限公司

Catalytic cracking diesel oil hydro-upgrading catalyst and application thereof

InactiveCN103372457AReduce coking deactivation speedHigh acid strengthMolecular sieve catalystsHydrocarbon oils treatmentMolecular sieveAmorphous silicon

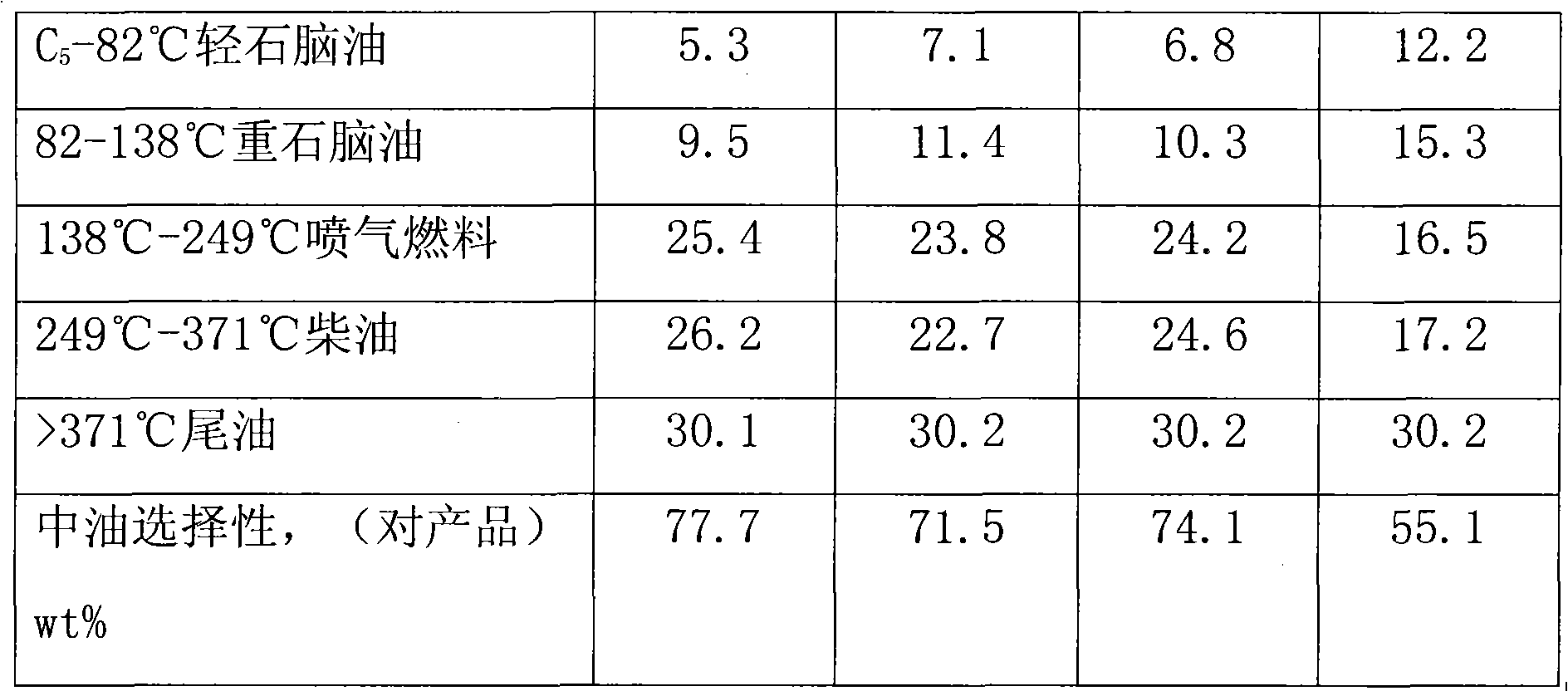

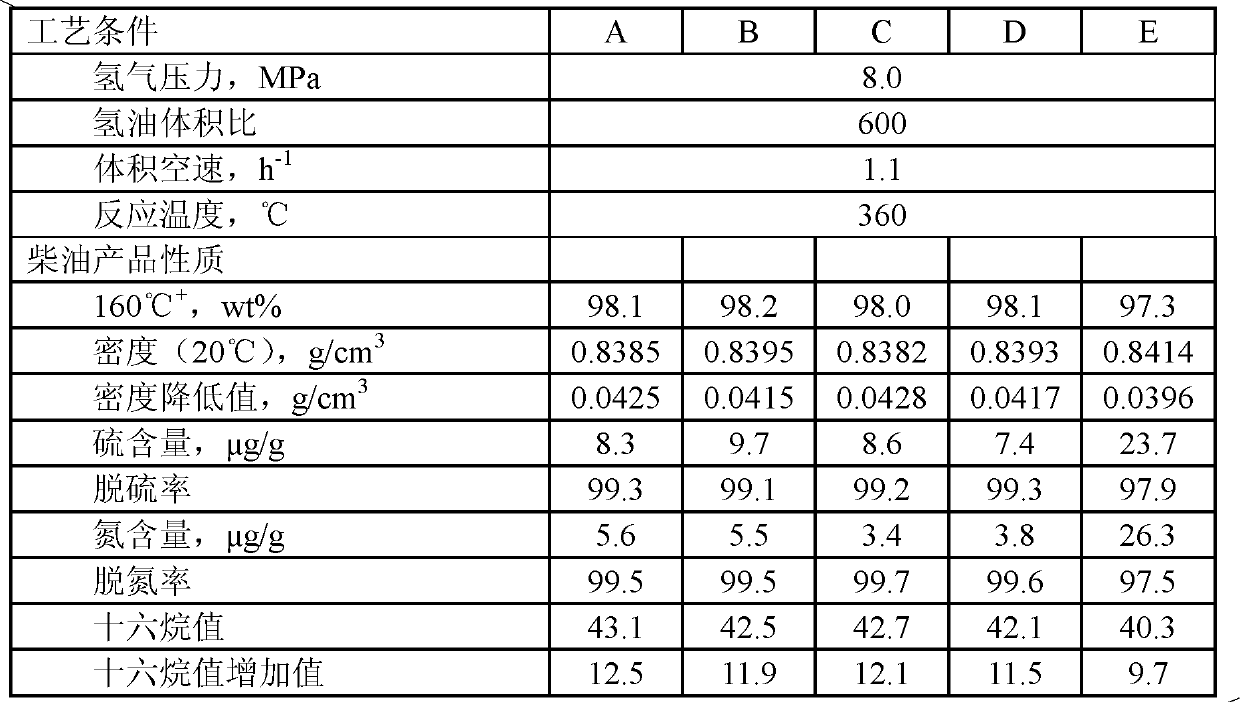

The invention relates to a catalytic cracking diesel oil hydro-upgrading catalyst and applications thereof. The catalyst is composed of VIII-group and VIB-group hydrogenation active metal components and a carrier containing a modified Y molecular sieve, amorphous silicon aluminum and alumina; the modified Y molecular sieve is prepared from a NaY molecular sieve by the steps of carrying out ammonium exchange twice, carrying out roasting one time and carrying out hydro-thermal treatment one time. The catalyst is used for carrying out hydro-upgrading on distillate or catalytic cracking diesel oil at a temperature of 160-380 DEG C. After inferior diesel distillate of which the sulfur content is higher than 1000 mu g / g, the nitrogen content is higher than 1000 mu g / g, the aromatics content is higher than 55v% is treated by using the catalyst, the desulfurization rate and the denitrification rate are both higher than 98%, the cetane number is increased by more than 10 units, and the yield of the diesel distillate is over 98wt%.

Owner:PETROCHINA CO LTD

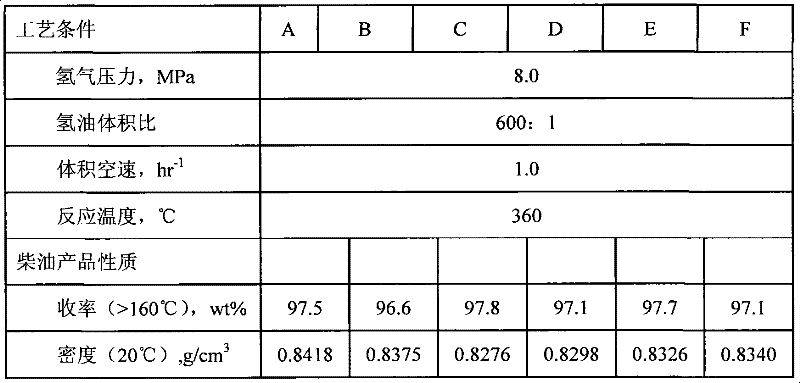

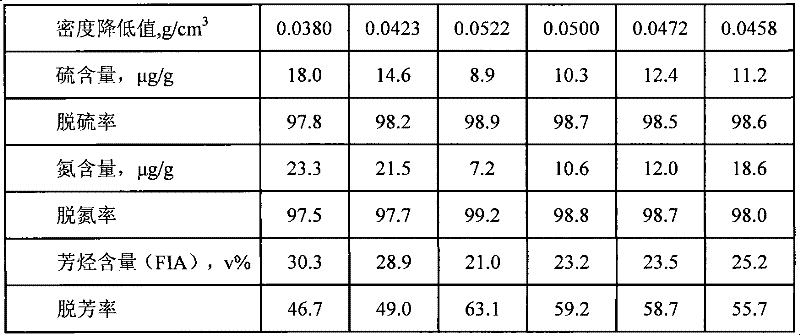

Method for hydro-dearomatization for catalyzing diesel

ActiveCN101328430AIncreased diffusion rateImprove activity stabilityRefining by aromatic hydrocarbon hydrogenationMolecular sieveDistillation

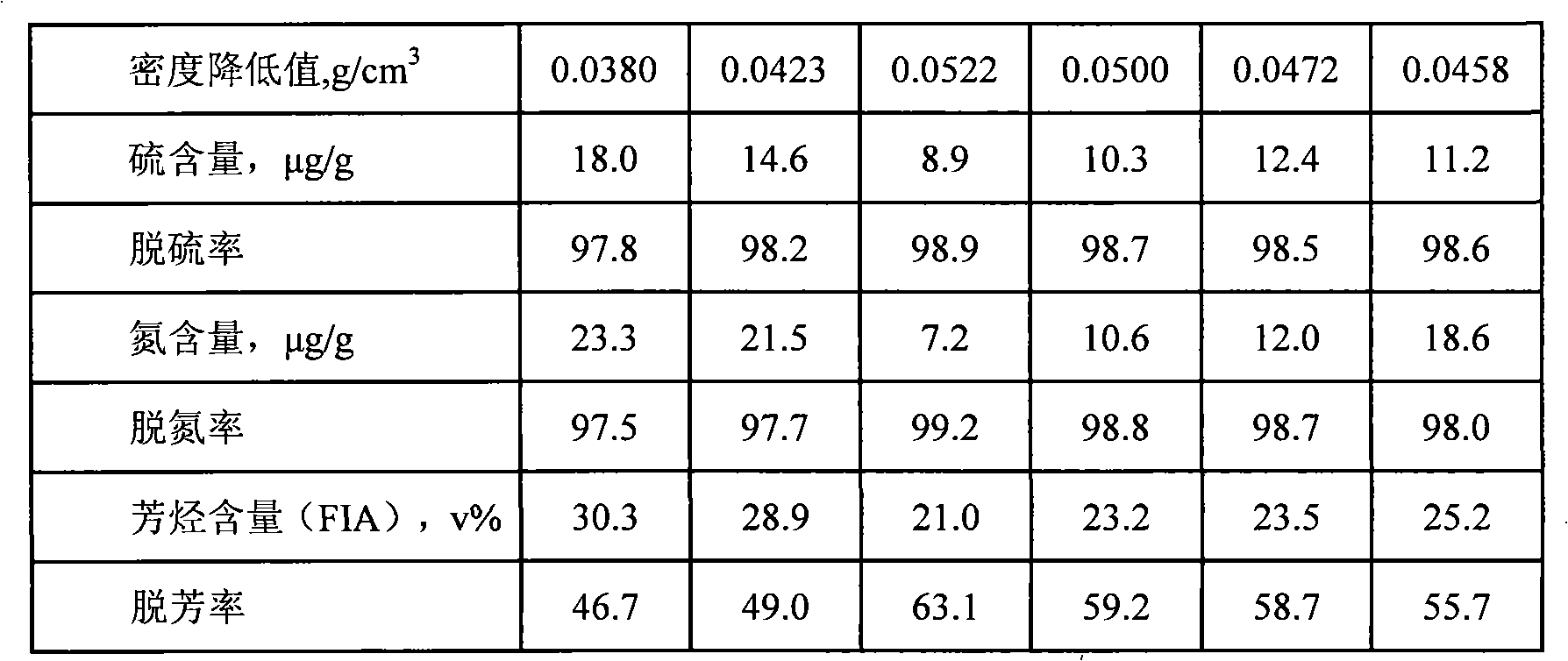

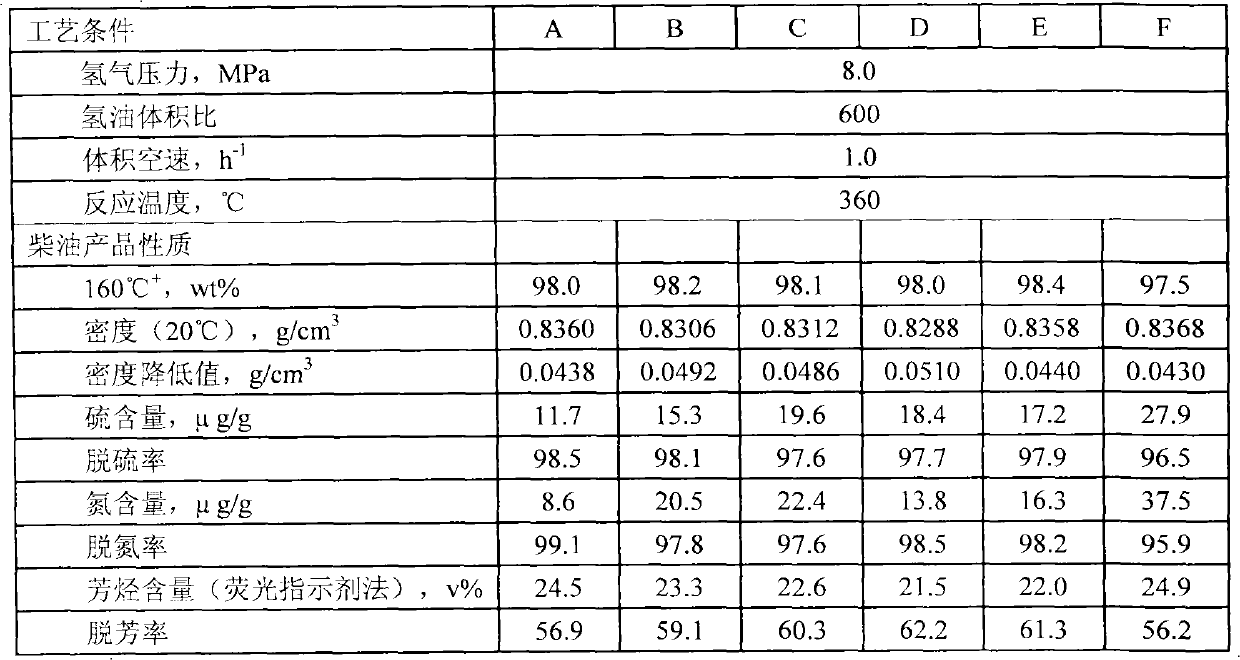

The invention relates to a method for catalyzing diesel oil to realize hydrogenation dearomatization. The method comprises the following steps that: distillation range of catalyzing diesel oil feeding is at a temperature of between 150 and 380 DEG C; in the presence of hydrogen, a reaction is carried out, the reaction temperature is between 330 and 370 DEG C, the hydrogen partial pressure is between 6 and 9 MPa, the hydrogen-oil volume ratio is between 500:1 and 1,000:1 and the liquid hourly volume space velocity is between 1.0 and 2.0 hr-1; the compositions in percentage by weight of a catalyst are: 15 to 40 percent of amorphous silica alumina, 5 to 30 percent of aluminum oxide, 10 to 40 percent of VIB group metal oxide, 1 to 15 percent of VIII group metal oxide and 5 to 30 percent of Beta / Y molecular sieve; moreover, the total weight of the compositions is counted as 100 percent. The method has the advantages that: diesel oil yield is more than 97 weight percent, and the dearomatization rate of diesel oil reaches to above 60 percent; meanwhile, total desulfurization rate and total denitrification rate reach above 98.5 percent, and product density is reduced by above 0.0400g / cm3.

Owner:PETROCHINA CO LTD

Preparation method for metal phosphide type hydrocracking catalyst

ActiveCN102909055AHigh activityImprove nitrogen toleranceMolecular sieve catalystsHydrocarbon oil crackingMolecular sievePtru catalyst

The invention describes a preparation method of a metal phosphide type hydrocracking catalyst. The method comprises the following steps of (1) preparing a catalyst carrier containing a molecular sieve and an inorganic refractory oxide; (2) preparing a dipping solution containing a VIB group metallic compound, a VIII group metallic compound and an inorganic phosphorus-containing compound; (3) dipping the catalyst carrier obtained for the step (1) with the dipping solution prepared by the step (2), and then drying the dipped material; and (4) performing hydrogen activation on the material obtained from the step (4), obtaining the hydrocracking catalyst used for hydrocracking reactions after the activation. The hydrocracking catalyst prepared by the method has outstanding usage performance, and is particularly suitable for a hydrocracking process of increasing middle distillates.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for hydro-dearomatization in catalytic cracking of diesel

InactiveCN102533315AReduce coking deactivation speedHigh acid strengthMolecular sieve catalystsRefining by aromatic hydrocarbon hydrogenationMolecular sieveCrystallinity

The invention relates to a method for hydro-dearomatization in catalytic cracking of diesel. According to the invention, Ni and W are adopted as hydrogenation active metal components of a catalyst and modified Y molecular sieve, modified Beta molecular sieve, amorphous silica-alumina and alumina are adopted as carriers of the catalyst, wherein the average crystal size of the modified Y molecular sieve is 100-400nm, the mole ratio of SiO2 / Al2O3 is 5-40:1; the relative crystallinity is greater than 90% and the specific surface area is 700-1000m<2> / g; the average crystal size of the modified Beta molecular sieve is 50-200nm, the mole ratio of SiO2 / Al2O3 is 50-200:1; the relative crystallinity is greater than 85% and the specific surface area is 700-900m<2> / g. When the method is adopted to process inferior diesel fraction, the desulfurization rate and the denitrification rate are up to more than 97.5%, the dearomatization rate is up to more than 55% and the diesel fraction yield is up to more than 98wt%.

Owner:PETROCHINA CO LTD

Preparation method for middle distillate type hydrocracking catalyst containing metal nitride

ActiveCN103785440AHigh activityImprove nitrogen toleranceMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveBiological activation

The invention discloses a preparation method for a middle distillate type hydrocracking catalyst containing metal nitride. The preparation method comprises the following steps: (1) preparing a catalyst carrier containing a molecular sieve and inorganic refractory oxide; (2) preparing a hydrazine derivative solution, dipping the catalyst carrier prepared in the step (1) in the hydrazine derivative solution and drying the catalyst carrier; (3) preparing a dipping solution containing a group VI-B metal compound and a group VIII metal compound; (4) dipping a material obtained in the step (2) in the dipping solution prepared in the step (3) and drying the material; and 5) subjecting a material obtained in the step (4) to hydrogen activation so as to obtain the hydrocracking catalyst used for a hydrocracking reaction. The hydrocracking catalyst provided by the invention is used for treating heavy hydrocarbon materials and can realize maximum production of intermediate distillate oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-activity hydrocracking catalyst and preparation method thereof

ActiveCN103785446AHigh activityImprove nitrogen toleranceMolecular sieve catalystsHydrocarbon oil crackingMolecular sievePtru catalyst

The present invention discloses a preparation method of a hydrocracking catalyst. The method of the present invention includes the following steps: (1) preparing a catalyst carrier containing a molecular sieve and an inorganic refractory oxide; (2) preparing a dipping solution containing a VIB group metallic compound, a VIII group metallic compound and a hydrazine derivative, (3)dipping the catalyst carrier obtained in the step (1) in the dipping solution obtained in the step (2), and then drying the carrier; and (4) activating the materials obtained in the step (3) by using hydrogen, so as to obtain the hydrocracking catalyst used for the hydrocracking reaction after the activation. The hydrocracking catalyst provided by the invention has high activity, and the preparation method is simple, can be used for the treatment of heavy hydrocarbon materials and can produce middle distillates by the maximum amount.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method for hydrocracking catalyst

ActiveCN102909049AHigh activityImprove nitrogen toleranceMolecular sieve catalystsHydrocarbon oil crackingAir atmosphereMolecular sieve

The invention describes a preparation method for a hydrocracking catalyst. The method comprises the following steps of (1) preparing a catalyst carrier containing a molecular sieve and an inorganic refractory oxide; (2) preparing a dipping solution containing a VIB group metallic compound, a VIII group metallic compound and an inorganic phosphorous-containing compound; (3) dipping the catalyst carrier obtained from the step (1) with the dipping solution prepared by the step (2), and then drying the dipped material; (4) performing heat treatment on the material obtained from the step (3) in an air atmosphere; and (5) performing hydrogen activation on the material obtained from the step (4), and obtaining the hydrocracking catalyst used for hydrocracking reactions after the activation. The hydrocracking catalyst prepared by the method has outstanding usage performance, and is particularly suitable for a hydrocracking process of increasing middle distillates.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of metal phosphide-containing medium oil type hydrocracking catalyst

ActiveCN102909056AHigh activityImprove nitrogen toleranceMolecular sieve catalystsHydrocarbon oil crackingMolecular sievePtru catalyst

The invention describes a preparation method of a metal phosphide-containing medium oil type hydrocracking catalyst. The method comprises the following steps of (1) preparing a catalyst carrier containing a molecular sieve and an inorganic refractory oxide; (2) preparing a phosphorus compound containing solution, dipping the catalyst carrier obtained for the step (1), and then drying the dipped catalyst carrier; (3) preparing a dipping solution containing a VIB group metallic compound and a VIII group metallic compound; (4) dipping the material obtained from the step (2) with the dipping solution prepared by the step (3), and then drying the dipped material; and (5) performing hydrogen activation on the material obtained from the step (4), obtaining the hydrocracking catalyst used for hydrocracking reactions after the activation. The hydrocracking catalyst prepared by the method has outstanding usage performance, and is particularly suitable for a hydrocracking process of increasing middle distillates.

Owner:CHINA PETROLEUM & CHEM CORP +1

Metal nitride hydrocracking catalyst, and preparation method and application thereof

ActiveCN103785442AHigh activityImprove nitrogen toleranceMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNitride

The invention discloses a metal nitride hydrocracking catalyst. In terms of the weight of a catalyst carrier, the content of a molecular sieve is normally 2 to 45%, preferably, 4 to 15%; in terms of the weight of the catalyst, the content of a group VI-B metal component (in terms of the nitride of W and / or Mo) is normally 10 to 40%, preferably, 15 to 35%, most preferably, 18 to 28%, and the content of a group VIII metal component (in terms of the nitride of Ni and / or Co) is normally 1 to 10%, preferably, 2 to 9%, most preferably, 4 to 8%. The hydrocracking catalyst provided by the invention is used for treating heavy hydrocarbon materials and can realize maximum production of intermediate distillate oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method for hydrocracking catalyst

ActiveCN102909060AImprove performanceImprove nitrogen toleranceMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveAir atmosphere

The invention describes a preparation method for a hydrocracking catalyst. The method comprises the following steps of (1) preparing a catalyst carrier containing a molecular sieve and an inorganic refractory oxide; (2) preparing a dipping solution containing a VIB group metallic compound and / or a VIII group metallic compound; (3) dipping the catalyst carrier obtained from the step (1) with the dipping solution prepared by the step (2), and then drying the dipped material; (4) preparing an inorganic phosphorus-containing compound solution, dipping the material obtained from the step (3), and drying the dipped material; (5) performing heat treatment on the material obtained from the step (4) in an air atmosphere; and (6) performing hydrogen activation on the material obtained from the step (5), and obtaining the hydrocracking catalyst used for hydrocracking reactions after the activation. The hydrocracking catalyst prepared by the method has outstanding usage performance, and is particularly suitable for a hydrocracking process of increasing middle distillates.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of metal phosphide type hydrocracking catalyst

ActiveCN102909054AHigh activityImprove nitrogen toleranceMolecular sieve catalystsHydrocarbon oil crackingMolecular sievePtru catalyst

The invention describes a preparation method for a metal phosphide type hydrocracking catalyst. The method comprises the following steps of (1) preparing a catalyst carrier containing a molecular sieve and an inorganic refractory oxide; (2) preparing a dipping solution containing a VIB group metallic compound and / or a VIII group metallic compound; (3) adding simple substance phosphorus in the dipping solution prepared by the step (2), performing ultrasonic wave dispersion, dipping the catalyst carrier obtained from the step (1), and drying the dipped carrier; and (4) performing hydrogen activation on the material obtained from the step (3), and obtaining the hydrocracking catalyst used for hydrocracking reactions after the activation. The hydrocracking catalyst prepared by the method has outstanding usage performance, and is particularly suitable for a hydrocracking process of increasing middle distillates.

Owner:CHINA PETROLEUM & CHEM CORP +1

Coal tar hydrocracking catalyst and preparation method thereof

ActiveCN102847549AIncrease acidityImprove water resistanceMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveCarbonization

The invention relates to a coal tar hydrocracking catalyst and a preparation method thereof. The method comprises the steps of: preparing amorphous silicon aluminium into a slurry with pH value of 3.0-5.5; evenly mixing a modified Y molecular sieve solid powder and the amorphous silicon aluminum slurry; then dehydrating the mixture to prepare a shapable paste; molding, drying and roasting the paste to prepare a catalyst carrier; and finally loading and hydrogenating a metal component by an impregnation method to obtain the final hydrocracking catalyst. The amorphous silicon aluminum is prepared by a carbonization method, and the silicon needed in the reaction is introduced through an alkaline silicon-containing material. The hydrocracking catalyst produced by the method provided by the invention has high activity, high middle distillate selectivity, strong nitrogen resistance and water resistance, and can be used for hydrocracking process of coal tar.

Owner:上海竣铭化工工程设计有限公司

Preparation method of hydrocracking catalyst

ActiveCN106669785ALow toxicityImprove nitrogen toleranceMolecular sieve catalystsHydrocarbon oil crackingSolventMolecular sieve

The invention discloses a preparation method of a hydrocracking catalyst, comprising the following contents: 1, selecting the hydrocracking catalyst's carrier material which contains at least an acid cracking material, adding an acid peptizer, moulding, drying and roasting to prepare a hydrocracking catalyst carrier, wherein the acid cracking material contains modified molecular sieve and an amorphous acidic component; 2, preparing an Mo-Co active metallic salt solution, carrying out saturated impregnation on the carrier, drying, and roasting; 3, carrying out saturated impregnation on the roasted carrier by the use of a water-insoluble organic solvent, and drying; and 4, preparing an Mo-Ni or W-Ni active metallic salt solution, carrying out unsaturated impregnation on the dried carrier, drying, and roasting to obtain the hydrocracking catalyst. The hydrocracking catalyst prepared by the above method can carry out selective hydrogenation on a gasoline fraction and catalytic diesel oil in a cracked product, and the catalyst has high activity and high nitrogen tolerance. Therefore, long-term stable operation of a catalytic diesel oil hydro-conversion device under the condition of low hydrogen consumption is guaranteed.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for catalytic diesel hydrodearomatization

ActiveCN101328430BIncreased diffusion rateImprove activity stabilityRefining by aromatic hydrocarbon hydrogenationDistillationSulfur

The invention relates to a method for catalyzing diesel oil hydrogenation dearomatization. The distillation range of catalytic diesel feed is 150-380°C; in the presence of hydrogen, the reaction temperature is 330-370°C, the hydrogen partial pressure is 6-9MPa, and the hydrogen oil The volume ratio is 500:1~1000:1, the liquid hourly volume space velocity is 1.0~2.0hr-1; the catalyst composition is by weight: amorphous silicon aluminum: 15~40wt%, alumina: 5~30wt%, VIB Group metal oxide: 10-40wt%, Group VIII metal oxide: 1-15wt%, Beta / Y molecular sieve: 5-30wt%, the total weight of each component is 100wt%; the yield of diesel oil is above 97wt%, and the The removal rate of aromatics is above 60%, the removal rate of total sulfur and total nitrogen is above 98.5%, and the density of the product is reduced by more than 0.0400g / cm3.

Owner:PETROCHINA CO LTD

Coal tar hydrocracking catalyst and preparation method thereof

ActiveCN102847549BIncrease acidityImprove water resistanceMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveCarbonization

The invention relates to a coal tar hydrocracking catalyst and a preparation method thereof. The method comprises the steps of: preparing amorphous silicon aluminium into a slurry with pH value of 3.0-5.5; evenly mixing a modified Y molecular sieve solid powder and the amorphous silicon aluminum slurry; then dehydrating the mixture to prepare a shapable paste; molding, drying and roasting the paste to prepare a catalyst carrier; and finally loading and hydrogenating a metal component by an impregnation method to obtain the final hydrocracking catalyst. The amorphous silicon aluminum is prepared by a carbonization method, and the silicon needed in the reaction is introduced through an alkaline silicon-containing material. The hydrocracking catalyst produced by the method provided by the invention has high activity, high middle distillate selectivity, strong nitrogen resistance and water resistance, and can be used for hydrocracking process of coal tar.

Owner:上海竣铭化工工程设计有限公司

Preparation method for middle distillate-type hydrocracking catalyst

ActiveCN102909053AHigh activityImprove nitrogen toleranceMolecular sieve catalystsHydrocarbon oil crackingAir atmospherePtru catalyst

The present invention discloses a preparation method for a middle distillate-type hydrocracking catalyst. The method of the present invention includes the following processes: (1) preparing a catalyst carrier containing zeolite(s) and an inorganic refractory oxide(s); (2) preparing a phosphorus-containing compound solution, dipping the catalyst carrier obtained in step (1), and then drying the carrier; (3) preparing a VIB group metal compound and VIII group metal compound-containing dipping solution; (4) dipping the materials obtained in step (2) in the dipping solution prepared in step (3), and then drying; (5) performing a heat treatment in the air atmosphere to the materials obtained in step (4); and (6) activating the materials obtained in step (5) after the heat treatment by using hydrogen, and obtaining the hydrocracking catalyst used for the hydrocracking reaction after the activation. The hydrocracking catalyst prepared by the method of the present invention has more prominent usability, and is particularly applicable to the hydrocracking process for maximum production of middle distillates.

Preparation method of middle distillate-type hydrocracking catalyst

ActiveCN103785445AReduce cokingReduced inactivation rateMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveAir atmosphere

The present invention discloses a preparation method of a middle distillate-type hydrocracking catalyst. The method of the present invention includes the following steps: (1) preparing a catalyst carrier containing a molecular sieve and an inorganic refractory oxide; (2) preparing a solution containing a hydrazine derivative, dipping the catalyst carrier obtained in the step (1), and then drying the carrier; (3) preparing a dipping solution containing a VIB group metal compound and a VIII group metal compound; (4) dipping the materials obtained in the step (2) in the dipping solution prepared in the step (3), and then drying; (5) performing a heat treatment at 200-450 DEG C in the air atmosphere to the materials obtained in the step (4) for 1-6 h; and (6) activating the materials obtained in the step (5) after the heat treatment by using hydrogen, so as to obtain the hydrocracking catalyst used for the hydrocracking reaction after the activation. The hydrocracking catalyst provided by the invention is used for the treatment of heavy hydrocarbon materials, does not require prevulcanization, has low inactivation rate, and can facilitate the highest-yield production of middle distillates.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for producing high-performance catalyst for hydrocracking

ActiveCN101402048BImprove nitrogen toleranceImprove water resistanceMolecular sieve catalystsHydrocarbon oil crackingPolymer scienceRare earth

The invention relates to a method for preparing a high-performance hydrocracking catalyst, which comprises the following steps: preparing amorphous aluminium-silicon into a paste material of which the pH value is between 3.0 and 5.5, evenly mixing Y zeolite solid powder of modified rare earth with the paste material of the amorphous aluminium-silicon, and then drying and dehydrating the mixture to prepare a moldable paste so as to prepare a catalyst carrier through molding, drying, and calcining, and finally obtaining the final hydrocracking catalyst by loading hydrogenation metal components through an impregnation method. The hydrocracking catalyst prepared by the method has the advantages of high activity and middle oil selectivity, and strong nitrogen resisting performance and water resistance, thus the hydrocracking catalyst can be used in the process of an unrefined single-stage hydrocracking, which not only can be used for processing heavy oil fraction of oil, but also can be used for processing heavy raw materials of other sources, such as the heavy distillate of coal liquefaction oil.

Owner:胜帮科技股份有限公司

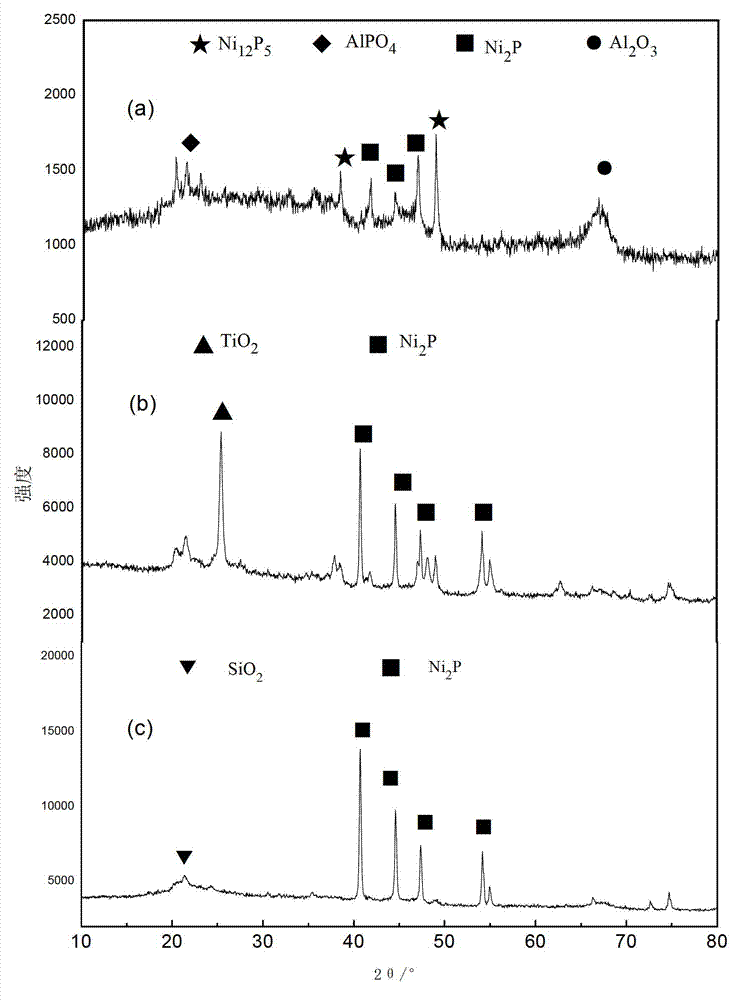

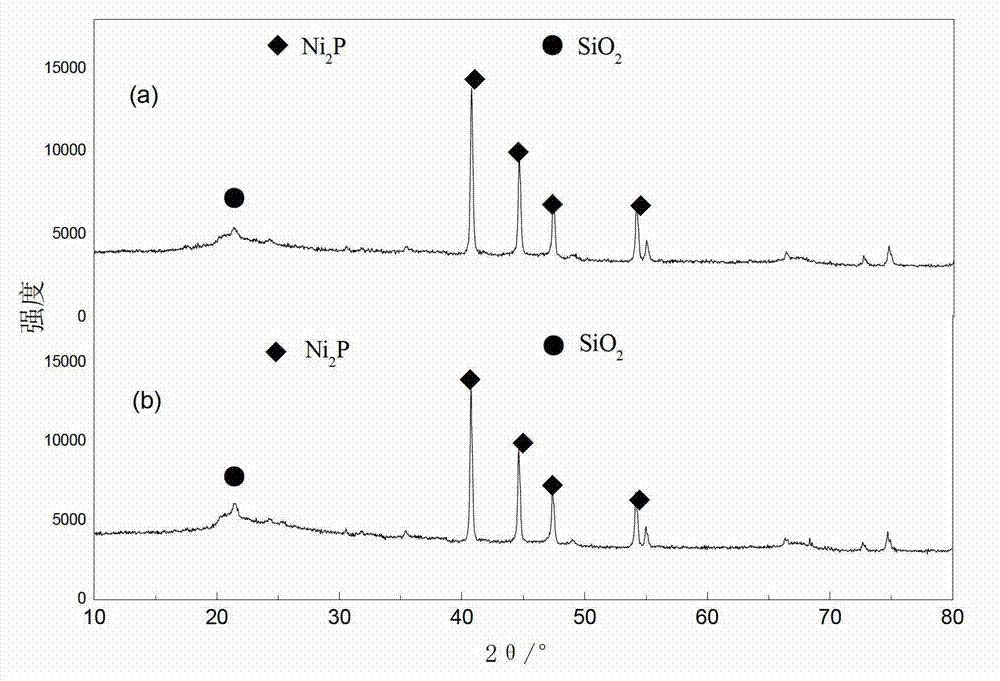

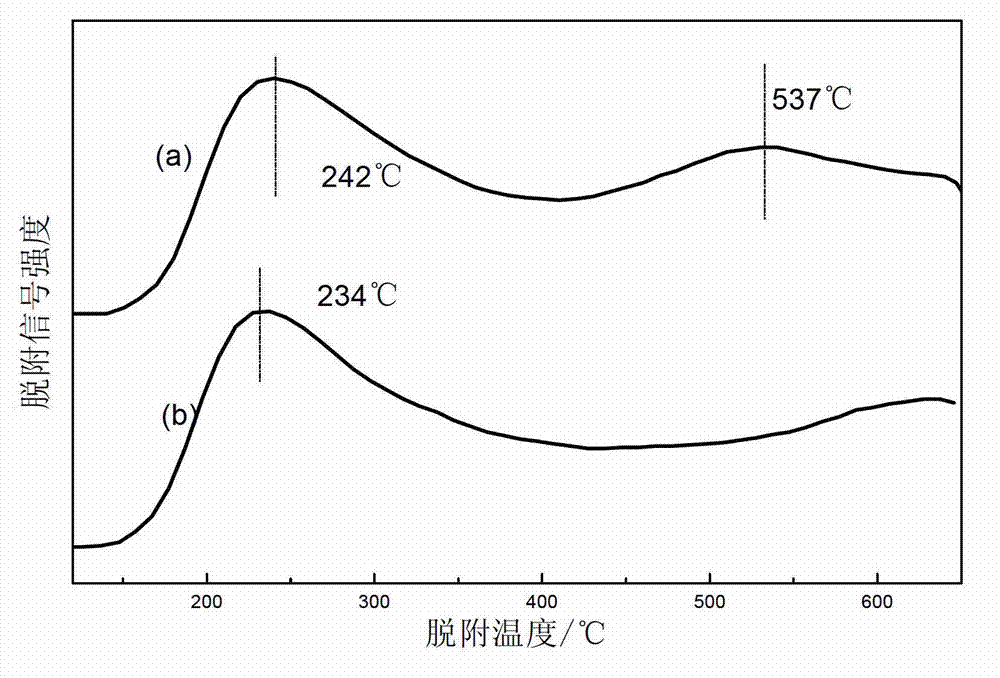

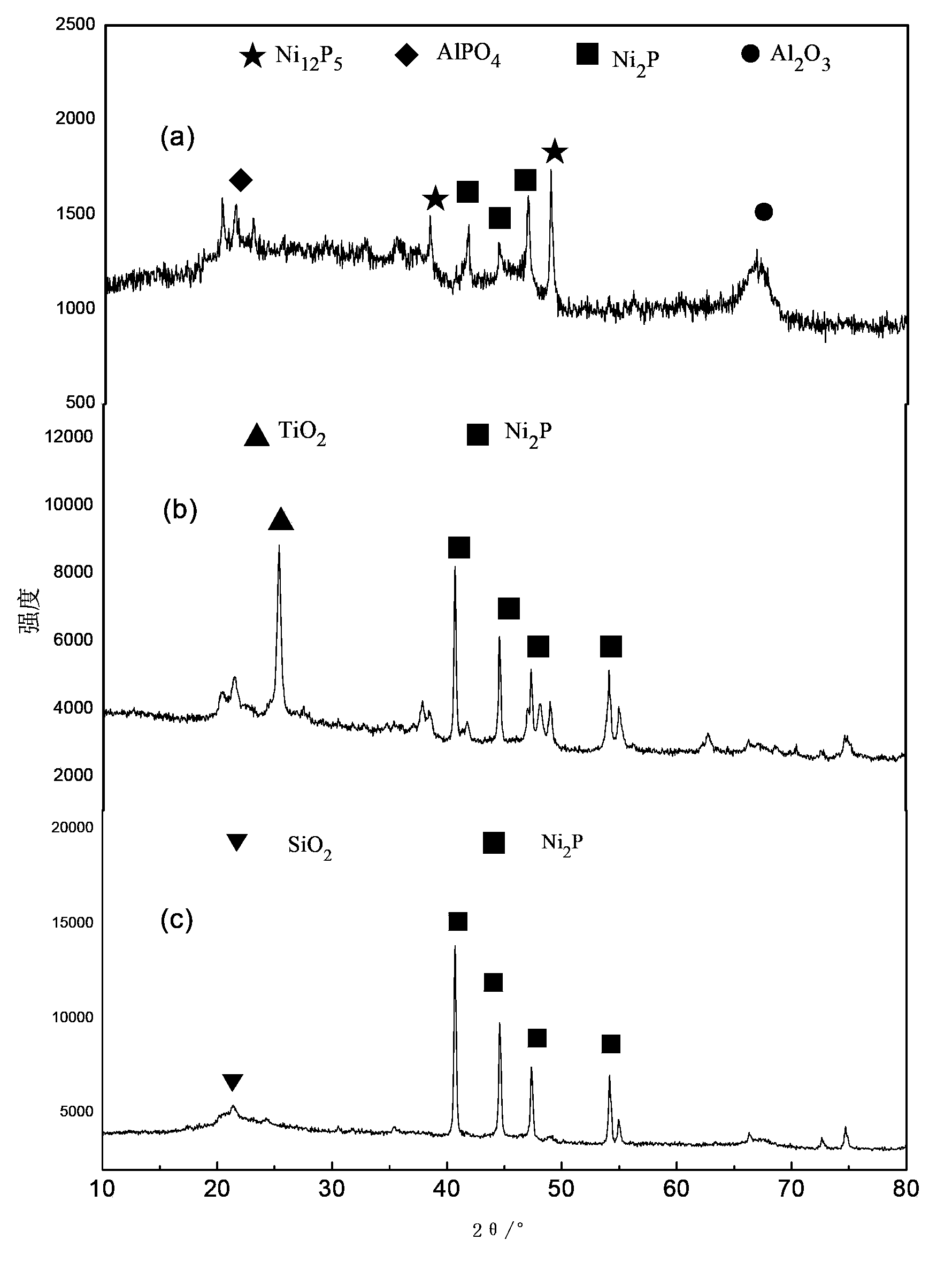

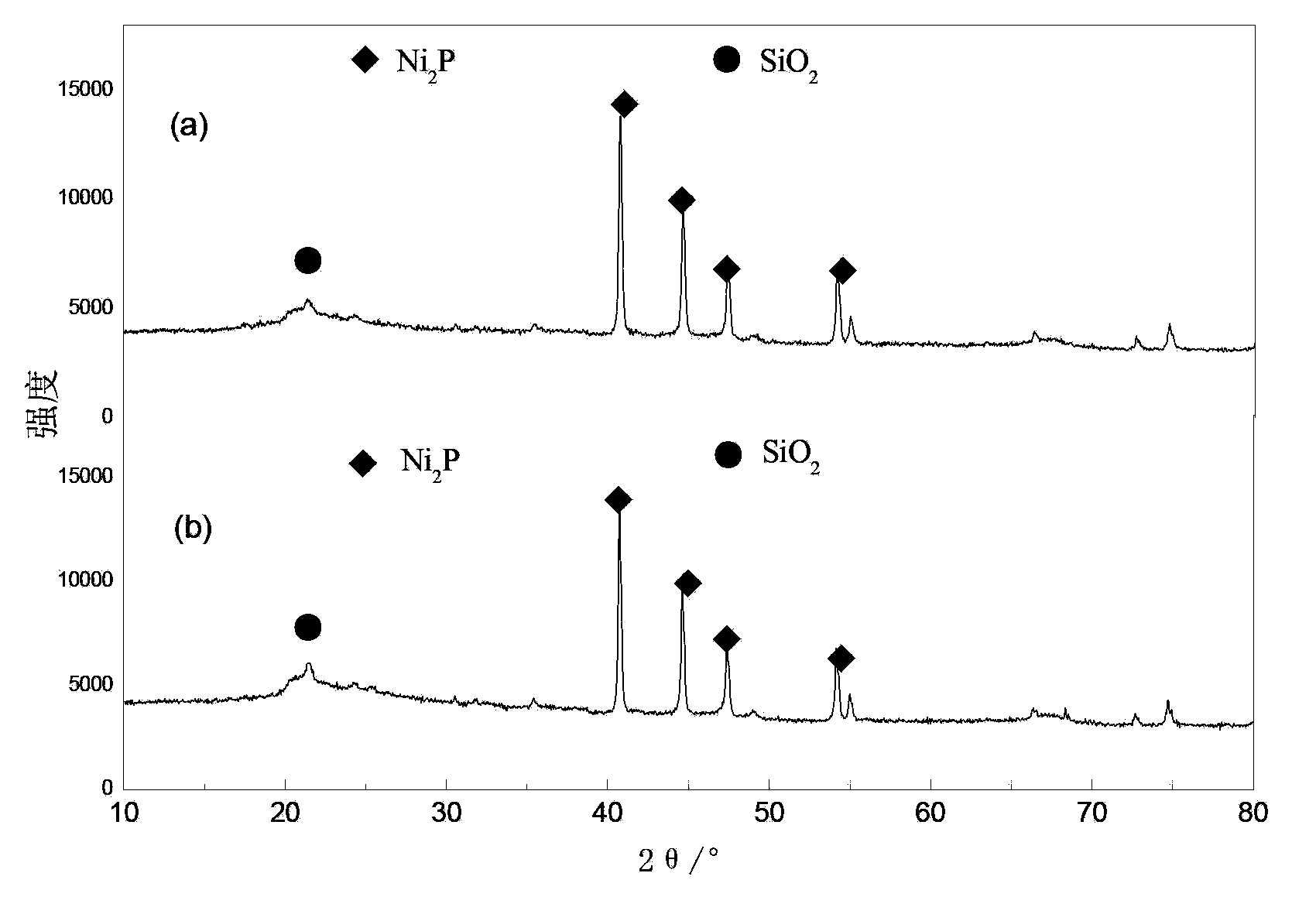

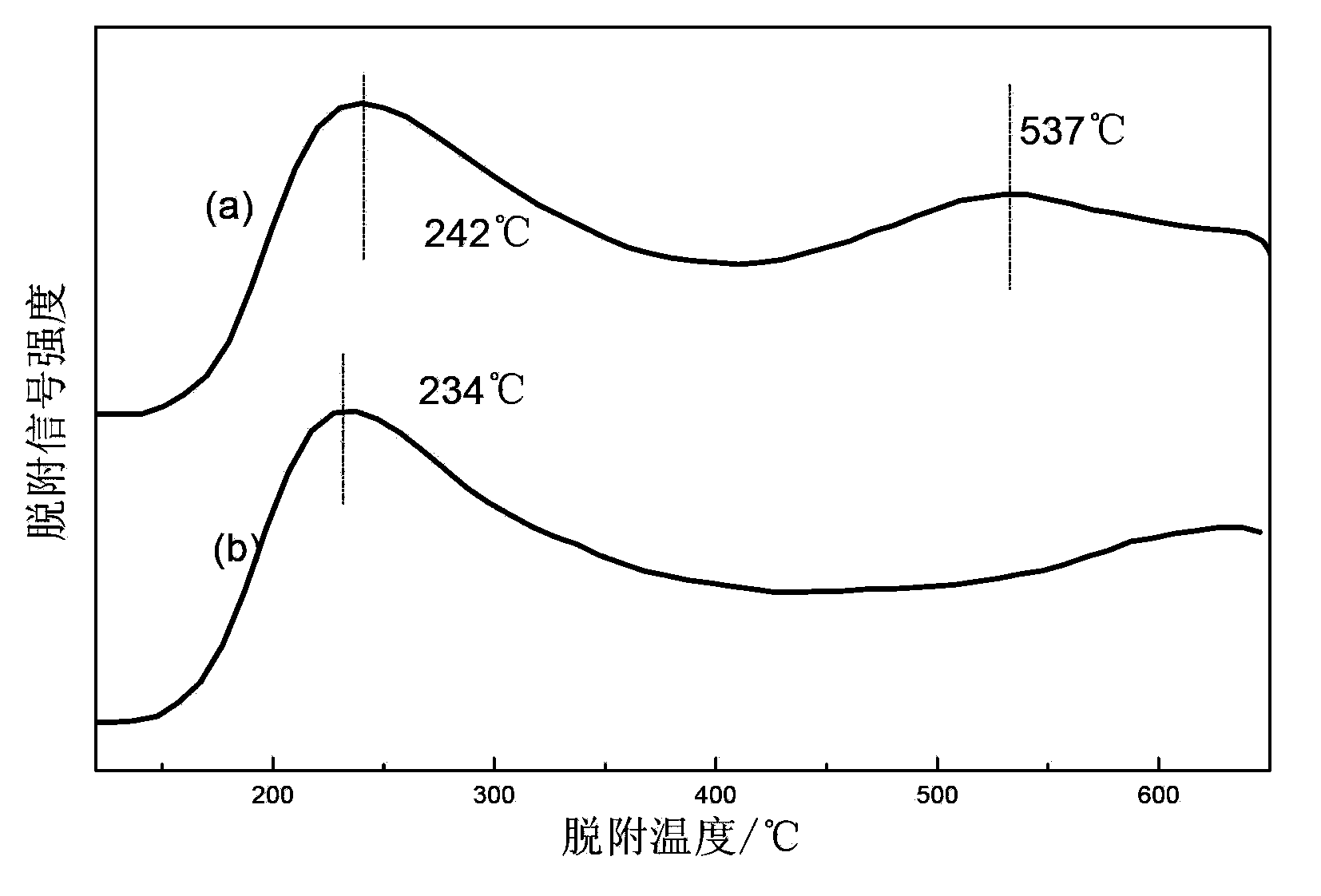

Method for preparing ternary complex carrier supported nickel phosphide catalyst

InactiveCN102773112AThe carrier has a large specific surface areaImprove thermal stabilityPhysical/chemical process catalystsRefining to eliminate hetero atomsHydrodesulfurizationActive phase

The invention discloses a method for preparing ternary complex carrier supported nickel phosphide catalyst, comprising the following steps: preparing a SiO2-TiO2-Al2O3 composite support from raw materials including a silicon-containing compound such as the ethyl orthosilicate, activated alumina particles and butyl titanate by adopting the improved sol-gel process, impregnating, drying and calcinating at high temperature to obtain the precursor of the catalyst by using nickel nitrate and diammonium phosphate, and finally carrying out the temperature-programmed reduction to obtain the catalyst. Due to the introduction of the SiO2, the degree of crystallinity of the active phase of nickel phosphide is improved, the acidity of the catalyst is decreased, the adsorption of the nitrogen-containing compound in the oil on the surface of the catalyst is reduced, the problem on the deactivation of the catalyst due to coking and carbon depositing is avoided, and the catalyst has excellent oil hydrodesulfurization and hydrodenitrification performance.

Owner:XI AN JIAOTONG UNIV

Planting method of selenium-enriched and zinc-enriched rice

ActiveCN110463544AIncrease contentBarrier entryAgriculture tools and machinesOrganic fertilisersWater bathsSoil conditioner

The invention provides a planting method of selenium-enriched and zinc-enriched rice. The method includes the following specific steps: (1) soaking seeds in water, then taking the seeds out and drip-dried the seeds, steaming the seeds in a water bath, and planting the steamd wet seeds to produce rice seedlings; (2) before transplanting, applying a soil conditioner rich in selenium and zinc to thesoil to be used for transplanting; (3) transplanting the rice seedlings to the soil applied with the soil conditioner rich in selenium and zinc when the rice seedlings reach 20-40 cm; (4) when the transplanted rice seedlings reach a stage between tillering and jointing, applying a selenium-enriched foliar fertilizer; (5) irrigating rice after applying the selenium fertilizer and maintaining the soil being wet. The method provided by the invention increases the content of selenium and zinc in the soil, and prevents heavy metal ions from entering the rice, thus increasing the content of seleniumand zinc in the rice. And the using cost is low, the operation is simple, and the cultivating method can be extensively used.

Owner:IRONMAN ENVIRONMENTAL TECH CO LTD

Preparation method for hydrocracking catalyst

ActiveCN102909060BImprove performanceImprove nitrogen toleranceMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveAir atmosphere

The invention describes a preparation method for a hydrocracking catalyst. The method comprises the following steps of (1) preparing a catalyst carrier containing a molecular sieve and an inorganic refractory oxide; (2) preparing a dipping solution containing a VIB group metallic compound and / or a VIII group metallic compound; (3) dipping the catalyst carrier obtained from the step (1) with the dipping solution prepared by the step (2), and then drying the dipped material; (4) preparing an inorganic phosphorus-containing compound solution, dipping the material obtained from the step (3), and drying the dipped material; (5) performing heat treatment on the material obtained from the step (4) in an air atmosphere; and (6) performing hydrogen activation on the material obtained from the step (5), and obtaining the hydrocracking catalyst used for hydrocracking reactions after the activation. The hydrocracking catalyst prepared by the method has outstanding usage performance, and is particularly suitable for a hydrocracking process of increasing middle distillates.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of metal phosphide type hydrocracking catalyst

ActiveCN102909054BHigh activityImprove nitrogen toleranceMolecular sieve catalystsHydrocarbon oil crackingMolecular sievePtru catalyst

The invention describes a method for preparing a metal phosphide type hydrocracking catalyst. The method of the present invention includes the following processes: (1) preparing a catalyst carrier containing molecular sieves and inorganic refractory oxides; (2) preparing an impregnating solution containing a metal compound of Group VIB and a metal compound of Group VIII; (3) preparing in step (2) Add elemental phosphorus to the impregnating solution, perform ultrasonic dispersion, then impregnate the catalyst carrier in step (1), and then dry; (4) The material obtained in step (3) is activated with hydrogen, and after activation, hydrogenation for hydrocracking reaction is obtained. cracking catalyst. The hydrocracking catalyst prepared by the method of the invention has more outstanding performance and is especially suitable for the hydrocracking process of prolific middle distillate oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of medium oil type hydrocracking catalyst containing metal nitride

ActiveCN103785440BHigh activityImprove nitrogen toleranceMolecular sieve catalystsHydrocarbon oil crackingMolecular sievePtru catalyst

The invention discloses a method for preparing a medium-oil hydrocracking catalyst containing metal nitrides, comprising the following steps: (1) preparing a catalyst carrier containing molecular sieves and inorganic refractory oxides; (2) preparing a hydrazine derivative solution, and impregnating the catalyst carrier in step (1), and then drying; (3) preparing an impregnating solution containing a metal compound of Group VIB and a metal compound of Group VIII; (4) impregnating the material obtained in step (2) with the impregnating solution prepared in step (3), Then dry; (5) The material obtained in step (4) is activated with hydrogen, and after activation, a hydrocracking catalyst for hydrocracking reaction is obtained. The hydrocracking catalyst of the present invention is used for processing heavy hydrocarbon materials and producing middle distillates in a maximum amount.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of hydrocracking catalyst and its preparation method and application

ActiveCN103785443BHigh activityImprove nitrogen toleranceMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNitrogen

The invention discloses a hydrocracking catalyst. In terms of the weight of a catalyst carrier, the content of a molecular sieve is normally 2 to 45%, preferably, 4 to 15%; in terms of the weight of the catalyst, the content of a group VI-B metal component (in terms of the oxide of W and / or Mo) is normally 10 to 40%, preferably, 15 to 35%, most preferably, 18 to 28%, the content of a group VIII metal component (in terms of the oxide of Ni and / or Co) is normally 1 to 10%, preferably, 2 to 9%, most preferably, 4 to 8%, and the content of elemental nitrogen is 1 to 1.5%, preferably, 1.2 to 1.4%. The hydrocracking catalyst provided by the invention is used for treating heavy hydrocarbon materials and can realize maximum production of intermediate distillate oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of middle distillate-type hydrocracking catalyst

ActiveCN103785445BHigh activityImprove nitrogen toleranceMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveAir atmosphere

The present invention discloses a preparation method of a middle distillate-type hydrocracking catalyst. The method of the present invention includes the following steps: (1) preparing a catalyst carrier containing a molecular sieve and an inorganic refractory oxide; (2) preparing a solution containing a hydrazine derivative, dipping the catalyst carrier obtained in the step (1), and then drying the carrier; (3) preparing a dipping solution containing a VIB group metal compound and a VIII group metal compound; (4) dipping the materials obtained in the step (2) in the dipping solution prepared in the step (3), and then drying; (5) performing a heat treatment at 200-450 DEG C in the air atmosphere to the materials obtained in the step (4) for 1-6 h; and (6) activating the materials obtained in the step (5) after the heat treatment by using hydrogen, so as to obtain the hydrocracking catalyst used for the hydrocracking reaction after the activation. The hydrocracking catalyst provided by the invention is used for the treatment of heavy hydrocarbon materials, does not require prevulcanization, has low inactivation rate, and can facilitate the highest-yield production of middle distillates.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of planting method of selenium-rich and zinc-rich rice

ActiveCN110463544BIncrease contentBarrier entryAgriculture tools and machinesOrganic fertilisersBiotechnologySoil conditioner

The present disclosure provides a method for planting selenium-rich and zinc-rich rice. The specific steps of the method are: (1) first soak the seeds in water, then remove and drain, and fumigate in a water bath, and then fumigate the seeds Seeds are sown in moisture to grow rice seedlings; (2) before transplanting, apply a zinc-rich and selenium-rich soil conditioner to the transplanted soil; (3) when the rice seedlings grow to 20-40cm, transplant the rice seedlings (4) Then, between the rice seedling growth after transplanting and the tillering stage to the jointing stage, apply selenium-enriched foliar fertilizer; (5) apply selenium-enriched fertilizer Afterwards, the rice is irrigated to keep the soil moist. The method increases the content of selenium and zinc in the soil, can block heavy metal ions from entering rice, enhances the content of selenium and zinc in rice, has low use cost, simple operation and can be widely used.

Owner:IRONMAN ENVIRONMENTAL TECH CO LTD

A kind of metal nitride type hydrocracking catalyst and its preparation method and application

ActiveCN103785442BHigh activityImprove nitrogen toleranceMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNitride

The invention discloses a metal nitride hydrocracking catalyst. In terms of the weight of a catalyst carrier, the content of a molecular sieve is normally 2 to 45%, preferably, 4 to 15%; in terms of the weight of the catalyst, the content of a group VI-B metal component (in terms of the nitride of W and / or Mo) is normally 10 to 40%, preferably, 15 to 35%, most preferably, 18 to 28%, and the content of a group VIII metal component (in terms of the nitride of Ni and / or Co) is normally 1 to 10%, preferably, 2 to 9%, most preferably, 4 to 8%. The hydrocracking catalyst provided by the invention is used for treating heavy hydrocarbon materials and can realize maximum production of intermediate distillate oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing ternary complex carrier supported nickel phosphide catalyst

InactiveCN102773112BThe carrier has a large specific surface areaImprove thermal stabilityPhysical/chemical process catalystsRefining to eliminate hetero atomsHydrodesulfurizationActive phase

The invention discloses a method for preparing ternary complex carrier supported nickel phosphide catalyst, comprising the following steps: preparing a SiO2-TiO2-Al2O3 composite support from raw materials including a silicon-containing compound such as the ethyl orthosilicate, activated alumina particles and butyl titanate by adopting the improved sol-gel process, impregnating, drying and calcinating at high temperature to obtain the precursor of the catalyst by using nickel nitrate and diammonium phosphate, and finally carrying out the temperature-programmed reduction to obtain the catalyst. Due to the introduction of the SiO2, the degree of crystallinity of the active phase of nickel phosphide is improved, the acidity of the catalyst is decreased, the adsorption of the nitrogen-containing compound in the oil on the surface of the catalyst is reduced, the problem on the deactivation of the catalyst due to coking and carbon depositing is avoided, and the catalyst has excellent oil hydrodesulfurization and hydrodenitrification performance.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com