Process for producing high-performance catalyst for hydrocracking

A hydrocracking and catalyst technology, applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of low acid center strength, short operation period, poor selectivity of medium oil, etc., and achieve crystallinity without falling , Improve nitrogen resistance and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Prepare modified Y molecular sieve A.

[0035] (1) Add 160kg industrial NH to the exchange tank 4 NO 3 (product of Liaoyang Petrochemical Company, purity > 99.5%) and 910kg deionized water, then add 100kg NaY molecular sieve (product of Wenzhou Catalyst Factory, crystallinity is 100%, unit cell constant is 2.470nm, SiO 2 / Al 2 o 3 Molar ratio is 5.1, Na 2 O content is 12.0wt%), the temperature is raised to 90 ° C, exchanged for 1.0 hour under agitation, filtered, repeated exchange 2 times, the filter cake is washed to neutral, dried to obtain Na 2 NH with an O content of 2.2 wt% 4 NaY molecular sieve.

[0036] (2) Take NH 4 1.0kg of NaY molecular sieves were placed in a heat treatment furnace, the temperature was raised to 600°C in 1.5 hours, and treated at 600°C, 0.15MPa steam pressure for 2.0 hours, and the samples were taken out after cooling down.

[0037] (3) Take 500 g of the molecular sieve sample after the first heat treatment and contact with 5.0 L o...

Embodiment 2

[0051] 1. Preparation of hydrocracking catalyst E.

[0052] Composed by catalyst weight: WO 3 22.0%, NiO 9.0%, molecular sieve content 20%, amorphous silicon aluminum content balance to prepare the catalyst.

[0053] Amorphous silica-alumina (silica weight content is 45%, pore volume 1.2ml / g, specific surface area 500m 2 / g, the pore volume of hole between 4-15nm accounts for 85% of total pore volume) add water and make slurry, slurry is adjusted pH value to 5.0 with nitric acid solution, adds modified Y molecular sieve A, stirs and mixes fully, It was dried and dehydrated at 90°C for 3 hours, then extruded, dried at 150°C for 2 hours, and calcined at 550°C for 3 hours to obtain a catalyst carrier. The catalyst carrier was impregnated with an equal volume of a mixed solution of ammonium metatungstate and nickel nitrate, dried at 120°C for 4 hours, and calcined at 450°C for 2 hours to obtain the final catalyst E.

[0054] 2. Preparation of hydrocracking catalyst F.

[0055]...

Embodiment 3

[0066] The evaluation of each catalyst is obtained in Example 2, and the evaluation of the catalyst adopts a single-stage one-pass hydrocracking process (the raw material is not subjected to hydrorefining, and the unconverted tail oil is not recycled).

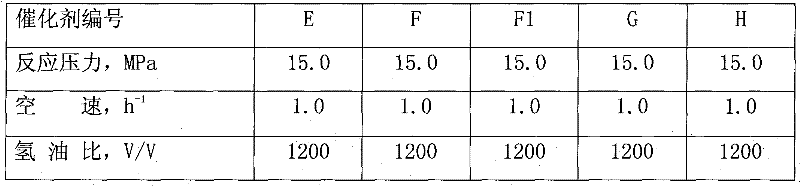

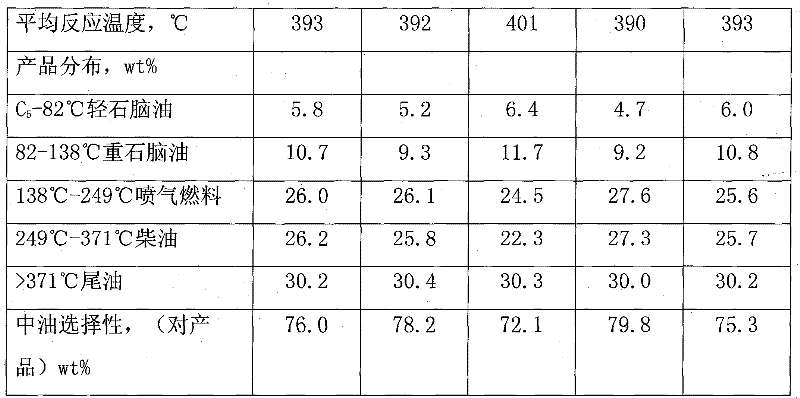

[0067] 1. Iranian VGO is used for evaluation as heavy distillate oil, and its main properties are as follows: Density 0.9046g / cm 3 , distillation range 342-520°C, sulfur 1.23wt%, nitrogen 0.12wt%, carbon residue 0.01wt%, freezing point 32°C, BMCI value 44.3. See Table 2 for the evaluation results.

[0068] Table 2. Catalyst evaluation results

[0069]

[0070]

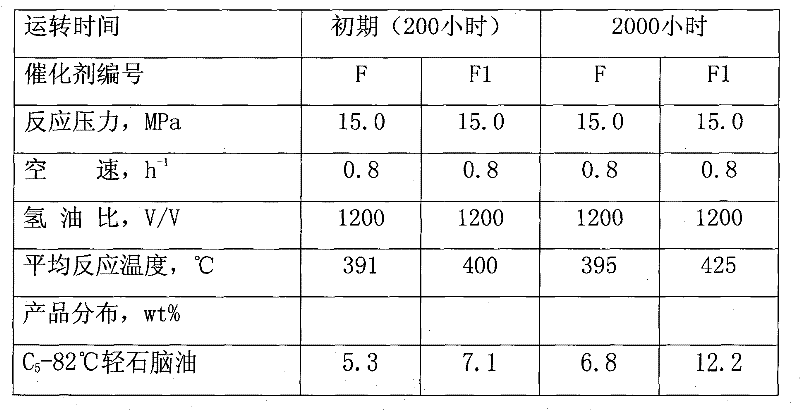

[0071] It can be seen from Table 2 that the catalyst of the present invention can all achieve the effect of the present invention under the hydrocracking process conditions of the present invention. The comparative catalysts require a higher reaction temperature to achieve the same conversion rate, indicating that their nitrogen tolerance is relatively poor, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com