A method for catalytic diesel hydrodearomatization

A technology of hydrodearomatization and catalytic diesel, which is applied in the direction of hydrogenation and refining of aromatics, and can solve the problem of high initial boiling point of diesel raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

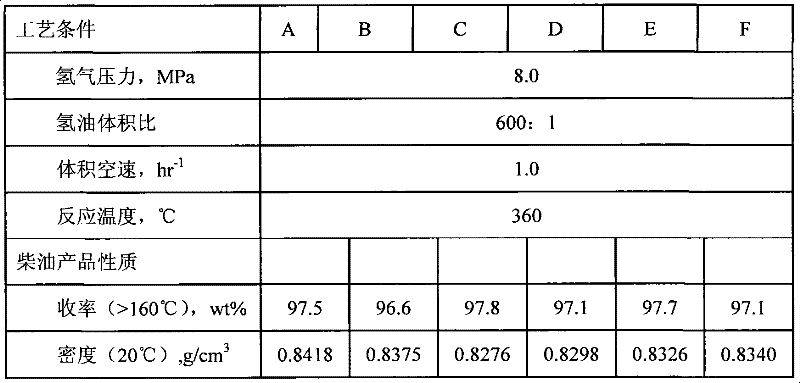

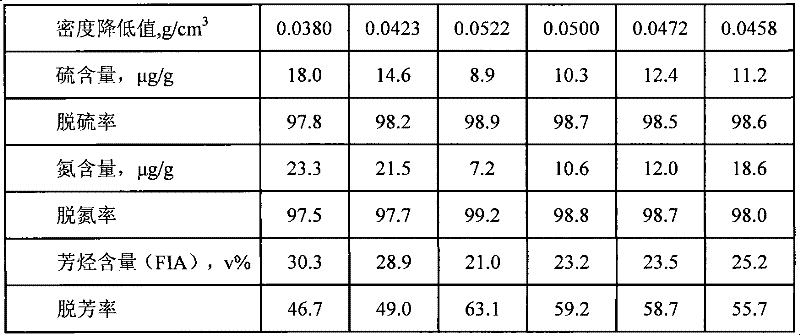

Examples

Embodiment 1

[0025] With 39g modified Y molecular sieve, with 119.5g alumina (Jiangyan Chemical Auxiliary Factory, dry basis 72wt%), 41g amorphous silicon aluminum (SiO 2 The content is 45wt%, the pore volume of amorphous silicon aluminum is 0.51ml / g, and the specific surface area is 360m 2 / g), 5.9g scallop powder, after mixing, add dropwise the mixed solution of 8.0g concentrated nitric acid (96wt%), 5.4g citric acid and 135g water, extrude into 1.3mm cylindrical shape, dry at 100°C, and dry at 520°C Air atmosphere roasting 4hr. Then impregnate with 22g of nickel nitrate and 35g of ammonium metatungstate dissolved in 50ml of water for 4hr, dry at 100°C, and calcine at 470°C for 5hr in an air atmosphere to obtain catalyst A. According to specific requirements, it can be crushed or cut into the required particle size or length, and hydrogenation reaction can be carried out after vulcanization.

Embodiment 2

[0027] Beta molecular sieve after 39g modification, and 119.5g aluminum oxide (Jiangyan Chemical Auxiliary Factory, dry basis 72wt%), 41g amorphous silicon aluminum (SiO 2 The content is 45wt%, the pore volume of amorphous silicon aluminum is 0.51ml / g, and the specific surface area is 360m 2 / g), 5.9g scallop powder, after mixing, add dropwise the mixed solution of 8.0g concentrated nitric acid (96wt%), 5.4g citric acid and 135g water, extrude into a 1.3mm cylindrical shape, dry at 100°C, and then Baking in air atmosphere at 520°C for 4hr. Then impregnate with a solution of 22g nickel nitrate and 35g ammonium metatungstate dissolved in 50ml water for 4hr, dry at 100°C, and roast in air atmosphere at 470°C for 5hr to obtain catalyst B. According to specific requirements, it can be crushed or cut into the required particle size or length, and hydrogenation reaction can be carried out after vulcanization.

Embodiment 3

[0029] With 39g modified Y / Beta (mass ratio 3: 1) microporous molecular sieve, and 119.5g alumina (Jiangyan Chemical Auxiliary Factory, dry basis 72wt%), 41g amorphous silicon aluminum (SiO 2 The content is 45wt%, the pore volume of amorphous silicon aluminum is 0.51ml / g, and the specific surface area is 360m 2 / g), 5.9g scallop powder, after mixing, add dropwise the mixed solution of 8.0g concentrated nitric acid (96wt%), 5.4g citric acid and 135g water, extrude into a 1.3mm cylindrical shape, dry at 100°C, and then Baking in air atmosphere at 520°C for 4hrs. Then impregnate with a solution of 22g nickel nitrate and 35g ammonium metatungstate dissolved in 50ml water for 4hr, dry at 100°C, and roast at 470°C in air atmosphere for 5hr to obtain catalyst C. According to specific requirements, it can be crushed or cut into the required particle size or length, and hydrogenation reaction can be carried out after vulcanization.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com