Patents

Literature

304 results about "Amorphous silica-alumina" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Amorphous silica alumina is a synthetic substance that is used as a catalyst or catalyst support. Water-soluble contaminants, e.g. sodium salts, are removed by washing. Some of the alumina is present in tetrahedral coordination as shown by NMR studies ²⁹Si MASNMR and ²⁷Al NMR Amorphous silica-alumina contains sites which are termed Brønsted acid (or protic) sites, with an ionizable hydrogen atom, and Lewis acid (aprotic), electron accepting sites and these different types of acidic site can be distinguished by the ways in which, say, pyridine attaches. On Lewis acid sites it forms complexes and on the Brønsted sites it adsorbs as the pyridinium ion. Examples of processes that use silica-alumina catalysts are the production of pyridine from crotonaldehyde, formaldehyde, steam, air and ammonia and the cracking of hydrocarbons,

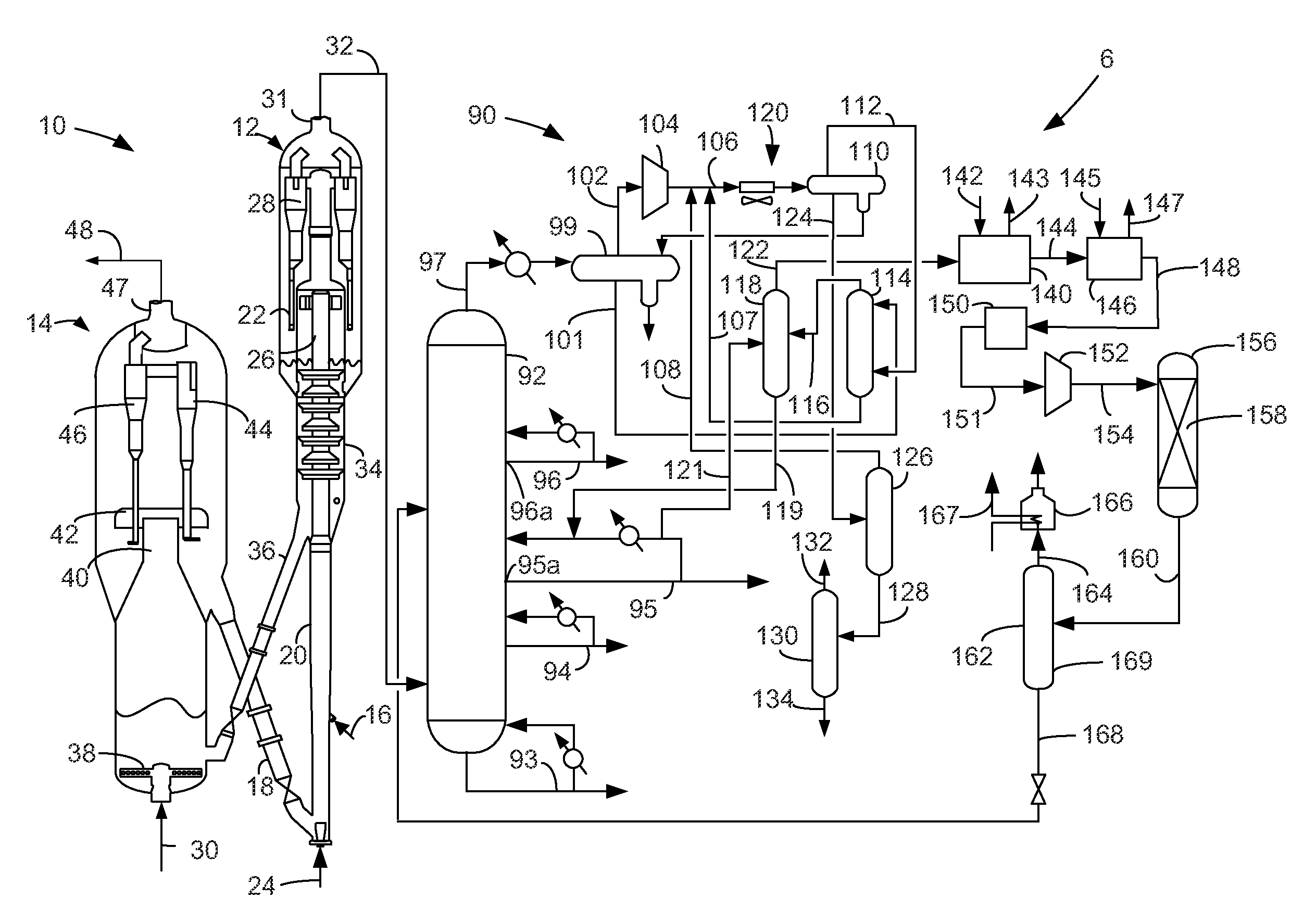

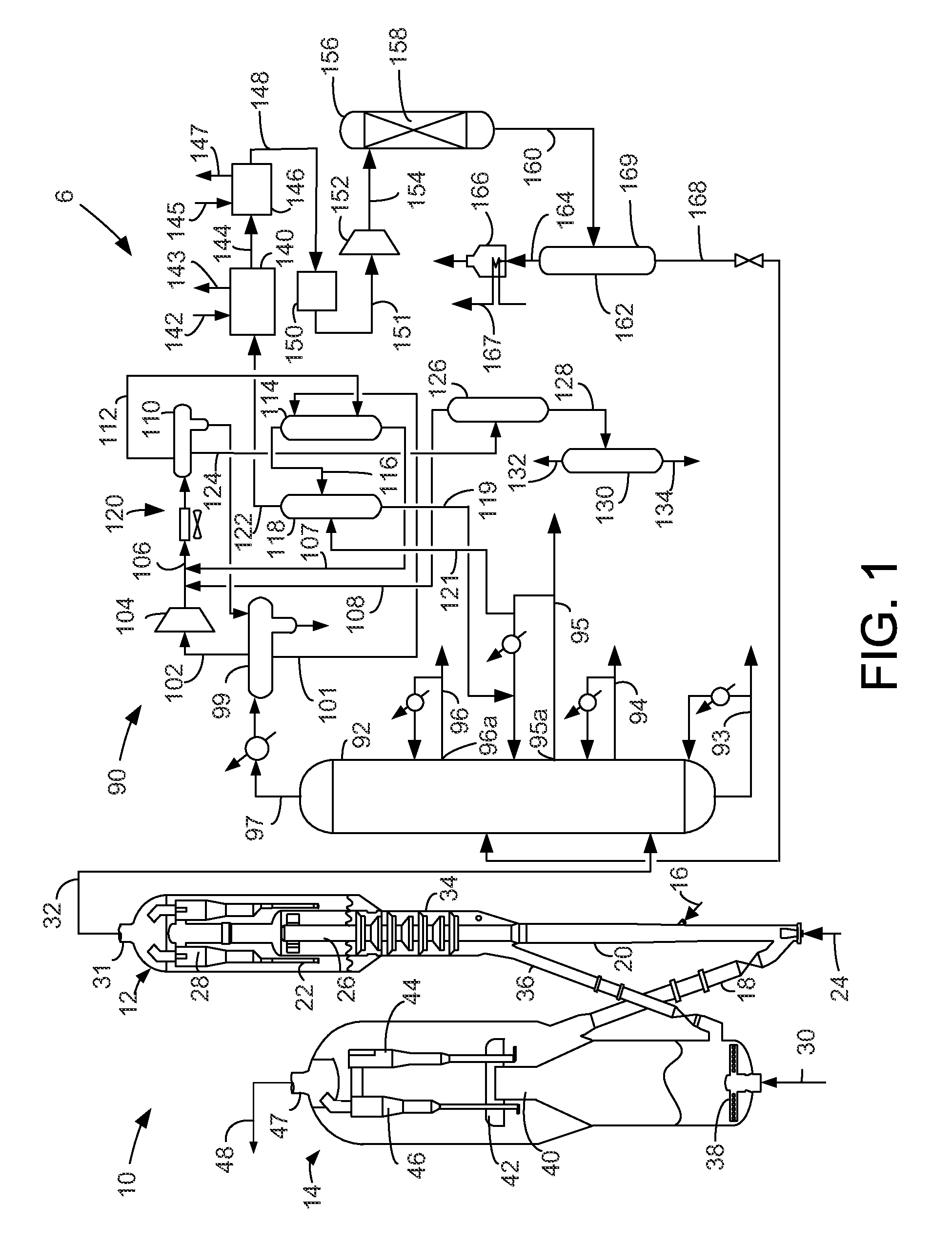

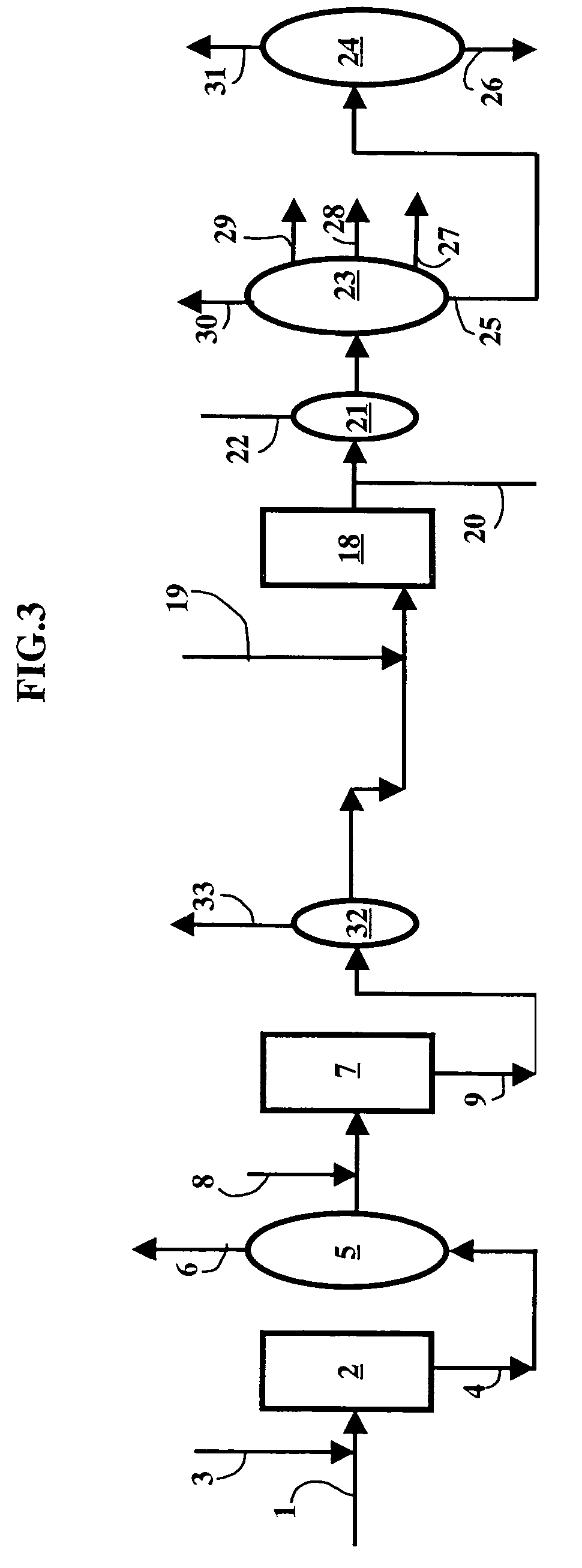

Method and apparatus for making a middle distillate product and lower olefins from a hydrocarbon feedstock

ActiveUS20060178546A1Yield maximizationCatalytic crackingCatalytic naphtha reformingPetroleum productGasoline

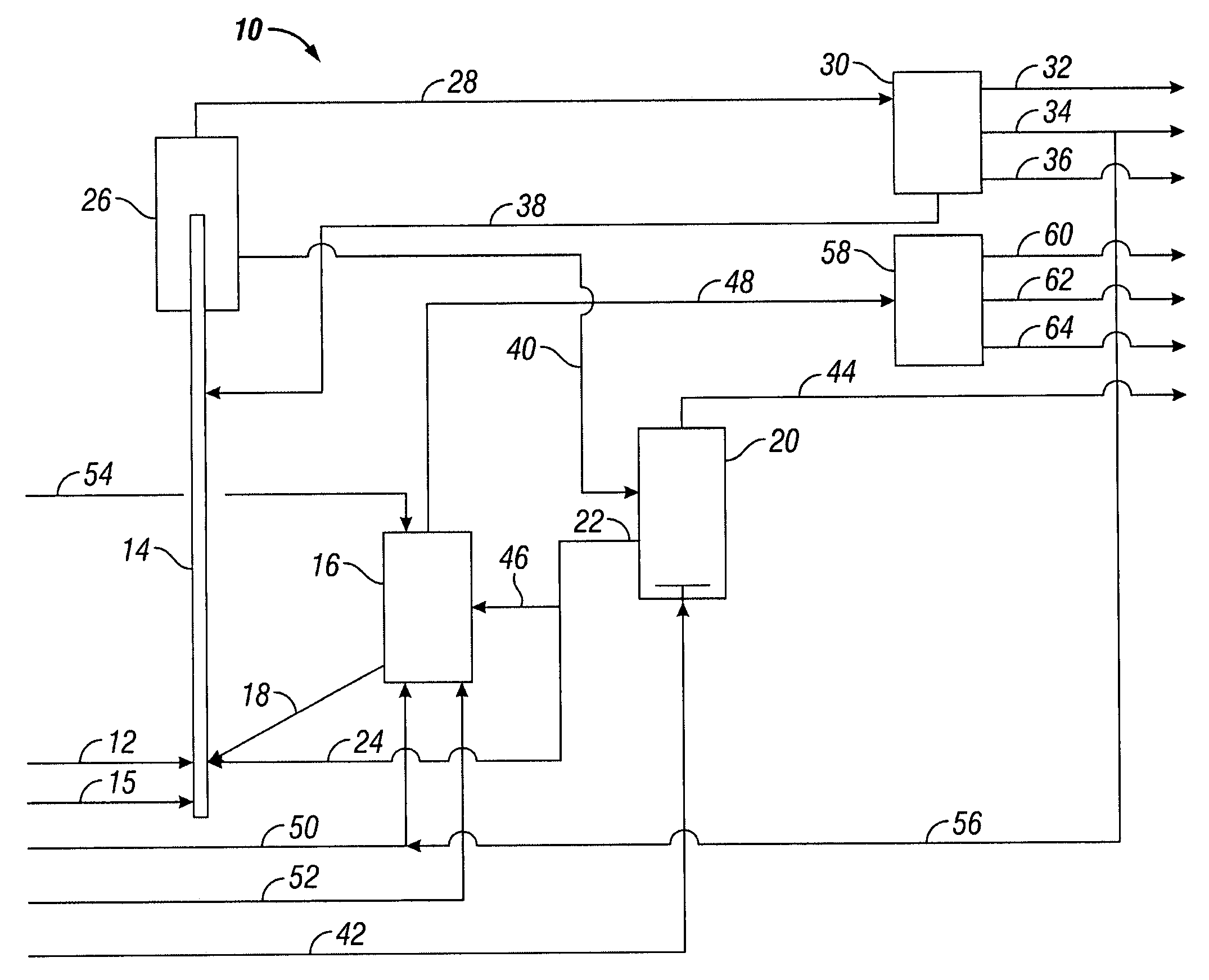

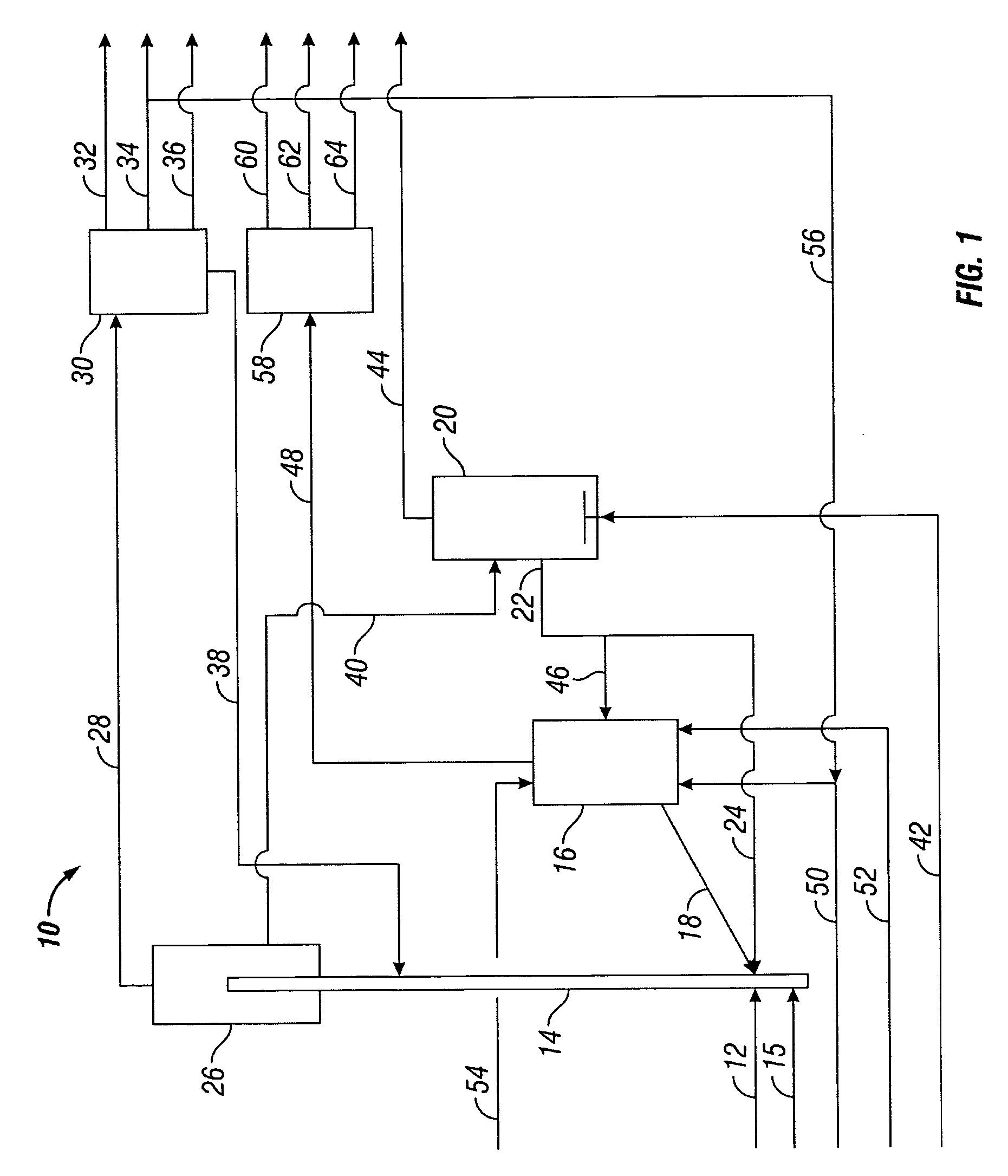

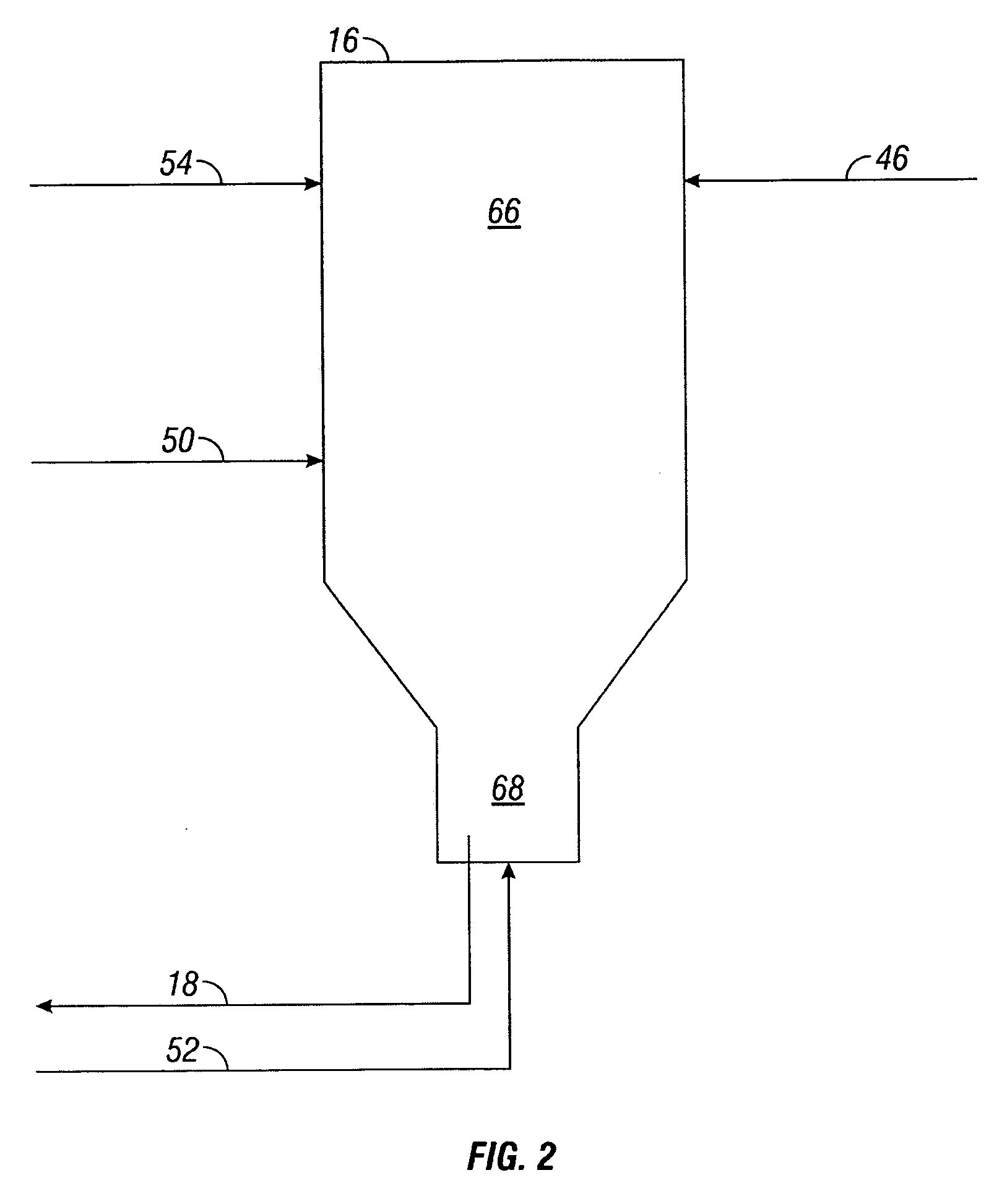

Disclosed is a process for making middle distillate and lower olefins. The process includes catalytically cracking a gas oil feedstock within a riser reactor zone by contacting under suitable catalytic cracking conditions within the riser reactor zone the gas oil feedstock with a middle distillate selective cracking catalyst that comprises amorphous silica alumina and a zeolite to yield a cracked gas oil product and a spent cracking catalyst. The spent cracking catalyst is regenerated to yield a regenerated cracking catalyst. Within an intermediate cracking reactor such as a dense bed reactor zone and under suitable high severity cracking conditions a gasoline feedstock is contacted with the regenerated cracking catalyst to yield a cracked gasoline product and a used regenerated cracking catalyst. The used regenerated cracking catalyst is utilized as the middle distillate selective catalyst.

Owner:SHELL USA INC

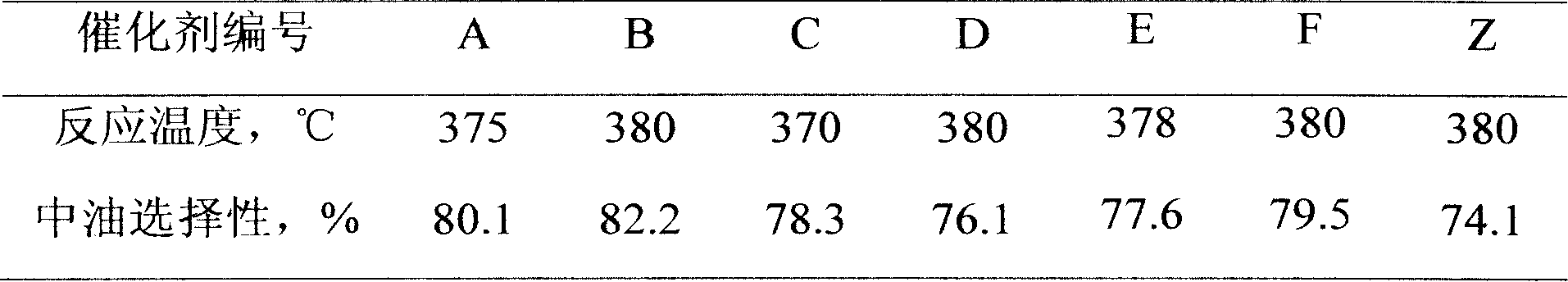

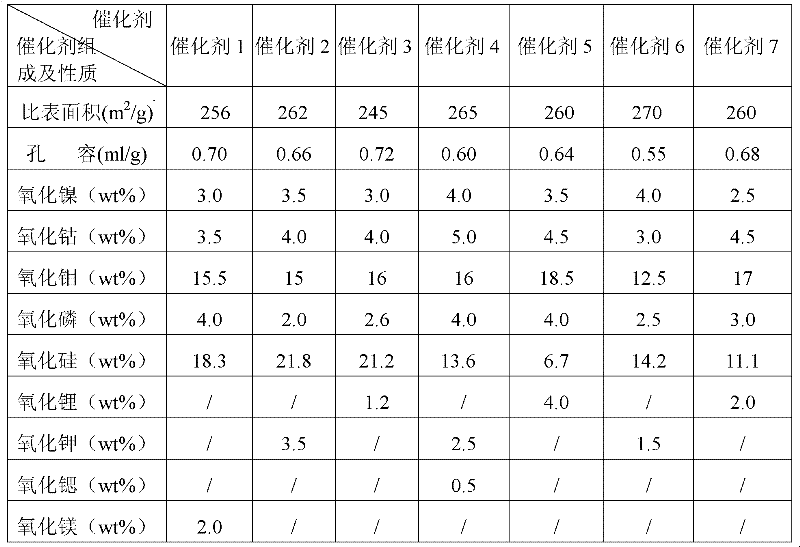

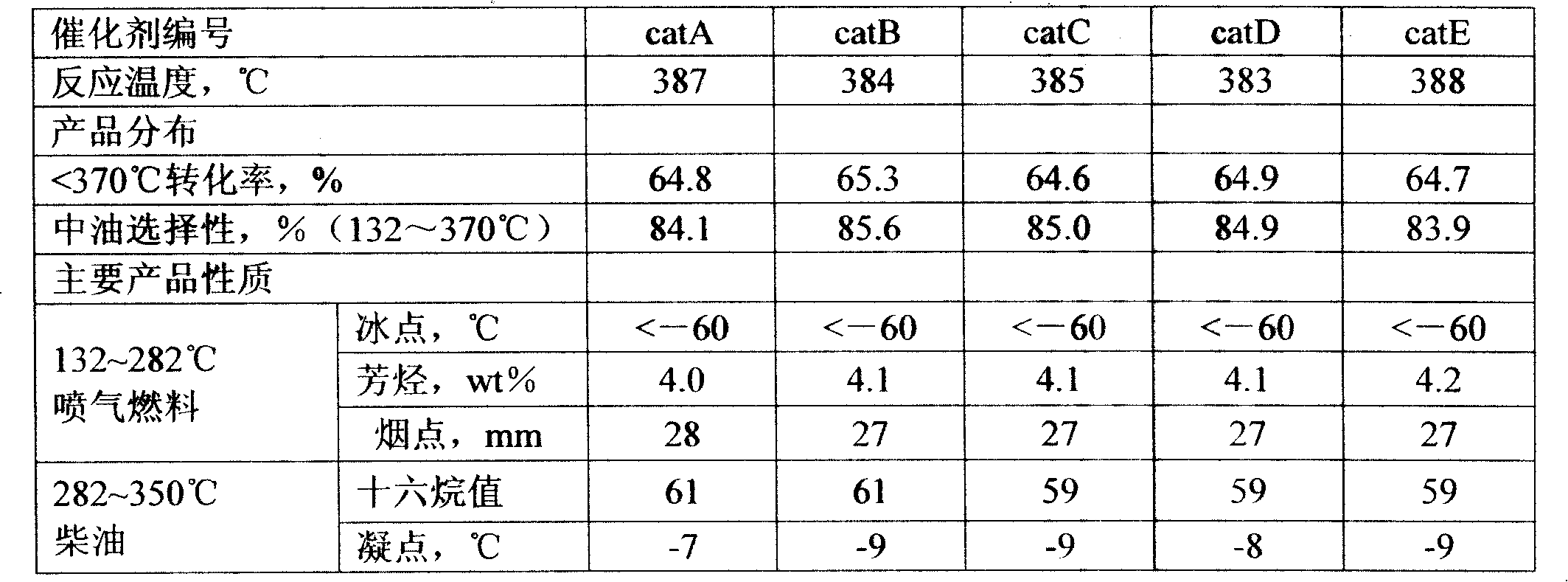

High active high medium oil selective hydrocracking catalyst and preparation thereof

ActiveCN101239324AHigh crystallinityLow cell parametersMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveSingle stage

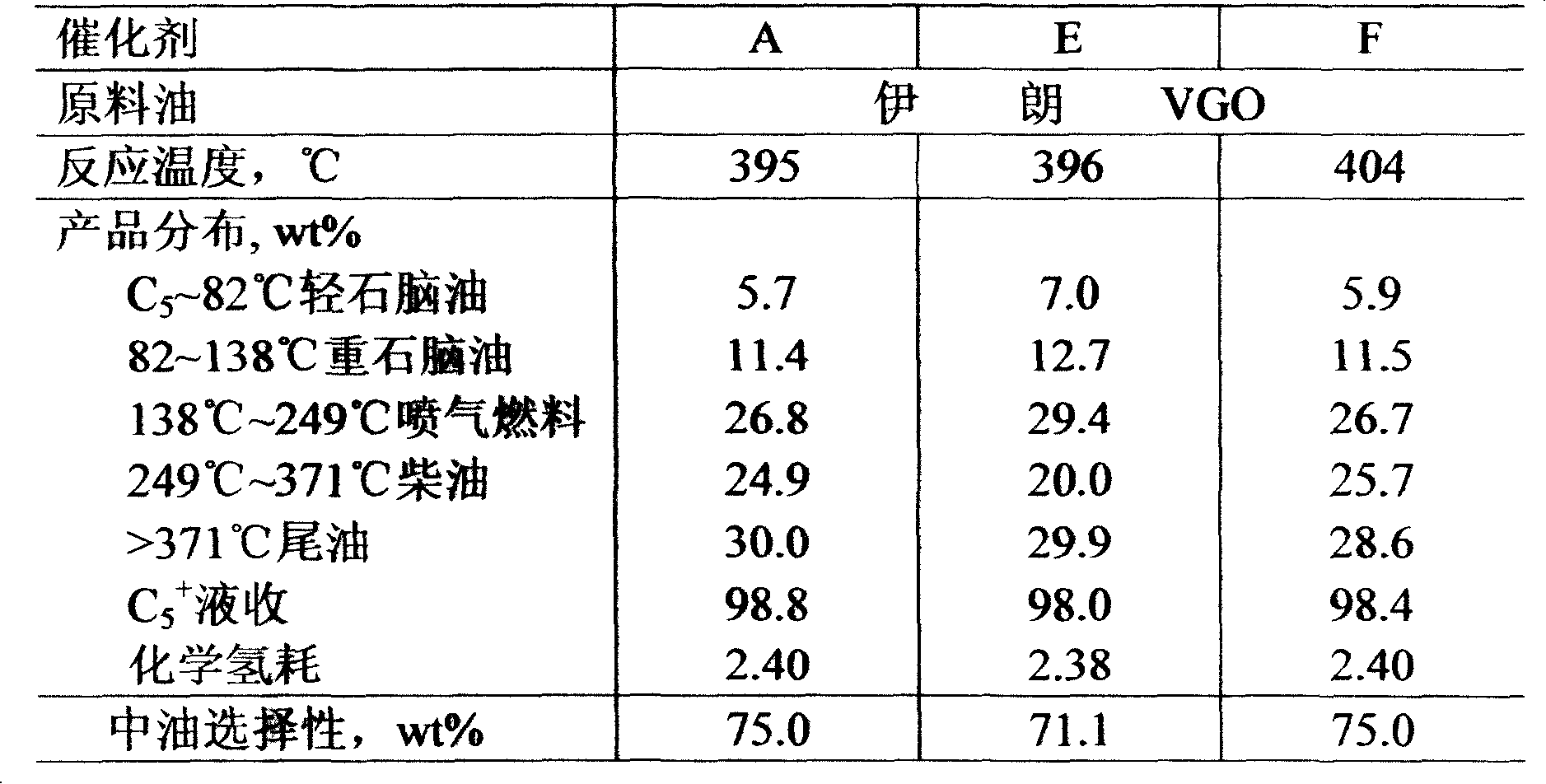

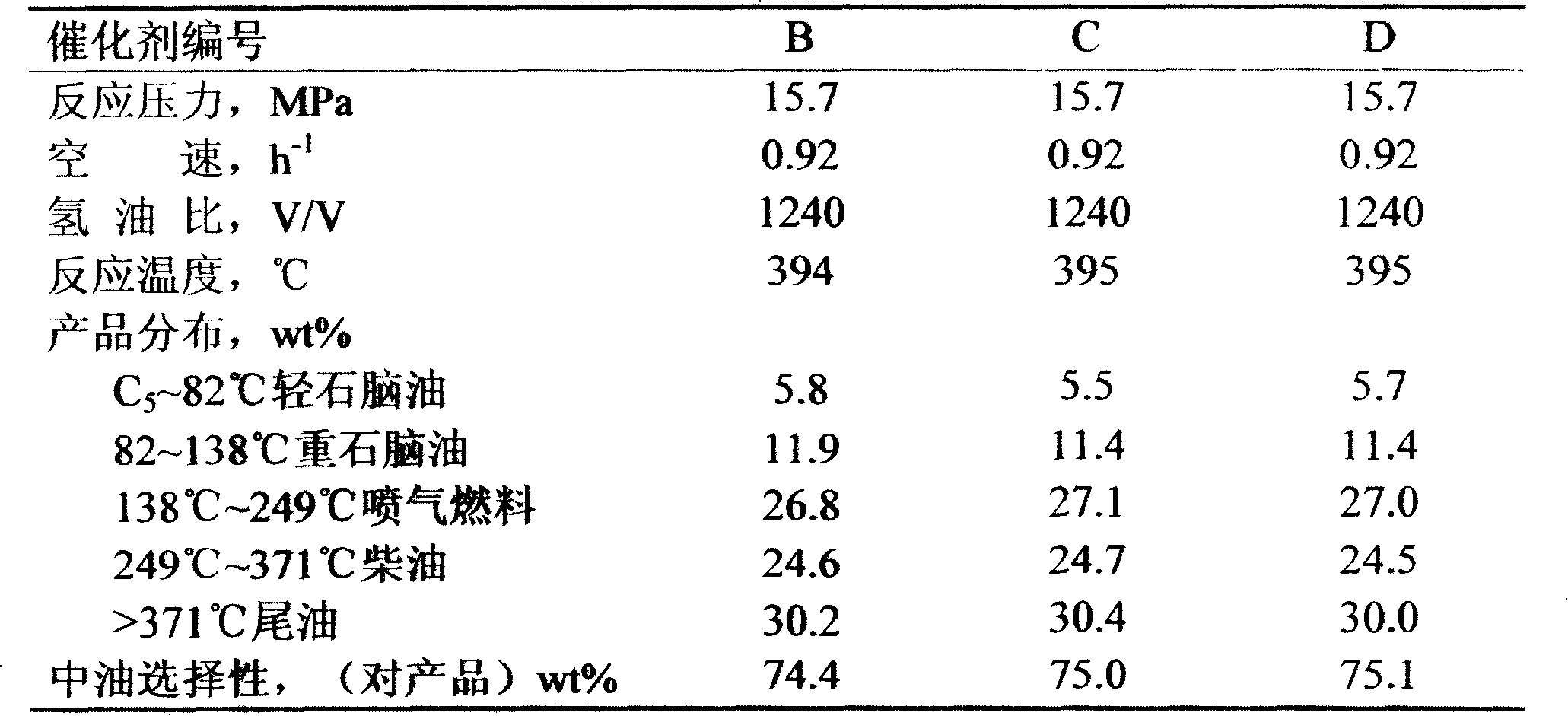

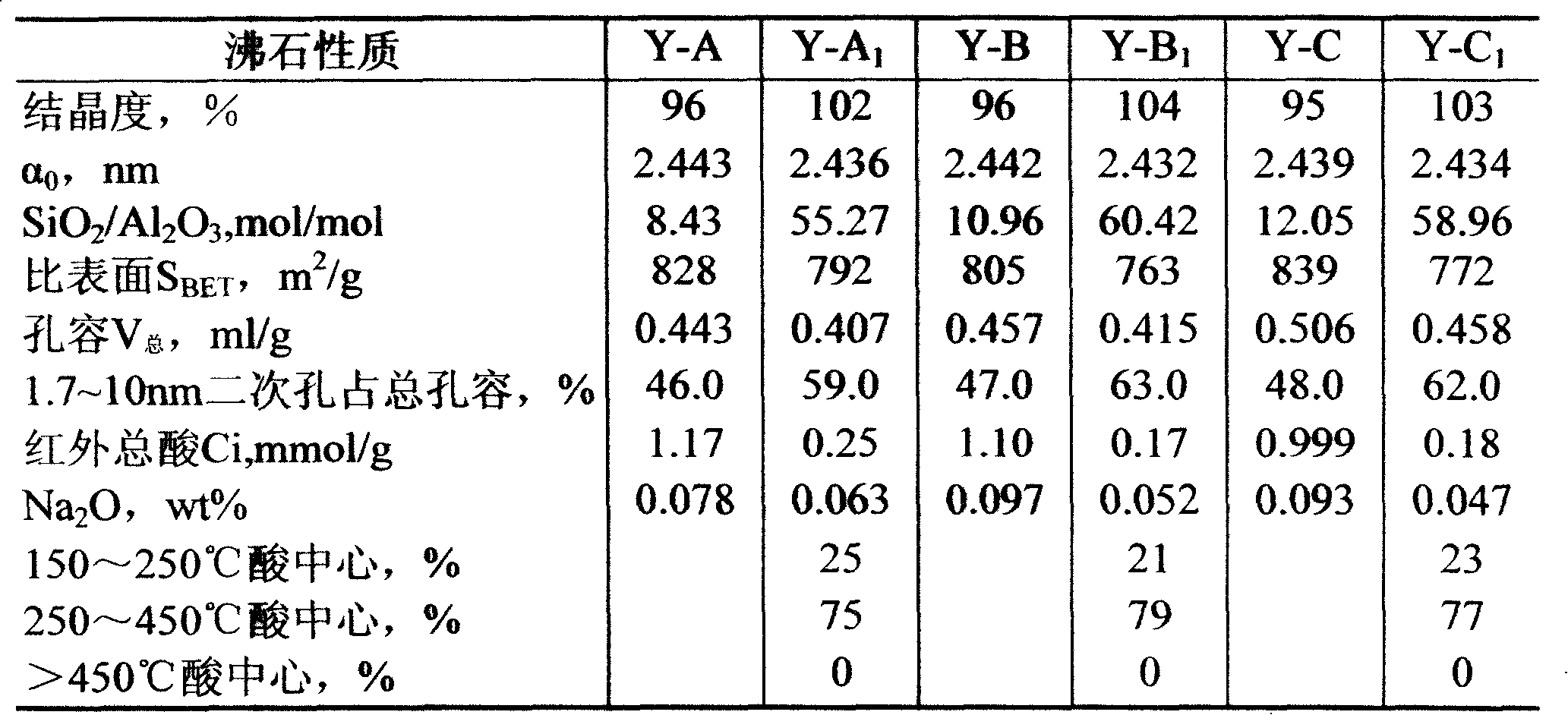

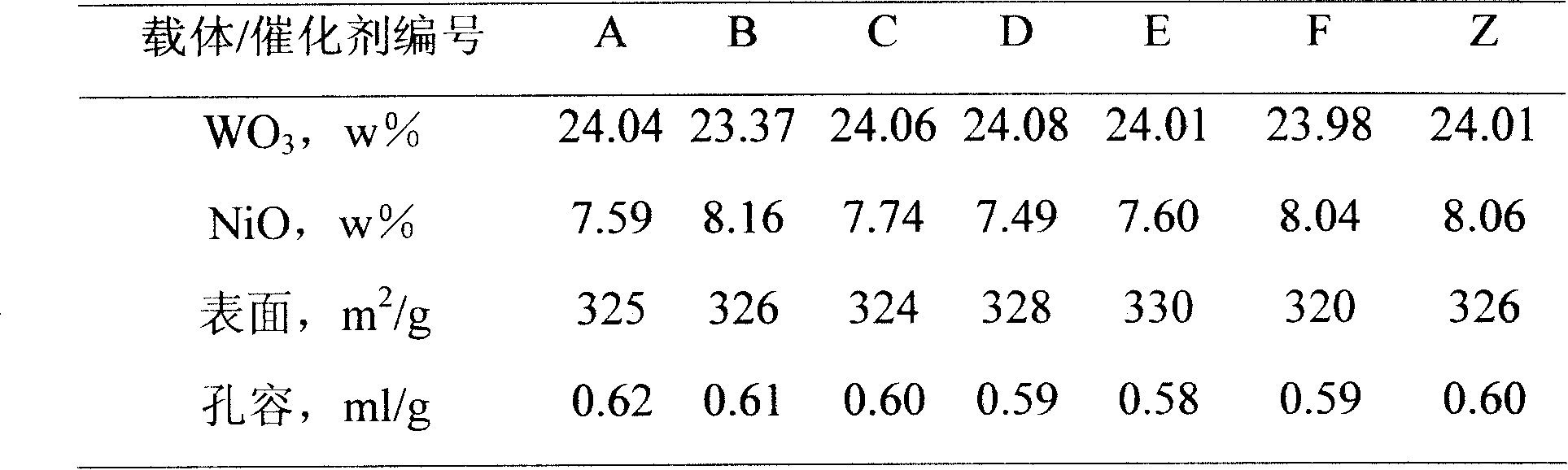

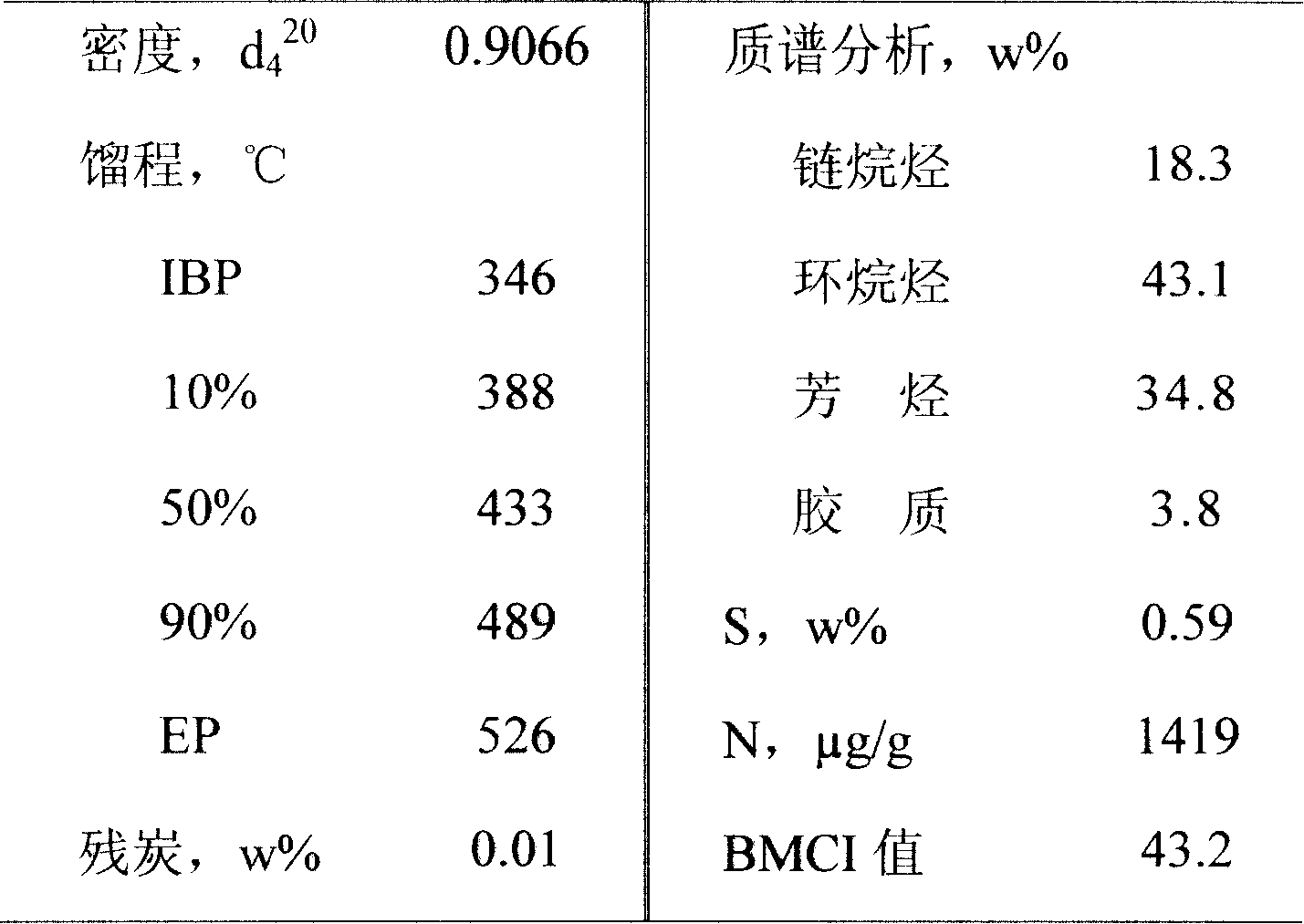

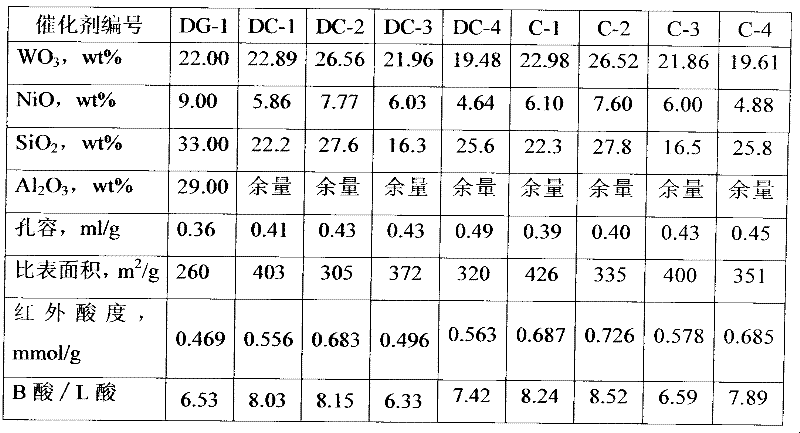

The present invention provides a hydrocracking catalyst having high activity, high medium oil selectivity, catalyst constitute uses amorphous silica-alumina as a carrier, Y type molecular sieve processed by special modification is an acidity component, the molecular sieve has a high crystallinity and a lower cell parameter, a plenty quadric hole, larger surface, in addition, has a small acid center, even distribution, no strong acid center, 70-80% is moderate intensity acid center, 20-30% is weak acid center, and the molecular sieve also has a strong anti-nitrogen ability and better damaging ability, the hydrocracking catalyst using the molecular sieve has a better hydrocracking activity, and a higher medium oil selectivity, and a strong anti-nitrogen ability at the same time. The invention uses heavy hydrocarbon single stage or single stage serial hydrocracking process generate midbarrel oil product, and has better activity and medium oil selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation of hydrogenation catalyst

ActiveCN101172260AEasy to useEvenly dispersedMolecular sieve catalystsCatalyst activation/preparationMolecular sievePolymer science

The invention discloses a preparation method of a hydrogenation catalyst. The final catalyst is prepared by impregnation method or coprecipitation method using a carrier material containing molecular sieve and amorphous silica-alumina. The carrier material is prepared by introducing molecular sieve slurry in the process of forming amorphous silica-alumina gel, which improves the distribution of molecular sieve in the silica-alumina carrier, improves the coordinated catalytic effect of the two carrier materials, and greatly improves the performance of the catalyst. The catalyst prepared by the method of the present invention can be used in various hydrogenation processes.

Owner:CHINA PETROLEUM & CHEM CORP +1

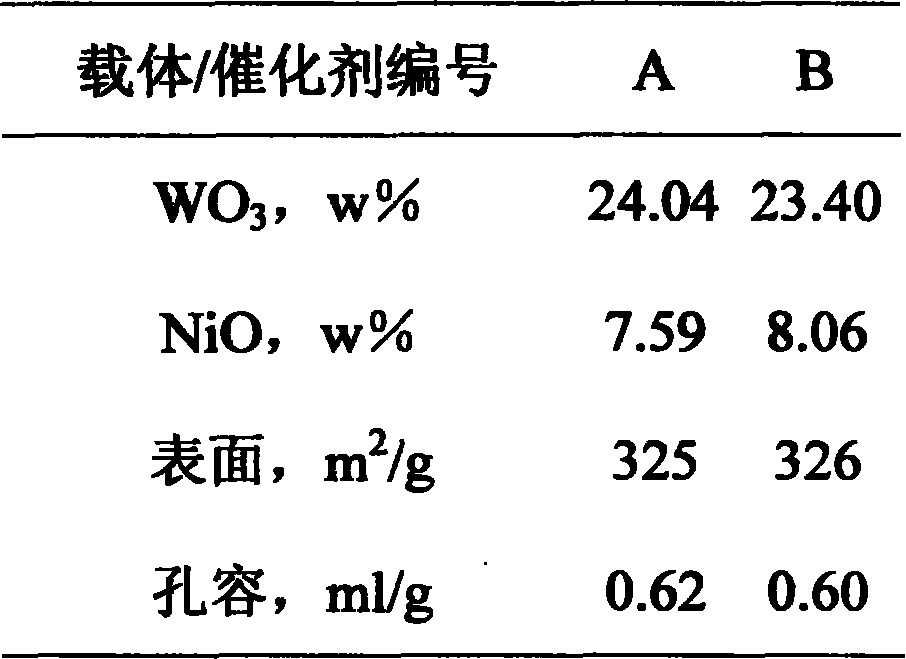

Amorphous silica-alumina, a carrier combination and a hydrocracking catalyst containing the same, and processes for the preparation thereof

InactiveUS6399530B1Increase surface areaLarge hole volumeMolecular sieve catalystsHydrocarbon oil crackingSilicon dioxideHigh activity

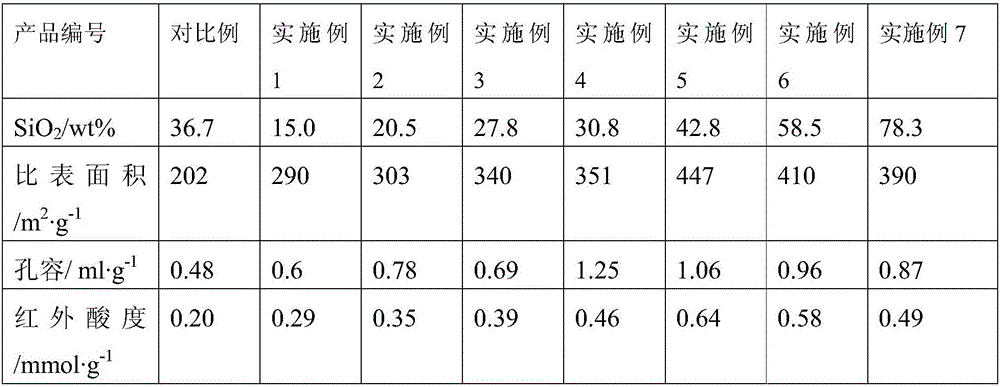

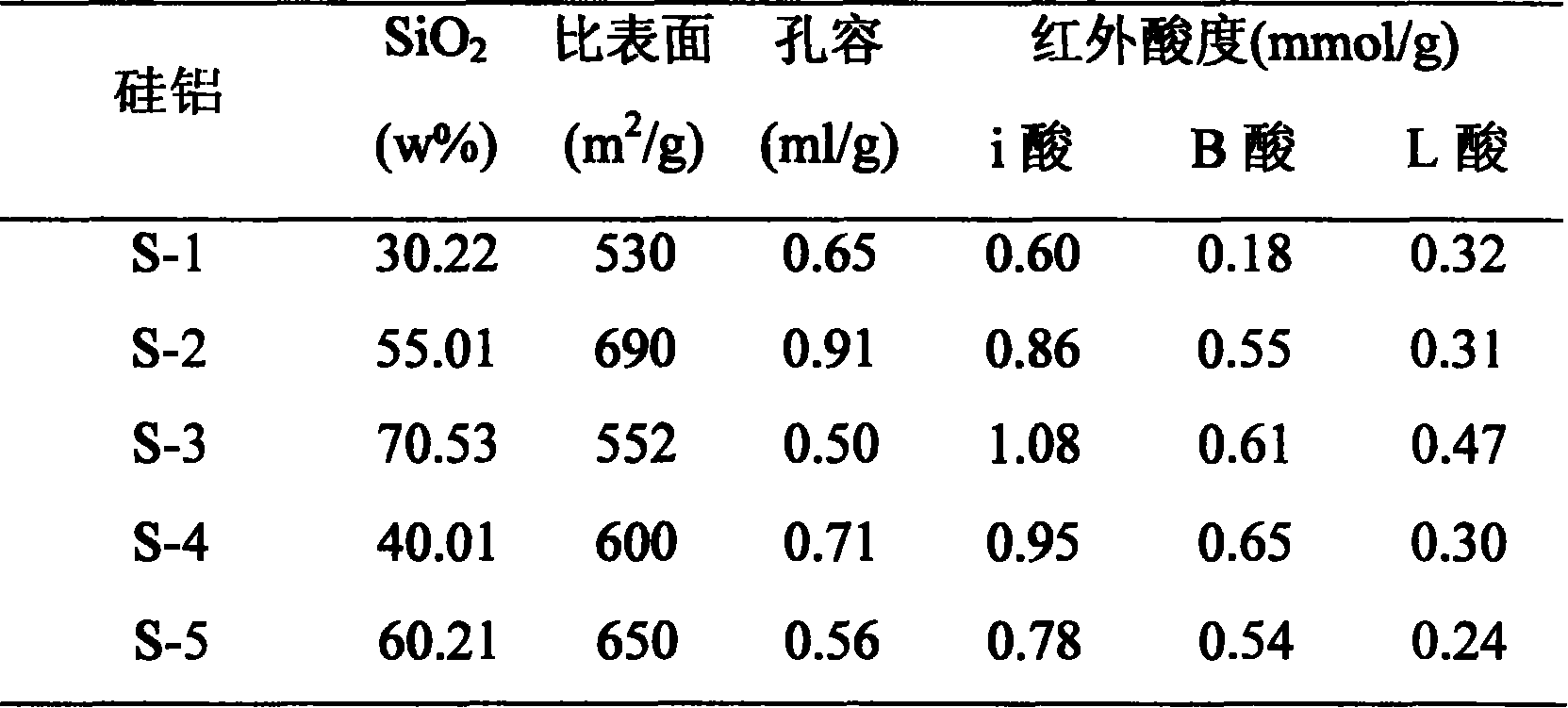

An acidic amorphous silica-amumina has a large specific surface area and a large pore volume. A carrier complex and a hydrotreating catalyst containing acidic amorphous silica-alumina, in particular a hydrocracking catalyst containing acidic amorphous silica-alumina in combination with a modified zeolite-Y, treats petroleum hydrocarbon materials to produce middle distillates. The amorphous silica-alumina has a SiO2 content of 10-50 wt. %, a specific surface area of 300-600 m2 / g, a pore volume of 0.8-1.5 ml / g and an IR acidity of 0.25-0.60 mmol / g. The catalyst shows a relatively high activity and mid-distillate selectivity and can be particularly used in hydrocracking process for producing mid-distillates with a higher yield.

Owner:CHINA PETROCHEMICAL CORP +1

Method of preparing amorphous silica-alumina using carbonization

InactiveCN1597093AEasy to controlSimple processCatalyst activation/preparationReaction temperatureSodium aluminate

A process for preparing the amorphous Si-Al material by the carbonizing method includes such steps as adding part of sodium silicate solution to sodium aluminate solution, introducing CO2 gas to it for a certain time, adding the rest of sodium silicate solution while reacting, stabilizing, filtering, washing and drying. It can be used as the carrier of catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

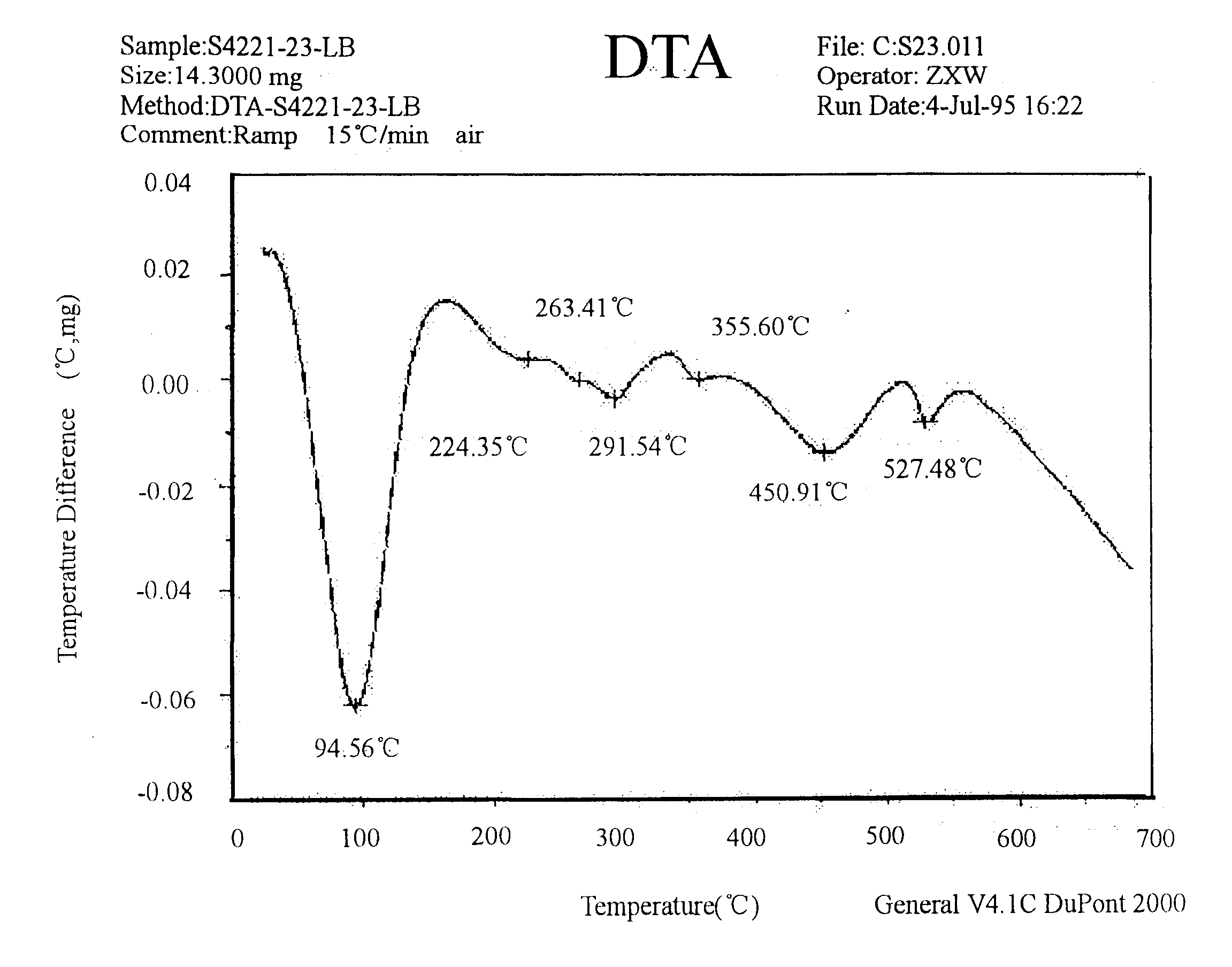

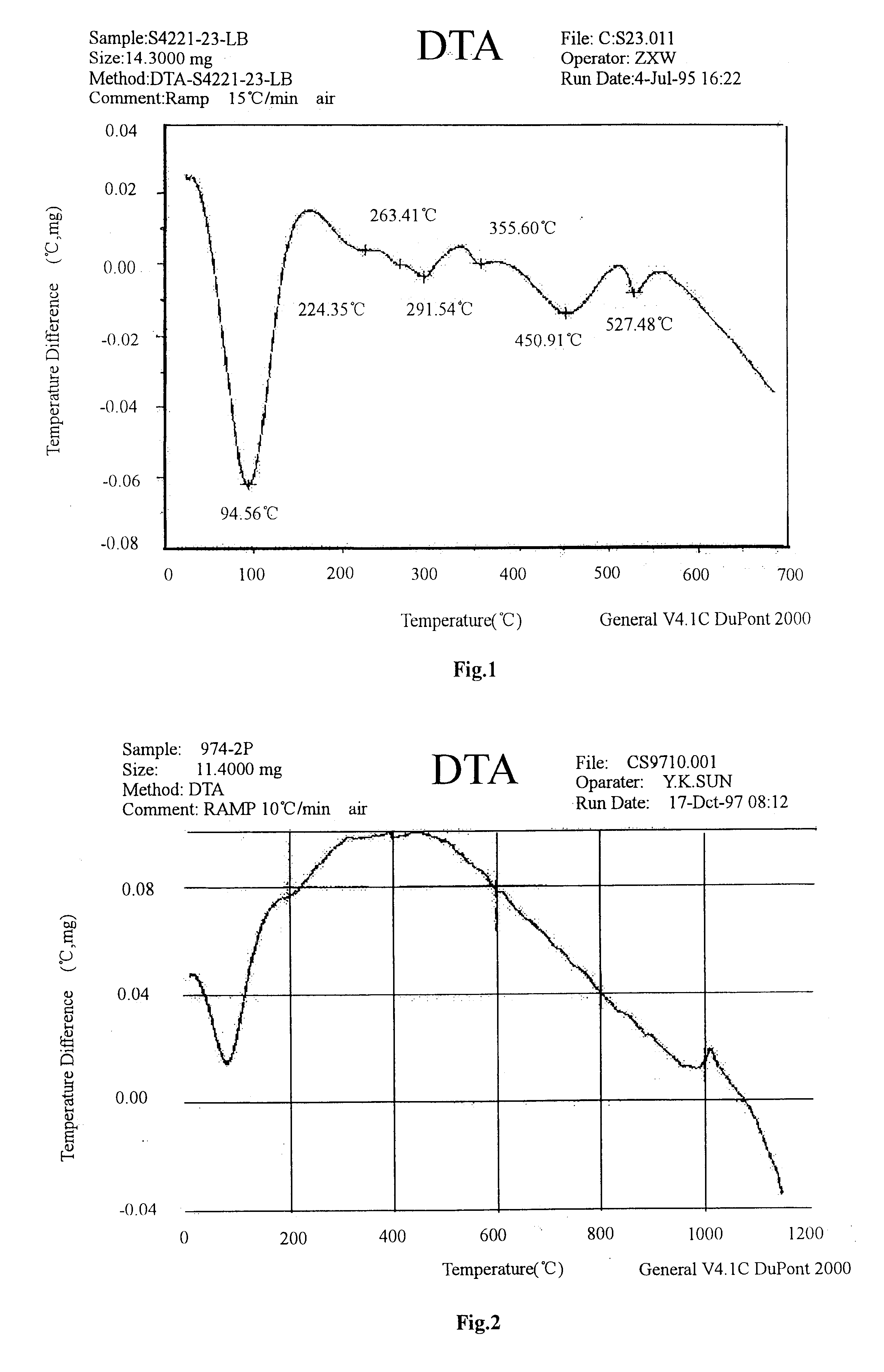

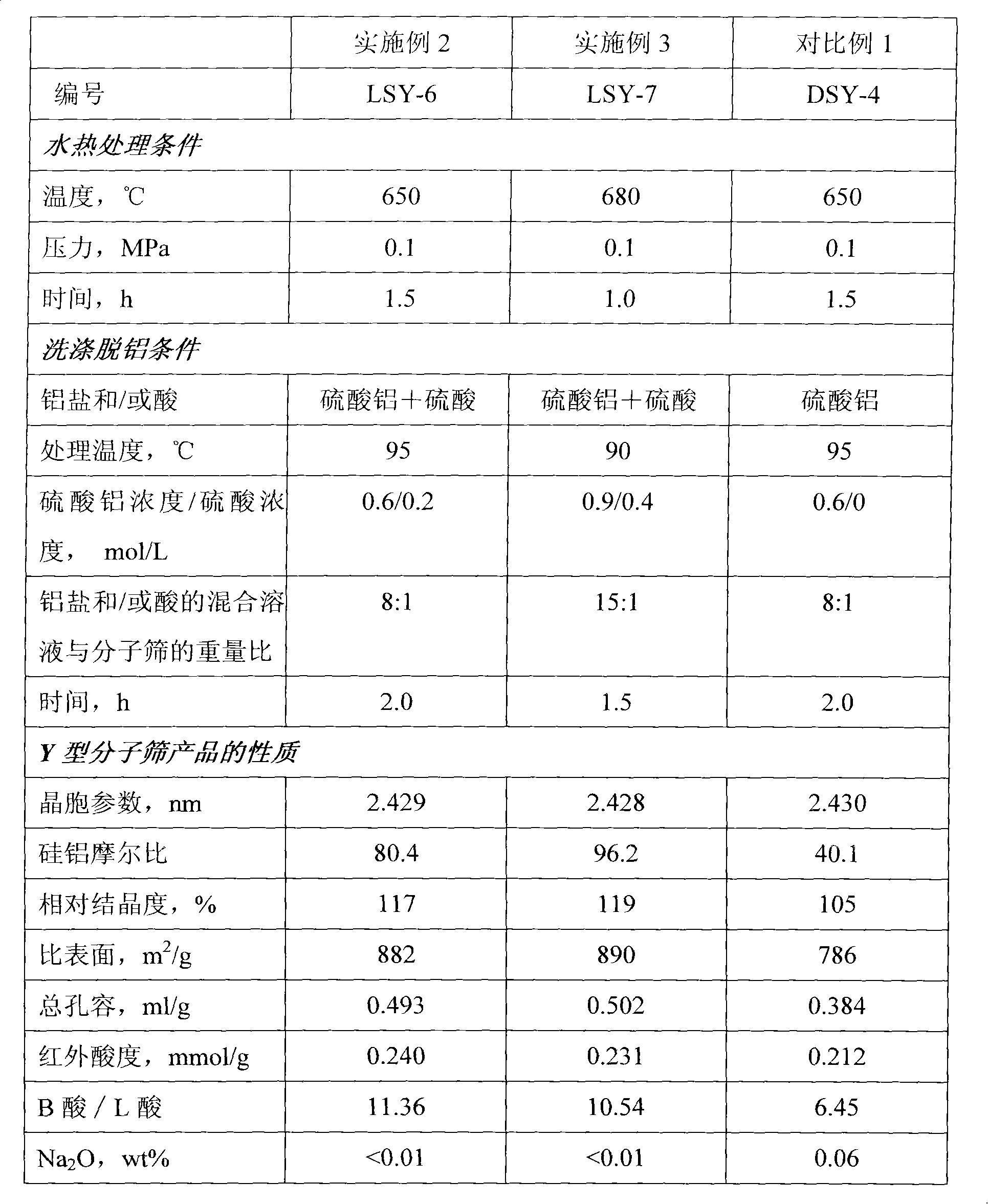

Hydrocracking catalyst carrier and preparation method thereof

ActiveCN101618348AHigh activityHigh selectivityCatalyst carriersMolecular sieve catalystsMolecular sieveCrystallinity

The invention discloses a hydrocracking catalyst carrier and a preparation method thereof. The catalyst carrier comprises a modified Y-type molecular sieve, amorphous silica-alumina and alumina, wherein the modified Y-type molecular sieve is Y-type molecular sieve treated by mixed aqueous solution of an aluminum salt and an acid and by hydrothermal process. In the carrier, the modified Y-type molecular sieve has a high crystallinity, high silicon to aluminum ratio and proper total acidity and acid distribution and can form an acid component with the amorphous silica-alumina. Therefore, the carrier is particularly suitable for serving as a hydrocracking catalyst carrier to improve the activity of a hydrocracking catalyst and the selectivity of middle distillates.

Owner:CHINA PETROLEUM & CHEM CORP +1

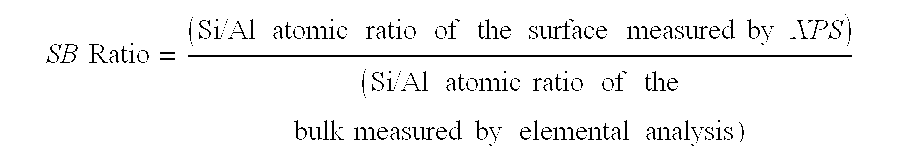

Extremely low acidity USY and homogeneous, amorphous silica-alumina hydrocracking catalyst and process

InactiveUS6902664B2High catalytic activityLow pollution rateMolecular sieve catalystsRefining to change hydrocarbon structural skeletonSingle stageAmorphous silica-alumina

A catalyst composition comprising a minor amount of a low acidity, highly dealuminated ultra stable Y zeolite having an Alpha value of less than about 5, preferable less than about 3 and Broensted acidity measured by FT-IR from about 1 to about 20, preferably from about 1-10, micro mole / g of, a homogeneous, amorphous silica-alumina cracking component having an SB ratio of from about 0.7 to about 1.3, wherein a crystalline alumina phase is present in an amount of no greater than about 10%, preferably no greater than 5% and a catalytic amount of hydrogenation component selected from the group consisting of a Group VI metal, a Group VIII metal, and mixtures thereof is disclosed. The present invention provides for a process for converting hydrocarbonaceous oils comprising contacting the hydrocarbonaceous oils with the catalyst under suitable hydrocarbon conversion conditions. Such processes in include, but are not limited to, single stage hydrocracking, two-stage hydrocracking, series-flow hydrocracking, mild hydrocracking, lube hydrocracking, hydrotreating, lube hydrofinishing, hydrodesulphurization, hydrodenitrification, catalytic dewaxing and catalytic cracking.

Owner:CHEVROU USA INC

Hydrocracking catalyst containing small crystal grain Y-shaped molecular sieve and preparation method thereof

ActiveCN102049280ASkeleton silicon aluminum ratio is highLarger than surfaceMolecular sieve catalystsCatalyst activation/preparationMolecular sieveNaphtha

The invention discloses a hydrogenation catalyst and a preparation method thereof. The catalyst comprises hydrogenation active metal components and a carrier consisting of the small crystal grain Y-shaped molecular sieve, amorphous silica-alumina and aluminum oxide, wherein the small crystal grain Y-shaped molecular sieve is a small crystal grain Y-shaped molecular sieve subjected to hydro-thermal treatment. The hydrocracking catalyst provided by the invention has the characteristics of high catalyst activity, excellent target product selectivity, great preparation flexibility, and the like, thus the catalyst can be used for preparing products such as heavy naphtha, aviation kerosene, diesel oil and the like with high yield and good product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for producing paraffinic hydrocarbons

ActiveUS20100076236A1Carry-outIncrease temperatureFatty acid chemical modificationBiofuelsAlkaneMonoglyceride

Process for producing paraffinic hydrocarbons, the process comprising the following steps: (a) contacting hydrogen and a feedstock comprising triglycerides, diglycerides, monoglycerides and / or fatty acids with a hydrogenation catalyst under hydro-deoxygenation conditions; and (b) contacting the whole effluent of step (a) with a hydroprocessing catalyst comprising sulphided Ni and sulphided W or Mo as hydrogenation components on a carrier comprising amorphous silica-alumina and / or a zeolitic compound under hydro-isomerisation conditions.

Owner:SHELL USA INC

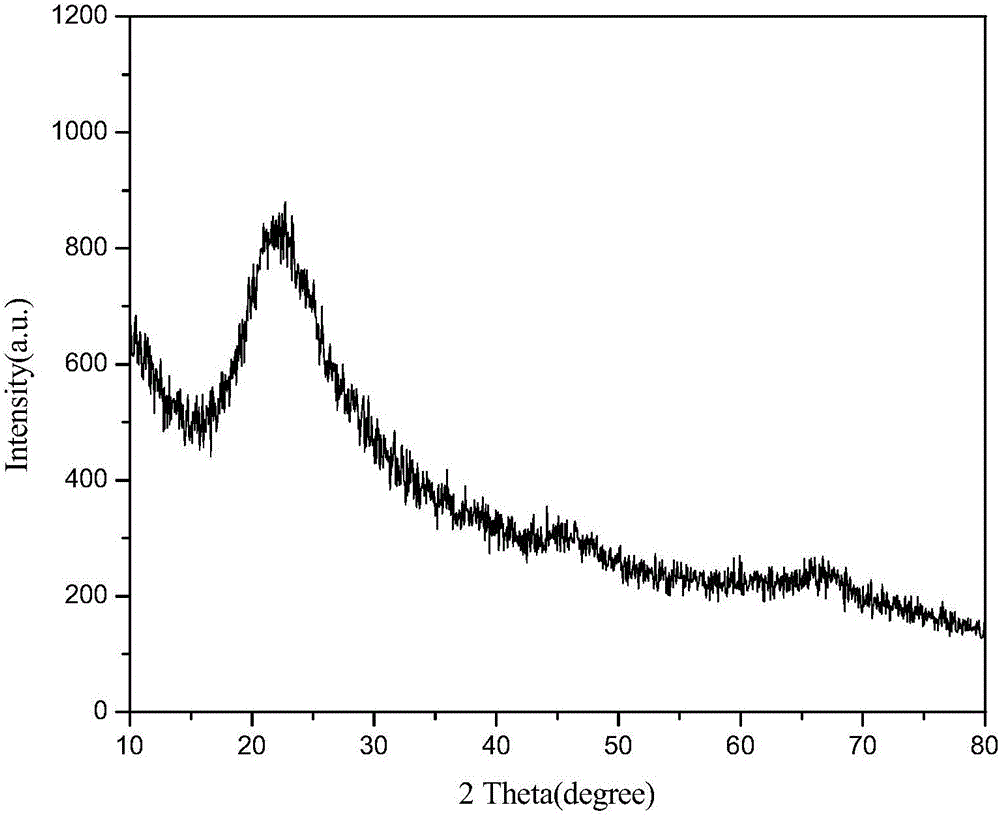

High-activity amorphous silica-alumina, hydrocracking catalyst supported by amorphous silica-alumina, and preparation methods thereof

The invention discloses a high-activity amorphous silica-alumina, a hydrocracking catalyst supported by amorphous silica-alumina, and preparation methods thereof. The preparation method of the amorphous silica-alumina supporter comprises the following steps: preparing a silicon source-aluminum source mixed water solution, mixing the mixed water solution with a precipitant solution, carrying out cocurrent flow coprecipitation to obtain a precipitated slurry, transferring the slurry into a closed vessel, aging, molding, and roasting. The invention also provides a preparation method of a hydrocracking catalyst by using the amorphous silica-alumina as the supporter. The preparation method of the hydrocracking catalyst is as follows: in the preparation method of the amorphous silica-alumina supporter, a nickel salt or nickel salt and metal aid M salt is / are added into the silicon source-aluminum source mixed water solution in the step (1), and the rest steps are the same as those in the preparation method of the amorphous silica-alumina supporter. The coprecipitation process is adopted in the preparation process, and the silicon source and aluminum source finally exist in the catalyst in the form of the amorphous silica-alumina, but the catalyst has much higher activity than the common amorphous silica-alumina catalyst.

Owner:SYNFUELS CHINA TECH CO LTD

Silica-alumina catalyst support with bimodal pore distribution, catalysts, methods of making and using same

ActiveUS20050107479A1Dispersion of catalytic metal and product diffusion can be optimizedMolecular sieve catalystsOrganic compound preparationPore distributionSilicon dioxide

An effective catalyst includes an amorphous silica-alumina support having a bimodal pore size-distribution. The support may be prepared by a method that includes the physical mixing of two silica-alumina gels prepared so as to have two different average pore sizes. The catalyst has the advantage that both metal dispersion on the support and product diffusion in the pores are optimized. Further, the catalyst has improved performance in the production of hydrocarbons from synthesis gas.

Owner:CLARIANT INT LTD

Composite mesoporous molecular sieve hydrocracking catalyst and uses thereof

ActiveCN101269343AHigh activityHigh oil selectivityMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveAdhesive

The invention relates to a composite mesoporous molecular sieve hydrocracking catalyst and the application thereof. The catalyst composed of following components of 20 to 50 percent of amorphous silica-alumina, 5 to 30 percent of alumina, 10 to 25 percent of adhesives, 10 to 40 percent of Group VIB-the metal oxides, 1 to 20 percent of Group VIII-the metal oxides, 0.1 to 10 percent of Group VA-the metal oxides, and 1 to 40 percent of composite mesoporous molecular sieve, wherein, the composite mesoporous molecular sieve is a composite molecular sieve composed of a mesoporous molecular sieve AlSBA-15 and / or AlSBA-15 / Y; the weight ratio of the composite molecular sieve AlSBA-15 / Y in the AlSBA-15 and a Y molecular sieve is 9:1 to 1:9; the weight ratio of the mesoporous molecular sieve and a pore molecular sieve is 3:1 to 1:3, the silica alumina ratio is 10:1 to 40:1, and the silica alumina ratio of the Y molecular sieve is 5:1to 20 :1. The catalyst used for hydrocracking for heavy oil shows high activity for hydrocracking and high medium oil selectivity.

Owner:PETROCHINA CO LTD

Method for preparing carrier material

ActiveCN101172259AEvenly dispersedEasy to useCatalyst carriersMolecular sieve catalystsMolecular sieveAmorphous silica-alumina

The invention discloses a preparation method of a carrier material containing molecular sieve and amorphous silicon aluminum. The molecular sieve in the carrier of the present invention is introduced during the process of forming amorphous silica-alumina gel, which greatly improves the specific surface area and acidity of the silica-alumina carrier, and makes the molecular sieve evenly distributed in the silica-alumina carrier, which has a good effect on the dispersion of active metal components in the catalyst. It is beneficial to coordinate with both. The silica-alumina of the invention is suitable as a catalyst material for petroleum processing catalysts, especially as a carrier component for hydrotreating and hydrocracking catalysts.

Owner:CHINA PETROLEUM & CHEM CORP +1

Amorphous silica-alumina, a carrier combination and a hydrocracking catalyst containing the same, and processes for the preparation thereof

InactiveUS20020160906A1Increase surface areaLarge hole volumeMolecular sieve catalystsAluminium silicatesPtru catalystPhysical chemistry

Owner:CHINA PETROCHEMICAL CORP +1

Preparation method of hydrogenation catalyst

ActiveCN102451743AReduce roasting stepsEasy to manufactureMolecular sieve catalystsHydrocarbon oil crackingAmorphous silica-aluminaCoal

The invention discloses a preparation method of a hydrogenation catalyst. According to the catalyst, a cracking molecular sieve, amorphous silica-alumina and alumina are used as carriers, and VIII and VIB metals are used as hydrogenation active components. The preparation process comprises the following steps of: mixing the cracking molecular sieve, amorphous silica-alumina and alumina for molding, drying, loading the active metals by an immersion method, drying and roasting to obtain the catalyst. In comparison with the routine immersion method, the method provided by the invention can be used to prepare the molded carriers without roasting, simplify time and energy, minimize strong interaction, help uniform distribution of the metals as well as performance of the metal activity, and avoid specific surface area loss caused by multi-step roasting. The catalyst prepared by the method is especially applicable to be used as a hydrogenation catalyst for high-yield high-quality heavy naphtha, aviation kerosene and diesel oil. By the adoption of the preparation method, activity and selectivity of the catalyst are raised.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing hydrocracking catalyst containing hierarchical pore Beta molecular sieve

The invention relates to a method for preparing a hydrocracking catalyst containing a hierarchical pore Beta molecular sieve. A carrier of the catalyst consists of the hierarchical pore Beta molecular sieve, a modified Y molecular sieve, alumina and amorphous silica-alumina, wherein a hydrogenated active ingredient is an oxide of Ni and W, and an aid is P or F. The catalyst has the characteristics that the modified Y molecular sieve and the hierarchical pore Beta molecular sieve serve as acid components, and has a good synergetic and complementary effect. The hydrocracking catalyst prepared by the method has enriched mesoporous channels and uniform moderately strong acid center distribution, and macromolecule mass transfer and conversion are promoted; and therefore, the catalyst has the advantages of high hydrocracking activity, high nitrogen resistance, high stability, high medium oil selectivity, low diesel oil condensation point and the like.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Pseudo-boehmite containing amorphous silica alumina and preparation method thereof

ActiveCN102139204AImprove molding conditionsIncrease acidityCatalyst activation/preparationSilicon oxideSlurry

The invention relates to pseudo-boehmite containing amorphous silica alumina and a preparation method thereof. The pseudo-boehmite containing the amorphous silica alumina is obtained according to the conventional ageing, filtering and washing methods after amorphous silica alumina slurry and pseudo-boehmite slurry are mixed. The pseudo-boehmite contains 5 to 40 weight percent of silicon oxide, the specific surface area is 250 to 400 m<2> / g, the pore volume is 0.7 to 1.4ml / g, the surface acid site mainly comprises weak acid site, and the infrared acidity is 0.28 to 0.55mmol / g. The prepared pseudo-boehmite containing the amorphous silica alumina has the properties of high acidity and high specific surface area of the amorphous silica alumina, simultaneously has the advantages of the pseudo-boehmite, and solves the problem of poor formation of the amorphous silica alumina. The pseudo-boehmite containing the amorphous silica alumina is mainly applied to hydrogenation treatment, particularly preparation of an intermediate distillate hydrogenation catalyst carrier.

Owner:PETROCHINA CO LTD

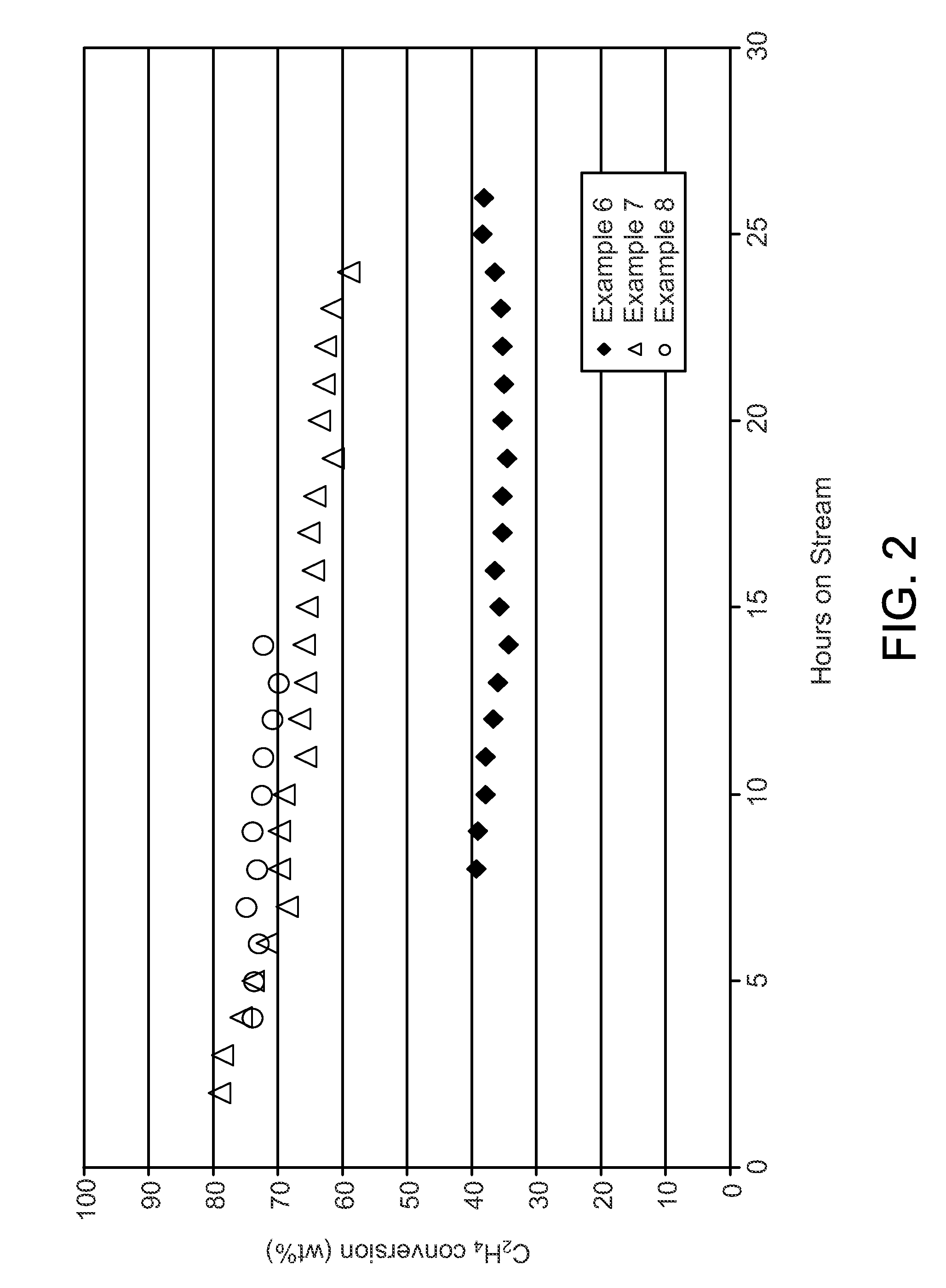

Process for oligomerizing dilute ethylene

ActiveUS8748682B2Easy to separateMolecular sieve catalystsHydrocarbons from unsaturated hydrocarbon additionHydrogenCarbon oxide

The process and apparatus converts ethylene in a dilute ethylene stream that may be derived from an FCC product to heavier hydrocarbons. The catalyst may be an amorphous silica-alumina base with a Group VIII and / or VIB metal. The catalyst is resistant to feed impurities such as hydrogen sulfide, carbon oxides, hydrogen and ammonia. At least 40 wt-% of the ethylene in the dilute ethylene stream can be converted to heavier hydrocarbons.

Owner:UOP LLC

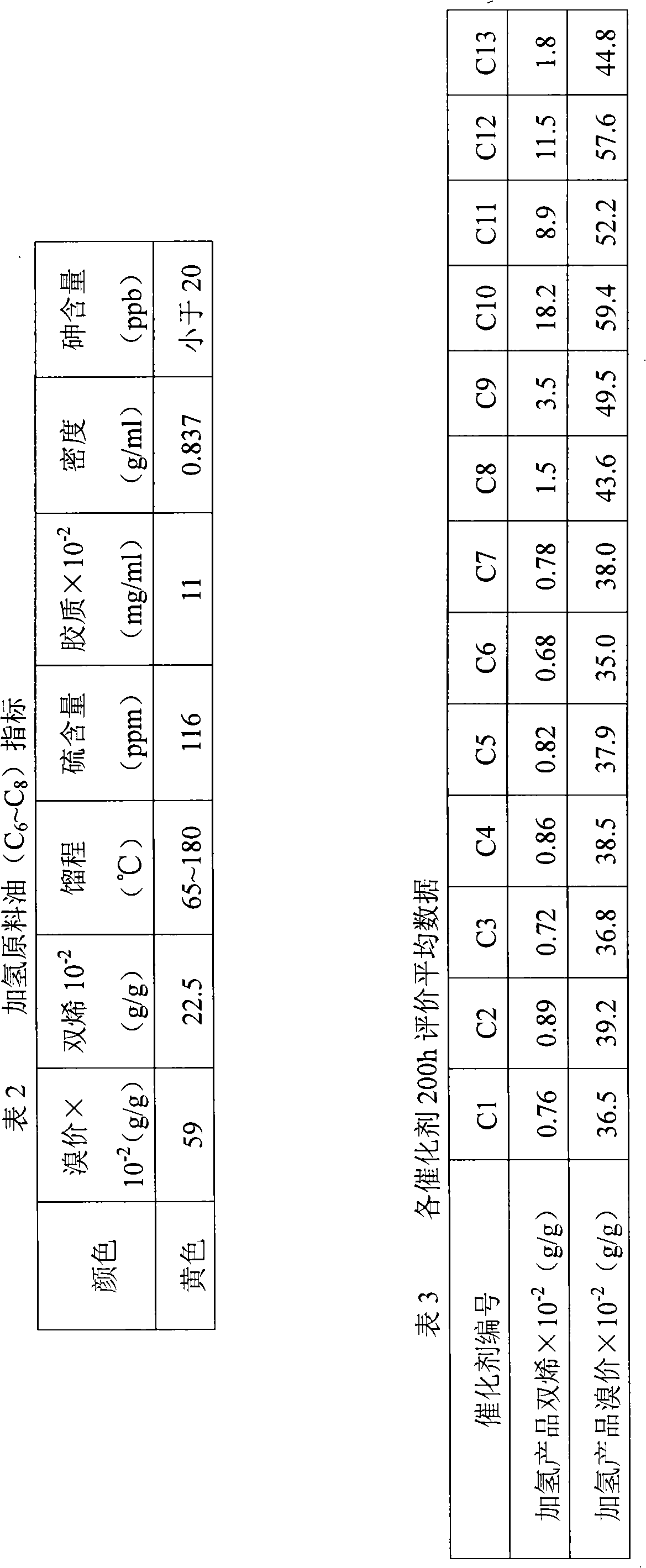

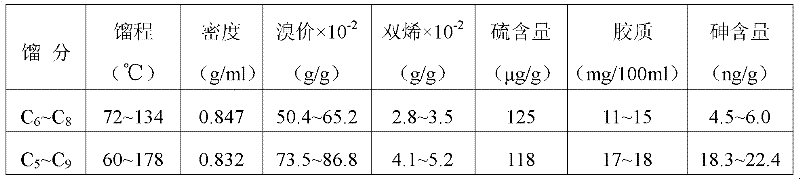

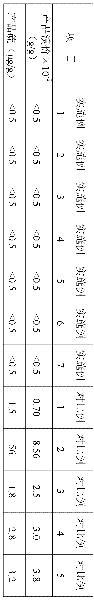

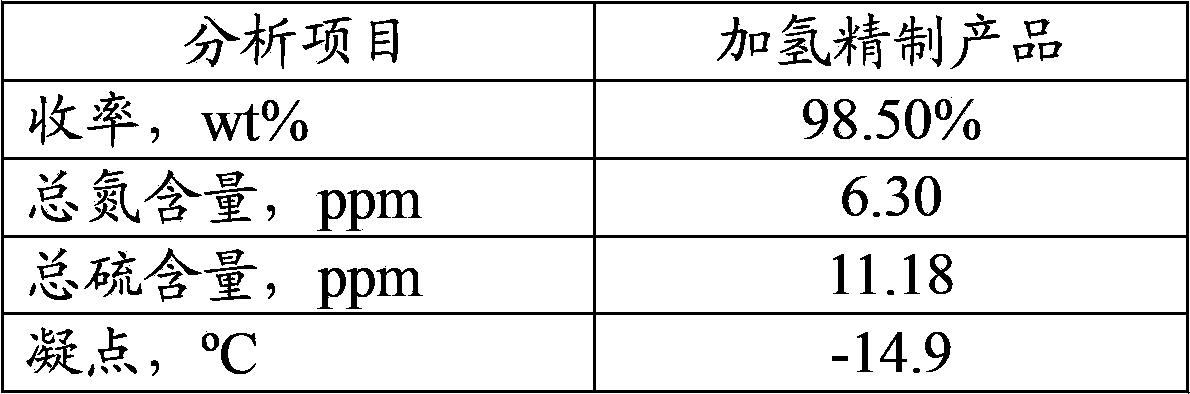

A kind of hydrorefining method of distillate oil

ActiveCN102268283AImprove hydrogenation activityImprove stabilityPhysical/chemical process catalystsHydrocarbon oils treatmentSlurryCobalt

The invention provides a hydrorefining method of distillate oil. In the hydrorefining method, a cobalt molybdenum nickel hydrogenation catalyst is used; hydrogenation process conditions are as follows: the inlet temperature is 200-320 DEG C, the operation pressure is larger than or equal to 2.4MPa, the volume space velocity of a liquid is 1-5h<-1>, and the volume ratio of hydrogen to oil is 100-500; in the cobalt molybdenum nickel hydrogenation catalyst, silicon-containing alumina is used as a carrier, cobalt, molybdenum and nickel are used as active components, and phosphorus and alkali metal are added to be used as auxiliaries; and the precursor of the silicon-containing alumina carrier is pseudo boehmite containing amorphous silica-alumina and is obtained by the steps of firstly preparing an amorphous silica-alumina slurry and a pseudo boehmite slurry, mixing the two slurries, ageing, and then carrying out posttreatment processes such as filtering, washing and drying. According to the invention, hydrorefining is carried out on a first-stage hydrogenation product of full-fraction cracked gasoline by using the hydrorefining method, wherein the bromine value in the hydrogenation product is less than 1.0*10<-2>g / g and the content of sulfur in the hydrogenation product is less than 1.0mu g / g, thereby meeting the second-stage hydrogenation requirements of the cracked gasoline.

Owner:PETROCHINA CO LTD

Preparation of rare earth contained hydrocracking catalyst

InactiveCN1400287AImprove performanceEasy to operateHydrocarbon oil crackingMolecular sieveAmorphous silica-alumina

The preparation method of hydrocracking catalyst containing rare earth includes the following steps: mixing molecular sieve, alumina precursor and / or amorphous silica-alumina and rare earth salt according to the required propertion, and is necessary, adding peptizator, kneading or extruding-forming, drying and roasting to obtain formed catalyst carrier, then loading the hydrogenated metal active component on the formed catalyst carrier. The adoption of said invention method can make the rare earth content of catalyst reach to the required level by one-step operation, at the same time its operation is simple.

Owner:CHINA PETROLEUM & CHEM CORP +1

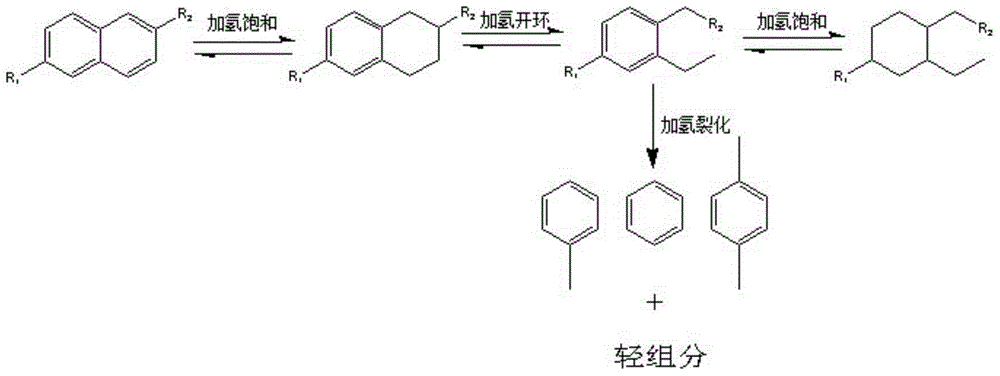

Method for preparing selective hydrogenation ring-opening catalyst for aromatic hydrocarbons with double rings or more

ActiveCN104646052AHigh selectivityGood choiceMolecular sieve catalystsHydrocarbon oils treatmentIsomerizationHydrogenation process

The invention discloses a method for preparing a selective hydrogenation ring-opening catalyst for aromatic hydrocarbons with double rings or more. The method is characterized in that the selective hydrogenation ring-opening catalyst for aromatic hydrocarbons with double rings or more is prepared from a carrier, active ingredients and aids, wherein the carrier is prepared from alumina, amorphous silica-alumina, a modified small grain Beta-type molecular sieve and an SPAO-5 / ZSM-5 composite molecular sieve; the active ingredients at least include an oxide of Mo or W and at least include an oxide of Co or Ni; and the aids refer to one or two out of F and P. The invention also relates to a preparation method of the catalyst and a method for synthesizing the SPAO-5 / ZSM-5 composite molecular sieve. The catalyst is effectively matched with a hydrogenation active center, an isomerization active center and a cracking active center, so that the catalyst has excellent aromatic hydrocarbon hydrogenation ring-opening selectivity in the hydrogenation process of low-quality distillate oil enriched in aromatic hydrocarbons with double rings or more.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

Carrier material containing molecular sieve and amorphous silica-alumina and preparation method thereof

ActiveCN103100441AAvoid reunionAvoid reunions,Catalyst carriersMolecular sieve catalystsMolecular sieveSlurry

The invention discloses a carrier material containing a molecular sieve and amorphous silica-alumina and a preparation method thereof. The preparation method is characterized in that in NaY molecular sieve modification, before final hydrothermal treatment, amorphous silica-alumina slurry and a surfactant are introduced so that the molecular sieve and the amorphous silica-alumina are dispersed uniformly and molecular sieve agglomeration or channel blocking is avoided, and thus a specific surface area and a pore volume of the carrier material are improved and catalyst performances are improved. The carrier material is especially suitable for being used as a carrier component of a hydrocracking catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Flexible method for producing oil bases and distillates by hydroisomerization-conversion on a weakly dispersed catalyst followed by a catalyctic dewaxing

InactiveUS7371315B2Reduce volatilityImproves UV stabilityHydrocarbon oil crackingTreatment with hydrotreatment processesMolecular sieveBase oil

A process for production of very high-quality base oils, and simultaneous production of high-quality middle distillates, comprises the successive stages of hydroisomerization and catalytic dewaxing. The hydroisomerization takes place in the presence of a catalyst containing at least one noble metal deposited on an amorphous acid support, the metal dispersion being less than 20%. The support is preferably an amorphous silica-alumina. The catalytic dewaxing takes place in the presence of a catalyst containing at least one hydrodehydrogenating element (Group VIII) and at least one molecular sieve chosen from ZBM-30, EU-2, and EU-11.

Owner:INST FR DU PETROLE

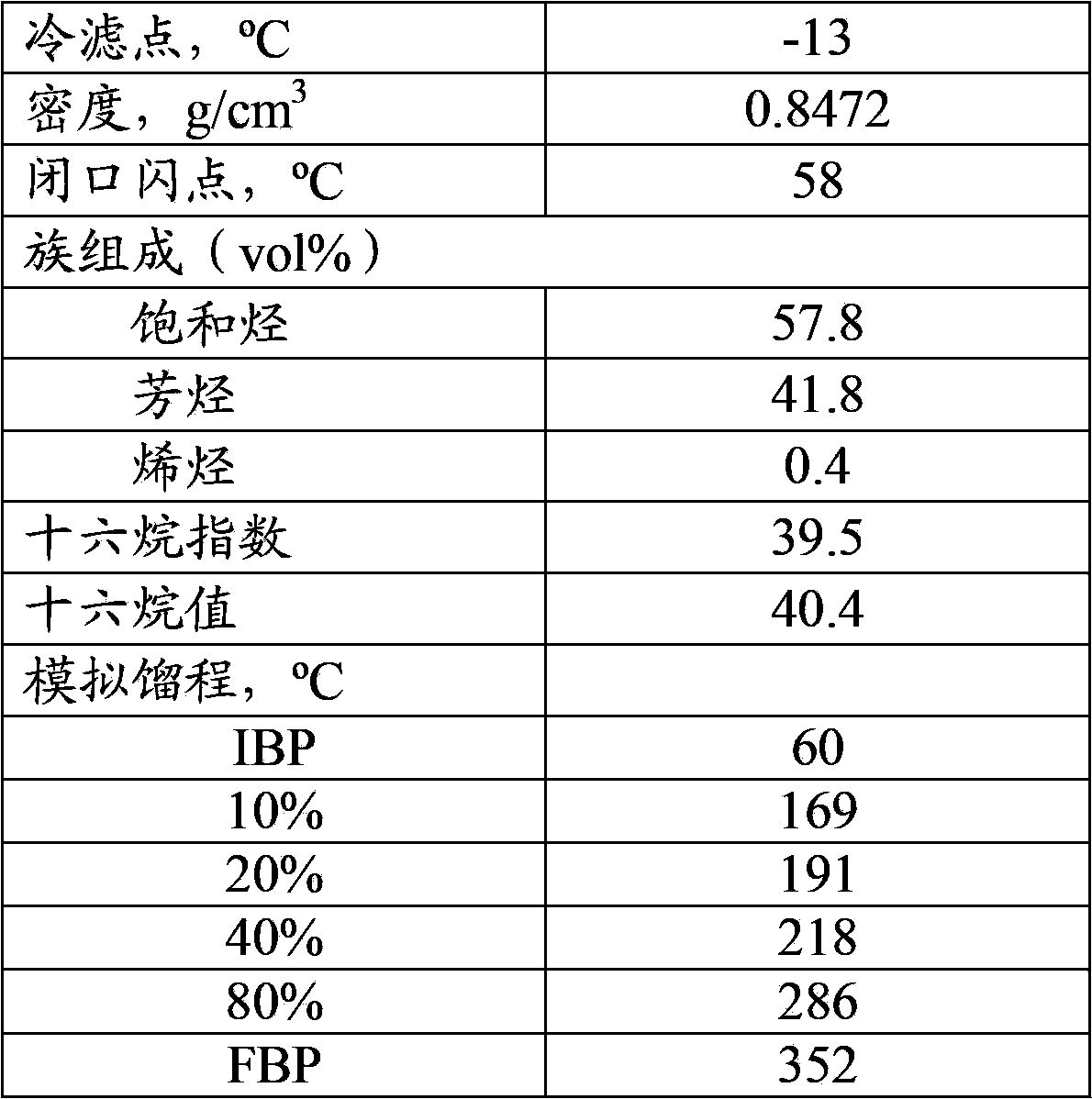

Rare earth-containing diesel fuel distillate oil hydrogenation catalyst, preparation and application thereof

ActiveCN103480408AMolecular sieve catalystsHydrocarbon oils treatmentRare-earth elementMolecular sieve

The present invention relates to a rare earth-containing diesel fuel distillate oil hydrogenation catalyst, preparation and an application thereof. The catalyst comprises 5-60 wt% of a rare earth-modified USY molecular sieve, 5-80 wt% of amorphous silica-alumina, 0.1-10 wt% of a hydrogenation active component and the balance of macroporous alumina, wherein the hydrogenation active component is a group VIII metal. The catalyst has excellent activities such as hydrogenation, isomerizing, and selective aromatic hydrocarbon ring opening. When the catalyst is adopted to treat FCC hydrorefining diesel fuel distillate oil, under relatively mild reaction conditions, cetane number can be significantly increased, a freezing point can be reduced, product quality can be increased, and the diesel fuel yield can be maintained to more than 95%. In addition, with addition of rare earth elements, activity and a service life of the catalyst are increased, and the catalyst is particularly suitable for deep hydrogenation saturation of the aromatic hydrocarbon in the second stage in the diesel fuel two-stage hydrogenation modification so as to selectively open the ring.

Owner:PETROCHINA CO LTD +1

Nano-polycrystalline SAPO molecular sieve with high specific surface area, and preparation method and application thereof

InactiveCN104760975AImprove performanceNew structureMolecular sieve catalystsOther chemical processesPhosphoric acidAluminium phosphate

The invention belongs to the technical field of zeolite molecular sieve materials, and concretely relates to a nano-polycrystalline SAPO molecular sieve with a high specific surface area, and a preparation method and an application thereof. The nano-polycrystalline SAPO molecular sieve with a high specific surface area is a CHA structure type or RHO structure type or CHA structure and RHO structure eutectic silicoaluminophosphate (SAPO) molecular sieve, is synthesized through a gas and solid phase crystal transformation reaction of a amorphous silica alumina phosphorus oxide dry glue in steam of a water and diethylamine mixed template, and is especially suitable for catalyzing adsorbing separation of micro-molecular gases from low carbon olefins prepared from methanol.

Owner:SHANGHAI FUYU NEW MATERIAL TECH

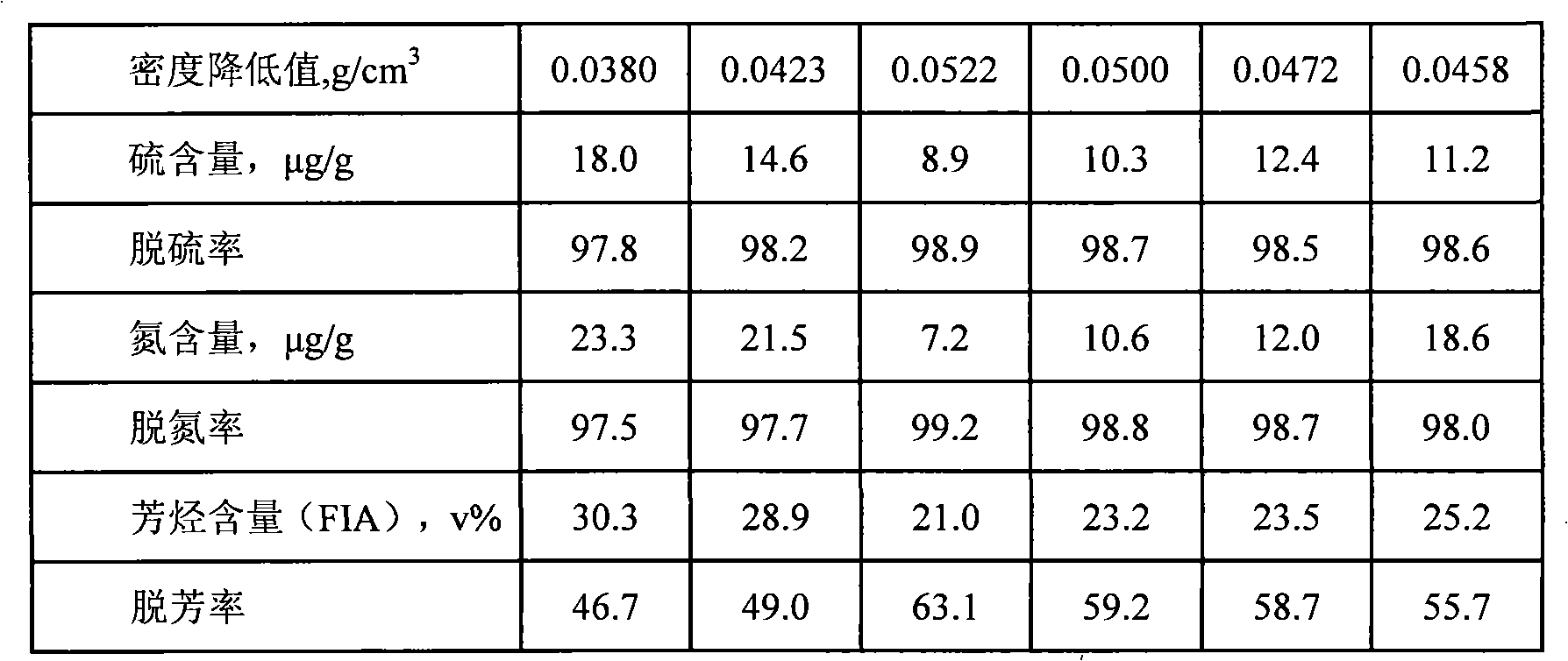

Method for hydro-dearomatization for catalyzing diesel

ActiveCN101328430AIncreased diffusion rateImprove activity stabilityRefining by aromatic hydrocarbon hydrogenationMolecular sieveDistillation

The invention relates to a method for catalyzing diesel oil to realize hydrogenation dearomatization. The method comprises the following steps that: distillation range of catalyzing diesel oil feeding is at a temperature of between 150 and 380 DEG C; in the presence of hydrogen, a reaction is carried out, the reaction temperature is between 330 and 370 DEG C, the hydrogen partial pressure is between 6 and 9 MPa, the hydrogen-oil volume ratio is between 500:1 and 1,000:1 and the liquid hourly volume space velocity is between 1.0 and 2.0 hr-1; the compositions in percentage by weight of a catalyst are: 15 to 40 percent of amorphous silica alumina, 5 to 30 percent of aluminum oxide, 10 to 40 percent of VIB group metal oxide, 1 to 15 percent of VIII group metal oxide and 5 to 30 percent of Beta / Y molecular sieve; moreover, the total weight of the compositions is counted as 100 percent. The method has the advantages that: diesel oil yield is more than 97 weight percent, and the dearomatization rate of diesel oil reaches to above 60 percent; meanwhile, total desulfurization rate and total denitrification rate reach above 98.5 percent, and product density is reduced by above 0.0400g / cm3.

Owner:PETROCHINA CO LTD

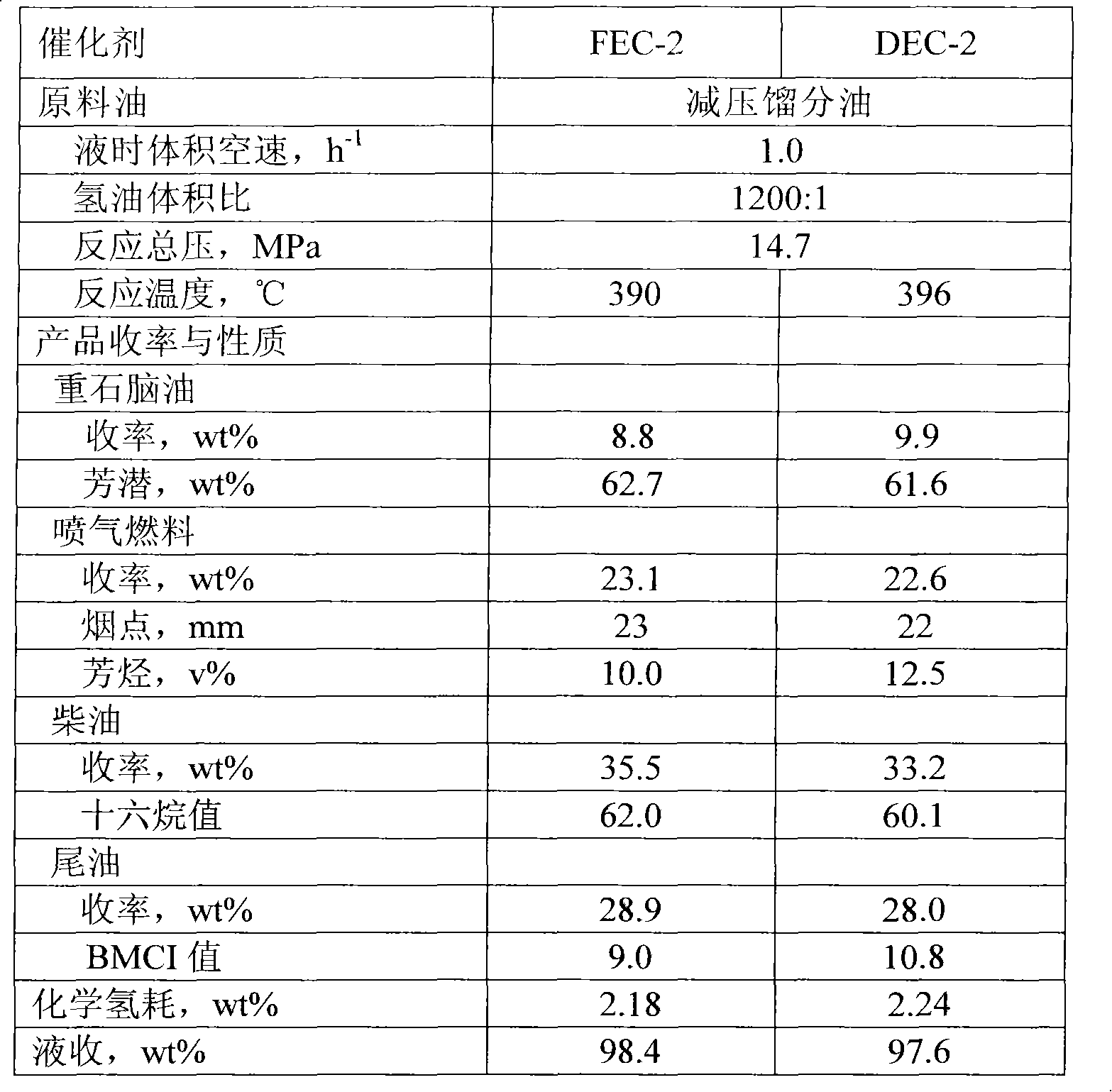

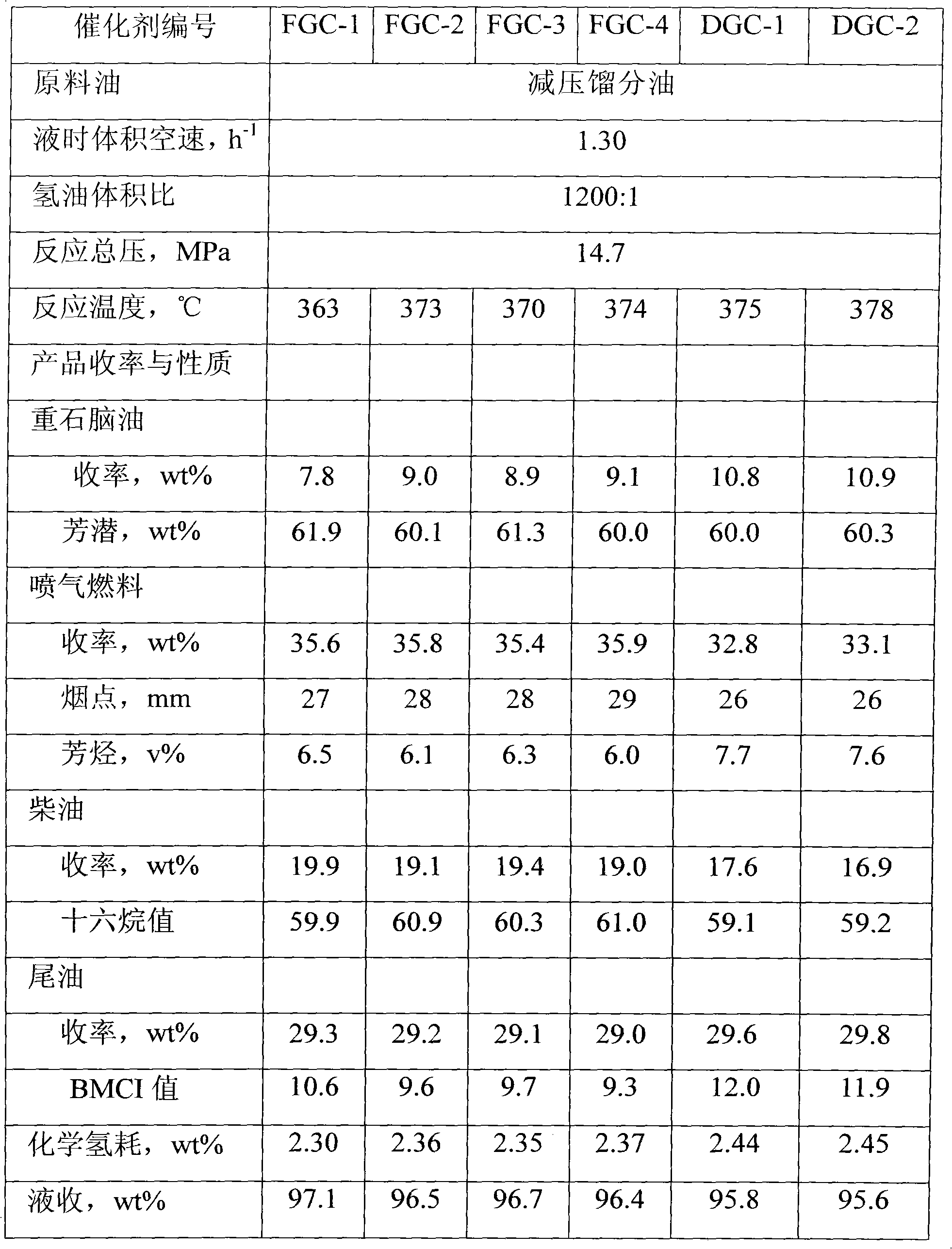

Method of producing middle distillate oil through hydrocracking

ActiveCN103254929AGood choiceQuality improvementMolecular sieve catalystsHydrocarbon oil crackingAdhesiveDistillation

The invention relates to a method of producing middle distillate oil through hydrocracking. A distillation range of raw materials is between 250-570 DEG C; a nitrogen content is 0.1-2000 [mu]g / g; and a catalyst is composed of 20-65 % of amorphous silica-alumina, 8-25 % of macroporous alumina, 8-25 % of an adhesive, 4-40 % of a composite molecular sieve, 1.5-5 % of an extrusion aid, 12-30 % of VIB-group metal oxides, 3-10 % of VIII-group metal oxides, and 0.1-5 % of VA-group metal oxides, wherein the composite molecular sieve is composed of an AlSBA-15 / Y mediated-microporous composite molecular sieve and a [beta]microporous molecular sieve. The catalyst is relatively high in catalytic activity and middle distillate oil selectivity, and can be used to produce heavy naphtha, jet fuel, diesel oil, tail oil, etc.; and the produced products are good in quality.

Owner:PETROCHINA CO LTD

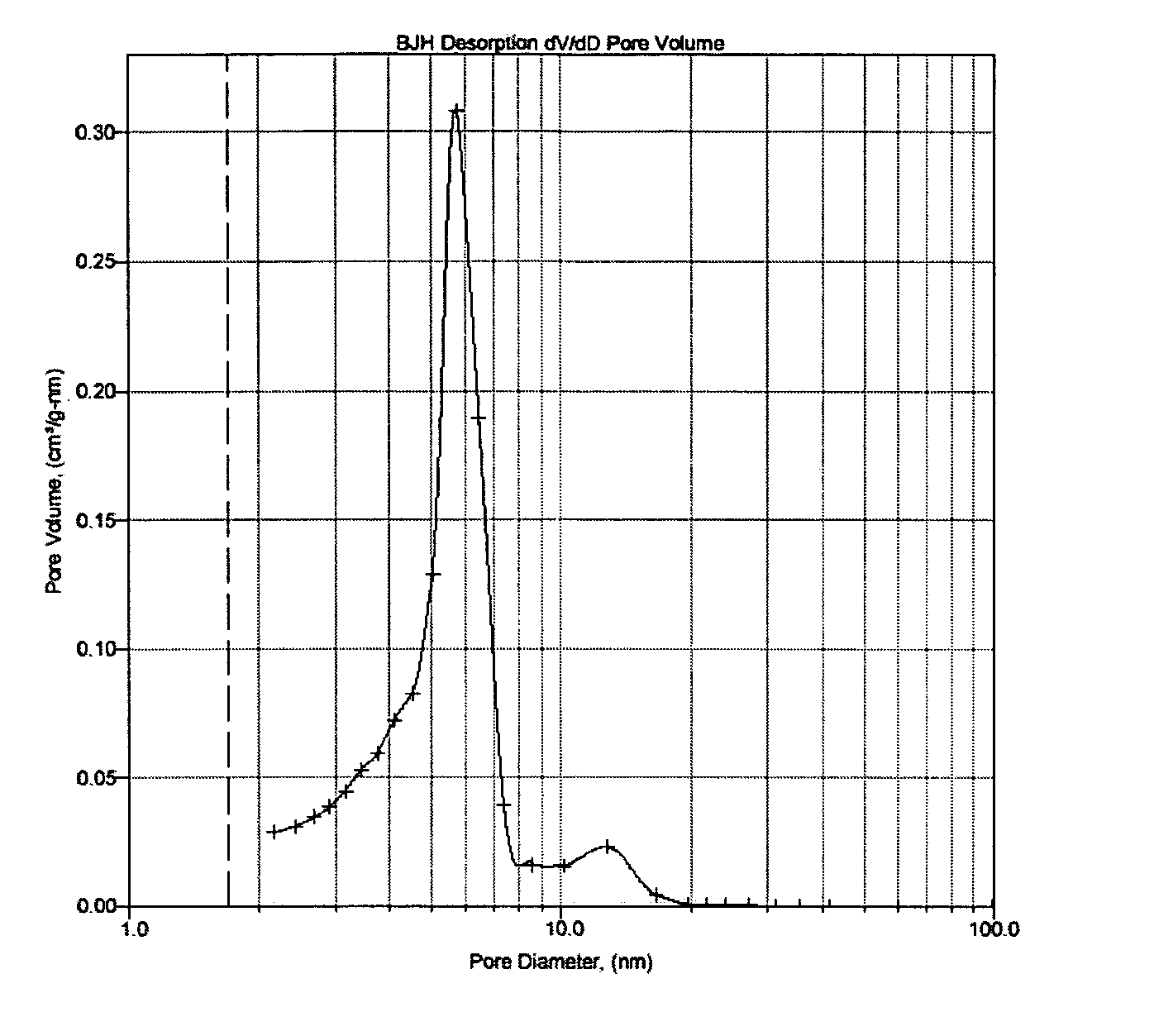

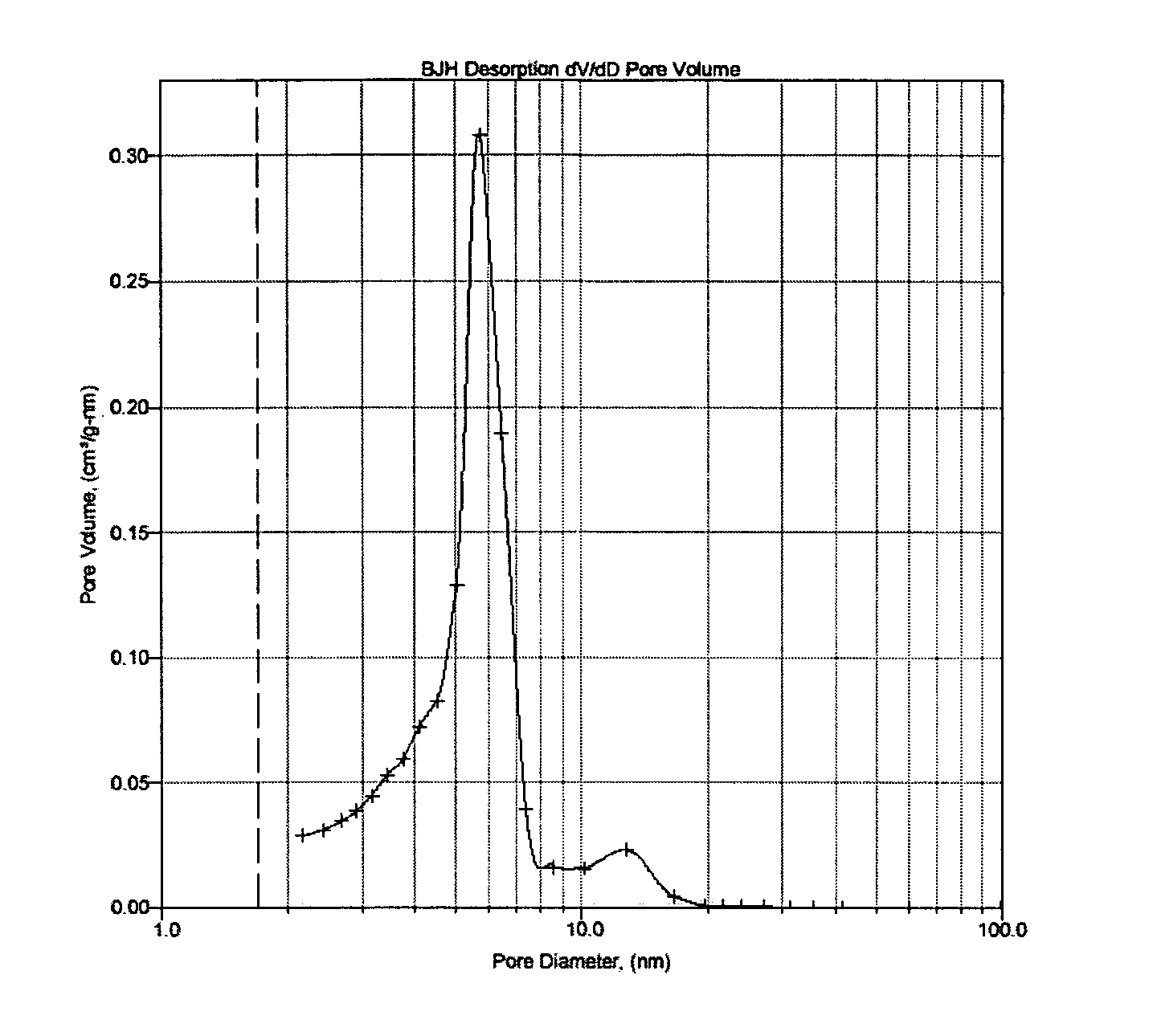

Amorphous silica-alumina and its preparing method

ActiveCN101239328AMix well and evenlyEffective interactionCatalyst carriersNitrogenAmorphous silicon

The present invention provides a amorphous silica-alumina and its preparing method. The amorphous silica-alumina employs parallel current coprecipitation method, the method has a simple preparation, easily controlled, and adopts CO2 and wind mix at the same time, the reactant is fully mixed, and effectively mutual action of silica and aluminum is ensured, so silica-alumina having large specific surface area and a large specific pore volume is formed, the distribution of pore is concentrative, 4-10nm pore volume is about 85%-95% of the total pore volume, pore volume which aperture is bigger than 15nm, is below 5% of the total pore volume. The preparing step has no discharge of waste water containing ammonia, nitrogen, and has no environment pollution.

Owner:CHINA PETROLEUM & CHEM CORP +1

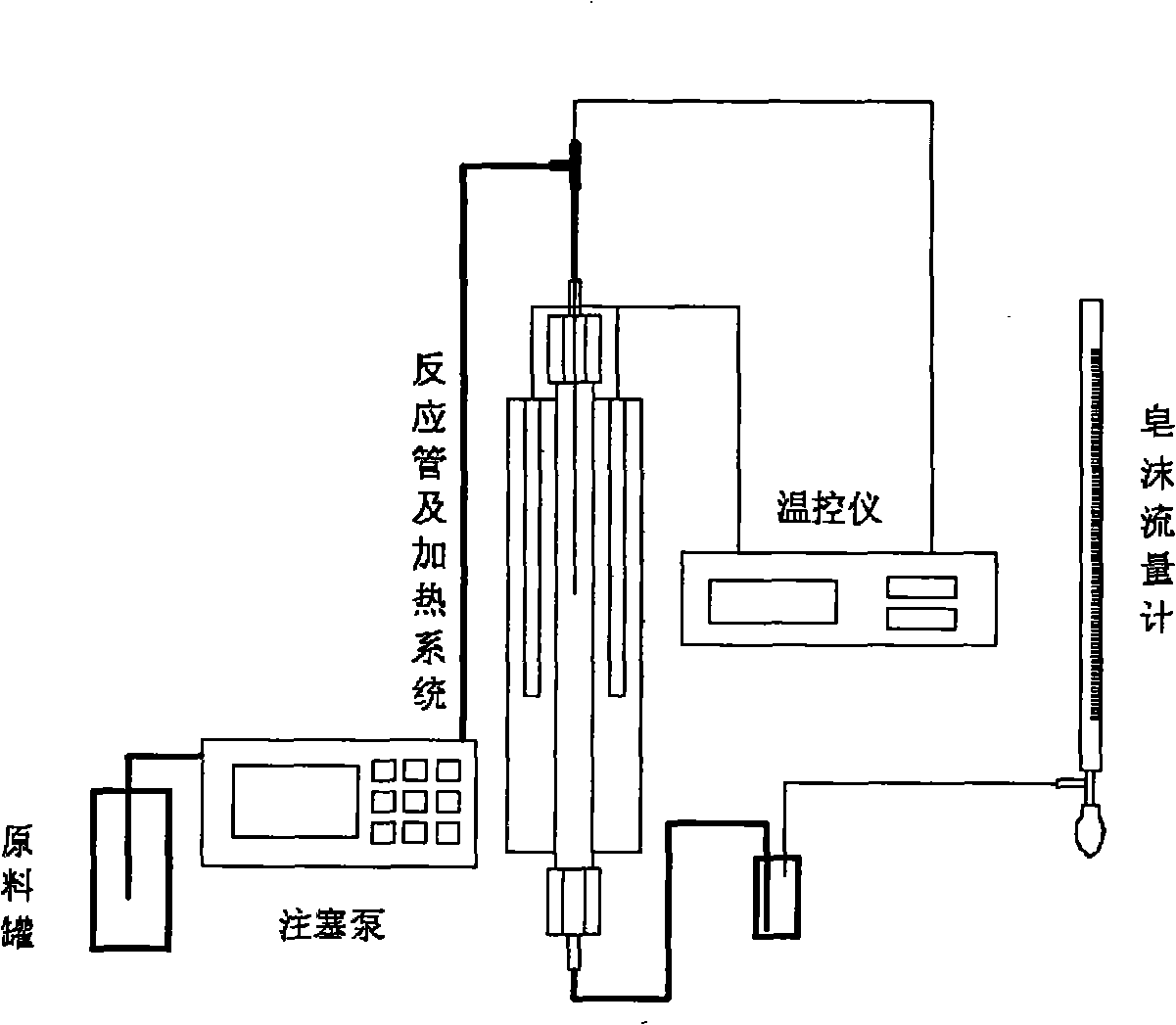

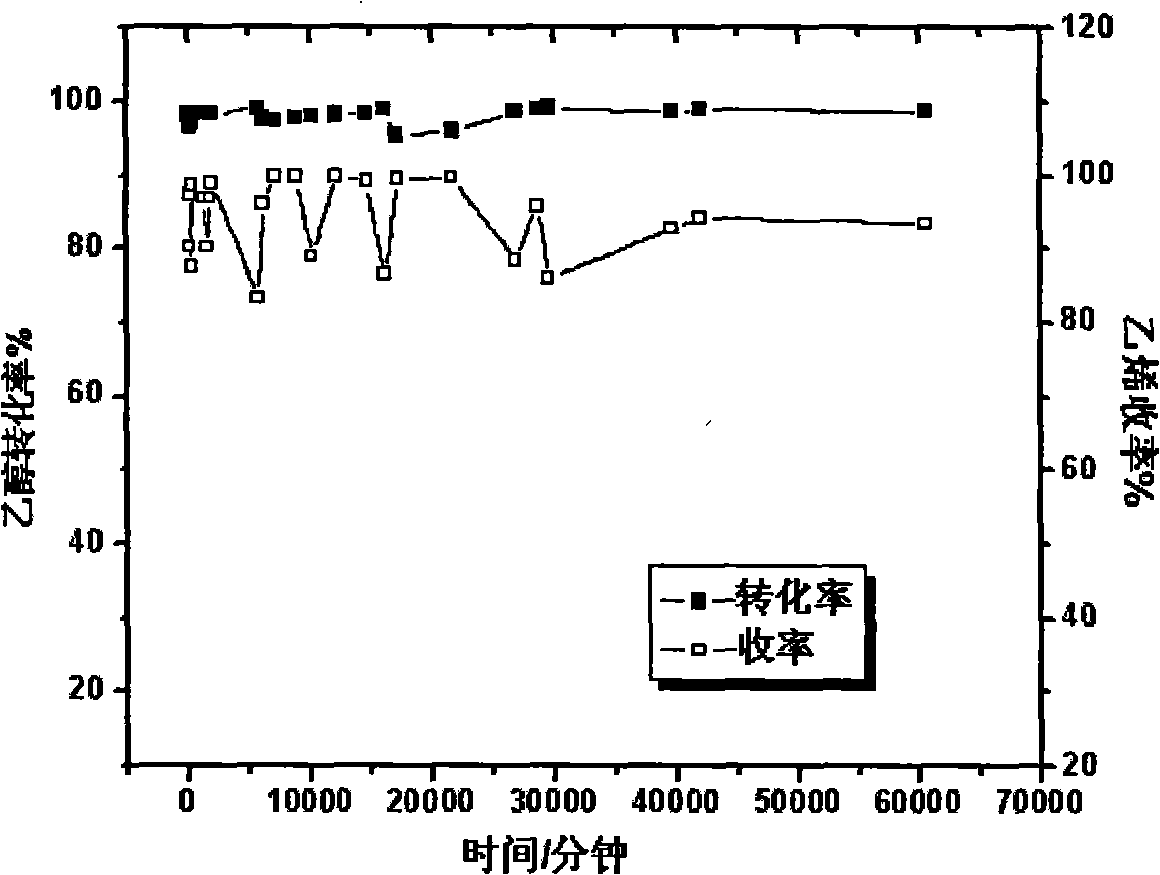

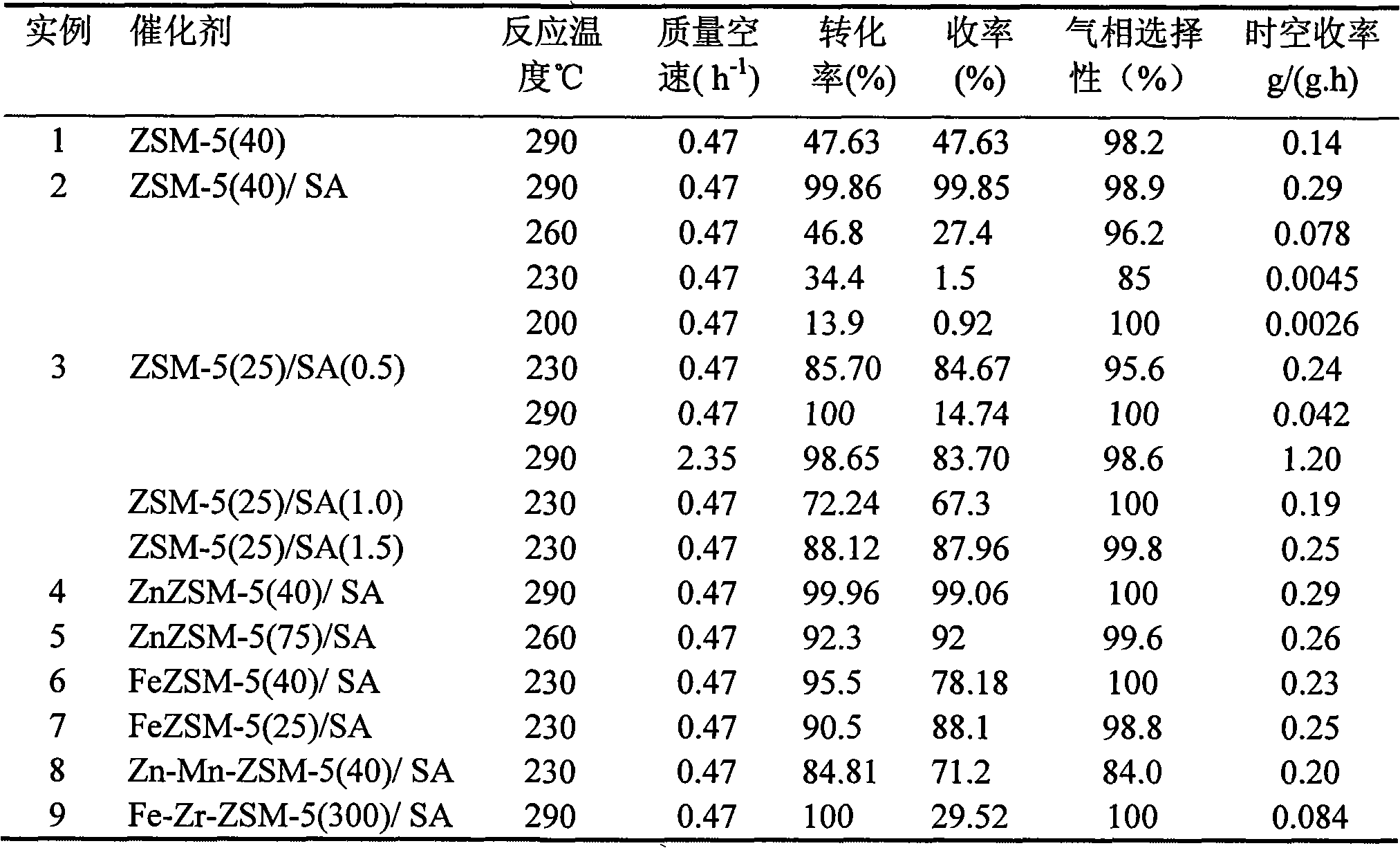

Catalyst used in reaction process of producing ethylene from dehydration of ethanol

InactiveCN101274286AReduced tendency to coke inactivationIncrease one-way productionMolecular sieve catalystsHydrocarbon from oxygen organic compoundsReaction temperatureFixed bed

The invention relates to a catalyst used in a reaction for producing ethylene by ethanol dehydration, which is characterized in that the catalyst of the invention consists of HZSM-5, in which the ratio of the 0.5 to 7 percent of one or a plurality of kinds of active metallic components by weight to the 5 to 30 percent of amorphous silica-alumina gel and skeleton silica-alumina by weight is 5 to 300. In the reaction implemented in a fixed bed fluid reactor, the catalyst of the invention can achieve high conversion rate and high selectivity for converting ethanol to ethylene under the conditions of normal pressure, reaction temperature of 200 to 290 DEG C and reactant airspeed of 0.1-10h<-1>, and with 10 to 100 percent of the ethanol water solution as raw reaction materials. Under optimized conditions, the ethanol conversion rate, the vapor ethylene selectivity and the overall ethylene yield all approximate 100 percent. The catalyst of the invention is used for the reaction for producing ethylene by ethanol dehydration, and has the outstanding features of wide concentration range of the raw reaction material solution, lower reaction temperature and wider airspeed range, does not need the preliminary gasification of the raw reaction material solution, does not use the inert diluent gas, and has high catalyst activity and selectivity as well as long catalytic life.

Owner:HUNAN UNIV

Hydrocracking catalyst containing amorphous aluminum silicide and preparation thereof

ActiveCN101239314AReduce severitySuitable lytic activityMolecular sieve catalystsHydrocarbon oil crackingPore distributionAmorphous silica-alumina

The present invention provides a hydrocracking catalyst containing amorphous silica-alumina and preparing method. The amorphous silica-alumina in the catalyst employs parallel current coexisting method, not only has a simple process, easily controlling, but also employs CO2 and wind mixing, the reactant is adequately mixed, silica and alumina are effectively mutual action, a large specific surface area and a large specific pore volume are formed, pore distribution is very concentrative, 4-10nm pore volume is about 85%-95% of the total pore volume, pore volume which aperture is bigger than 15nm, is below 5% of the total pore volume. The amorphous silica-alumina provides enough channel to the reactant, benefits for enter and exit of reactant and resultant, greatly enhances effectively element of carrier, enhances the homogeneity of the acid center distributing on the channel, in addition, the invention provides larger space and specific surface to carry metal, the hydrogenation metal has high dispersivity, the catalyst not only has feasible schizolysis activity, but also bas high hydrogenation activity and medium oil selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com