Hydrocracking catalyst containing amorphous aluminum silicide and preparation thereof

An amorphous silica-alumina, hydrocracking technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problem of low specific surface and pore volume of amorphous silica-alumina , pore volume, low specific surface area, non-concentrated pore distribution, etc., to achieve the effect of large space and specific surface carrying metal, increasing effective components, and improving the uniformity of distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

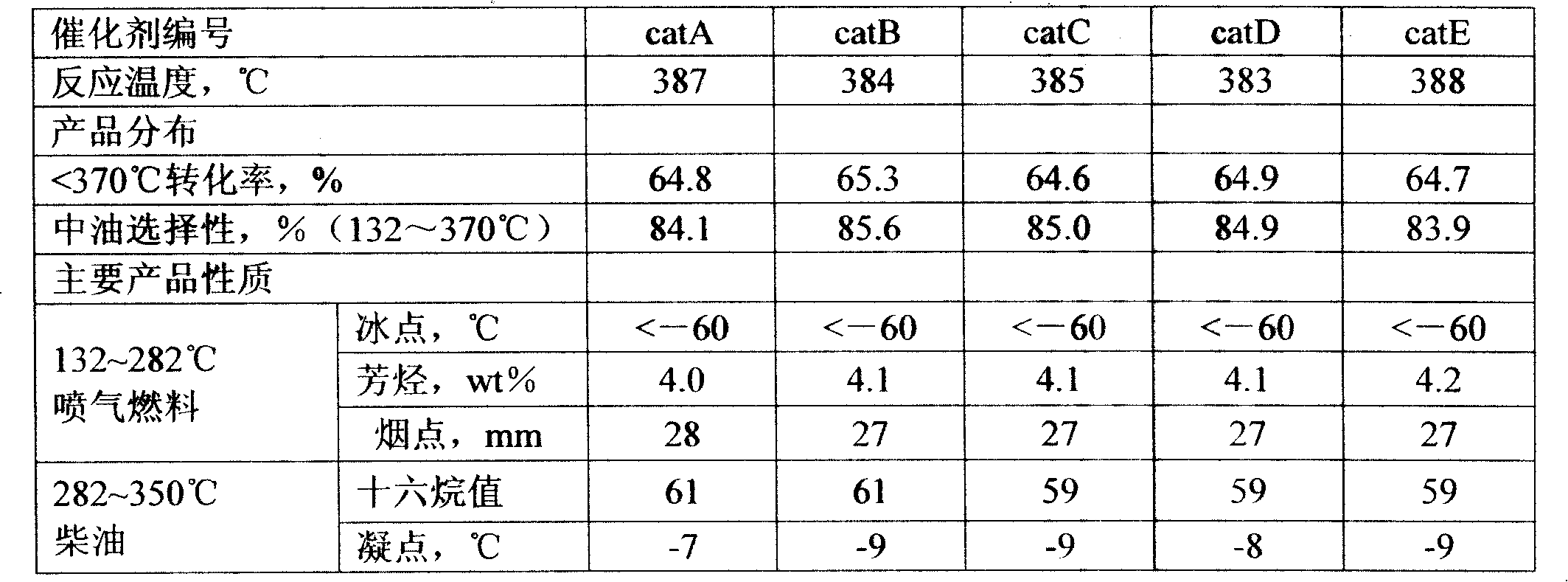

Examples

example 1

[0034] Prepare 700 solid sodium aluminate to a concentration of 200g Al 2 O 3 / l concentrated sodium aluminate solution, and then diluted to a concentration of 35gAl 2 O 3 / L Sodium aluminate working solution (a), which contains SiO 2 28wt% sodium silicate solution, then diluted to a concentration of 150gSiO 2 / l Sodium silicate working solution 2L (b). Take a 30L steel to make a rubber tank, and open the valves of the containers (a) and (b) respectively, and at the same time ventilate and pass in CO with a concentration of 45v% 2 Gas, set the flow rate of (a) and (b) so that the reaction time is 1 hour, and quickly adjust CO 2 The pH of the system is maintained at about 10.0, and the reaction temperature is 30°C. After the reaction of (a) and (b) is completed, stop the introduction of CO 2 , Then ventilate and stabilize for 40 minutes, filter the slurry and wash with 85°C deionized water until it is neutral. It was dried at 120°C for 8 hours, crushed and sieved to obtain amorphou...

example 2

[0036] Formulated 800 solid sodium aluminate to a concentration of 200g Al 2 O 3 / l concentrated sodium aluminate solution, and then diluted to a concentration of 40gAl 2 O 3 / L Sodium aluminate working solution (a), which contains SiO 2 28wt% sodium silicate solution, and then diluted to a concentration of 200gSiO 2 / l Sodium silicate working solution 1L (b). Take a 30L steel to make a rubber tank, and open the valves of the containers (a) and (b) respectively, and at the same time ventilate and inject CO with a concentration of 50v% 2 Gas, set the flow rate of (a) and (b) so that the reaction time is 50 minutes, and quickly adjust the CO 2 The pH of the system is maintained at about 10.5, and the reaction temperature is 35°C. After the reaction of (a) and (b) is completed, stop the introduction of CO 2 , Then ventilate and stabilize for 40 minutes, filter the slurry and wash with 80℃ deionized water to neutrality. It was dried at 120°C for 8 hours, crushed and sieved to obtain a...

example 3

[0038] Prepare 600 solid sodium aluminate to a concentration of 200g Al 2 O 3 / l concentrated sodium aluminate solution, and then diluted to a concentration of 30gAl 2 O 3 / L Sodium aluminate working solution (a), which contains SiO 2 28wt% sodium silicate solution, then diluted to a concentration of 100gSiO 2 / l Sodium silicate working solution 4L (b). Take a 30L steel to make a rubber tank, and open the valves of the containers (a) and (b) respectively, and at the same time ventilate and inject CO with a concentration of 50v% 2 Gas, set the flow rate of (a) and (b) so that the reaction time is 70 minutes, and quickly adjust the CO 2 The pH of the system is maintained at about 9.5, and the reaction temperature is 40°C. After the reaction of (a) and (b), stop the introduction of CO 2 , Then ventilate and stabilize for 1 hour, filter the slurry and wash with 85°C deionized water until it is neutral. It was dried at 120°C for 8 hours, crushed and sieved to obtain amorphous silicon-a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com