Method for preparing carrier material

A carrier material and preparation process technology, applied in the direction of catalyst carrier, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of modification process limitation, influence of amorphous silica-alumina properties, reduction of molecular sieve pore volume, etc., to achieve The effect of improving usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The carrier material prepared according to the method provided by the present invention.

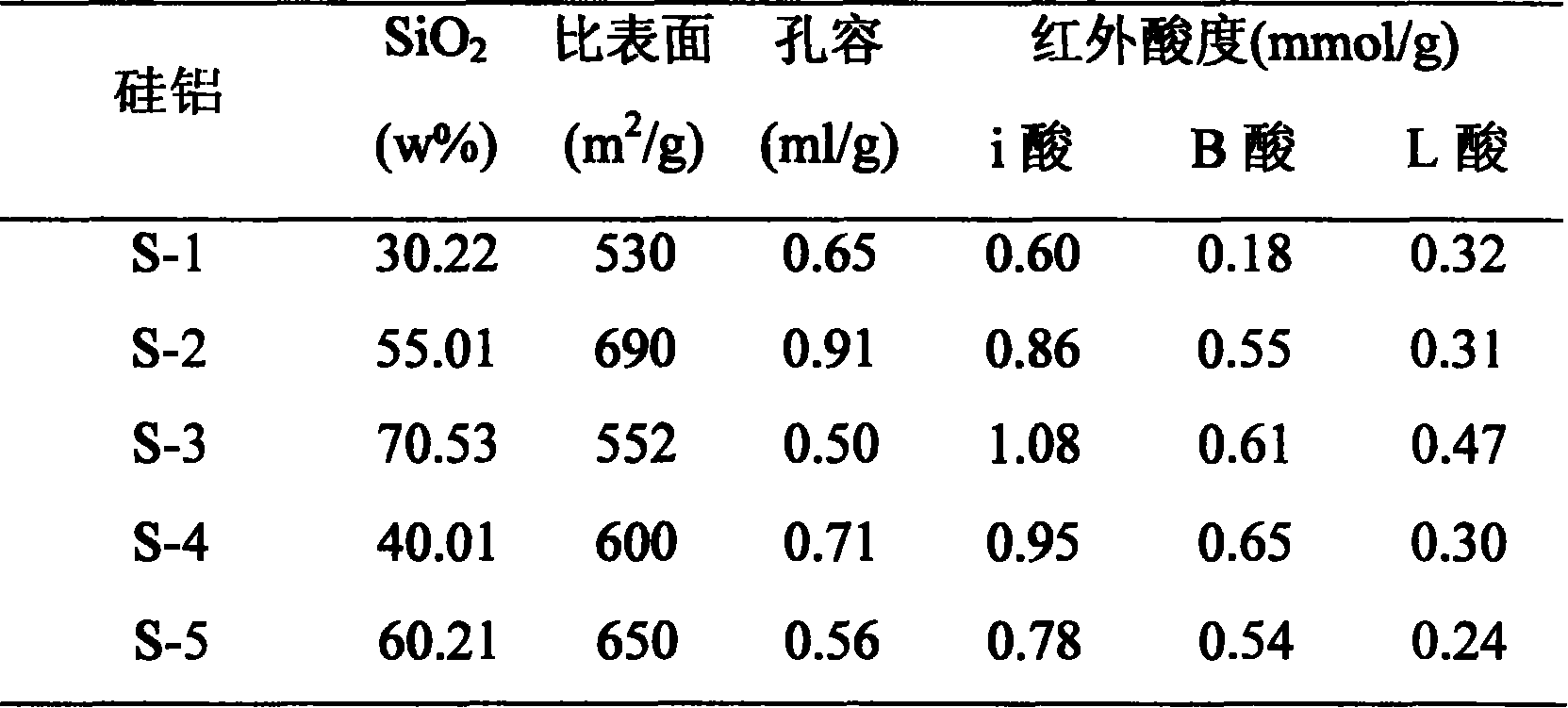

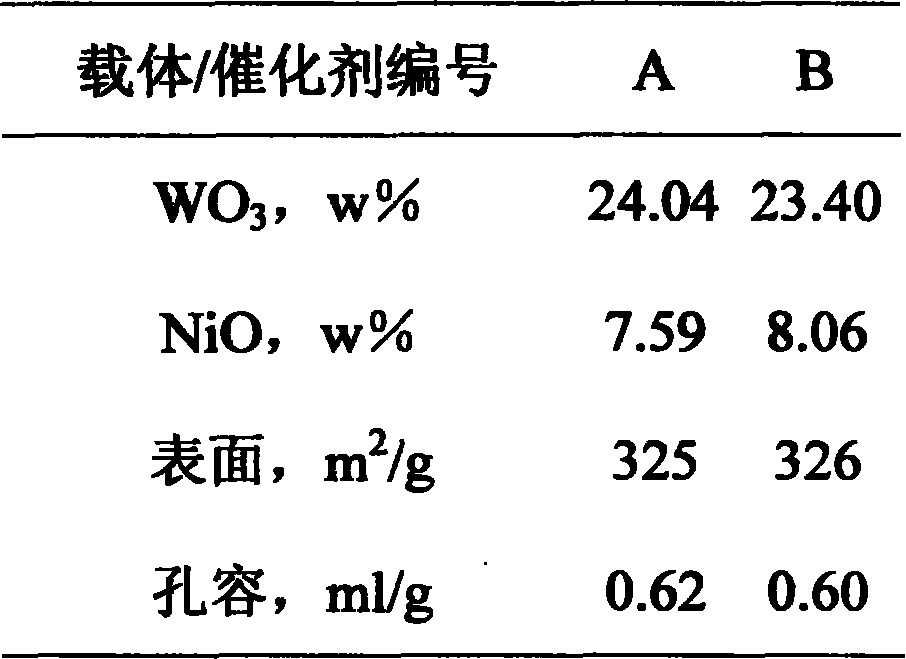

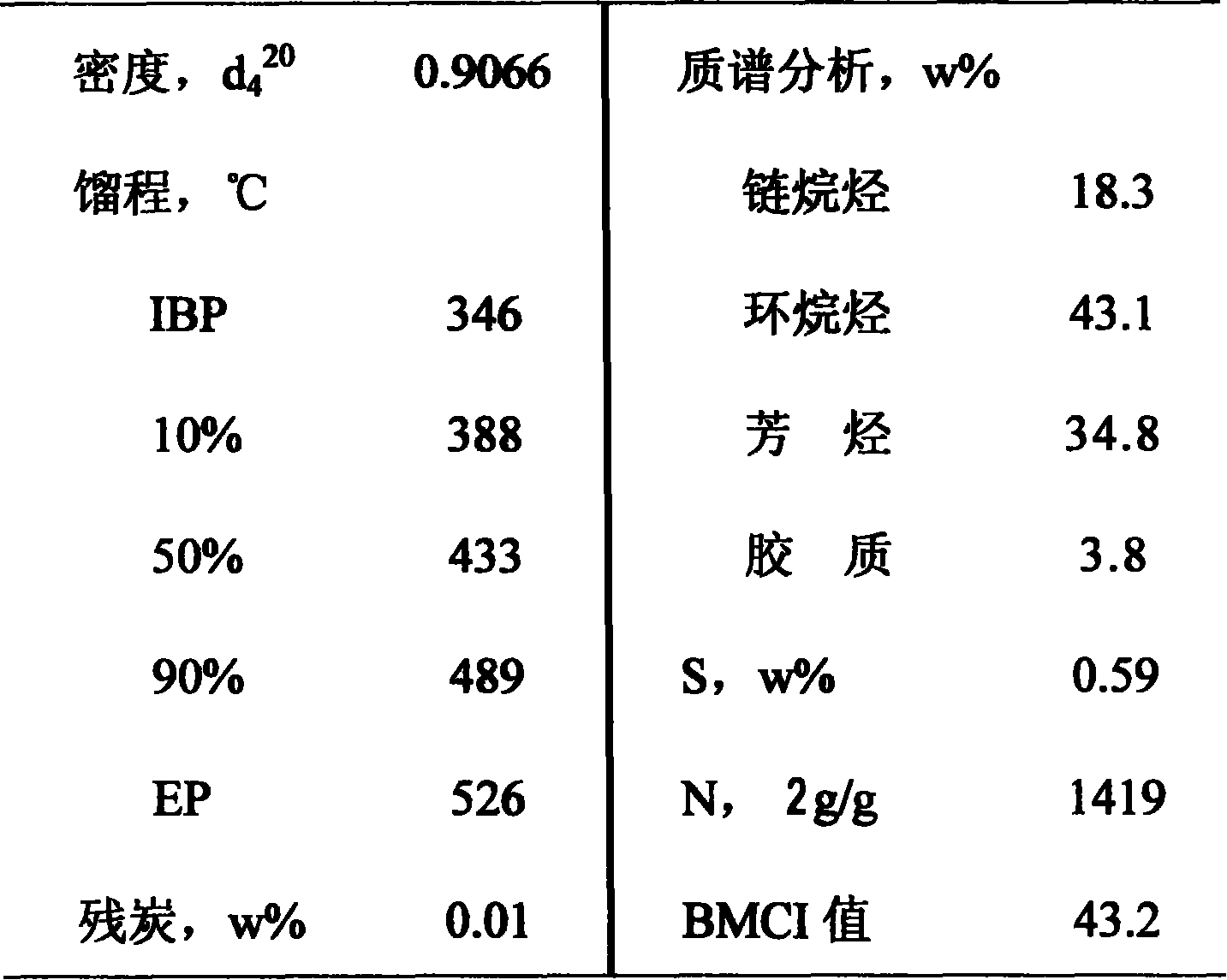

[0038] With 150g modified hydrogen type Y molecular sieve (SiO 2 / Al 2 o 3 =5.1 (molecular ratio, the same below), the unit cell constant is Relative crystallinity is 90%) add 2 liters of distilled water, stir beating, form slurry (a), add 4000g solid aluminum sulfate to 7.5 liters of distilled water, heat simultaneously and stir until dissolving, obtain aluminum sulfate solution (b), Al 2 o 3 The concentration is about 4g / 100ml. Dilute the concentrated ammonia water into about 10% dilute ammonia water (c) by adding appropriate amount of distilled water. 10 liters of distilled water is added in the strong water glass of 4.8 liters of a kind of industrial grade modulus 3.0, obtains dilute water glass solution (d). Take a 15-liter steel reaction tank, add 2 liters of distilled water in the tank and stir and heat to 70°C, open the valves of the containers containing aluminum s...

Embodiment 2

[0040] 150g of modified hydrogen form β (SiO 2 / Al 2 o 3 =28, the unit cell constant is Relative crystallinity is 87%) Molecular sieve is added into 2 liters of distilled water, stirs beating, forms slurry (a), 4000g solid aluminum sulfate is added into 7.5 liters of distilled water, heats simultaneously and stirs until dissolving, obtains aluminum sulfate solution (b), al 2 o 3 The concentration is about 4g / 100ml. Dilute the concentrated ammonia water into about 10% dilute ammonia water (c) by adding appropriate amount of distilled water. 10 liters of distilled water is added in the strong water glass of 4.8 liters of a kind of industrial grade modulus 3.0, obtains dilute water glass solution (d). Take a 15-liter steel reaction tank, add 2 liters of distilled water in the tank and stir and heat to 70°C, open the valves of the containers containing aluminum sulfate and ammonia water respectively, and slowly add (a) into the reaction tank, press Prepare 750g of silicon-...

Embodiment 3

[0042] With 150g modified hydrogen type Y molecular sieve (SiO 2 / Al 2 o 3 =5.1, the unit cell constant is Relative crystallinity is 90%) add 2 liters of distilled water, stir beating, form slurry (a), add 4000g solid aluminum sulfate to 7.5 liters of distilled water, heat simultaneously and stir until dissolving, obtain aluminum sulfate solution (b), Al 2 o 3 The concentration is about 4g / 100ml. Mix (a) and (b) into (b'). Dilute the concentrated ammonia water into about 10% dilute ammonia water (c) by adding appropriate amount of distilled water. 10 liters of distilled water is added in the strong water glass of 4.8 liters of a kind of industrial grade modulus 3.0, obtains dilute water glass solution (d). Get a 15-liter steel reaction tank, add 2 liters of distilled water in the tank and stir and heat to 70 ° C, open the valves of the containers that respectively store aluminum sulfate (containing molecular sieve slurry) and ammonia water, and prepare 750 g of silicon-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com