Catalyst used in reaction process of producing ethylene from dehydration of ethanol

A catalyst and preparation process technology, applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, chemical/physical processes, etc., can solve the problems of using inert diluent gas, high reaction temperature, etc., to increase single-pass production, ethanol conversion rate and ethylene selection High performance and reduced heating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1H

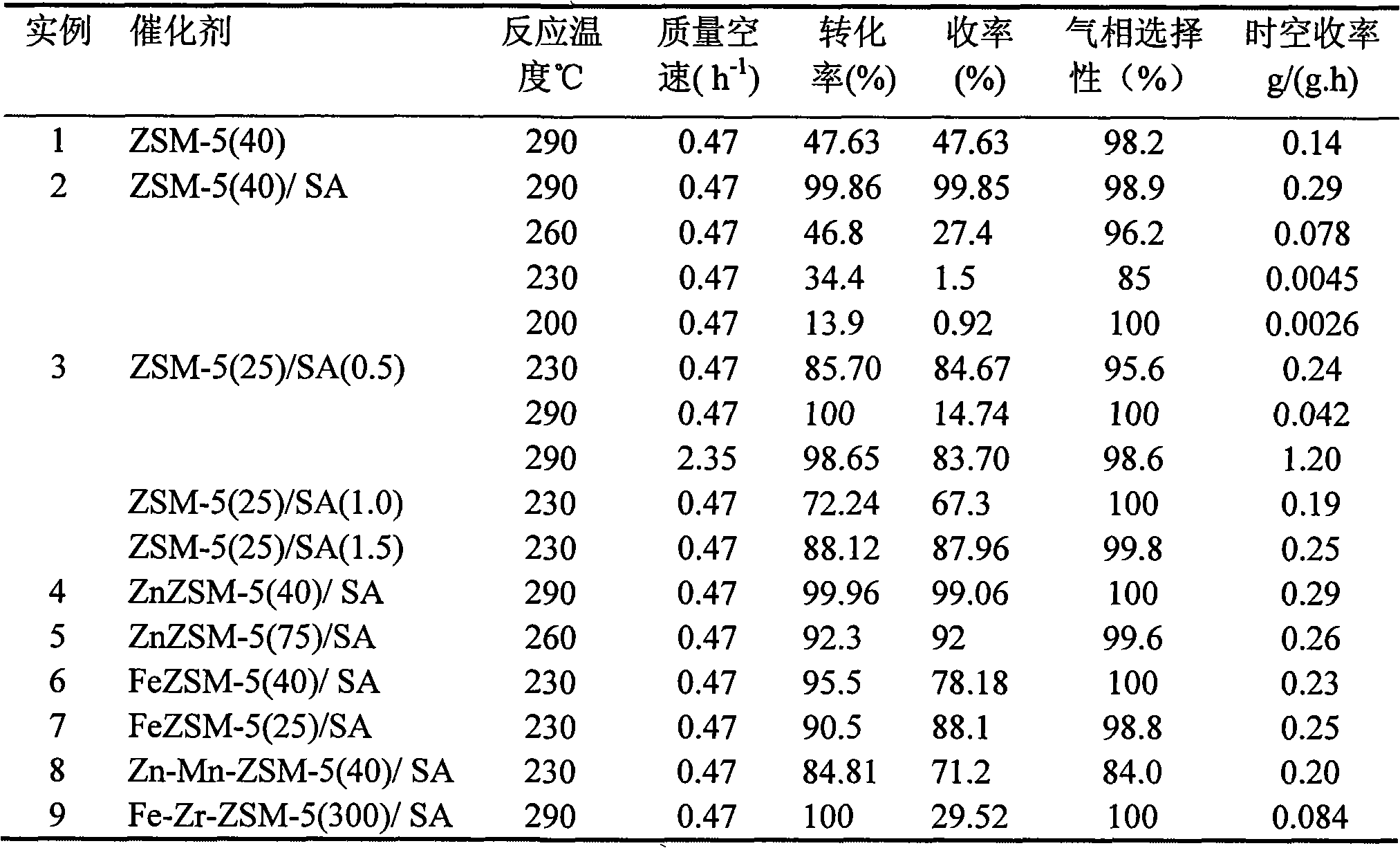

[0024] Example 1HZSM-5(40)

[0025] Weigh 10g of HZSM-5 raw powder with Si / Al=40, wash it with deionized water, dry it at 110°C, and put it into a muffle furnace at 500-700°C for 2-5 hours to prepare HZSM-5(40) catalyst.

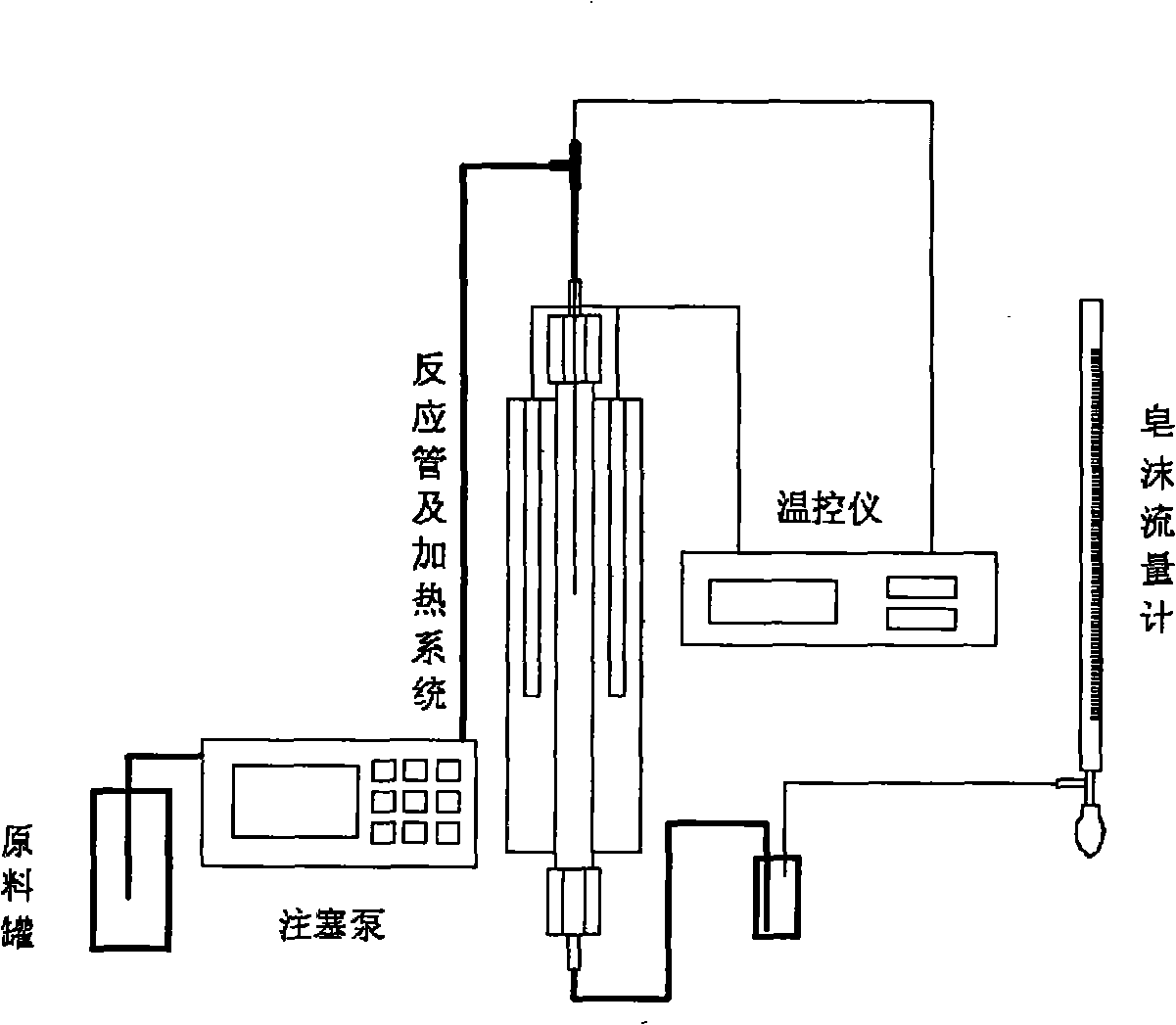

[0026] The prepared catalyst was put into an atmospheric fixed-bed reactor (see Figure 1) for investigation, and the dehydration performance of the catalyst is shown in Table 1.

example 2H

[0027] Example 2HZSM-5(40) / SA

[0028] Weigh 28.8g33.3% silica sol, 12gNaOH particles, 6.6g Al 2 (SO4) 3 powder and 192gH 2 O, move the silica sol into a three-necked flask, add NaOH solution, heat until clarified, then add Al 2 (SO4) 3 solution, kept stirring for 2 hours, cooled to room temperature, and adjusted the pH value to 6.5-7 to obtain amorphous silica-alumina gel; weigh 10g of HZSM-5 raw powder with Si / Al=40, add 5-10g of amorphous silicon Mix aluminum glue, heat at 60-100°C for 5-8 hours under reflux, dry at 110°C, and then bake in a muffle furnace at 500°C-700°C for 2-4 hours to prepare HZSM-5(40) / SA catalyst. The amount of the prepared amorphous silicon-alumina is 3.5wt%-6.5wt%.

[0029] The prepared catalyst was put into an atmospheric pressure fixed-bed reactor for investigation, and the dehydration performance of the catalyst is shown in Table 1.

example 3H

[0030] Example 3HZSM-5(25) / SA

[0031] Weigh 28.8g33.3% silica sol, 12gNaOH particles, 6.6g Al 2 (SO4) 3 powder and 192gH 2 O, move the silica sol into a three-necked flask, add NaOH solution, heat until clarified, then add Al 2 (SO4) 3 solution, keep stirring for 2 hours, cool to room temperature, and adjust the pH value to 6.5-7 to obtain amorphous silica-alumina gel; weigh 10g of HZSM-5 raw powder with Si / Al=25, add 5-15g of amorphous silicon Mix aluminum glue, heat at 60-100°C for 5-8 hours under reflux, dry at 110°C, and then bake in a muffle furnace at 500-700°C for 2-4 hours to prepare the HZSM-5(25) / SA catalyst. The 5g, 10g, and 15g of amorphous silica-alumina colloids added were mixed and recorded as HZSM-5(25) / SA(0.5), HZSM-5(25) / SA(1.0), HZSM-5(25) / SA(1.5 ). The amount of the prepared amorphous silicon-alumina is 3.5wt%-12.5wt%.

[0032] The prepared catalyst was put into an atmospheric pressure fixed-bed reactor for investigation, and the dehydration perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com