Patents

Literature

798results about "Refining by aromatic hydrocarbon hydrogenation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

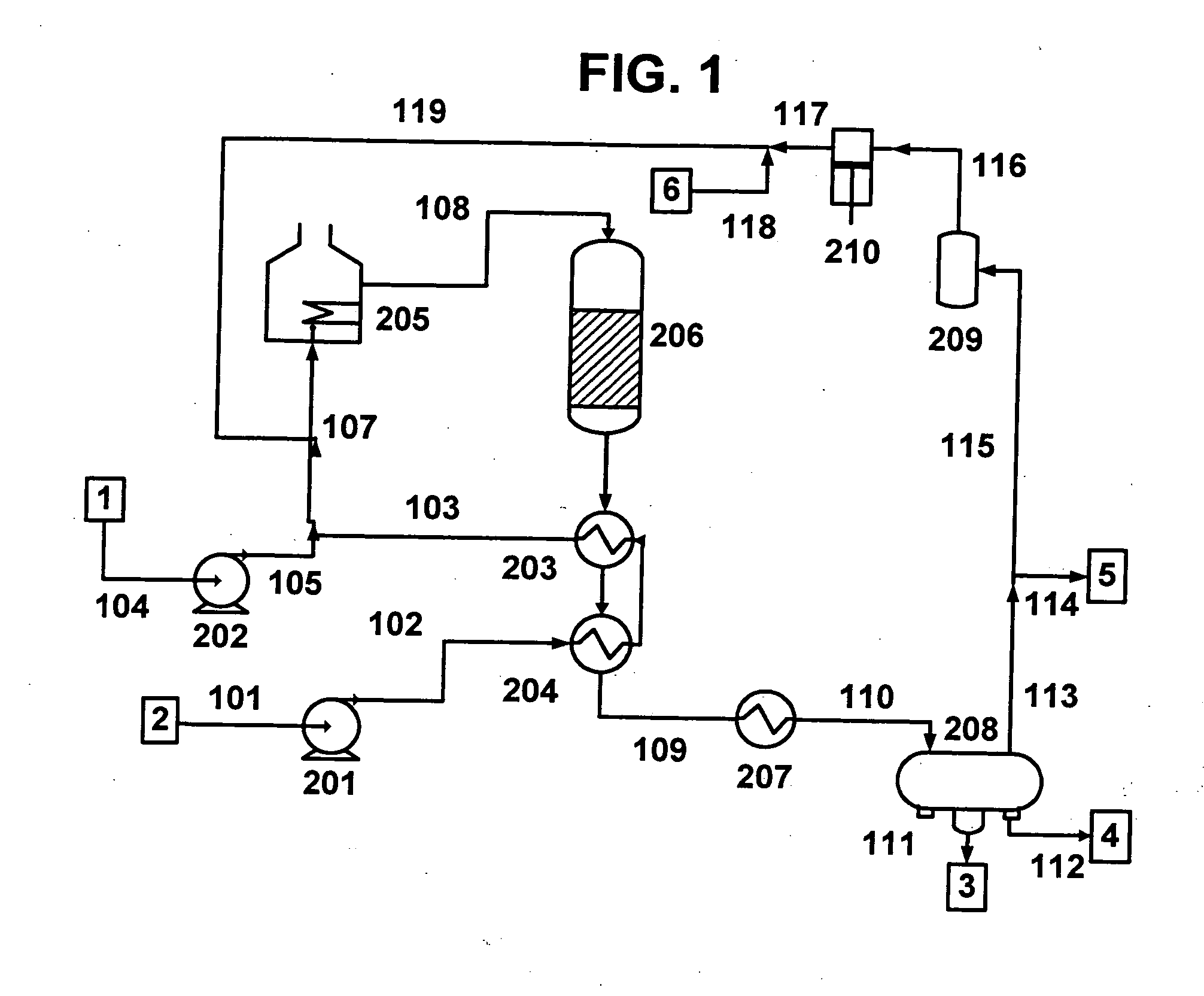

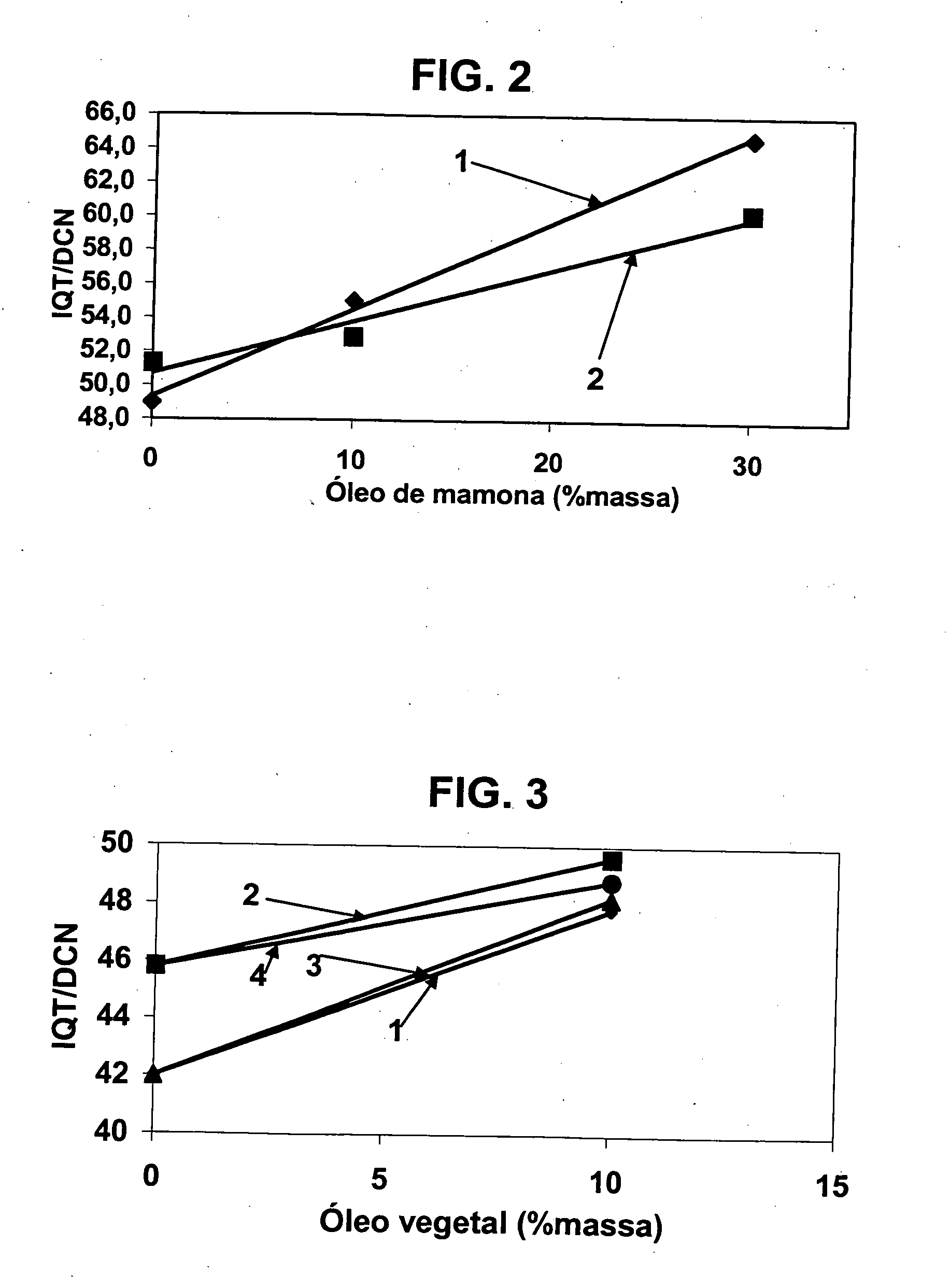

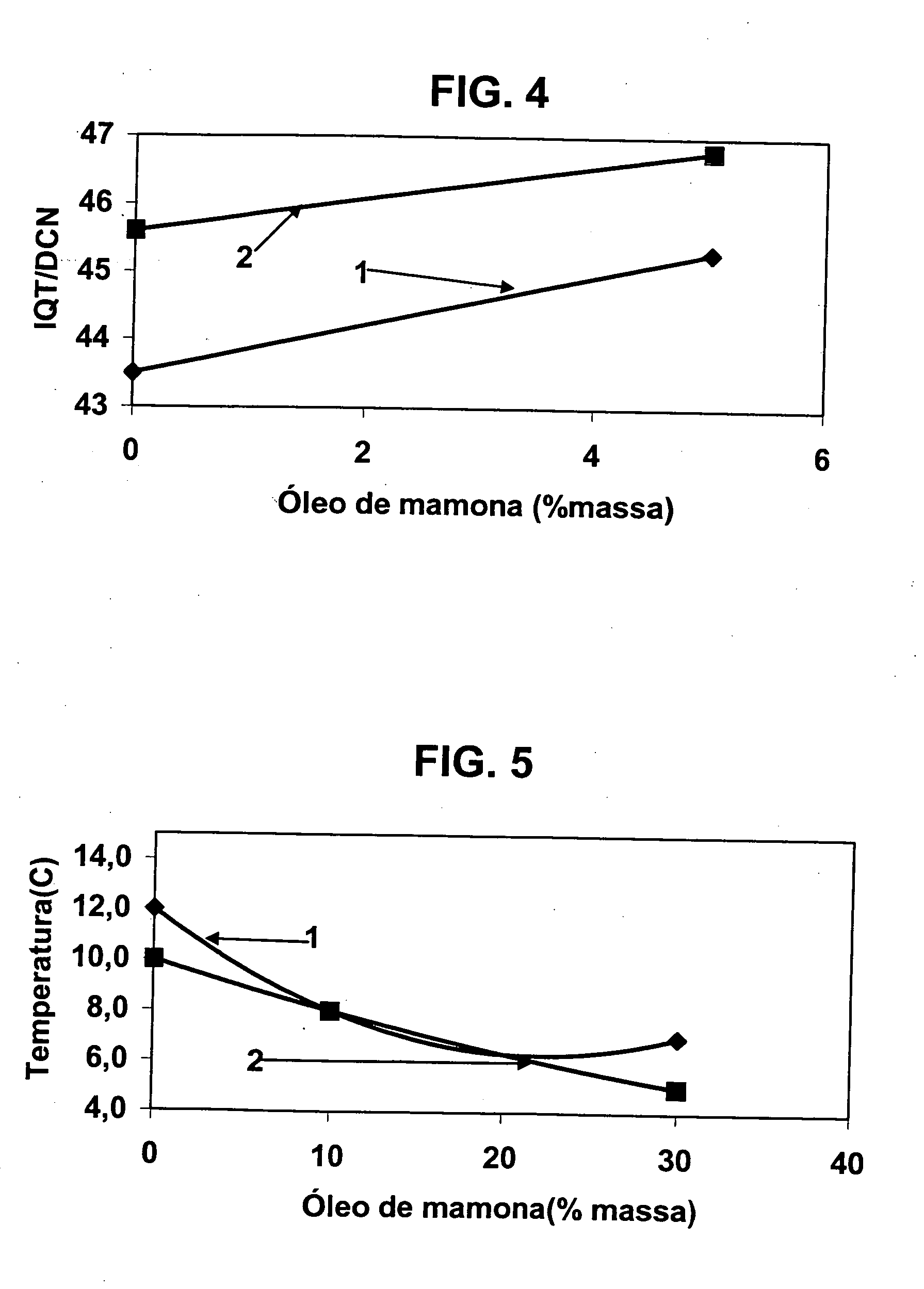

Vegetable oil hydroconversion process

InactiveUS20060186020A1Improved cetane indexAvoid excessive densityMolecular sieve catalystsBiofuelsVegetable oilHydrogen

A vegetable oil hydroconversion process is described for hydroconverting a mixture between 1 to 75% in mass of oil or natural fat (1) and the rest mineral oil (2), hydroconverted in a reactor (205) under conditions of pressure, temperature, hydrogen (flow 119) and sulfide catalyst of Groups VIII and VIB, obtaining, after sour water separation (flow 111) and rectification (flow 112), a specified diesel product (4). The product (4) has an ITQ / DCN (cetane number) higher than a product obtained from a pure mineral based oil would have, lower density than from a base oil and a plugging point depending on the mineral oil flow, as well as greater oxidation stability than the base oil.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

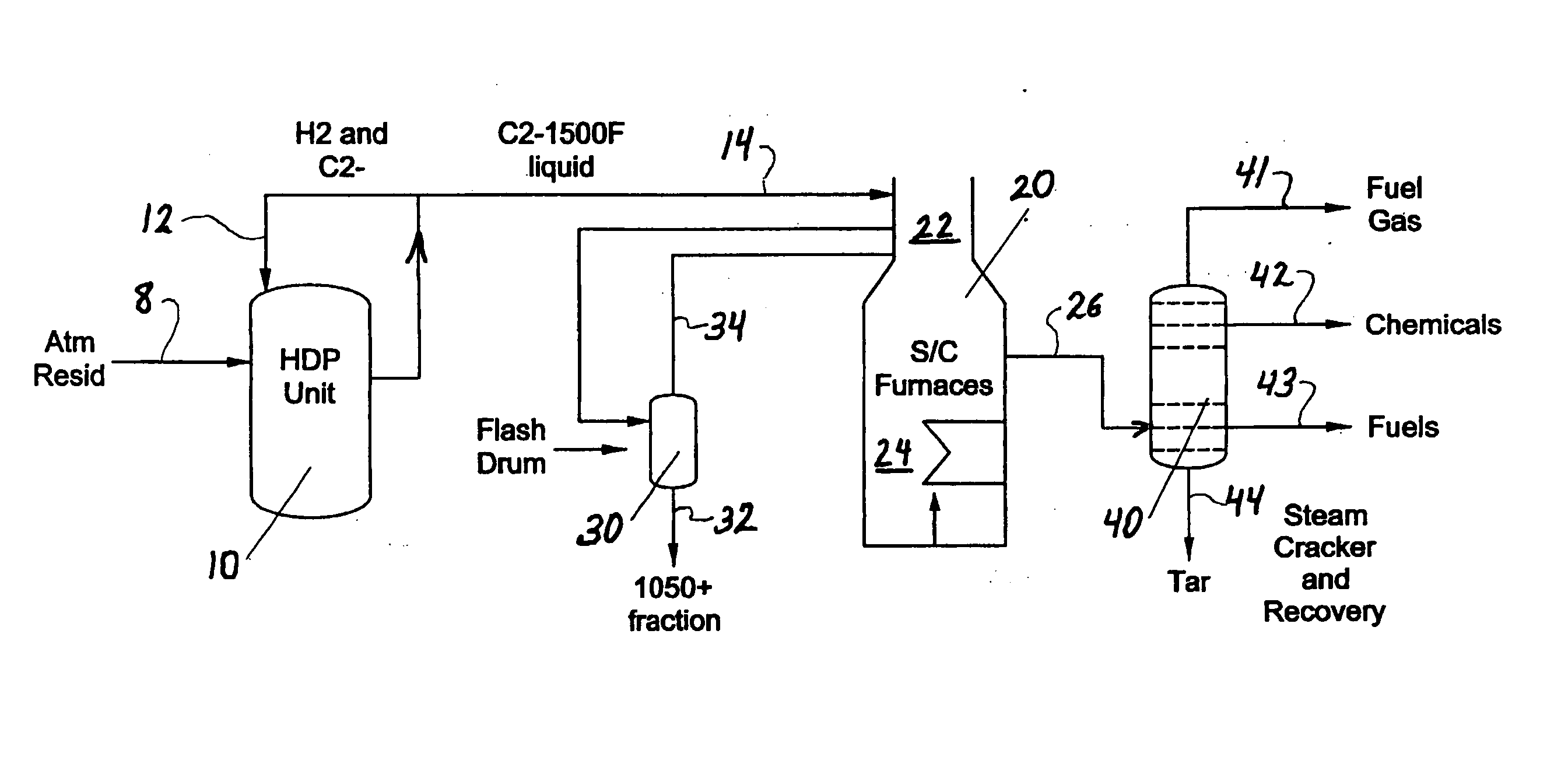

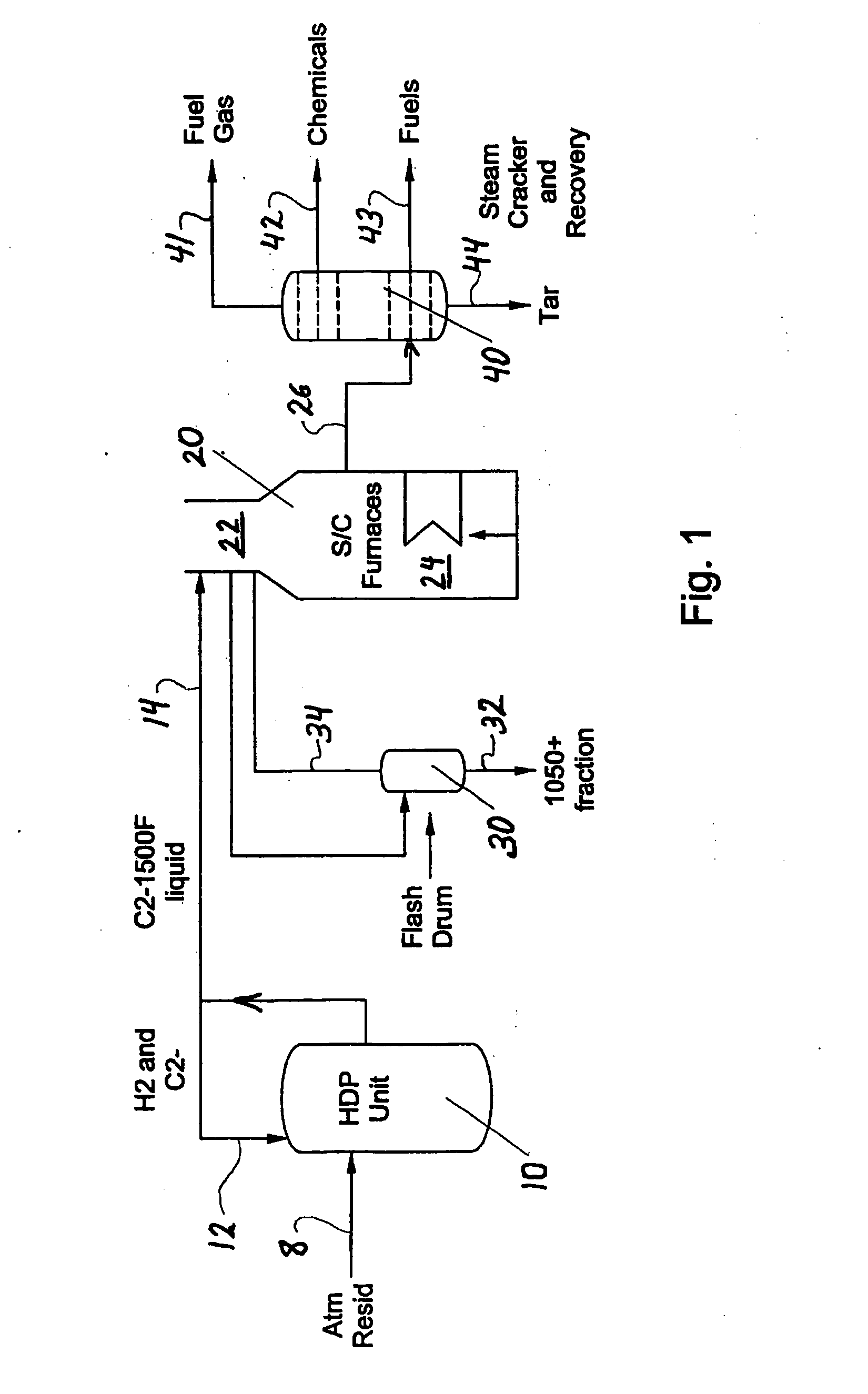

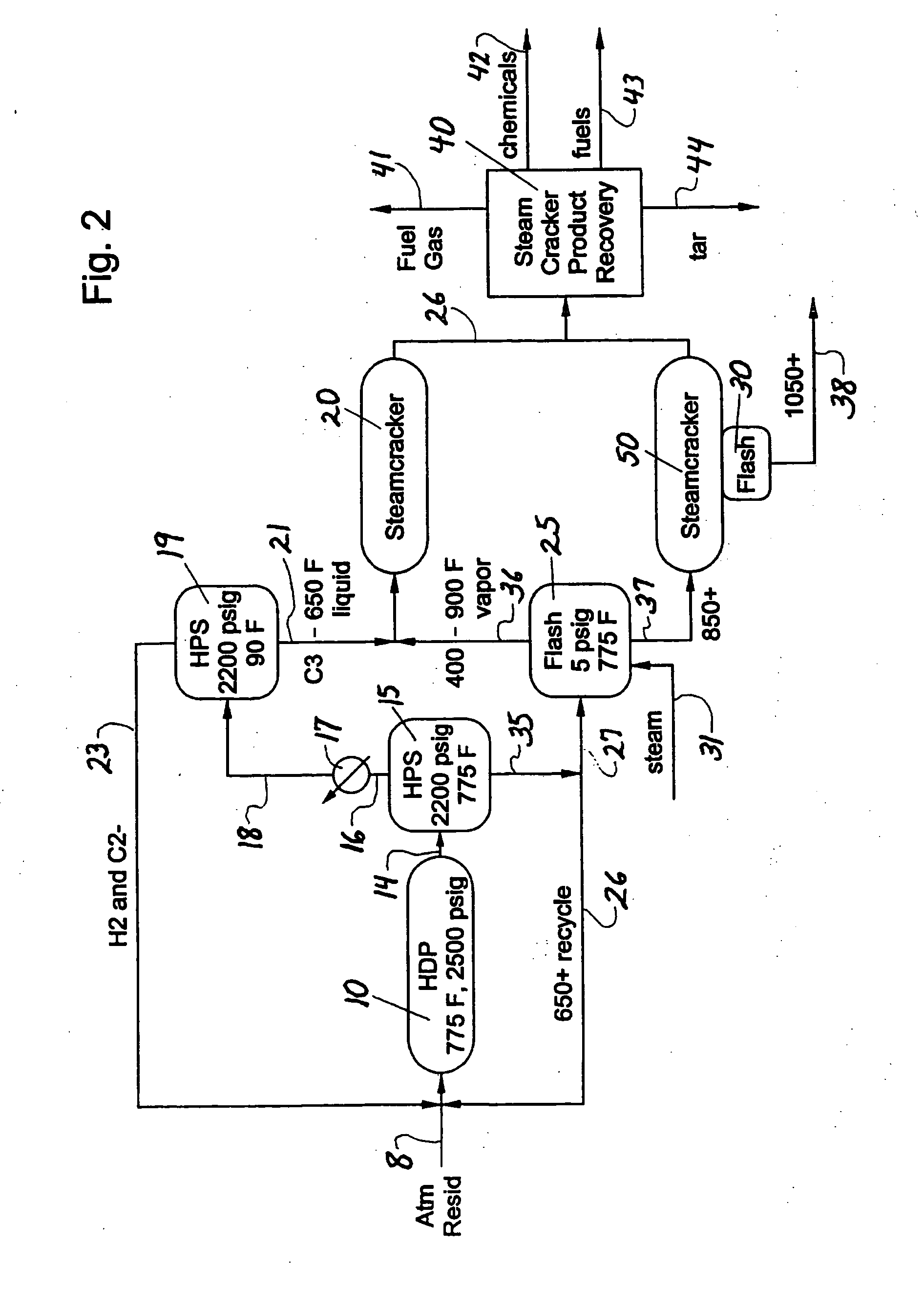

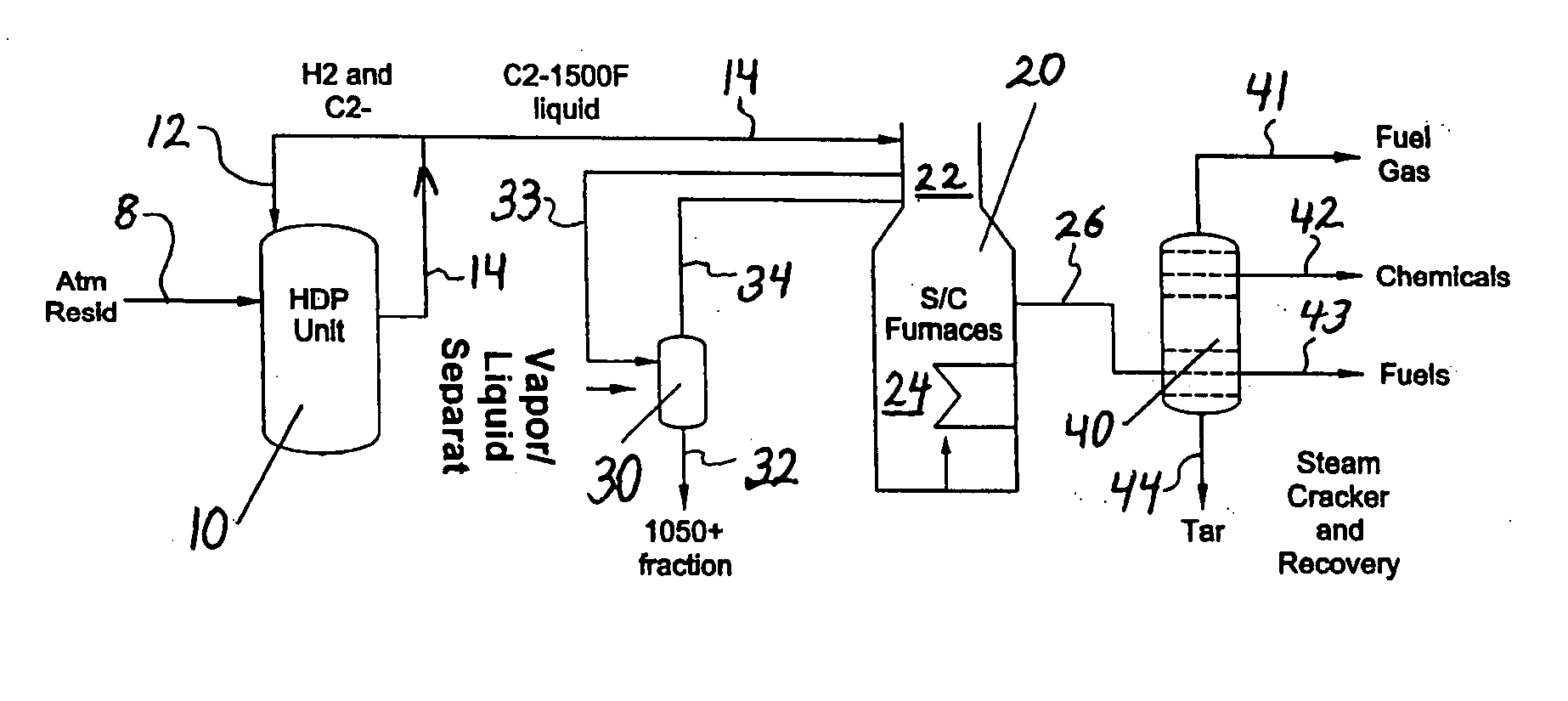

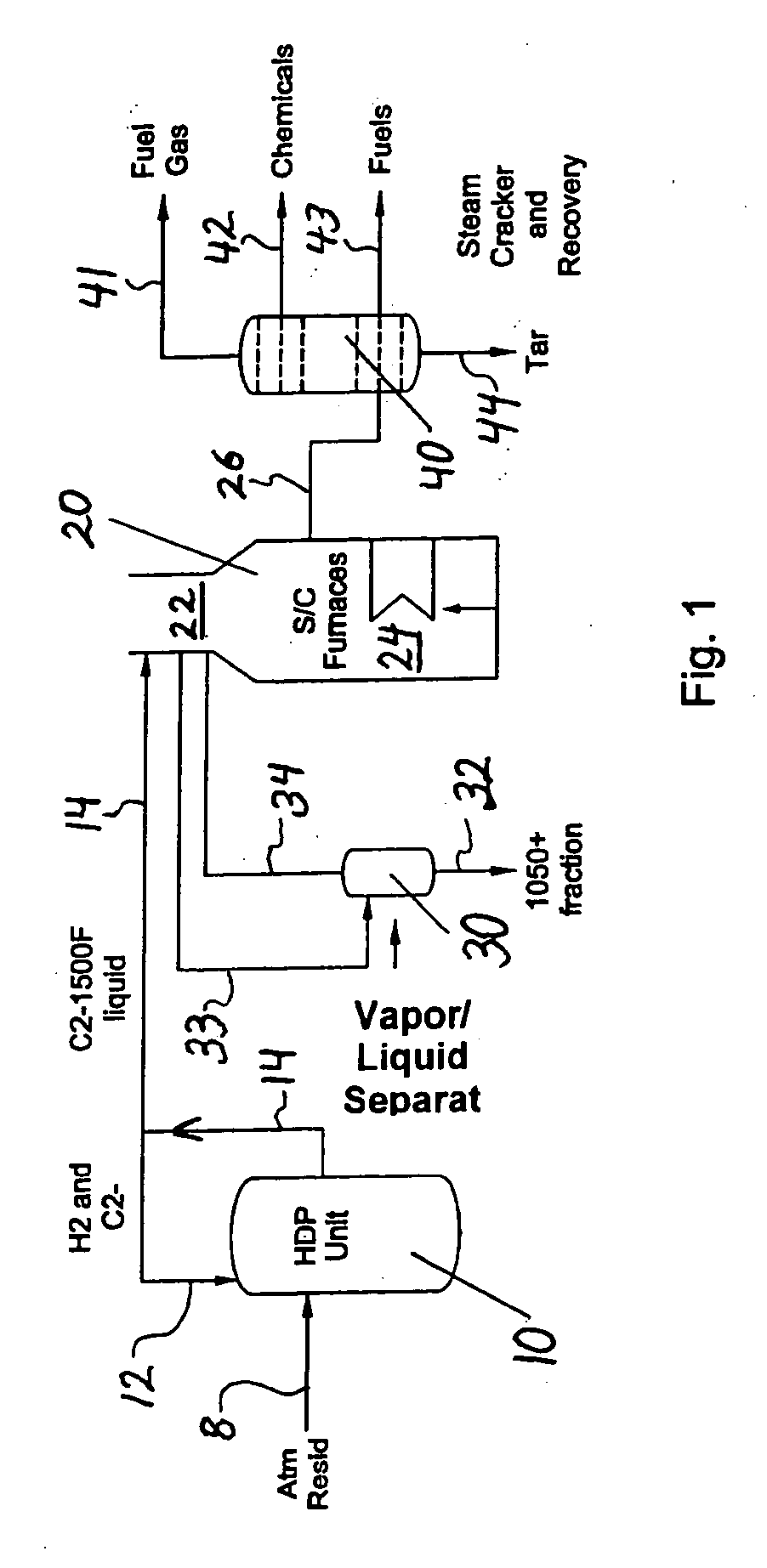

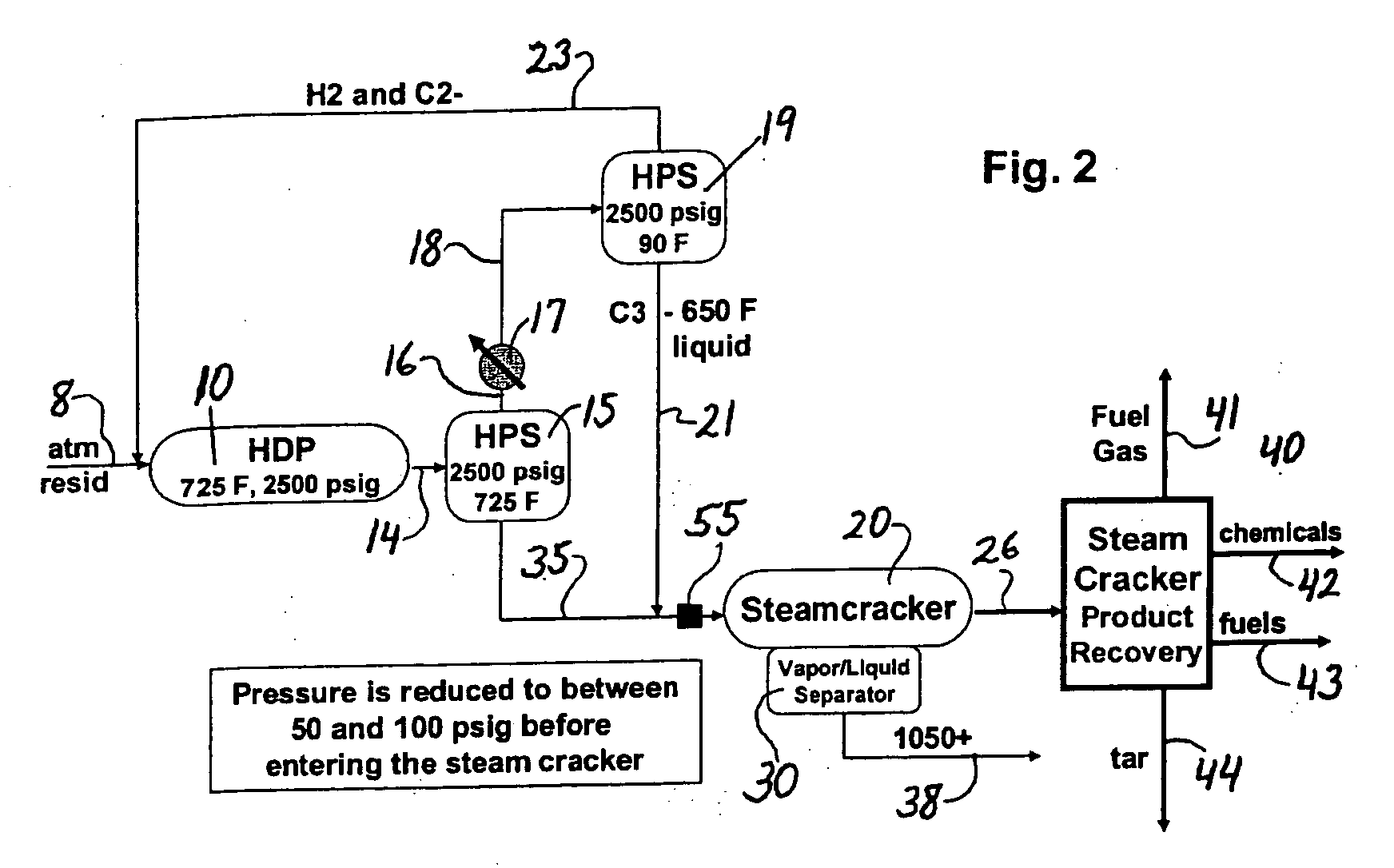

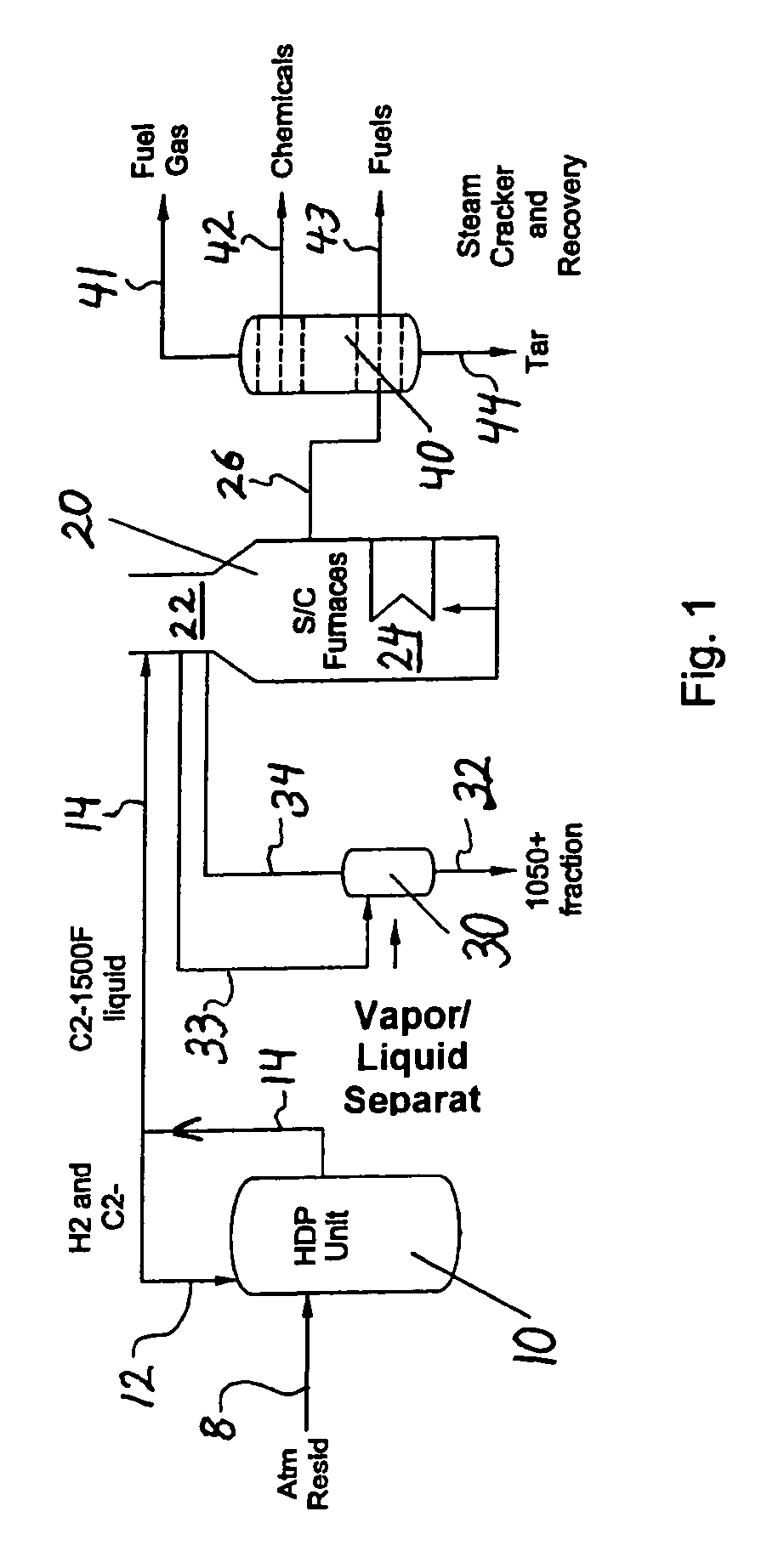

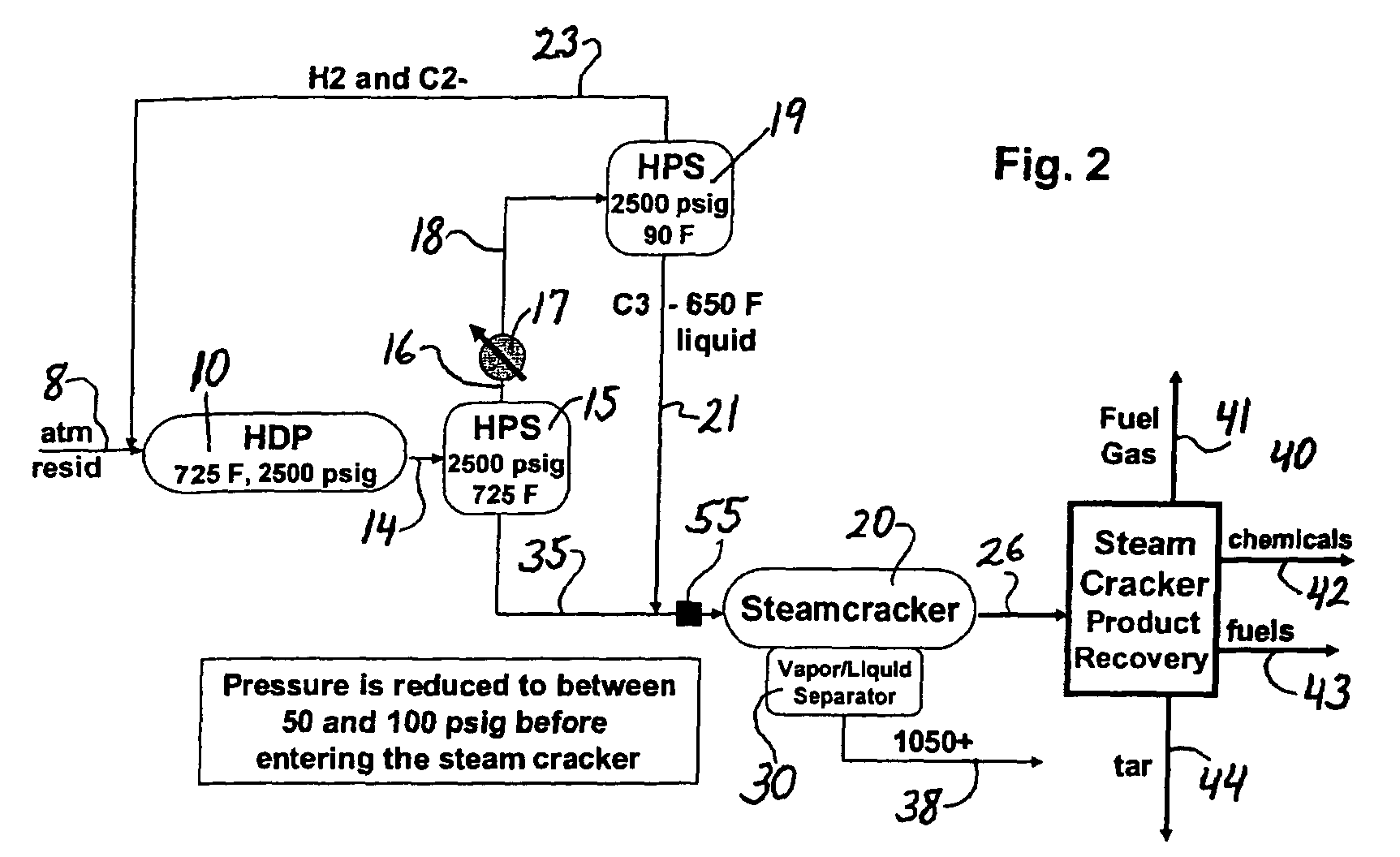

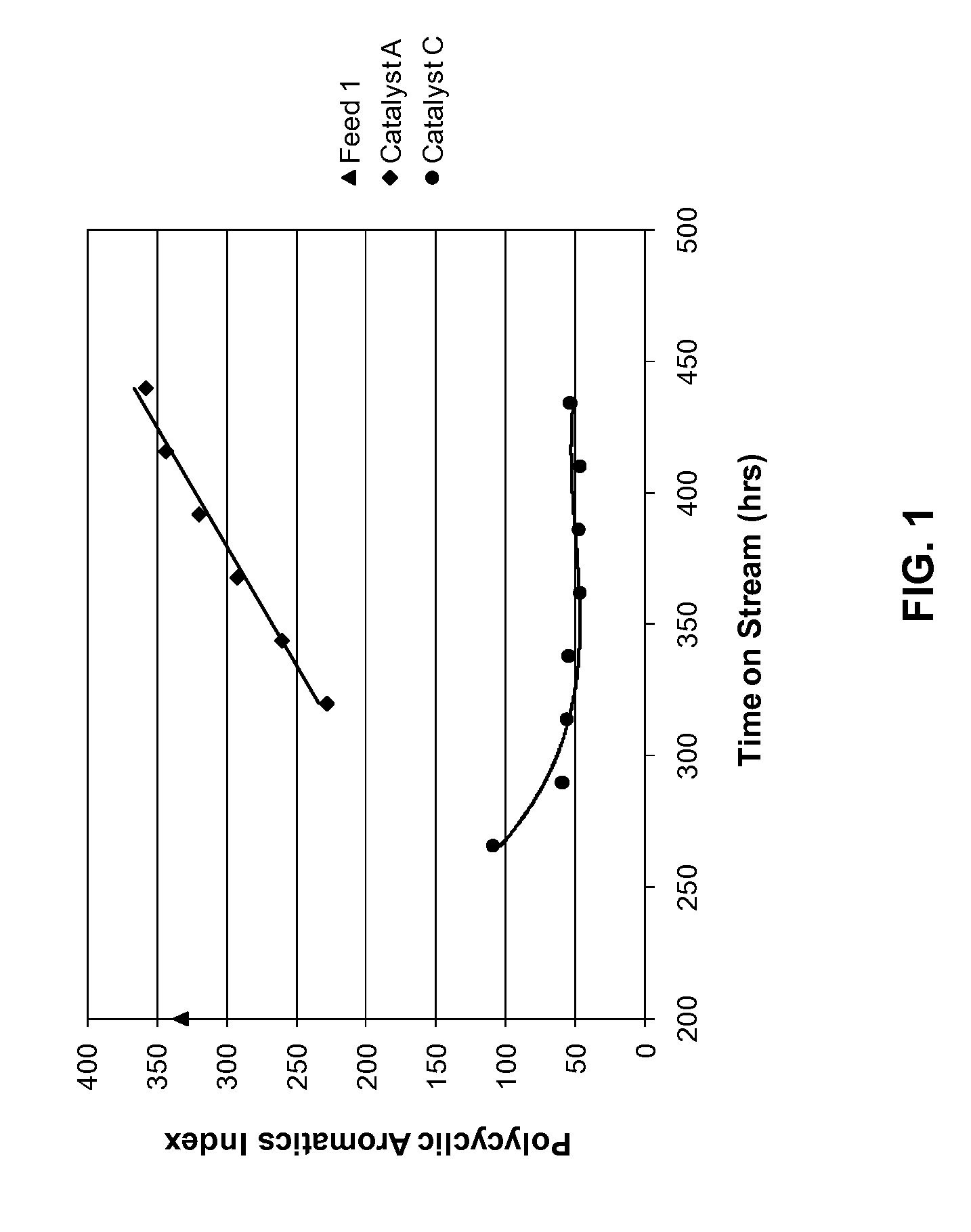

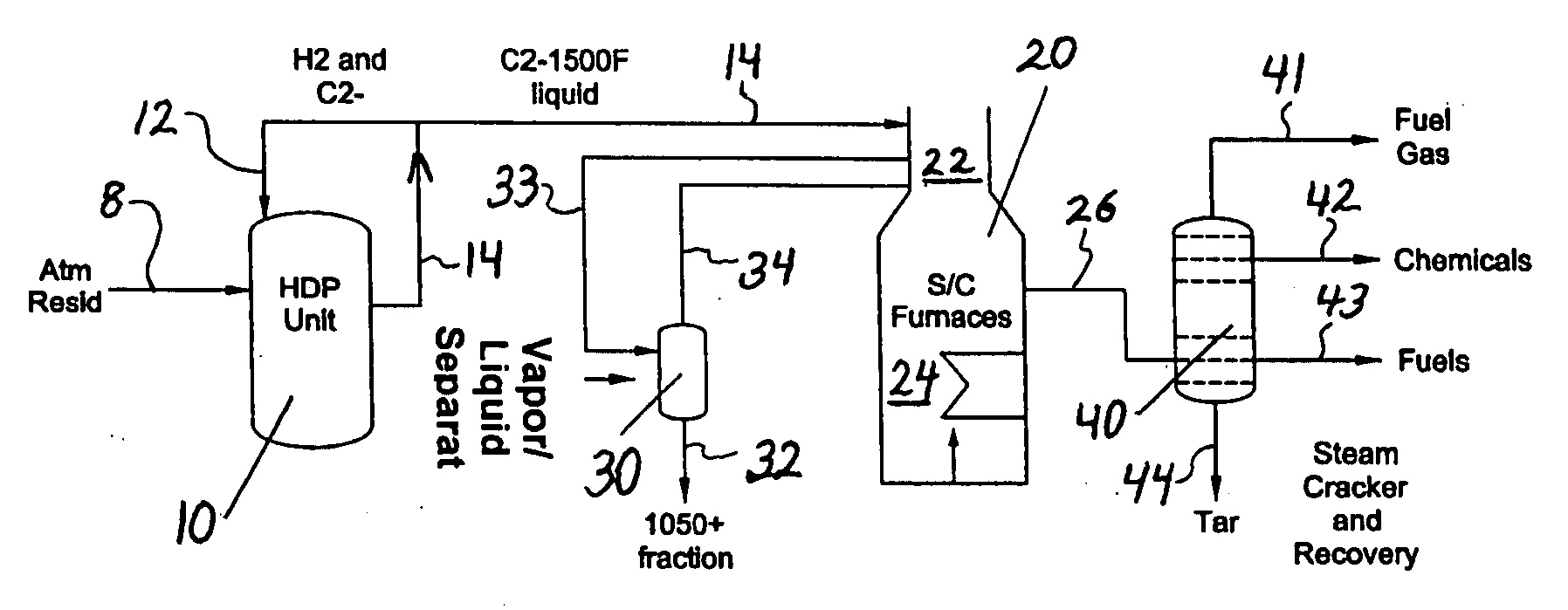

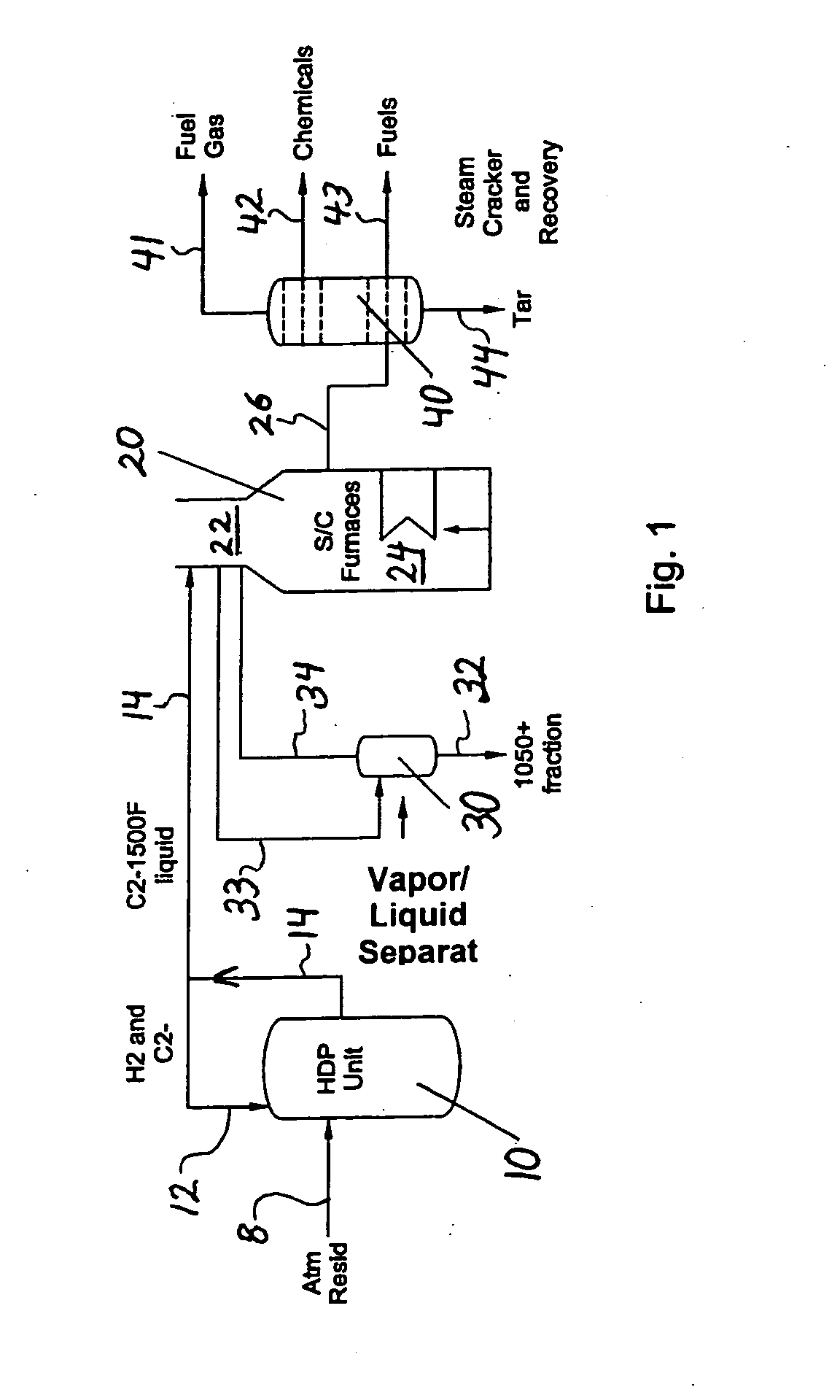

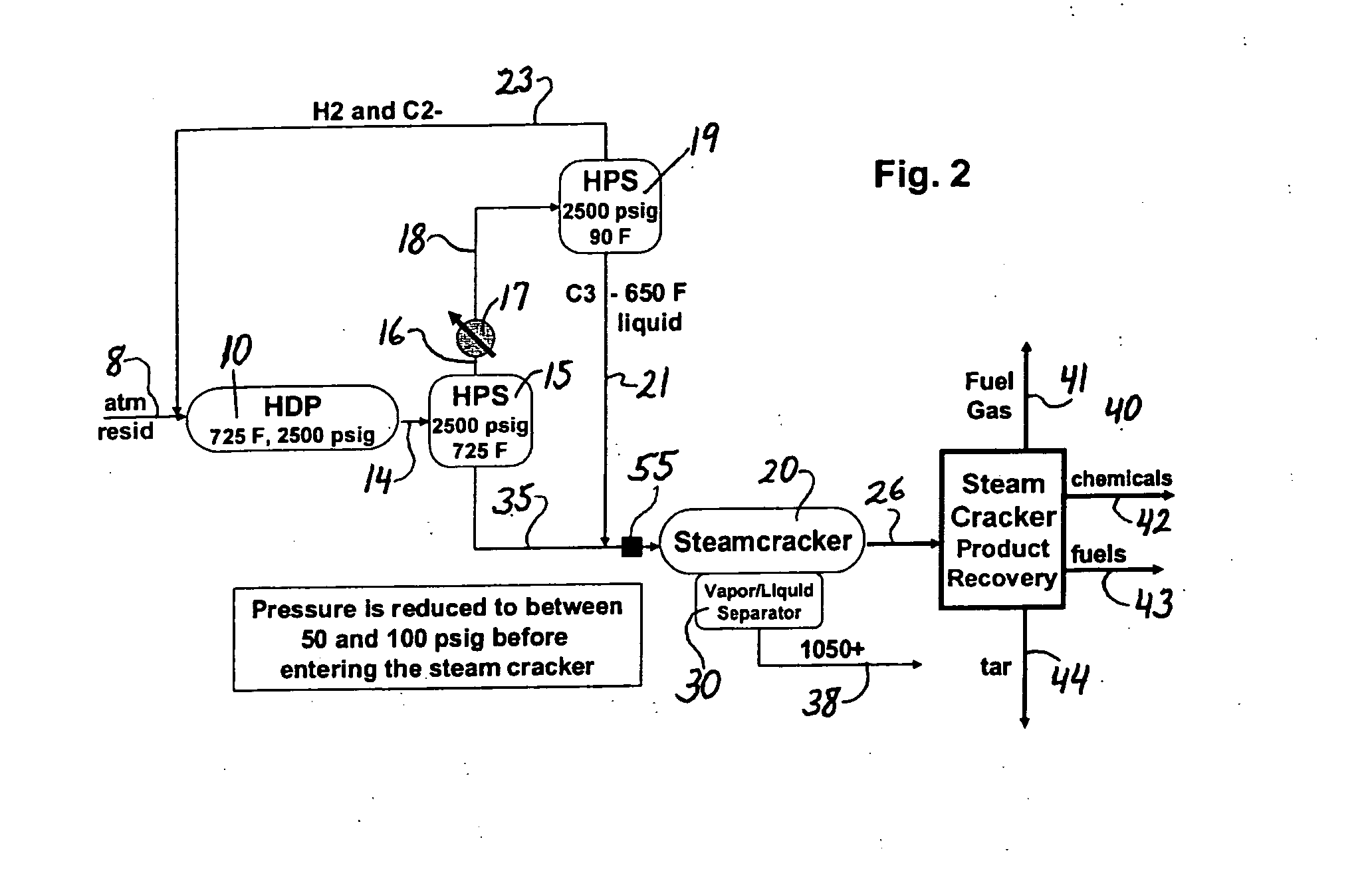

Hydrocarbon resid processing

ActiveUS20070090018A1Increase in severityReduce pressureThermal non-catalytic crackingHydrocarbon oil cracking processHydrocarbonChemistry

The invention concerns integration of hydroprocessing and steam cracking. A feed comprising crude or resid-containing fraction thereof is severely hydrotreated and passed to a steam cracker to obtain an olefins product.

Owner:EXXONMOBIL CHEM PAT INC

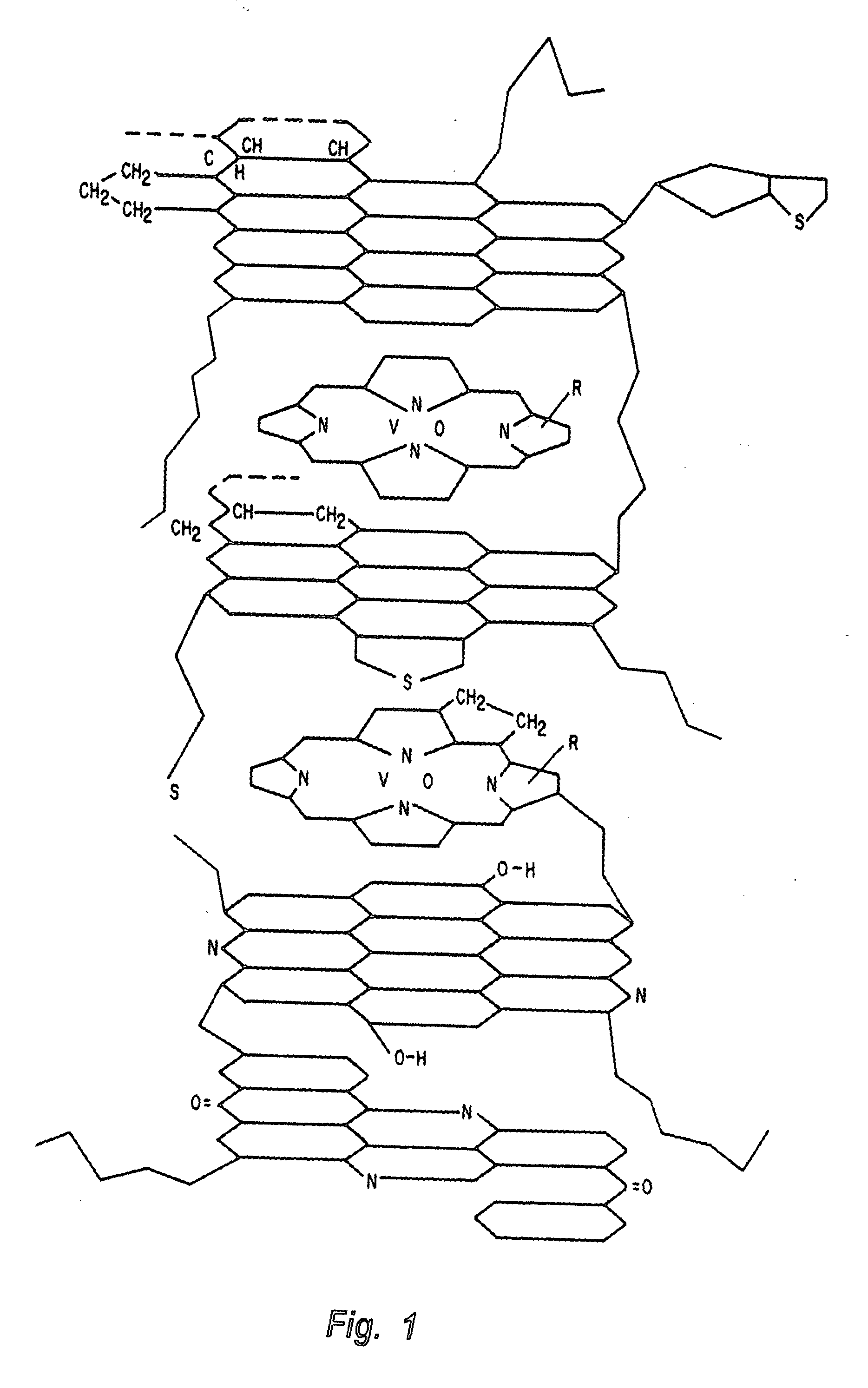

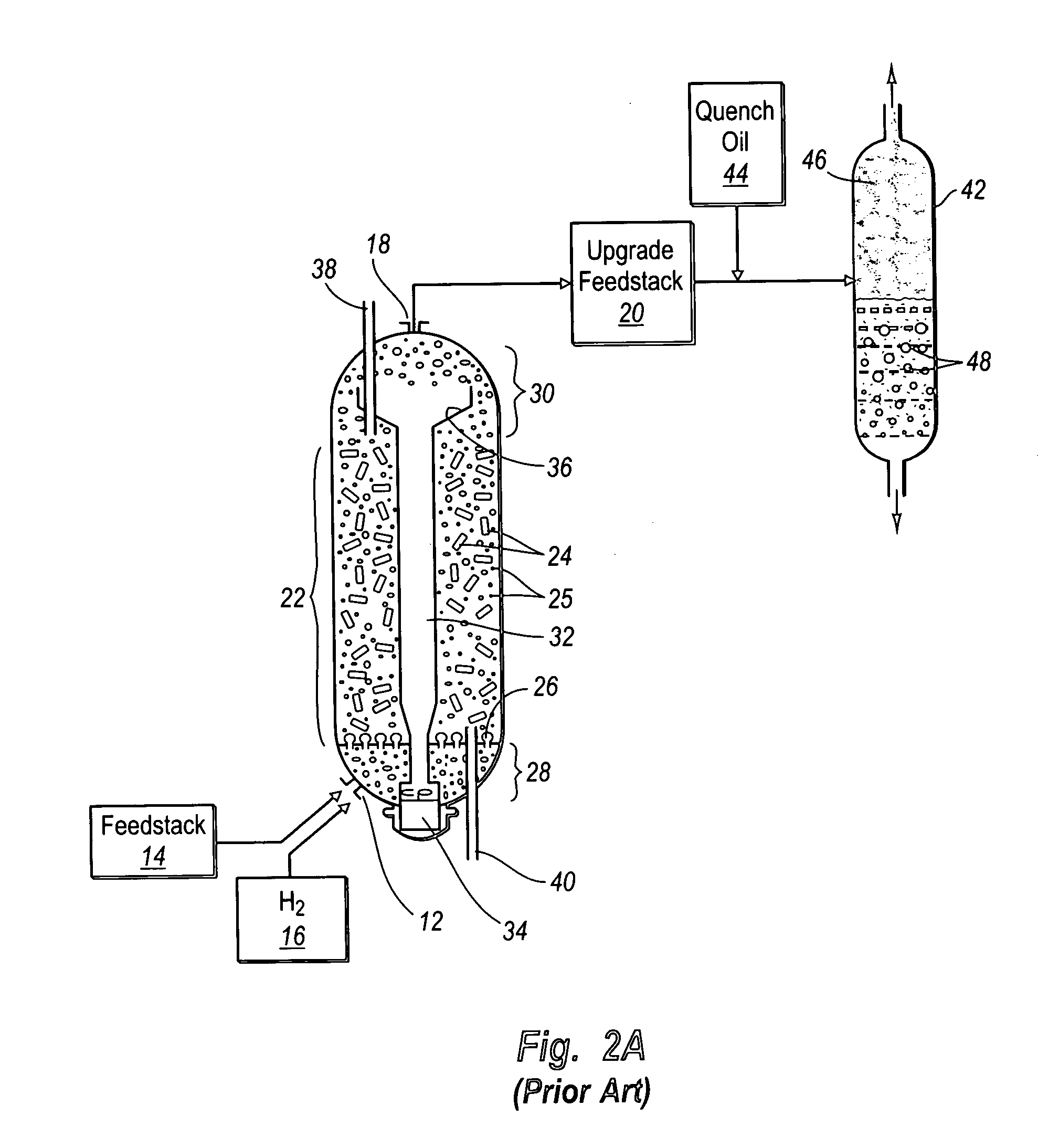

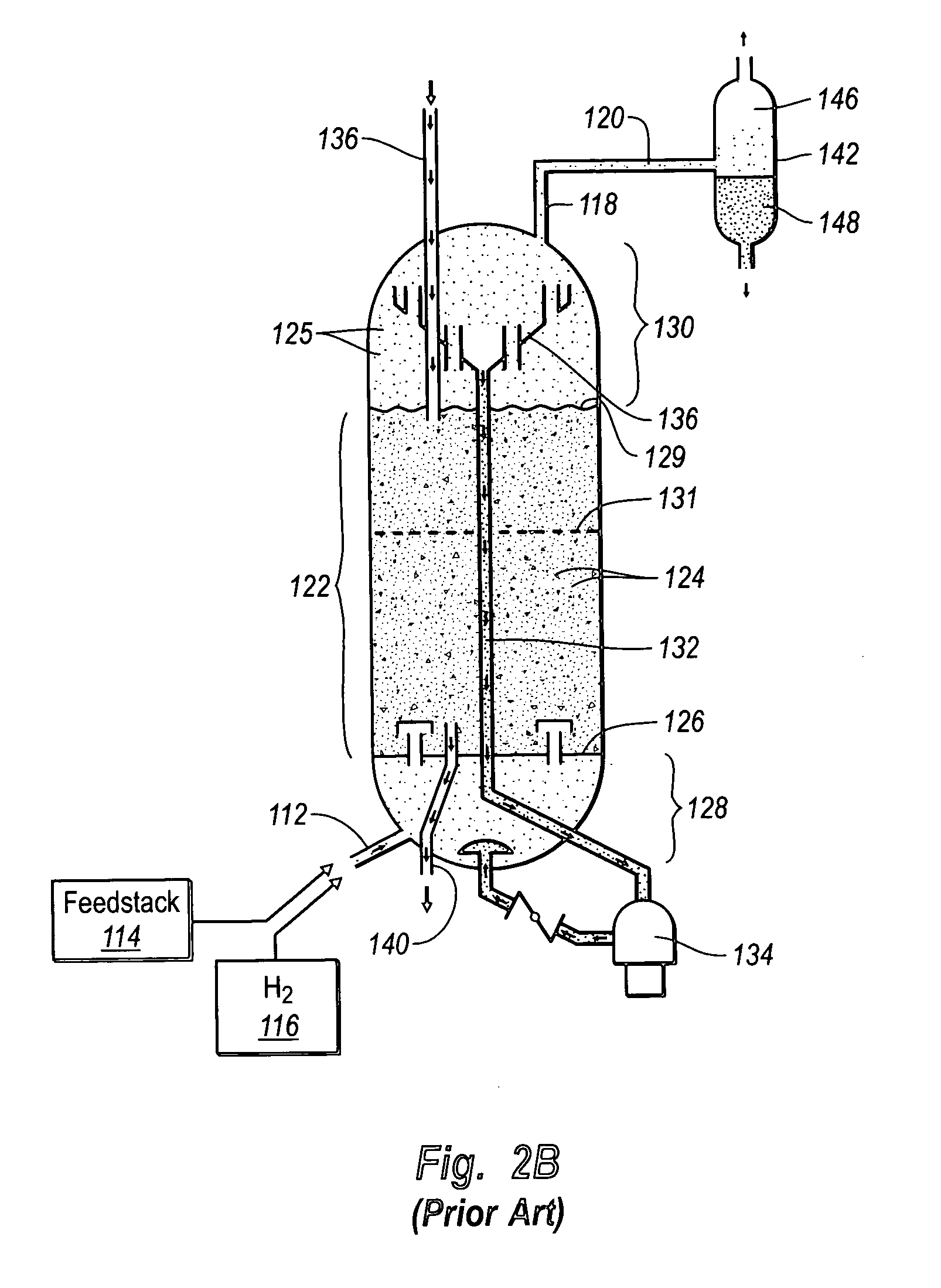

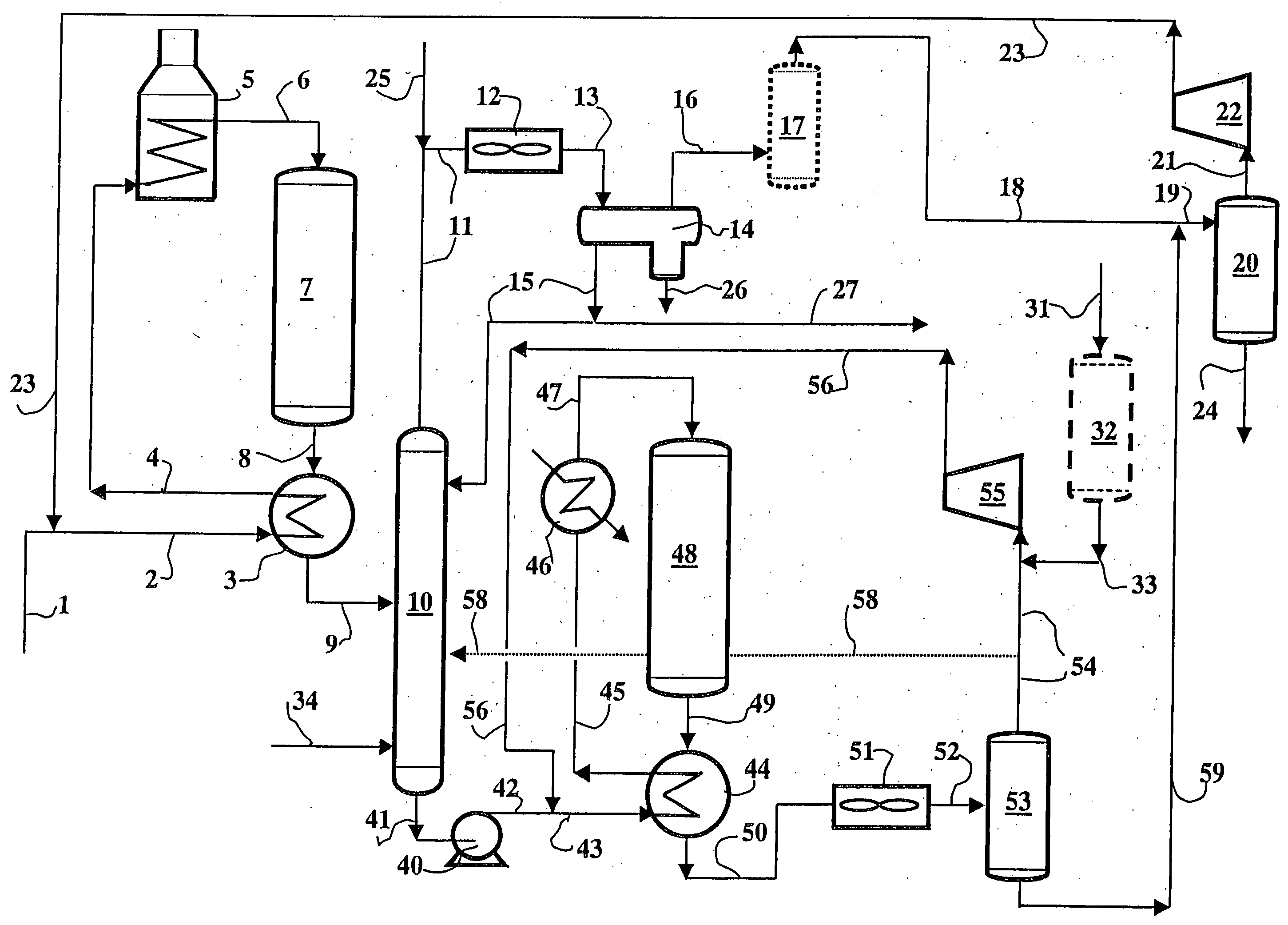

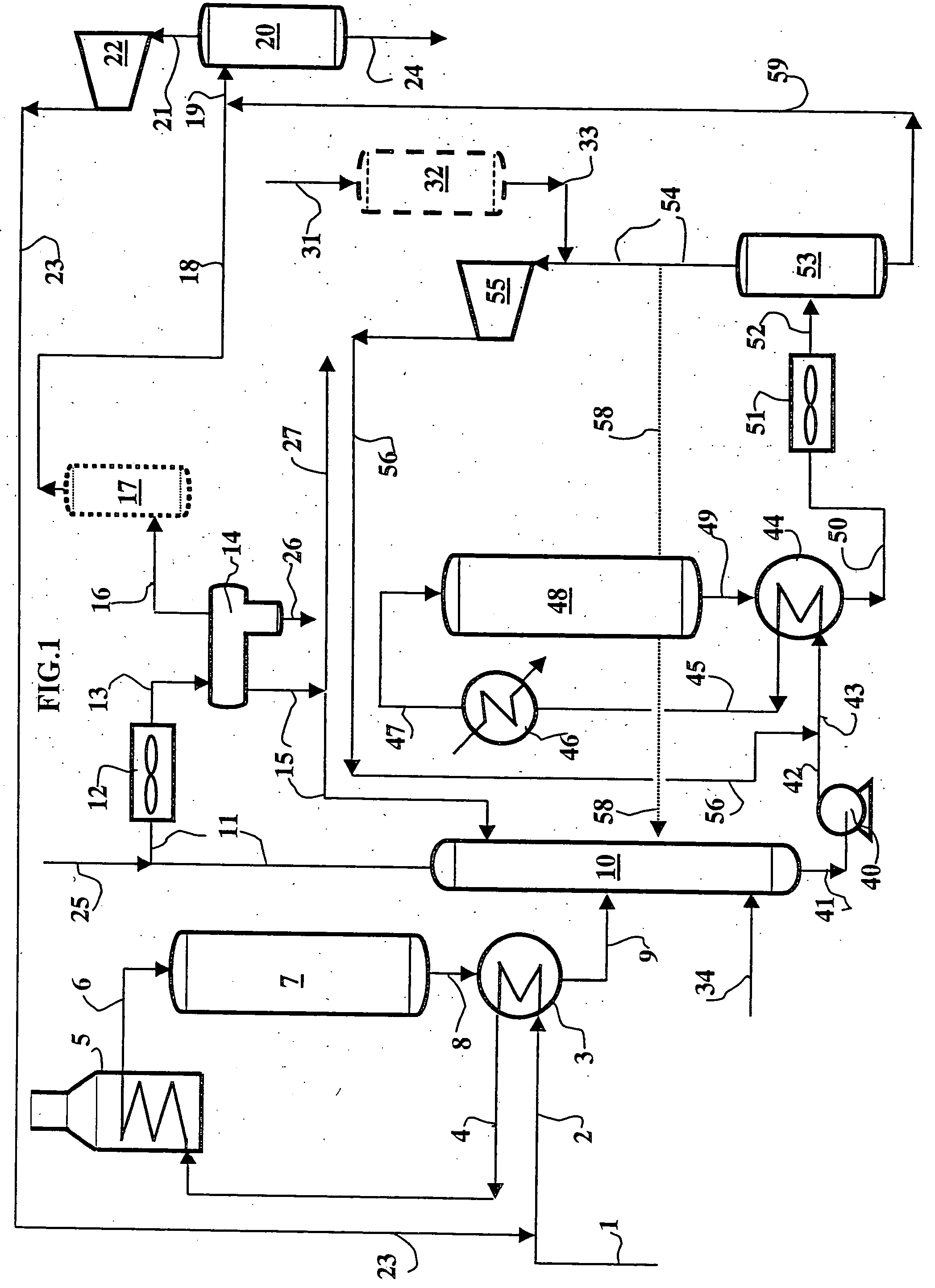

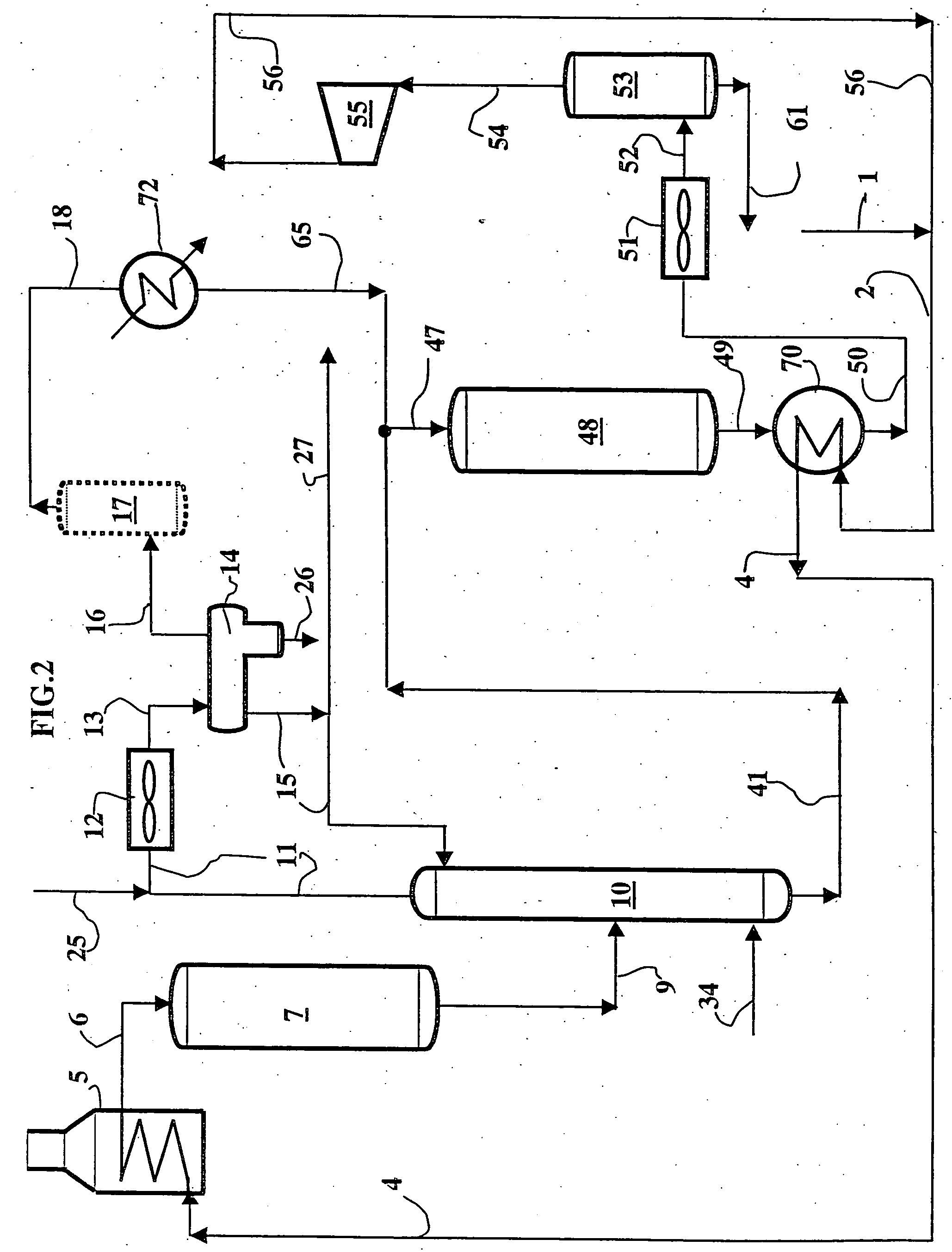

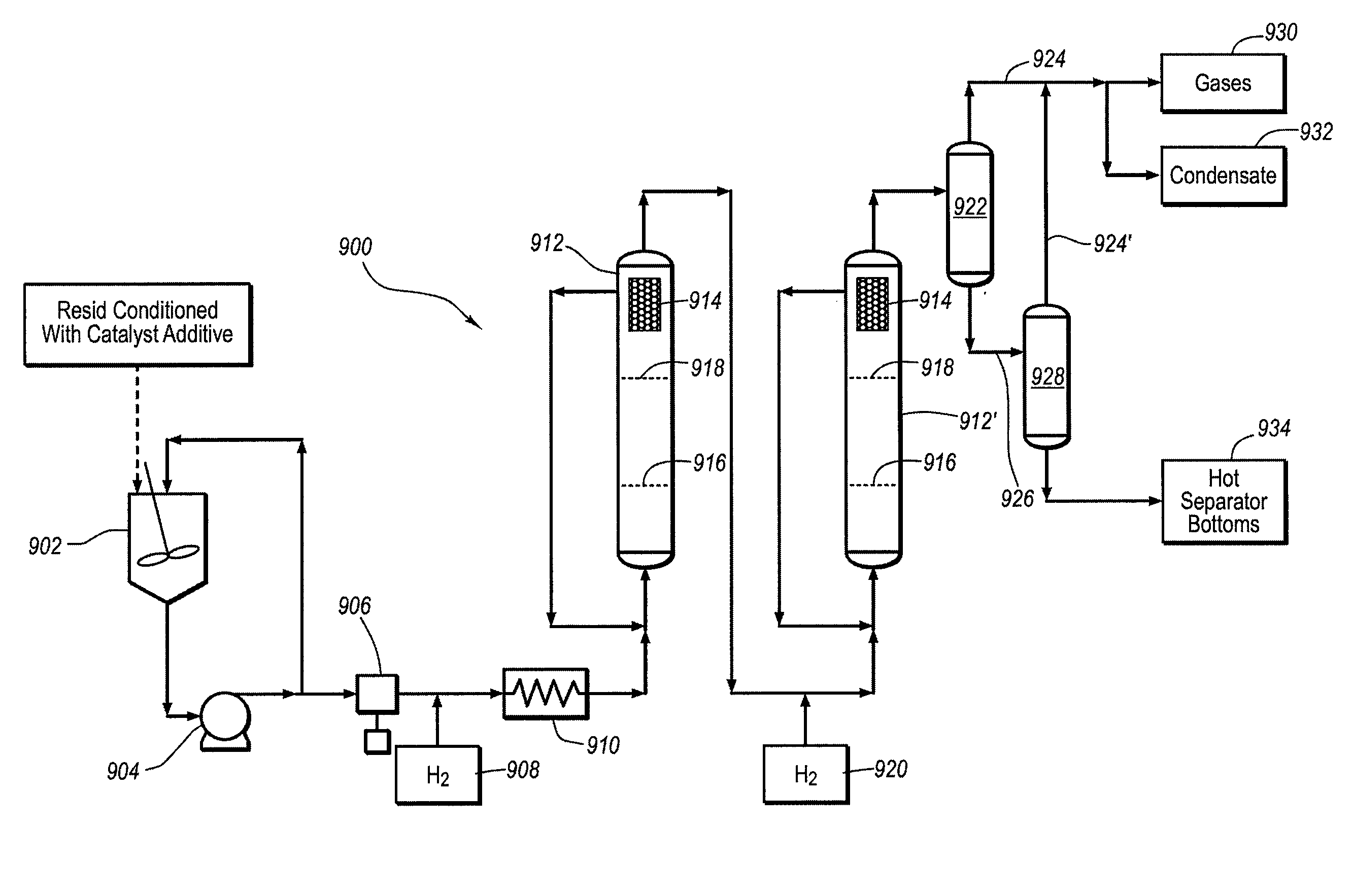

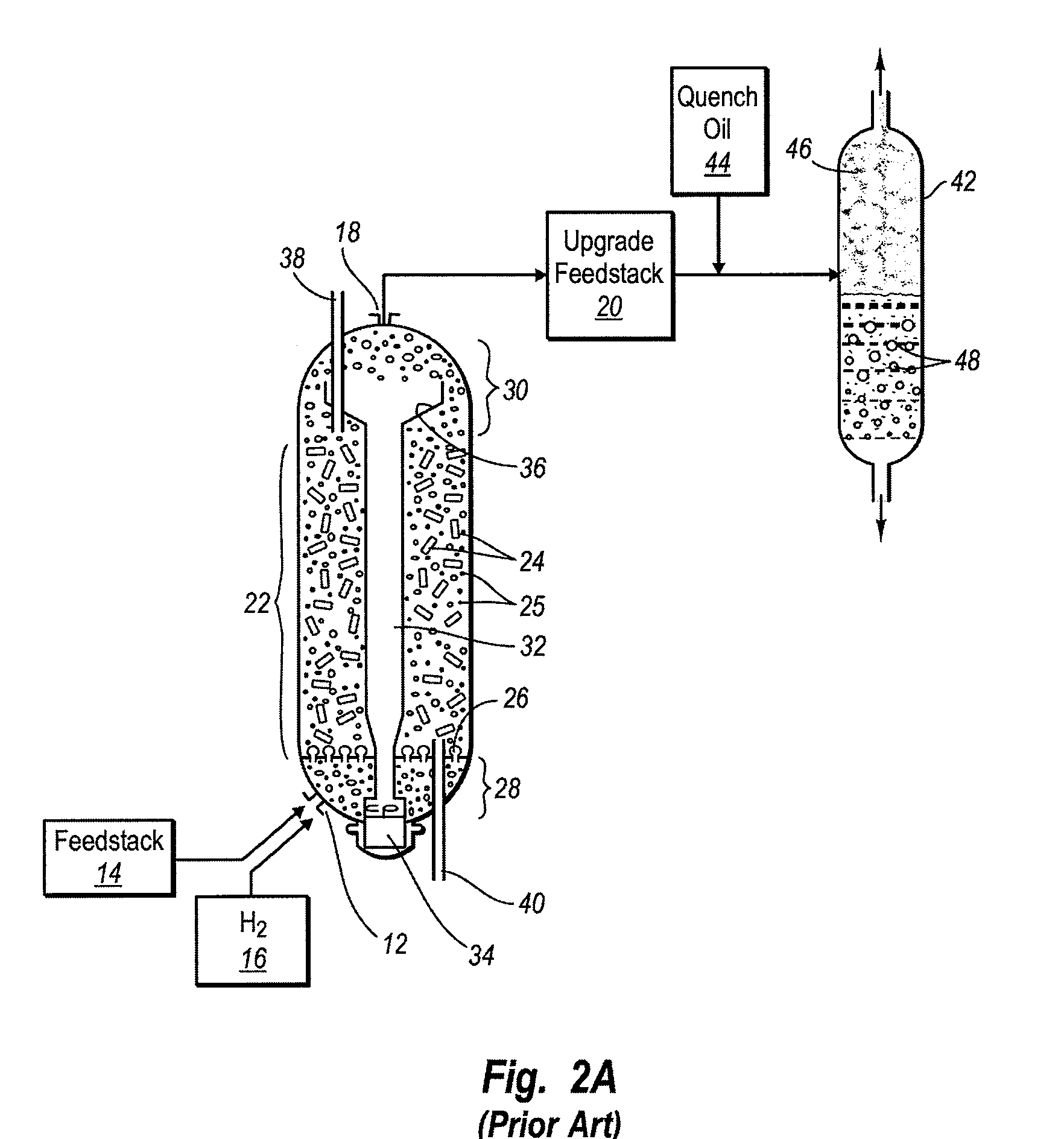

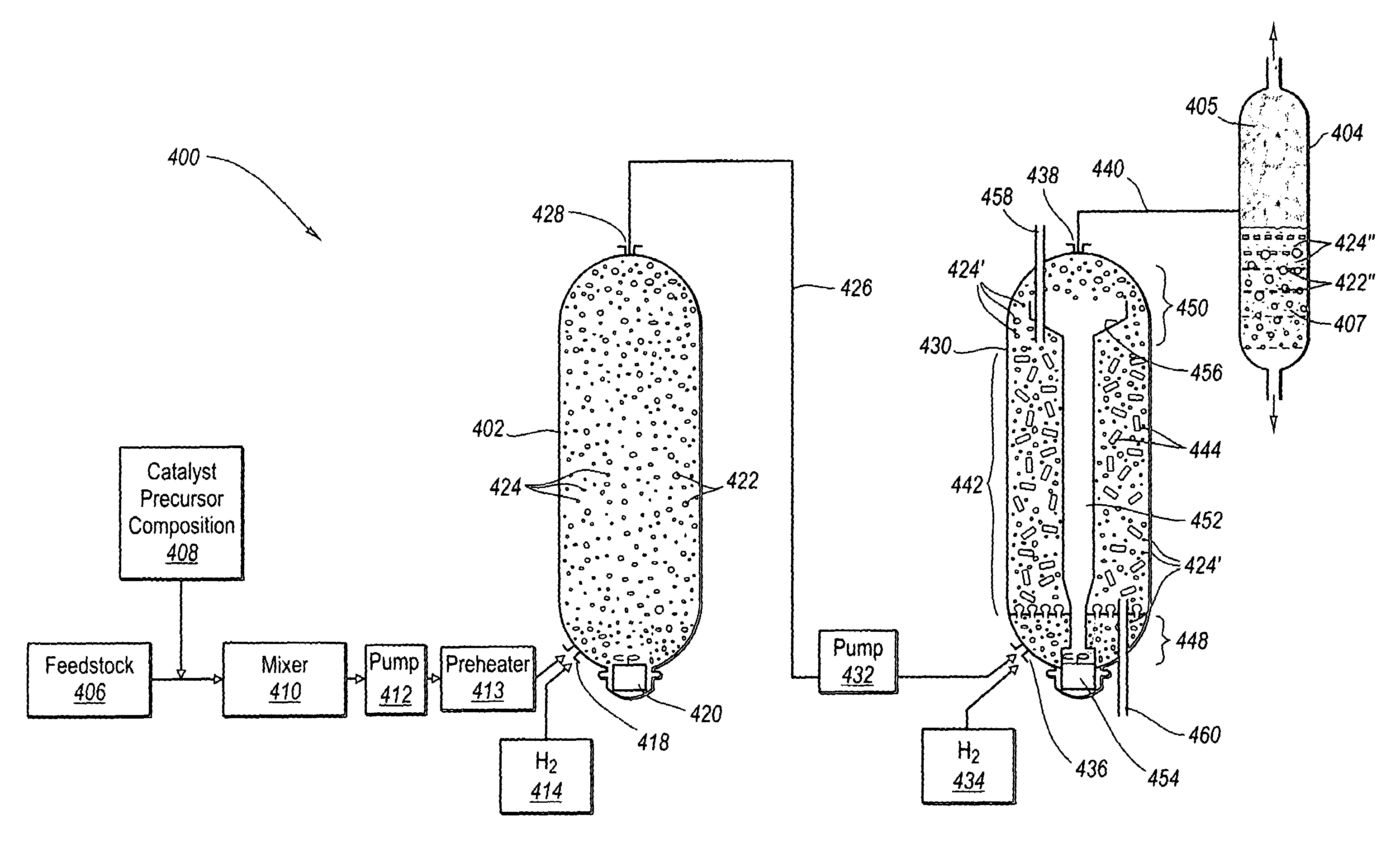

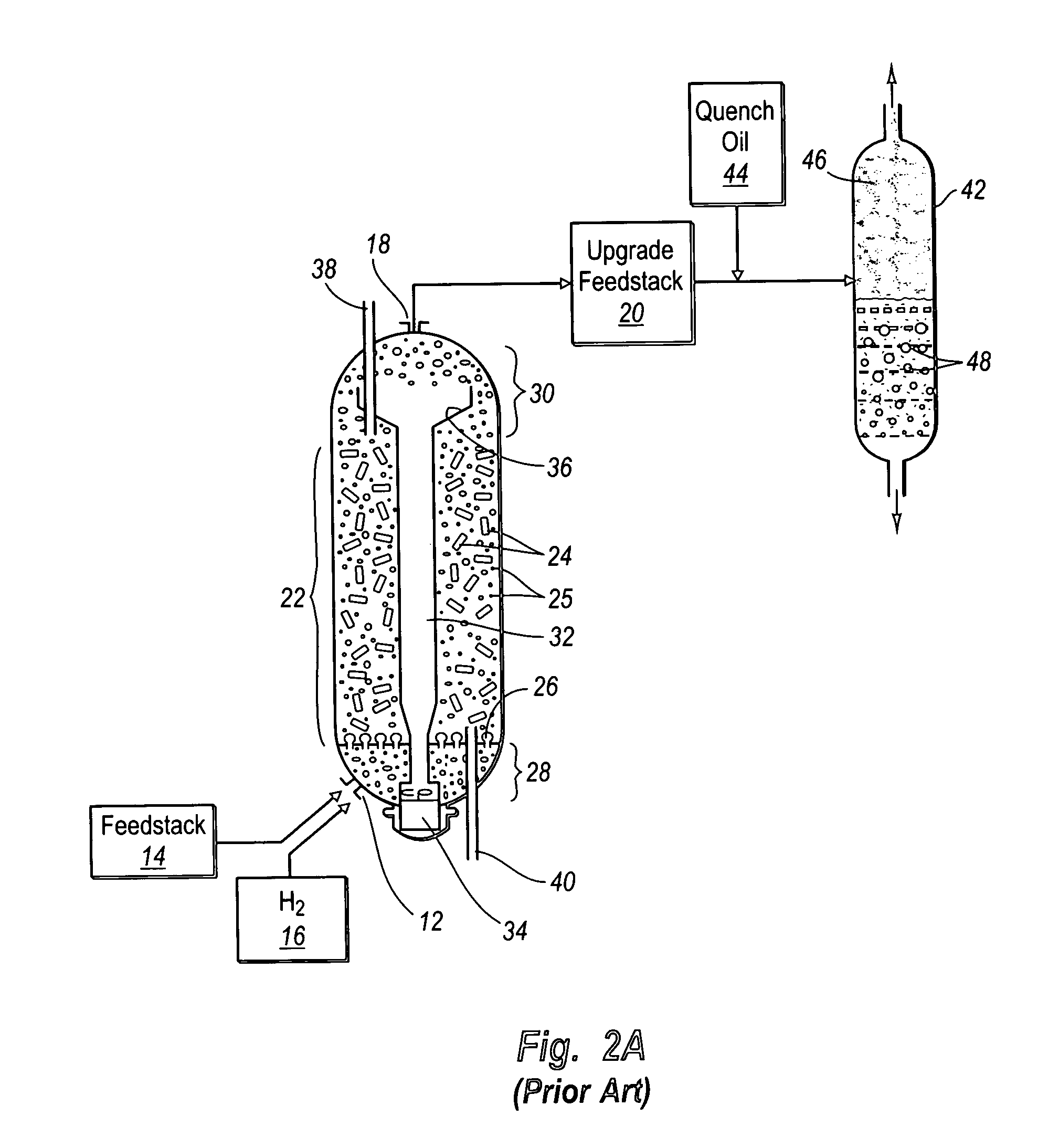

Ebullated bed hydroprocessing methods and systems and methods of upgrading an existing ebullated bed system

ActiveUS20050241991A1Quality improvementReduce formationHydrocarbon oil crackingLiquid hydrocarbon mixture productionHydrogenDecomposition

An ebullated bed hydroprocessing system, and also a method for upgrading a pre-existing ebullated bed hydroprocessing system, involves introducing a colloidal or molecular catalyst, or a precursor composition capable of forming the colloidal or molecular catalyst, into an ebullated bed reactor. The colloidal or molecular catalyst is formed by intimately mixing a catalyst precursor composition into a heavy oil feedstock and raising the temperature of the feedstock to above the decomposition temperature of the precursor composition to form the colloidal or molecular catalyst in situ. The improved ebullated bed hydroprocessing system includes at least one ebullated bed reactor that employs both a porous supported catalyst and the colloidal or molecular catalyst to catalyze hydroprocessing reactions involving the feedstock and hydrogen. The colloidal or molecular catalyst provides catalyst in what would otherwise constitute catalyst free zones within the ebullated bed hydroprocessing system. Asphaltene or other hydrocarbon molecules too large to diffuse into the pores of the supported catalyst can be upgraded by the colloidal or molecular catalyst. A slurry phase reactor may be positioned upstream from one or more ebullated bed reactors or converted from a pre-existing ebullated bed reactor.

Owner:HEADWATERS TECH INNOVATION LLC

Resid processing for steam cracker feed and catalytic cracking

ActiveUS20070090020A1High hydrogen contentEliminate needThermal non-catalytic crackingHydrocarbon oil cracking processProcess engineeringAlkene

The invention concerns integration of hydroprocessing and steam cracking. A feed comprising crude or resid-containing fraction thereof is treated by hydroprocessing and visbreaking and then passed to a steam cracker to obtain a product comprising olefins.

Owner:EXXONMOBIL CHEM PAT INC

Two phase hydroprocessing

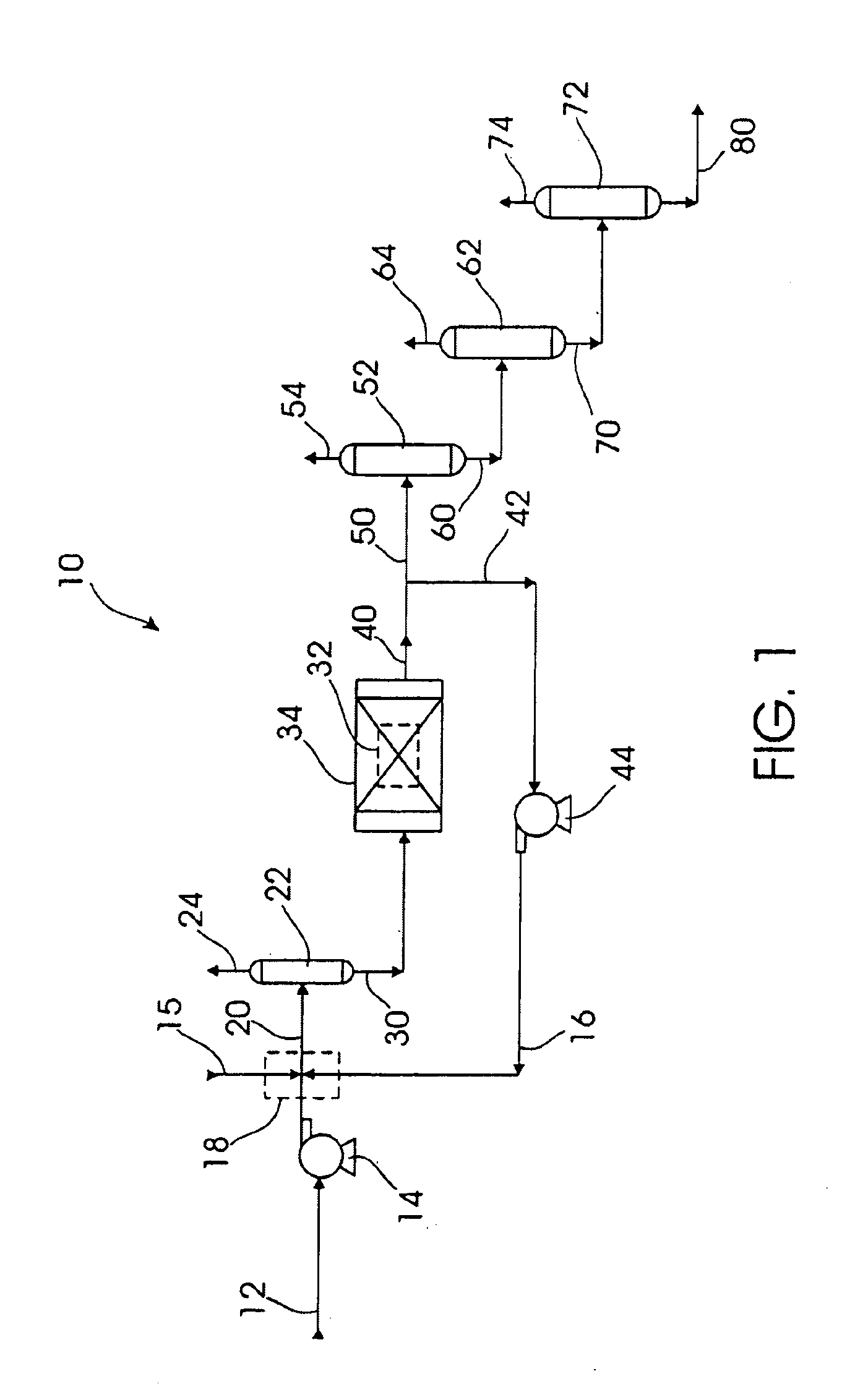

InactiveUS6881326B2Eliminate needHydrogen solubility is “Physical/chemical process catalystsOrganic compound preparationSolubilityHydrogen

A process where the need to circulate hydrogen through the catalyst is eliminated. This is accomplished by mixing and / or flashing the hydrogen and the oil to be treated in the presence of a solvent or diluent in which the hydrogen solubility is “high” relative to the oil feed. The type and amount of diluent added, as well as the reactor conditions, can be set so that all of the hydrogen required in the hydroprocessing reactions is available in solution. The oil / diluent / hydrogen solution can then be fed to a plug flow reactor packed with catalyst where the oil and hydrogen react. No additional hydrogen is required, therefore, hydrogen recirculation is avoided and trickle bed operation of the reactor is avoided. Therefore, the large trickle bed reactors can be replaced by much smaller tubular reactor.

Owner:EI DU PONT DE NEMOURS & CO

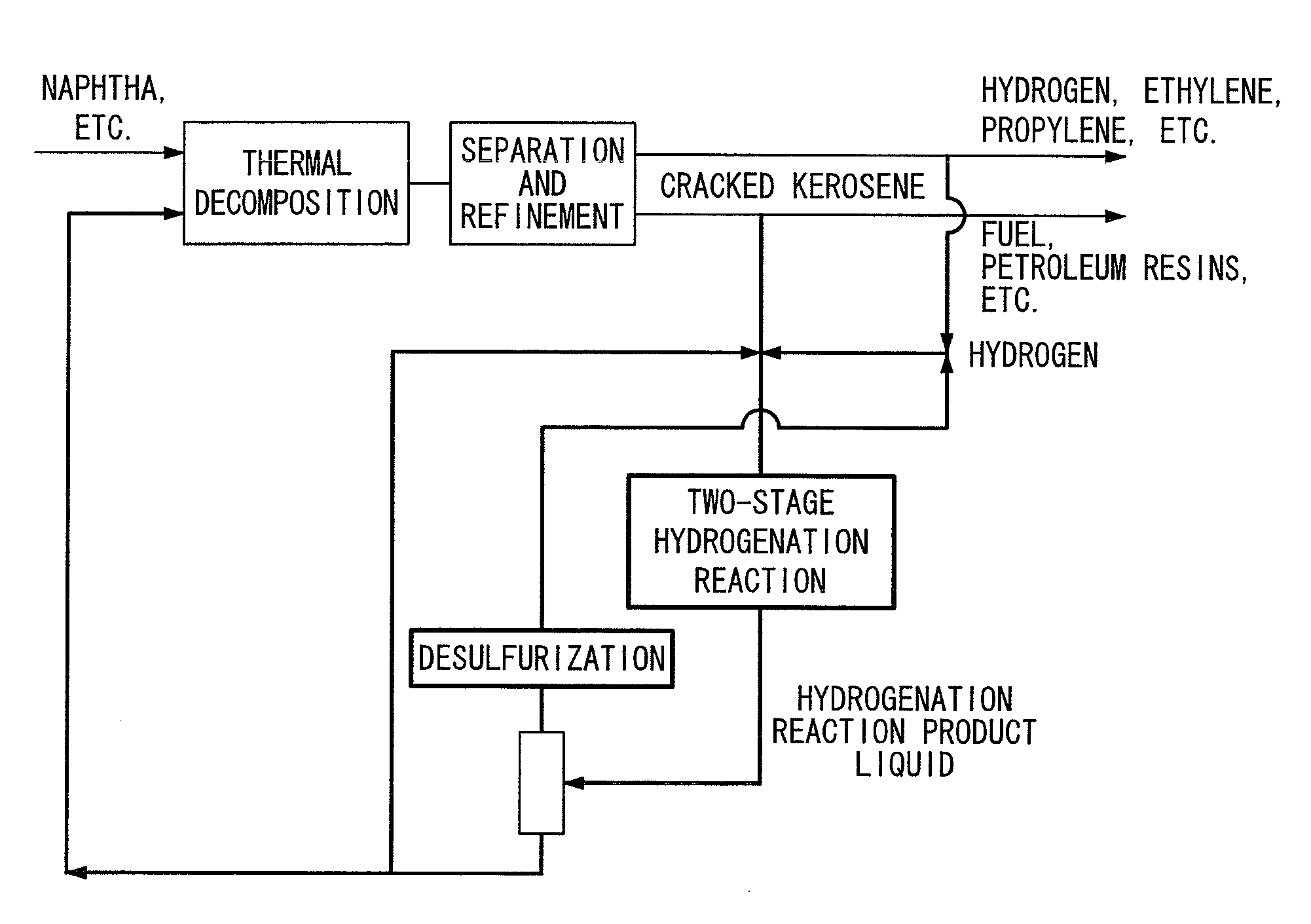

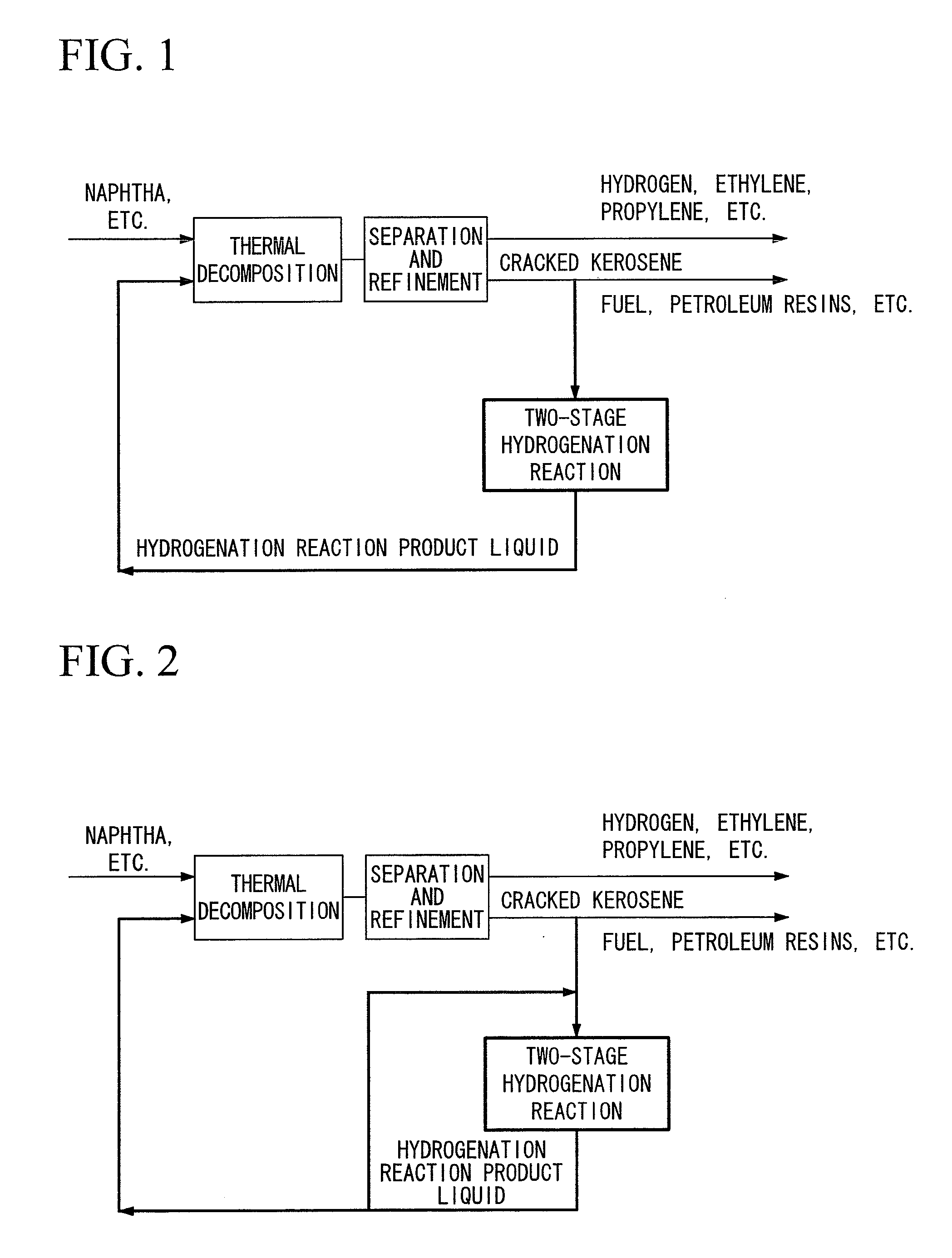

Hydrogenation method and petrochemical process

InactiveUS20100087692A1Long catalyst lifeHigh yieldThermal non-catalytic crackingHydrocarbon by dehydrogenationBenzeneNaphtha

The present invention provides a hydrogenation method capable of converting cracked kerosene into the raw materials for petrochemical cracking having a high thermal decomposition yield by a hydrogenation reaction. The present invention is a petrochemical process for producing at least any of ethylene, propylene, butane, benzene or toluene by carrying out a thermal decomposition reaction at least using naphtha for the main raw material, wherein cracked kerosene produced from a thermal cracking furnace is hydrogenated using a Pd or Pt catalyst in a two-stage method consisting of a first stage (I), in which a hydrogenation reaction is carried out within the range of 50 to 180° C., and a second stage (II), in which a hydrogenation reaction is carried out within the range of 230 to 350° C., followed by re-supplying all or a portion of these hydrogenated hydrocarbons to a thermal cracking furnace.

Owner:SHOWA DENKO KK

Metal aromatic hydrosaturation catalyst

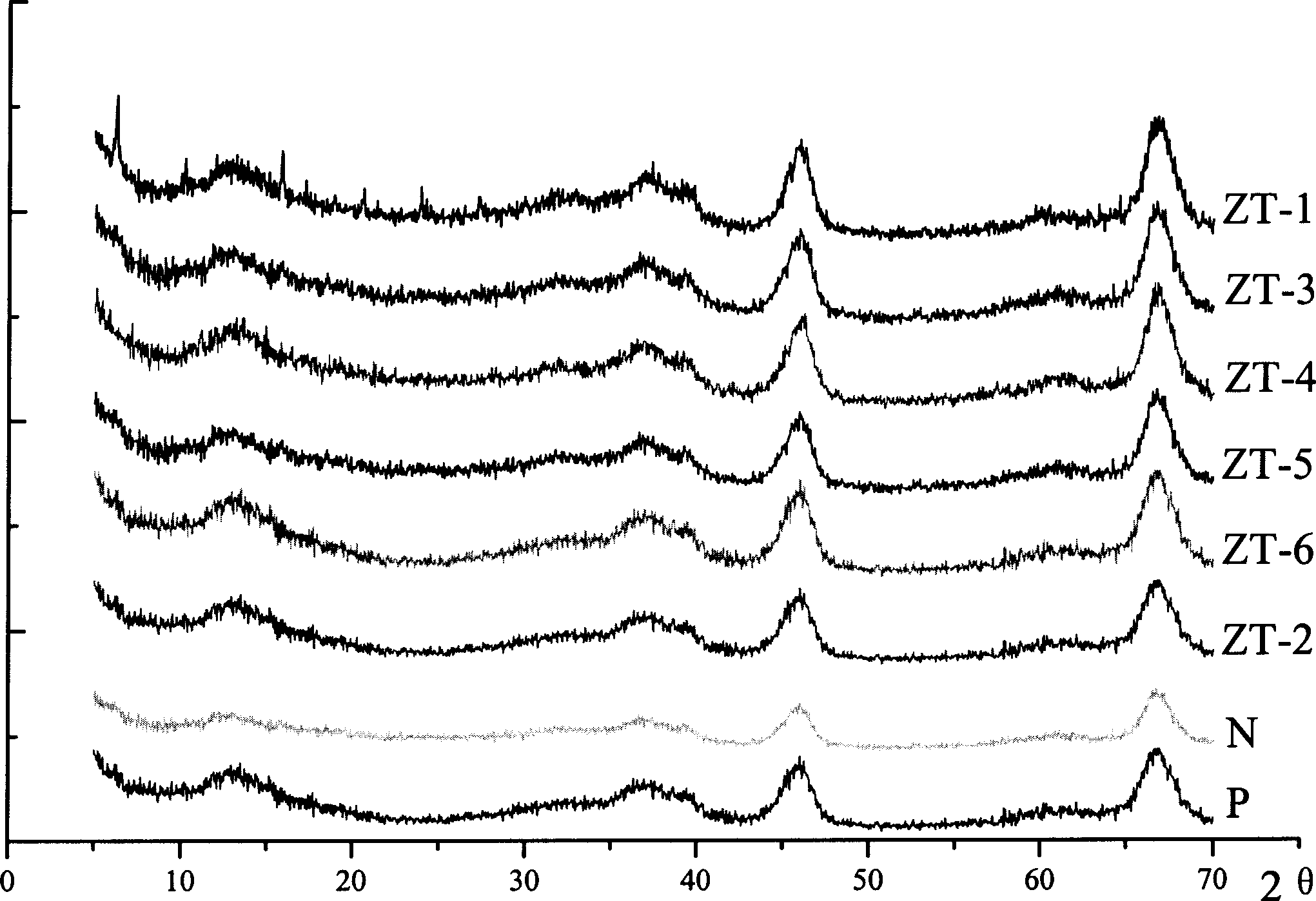

InactiveCN1510112AImprove performanceGood preparation and operabilityRefining by aromatic hydrocarbon hydrogenationHigh resistanceSulfur

A metal-type catalyst for hydrosaturating arylhydrocarbon is composed of the carrier containing porous silicon oxide-aluminium oxide and the hydrogenating active components. Said porous silicon oxide-aluminium oxide has the crystal type chosen from gamma, etc, theta, delta and X ones of aluminium oxide. Its advantages are easy preparing, high resistance to sulfur, and high hydrogenating activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Supported catalysts having a controlled coordination structure and methods for preparing such catalysts

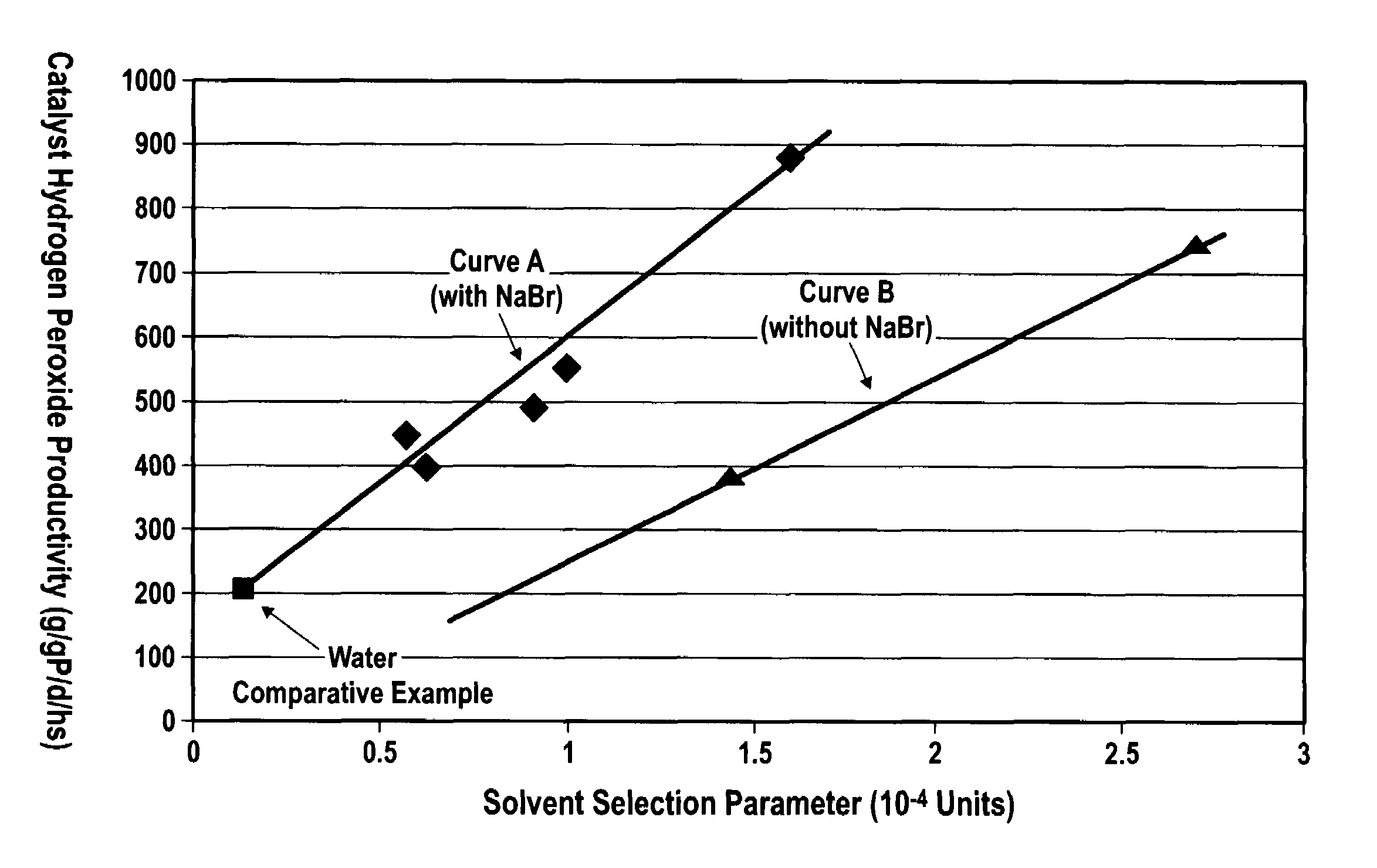

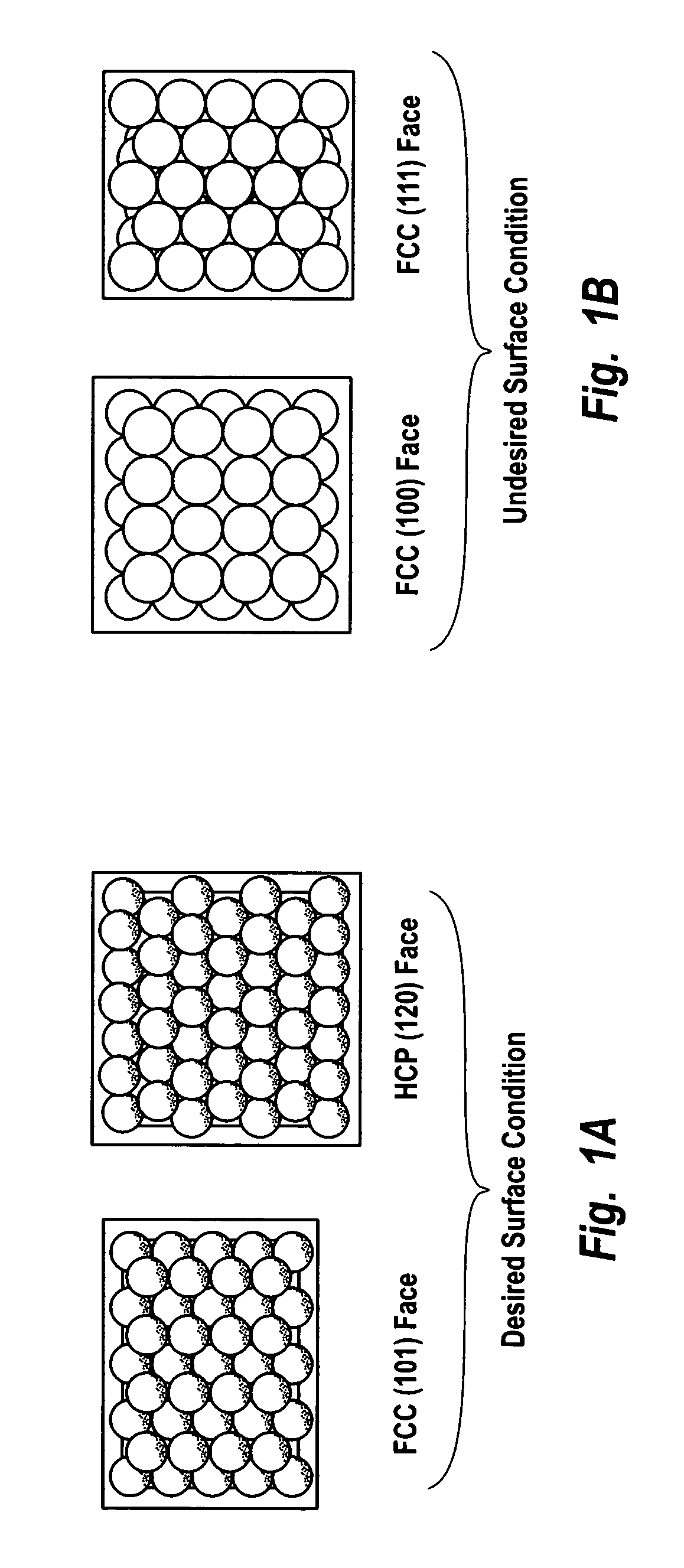

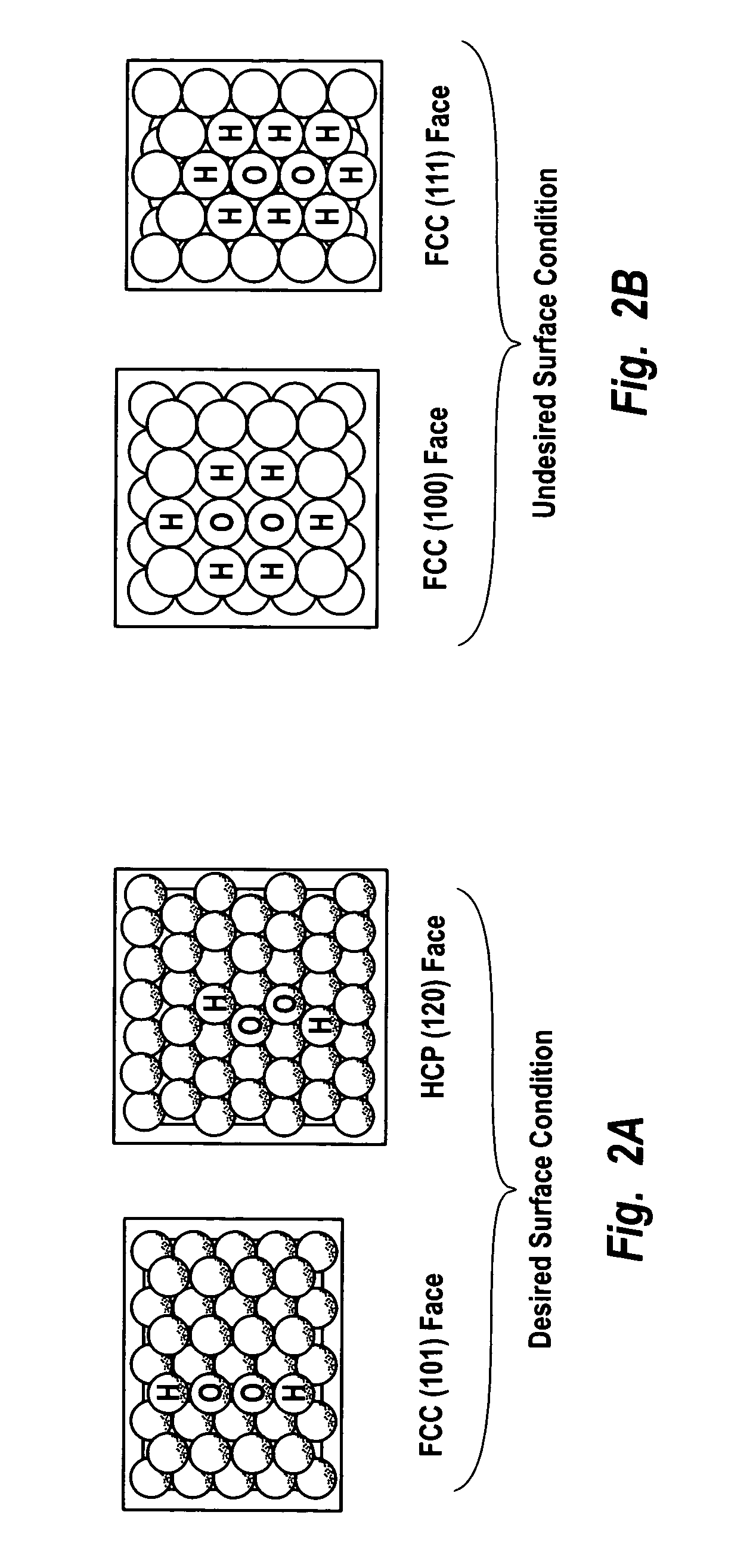

ActiveUS7011807B2Reduce molecular weightReduce the possibilityHydrogen peroxideHydrogenHydrogenOrganic fluid

Supported reactive catalysts having a controlled coordination structure and methods for their production are disclosed. The supported catalysts of the present invention are useful for the preparation of hydrogen peroxide with high selectivity in addition to other chemical conversion reactions. The supported catalyst comprises catalyst particles having top or outer layer of atoms in which at least a portion of the atoms exhibit a controlled coordination number of 2. The catalyst and methods may be used for the concurrent in situ and ex situ conversion of organic compounds. In addition, a process is provided for catalytically producing hydrogen peroxide from hydrogen and oxygen feeds by contacting them with the catalysts of the invention and a suitable organic liquid solvent having a Solvent Selection Parameter (SSP) between 0.14×10−4 and 5.0×10−4.

Owner:BORAL IP HLDG

Resid processing for steam cracker feed and catalytic cracking

ActiveUS7972498B2Eliminate needHigh hydrogen contentThermal non-catalytic crackingHydrocarbon oil cracking processProcess engineeringAlkene

The invention concerns integration of hydroprocessing and steam cracking. A feed comprising crude or resid-containing fraction thereof is treated by hydroprocessing and visbreaking and then passed to a steam cracker to obtain a product comprising olefins.

Owner:EXXONMOBIL CHEM PAT INC

Process for isomerization dewaxing of hydrocarbon streams

InactiveUS20030168379A1Yield maximizationReduce pointsMolecular sieve catalystsHydrocarbon by hydrogenationMolecular sieveIsomerization

A process for isomerization dewaxing of a hydrocarbon feed which includes contacting the hydrocarbon feed with a large pore size, small crystal size, crystalline molecular sieve and an intermediate pore size, small crystal size, crystalline molecular sieve to produce a dewaxed product with a reduced pour point and a reduced cloud point. In a preferred embodiment, the feed is contacted with the molecular sieves sequentially, first with the large pore sieve followed by the intermediate pore sieve.

Owner:EXXON RES & ENG CO

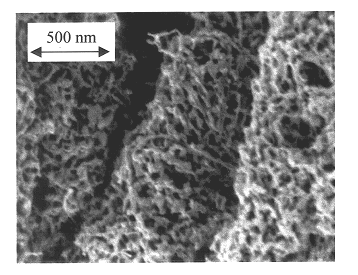

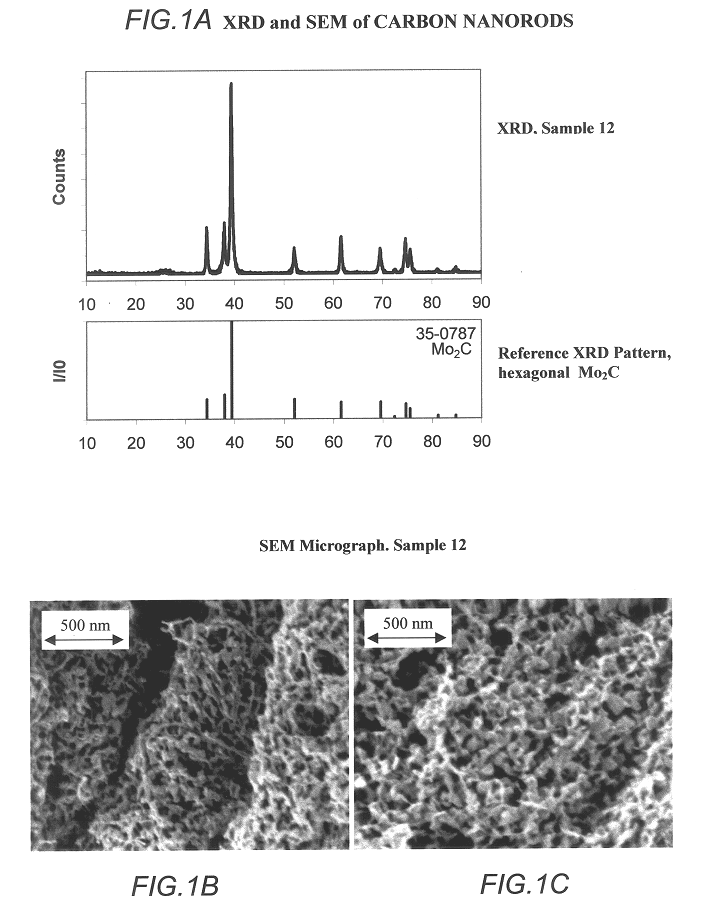

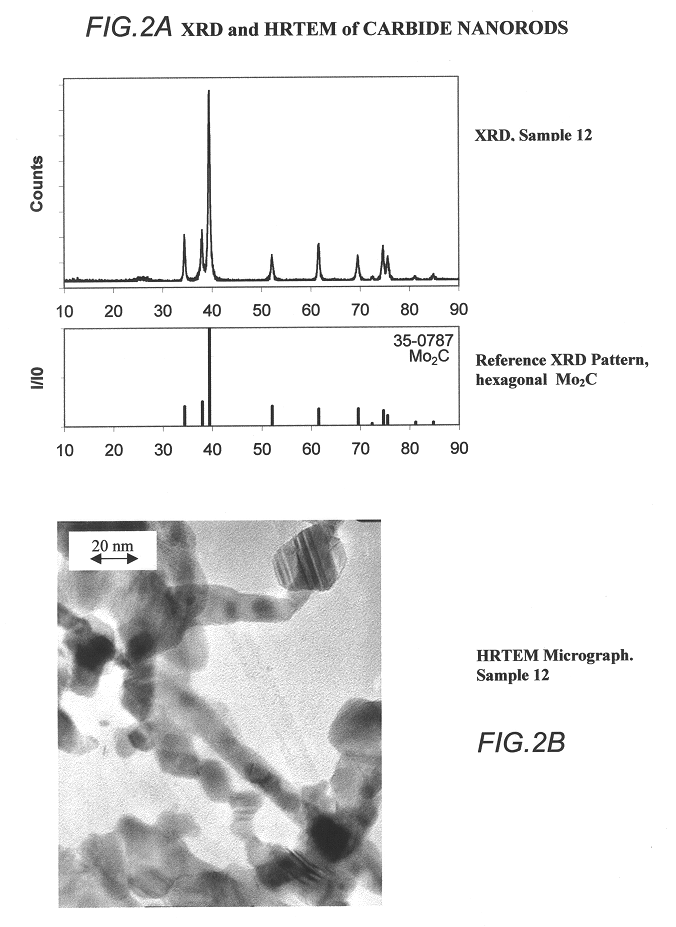

Carbide and oxycarbide based compositions, rigid porous structures including the same, methods of making and using the same

InactiveUS6514897B1Easy to diffuseSpeed up the flowMaterial nanotechnologyHydrocarbon by isomerisationIsomerizationChemical reaction

The present invention relates to compositions and rigid porous structures that contain nanorods having carbides and / or oxycarbides and methods of making and using such compositions and such rigid porous structures. The compositions and rigid porous structures can be used either as catalysts and / or catalyst supports in fluid phase catalytic chemical reactions. Processes for making supported catalyst for selected fluid phase catalytic reactions are also provided. The fluid phase catalytic reactions catalyzed include hydrogenation hydrodesulfuriaation, hydrodenitrogenation, hydrodemetallization, hydrodeoxygenation, hydrodearomatization, dehydrogenation, hydrogenolyis, isomerization, alkylation, dealkylation, oxidation and transalkylation.

Owner:HYPERION CATALYSIS INT

Multigrade engine oil prepared from Fischer-Tropsch distillate base oil

InactiveUS20060027486A1Refining to change hydrocarbon structural skeletonLiquid carbonaceous fuelsCycloparaffinsPackage design

A multigrade engine oil meeting the specifications for SAE J300 revised June 2001 requirements and a process for preparing it, said engine oil comprising (a) between about 15 to about 94.5 wt % of a hydroisomerized distillate Fischer-Tropsch base oil characterized by (i) a kinematic viscosity between about 2.5 and about 8 cSt at 100° C., (ii) at least about 3 wt % of the molecules having cycloparaffin functionality, and (iii) a ratio of weight percent molecules with monocycloparaffin functionality to weight percent of molecules with multicycloparaffin functionality greater than about 15; (b) between about 0.5 to about 20 wt % of a pour point depressing base oil blending component prepared from an hydroisomerized bottoms material having an average degree of branching in the molecules between about 5 and 9 alkyl-branches per 100 carbon atoms and wherein not more than 10 wt % boils below about 900° F.; and (c) between about 5 to about 30 wt % of an additive package designed to meet the specifications for ILSAC GF-3.

Owner:CHEVROU USA INC

Hydroprocessing catalyst and method of making the same

ActiveUS20110000824A1Molecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsMolecular sieveOrganic chemistry

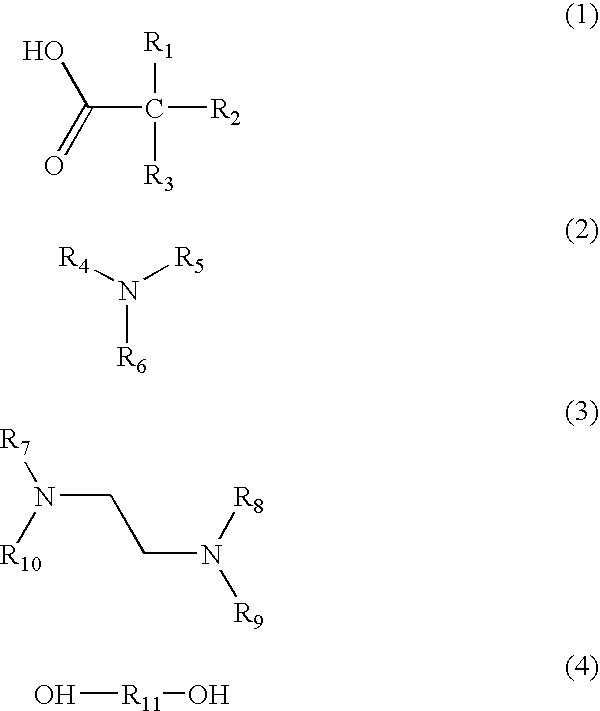

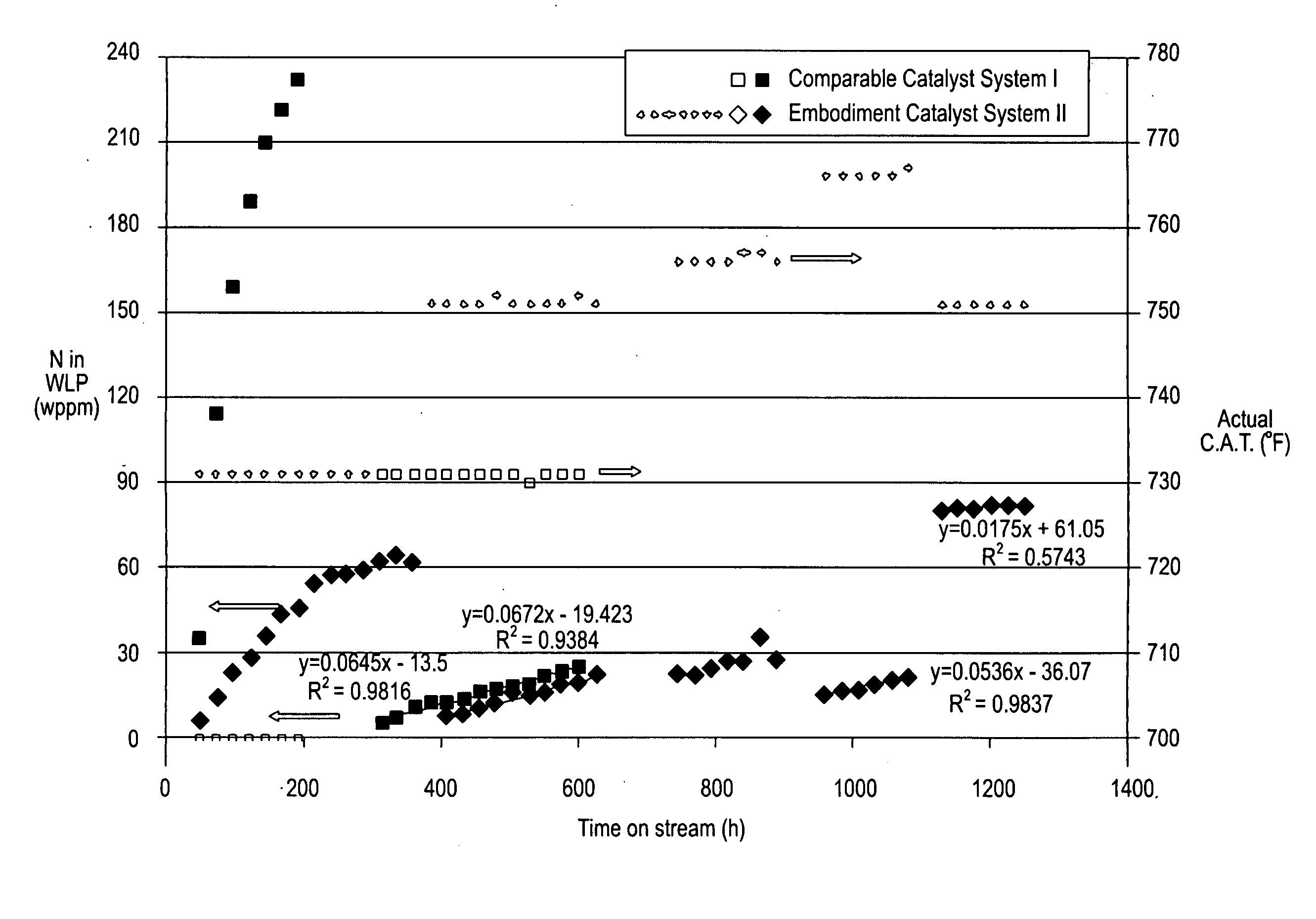

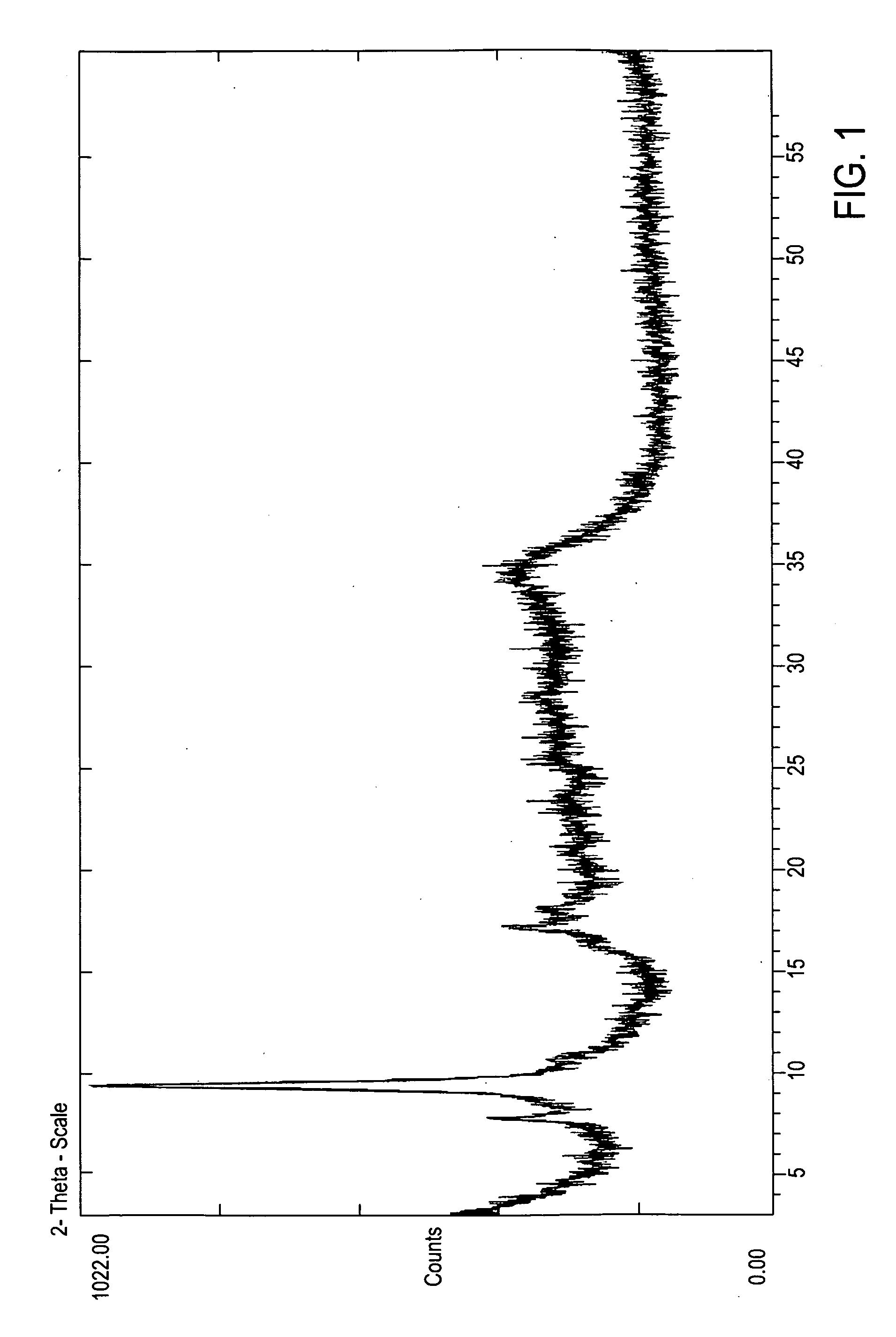

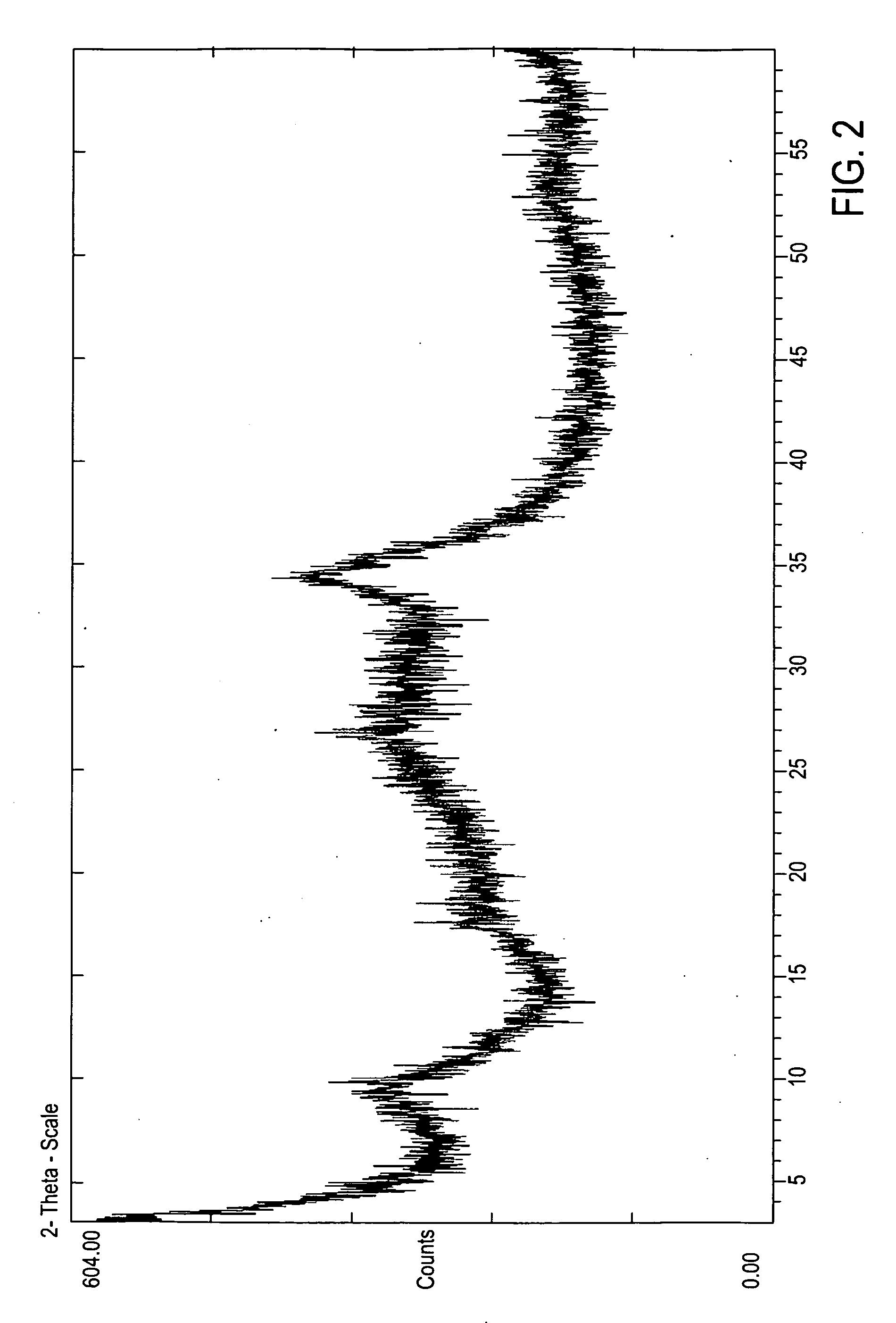

The present invention is directed to a hydroprocessing catalyst containing at least one catalyst support, one or more metals, optionally one or more molecular sieves, optionally one or more promoters, wherein deposition of at least one of the metals is achieved in the presence of a modifying agent.

Owner:CHEVROU USA INC

Hydroconversion Processes Employing Multi-Metallic Catalysts and Method for Making Thereof

ActiveUS20090107883A1Organic-compounds/hydrides/coordination-complexes catalystsHeterogenous catalyst chemical elementsCelluloseDiluent

A catalyst precursor composition and methods for making such catalyst precursor is disclosed. In one embodiment, the catalyst precursor is of the general formula Av[(MP)(OH)x(L)ny]z(MVIBO4), wherein MP is selected from Group VIII, Group IIB, Group IIA, Group IVA and combinations thereof; L is one or more oxygen-containing ligands, and L has a neutral or negative charge n<=0, MVIB is at least a Group VIB metal having an oxidation state of +6; MP:MVIB has an atomic ratio between 100:1 and 1:100; v−2+P*z−x*z+n*y*z=0; and 0≦y≦−P / n; 0≦x≦P; 0≦v≦2; 0≦z. In one embodiment, the catalyst precursor further comprises a cellulose-containing material. In another embodiment, the catalyst precursor further comprises at least a diluent (binder). In one embodiment, the diluent is a magnesium aluminosilicate clay.

Owner:CHEVROU USA INC

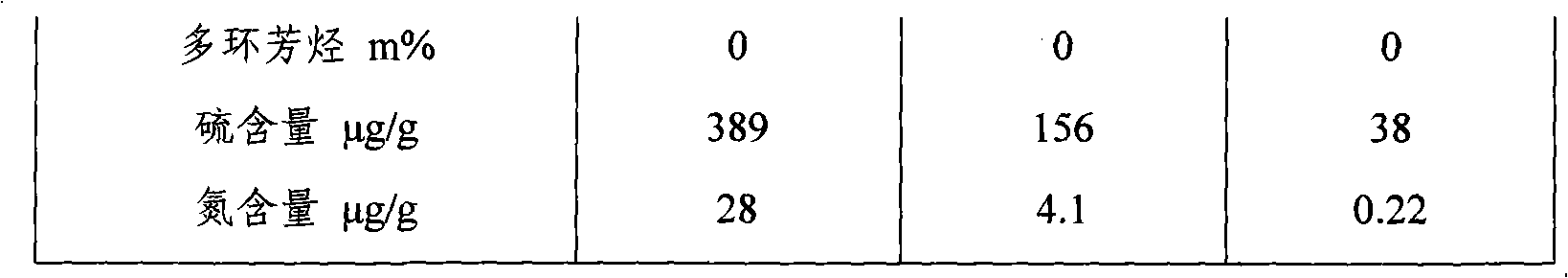

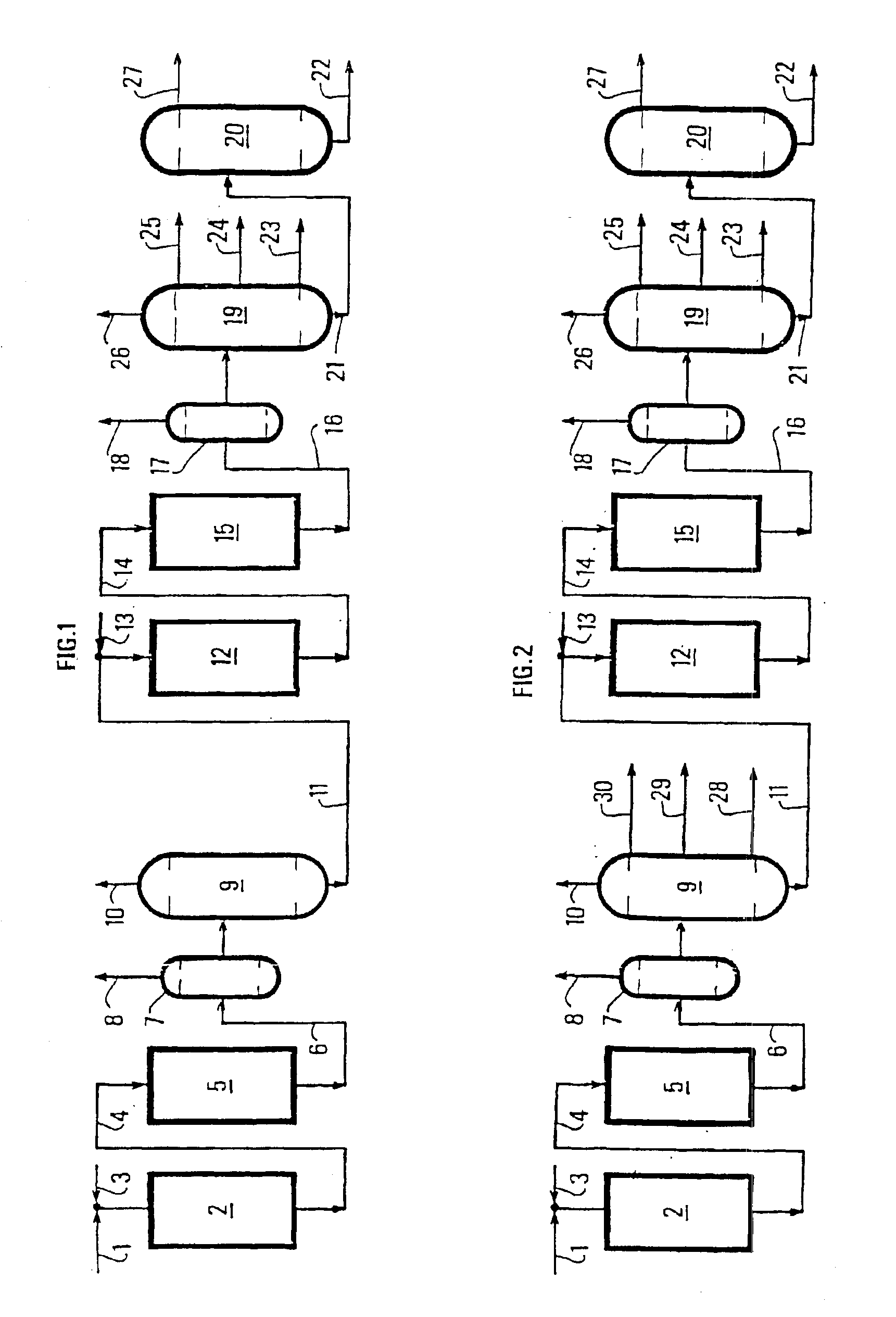

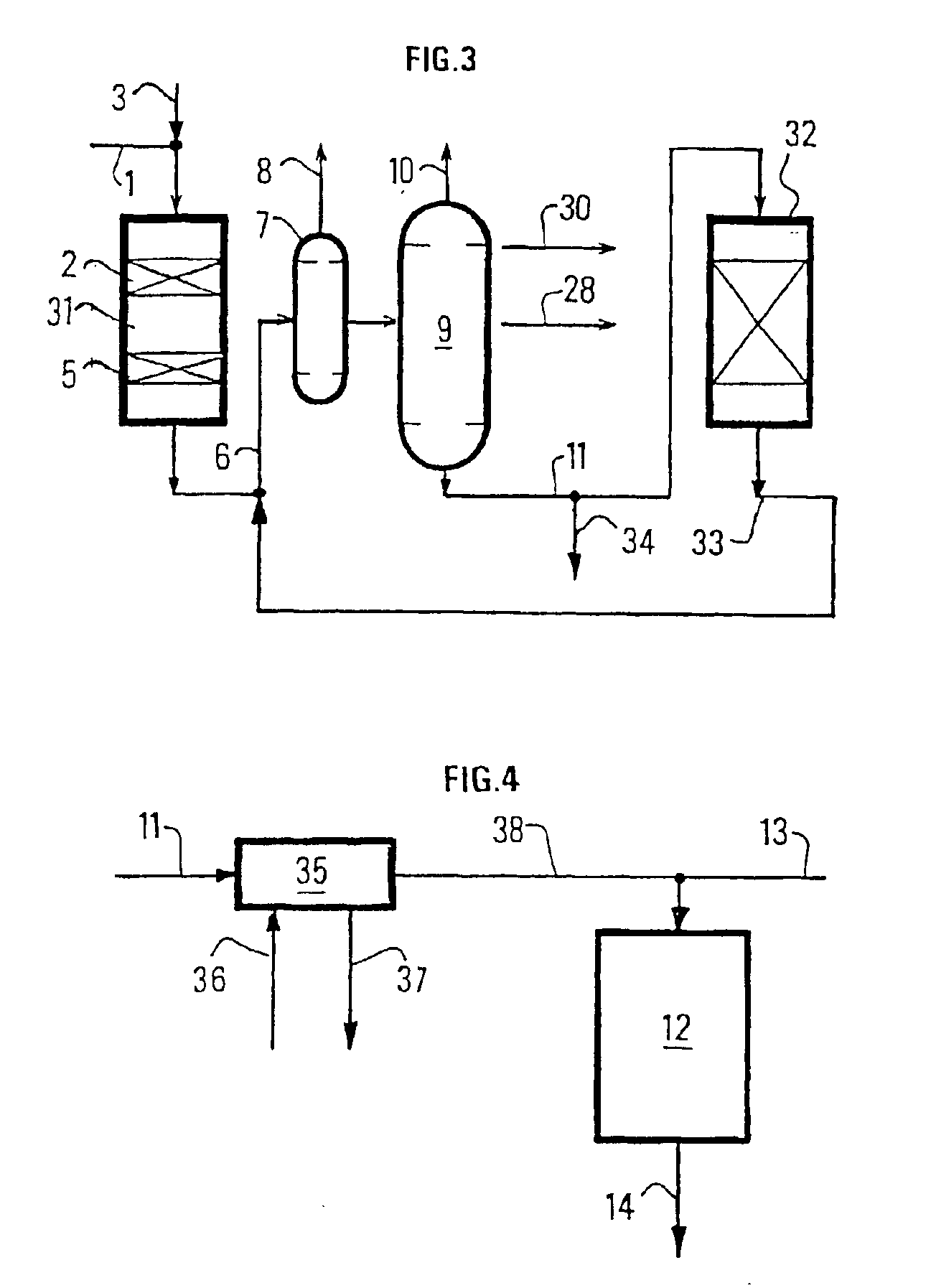

Two-step method for hydrotreating of a hydrocarbon feedstock comprising intermediate fractionation by rectification stripping

InactiveUS20060118466A1Reduce sulfur contentReduce nitrogen contentHydrocarbon distillation control/regulationTreatment with hydrotreatment processesPtru catalystPhysical chemistry

A process for hydrotreatment of a hydrocarbon feed comprises at least two reaction steps with intermediate fractionation of the effluent from the first step to eliminate unwanted impurities for the catalyst of the second step and to produce a desulphurized light liquid fraction. The intermediate fractionation comprises stripping the liquid effluent from the first step using low pressure hydrogen with rectification of the stripping vapours using a substantially desulphurized liquid reflux. The conditions for said fractionation and for the first hydrotreatment step can produce a substantially desulphurized light liquid fraction which is not supplied to the second step.

Owner:INST FR DU PETROLE

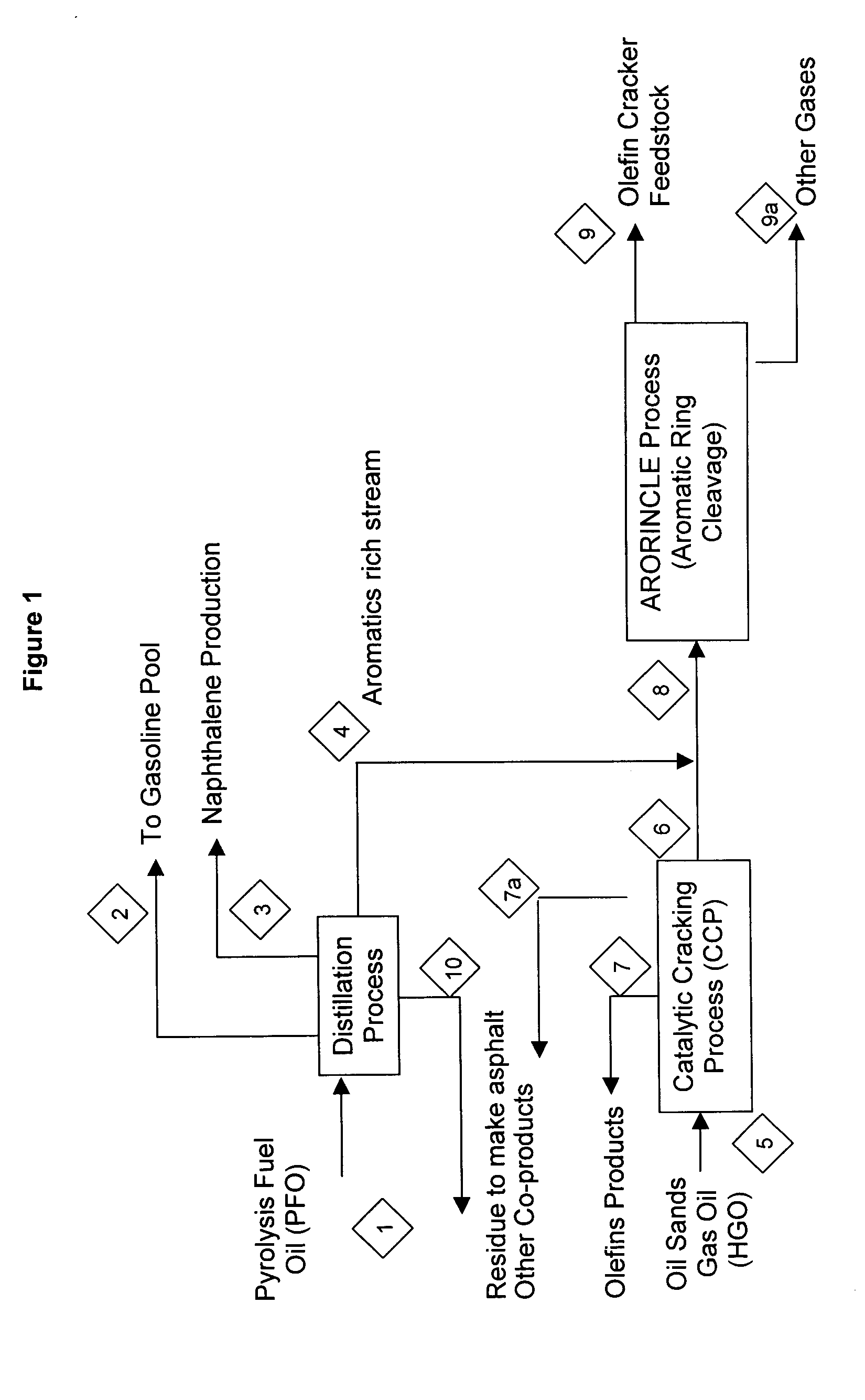

Integrated process to convert heavy oils from oil sands to petrochemical feedstock

ActiveUS20050258073A1Thermal non-catalytic crackingTreatment with plural serial cracking stages onlyAlkaneFuel oil

An aromatics / naphthalene rich stream obtained by processing heavy gas oil derived from tar sands and cycle oils derived from cracking heavy gas oil may optionally be blended and subjected to a hydrogenation process and a ring opening reaction typically in the presence of a zeolite, alumina, or silica alumina based catalyst which may contain noble metals and or copper or molybdenum to produce paraffinic feedstocks for further chemical processing.

Owner:NOVA CHEM (INT) SA

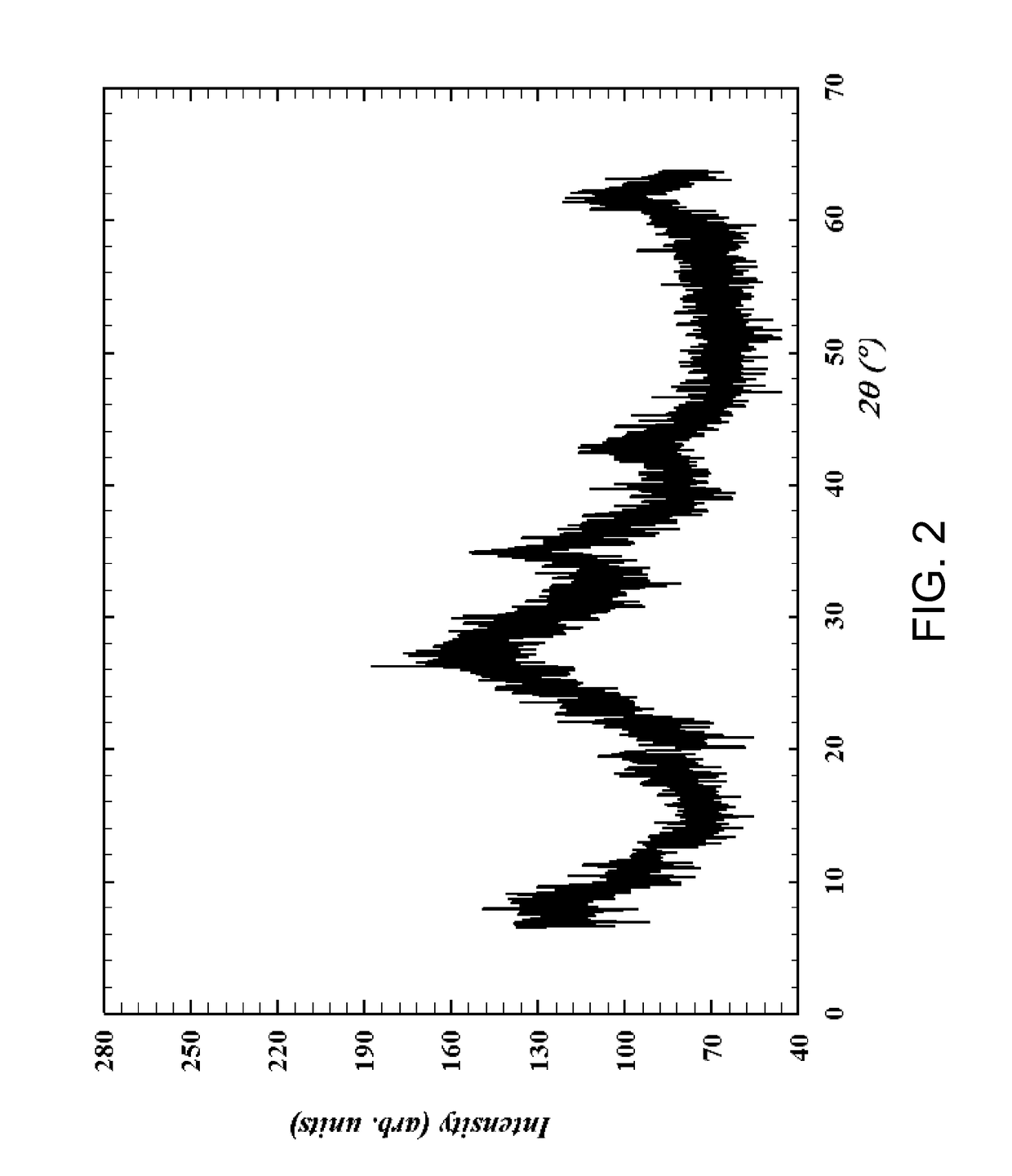

Novel mixed metal oxides

ActiveUS20170165645A1Catalyst activation/preparationHydrocarbon oil crackingHydrodesulfurizationMaterials science

A unique mixed metal molybdotungstate material has been developed. The material may be used as a hydroprocessing catalyst. The hydroprocessing may include hydrodenitrification, hydrodesulfurization, hydrodemetallation, hydrodearomatization, hydrodesilication, hydroisomerization, hydrotreating, hydrofining, and hydrocracking.

Owner:UOP LLC

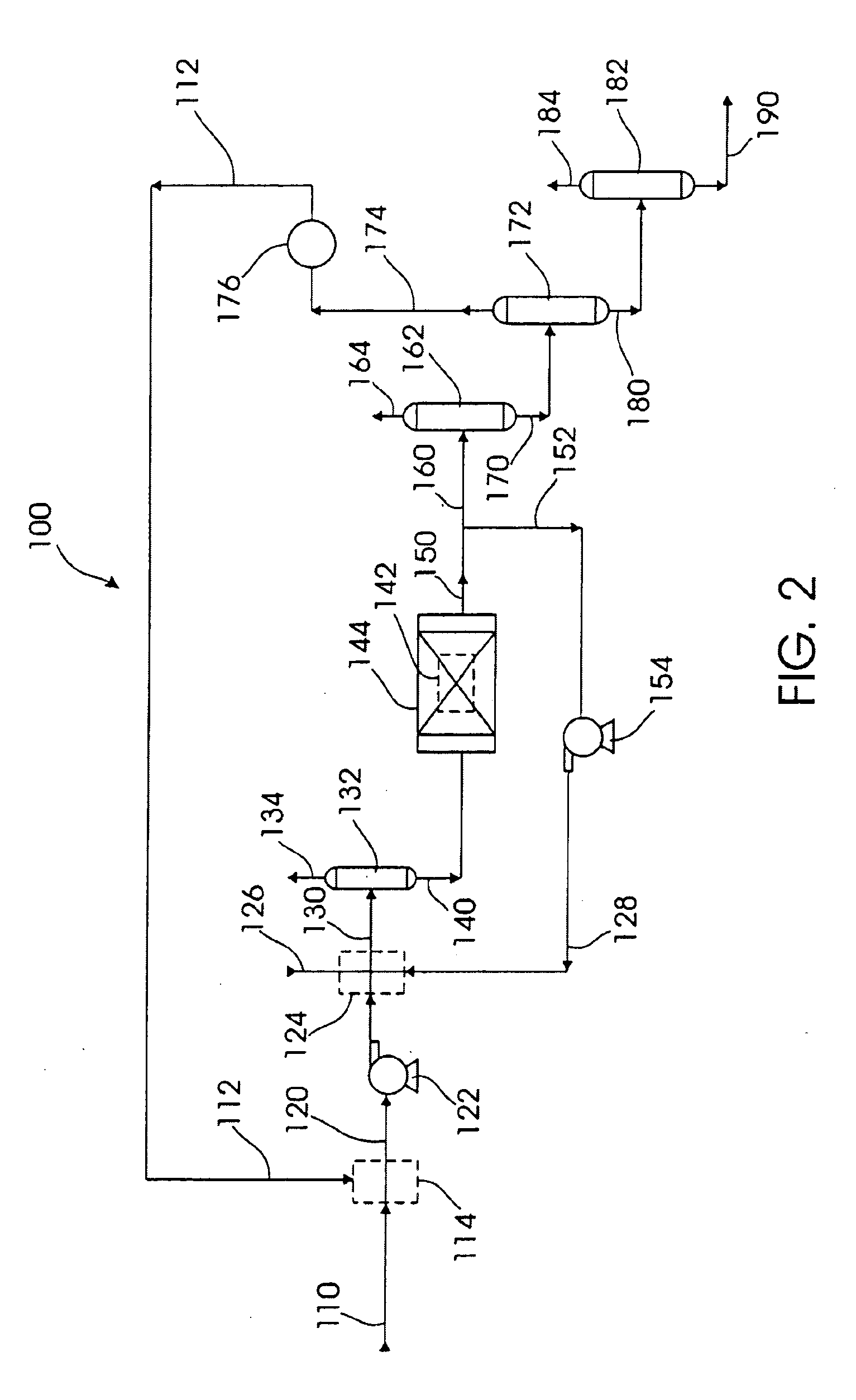

Ebullated bed hydroprocessing systems

ActiveUS20080193345A1Quality improvementReduce formationHydrocarbon oil crackingTreatment with hydrotreatment processesHydrogenDecomposition

An ebullated bed hydroprocessing system, and also a method for upgrading a pre-existing ebullated bed hydroprocessing system, involves introducing a colloidal or molecular catalyst, or a precursor composition capable of forming the colloidal or molecular catalyst, into an ebullated bed reactor. The colloidal or molecular catalyst is formed by intimately mixing a catalyst precursor composition into a heavy oil feedstock and raising the temperature of the feedstock to above the decomposition temperature of the precursor composition to form the colloidal or molecular catalyst in situ. The improved ebullated bed hydroprocessing system includes at least one ebullated bed reactor that employs both a porous supported catalyst and the colloidal or molecular catalyst to catalyze hydroprocessing reactions involving the feedstock and hydrogen. The colloidal or molecular catalyst provides catalyst in what would otherwise constitute catalyst free zones within the ebullated bed hydroprocessing system. Asphaltene or other hydrocarbon molecules too large to diffuse into the pores of the supported catalyst can be upgraded by the colloidal or molecular catalyst. A slurry phase reactor may be positioned upstream from one or more ebullated bed reactors or converted from a pre-existing ebullated bed reactor.

Owner:HEADWATERS TECH INNOVATION LLC

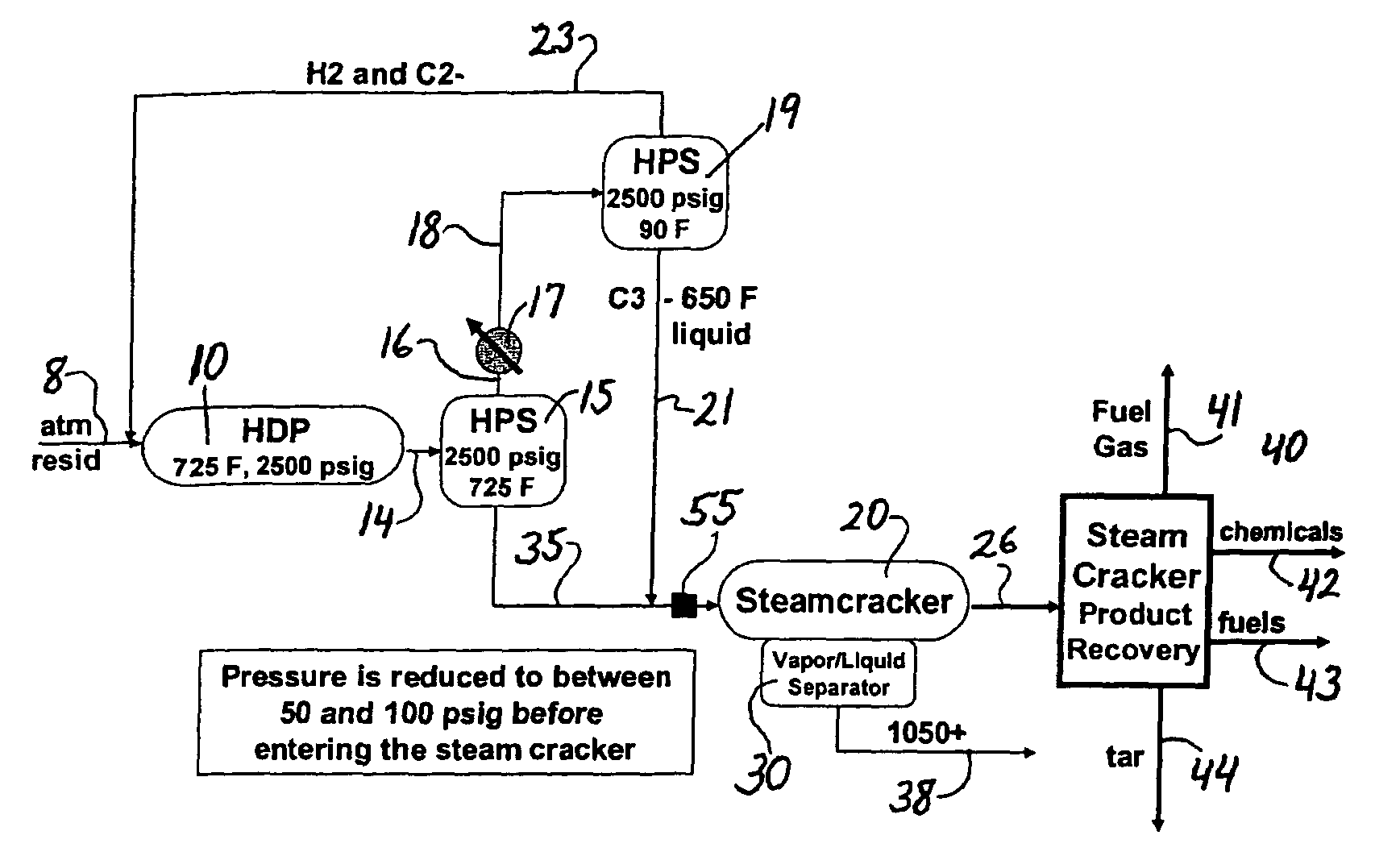

Hydrocarbon resid processing and visbreaking steam cracker feed

ActiveUS20070090019A1High hydrogen contentEliminate needThermal non-catalytic crackingHydrocarbon oil cracking processProcess engineeringHydrogen treatment

The invention concerns integration of hydroprocessing and steam cracking. A feed comprising crude or resid-containing fraction thereof is treated by hydroprocessing and visbreaking and then passed to a steam cracker to obtain a product comprising olefins.

Owner:EXXONMOBIL CHEM PAT INC

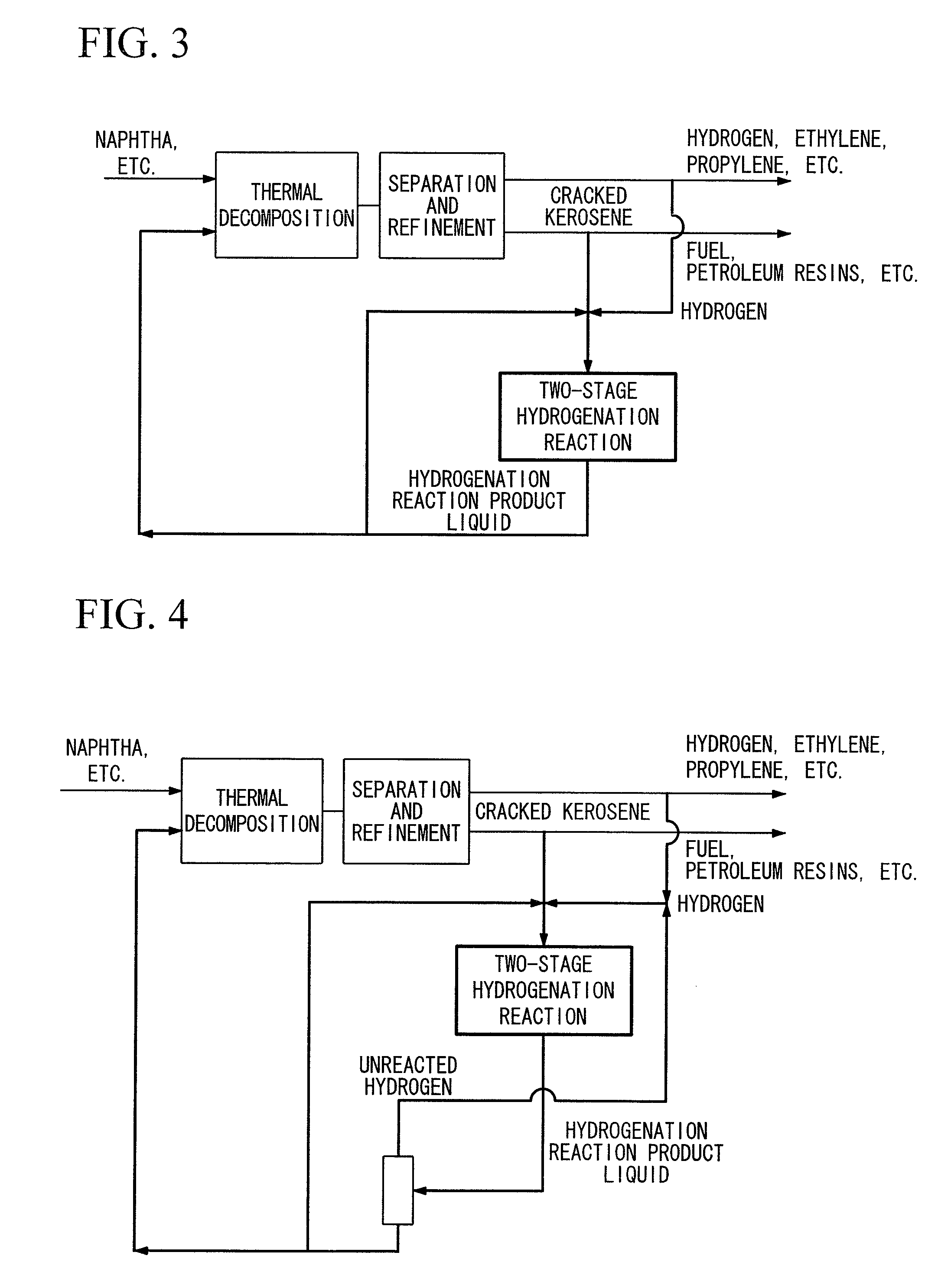

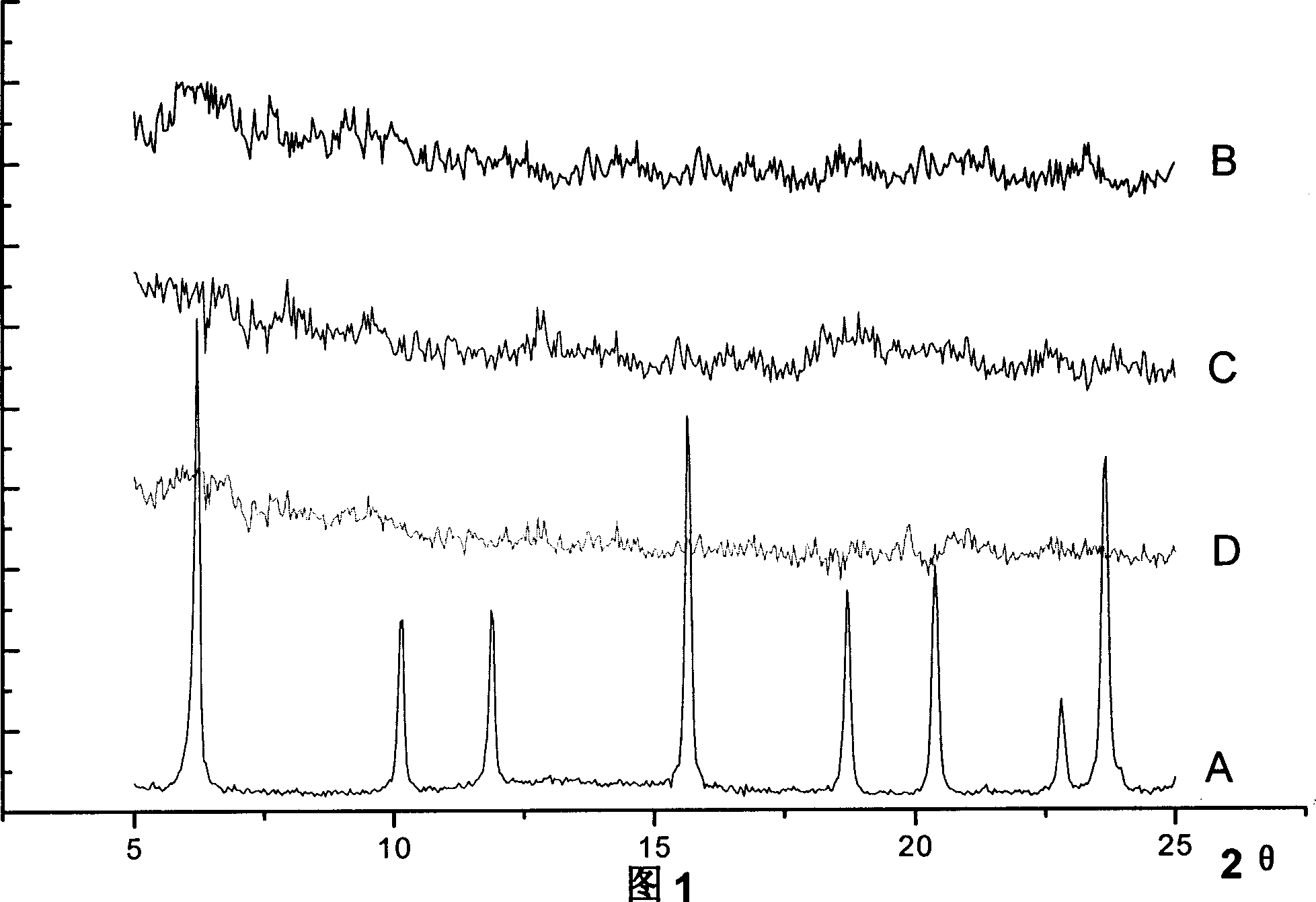

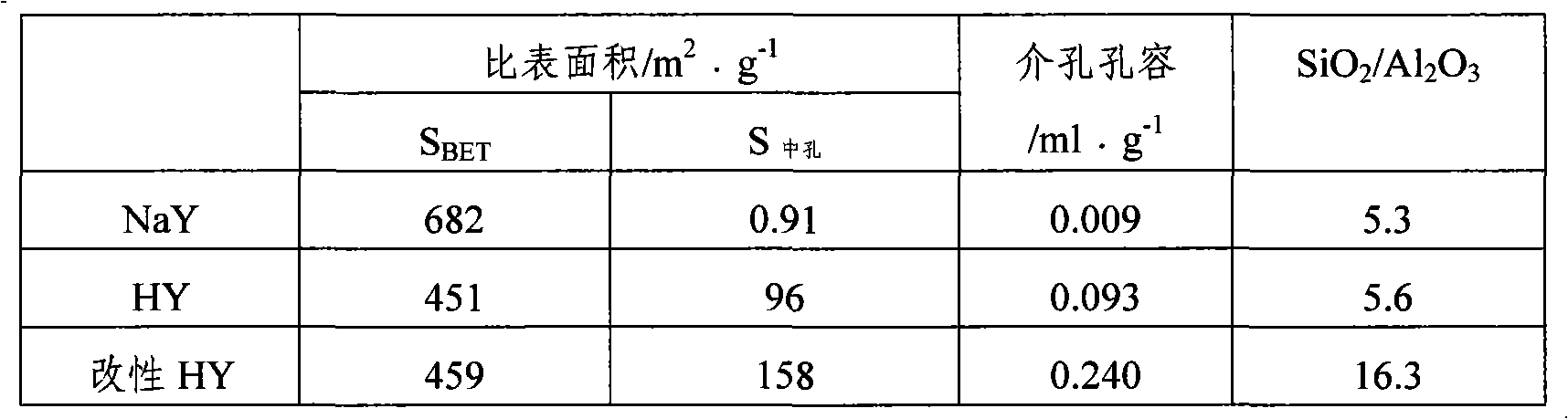

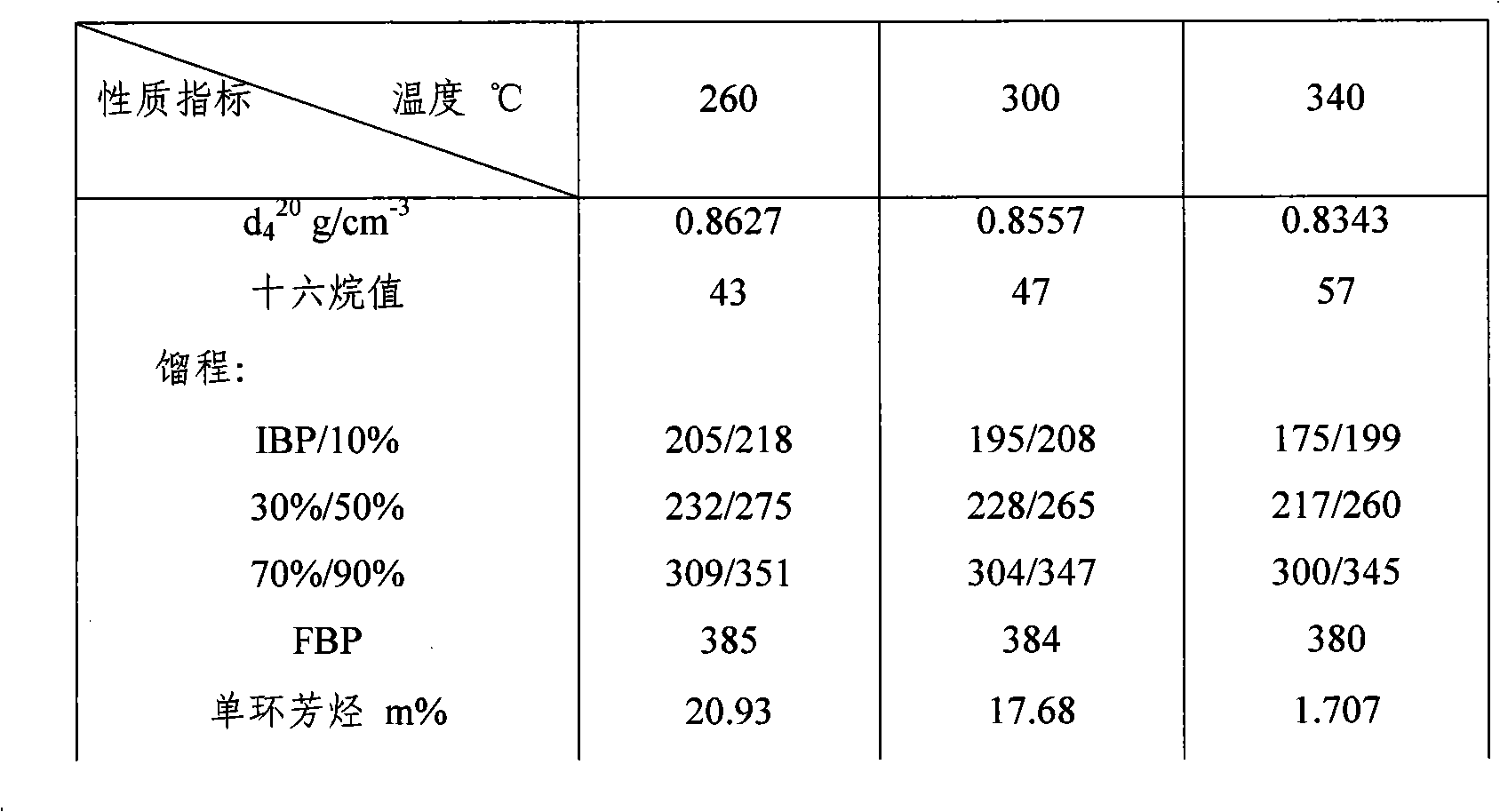

Modified molecular screen base precious metal diesel oil deepness hydrogenation dearomatization catalyst and method of preparing the same

ActiveCN101254471AMolecular sieve catalystsRefining by aromatic hydrocarbon hydrogenationMolecular sieveActive component

The invention discloses a modified molecular sieve-based noble metal catalyst for deep hydrodearomatization of diesel and the preparation method thereof. The catalyst is suitable for hydrodearomatization of the FCC diesel, particularly suitable for deep hydrodearomatization of diesel after hydro-upgrading of the FCC diesel. The dearomatized diesel can be used as a blend component of high-quality diesel. The catalyst contains modified HY molecular sieve as carriers and noble metals such as Pt, Pd and Ir as active components. The industrialized HY molecular sieve is modified to have microporous-mesoporous structure, and the carrier has medium acidity and is doped with Cr, Zn, Sn and Mo oxides of the active components with ring-opening selectivity, so that the inventive catalyst is characterized in deep cracking inhibition and ring-opening selection. The catalyst is used in the deep hydrodearomatization of the second stage in the two-stage hydro-upgrading of diesel.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Flexible method for producing oil bases with a ZSM-48 zeolite

InactiveUS6884339B2Reduce contentImproves UV stabilityTreatment with plural serial cracking stages onlyCoke ovensBase oilAzeotropic distillation

A process for the production of very high quality base oils optionally with simultaneous production of high quality middle distillates comprises the stages for hydrotreatment, preferably hydrocracking, on Y or beta zeolite, and atmospheric distillation. The effluent is subjected to a catalytic dewaxing on the ZSM-48 catalyst. The process then comprises a hydrofinishing stage for hydrogenating the aromatic compounds, preferably on a catalyst that comprises at least one noble metal of group VIII, chlorine and fluorine, and the stages of atmospheric and vacuum distillation. The hydrofinishing stage is conducted at a temperature lower by 20-200° C. than the catalytic dewaxing stage.

Owner:INST FR DU PETROLE

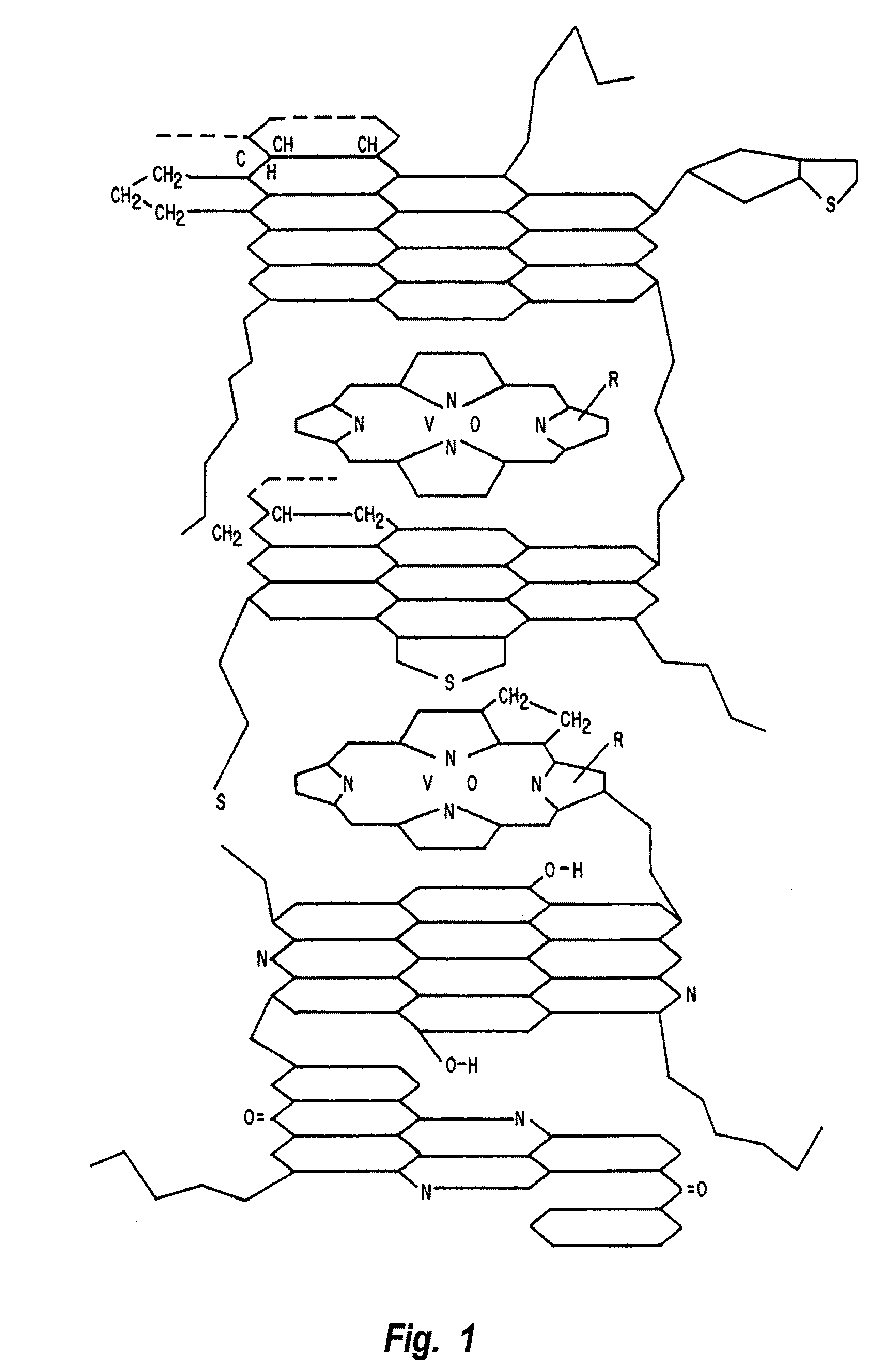

Hydrotreated hydrocarbon tar, fuel oil composition, and process for making

InactiveUS20140174980A1Thermal non-catalytic crackingWorking-up pitch/asphalt/bitumen by chemical meansBoiling pointTar

Provided is a hydrocarbon tar. The tar has 75 wt % or more of aromatics of 10 carbons to 75 carbons based on the total weight of the tar. The aromatics exhibit 40% to 80% aromaticity. The tar has a boiling point of from 300° F. to 1350° F. There is also a fuel oil composition having the tar therein. There are also processes for making the hydrocarbon tar.

Owner:EXXONMOBIL CHEM PAT INC

Process for isomerization dewaxing of hydrocarbon streams

InactiveUS6652735B2Yield maximizationReduce pointsHydrocarbon by isomerisationRefining to change hydrocarbon structural skeletonMolecular sieveIsomerization

A process for isomerization dewaxing of a hydrocarbon feed which includes contacting the hydrocarbon feed with a large pore size, small crystal size, crystalline molecular sieve and an intermediate pore size, small crystal size, crystalline molecular sieve to produce a dewaxed product with a reduced pour point and a reduced cloud point. In a preferred embodiment, the feed is contacted with the molecular sieves sequentially, first with the large pore sieve followed by the intermediate pore sieve.

Owner:EXXON RES & ENG CO

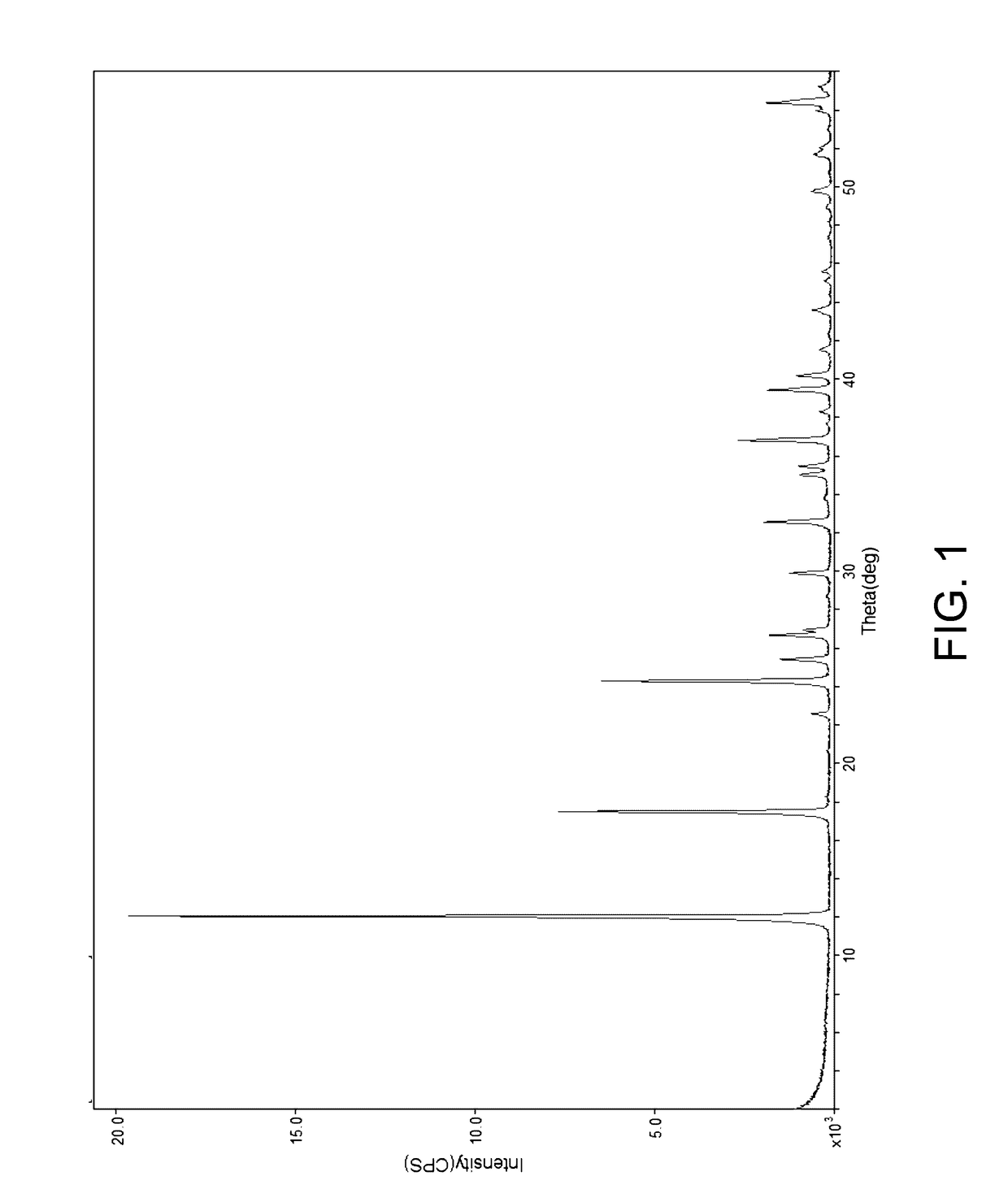

Crystalline transition metal tungstate

ActiveUS20170165650A1Catalyst activation/preparationHydrocarbon oil crackingTungstateHydrodesulfurization

A hydroprocessing catalyst has been developed. The catalyst is a unique transition metal tungstate material. The hydroprocessing using the crystalline ammonia transition metal dimolybdotungstate material may include hydrodenitrification, hydrodesulfurization, hydrodemetallation, hydrodesilication, hydrodearomatization, hydroisomerization, hydrotreating, hydrofining, and hydrocracking.

Owner:UOP LLC

Aromatics hydrogenation catalyst and preparation method and application of aromatics hydrogenation catalyst

InactiveCN102688770AMolecular sieve catalystsRefining by aromatic hydrocarbon hydrogenationPolycyclic aromatic hydrocarbonMolecular sieve

Discloses is an aromatics hydrogenation catalyst. Mesoporous zeolite is used as a catalyst carrier, an active component of the aromatic hydrogenation catalyst includes precious metal, and the mass of the precious metal in the catalyst ranges from 0.1% to 2.0%. The precious metal is used as the hydrogenation active component of the catalyst, the mesoporous zeolite with the advantages of a zeolite molecular sieve and advantages of mesoporous materials is used as the carrier, and the catalyst is applicable to a polycyclic aromatic hydrocarbon hydrogenation reaction process, and is higher in hydrogenation activity and sulfur poisoning resistance. When the aromatic hydrogenation catalyst and a catalyst comprising a conventional zeolite molecular sieve and commercial aluminum oxide load precious metal by the same evaluation device, the aromatic hydrogenation catalyst is higher in hydrogenation and dearomatization activity and sulfuric resistance.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI +1

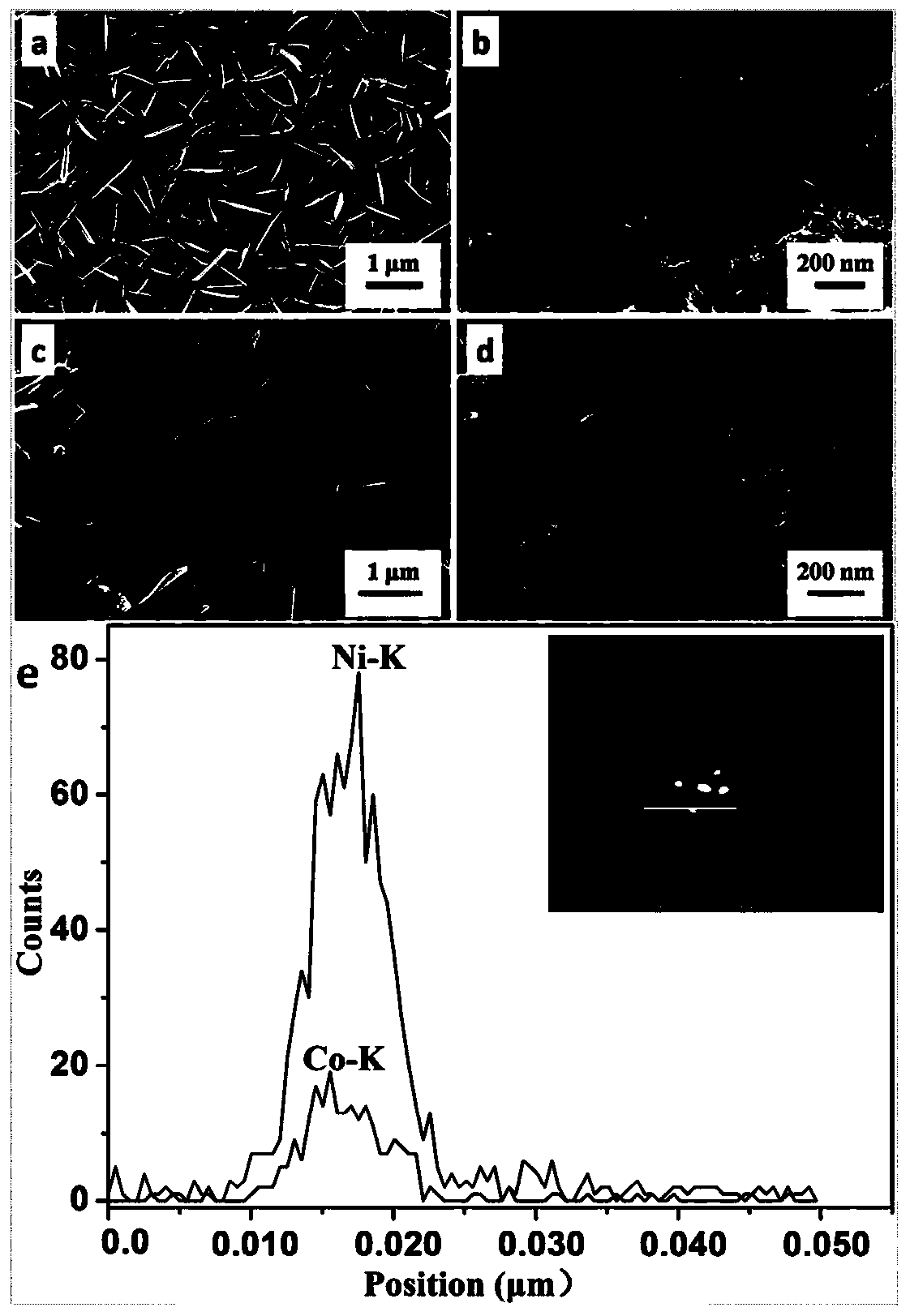

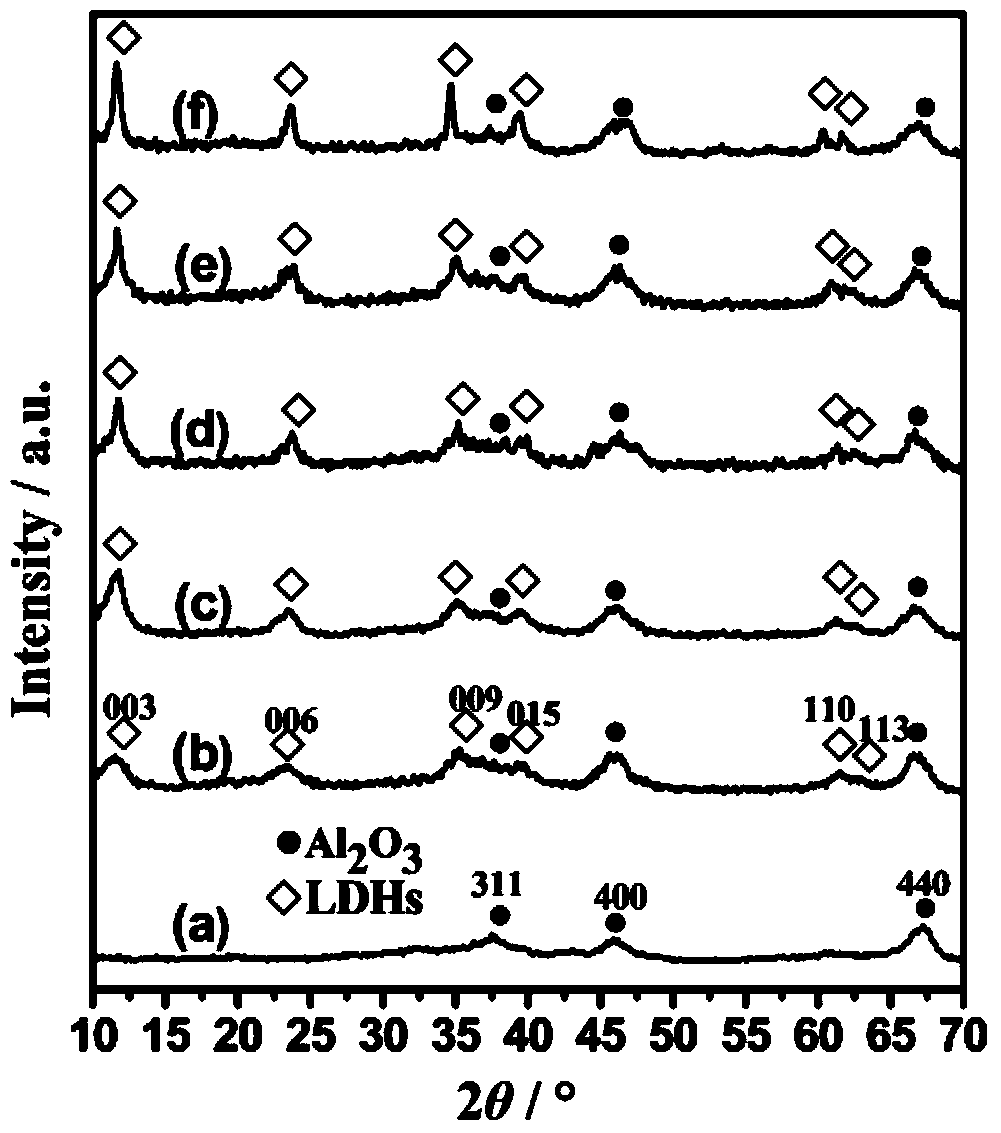

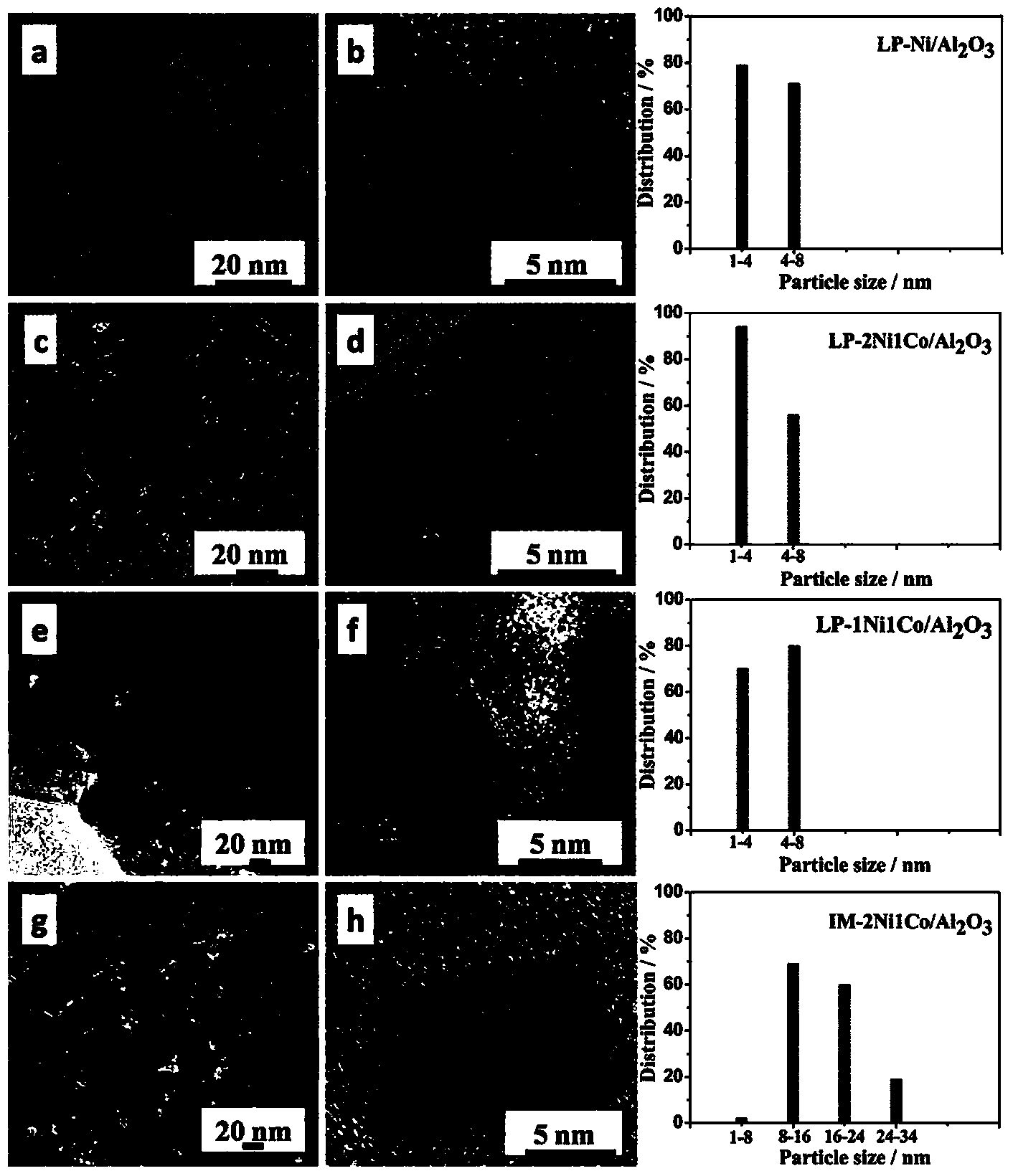

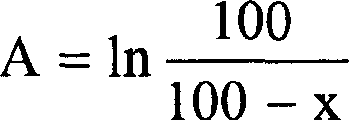

Preparation method and catalytic application of supported type high-dispersion nickel-based alloy catalyst

InactiveCN104368345AImprove conversion rateHigh selectivityMetal/metal-oxides/metal-hydroxide catalystsRefining by aromatic hydrocarbon hydrogenationPtru catalystAlloy catalyst

The invention discloses a preparation method and a catalytic application of a supported type high-dispersion nickel-based alloy catalyst. The preparation method comprises the following steps: by virtue of an in-situ growth method, supporting Ni, M (M=Co, Zn, Cu, Fe, Cr and the like) metal in the form of hydrotalcite on the surface of a microsphere-form gamma-Al2O3 carrier with grain size of 20-40 meshes and in a duct of the microsphere-form gamma-Al2O3 carrier, namely growing lamellar precursor LDHs containing Ni and M metal ions outside and inside a Al2O3 particle to form supported type high-dispersion distribution, converting the lamellar precursor LDHs into a corresponding composite metal oxide by drying and roasting at high temperature, and reducing the composite metal oxide to obtain the supported type high-dispersion nickel-based alloy catalyst with NiM distributed on the outer surface and in the duct of the carrier particle. The supported type high-dispersion nickel-based alloy catalyst is applied to first selective hydrogenation reaction of cracked gasoline, so that the conversion rate, the selectivity and the stability of the catalyst can be effectively improved; and moreover, the supported type high-dispersion nickel-based alloy catalyst can be used for methane reforming, and catalyzing reaction of preparing low-carbon hydrocarbon and alcohol by virtue of CO and CO2 hydrogenation.

Owner:BEIJING UNIV OF CHEM TECH

Fluorinated hydrogenation catalyst with silicon oxide-alumina as carrier and its production

ActiveCN1853779AHigh activityPhysical/chemical process catalystsRefining by aromatic hydrocarbon hydrogenationSilicon oxideChemistry

Owner:CHINA PETROLEUM & CHEM CORP +1

Ebullated bed hydroprocessing methods and systems and methods of upgrading an existing ebullated bed system

ActiveUS7449103B2Quality improvementReduce formationHydrocarbon oil crackingLiquid hydrocarbon mixture productionHydrogenDecomposition

An ebullated bed hydroprocessing system, and also a method for upgrading a pre-existing ebullated bed hydroprocessing system, involves introducing a colloidal or molecular catalyst, or a precursor composition capable of forming the colloidal or molecular catalyst, into an ebullated bed reactor. The colloidal or molecular catalyst is formed by intimately mixing a catalyst precursor composition into a heavy oil feedstock and raising the temperature of the feedstock to above the decomposition temperature of the precursor composition to form the colloidal or molecular catalyst in situ. The improved ebullated bed hydroprocessing system includes at least one ebullated bed reactor that employs both a porous supported catalyst and the colloidal or molecular catalyst to catalyze hydroprocessing reactions involving the feedstock and hydrogen. The colloidal or molecular catalyst provides catalyst in what would otherwise constitute catalyst free zones within the ebullated bed hydroprocessing system. Asphaltene or other hydrocarbon molecules too large to diffuse into the pores of the supported catalyst can be upgraded by the colloidal or molecular catalyst. A slurry phase reactor may be positioned upstream from one or more ebullated bed reactors or converted from a pre-existing ebullated bed reactor.

Owner:HEADWATERS TECH INNOVATION LLC

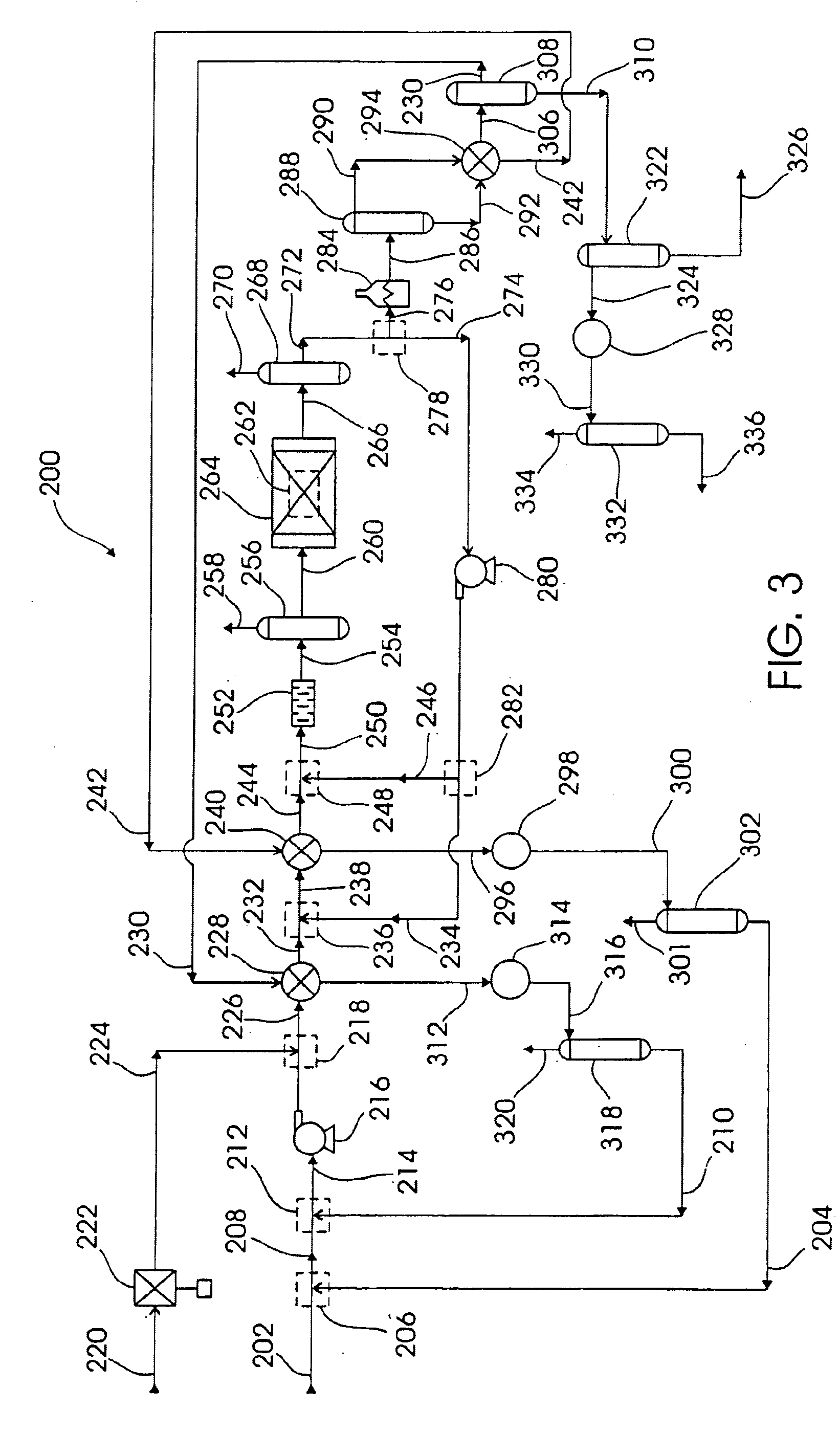

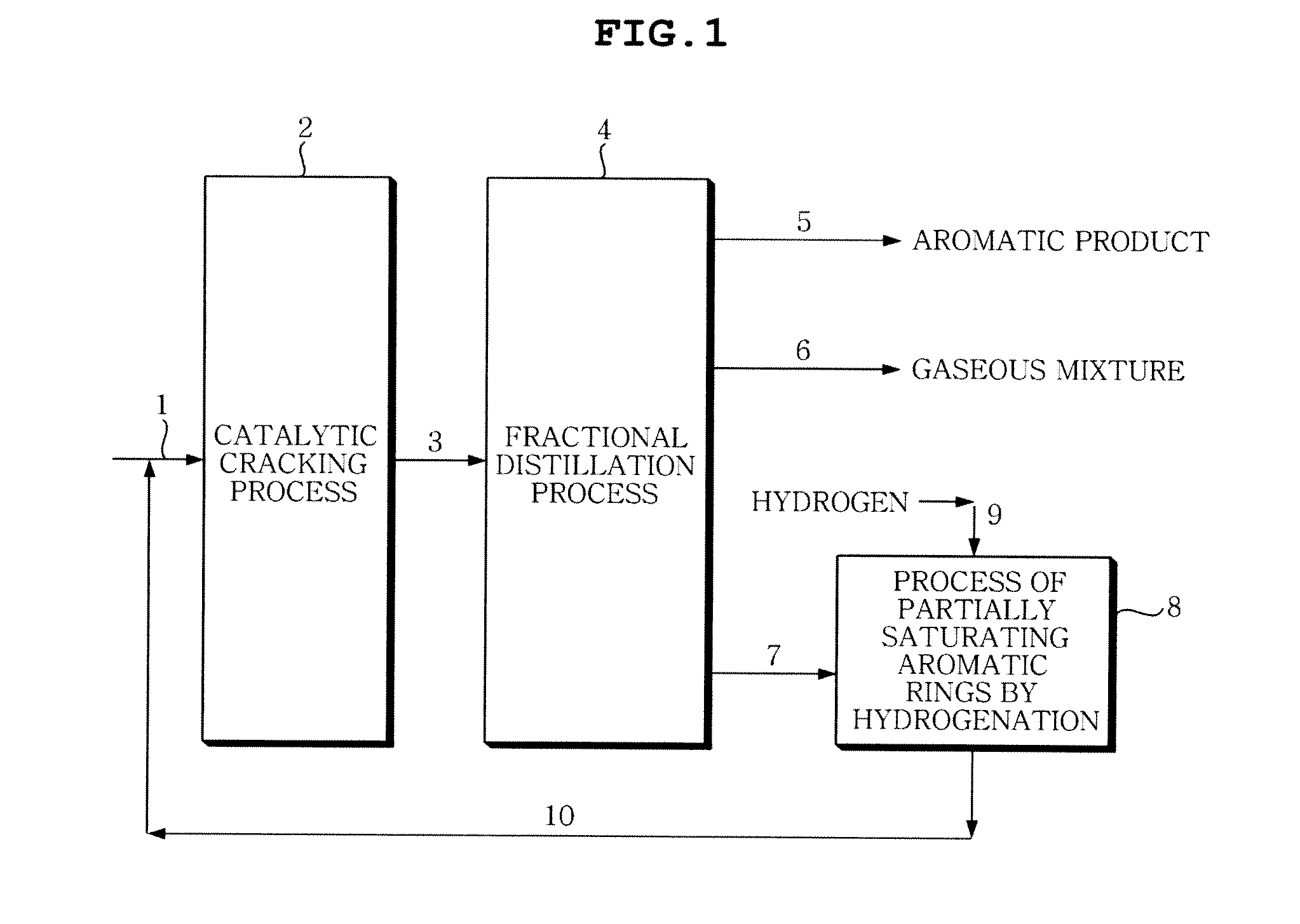

Method for producing high value aromatics and olefin from light cycle oil produced by a fluidized catalytic cracking process

ActiveUS20110207979A1Increase productionMaximize processing efficiencyCatalytic crackingHydrocarbonsHigh concentrationPetroleum

The present invention relates to a method of producing aromatic products (benzene / toluene / xylene) and olefin products from petroleum fractions obtained by fluid catalytic cracking, and, more particularly, to a method of producing products comprising high-concentration aromatic products and high value-added light olefin products from light cycle oil obtained by fluid catalytic cracking.

Owner:SK INNOVATION CO LTD

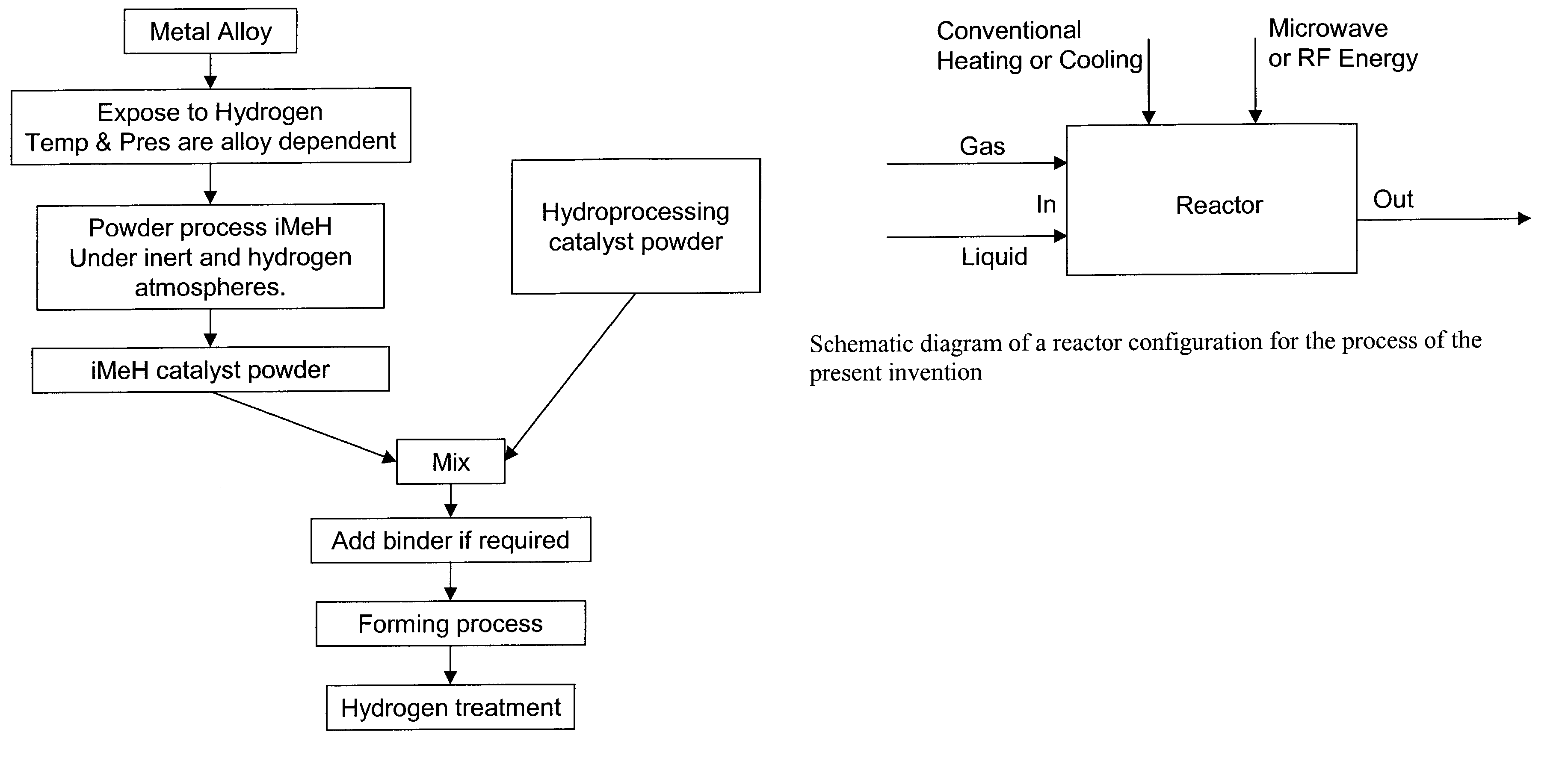

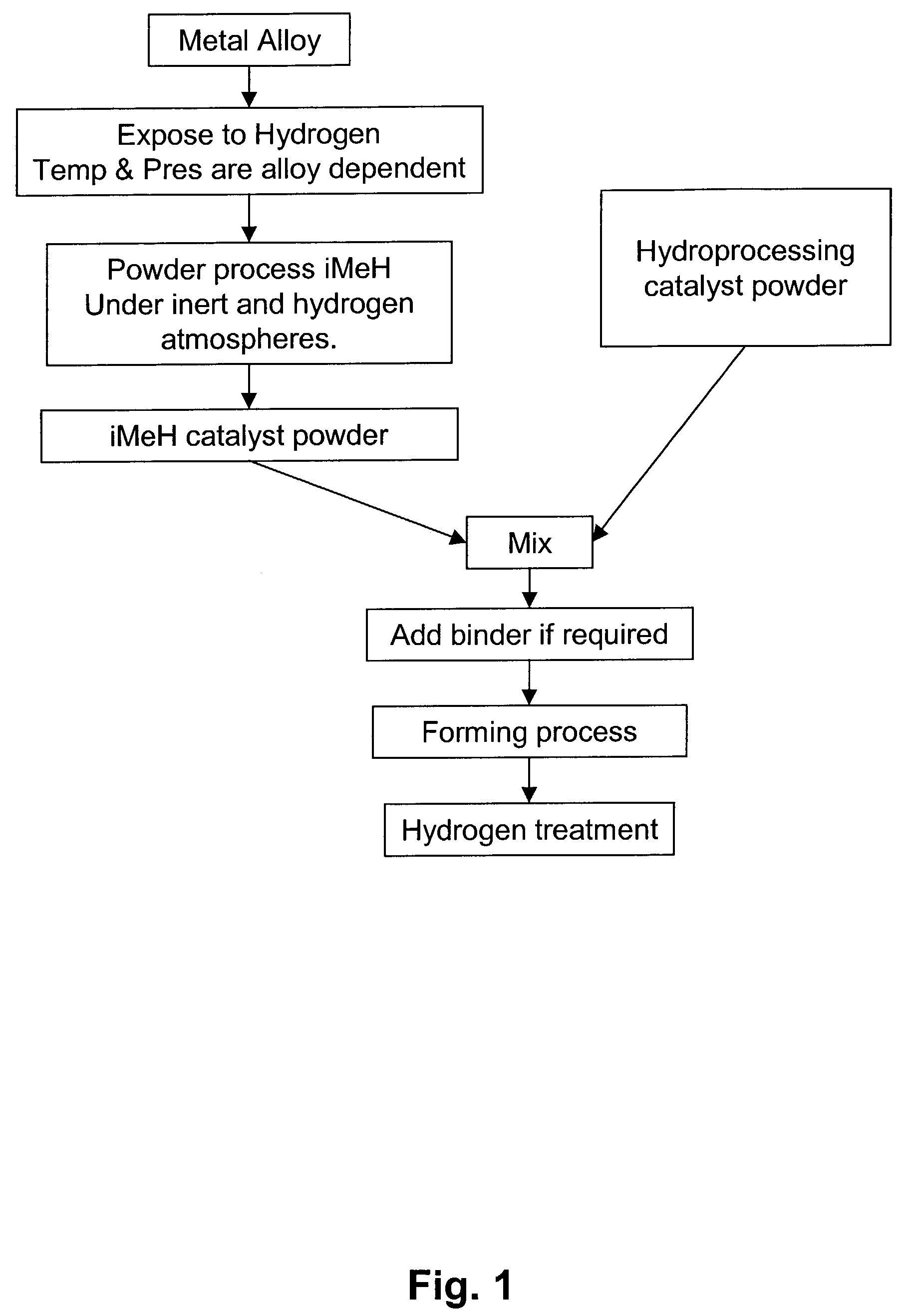

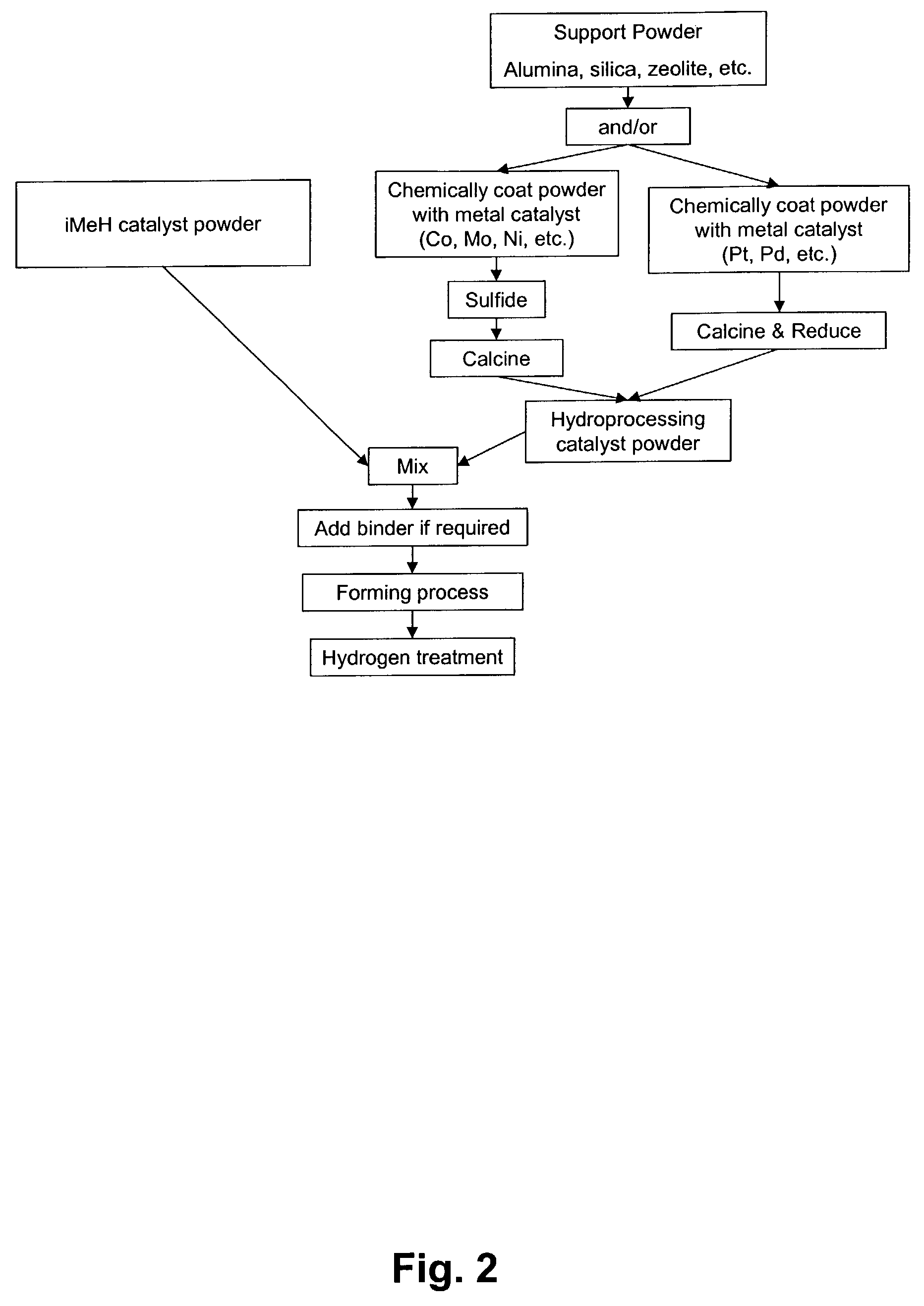

Catalytic process for the treatment of organic compounds

InactiveUS7387712B2Group 1/11 element organic compoundsCatalytic crackingSimple Organic CompoundsPtru catalyst

A process for the catalytic reaction of organic compounds, in which the organic compounds are contacted with a catalyst comprising an interstitial metal hydride, having a reaction surface, to produce a catalyst-organic compound mixture, energy is applied, monatomic hydrogen is produced at the reaction surface of the interstitial metal hydride, and the organic compounds are reacted with the monatomic hydrogen. Reactions accomplished by this process include petroleum hydrocracking and hydrotreating processes. The method's performance can be further enhanced using radio frequency (RF) or microwave energy.

Owner:CARNEGIE MELLON UNIV

Popular searches

Bio-feedstock Hydrocarbon oils treatment products Distillation separation Liquid-gas reaction processes Hydrocarbon by hydrocarbon cracking Refining by selective hydrogenation Chemical/physical processes Treatment with moving solid particles Refining to eliminate hetero atoms Oxygen compounds preparation by reduction

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com