Patents

Literature

246results about "Treatment with moving solid particles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

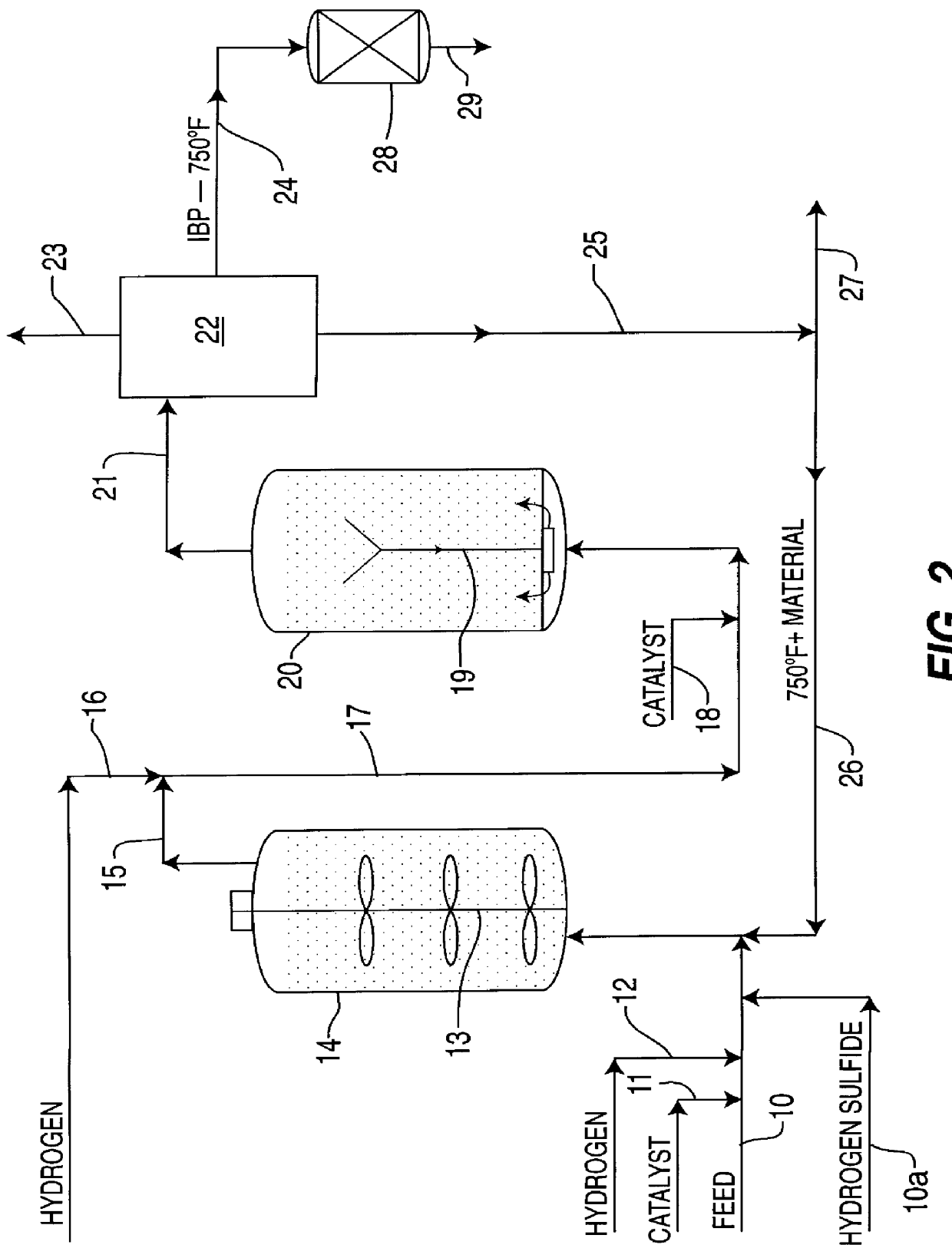

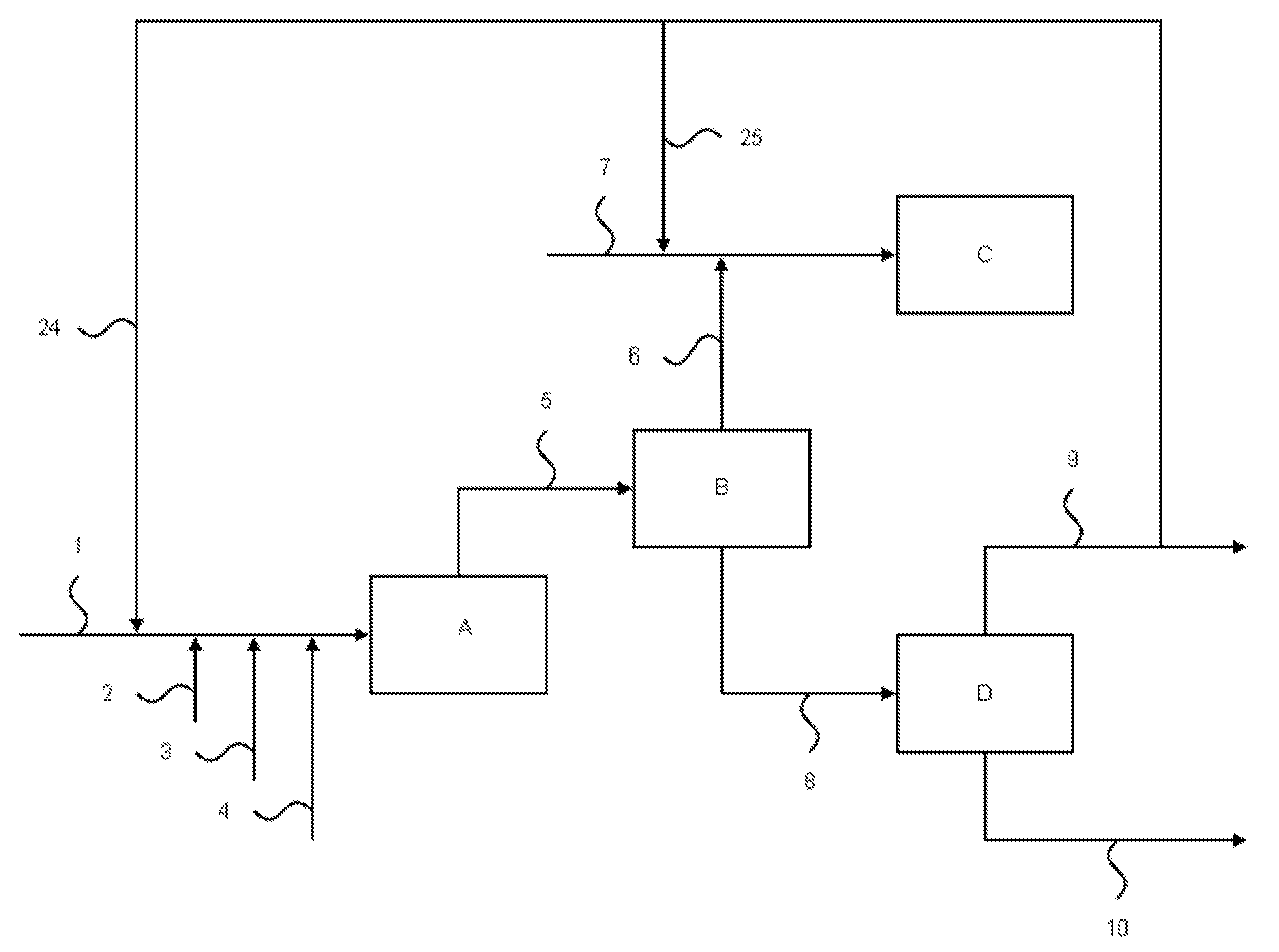

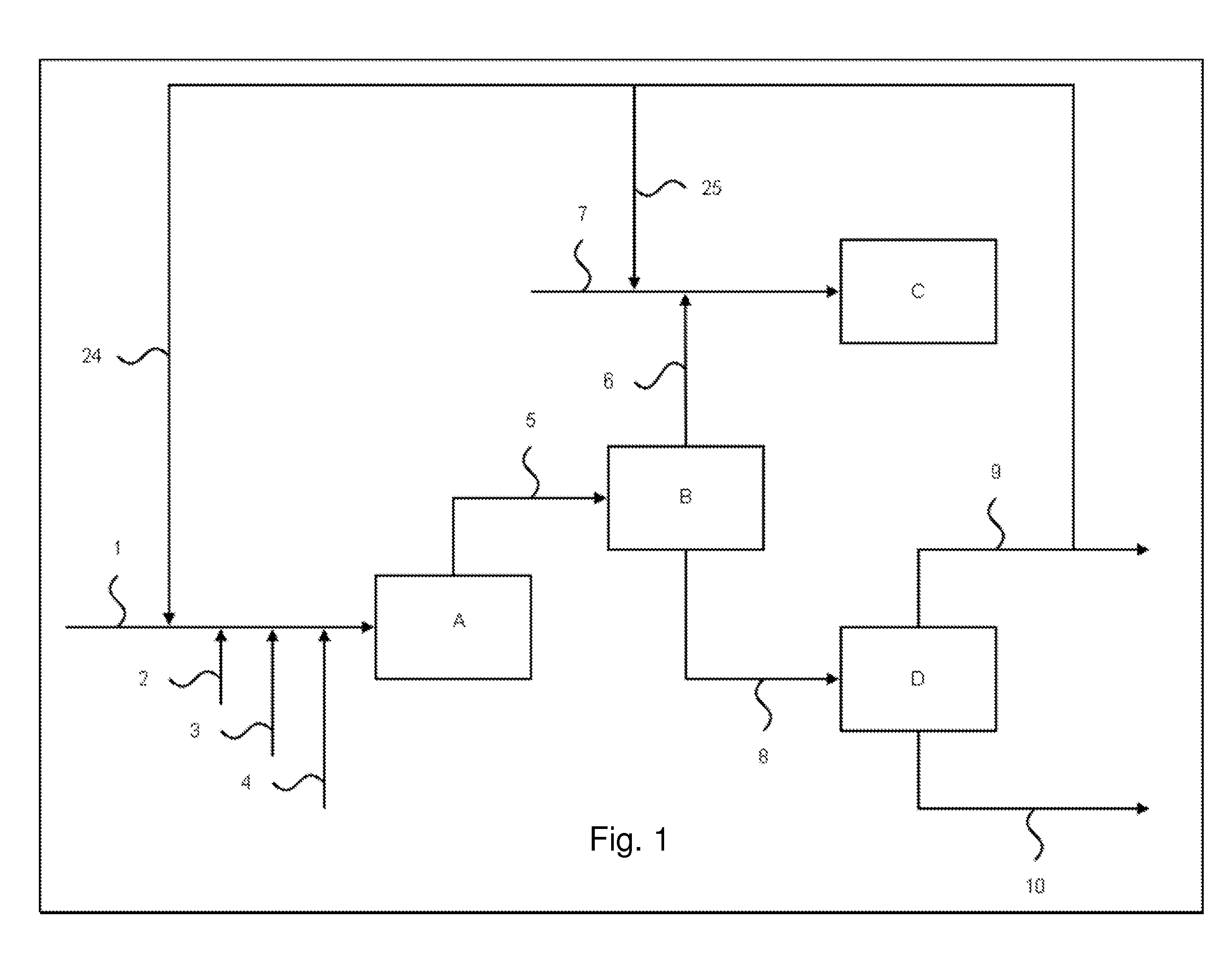

Catalytic multi-stage process for hydroconversion and refining hydrocarbon feeds

InactiveUS6190542B1Improve distillation yieldQuality improvementCatalyst activation/preparationLiquid hydrocarbon mixture productionLiquid productDistillates petroleum

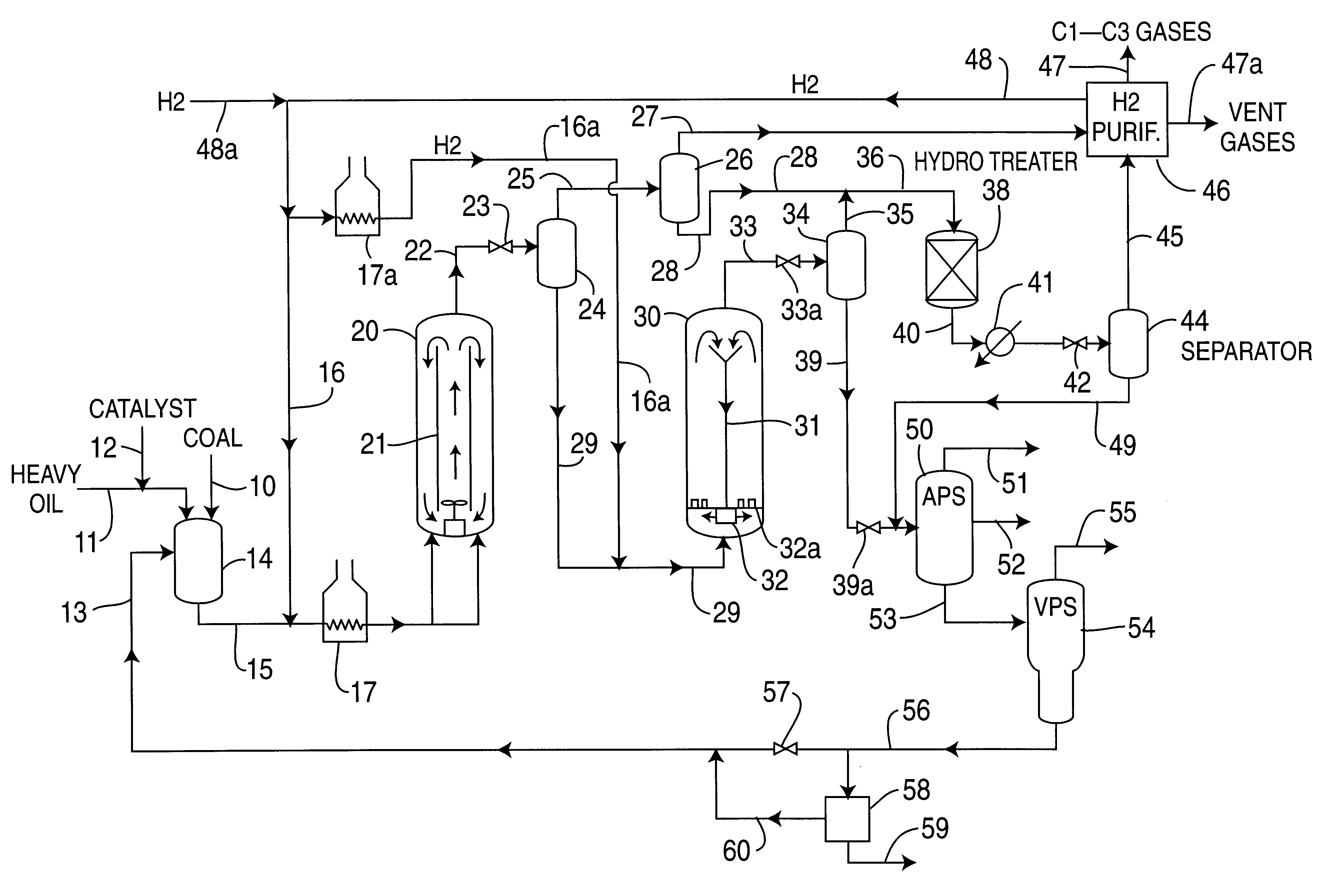

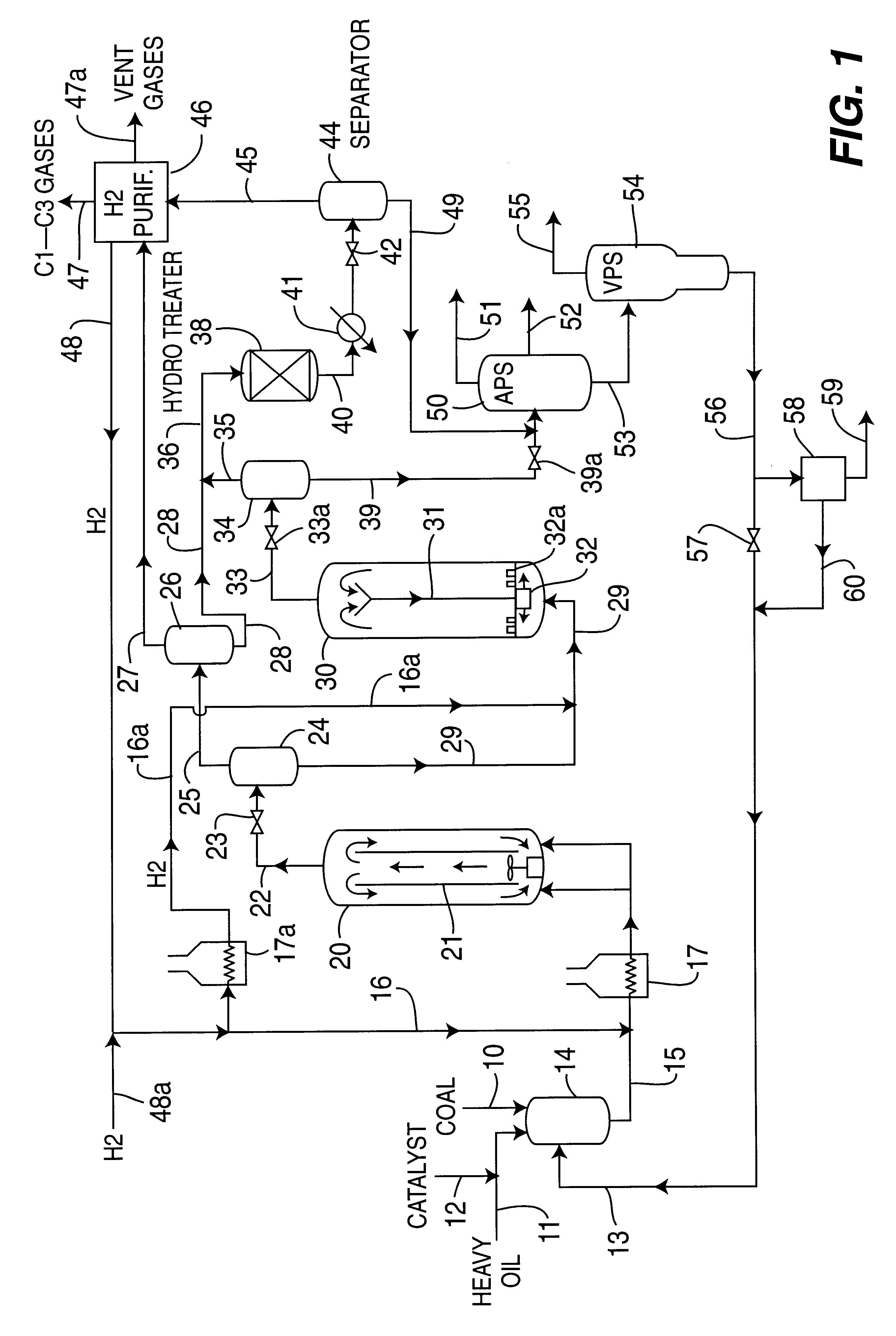

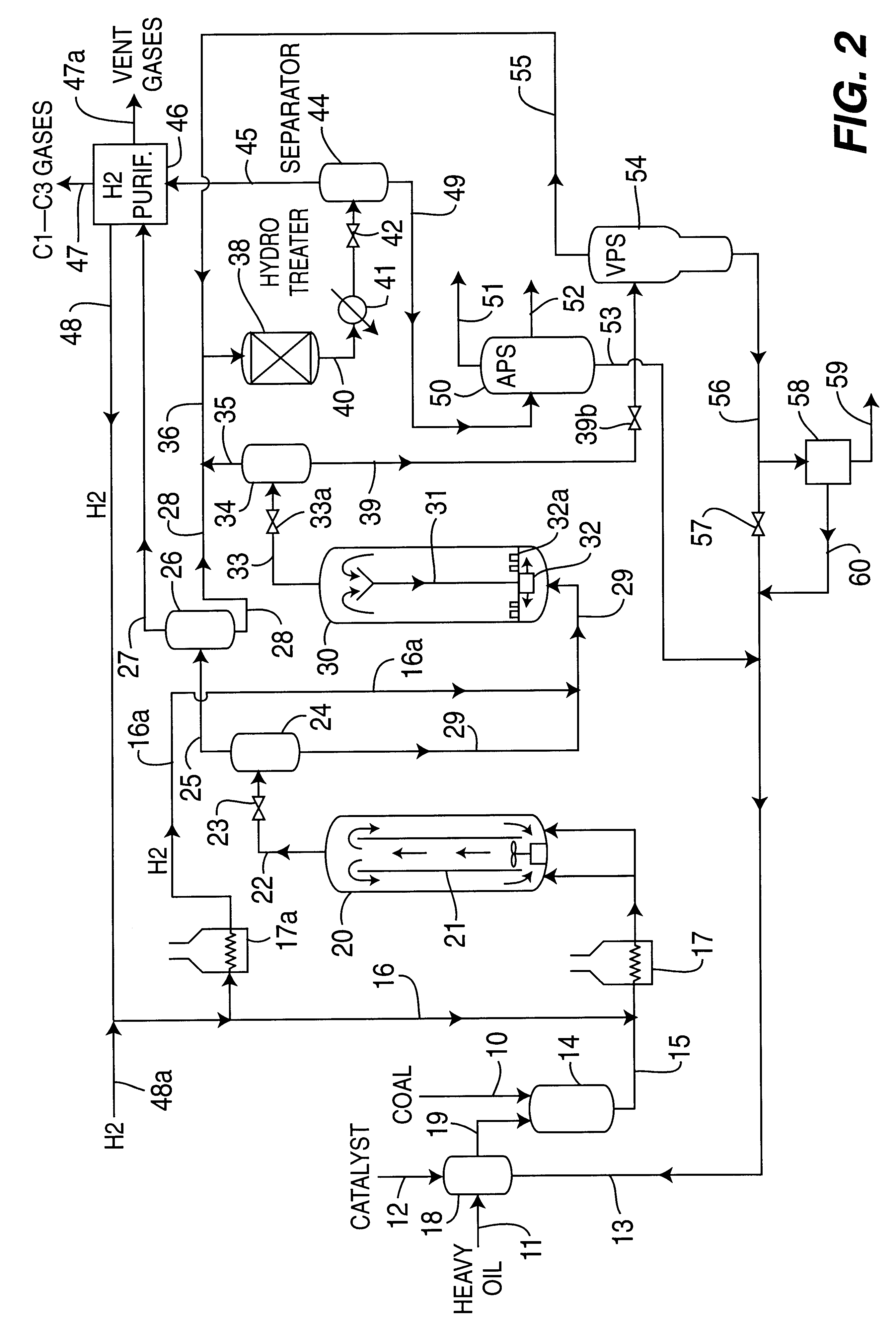

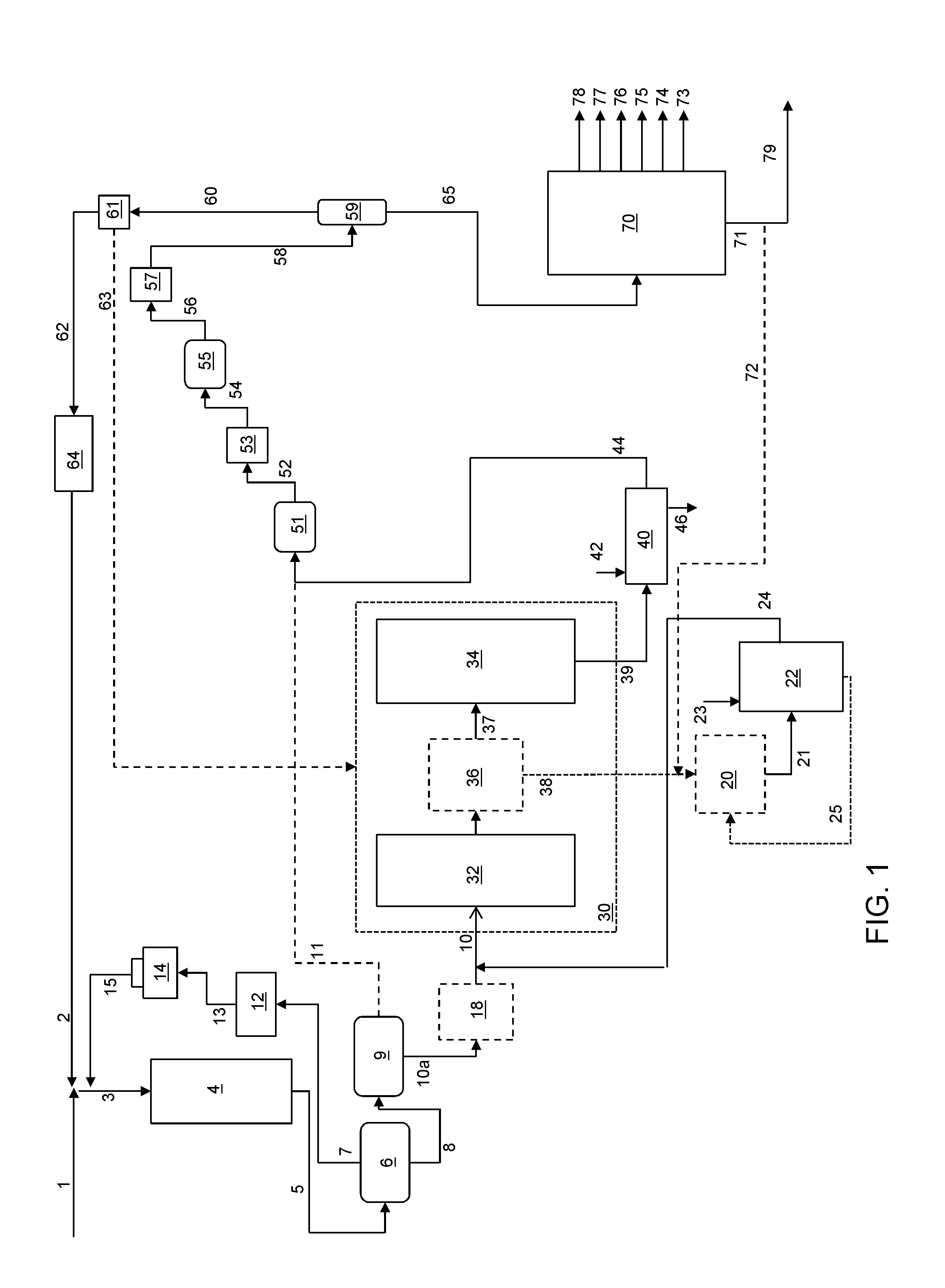

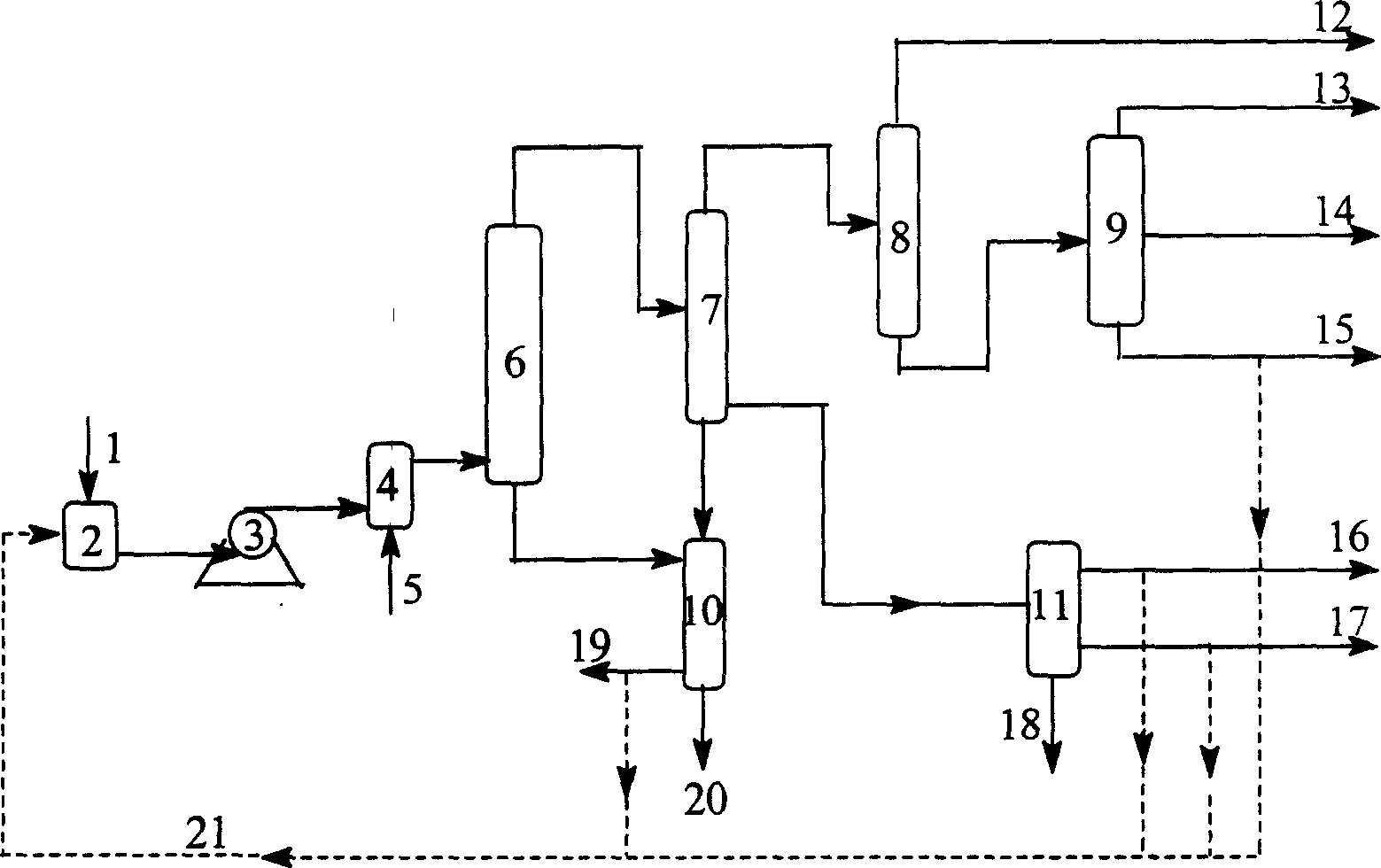

A multi-stage catalytic hydrogenation and hydroconversion process for heavy hydrocarbon feed materials such as coal, heavy petroleum fractions, and plastic waste materials. In the process, the feedstock is reacted in a first-stage, back-mixed catalytic reactor with a highly dispersed iron-based catalyst having a powder, gel or liquid form. The reactor effluent is pressure-reduced, vapors and light distillate fractions are removed overhead, and the heavier liquid fraction is fed to a second stage back-mixed catalytic reactor. The first and second stage catalytic reactors are operated at 700-850.degree. F. temperature, 1000-3500 psig hydrogen partial pressure and 20-80 lb. / hr per ft.sup.3 reactor space velocity. The vapor and light distillates liquid fractions removed from both the first and second stage reactor effluent streams are combined and passed to an in-line, fixed-bed catalytic hydrotreater for heteroatom removal and for producing high quality naphtha and mid-distillate or a full-range distillate product. The remaining separator bottoms liquid fractions are distilled at successive atmospheric and vacuum pressures, low and intermediate-boiling hydrocarbon liquid products are withdrawn, and heavier distillate fractions are recycled and further upgraded to provide additional low-boiling hydrocarbon liquid products. This catalytic multistage hydrogenation process provides improved flexibility for hydroprocessing the various carbonaceous feedstocks and adjusting to desired product structures and for improved economy of operations.

Owner:HEADWATERS CTL

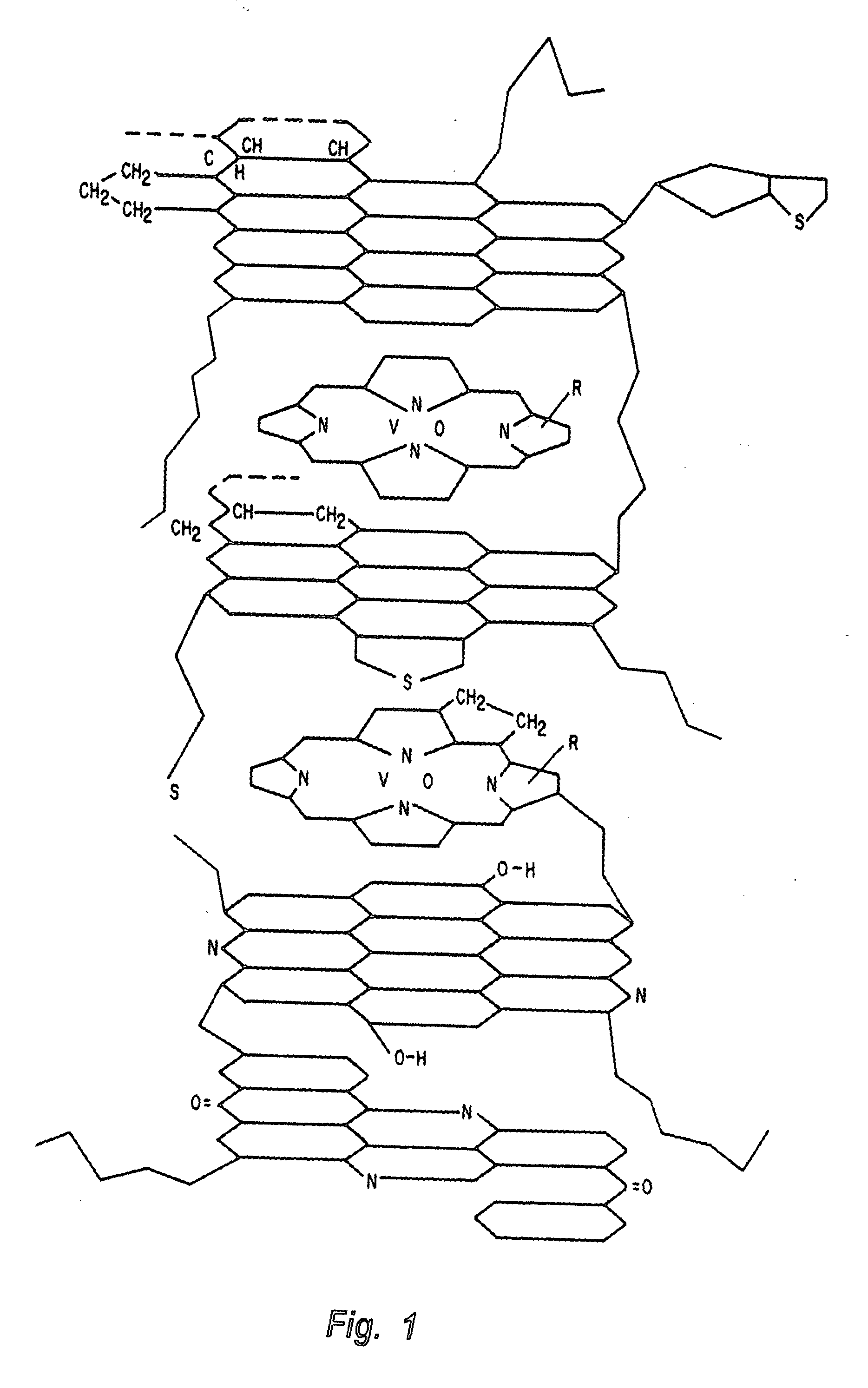

Iron-based ionic liquid catalysts for hydroprocessing carbonaceous feeds

InactiveUS6139723AIncrease hydrocracking ability of catalystIndirect and direct heating destructive distillationCatalyst activation/preparationLiquid productIron salts

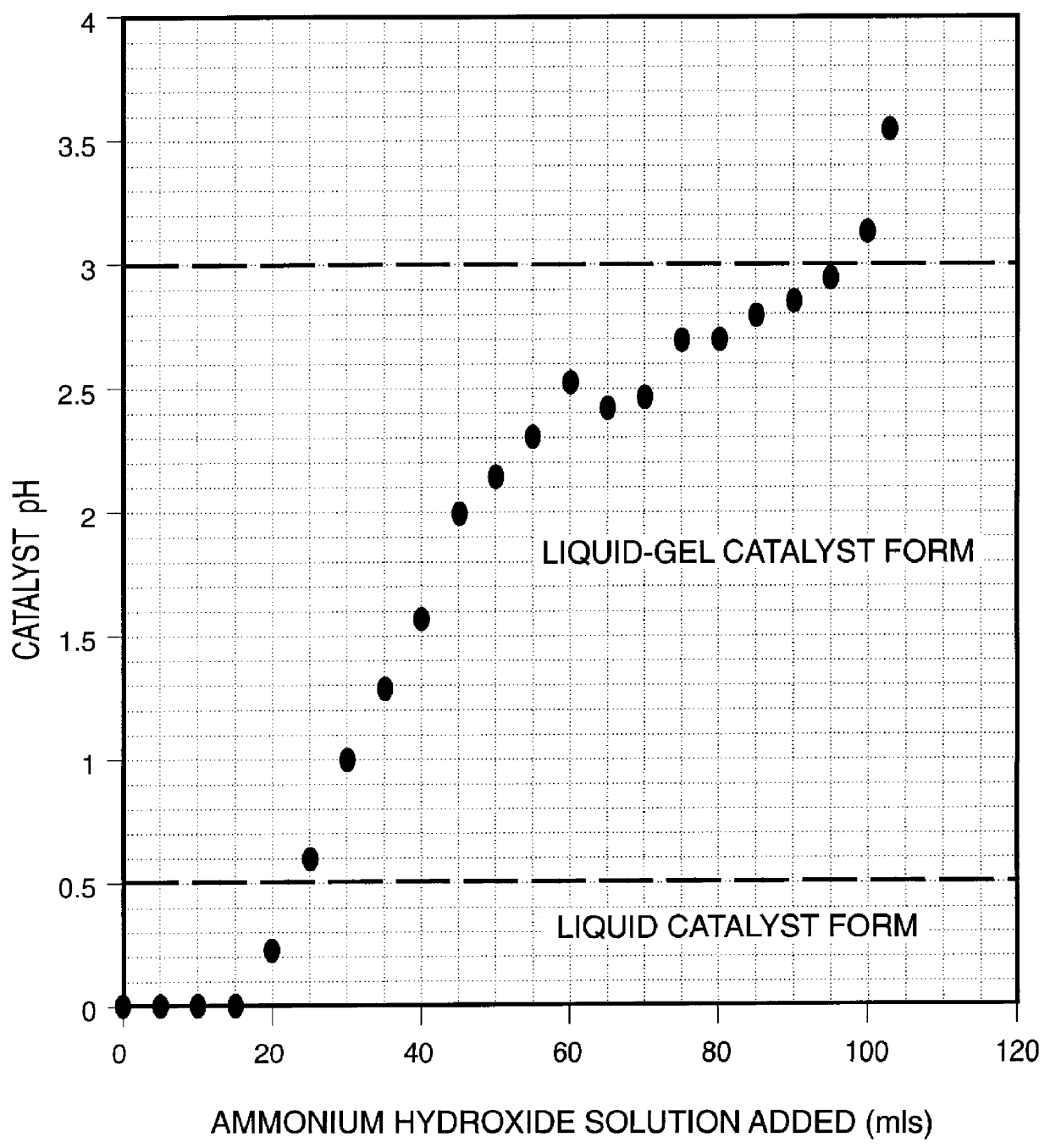

A highly dispersed iron-based ionic liquid or liquid-gel catalyst which may be anion-modified and metals-promoted has high catalytic activity, and is useful for hydrocracking / hydrogenation reactions for carbonaceous feed materials. The catalyst is produced by aqueous precipitation from saturated iron salt solutions such as ferric sulfate and ferric alum, and may be modified during preparation with anionic sulfate (SO42-) and promoted with small percentages of at least one active metal such as cobalt, molybdenum, palladium, platinum, nickel, or tungsten or mixtures thereof. The resulting catalyst may be used in a preferred ionic liquid form or in a liquid-gel form, and either fluidic form can be easily mixed and reacted with carbonaceous feed materials such as coal, heavy petroleum fractions, mixed plastic waste, or mixtures thereof. The invention includes methods for making the ionic liquid or liquid-gel catalyst, and processes for using the fluidic catalysts for hydroprocessing the carbonaceous feed materials to produce desirable low-boiling hydrocarbon liquid products.

Owner:HEADWATERS CTL

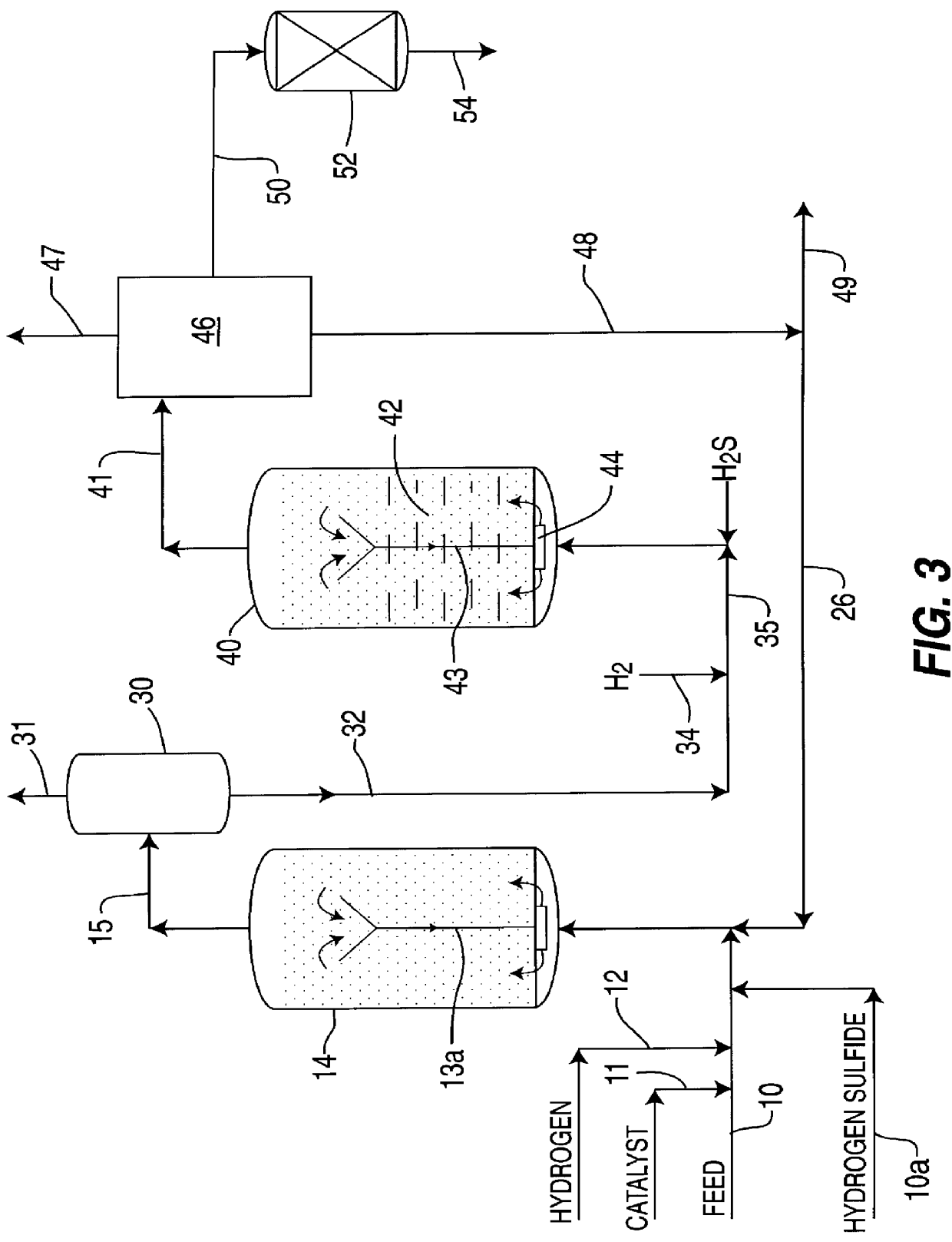

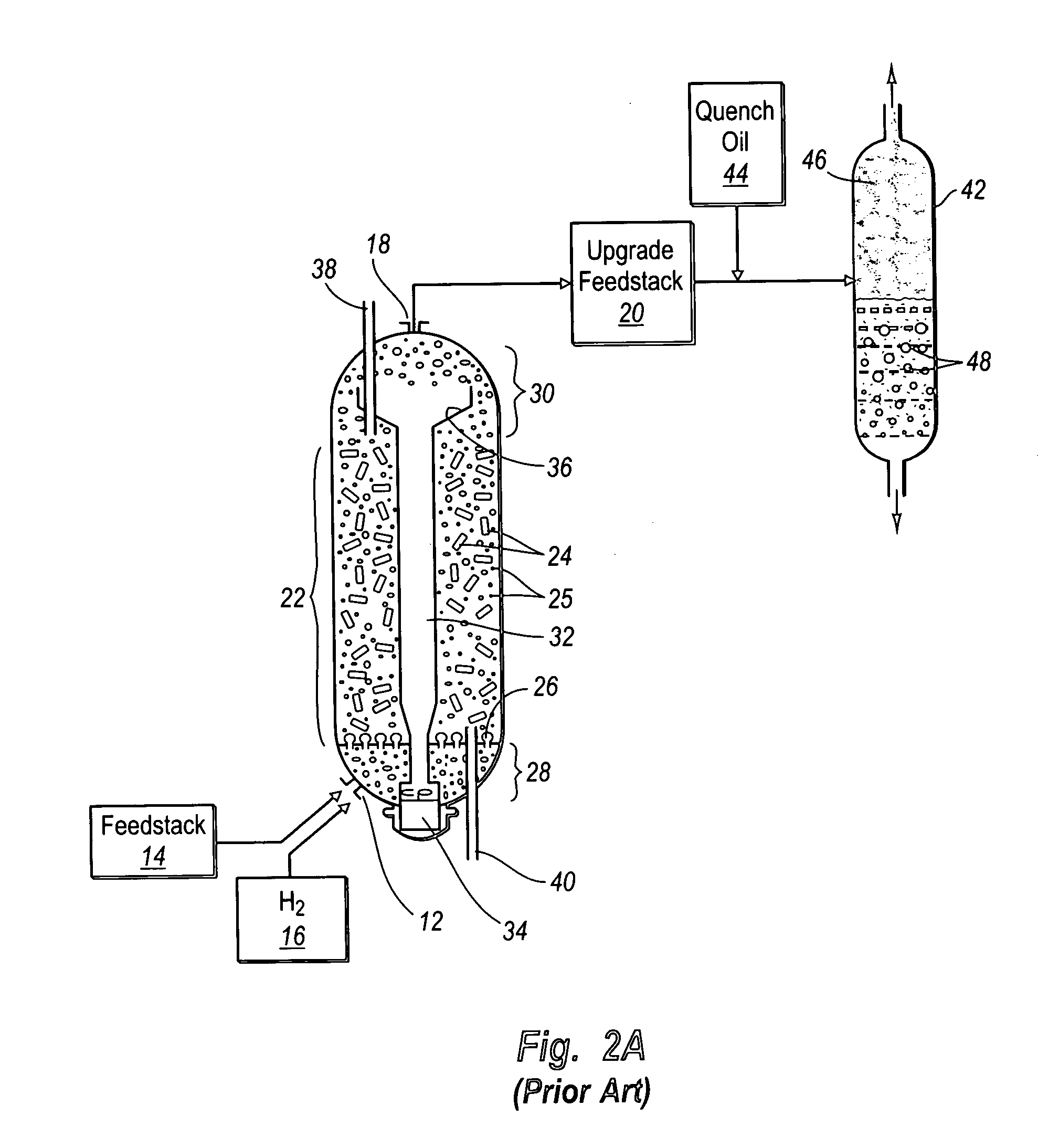

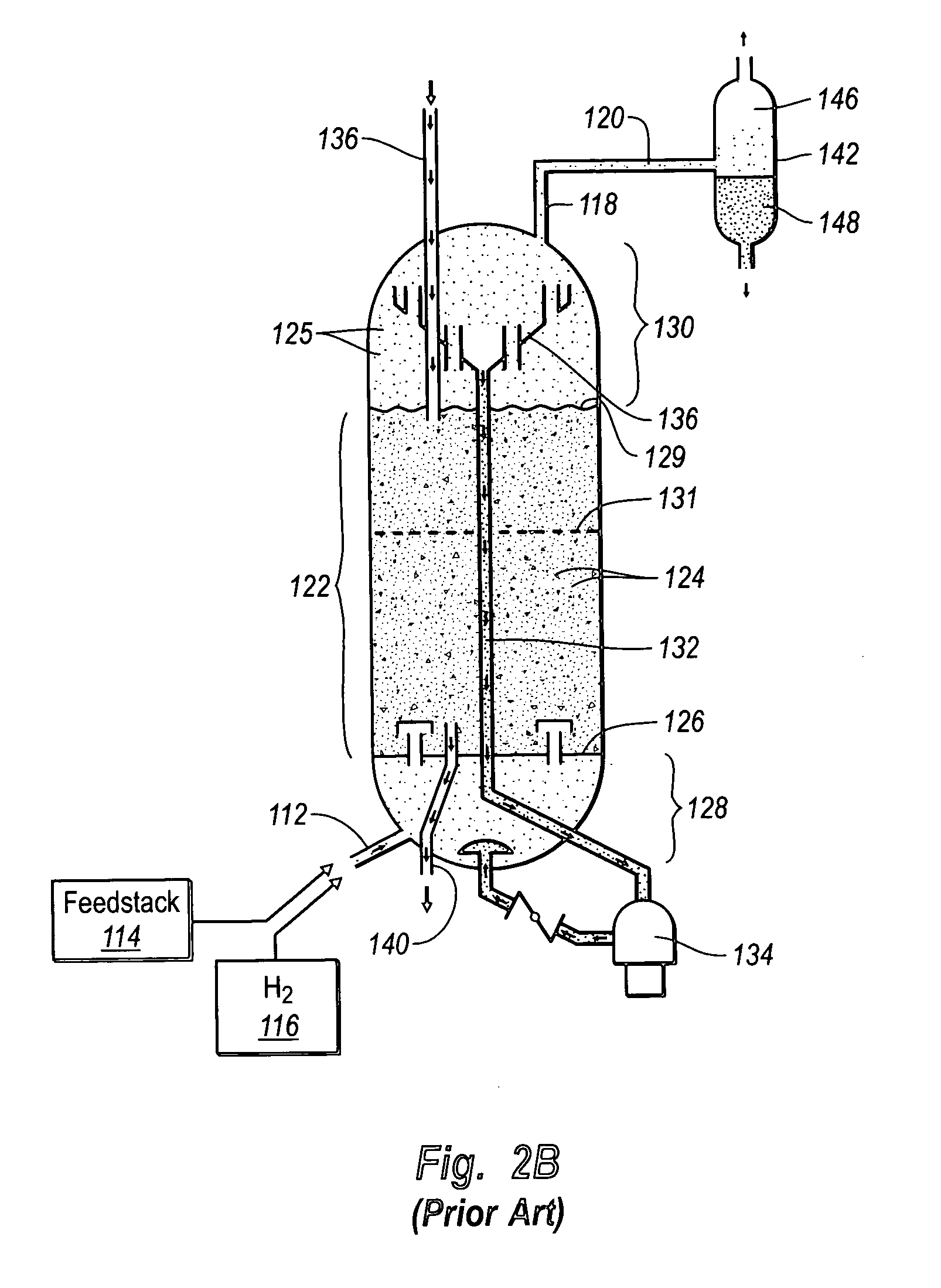

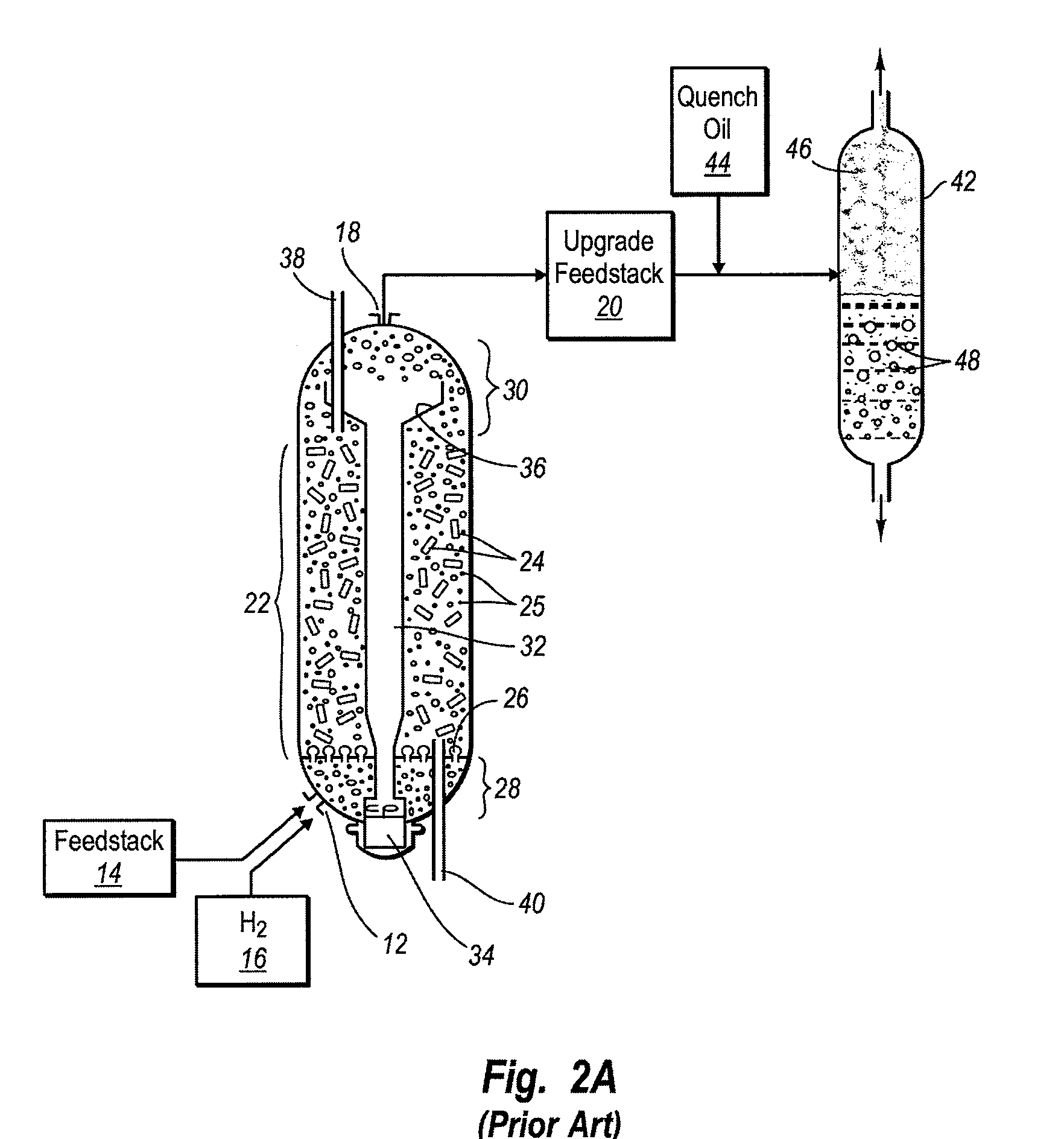

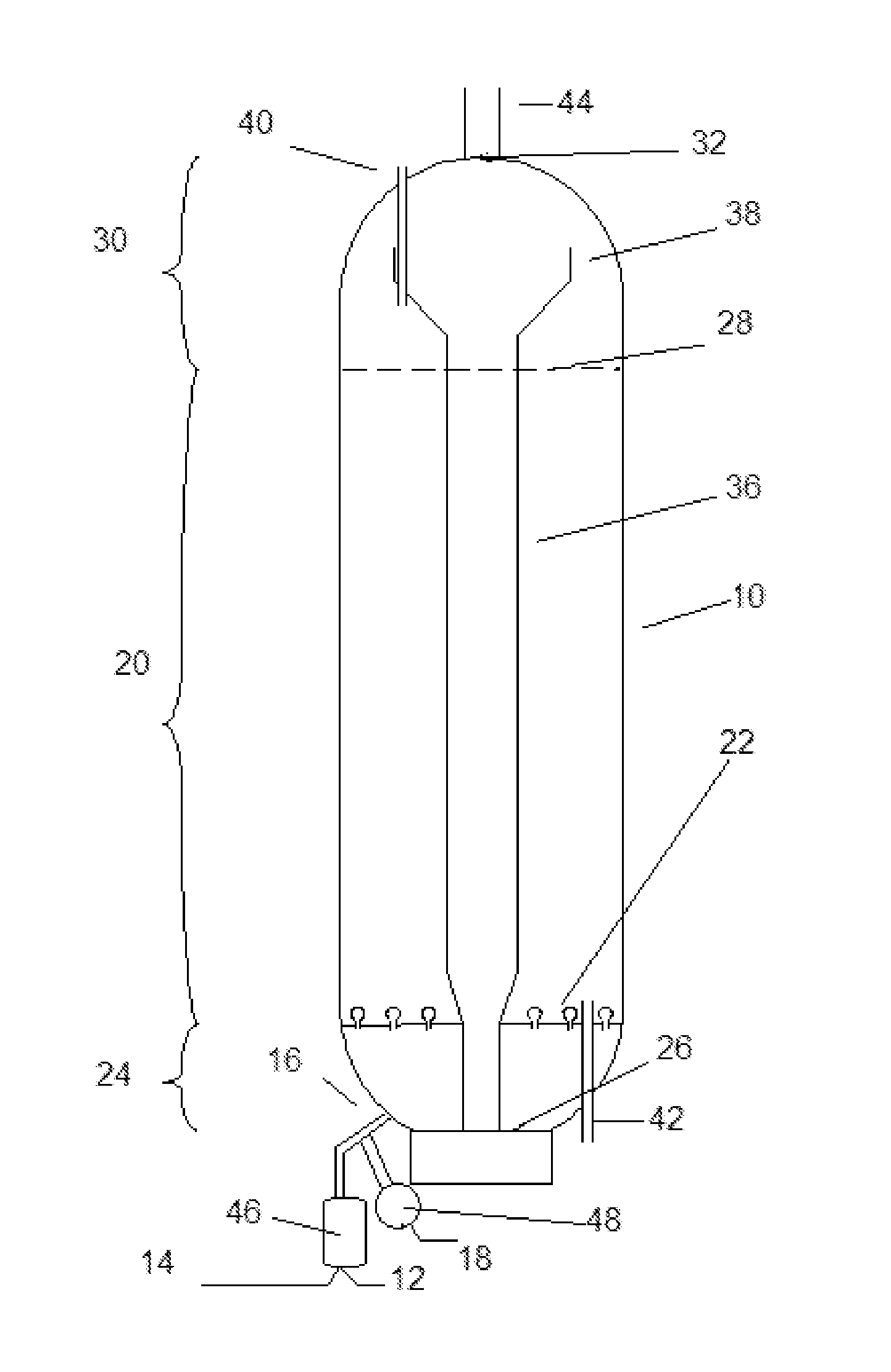

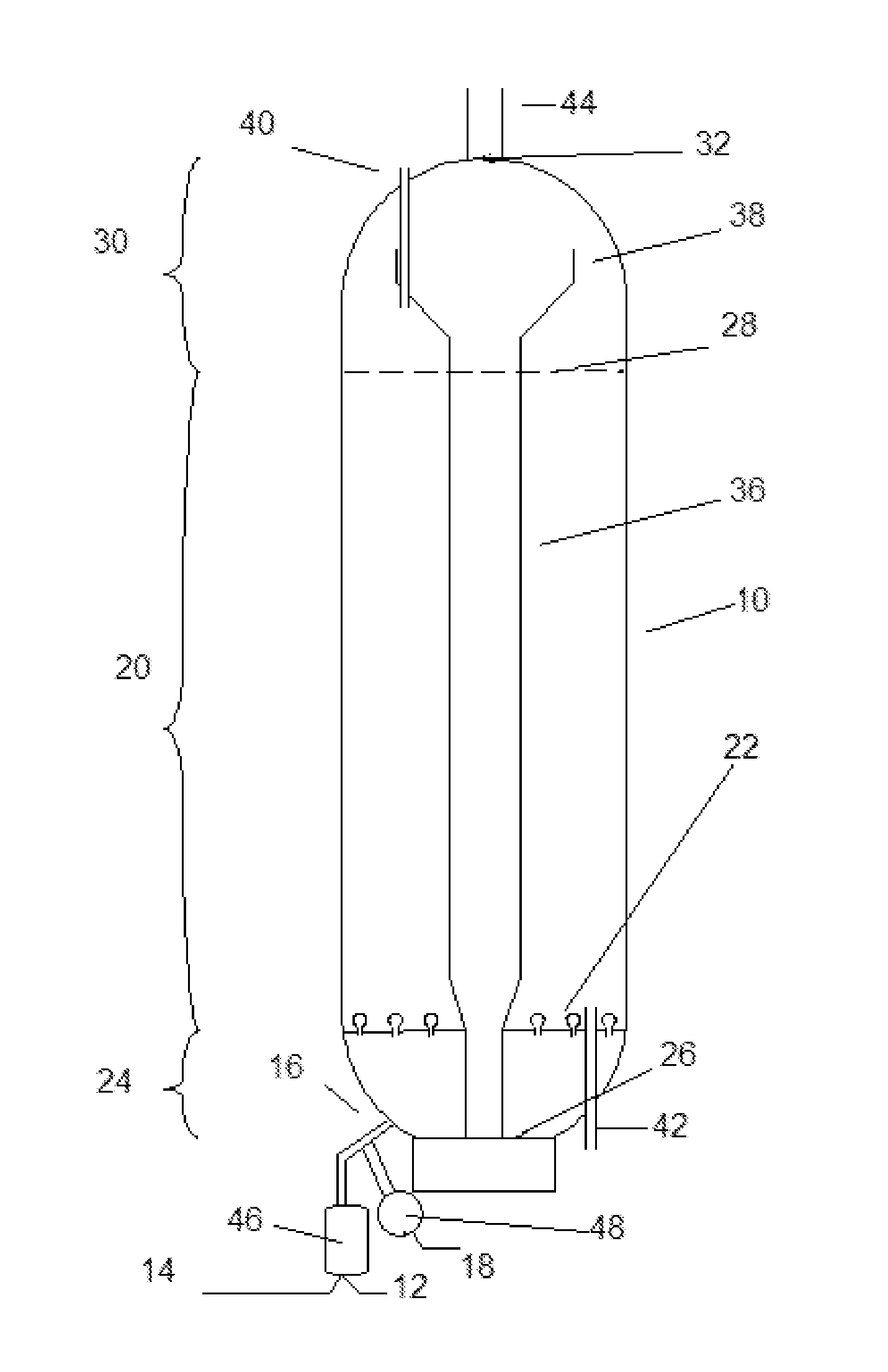

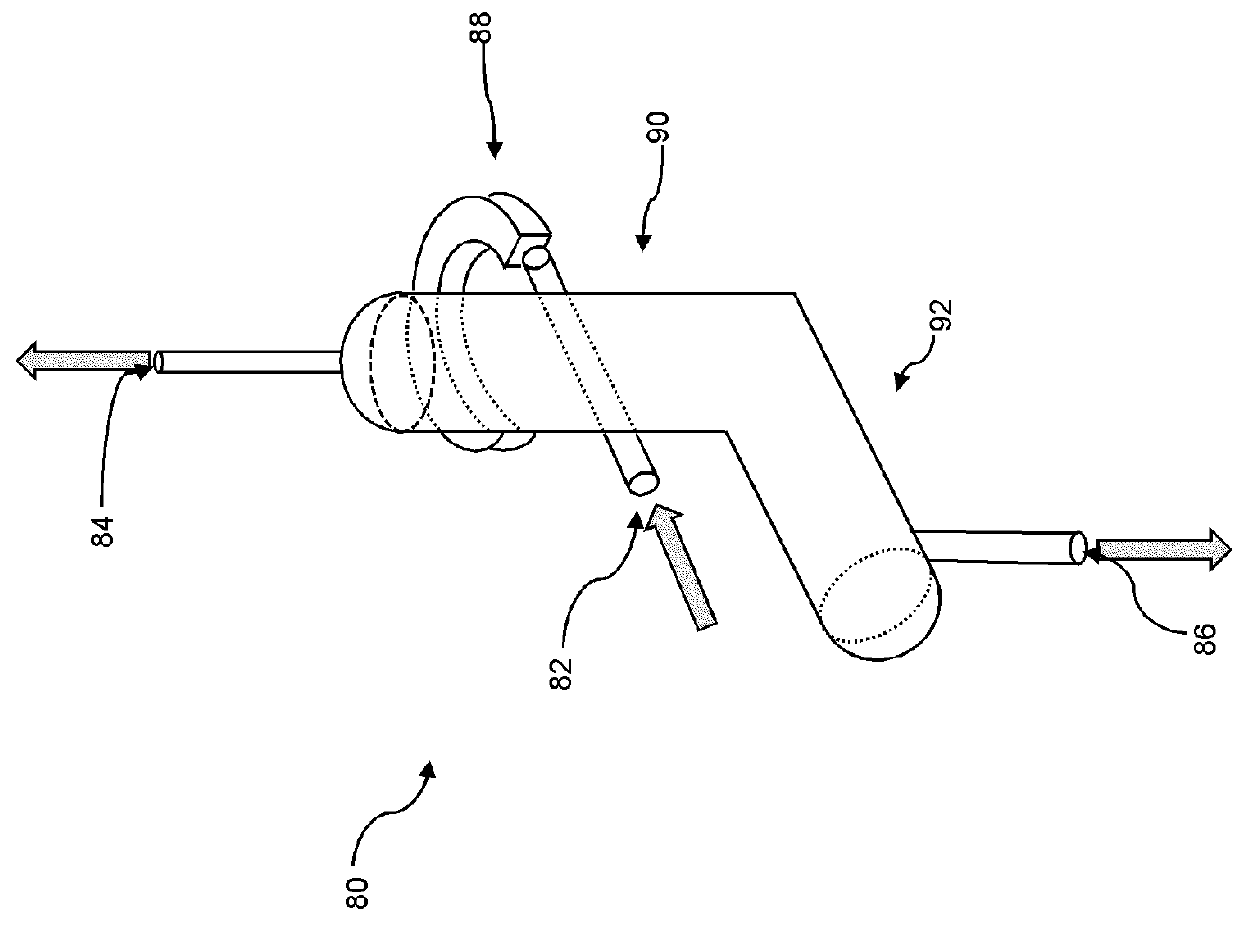

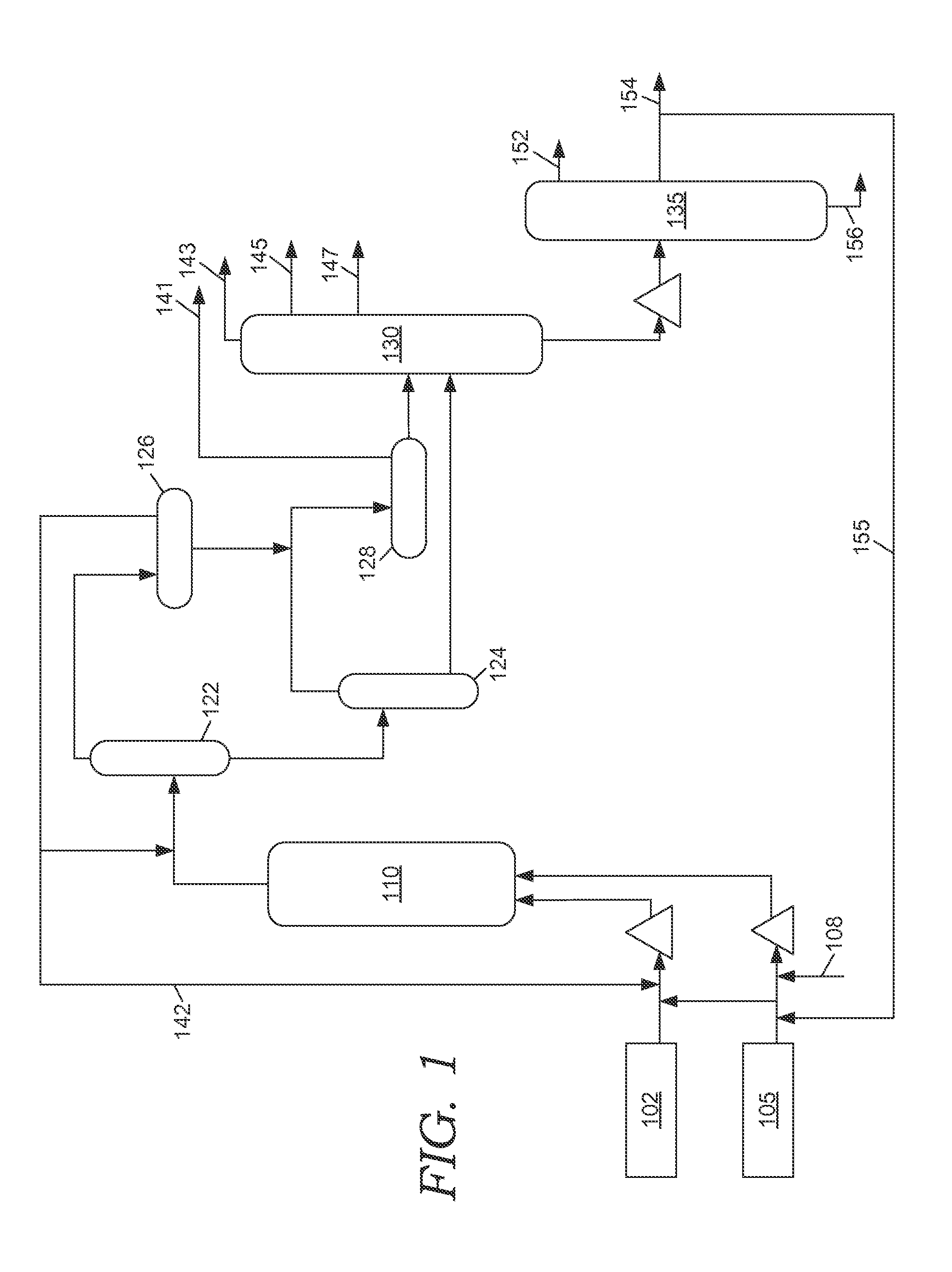

Ebullated bed hydroprocessing methods and systems and methods of upgrading an existing ebullated bed system

ActiveUS20050241991A1Quality improvementReduce formationHydrocarbon oil crackingLiquid hydrocarbon mixture productionHydrogenDecomposition

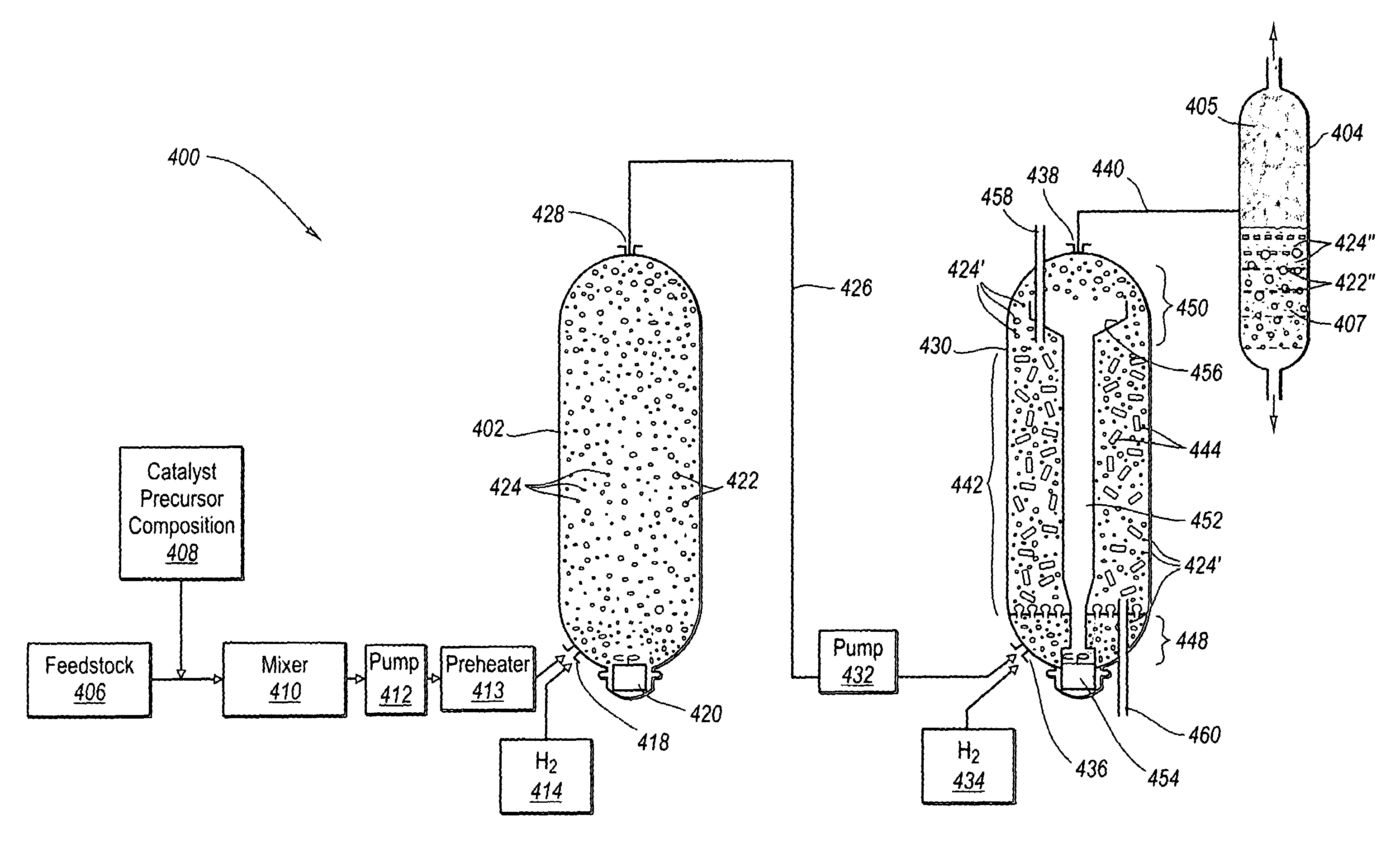

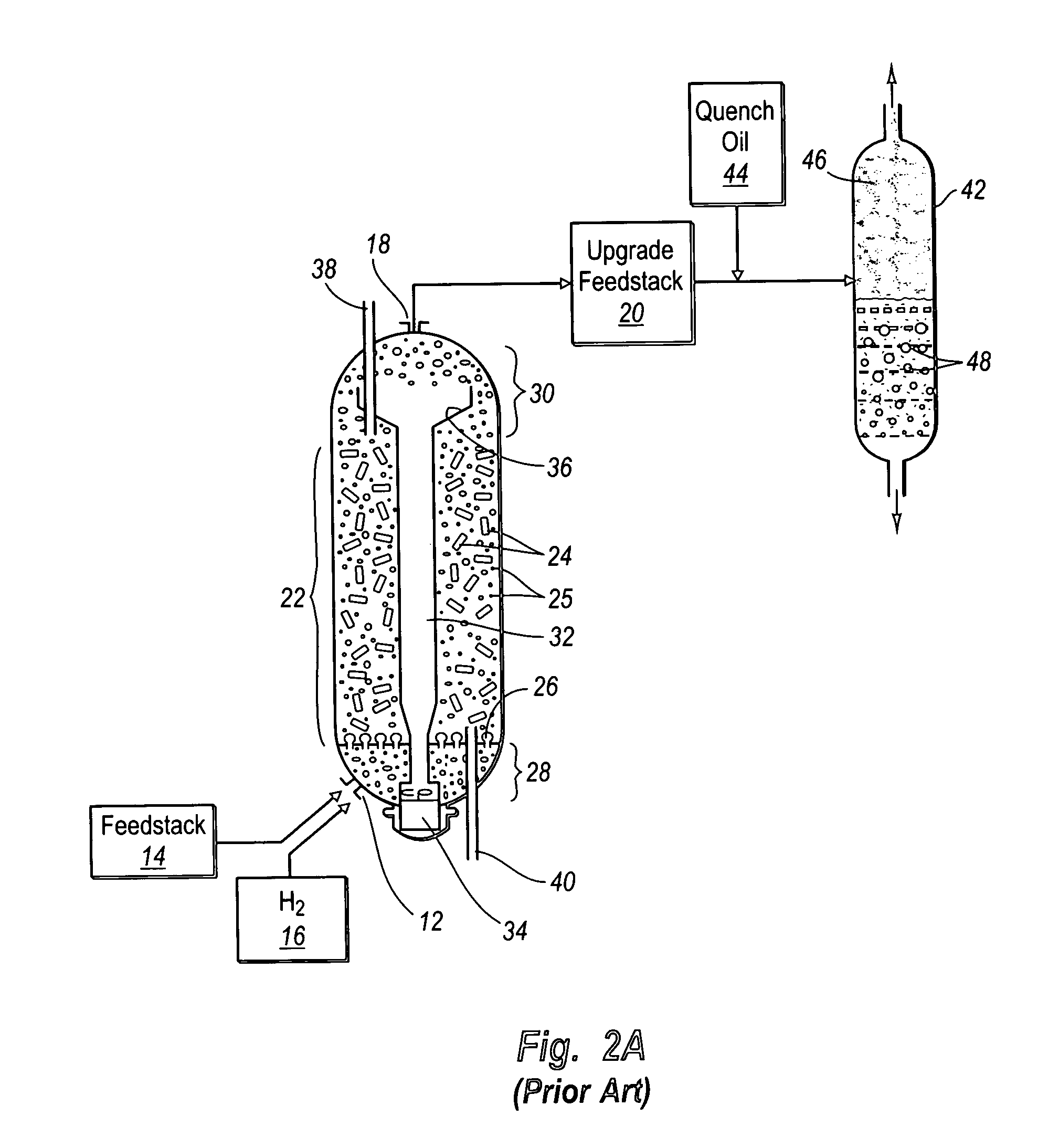

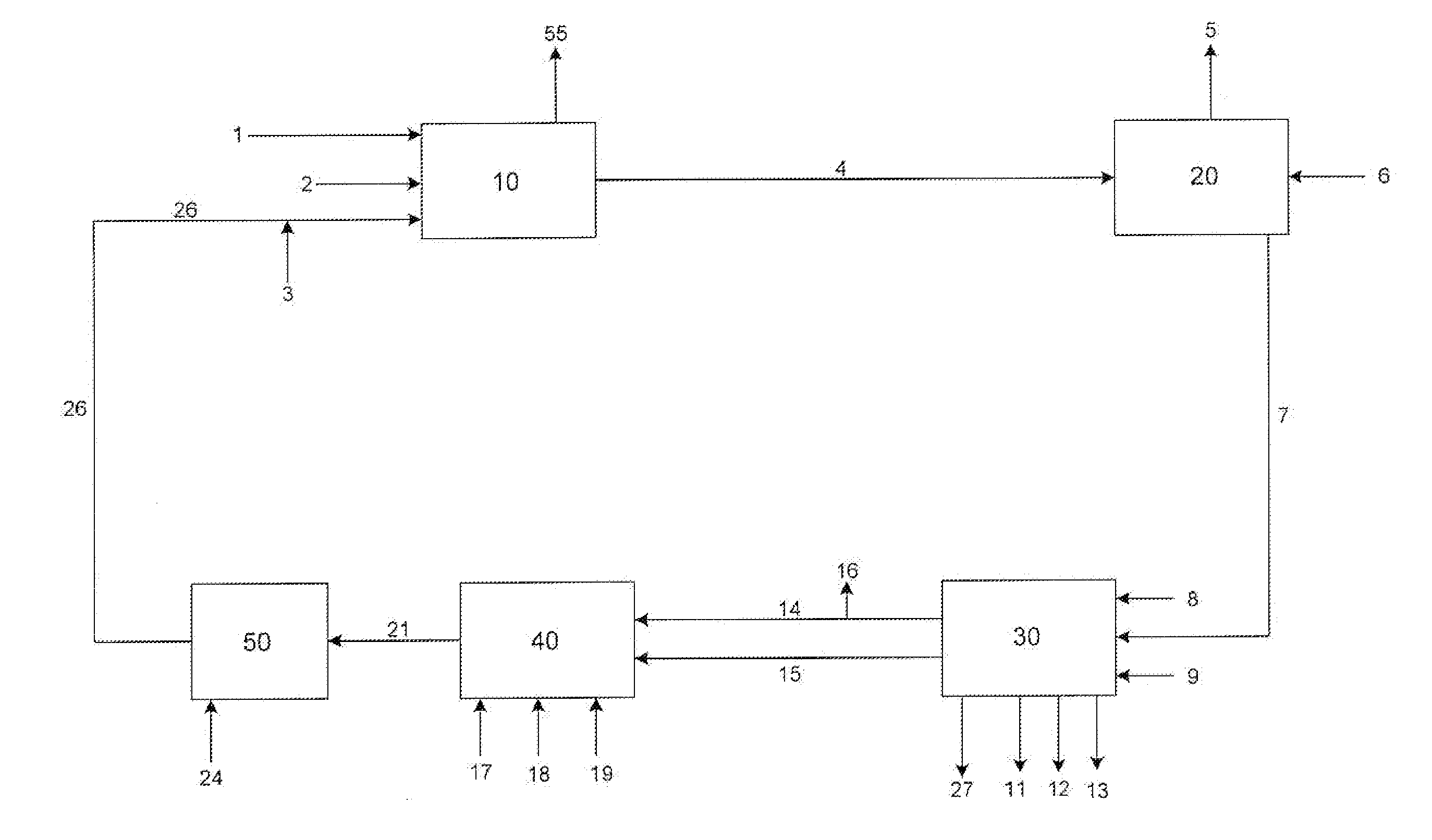

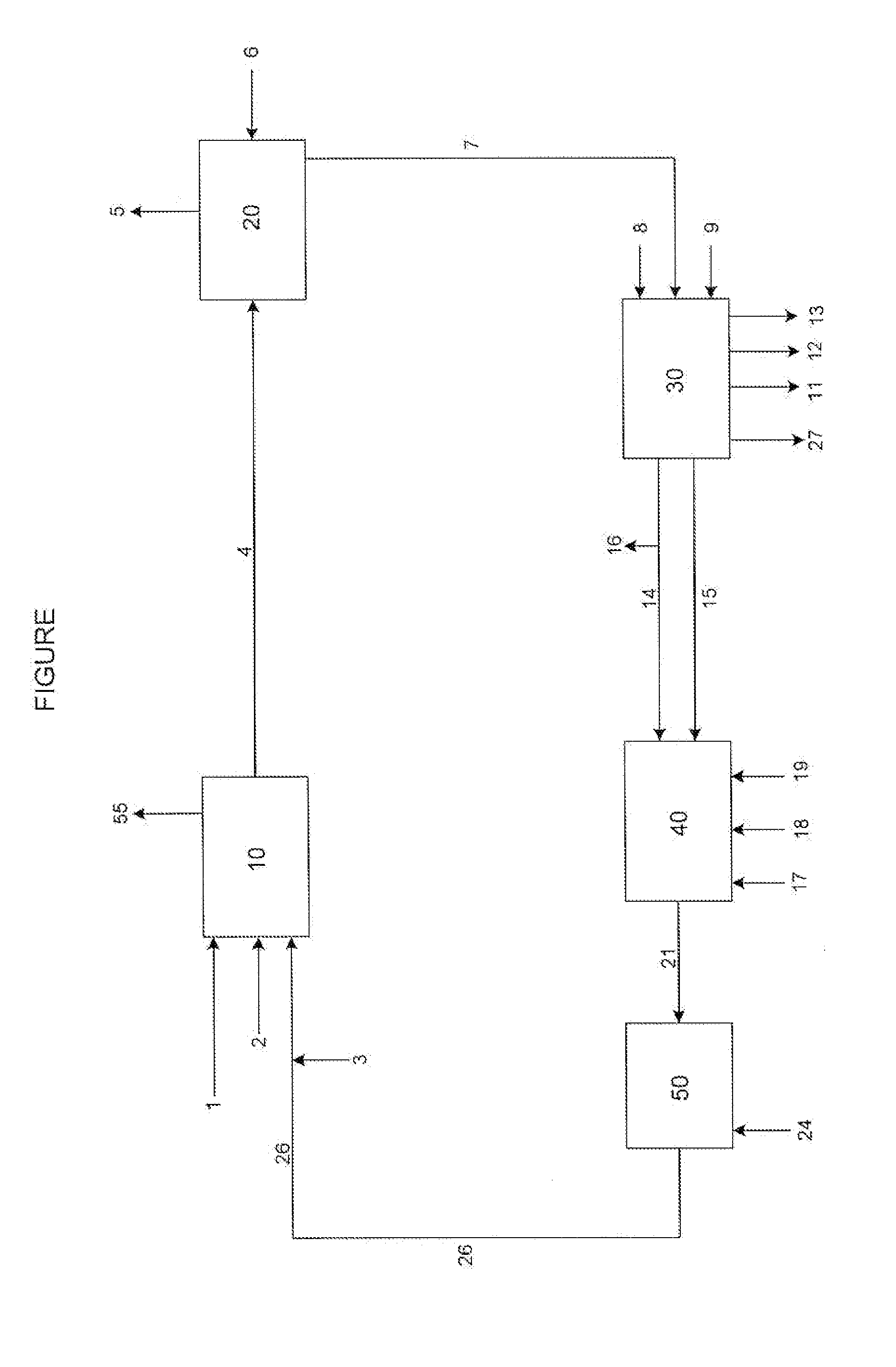

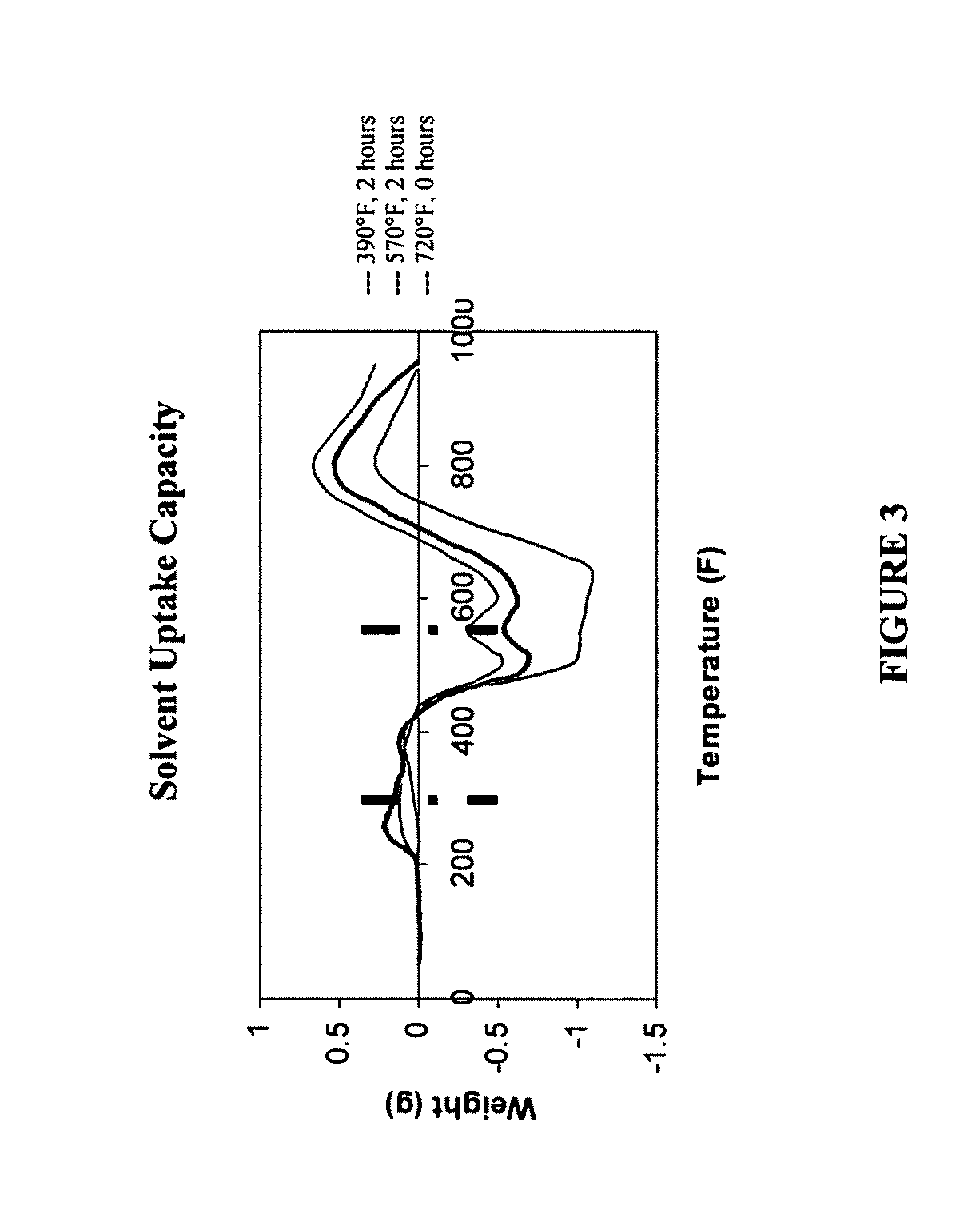

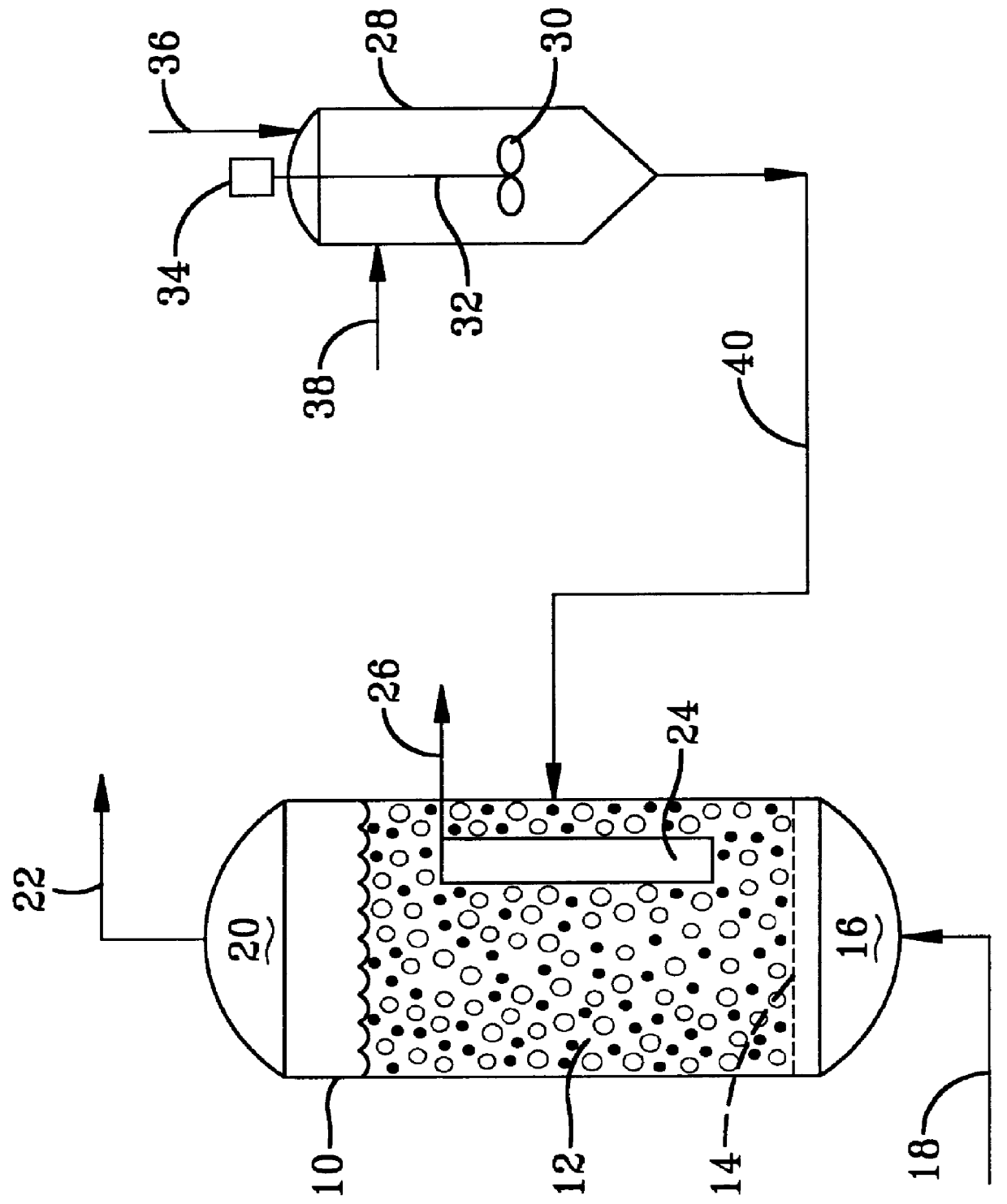

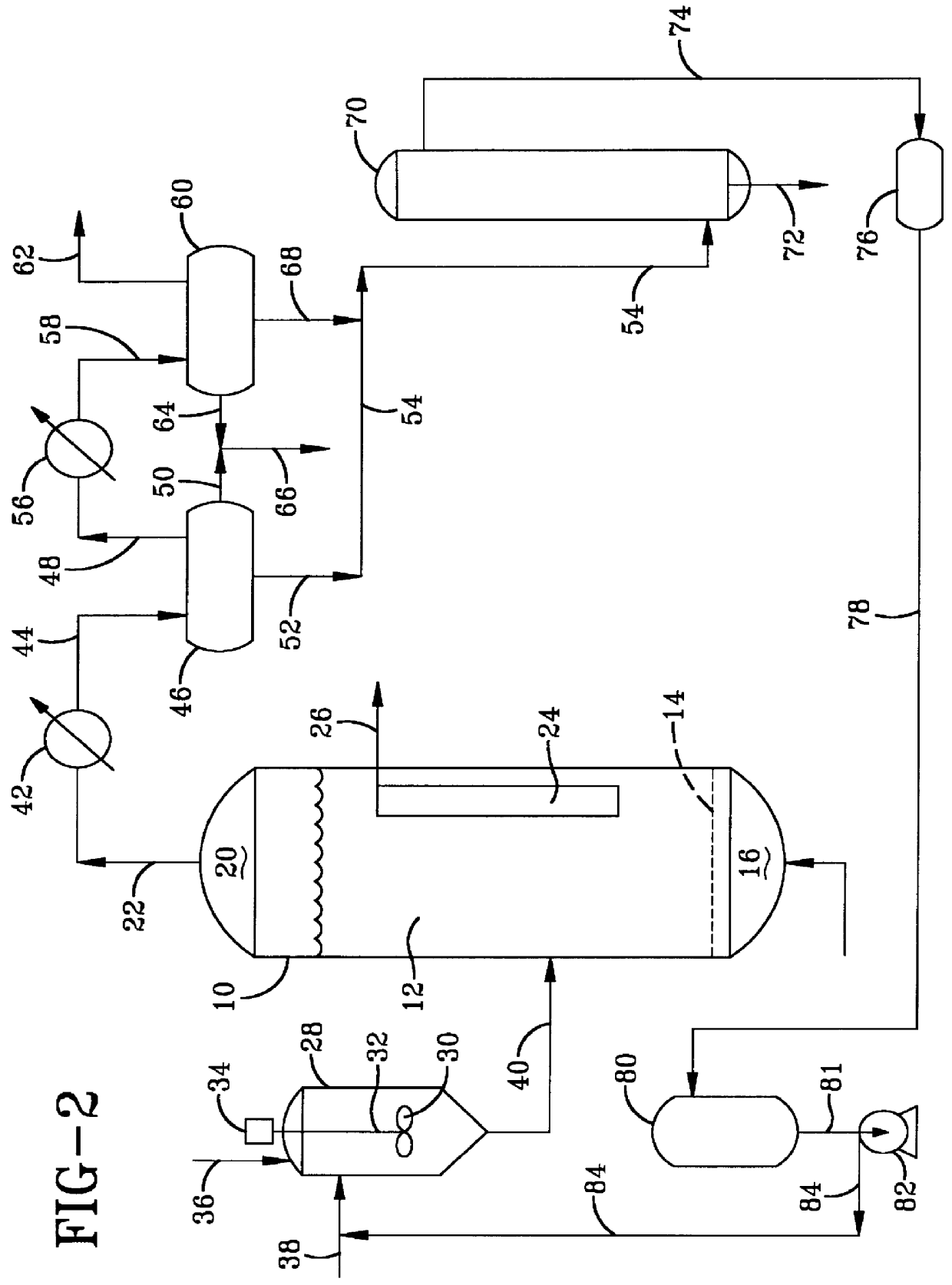

An ebullated bed hydroprocessing system, and also a method for upgrading a pre-existing ebullated bed hydroprocessing system, involves introducing a colloidal or molecular catalyst, or a precursor composition capable of forming the colloidal or molecular catalyst, into an ebullated bed reactor. The colloidal or molecular catalyst is formed by intimately mixing a catalyst precursor composition into a heavy oil feedstock and raising the temperature of the feedstock to above the decomposition temperature of the precursor composition to form the colloidal or molecular catalyst in situ. The improved ebullated bed hydroprocessing system includes at least one ebullated bed reactor that employs both a porous supported catalyst and the colloidal or molecular catalyst to catalyze hydroprocessing reactions involving the feedstock and hydrogen. The colloidal or molecular catalyst provides catalyst in what would otherwise constitute catalyst free zones within the ebullated bed hydroprocessing system. Asphaltene or other hydrocarbon molecules too large to diffuse into the pores of the supported catalyst can be upgraded by the colloidal or molecular catalyst. A slurry phase reactor may be positioned upstream from one or more ebullated bed reactors or converted from a pre-existing ebullated bed reactor.

Owner:HEADWATERS TECH INNOVATION LLC

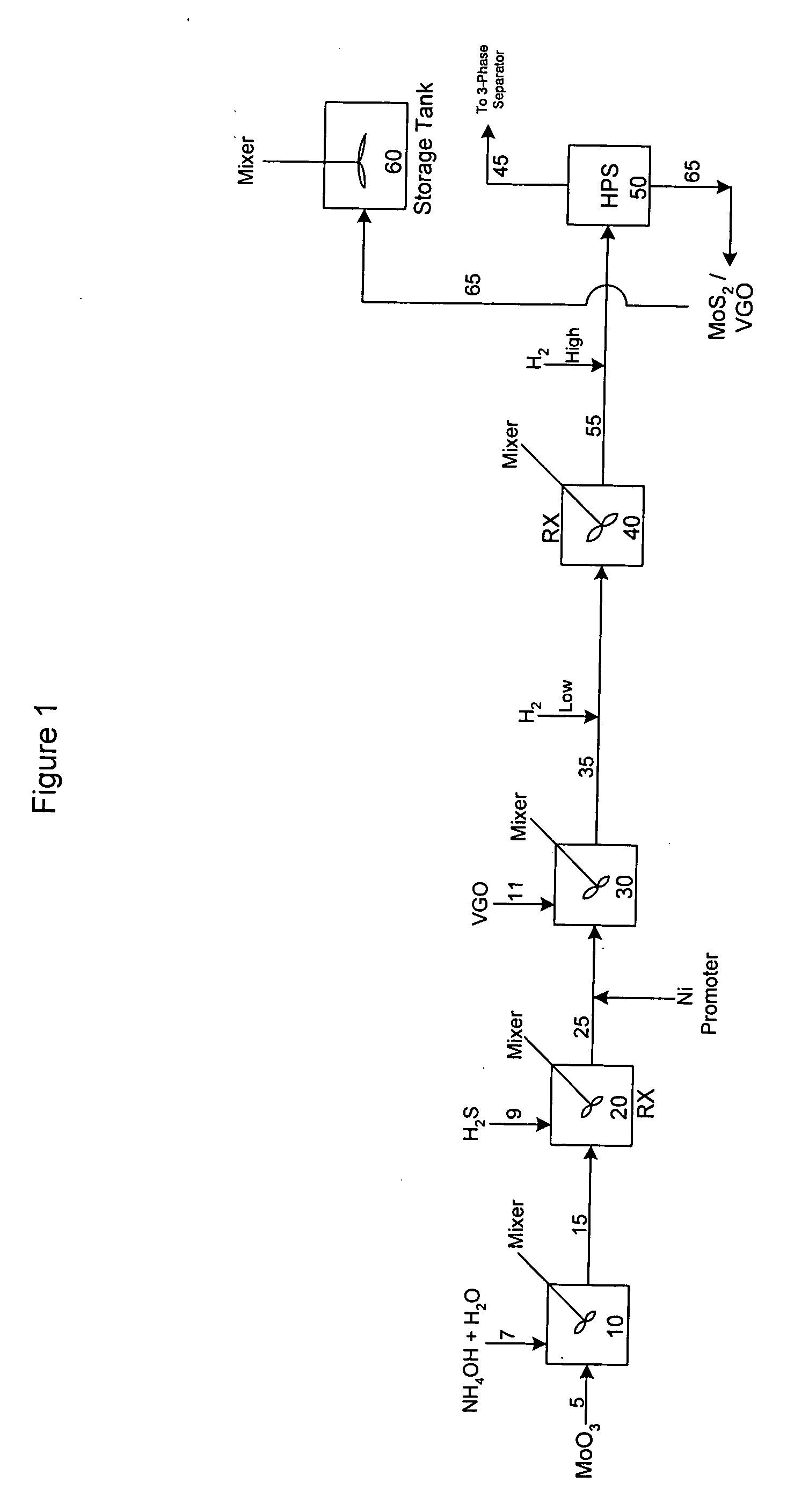

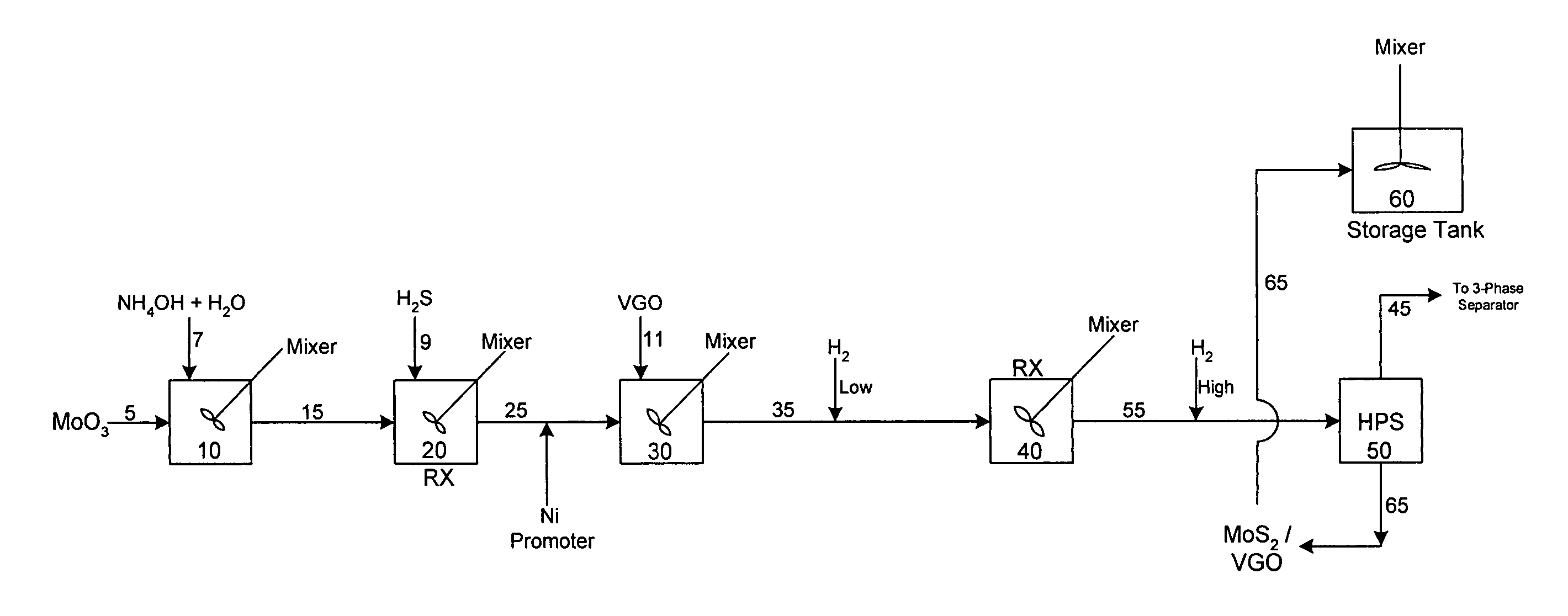

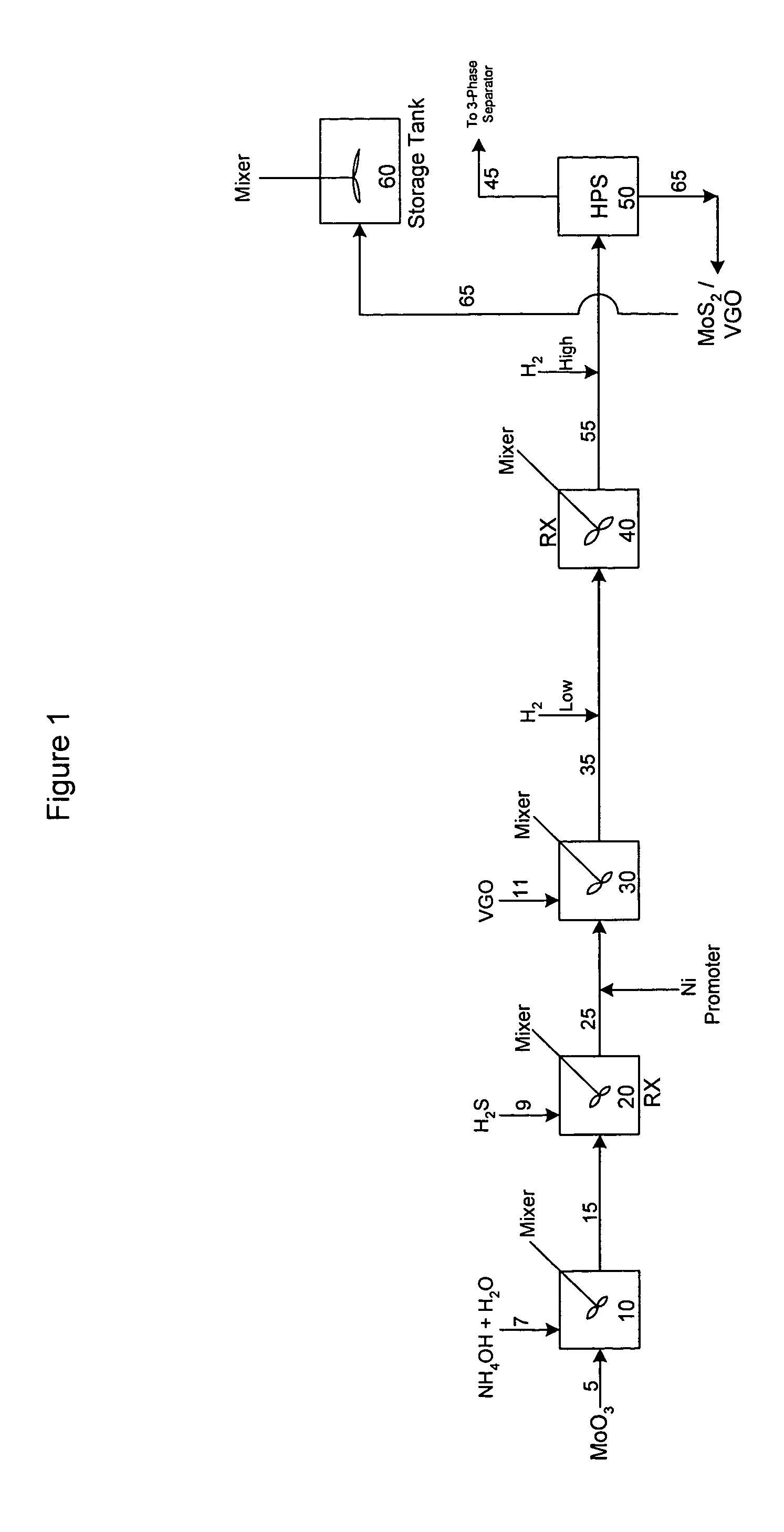

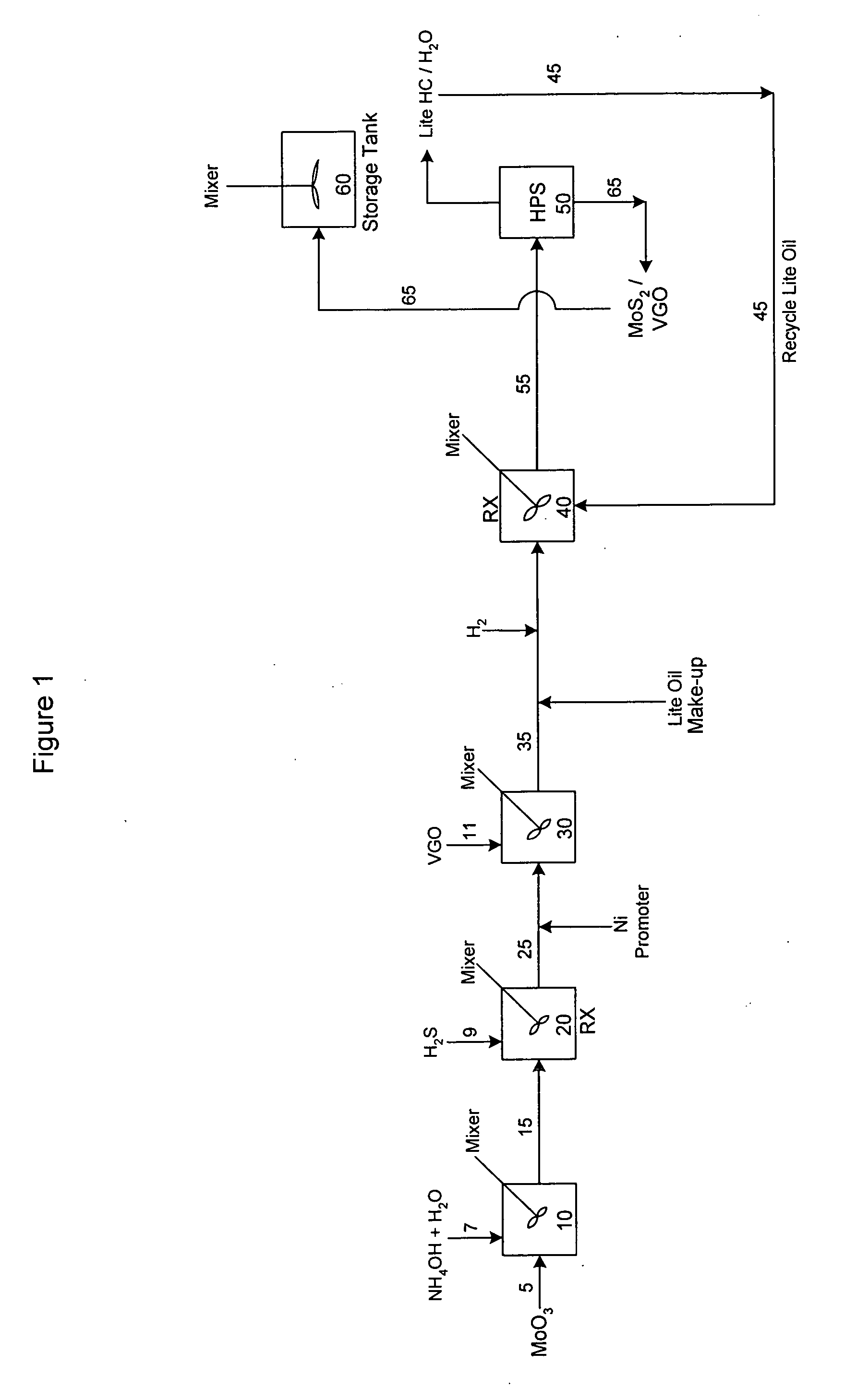

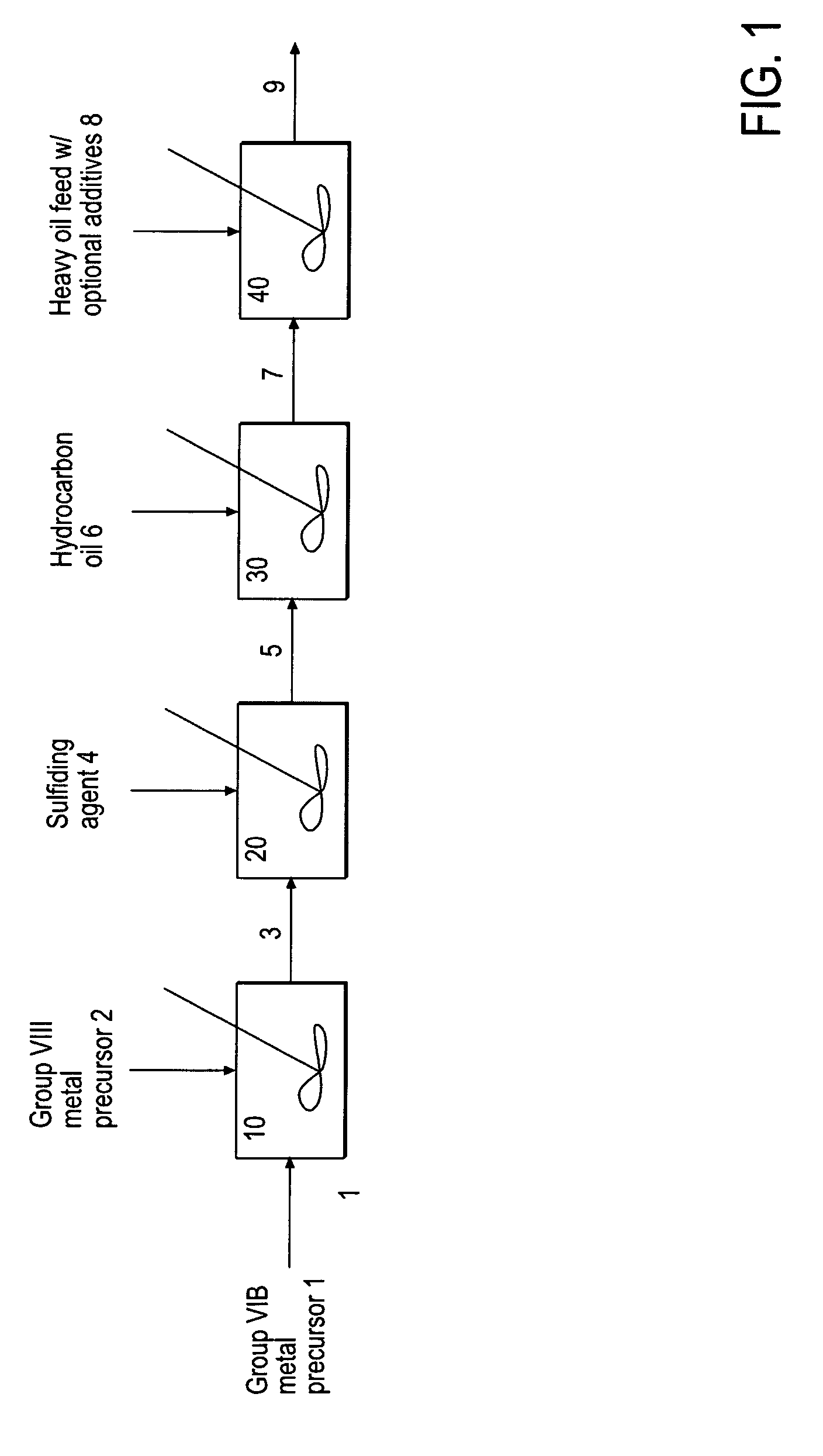

Highly active slurry catalyst composition

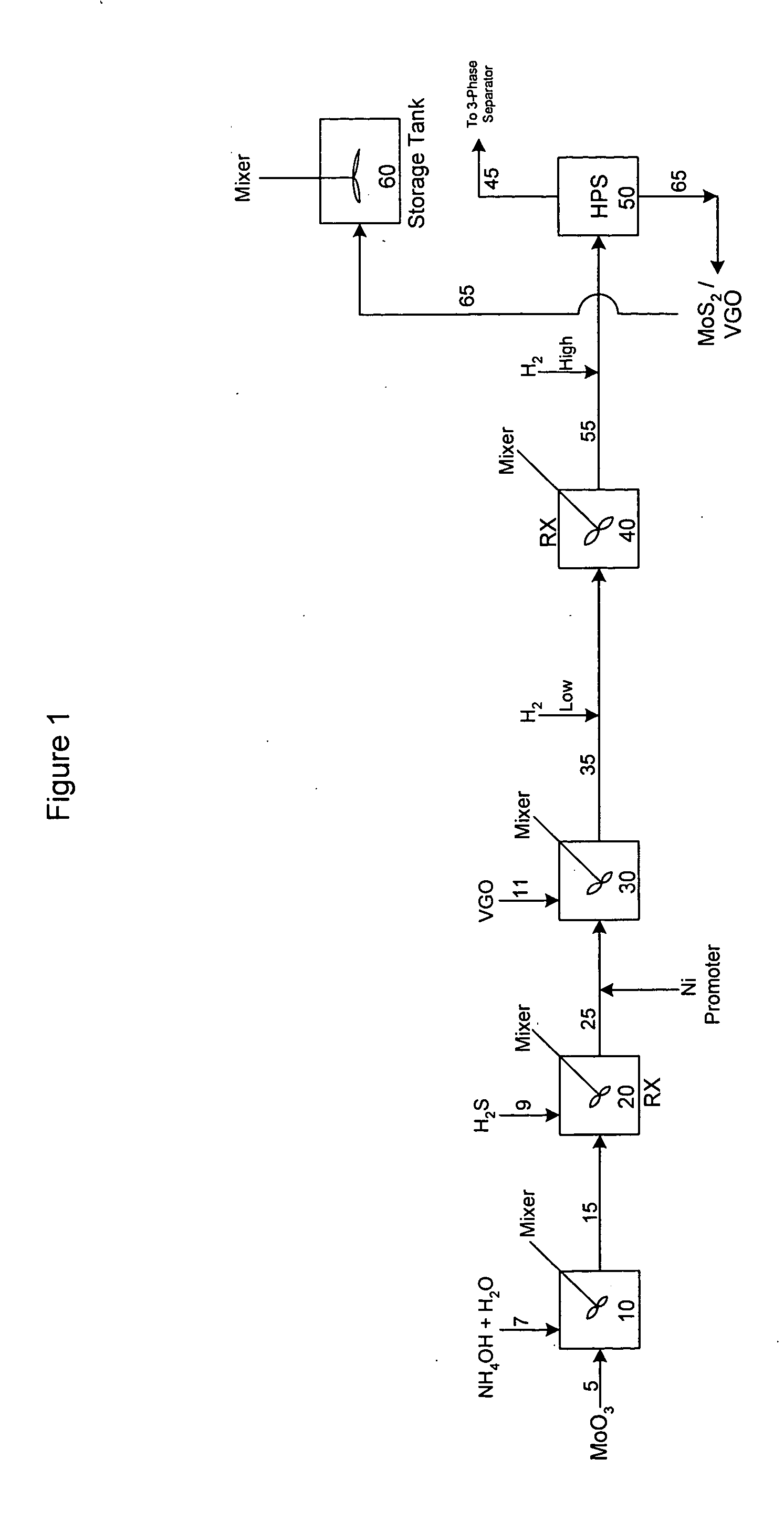

InactiveUS20060058174A1High viscosity carbonaceousHigh viscosityInorganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsHydrogenSlurry

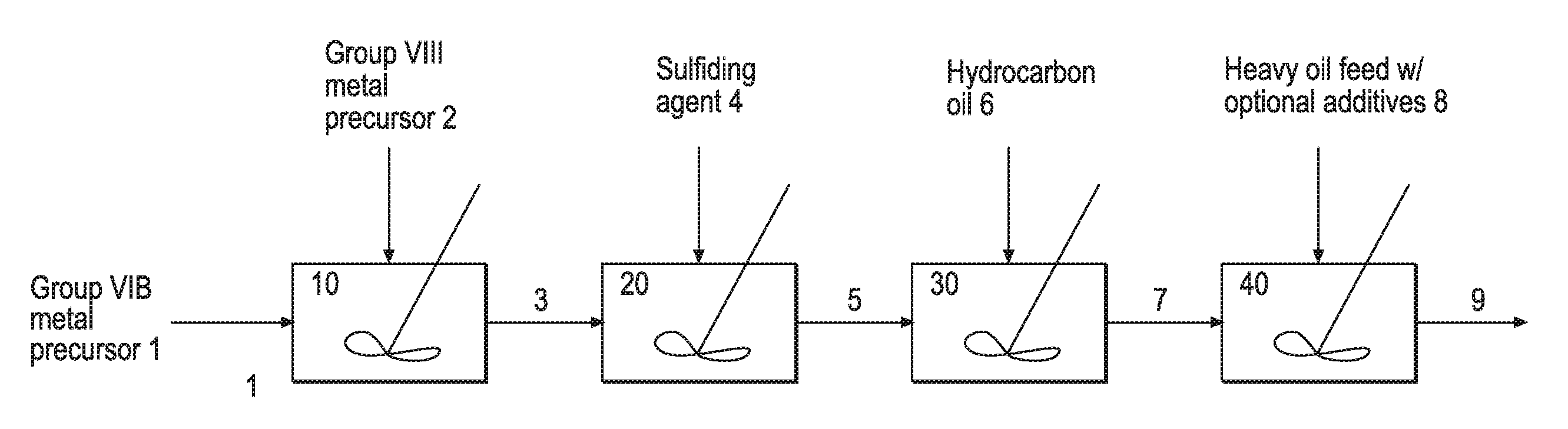

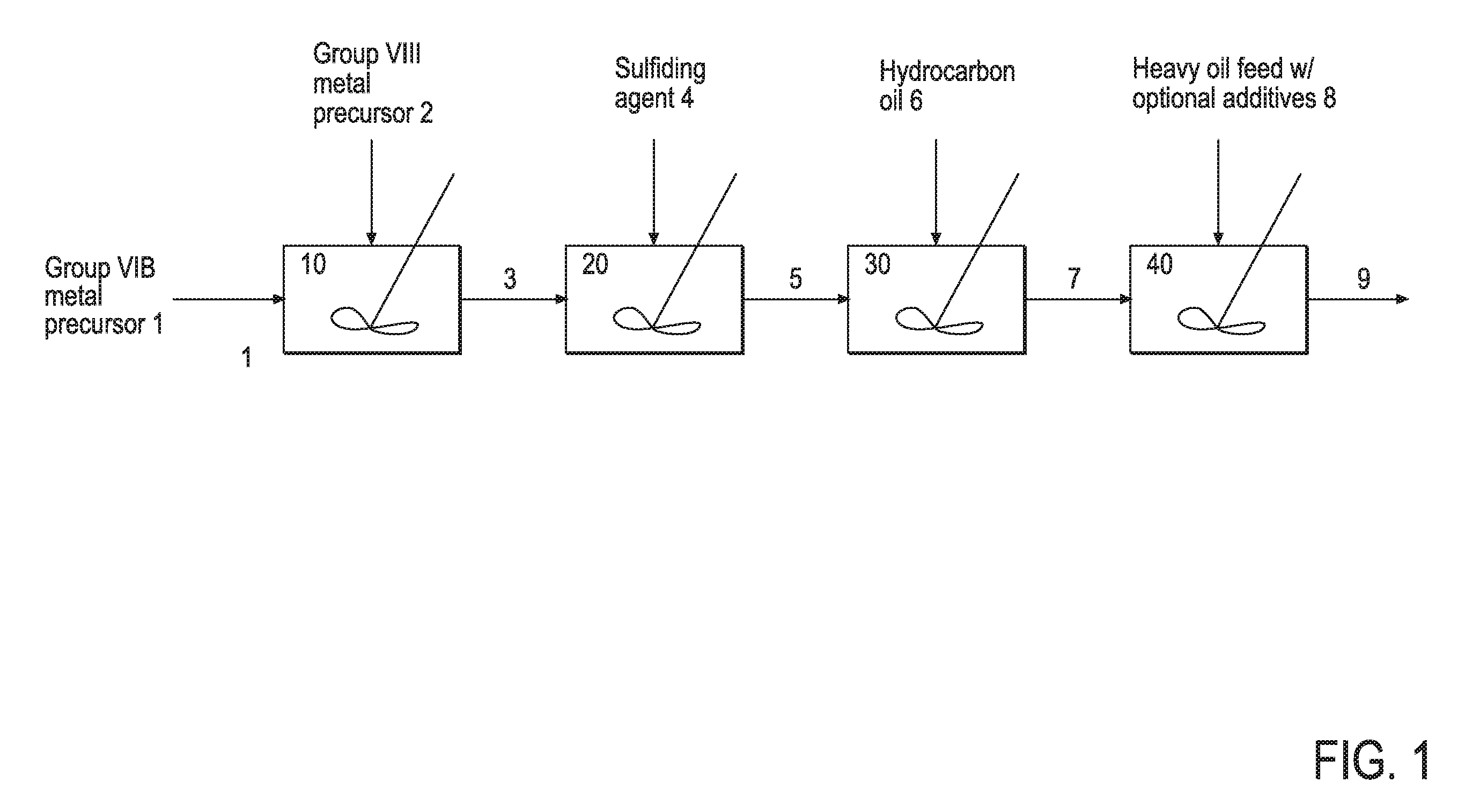

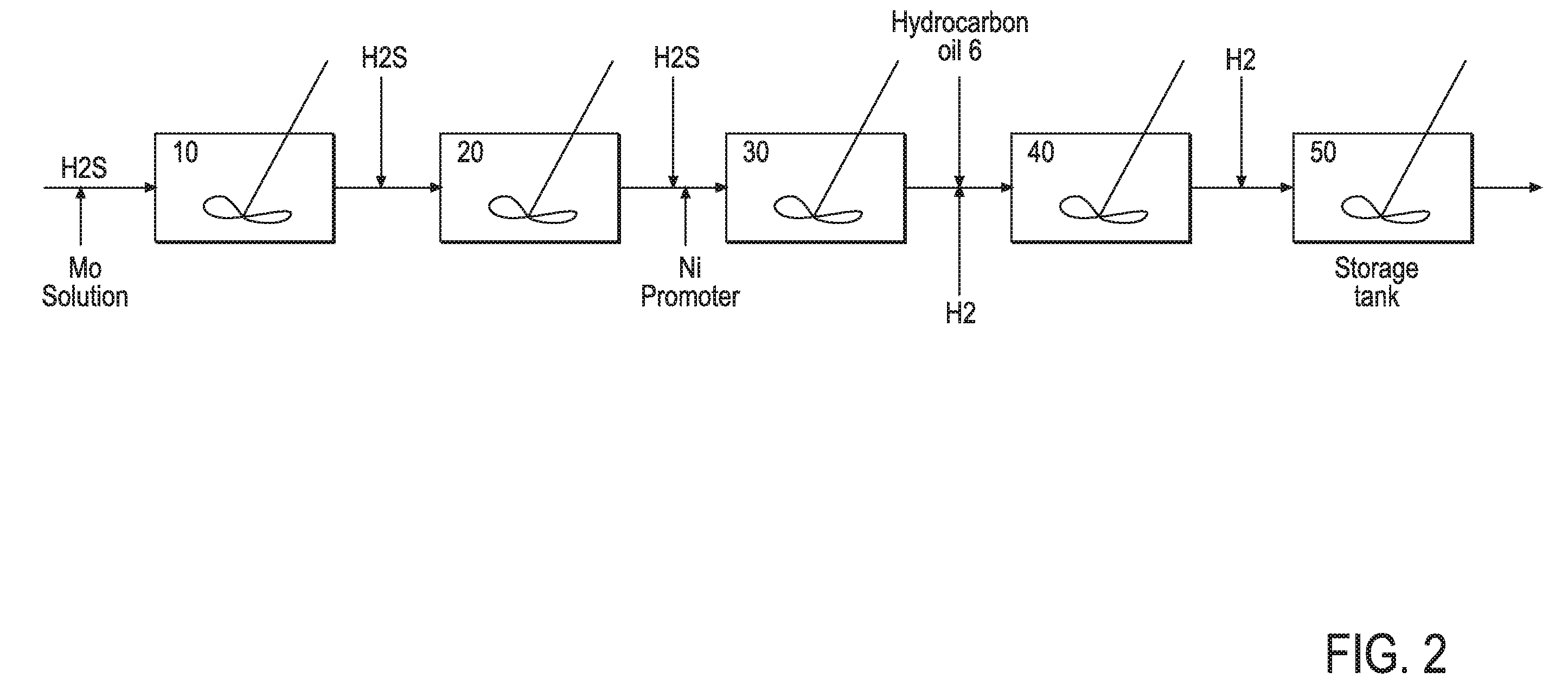

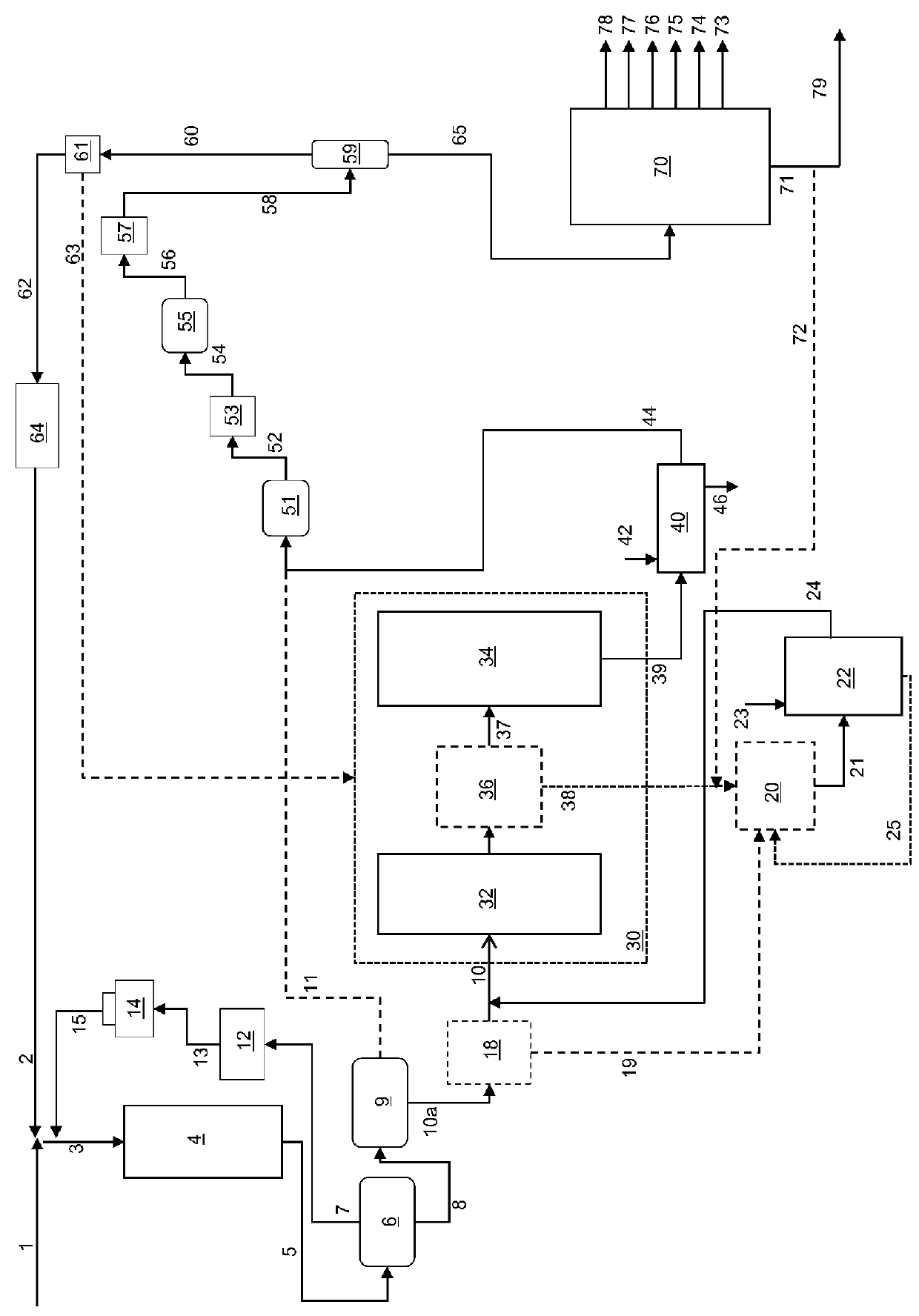

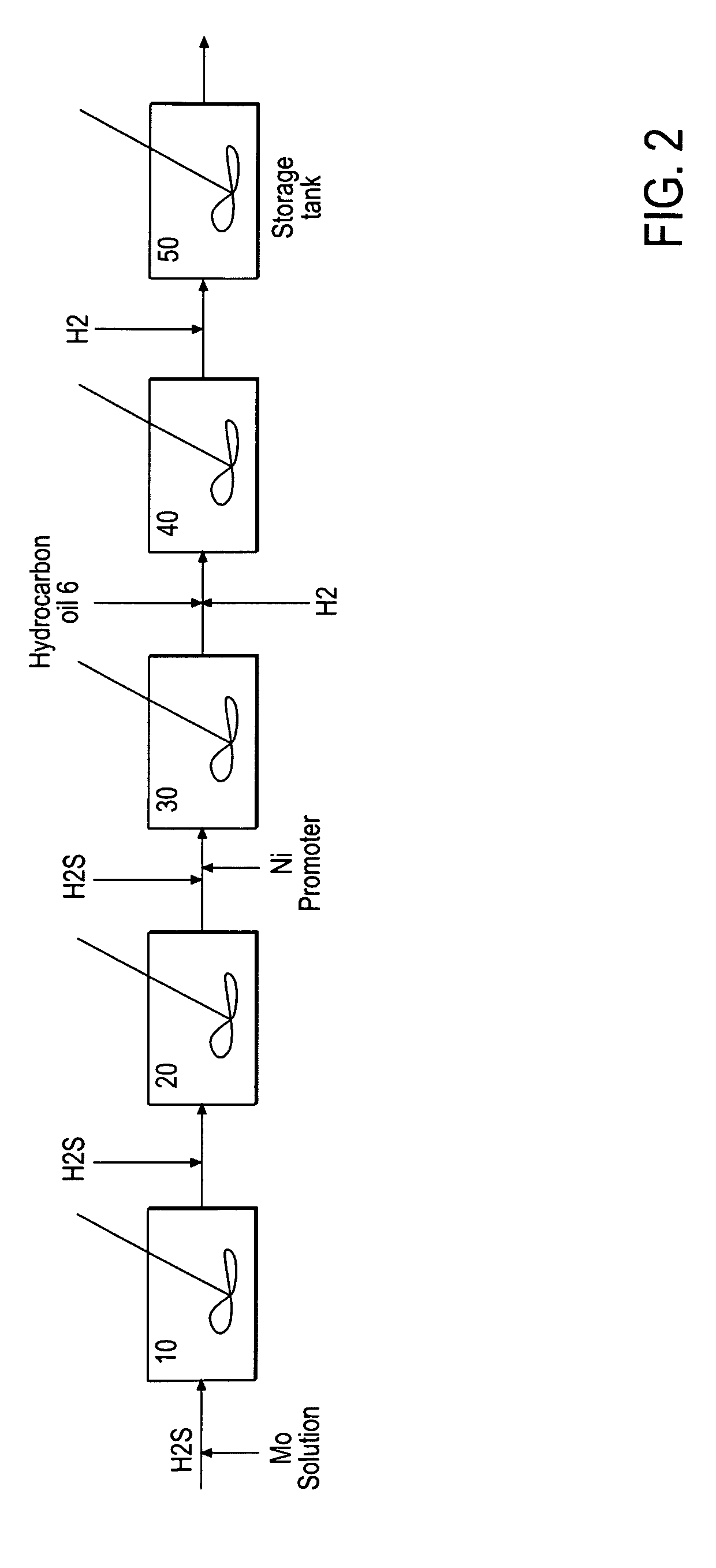

The instant invention is directed to the preparation of a slurry catalyst composition. The slurry catalyst composition is prepared in a series of steps, involving mixing a Group VIB metal oxide and aqueous ammonia to form an aqueous mixture and sulfiding the mixture to form a slurry. The slurry is then promoted with a Group VIII metal. Subsequent steps involve mixing the slurry with a hydrocarbon oil, and combining the resulting mixture with hydrogen gas (under conditions which maintain the water in a liquid phase) to produce the active slurry catalyst.

Owner:CHEVROU USA INC

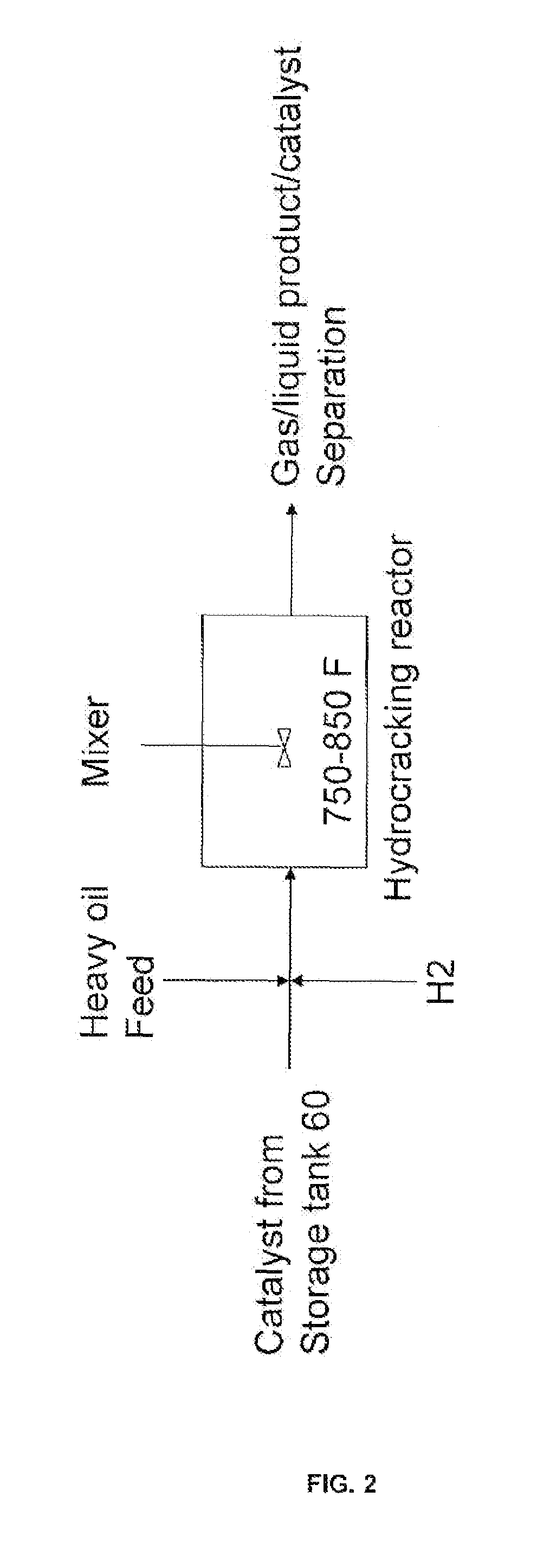

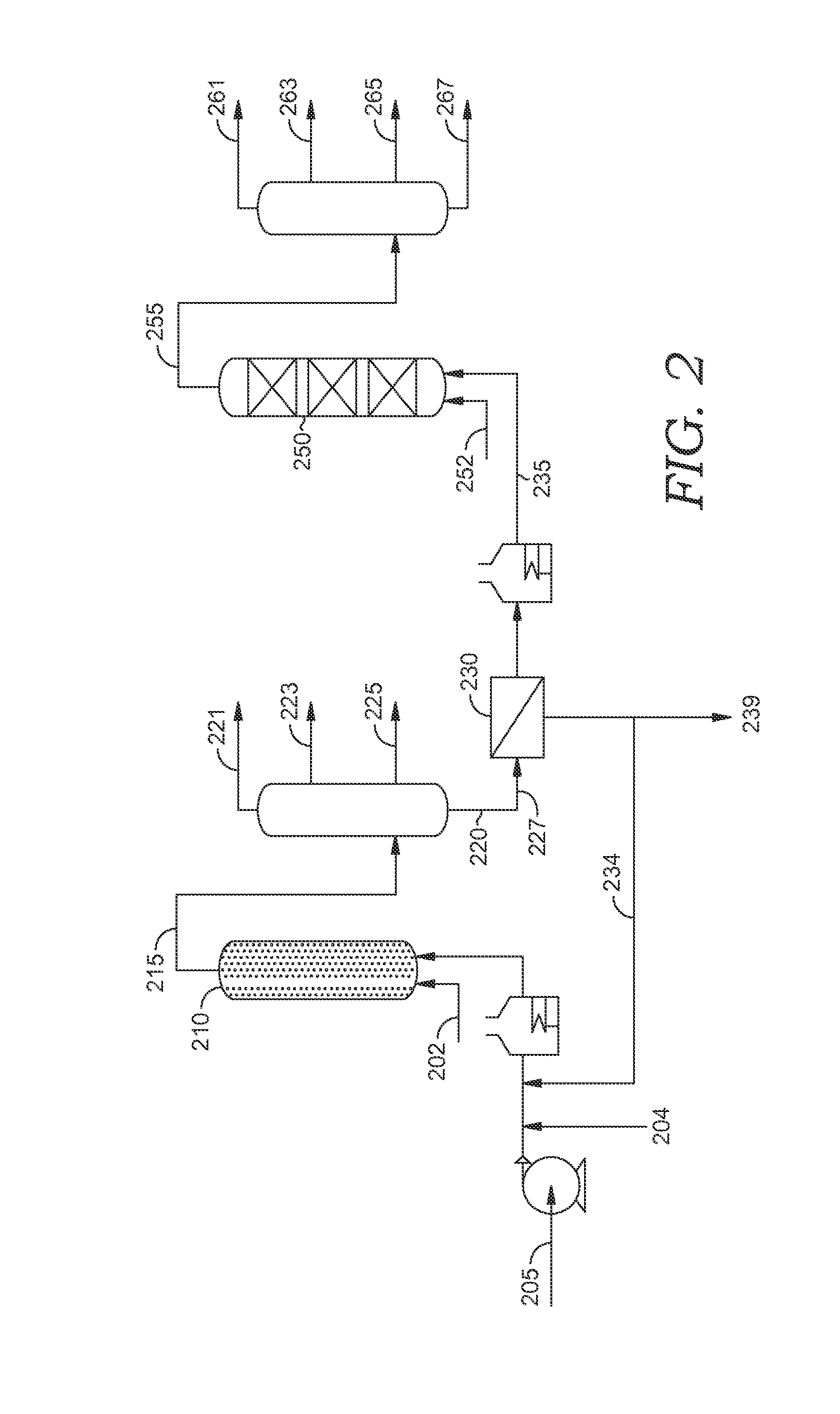

Process for upgrading heavy oil using a highly active slurry catalyst composition

ActiveUS7214309B2High viscosityTreatment with plural serial cracking stages onlyTreatment with plural serial stages onlyHydrogenSlurry

The instant invention is directed to a process for upgrading heavy oils using a slurry composition. The slurry composition is prepared in a series of steps, involving mixing a Group VIB metal oxide with aqueous ammonia to form an aqueous mixture and sulfiding the mixture to form a slurry. The slurry is then promoted with a Group VIII metal compound. Subsequent steps involve mixing the slurry with a hydrocarbon oil, and combining the resulting mixture with hydrogen gas (under conditions which maintain the water in a liquid phase) to produce the active slurry catalyst.

Owner:CHEVROU USA INC

Highly active slurry catalyst composition

InactiveUS20060058175A1High viscosity carbonaceousHigh viscosityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationHydrogenSlurry

The instant invention is directed to the preparation of a catalyst composition suitable for the hydroconversion of heavy oils. The catalyst composition is prepared by a series of steps, involving mixing a Group VIB metal oxide and aqueous ammonia to form an aqueous mixture, and sulfiding the mixture to form a slurry. The slurry is then promoted with a Group VIII metal. Subsequent steps involve mixing the slurry with a hydrocarbon oil and combining the resulting mixture with hydrogen gas and a second hydrocarbon oil having a lower viscosity than the first oil. An active catalyst composition is thereby formed.

Owner:CHEVROU USA INC

Ebullated bed hydroprocessing systems

ActiveUS20080193345A1Quality improvementReduce formationHydrocarbon oil crackingTreatment with hydrotreatment processesHydrogenDecomposition

An ebullated bed hydroprocessing system, and also a method for upgrading a pre-existing ebullated bed hydroprocessing system, involves introducing a colloidal or molecular catalyst, or a precursor composition capable of forming the colloidal or molecular catalyst, into an ebullated bed reactor. The colloidal or molecular catalyst is formed by intimately mixing a catalyst precursor composition into a heavy oil feedstock and raising the temperature of the feedstock to above the decomposition temperature of the precursor composition to form the colloidal or molecular catalyst in situ. The improved ebullated bed hydroprocessing system includes at least one ebullated bed reactor that employs both a porous supported catalyst and the colloidal or molecular catalyst to catalyze hydroprocessing reactions involving the feedstock and hydrogen. The colloidal or molecular catalyst provides catalyst in what would otherwise constitute catalyst free zones within the ebullated bed hydroprocessing system. Asphaltene or other hydrocarbon molecules too large to diffuse into the pores of the supported catalyst can be upgraded by the colloidal or molecular catalyst. A slurry phase reactor may be positioned upstream from one or more ebullated bed reactors or converted from a pre-existing ebullated bed reactor.

Owner:HEADWATERS TECH INNOVATION LLC

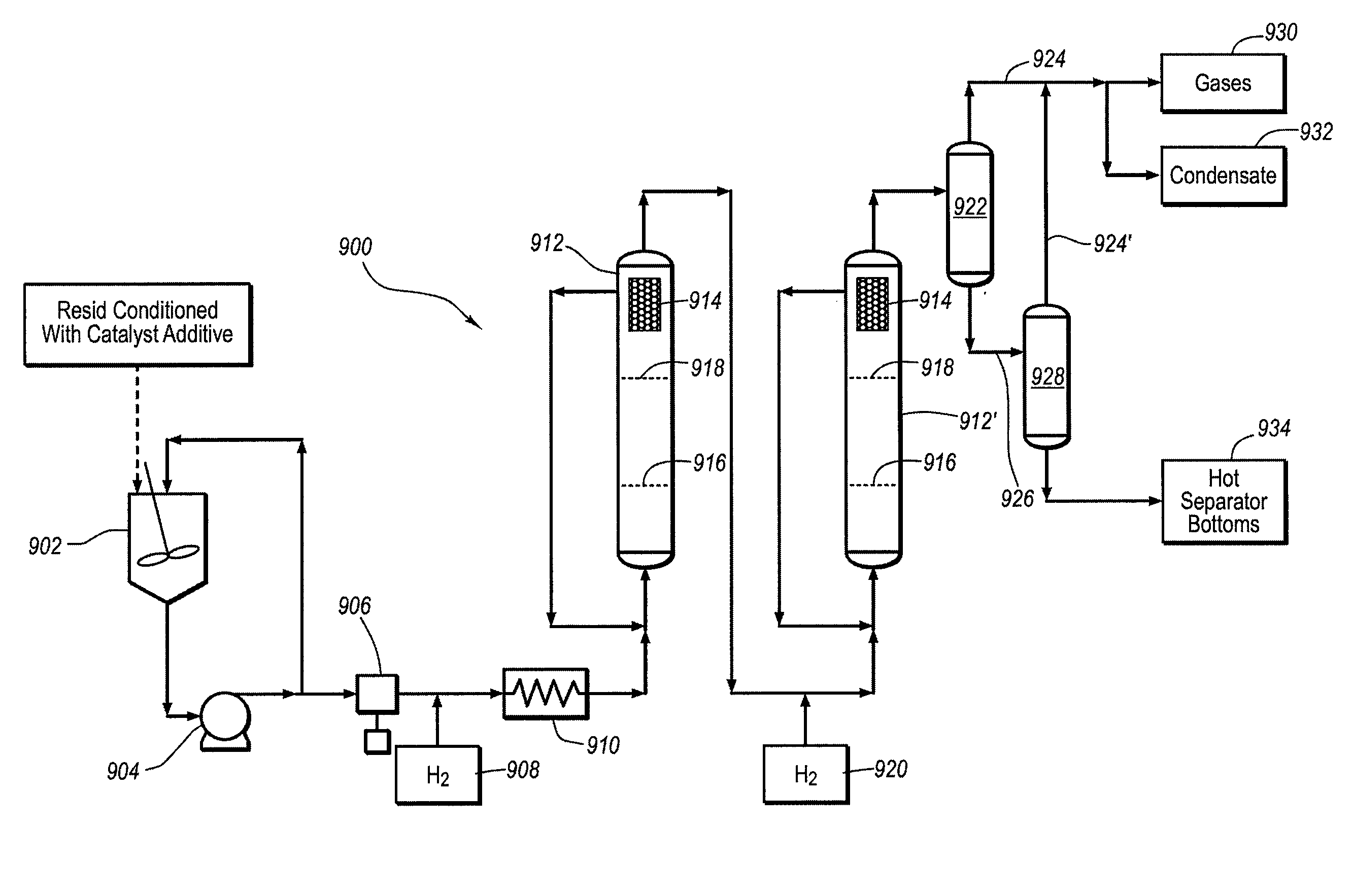

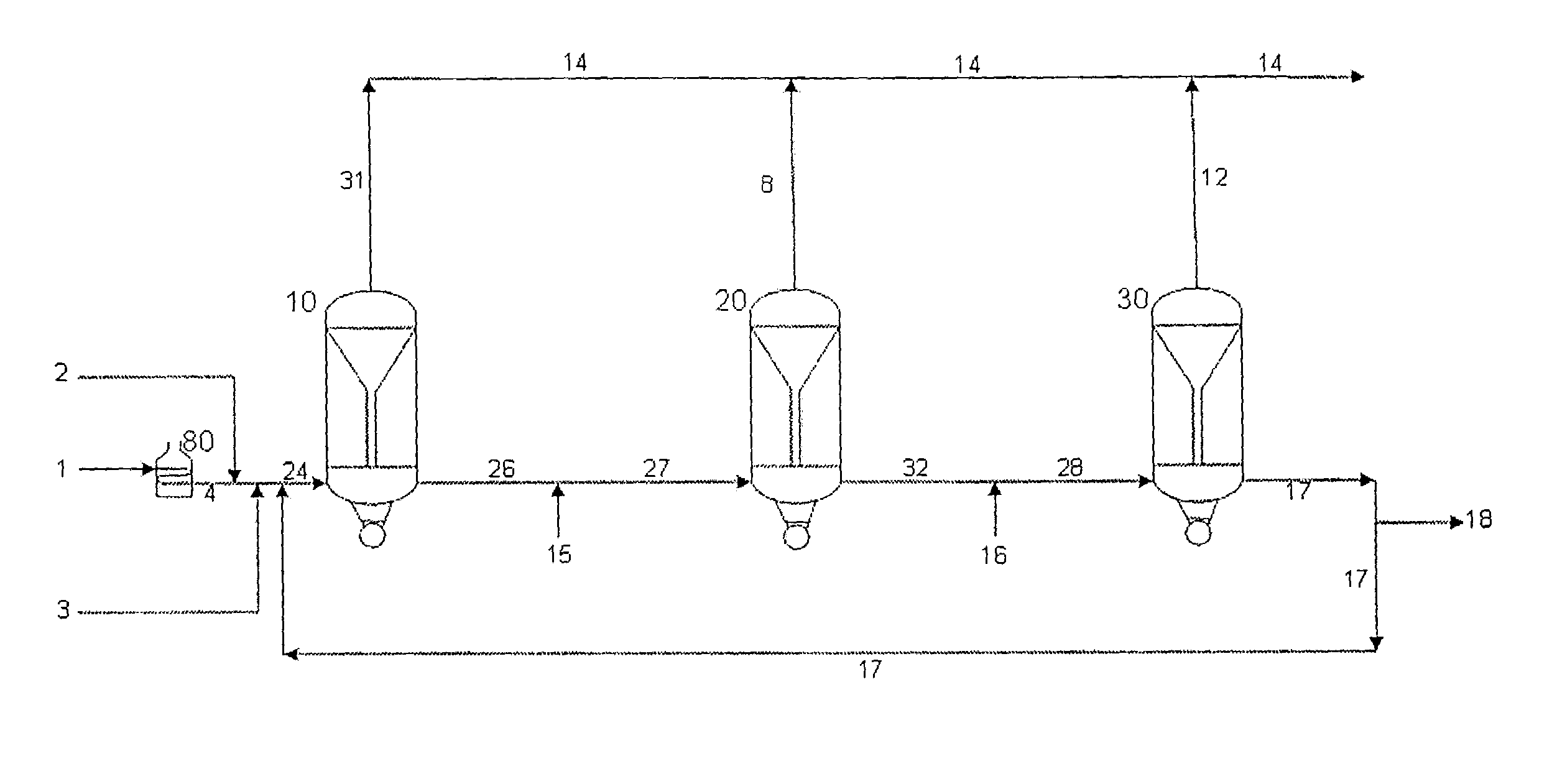

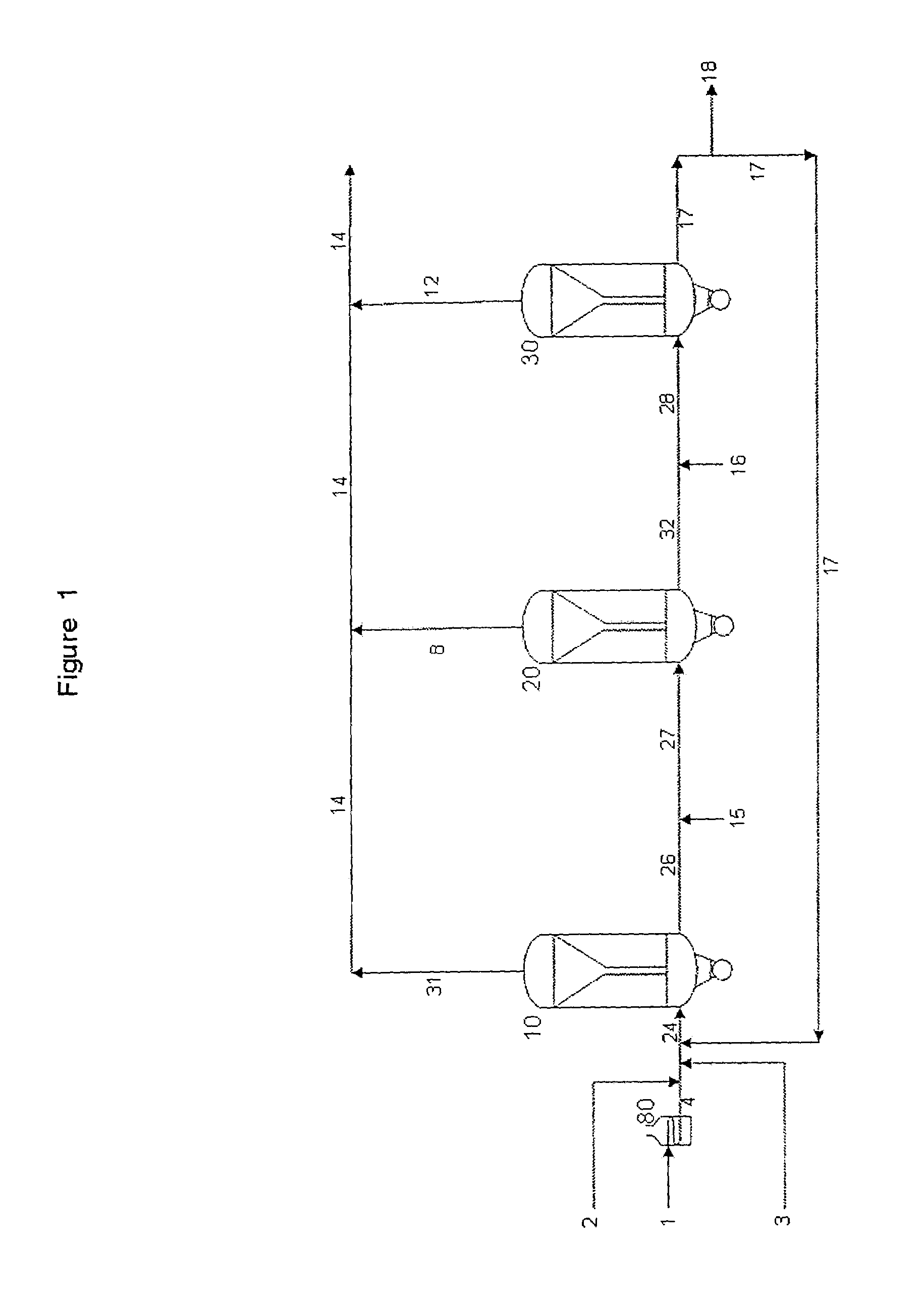

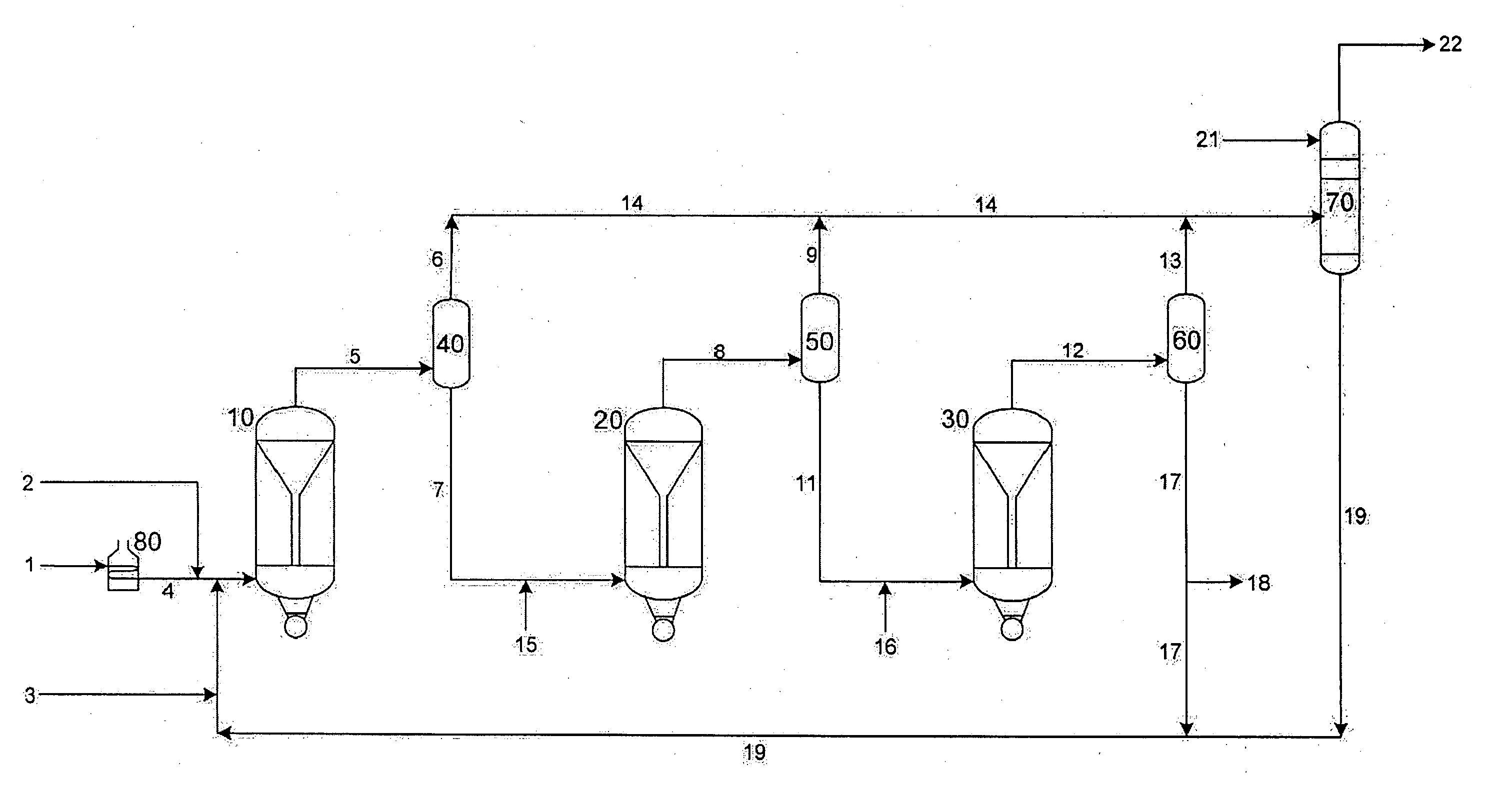

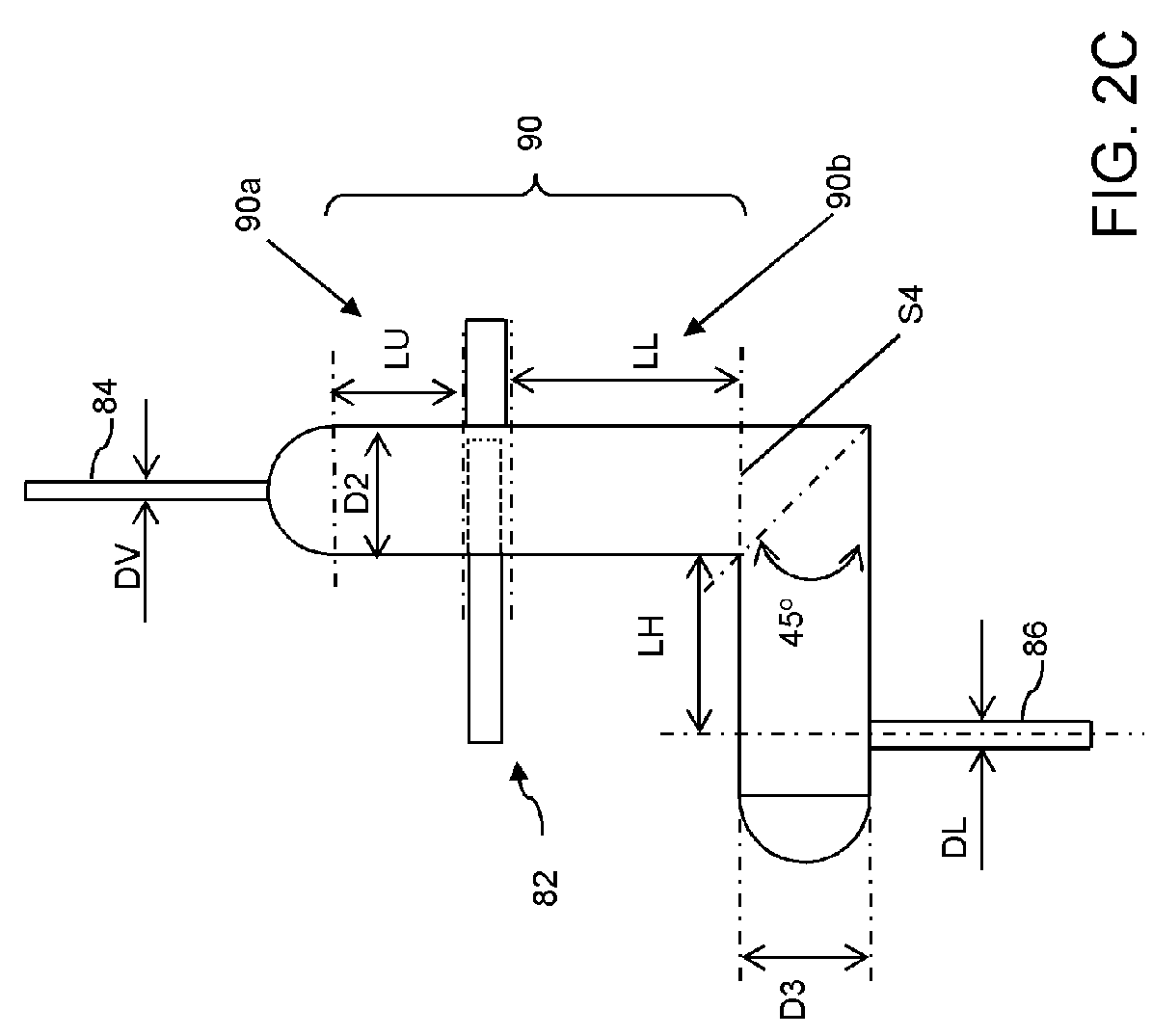

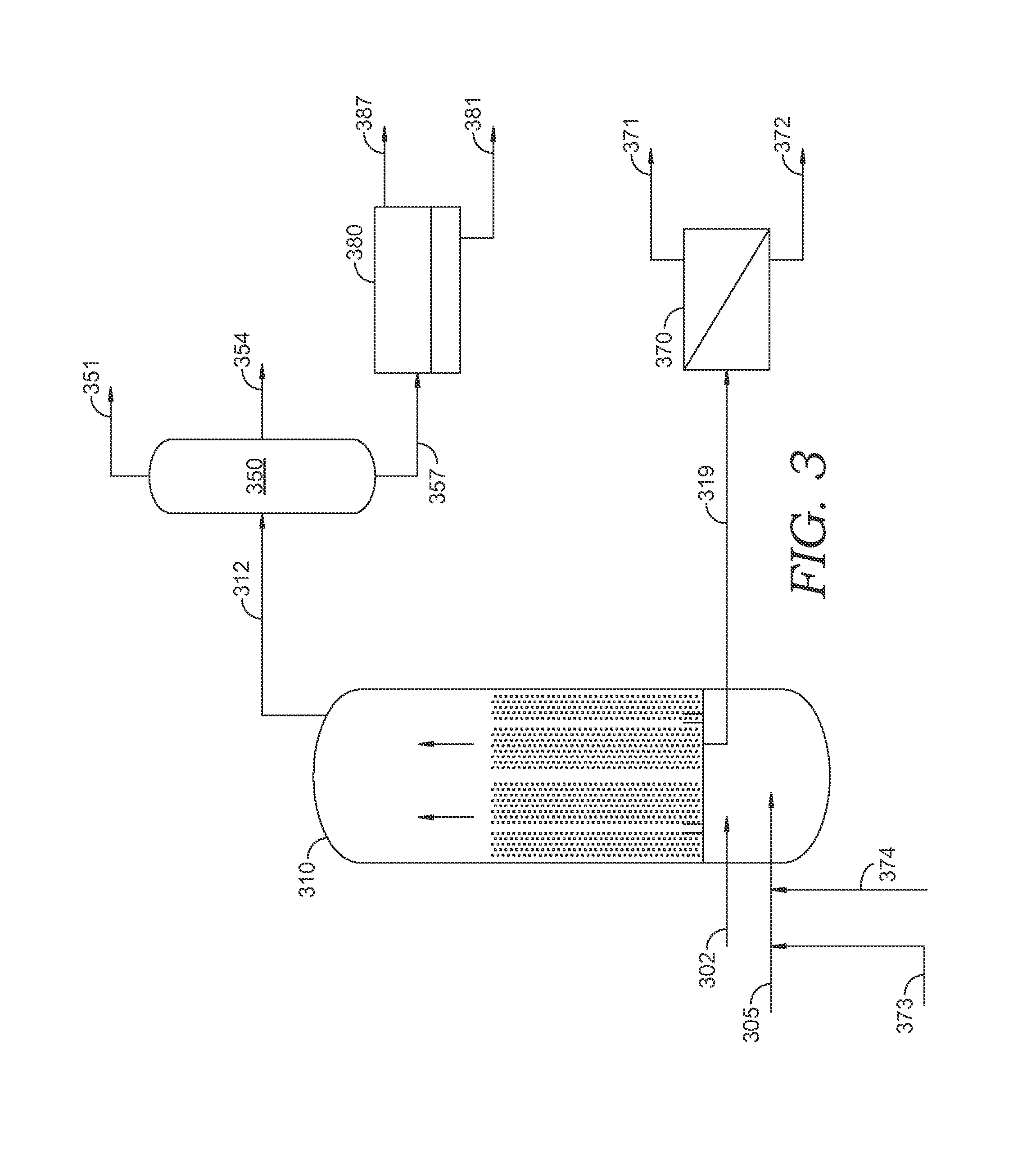

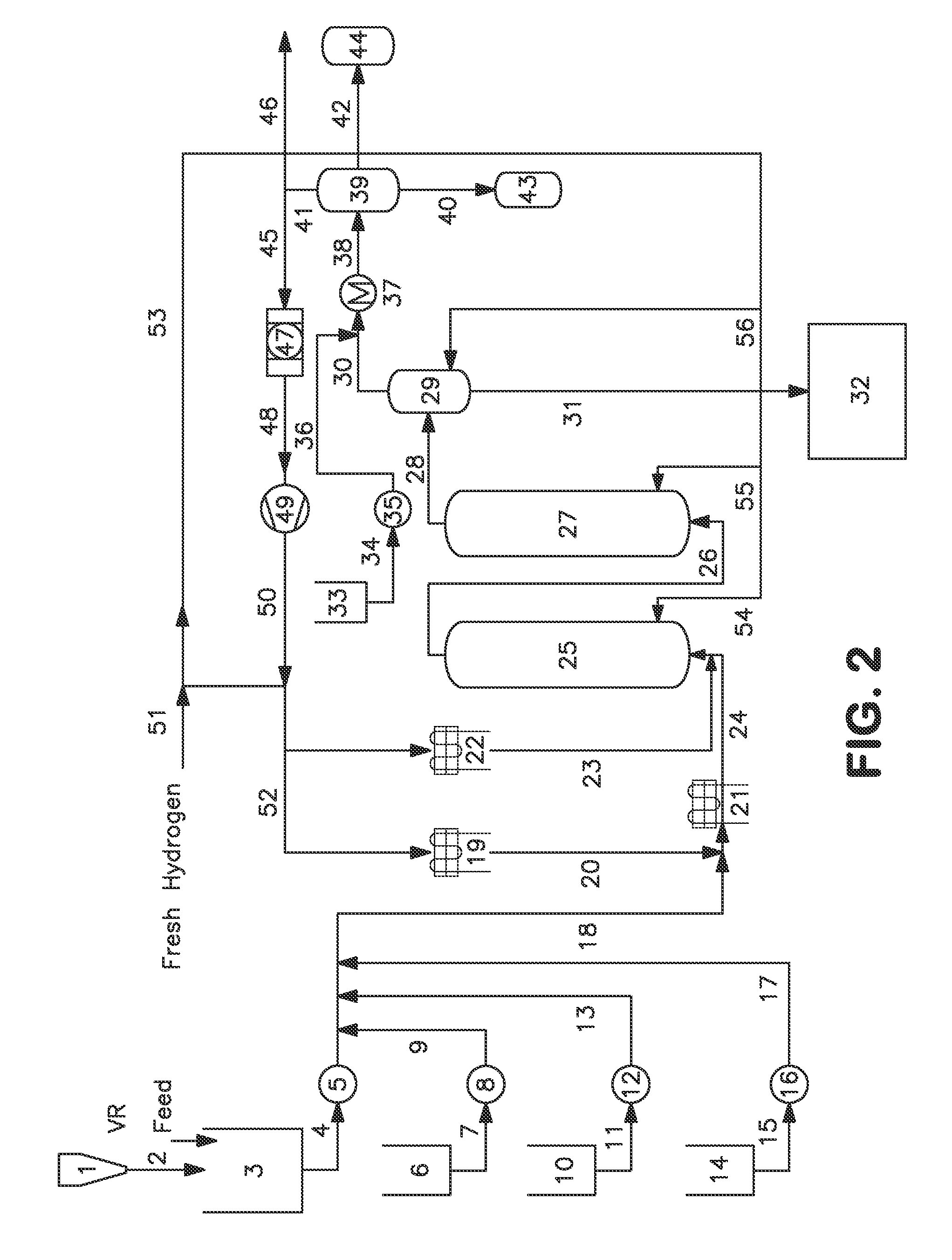

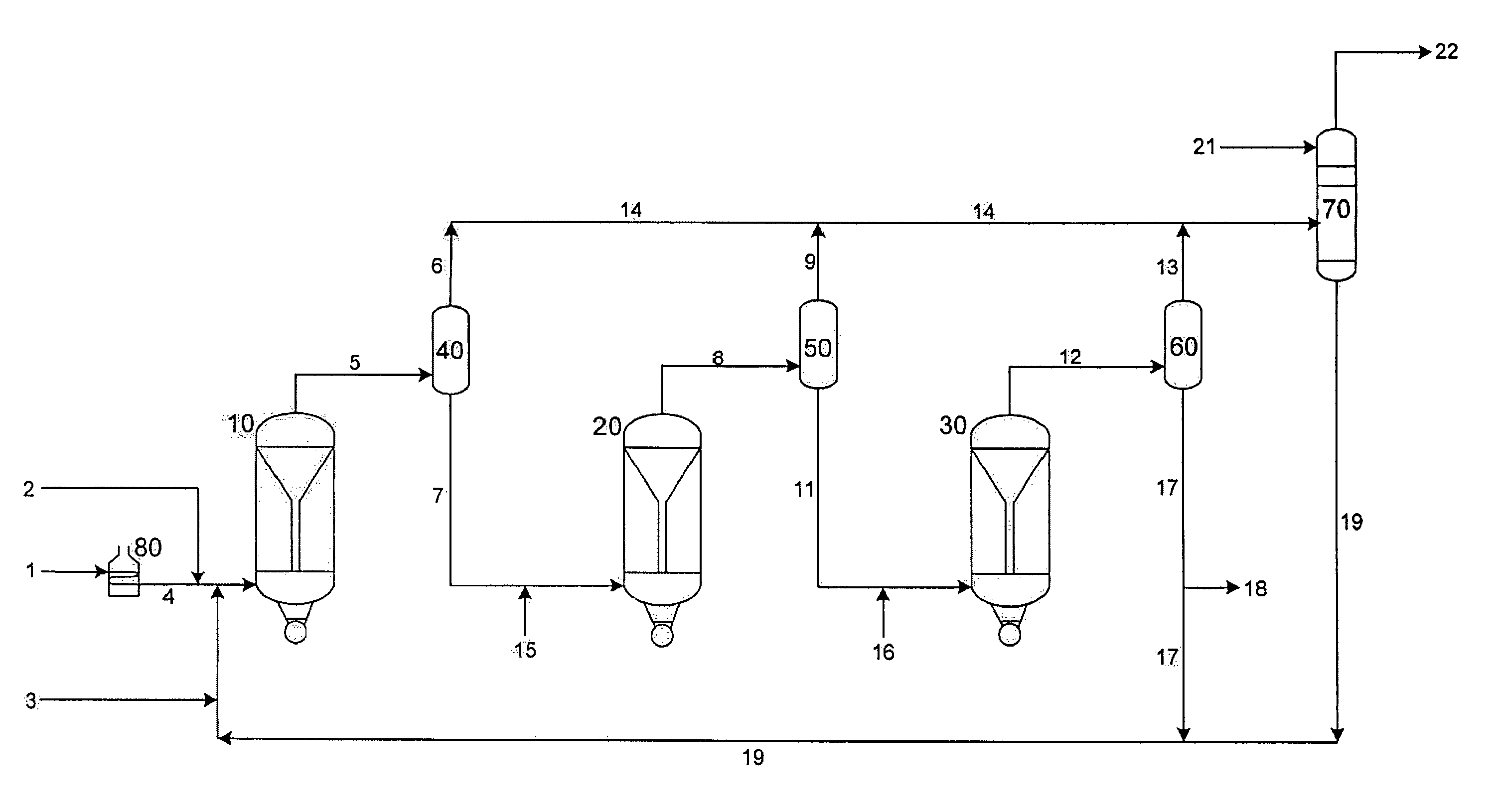

Process for upgrading heavy oil using a reactor with a novel reactor separation system

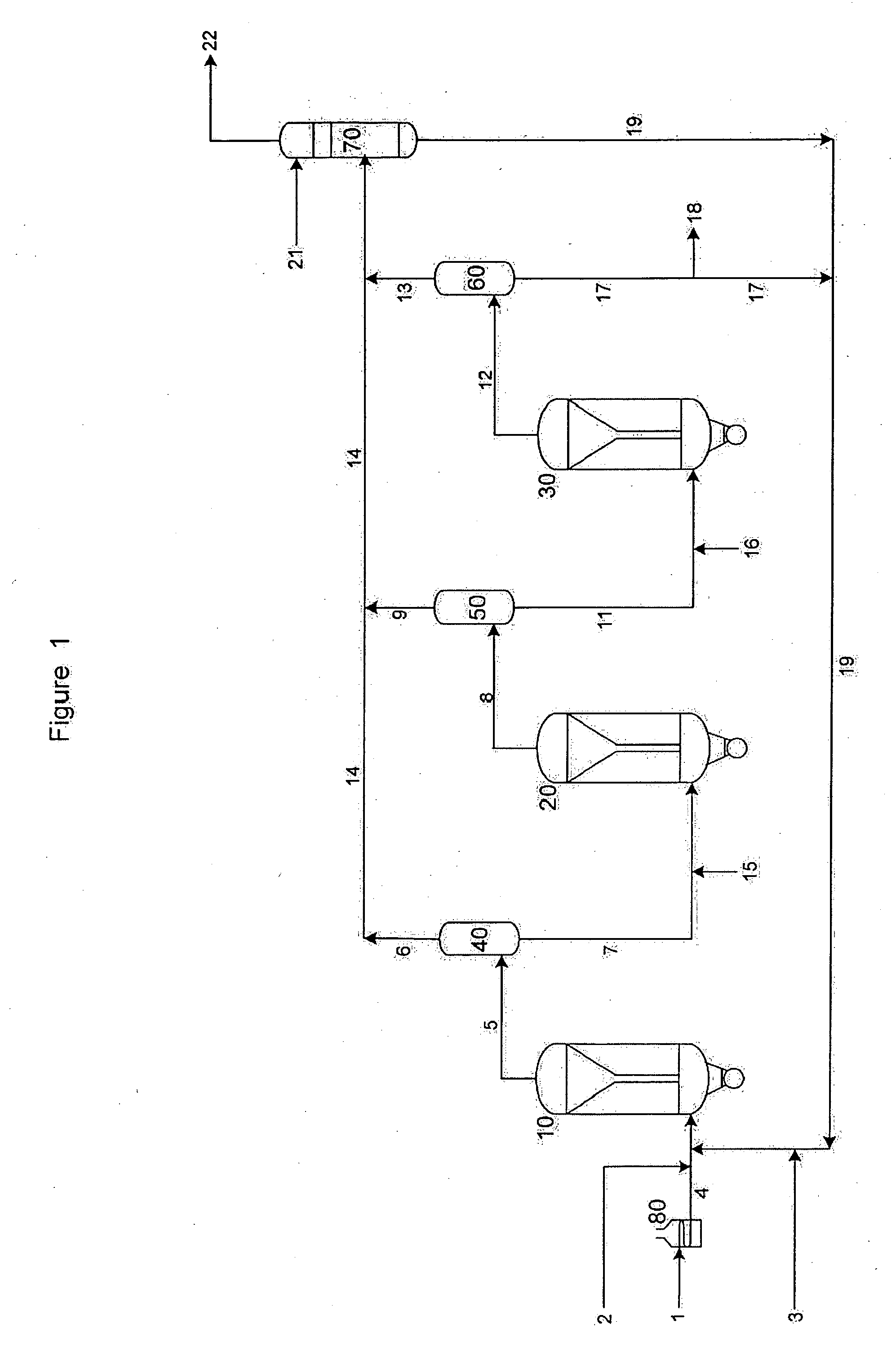

ActiveUS7431822B2Treatment with plural serial cracking stages onlyTreatment with plural parallel cracking stages onlyLiquid productHydrogen

Applicants have developed a new residuum full hydroconversion slurry reactor system that allows the catalyst, unconverted oil, hydrogen, and converted oil to circulate in a continuous mixture throughout an entire reactor with no confinement of the mixture. The mixture is separated internally, within one of more of the reactors, to separate only the converted oil and hydrogen into a vapor product while permitting the unconverted oil and the slurry catalyst to continue on into the next sequential reactor as a liquid product. A portion of the unconverted oil is then converted to lower boiling point hydrocarbons in the next reactor, once again creating a mixture of unconverted oil, hydrogen, converted oil, and slurry catalyst. Further hydroprocessing may occur in additional reactors, fully converting the oil. The oil may alternately be partially converted, leaving a concentrated catalyst in unconverted oil which can be recycled directly to the first reactor.

Owner:CHEVROU USA INC

Process for upgrading heavy oil using a highly active slurry catalyst composition

ActiveUS20070138057A1Treatment with plural serial cracking stages onlyTreatment with plural parallel cracking stages onlyHydrogenSlurry reactor

The instant invention is directed to a new residuum full hydroconversion slurry reactor system that allows the catalyst, unconverted oil and converted oil to circulate in a continuous mixture throughout an entire reactor with no confinement of the mixture. The mixture is partially separated in between the reactors to remove only the products and hydrogen, while permitting the unconverted oil and the slurry catalyst to continue on into the next sequential reactor where a portion of the unconverted oil is converted to lower boiling point hydrocarbons, once again creating a mixture of unconverted oil, converted oil, and slurry catalyst. Further hydroprocessing may occur in additional reactors, fully converting the oil. The oil may alternately be partially converted, leaving a highly concentrated catalyst in unconverted oil which can be recycled directly to the first reactor.

Owner:CHEVROU USA INC

Process for upgrading heavy oil using a highly active slurry catalyst compositon

ActiveUS20060054534A1High viscosity carbonaceousHigh viscosityTreatment with plural serial cracking stages onlyTreatment with plural serial stages onlyHydrogenCompound (substance)

The instant invention is directed to a process for upgrading heavy oils using a slurry composition. The slurry composition is prepared in a series of steps, involving mixing a Group VIB metal oxide with aqueous ammonia to form an aqueous mixture and sulfiding the mixture to form a slurry. The slurry is then promoted with a Group VIII metal compound. Subsequent steps involve mixing the slurry with a hydrocarbon oil, and combining the resulting mixture with hydrogen gas (under conditions which maintain the water in a liquid phase) to produce the active slurry catalyst.

Owner:CHEVROU USA INC

Ebullated bed hydroprocessing methods and systems and methods of upgrading an existing ebullated bed system

ActiveUS7449103B2Quality improvementReduce formationHydrocarbon oil crackingLiquid hydrocarbon mixture productionHydrogenDecomposition

An ebullated bed hydroprocessing system, and also a method for upgrading a pre-existing ebullated bed hydroprocessing system, involves introducing a colloidal or molecular catalyst, or a precursor composition capable of forming the colloidal or molecular catalyst, into an ebullated bed reactor. The colloidal or molecular catalyst is formed by intimately mixing a catalyst precursor composition into a heavy oil feedstock and raising the temperature of the feedstock to above the decomposition temperature of the precursor composition to form the colloidal or molecular catalyst in situ. The improved ebullated bed hydroprocessing system includes at least one ebullated bed reactor that employs both a porous supported catalyst and the colloidal or molecular catalyst to catalyze hydroprocessing reactions involving the feedstock and hydrogen. The colloidal or molecular catalyst provides catalyst in what would otherwise constitute catalyst free zones within the ebullated bed hydroprocessing system. Asphaltene or other hydrocarbon molecules too large to diffuse into the pores of the supported catalyst can be upgraded by the colloidal or molecular catalyst. A slurry phase reactor may be positioned upstream from one or more ebullated bed reactors or converted from a pre-existing ebullated bed reactor.

Owner:HEADWATERS TECH INNOVATION LLC

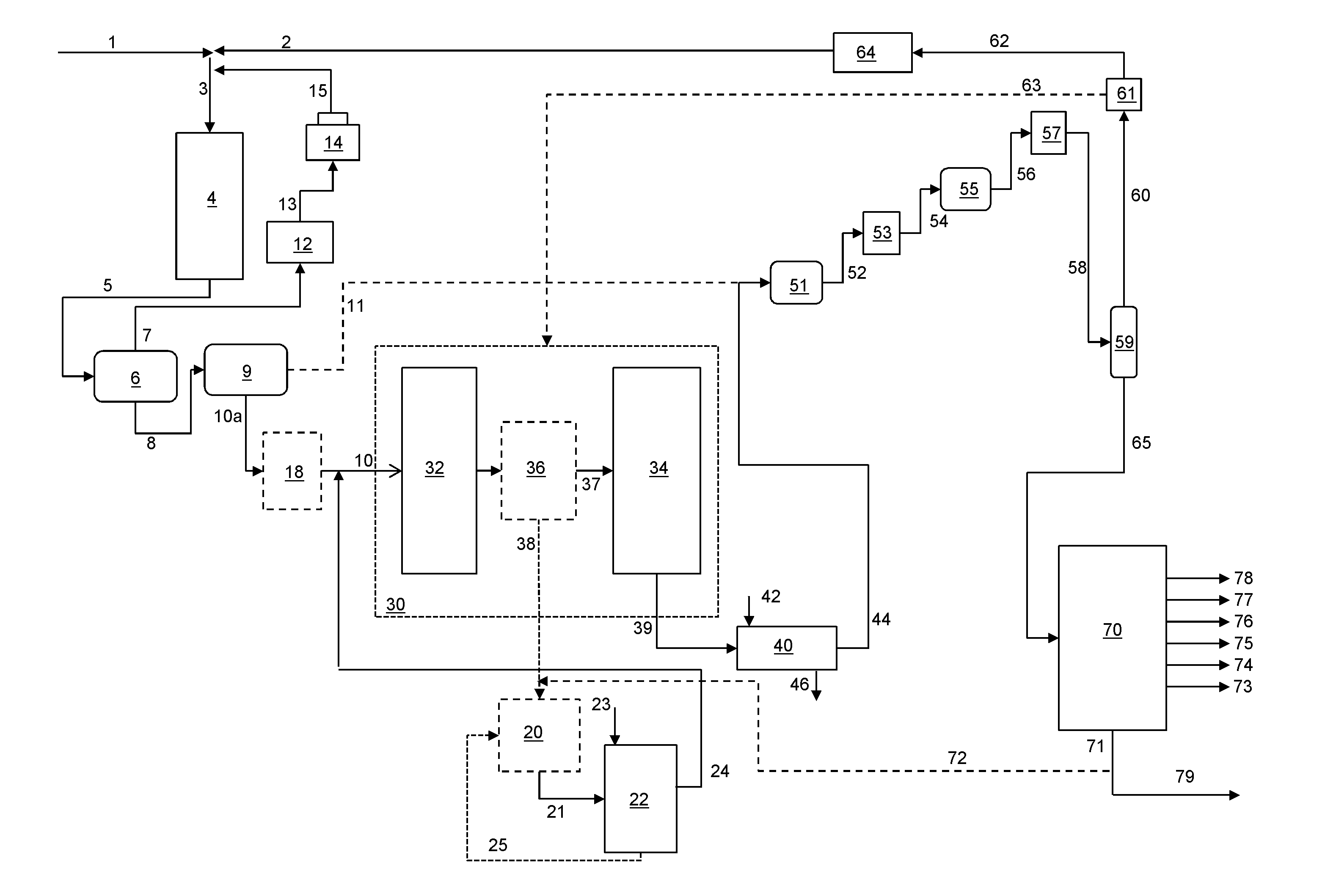

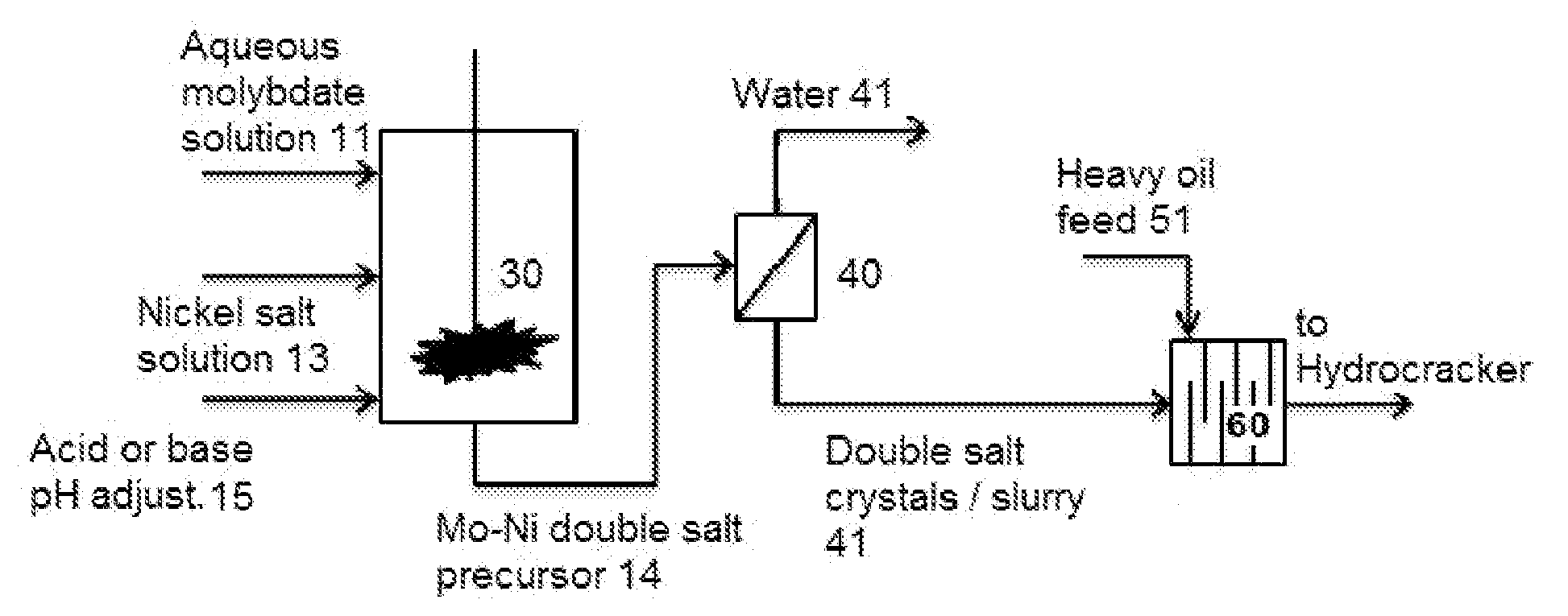

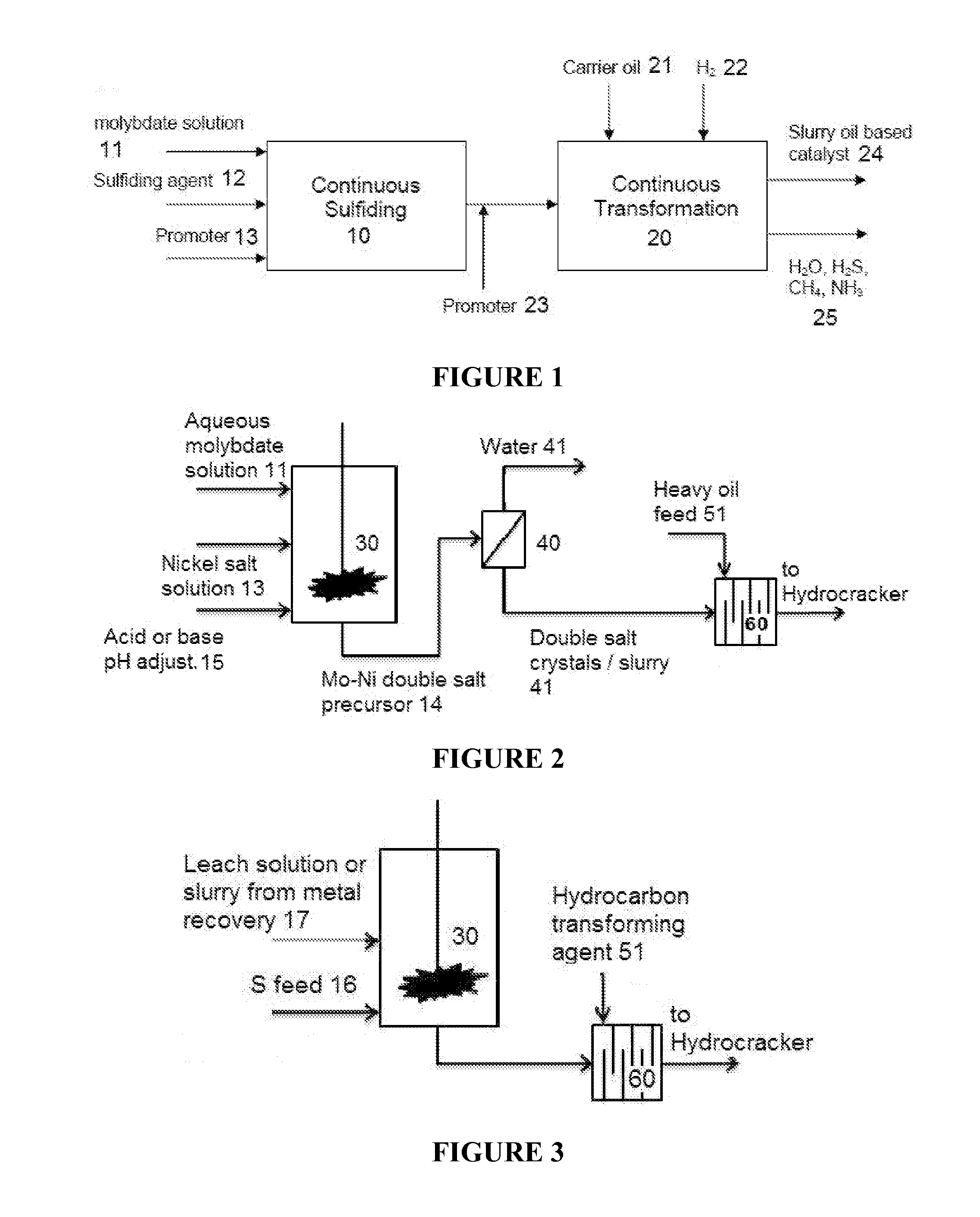

Hydroprocessing catalysts and methods for making thereof

ActiveUS20120168350A1Speed up the processRefining with metalsOrganic-compounds/hydrides/coordination-complexes catalystsSlurryFuel oil

An improved process for preparing a slurry catalyst for the upgrade of heavy oil feedstock is provided. The process employs a polar aprotic solvent to mix with the inorganic metal precursor feed to form an oil-dispersible inorganic metal precursor, at a weight ratio of solvent to inorganic metal precursor of 1:1 to 10:1; the oil-dispersible inorganic metal precursor is subsequently sulfided forming the slurry catalyst. In one embodiment, the sulfiding is in-situ upon mixing the oil-dispersible inorganic metal precursor with a hydrocarbon diluent containing a heavy oil feedstock under in-situ sulfiding conditions.

Owner:CHEVROU USA INC

Integrated hydroprocessing, steam pyrolysis and slurry hydroprocessing of crude oil to produce petrochemicals

ActiveUS20130248417A1Increased paraffinicityReduce pollutant contentThermal non-catalytic crackingPhysical/chemical process catalystsSteam pyrolysisSlurry

Crude oil is charged to a hydroprocessing zone in the presence of hydrogen operating under conditions effective to produce a hydroprocessed effluent, which is thermally cracked in the presence of steam in a steam pyrolysis zone to produce a mixed product stream. Heavy components, which are derived from one or more of the hydroprocessed effluent, a heated stream within the steam pyrolysis zone, or the mixed product stream catalytically cracking are charged to a slurry hydroprocessing zone to produce a slurry intermediate product which is then thermally cracked. Olefins and aromatics are recovered from the separated mixed product stream as product.

Owner:SAUDI ARABIAN OIL CO

Integrated unsupported slurry catalyst preconditioning process

InactiveUS20080135450A1Reduce shockIncrease temperatureOrganic-compounds/hydrides/coordination-complexes catalystsCentrifugal force sediment separationSlurryEngineering

A process for slurry hydroprocessing, which involves preconditioning a slurry catalyst for activity improvement in vacuum residuum hydroprocessing units Preconditioning the slurry catalyst raises its temperature, thereby reducing shock on the catalyst slurry as it enters the hydroprocessing reactor.

Owner:CHEVROU USA INC

Hydroprocessing Catalysts and Methods for Making Thereof

ActiveUS20120152805A1Reduces coke formationReduce formation of sedimentMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystReactor system

A method to upgrade heavy oil feedstock using an ebullated bed reactor and a novel catalyst system is provided. The ebullated bed reactor system includes two different catalyst with different characteristics: an expanded catalyst zone containing particulate catalyst having a particle size of greater than 0.65 mm; and a slurry catalyst having an average particle size ranging from 1 to 300 μm. The slurry catalyst is provided to the ebullated bed system containing the heavy oil feedstock, and entrained in the upflowing hydrocarbon liquid passing through the ebullated bed reaction zone. The slurry catalyst reduces the formation of sediment and coke precursors in the ebullating bed reactor system. The slurry catalyst is prepared from rework materials, which form a slurry catalyst in-situ upon mixing with the heavy oil feedstock.

Owner:CHEVROU USA INC

Hydroprocessing catalysts and methods for making thereof

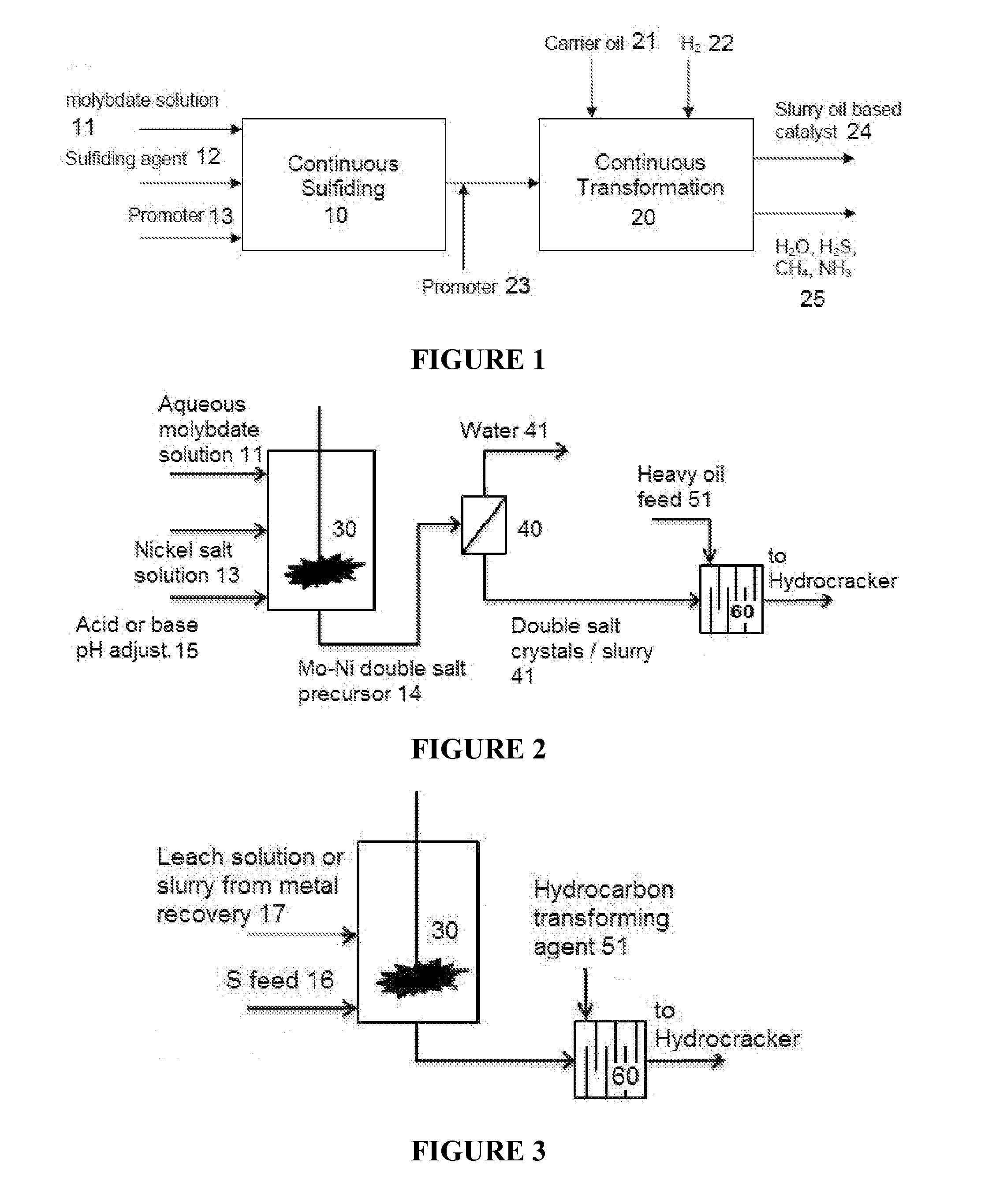

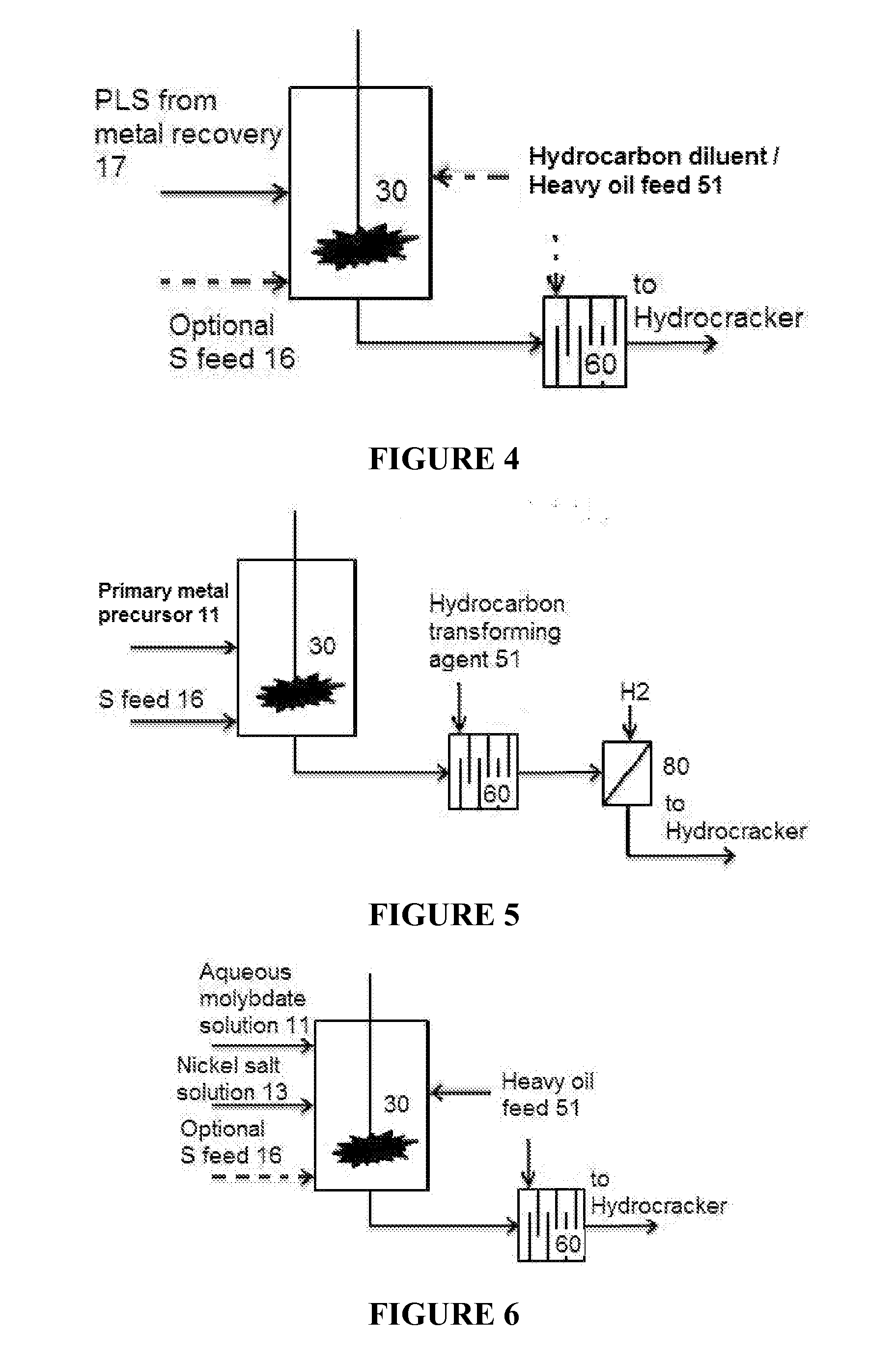

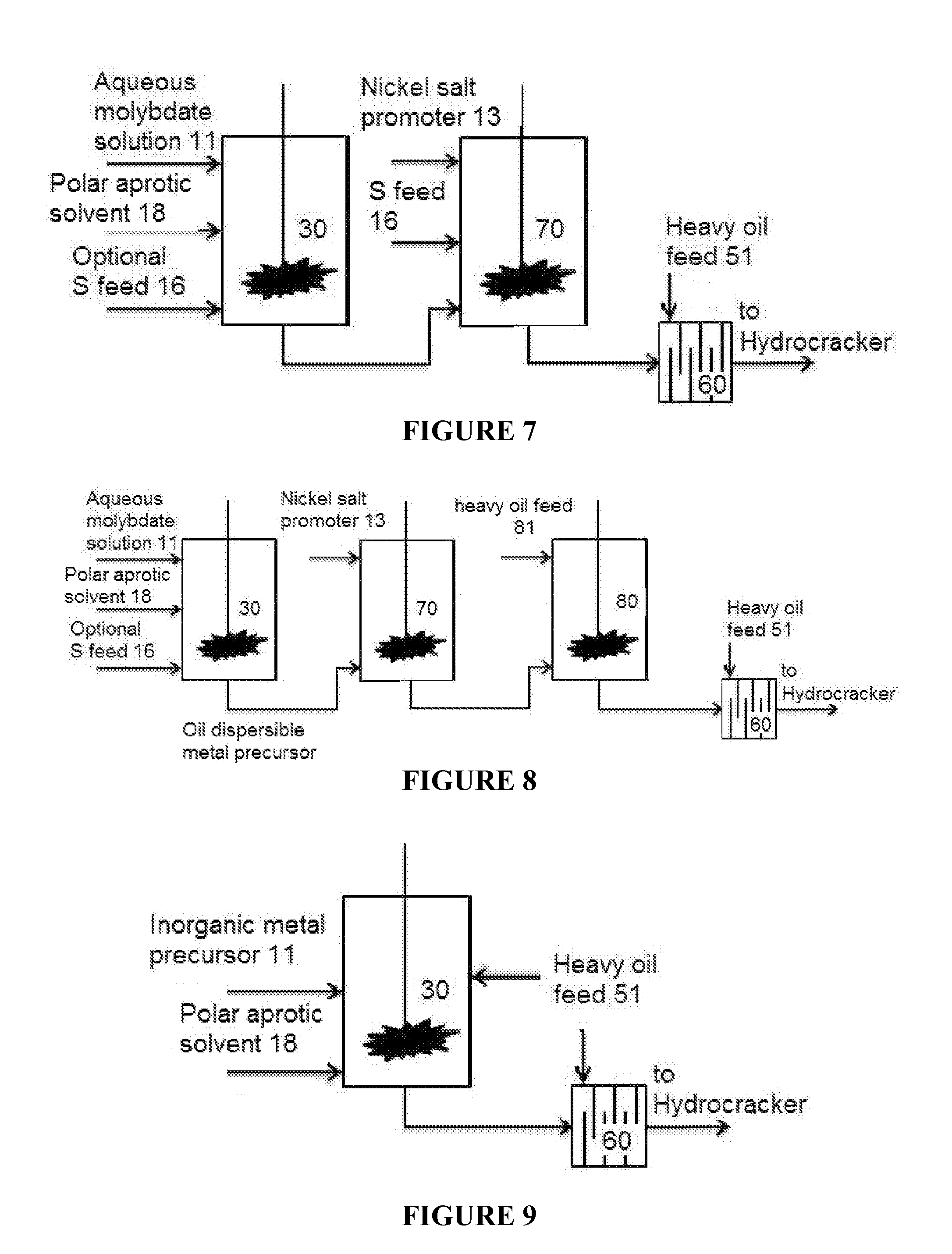

ActiveUS20120172199A1Speed up the processOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationWater basedSulfidation

An improved process to make a slurry catalyst for the upgrade of heavy oil feedstock is provided. In the process, at least a metal precursor feedstock is portioned and fed in any of the stages: the promotion stage; the sulfidation stage; or the transformation stage of a water-based catalyst precursor to a slurry catalyst. In one embodiment, the promoter metal precursor feedstock is split into portions, the first portion is for the sulfiding step, the second portion is for the promotion step; and optionally the third portion is to be added to the transformation step in the mixing of the sulfided promoted catalyst precursor with a hydrocarbon diluent to form the slurry catalyst. In another embodiment, the Primary metal precursor feedstock is split into portions.

Owner:CHEVROU USA INC

Integrated slurry hydroprocessing and steam pyrolysis of crude oil to produce petrochemicals

ActiveUS9284501B2Thermal non-catalytic crackingTreatment with plural parallel cracking stages onlyHydrogen contentEngineering

An integrated slurry hydroprocessing and steam pyrolosyis process for the production of olefins and aromatic petrochemicals from a crude oil feedstock is provided. Crude oil, a steam pyrolysis residual liquid fraction and slurry reside are combined and treated in a hydroprocessing zone in the presence of hydrogen under conditions effective to produce an effluent having an increased hydrogen content. The effluent is thermally cracked with steam under conditions effective to produce a mixed product stream and steam pyrolysis residual liquid fraction. The mixed product stream is separated and olefins and aromatics are recovered and hydrogen is purified and recycled.

Owner:SAUDI ARABIAN OIL CO

Hydroprocessing Bulk Catalyst and Uses Thereof

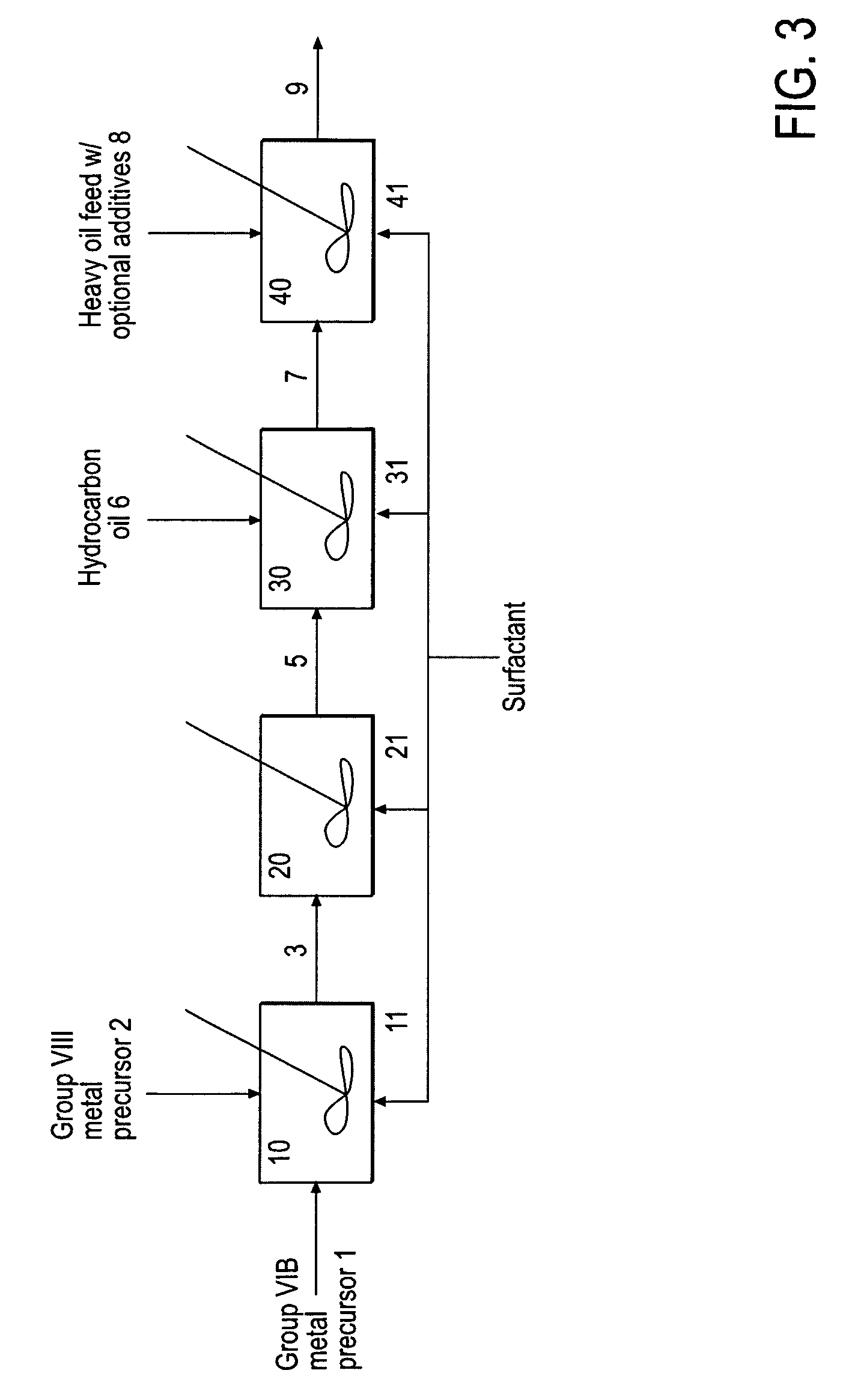

ActiveUS20090054225A1Inorganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsTO-18X-ray

A hydroprocessing bulk catalyst is provided. A process to prepare hydroprocessing bulk catalysts is also provided. The hydroprocessing catalyst has the formula (Mt)a(Lu)b(Sv)d(Cw)e(Hx)f(Oy)gNz)h, wherein M is at least one group VIB metal; L is optional and if present, L is at least one Group VIII non-noble metal; t, u, v, w, x, y, z representing the total charge for each of the components (M, L, S, C, H, O and N, respectively); ta+ub+vd+we+xf+yg+zh=0; 0=<b; and 0=<b / a=<5, (a+0.5b)<=d<=(5a+2b), 0<=e<=11(a+b), 0<=f<=7(a+b), 0<=g<=5(a+b), 0<=h<=0.5(a+b). The catalyst has an X-ray powder diffraction pattern with at least one broad diffraction peak at any of Bragg angles: 8 to 18°, 32 to 40°, and 55 to 65° (from 0 to 70° 2-θ scale). In one embodiment, the catalyst is prepared by sulfiding at least one Group VIB metal compound and optionally at least one group VIII metal compound with a sulfiding agent forming a catalyst precursor; and mixing the catalyst precursor with a hydrocarbon compound to form the hydroprocessing catalyst composition, and wherein at least a surfactant is employed in making the preparation.

Owner:CHEVROU USA INC

Integrated hydroprocessing, steam pyrolysis and slurry hydroprocessing of crude oil to produce petrochemicals

ActiveUS9228141B2Thermal non-catalytic crackingPhysical/chemical process catalystsSteam pyrolysisSlurry

Crude oil is charged to a hydroprocessing zone in the presence of hydrogen operating under conditions effective to produce a hydroprocessed effluent, which is thermally cracked in the presence of steam in a steam pyrolysis zone to produce a mixed product stream. Heavy components, which are derived from one or more of the hydroprocessed effluent, a heated stream within the steam pyrolysis zone, or the mixed product stream catalytically cracking are charged to a slurry hydroprocessing zone to produce a slurry intermediate product which is then thermally cracked. Olefins and aromatics are recovered from the separated mixed product stream as product.

Owner:SAUDI ARABIAN OIL CO

Process for hydroconversion of petroleum feedstocks via a slurry technology allowing the recovery of metals from the catalyst and from the feedstock using a coking step

InactiveUS20130075303A1Yield maximizationReduce in quantityThermal non-catalytic crackingCatalyst activation/preparationCombustionSlurry

A process for hydroconversion of heavy petroleum feedstocks comprising a hydroconversion step of the feedstock in at least one reactor containing a slurry catalyst and allowing the recovery of metals in the unconverted residual fraction, in particular those used as catalysts, The process comprises a hydroconversion step, a gas / liquid separation step, a coking step, a combustion step, a metals extraction step and a step of preparing catalytic solutions which are recycled to the hydroconversion step.

Owner:INTREVEP SA

Moving Bed Hydrocarbon Conversion Process

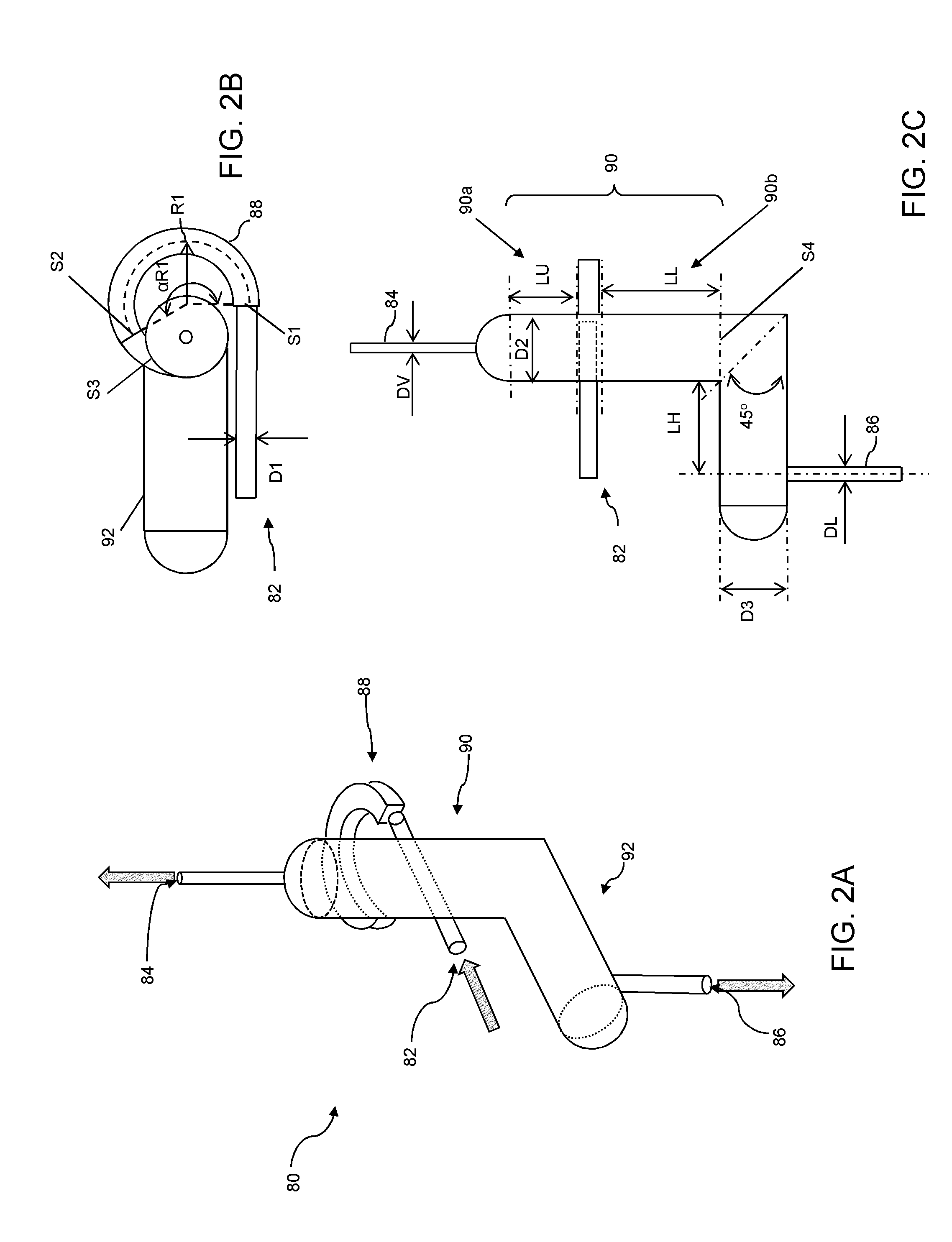

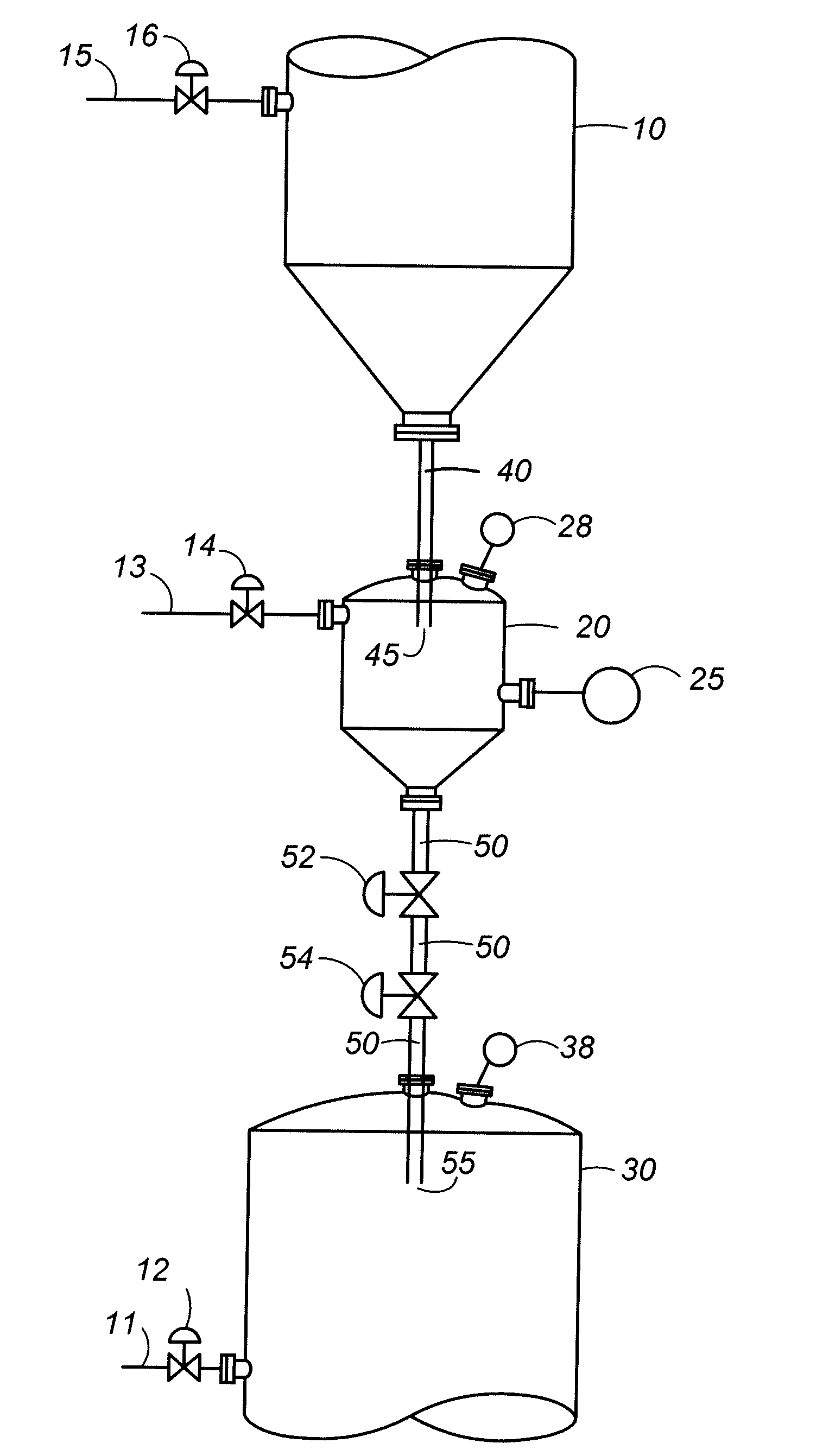

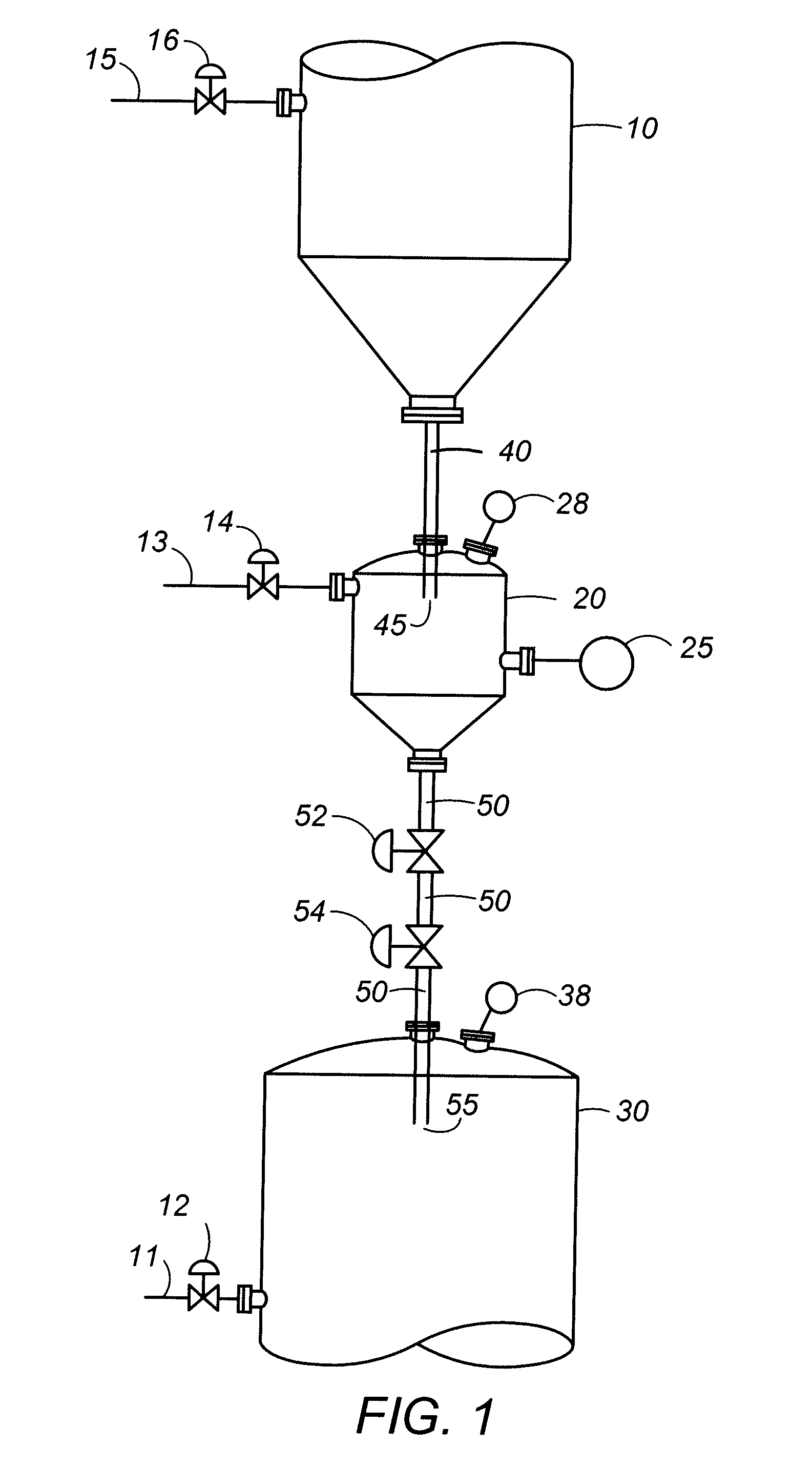

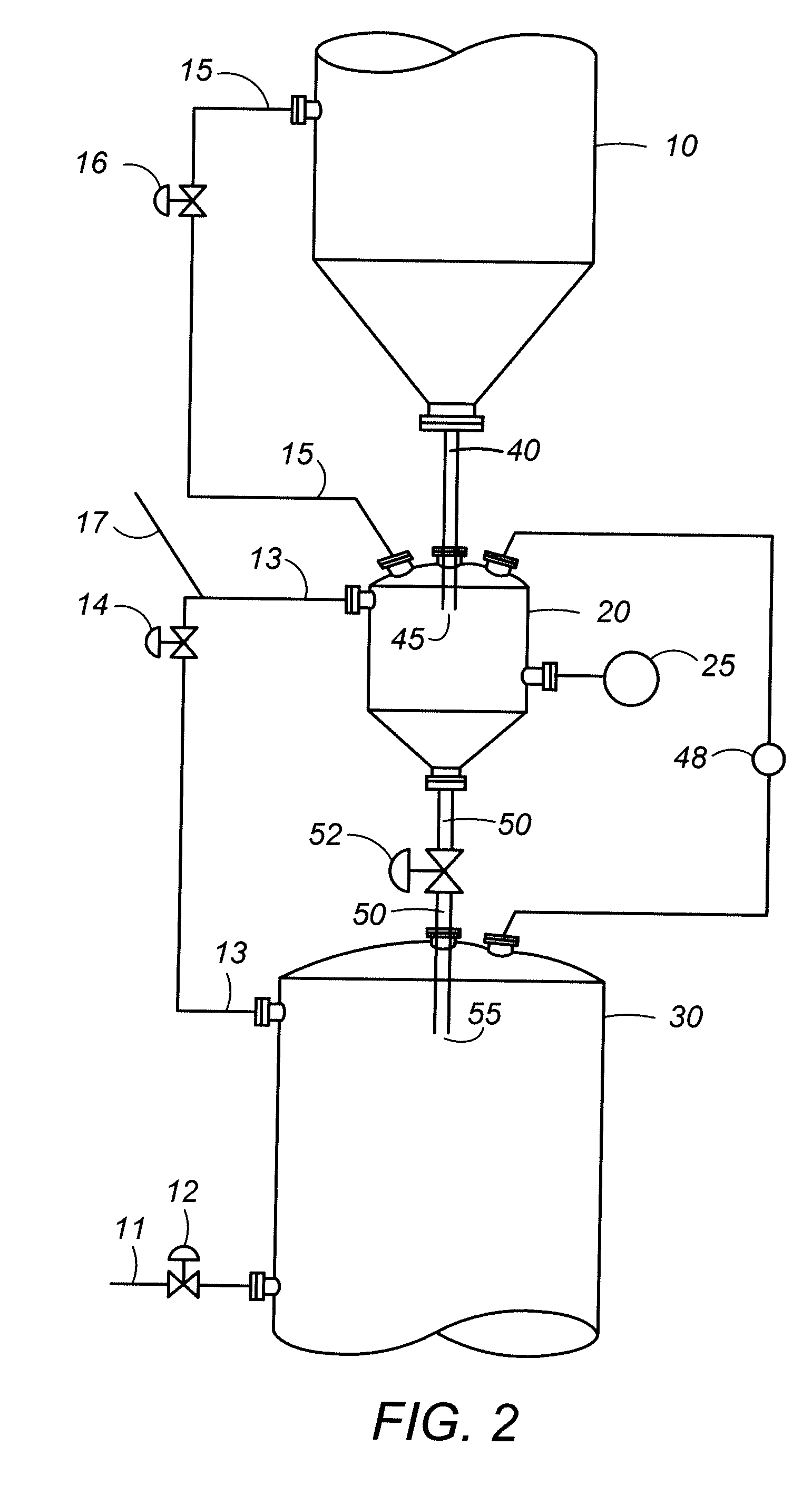

InactiveUS20100187159A1Little no damageIncrease pressureCatalytic naphtha reformingHydrocarbon oil crackingParticle transferValved conduit

Moving bed hydrocarbon conversion processes are provided for contacting a catalyst moving downward through a reaction zone with a hydrocarbon feed, withdrawing the catalyst from the reaction zone and conveying the catalyst to a regeneration zone wherein the catalyst moves downward. The catalyst is withdrawn from the regeneration zone and passed downward to an upper zone of a particle transfer apparatus wherein the transfer of catalyst from the upper zone through a middle zone to a lower zone is regulated by varying the pressure of the middle zone, the flow rate of gas passing through an upper valveless conduit, and a valve in a lower valved conduit. The catalyst from the lower zone of the particle transfer apparatus is conveyed to the reactions zone.

Owner:UOP LLC

Slurry hydroconversion with high activity catalysts

Systems and methods are provided for slurry hydroconversion of a heavy oil feed, such as an atmospheric or vacuum resid. The systems and methods allow for slurry hydroconversion using catalysts with enhanced activity. The catalysts with enhanced activity can be used in conjunction with demetallization catalysts or catalysts that can be recycled as a side product from a complementary refinery process.

Owner:EXXON RES & ENG CO

Hydroprocessing bulk catalyst and uses thereof

ActiveUS7678731B2Inorganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystMetallurgy

Owner:CHEVROU USA INC

System and method for pretreatment of solid carbonaceous material

ActiveUS20090314684A1Improve efficiencyCatalytic crackingPhysical/chemical process catalystsPre treatmentHydrocarbon

Owner:CHEVROU USA INC

Small catalyst particle addition to slurry reactor (Law749)

InactiveUS6090859ARefining to change hydrocarbon structural skeletonHydroxy compound preparationAlcoholSlurry reactor

Small particle size catalysts having an average particle size of less than 20 or 10 microns, which agglomerate when contacted with a hydrocarbon liquid, are easily dispersed in the hydrocarbon liquid by first forming a mixture comprising the catalyst particles and one or more non-acidic, liquid polar oxygenates, such as an alcohol, ketone, ester, ether or mixture thereof. The mixture is contacted with the hydrocarbon liquid in which the particles then readily disperse. This process is useful for adding fresh or regenerated small particle size catalyst to catalytic hydroprocessing process slurries, including a reactive Fischer-Tropsch hydrocarbon synthesis slurry. One to four carbon atom alcohols are preferred oxygenates for use with a Fischer-Tropsch slurry.

Owner:EXXON RES & ENG CO

Pyrolysis Tar Upgrading Process

InactiveUS20150344790A1Hydrocarbon oil crackingTreatment with hydrotreatment processesPtru catalystSulfide

A process for upgrading pyrolysis tar to higher value products. More particularly, this invention relates to the upgrading of steam cracker tar using relatively small amounts of a transition metal sulfide-containing particulate catalyst dispersed throughout the tar chargestock and in the presence of hydrogen, at relatively mild hydroconversion conditions.

Owner:EXXONMOBIL CHEM PAT INC

Process for hydrocracking of Fischer-Tropsch synthesized heavy hydrocarbon and/or kettle bottom wax

The invention discloses a process for hydrocracking of Fischer-Tropsch synthesized heavy hydrocarbon and / or kettle bottom wax which comprises, mixing waste ferrum based catalyst with heavy weight hydrocarbons and / or kettle bottom wax raw material, mixing with hydrogen, heating to 300-400 deg. C, loading into suspending bed reactor for hydrogenation conversion.

Owner:SYNFUELS CHINA TECH CO LTD

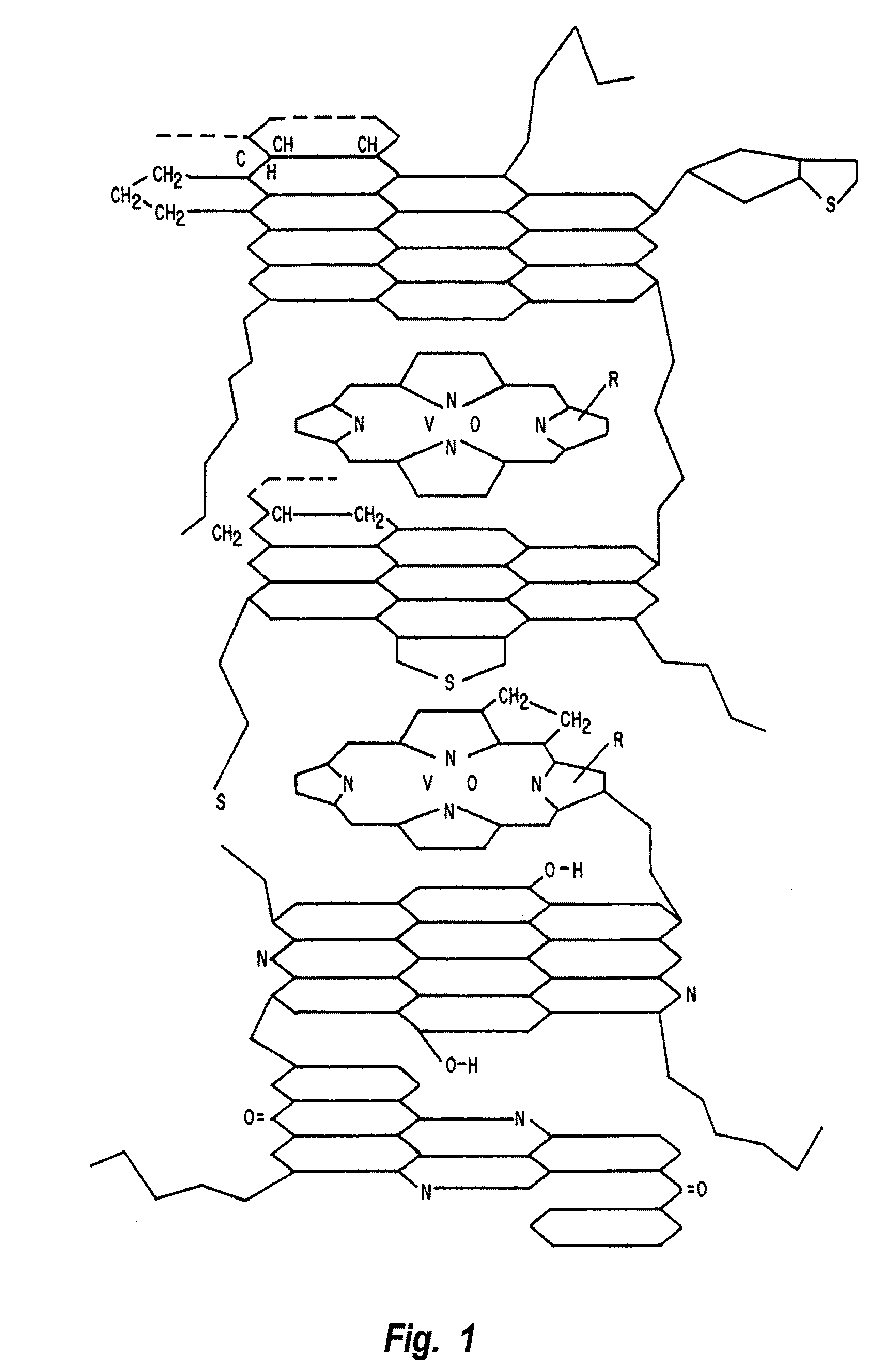

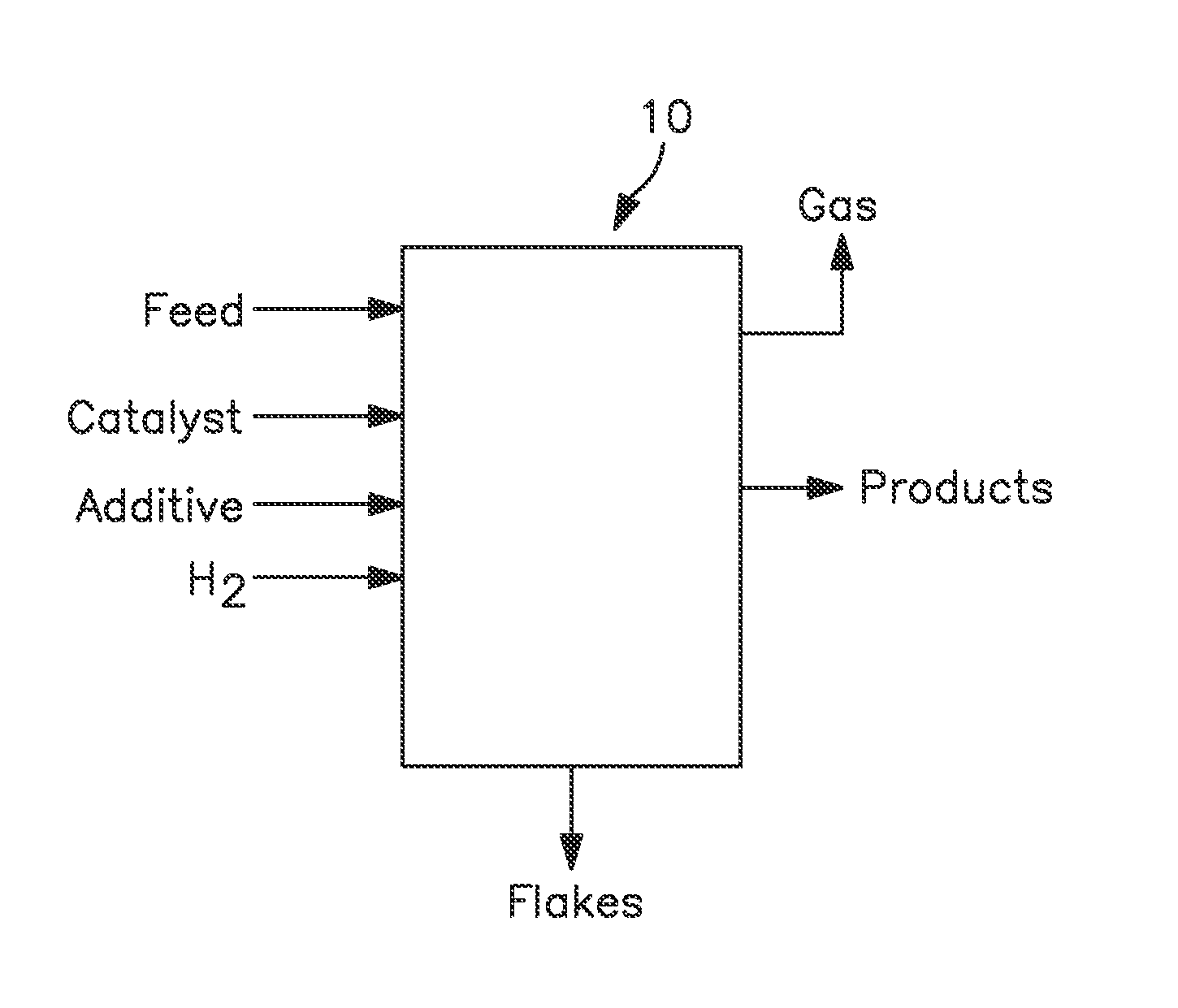

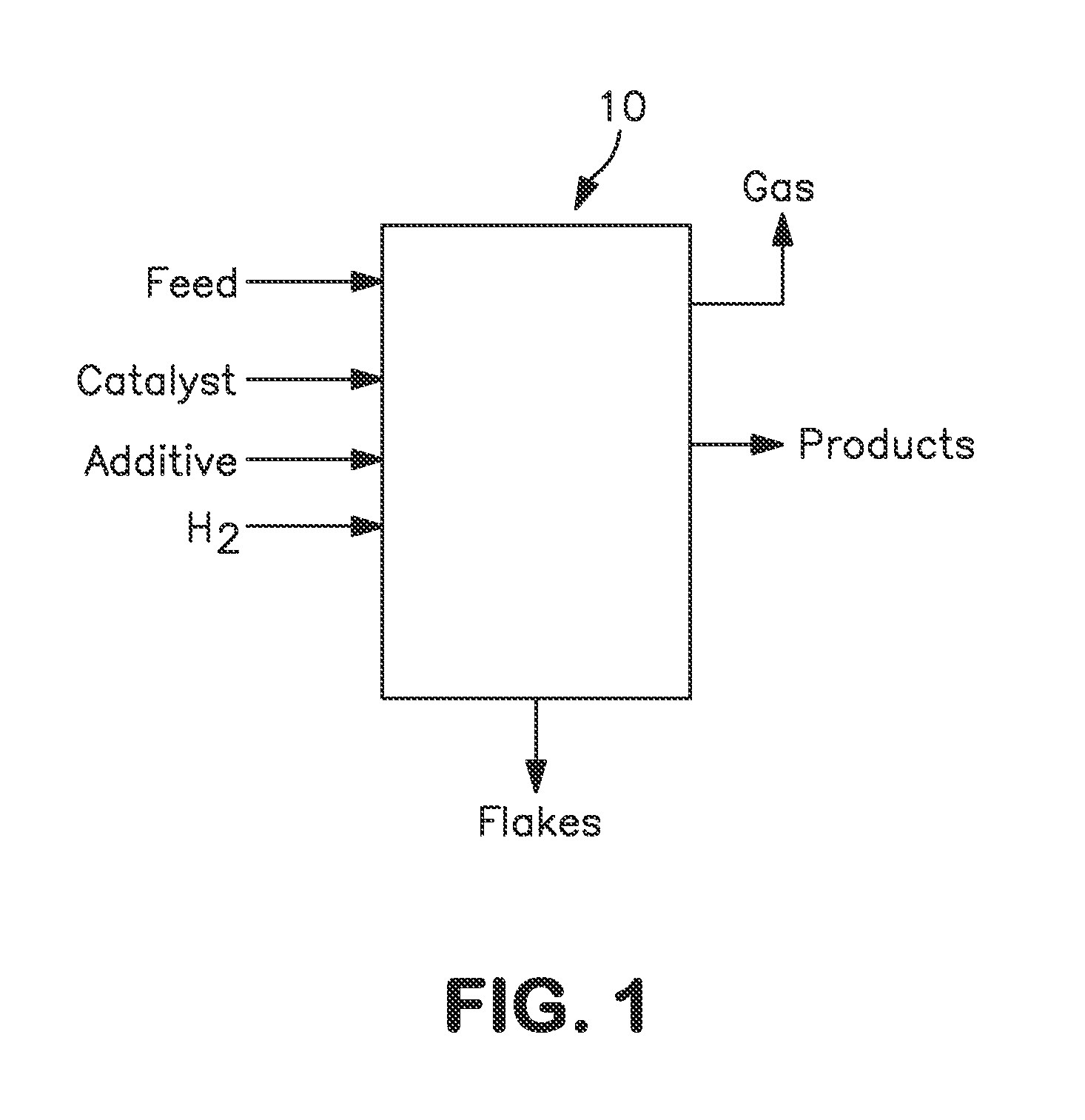

Hydroconversion process for heavy and extra heavy oils and residuals

InactiveUS8679322B2Improve overall fluid-dynamicsEasy temperature controlLiquid organic insulatorsCatalytic naphtha reformingSolid carbonPtru catalyst

A hydroconversion process includes feeding a heavy feedstock containing vanadium and / or nickel, a catalyst emulsion containing at least one group 8-10 metal and at least one group 6 metal, hydrogen and an organic additive to a hydroconversion zone under hydroconversion conditions to produce an upgraded hydrocarbon product and a solid carbonaceous material containing the group 8-10 metal, the group 6 metal, and the vanadium and / or nickel.

Owner:INTREVEP SA

Process for upgrading heavy oil using a highly active slurry catalyst composition

ActiveUS7431823B2Treatment with plural serial cracking stages onlyTreatment with plural parallel cracking stages onlySlurry reactorHydrogen

The instant invention is directed to a new residuum full hydroconversion slurry reactor system that allows the catalyst, unconverted oil and converted oil to circulate in a continuous mixture throughout an entire reactor with no confinement of the mixture. The mixture is partially separated in between the reactors to remove only the products and hydrogen, while permitting the unconverted oil and the slurry catalyst to continue on into the next sequential reactor where a portion of the unconverted oil is converted to lower boiling point hydrocarbons, once again creating a mixture of unconverted oil, converted oil, and slurry catalyst. Further hydroprocessing may occur in additional reactors, fully converting the oil. The oil may alternately be partially converted, leaving a highly concentrated catalyst in unconverted oil which can be recycled directly to the first reactor.

Owner:CHEVROU USA INC

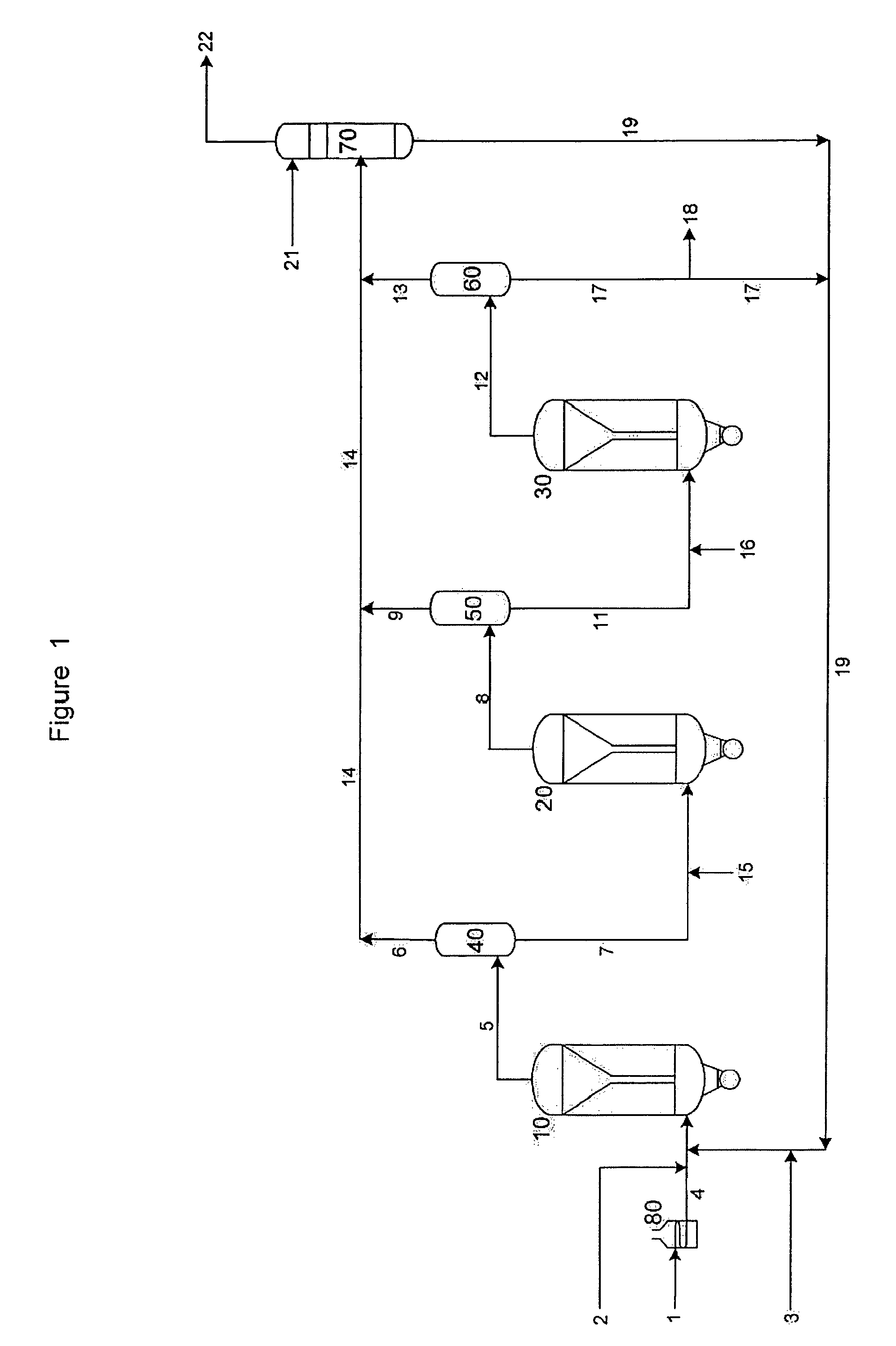

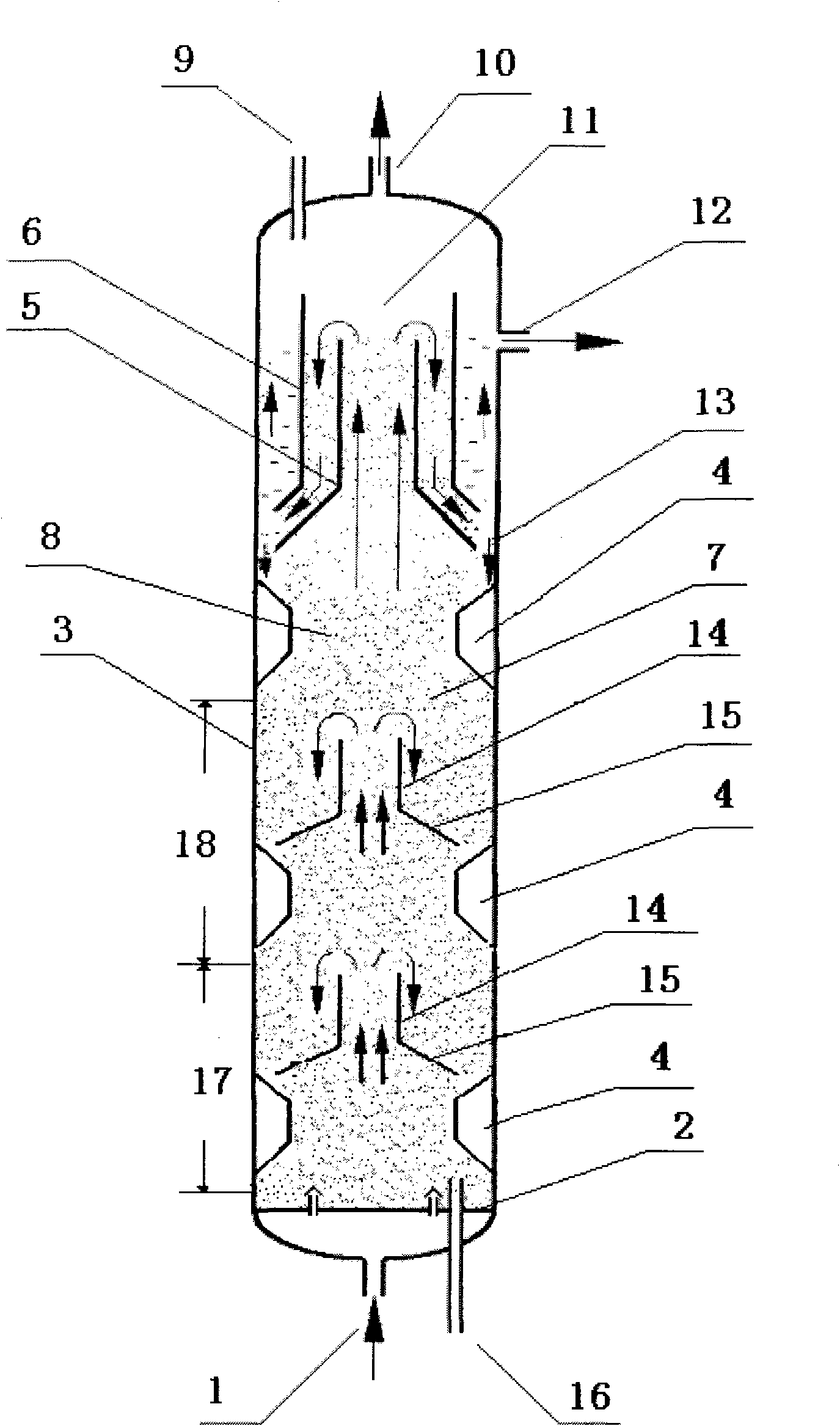

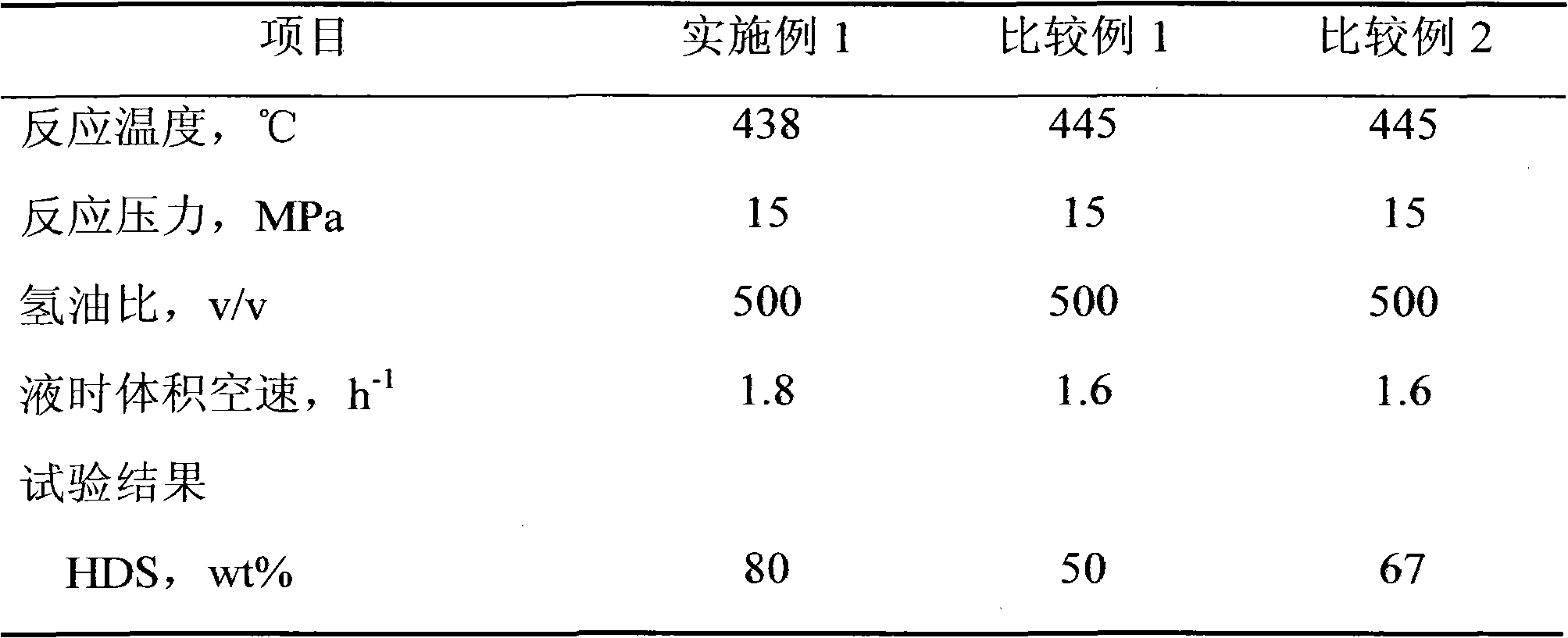

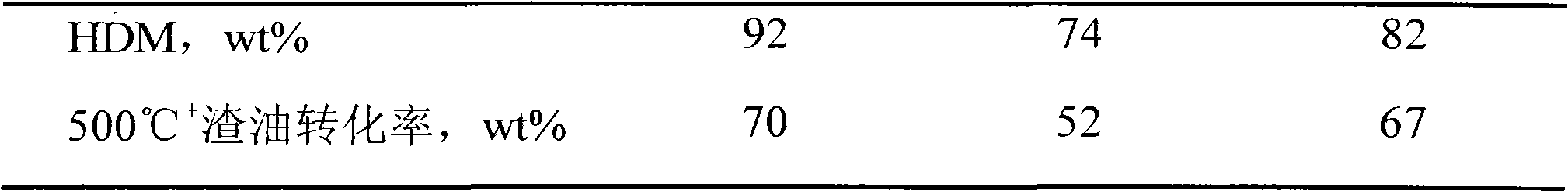

Catalyst-graded fluidized bed hydrogenation process

ActiveCN102311763AReduce usageLarge voids between particlesHydrocarbon oil crackingHydrocarbon oils refiningFluidized bedHydrogenation process

The invention discloses a catalyst-graded fluidized bed hydrogenation process. In the method, a hydrocarbon raw material and hydrogen are mixed and introduced into a fluidized bed reactor from the bottom of the fluidized bed reactor to react under hydrogen treatment condition, the fluidized bed reactor comprises two or more than two internal circulation regions, the particle sizes of the catalyst used in different internal circulation region gradually reduce according to the sequence of the contact between the hydrocarbon raw material and the catalyst, and the reduction range is 0.01 to 1 millimeter. In the invention, the plurality of internal circulation regions are arranged in the fluidized bed reactor to form a plurality of boiling operation intervals, so the operation of the whole fluidized bed reactor is more flexible; meanwhile, catalysts of different particle sizes and different activities are used in different internal circulation regions, the reasonable matching of the property of a reaction material flow and the performance of the catalysts can be realized, the activity of the catalysts can be fully placed, the yield of light oil can be increased, and the product quality can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Popular searches

Metal/metal-oxides/metal-hydroxide catalysts Hydrocarbons Drying peat Hydrocarbon preparation Refining by selective hydrogenation Chemical/physical processes Refining by aromatic hydrocarbon hydrogenation Refining to eliminate hetero atoms Group 8/9/10/18 element organic compounds Thin material handling

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com