Moving Bed Hydrocarbon Conversion Process

a hydrocarbon conversion and moving bed technology, applied in the direction of catalytic naphtha reforming, chemistry apparatus and processes, treatment with moving solid particles, etc., can solve the problems of physical damage to the particles as well as the equipment, insufficient pneumatic conveying system alone, and sporadic upsets, so as to eliminate unexpected and unpredictable upsets, the particle transfer system is more stable, and the damage to the particles and/or the equipment is small or no

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

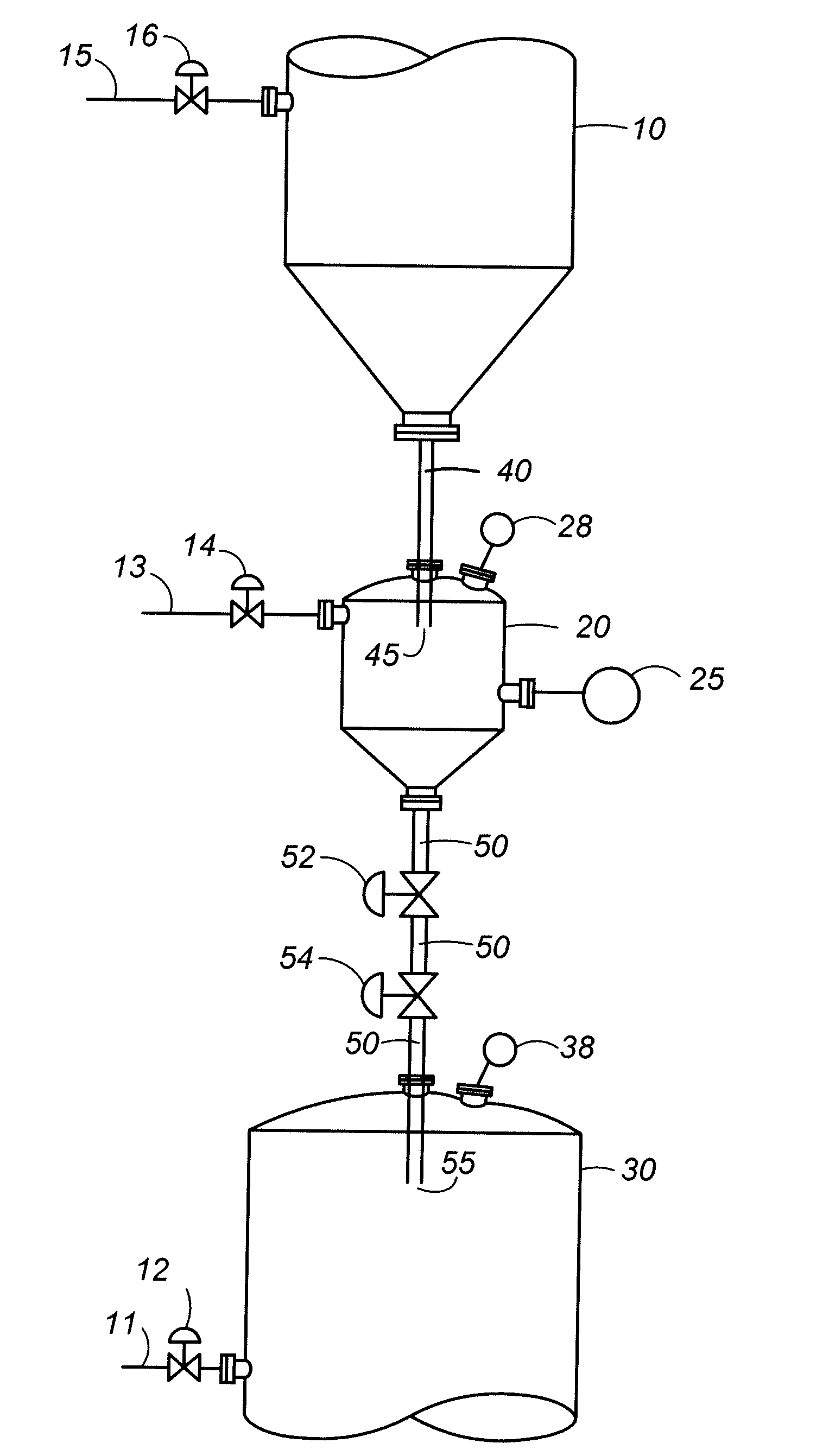

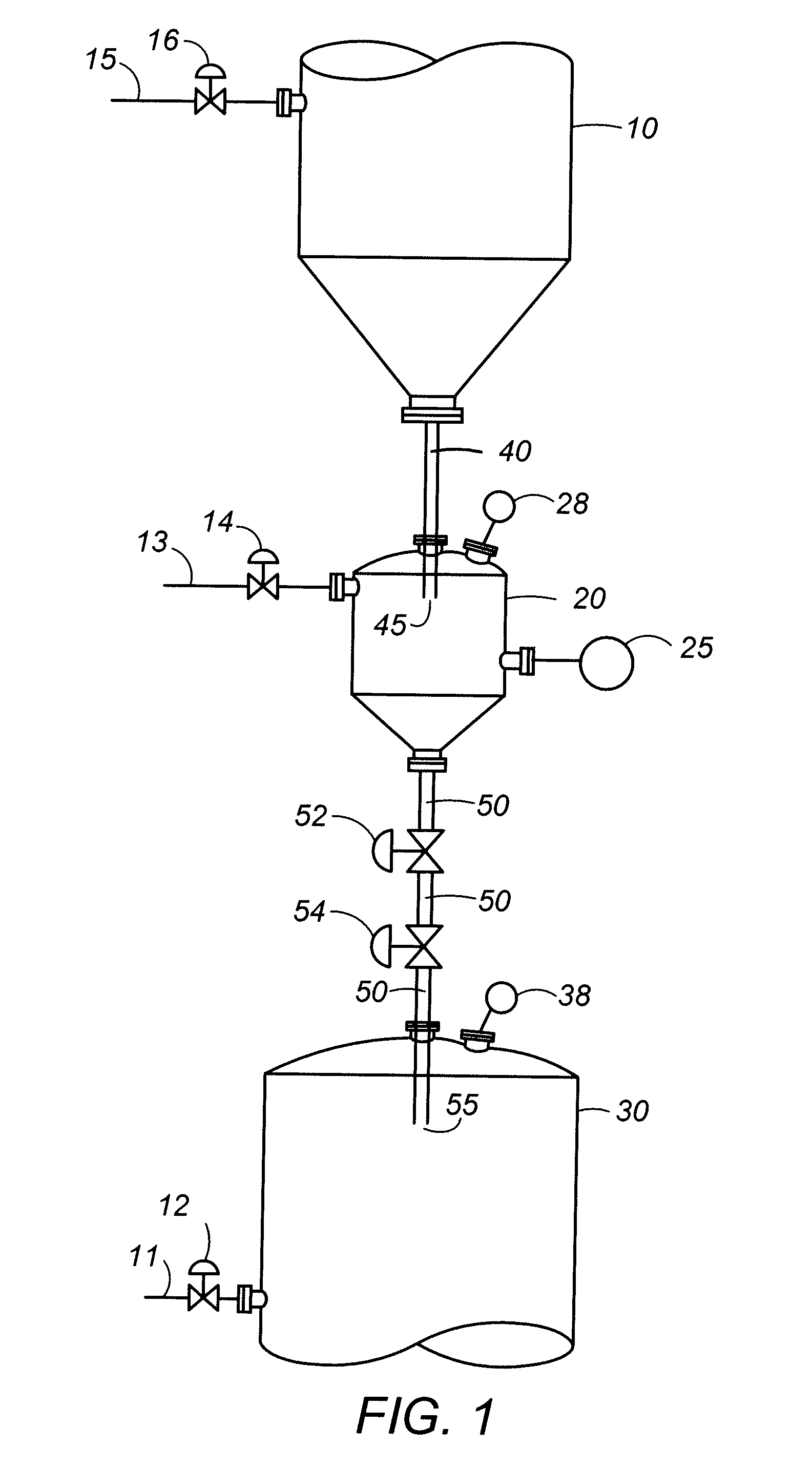

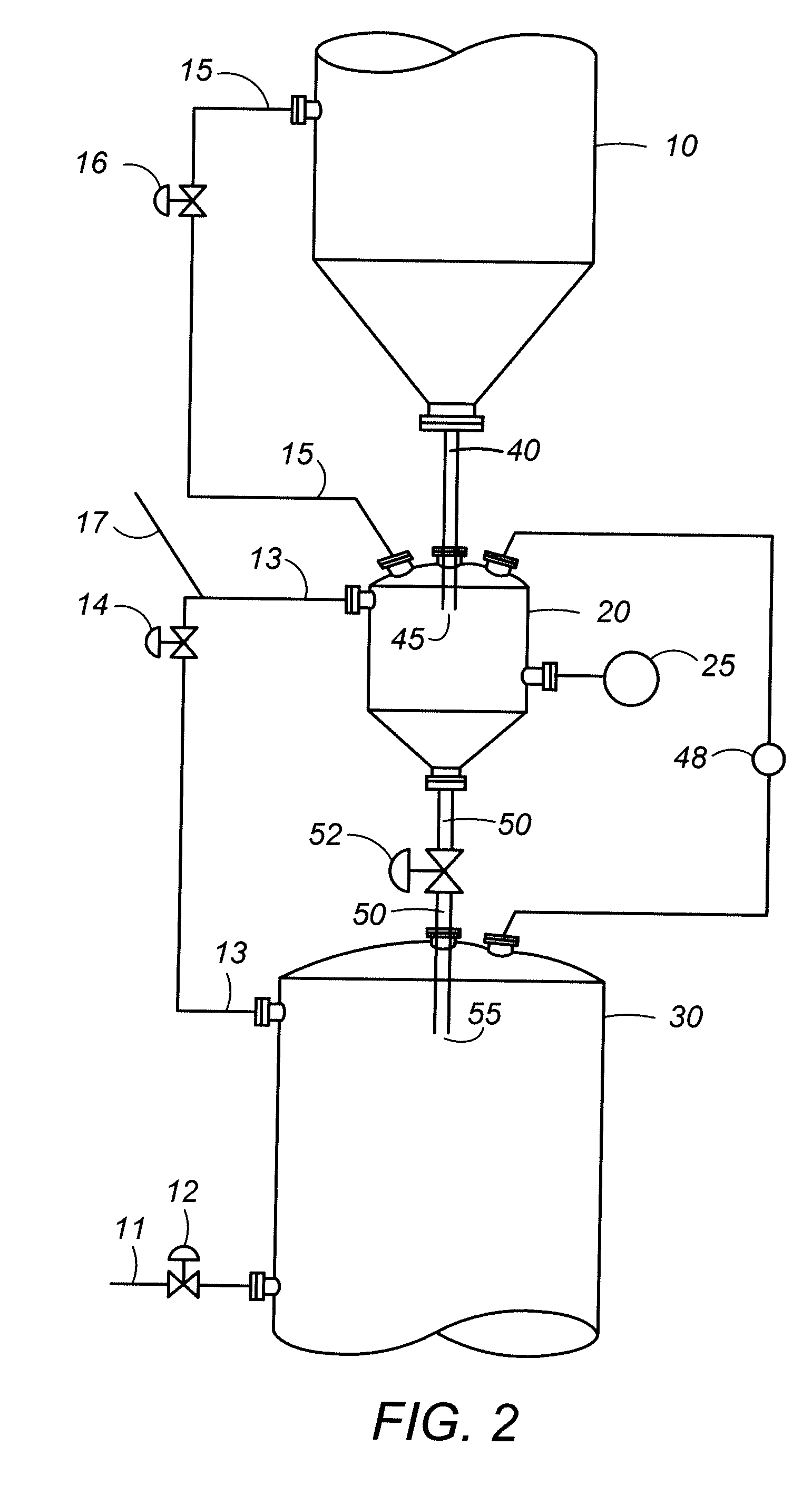

[0018]The invention may be used to transfer solid particulate matter from an upper zone, through a middle zone, to a lower zone where the lower zone pressure is greater than the upper zone pressure. Generally, particles received in an upper zone are transferred through an upper valveless standpipe or transfer conduit to a middle zone. That is, the upper transfer conduit does not include moving equipment such as valves which would block the particle flow path to the middle zone. A lower valved standpipe or transfer conduit is used to transfer the particles from the middle zone to a lower zone. That is, the lower transfer conduit comprises at least one valve. Thus, the zones and transfer conduits may be in particle communication and the transfer conduits may provide particle communication.

[0019]The invention can be used within and / or between a variety of process units to transfer particles, such as catalyst and adsorbents. The upper zone of the invention may receive particles from a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com