Patents

Literature

66 results about "Particle transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Transfer of particles is defined as a process of particle motion over macroscopic distances from the bulk of suspensions in the immediate vicinity of interfaces (often called collectors). This process is a necessary but not sufficient condition of particle deposition and adhesion at interfaces.

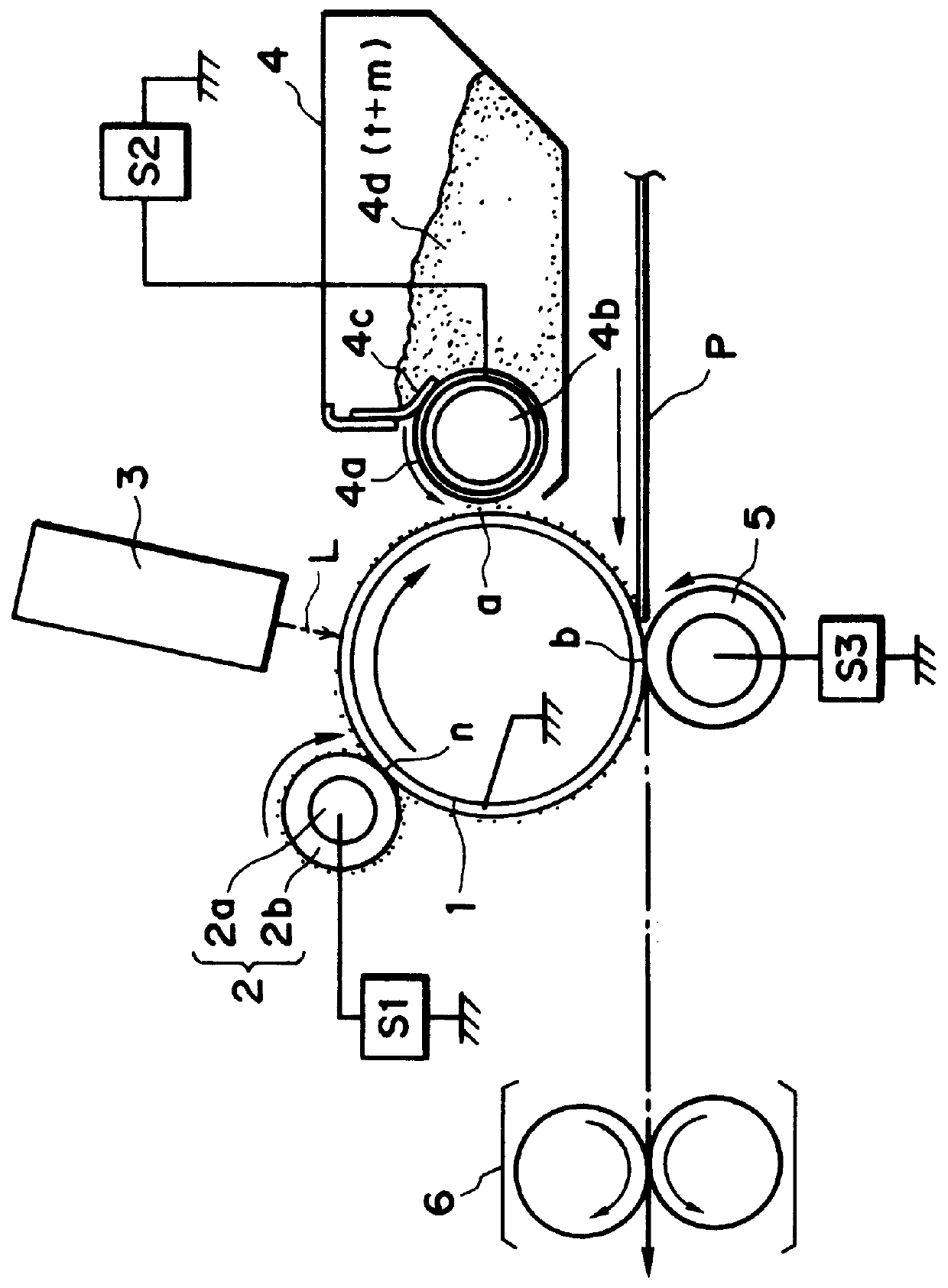

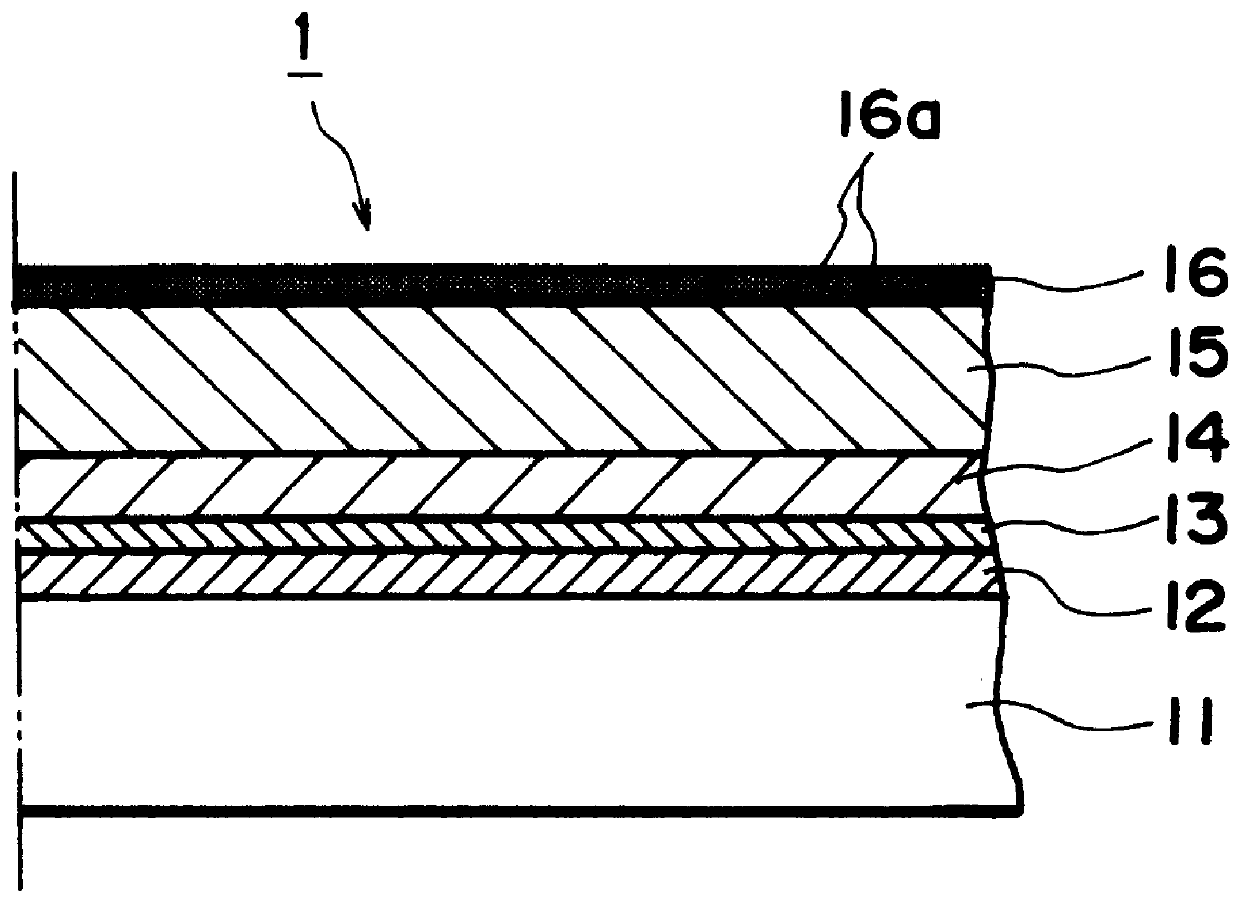

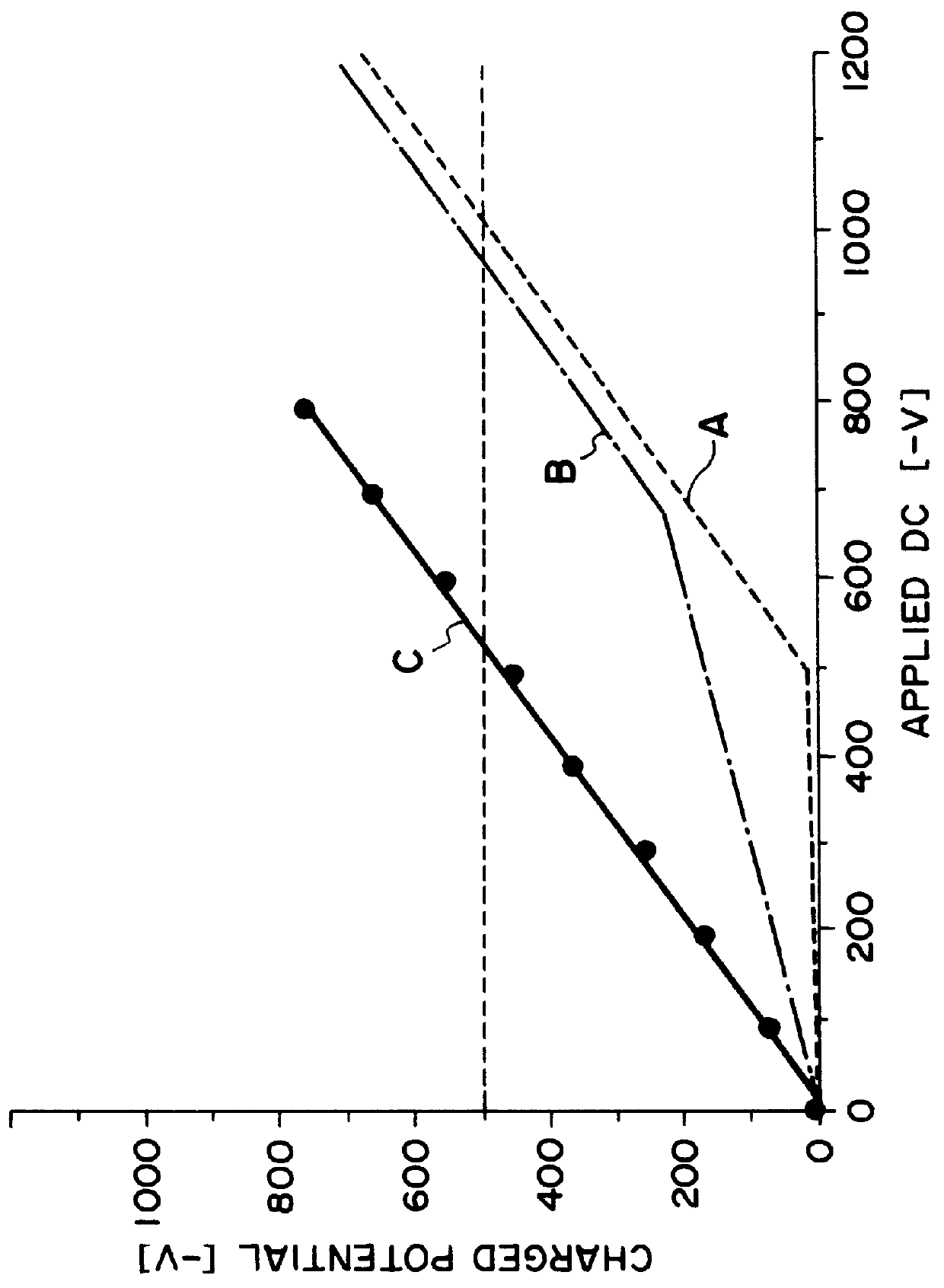

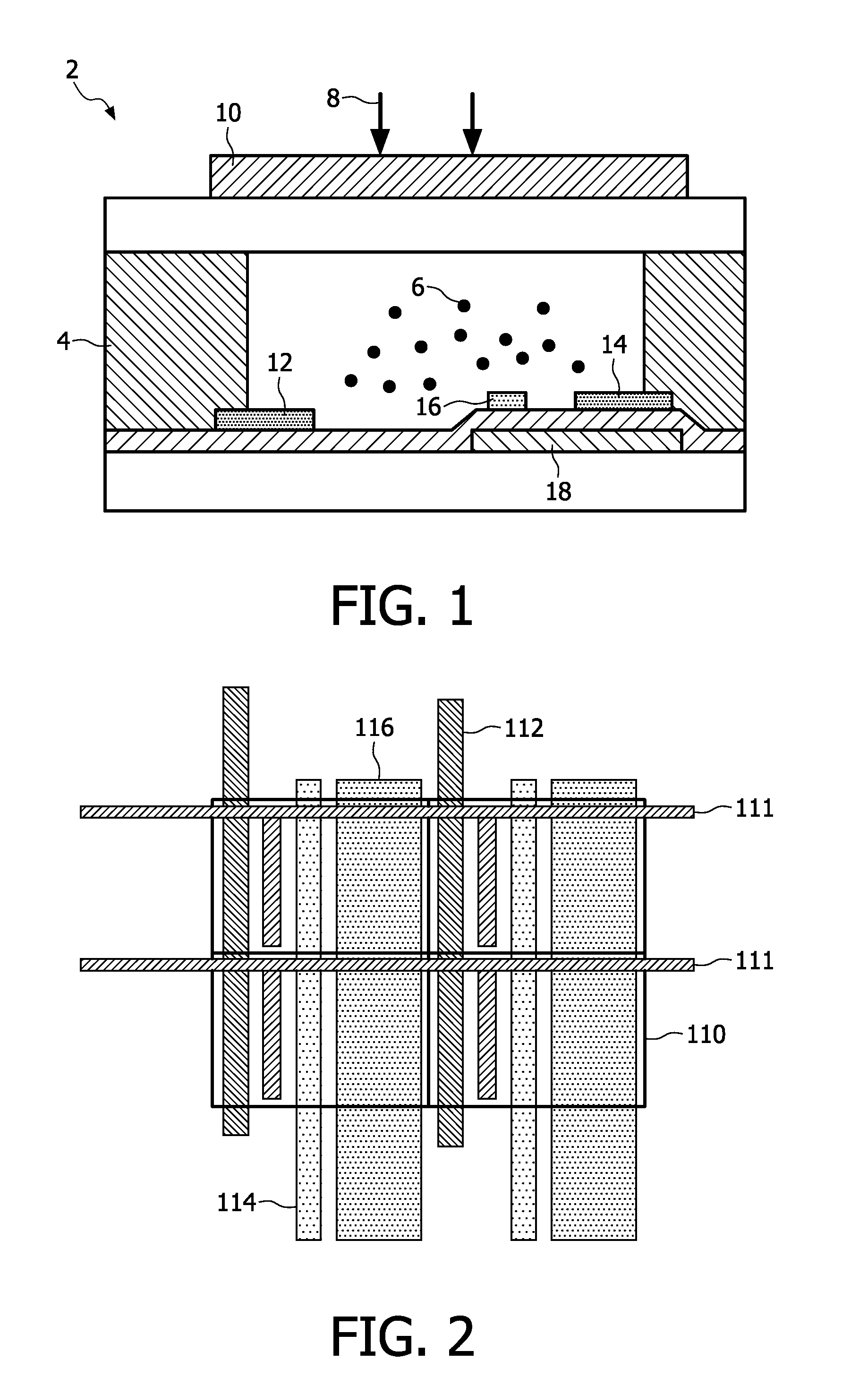

Image forming apparatus having a charging member applying an electric charge through electrically conductive or electroconductive particles to the surface of a photosensitive or image bearing member

An image forming apparatus includes an image bearing member with a recirculatively movable peripheral surface; and a device for forming electrostatic latent images on the peripheral surface of the image bearing member, the device including a charging member to which voltage is applicable to charge the image bearing member. The charging member includes a flexible member capable of forming a nip between itself and the image bearing member; a developer for developing the latent image with the use of developer composed of toner particles and electrically conductive particles. The developer is capable of cleaning the residual toner particles from the image bearing member. The electrically conductive particles transferred onto the image bearing member by the developer are delivered to the nip by the image bearing member. The flexible member is moved so that it maintains a peripheral velocity difference relative to the image bearing member.

Owner:CANON KK

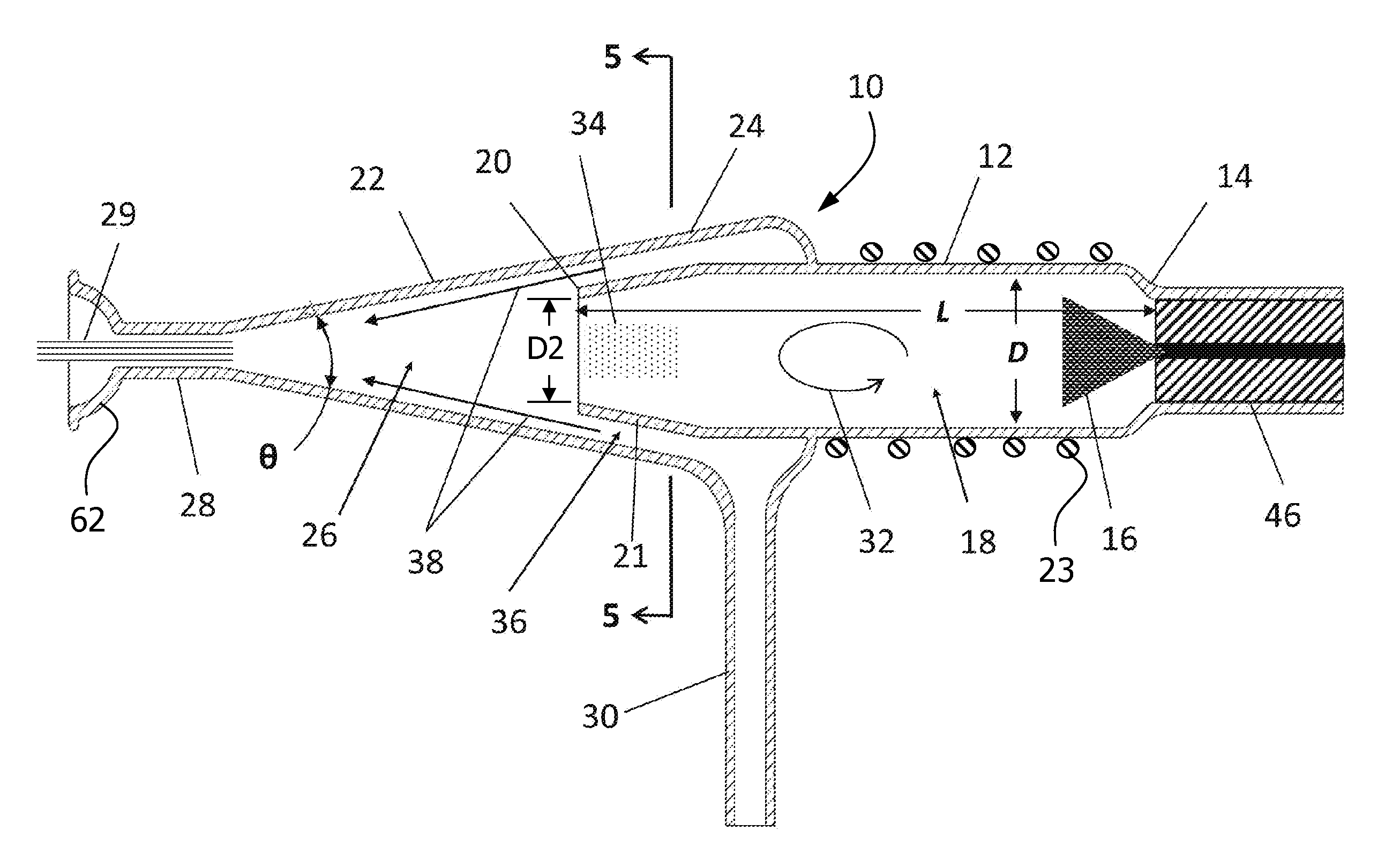

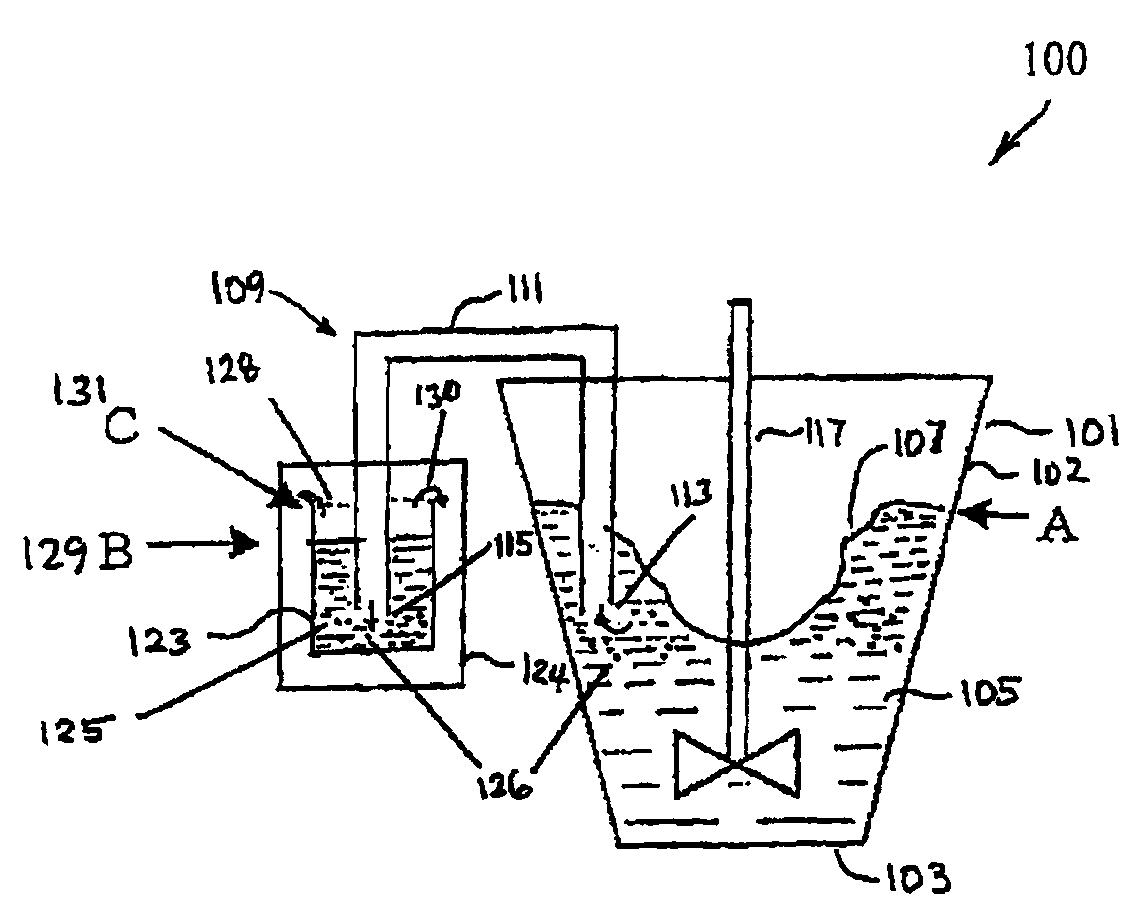

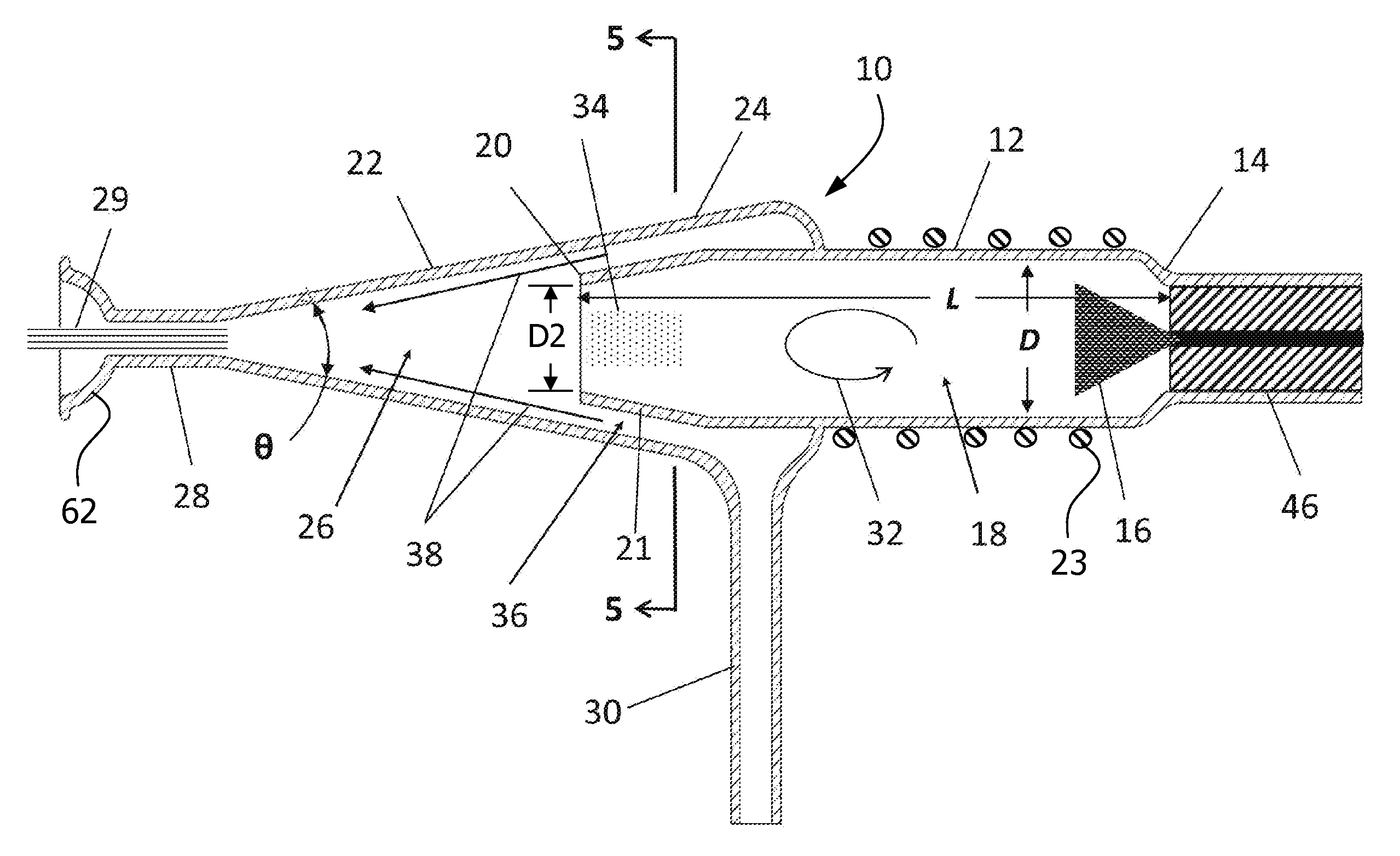

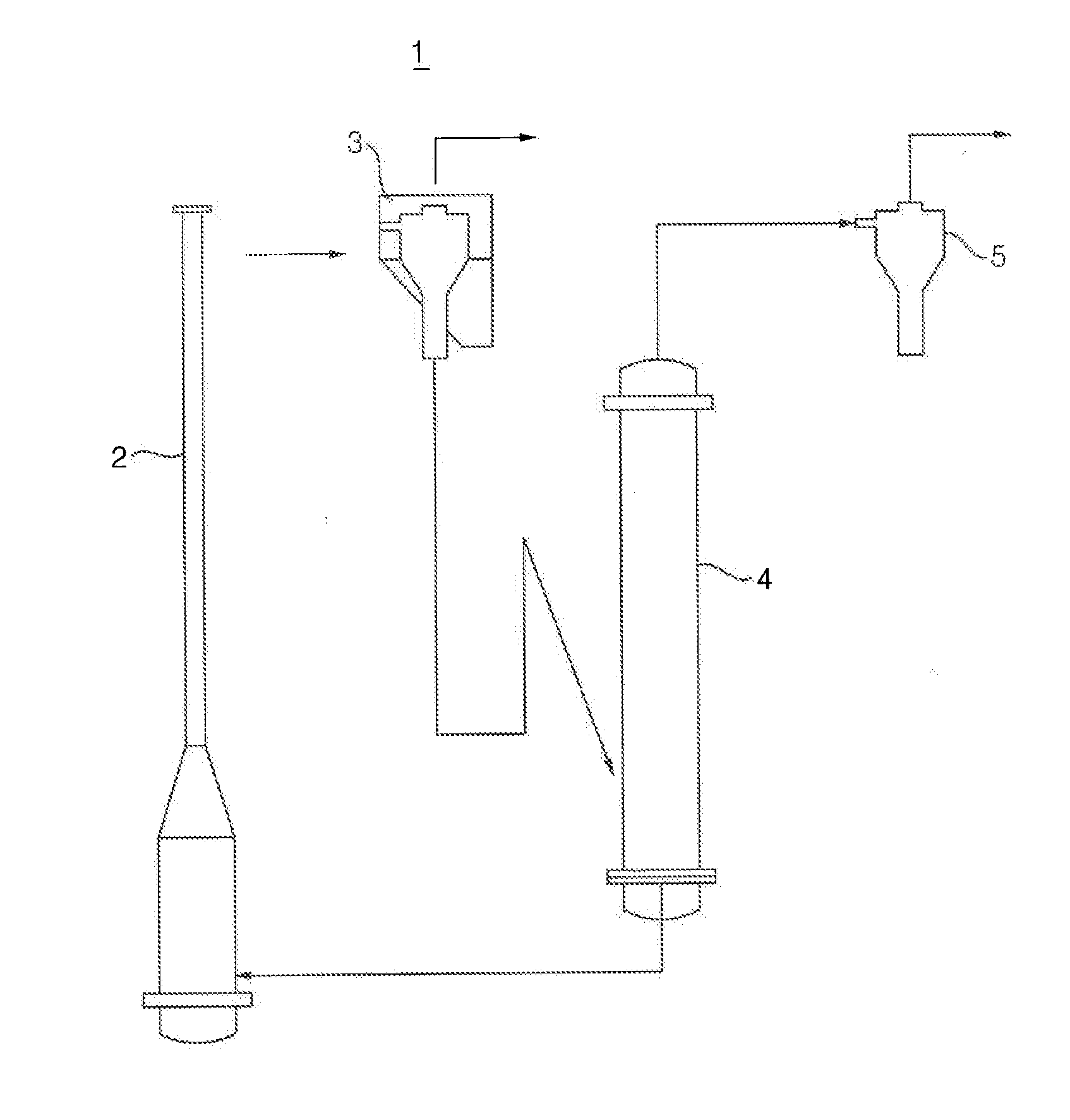

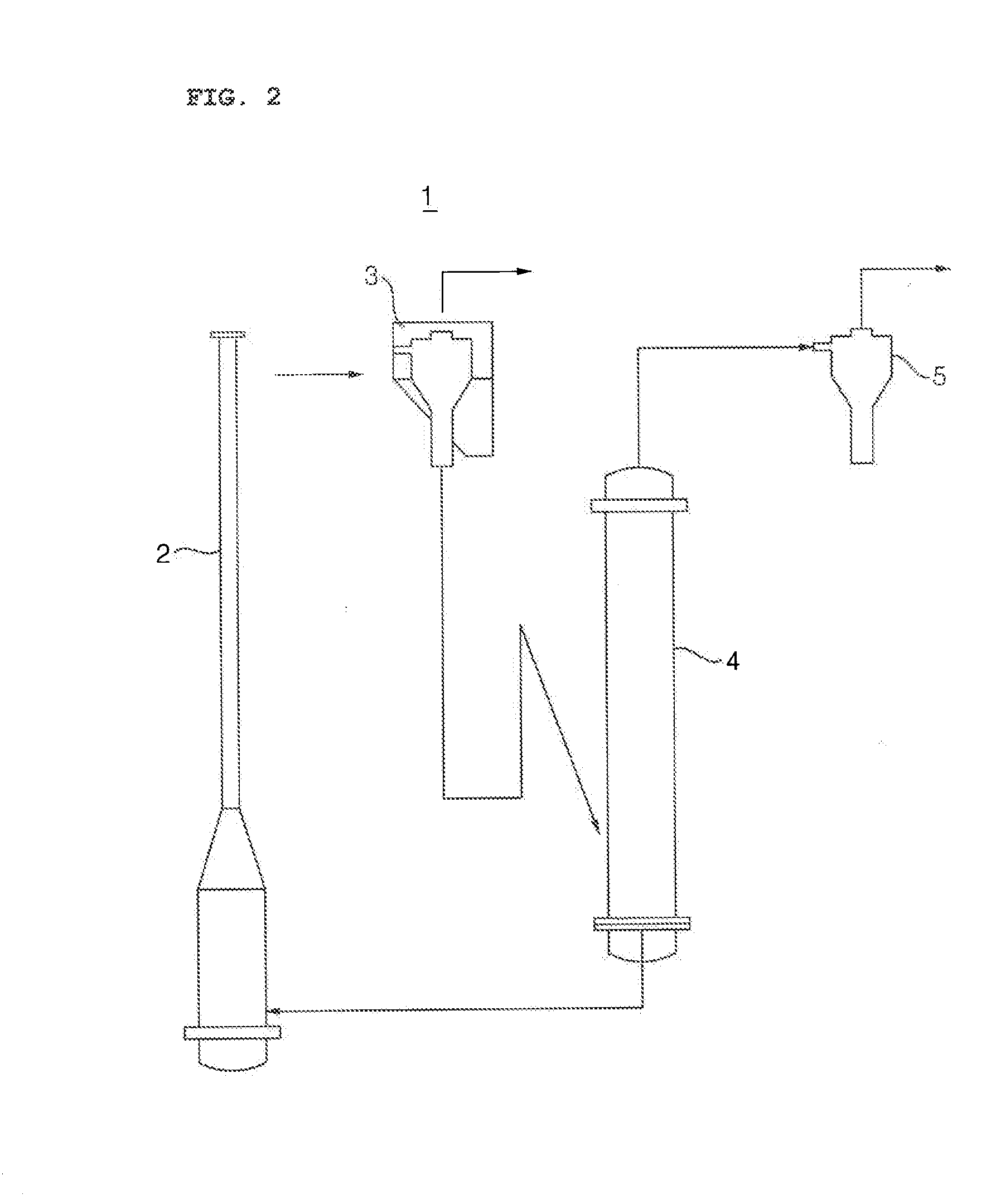

Sample Transferring Apparatus for Mass Cytometry

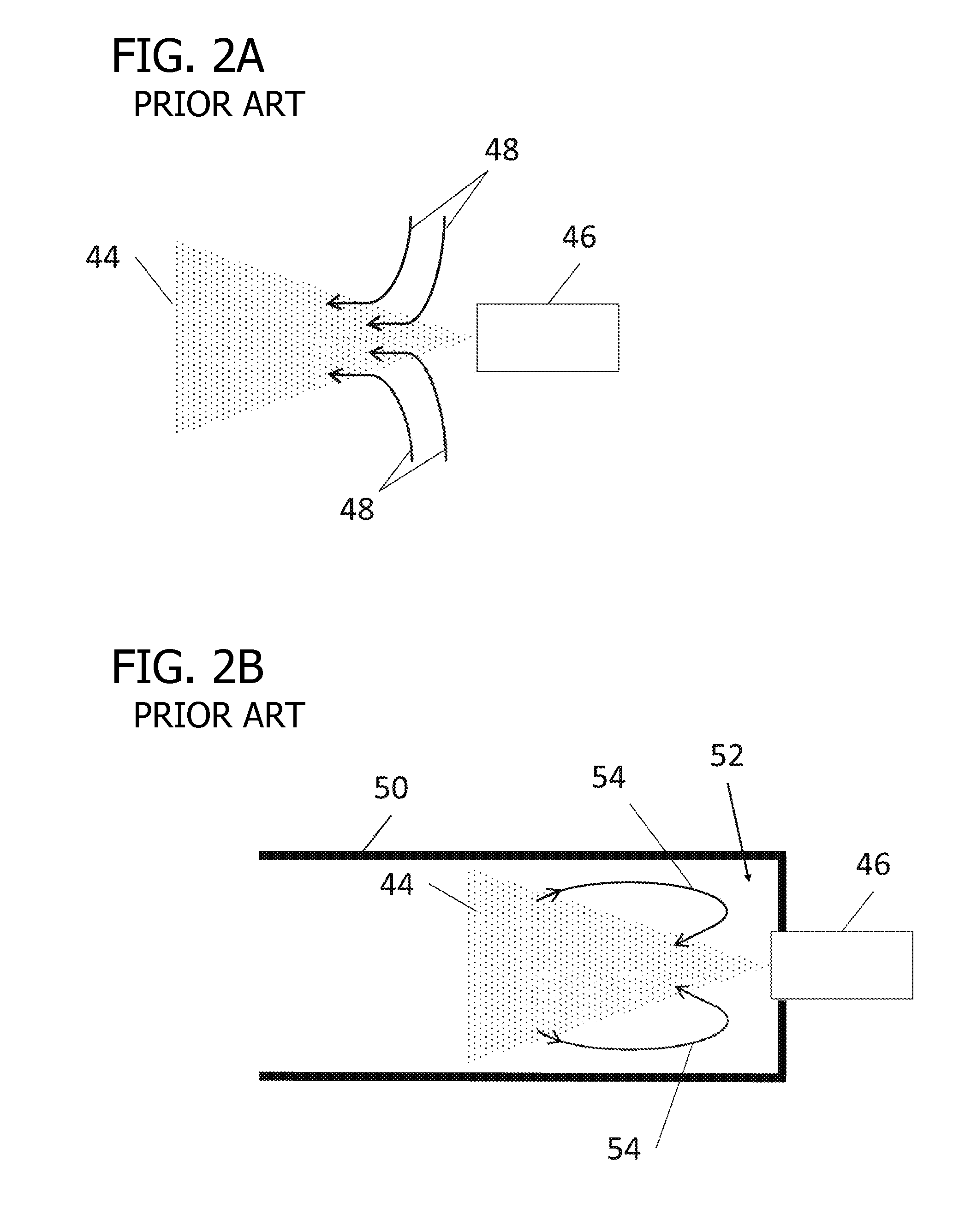

In a mass cytometer or mass spectrometer, a sample of elemental tagged particles is transferred from a dispersion to a gas flow through a carrier aerosol spray for atomization and ionization by inductively coupled plasma (ICP) source. The configuration of the sample transfer apparatus allow for total consumption of the sample by passing the sample spray through a deceleration stage to decelerate the spray of particles from its high velocity expansion. Following the deceleration stage, the decelerated sample of particles can be accelerated and focused through an acceleration stage for transferring into the ICP. This effectively improves the particle transfer between the sample spray and the ICP.

Owner:STANDARD BIOTOOLS CANADA INC

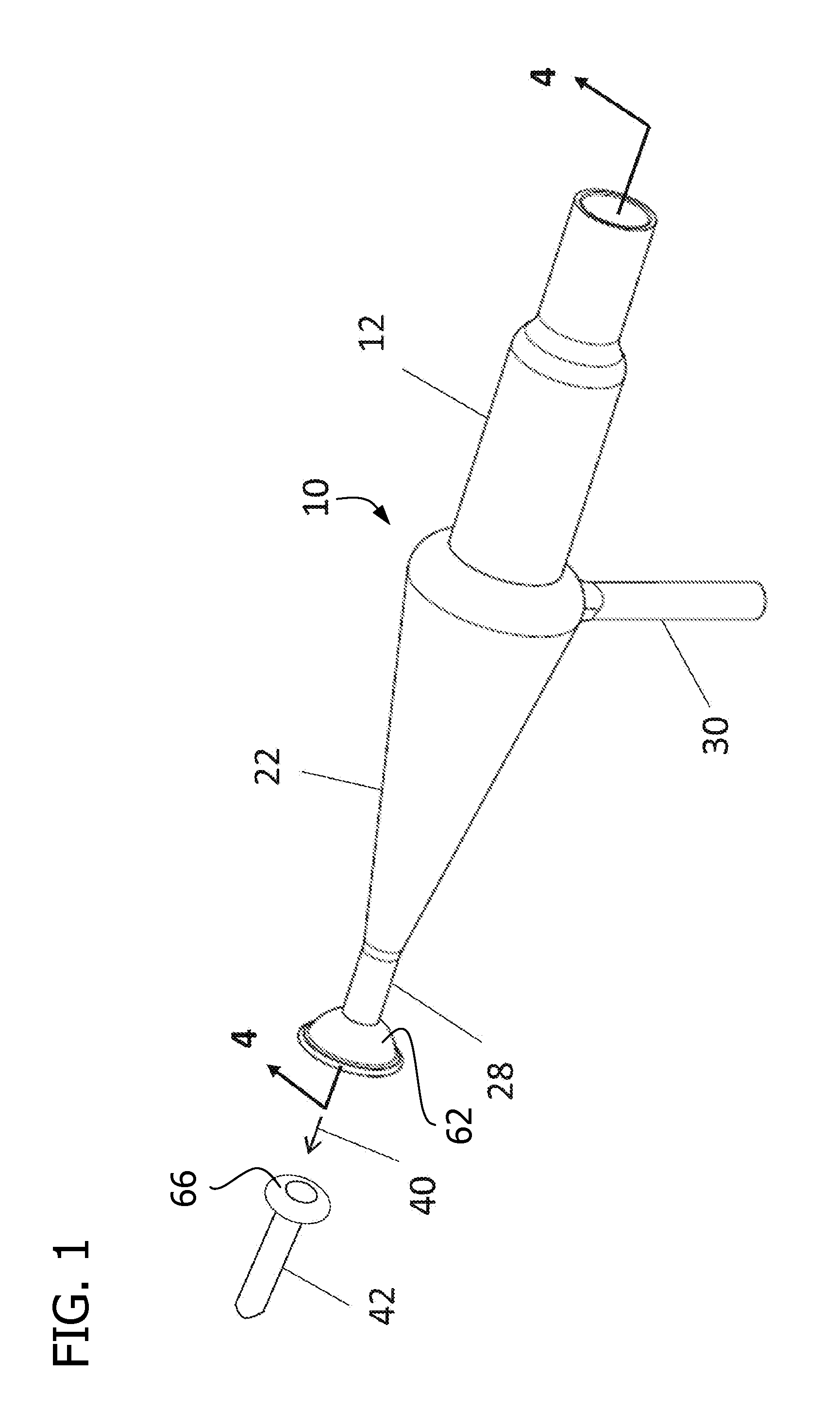

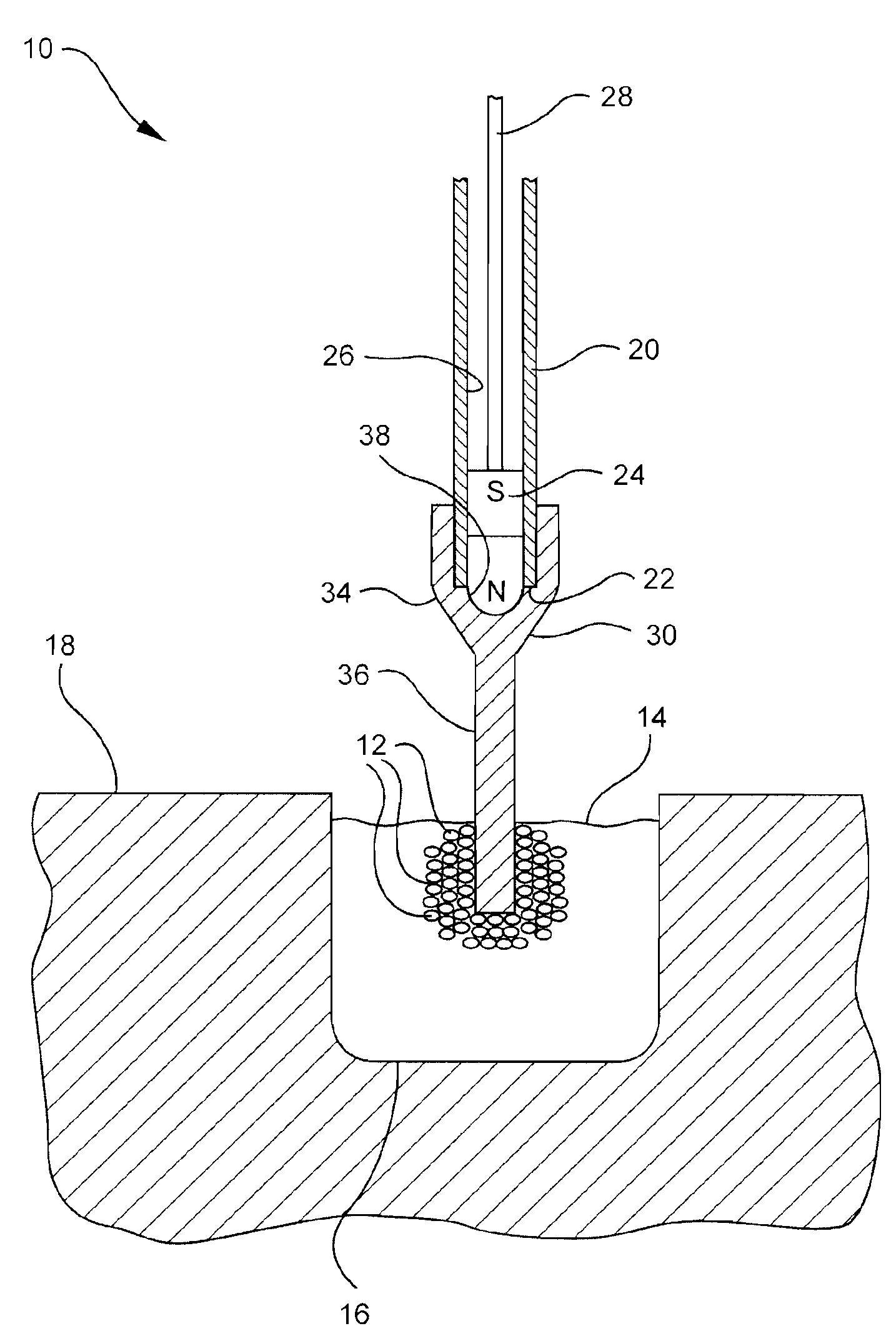

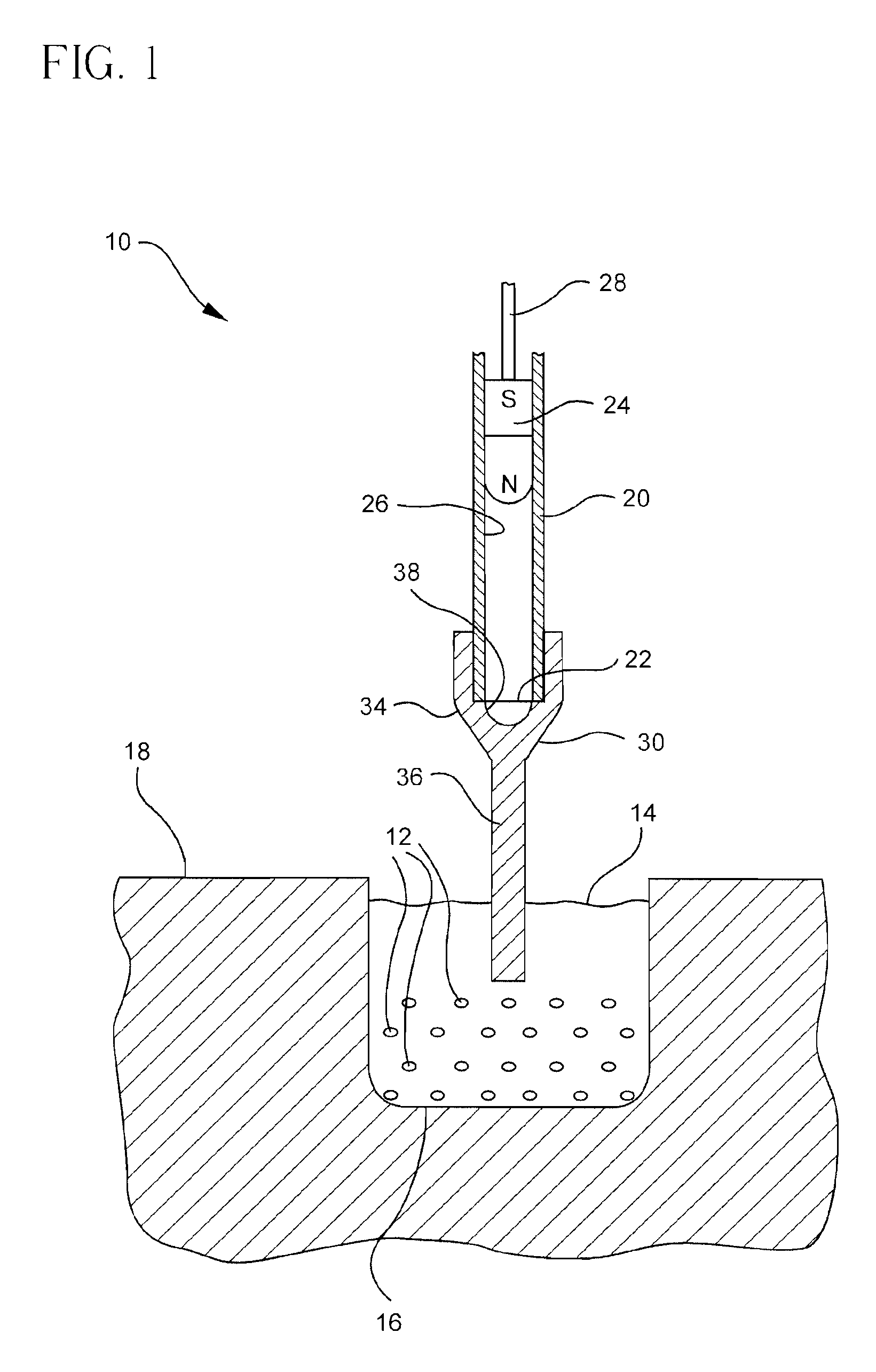

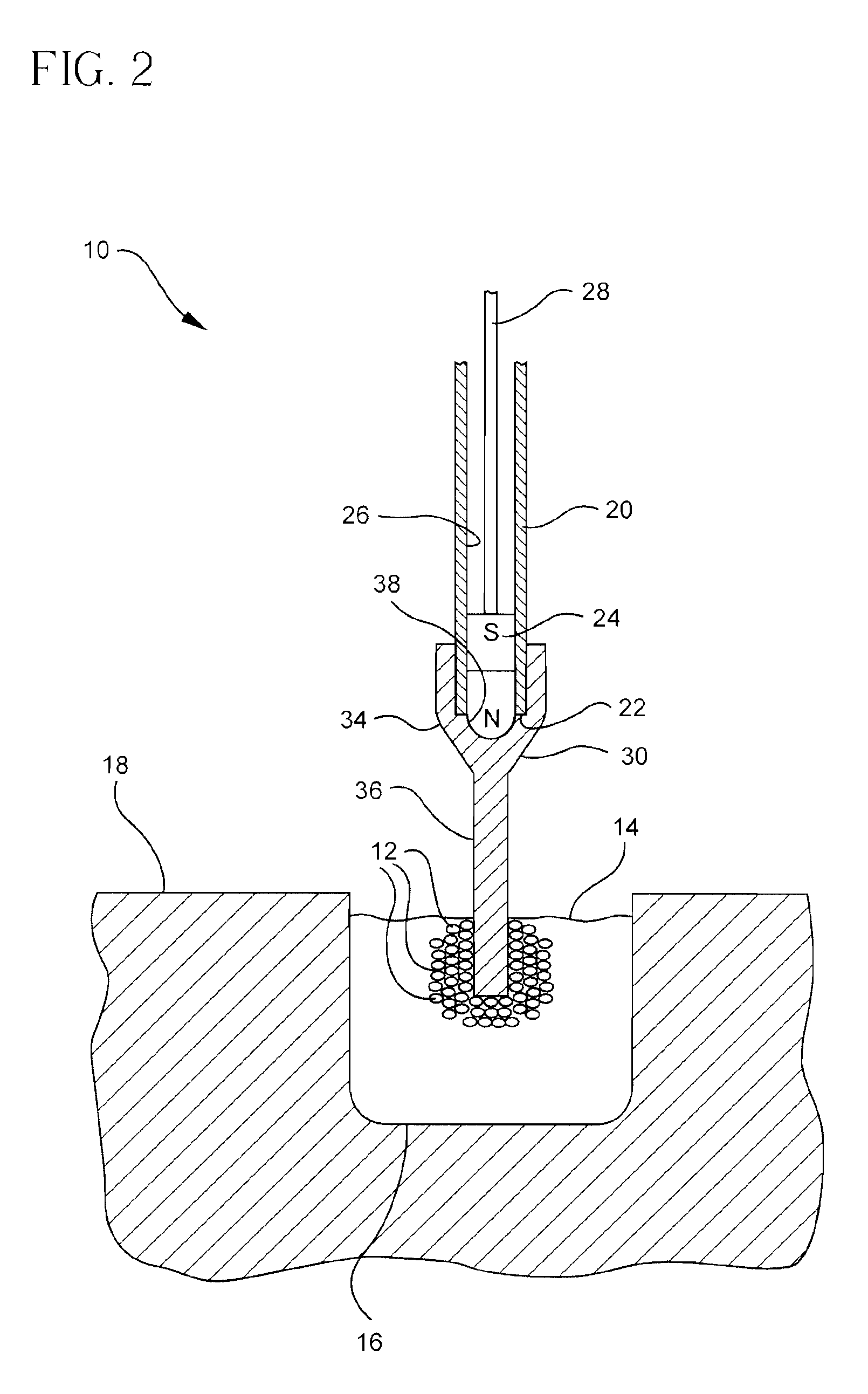

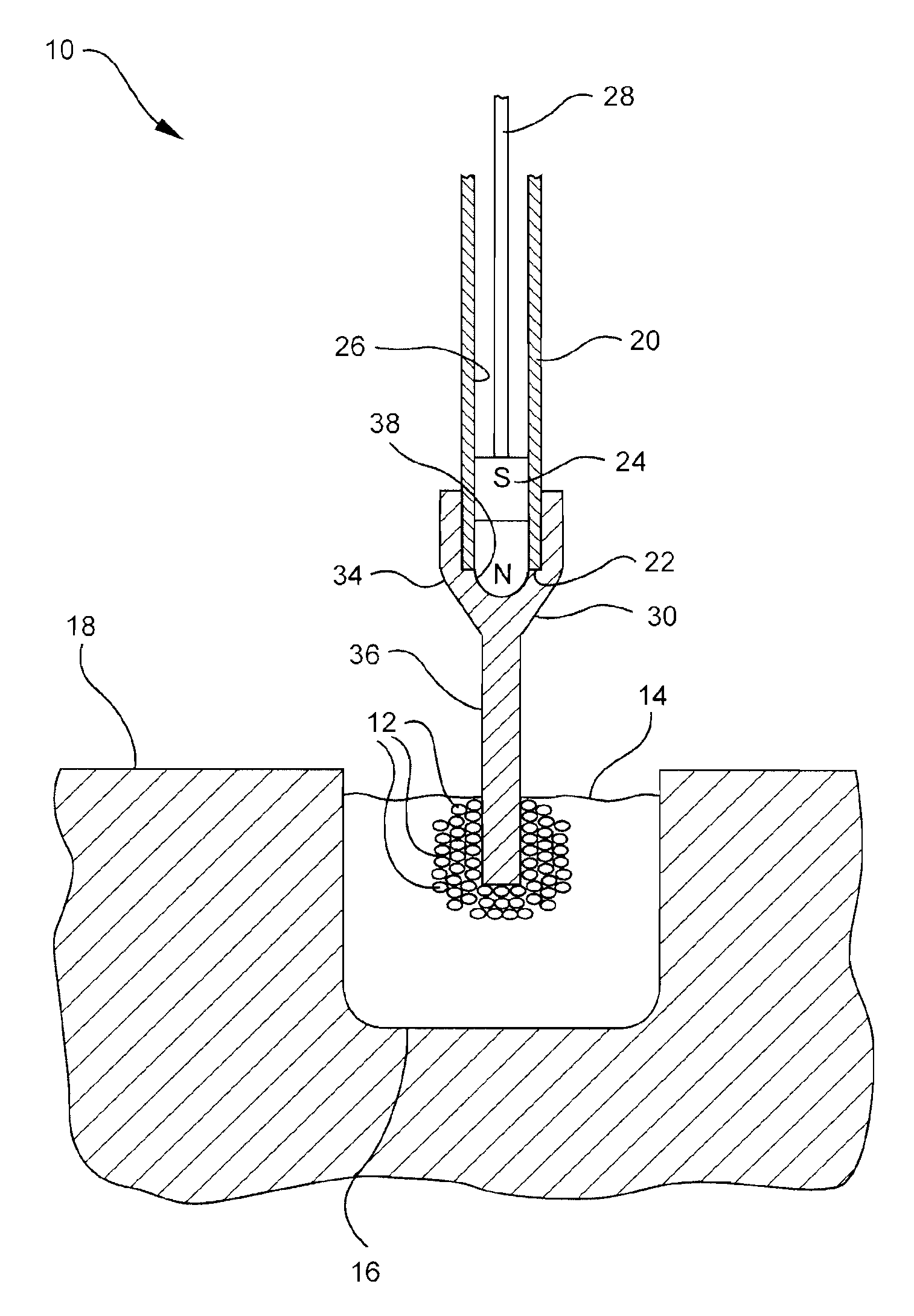

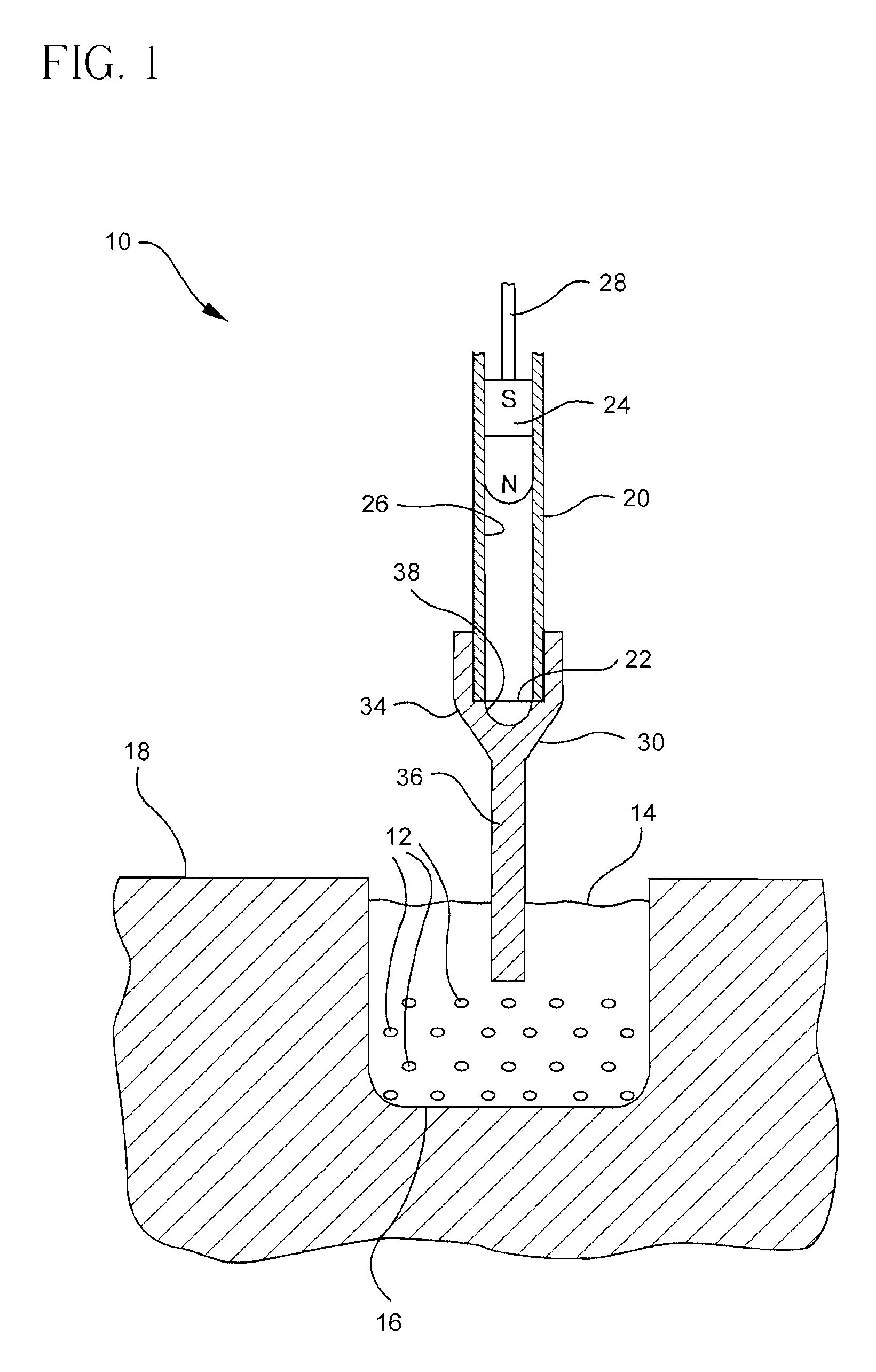

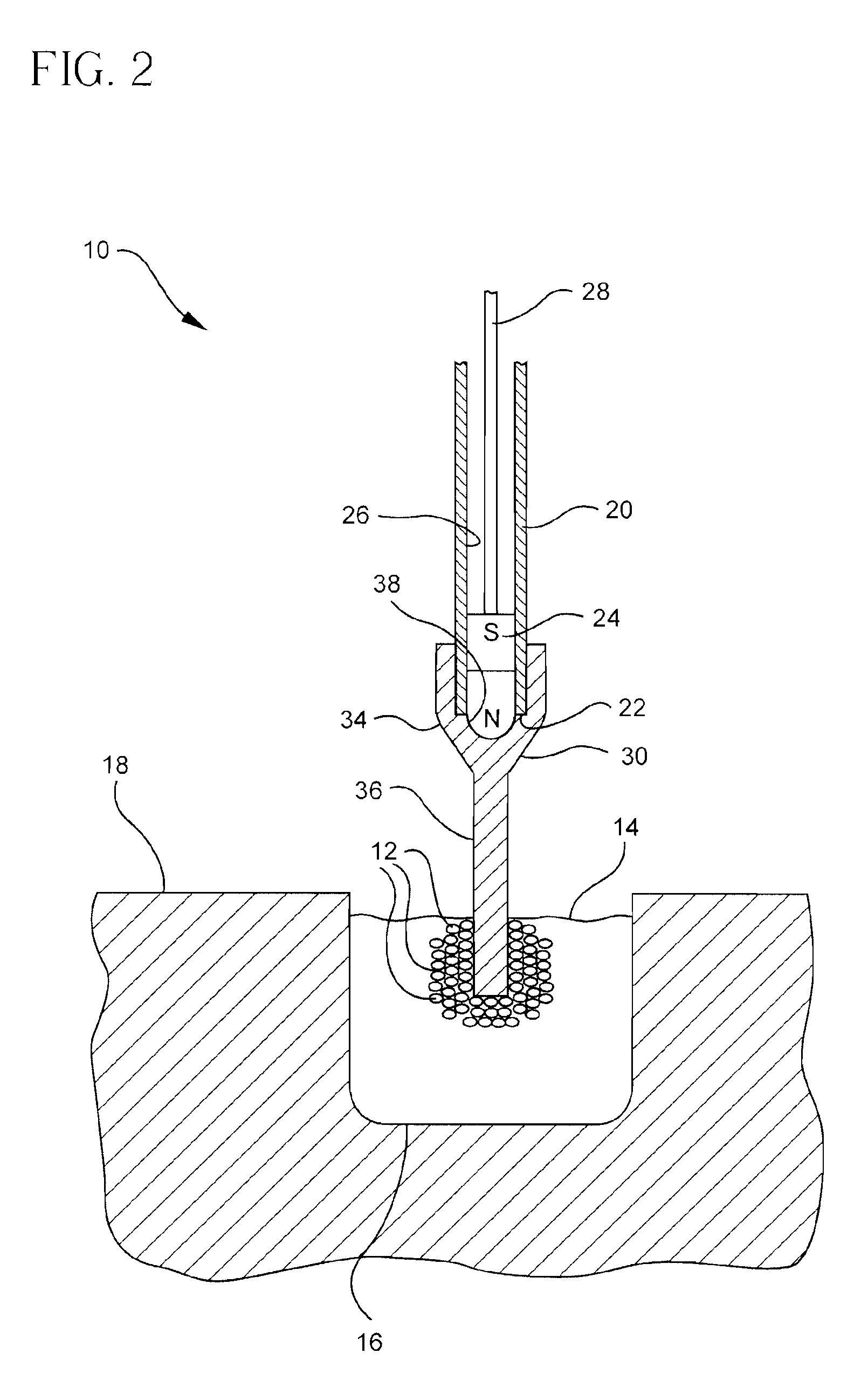

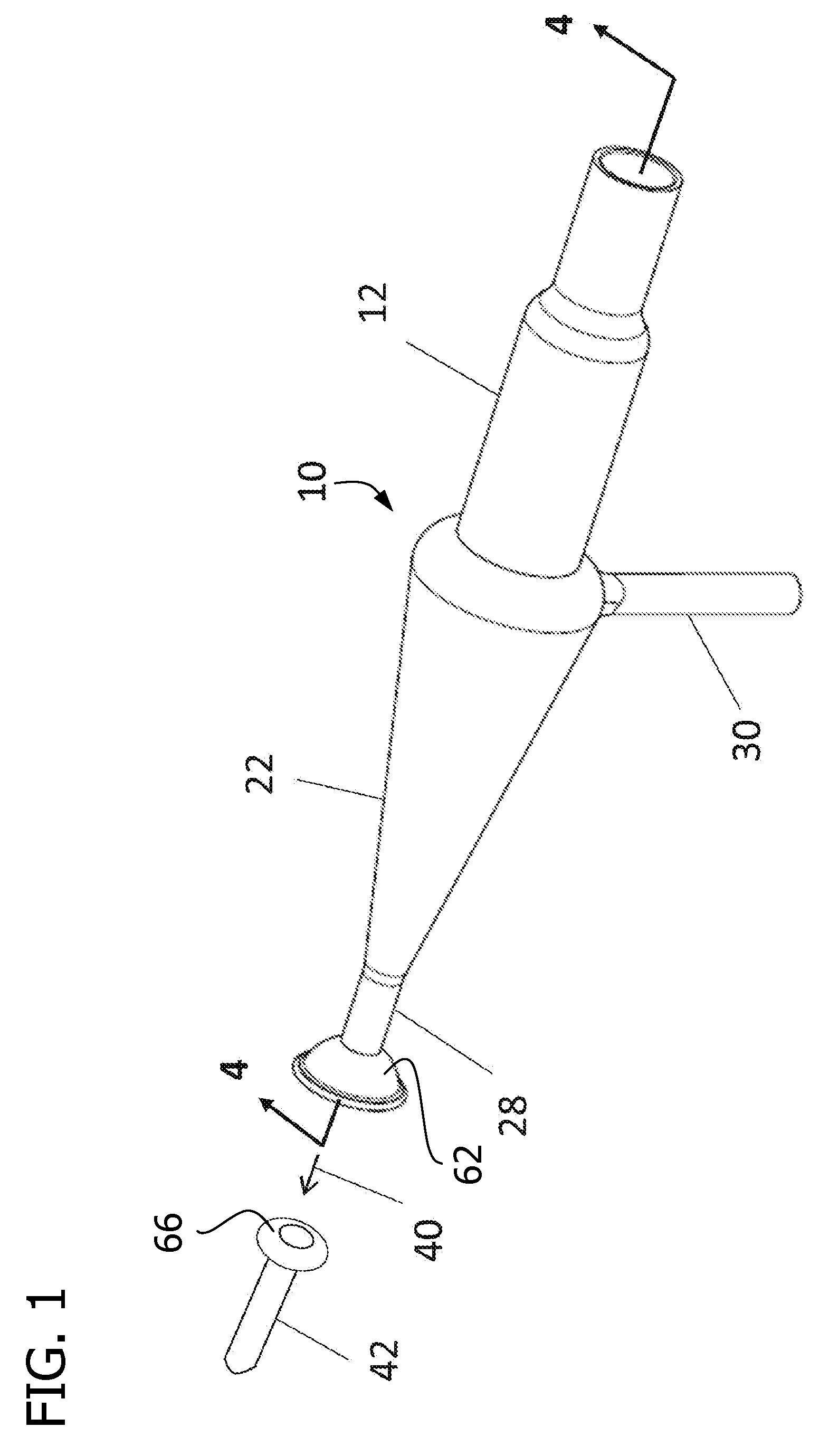

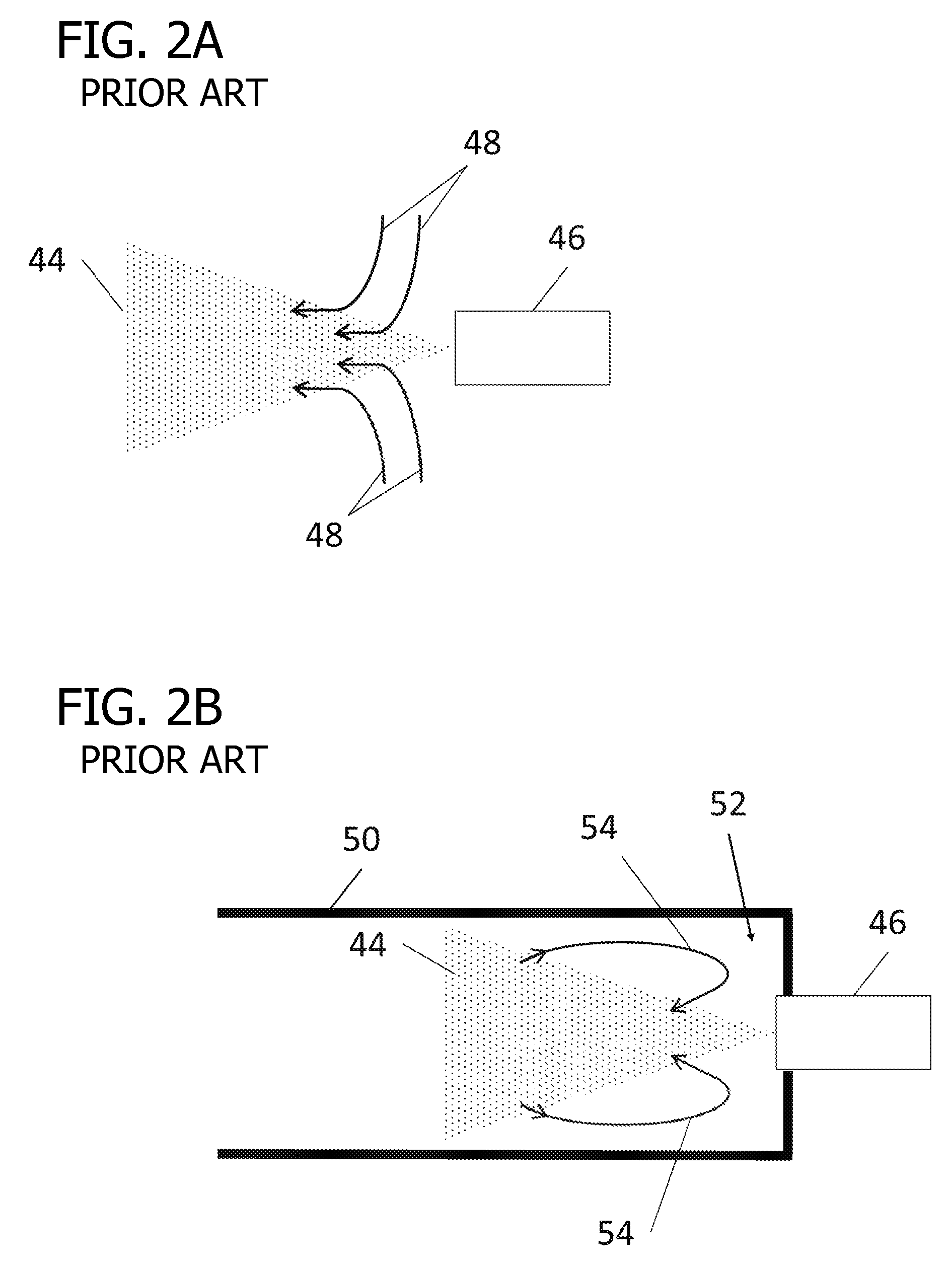

Flux concentrator for biomagnetic particle transfer device

InactiveUS7799281B2Analysis using chemical indicatorsWithdrawing sample devicesParticle transferBiomagnetism

A tip for a biomagnetic particle transfer device generally includes a solid body made from a highly magnetically permeable material and having a shape adapted to concentrate a magnetic field generated by the transfer device on the body. The tip body preferably includes a truncated cone-shaped portion and a solid probe portion. The cone-shaped portion defines an attachment end engageable with an end of the transfer device and an apex opposite the attachment end. The probe portion extends from the apex of the cone-shaped portion, and the magnetic field is concentrated on the probe portion.

Owner:FESTO CORPORATION

Flux Concentrator for Biomagnetic Particle Transfer Device

InactiveUS20080170966A1Analysis using chemical indicatorsWithdrawing sample devicesParticle transferBiomagnetism

A tip for a biomagnetic particle transfer device generally includes a solid body made from a highly magnetically permeable material and having a shape adapted to concentrate a magnetic field generated by the transfer device on the body. The tip body preferably includes a truncated cone-shaped portion and a solid probe portion. The cone-shaped portion defines an attachment end engageable with an end of the transfer device and an apex opposite the attachment end. The probe portion extends from the apex of the cone-shaped portion, and the magnetic field is concentrated on the probe portion.

Owner:FESTO CORPORATION

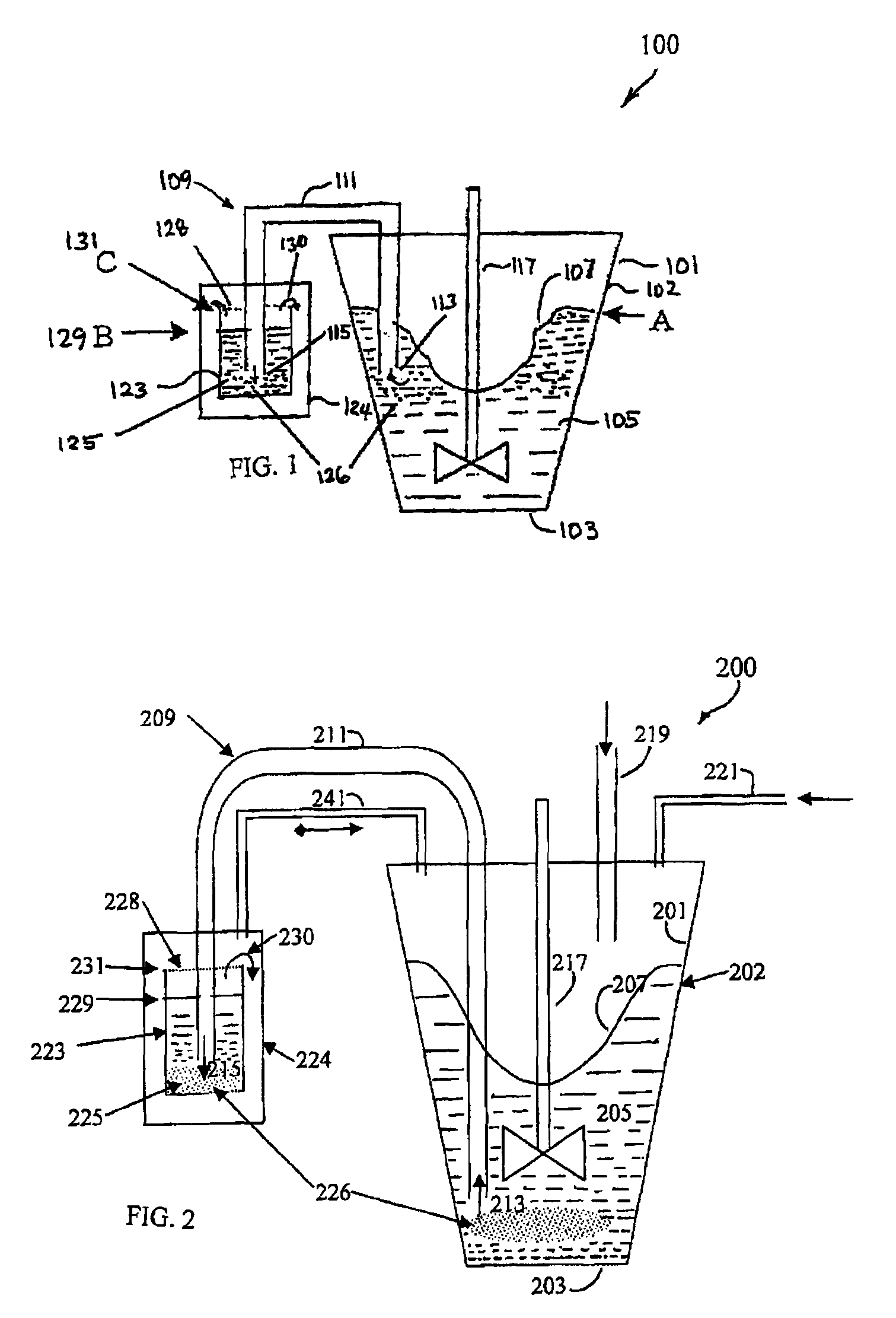

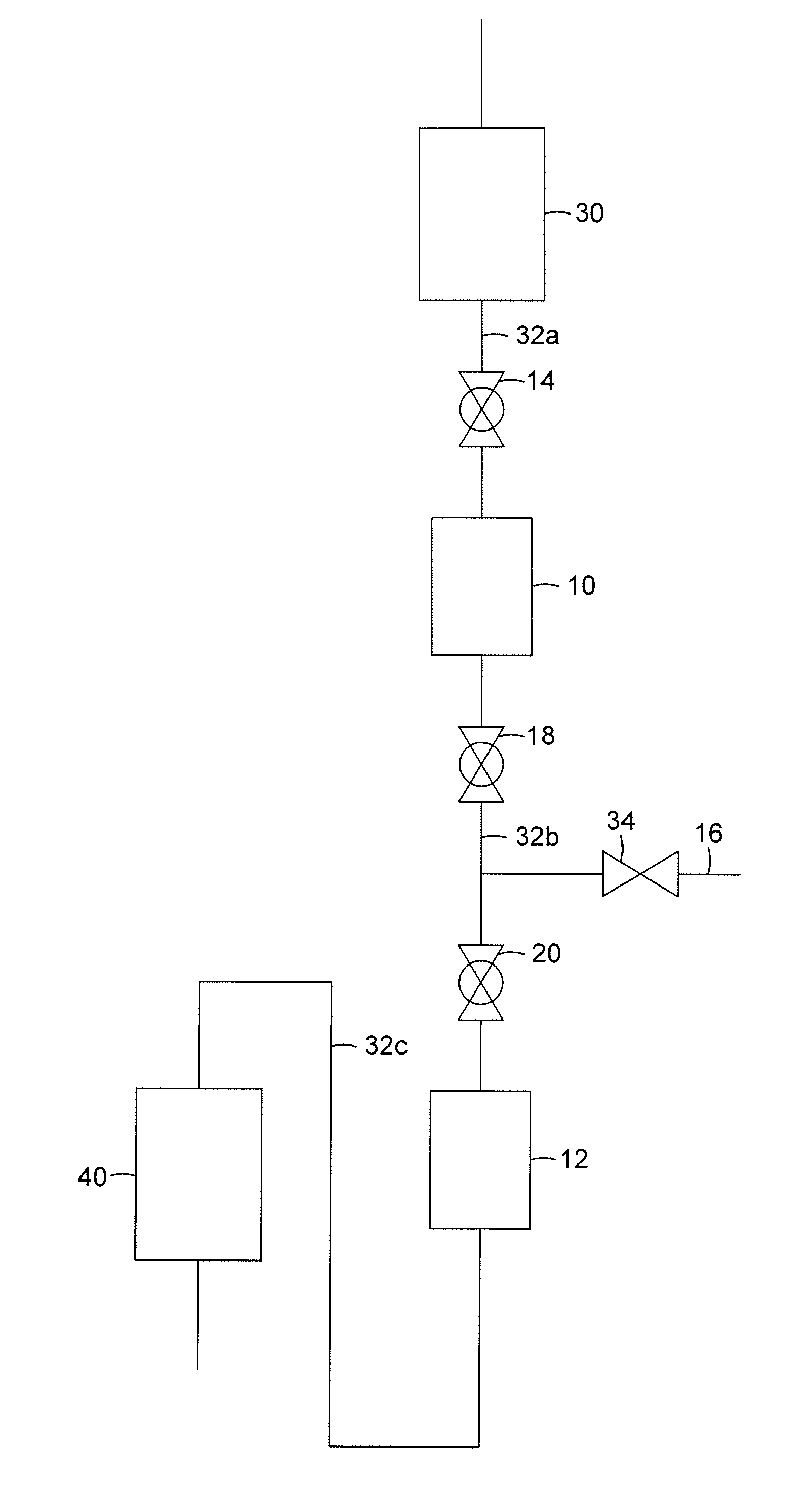

Moving Bed Hydrocarbon Conversion Process

InactiveUS20100187159A1Little no damageIncrease pressureCatalytic naphtha reformingHydrocarbon oil crackingParticle transferValved conduit

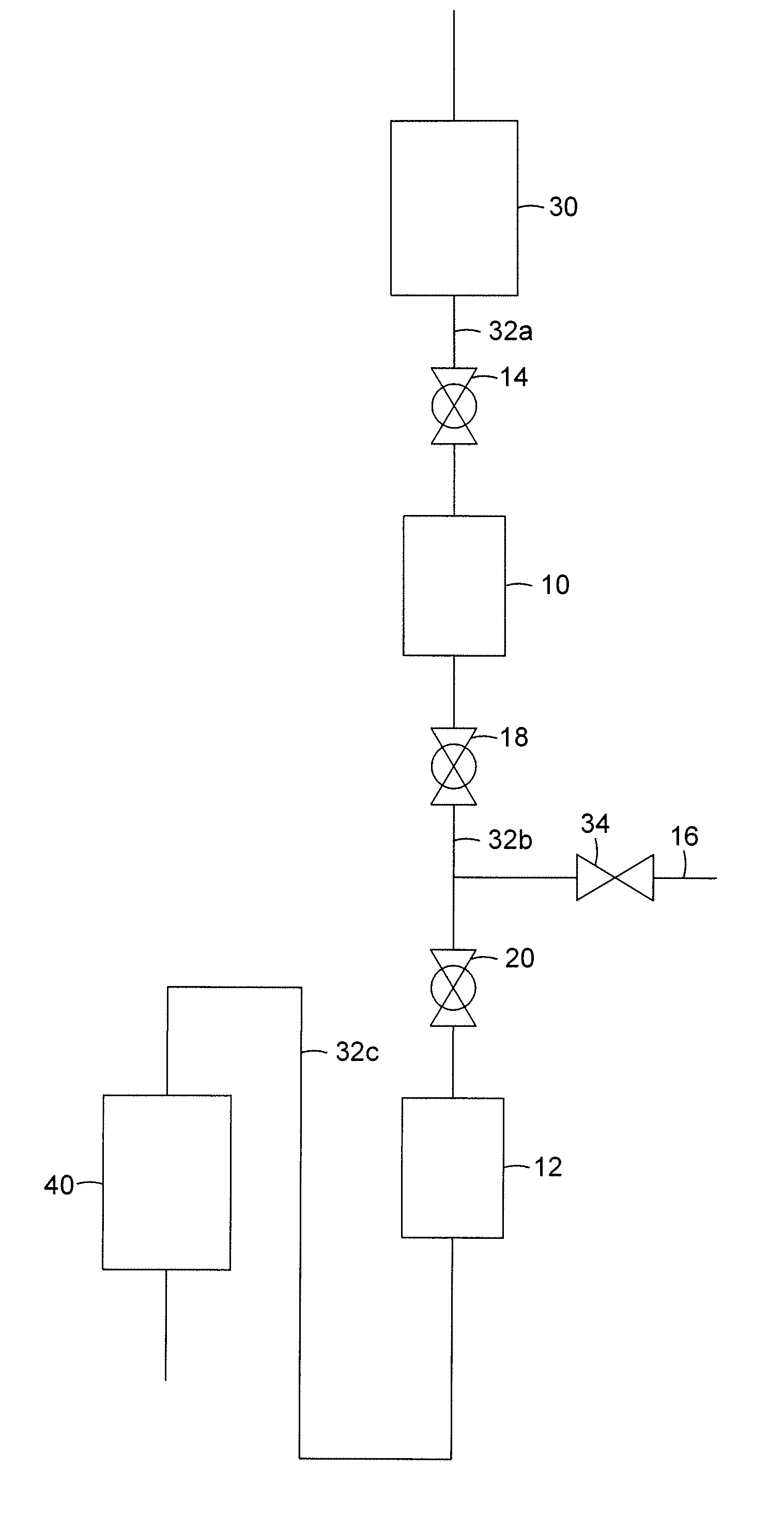

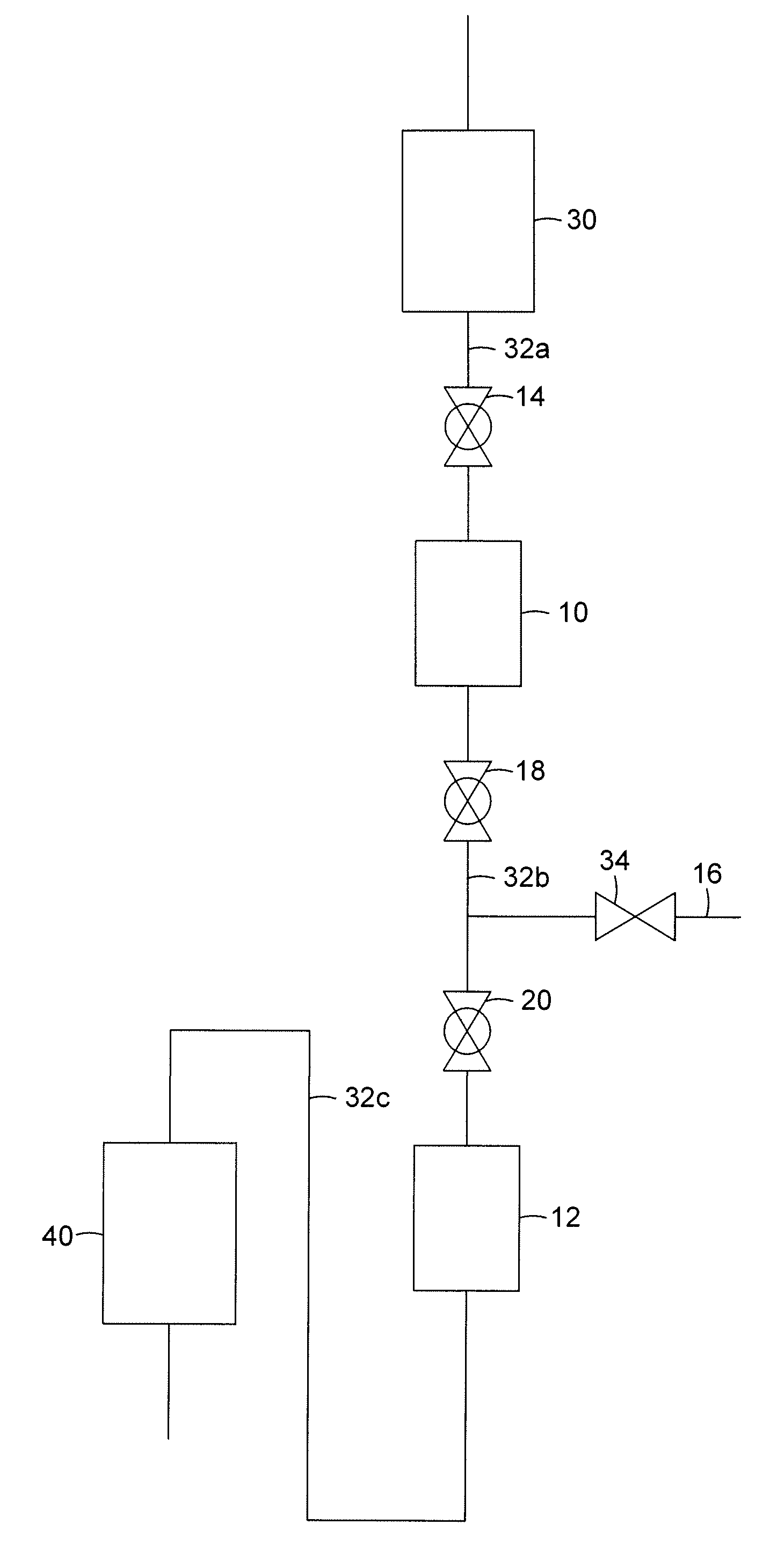

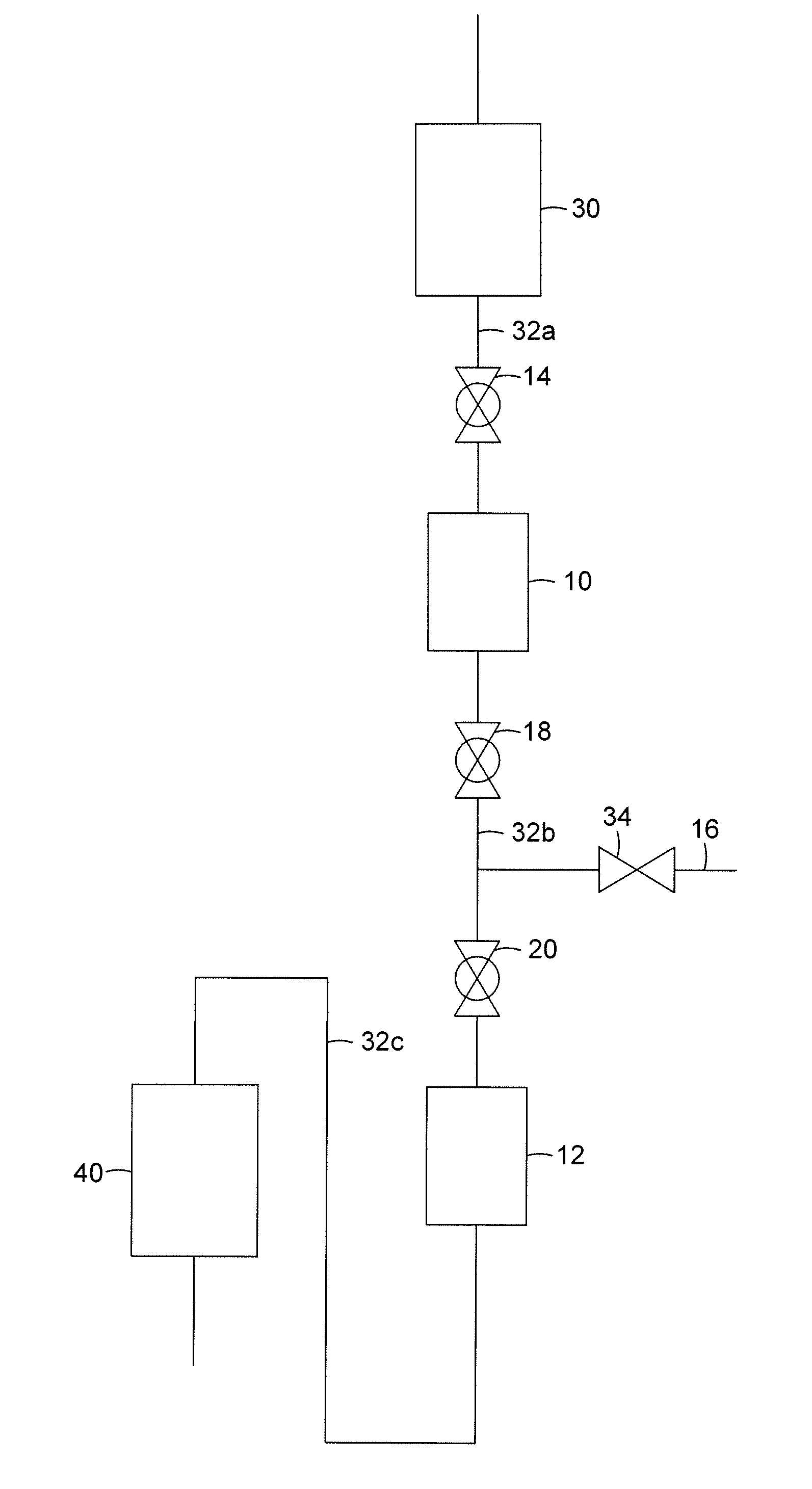

Moving bed hydrocarbon conversion processes are provided for contacting a catalyst moving downward through a reaction zone with a hydrocarbon feed, withdrawing the catalyst from the reaction zone and conveying the catalyst to a regeneration zone wherein the catalyst moves downward. The catalyst is withdrawn from the regeneration zone and passed downward to an upper zone of a particle transfer apparatus wherein the transfer of catalyst from the upper zone through a middle zone to a lower zone is regulated by varying the pressure of the middle zone, the flow rate of gas passing through an upper valveless conduit, and a valve in a lower valved conduit. The catalyst from the lower zone of the particle transfer apparatus is conveyed to the reactions zone.

Owner:UOP LLC

Moving Bed Hydrocarbon Conversion Process

InactiveUS20100152516A1Molecular sieve catalystsCatalytic naphtha reformingParticle transferGas passing

Moving bed hydrocarbon conversion processes are provided for contacting a catalyst moving downward through a reaction zone with a hydrocarbon feed, withdrawing the catalyst from the reaction zone and conveying the catalyst to a regeneration zone wherein the catalyst moves downward. The catalyst is withdrawn from the regeneration zone and passed downward to an upper zone of a particle transfer apparatus wherein the transfer of catalyst from the upper zone through an intermediate zone to a lower zone is regulated by varying the pressure of the intermediate zone and the flow rate of gas passing through the valveless conduits. A body within the lower zone is in catalyst communication with a valveless conduit and provides more consistent catalyst flows. The catalyst from the lower zone of the particle transfer apparatus is conveyed to the reactions zone.

Owner:UOP LLC

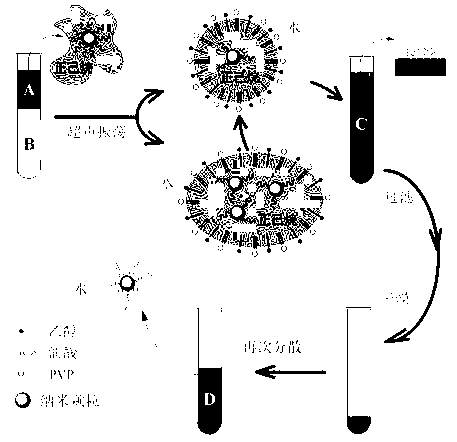

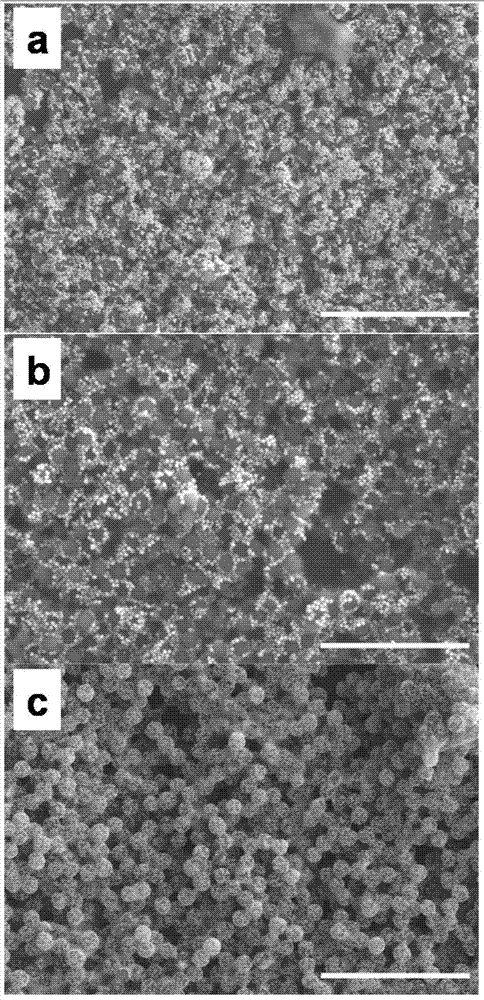

Method for transferring nano-particles from oil phase into aqueous phase

ActiveCN103127744AUniform size without changeImprove solubilityLiquid displacementCooking & bakingUltrasonic emulsification

The invention provides a method for transferring nano-particles from an oil phase into an aqueous phase. The method includes the steps of mixing nano-particle solution dispersed in the non-polar oil phase with water, a stabilizer and cosurfactant solution, enabling the mixture to be subjected to ultrasonic emulsification and made into oil-in-water microemulsion, carrying out evaporation and drying on the microemulsion in a baking oven to obtain stabilizer-nano-particle composite dry jelly, adding polar solvent capable of dissolving the stabilizer into the dry jelly, slightly shaking so as to enable the dry jelly to be dissolved and dispersed into the solvent, and finally achieving the purpose of dispersion of the nano-particles transferred from the non-polar oil phase to the polar solvent. The method is simple in process, simple, convenient and quick in operation, and capable of effectively transferring the nano-particles dispersed in the oil phase to the aqueous phase.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

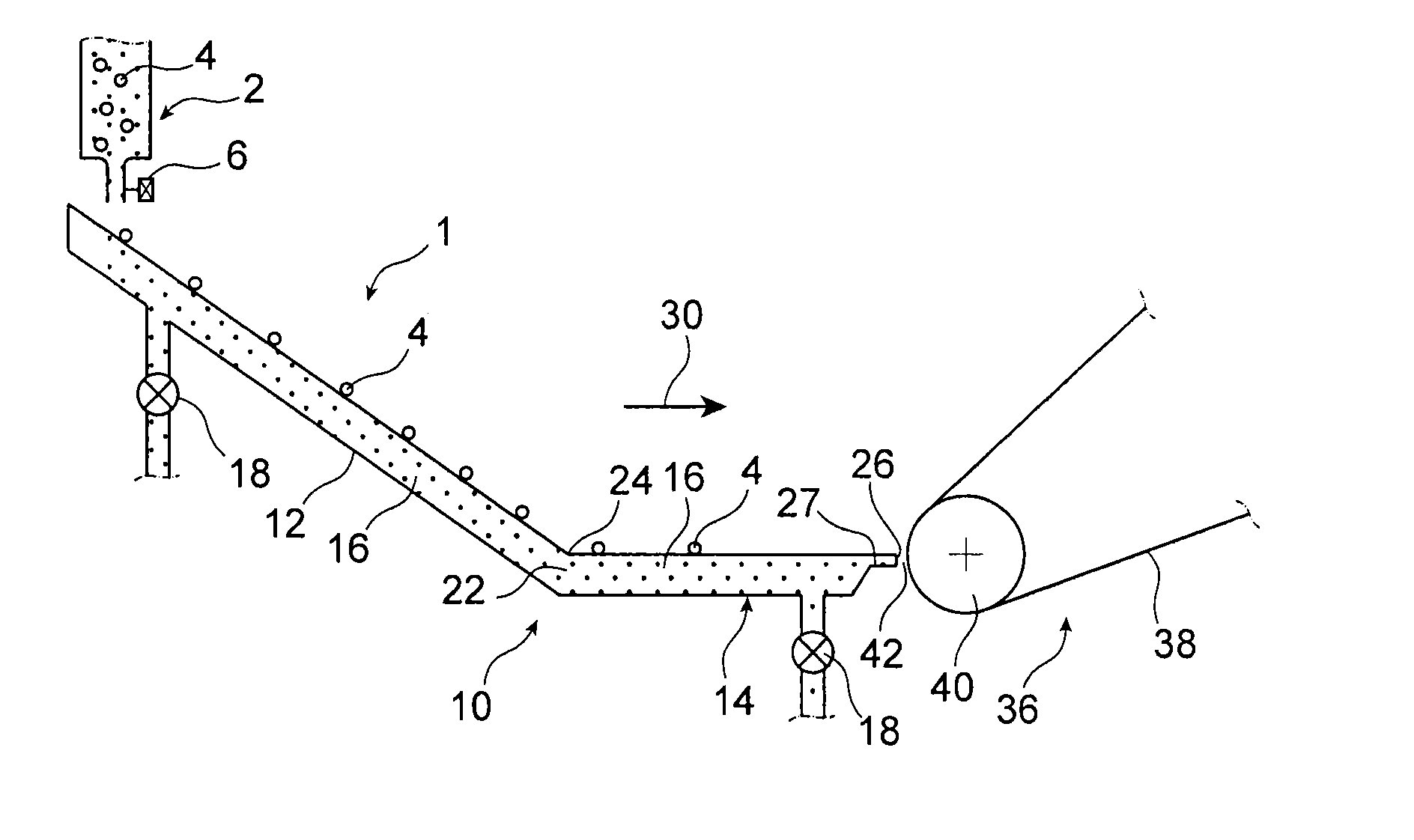

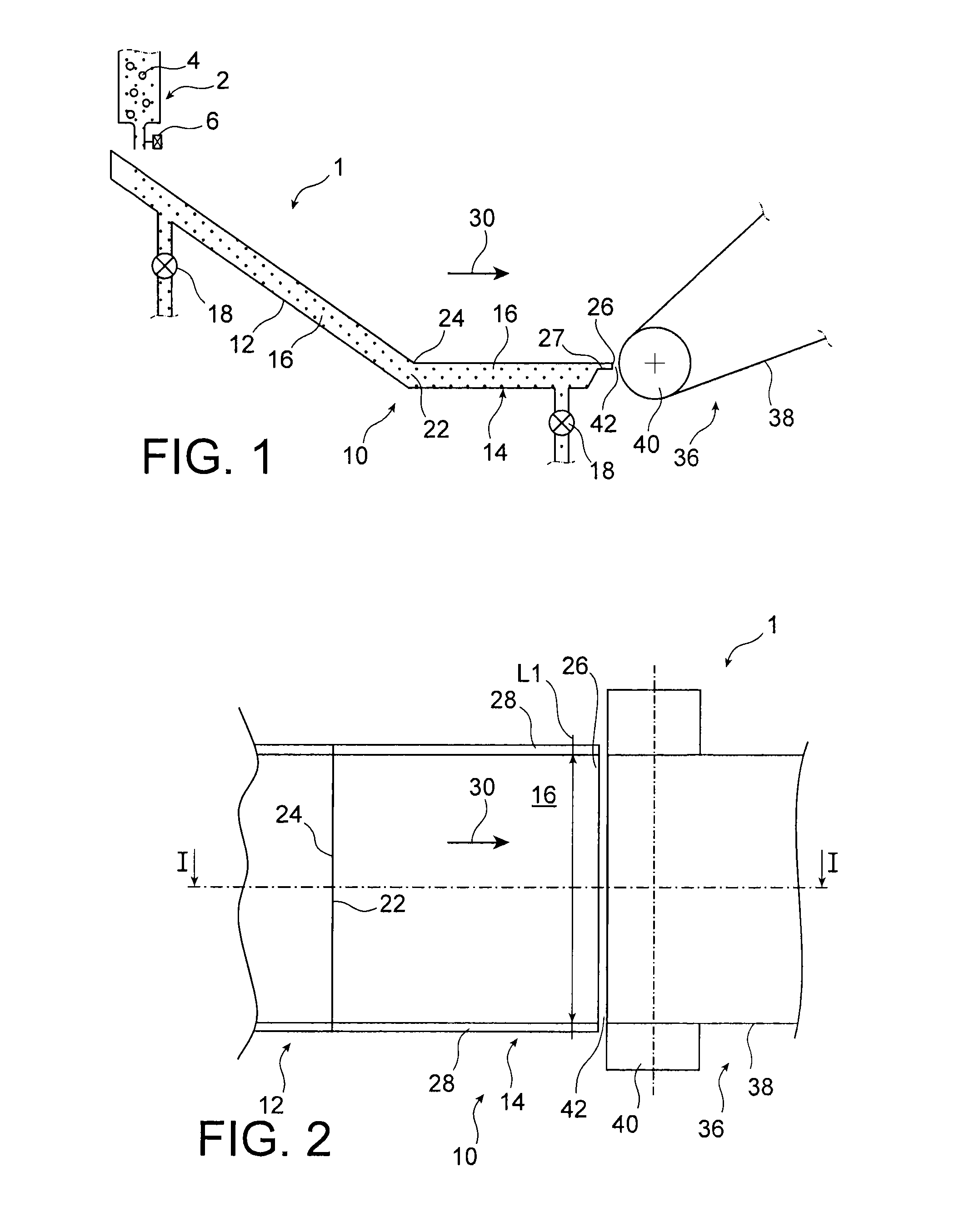

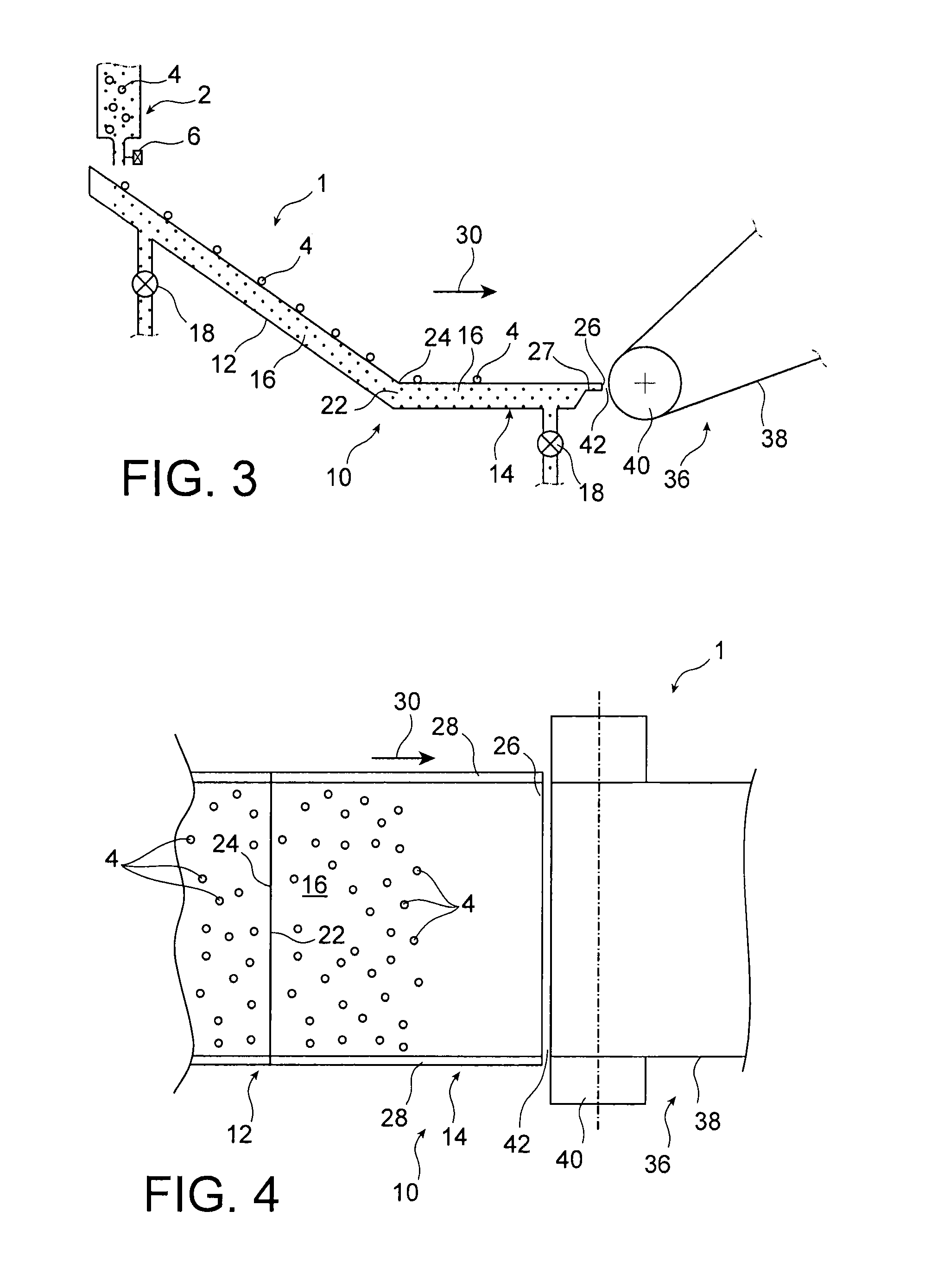

Facility and method for depositing a width adjustable film of ordered particles onto a moving substrate

InactiveUS20140147583A1Efficiently cut offPromotes the advance and withdrawal of the carrier liquidPretreated surfacesLiquid spraying apparatusParticle transferEngineering

A facility for depositing a film of ordered particles onto a moving substrate, the facility configured to allow deposition, onto the substrate, of a film of ordered particles escaping from a particle outlet of a transfer zone having a first width. The facility further includes an accessory device in a form of a deposit head, provided to seal the particle outlet and configured to allow the deposition, onto the substrate, of a film of ordered particles escaping from an end of a particle transfer channel of the deposit head, the end having a second width strictly lower than the first width.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Electronic paper displaying device and manufacturing method thereof

ActiveCN104317131AImprove picture qualityAdjust display refresh rateNon-linear opticsElectronic structureParticle transfer

The invention discloses an electronic paper displaying device and a manufacturing method thereof. The electronic paper displaying device comprises an upper substrate and a lower substrate arranged oppositely and displaying layers filled between the upper substrate and the lower substrate, the electronic displaying device is provided with a plurality of displaying units arranged in a shape of a plurality of arrays, in every displaying unit, the displaying layer comprises microgel particles of a hole-shaped structure and sensitive to an electric field, electrolyte and colored particles transferred between the hole-shaped structure of the microgel particles and the electrolyte, the upper substrate and / or the lower substrate are / is provided with an electrode structure, wherein the electronic structure provided in every displaying unit can generate an electronic field capable of controlling the swelling states of the microgel particles and enabling the colored particles to transfer between the hole-shaped structure of the microgel particles and the electrolyte, due to the fact that microgel particles can swell or deswell when the electronic field generated by the electrode structure changes to further absorb or release colored particles, and black and white, grey or color display can be achieved and display refresh rate can be adjusted due to the controlled release of the colored particles.

Owner:BOE TECH GRP CO LTD +1

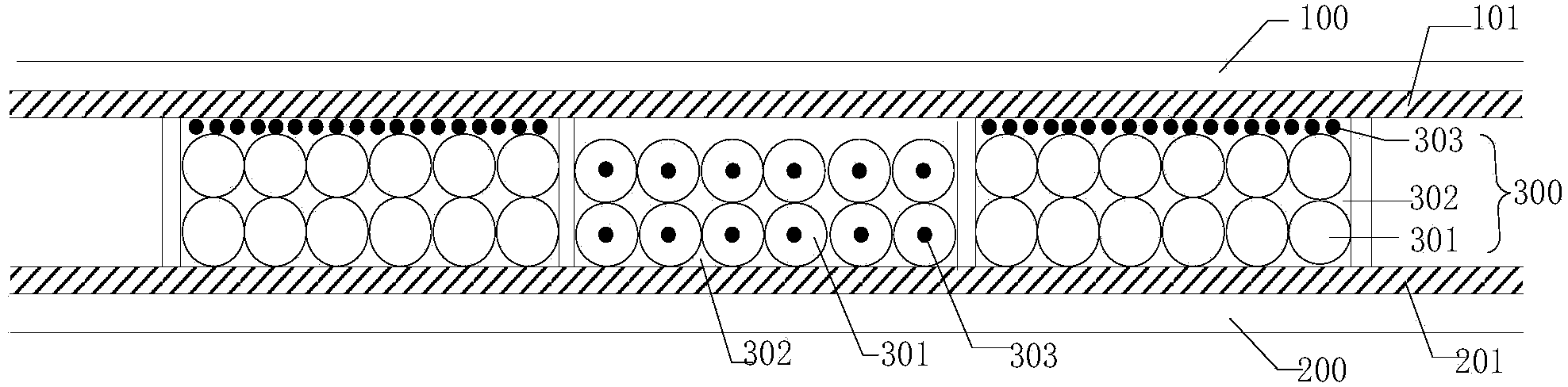

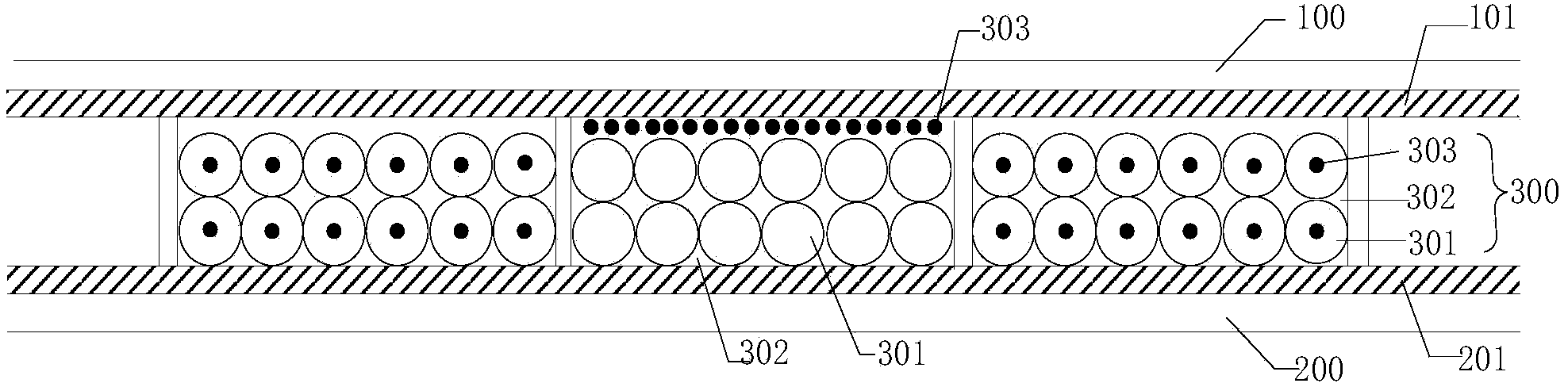

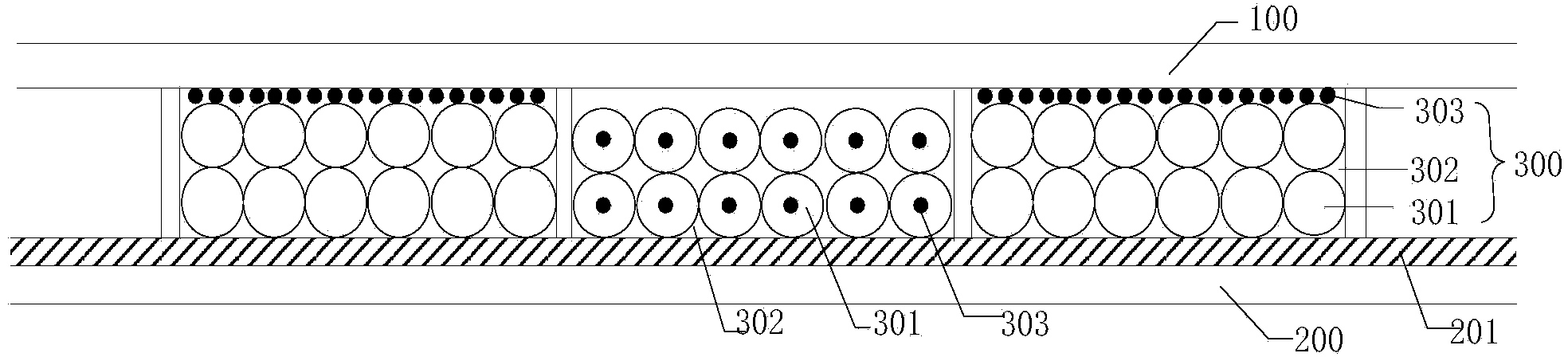

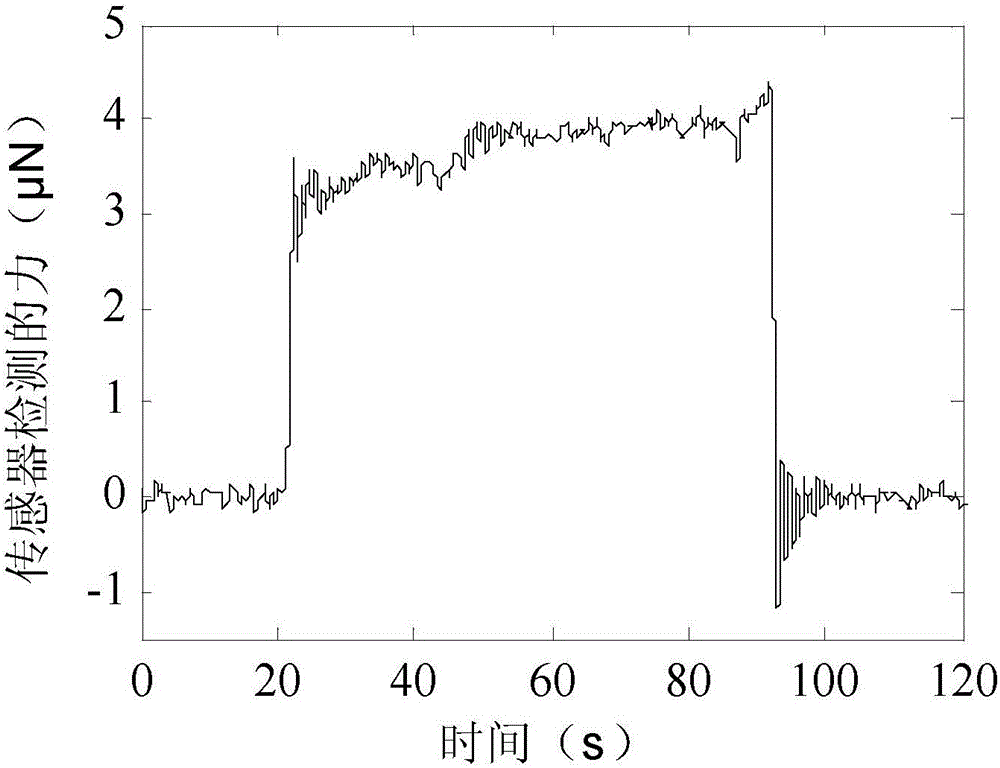

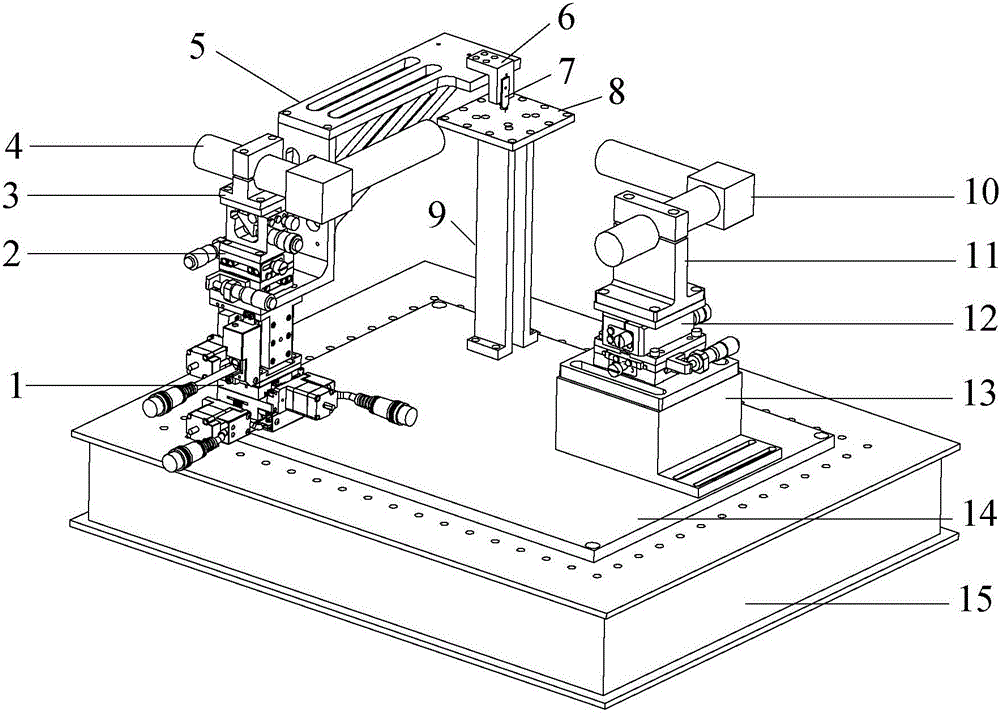

Micro/nano particle transfer method having micro force sensing and liquid drop self-calibration functions, and apparatus for realizing the same

InactiveCN104990665APick up suppleRelease suppleControlling ratio of multiple fluid flowsFluid pressure measurement using capacitance variationParticle transferEngineering

The invention, which relates to the micro / nano particle operation technology, relates to a micro / nano particle transfer method having micro force sensing and liquid drop self-calibration functions, and an apparatus for realizing the same. Therefore, a problem that capillary force detection can not be realized by using the existing capillary-force-based micro / nano particle transfer method can be solved. According to the method, one operating liquid drop is allocated at a micro / nano particle to-be-released position; an operating probe having a micro force sensing function is used for dipping and taking the liquid drop, the operating probe is moved above the micro / nano particle, and picking up of the micro / nano particle is realized by the capillary force for picking up the liquid drop; and the operating probe is moved to a to-be-released position and releasing of the micro / nano particle is realized by using the capillary force for releasing the liquid drop. According to the invention, the liquid bridge capillary force during the micro / nano particle transfer process can be detected in real time and the precision is at an nN order; on the basis of the self-calibration characteristic of the capillary force and the liquid drop, reliable releasing of the micro / nano particle can be realized; and a proper liquid drop operating condition can be created by controlling the speed of liquid drop dipping by the probe and changing the structural morphology of the end effector.

Owner:HARBIN INST OF TECH

Fine particle recovery methods for valve metal powders

A process and system for producing tantalum or other valve metal particles is provided comprising forming tantalum particles in a reduction process carried out in a reactor vessel, and using a siphon to transfer fine tantalum particles out of the reaction mixture to a recovery vessel. This particle transfer can occur while the reaction mixture is agitated. The tantalum particles can be automatically withdrawn when the reaction mixture has a depth level greater than the fluid level of the tantalum fine particle recovery vessel, and outflow automatically stops when the fluid levels of the reactor and particle recovery vessel equilibrate. Tantalum or other valve metal powders made by the processes, and capacitors made with valve metal powders are also provided.

Owner:GLOBAL ADVANCED METALS USA

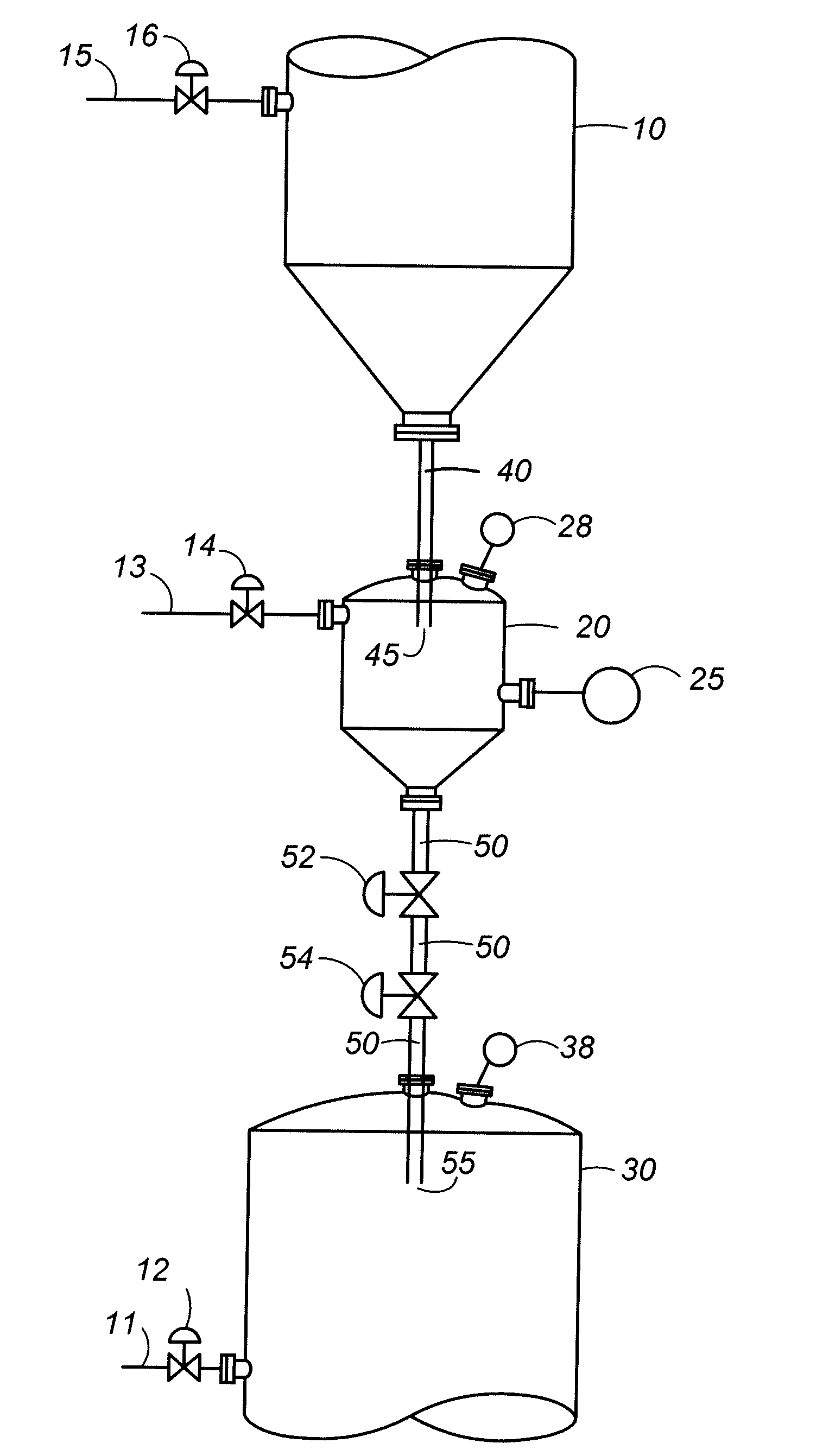

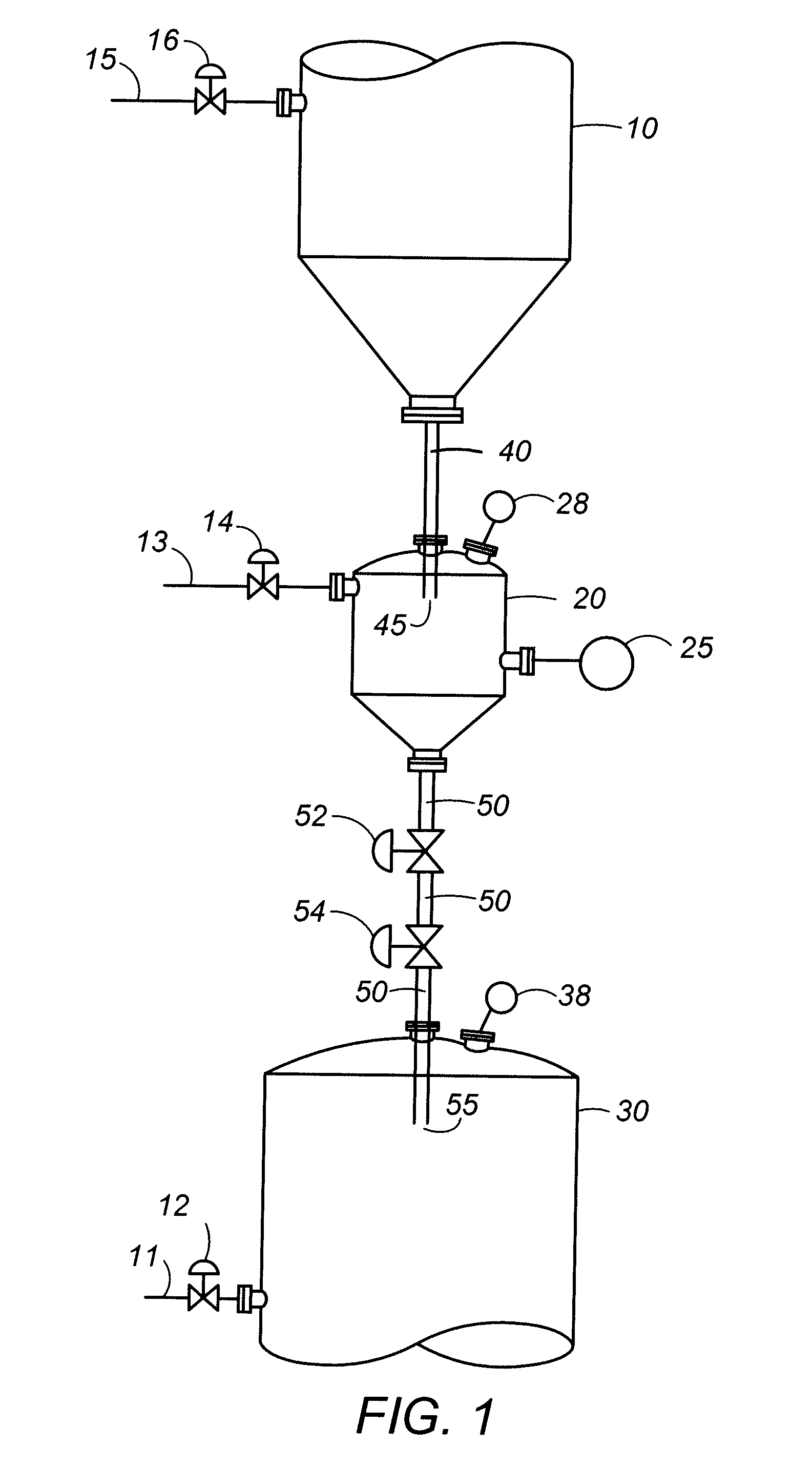

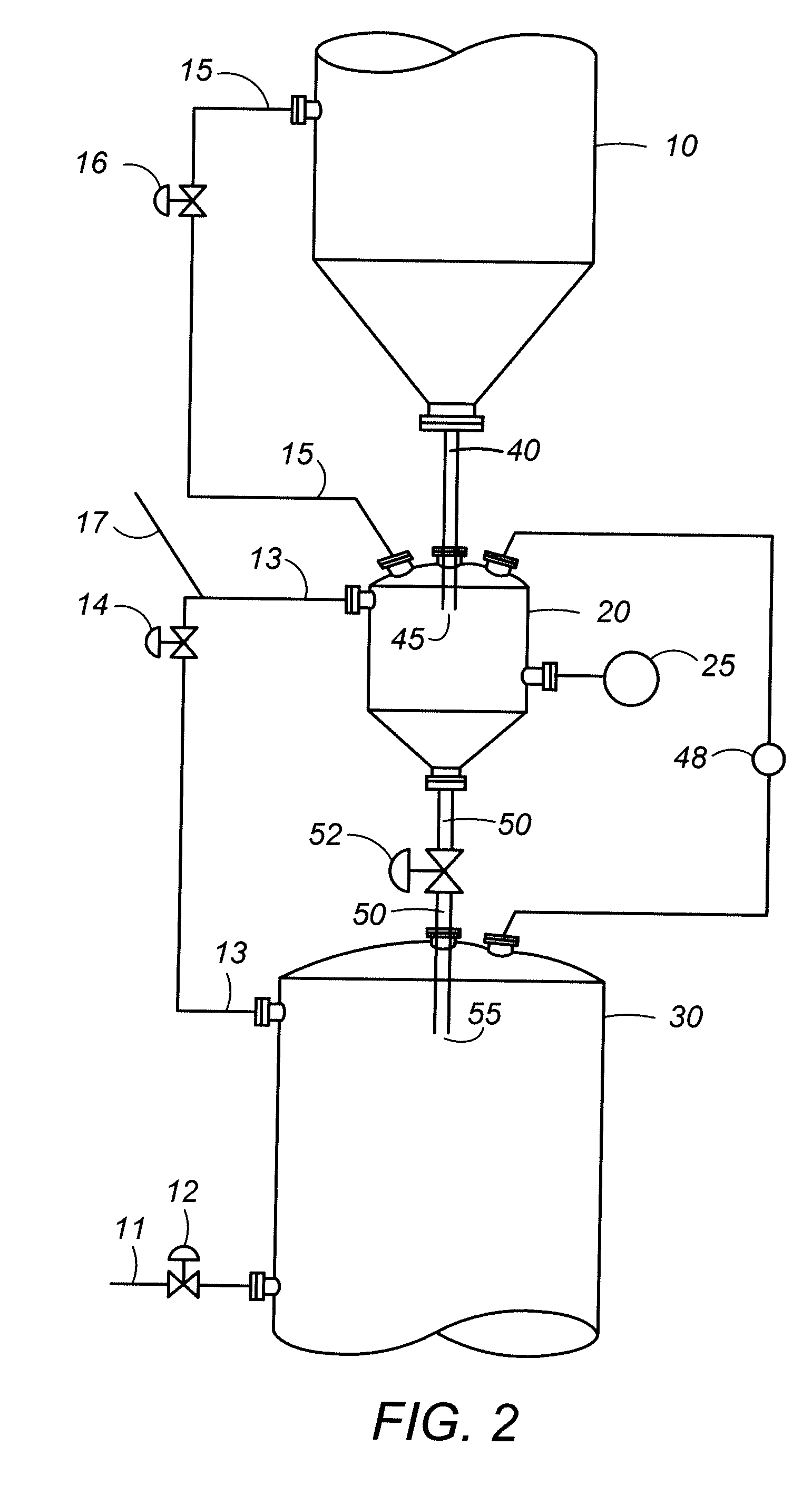

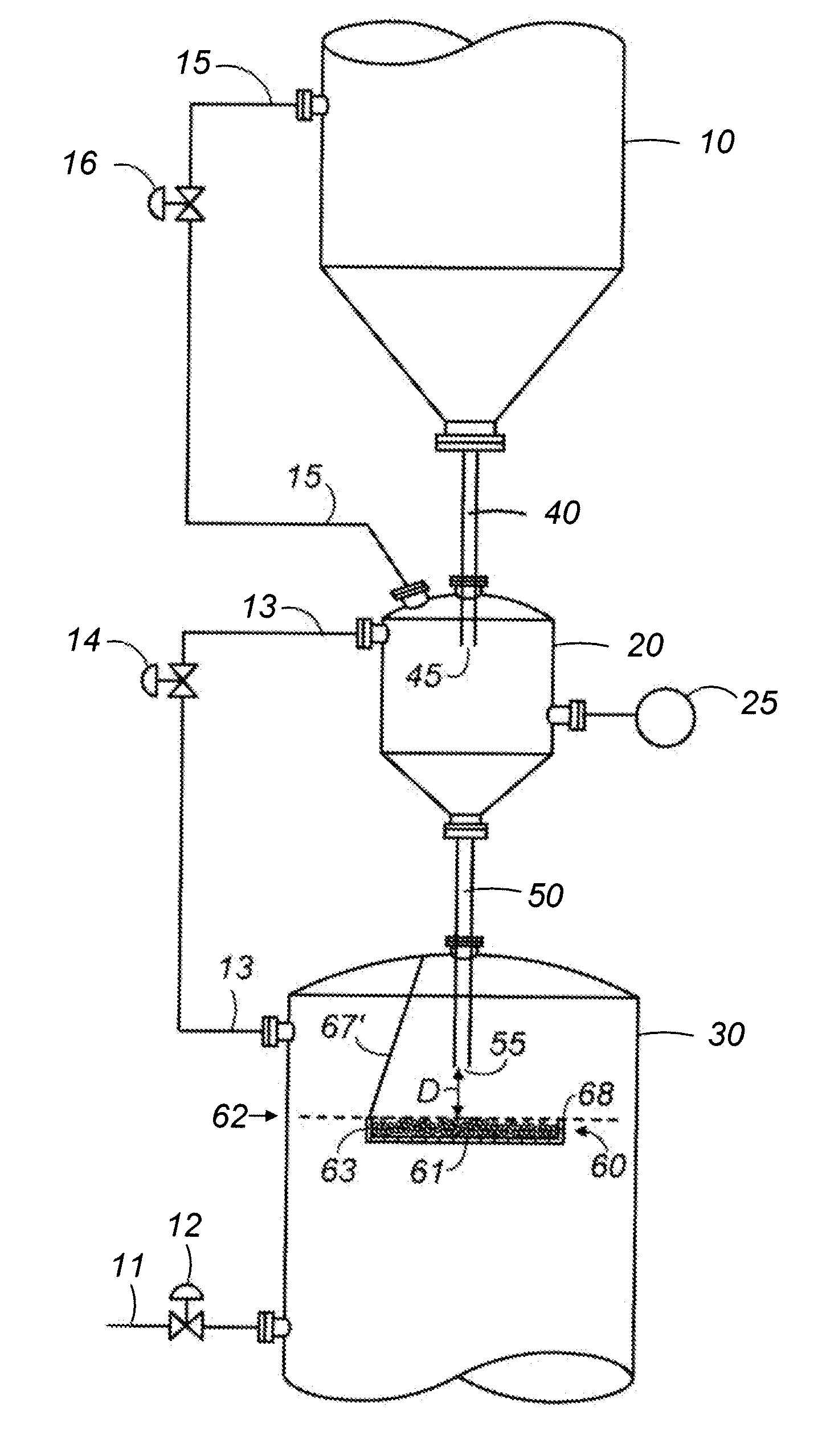

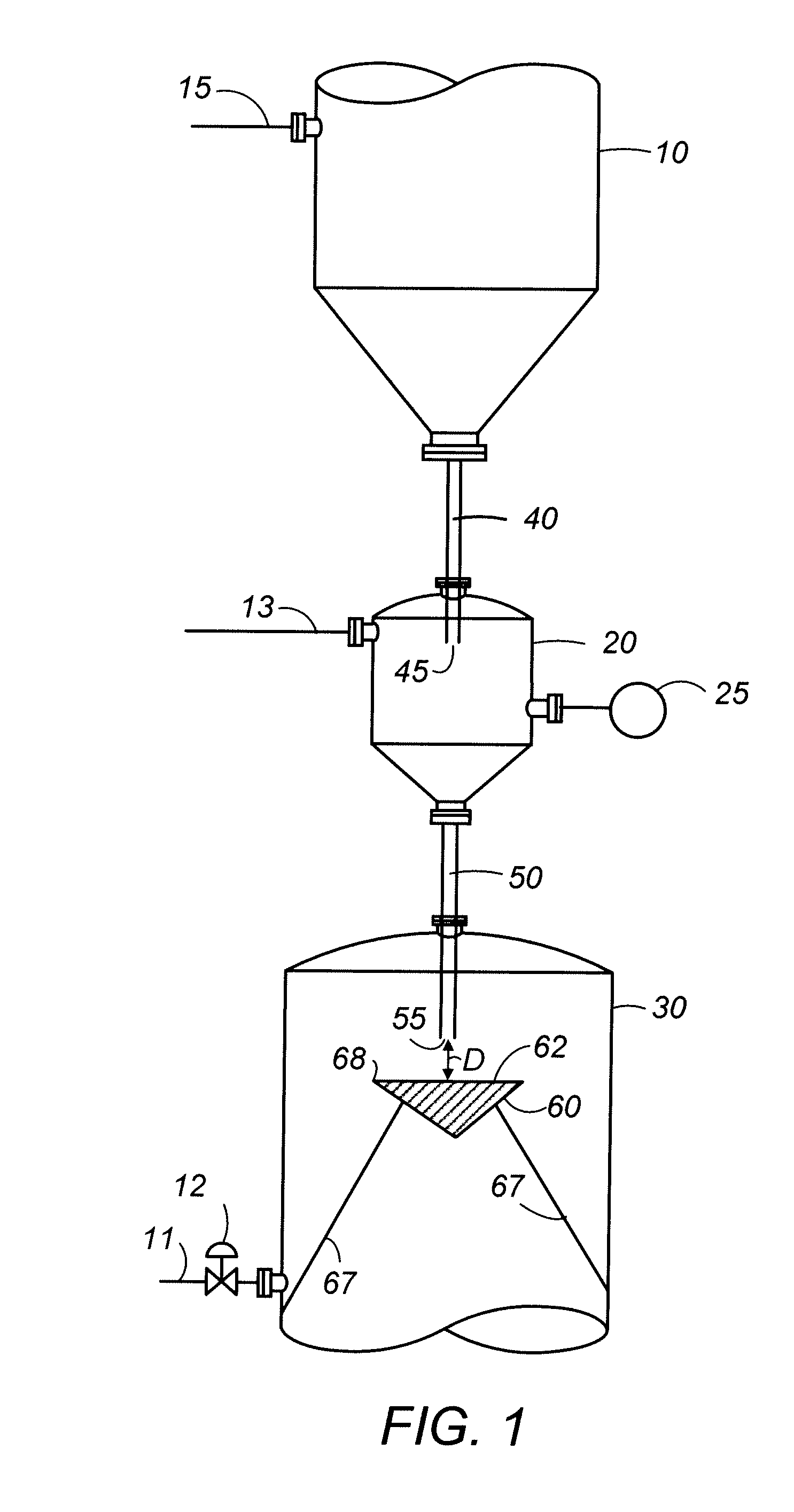

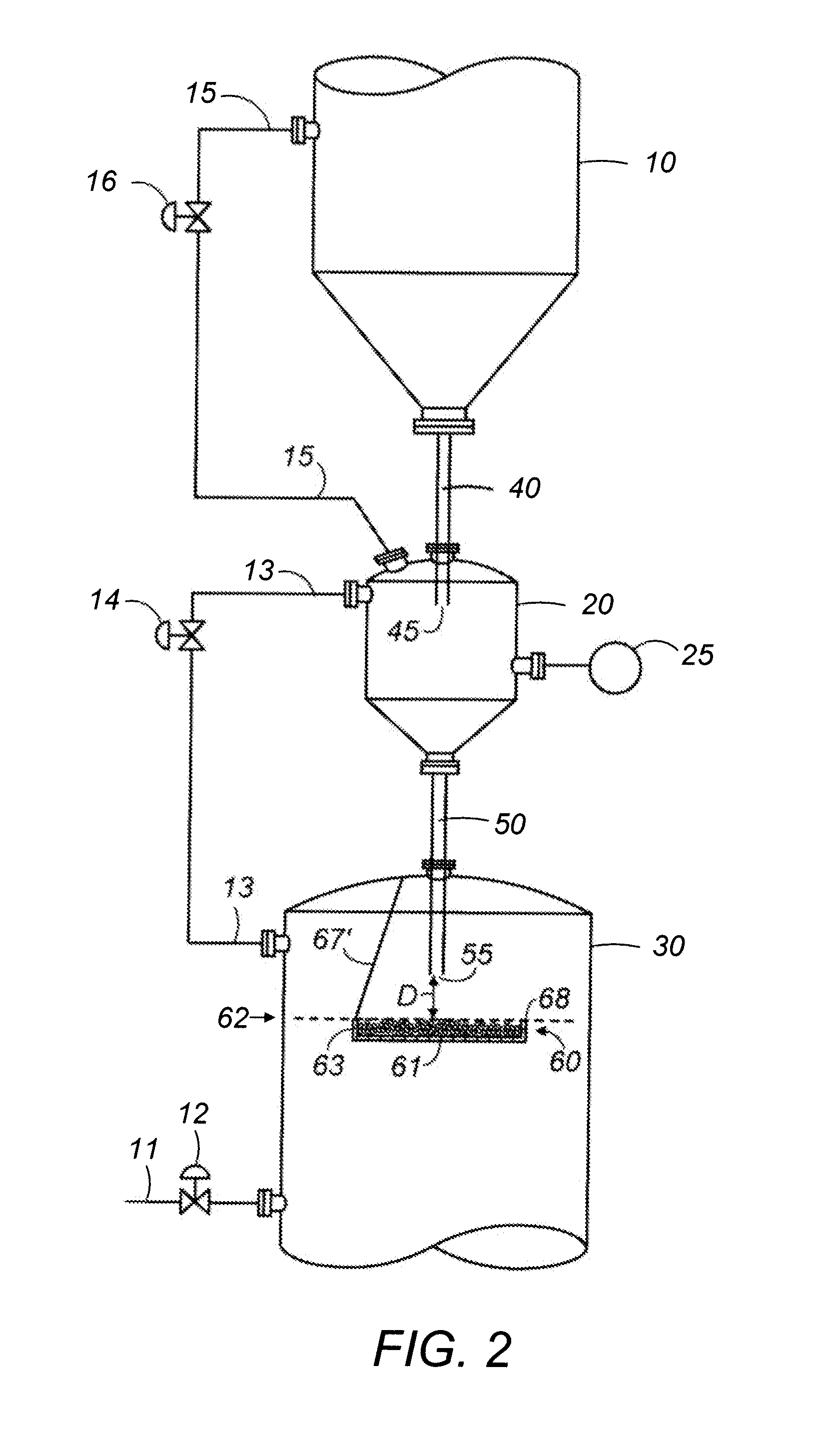

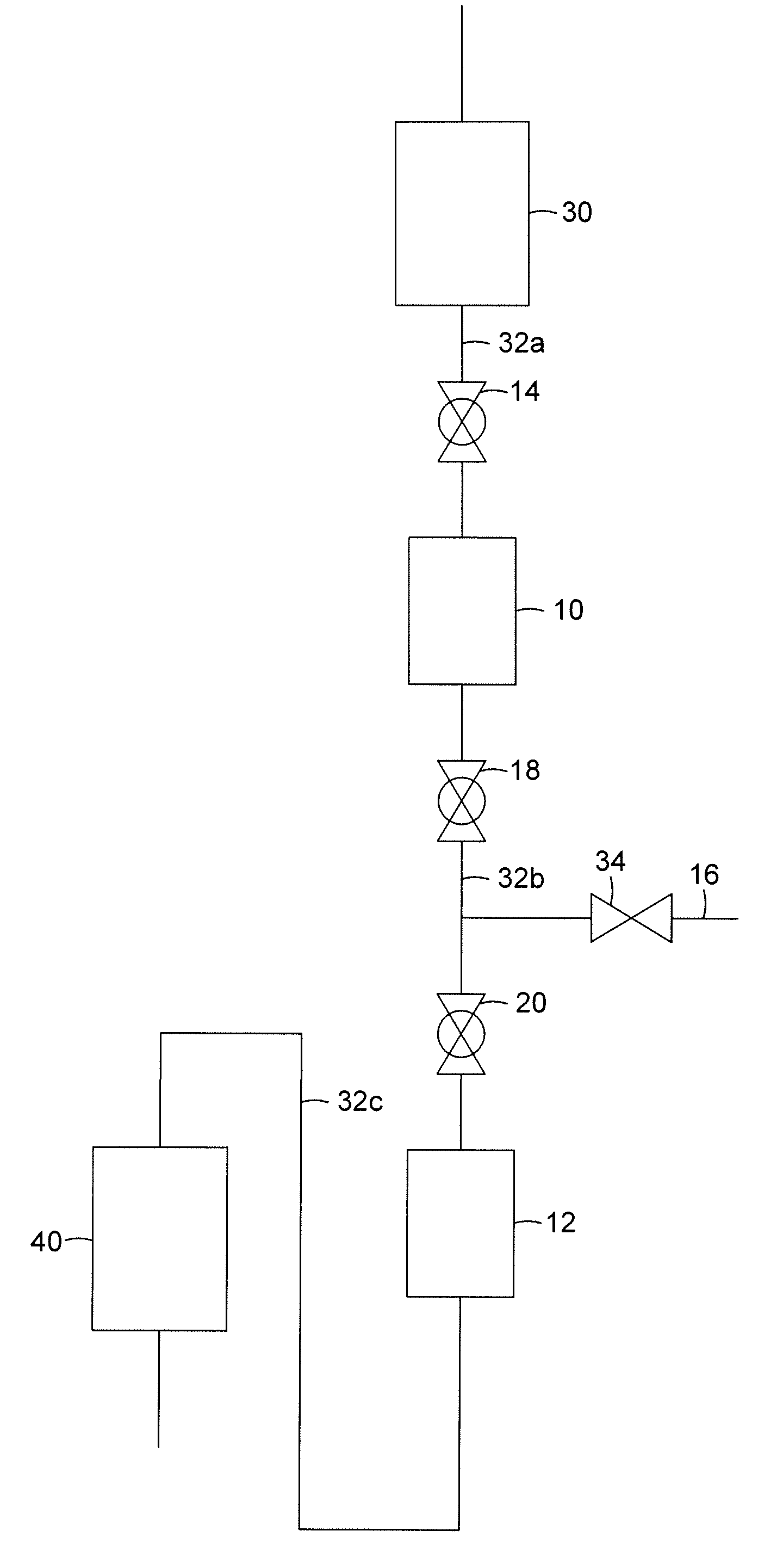

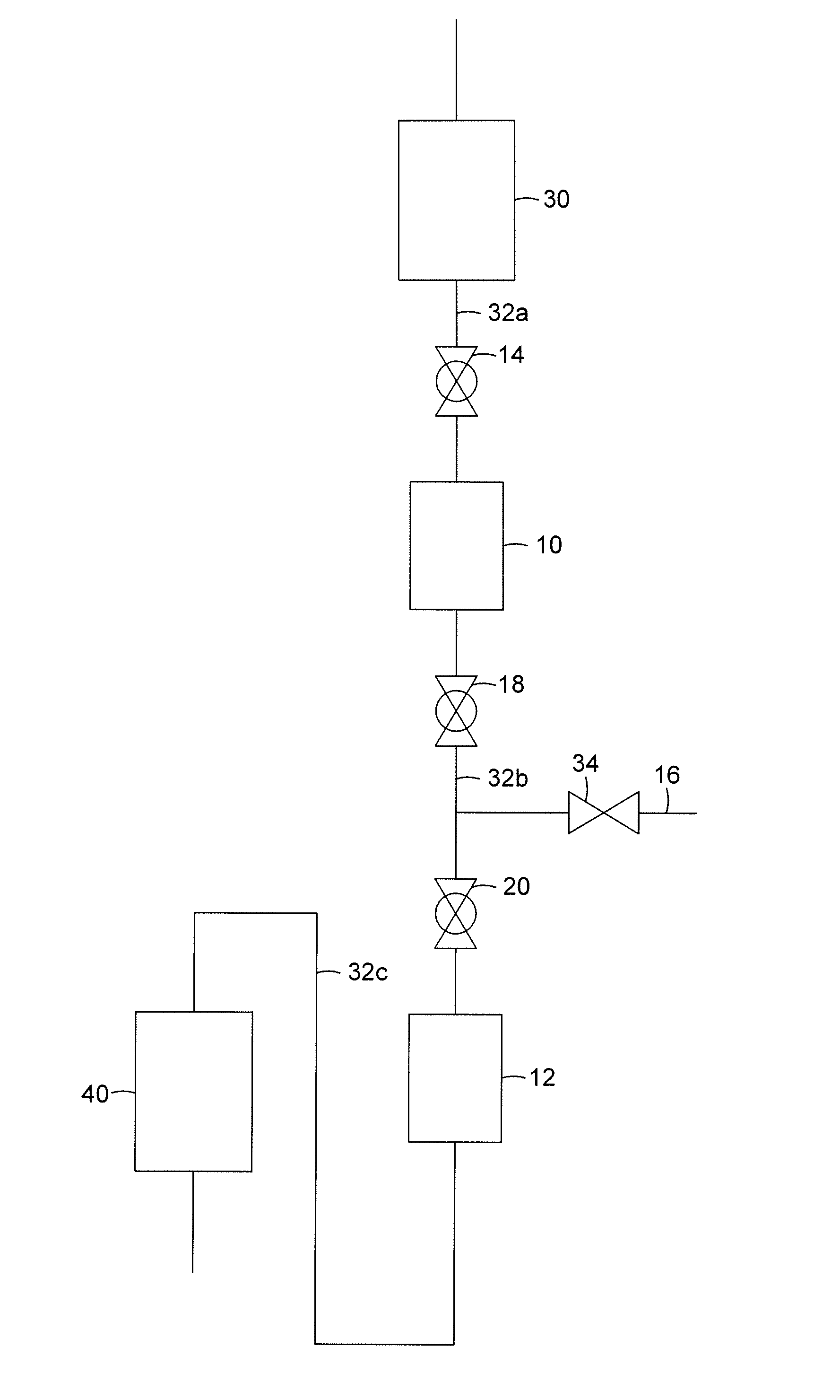

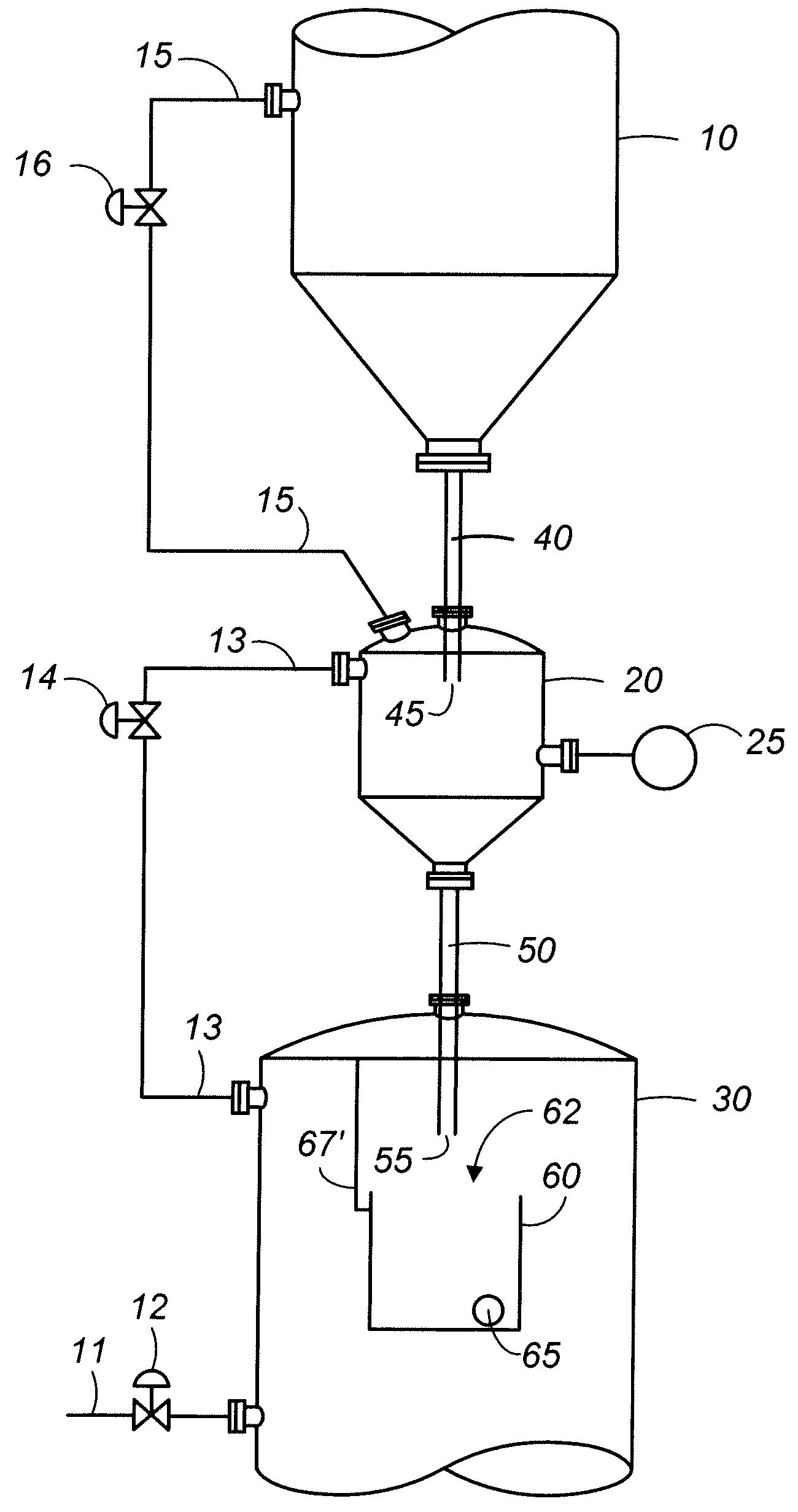

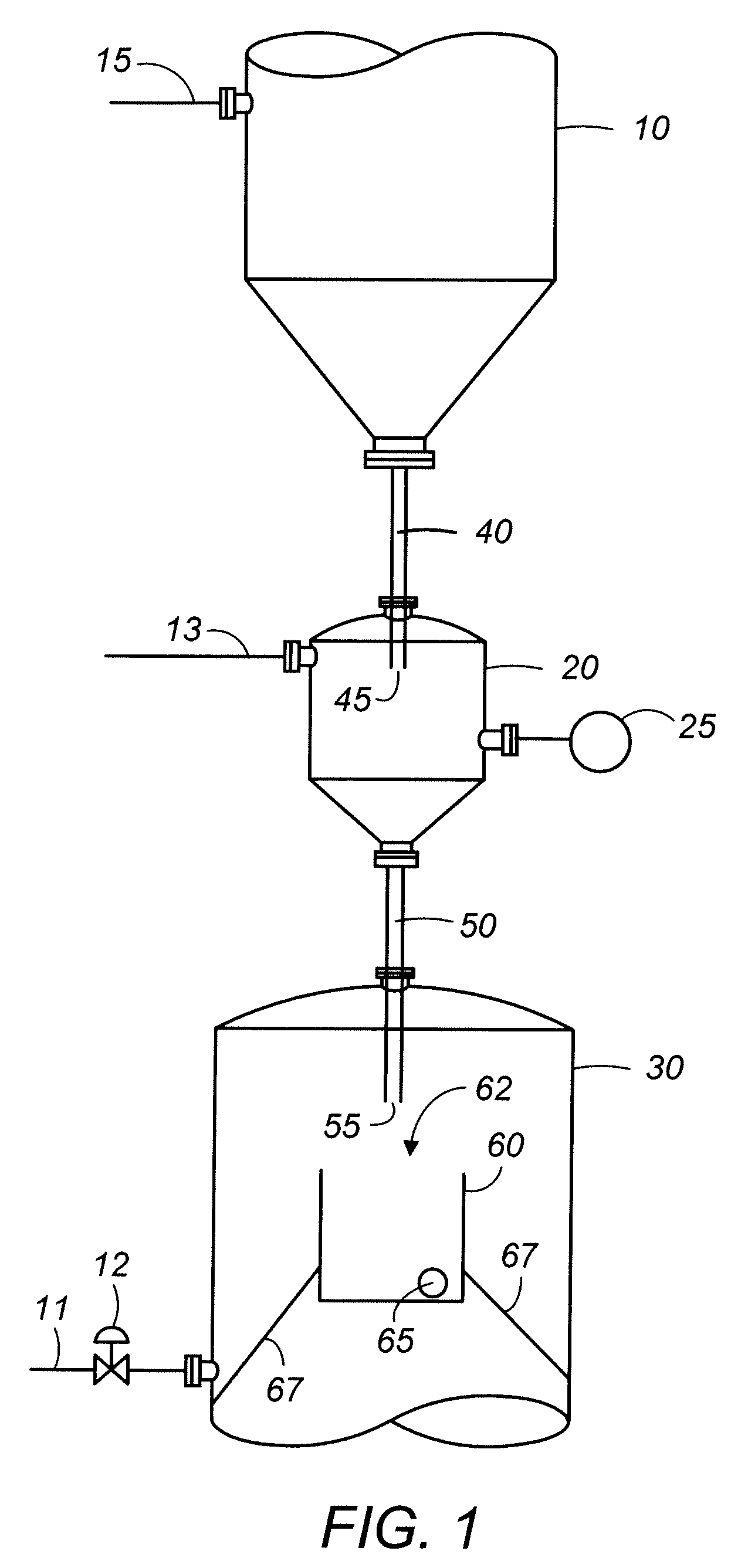

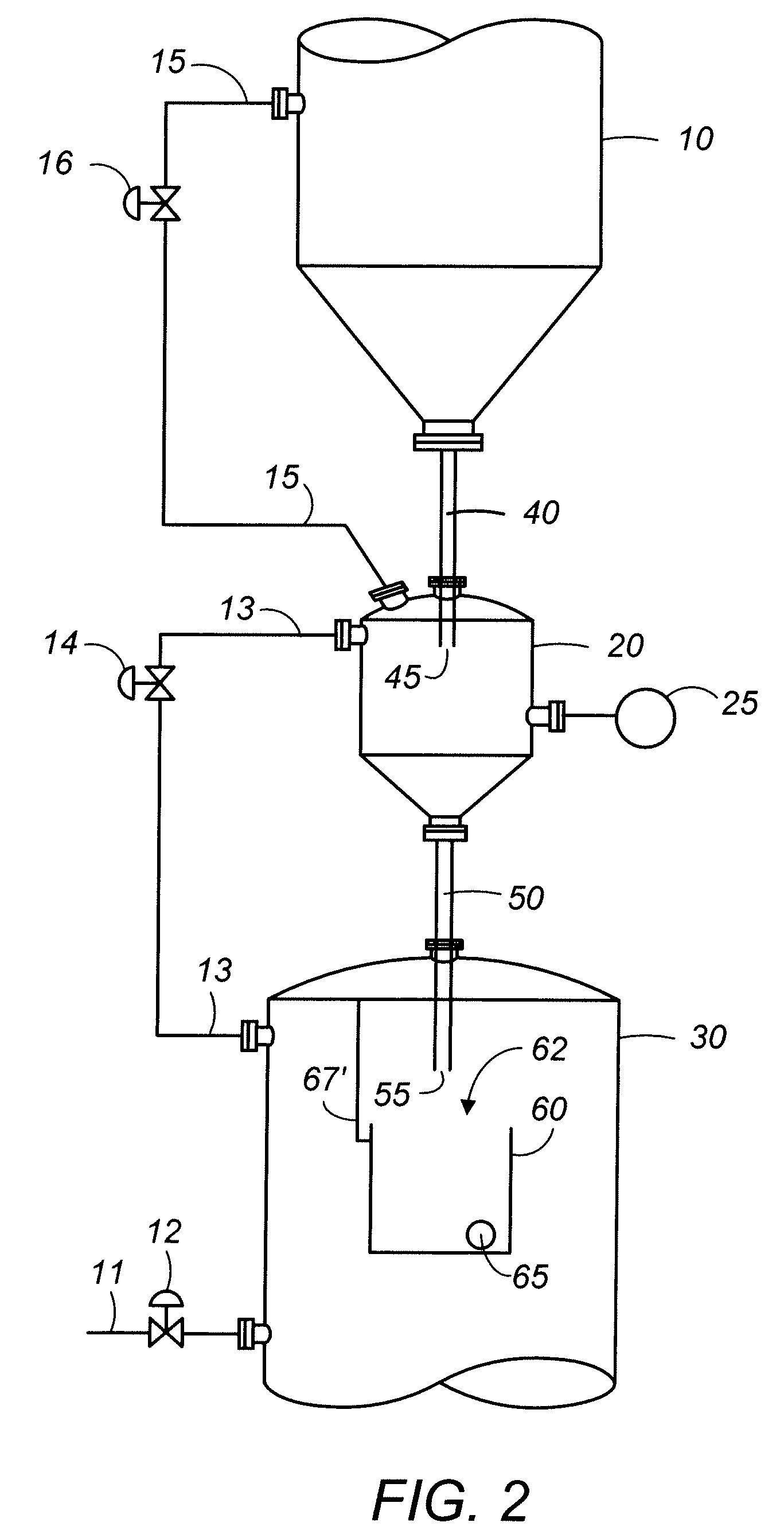

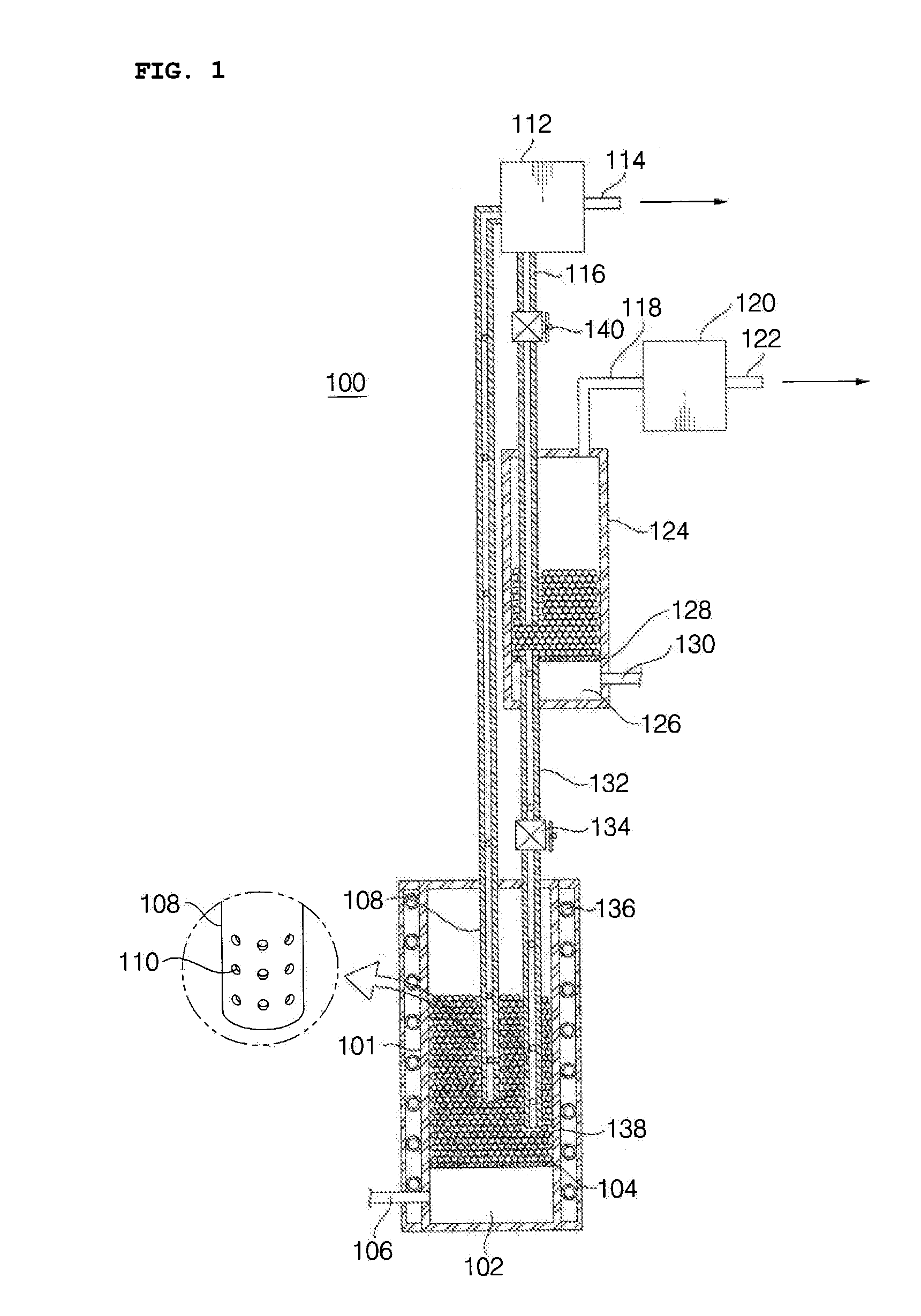

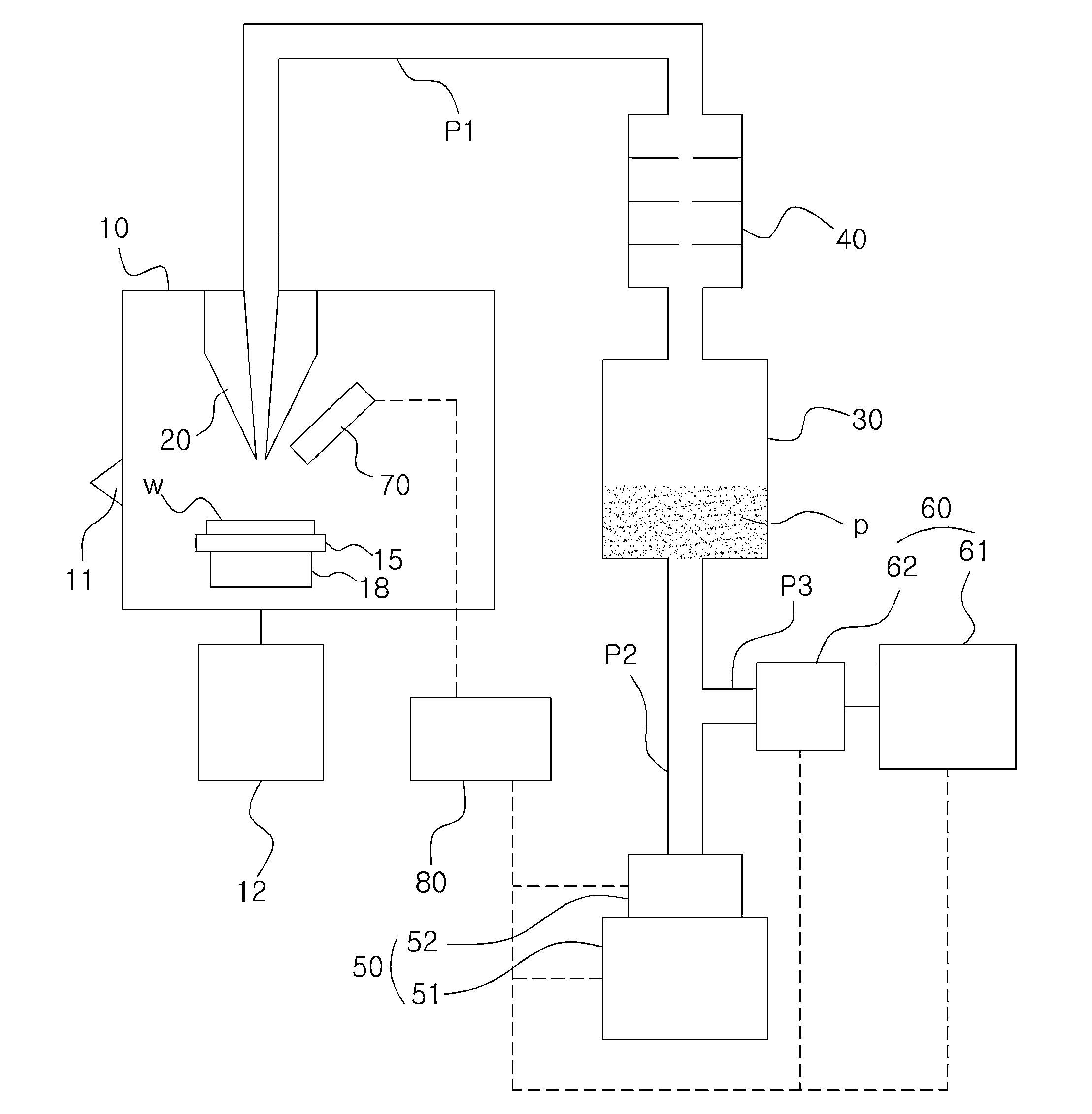

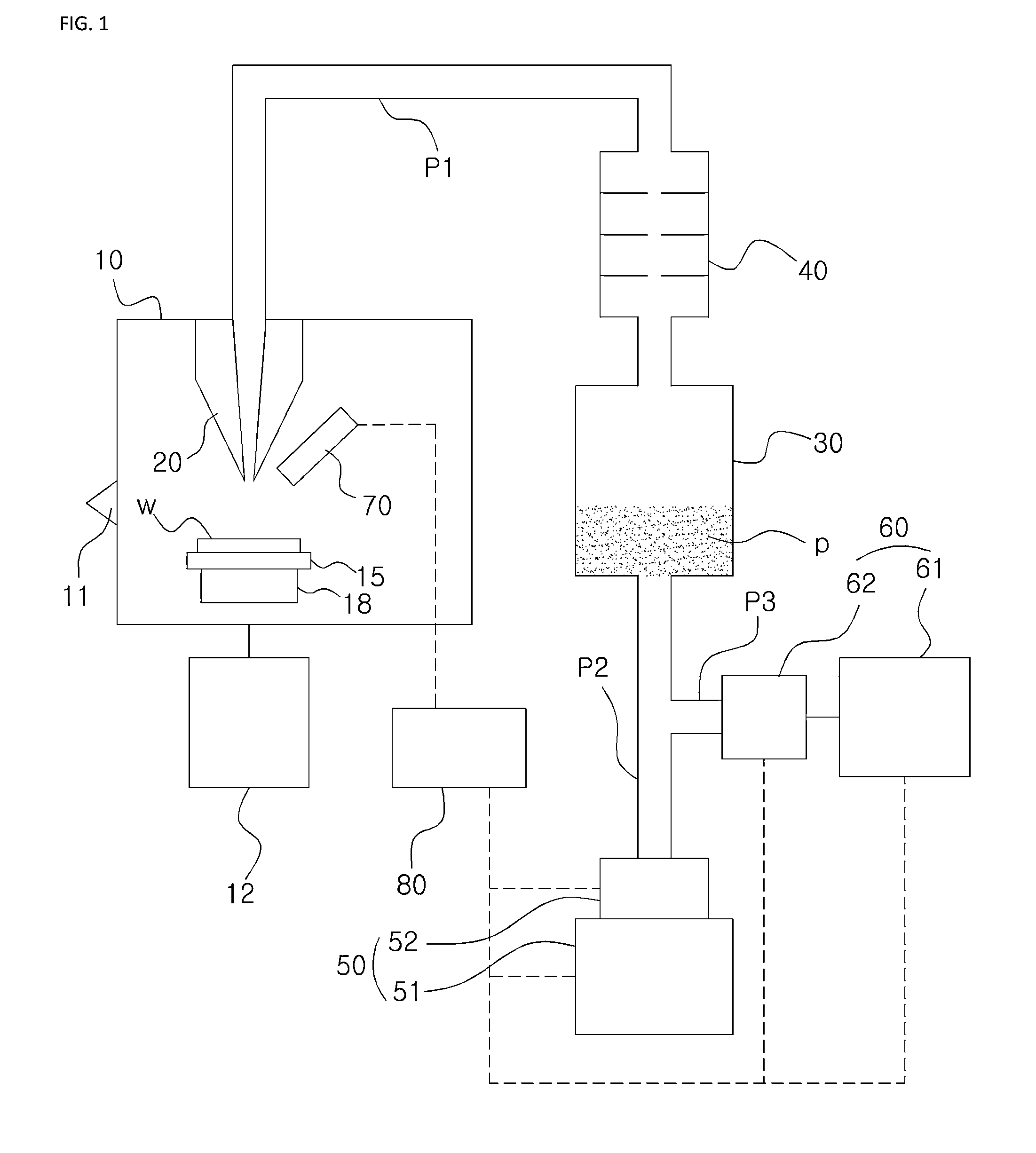

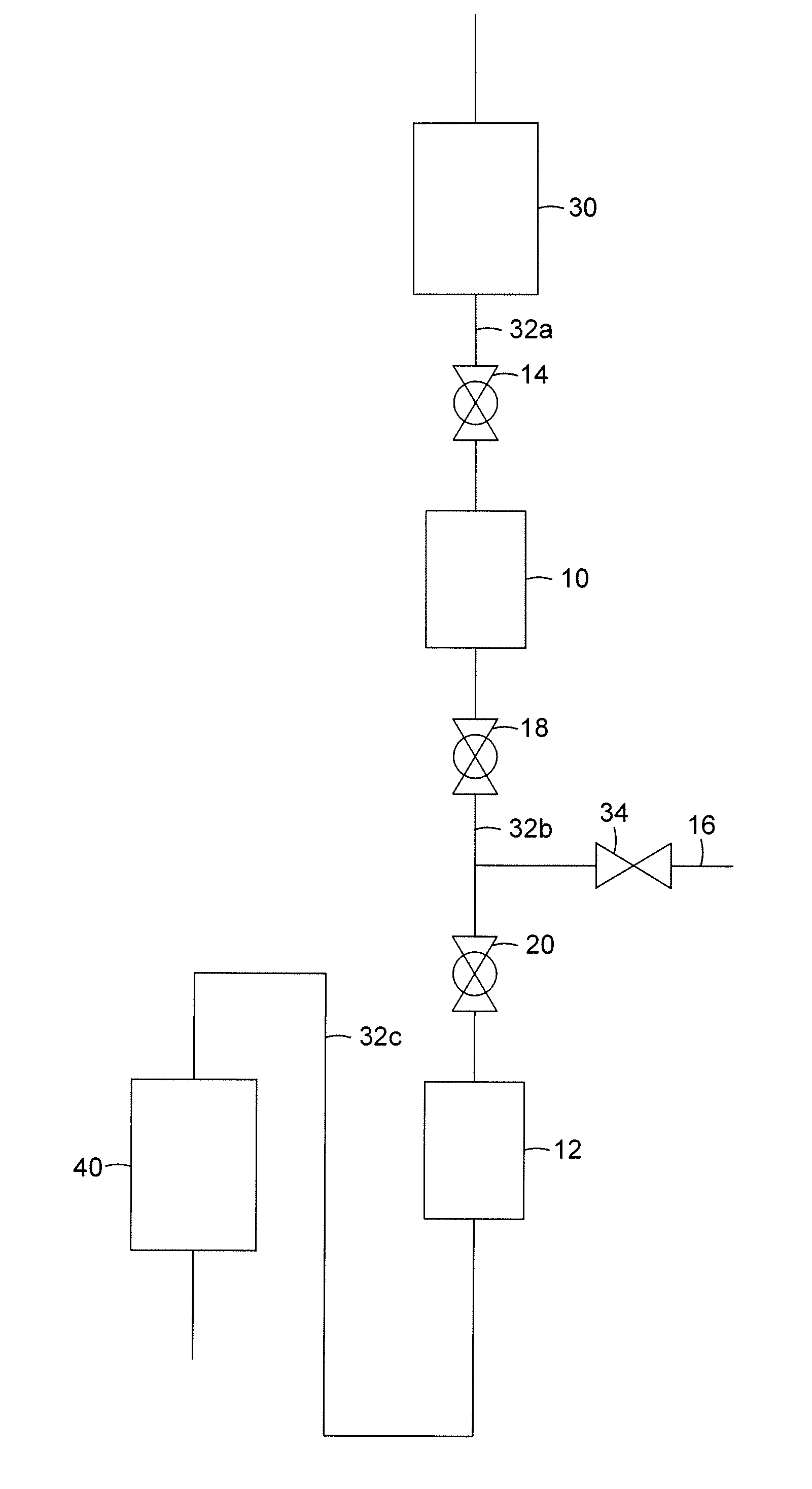

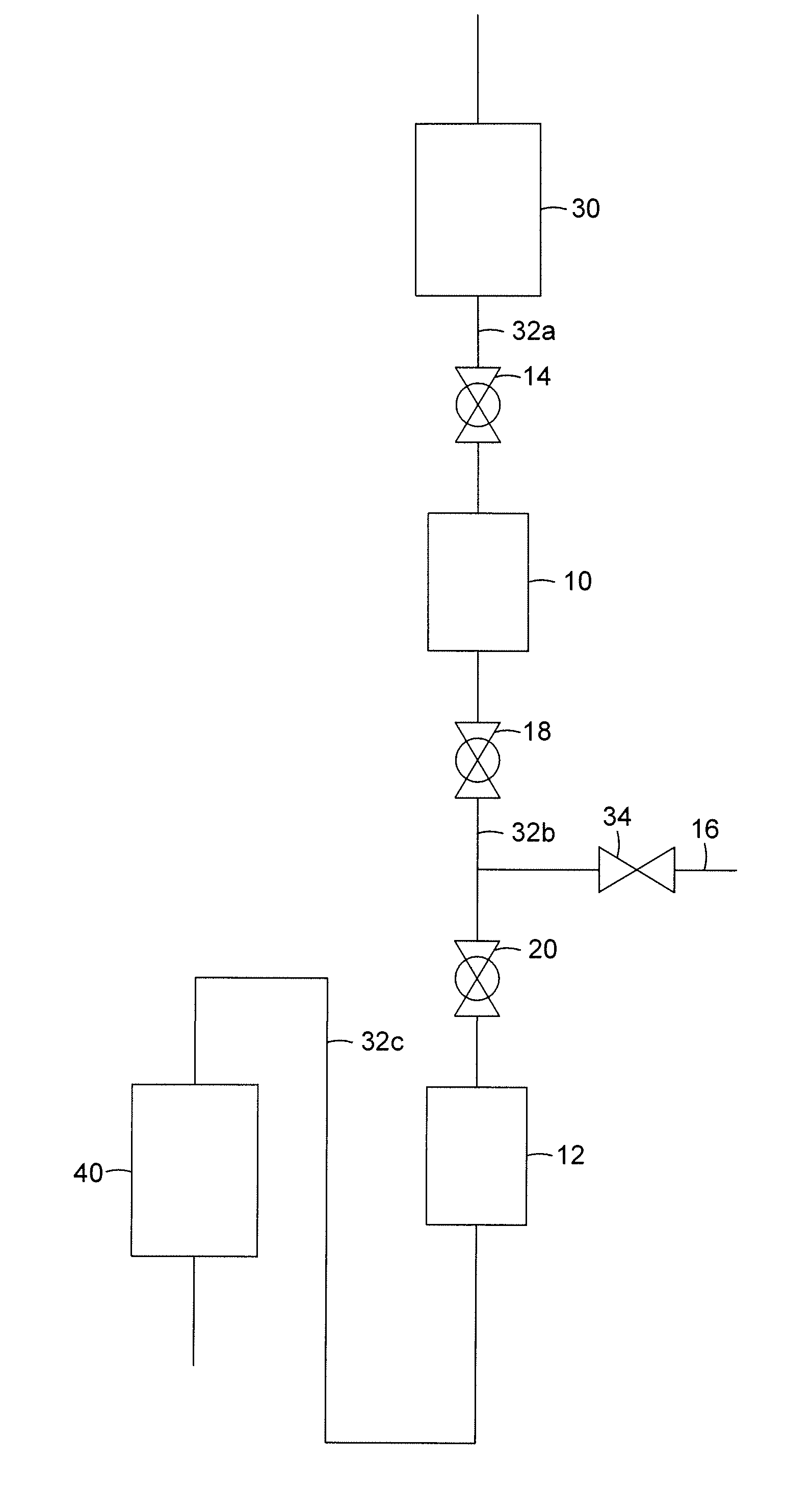

Device to transfer catalyst from a low pressure vessel to a high pressure vessel and purge the transferred catalyst

ActiveUS7600950B2Easy to operateShorten the timeBulk conveyorsChemical/physical processesParticulatesParticle transfer

Owner:UOP LLC

Device to transfer catalyst from a low pressure vessel to a high pressure vessel and purge the transferred catalyst

ActiveUS8075227B2Easy to operateShorten the timeCatalytic naphtha reformingLavatory sanitoryParticulatesReactor pressure vessel

Owner:UOP LLC

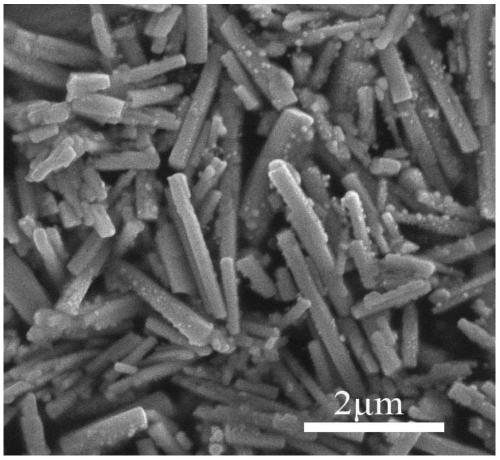

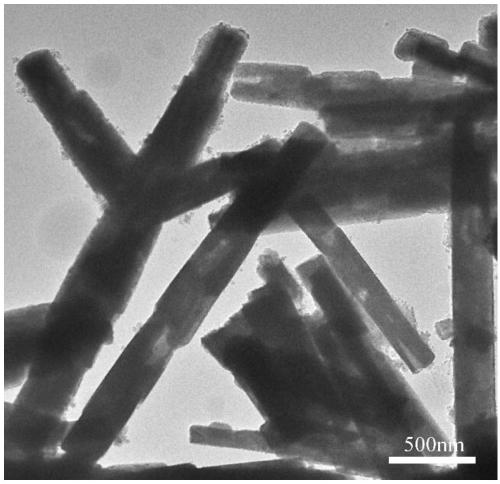

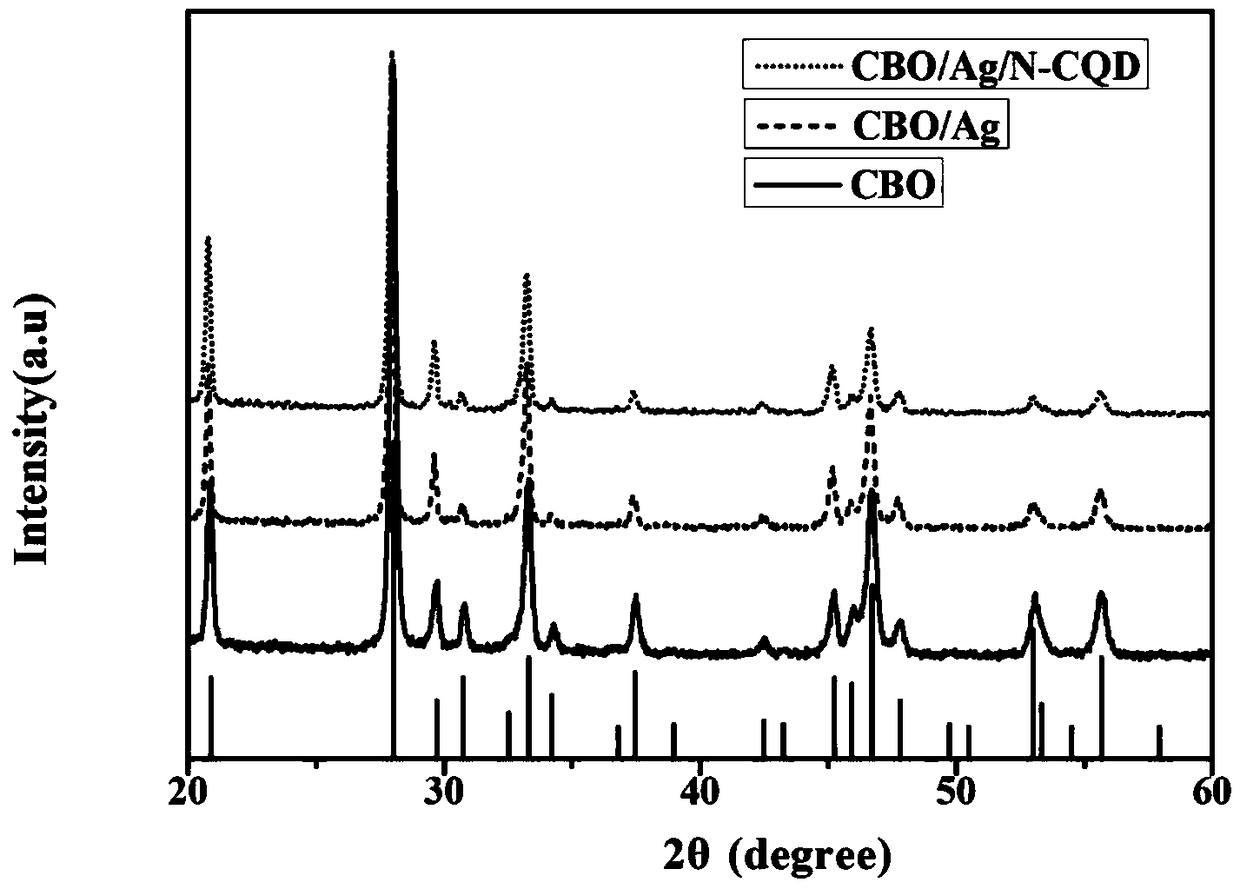

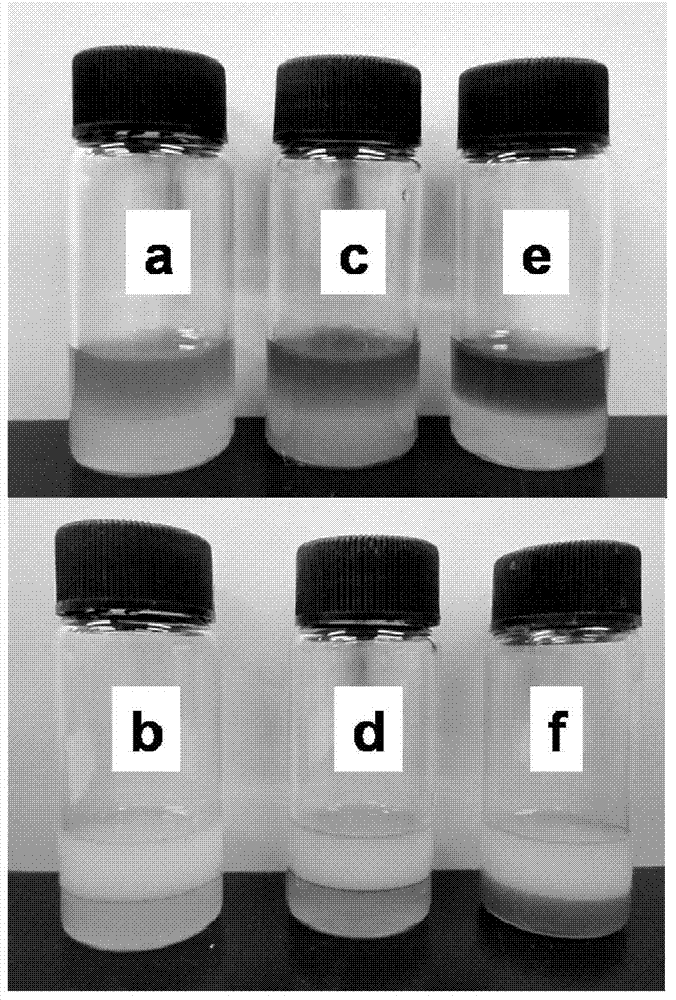

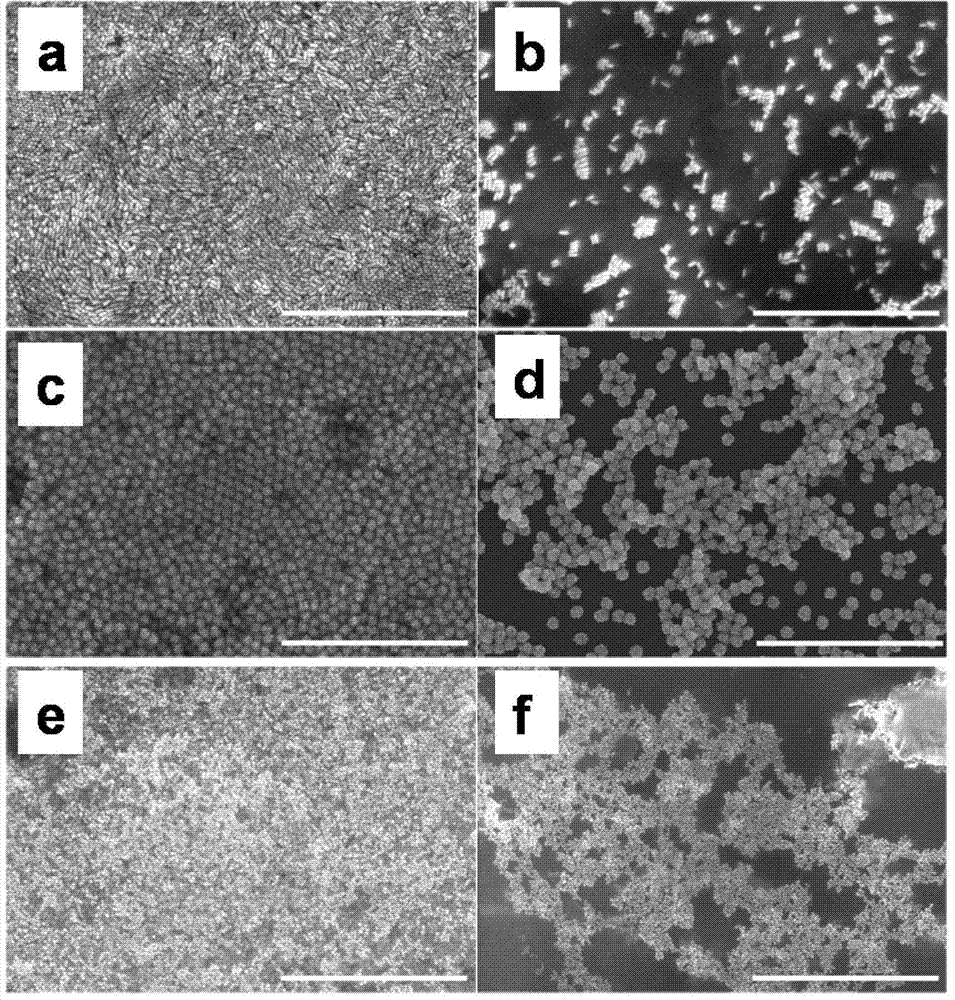

Preparation method for co-modified copper bismuthate nanorod photocathodes

ActiveCN109308982AHigh activityImprove featuresMaterial nanotechnologyPhoto-emissive cathodes manufacturePhotocathodeDecomposition

The invention discloses a preparation method for co-modified copper bismuthate nanorod photocathodes. The preparation method includes the following steps: (1) performing hydro-thermal synthesis of a CuBi2O4 nanorod under an alkaline condition by utilizing abundant and cheap bismuth sources and copper sources; (2) loading silver ions on the CuBi2O4 nanorod by adopting an ion alternating physical adsorption method; (3) taking FTO conductive glass as a substrate, forming a CuBi2O4 / Ag film by adopting a drop-coating method, and performing annealing processing through a CVD method; and (4) peelinga material by adopting a particle transfer technology to transfer to second FTO glass, performing ultrasonic processing, and preparing a nitrogen doped carbon quantum dot and sliver co-modified CuBi2O4 nanorod photocathode through the physical adsorption of nitrogen-doped carbon quantum dots. The photocathode prepared through the method can show good photo-electrocatalytic activity and visible light response characteristics under visible light, and stability can be improved, so that the preparation method can be effectively applied to the field of photo-electrocatalytic water decomposition forhydrogen production.

Owner:WENZHOU UNIVERSITY

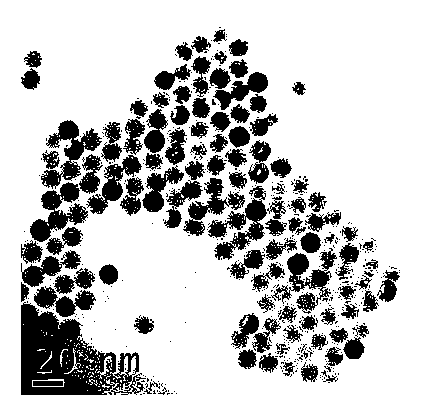

Method for phase transferring and three-dimensional assembling of precious metal nano-particles

InactiveCN103496666AStrong adsorptionIncrease adsorption densityNanostructure manufactureParticle transferCentrifugation

The invention discloses a method for phase transferring and three-dimensional assembling of precious metal nano-particles. The method comprises the following steps that after centrifugation is carried out on the aqueous solutions of the precious metal nano-particles, the aqueous solutions of 2 (diethyl aminoethyl acyl methyl ethyl) octadecylamine are added to sediments acquired through the centrifugation for ultrasonication, obtained dispersion liquid and the organic solutions of the 2 (diethyl aminoethyl acyl methyl ethyl) octadecylamine are mixed and vibrated, standing is carried out, and the precious metal nano-particles are transferred from a water phase to an oil phase. Centrifugation is carried out on the precious metal nano-particles transferred to the oil phase for the first time, the organic solutions of the 2 (diethyl aminoethyl acyl methyl ethyl) octadecylamine are added to the sediments acquired through the centrifugation for the ultrasonication, then obtained dispersion liquid and the organic solutions of silicon dioxide balls decorated by sulfydryl are mixed and stirred, centrifugation is carried out for the second time, obtained sediments are the precious metal nano-particles after the three-dimensional assembling, and the three-dimensional assembling of the precious metal nano-particles is achieved. The method is simple in operation, balance time for the phase transferring is short, and repeatability and controllability are better.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Device to Transfer Catalyst from a Low Pressure Vessel to a High Pressure Vessel and purge the Transferred Catalyst

ActiveUS20090142148A1Easy to operateShorten the timeBulk conveyorsChemical/physical processesParticulatesPressure system

An apparatus for the transfer of solid particulate matter from a low pressure system to a high pressure system is presented. The apparatus simplifies the particle transfer process, and is useful for systems where solid catalyst particles are cycled through a reactor and a regenerator.

Owner:UOP LLC

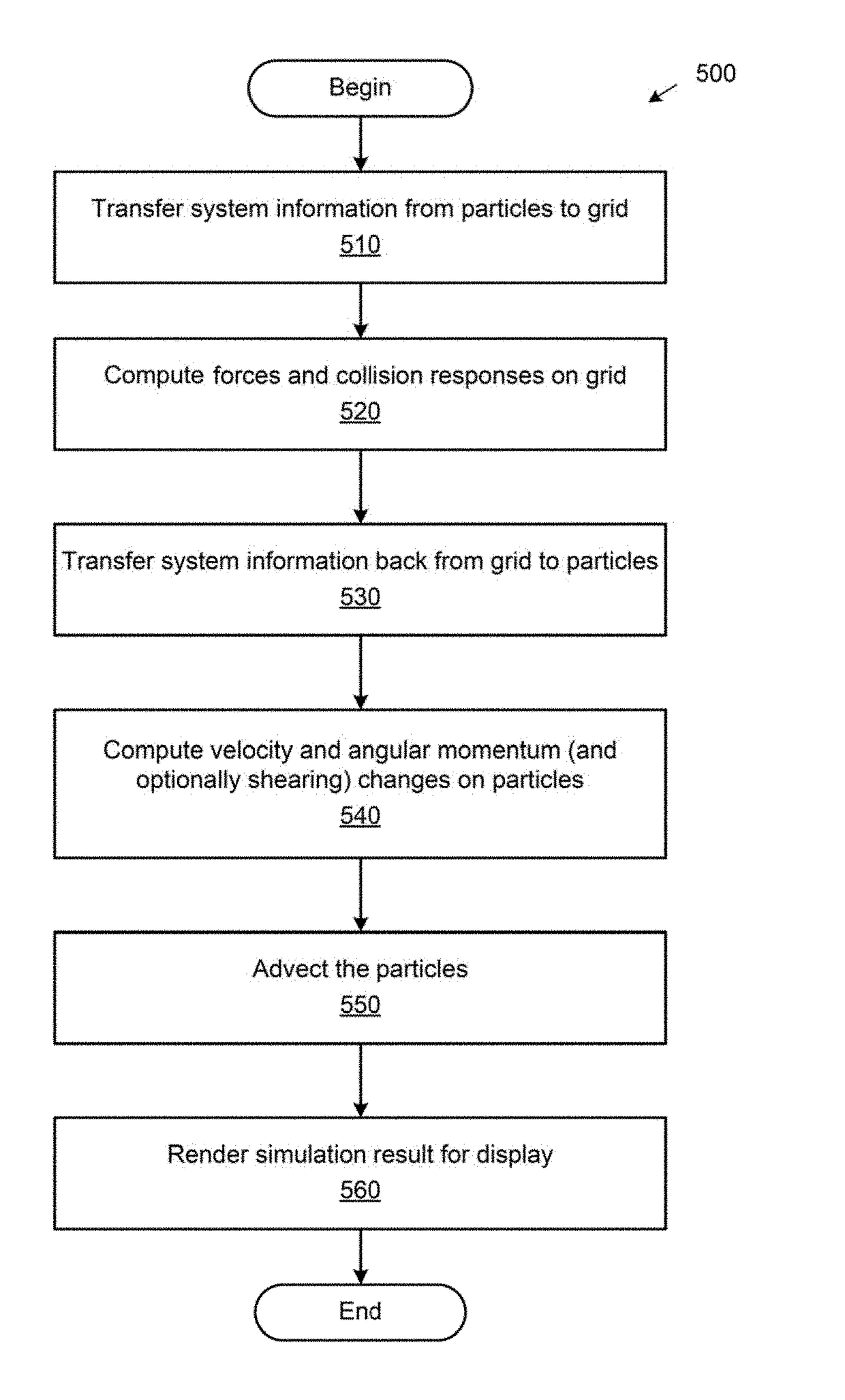

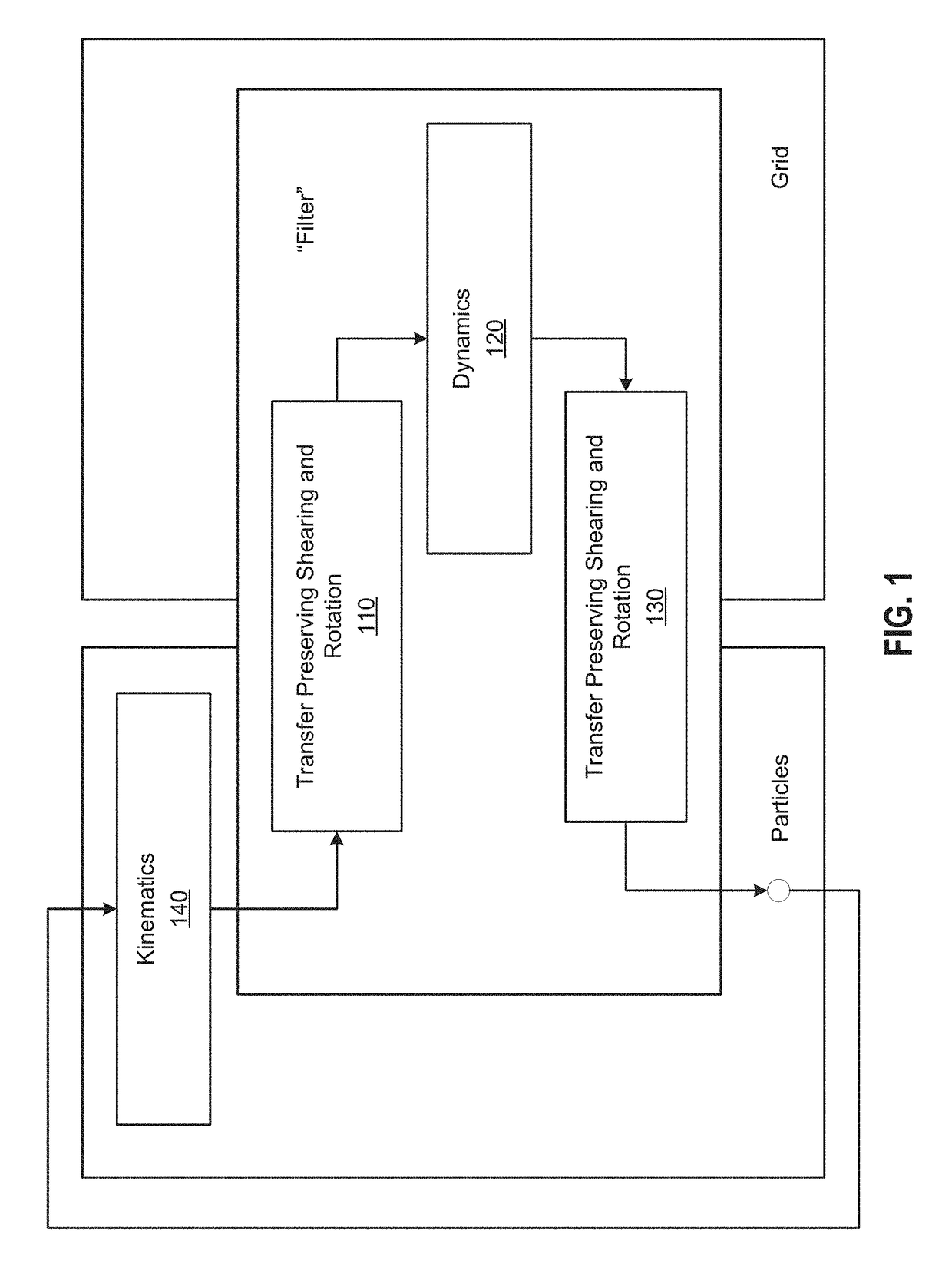

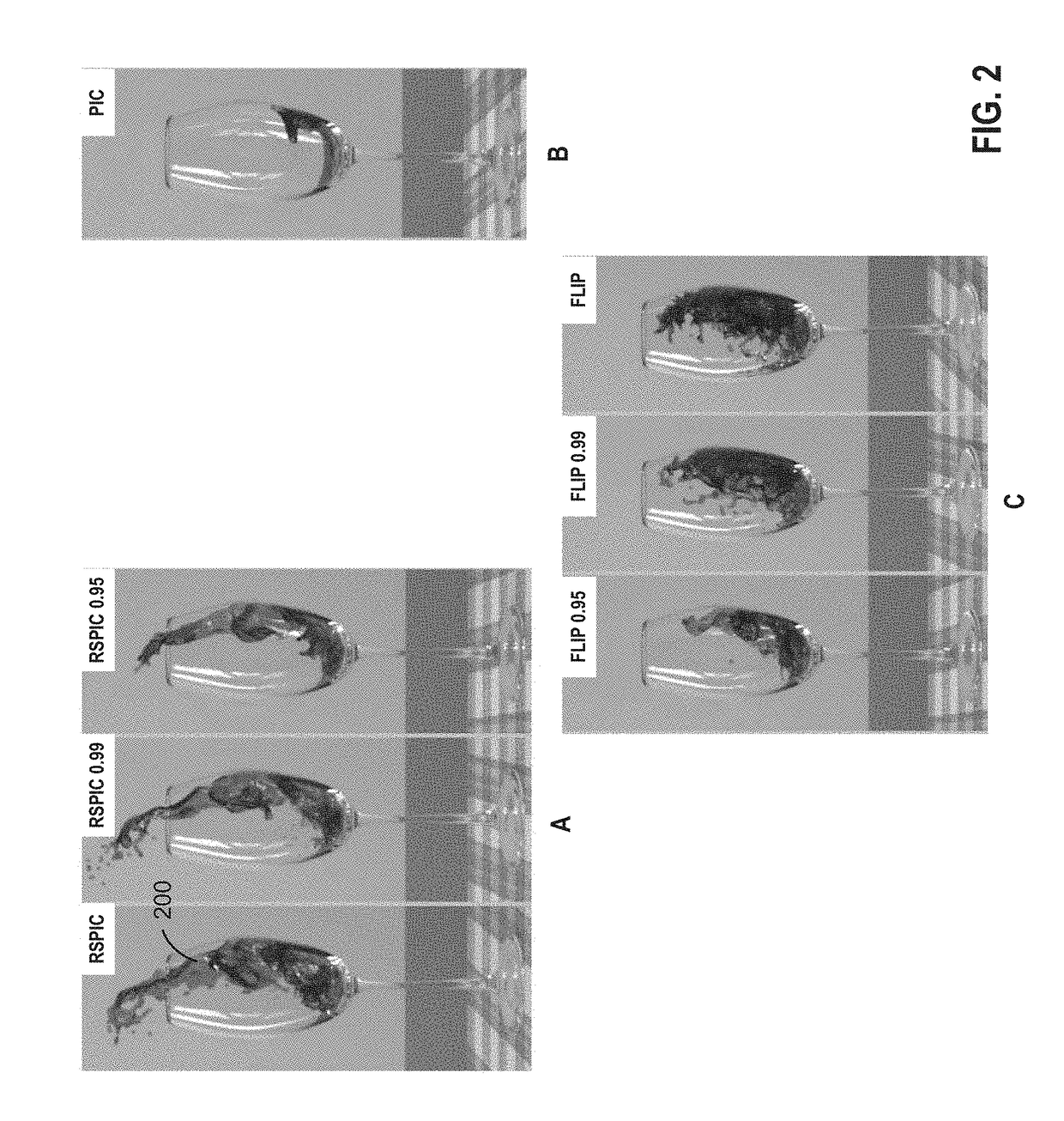

Particle-in-cell methods preserving shearing and rotation

The disclosure provides an approach for reducing information loss when transferring from particles to grid and vice versa in a hybrid Lagrangian / Eulerian simulation, while also preserving stability. In one aspect, referred to as the rigid particle-in-cell (RPIC) method, a simulation application stores a sampling of local angular momentum for each particle, helping to preserve the angular momentum that would otherwise be lost in the transfer from grid to particles. In another aspect that is more generally applicable and referred to herein as the rigid and shearing particle-in-cell (RSPIC) method, the simulation application stores, for each particle, a matrix with rotational and shearing information. The RSPIC method effectively reduces dissipation, preserves angular momentum exactly, and prevents instabilities. Further, the RSPIC method is applicable to both incompressible liquids and material point method (MPM) simulations of materials such as solids.

Owner:DISNEY ENTERPRISES INC

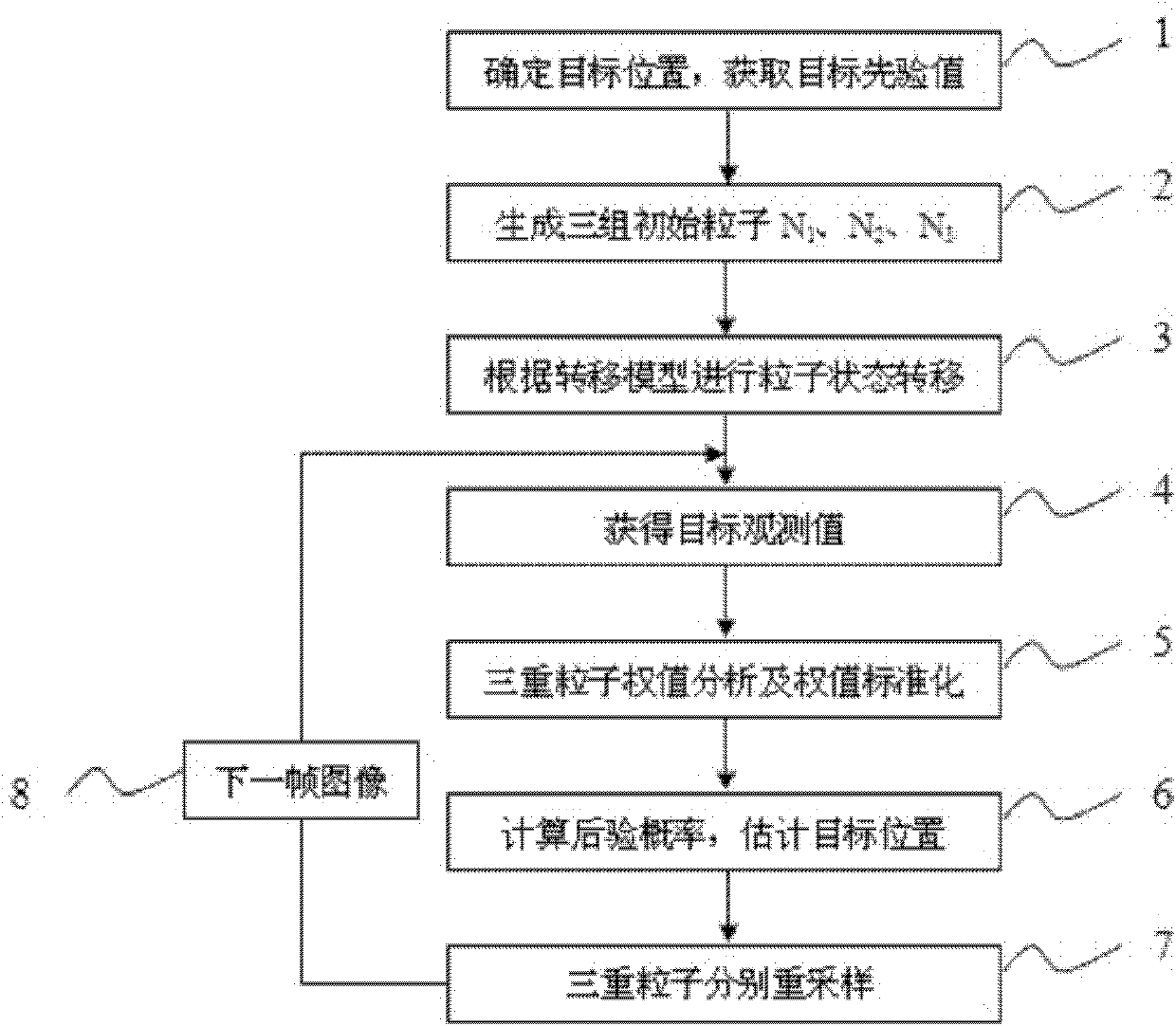

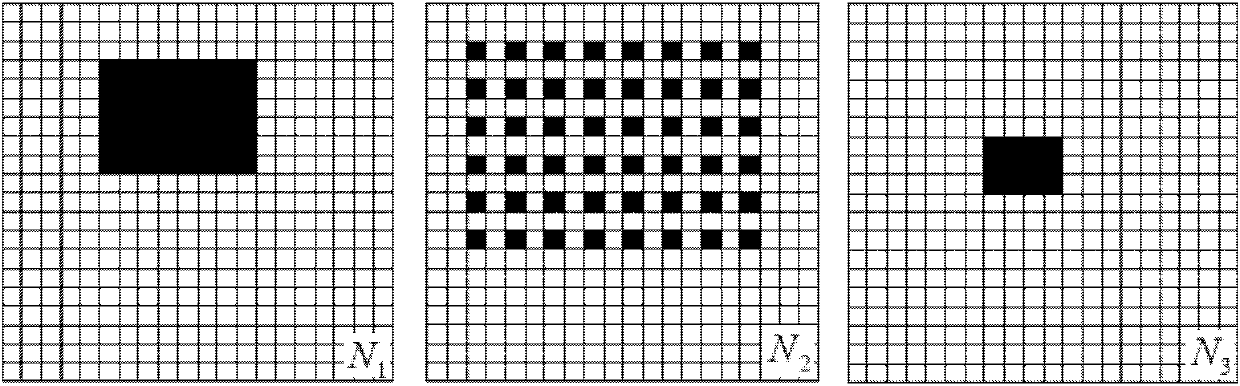

Visual object tracking method based on particle filter of triple particles

InactiveCN102663770AAccurate descriptionReduce tracking errorImage analysisCamera lensVisual field loss

The present invention belongs to a mobile object visual tracking technology of a mechanical visual field to solve a problem of missing a tracked object resulted from a size change of an object image in an object tracking of a particle filter. Provided is a visual object tracking method based on a particle filter of triple particles. Specifically an improvement reflects in tracking an object using three groups of particles in the particle filter, wherein the differences among the three groups of particles are the difference in the number and the form of contained pixels, and parameters of three groups of particle transfer models are set differently in a process of a state transfer of particles. When a distance between the tracked object and a shooting lens is changed resulting in the size change of the object image, at least one group of the three groups of particles have a larger weight so that the group of particles can describe the tracked object more accurately. Thereby, the method in the invention can reduce a tracking error and enhance a tracking precision.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Sample transferring apparatus for mass cytometry

In a mass cytometer or mass spectrometer, a sample of elemental tagged particles is transferred from a dispersion to a gas flow through a carrier aerosol spray for atomization and ionization by inductively coupled plasma (ICP) source. The configuration of the sample transfer apparatus allow for total consumption of the sample by passing the sample spray through a deceleration stage to decelerate the spray of particles from its high velocity expansion. Following the deceleration stage, the decelerated sample of particles can be accelerated and focused through an acceleration stage for transferring into the ICP. This effectively improves the particle transfer between the sample spray and the ICP.

Owner:STANDARD BIOTOOLS CANADA INC

Moving Bed Hydrocarbon Conversion Process

InactiveUS20100125159A1Molecular sieve catalystCatalytic naphtha reformingParticle transferGas passing

Moving bed hydrocarbon conversion processes are provided for contacting a catalyst moving downward through a reaction zone with a hydrocarbon feed, withdrawing the catalyst from the reaction zone and conveying the catalyst to a regeneration zone wherein the catalyst moves downward. The catalyst is withdrawn from the regeneration zone and passed downward to an upper zone of a particle transfer apparatus wherein the transfer of catalyst from the upper zone through an intermediate zone to a lower zone is regulated by varying the pressure of the intermediate zone and the flow rate of gas passing through the valveless conduits. A container within the second zone is in catalyst communication with a valveless conduit and provides more consistent catalyst flows. The catalyst from the lower zone of the particle transfer apparatus is conveyed to the reactions zone.

Owner:UOP LLC

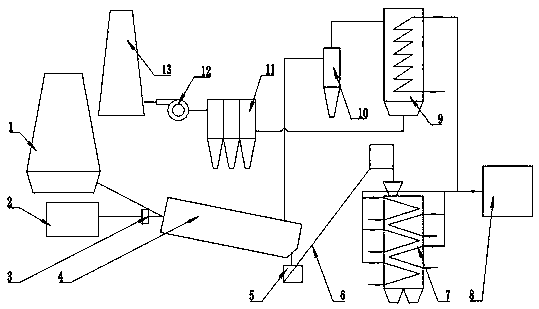

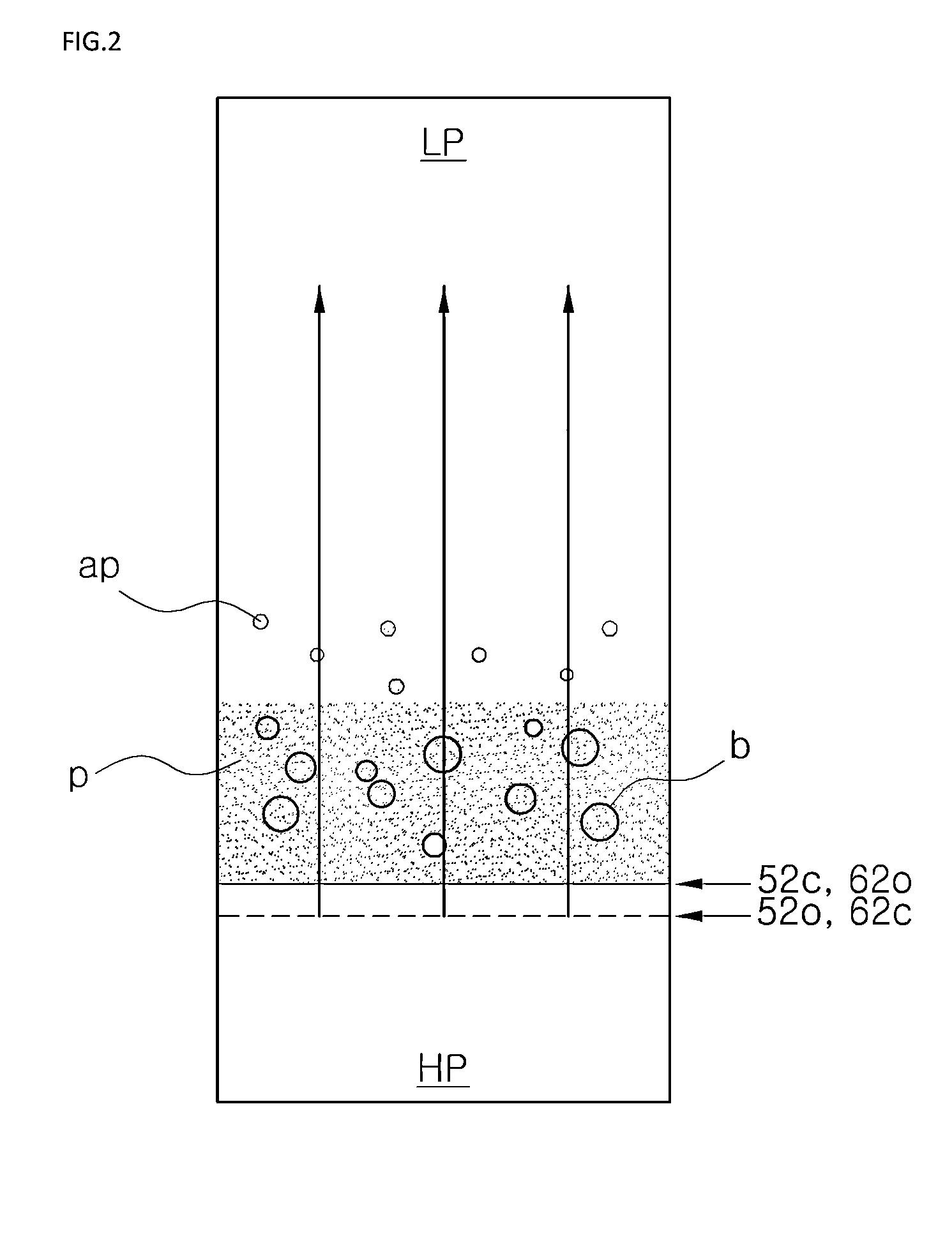

Dry Carbon Dioxide Capture Apparatus

ActiveUS20120132078A1Preventing a gas backflowImprove capture efficiencyIsotope separationBy adsorptionParticle transferSorbent

Disclosed is a dry carbon dioxide capture apparatus with improved carbon dioxide capture efficiency through preventing gas backflows into vertical transport lines. The dry CO2 capture apparatus includes a capture reactor having a capture buffer chamber on the bottom side, a capture diffusion plate on top of the capture buffer chamber, and adsorbent particles in a space above the capture diffusion plate; a first separator connected to the capture reactor through a vertical transport line; a regenerator having a regeneration buffer chamber on the bottom side, a regenerating diffusion plate on top of the regeneration buffer chamber, and adsorbent particles in a space above the regenerating diffusion plate; a second separator connected to the regenerator through a gas separation line; and a second particle transfer line connected to the regenerator at one end and connected to the capture reactor at the other end.

Owner:KOREA INST OF ENERGY RES

Blast furnace slag gas quenching microsphere waste heat recovery device

PendingCN108277311AHigh economic valueGood energy saving and emission reduction effectIncreasing energy efficiencyRecycling and recovery technologiesLiquid wasteSlag

The invention relates to a blast furnace slag gas quenching microsphere waste heat recovery device which comprises a gas quenching pelleting system and a waste heat recovering system. The gas quenching pelleting system comprises a blast furnace, a gas quenching device used for gas quenching of high temperature liquid state blast furnace slag flowing out from the blast furnace into microspheres, and a rotary slag particle solidification device connected with the blast furnace and the gas quenching device and used for molding and cooling the microspheres; the waste heat recovering system comprises a solid-liquid waste heat boiler and a gas-liquid waste heat boiler; the top end of the tail of the rotary slag particle solidification device is connected with the gas-liquid waste heat boiler through a multi-pipe dust removal device, and the bottom of the gas-liquid waste heat boiler communicates with a chimney through a bag-type dust collector and an induced draft fan; and the lower end of the tail of the rotary slag particle solidification device is connected with the top of the solid-liquid waste heat boiler through a slag wool separating system and a slag particle transferring system.The waste heat recovery device special for the blast furnace slag is disclosed, transformation is convenient, high-quality waste heat of a steel mill can be greatly improved, the energy saving and emission reduction effect is obvious, and the high economic benefit is achieved.

Owner:唐山金沙燃烧热能股份有限公司

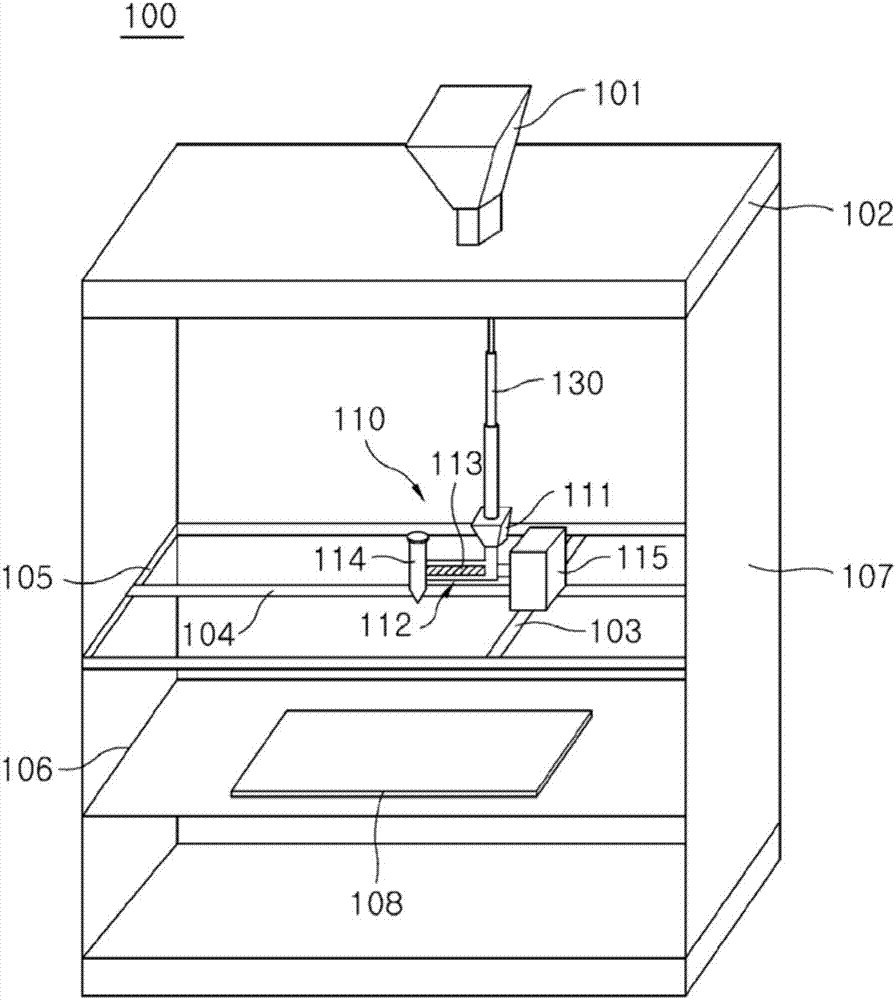

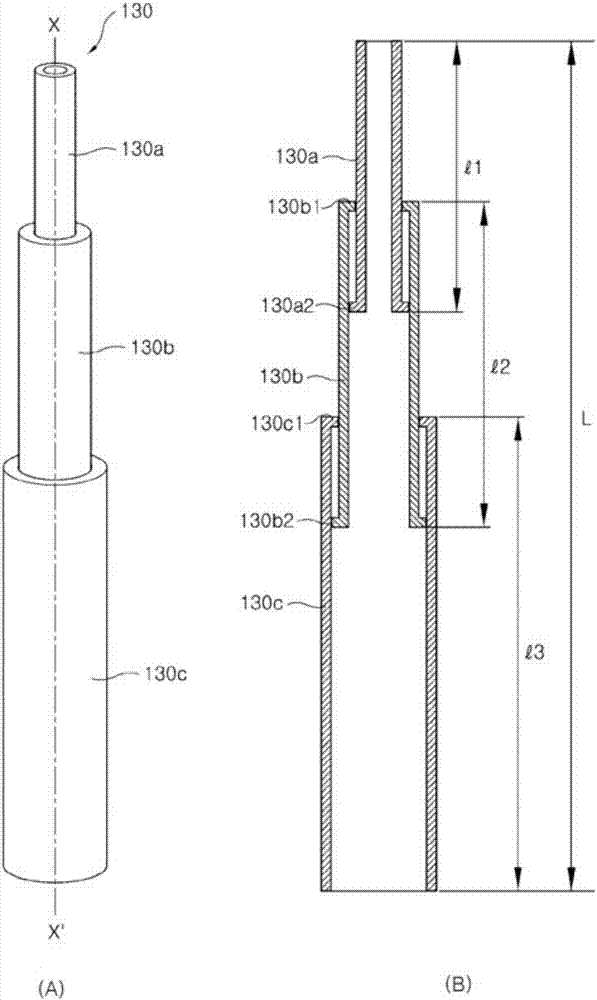

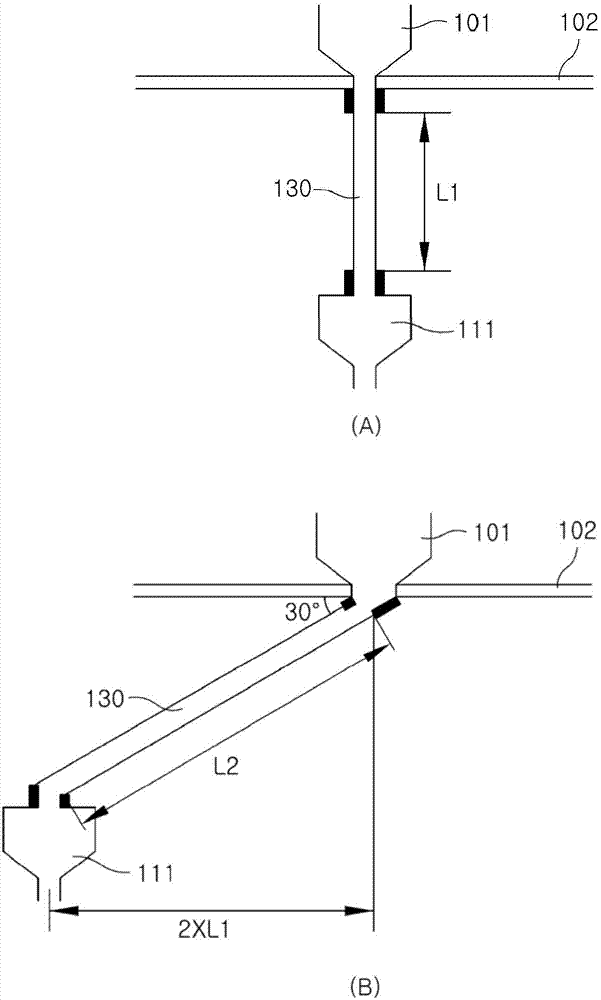

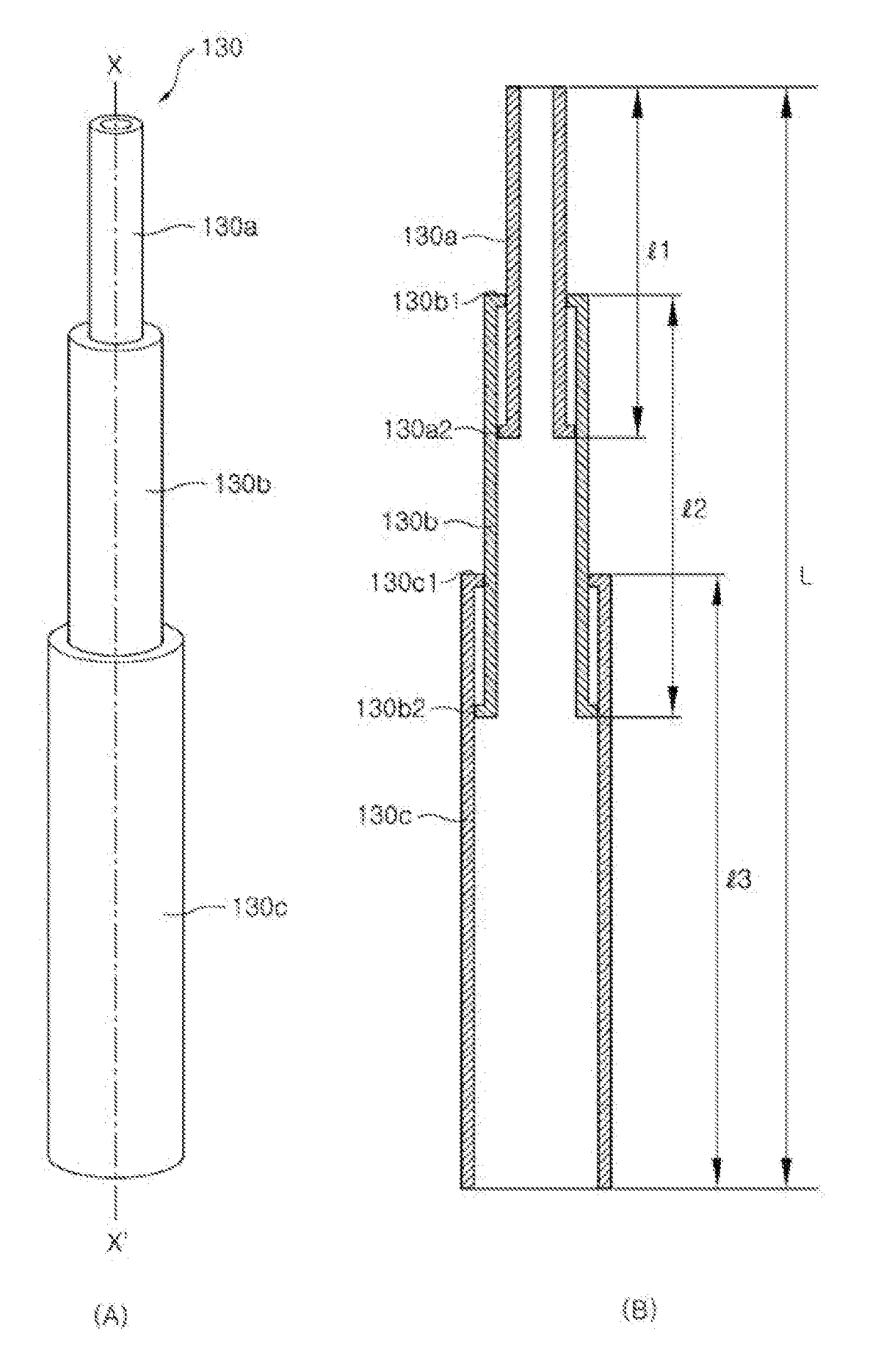

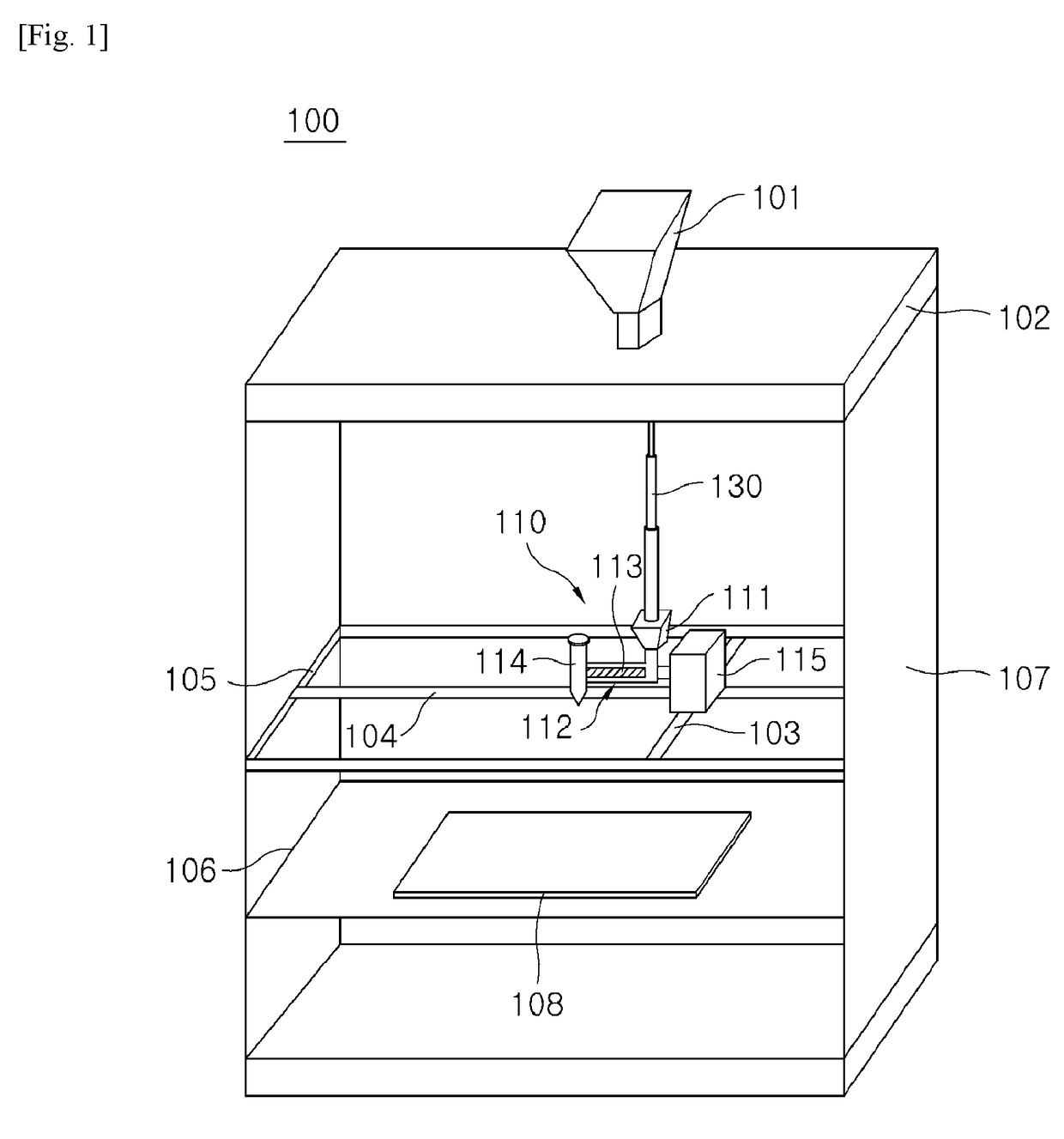

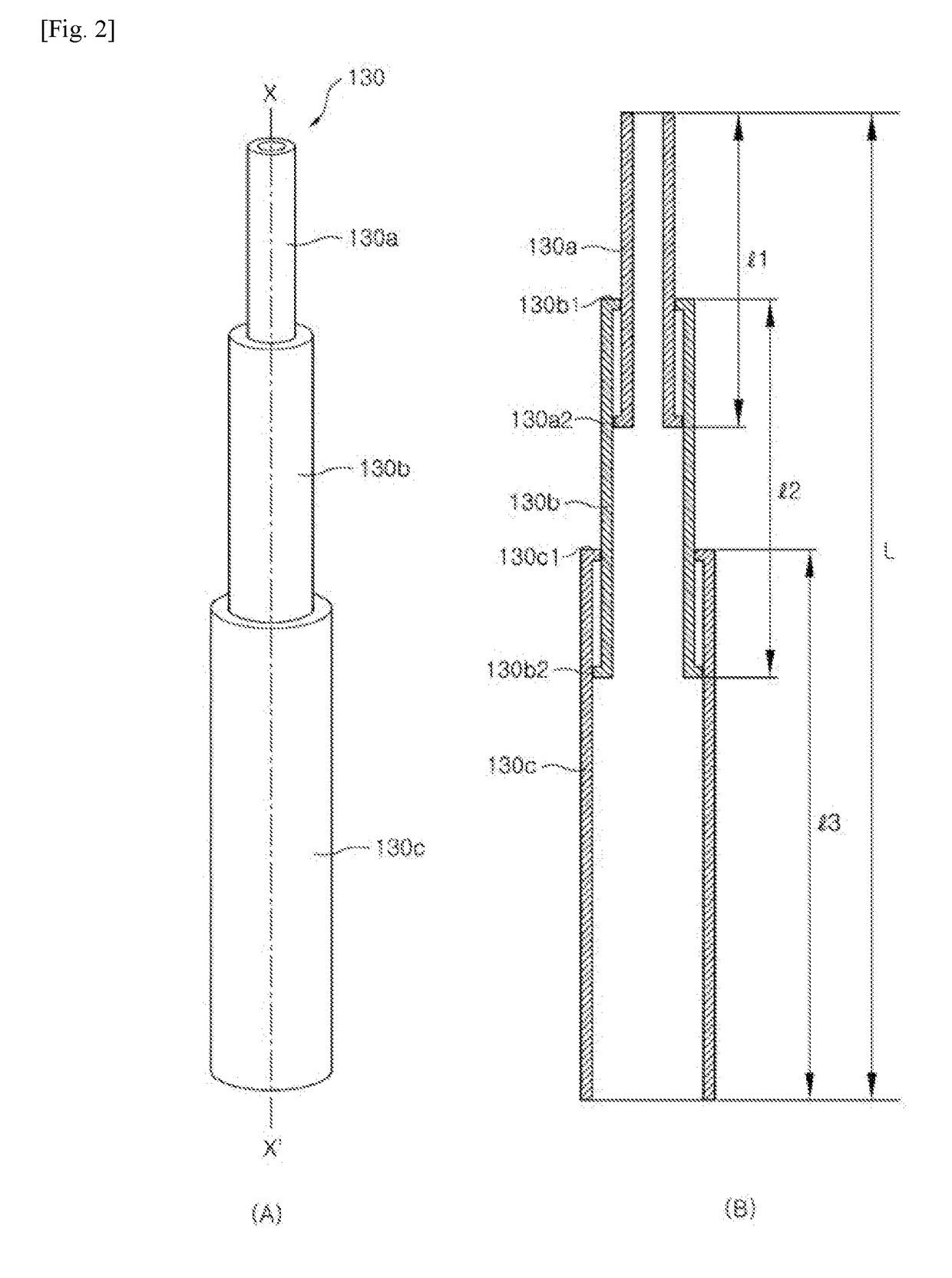

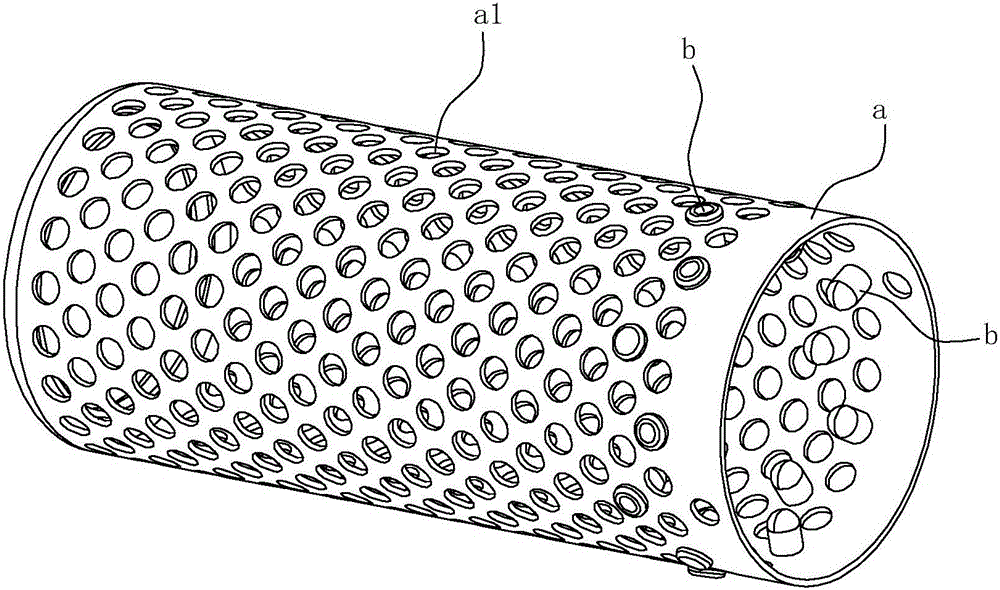

Apparatus for producing three-dimensional molded article, comprising particle transfer pipe

InactiveCN107249857AAdjustable lengthSmooth supplyManufacturing enclosures3D object support structuresParticle transferPosition control

The present invention relates to an apparatus for producing a predetermined three-dimensional molded article by melting molding material particles and controlling the discharge position of the melted molding material particles. The apparatus comprises: an extrusion part which performs three-dimensional molding by melting and discharging, through a nozzle, the molding material particles; a storage container which temporarily stores the molding material particles supplied to the extrusion part; a transfer pipe which provides a path for transferring, to the extrusion part, the molding material particles stored in the storage container; and an extraction part position control part which controls the position of the extrusion part, wherein the transfer pipe is formed by connecting a plurality of unit transfer pipes.

Owner:FINE CHEM

Apparatus for producing three-dimensional molded article including particle transfer pipe

InactiveUS20180015673A1Increase supplyMovement rangeManufacturing enclosures3D object support structuresParticle transferMaterials science

The present invention relates to an apparatus for producing a desired three-dimensional molded article. In the apparatus of the present invention, molding material particles are melted and the discharge position of the molten molding material particles is controlled. The apparatus of the present invention includes an extrusion unit for three-dimensional molding where the molding material particles are melted and discharged through a nozzle, a storage container where the molding material particles to be supplied to the extrusion unit are temporarily stored, a transfer pipe as a passage through which the molding material particles stored in the storage container are transferred to the extrusion unit, and a control unit for controlling the position of the extrusion unit. The transfer pipe consists of a plurality of connected unit transfer pipes.

Owner:FINE CHEM

Apparatus and method of transferring, focusing and purging of powder for direct printing at low temperature

ActiveUS20150174909A1Effective controlReliable formingPrintingPressure inorganic powder coatingParticle transferProcess engineering

Disclosed herein are apparatus and method for transferring, focusing and purging powder for direct printing at low temperature. A filter is provided between an operation chamber housing in which a work target is disposed and a reservoir tank which contains powder to adjust the amount of particles transferred from the reservoir tank into the operation chamber housing. A pressure unit connected to the reservoir tank generates air pressure for applying powder to the work target. A purging unit connected to the reservoir tank generates pressure for returning powder that has remained in the operation chamber housing, the filter, etc. to the reservoir tank after work has been completed. The apparatus is configured such that a series of process of transferring powder to be applied to the surface of the work target and returning remnant powder to the reservoir tank can be rapidly and smoothly conducted.

Owner:SEOUL NAT UNIV R&DB FOUND

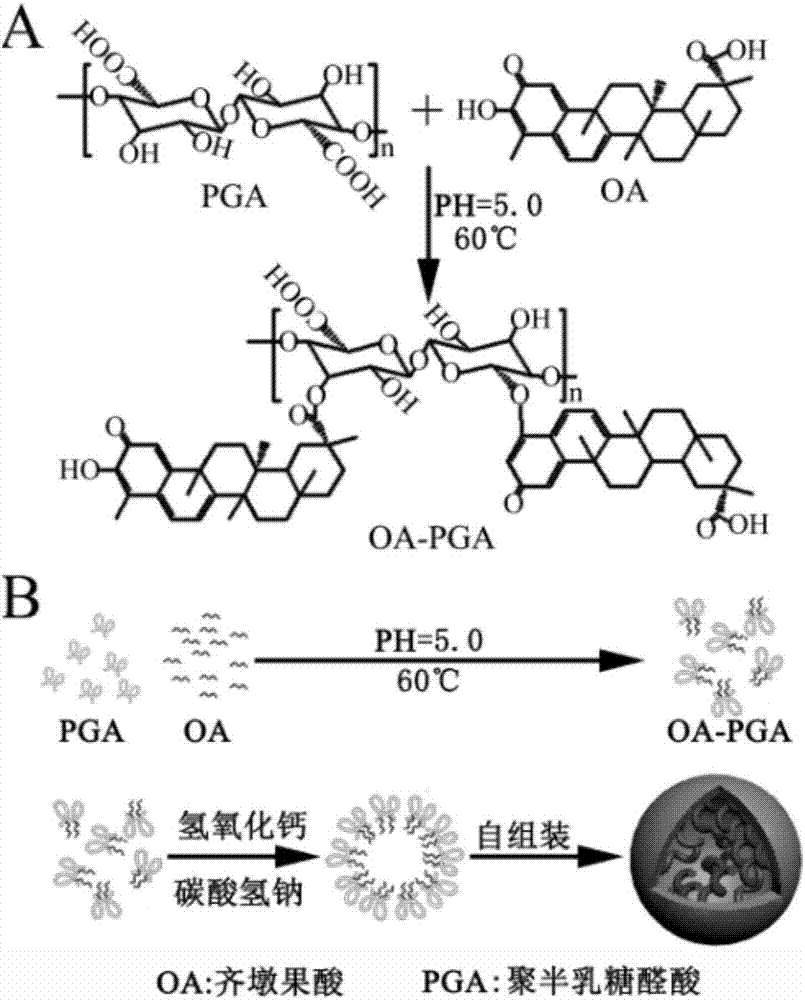

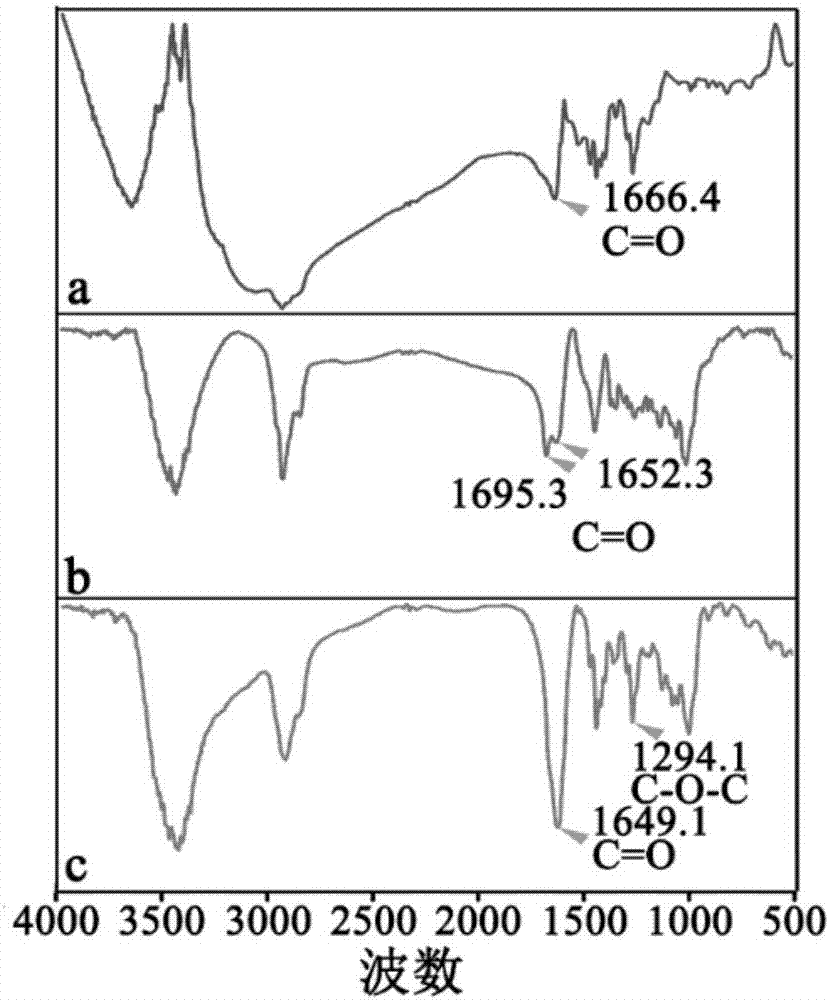

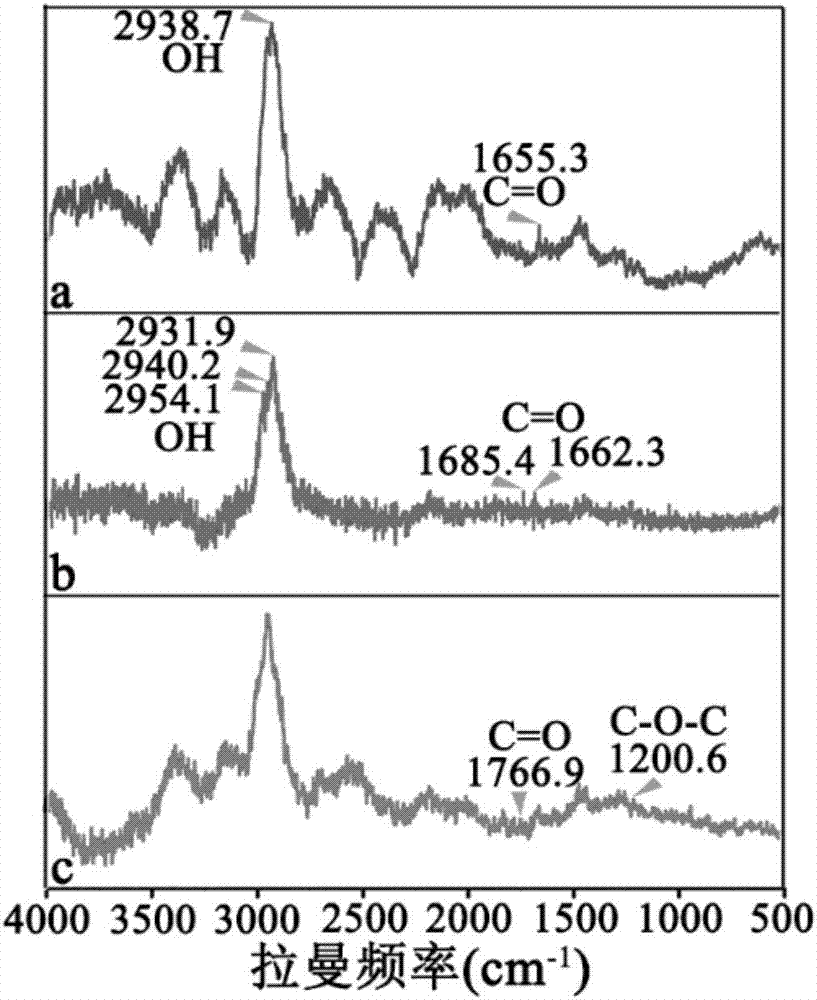

Oleanolic acid nanometer oral system with inhibiting effect on insulin resistance

ActiveCN107296960ATreatment safetyImprove guidanceOrganic active ingredientsPharmaceutical non-active ingredientsPentagalacturonic acidIslet cells

The invention discloses an oleanolic acid nanometer oral system with an inhibiting effect on insulin resistance. A hydrophilic substance polygalacturonic acid (PGA) and a hydrophobic substance oleanolic acid (OA) are connected together via esterification reaction and then are self-assembled to form nano-scale micelle particles OA-PGA. The micelle particles increase the utilization rate of medicines while maintaining the characteristics of the two substances; serving as an insulin resistance nanometer targeted oral delivery system, the micelle particles can realize targeted transportation of the medicines and can convey the medicines into a body well, and the nanoparticles have high stability, so the sensitivity of the insulin can be improved, the activity of islet cells can be improved, and effects of inhibiting and relieving insulin resistance and organ damage are obvious; the OA-PGA micelle particles transfer natural insulin sensitizers harmless to a body by taking natural substances as carriers, do not have toxicity on cells, and have great potential and application prospect in the aspect of treating type II diabetes.

Owner:SOUTH CHINA NORMAL UNIVERSITY

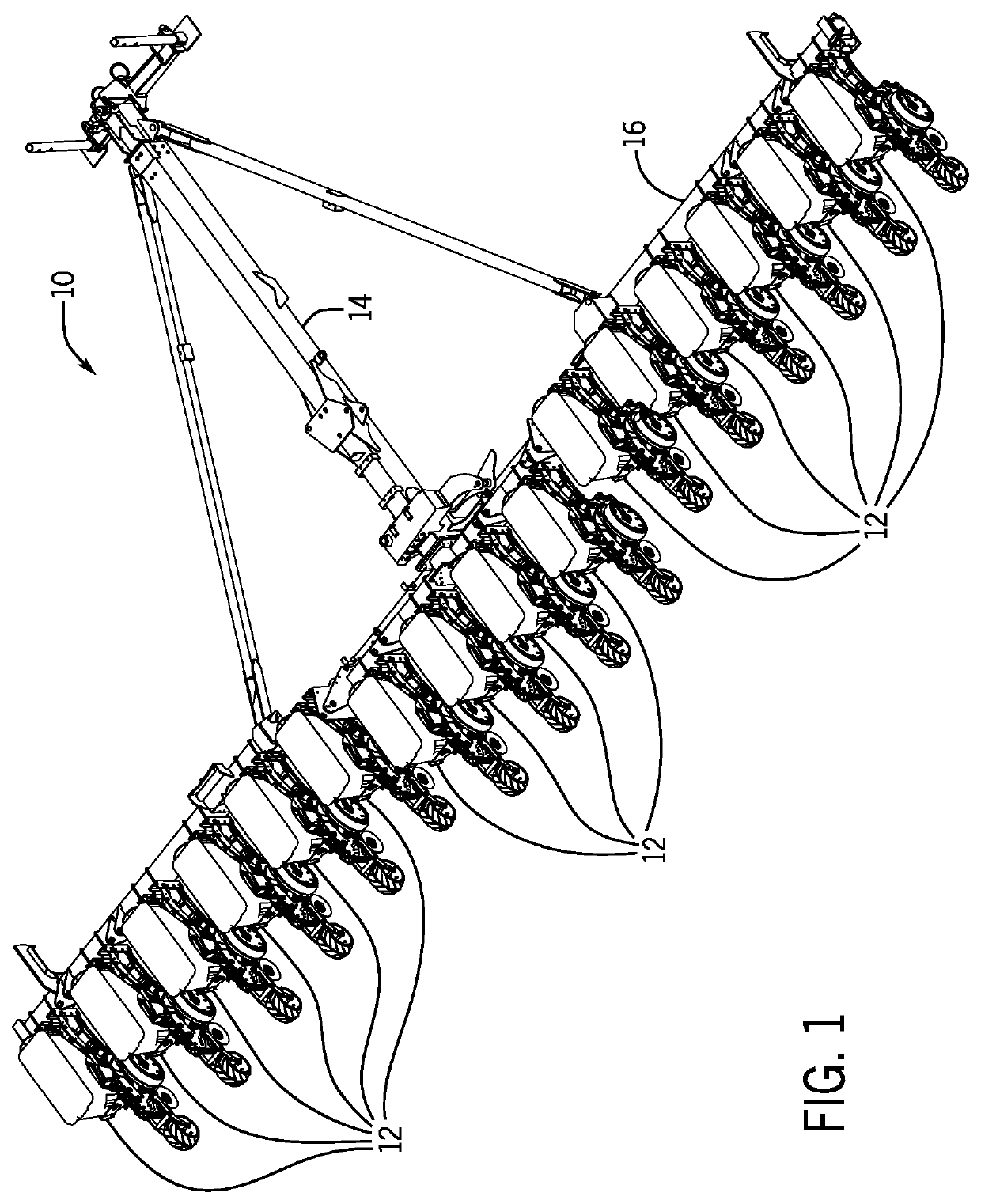

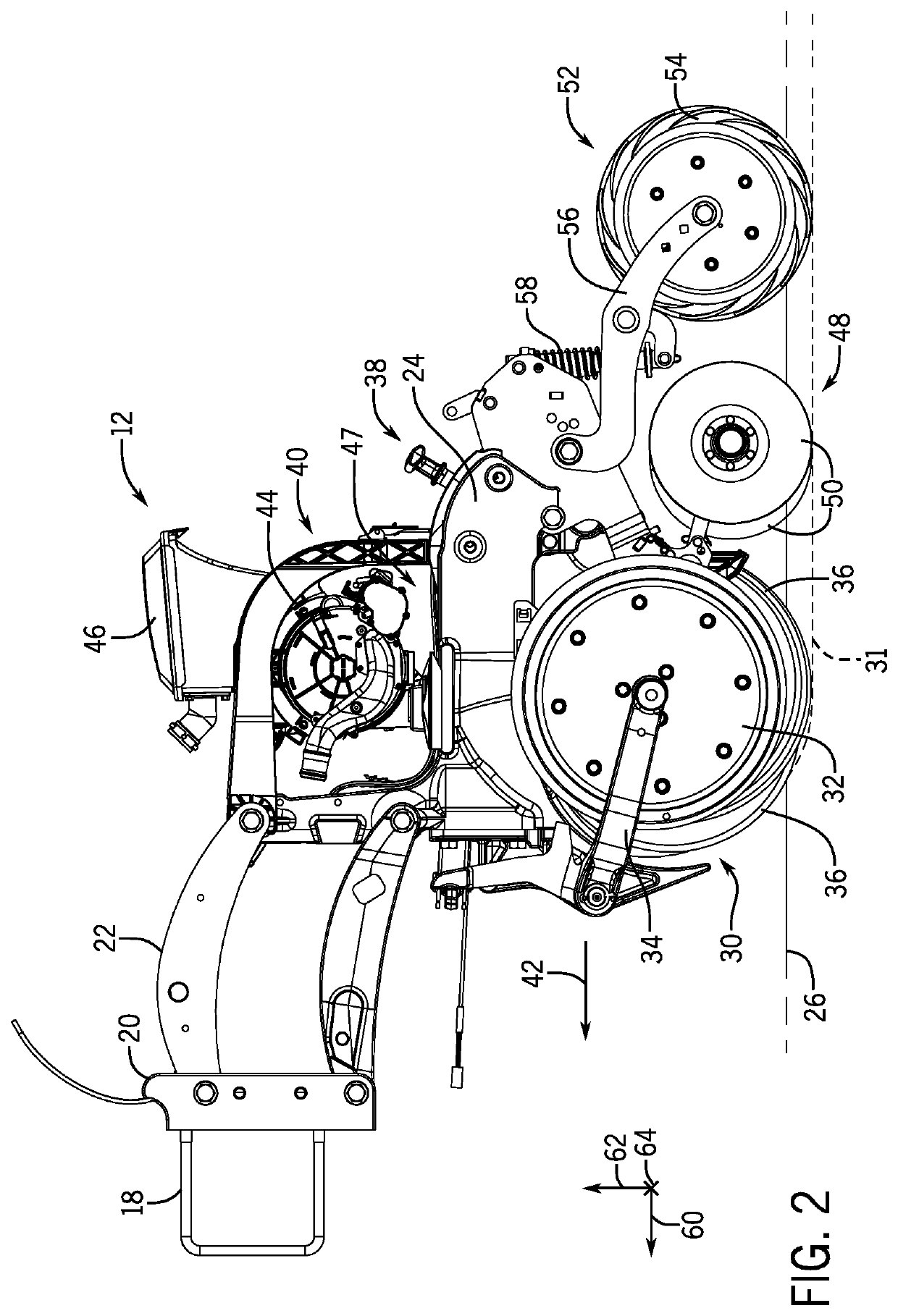

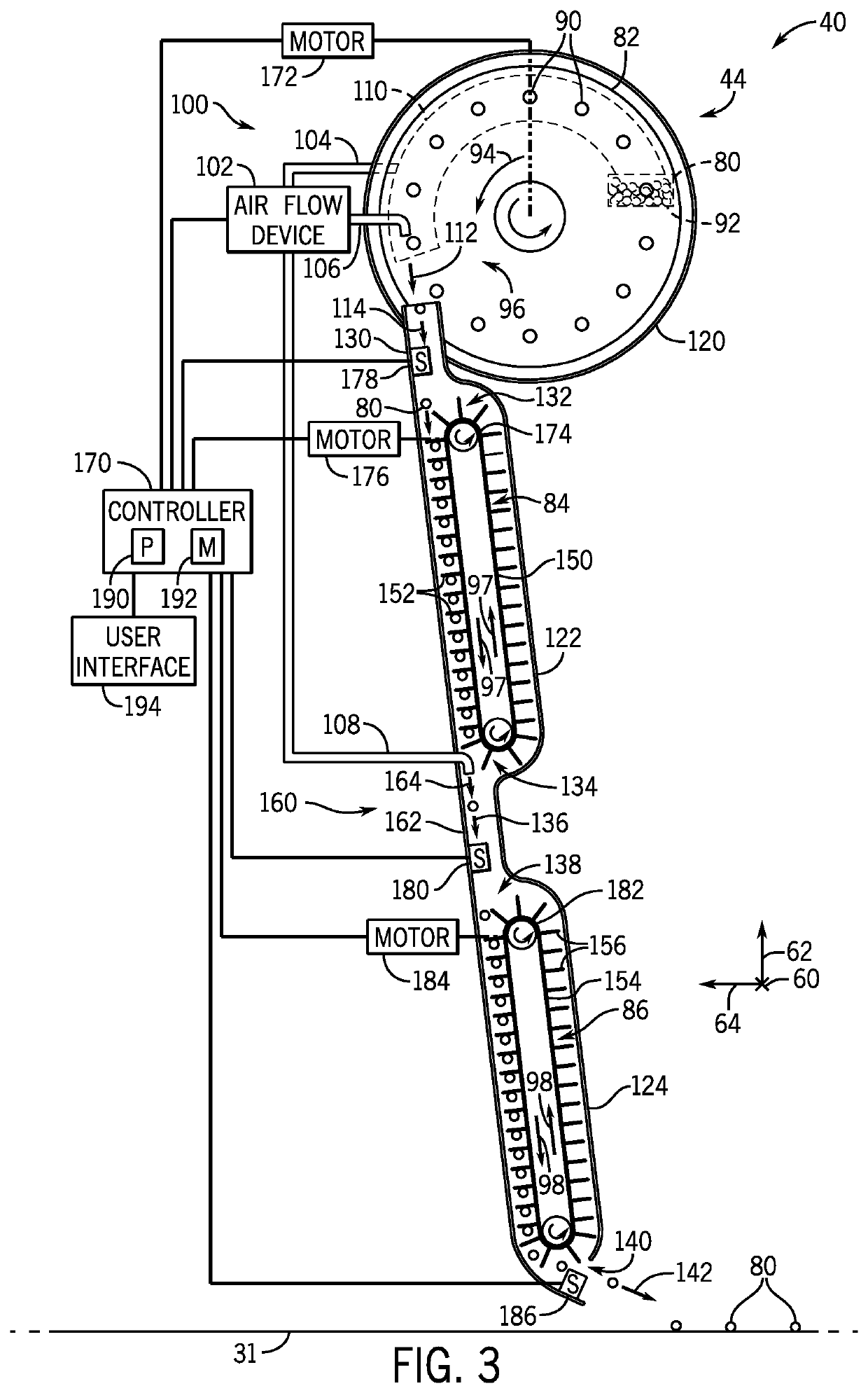

Particle delivery system of an agricultural row unit

A particle delivery system of an agricultural row unit includes a first particle belt configured to receive a particle from a particle metering and singulation unit, a second particle belt configured to receive the particle from the first particle belt and to expel the particle to a trench in soil, and a particle transfer assembly configured to facilitate transfer of the particle from the first particle belt to the second particle belt. The first particle belt is configured to accelerate the particle to a target particle transfer speed, and the second particle belt is configured to accelerate the particle to a target particle exit speed greater than the target particle transfer speed.

Owner:BLUE LEAF I P INC

Device to Transfer Catalyst from a Low Pressure Vessel to a High Pressure Vessel and Purge the Transferred Catalyst

ActiveUS20110217130A1Easy to operateShorten the timeCatalytic naphtha reformingLavatory sanitoryParticulatesParticle transfer

An apparatus for the transfer of solid particulate matter from a low pressure system to a high pressure system is presented. The apparatus simplifies the particle transfer process, and is useful for systems where solid catalyst particles are cycled through a reactor and a regenerator.

Owner:UOP LLC

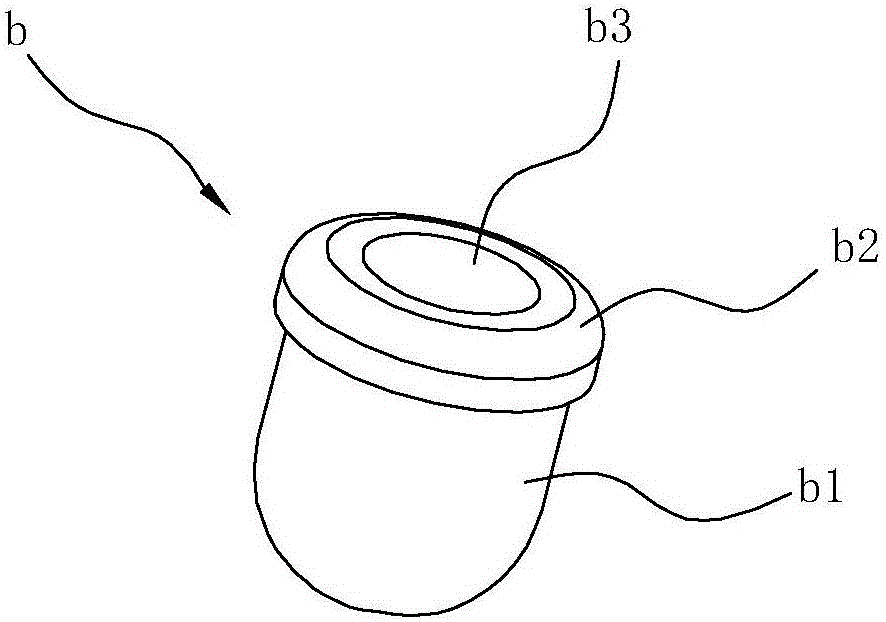

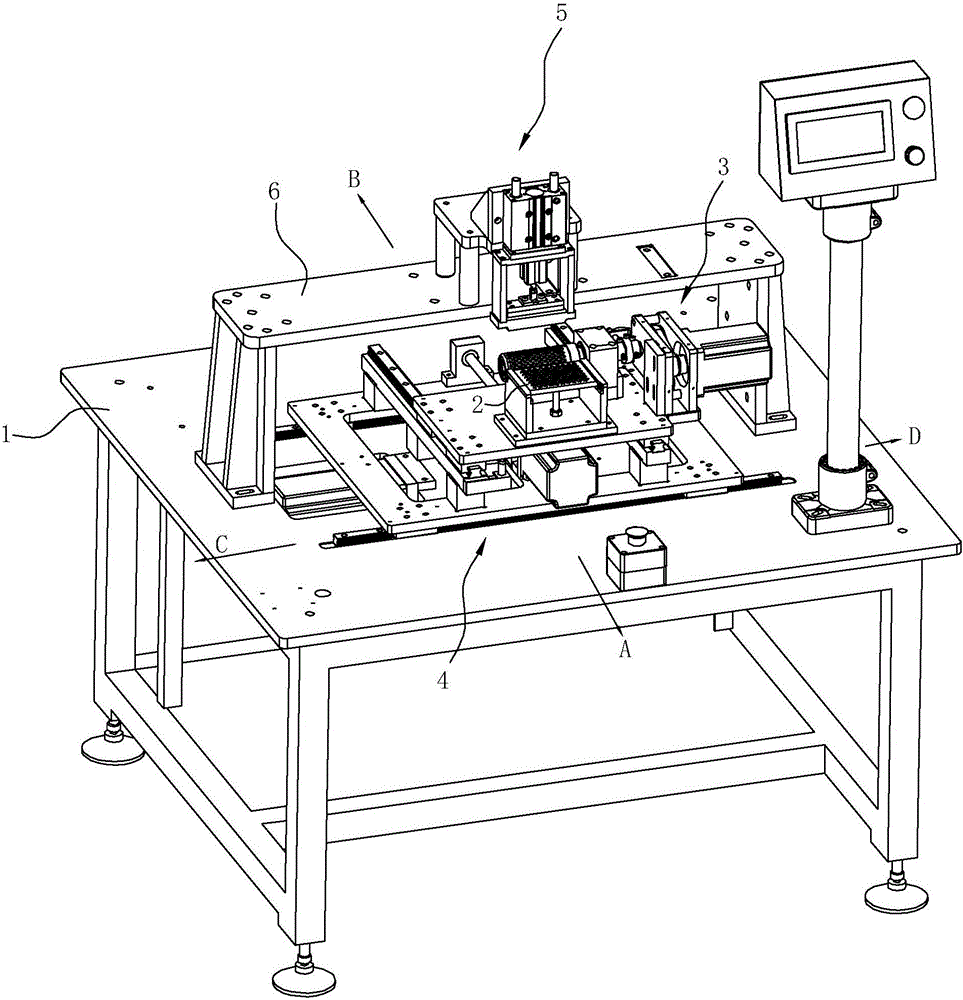

Metal barrel particle-planting machine of comb handle

ActiveCN105855846ARealize continuous grain plantingEasy to useMetal working apparatusParticle transferEngineering

The invention relates to a metal barrel particle-planting machine of a comb handle. The metal barrel particle-planting machine comprises an operation platform, a flocking particle bearing plate, a barrel rotating mechanism and a flocking particle transferring mechanism. When the metal barrel particle-planting machine is in use, flocking particles are placed in a containing groove of the flocking particle bearing plate in advance, the flocking particle transferring mechanism moves downward, an object fetching needle inserts a row of flocking particles on the flocking particle bearing plate and moves upward, the flocking particle transferring mechanism moves downward again, the flocking particles on the object fetching needle are correspondingly inserted into a row of through holes of a barrel, a second cylinder drives a connecting plate to drive the object fetching needle to move upward, a first cylinder does not run at the same time, and a pressing plate presses the flocking particles on the object fetching needle into the through holes of the barrel to complete particle planting of one row. Compared with the prior art, the metal barrel particle-planting machine has the advantages that the particle-planting machine is convenient to use, so that particle planting efficiency is improved; the above process is completed under control of a control program, so that influence of artificial factors is reduced, missed planting is avoided, and product quality stability is improved effectively.

Owner:NINGBO RAVO IND GRP CO LTD

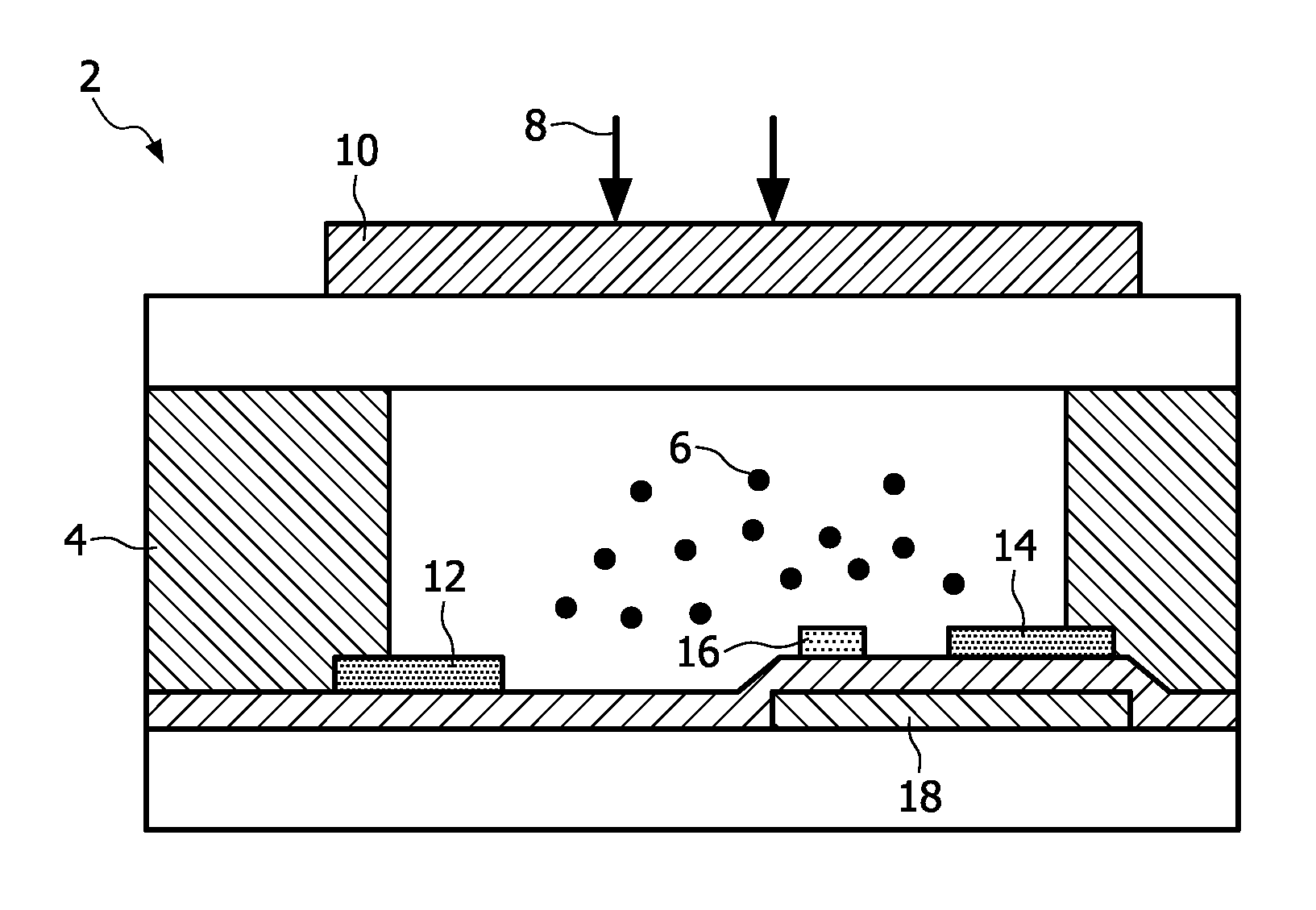

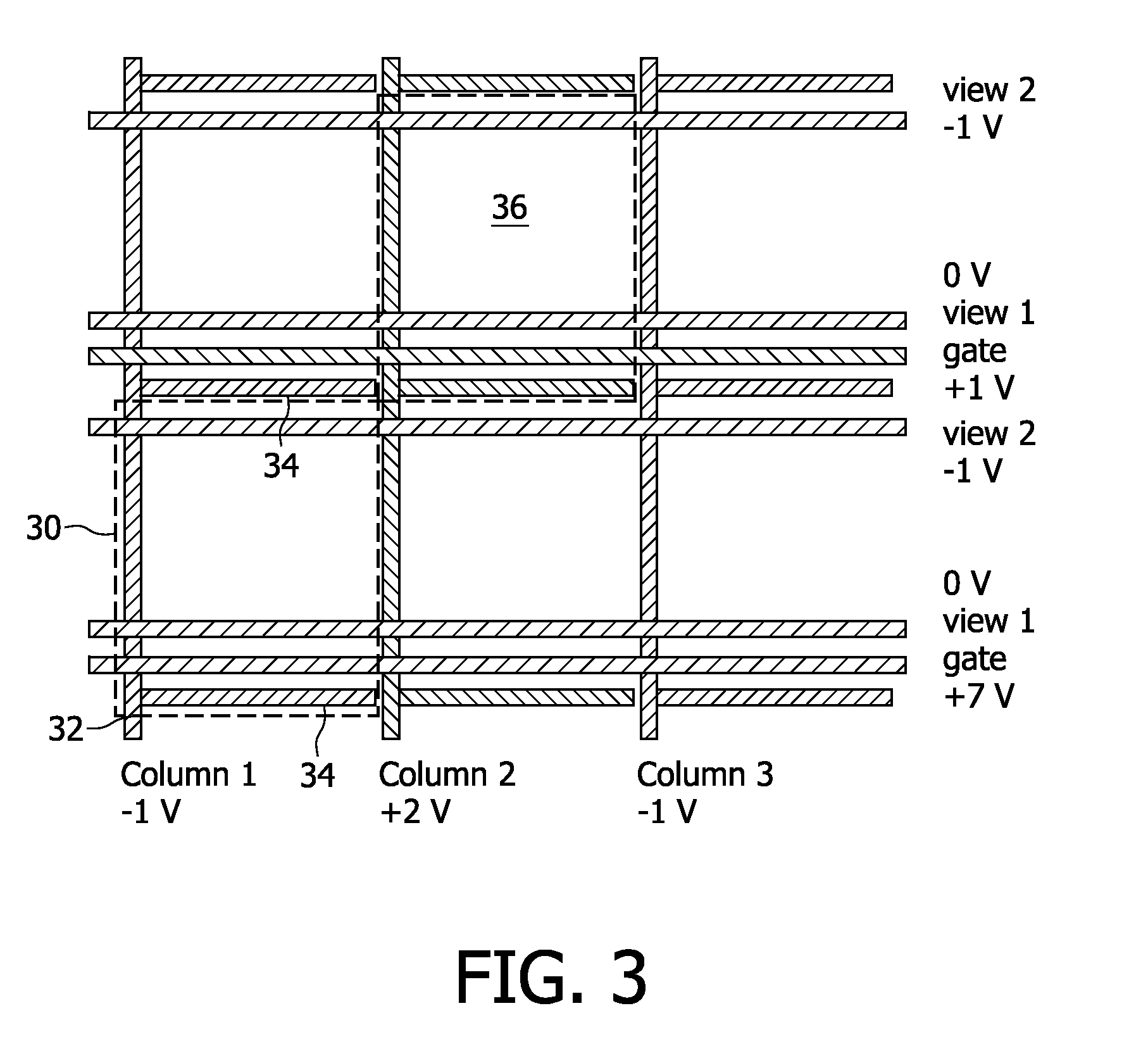

Electronic device using movement of particles

ActiveUS20100053135A1Inhibition effectAccurately grey levelCathode-ray tube indicatorsInput/output processes for data processingParticle transferControl signal

A method is provided of driving an electronic device comprising an array of device elements, each device element comprising particles which are moved to control a device element state, and each device element comprising a collector electrode, and an output electrode. The method comprises: in a reset phase, applying a first set of control signals to control the device to move the particles to the a reset electrode; and in an addressing phase, applying a second set of control signals to control the device to move the particles from the reset electrode such that a desired number of particles are at the output electrode. The second set of control signals comprises a pulse waveform oscillating between first and second voltages in which the first voltage is for attracting the particles to the reset electrode and the second voltage is for attracting the particles from the reset electrode to the output electrode, and wherein the duty cycle of the pulse waveform determines the proportion of particles transferred to the output electrode in the addressing phase. This control method provides well-controlled packets of particles which are collected in a vortex at the reset electrode before being passed on, in part, towards the output electrode (for example via the gate electrode).

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com