Electronic paper displaying device and manufacturing method thereof

A technology for display devices and electronic paper, which is applied to instruments, nonlinear optics, optics, etc., can solve the problems of unstable dyeing, reducing the brightness and contrast of electronic paper display devices, and uneven color rendering of electronic paper display devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

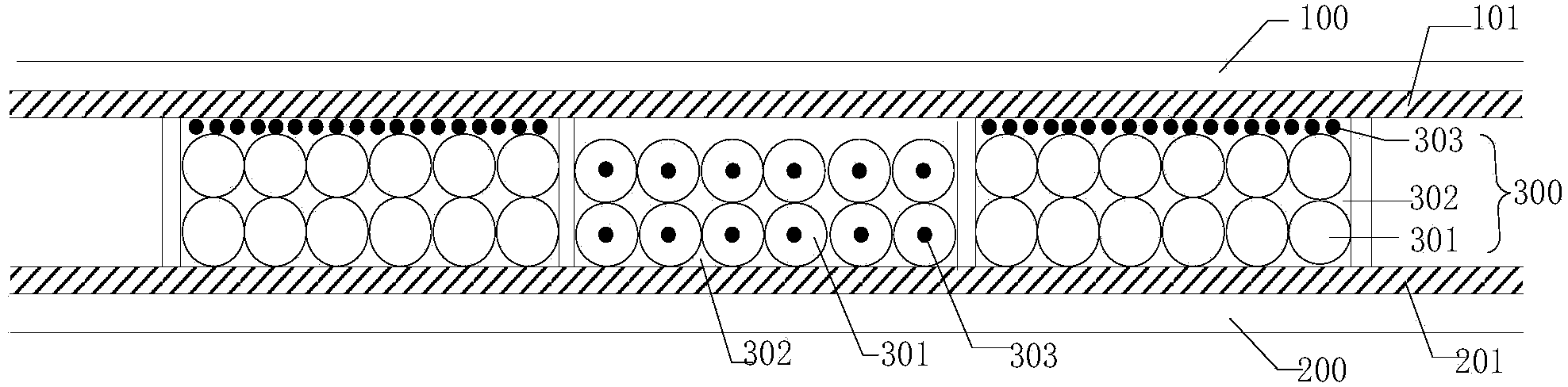

[0089] Example 1: If Image 6 As shown, the specific steps for making an electronic paper display device are as follows:

[0090] S201. Inject or print gel particles with a porous structure on the lower substrate; specifically, make a metal or black resin array layer on the lower substrate by photolithography, inject or print a layer of uniform dried The gel particles have not yet absorbed colored particles, and the thickness is between 1um and 10um;

[0091] S202. Place the lower substrate with the gel particles in a tank filled with an electrolyte that dissolves the colored particles; specifically, the electrolyte can be a neutral solution or an ionizable solution, such as deionized water, chlorinated Sodium solution can be selectively selected according to the different gel particles.

[0092] S203. Apply an electric field to the canning tank to cause the gel particles to swell and absorb the colored particles; specifically, place the lower substrate with the gel particle...

example 2

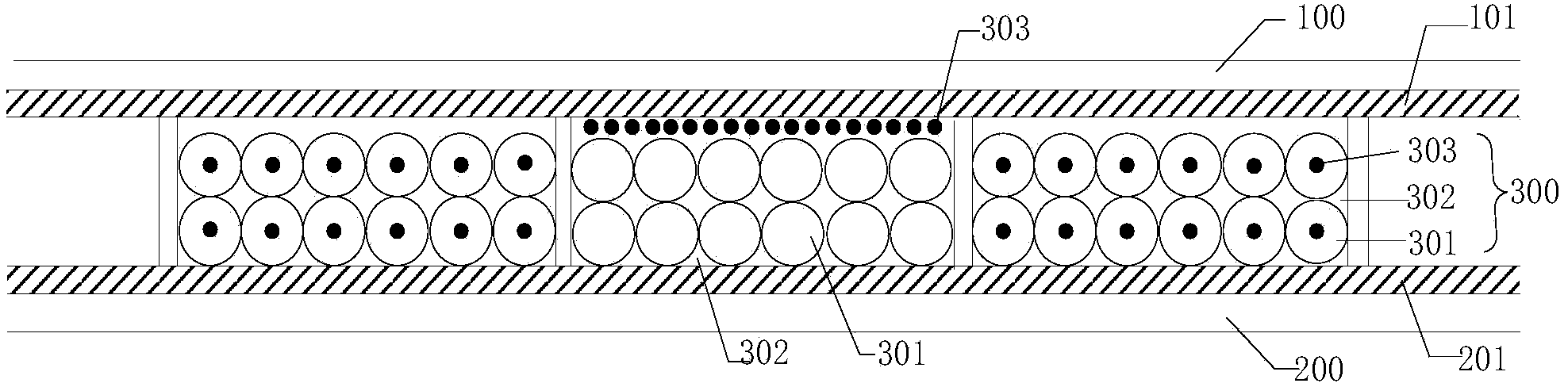

[0096] Example 2: If Figure 7 As shown, the specific steps for making an electronic paper display device are as follows:

[0097] S301. Place the gel particles with a pore-like structure in a canned tank containing an electrolyte that dissolves colored particles; specifically, the electrolyte can be a neutral solution or an ionizable solution, such as deionized water, chlorine Sodium chloride solution can be selectively selected according to the difference of gel particles.

[0098] S302. Apply an electric field to the canning tank to cause the gel particles to swell and absorb the colored particles; specifically, place the gel particles in an electric field environment and add a uniformly mixed colored particle system to allow the gel particles to swell and fully Earth absorbs colored particles;

[0099] S303. Inject or print the gel particles that absorb the colored particles on the lower substrate, and at this time, form the pattern of the display layer on the lower subs...

example 3

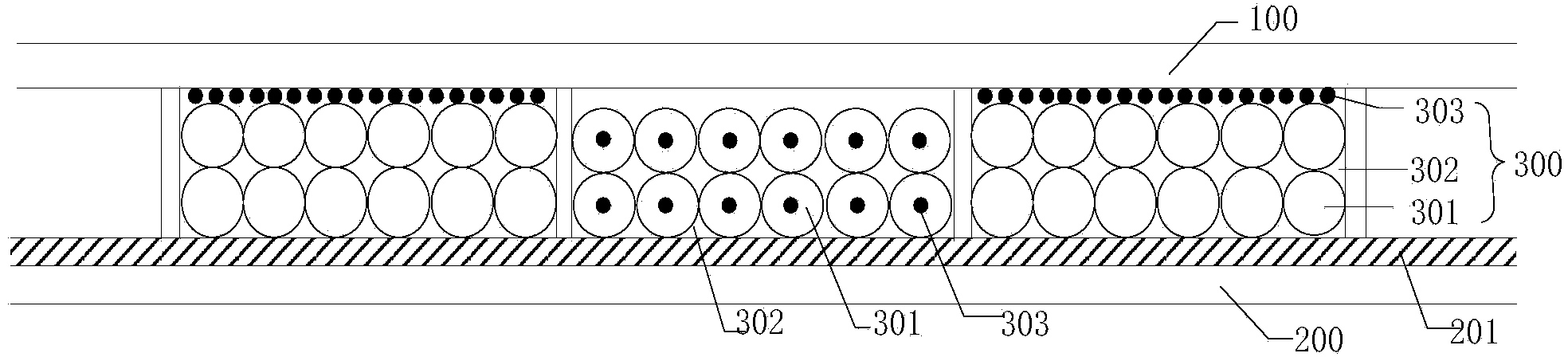

[0102] Example 3: If Figure 8 As shown, the specific steps for making an electronic paper display device are as follows:

[0103] Steps S401 and S404 are completely the same as steps S201 and S204 in the first example, and will not be repeated here.

[0104] S405. Form a covering layer with a microporous structure on the display layer; specifically, coat or print a white covering layer with micropores on the display layer, and the diameter of the micropores is slightly larger than the colored band absorbed by the gel particles. The diameter of the particle, a certain space is reserved between the covering layer and the upper substrate, and the thickness of the space is close to the diameter of the particle;

[0105] S406 , packaging the lower substrate and the upper substrate on which the display layer is formed to form an electronic paper display device.

[0106] So far, the above-mentioned electronic paper display device provided by the embodiment of the present invention...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com