Apparatus for producing three-dimensional molded article, comprising particle transfer pipe

A technology of three-dimensional molding and transportation tubes, which is applied in the direction of manufacturing auxiliary devices, coating devices, manufacturing tools, etc., can solve the problems of lower printing accuracy, heavier supporting plates of molded objects, and higher prices, so as to reduce manufacturing costs, Effects of improving manufacturing quality and improving positional control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

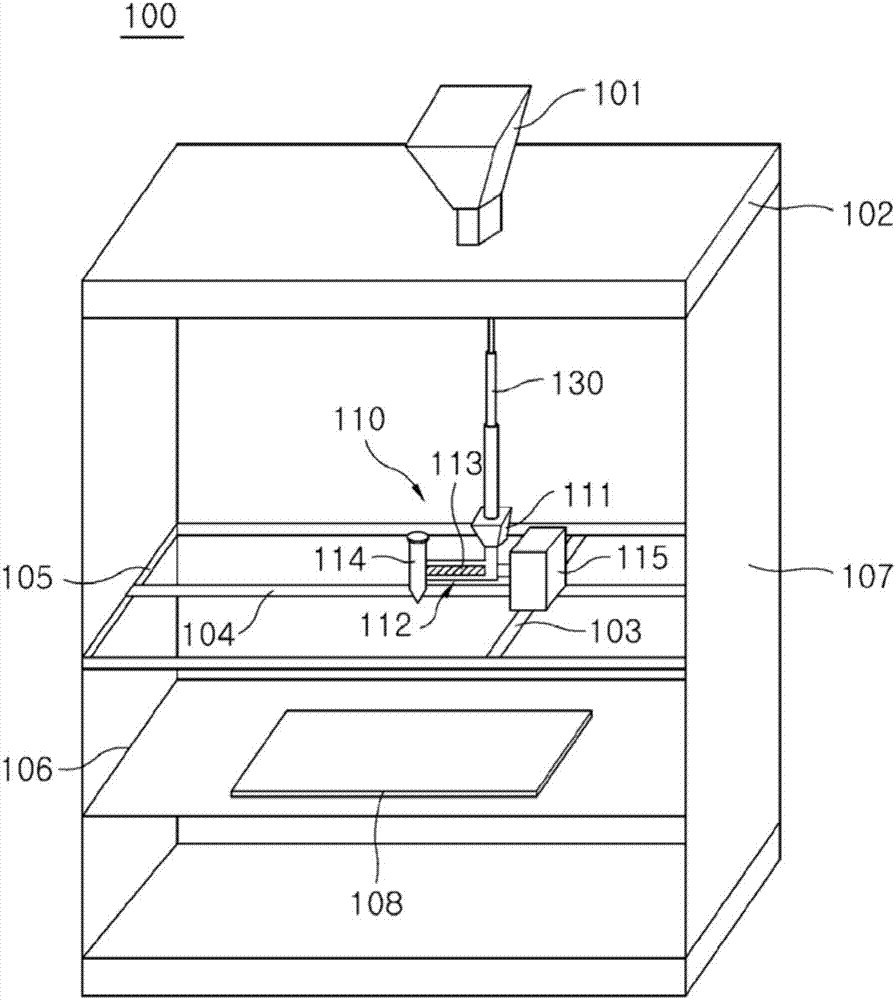

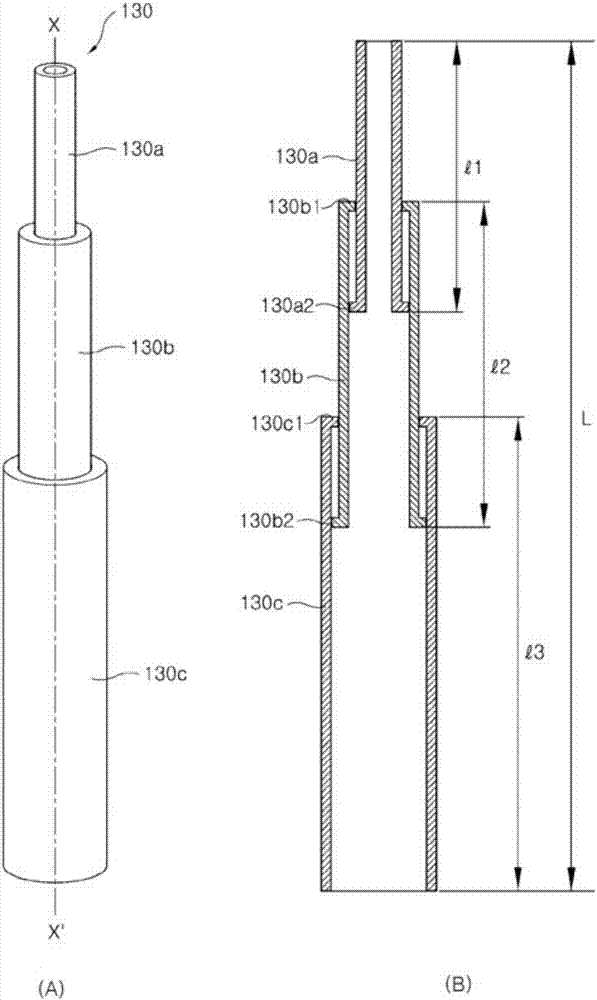

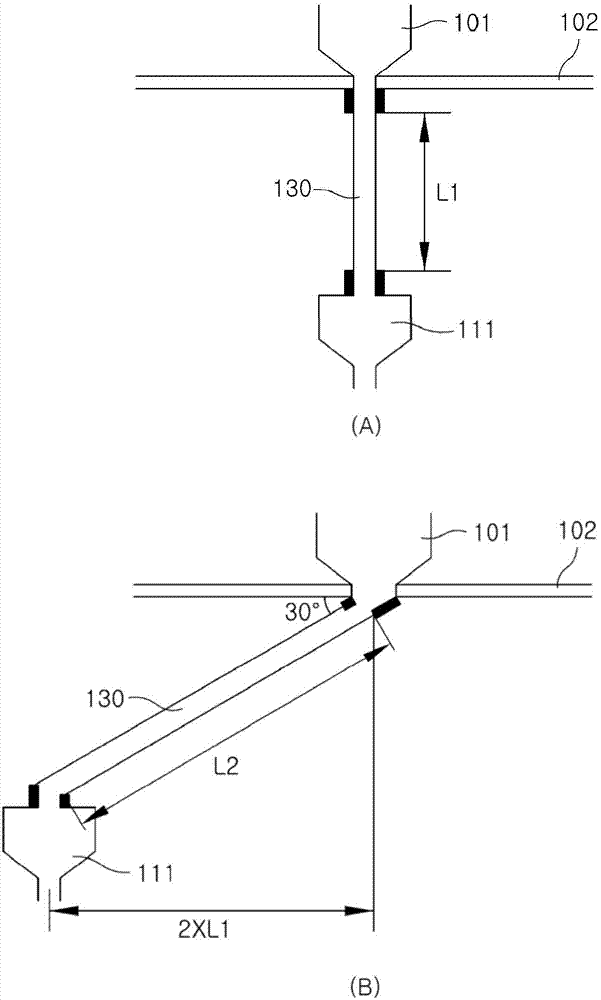

[0070] The present invention aims to protect a device for manufacturing three-dimensional moldings, in which molding material particles are melted and the discharge position of the molten molding material particles is controlled. The device includes: an extrusion part for three-dimensional molding, wherein, The molding material particles are melted and discharged through a nozzle; a storage container in which the molding material particles supplied to the squeezing part are temporarily stored in the storage container; a transportation pipe providing a passage through which the molding material particles stored in the storage container pass through the transportation pipe And transport to the squeezing part; and, a control part for controlling the position of the squeezing part, wherein the transport tube is composed of a plurality of connected unit transport tubes.

[0071] The three-dimensional molded product manufacturing apparatus of the present invention is characterized in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com