Method for phase transferring and three-dimensional assembling of precious metal nano-particles

A technology of nanoparticles and precious metals, which is applied in nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of long equilibration time and limited application range, and achieve the effect of short equilibration time, expanded application scope and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] Embodiment 1, utilize surfactant two (amino ethyl acyl methyl ethyl) octadecylamine (C 18 N 3 ) phase-transfer the gold nanorods

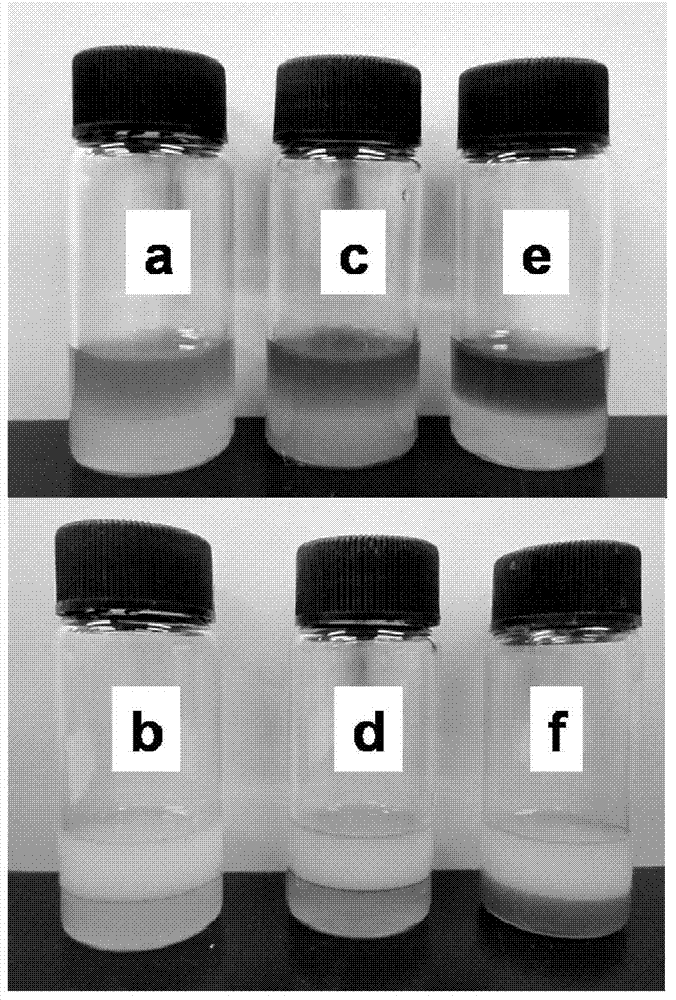

[0091] The original solution of gold nanorods (4mL) was centrifuged and washed three times under the condition of centrifugal force of 8000g and 10min / time to remove excess CTAB during the preparation process, and 4mL of C with a concentration of 1mM was added to the centrifuged product. 18 N 3 Aqueous solution, which was ultrasonicated under the condition of 600W for 30s. The solution obtained above was mixed with 1% C 18 N 3 mixed with the chloroform solution, vibrated for 30s, and stood for 1 minute to complete the phase transfer, and the gold nanorods were transferred from the upper aqueous phase to the lower chloroform phase, as figure 1 (a) shown.

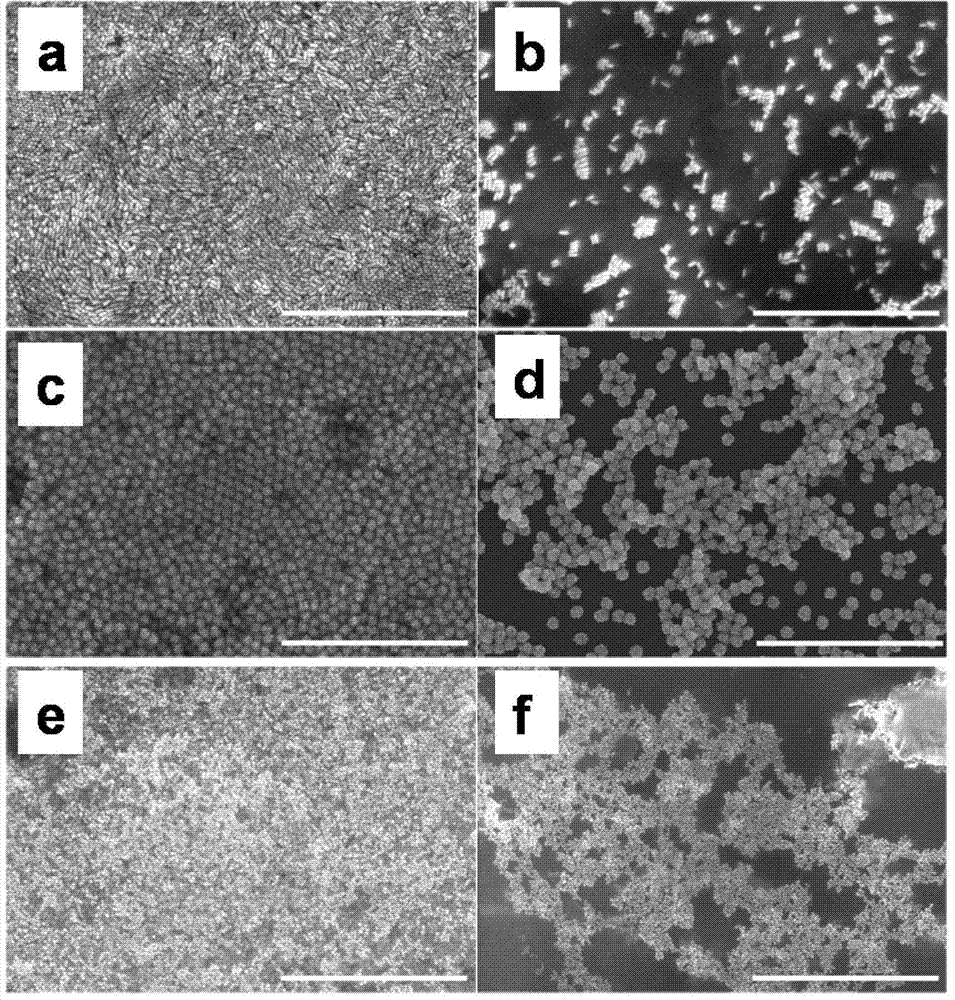

[0092] The morphology of gold nanorods in water phase and oil phase are as follows: figure 2 As shown in (a) and 2(b), it can be seen that the morphology hardly changes before and a...

Embodiment 2

[0093] Embodiment 2, utilize surfactant two (amino ethyl acyl methyl ethyl) octadecylamine (C 18 N 3 ) to transfer the nanogold flower phase

[0094] According to the steps of Example 1, only the nano-gold rods in Example 1 were replaced with nano-gold flowers, and the centrifugal force was replaced with 7000g to complete the phase transfer of the nano-gold flowers.

[0095] Such as figure 1 (b) shown. The morphologies of the nano-golden flowers in the water phase and the oil phase are as follows: figure 2 As shown in (c) and 2(d), it can be seen that the morphology hardly changes before and after the phase transition.

Embodiment 3

[0096] Embodiment 3, utilize surfactant two (amino ethyl acyl methyl ethyl) octadecylamine (C 18 N 3 ) to transfer the phase transfer of gold nanospheres

[0097] Mix the original solution of gold nanospheres (4mL) with a mass percent concentration of 1%C 18 N 3 mixed with the chloroform solution, vibrated for 30s, and stood for 1 minute to complete the phase transfer, and the gold nanospheres were transferred from the upper aqueous phase to the lower chloroform phase, as figure 1 (c) shown.

[0098] The morphologies of gold nanoparticles in water and oil phases are as follows: figure 2 As shown in (e) and 2(f), it can be seen that the morphology hardly changes before and after the phase transition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com