Patents

Literature

780results about How to "Good energy saving and emission reduction effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

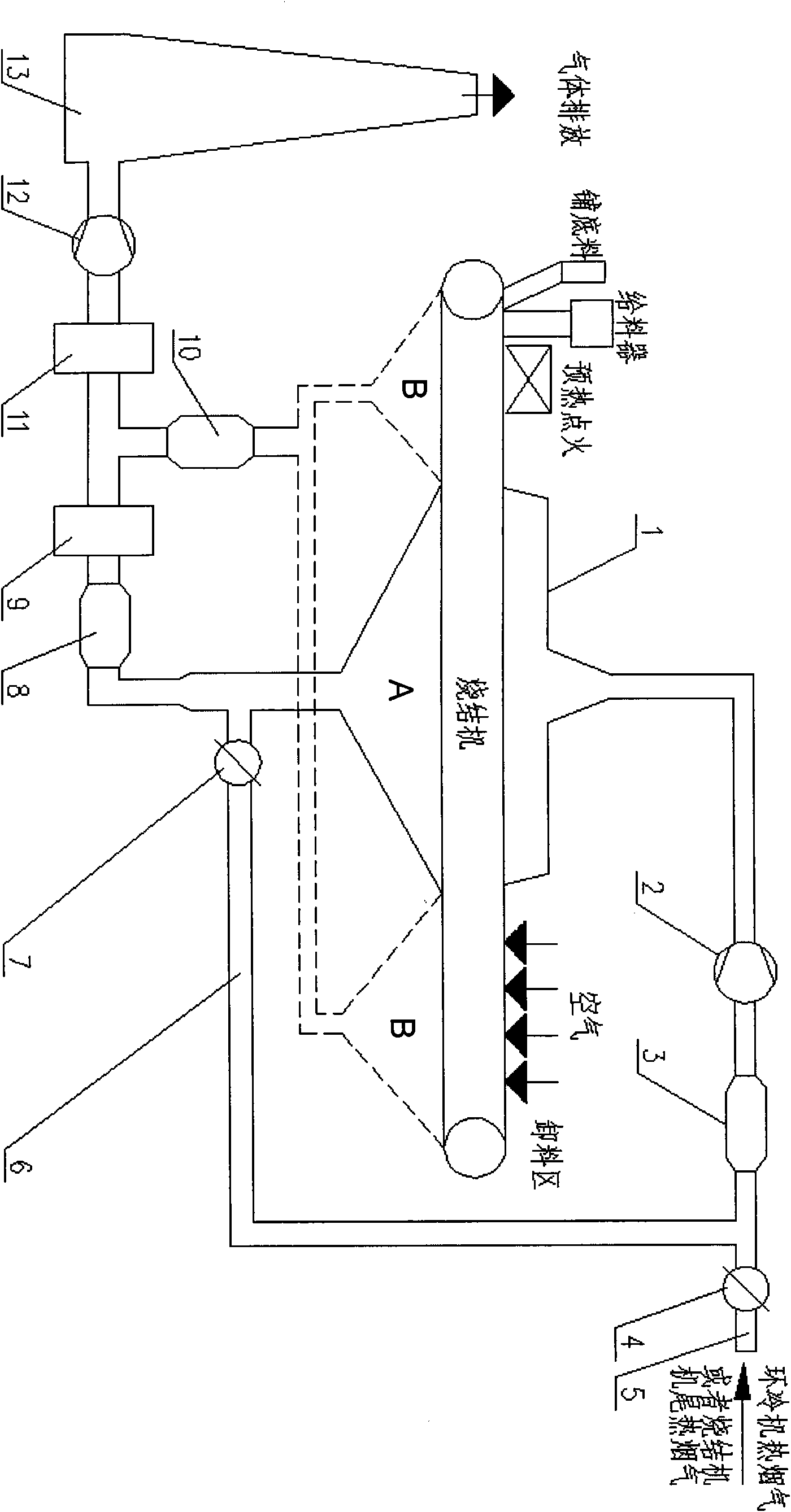

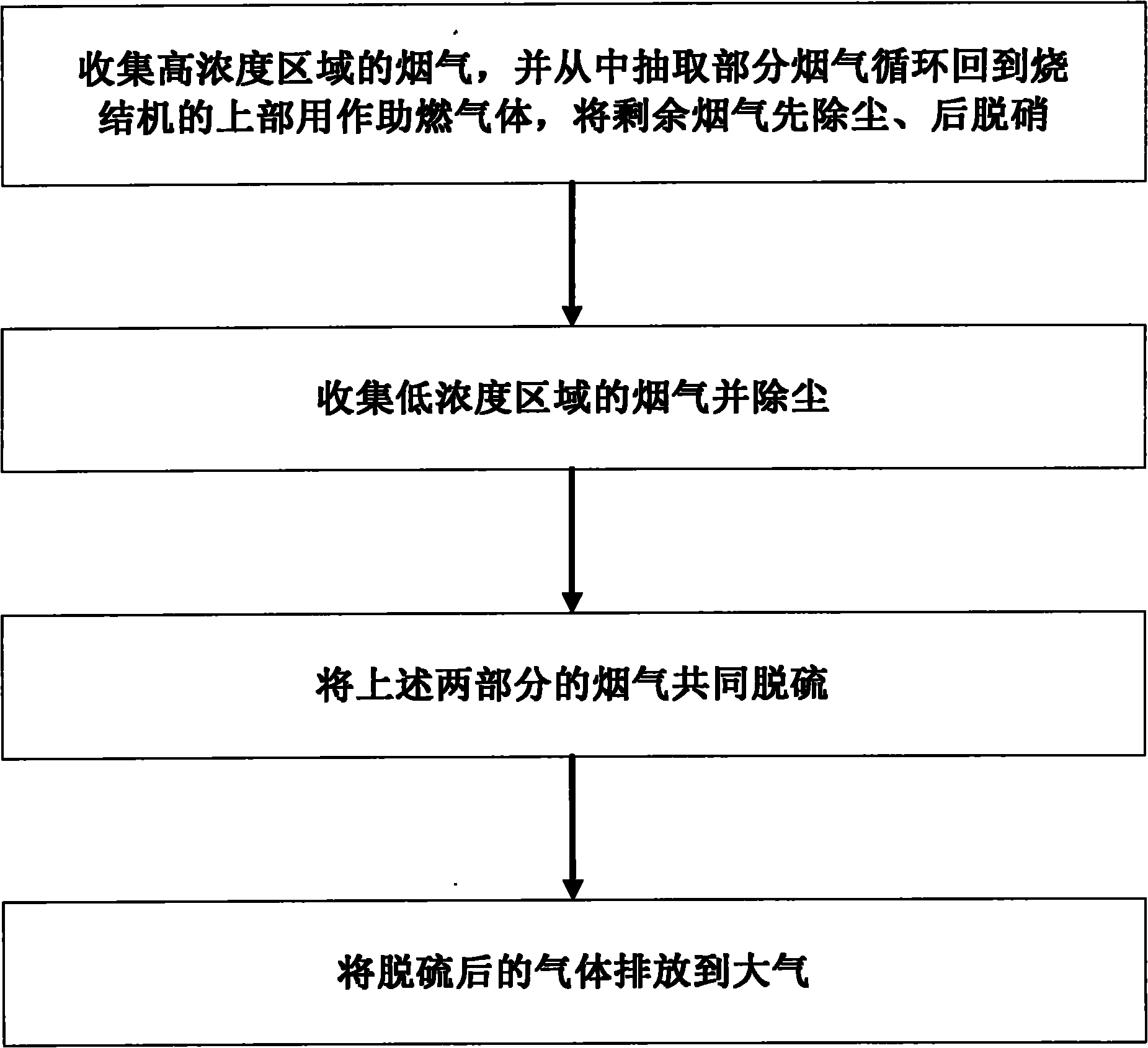

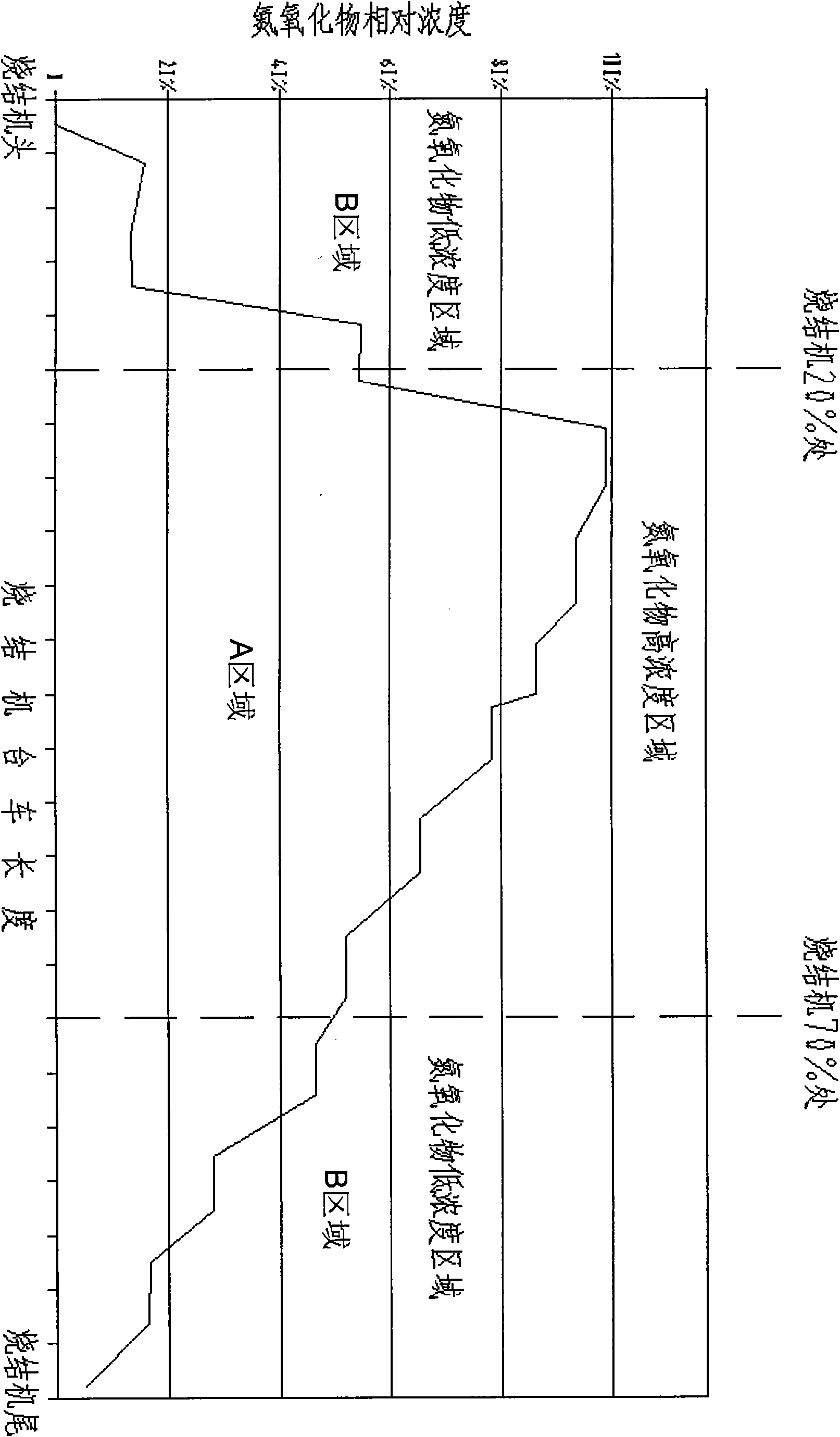

Emission reduction system of sintered fume nitric oxide with low energy consumption and method thereof

InactiveCN101829481ASimple systemSimple operation management and maintenanceDispersed particle separationNitric oxideHigh concentration

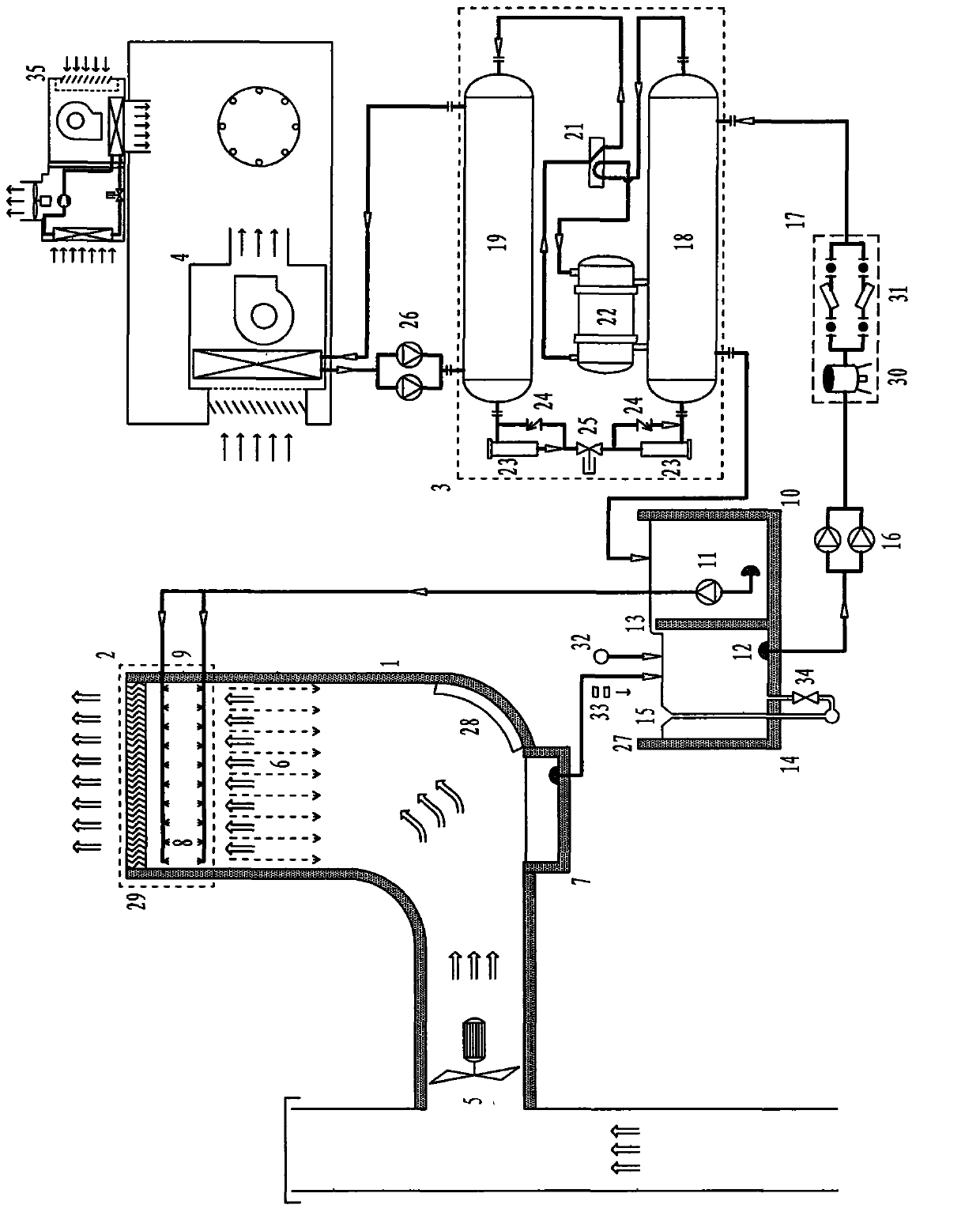

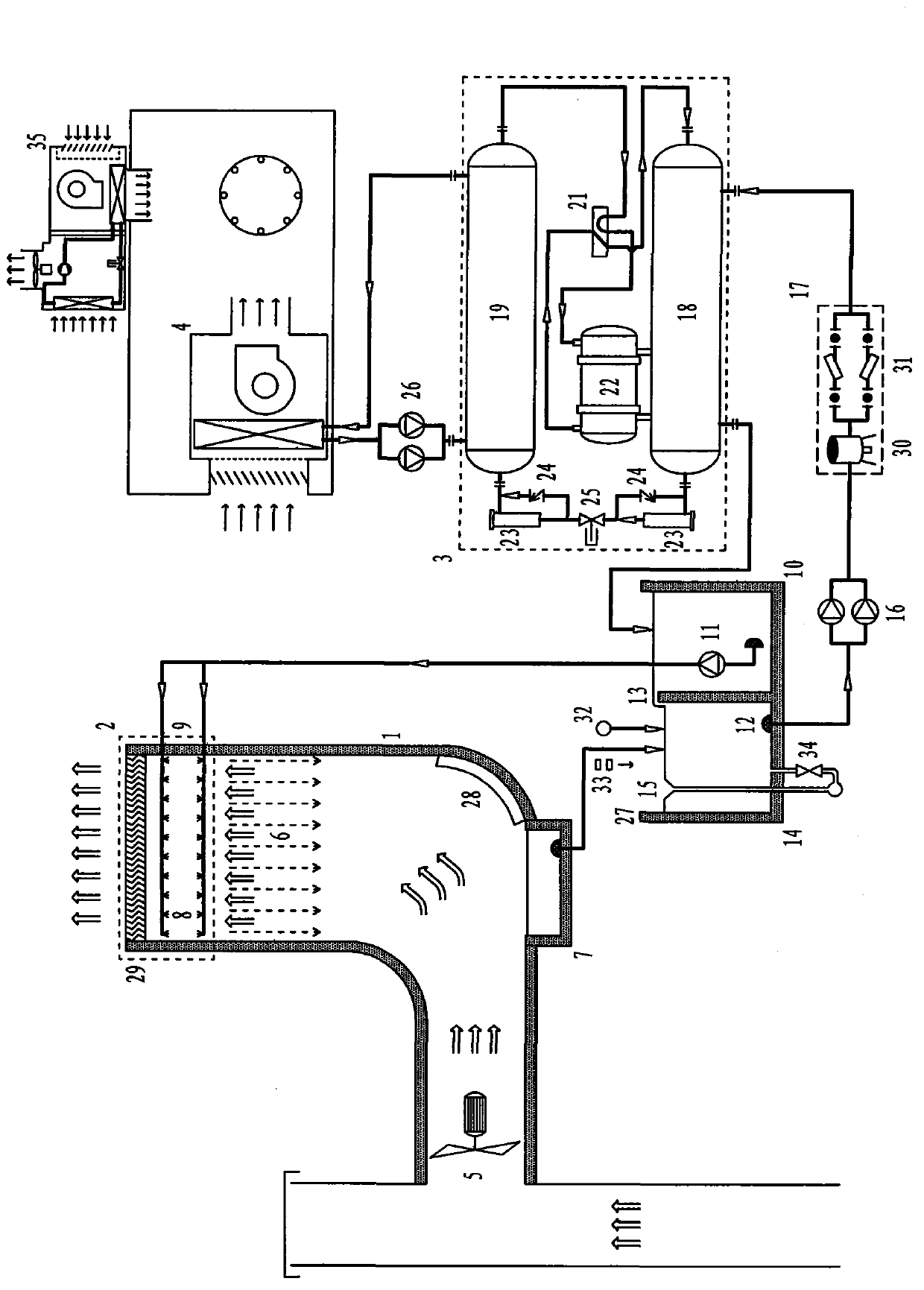

The invention relates to an emission reduction system of sintered fume nitric oxide with low energy consumption and a method thereof. The system comprises a nitric oxide high-concentration region air bellow A, a nitric oxide low-concentration region air bellow B, a denitration dust remover, a denitration device, a dust remover, a desulfuration device, a main exhaust fan, an emission chimney and a circulation loop. The denitration dust remover is connected with the air bellow A to collect the fume in the air bellow; the denitration dust remover is sequentially connected with the denitration device and the desulfuration device; and the fume subjected to dust removal and denitration is guided into the desulfuration device. The dust remover is connected with the nitric oxide low-concentration region air bellow B to collect the fume; the dust remover is connected with the desulfuration device; and the fume subjected to dust removal is guided into the desulfuration device. The desulfuration device is sequentially connected with the main exhaust fan and the emission chimney so as to desulfur the fume and discharge into the atmosphere. The circulation loop at least comprises a circulation fume hood, a circulation blower, a circulation fume dust remover and a circulation pipeline. The method comprises the following steps of collecting fume, removing dust, denitrating, desulfuring, discharging fume into the atmosphere and the like. The whole system is relatively simple and has obvious effects of energy saving and emission reduction.

Owner:BAOSTEEL ENG & TECH GRP

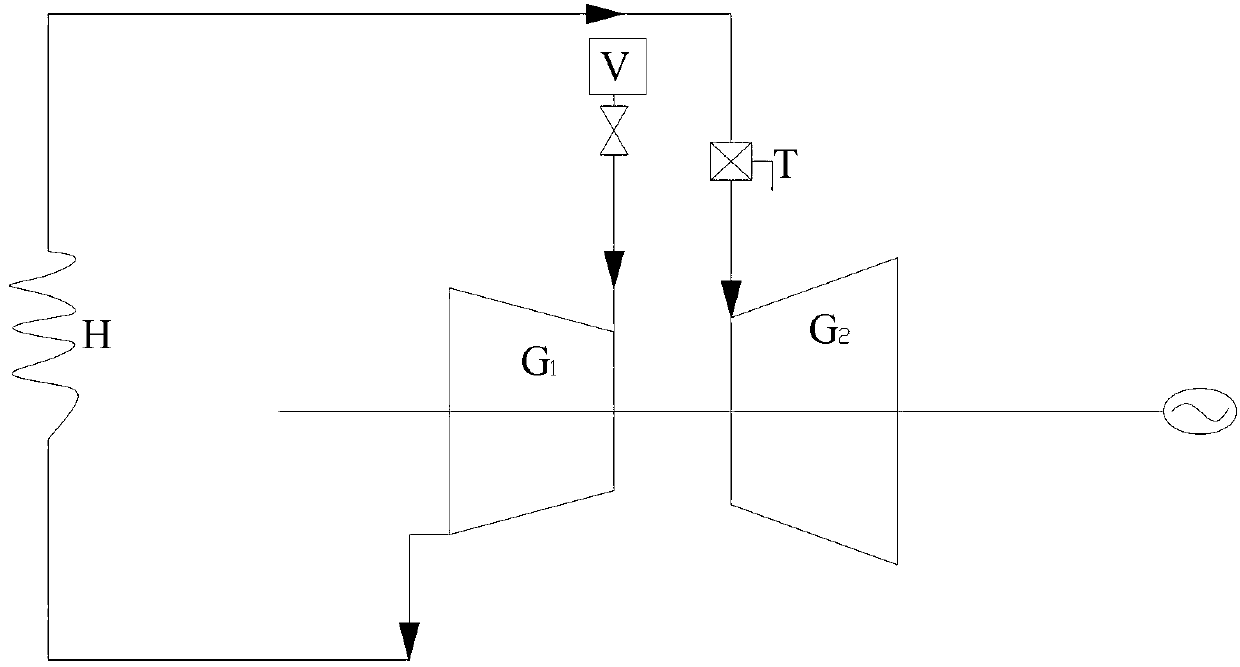

Double-extraction adjustable heating system of thermal power generating unit

ActiveCN102996191ARealize adjustable heatingAdjust supplySteam useCombined combustion mitigationHeating systemEngineering

The invention relates to the field of thermal power generating unit heating modification and discloses a double-extraction adjustable heating system of the thermal power generating unit. By modifying a turbine heating pipeline, a first by-pass pipeline and a second by-pass pipeline connected with a high-pressure cylinder and a medium-pressure cylinder in parallel are arranged on a steam supplying pipeline of the high-pressure cylinder and the medium-pressure cylinder respectively. Each by-pass pipeline is connected with an adjusting gate, a spray type desuperheater and a pressure matcher, and the pressure matcher of the first by-pass pipeline injects exhaust steam of the high-pressure cylinder to achieve high-pressure steam supplying. The second by-pass pipeline injects low-pressure extraction steam of the medium-pressure cylinder to achieve medium-pressure steam supplying. Simultaneously, the opening degree of a middle adjusting gate is adjustable, and the opening degree of the middle adjusting gate is adjusted according to exhaust steam pressure change of the high-pressure cylinder and reheating steam pressure change caused by load change. Therefore, a steam supplying pressure requirement towards the outside is met, qualified steam supplying pressure is guaranteed, a purpose of double-extraction, adjustability and heating of steam of the unit for high-pressure industries and medium-pressure industries is achieved, modification cost of a unit body is saved, and an effect of reducing energy and emission is achieved.

Owner:GUODIAN LONGYUAN ENERGY SAVING TECH

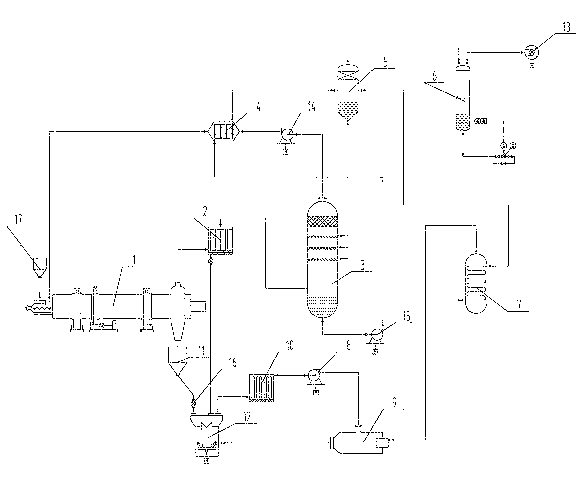

Powder coal gasification powder processing and water recovery integrated system for high-moisture coal and method of system

ActiveCN103234214AReduce water dischargeTake advantage ofDrying solid materials with heatIndirect carbon-dioxide mitigationMoistureVacuum pump

The invention relates to a powder coal gasification powder processing and water recovery integrated system for high-moisture coal. The system comprises a steam indirect heat transfer drying machine, an absorption tower, a flash tower, a vacuum pump / Venturi injection pump and a raw coal bunker. The steam indirect heat transfer drying machine is connected with the raw coal bunker, a bag-type dust collector I and a surge bunker; the surge bunker is connected with a coal mill; the coal mill is connected with a hot blast heater, and a bag-type dust collector II and a delivery pipe II are arranged at the top of the coal mill respectively; the top of the absorption tower is connected with a carrier gas initial heater, a circulating pump is arranged at the bottom, and the side of the absorption tower is connected with the flash tower; the circulating pump is connected with an air heater and connected with the carrier gas initial heater; the air heater is connected with the flash tower and the hot blast heater respectively; the flash tower is connected with a condenser which is connected with the vacuum pump / Venturi injection pump; and the flash tower is connected with the carrier gas initial heater. The invention further discloses an application method of the system. According to the system and the method, the investment is small, and energy consumption can be reduced effectively.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

Cooperative pretreatment method for biological catalysis and controlled oxidation of cotton and cotton-type fabrics

InactiveCN102191692AReduce dosageReduce wasted waterBiochemical fibre treatmentDry-cleaning apparatus for textilesElectricityChemical oxygen demand

The invention relates to a cooperative pretreatment method for biological catalysis and controlled oxidation of cotton and cotton-type fabrics, comprising the following steps: (1) preparing a biological compound enzyme preparation, a biological enzyme synergist and a non-ionic surfactant into an enzyme working solution, wherein the pH of a processing bath is 6-7.5; padding the fabrics into the working solution; carrying out heat preservation; (2) washing the processed fabrics with cold water; padding the fabrics into a hydrogen peroxide bleaching solution containing the controlled decomposition additive of hydrogen peroxide; and steaming, washing with water and drying to obtain the finished products. In the method, high-density strong base is not required to serve as a scouring agent, thepH value of pretreatment waste water is 7-8, the chromaticity is low, the COD (Chemical Oxygen Demand) value is lowered by 30% compared with that of the traditional alkali kiering pretreatment technology, the water is saved by 10-30%, and the steam and electricity can be saved by 20%. The indexes (whiteness, capillary effect, water absorption, cotton seed hull strainaway rate, desizing rate, strong force and the like) of the processed cotton and cotton-type fabric all reach the quality indexes of a semi-product, cotton seed hulls can be completely removed, and the fabrics have vivid color andgood levelling property after being dyed.

Owner:DONGHUA UNIV

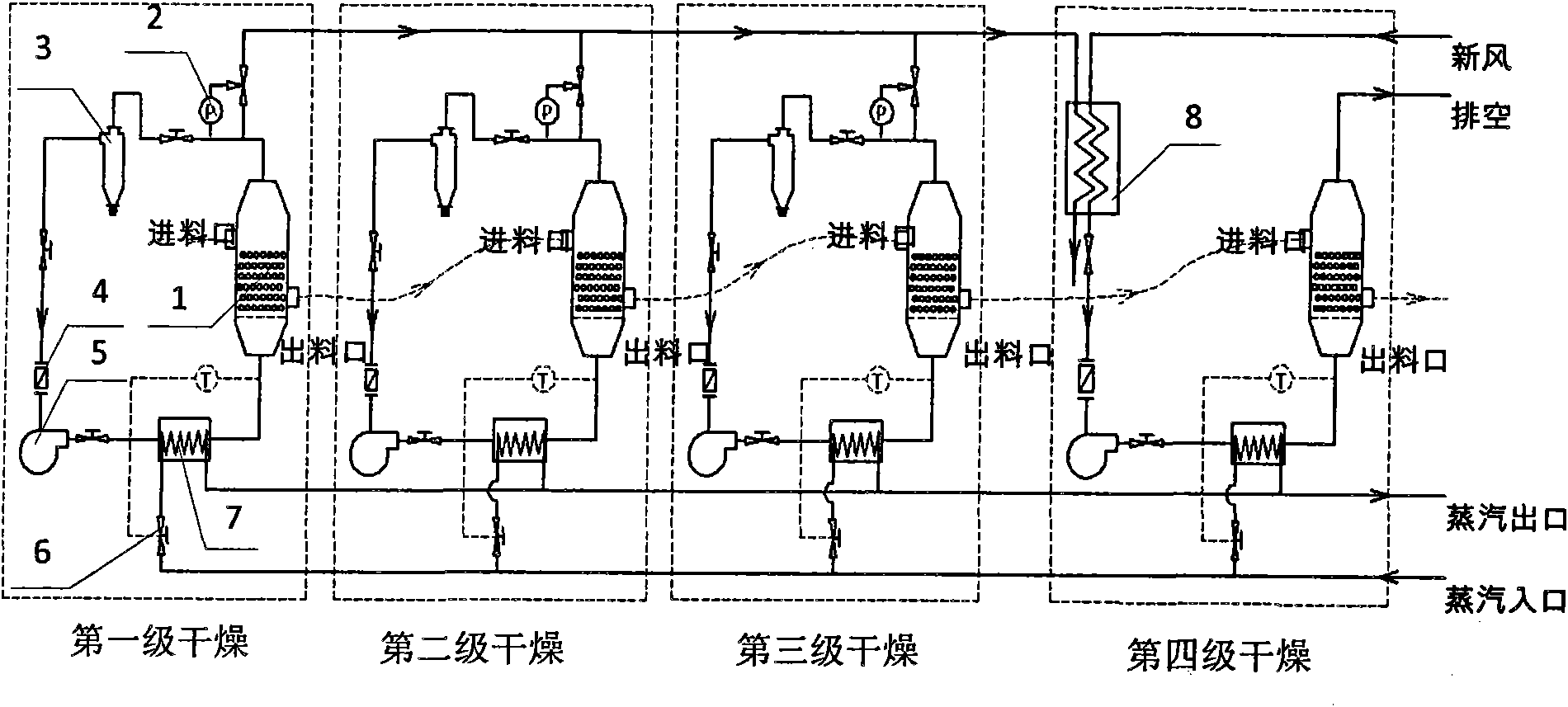

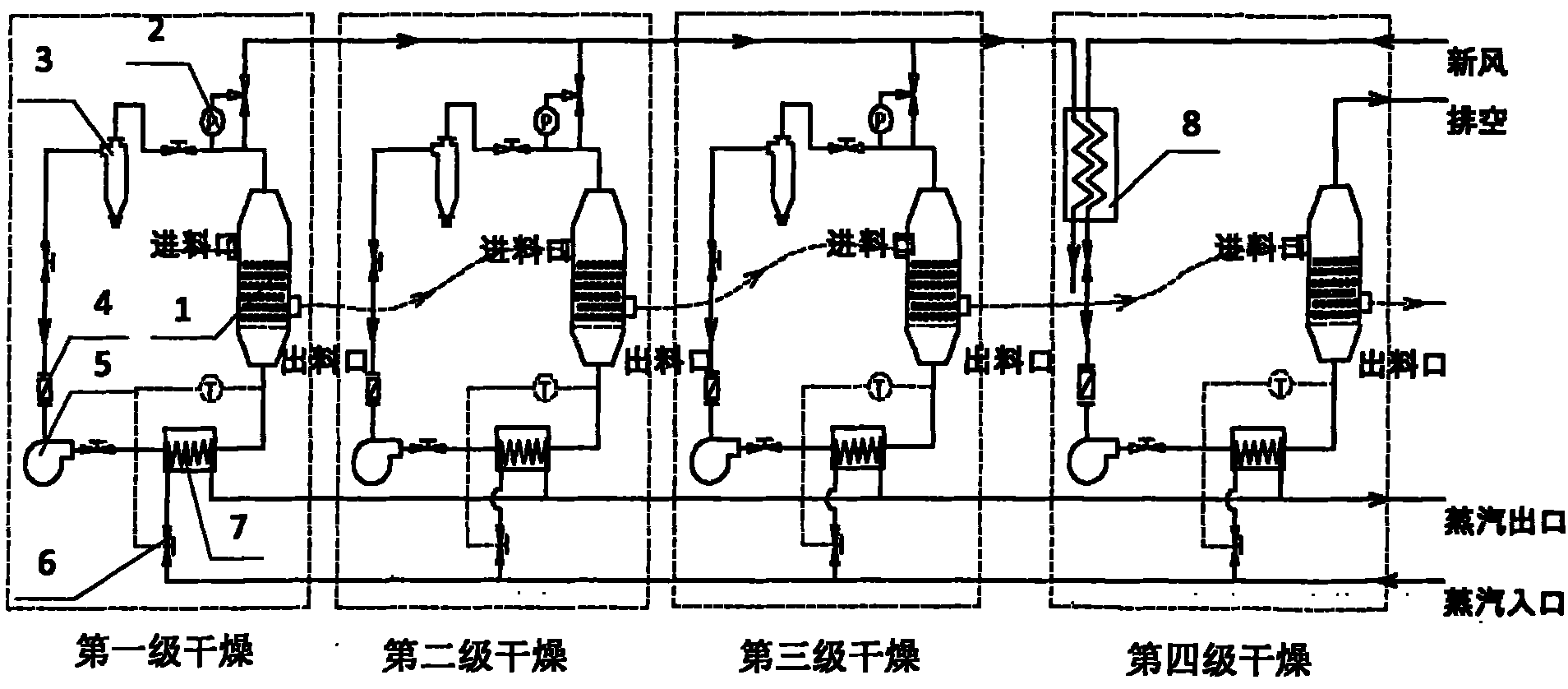

Novel silica gel energy-saving drying device and process thereof

ActiveCN101788221AImprove drying qualityImprove qualityDrying solid materials with heatDrying gas arrangementsThree stageProcess engineering

The invention discloses a novel energy-saving silica gel drying device and a process thereof, which can dry silica gel rapidly and efficiently with the drying thermal efficiency improved to 50 percent from 35 percent of the prior art. The device comprises at least one superheated steam drying unit and at least one hot air drying unit. A required material can be obtained through speed-raising drying and constant-speed drying of the superheated steam drying unit and drying of the hot air drying unit. The process is a superheated steam-hot air combined multi-stage silica gel drying process, the first three stages adopt superheated steam drying, the first-stage steam drying is mainly a speed-raising drying stage, the second stage and the third stage are respectively a stage of constant-speed drying at the corresponding temperature, wherein the silica gel drying speed is high, no breakage or cracking can be easily caused, good properties of the porous structure can be maintained, the drying quality is high, and the fourth-stage hot air drying can maintain a relatively high drying speed. The superheated steam-hot air combined multi-stage silica gel drying process has the advantages of good quality of the dried silica gel and high speed, and the closed drying circulation system has significant effect on energy conservation and emission reduction.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

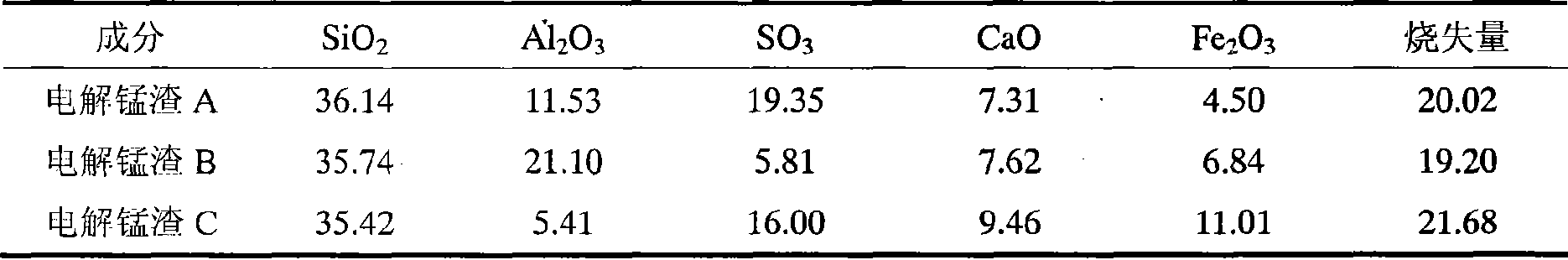

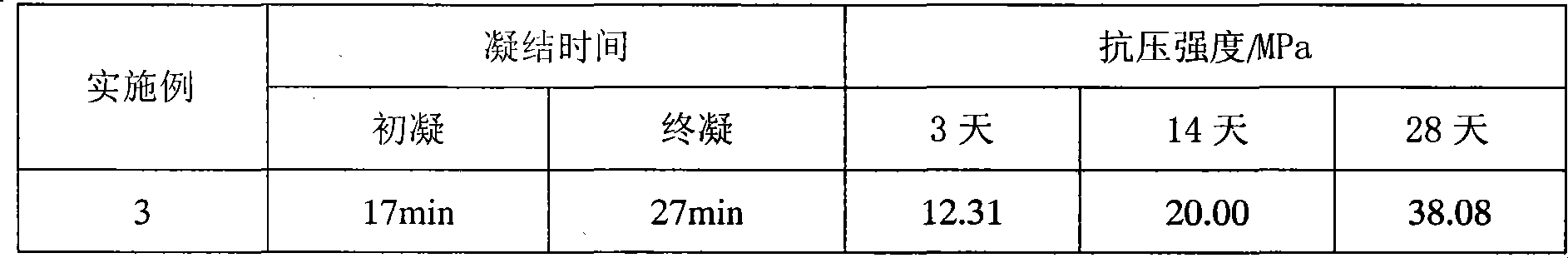

Manufacture of sulphur aluminate cements with electrolytic manganesium residue and method of manufacturing the same

A sulphate-aluminium-like cement produced by using electrolytic manganese slag and the preparation method of the cement relate to the production of the sulphate-aluminium-like by using industrial wastes and the preparation method of the cement. The raw materials of the cement clinker of the invention contain limestone, electrolytic manganese slag, kaolin and soft coal, and dihydrate gypsum is added to the fired cement clinker; the preparation method comprises the following steps: using the limestone, electrolytic Manganese slag, kaolin and soft coal as the raw materials of the clinker; first, levigating and homogenizing the raw materials, and calcining the raw materials into the clinker at a relatively low temperature; then adding the dihydrate gypsum to the clinker according to the requirement and then levigating the mixture to be the finished product. The cement is characterized in that the firing temperature ranges from 150 DEG C to 200 DEG C which is lower than that of the common Portland cement, and the energy-saving advantage is obvious; the mixture proportion range of the components is wide; the mixing amount of the manganese slag is great; and the fired cement has wide application, and so on. The preparation method can be widely used for producing the sulphate-aluminium-like cement by using electrolytic the manganese slag, and is in particular applicable to the production of early strength cement, rapid-hardening high-strength cement, expansive cement and low-alkali cement, and the like.

Owner:CHONGQING UNIV

Efficient energy-saving steam cabinet

ActiveCN102631131AEmission reductionImprove energy savingCooking vesselsBoiler controlCombustion chamberProcess engineering

The invention discloses an efficient energy-saving steam cabinet. The efficient energy-saving steam cabinet comprises an oven body, wherein a plurality of combustion heads are arranged inside the oven body; the plurality of combustion heads are located in a combustion chamber; a steam generating pot is arranged on the combustion chamber; a horizontal discharge flue is arranged at the lateral wall of the combustion chamber; a smoke discharge port is arranged on the side wall of the combustion chamber; and a burner port is arranged at the bottom of the combustion chamber. The efficient energy-saving steam cabinet disclosed by the invention has the beneficial effects of being obvious in energy-saving effect, very little in exhausted air quantity, very high in energy utilization rate and very obvious in national energy-saving and emission-reducing effects, and the utilization efficiency of the heat energy can be up to over 90%, the discharge temperature is close to ambient temperature, and the discharge of greenhouse gas is greatly reduced.

Owner:浙江合隆智能设备有限公司

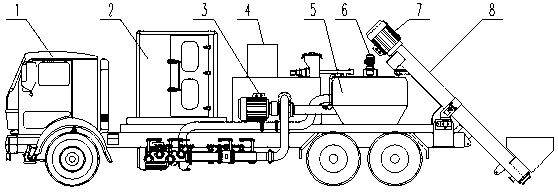

Electric drive sand mixing truck

InactiveCN103912259ASimple structureHigh localization rateFluid removalItem transportation vehiclesAutomatic controlElectric discharge

The invention belongs to the technical field of petroleum drilling and recovery and particularly relates to an electric drive sand mixing truck. The electric drive sand mixing truck comprises a truck chassis, a control room, a transformer, an electric discharge pump, an electric suction pump, a mixing tank stirring device, a sand conveying auger, a dry feeding system, a liquid feeding system, a suction manifold and a discharge manifold. The control room comprises a sand mixing truck automatic control system and a motor drive device. The electric drive sand mixing truck has the advantages that a motor is used as power source; compared with traditional sand mixing trucks using diesel engines and torque converters as main power output, the electric drive sand mixing truck is simple in structure, novel and reasonable in design, low in cost, low in noise, low in discharge, simple to control, high in sand-liquid matching precision, and convenient to popularize and use.

Owner:四机赛瓦石油钻采设备有限公司

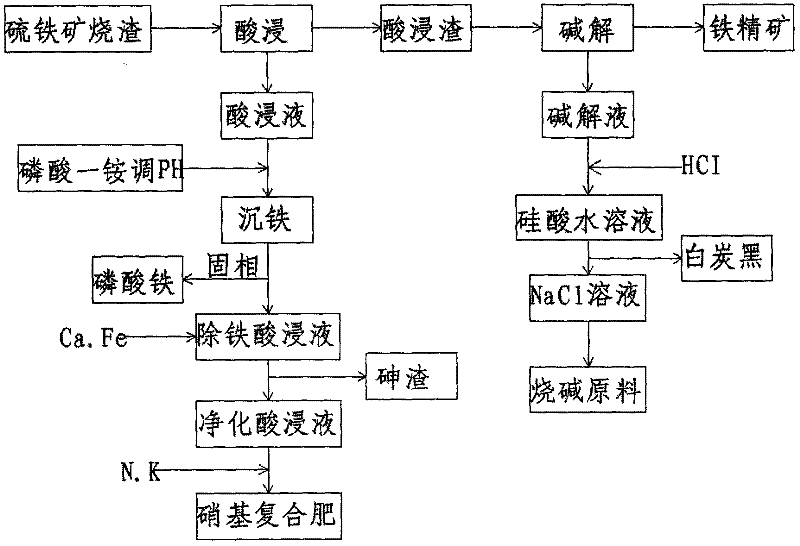

Method for treating pyrite cinder by combining acidic leaching with alkaline dissolving

ActiveCN102534187AEfficient enrichmentRealize cleaner productionProcess efficiency improvementNitro compoundResource utilization

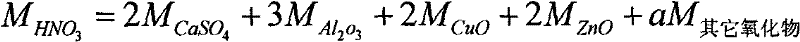

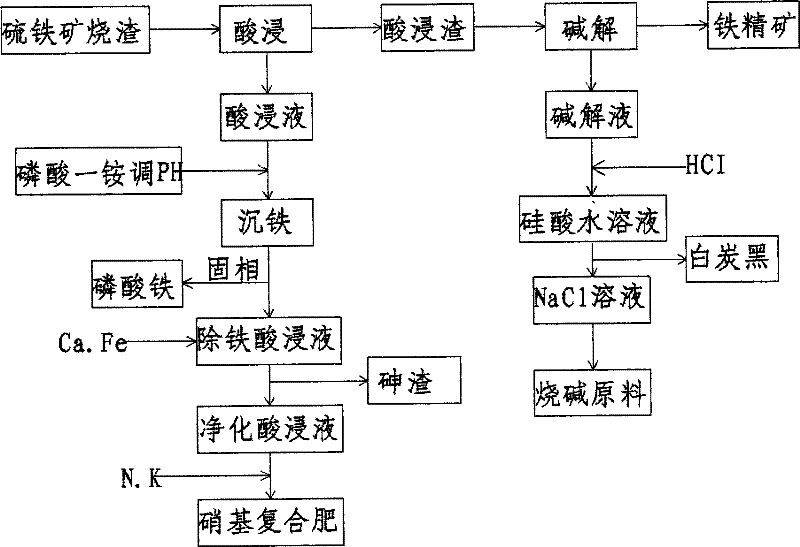

The invention relates to a method for treating pyrite cinder by combining acidic leaching with alkaline dissolving. The method mainly comprises the following steps that: nitric acid is adopted to leach the pyrite cinder, so that alkaline oxide impurities containing sulfur and arsenic are desorbed, most of iron can still exist in a solid phase in the form of ferric oxide, and the iron is effectively enriched, wherein the iron enrichment ratio is more than 90%, the sulfur removal ratio is more than 98%, the arsenic removal ratio is more than 99%, the solid phase is acid-leached residue, and the liquid phase is acid-leached liquor; when the content of silicon dioxide is more than 15% and the total iron content can reach about 50% in the pyrite cinder, an alkaline dissolving treatment is needed, the alkaline-dissolved residue is iron ore concentrate, white carbon black is obtained after acidifying alkaline-dissolved liquor, and the liquid phase is a sodium chloride solution which can be used as a raw material of sodium hydroxide; the acid-leached liquor is added into ammonium dihydrogen phosphate to produce ferric phosphate which can be used as raw materials and ceramic raw materials of a lithium iron phosphate electromagnetic material; and purified acid-leached liquor is obtained after carrying out arsenic removal and can be applied to the production of nitro compound fertilizer. With the adoption of the method for treating the pyrite cinder by combining the acidic leaching with the alkaline dissolving, the pyrite cinder can be fully and comprehensively utilized, and thus, the resource utilization ratio is increased; and the energy-saving and emission-reduction effect is good, the method is beneficial to environment-friendliness, and the clean production in the acid making industry by using the pyrite cinder can be achieved.

Owner:师兆忠

Low-alkali pretreatment method for in-situ catalytic degradation of impurities in cotton and cotton fabrics

InactiveCN102978960AStrong process adaptabilityGood energy saving and emission reduction effectBiochemical fibre treatmentBleaching apparatusElectricityPretreatment method

The invention relates to a low-alkali pretreatment method for the in-situ catalytic degradation of impurities in cotton and cotton fabrics, which comprises the following steps: (1) preparing a biological compound enzyme preparation, a biological enzyme synergist and a nonionic surfactant into enzyme working fluid; padding a fabric in the enzyme working fluid; and carrying out heat preservation on the fabric; and (2) directly padding the treated fabric into hydrogen peroxide bleaching liquid containing a hydrogen peroxide controlled decomposing additive, and then steaming, washing and drying the fabric. According to the invention, sizes and impurities are subjected to in-situ catalytic degradation in fabrication processing, therefore, an effect of ultrahigh-concentration wastewater treatment is achieved, fabrics are easy to wash, the washing temperature and washing frequency are reduced, more than 25% of water is saved, more than 30% of steam is saved, and more than 10% of electricity is saved. The COD (chemical oxygen demand) value is reduced by more than 30% in comparison with that of a traditional alkali scouring process, the B / C value of pretreated wastewater is about 0.4, and the biodegradability is improved. All indexes (such as whiteness, capillary effect, cottonseed hull removal rate, desizing ratio, strength, and the like) of treated cotton and cotton fabrics meets the quality requirements of semi-finished products.

Owner:DONGHUA UNIV

Assembly type building component joint gypsum base sealing material and application thereof

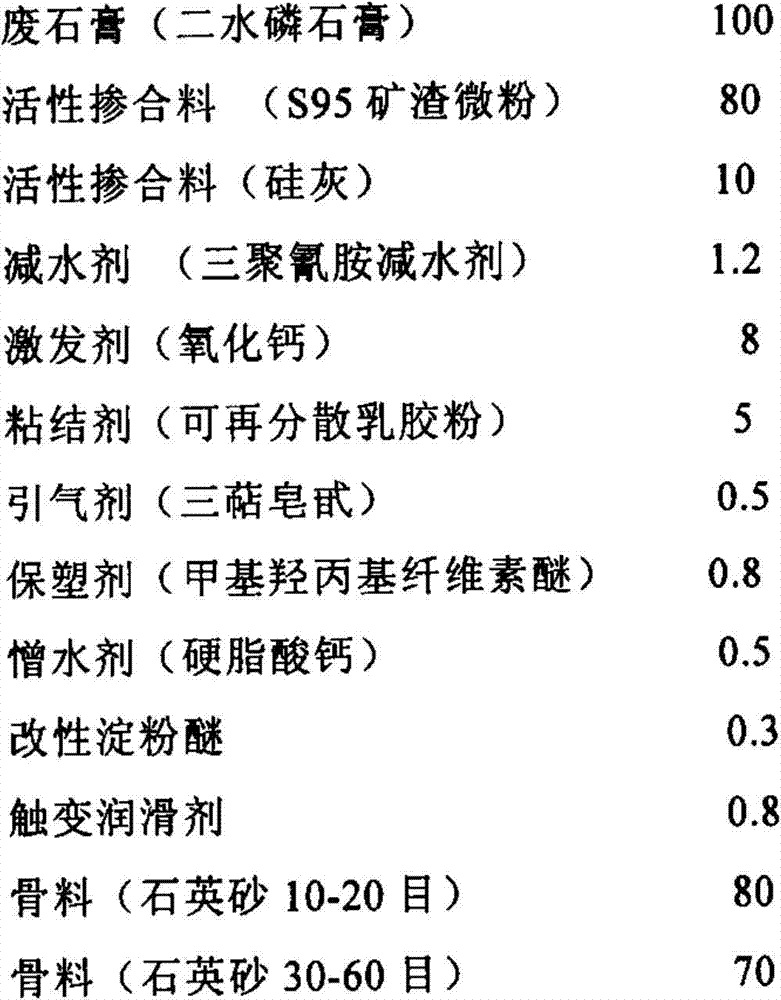

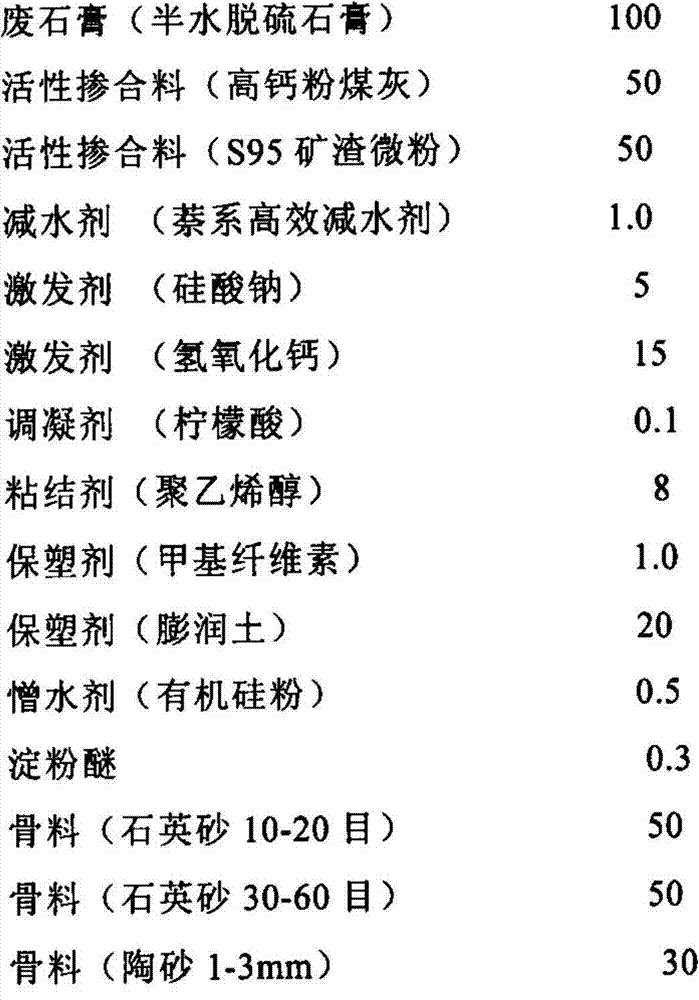

ActiveCN103496936AEasy constructionImprove plasticityBuilding constructionsResource utilizationEther

The invention relates to an assembly type building component joint gypsum base sealing material and application thereof. The assembly type building component joint gypsum base sealing material comprises, by weight, 100 parts of waste gypsum, 20-200 parts of active admixture, 0.01-10 parts of water reducer, 0.1-50 parts of excitant, 0-10 parts of thickening control agent, 0-30 parts of binder, 0-10 parts of air entraining agent, 0.01-30 parts of plastic retaining agent, 0.01-10 parts of water repellent, 0-5 parts of starch ether, 0-10 parts of thixotropic lubricant, 0-150 parts of powder filler and 0-300 parts of aggregate, and can be applied to joint sealing after being mixed with water uniformly. Compared with the prior art, the assembly type building component joint gypsum base sealing material has the advantages of convenience in use, good filling ability, high binding power, durability, low cost and the like. In the sealing material, much industrial waste gypsum is used as gelatinization materials, so that performance of sealing mortar can be improved, material cost is reduced, pollution control and emission reduction are facilitated, and a new way for resource utilization of the industrial waste gypsum is provided.

Owner:SHANGHAI LIVABLE BUILDING SCI & TECH CO LTD

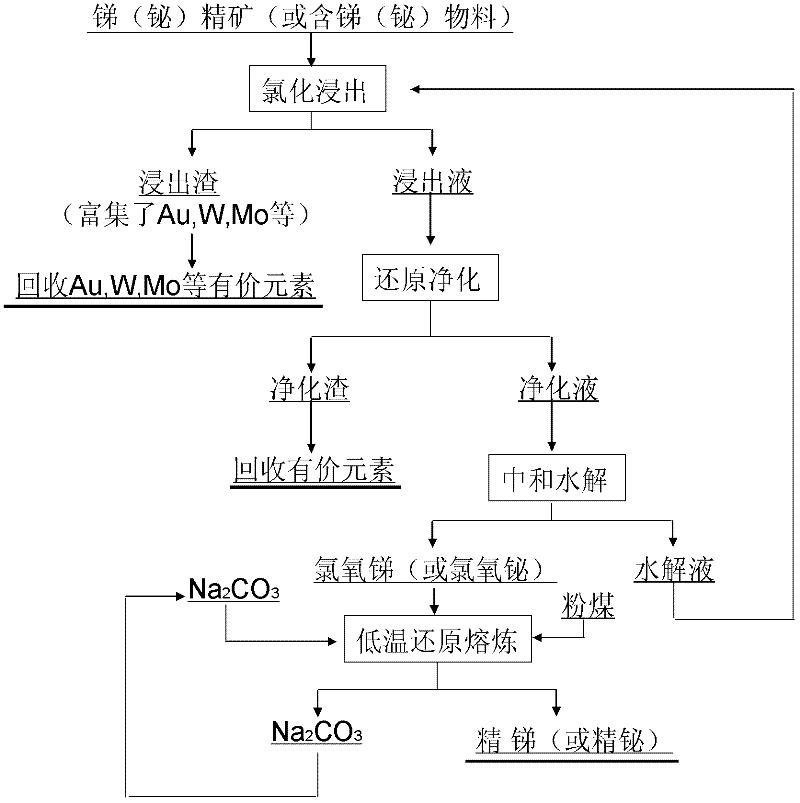

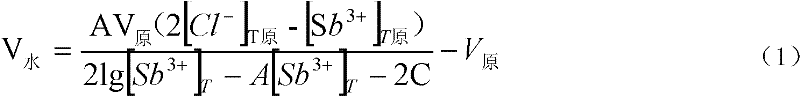

Wet process-pyrogenic process joint smelting process for antimony or bismuth

The invention discloses a wet process-pyrogenic process joint smelting process for antimony or bismuth. First, antimony is leached out from a material containing antimony (or bismuth), then reduction and purification are conducted on leaching liquid, then hydrolysis is conducted on the purified liquid to obtain antimony oxychloride (or bismuth oxychloride), and finally refined antimony (or refined bismuth) is obtained through inertia reduction smelting in a Na2CO3 system with the obtained antimony oxychloride (or bismuth oxychloride) serving as a raw material. The method solves the problems in the existing high temperature smelting of antimony (or bismuth) that pollution of low concentration SO2 and heavy metal powder is severe, energy consumption is big, efficiency is low, precious and rare metal is dispersed and the like. Simultaneously, Na2CO3 is not consumed during reduction smelting and can be used as an inertia fusing agent to return to smelting again, therefore energy consumption and reagent consumption are greatly reduced, and defects that a large amount of arsenic sludge hard to process is produced in the existing smelting process and the like are avoided. The wet process-pyrogenic process joint smelting process has the prominent advantages of being small in environment pressure, strong in raw material adaptability, high in metal (enrichment rate) recovery rate, small in energy consumption and low in cost.

Owner:YIYANG SHENGLI CHEM IND

Low-load feed-water heating system of thermal power generating unit

ActiveCN103335301AIncrease feed water temperatureImprove efficiencyFeed-water heatersEngineeringGenerating unit

A low-load feed-water heating system of a thermal power generating unit comprises a jet heat pump and a steam turbine which are communicated with a main steam pipeline, wherein a steam valve is mounted on a pipeline between the main steam pipeline and the jet heat pump; regenerative extraction steam of the steam turbine is led out by a regenerative extraction steam pipe; one path is communicated with a high pressure heater; the other path is communicated with the jet heat pump after passing through an ejected steam valve; an outlet of the jet heat pump is communicated with a steam side of a low-load feed-water heater; a heating water inlet side of the low-load feed-water heater is communicated with a feed-water side of the high pressure heater; and a feed-water pipeline is communicated with a boiler after sequentially penetrating through the high pressure heater and the low-load feed-water heater. The system takes main steam as ejection steam; one-section regenerative extraction steam with highest ejection regenerative extraction steam pressure is ejected, so that mixed steam with the pressure higher than the one-section regenerative extraction steam pressure is obtained; and the mixed steam at the outlet of the jet heat pump heats feed water of the boiler to raise the temperature of the feed water.

Owner:XI AN JIAOTONG UNIV

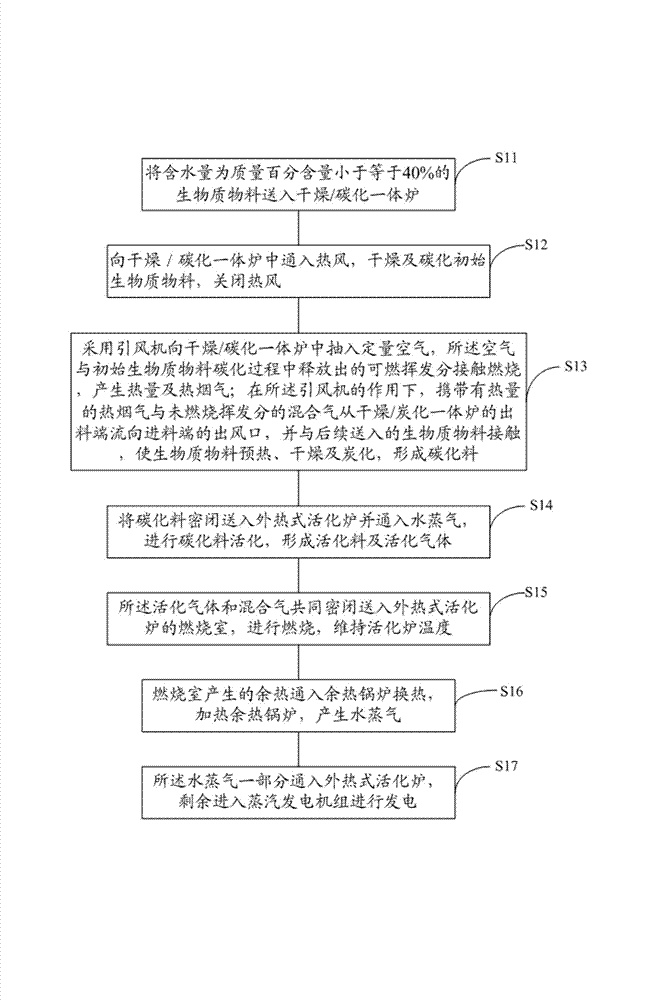

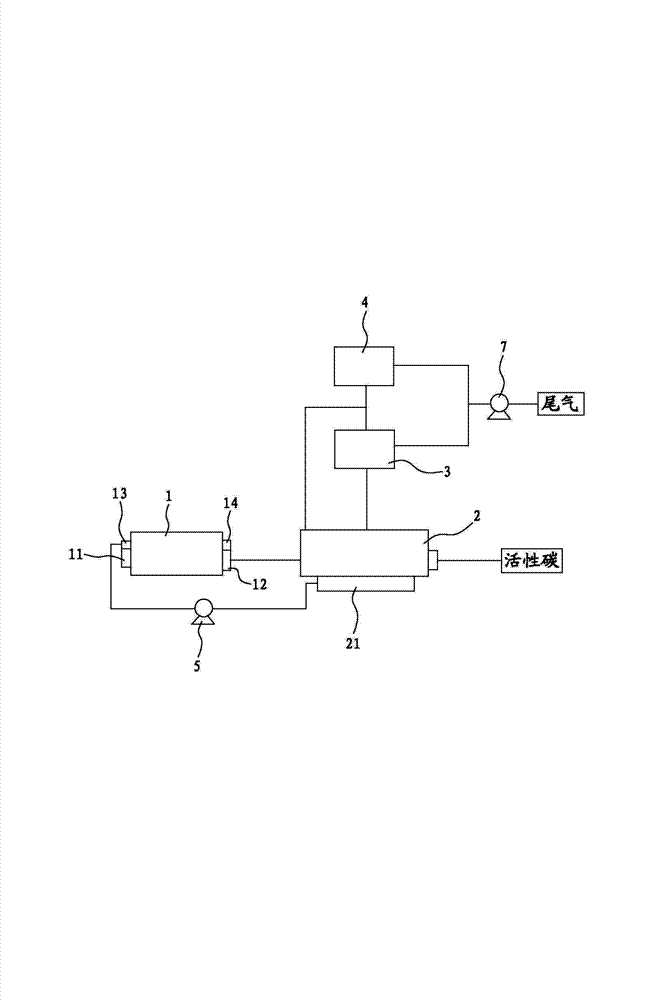

Self-heating continuous carbonization and activation processing method for biomass and device thereof

ActiveCN103708452AReduce energy consumptionGood environmental effectCarbon compoundsEnergy inputBiomassCombustion chamber

The invention discloses a self-heating continuous carbonization and activation processing method for biomass. The method comprises steps of: feeding biomass materials into a drying / carbonization integrated furnace, feeding hot wind, drying and carbonizing the initial biomass materials, and stopping the hot wind; feeding a fixed quantity of air into the drying / carbonization integrated furnace, combusting combustible volatile compounds formed in the carbonization process of the initial biomass materials, and adopting the generated heat to dry, heat and carbonize subsequent biomass materials, thus forming a carbonized material and a mixed gas; feeding the carbonized material to an external-heated type activation furnace to perform activation, thus forming an activated material and an activated gas; feeding the activated gas and the mixed gas to a combustion chamber of the external-heated type activation furnace to be combusted so as to maintain the temperature of the external-heated type activation furnace and feeding the waste heat to a waste heat boiler to prepare water vapor; and feeding a portion of the water vapor to the external-heated type activation furnace, and feeding the rest of the water vapor into steam power generating units to generate power. The processing method is maintained by the heat generated in the whole processing process, thus achieving effects of energy conservation, emission reduction and efficient energy utilization.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI +1

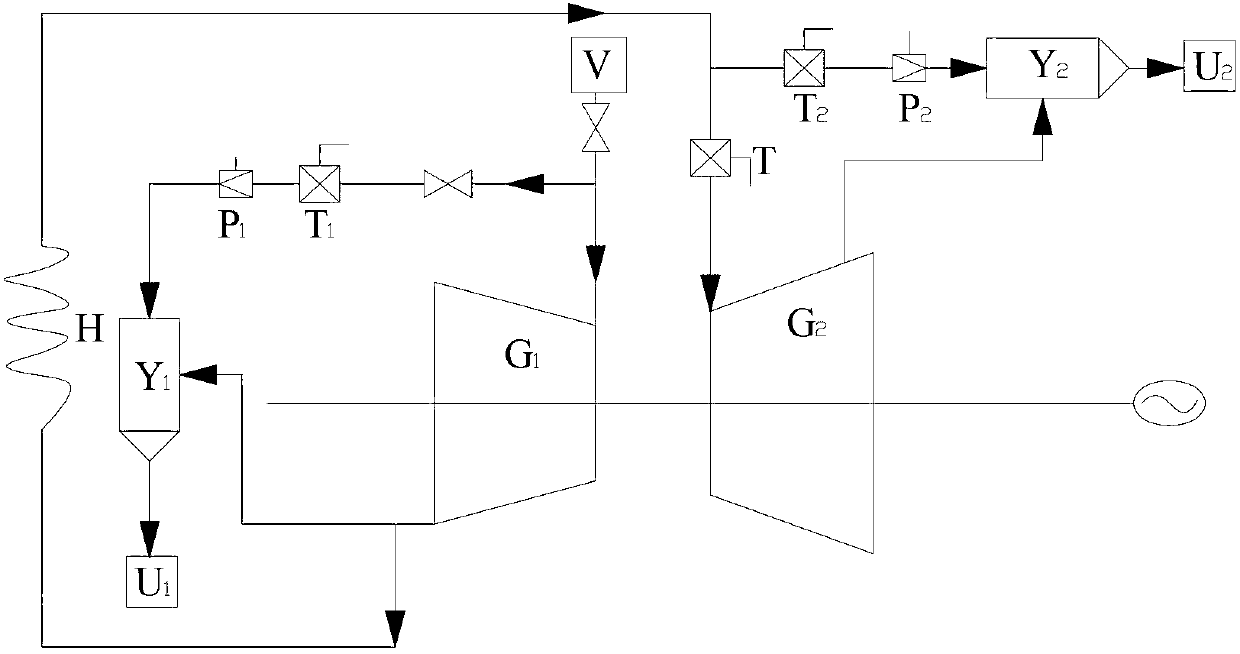

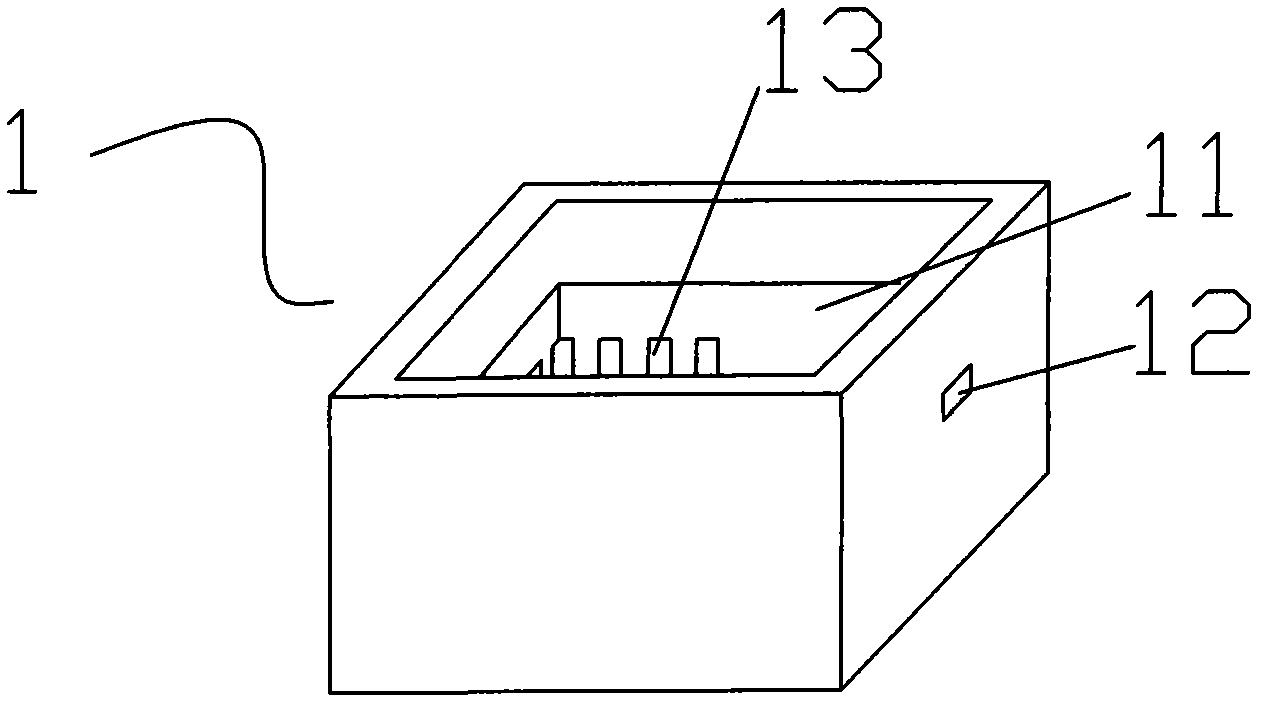

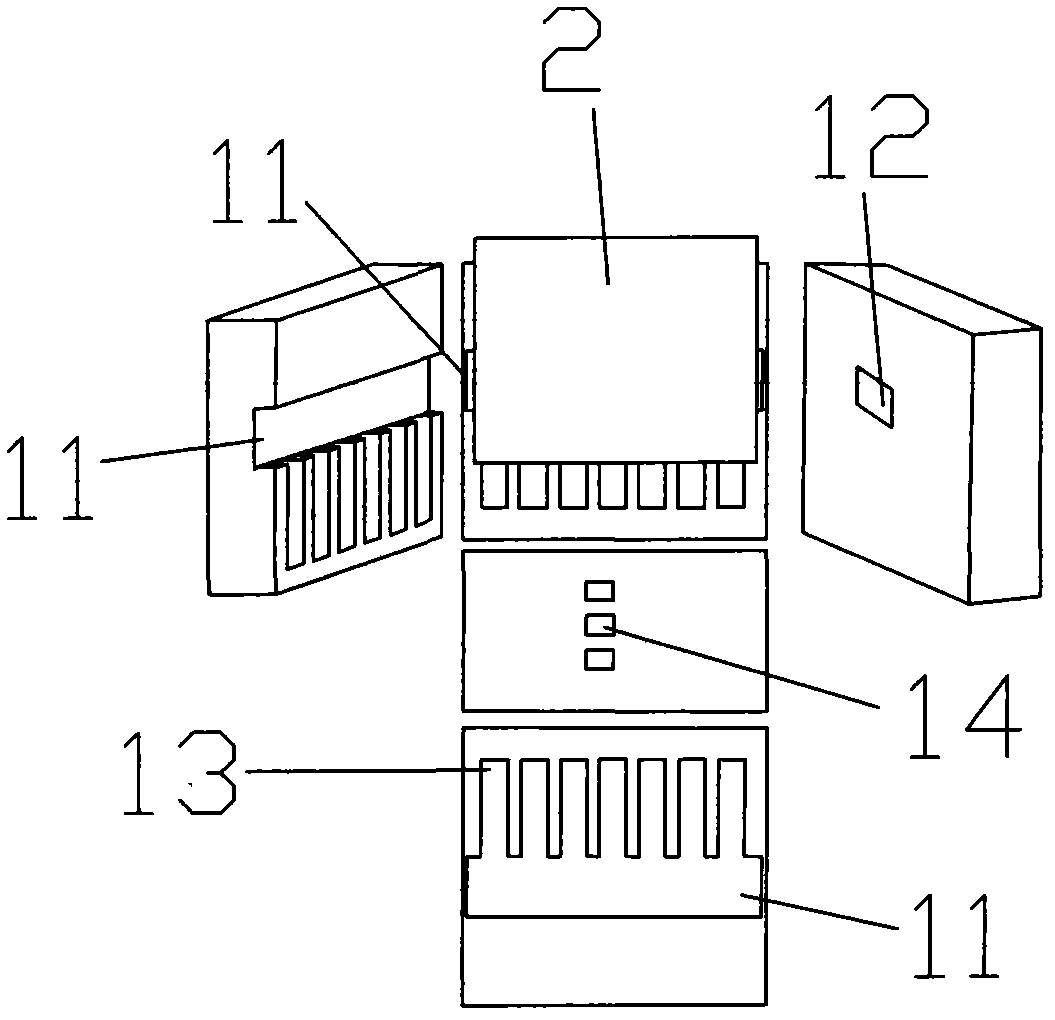

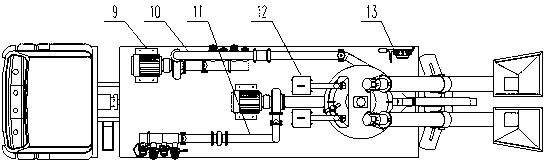

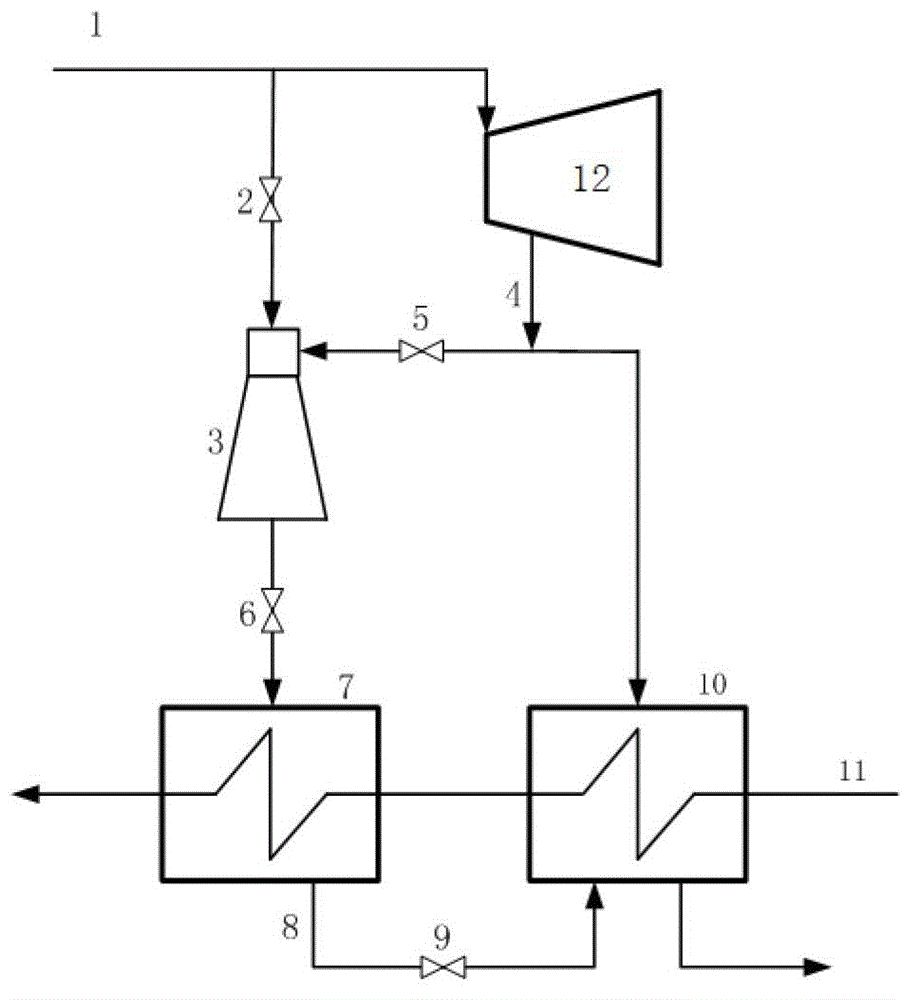

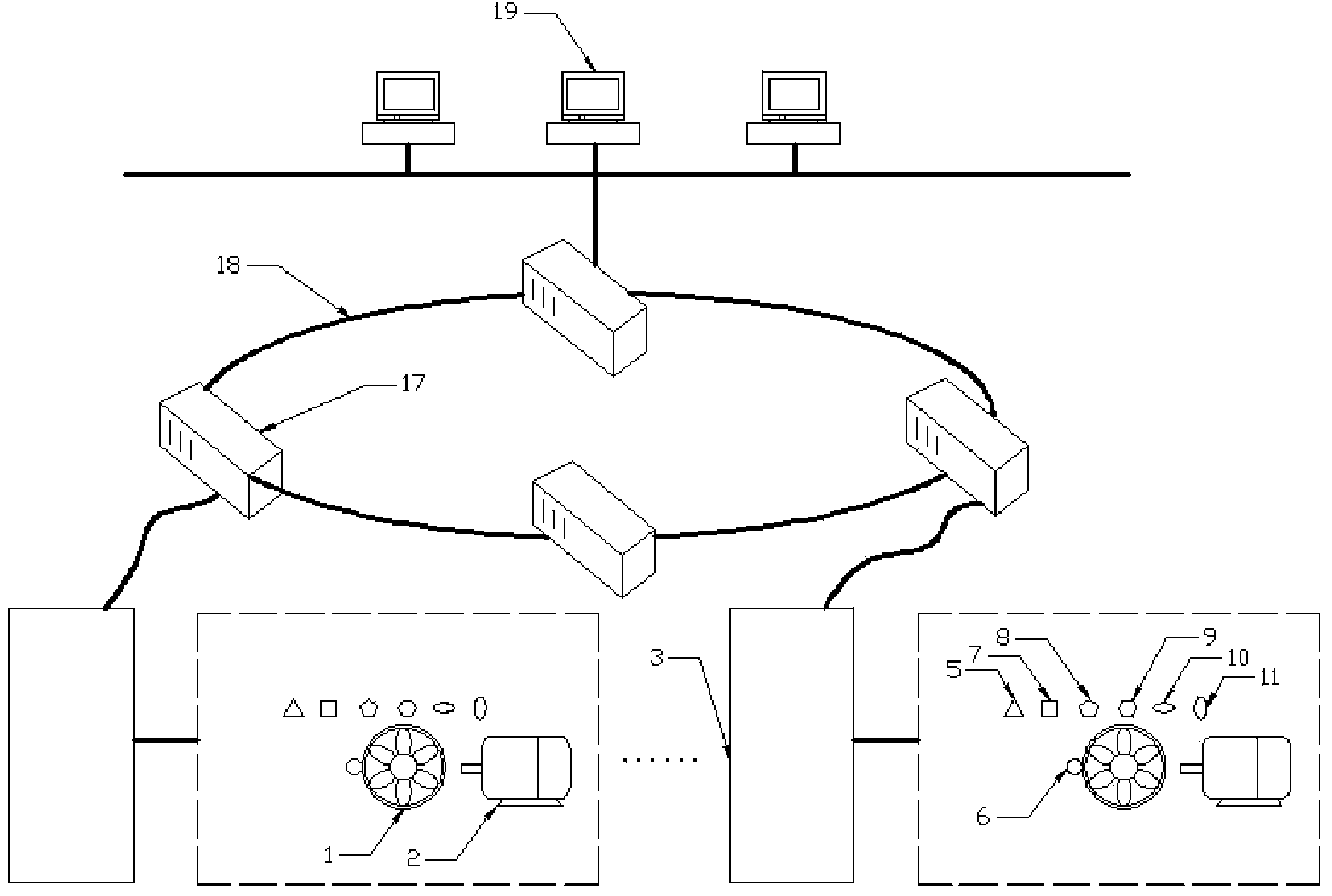

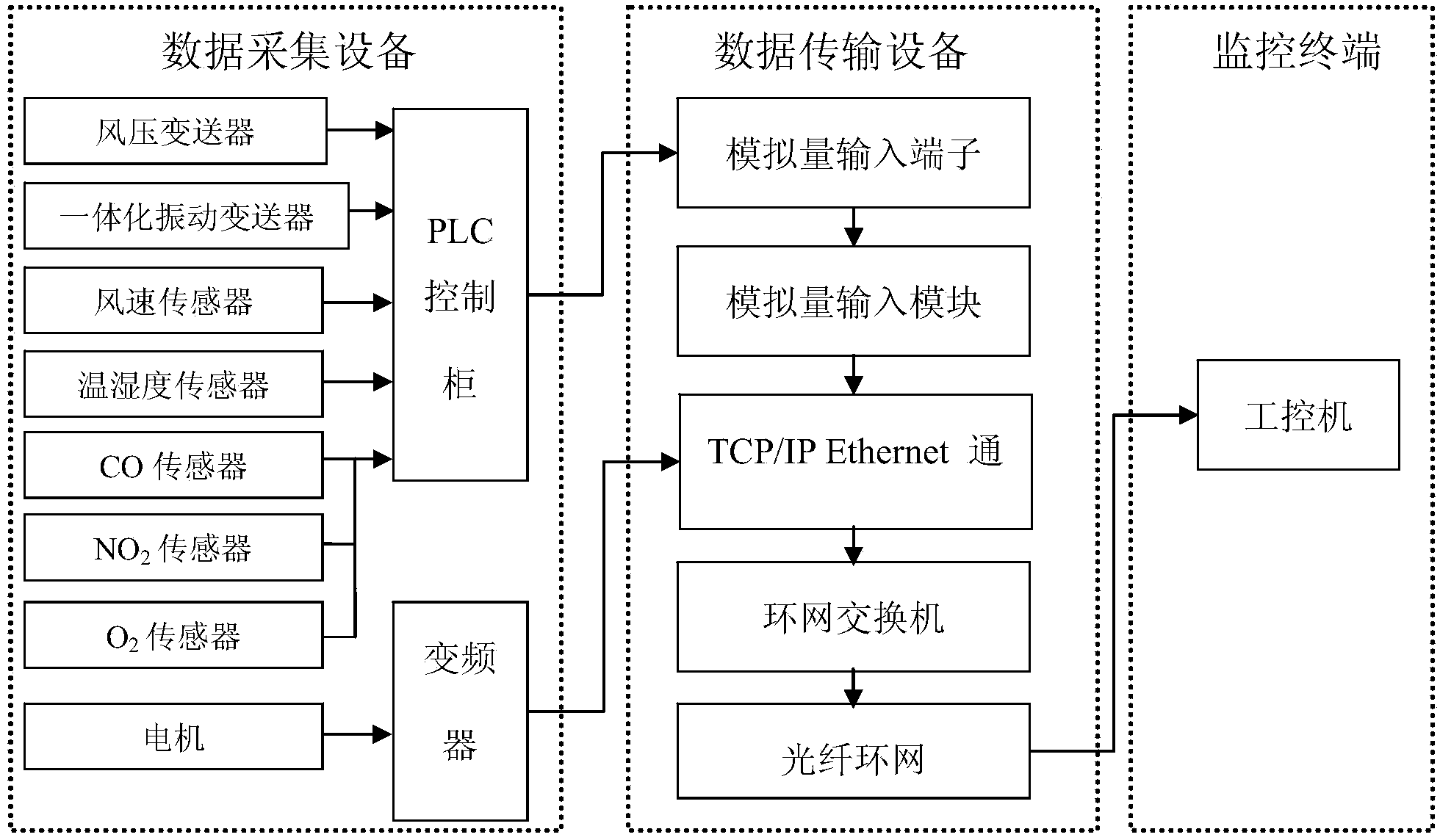

Intelligent sensing and remote and unified regulating system for deep-mining mine ventilation

ActiveCN104018884AImprove ventilationImprove efficiencyMining devicesTunnel/mines ventillationRing networkEngineering

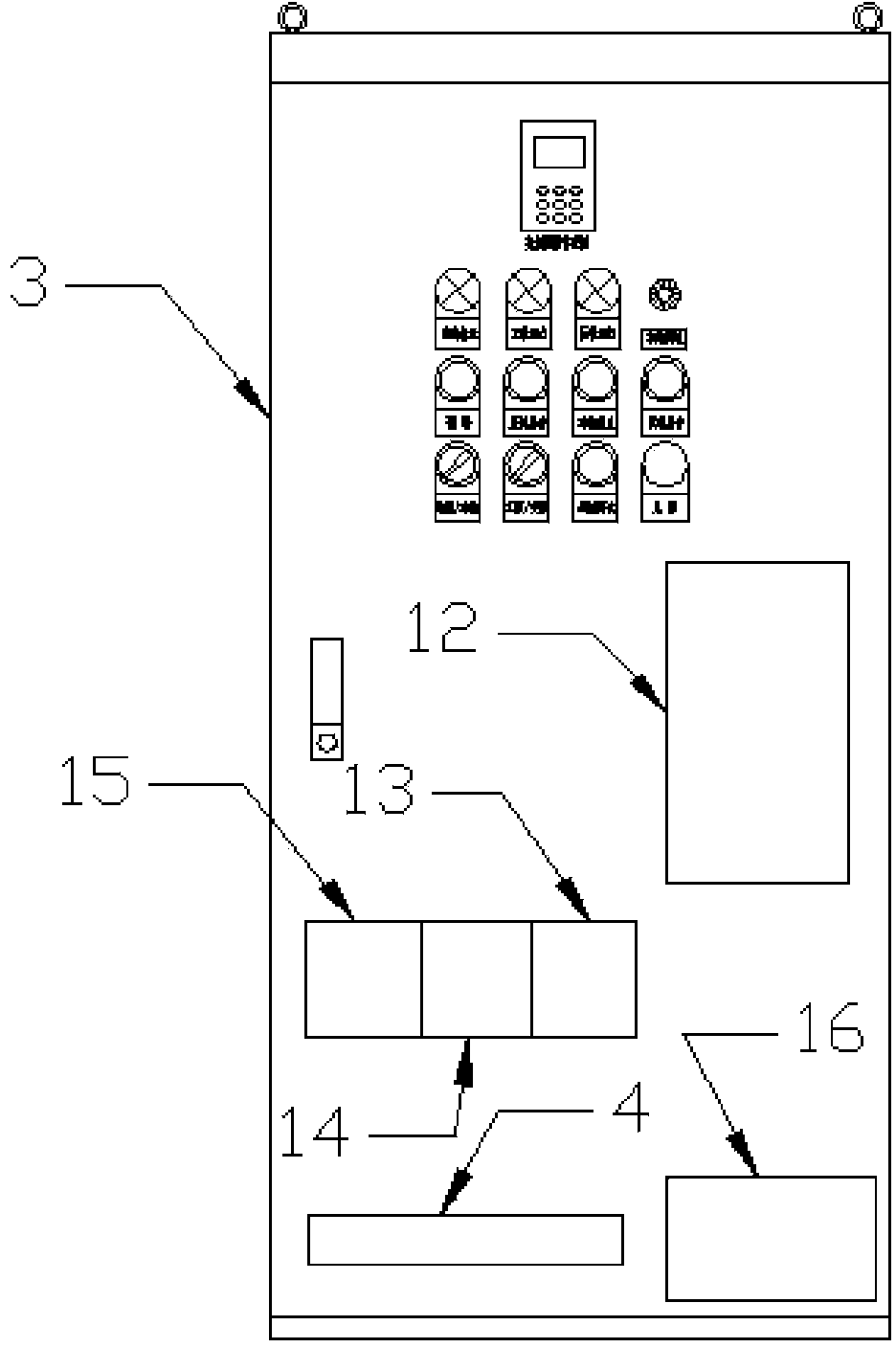

The invention provides an intelligent sensing and remote and unified regulating system for deep-mining mine ventilation. The intelligent sensing and remote and unified regulating system is mainly composed of intelligent sensing equipment, a PLC control cabinet (3), a middle-layer optical fiber ring network (18), a ring network exchanger (17) and an industrial personal computer (19). The PLC control cabinet (3) is provided with an analog input terminal (4), a frequency converter (12), an analog input module (13), a communication module (14) and a CPU module (15), wherein the analog input terminal (4) is connected with the intelligent sensing equipment through a cable, the frequency converter (12) is connected with a ventilation motor (2) and can automatically acquire operation parameters of the motor, and then the frequency converter is communicated with the industrial personal computer (19) of an upper-layer monitoring terminal through the CPU module, the communication module, the analog input module, the middle-layer optical fiber ring network and the ring network exchanger. The intelligent sensing and remote and unified regulating system is strong in expansibility and improves the unified regulating efficiency and the real-time controlling and optimizing capacity to multiple fans in deep-mining mines.

Owner:湖北三鑫金铜股份有限公司

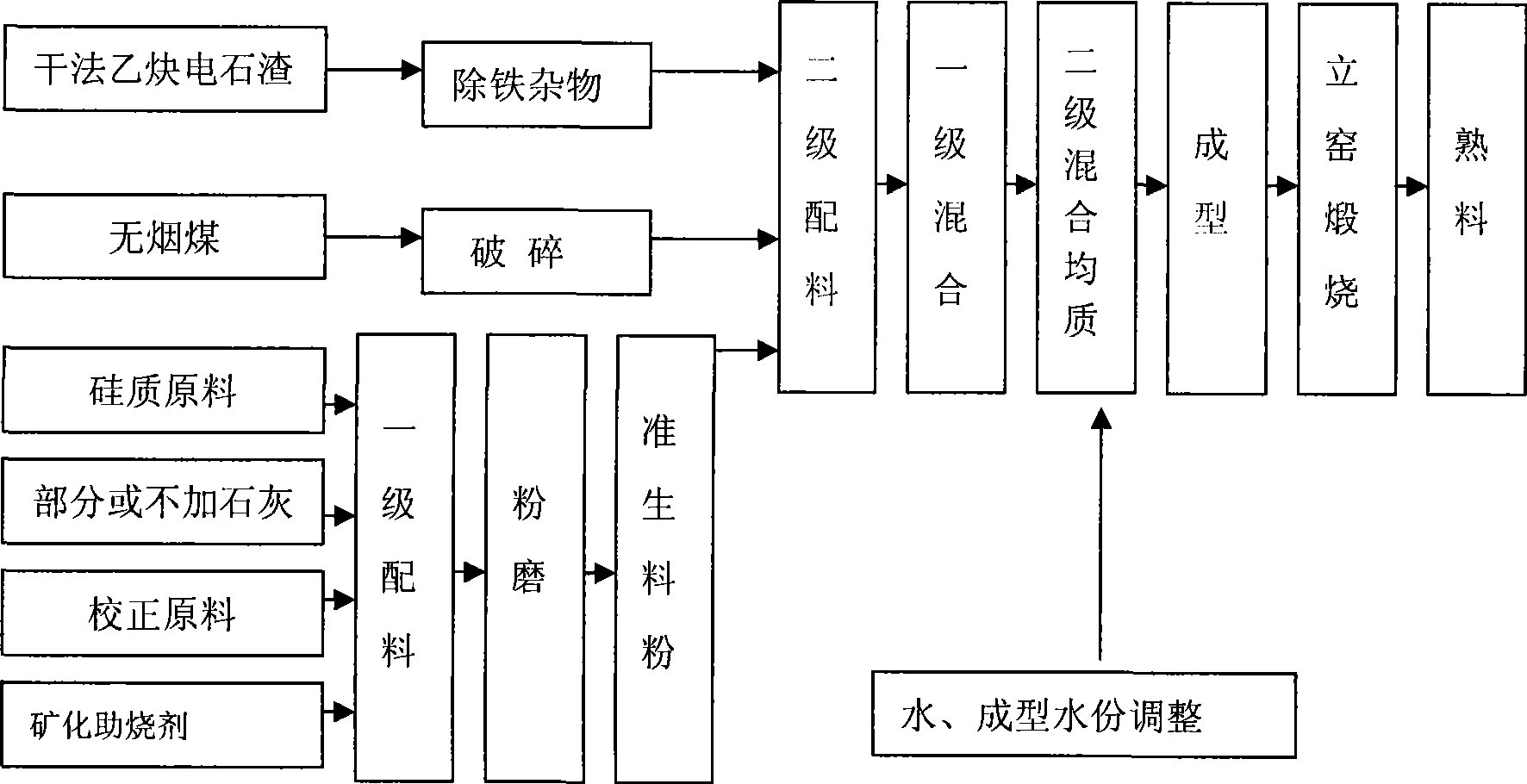

Novel technology of vertical kiln for manufacturing cement clinker by utilizing dry acetylene sludge two-stage batching

The invention discloses a novel technology of a vertical kiln for manufacturing cement clinker by utilizing dry acetylene sludge two-stage batching, which comprises the steps of utilizing dry acetylene sludge to substitute limestone in cement raw meal batching fully or partially, taking the dry acetylene sludge as the main material of the cement raw meal to be subjected to second-stage batching directly with other materials after first-stage batching grinding, mixing evenly, manufacturing a raw meal rod or a raw meal ball, entering the vertical kiln and forming the cement clinker by calcining. The invention has less investment and low energy consumption, takes effect rapidly, is easy for achieving environment protection standard, saves resources of coal, electricity and limestone and reduces CO2 discharge, thus being a novel energy-saving, consumption-reducing and environment-protecting technology.

Owner:尹小林

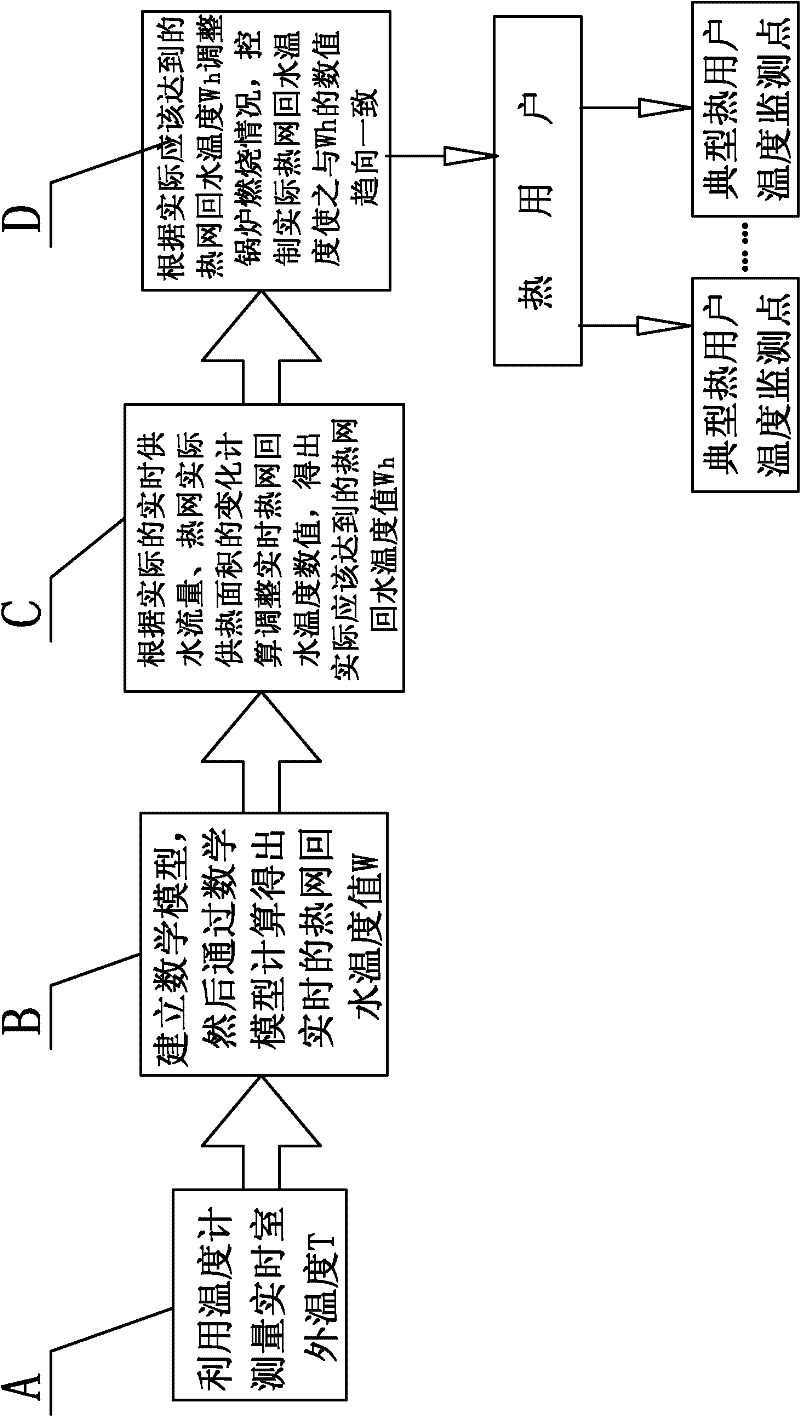

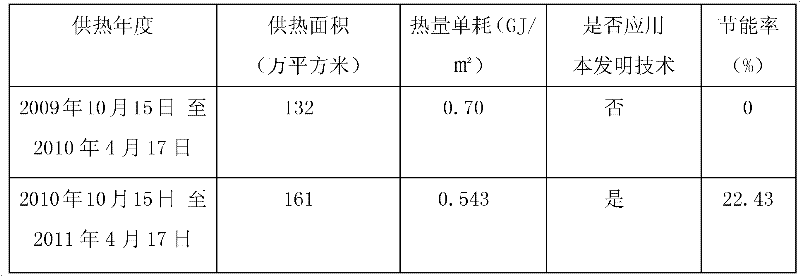

Method for compensating and regulating heating temperature of centralized heat supply network

InactiveCN102252364AEasy to operateEasy to implementLighting and heating apparatusSpace heating and ventilation detailsCombustionMathematical model

The invention relates to a method for compensating and regulating the heating temperature of a centralized heat supply network, and belongs to the technical field of heat supply regulation. By the method, the problem that the aims of saving fuel, reducing discharge and allowing the indoor temperature of users to reach the standard cannot be fulfilled by the conventional method for controlling the temperature of a heating boiler. The method comprises the following steps of: measuring real-time outdoor temperature T by utilizing a thermometer; establishing a mathematical model, and calculating by the mathematical model to obtain a real-time water return temperature value W of the heat supply network; calculating and adjusting the real-time water return temperature value of the heat supply network according to the change of actual real-time water supply flow and actual heat supply areas of the heat supply network to obtain an actually-reached water return temperature value Wh of the heat supply network; and adjusting the combustion condition of the boiler according to the actually-reached water return temperature value Wh of the heat supply network in the step C, and controlling the actual water return temperature Wh1 of the heat supply network, so that a numerical value of the actual water return temperature Wh1 is consistent with that of the Wh. By the method, the fuel is saved, the discharge is reduced, the indoor temperature of the users reaches the standard, and the optimal state of heating is achieved.

Owner:江丛兴

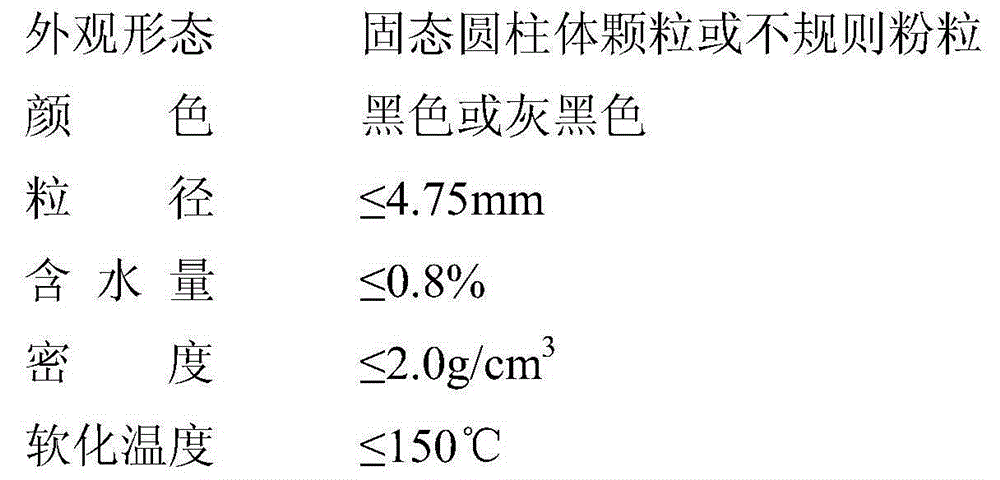

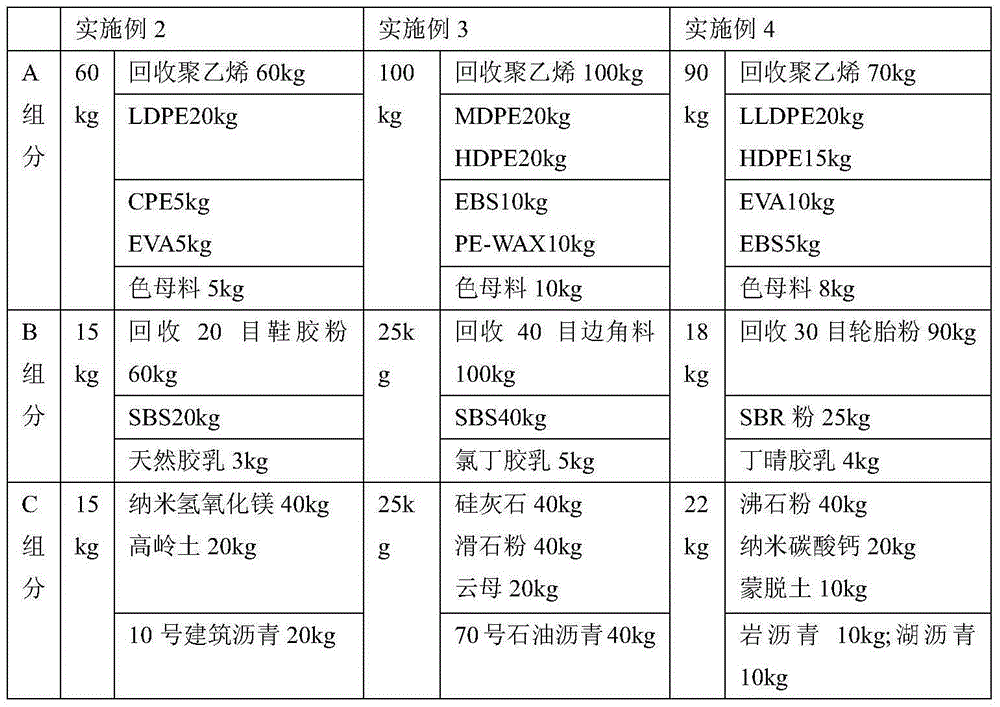

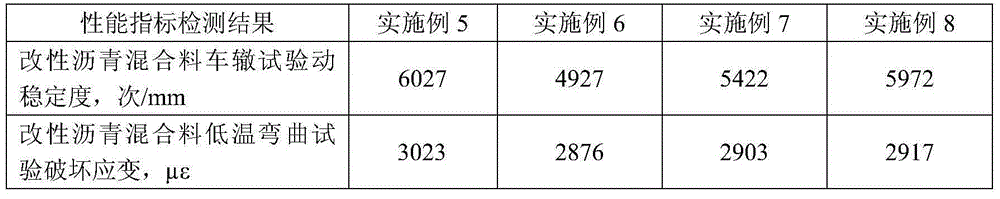

Modified asphalt mixture modifier and preparation method therefor

InactiveCN105153511AImprove high temperature anti-rutting performanceImprove low temperature crack resistanceBuilding insulationsMasterbatchAsphalt

The invention relates to a modified asphalt mixture modifier and a preparation method therefor. The modified asphalt mixture modifier is prepared from the following components in parts by weight: 60-100 parts of a component A, 15-25 parts of a component B and 15-25 parts of a component C, wherein the component A is prepared from the following components in parts by weight: 60-100 parts of recovered polyethylene, 20-40 parts of polyethylene, 10-20 parts of auxiliaries and 5-10 parts of color masterbatch; the component B is prepared from the following components in parts by weight: 60-100 parts of recovered rubber powder, 20-40 parts of rubber powder and 3-5 parts of latex; the component C is prepared from the following components in parts by weight: 60-100 parts of inorganic powder and 20-40 parts of an asphalt material. According to the modifier provided by the invention, the comprehensive performance of the modified asphalt mixture can be improved. By directly inputting the modifier into a stirring cylinder of a mixing plant, stirring and modification are synchronously implemented. The produced modified asphalt mixture is superior to a conventional modified asphalt mixture in performance.

Owner:陕西长大博源公路养护科技有限公司

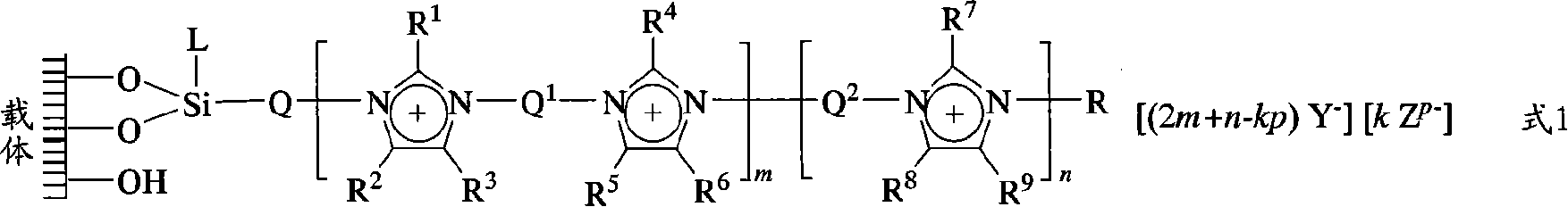

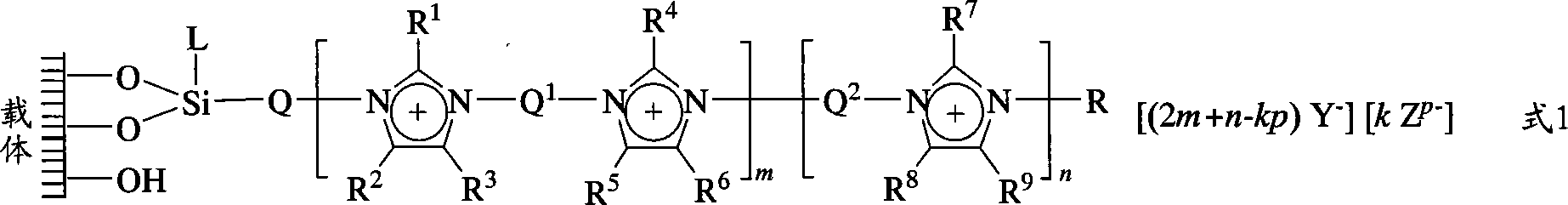

Solid-loaded ionic-liquid catalyst for olefin-dihydroxy reaction, its production and use

InactiveCN101073783AHigh activityEasy to separate and recycleOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by hydroxy group additionOrganic acidOrganic solvent

The invention is concerned with immobilization ion liquid activators, production for the dihydroxylation of olefin and the method producing rare H2O2 solution into vicinal diol by those activators and under the acidity condition with organic solution or without organic solution. The said activator is based with immobilization ion liquid and loaded transition metal active center. The activator can be reused and the loaded transition metal tungsten is innocuous and cheap. Compare with traditional method, it takes rare H2O2 solution as oxidant with high utilization ratio and cleaning to avoid pollute for too much of organic acid. The transform ration is 98 percent of H2O2 during the process without organic solution and superfluous olefin and the separate ration of 1,2-cyclohexanediol is 92 percent. The activator can be reused for eight times and still has good active nature and the process is easy and applied for industry exploitation.

Owner:SHAANXI NORMAL UNIV

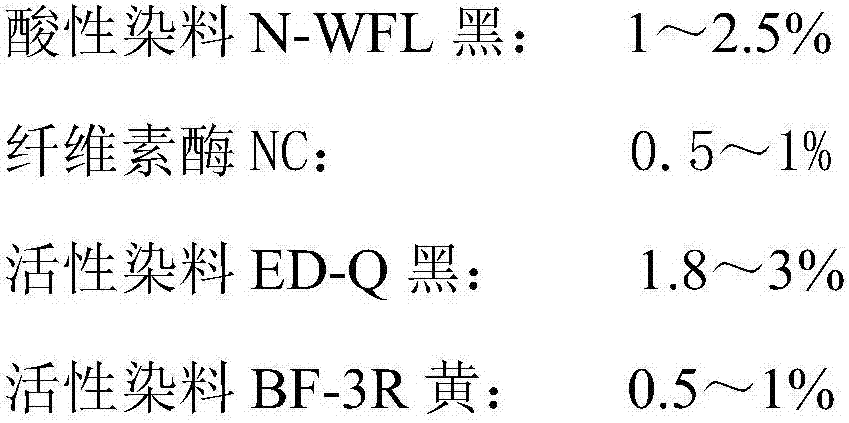

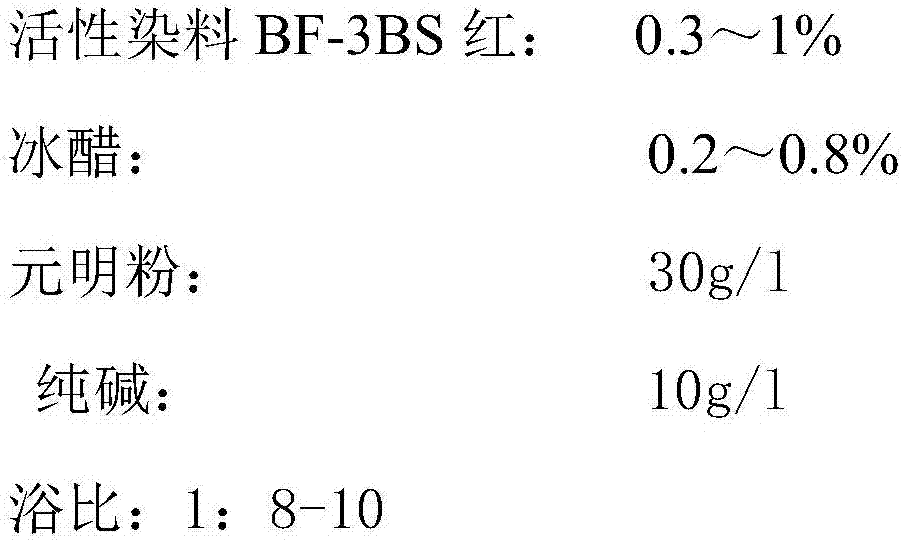

Nylon/cotton fabric hair removal and reactive dye dyeing one-bath process

InactiveCN106958152AReduce consumptionReduce production processShrinkingMercerising of indefinite length fabricsHair removalNylon material

The invention relates to a one-bath dyeing process, in particular to a one-bath process for hair removal and reactive dye dyeing of brocade / cotton fabrics. Follow the steps below: select sample cloth → gray cloth desizing → gray cloth pre-setting → gray cloth mercerizing → dyeing formula design → sample vat dyeing → drying and setting → oiling and setting → pre-shrinking finishing → finished product inspection. A one-bath process of hair removal and reactive dye dyeing of nylon / cotton fabrics, which has obvious energy-saving and emission-reduction effects, and the hand-feel elasticity, color fullness, and various quality internal indicators of the processed fabrics can meet the requirements of different customers.

Owner:HANGZHOU AOMEI PRINTING & DYEING

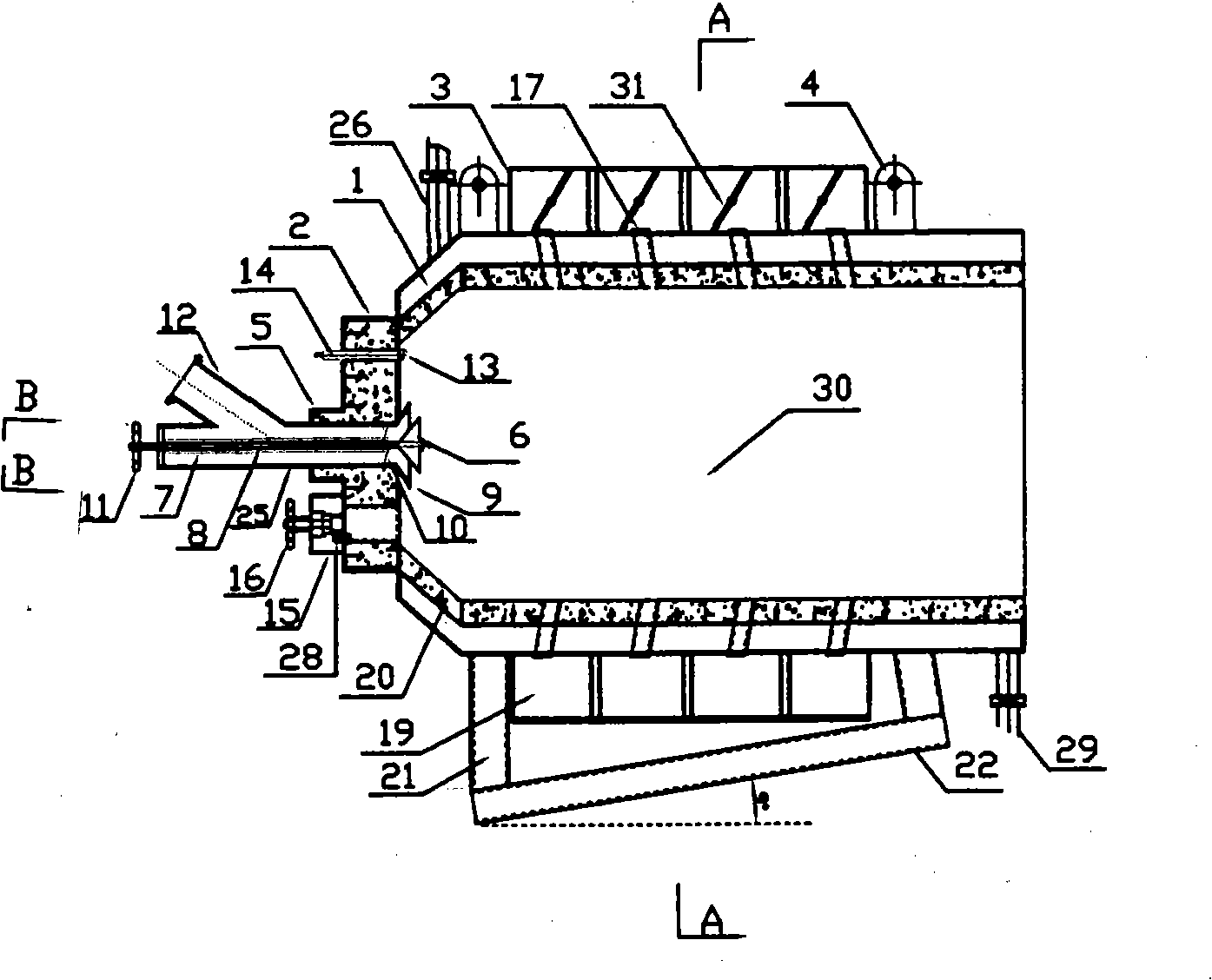

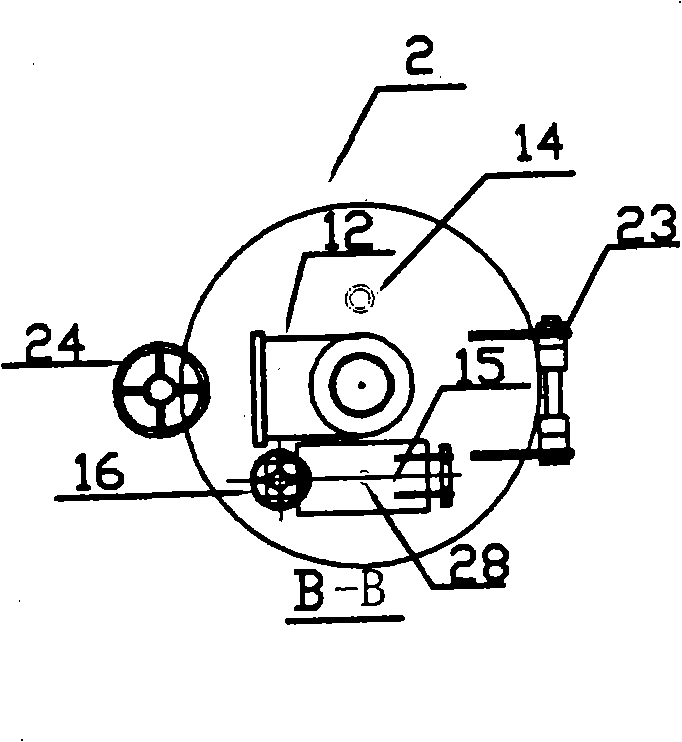

Low NOx liquid state slag-off double-eddy flow coal-powder combustor

ActiveCN101324334ABurn fastReduce smoke and dust emissionsPulverulent fuel combustion burnersSlagCoal

The invention relates to a low-NOx slag tapping double-swirl pulverized coal burner, which is suitable for 2-35 ton steam and hot water boiler and burning devices desired for heat energy for various kinds of industrial productions such as furnace, forging, steel making, road and bridge mixing station, and cold aggregate heating. The low-NOx slag tapping double-swirl pulverized coal burner comprises an adjustable burning device and a cylindrical burning chamber and is characterized in that the housing of the burning chamber is a heat insulating layer; a cooling water channel or a secondary air heat exchange fin is arranged between the housing the burning chamber and a secondary air chamber; a cooling water outlet pipe and a cooling water inlet pipe are respectively arranged on the upper and the lower ends of the cooling water channel; and a primary gas axial flow generator is arranged on the top of the jacket of an adjusting screw. The low-NOx slag tapping double-swirl pulverized coal burner has the advantages of sufficient burning and improved service life.

Owner:SHANGHAI TIQIAO TEXTILE & YARN DYEING

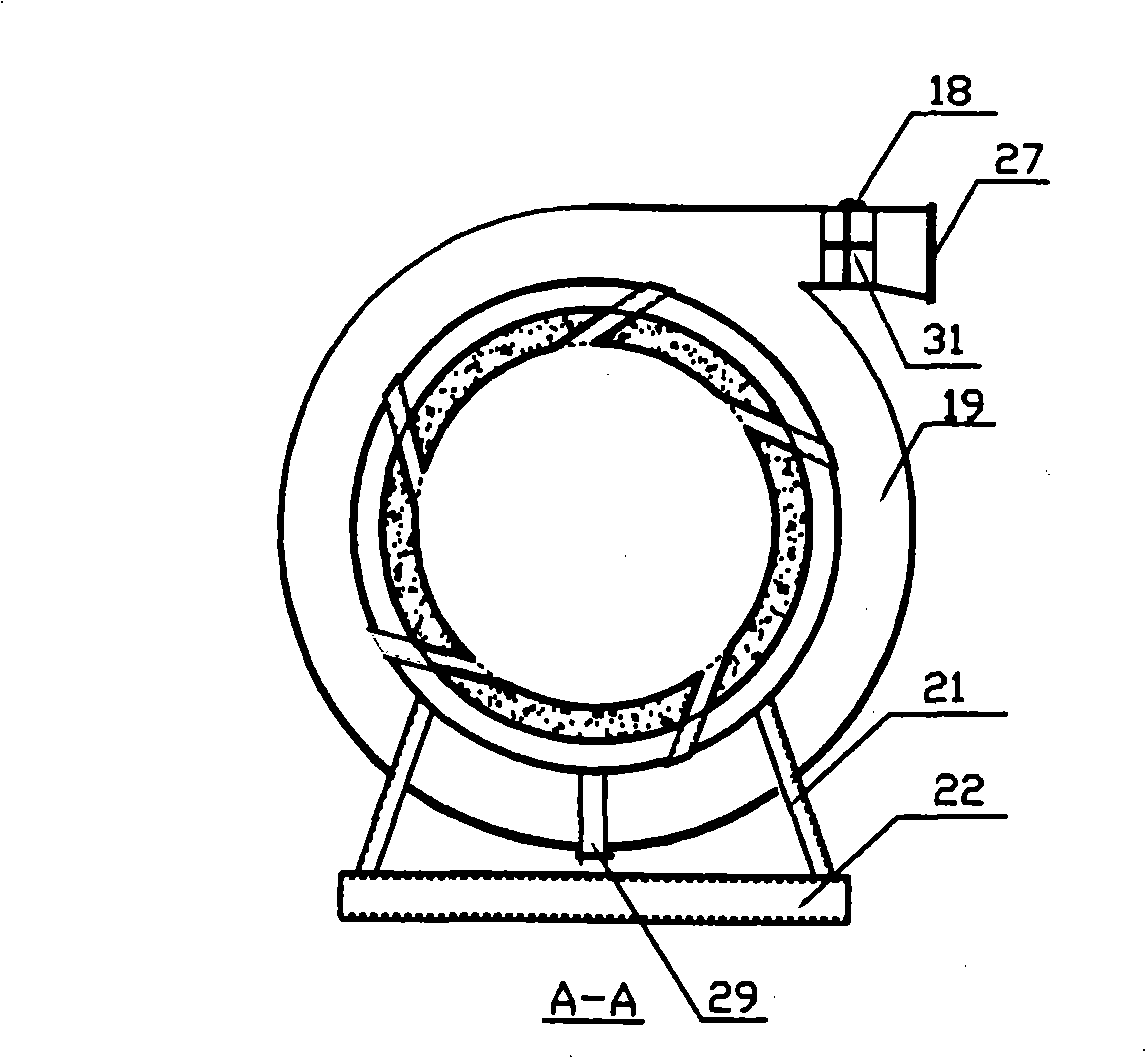

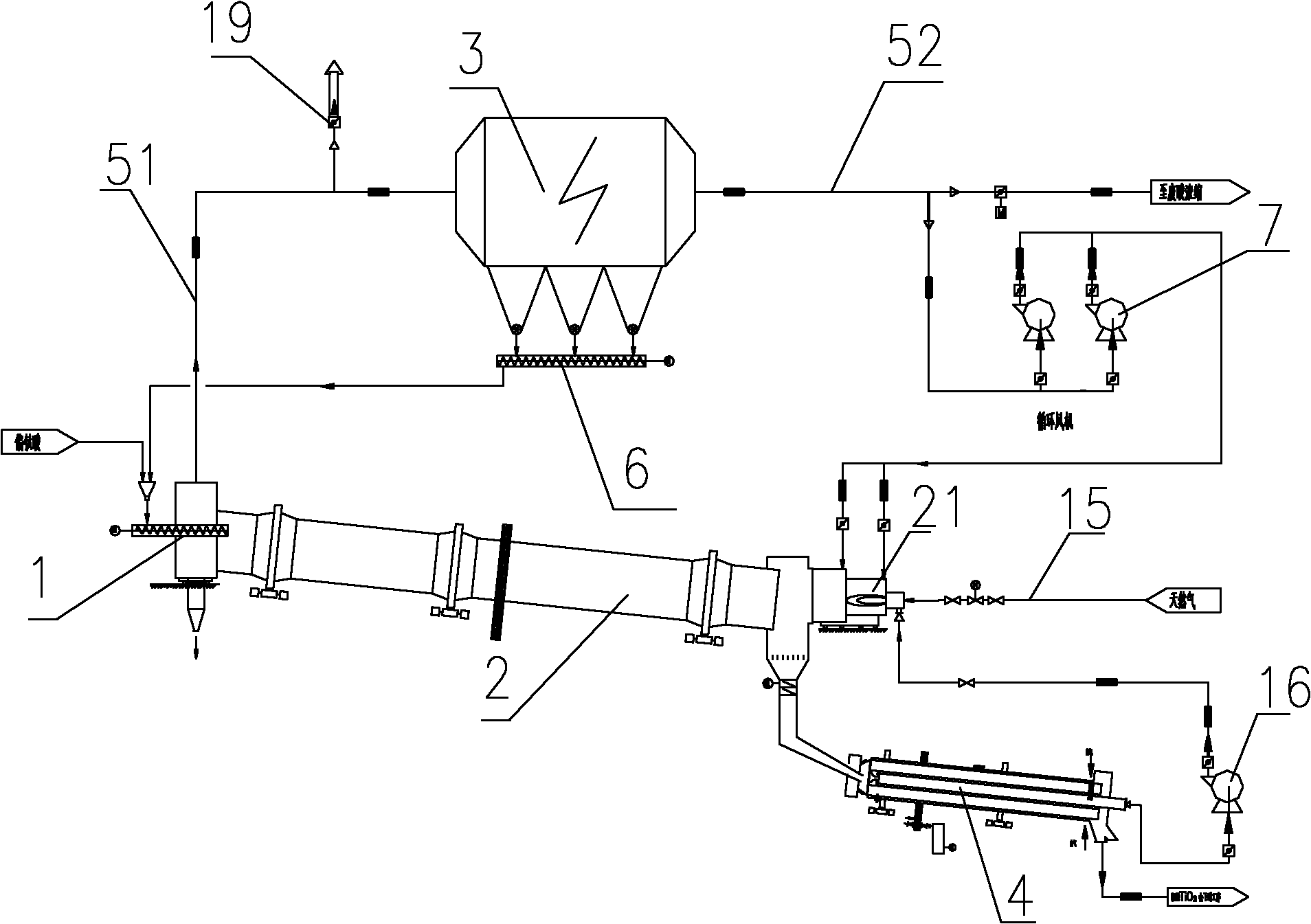

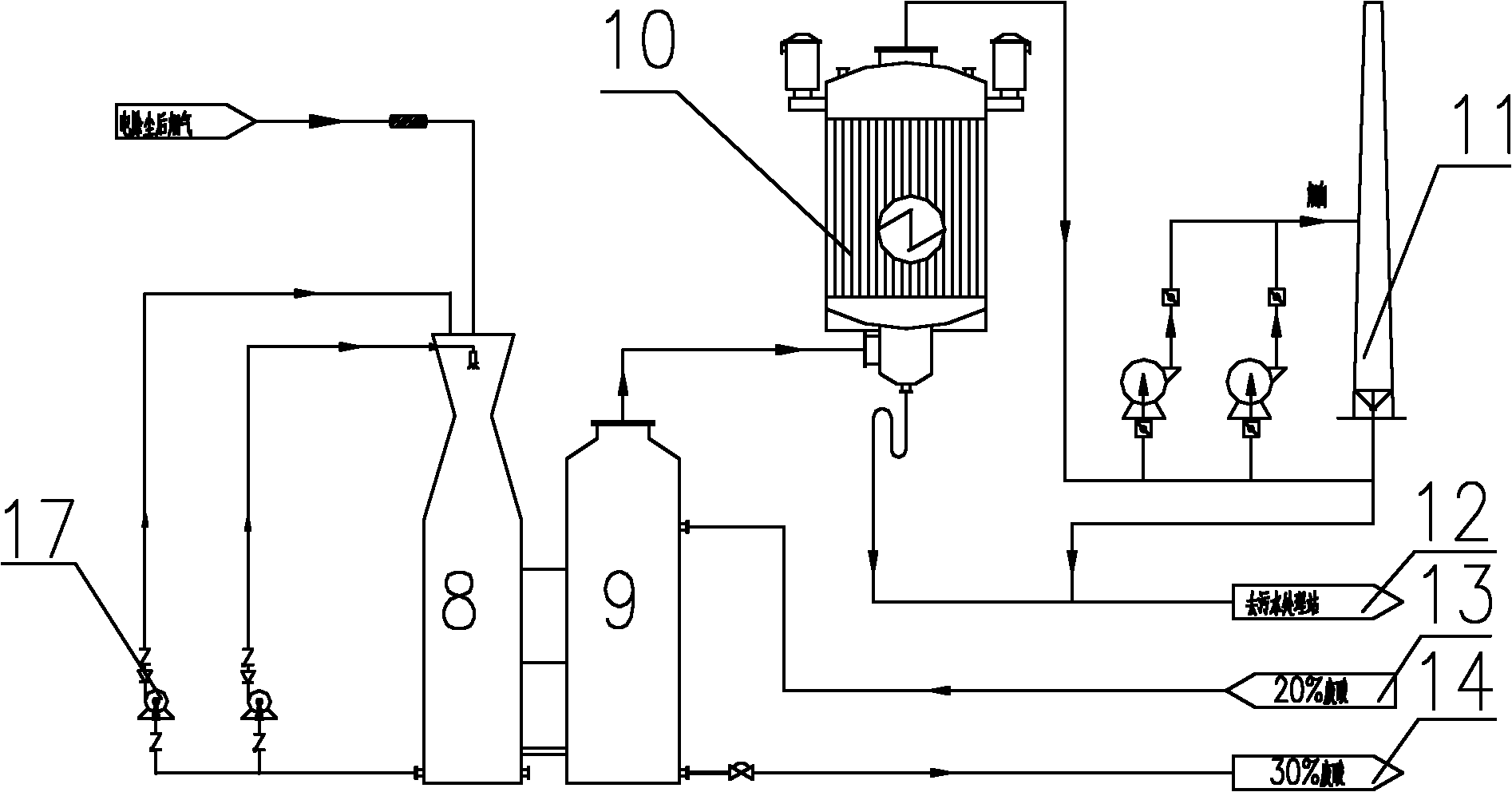

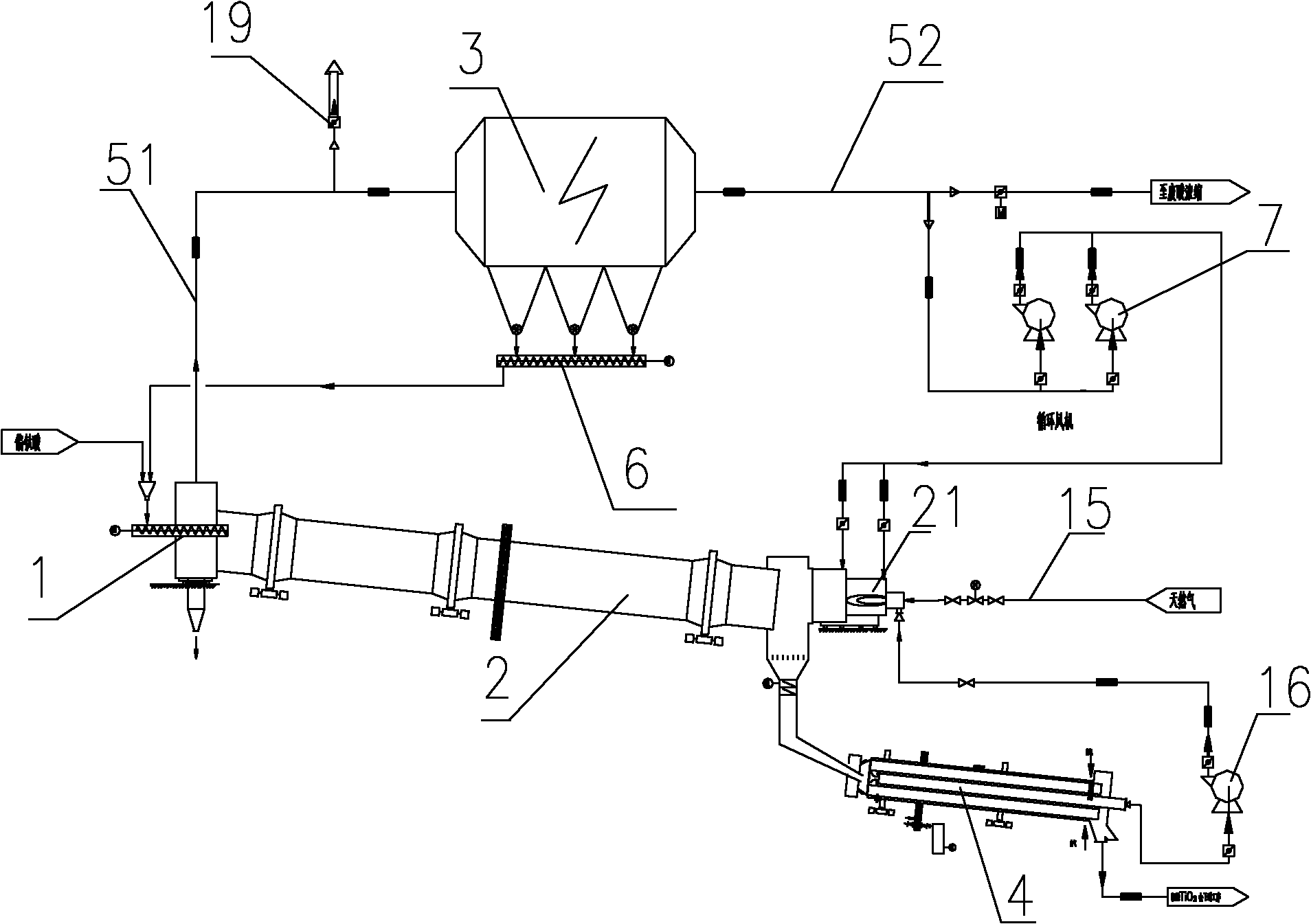

Method and device for utilizing heat energy of flue gas produced by calcining in rotary kiln in process of producing titanium dioxide by sulfuric acid method

ActiveCN102080928AHigh yieldGood energy saving and emission reduction effectRotary drum furnacesIncreasing energy efficiencyMoisturePrecipitation

The invention relates to a method for utilizing heat energy of flue gas produced by calcining in a rotary kiln in the process of producing titanium dioxide by a sulfuric acid method, which comprises the following three aspects of: (1) performing electric precipitation to purify high-temperature flue gas produced in a rotary calcining kiln, collecting dust by a dry method, and returning a recycled product to the rotary kiln for calcining again; (2) spraying 20 percent waste acid produced in the production process to one part of the purified high-temperature flue gas, performing mass transfer and heat transfer, evaporating moisture in the waste acid to improve the concentration of the waste acid to 30 percent, purifying 70 to 80 DEG C low-temperature tail gas produced by concentrating the waste acid by using an electric demisting system, and discharging the tail gas when the tail gas reaches the standard; and (3) returning the other part of the purified high-temperature flue gas to the rotary calcining kiln for recycling, supplementing heat, and adjusting temperature gradient in the kiln. Materials in the flue gas are recycled by the dry method, and the yield of a product is improved by about 0.6 percent; and a large amount of flue gas waste heat is comprehensively utilized, and the effects of saving energy and reducing emission are obvious. Meanwhile, the invention discloses a set of device for utilizing the heat energy of the flue gas produced by calcining in the rotary kiln, which is designed according to the method.

Owner:潜江方圆钛白有限公司

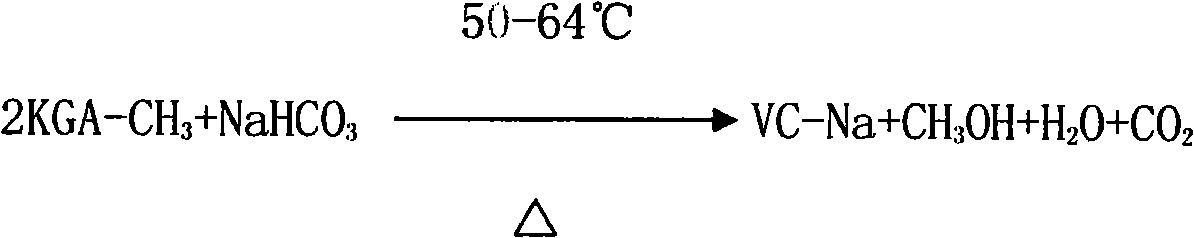

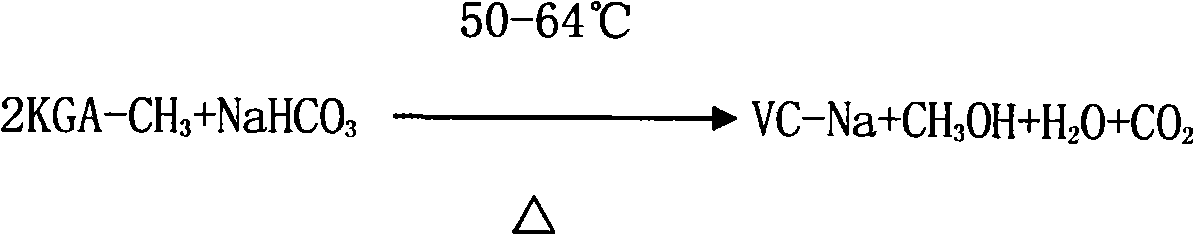

Method for directly preparing vitamin C with sodium gulonate

InactiveCN101298445ASignificant technological progressGood energy saving and emission reduction effectOrganic chemistryFermentationHigh concentrationVitamin C

The invention relates to a method for preparing ascorbic acid by using gulconic sodium to converse directly; the invention is importantly improved based on the existing two-step fermentation method for manufacturing VC: a 2KGA-Na crystal of high purity can be obtained by the techniques of hyperfiltration clarification, low temperature concentration and constant temperature crystallization, etc.; the completely novel method for separating the gulonic acid that are not converted into VC by the technique conditions of separating Na[2]SO[4] solid during the prophase of methyl reaction and optimizing and conversion reaction as well as by adopting an advanced chromatogram technology during the processes of acidification and refining leads to obtain the top-grade product from the crude VC by one-step crystallization, thereby leading the total yield for manufacturing VC by the two-step fermentation method to be improved to more than 86 percent; the waste water with high concentration is completely removed; and the energy consumption can be reduced by about 20 percent.

Owner:徐昌洪

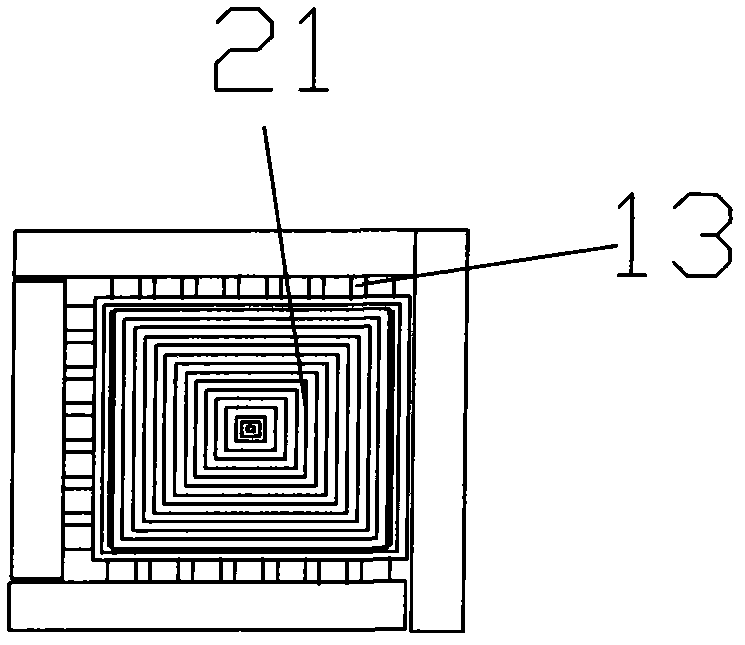

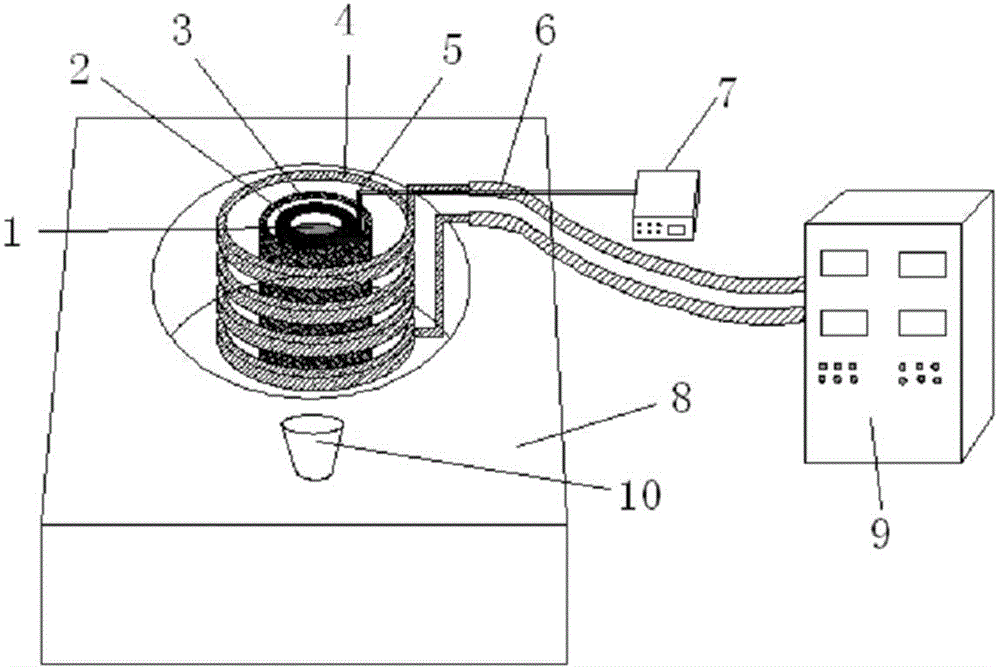

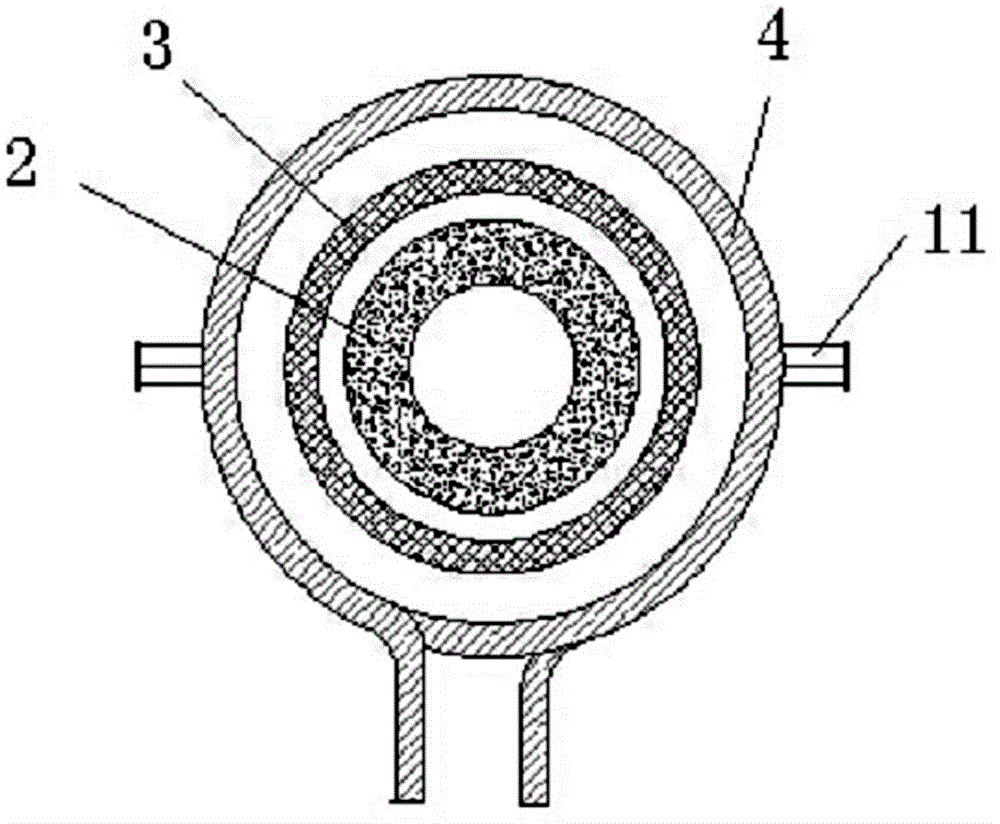

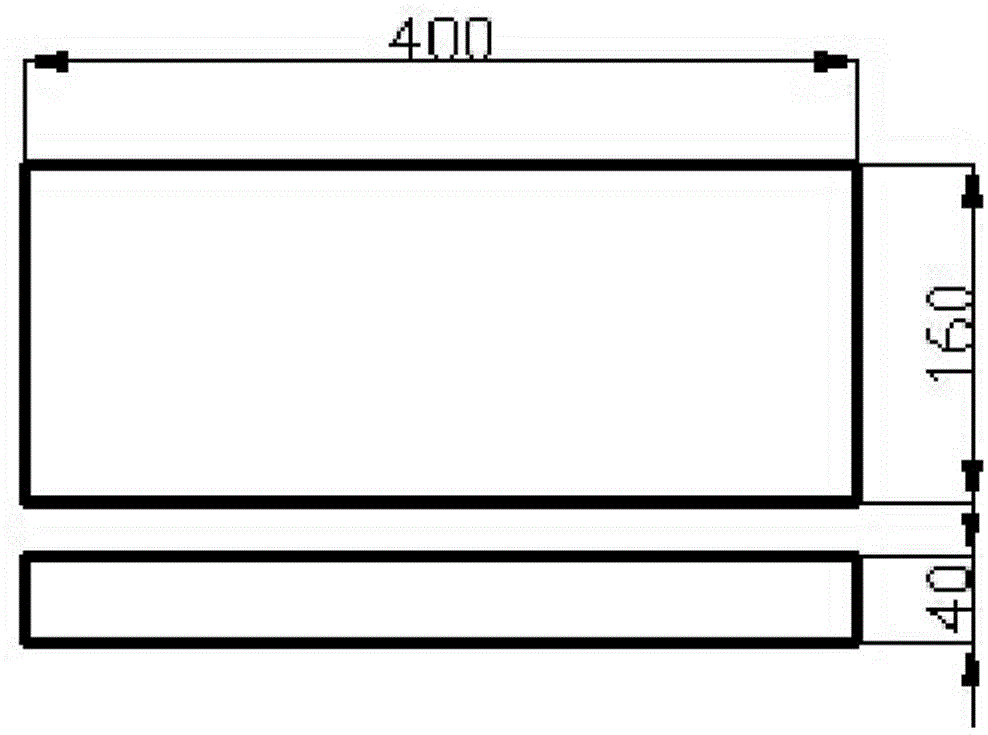

Casting riser induction heating device, and casting riser induction heating method

ActiveCN104826997AIncrease temperaturePlay a feeding roleFoundry mouldsFoundry coresEngineeringConductive materials

The invention discloses a casting riser induction heating device. The casting riser induction heating device comprises a riser sleeve; an annular sleeve prepared of graphite, steel, or other conductive materials; an induction coil; a thermoelectric couple; water cooled cables; a temperature recorder; and an induction heating power supply cabinet. Compared with conventional insulated risers and exothermic risers, the casting riser induction heating device possesses following advantages: riser setting time prolonging effect is more excellent than that of the conventional insulated risers and exothermic risers; real-time control on the temperature of molten metal in risers can be realized; recycling of induction heating risers can be realized; production cost is reduced; no environmental pollution is caused in using process; and environmental requirements are satisfied preferably.

Owner:SHENYANG POLYTECHNIC UNIV

Low-temperature exhaust air source spray heat capturing efficient water source heat pump fresh air system

InactiveCN102778082APrevent freezingGood energy saving and emission reduction effectHeat pumpsWater source heat pumpWater source

The invention relates to a low-temperature exhaust air source spray heat capturing efficient water source heat pump fresh air system. The low-temperature exhaust air source spray heat capturing efficient water source heat pump fresh air system has the advantages that antifreeze fluid is sprayed to capture heat from a low-temperature exhaust air source, and the heat is boosted to be the heat of high quantity by a water source heat pump and then used for heating fresh air of a mine, so that the freezing of spray water is avoided; the heat pump absorbs heat in a high flow manner so as to increase evaporating temperature and energy efficiency; a fluid supply pool and a fluid return pool are subjected to cold-hot separation, and the heat pump is enabled to obtain fluid from the fluid supply pool which is heated after spray heat capturing, so as to increase the evaporating temperature and the energy efficiency; a spraying chamber is enabled to obtain fluid from the fluid return pool which is cooled after the heat pump carries out evaporating heat absorption, so as to increase heat exchange temperature difference and heat capturing efficiency; the temperature of supply water of the heat pump is reduced so as to increase heating efficiency; and the heat pump supplies heat in a low flow manner so as to reduce circulatory pumping power.

Owner:合肥天鹅制冷科技有限公司 +1

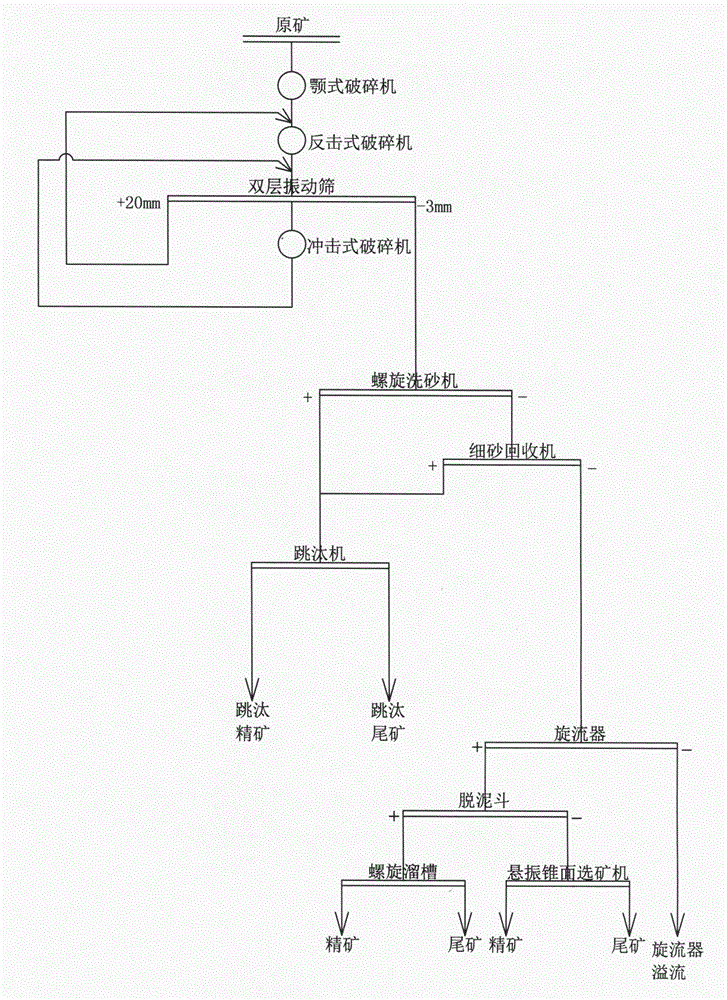

Comprehensive recovery technology of multi-metal low-grade ore and ore-bearing waste rock resources thereof

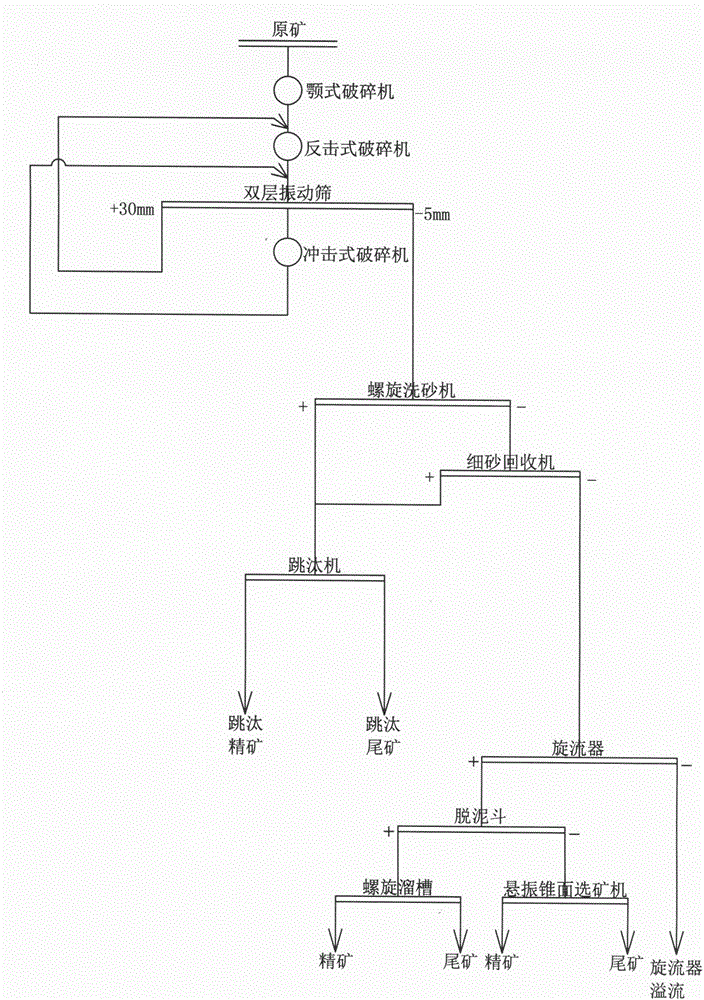

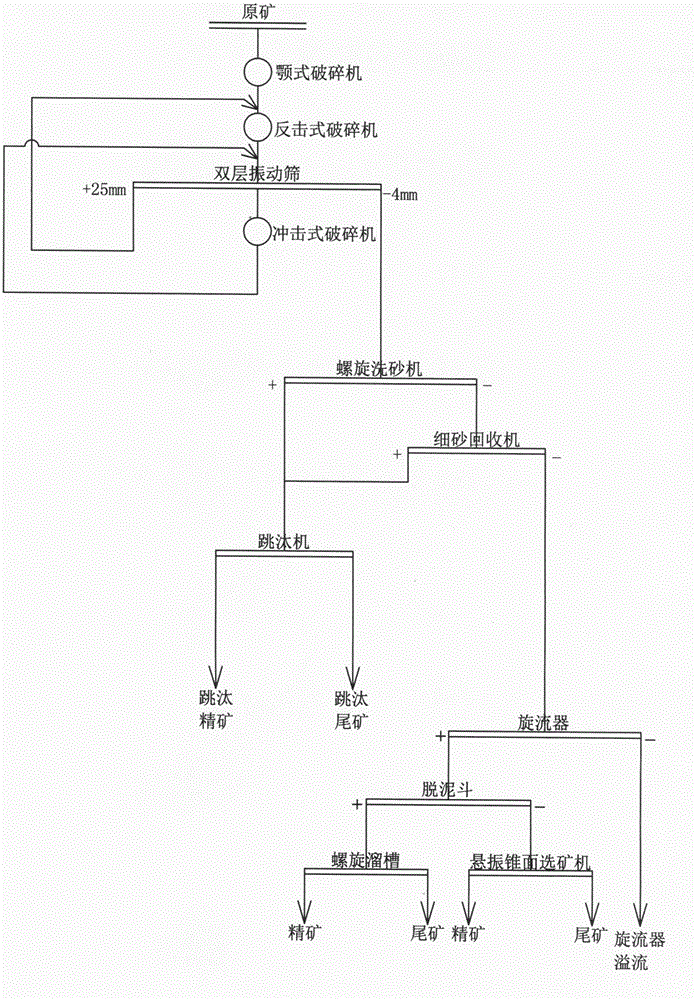

The invention provides a comprehensive recovery technology of multi-metal low-grade ore and ore-bearing waste rock resources thereof, and relates to the field of metallurgy. The technology comprises the steps that materials are smashed to the size fraction of -5 mm through smashing and screening combining equipment, ore washing grading is conducted by adopting equipment combining a screw sand washer and a fine sand recycling machine, two materials of a coarse particle material and ore washing overflow are produced, the particle size of the coarse particle material is controlled to the situation that the content of particles with the size fraction of +0.02 mm is over 90%, and the particle size of the ore washing overflow is controlled to the situation that the content of particles with the size fraction of -0.02 mm is over 90%; grading of the coarse particle material is conducted through a jigging machine, tailings are discarded, and ore concentrate is ore which reaches the economic ore feed grade; desliming is conducted on the ore washing overflow through a hydrocyclone, the overflow particle size of the hydrocyclone is controlled to be -0.01 mm, the content is over 80%, and tailings discarding is conducted directly; hydrocyclone settling sand is graded through a spiral chute after being subjected to slurry mixing through a mixing barrel, tailings are discarded, and ore concentrate is ore which reaches the economic ore feed grade; the purpose of efficiently and economically recycling the low-grade ore and the ore-bearing waste rock resources thereof is achieved.

Owner:YUNNAN HUALIAN ZINC & INDIUM

Method for extracting L-proline from fermentation liquor by membrane separation technology

InactiveCN101633634AReduce supporting costsHigh filtration precisionSemi-permeable membranesOrganic chemistryChemistryDialyzates

The invention discloses a method for extracting L-proline from fermentation liquor by a membrane separation technology. The method comprises the following steps: firstly performing microfiltration, ultrafiltration and reverse osmosis concentration on the fermentation liquor of the L-proline to obtain reverse osmosis dialyzate, evaporating and concentrating the reverse osmosis dialyzate by a conventional method, and then crystallizing at the reduced temperature to obtain a crude product L-proline. The method helps fundamentally solve the problem of environmental pollution during the extraction process of the L-proline, reduce production cost, increase economic benefit, improve the product grade and promote sustainable development of production of the L-proline.

Owner:山东阜丰生物科技开发有限公司

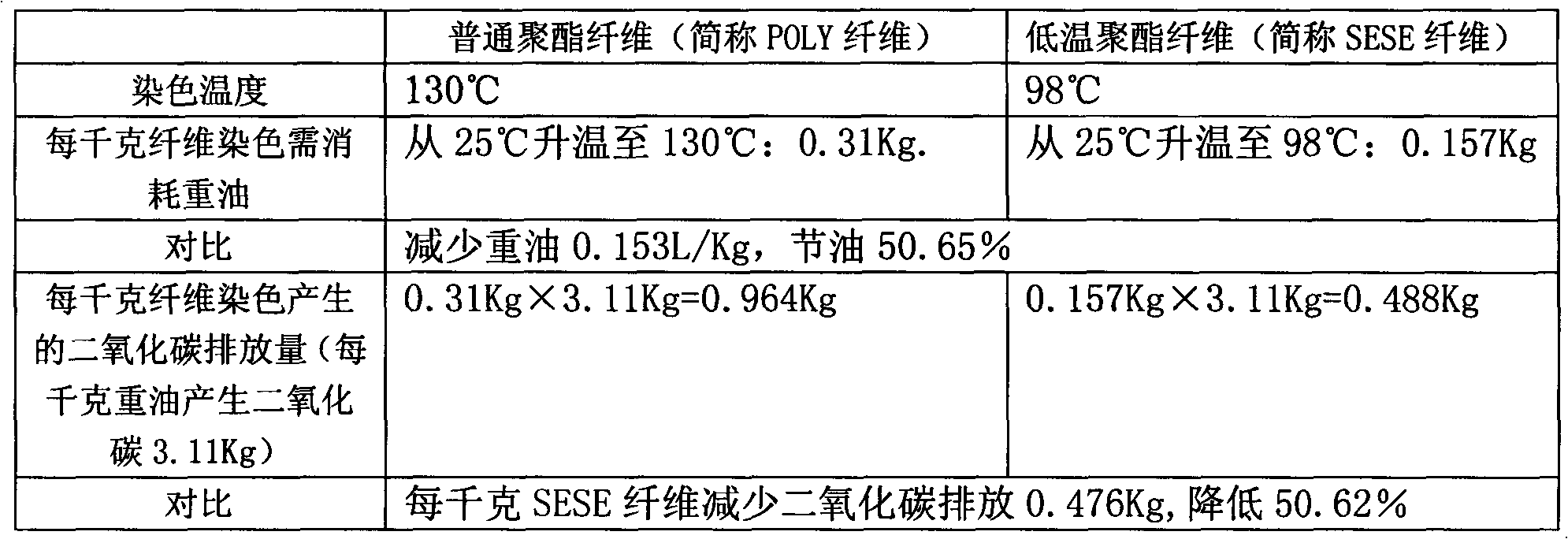

Method for producing low-temperature polyester fiber double-color strip fabric

The invention relates to a method for producing low-temperature polyester fiber double-color strip fabric. By the method, the production process flow of the strip fabric is optimized, energy resources are saved to the greatest extent and the emission of carbon dioxide is reduced. The method comprises the following steps of: 1, performing a weaving process, namely weaving grey cloth on a double-sided circular knitting machine by selecting a low-temperature polyester fiber yarn and a positive ion yarn as upper face yarns and an ordinary polyester fiber yarn as a bottom face yarn according to double-sided acrylic cloth; and 2, performing dyeing and finishing processes, namely removing oil from the grey cloth, placing in a vat, throwing disperse dye stuff and positive dye stuff in a dye vat, dyeing in a bath, raising the temperature of dye liquid in the dye vat from room temperature to between 96 and 99 DEG C, preserving temperature for 40 to 60 minutes, reducing and washing for 20 to 30 minutes at the temperature of between 60 and 80 DEG C, taking the cloth out, dewatering, drying, forming and obtaining a finished product.

Owner:佛山市妙湛纺织科技有限公司

Method for preparing calcium alginate based cavernous body functional material

The invention discloses a method for preparing a calcium alginate based cavernous body functional material. The method comprises the following steps of: uniformly mixing sodium alginate powder with a soluble calcium salt, magnesium salt or aluminum salt and an enhancer; sequentially forming into membranes and pieces by virtue of equipment; performing infiltration reaction and pore formation reaction to obtain the material, wherein the sodium alginate powder, the soluble calcium salt, magnesium salt or aluminum salt and the enhancer are 10-65 to 7-30 to 15-35 to 10-30 in percentage by weight. The method is simple in process control and has less equipment investment, and sewage discharge is basically avoided; the prepared functional material is a cavernous body having a nanometer structure, has the characteristics of high consistency of internal structure and external structure and composition, high imbibition air permeability, powerful mechanical strength, high flexibility and elasticity and the like, and can be used as medical auxiliaries, antibacterial materials, flame-resistant materials, absorption materials and sound-absorbent materials, vibration-absorptive materials and the like.

Owner:QINGDAO UNIV

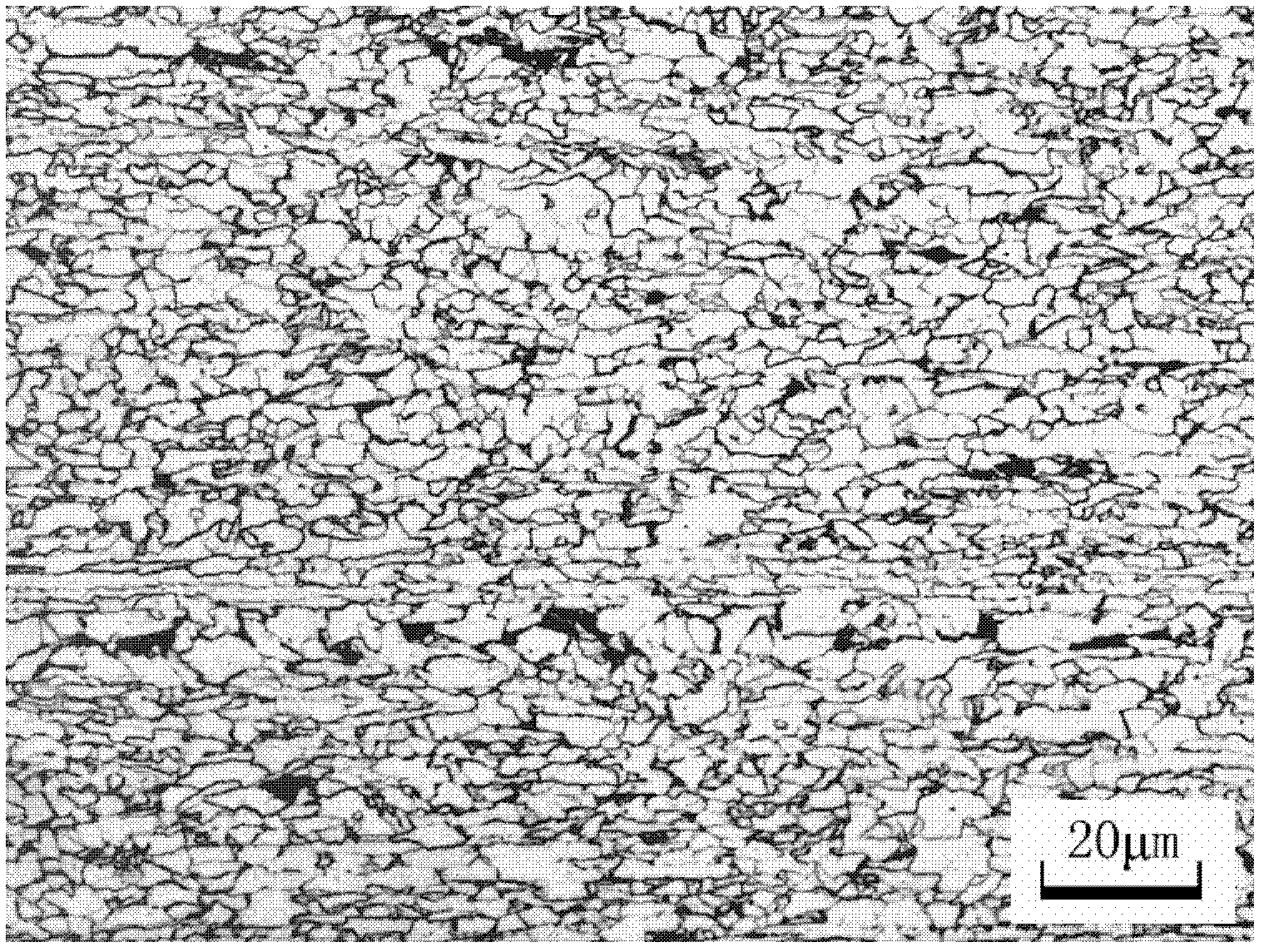

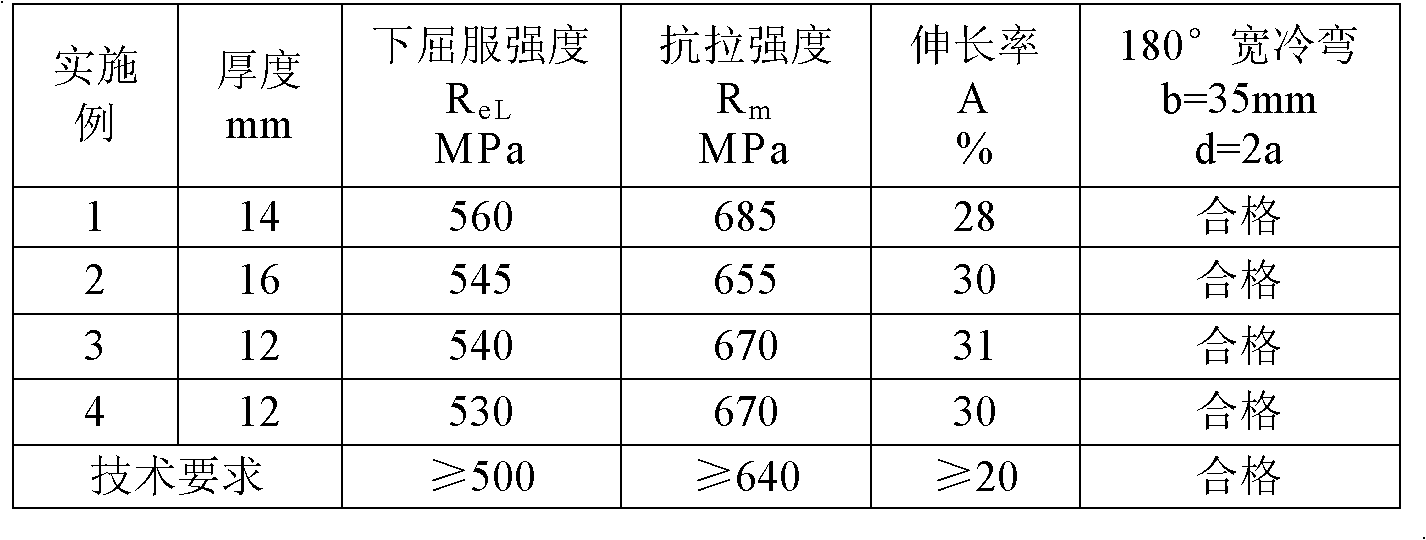

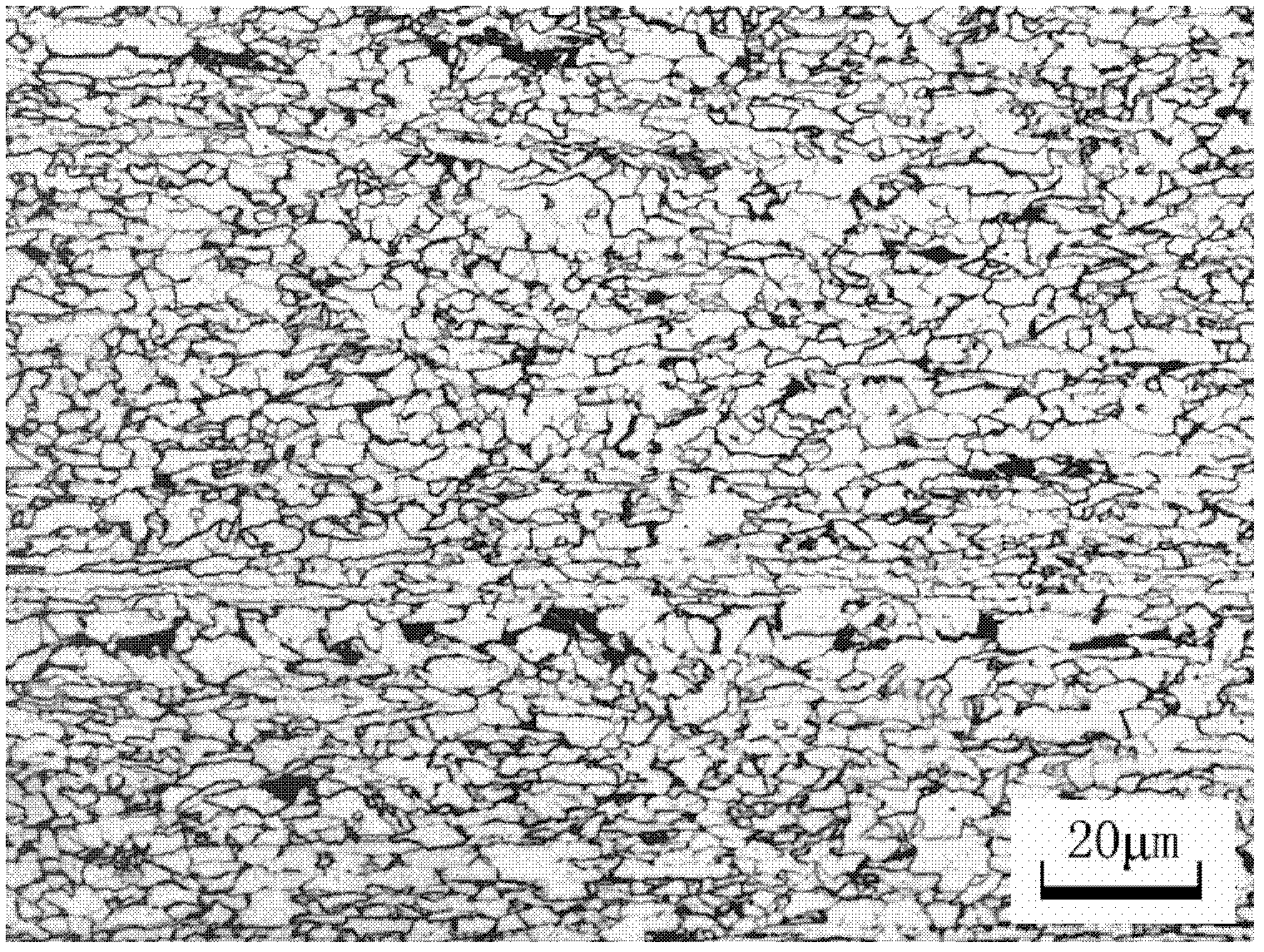

Steel for 13-dwt vehicle axle housing and production method thereof

The invention relates to steel for 13-dwt vehicle axle housing and a production method thereof. The steel comprises the following chemical components by weight: 0.04%-0.08% of C, 0.10%-0.60% of Si, 1.3%-1.45% of Mn, not more than 0.025% of P, not more than 0.08% of S, 0.01%-0.06% of Al, 0.04%-0.06% of Nb, 0.03%-0.05% of Ti, and the balance of Fe and inevitable impurities; The preparation method comprises the following steps: converter smelting; vacuum treatment; continuous casting; casting blank heating; rough rolling; finish rolling by a 7 frame; cooling with laminar flow; coiling. Because of the low carbon content of the steel of the invention, the steel has excellent stamping performance and welding performance, has a stable dimension after cold forming, and completely meets the requirements for manufacturing and application of 13-dwt vehicle axle housing. Through bench tests of the manufactured 13-dwt vehicle axle housing assembly, the product has excellent vertical bending fatigue life, vertical bending rigidity, and vertical bending static strength, and completely meets the requirements of users.

Owner:武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com