Patents

Literature

44results about How to "Improve high temperature anti-rutting performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

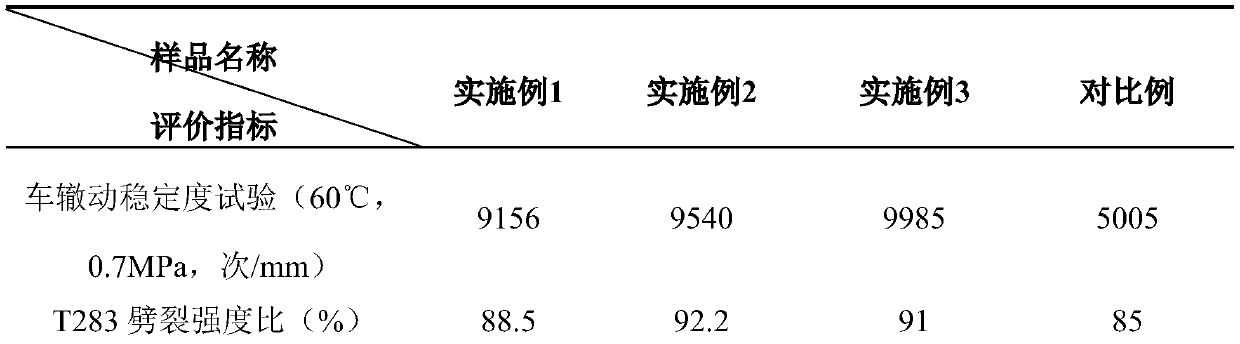

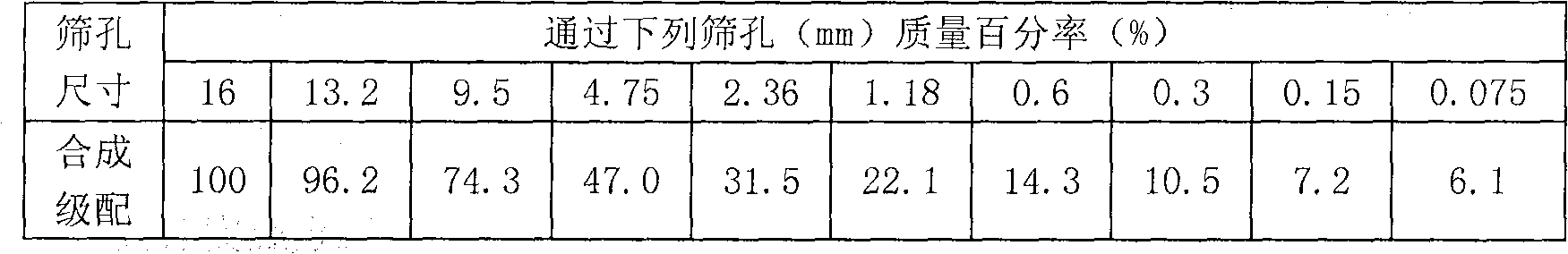

Warm mix recycled asphalt mixture with high RAP (Reclaimed Asphalt Pavement) mixing amount and high performance and preparation method of warm mix recycled asphalt mixture

InactiveCN106186837AHigh strengthImprove fatigue resistanceSolid waste managementClimate change adaptationLow emissionMaterials science

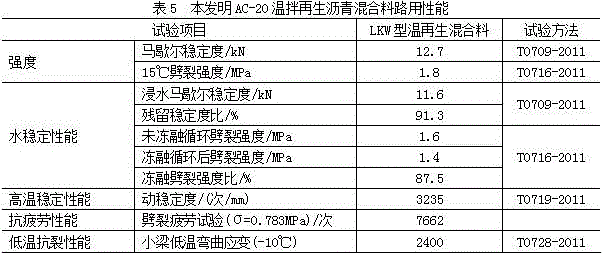

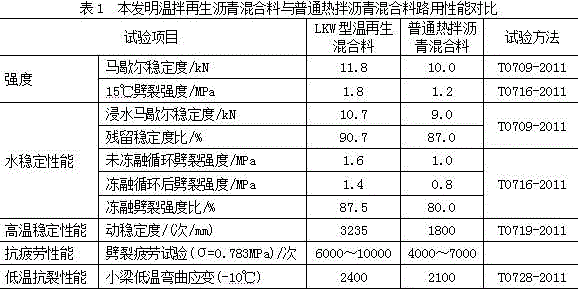

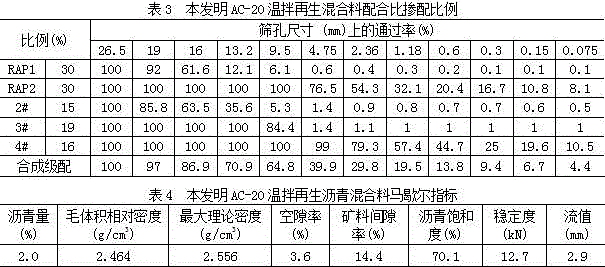

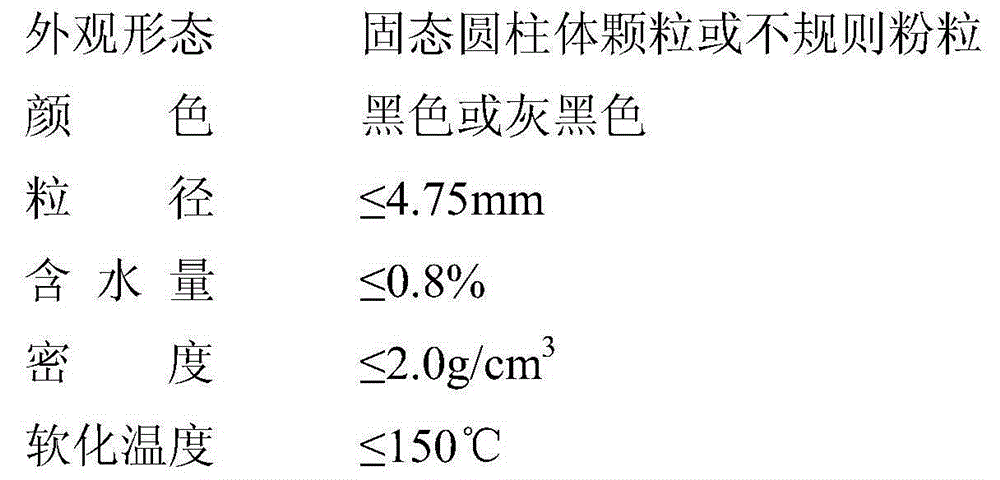

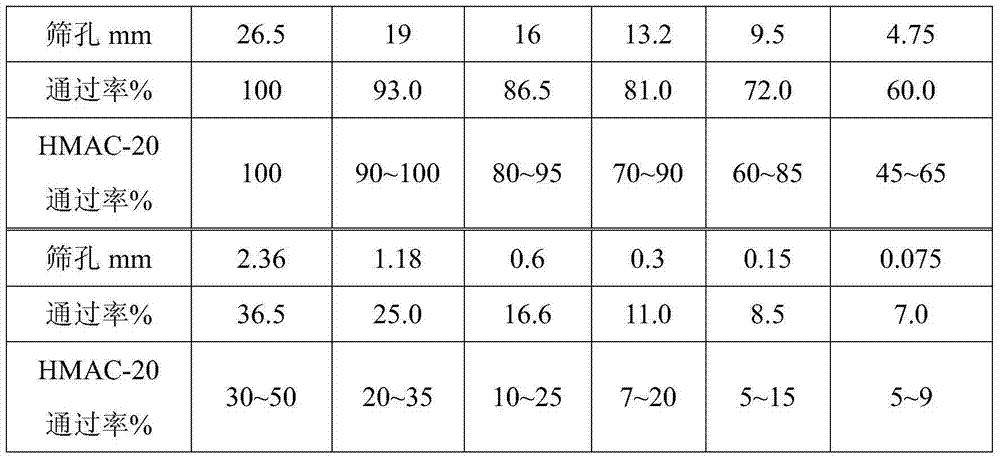

The invention provides a warm mix recycled asphalt mixture with a high RAP (Reclaimed Asphalt Pavement) mixing amount and high performance and a preparation method of the warm mix recycled asphalt mixture, and belongs to the technical field of highway construction materials. The mixture is prepared from the following components in percentage by mass: 50 to 70 percent of RAP material, 28.2 to 47.2 percent of aggregate and 1.8 to 2.8 percent of newly-doped asphalt and warm mix regenerant; the content of the warm mix regenerant is 0.3 to 0.5 percent of the mass of the newly-doped asphalt. The preparation method comprises the following steps of reclaiming and stacking of the RAP material, crushing and screening of a reclaimed material, stacking and detection of a reference material in different bins, and preparation of the warm mix recycled asphalt mixture. The RAP material, the aggregate, the asphalt and the warm mix regenerant are taken according to the requirement of raw material proportioning and are subjected to mixing treatment according to a conventional production technique of a hot-mixed asphalt mixture, wherein the mixing temperature is 120 to 140DEG C, and the mixing time is 20 to 35s, and finally the recycled asphalt mixture is obtained. The warm mix recycled asphalt mixture has the advantages of high RAP mixture ratio, low heating and constructing temperature, good constructability, easiness and pavement performance, low energy consumption, low emission and the like.

Owner:云南省公路科学技术研究院

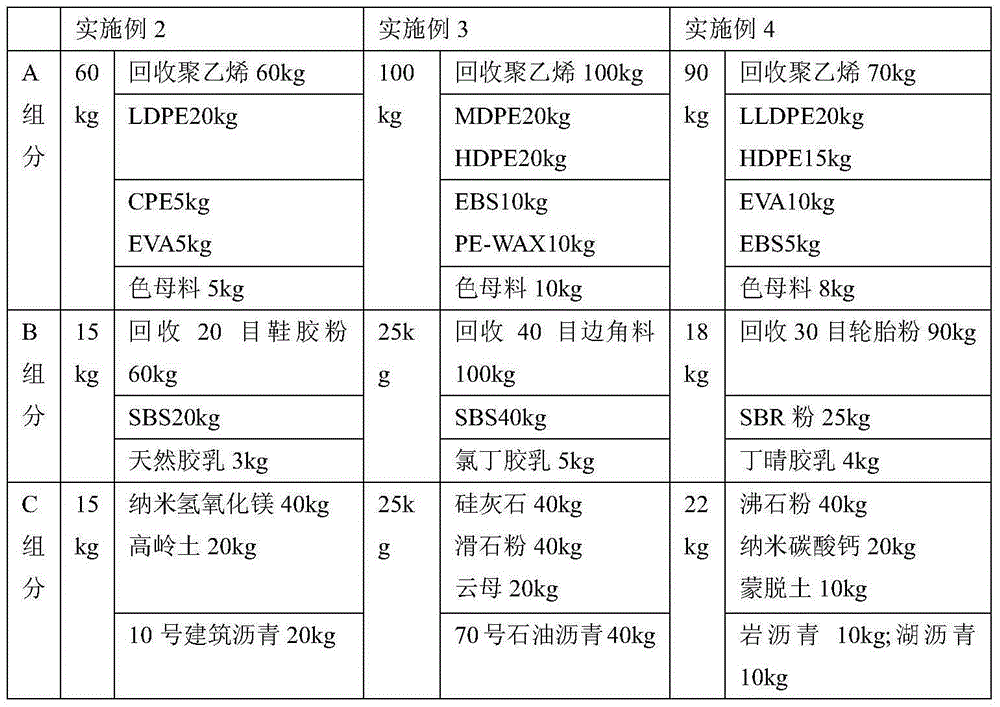

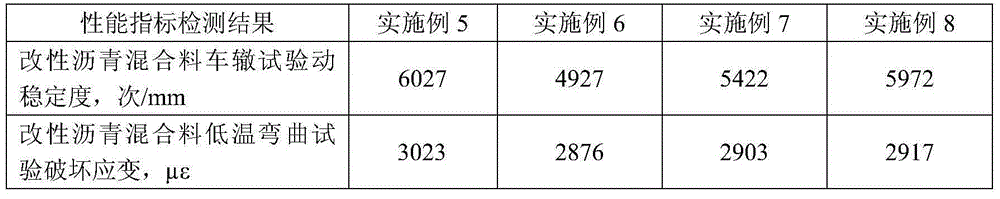

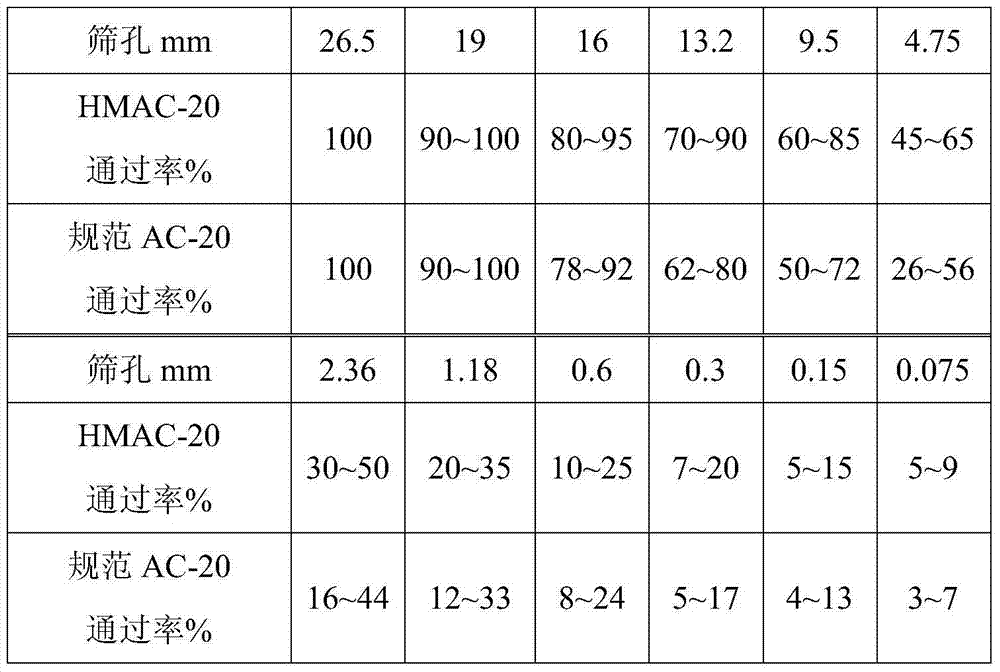

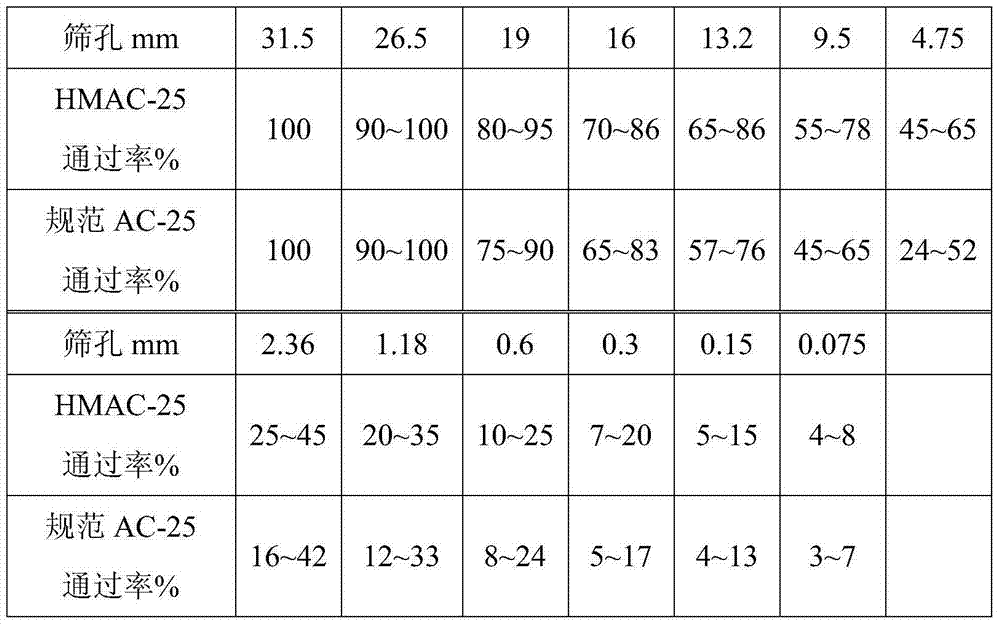

Modified asphalt mixture modifier and preparation method therefor

InactiveCN105153511AImprove high temperature anti-rutting performanceImprove low temperature crack resistanceBuilding insulationsMasterbatchAsphalt

The invention relates to a modified asphalt mixture modifier and a preparation method therefor. The modified asphalt mixture modifier is prepared from the following components in parts by weight: 60-100 parts of a component A, 15-25 parts of a component B and 15-25 parts of a component C, wherein the component A is prepared from the following components in parts by weight: 60-100 parts of recovered polyethylene, 20-40 parts of polyethylene, 10-20 parts of auxiliaries and 5-10 parts of color masterbatch; the component B is prepared from the following components in parts by weight: 60-100 parts of recovered rubber powder, 20-40 parts of rubber powder and 3-5 parts of latex; the component C is prepared from the following components in parts by weight: 60-100 parts of inorganic powder and 20-40 parts of an asphalt material. According to the modifier provided by the invention, the comprehensive performance of the modified asphalt mixture can be improved. By directly inputting the modifier into a stirring cylinder of a mixing plant, stirring and modification are synchronously implemented. The produced modified asphalt mixture is superior to a conventional modified asphalt mixture in performance.

Owner:陕西长大博源公路养护科技有限公司

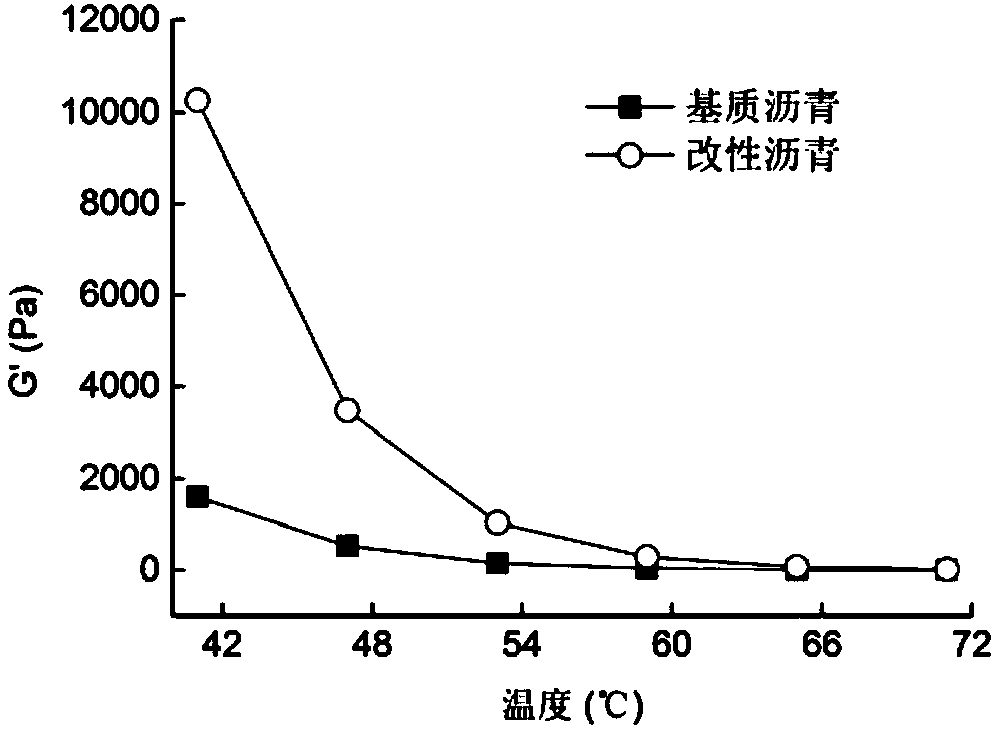

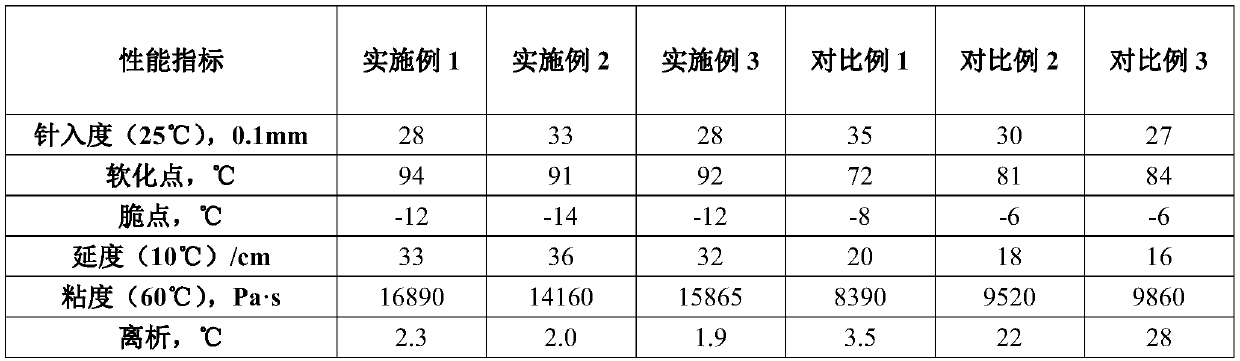

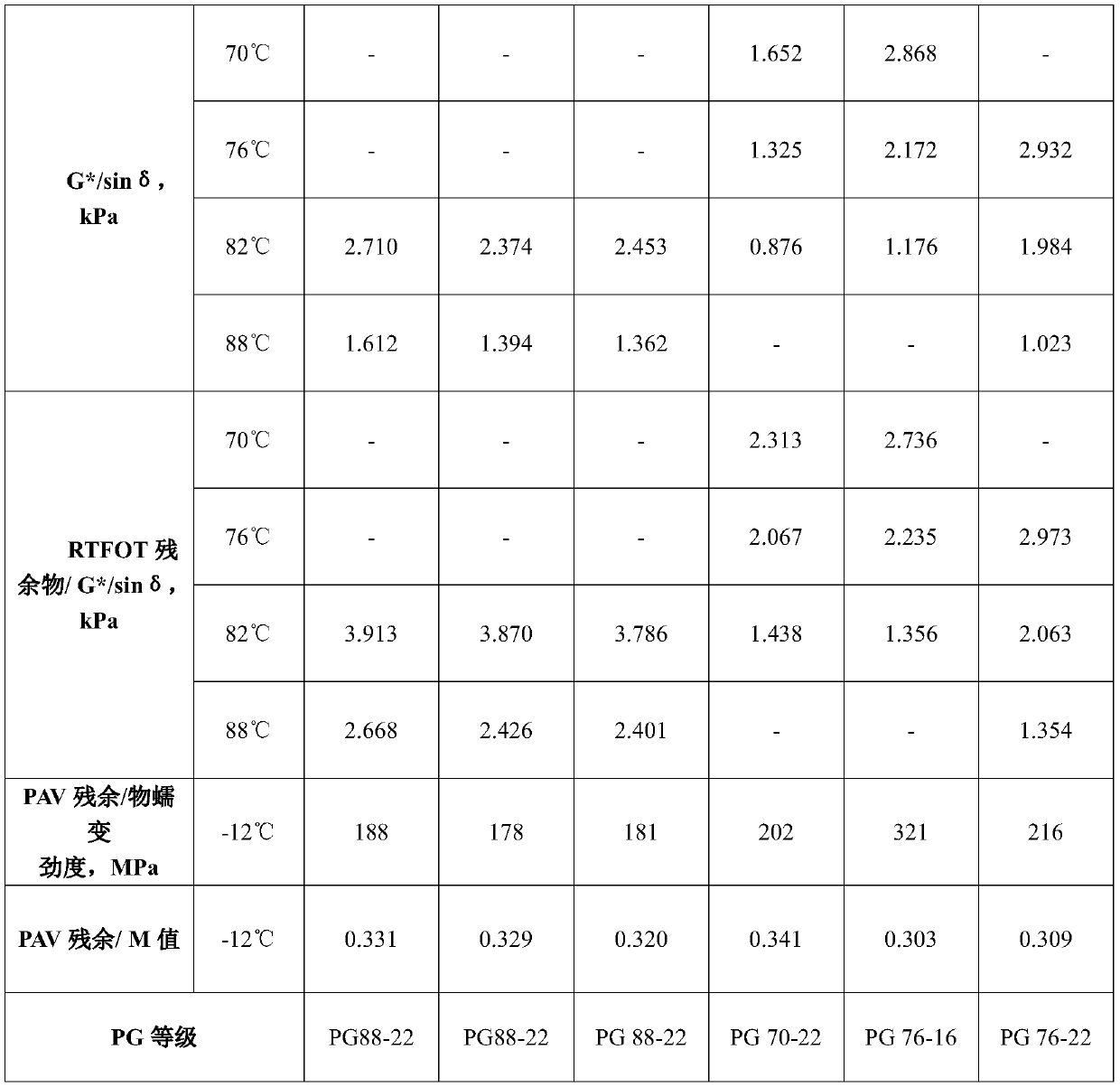

High-modulus asphalt based on natural asphalt modification, as well as preparation method and application thereof

InactiveCN104725882ASimple preparation processLow costRoads maintainenceBuilding insulationsRoad surfaceMaterials science

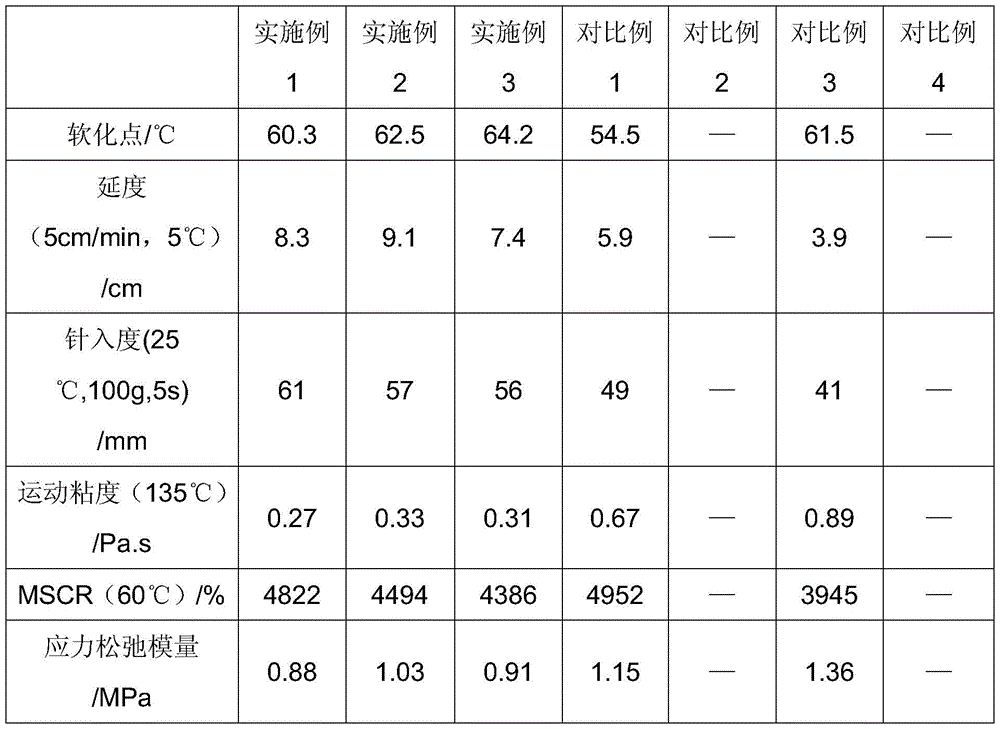

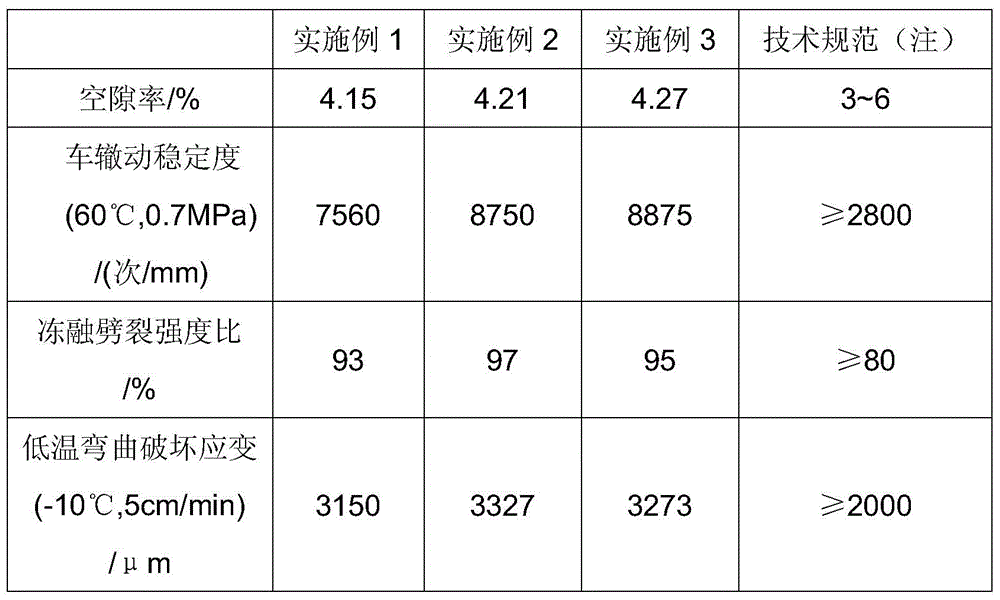

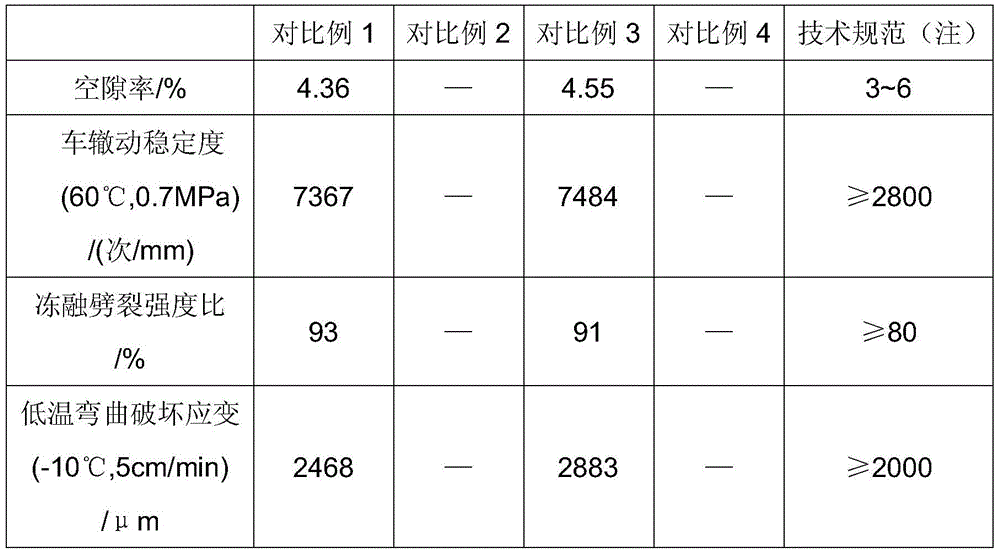

The invention provides high-modulus asphalt based on natural asphalt modification. The high-modulus asphalt is prepared by modifying natural asphalt with SEBS modifying agent, stabilizing agent, compatilizer and matrix asphalt, wherein the weight ratio of the natural asphalt to the matrix asphalt is (40-50):(50-60), the SEBS modifying agent is 1-3 percent of the total mass of the natural asphalt and the matrix asphalt, the stabilizing agent is 0.5-1.0 percent of the total mass of the natural asphalt and the matrix asphalt, and the compatilizer is 0.3-0.5 percent of the total mass of the natural asphalt and the matrix asphalt. The invention further provides a preparation method and application of the high-modulus asphalt. The high-modulus asphalt is simple in preparation process and low in cost, can be used for effectively improving the permanent deformation resistance, shearing resistance, high-temperature track resistance, water damage resistance and fatigue performance of asphalt mixture and achieving double aims of improving high-temperature track resistance and pavement durability of the asphalt pavement, and reducing construction cost in the total life cycle.

Owner:JIANGSU SOBUTE NEW MATERIALS

Warm mixing additive of asphalt mixture, preparation method and application method thereof

ActiveCN102827484AImprove workabilityImprove toughnessClimate change adaptationBuilding insulationsEmulsionBituminous materials

The invention relates to technology of road asphalt materials, and discloses a warm mixing additive of asphalt mixture, a preparation method and an application method thereof. The warm mixing additive of the asphalt mixture comprises the following components by weight percent: 50 to 70 % of zeolite powder, 20 to 28 % of emulsion and the balance being dispersing auxiliary agents. The preparation method comprises adding the zeolite powder and then the emulsion into a feed mixer, uniformly stirring, adding the dispersing auxiliary agents, and then sending into a comminutor after uniformly stirring to obtain the warm mixing additive of the asphalt mixture. The application method comprises putting the warm mixing additive of the asphalt mixture accounting for 0.2 to 0.6 % of total weight of aggregates and the asphalt into a mixing plant to mix evenly.

Owner:CHANGAN UNIV +1

Waste polymer compound asphalt anti-rutting agent as well as preparation method and application thereof

ActiveCN104194362AImprove performanceSimple processBuilding insulationsTetrafluoroethylenePolymer science

The invention discloses a waste polymer compound asphalt mixture anti-rutting agent as well as a preparation method and application thereof. The waste polymer compound asphalt mixture anti-rutting agent is composed of the following components in parts by weight: 45-87.5 parts of a crushed waste non-PVC multi-layer co-extruded film crushed material, 2-30 parts of reclaimed polytetrafluoroethylene particles, 2-10 parts of waste tire rubber powders, 0.5-5 parts of a compatilizer and 5-20 parts of asphalt and the balance of an antioxidant. The invention also discloses a preparation method of the anti-rutting agent and a method for preparing an asphalt mixture by directly feeding the anti-rutting agent. The waste polymer compound asphalt mixture anti-rutting agent is capable of obviously improving the high-temperature property and anti-rutting property of the asphalt mixture and improving the water damage resistance and the low-temperature cracking resistance of the asphalt mixture, and is high in cost performance; besides, the preparation method is simple in process and convenient to operate.

Owner:FUJIAN NORMAL UNIV

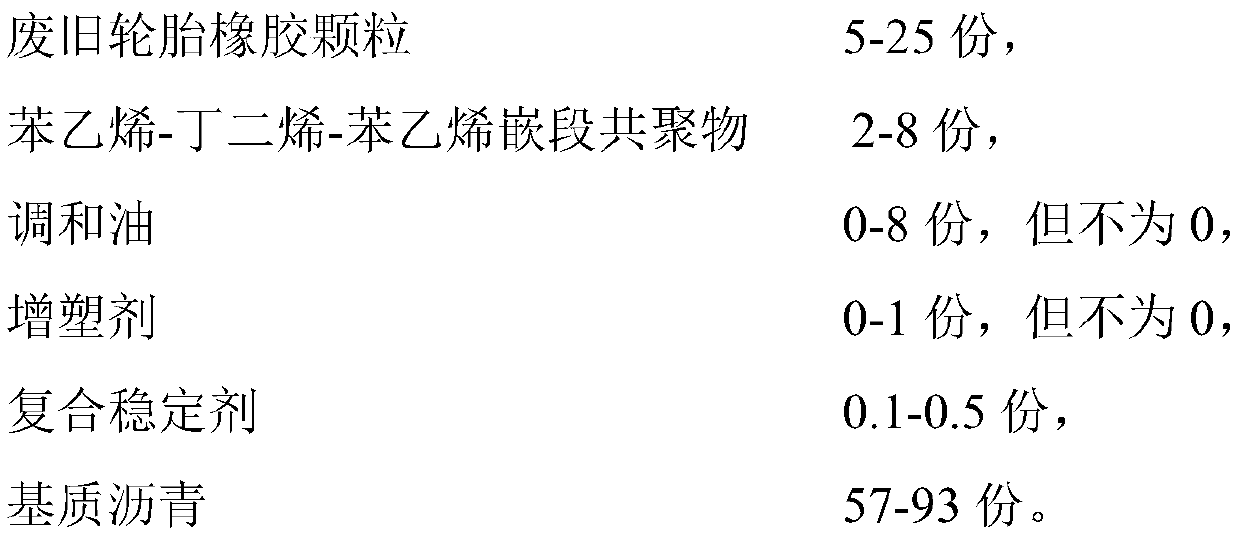

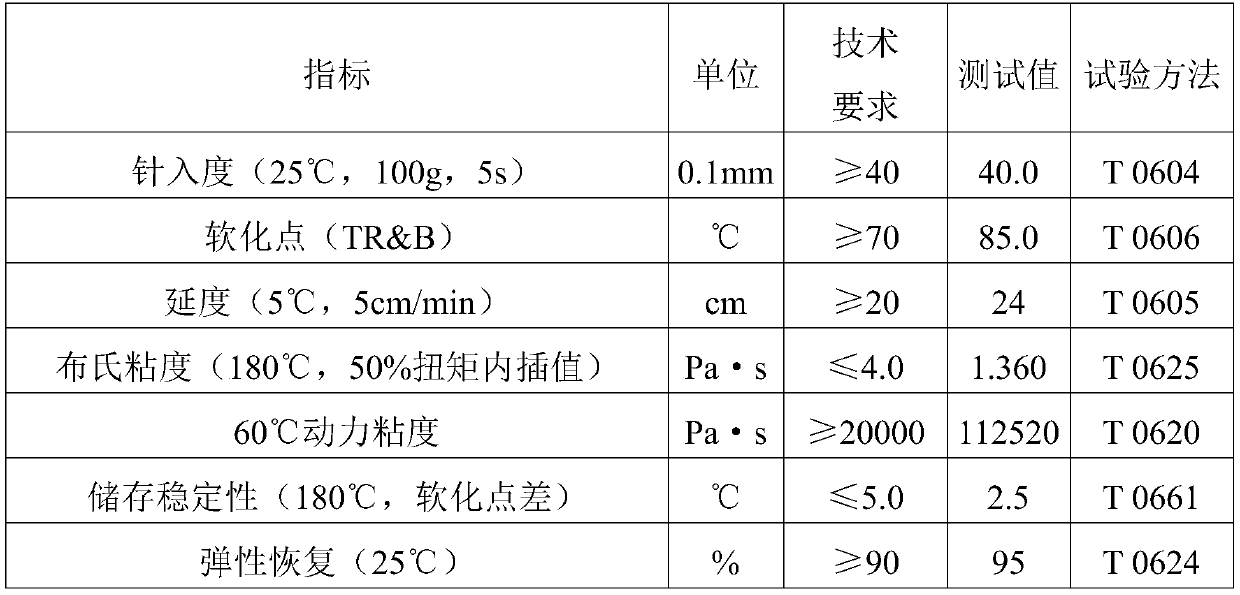

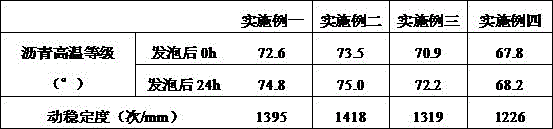

Compounded high-viscosity high-elasticity asphalt material and preparation method therefor

InactiveCN110452550AHigh viscosityIncreasing the thicknessBuilding insulationsPlasticizerBituminous materials

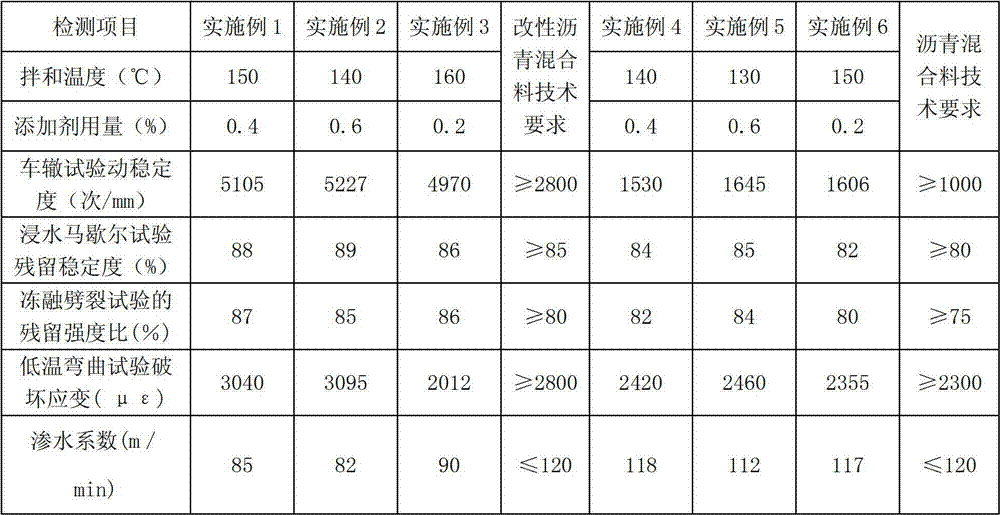

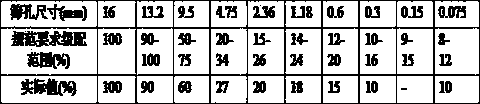

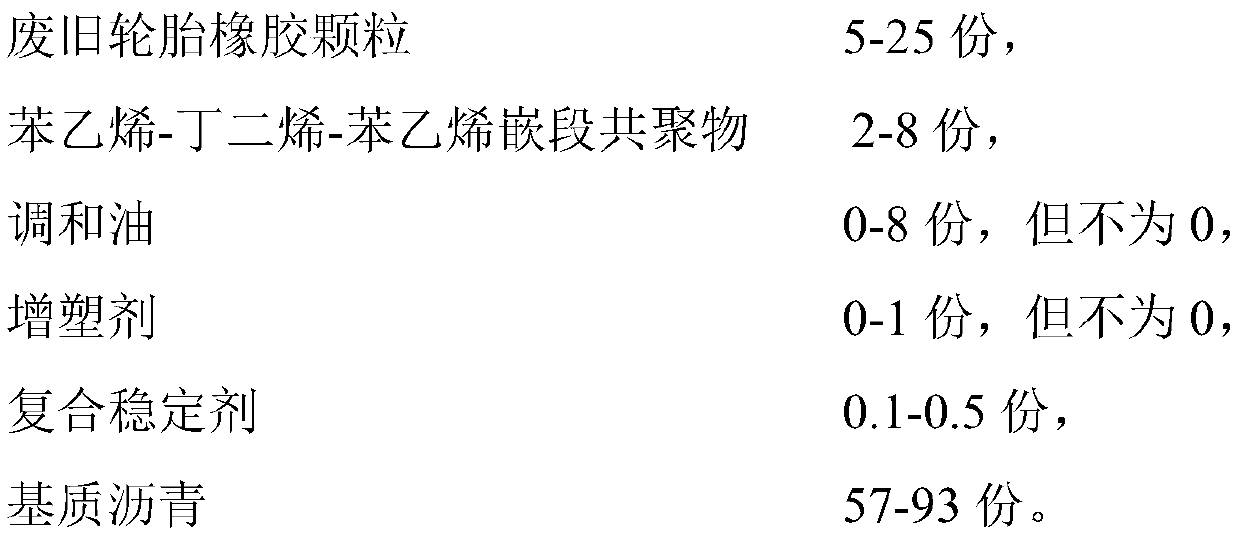

The invention relates to a compounded high-viscosity high-elasticity asphalt material and a preparation method therefor. The asphalt material is prepared from the following ingredients in parts by weight: 5-25 parts of waste tire rubber granules, 2-8 parts of styrene-butadiene-styrene block copolymer, 0-8 (but 0 is exclusive) parts of blend oil, 0-1 (but 0 is exclusive) part of plasticizer, 0.1-0.5 part of composite stabilizer and 57-93 parts of matrix asphalt. Compared with the prior art, the asphalt material prepared by the method has the advantages that the kinetic viscosity at the temperature of 60 DEG C is not smaller than 20,000Pa.s, the recovery of elasticity at the temperature of 25 DEG C is not smaller than 90%, the storage stability at the temperature of 180 DEG C is not greaterthan 4.0 DEG C, the asphalt material has good mechanical properties and storage stability, the high-temperature rut resistance of pervious asphalt concrete can be improved, the low-temperature frost heave resistance of the pervious asphalt concrete can also be improved, the durability of the pervious asphalt concrete is remarkably improved, and the service life of the pervious concrete is prolonged.

Owner:TONGJI UNIV +1

High-performance foam warm mix asphalt and preparation method thereof

ActiveCN105907111AImprove water stabilityImprove high temperature anti-rutting performanceClimate change adaptationBuilding insulationsFoaming agentRoad engineering

The invention discloses high-performance foam warm mix asphalt and a preparation method thereof, and belongs to the field of road engineering. The warm mix asphalt is prepared from a certain amount of petroleum asphalt, polyphosphoric acid, foaming agents and water. Compared with the prior art, the high-performance foam warm mix asphalt provided by the invention has the advantages that the water stability and the high-temperature trace-resistant performance of the foam warm mix asphalt mixture can be obviously improved; good popularization values are realized.

Owner:SHANDONG TRANSPORTATION INST +1

Rubber and plastic compound modified asphalt with high temperature resistance and thermal storage stability and preparation method of rubber and plastic compound modified asphalt

ActiveCN104448864AImprove high temperature anti-rutting performanceImprove heat storage performanceBuilding insulationsPolymer scienceTemperature resistance

The invention discloses rubber and plastic compound modified asphalt with high temperature resistance and thermal storage stability. The rubber and plastic compound modified asphalt is prepared from matrix asphalt, waste tire rubber powder, polyethylene and a double-25 modifying agent, wherein the content of the waste tire rubber powder accounts for 10-35% of the weight of the matrix asphalt, the content of polyethylene accounts for 3-10% of the weight of the matrix asphalt, and the content of the double-25 modifying agent accounts for 0.5-4.0% of the weight of the waste tire rubber powder. The preparation method of the rubber and plastic compound modified asphalt comprises the steps of (1) heating the matrix asphalt to be in a hot melting state, slowly adding the weighed mixture of the weighed waste tire rubber powder, polyethylene and the double-25 modifying agent, and stirring to uniformly mix the mixture; and (2) shearing at a high speed for 45-120 minutes when heating the modified asphalt mixture obtained in the step (1) to 185-200 DEG C. The rubber and plastic compound modified asphalt disclosed by the invention is good in flowability under the condition of high-temperature service, easy to construct and spread, favorable in thermal storage stability and capable of reducing the cost and reducing environment pollution through recycling waste and old plastics and waste tires.

Owner:重庆路面科技有限公司 +1

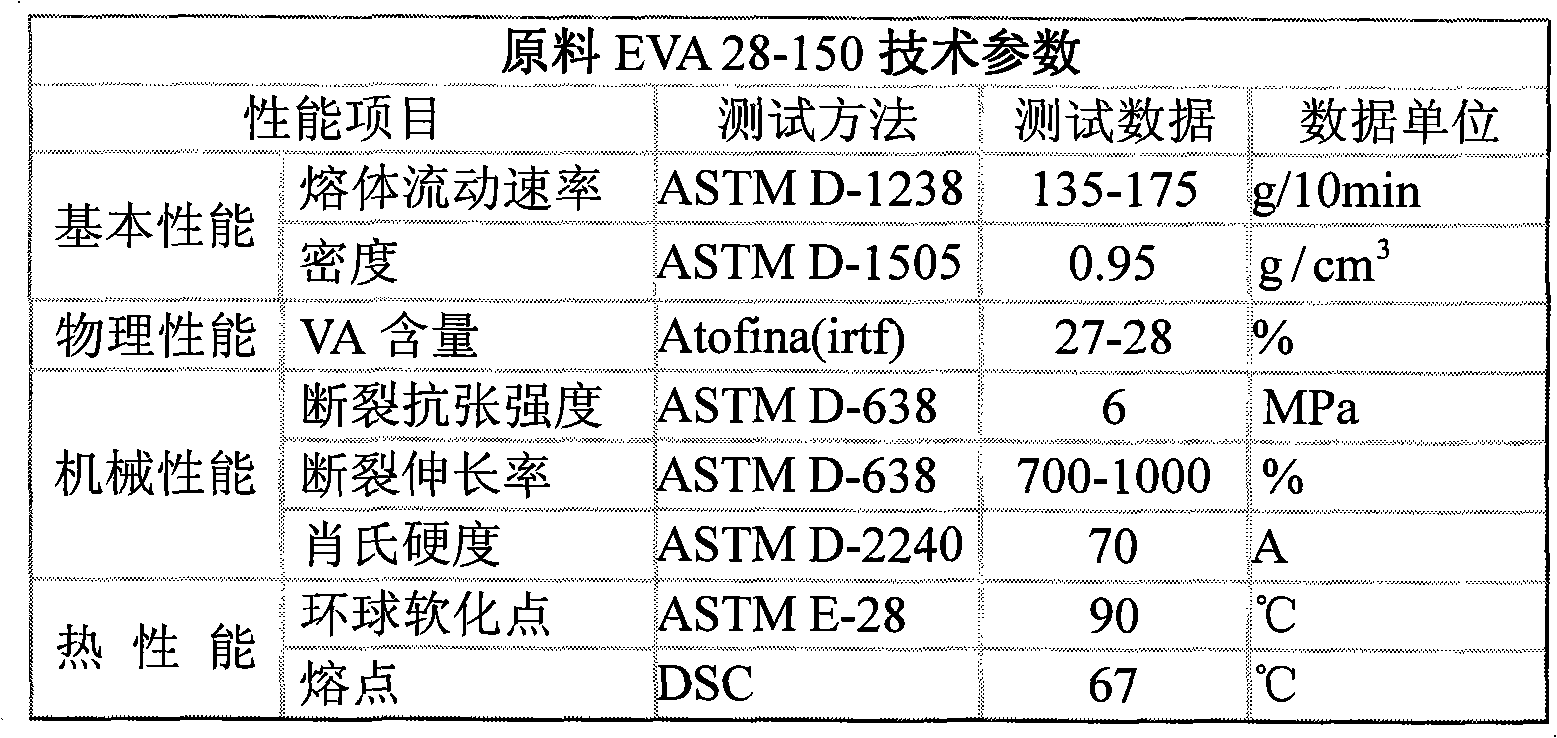

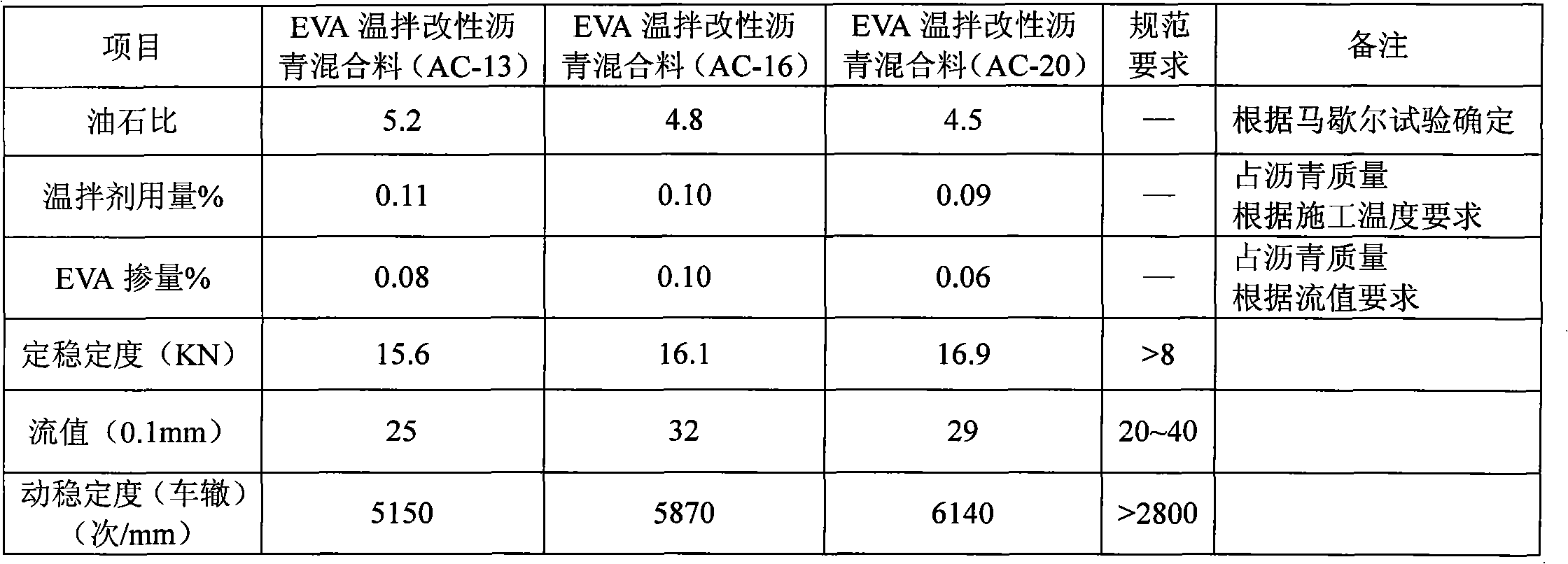

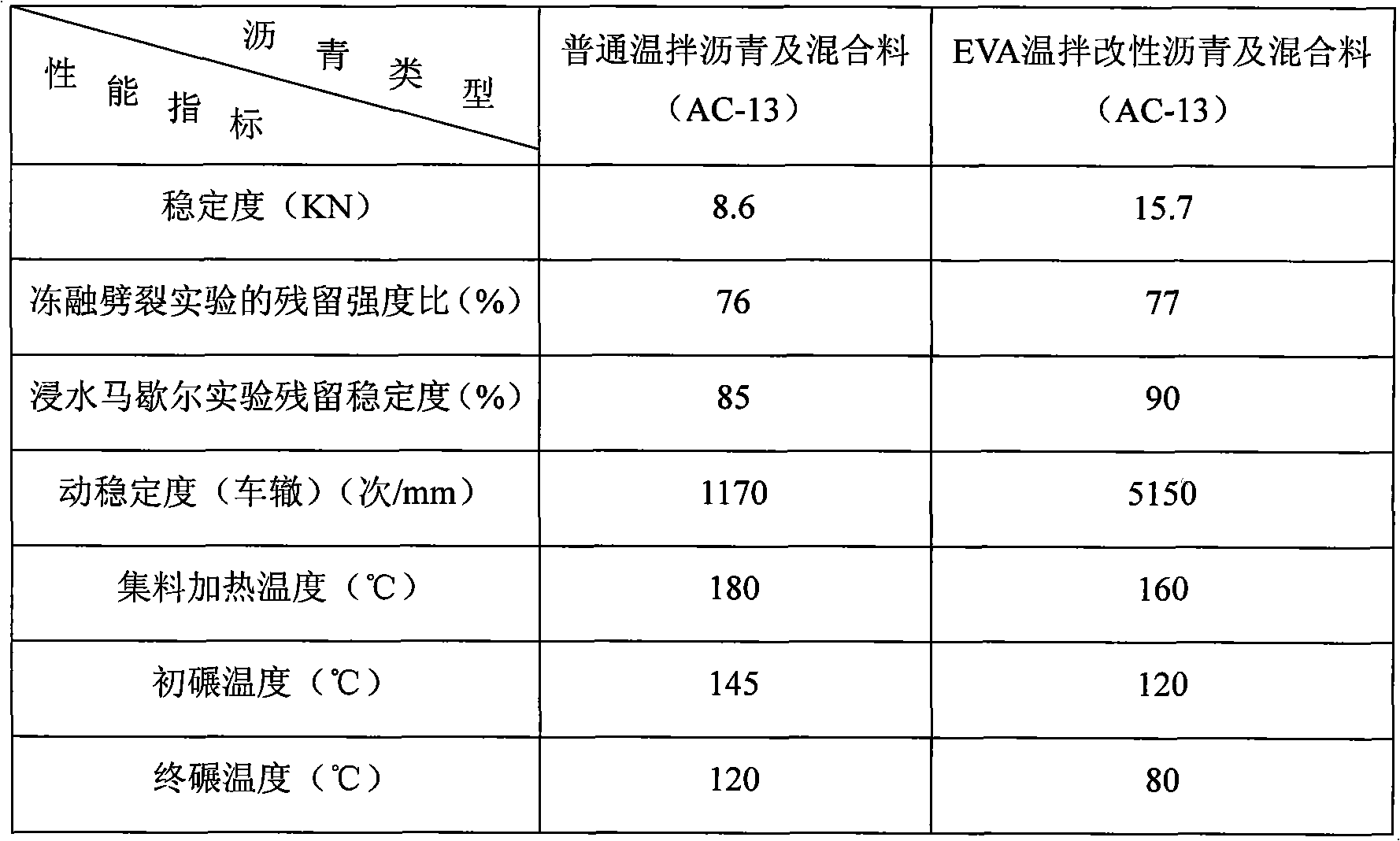

Method for preparing plastic warm-stirred modified asphalt mixture

InactiveCN102050599AImprove high temperature anti-rutting abilityRelaxation of construction conditionsClimate change adaptationColloidal particlePitch blende

The invention discloses a method for preparing a plastic warm-stirred modified asphalt mixture, which comprises the steps of: taking asphalt, aggregate, warm-stirred modifier and ethylene-vinylacetate copolymer colloidal particles as raw materials, putting the aggregate preheated to 160 DEG C into a blender, adding the ethylene-vinylacetate copolymer colloidal particles and dry blending, and then adding 145-DEG C hot melted asphalt and warm-stirred modified asphalt for stirring to acquire the plastic warm-stirred modified asphalt mixture. The raw materials are in the following parts by mass: 100 parts of aggregate and 4.5-5.5 parts of asphalt, wherein the mass part of the warm-stirred modified asphalt is 0.09-0.12 time that of the asphalt and the mass part of the ethylene-vinylacetate copolymer colloidal particles is 0.06 to 0.10 time that of the asphalt. The plastic warm-stirred modified asphalt mixture can be used for bituminous pavements with extra heavy traffic volumes, has all better technical indexes compared with the common bituminous pavement, is economic and environment-friendly, and has better water damage resistance property and track resistance property.

Owner:GUANGDONG UNIV OF TECH

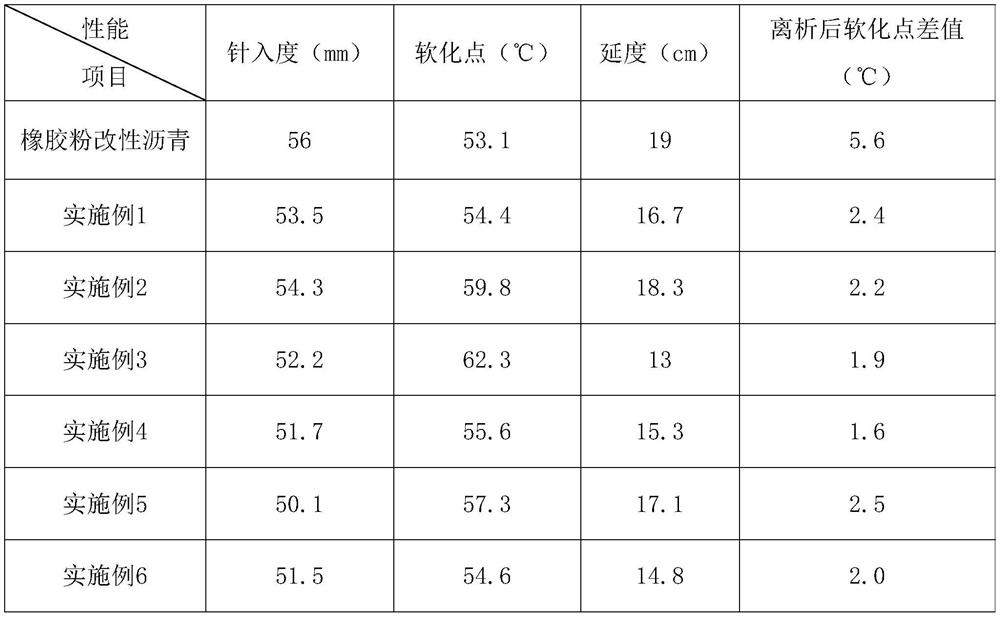

Novel rubber powder composite modified asphalt and preparation method thereof

InactiveCN111793368AChange structural propertiesImprove macro performanceBuilding insulationsAsphaltWaste tires

The invention provides novel rubber powder composite modified asphalt and a preparation method thereof. The novel rubber powder composite modified asphalt is prepared from the following components bymass percentage: 12%-18% of waste tire rubber powder, 2%-5% of nano-material modifier and 80%-86% of matrix asphalt; by compounding the nano material with the rubber powder modified asphalt, the structural characteristics of the raw materials can be changed on the nanoscale, so that the macroscopic properties of the material are greatly optimized, the high-temperature rutting resistance of the rubber powder modified asphalt can be improved, and the storage stability of the rubber powder modified asphalt is improved.

Owner:CHANGAN UNIV

Anti-rut agent and preparation method therefor

The invention relates to an anti-rut agent, which is characterized in that the anti-rut agent is composed of the following materials by weight: 40-50% of trivalent ferric salt, 40-50% of synthetic rubber and 10-12% of sulphur stabilizer. A preparation method for the anti-rut agent is characterized in that the steps are as follows: (1), the synthetic rubber is smashed to the degree that the fineness is less than 80 meshes; (2), the smashed synthetic rubber and the sulphur stabilizer are added into trivalent ferric salt solution according to the component proportion; and (3), the mixed solution is stirred uniformly under the normal temperature, so as to obtain the anti-rut agent. The raw materials of the anti-rut agent are obtained easily, the preparation method is simple, the excellent effect can be realized with smaller dosage of the raw materials, the cost is low, the mixing time is short, and the energy consumption is low; the construction is realized under the normal temperature, so that the construction process is controlled easily, and no pollution is discharged, thereby improving the high-temperature stability and the anti-rut capability of an asphalt mixture and realizing higher innovation. The preparation method for the anti-rut agent is simple in operation, is controlled easily and does not cause pollution.

Owner:天津市市政工程研究院

Asphalt-based graphene asphalt warm mix agent and preparation method thereof

InactiveCN109852084ACounteract viscous effectGood compatibilityBuilding insulationsAliphatic amineAsphalt

The invention discloses an asphalt-based graphene asphalt warm mix agent and a preparation method thereof, which is prepared from the following steps: 1) chemical oxidation of petroleum asphalt with concentrated nitric acid to obtain asphalt-based graphene quantum dots; 2) adding asphalt-based graphene quantum dots and long-chain aliphatic amine into a reactor, adding a certain amount of water carrying agent, stirring and heating, refluxing, and performing amidation reaction at that refluxing temperature to obtain an intermediate; 3) evaporating that water carrying agent in the reactant obtained in the step 2), heating the temperature under vacuum to carry out the imidazoline cyclization reaction to obtain the imidazoline intermediate; 4) preparing a certain quantity of quaternary aminating reagent into a certain mass fraction of ethanol solution, slowly dropping the ethanol solution into an imidazoline intermediate, reacting at a certain temperature under stirring conditions, and after the reaction is finished, distilling ethanol and unreacted quaternary aminating reagent under reduced pressure to obtain asphalt-based graphene asphalt warm mixer. The invention has good compatibility and storage stability, and the rutting resistance at high temperature is obviously improved.

Owner:SHANDONG JIANZHU UNIV

Composite modified asphalt and preparation method thereof

ActiveCN104448657AImprove high temperature anti-rutting performanceImprove performanceBuilding insulationsFiberPolyvinyl alcohol

The invention relates to composite modified asphalt. The composite modified asphalt is prepared from the following raw materials in parts by weight: 72-78 parts of petroleum asphalt, 0.8-1 part of nonylphenol polyoxyethylene ether, 1-1.2 parts of octadecyl dimethyl benzyl aluminum chloride, 8-10 parts of deionized water, 0.8-1 part of azobisisobutyronitrile, 9-10 parts of 2-methyl-1,3-butadiene, 1-1.8 parts of sodium pyrophosphate, 5-6 parts of guar gum, 10-12 parts of polyvinyl alcohol fiber, 2-3 parts of zirconia. The composite modified asphalt provided by the invention has outstanding overall performance, has good fatigue resistance and aging resistance, excellent tensile properties, outstanding elastic recovery rate and a high softening point and can be used for significantly improving the key index such as high-temperature anti-rutting performance of an asphalt mixture.

Owner:山西喜跃发道路建设养护集团有限公司

High-toughness, durable and anti-skid steel bridge deck pavement structure and construction method thereof

InactiveCN110952447AIncrease stiffnessImprove stabilityBridge structural detailsBridge erection/assemblyEpoxyBridge deck

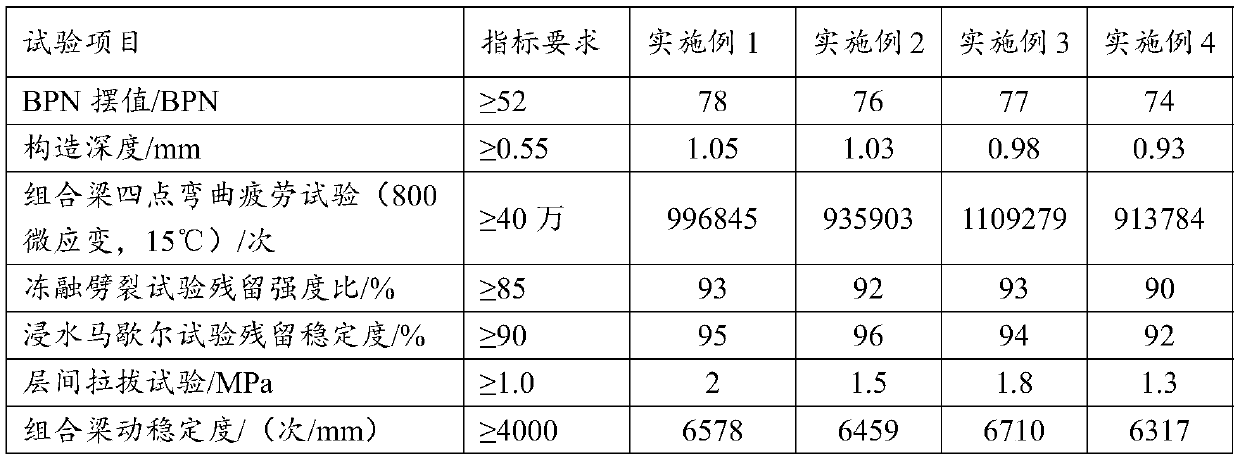

The invention discloses a high-toughness, durable and antiskid steel bridge deck pavement structure and a construction method thereof. The steel bridge deck pavement structure comprises a steel bridgedeck steel plate; a bonding bottom layer, a buffer layer, an adhesion layer and a wearing layer are sequentially laid on the surface of the steel bridge deck steel plate from bottom to top; the buffer layer and the wearing layer are both made of high-toughness modified asphalt concrete composed of aggregate, filler and asphalt cement, the thickness of the buffer layer is 1-3 cm, and the thicknessof the wearing layer is 2-3 cm. The bridge deck pavement structure has good high-temperature rut resistance, fatigue durability, skid resistance, bonding strength and deformation compliance, comparedwith epoxy asphalt concrete, the engineering cost is greatly reduced, the construction process is simple, and later maintenance is convenient.

Owner:广州市市维新材料科技有限公司

Utilization method of catalytic slurry oil

ActiveCN108059970AImprove performanceImprove temperature sensitivityVacuum distillationHydrocarbon oils treatmentPhosphatePhosphoric acid

The invention discloses a utilization method of a catalytic oil slurry. The method comprises the following steps: (1) adding a modifier to the catalytic oil slurry, and performing stirring to preparea modified catalytic oil slurry; and (2) mixing the obtained modified catalytic oil slurry with atmospheric pressure residual oil, and performing vacuum distillation to obtain vacuum residual oil, wherein total raw materials in step (1) comprise, by mass, 95.0-99.9% of the catalytic oil slurry and 0.1-5.0% of the modifier; and the modifier is one or more of a condensed aluminum phosphate curing agent and a silicon phosphate curing agent. The method can fully utilize the catalytic oil slurry, improve the problems of poor temperature sensitivity and poor anti-aging performance of the catalytic oil slurry and increase the flash point of the vacuum residual oil, and can be used to prepare road asphalt having excellent performances or a road asphalt production raw material.

Owner:CHINA PETROLEUM & CHEM CORP +1

A low-temperature-resistant high-modulus asphalt modifier and its preparation method

ActiveCN104194366BContinuous productionFix stability issuesBuilding insulationsRoad surfaceHot Temperature

The invention provides a low temperature resistant high modulus composite asphalt modifier and a preparation method thereof. The low-temperature-resistant high-modulus asphalt modifier of the present invention is composed of the following raw materials: a low-temperature-resistant high-modulus main agent, a reinforced binder, and a release agent; Solubilizers. The low-temperature-resistant high-modulus asphalt modifier of the present invention is a polymer composite additive for asphalt, which can comprehensively enhance the high-low temperature performance of asphalt, and significantly improve the low-temperature crack resistance, high-temperature rutting resistance and resistance to asphalt pavement. Water damages performance.

Owner:JIANGSU SOBUTE NEW MATERIALS

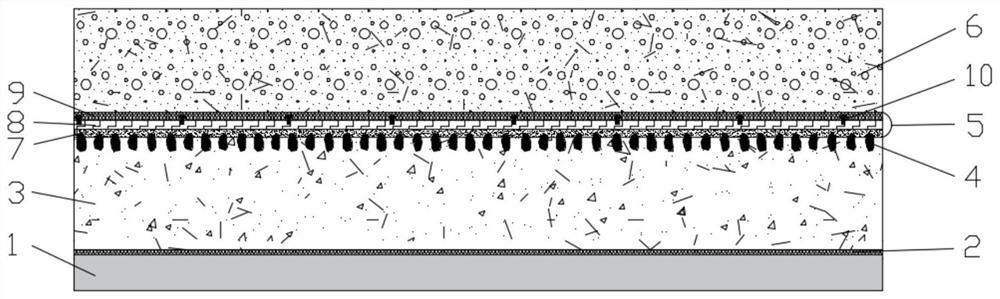

Bridge and tunnel fiber composite pouring flexible waterproof pavement and construction method

ActiveCN112681134ASolve the problem of uncoordinated deformationImprove aging resistanceBridge structural detailsBridge erection/assemblyEpoxyThermoplastic

The invention discloses a bridge and tunnel fiber composite pouring flexible waterproof pavement and construction method. A bridge and tunnel fiber composite pouring flexible waterproof pavement is of a layered composite structure. A two-stage thermoplastic epoxy resin waterproof bonding layer, a fiber composite pouring type asphalt concrete lower surface layer, a gravel embedding layer, a superimposed fiber epoxy resin bonding layer and a fiber composite resin upper surface layer are sequentially arranged on a steel bridge deck slab; the fiber composite pouring type asphalt concrete lower surface layer is prepared by mixing pouring type asphalt concrete with carbon fibers; and the gravel embedding layer and the fiber composite pouring type asphalt concrete are synchronously constructed. The fiber composite pouring type asphalt concrete has good deformation following performance on the bridge steel bridge deck slab, and the problem that a large-span and large-flexibility bridge steel bridge deck system pavement structure and the steel bridge deck slab are inharmonious in deformation is solved. The fiber resin mixture has excellent strength performance and high-temperature stability performance under high-temperature and heavy-load conditions, and the problems of fatigue cracking of epoxy asphalt steel bridge deck pavement and insufficient working durability with cracks are solved.

Owner:JIANGSU SINOROAD ENG TECH RES INST CO LTD

Anti-rutting asphalt mixture and preparation method therefor

InactiveCN108658509AImprove high temperature anti-rutting performanceImproves rutting resistanceHigh energyParaffin oils

The invention belongs to the technical field of asphalt mixtures and particularly relates to an anti-rutting asphalt mixture and a preparation method therefor. The anti-rutting asphalt mixture is prepared from the following ingredients in parts by mass: 950 parts of mineral aggregates, 48 parts of matrix asphalt, 0.1-0.8 part of chlorinated paraffin, 1-10 parts of anti-rutting modifier A, 0.1-10 parts of anti-rutting modifier B and 1-8 parts of fatty acids. According to the anti-rutting asphalt mixture, the blending, spreading and rolling temperatures are low, the problems such as environmental pollution, high energy consumption and aging and decaying of asphalt in the prior art can be solved, meanwhile, the properties of the mixture can be free of influence, and the rut resistance of themixture is improved.

Owner:CHINA PETROLEUM & CHEM CORP

Warm mix type high modulus asphalt mixture additive and preparation method thereof

InactiveCN110643189AImprove high temperature anti-rutting performanceImprove low temperature performanceBuilding insulationsElastomerPolymer science

The invention discloses a warm mix type high modulus asphalt mixture additive and a preparation method thereof. The warm mix type high modulus asphalt mixture additive comprises the following raw materials in parts by weight: 15-35 parts of polymer organic wax, 25-40 parts of thermoplastic elastomer polymer, 10-20 parts of waste rubber powder, 5-10 parts of coupling agent, 5-10 parts of inorganicfiller, 5-15 parts of anti-aging agent and 10-35 parts of pitch-based material. Through the specific proportioning and processing technology of the invention, the additive obtained after compounding can reduce the production temperature of the mixture, improve the high-temperature rutting resistance of the asphalt mixture, and improve the low-temperature performance and water stability of the asphalt mixture to a certain extent. Compared with the imported rutting resistance agents on the market, the additive has low production cost and good application prospects.

Owner:CHINA FIRST HIGHWAY ENG +1

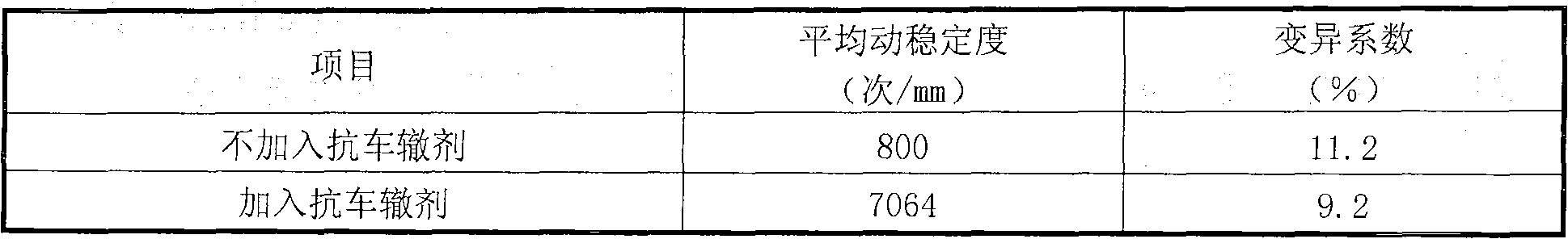

Asphalt mixture with high anti-rut capability and preparation method therefor

The invention relates to an asphalt mixture with high anti-rut capability, which is composed of the following materials by weight parts: 93.5-96.5 parts of mineral aggregates, 3.5-6.5 parts of asphalt and 0.175-0.65 parts of anti-rut agent. A preparation method for the asphalt mixture with high anti-rut capability is characterized in that the steps are as follows: (1), the asphalt is heated to 145-165 DEG C, and the mineral aggregates are heated to 150-180 DEG C; (2), 93.5-96.5% of mineral aggregates and 3.5-6.5% of asphalt are put into a mixer to be mixed, and the anti-rut agent with amount of 2-10% of asphalt is sprayed after the asphalt is put for 5-8s; and (3), after the anti-rut agent is sprayed in the step (2), the mixture is stirred for 10-15s, then mineral powder is added, the obtained mixture is stirred more than 15s continuously, thereby ensuring uniform stirring, so as to obtain the finished product (the asphalt mixture with high anti-rut capability). The asphalt mixture with high anti-rut capability is rich in raw materials, low in preparation cost, high in cost performance and strong in anti-rut capability; and the preparation process for the asphalt mixture is simple and easy, equipment is easy, and the preparation process is easy to realize.

Owner:天津市市政工程研究院

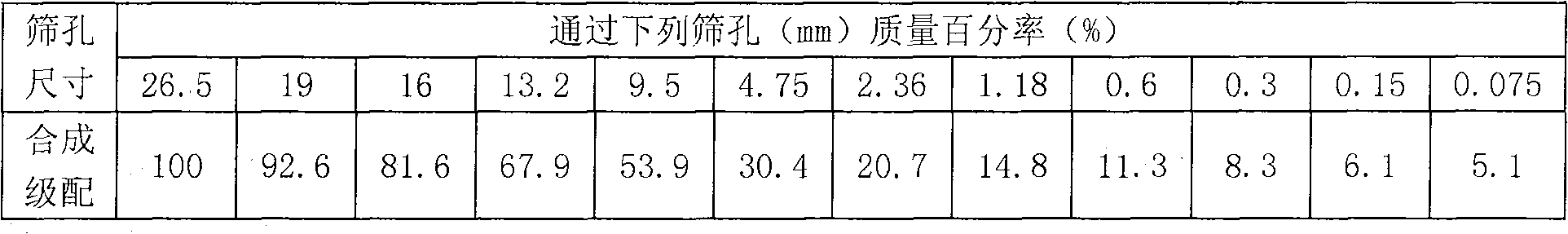

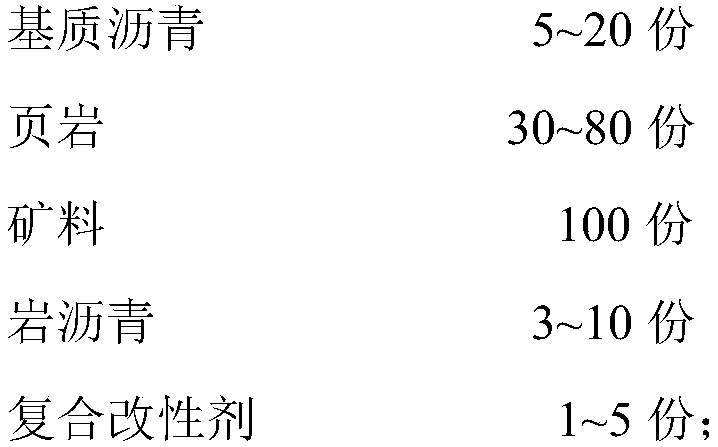

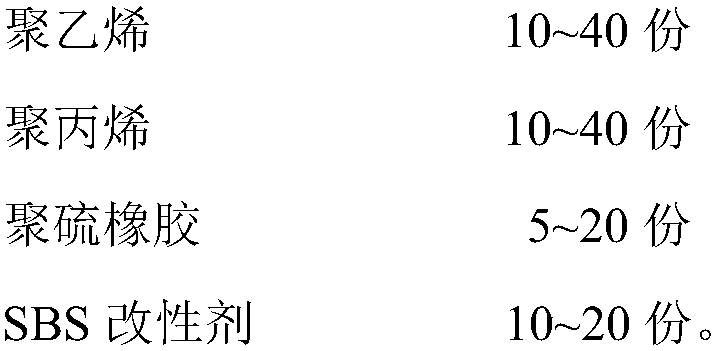

Lightweight high-strength dense water type asphalt mixture and preparation method thereof

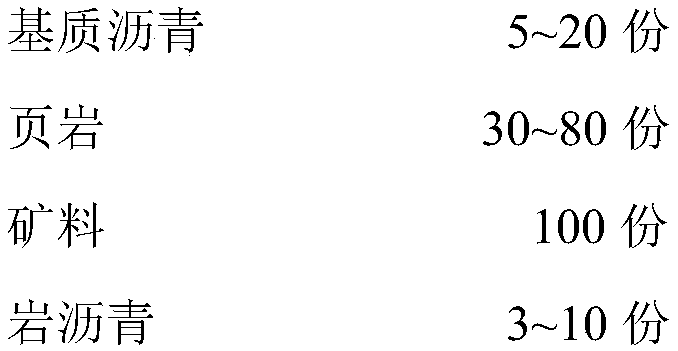

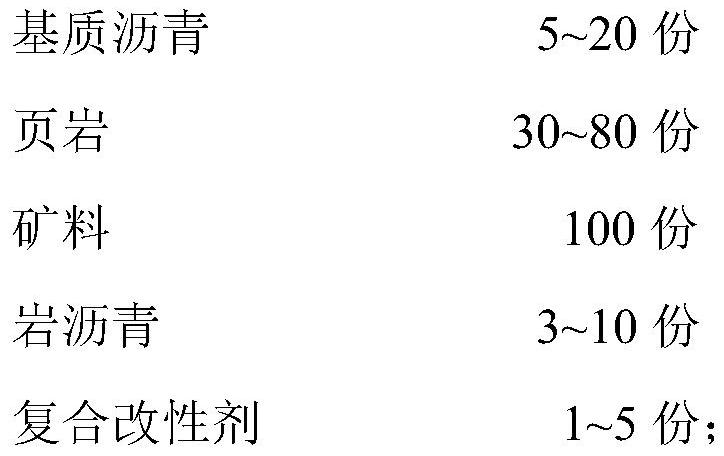

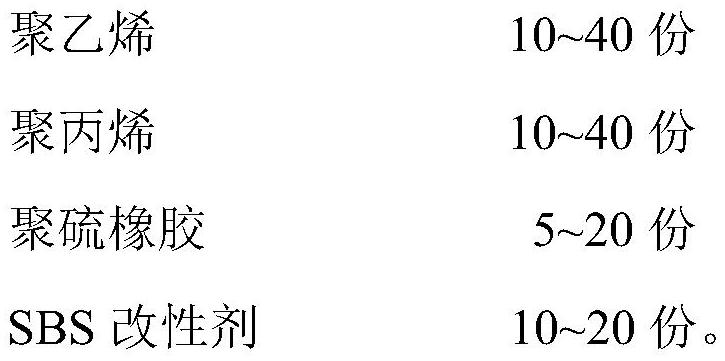

The invention discloses a lightweight high-strength dense water type asphalt mixture, which comprises the following components by weight: 5-20 parts of matrix asphalt; 30-80 parts of shale; 100 partsof a mineral material; 3-10 of rock asphalt and 1-5 parts of a composite modifier; wherein the mineral material comprises diabase having a particle diameter of 0.075 mm to 15 mm and limestone ore powder having a particle diameter of less than 0.075 mm in a weight ratio of 100:4 to 7. The lightweight high-strength dense water type asphalt mixture has small density, high modulus, small void ratio and good road performance. When used for concrete bridge deck pavement paving or highway pavement paving, the paving layer quality can be effectively reduced under the condition that the pavement structure thickness is constant, and the bearing of a concrete bridge structure or a semi-rigid base layer structure is reduced; under the same bearing capacity, the paving layer structure thickness can beincreased, reflection cracks caused by the crack of a concrete bridge deck or a semi-rigid base layer can be reduced, and the pavement durability can be improved.

Owner:JIANGSU SINOROAD ENG TECH RES INST CO LTD +1

A light-weight high-strength water-dense asphalt mixture and its preparation method

The invention discloses a lightweight high-strength dense water type asphalt mixture, which comprises the following components by weight: 5-20 parts of matrix asphalt; 30-80 parts of shale; 100 partsof a mineral material; 3-10 of rock asphalt and 1-5 parts of a composite modifier; wherein the mineral material comprises diabase having a particle diameter of 0.075 mm to 15 mm and limestone ore powder having a particle diameter of less than 0.075 mm in a weight ratio of 100:4 to 7. The lightweight high-strength dense water type asphalt mixture has small density, high modulus, small void ratio and good road performance. When used for concrete bridge deck pavement paving or highway pavement paving, the paving layer quality can be effectively reduced under the condition that the pavement structure thickness is constant, and the bearing of a concrete bridge structure or a semi-rigid base layer structure is reduced; under the same bearing capacity, the paving layer structure thickness can beincreased, reflection cracks caused by the crack of a concrete bridge deck or a semi-rigid base layer can be reduced, and the pavement durability can be improved.

Owner:JIANGSU SINOROAD ENG TECH RES INST CO LTD +1

Modified asphalt for asphalt pavement in seasonally frozen ground region

InactiveCN110079101ARaise the temperatureImprove anti-aging propertiesBuilding insulationsRoad surfacePetroleum

The invention provides modified asphalt for an asphalt pavement in a seasonally frozen ground region. The modified asphalt is prepared from components in percentage by mass as follows: 94.8%-95.7% of110# road petroleum asphalt and 4.3%-5.2% of refined diatomite, wherein the 110# road petroleum asphalt is high-grade asphalt applicable to the seasonally frozen ground region, and the refined diatomite is a product after beneficiation and purification of diatomite ore. The modified asphalt is used for the seasonally frozen ground region which is cold in winter and hot in summer, and the high temperature and anti-ageing performance of the high-grade asphalt can be improved on the premise that certain low-temperature performance is guaranteed, so that the service life of the asphalt pavement isprolonged, and pavement diseases are reduced. Besides, less refined diatomite is used, a better modification effect is obtained, and the modification cost is reduced.

Owner:SHANGHAI JIAO TONG UNIV

A kind of utilization method of catalytic oil slurry

ActiveCN108059970BImprove performanceImprove temperature sensitivityVacuum distillationHydrocarbon oils treatmentPhysical chemistryProcess engineering

The invention discloses a utilization method of a catalytic oil slurry. The method comprises the following steps: (1) adding a modifier to the catalytic oil slurry, and performing stirring to preparea modified catalytic oil slurry; and (2) mixing the obtained modified catalytic oil slurry with atmospheric pressure residual oil, and performing vacuum distillation to obtain vacuum residual oil, wherein total raw materials in step (1) comprise, by mass, 95.0-99.9% of the catalytic oil slurry and 0.1-5.0% of the modifier; and the modifier is one or more of a condensed aluminum phosphate curing agent and a silicon phosphate curing agent. The method can fully utilize the catalytic oil slurry, improve the problems of poor temperature sensitivity and poor anti-aging performance of the catalytic oil slurry and increase the flash point of the vacuum residual oil, and can be used to prepare road asphalt having excellent performances or a road asphalt production raw material.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for processing catalytic oil slurry

ActiveCN110437871BImprove performanceImprove temperature sensitivityTreatment with plural serial refining stagesPhysical chemistryAluminium phosphate

The invention discloses a method used for processing catalytic slurry oil. The method comprises following steps: by mass, 0.1 to 5.0% of a modifier is added into 95.0 to 99.9% of catalytic slurry oil,and stirring is carried out to obtain a modified catalytic slurry oil; the modified catalytic slurry oil and crude oil are mixed, and are introduced into an atmospheric vacuum distillation unit for normal pressure distillation and underpressure distillation to obtain pressure reduction residual oil; wherein the modifier is one or a mixture of a plurality of components selected from condensed aluminium phosphate and silicon phosphate curing agents. The method is capable of realizing full utilization of catalytic slurry oil, improving the poor temperature sensitivity and aging resistance of catalytic slurry oil, increasing the flashing point of pressure reduction residual oil, and realizing direct using of the pressure reduction residual oil as road asphalt or as a raw material used in blending road asphalt and waterproof asphalt.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-modulus modified asphalt and preparation method thereof

ActiveCN111393862AHigh softening pointImprove high temperature performanceBuilding insulationsPolymer scienceRoad surface

The invention relates to high-modulus modified asphalt and a preparation method thereof. The modified asphalt comprises matrix asphalt with the internal mixing amount of 80-85%, hard asphalt with theinternal mixing amount of 8-9%, SBS with the internal mixing amount of 4-6% and an auxiliary agent with the internal mixing amount of 0.1-1.0%. Oil sand deoiled asphalt can be cleanly and effectivelyutilized, the high-temperature anti-rutting performance of the asphalt binder is remarkably improved, the engineering cost is reduced, a pavement is thinned, and the pavement rutting disease is solved.

Owner:CHINA NAT OFFSHORE OIL CORP +3

Asphalt mixed material and mix proportion designing method thereof

InactiveCN109678396AImprove high temperature anti-rutting performanceImprove low temperature crack resistanceRoads maintainenceSlagMixed materials

The invention provides an asphalt mixed material and a mix proportion designing method thereof. The asphalt mixed material mainly comprises the following components in parts by weight: 80-100 parts ofaggregate, 1-20 parts of slag bottom mud and 4-8 parts of asphalt, wherein the slag bottom mud is a solid waste which is made of living garbage which is incinerated, treated by a wet-method treatmentprocess and precipitated. By adopting the asphalt mixed material, the problem that the environment is adversely affected as a great deal of slag bottom mud is directly emitted after living garbage incineration protogenesis furnace slag is treated the a wet-method process can be solved.

Owner:SHANGHAI MUNICIPAL PLANNING & DESIGN INST CO LTD +1

A kind of polyester fiber reinforced asphalt mixture and preparation method thereof

ActiveCN112723791BImprove thermal storage stabilityImprove anti-aging propertiesMonocomponent copolyesters artificial filamentPolymer scienceDicarboxylic acid

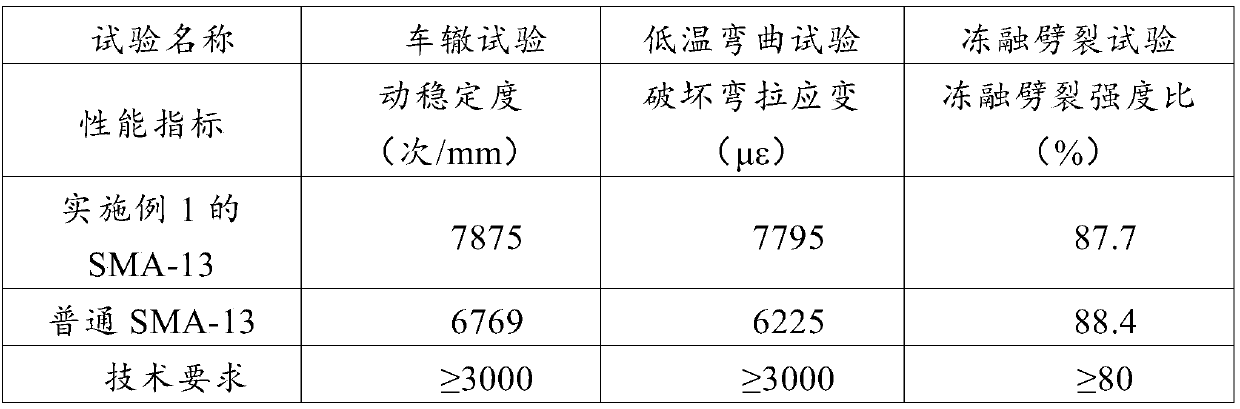

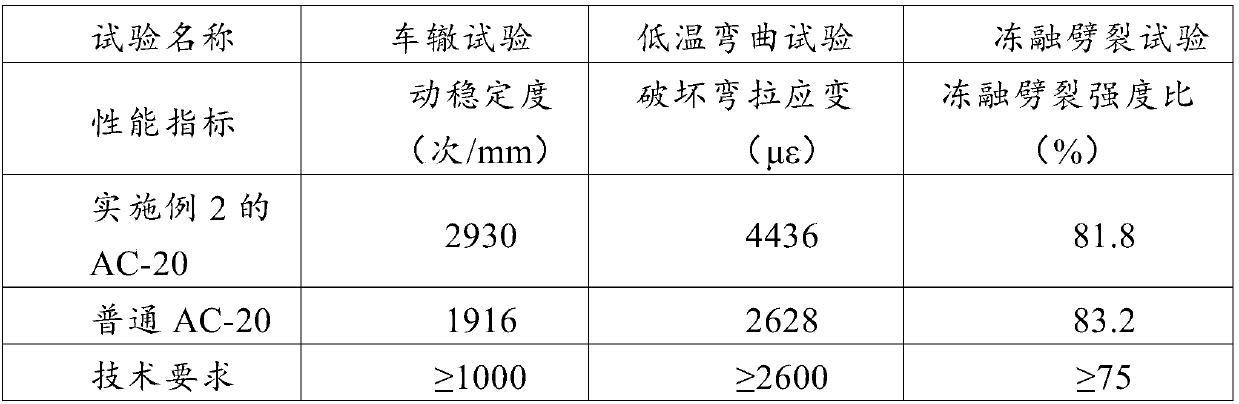

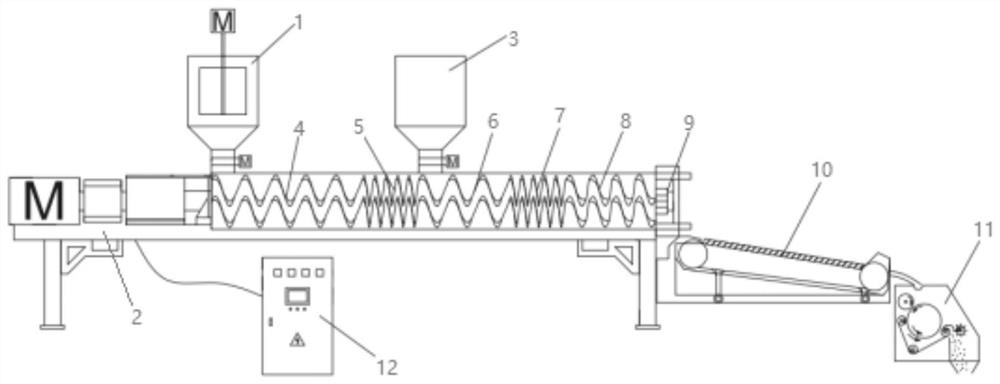

A polyester fiber-reinforced asphalt mixture and a preparation method thereof. The polyester fiber-reinforced asphalt mixture is obtained by mixing modified polyester short fibers, asphalt and aggregates; the asphalt ratio of the polyester fiber-reinforced asphalt mixture is 4.68-4.92% , the mass percentage of modified polyester staple fiber in polyester fiber reinforced asphalt mixture is 0.1-0.3%; the polyester segment of modified polyester staple fiber includes terephthalic acid segment, ethylene glycol segment and 2 , 5-pyridinedicarboxylic acid segment; the molar ratio of terephthalic acid segment and 2,5-pyridinedicarboxylic acid segment is 1:0.04~0.06; 2,5-pyridine in the modified polyester fiber of the present invention The dicarboxylic acid segment coordinates with iron, calcium, magnesium, nickel and other metal ions in asphalt, which increases the bonding force between fibers and asphalt molecules, forms physical cross-linking points, and enhances the high-temperature anti-rutting performance of asphalt pavement. At the same time, it increases the integrity and rigidity of the asphalt pavement, thereby improving the thermal storage stability, aging resistance and low temperature crack resistance of the asphalt.

Owner:JIANGSU HENGLI CHEM FIBER

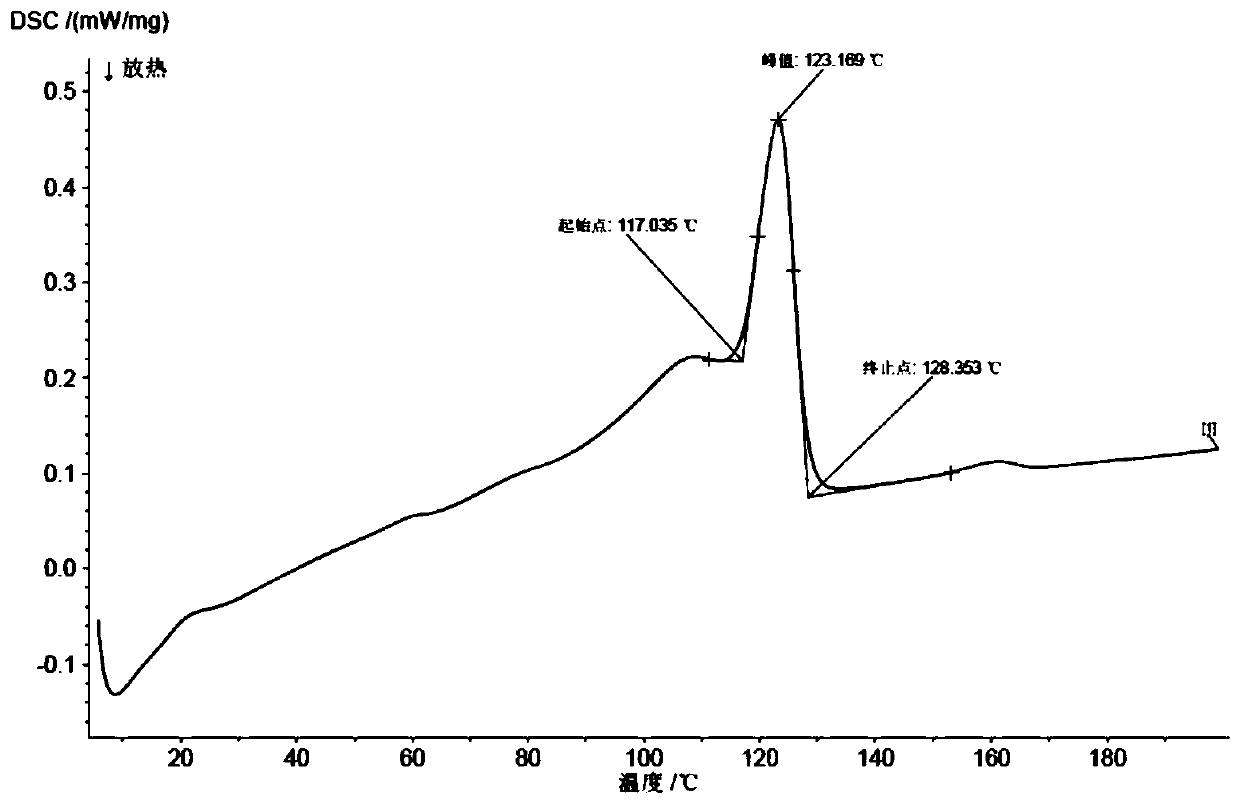

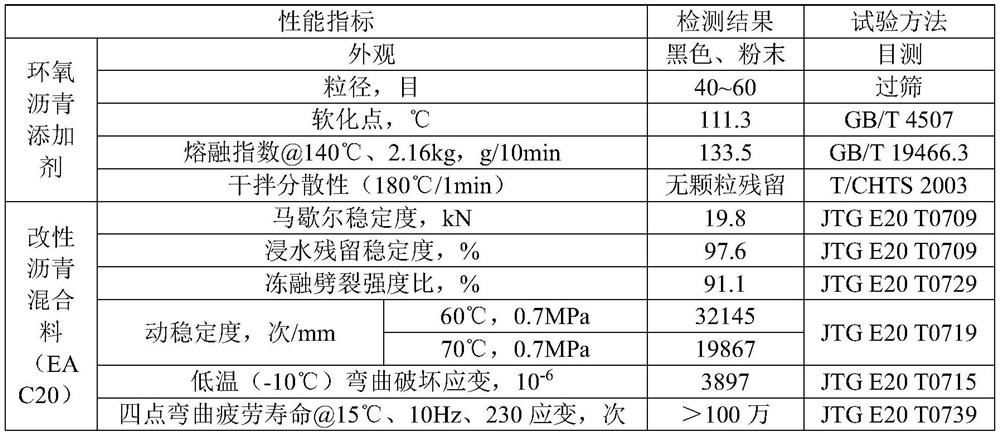

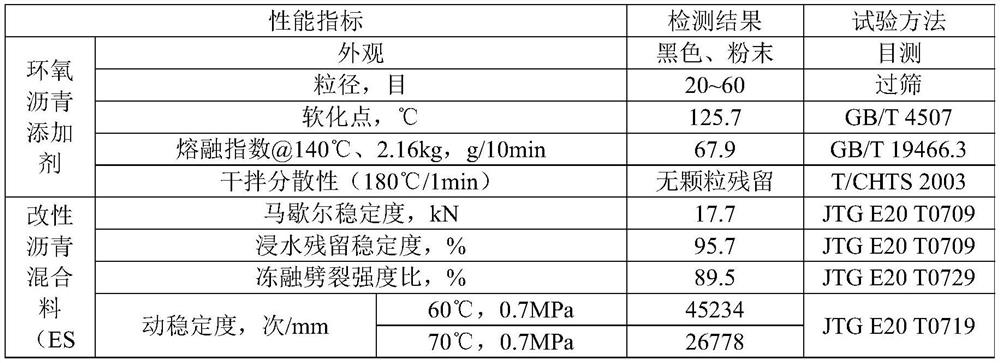

Epoxy asphalt additive for road and bridge pavement as well as preparation method and use method of epoxy asphalt additive

PendingCN114854223AReduce dilutionWell mixedClimate change adaptationBuilding insulationsPolyesterFirming agent

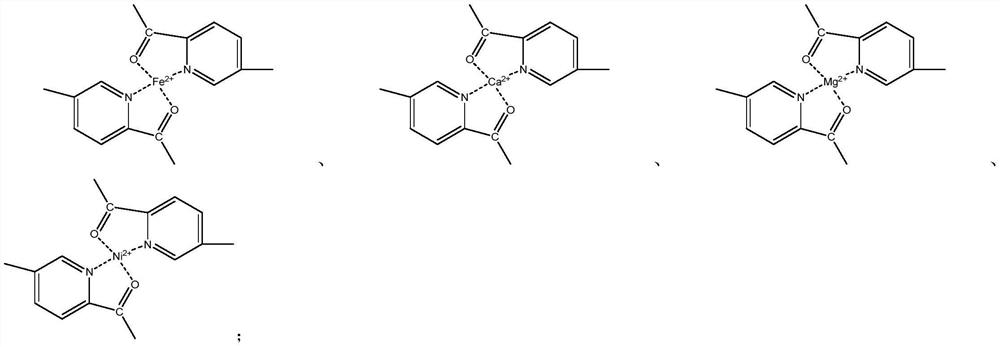

The invention belongs to the technical field of road and bridge materials, and relates to an epoxy asphalt additive for road and bridge pavement as well as a preparation method and a use method thereof. The technical key points are as follows: the water-damage-resistant asphalt mixture comprises the following components in parts by weight: 40-60 parts of solid epoxy resin, 5-20 parts of a water-damage-resistant improver, 5-10 parts of an ultra-high molecular weight epoxy flexibilizer, 30-45 parts of a latent polyester curing agent, 50-100 parts of hard asphalt particles, 0.1-0.5 part of a curing accelerator, 0.3-1 part of a lubricating separant and 0.5-2 parts of an antioxidant. The epoxy asphalt additive is prepared under the condition of 110 to 140 DEG C. The softening points of the main raw materials such as the resin component, the curing agent, the hard asphalt particles and the like in the epoxy asphalt additive are controlled within the range of 90-130 DEG C, and the epoxy asphalt additive for road and bridge pavement is prepared by adopting a 110-140 DEG C melt extrusion process. And then directly putting the mixture into a mixing cylinder of an asphalt mixing plant to prepare the high-performance epoxy asphalt concrete with high-temperature rut resistance, low-temperature crack resistance and medium-temperature fatigue resistance.

Owner:JIANGSU SINOROAD TRANSPORTATION SCI & TECH CO LTD

A kind of SBS modified asphalt based on graphene oxide and preparation method thereof

ActiveCN104448868BStable cross network structureSolid mesh structureBuilding insulationsPhysical chemistryAsphalt

The invention belongs to the technical field of modified asphalt, and particularly relates to SBS modified asphalt based on graphene oxide and a preparing method thereof. The SBS modified asphalt based on the graphene oxide comprises asphalt serving as a matrix, the graphene oxide serving as an additive, linear SBS serving as a modifier, and a sulfur-bearing accelerant, wherein the mass of the graphene oxide is 0.5-3% that of the matrix asphalt, the mass of the linear SBS is 3-5% that of the matrix asphalt, and the mass of the sulfur-bearing accelerant is 0.2-0.6% that of the matrix asphalt. Compared with the prior art, the SBS modified asphalt based on the graphene oxide has the advantages that the advantages of the graphene oxide are fully utilized, high-temperture stability, high-temperature rut resistance, low-temperature cracking resistance, fatigue resistance and water stability are high, the preparing method is simple, the process is mitigatory, and cost is low.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com