A low-temperature-resistant high-modulus asphalt modifier and its preparation method

An asphalt modifier, high modulus technology, applied in building insulation materials, building components, buildings, etc., can solve the problem of simultaneously improving the low-temperature crack resistance and high-temperature rutting resistance of asphalt pavement, and affecting the performance of asphalt modifiers In order to achieve the effects of obvious compatibility, prolong the service life and enhance the ease of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

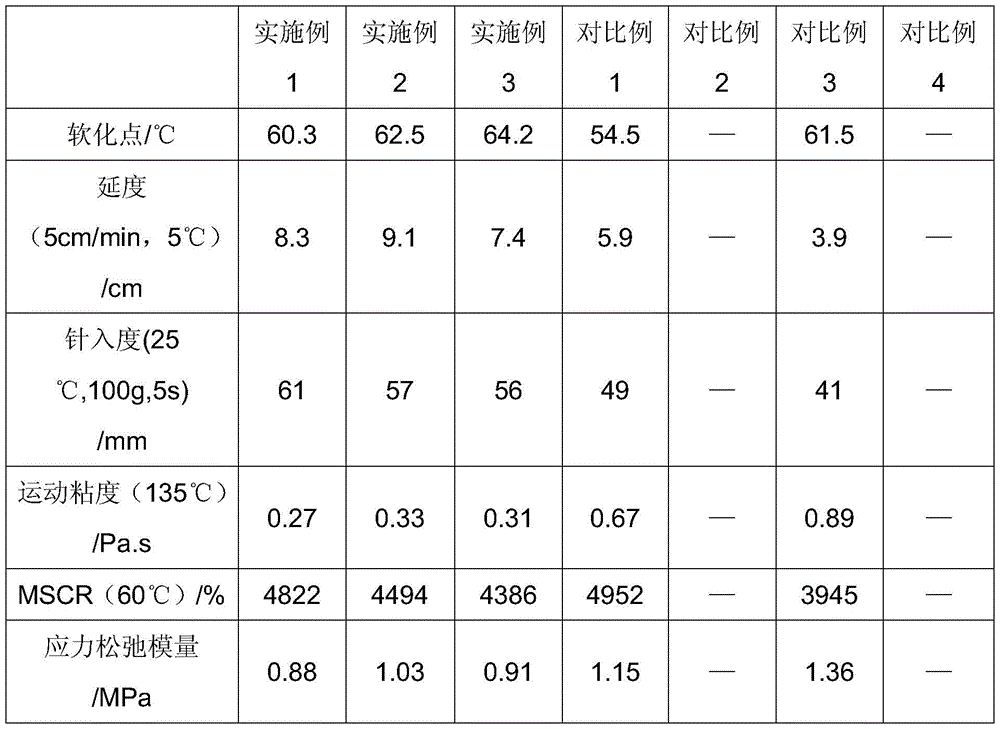

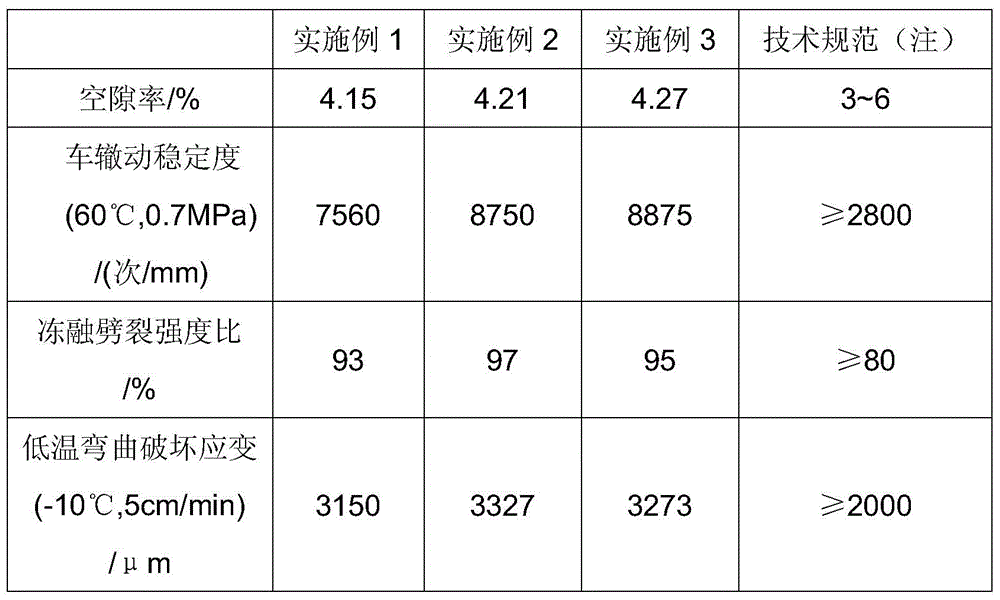

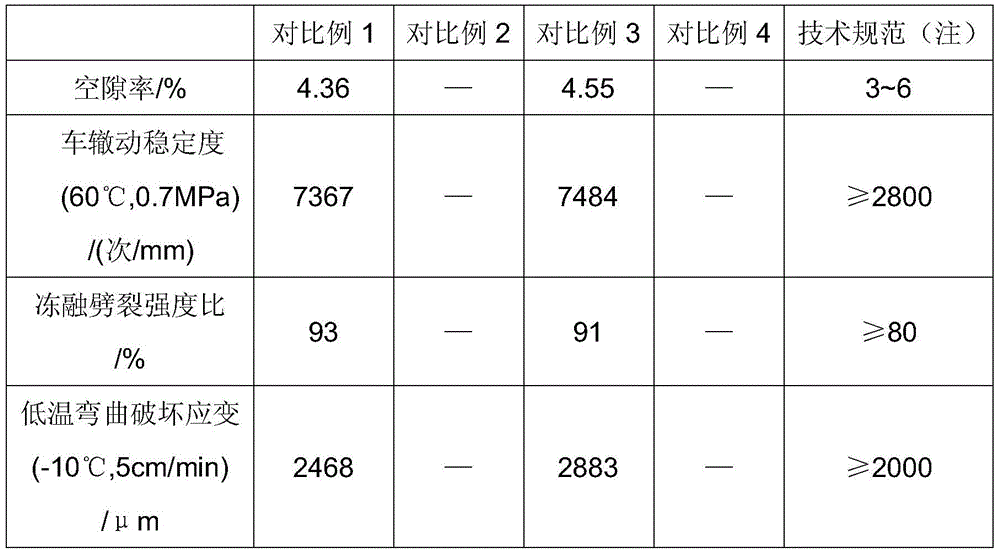

Embodiment 1

[0040] Preparation of low-temperature-resistant high-modulus asphalt modifier: put 50 parts of 40-mesh waste shoe sole rubber powder and 2 parts of silane coupling agent solution into a stirring tank, and stir for 15 minute, stop stirring, take it out, and continue drying at 120 degrees for 30 minutes; mix 21 parts of low-density polyethylene powder (molecular weight range 5-500,000), 21 parts of linear low-density polyethylene powder (molecular weight range 10-500,000) 1. Put 6 parts of natural asphalt powder and the above-mentioned surface-treated waste rubber powder into a stirring kettle together, stir for 5 minutes at normal temperature and a stirring rate of 800r / min, take it out, and set aside.

[0041] Preparation of binder: 55 parts of 7# aromatic oil for modified asphalt, 20 parts of carbon 9 modified petroleum resin, 14 parts of styrene-butadiene-styrene block copolymer, 0.5 part of antioxidant and 10.5 parts Parts of 70# bitumen were put into the reaction kettle to...

Embodiment 2

[0047] Preparation of low-temperature-resistant, high-modulus main agent: put 50 parts of 40-mesh waste shoe sole rubber powder and 2 parts of silane coupling agent solution into a stirring tank, and stir for 15 minutes at room temperature at a stirring rate of 800r / min. Stop stirring, take it out, and continue drying at 120 degrees for 30 minutes; 21 parts of low-density polyethylene powder (molecular weight range 5-500,000), 21 parts of linear low-density polyethylene powder (molecular weight range 10-500,000), 6 Parts of 40 mesh barium sulfate powder and the above-mentioned surface-treated waste rubber powder were put into a stirring tank, stirred at room temperature and a stirring rate of 800r / min for 5 minutes, taken out, and set aside.

[0048] Preparation of binder: Put 75 parts of 7# aromatic oil for modified asphalt, 14 parts of bentonite, 4 parts of maleic anhydride grafted polyethylene, 1.5 parts of antioxidant and 5.5 parts of 70# asphalt into the reaction kettle to...

Embodiment 3

[0054] Preparation of low-temperature-resistant, high-modulus main agent: put 50 parts of 40-mesh waste shoe sole rubber powder and 2 parts of silane coupling agent solution into a stirring tank, and stir for 15 minutes at room temperature at a stirring rate of 800r / min. Stop stirring, take it out, and continue drying at 120 degrees for 30 minutes; 21 parts of low-density polyethylene powder (molecular weight range 5-500,000), 21 parts of linear low-density polyethylene powder (molecular weight range 10-500,000), 6 1 part organic bentonite and 40-mesh barium sulfate powder are mixed in a ratio of 1:1 and put into a stirring tank together with the above surface-treated waste rubber powder, stirred at room temperature and a stirring rate of 800r / min for 5 minutes, taken out, and set aside.

[0055] Preparation of binder: 82 parts of 5# aromatic oil for modified asphalt, 5 parts of carbon 5 modified petroleum resin, 5 parts of polystyrene-butadiene copolymer, 3 parts of antioxidan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com