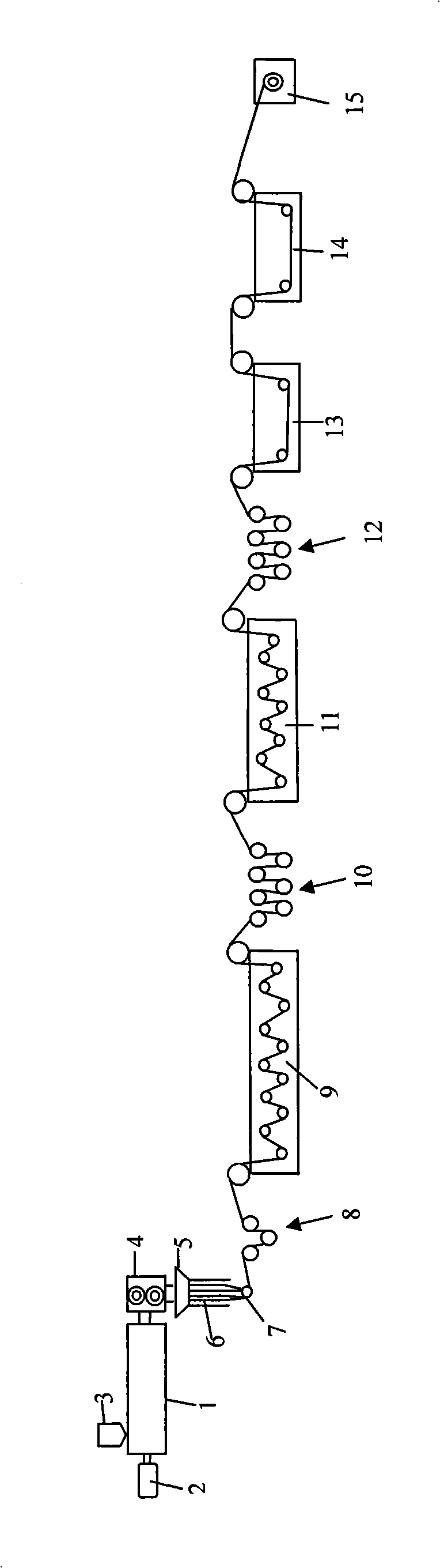

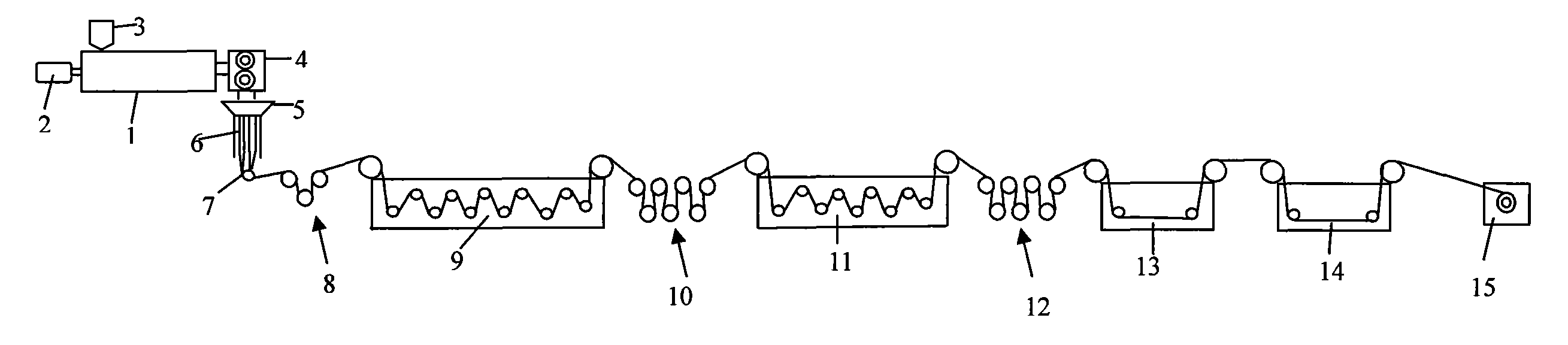

Method and equipment for preparing ultrahigh molecular weight polyethylene fibers

A technology of ultra-high molecular weight and polyethylene fibers, which is applied to the preparation of ultra-high molecular weight polyethylene fibers by melt spinning. The equipment field used in this method can solve the problems of high production cost and complicated production process, and achieve less equipment composition. , short process flow, continuous production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] After selecting 95 parts (parts by weight) of ultra-high molecular weight polyethylene with a viscosity average molecular weight of 3 million and 5 parts (parts by weight) of organic montmorillonite, they were mixed and granulated in a mixing type twin-screw extruder to produce A granular ultra-high molecular weight polyethylene / montmorillonite nanocomposite material is obtained, that is, a modified ultra-high molecular weight polyethylene raw material.

[0022] The ultra-high molecular weight polyethylene / montmorillonite nanocomposite material is melt-extruded in a Φ90 single-screw extruder. The outlet pressure of the pump, that is, the output pressure is 30MPa, and then a melt strip with a diameter of 4mm is formed through the spinning die. The melt strip is cooled with nitrogen in the cooling tunnel, the wind temperature is 20°C, the wind speed is 6m / s, and the godet roll is used for pre-drawing Stretching, the stretching ratio is 10 times to obtain as-spun silk, and...

Embodiment 2

[0024] After selecting 90 parts (parts by weight) of ultra-high molecular weight polyethylene with a viscosity-average molecular weight of 2.5 million and 10 parts (parts by weight) of organic montmorillonite, they were mixed and granulated in a mixing type twin-screw extruder to produce A granular ultra-high molecular weight polyethylene / montmorillonite nanocomposite material is obtained, that is, a modified ultra-high molecular weight polyethylene raw material.

[0025] The ultra-high molecular weight polyethylene / montmorillonite nanocomposite material is melt-extruded in a Φ90 single-screw extruder, the temperature of the extruder is 220°C or 260°C, the pressure is stabilized and pressurized by the melt pump, and the outlet pressure of the melt pump is That is, the output pressure is 10MPa, and then a melt strip with a diameter of 4mm is formed through the spinning die. The melt strip is cooled with nitrogen in the cooling tunnel, the wind temperature is 10°C, and the wind s...

Embodiment 3

[0027] After selecting 92 parts (parts by weight) of ultra-high molecular weight polyethylene with a viscosity average molecular weight of 1.5 million and 8 parts (parts by weight) of organic montmorillonite, they were mixed and granulated in a mixing type twin-screw extruder to prepare A granular ultra-high molecular weight polyethylene / montmorillonite nanocomposite material is obtained, that is, a modified ultra-high molecular weight polyethylene raw material.

[0028]The above ultra-high molecular weight polyethylene / montmorillonite nano-composite material is melt-extruded in a Φ90 single-screw extruder, the temperature of the extruder is 100°C, 180 or 220°C, and the melt pump is used to stabilize and pressurize the melt. The outlet pressure of the pump, that is, the output pressure is 50MPa, and then a melt strip with a diameter of 6mm is formed through the spinning die, and the melt strip is cooled with nitrogen in the cooling tunnel, the wind temperature is 35°C, the wind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com