High speed automatic tin-plating machine

A tin plating machine, automatic technology, applied in hot dip plating process, coating, metal material coating process and other directions, can solve the problems of low yield, low speed and low efficiency, and great impact on product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

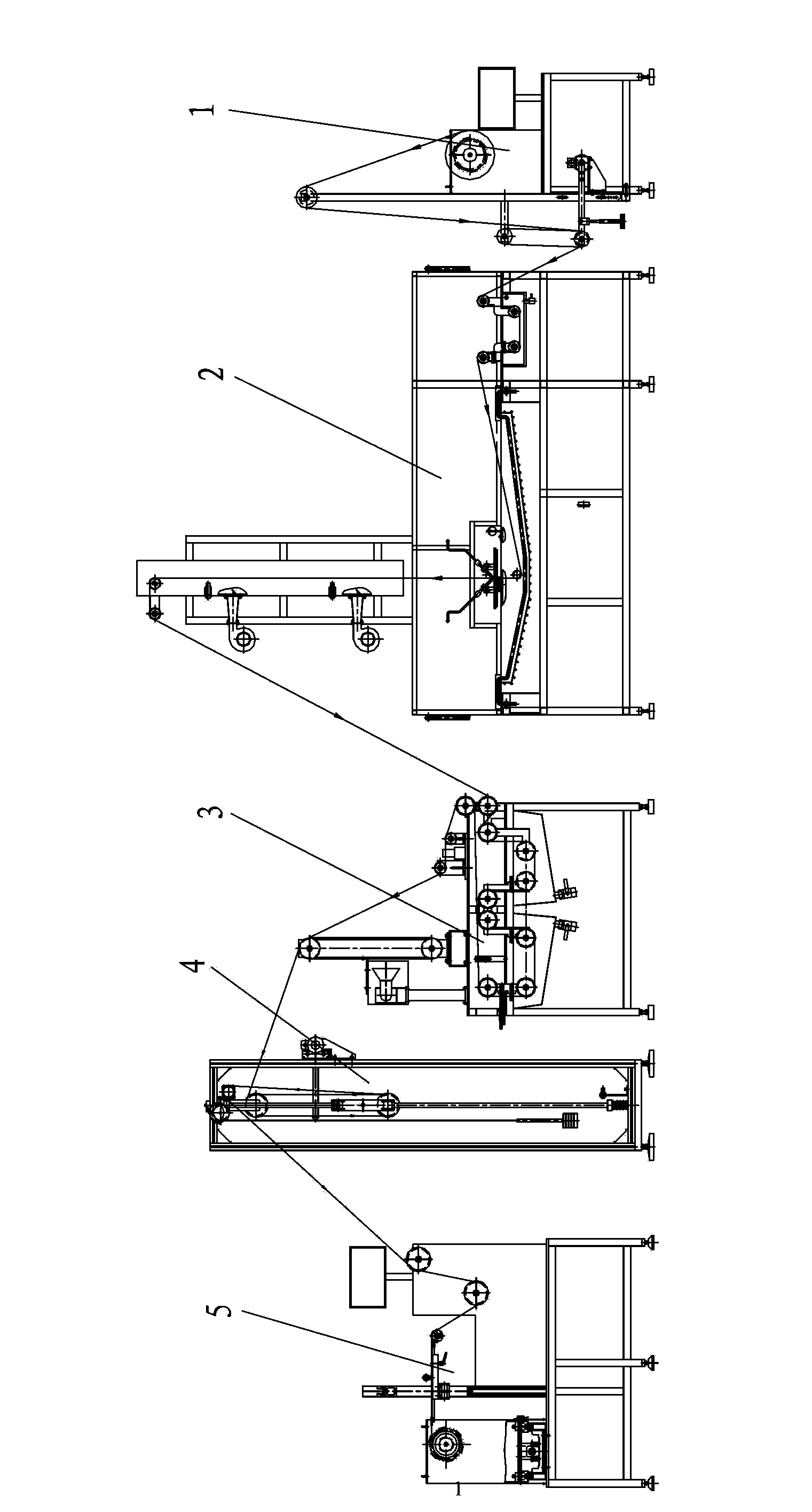

[0102] Such as figure 1 As shown, the present invention includes an unwinding mechanism, a tinning mechanism, a drive cleaning mechanism, a material storage mechanism and a winding mechanism arranged in sequence, and a control system for automatically controlling the tinning process;

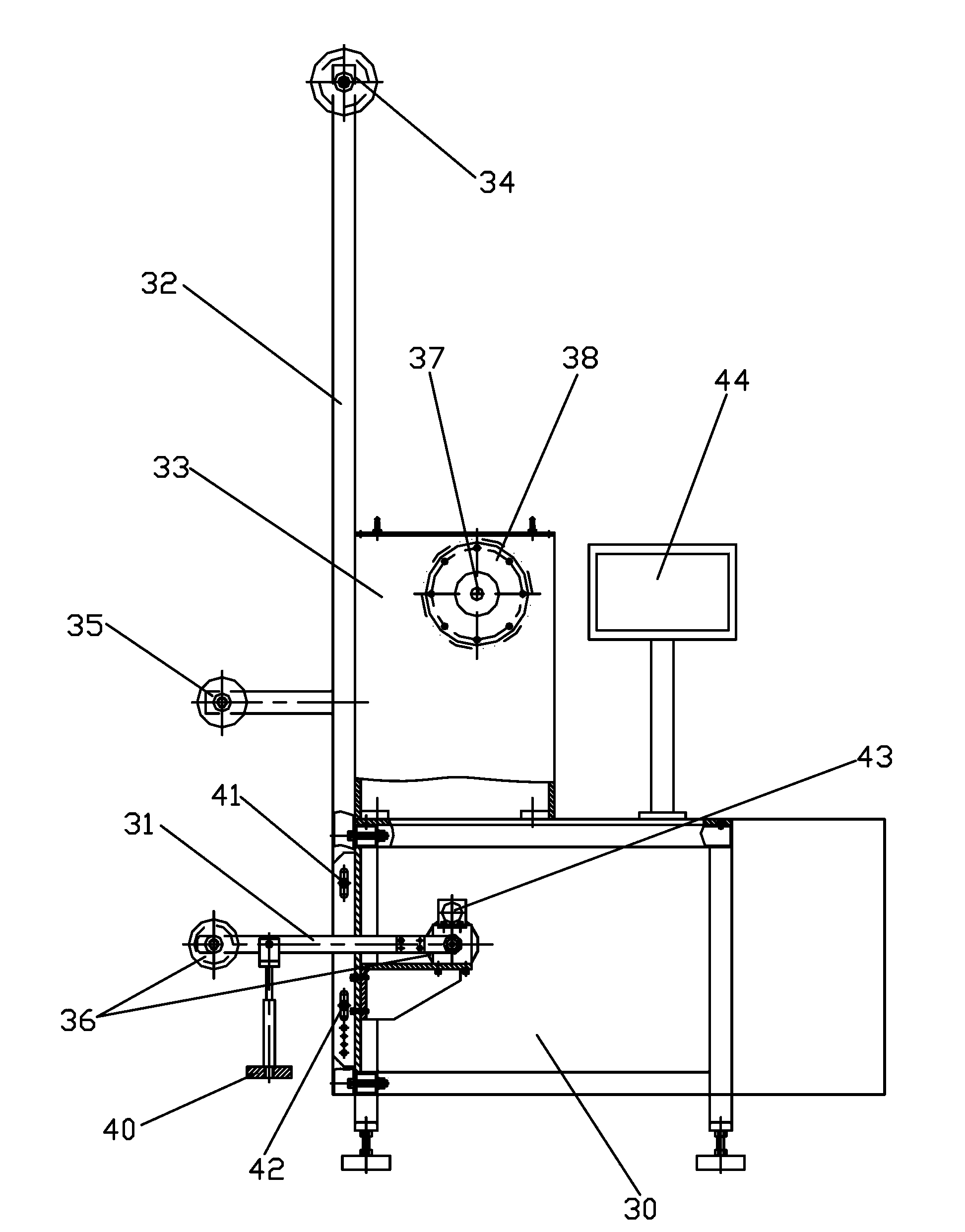

[0103] Such as figure 2 As shown, the unwinding mechanism includes an unwinding frame 30 and a pay-off swing lever 31 that is rotatably connected to the side of the unwinding frame 30 at one end, and an unwinding transition wheel installed at the top of the unwinding frame 30 Bar 32 and unwinding shaft cabinet 33, the top of described unwinding excessive wheel bar 32 is equipped with unwinding excessive wheel one 34, and the middle and lower part of described unwinding excessive wheel bar 32 is equipped with unwinding excessive wheel two 35, and described unwinding excessive wheel two 35 is installed. The two ends of line fork 31 are equipped with a tension adjustment wheel 36 respectively, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com