Patents

Literature

201results about How to "Improve low temperature crack resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Asphalt mixture mixing proportion design method based on inert solid fractal distribution characteristic

InactiveCN101318794AImprove road performanceSimple internal structureSolid waste managementCeramic shaping apparatusMathematical modelTest sample

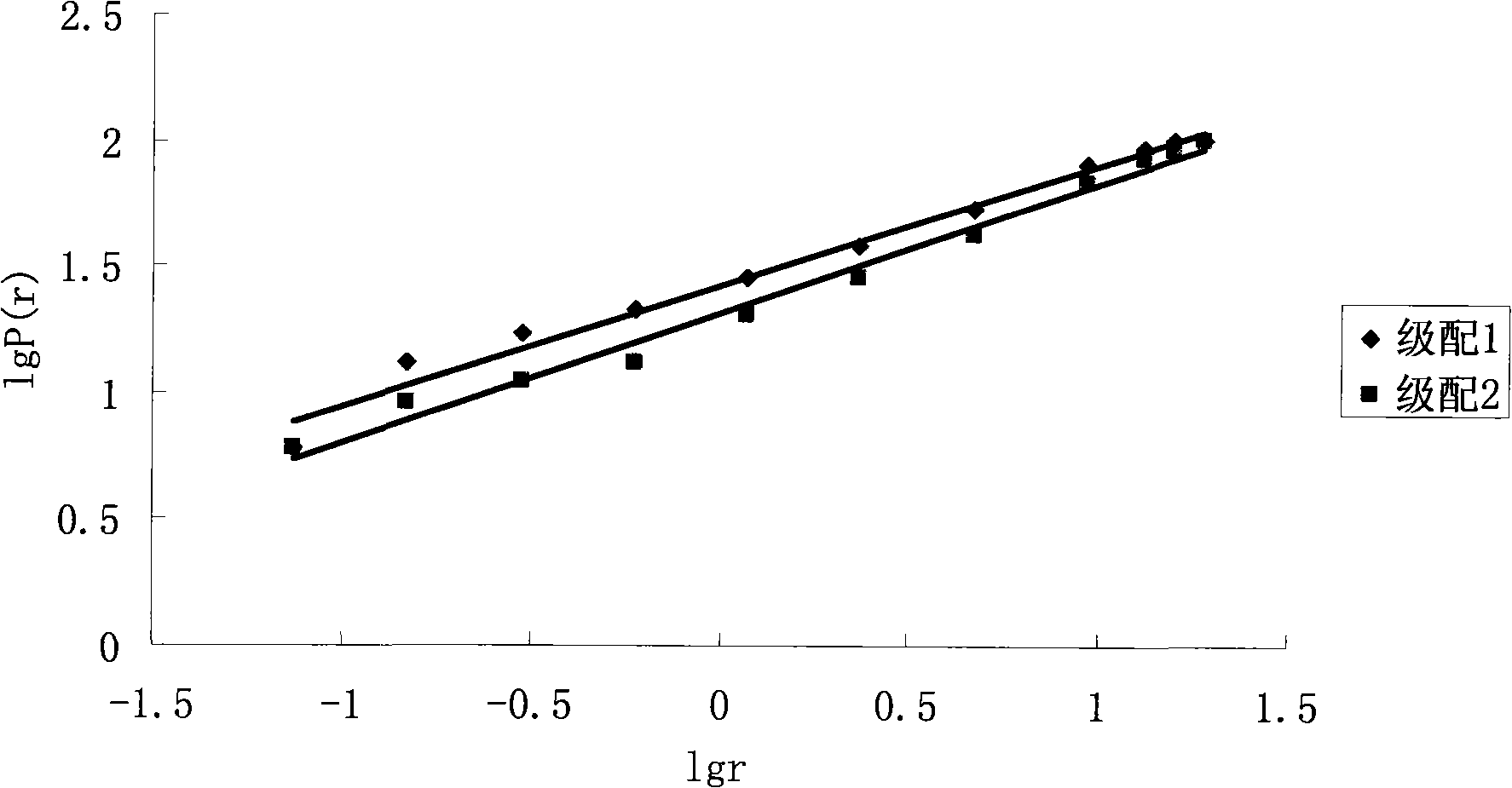

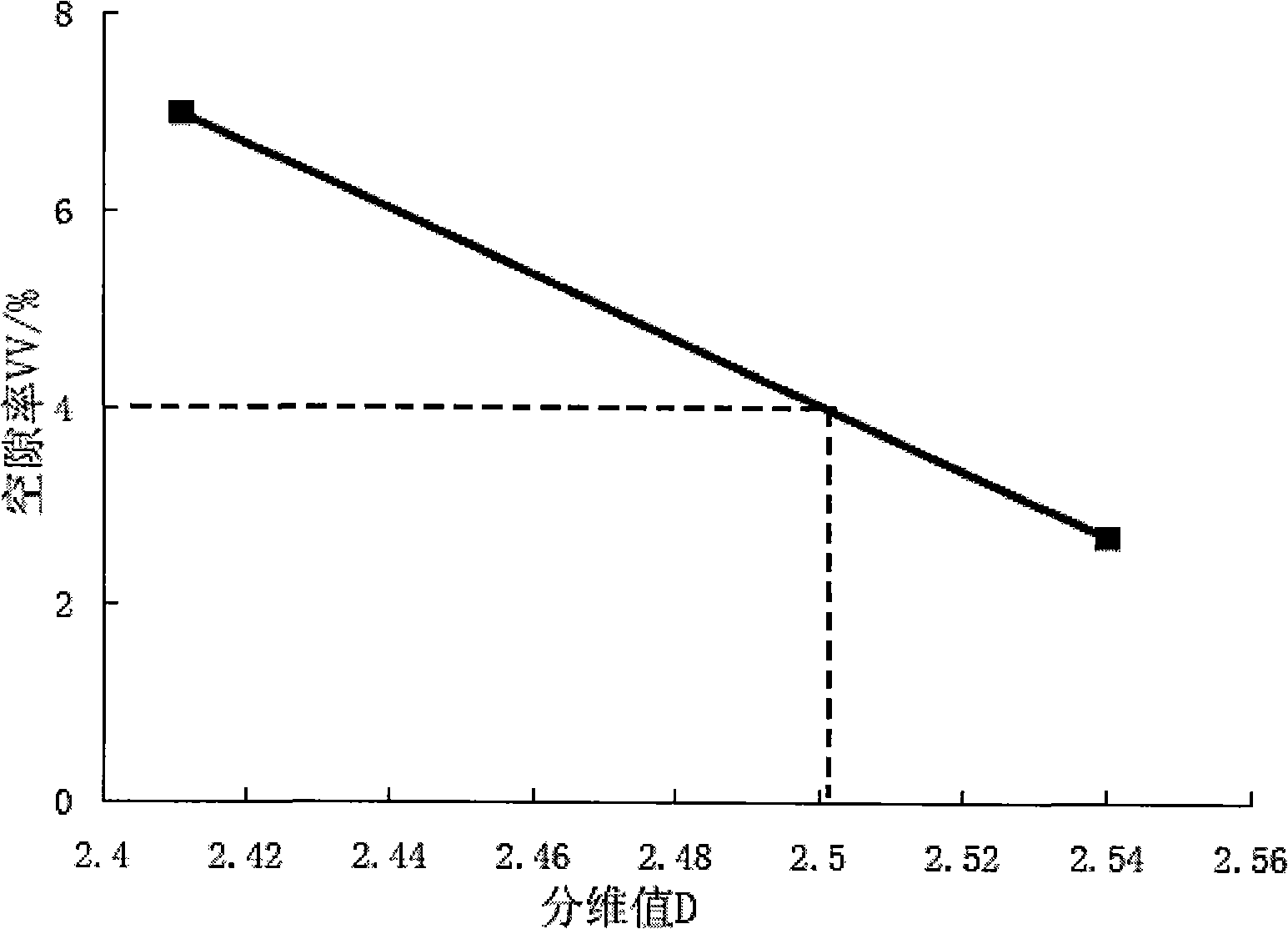

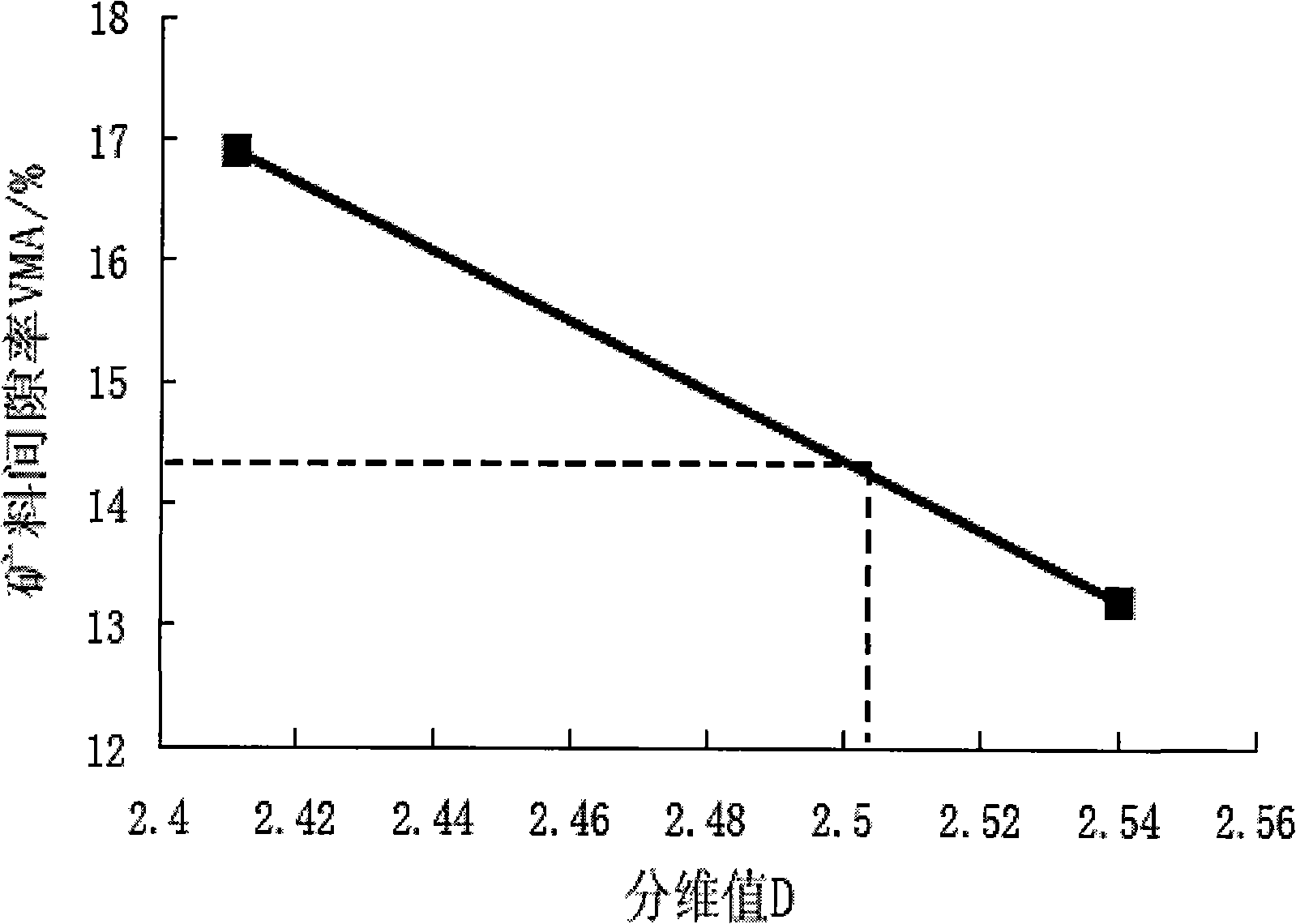

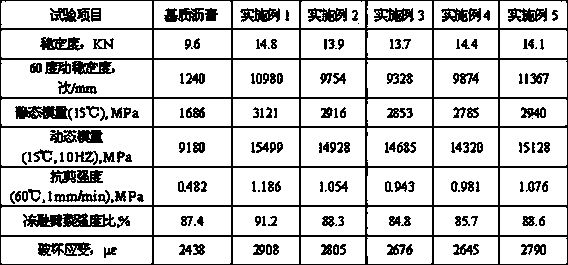

The invention relates to a method of designing a mixed ratio for a bitumen mixture based on fractal and distributional features of ore materials. The method comprises the following steps: (1) mathematical models for particle diameter distribution and mass distribution of the ore materials are set up respectively; (2) the type and the grading limit of the bitumen mixture are determined; (3) raw materials are selected and checked; (4) graduations of two arbitrary groups of the ore materials are determined and corresponding fractal dimension values(D) are worked out; (5) the use level of the bitumen is worked out; (6) the bitumen mixture is prepared by stirring; (7) a Marshall test sample is made, the relative density of the bulk volume of the test sample is determined, the theoretical maximum relative density is determined, and the volume index is worked out; (8) relationship curves between the fractal dimension values(D) and the volume indexes are drawn; (9) the graduation of the ore materials and the optimum use level of the bitumen are determined; (10) the road performance of the bitumen mixture is tested; and (11) the construction mixed ratio of the bitumen mixture is determined. The invention utilizes the fractal theory to set up the mathematical models, and in the process of designing the mixed ratio of the bitumen mixture, the optimum bitumen use level and the optimum graduation of the ore materials meeting and regulating all design rules of the bitumen mixture can be quickly determined.

Owner:LANZHOU JIAOTONG UNIV

High-modulus bituminous mixture additive and preparation method thereof

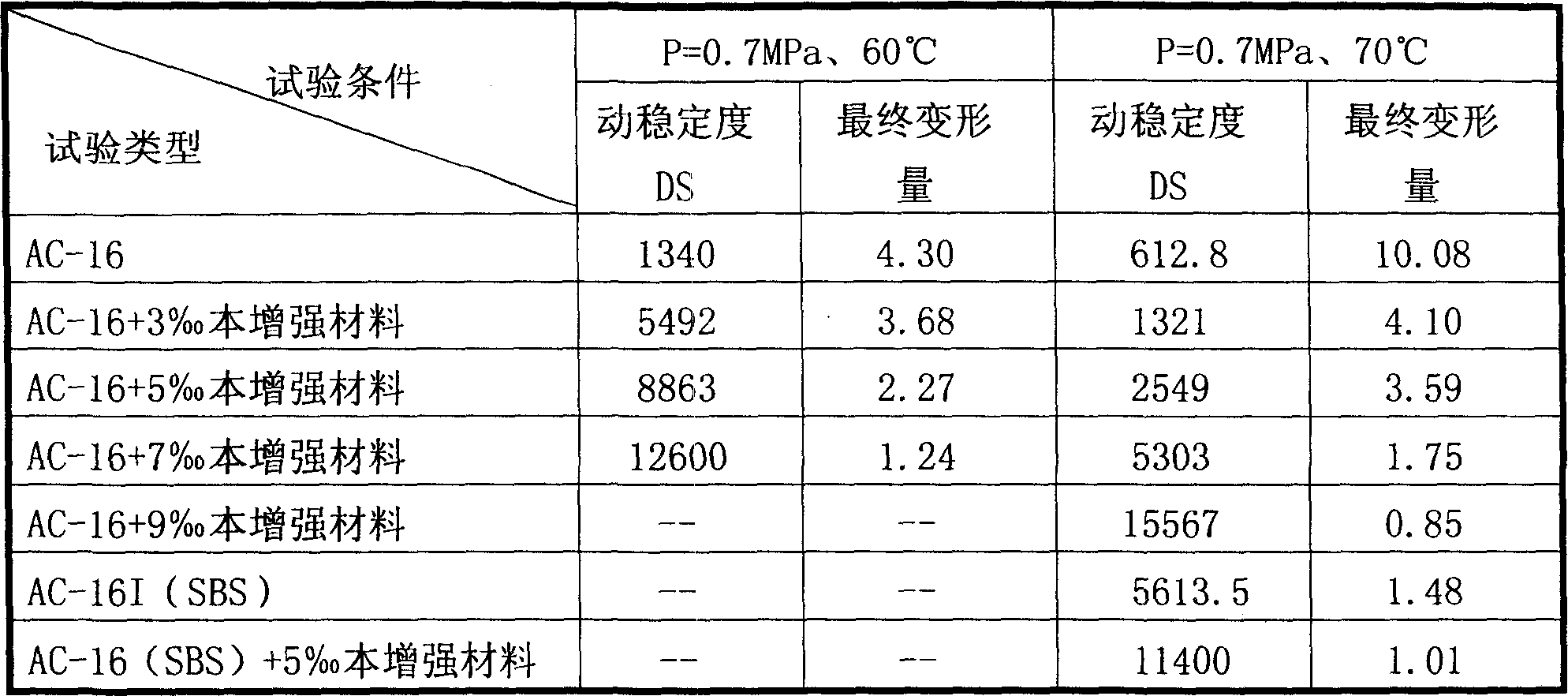

ActiveCN103773006AImprove dynamic stabilityImprove static modulusBuilding insulationsPolymer sciencePavement engineering

The invention discloses a high-modulus bituminous mixture additive and a preparation method thereof. The high-modulus bituminous mixture additive is composed of a modifying main agent, butadiene styrene rubber, polyethylene paraffin, a filling material, an anti-aging component, and a plasticizing component according to a mass percentage of 100:(10-30):(15-40):(40-80):(2-6):(5-20); wherein the modifying main agent consists of one or more components selected from waste PE, polypropylene, and EVA. The preparation method comprises the following steps: evenly mixing the modifying main agent, butadiene styrene rubber and polyethylene paraffin at a temperature of 160 to 190 DEG C, adding the filling material, anti-aging component and plasticizing component into the mixture, evenly mixing under a certain rotation speed, then extruding the mixture by a screw extruder, cooling at the room temperature, and finally cutting into particles. The high-modulus bituminous mixture additive is mainly applied to pavement projects such as new construction and reconstruction of high grade roads and heavy traffic roads, can improve the dynamic stability, static modulus, dynamic modulus and shearing resistant performance of bituminous mixture, thus prominently reduces the damages of rut, displacement, or the like, and can improve the low-temperature anti-cracking performance of high-modulus bituminous mixture at the same time.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

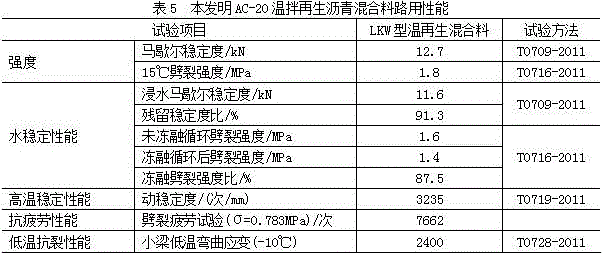

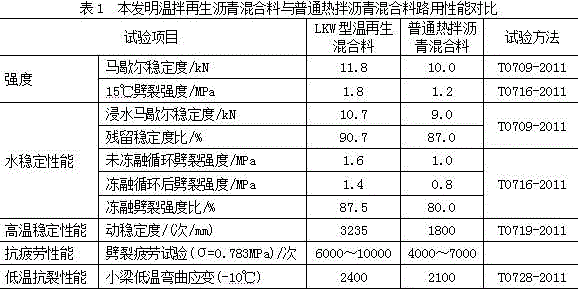

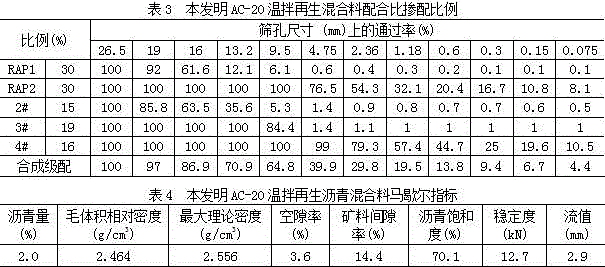

Warm mix recycled asphalt mixture with high RAP (Reclaimed Asphalt Pavement) mixing amount and high performance and preparation method of warm mix recycled asphalt mixture

InactiveCN106186837AHigh strengthImprove fatigue resistanceSolid waste managementClimate change adaptationLow emissionMaterials science

The invention provides a warm mix recycled asphalt mixture with a high RAP (Reclaimed Asphalt Pavement) mixing amount and high performance and a preparation method of the warm mix recycled asphalt mixture, and belongs to the technical field of highway construction materials. The mixture is prepared from the following components in percentage by mass: 50 to 70 percent of RAP material, 28.2 to 47.2 percent of aggregate and 1.8 to 2.8 percent of newly-doped asphalt and warm mix regenerant; the content of the warm mix regenerant is 0.3 to 0.5 percent of the mass of the newly-doped asphalt. The preparation method comprises the following steps of reclaiming and stacking of the RAP material, crushing and screening of a reclaimed material, stacking and detection of a reference material in different bins, and preparation of the warm mix recycled asphalt mixture. The RAP material, the aggregate, the asphalt and the warm mix regenerant are taken according to the requirement of raw material proportioning and are subjected to mixing treatment according to a conventional production technique of a hot-mixed asphalt mixture, wherein the mixing temperature is 120 to 140DEG C, and the mixing time is 20 to 35s, and finally the recycled asphalt mixture is obtained. The warm mix recycled asphalt mixture has the advantages of high RAP mixture ratio, low heating and constructing temperature, good constructability, easiness and pavement performance, low energy consumption, low emission and the like.

Owner:云南省公路科学技术研究院

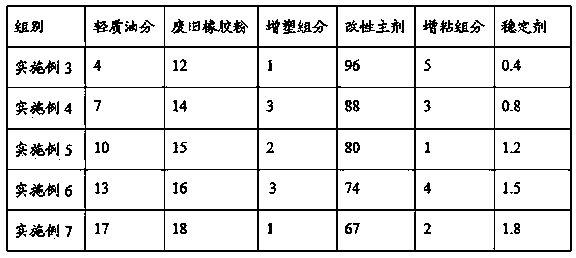

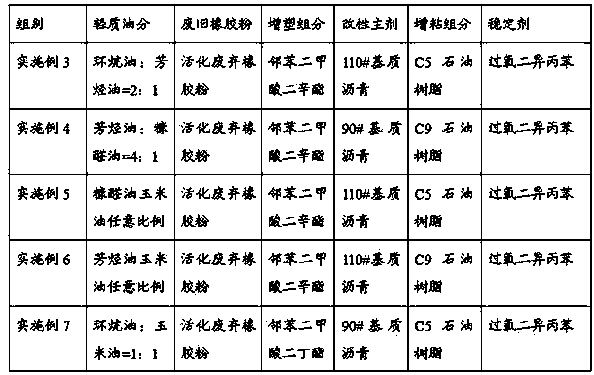

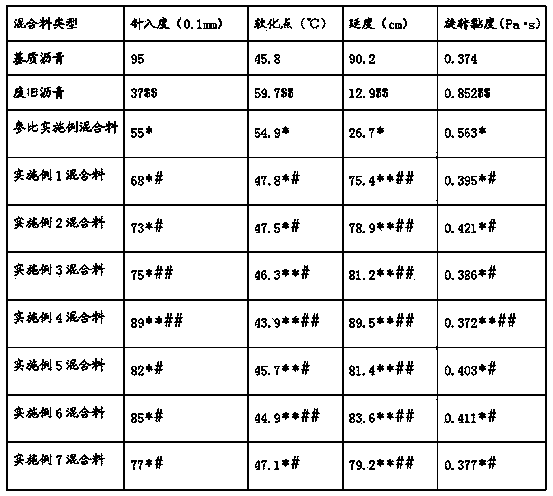

Material for waste asphalt regeneration pavement and preparation method of material

InactiveCN103468006AStrong penetrating powerHigh softening pointSolid waste managementBuilding insulationsRoad engineeringRoad surface

The invention relates to a material for a waste asphalt regeneration pavement and a preparation method of the material and belongs to the field of construction and maintenance of road engineering. For improving the property of waste asphalt and lowering the maintenance cost of the road, the invention provides a material for waste asphalt regeneration pavement and a preparation method of the material. The material for the waste asphalt regeneration pavement comprises lightweight oil, plasticized components, a modified main agent, tackifying components and a stabilizer, and the selection range and constitution of all components are specifically limited. Aging tests and low-temperature performance show that the viscoplastic performance of the regenerated asphalt and the anti-crack property and durability of the pavement can be greatly improved when the material for waste asphalt regeneration pavement is used for regeneration of the waste asphalt; therefore, the material for waste asphalt regeneration pavement has a bright application prospect.

Owner:GUANGZHOU MUNICIPAL ENG MAINTENANCE DEPT

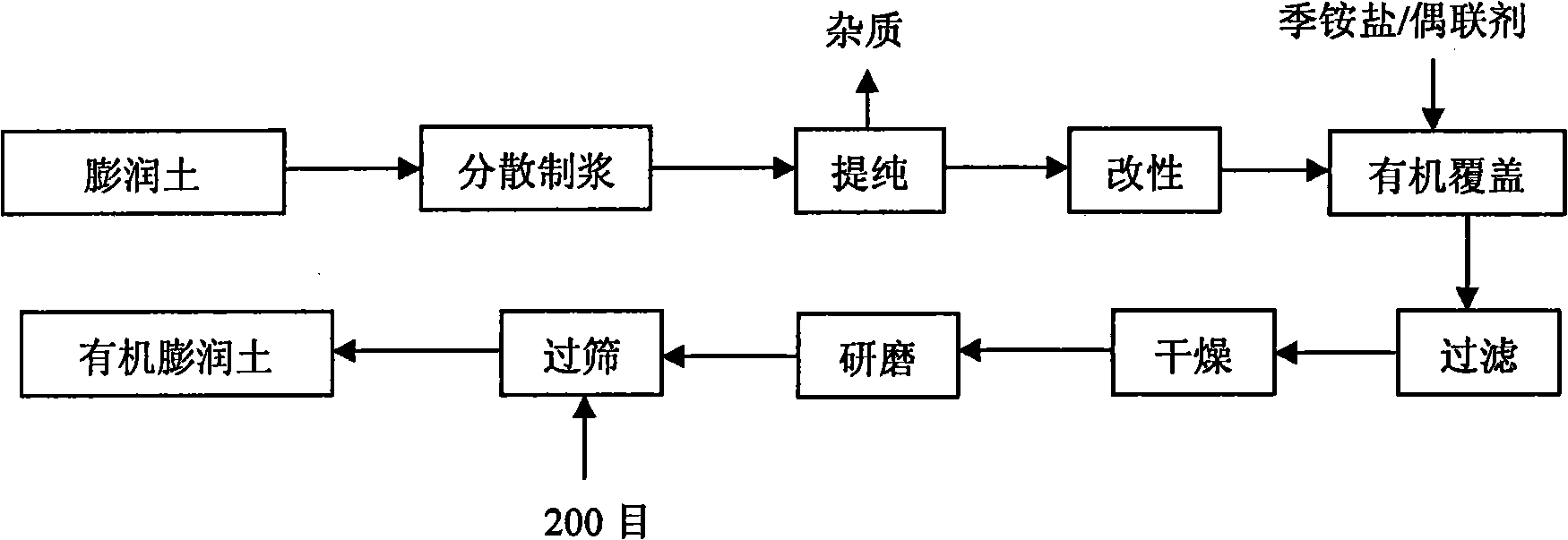

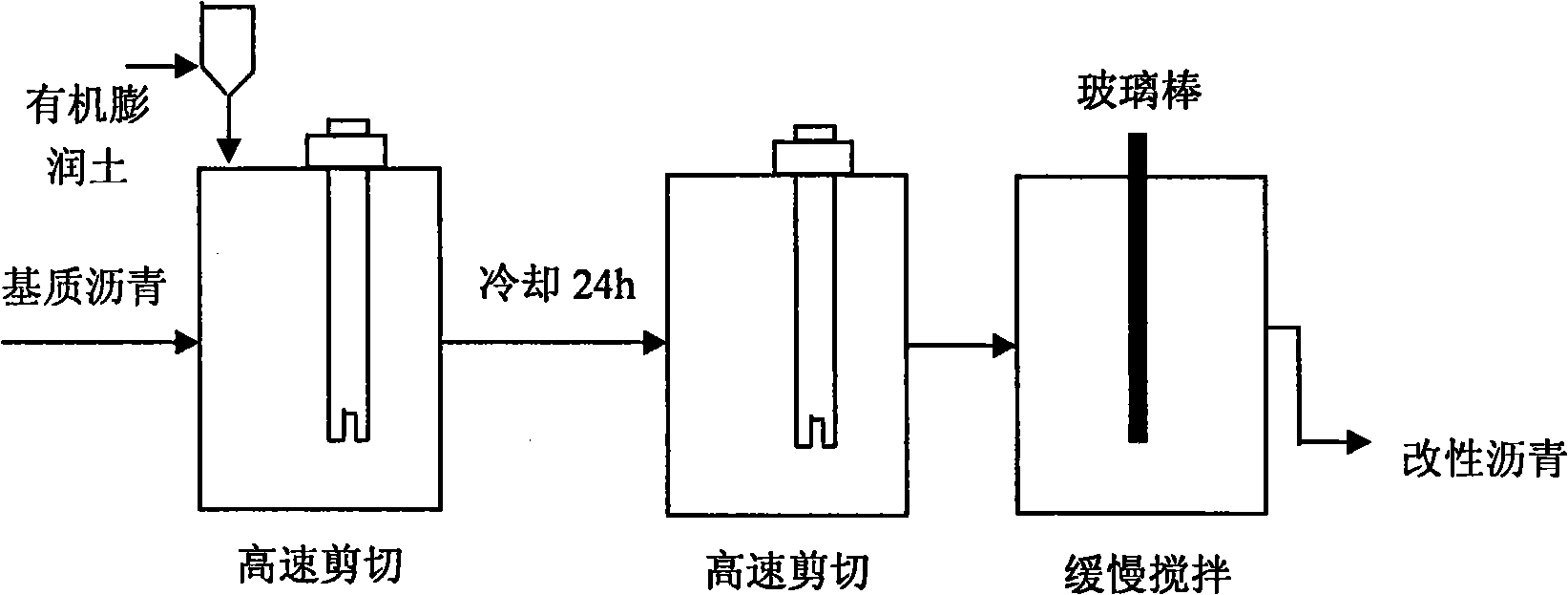

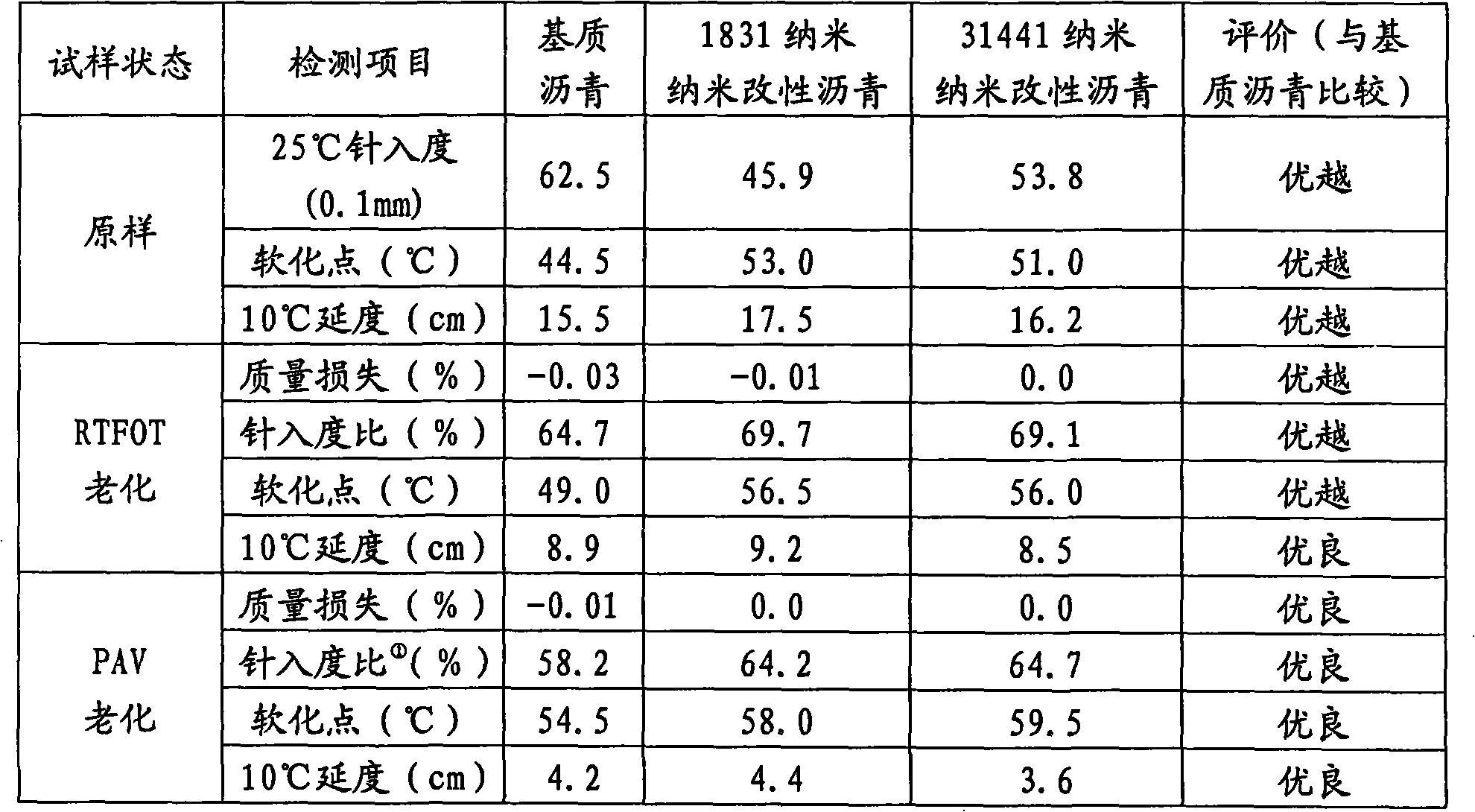

Phyllosilicate nano modified asphalt by dual processing of intercalation and coupling and preparation method thereof

InactiveCN101525492AImprove high temperature stabilityEnhanced toughening effectBuilding insulationsOrganificationCoupling

The invention adopts organic cation intercalator and coupling agent to carry out organification intercalation processing on laminated clay silicate, so as to prepare organification laminated clay silicate and mix the silicate with liquated road asphalt to form the modified asphalt. The invention also relates to the preparation process of the modified asphalt. The modified asphalt of the invention not only has better road performance than that of matrix asphalt but also prevents premature failure of asphalt road surface and lengthens service life of the road surface; in addition, the cost of materials and processing devices is far lower than the cost of polymer nano modified asphalt.

Owner:CHONGQING JIAOTONG UNIVERSITY

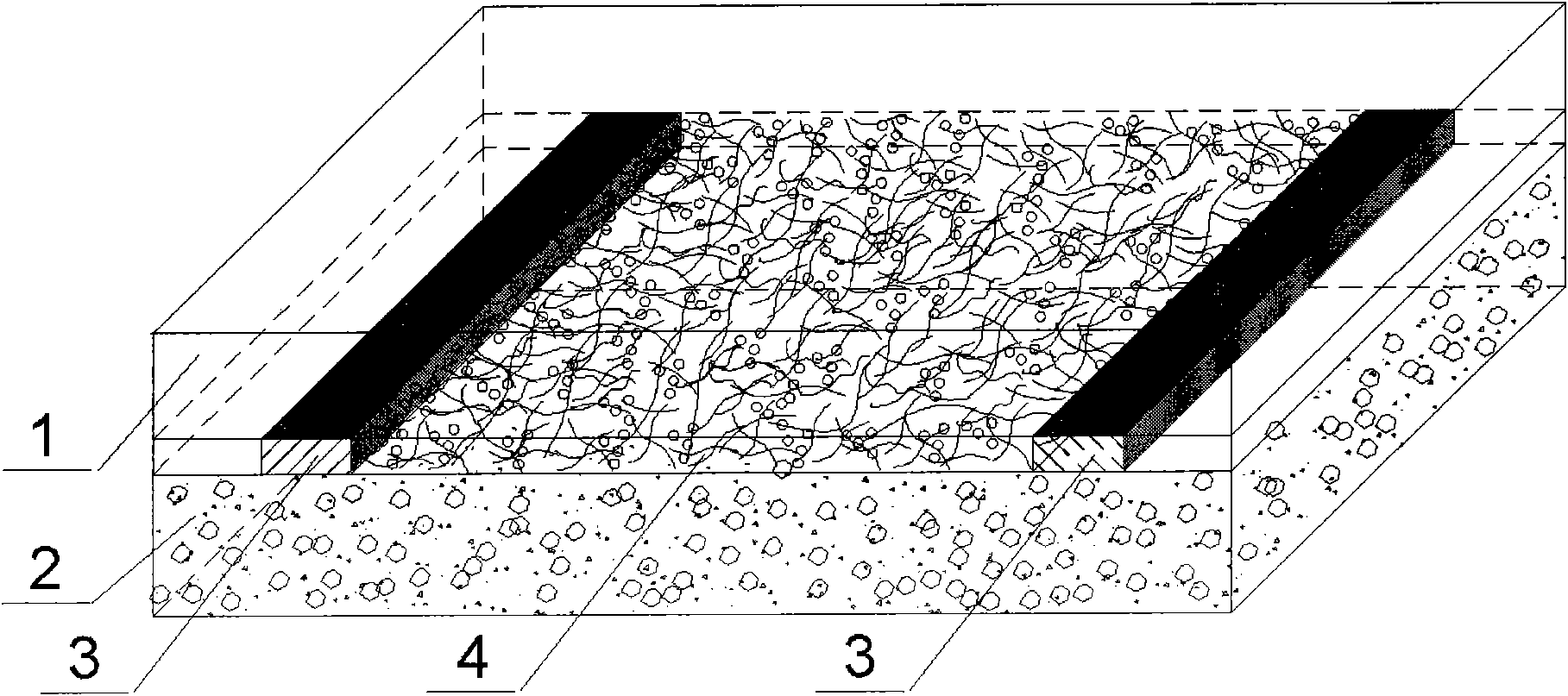

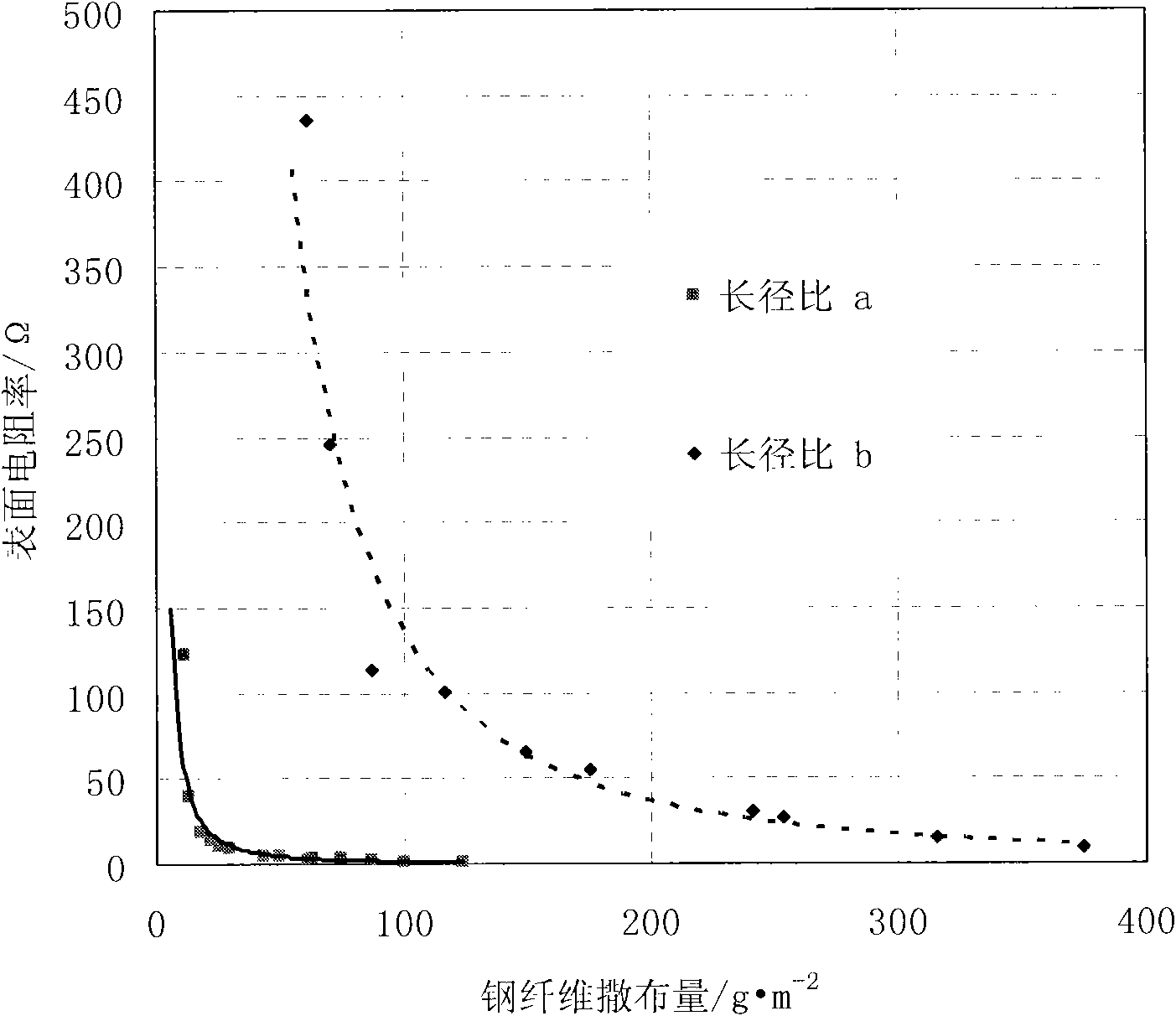

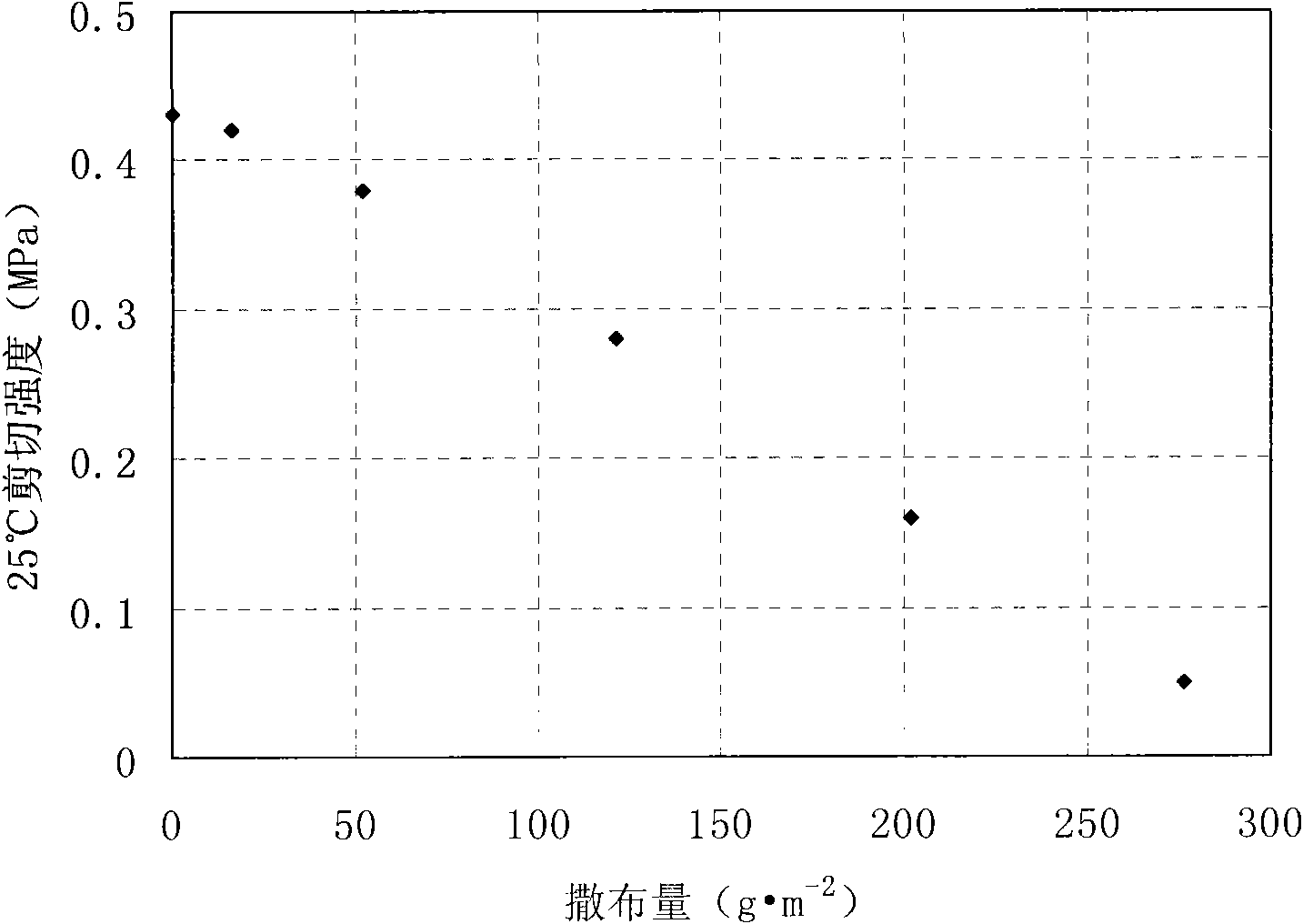

Layered steel fiber conductive bituminous concrete

ActiveCN101806028ALow costImprove conductivityIn situ pavingsPaving detailsCrack resistanceMetallurgy

The invention relates to a steel fiber bituminous concrete, in particular to a layered steel fiber conductive bituminous concrete. The layered steel fiber conductive bituminous concrete is characterized by comprising a bituminous concrete pavement, a steel fiber layer and a lower bearing layer which are sequentially arranged from top to bottom, wherein electrodes are embedded in the steel fiber layer; the steel fiber layer consists of steel fiber and conductive emulsified asphalt and is uniformly paved on the surface of the lower bearing layer with a spreading method, the conductive emulsified asphalt is sprayed on the steel fiber, the spreading amount of the steel fiber is 170-330g / m<2>, and the spraying amount of the emulsified asphalt is 0.6-0.81g / m<2>. The invention has the characteristics of low cost of construction, simple and convenient construction, easy control of quality and favorable conductive performance, and meanwhile, the high-temperature stability and the low-temperature crack resistance are improved. The layered steel fiber conductive bituminous concrete is applied to deicing and snow melting of bituminous pavements and self-healing or heat repairing of the diseases of bituminous pavements.

Owner:武汉理工大产业集团有限公司

Bituminous mixture used for thin layer overlay of cement concrete pavement and preparation and construction methods of bituminous mixture

The invention discloses a bituminous mixture used for a thin layer overlay of cement concrete pavement and preparation and construction methods of the bituminous mixture. The bituminous mixture comprises mineral aggregate, bitumen, a fiber stabilizer and an additive, wherein filler in the mineral aggregate is copper tailing power. The bituminous mixture has the advantages that the copper tailing power is used as the filler in the bituminous mixture, thus copper tailing is comprehensively recycled. Besides, the bituminous mixture is superior in performances, is easily compacted, and can be paved on the cement concrete pavement for 1.5-2.5cm; the damaged pavement can be quickly repaired after construction; the smoothness and the skid resistance of the pavement are restored; the quality of the pavement is improved; the service life of the pavement is prolonged; driving comfort and safety are improved; the pavement can also be precured; the construction cost is lowered; energy and resources are saved; influences on environment and facilities are reduced; and the like. Moreover, the preparation method and the construction method of the bituminous mixture are simple and practicable, easy to operate and high in practicability.

Owner:江苏航卓建设股份有限公司

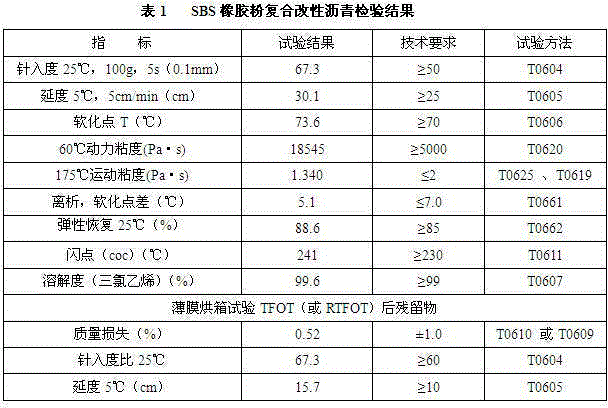

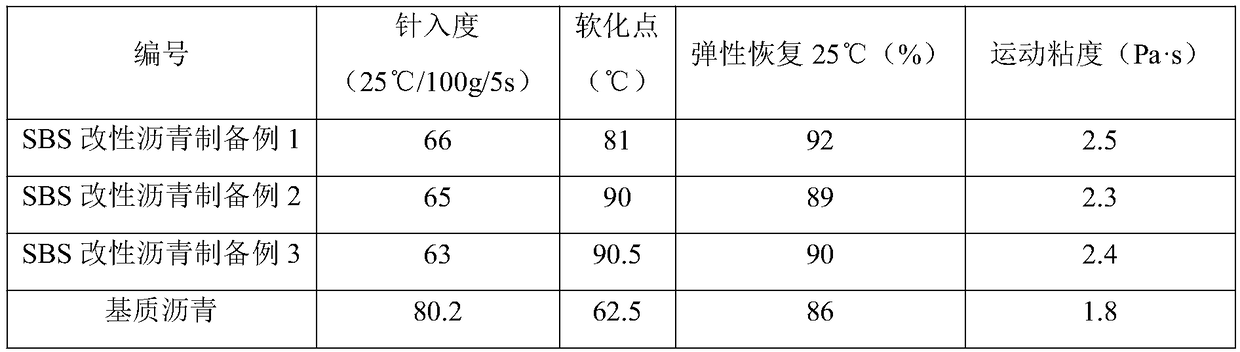

SBS-rubber powder composite modified asphalt and preparation method thereof

ActiveCN105176115AReduce waste of resourcesMaintain the balance of the ecological environmentBuilding insulationsPitch blendeWaste rubber

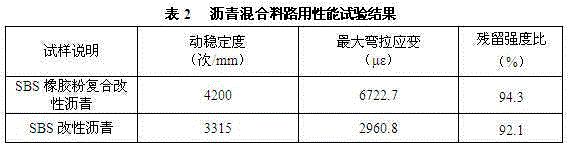

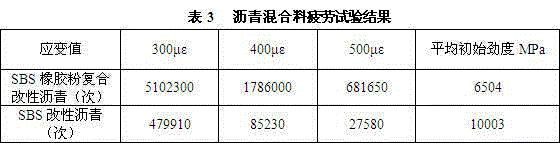

The invention belongs to the technical field of materials for asphalt pavements, and particularly relates to SBS-rubber powder composite modified asphalt and a preparation method thereof. The SBS-rubber powder composite modified asphalt is prepared from, by mass, 15-21 parts of waste rubber powder, 2-3 parts of SBS modifying agents, 0.2-0.4 part of stabilizing agents, 0.03-0.04 part of activating agents and 75-82 parts of asphalt. The preparation method of the asphalt comprises the steps that the matrix asphalt is preheated to 180 DEG C, the SBS modifying agents are added into the hot asphalt, high-speed shearing dispersion is performed for 20 min, then the activating agents, the rubber powder and the stabilizing agents are added, and high-speed shearing dispersion is performed on the temperature condition of 185 DEG C for 2 h. According to the SBS-rubber powder composite modified asphalt, a pavement paved with SBS-rubber powder composite modified asphalt mixtures has the advantages of being stable, comfort, low in noise and the like, the quality of the pavement can be obviously improved, the service life of the pavement can be prolonged, use is convenient, price is low, the properties are stable, and not only can the anti-rutting performance of the asphalt mixtures be improved, but also the obvious effects on improving the low-temperature crack resistance, water stability and fatigue resistance of the asphalt mixtures can be achieved.

Owner:辽宁省交通科学研究院有限责任公司

Waste superpolymer based comprehensive asphaltic-mixture modifier and preparation method and application thereof

InactiveCN104861676AImprove high temperature performanceImprove high and low temperature performanceBuilding insulationsFiberCrack resistance

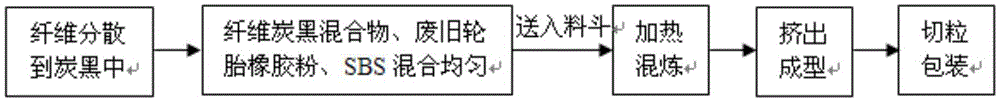

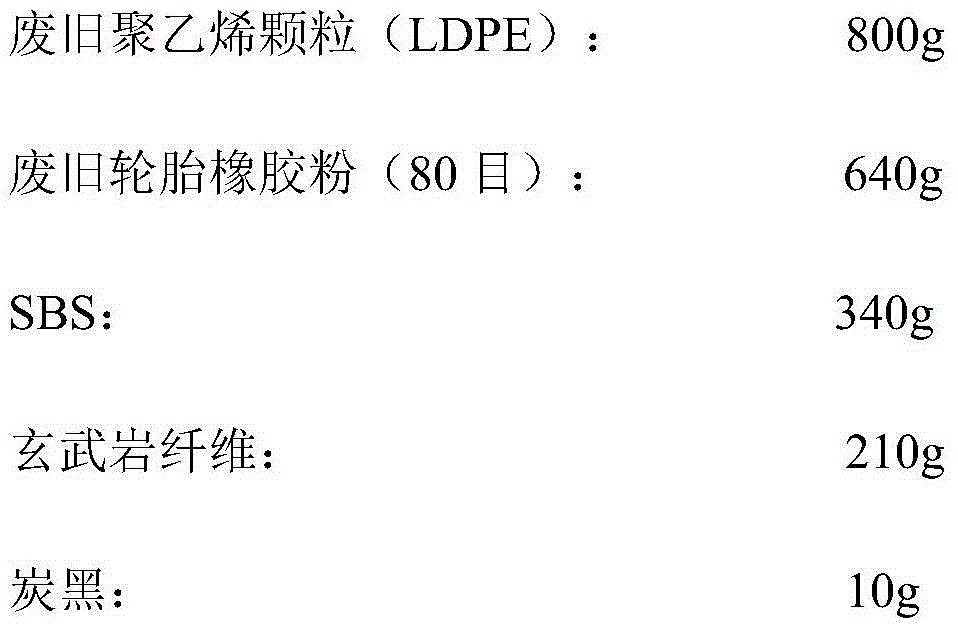

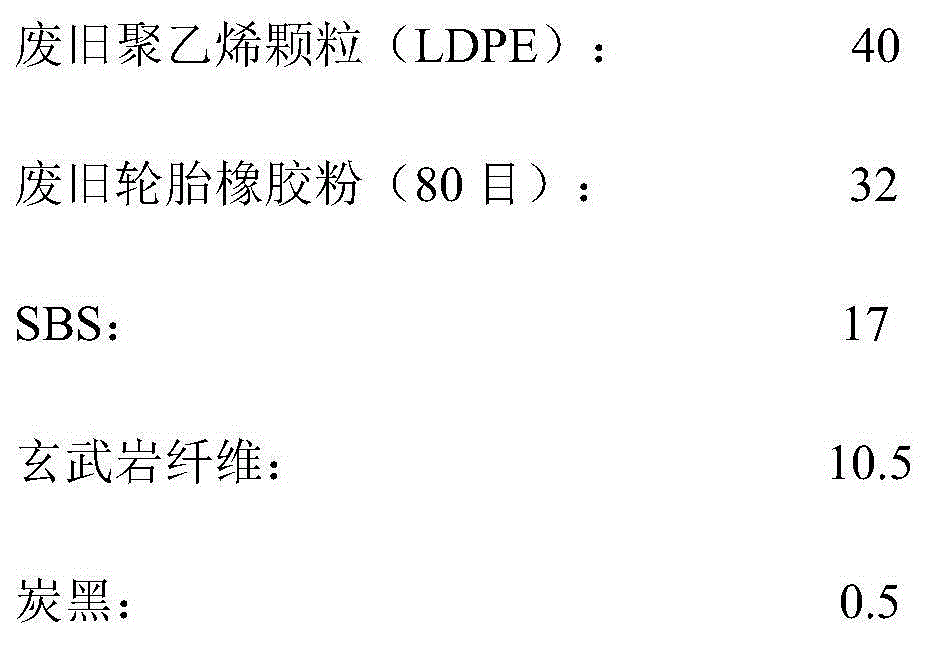

The invention belongs to the technical field of asphalt pavement materials and relates to a waste superpolymer based comprehensive asphaltic-mixture modifier and a preparation method and application thereof. The comprehensive asphaltic-mixture modifier comprises the following inorganic mineral filling materials in parts by weight: 30-60 parts of waste / reclaimed polyethylene particles, 20-50 parts of waste tire rubber powder, 10-20 parts of SBS, 5-15 parts of fiber and 0.5-1.5 parts of carbon black. The preparation method comprises the steps of raw material mixing, stirring, heating, mixing, extrusion and cutting. An application method of the comprehensive asphaltic-mixture modifier is simple, and the comprehensive asphaltic-mixture modifier of which the weight accounts for 0.1-0.3 percent of the weight of ores can be directly added to a mixing kettle. The product provided by the invention can comprehensively improve the high-temperature rutting resistance and low-temperature crack resistance of an asphaltic mixture and has remarkable economic benefits and social benefits.

Owner:SHANDONG UNIV +1

Construction method for rubber grain asphalt concrete pavement

InactiveCN101153478AImprove deformation abilityGood flexibilityIn situ pavingsSnowpackWear resistant

A method for constructing rubber particles asphalt concrete road surfaces relates to a method for constructing asphalt concrete road surfaces, aiming to resolve the problems that: the asphalt concrete road surfaces have weak wear-resistant, and the attachment coefficient and the adhesive force are reduced and vehicles have the problem of braking stability when the road surfaces are covered by snow and ice. The construction method comprises the following steps that: compositions by weigh percentage of the following materials are adopted: 76.5 to 91.5 percent of mineral aggregate, 2.5 to 7.5 percent of asphalt, 4 to 10 percent of mineral powder and 2 to 6 percent of rubber particles; the mineral aggregate is heated up to 190 to 200 DEG C, the rubber particles are added into the mineral aggregate with mixing about 20 to 25 seconds, the asphalt heated up in advance and the mineral powder are added into the rubber particles and the mineral aggregate with mixing lasting for 70 to 80 seconds, and then the road surfaces are subject to the pavement, the first stage initial pressure, the first and the second stage re-pressure and the second stage final pressure. The invention can increase the deformation capabilities of the road surfaces effectively, improve the bond state between the road surfaces and snow, and the invention can improve the attachment coefficient, increase the adhesive force, and improve the braking and turning operation stability of vehicles when the road surfaces are cover by snow and ice.

Owner:HARBIN INST OF TECH

Special low-viscosity easy-dispersion regenerant for modified asphalt and preparation method thereof

InactiveCN102140253AImprove high temperature stabilityImprove low temperature crack resistanceBuilding insulationsProcess engineeringAnoxomer

The invention provides a special low-viscosity easy-dispersion regenerant for modified asphalt and a preparation method thereof. The regenerant comprises the following components in parts by weight: 80-100 parts of regeneration composition, 1.0-10 parts of vulcanizer, 0.5-10 parts of accelerator, 1-10 parts of activating agent, 0-5 parts of anti-reducing agent, 0.1-2 parts of scorch retarder and 0.1-3 parts of antioxidant. The invention also discloses the preparation method of the asphalt regenerant. The processing steps comprises: a, pre-heating a reaction kettle, slowly adding the regeneration composition weighed in proportion into the reaction kettle, gradually heating to 40-100 DEG C and continuously stirring; b, putting the vulcanizer weighed in proportion into the reaction kettle, continuing to heat until the temperature is 50-130 DEG C, accelerating the stirring speed until the vulcanizer is evenly dispersed; c, continuing to rapidly stir and gradually cooling, as well as adding the scorch retarder and the antioxidant which are weighed in proportion in the process of stirring and cooling; and d, while cooling to 20-60 DEG C, adding the activating agent, the anti-reducing agent and the accelerator which are weighed in proportion, evenly stirring, and cooling to room temperature so as to obtain the special low-viscosity easy-dispersion regenerant product for the modified asphalt. The low-viscosity easy-dispersion regenerant has the characteristics of available raw material, simple preparation process and sustainable development, and meets green ecology.

Owner:SOUTHEAST UNIV

Epoxy asphalt for steel bridge deck pavement and preparation method thereof

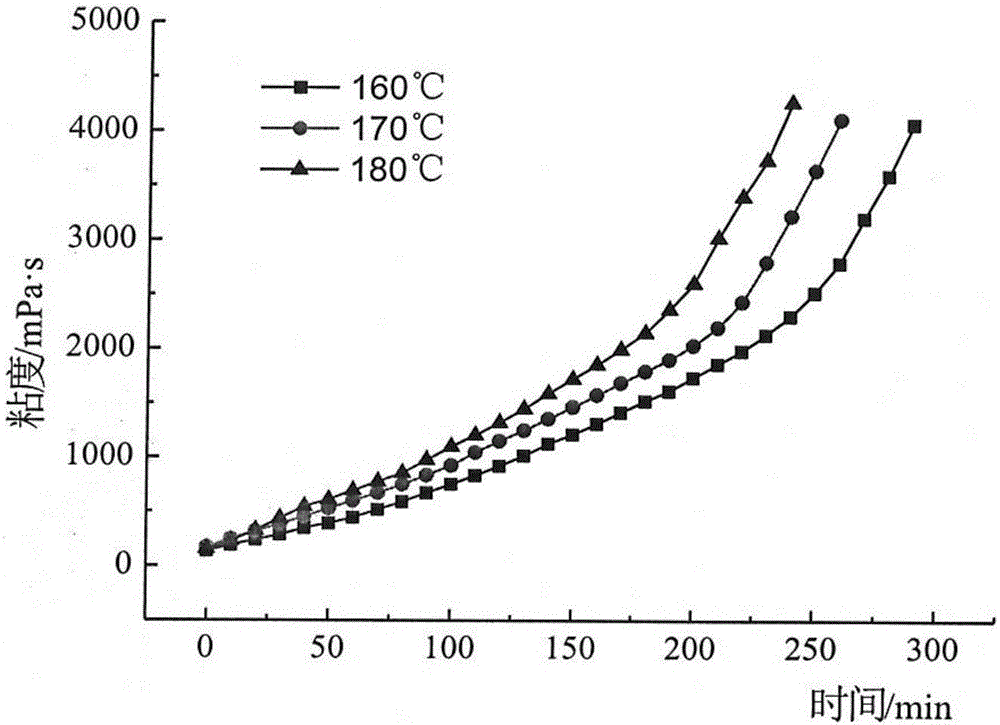

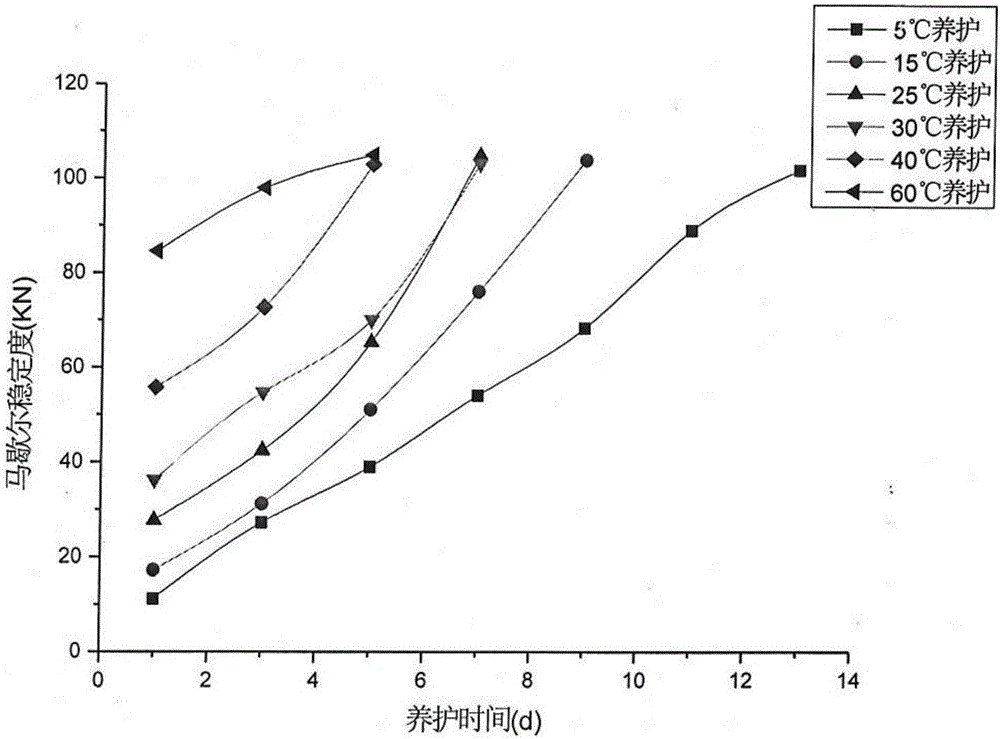

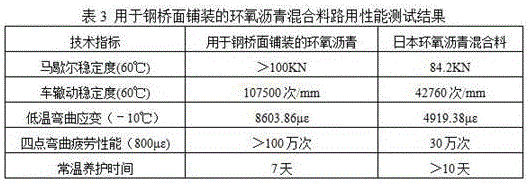

The invention discloses epoxy asphalt for steel bridge deck pavement and a preparation method thereof. The epoxy asphalt is prepared by a component A, a component B and 50-100 parts of petroleum asphalt, wherein the component A comprises 50-100 parts of epoxy resin, 0-40 parts of rubber modified epoxy resin, 1-10 parts of accelerator and 5-20 parts of diluent; the component B comprises 35-60 parts of latent curing agent, 1-10 parts of anhydride curing agent, 1-10 parts of toughening agent and 1-15 parts of compatibilizer. The epoxy asphalt has the advantages that the epoxy asphalt is high in toughness, high in stability, excellent in low-temperature crack resistance and fatigue durability, sufficient in construction reserved time in an environment of 160-190 DEG C, short in maintenance time under normal temperature, excellent in comprehensive performance, applicable to common steel bridge deck pavement and especially applicable to the deck pavement of heavy-load, high-temperature and large-span steel bridges and the paving of airport runway pavements and high-temperature-region pavements.

Owner:重庆市智翔铺道技术工程有限公司

Modified asphalt mixture modifier and preparation method therefor

InactiveCN105153511AImprove high temperature anti-rutting performanceImprove low temperature crack resistanceBuilding insulationsMasterbatchAsphalt

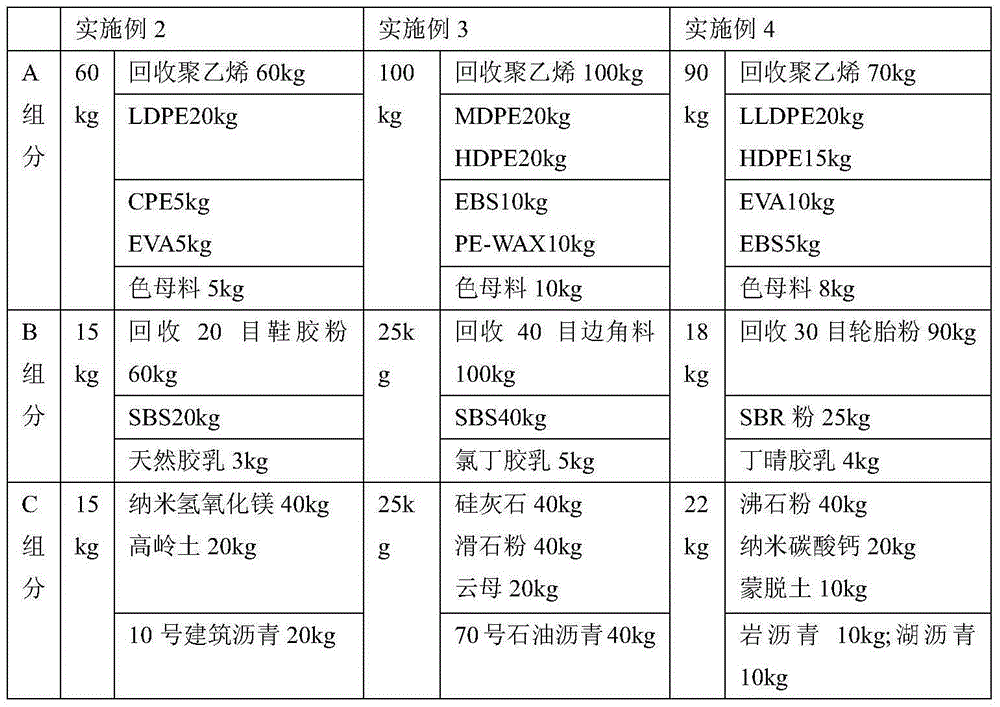

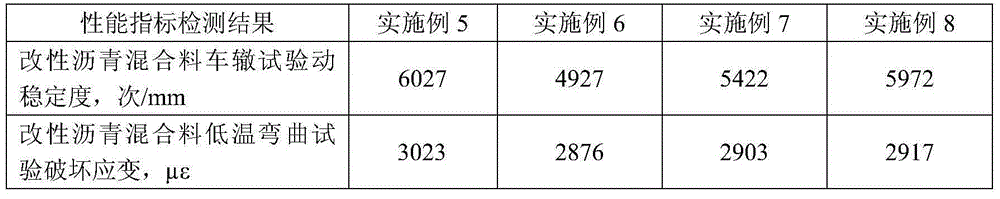

The invention relates to a modified asphalt mixture modifier and a preparation method therefor. The modified asphalt mixture modifier is prepared from the following components in parts by weight: 60-100 parts of a component A, 15-25 parts of a component B and 15-25 parts of a component C, wherein the component A is prepared from the following components in parts by weight: 60-100 parts of recovered polyethylene, 20-40 parts of polyethylene, 10-20 parts of auxiliaries and 5-10 parts of color masterbatch; the component B is prepared from the following components in parts by weight: 60-100 parts of recovered rubber powder, 20-40 parts of rubber powder and 3-5 parts of latex; the component C is prepared from the following components in parts by weight: 60-100 parts of inorganic powder and 20-40 parts of an asphalt material. According to the modifier provided by the invention, the comprehensive performance of the modified asphalt mixture can be improved. By directly inputting the modifier into a stirring cylinder of a mixing plant, stirring and modification are synchronously implemented. The produced modified asphalt mixture is superior to a conventional modified asphalt mixture in performance.

Owner:陕西长大博源公路养护科技有限公司

Modified asphalt viscosity decreasing agent

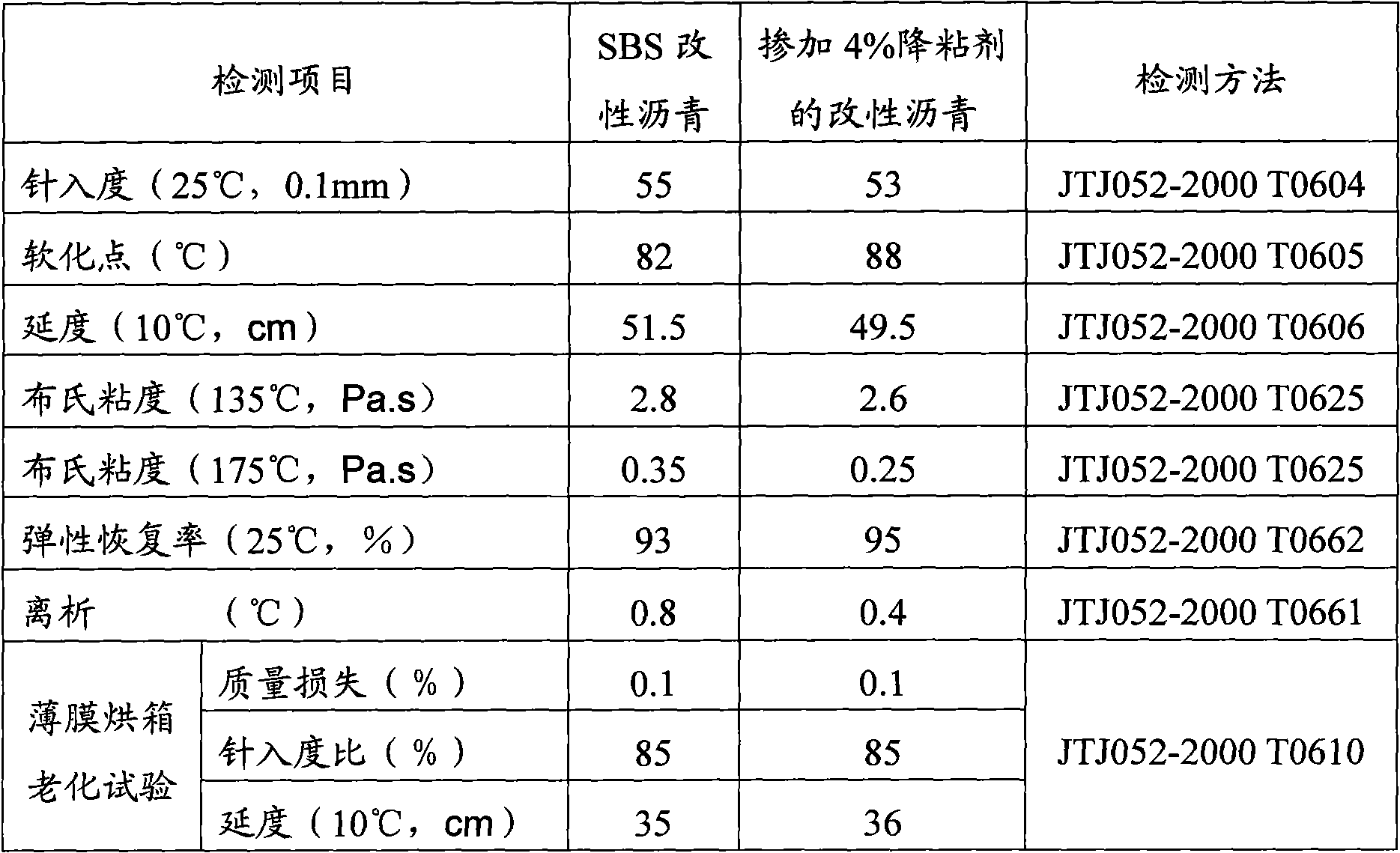

ActiveCN101781468AReduce high temperature viscosityImprove low temperature crack resistanceBuilding insulationsCasting typesEngineering

The invention provides a modified asphalt viscosity decreasing agent which relates to a paving material for roads, bridges and tunnels. The viscosity decreasing agent is prepared from the following components in parts by weight: 4-20 parts of organic acid, 1-30 parts of surface active agent, 5-80 parts of synthesis paraffin, and 1-30 parts of compatilizer. After the viscosity decreasing agent is doped, the high-temperature viscosity of the modified asphalt is greatly decreased, while other various indexes are not changed. Simultaneously, compared with the common modified asphalt, after the viscosity decreasing agent is doped, the concrete stirring temperature, low-temperature property and fatigue property of the casting type asphalt are greatly improved. The invention is mainly used for road petroleum asphalt and SBS modified asphalt.

Owner:重庆市智翔铺道技术工程有限公司

High-modulus asphalt concrete material doped with coal gasification slag and preparation method thereof

InactiveCN105417987AImprove adhesionImprove compatibilitySolid waste managementFiberPolymer modified

The invention relates to a high-modulus asphalt concrete material doped with coal gasification slag. The high-modulus asphalt concrete material doped with the coal gasification slag is prepared from, by weight, 4.5-5.5 parts of polymer modified asphalt, 80-88 parts of aggregate, 10-20 parts of the coal gasification slag and 0.2-0.3 part of polyacrylonitrile fiber. The invention further provides a preparation method of the high-modulus asphalt concrete material doped with the coal gasification slag. The high-modulus asphalt concrete material doped with the coal gasification slag and the preparation method thereof have the advantages that the coal gasification slag is rich in graphite phase and good in compatibility with asphalt and improves the adhesivity of the asphalt and the aggregate; the elasticity modulus and stiffness modulus of asphalt mortar are increased, accumulated deformation of the mixture is reduced, and ruts of an asphalt concrete pavement are effectively restrained; the asphalt concrete material is doped with the polyacrylonitrile fiber, good bridging and reinforcing effects are achieved, high-temperature stability, low-temperature crack resistance, anti-fatigue performance and water stability of high-modulus asphalt concrete are further promoted, and the service life of the asphalt pavement is prolonged; the coal gasification slag is used in an environment-friendly way, and a successful model of green development is achieved.

Owner:BAOJI HUIDE SANFEI DEV & UTILIZATION CO LTD

High-grade road asphalt prepared from coal tar pitch

ActiveCN102504556AIncrease elasticityImprove ductilityBuilding insulationsCrack resistanceCross linker

The invention relates to asphalt, in particular to high-grade road asphalt prepared from coal tar pitch. The high-grade road asphalt comprises the following raw materials by part by weight: 30 to 70 parts of coal tar pitch, 15 to 30 parts of petroleum asphalt, 30 to 50 parts of solvent naphtha, 3 to 5 parts of composite polymer additive, 2 to 10 parts of antiager, and 0.3 to 0.5 part of cross linker. The high-grade road asphalt prepared from the coal tar pitch has the advantages as follows: the addition of the petroleum asphalt is reduced, and the usage amount of the coal tar pitch is increased; and the cost is reduced, and the performances of the road asphalt prepared from the coal tar pitch are improved, that is, the Engler viscosity of the asphalt is increased, the asphalt softening point is raised, the penetration degree is lowered, the high temperature stability is improved, the low-temperature ductility is greatly increased, and the low-temperature cracking resistance is remarkably improved.

Owner:车春玲

Anti-rutting additive with high modulus and high strength as well as preparation method and applications thereof

The invention relates to an anti-rutting additive with high modulus and high strength for an asphalt mixture as well as a preparation method and applications thereof. The polymer composite additive of the asphalt mixture is formed by mixing crosslinkable polyethylene, random polypropylene, tackifier, styrene-butadiene rubber and fiber, wherein the tackifier is terpene resin. The production method of the anti-rutting additive comprises the following steps: adding the raw materials in a proper processing device so that the raw materials are fully mixed and reacted; and granulating and shaping. The anti-rutting additive has cheap price, and can be used for increasing the road performances of the asphalt mixture such as high temperature stability, low temperature crack resistance and water stability, and prolonging the service life of pavement.

Owner:北京厚德交通科技股份有限公司

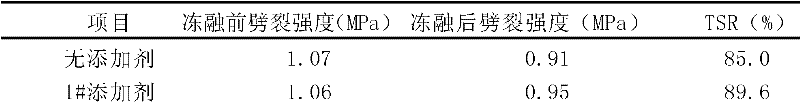

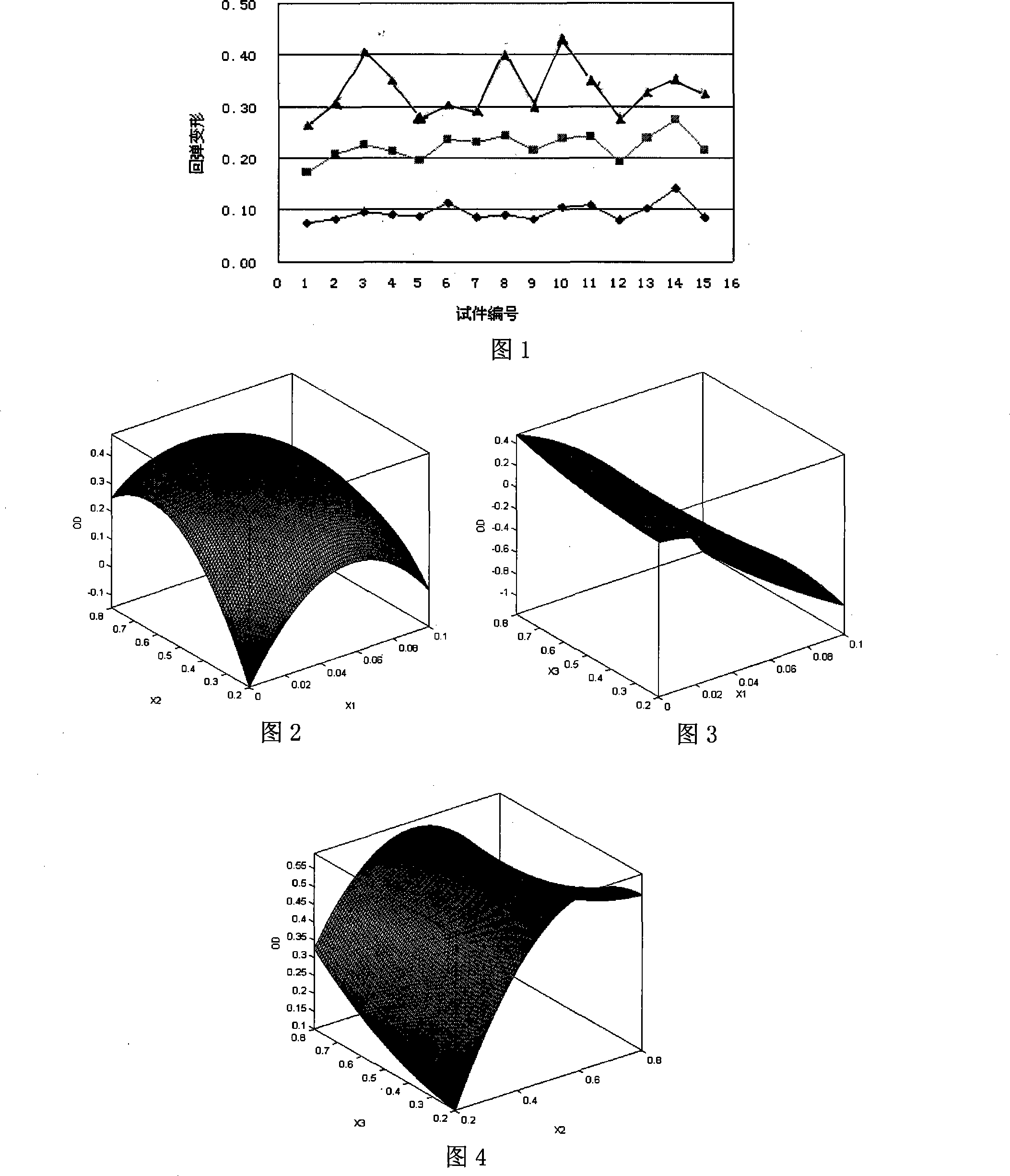

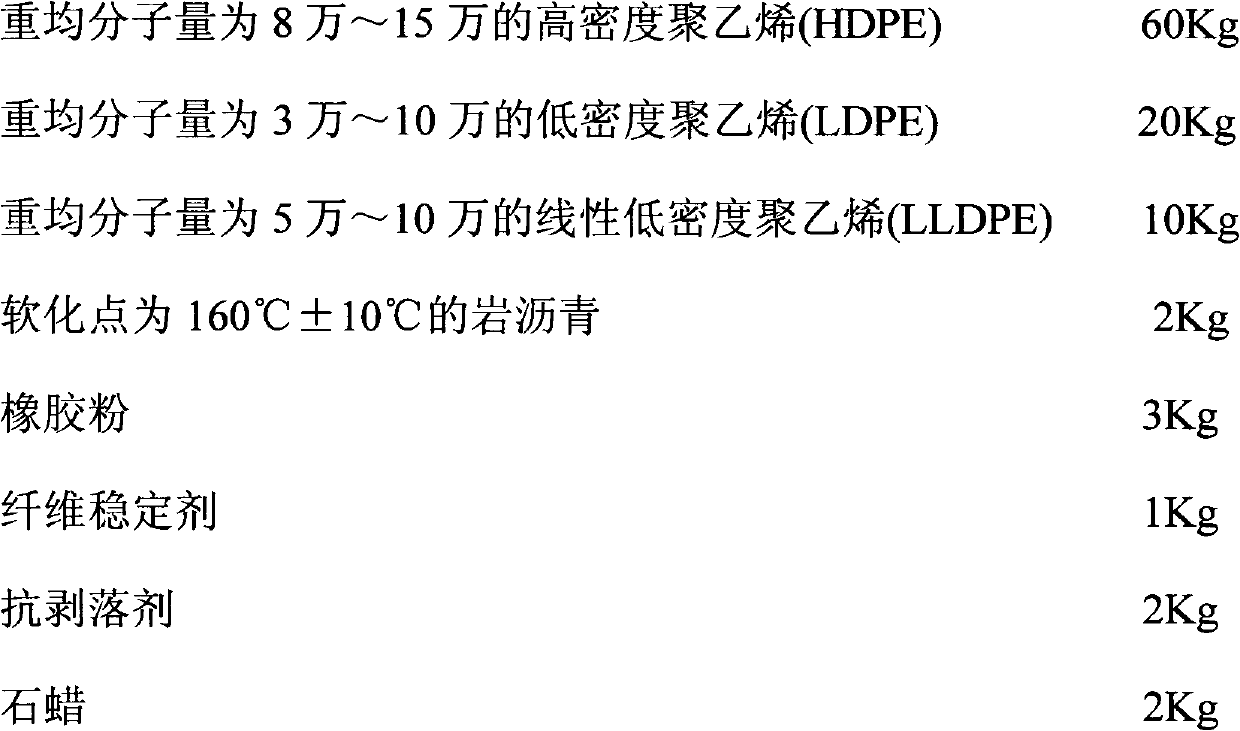

Method for determining composition ratio range of rubber particle asphaltum mixture

InactiveCN101161703AImprove skid resistanceImprove noise reductionBuilding insulationsSpecial data processing applicationsCrack resistanceControl objective

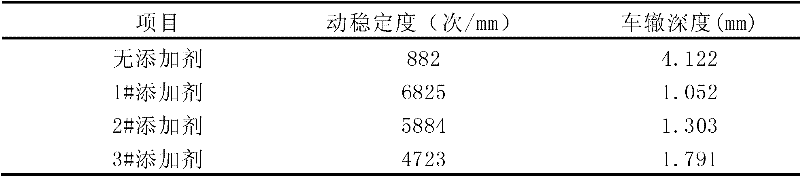

The present invention relates to a method for determining the proportioning range of components of rubberized bitumen composites, which can be realized in the following steps: 1. determining there factors and the numeric areas; 2. determining the control objectives; 3. calculating the overall rating value of the objectives and drawing response surface figure; and 4. analyzing the response surface figure to obtain the optimal value of the proportioning range of components of rubberized bitumen composites, wherein the composites comprises 2 percent-6 percent by mass of the admixture of rubber granules and 60 percent -75 percent by mass of coarse stone material, wherein the coarse rubber granules is 30 percent-60 percent based on the mass of rubber granules. The sliding resistance, the noise reducing performance, the set resistance at high-temperature, the crack resistance at low temperature, the water damage resistance and the fatigue resistance of road surface paved by the composites according to the proportioning range of the invention is raised substantially.

Owner:HARBIN INST OF TECH

Admixing type modifier of asphalt mixture

InactiveCN103289420AImprove stabilityImprove water stabilityBuilding insulationsLow-density polyethyleneFiber

The invention discloses an admixing type modifier of an asphalt mixture. The modifier comprises the following components by weight: 60-80% of high density polyethylene (HDPE) with weight-average molecular weight of 80,000-150,000, 20-35% of low density polyethylene (LDPE) with weight-average molecular weight of 30,000-100,000, 10-20% of linear low density polyethylene (LLDPE) with weight-average molecular weight of 50,000-100,000, 1-5% of rock asphalt with softening point of 160+ / -10 DEG C, 3-10% of rubber powder, 1-5% of fiber stabilizing agent, 1-3% of antistripping agent and 1-2% of paraffin. The modifier adopts the above components by weight percent, can be directly added during production of the asphalt mixture by way of admixing type modification, can substantially improve the high-temperature property of the mixture and effectively improve the low-temperature property, water stability and fatigue property of the mixture after being added, so the improved mixture can meet the use requirements.

Owner:XIAN RONGTAI POLYMERIC MATERIALS

Basalt mineral fiber used for asphalt concrete

InactiveCN101255011AImprove high temperature resistance to rutting deformationExtended service lifeBasaltChemical composition

A basalt mineral fiber used in asphalt concrete prepared by minerals such as the basalt, has the following chemical compositions by weight proportion: 42-48.3% of SiO2, 11-16.2% of Al2O3, 8-12.8% of CaO, 11-14% of MgO, 4.8-8.6% of FemOn and 0.8-2.3% of TiO2, and 4.6-7.8% of other components (K2O, NaO, B2O3, Cr2O3 and MnO2); the average particle size of the fiber is 4mm-8mm and the average fiber diameter is 0.004mm-0.006mm. By integrating proper fiber and the asphalt concrete, the high-temperature rut deformation resistant performance, low-temperature cracking resistant performance and fatigue damage resistant performance of the asphalt concrete road surface is greatly improved, the early-stage water damage of the road surface is effectively prevented and the service life of the road surface is greatly prolonged.

Owner:肖菁

Composite stabilizer for SBS modified asphalt

ActiveCN104513489ASolve the problem of high temperature storage stabilityImprove high and low temperature stabilityBuilding insulationsHigh temperature storageBenzoyl peroxide

The invention relates to a composite stabilizer for SBS modified asphalt. The composite stabilizer comprises the following components in parts by mass: 30 to 60 parts of a cross-linking agent, 10 to 40 parts of an accelerator, 10 to 20 parts of an activating agent and 5 to 20 parts of a compatilizer, wherein the cross-linking agent is one or more of sulfur, dithiomorpholine, polyphosphoric acid and maleic anhydride; the accelerator is one or more of tetraethylthiuram disulfide, 2-mercaptobenzothiazole, benzoyl peroxide, dicumyl peroxide and sodium isopropyl xanthate. Compared with the prior art, the composite stabilizer has the advantages that after the composite stabilizer is added into the SBS modified asphalt, the problem that the high-temperature storage stability of the SBS modified asphalt is poor is well solved, the performances such as high-temperature and low-temperature stability and water stability of an asphalt mixture are comprehensively improved, and high-temperature anti-rutting performance, low-temperature anti-cracking performance, moisture damage resistance and ageing resistance are remarkably improved.

Owner:山西省交通科技研发有限公司

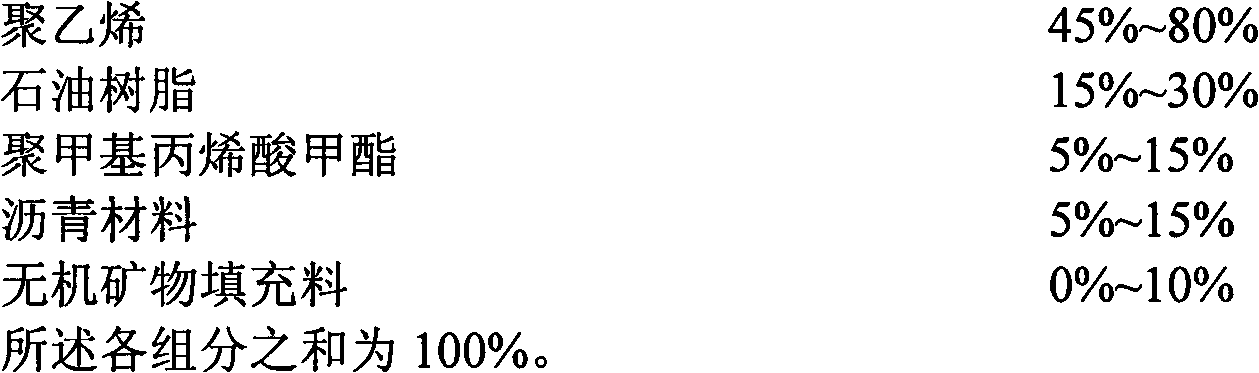

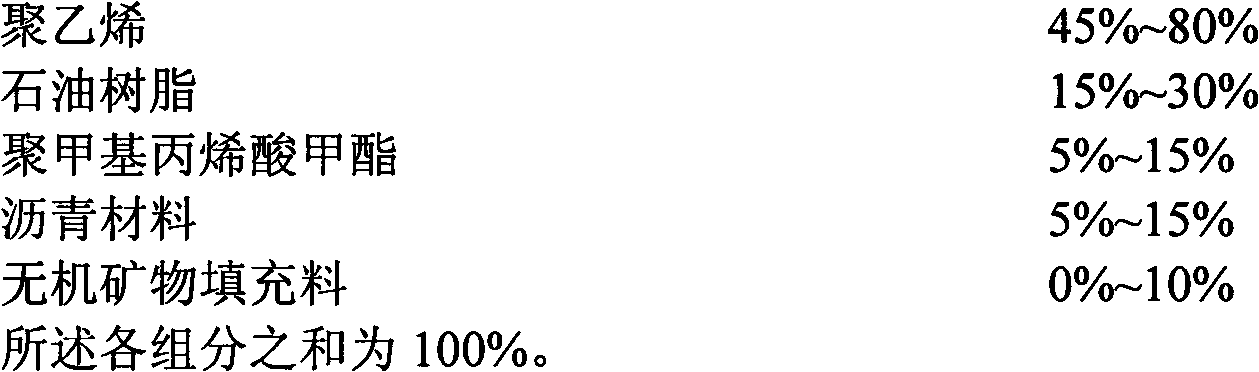

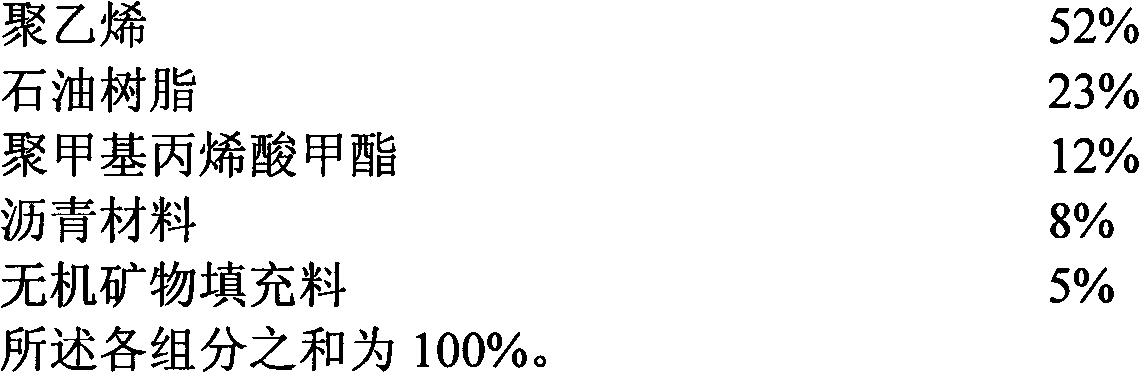

Environment-friendly asphalt pavement anti-rut agent and preparation method thereof

ActiveCN102702600AImprove protectionNo displacementBuilding insulationsLow-density polyethyleneMicrosphere

The invention discloses a preparation method of an environment-friendly asphalt pavement anti-rut agent and an application thereof. The method comprises the following steps of: mixing and stirring 45-80 percent of polyethylene and 15-30 percent of petroleum resin derived from 'plastic waste', 5-15 percent of polymethyl methacrylate, 5-15 percent of an asphalt material and 0-10 percent of an inorganic mineral filling material at a high speed; and extruding at a high temperature to prepare the environment-friendly asphalt pavement anti-rut agent. Due to the adoption of the environment-friendly asphalt pavement anti-rut agent, the performance of an asphalt pavement is enhanced, the service life of the pavement is prolonged, 'white waste' is recycled, and environmental pollution is lowered. Polyethylene serving as a major component is either or both of industrial production low-density polyethylene and industrial recycled waste polyethylene; the industrial recovered waste polyethylene is recovered polyethylene or regenerated low-pressure polyethylene or regenerated PE (Polyethylene); the molecular weight of the petroleum resin is 300-3,000; the molecular weight of the polymethyl methacrylate is 80,000-120,000; the asphalt material is one or more of natural asphalt, coal tar asphalt and petroleum asphalt; and the inorganic mineral filling material is one or over two of calcium carbonate of 500-800 meshes, talc powder, quartz sand, glass hollow microspheres and kaolin.

Owner:SHENZHEN KEZHONGDA POLYMER MATERIAL RES INST

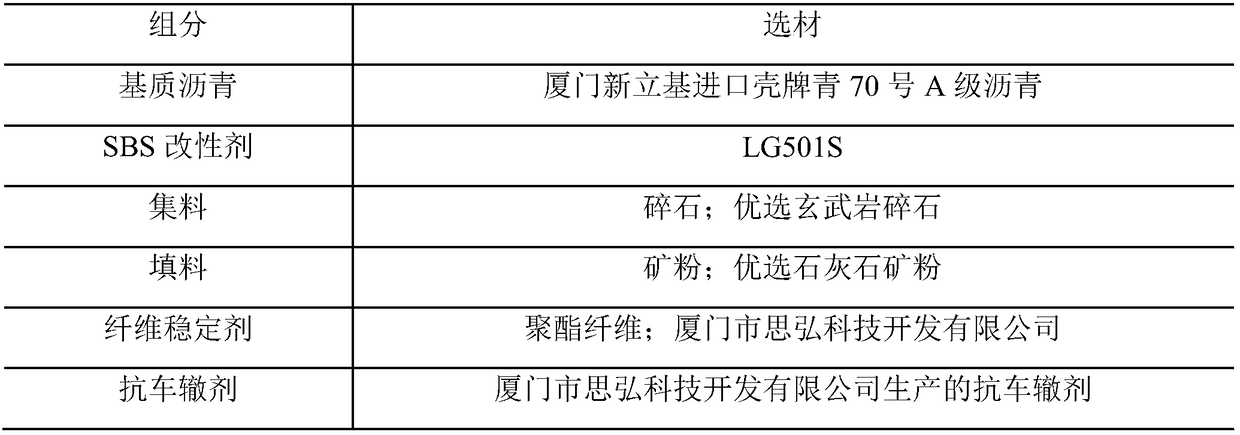

Asphalt mixture and production method thereof

ActiveCN109180077AImproves rutting resistanceImprove stress resistanceBuilding insulationsAsphaltPolymer chemistry

The invention discloses an asphalt mixture and a production method thereof and relates to the field of building materials. The asphalt mixture solves the problem that the existing asphalt mixture forthe airport runway has poor stability and anti-rutting ability, and comprises 4 to 12 wt% of modified asphalt, 72 to 88 wt% of aggregate, 5 to 10 wt% of a filler, 0.5 to 3 wt% of a fiber stabilizer and 0.5 to 3 wt% of an anti-rutting agent and has an asphalt-aggregate ratio of 5.6 to 14%. The modified asphalt comprises matrix asphalt and SBS and the weight of the SBS is 5-8 wt% that of the matrixasphalt. The asphalt mixture has the advantages of high dynamic stability, high temperature stability, strong rutting resistance and good water stability, and is suitable for airport runways.

Owner:厦门市政沥青工程有限公司 +2

High-strength modified asphalt

InactiveCN101270227AImprove high temperature stabilityNo additional costIn situ pavingsBuilding insulationsSulfurMass ratio

High-strength modified asphalt relates to road modified asphalt material with obvious stability at high temperature; the modified asphalt includes the following components: common asphalt; modifiers: SBS, DBS, uintaite mastic asphalt; auxiliary modifiers: uronic extract oil, sulfur; the mass of the 70# common asphalt is taken as reference quantity 1, and the mass ratio of the mixing amount of all modifiers relatively to the 70# common asphalt is: 3.5 percent to 4.5 percent of SBS, 1 percent to 2 percent of DBS, and 6 percent to 7 percent of uintaite mastic asphalt; and the dosage of the auxiliary modifiers is fixed as below: 0.1 percent of sulfur, and 2 percent of uronic extract oil. The asphalt not only has excellent economic benefits, but also has high-temperature stability equal to that of foreign high-strength asphalt and low-temperature performance better than that of the foreign high-strength asphalt.

Owner:SOUTHEAST UNIV

Anti-rut agent for asphalt pavements and preparation method thereof

InactiveCN101704644AImproves rutting resistanceImprove waterproof performanceRoad surfaceSolid particle

The invention discloses an anti-rut agent for asphalt pavements and a preparation method thereof. The method comprises the steps of: mixing 5 to 10 weight percent of petroleum asphalt, 5 to 10 weight percent of polymethylmethacrylate and 80 to 90 weight percent of polymer with a long flexible chain;, heating and stirring the mixture at the temperature of between 125 and 180 DEG C for 1.5 to 2.5 hours; and further granulating the mixture to obtain solid particles of the anti-rut agent with the diameter of between 50 and 500mu m. The anti-rut agent improves the anti-rut performance of the asphalt pavements; the adopted polymethylmethacrylate remarkably improves the waterproof ability and low-temperature cracking performance of the asphalt pavements; and through the optimization of production technology and the reduction of particle size of the particles, the anti-rut agent improves the adhesiveness between an aggregate and asphalt, reduces the gap between the aggregate and the asphalt, and strengthens the anti-stripping performance of an asphalt mixture.

Owner:TONGJI UNIV

Rubber powder modified asphalt and preparation method thereof

InactiveCN108517126AReduce penetrationHigh degree of softeningBuilding insulationsNeedle penetrationPolymer science

The invention discloses rubber powder modified asphalt and a preparation method thereof, and relates to the technical field of modified asphalt. The provided rubber powder modified asphalt is mainly prepared from the following raw materials in parts by weight: 30 to 40 parts of rock asphalt, 20 to 30 parts of polyphosphoric acid, 10 to 50 parts of rubber powder, 2 to 3 parts of stabilizing agents,1 to 5 parts of SBS modifying agents, 1 to 2 parts of PE modifying agents, 1 to 10 parts of solubilizers and 1 to 3 parts of aromatic hydrocarbon oil. The rubber powder modified asphalt has the advantages that the construction difficulty is low; the needle penetration degree is reduced; the softening degree is increased; the stability is improved.

Owner:THE THIRD ENG CO LTD OF THE HIGHWAY ENG BUREAU OF CCCC

Asphalt road surface reinforcing material

The road surface reinforcing asphalt material is one kind of post-added asphalt concrete modifier. It is prepared with PE, PP, POE, antioxidant 1010, stabilizer AT-168 and carbon black and through mixing. The road surface reinforcing asphalt material has wide material source and simple preparation process, and may be stirred and constructed with common asphalt mixer and matched with heavy traffic asphalt. Adding it in small amount of 0.3-0.7 % can raise the road use performance of mixed asphalt material, including strength, high temperature resistance, water resistance, etc. greatly.

Owner:湖北高科交通工程咨询有限公司

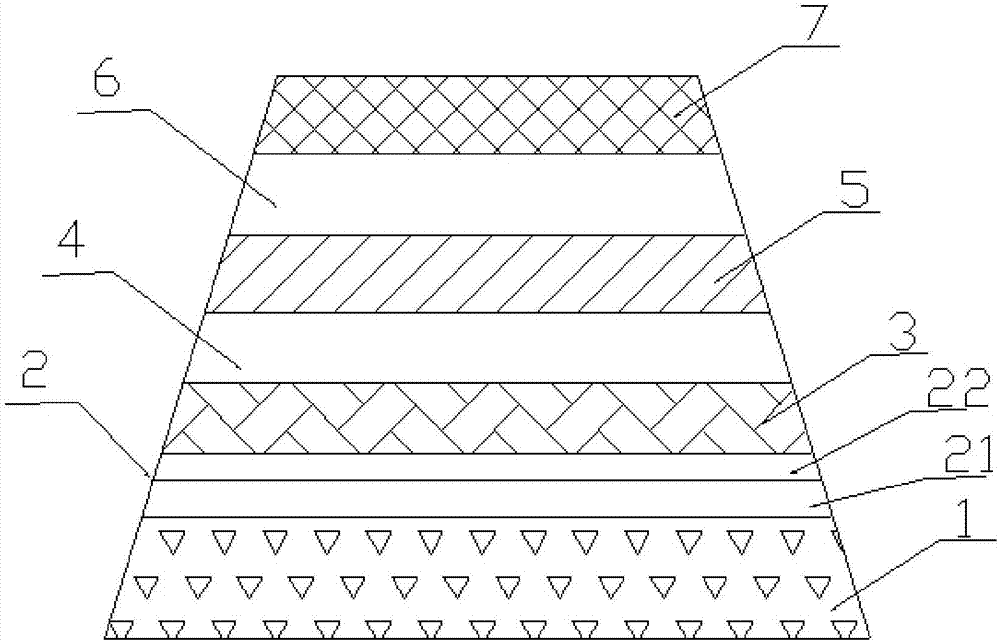

Asphalt pavement structure suitable for Tibet plateau area and construction method thereof

PendingCN106868972AImprove road performanceImprove bending deformationIn situ pavingsCushionSubgrade

The invention relates to an asphalt pavement structure suitable for the Tibet plateau area and a construction method thereof. The asphalt pavement structure suitable for the Tibet plateau area sequentially comprises a cushion layer, a semi-rigid base layer, a penetrable layer, an SBR emulsified asphalt lower sealing layer, a lower surface layer, a bonding layer and an upper surface layer from bottom to top. The construction method of the asphalt pavement structure suitable for the Tibet plateau area comprises the following steps of (1) tamping and leveling a roadbed, (2) laying the cushion layer on the roadbed, (3) laying a cement stabilized sand gravel layer on the cushion layer, (4) flatly laying a low-shrinkage super-early-strength cement stabilized macadam layer, (5) laying the penetrable layer, (6) laying the SBR emulsified asphalt lower sealing layer, (7) laying the lower surface layer, (8) laying the bonding layer, and (9) laying the upper surface layer.

Owner:青海省交通科学研究院 +1

Cold-regeneration quick repairing material and preparation method thereof

The invention discloses a cold-regeneration quick repairing material. The cold-regeneration quick repairing material is characterized by being prepared by mixing three parts of A, B and C in a mass ratio of 1: (0.05-0.10): (0.25-0.45), wherein the component A comprises the following raw materials in parts by mass: 40 to 70 parts of old asphalt mixtures, 30 to 60 parts of new aggregates, 2 to 4 parts of regenerants, and 10 to 20 parts of fine sand; the component B comprises the following raw materials in parts by mass: 100 parts of cement, 1.0 to 2.0 parts of early strength agents, 0.5 to 0.8 part of a water reducer, and 1.5 to 2.5 parts of fibers; the component C comprises the following raw materials in parts by mass: 60 to 80 parts of emulsified asphalt, 20 to 40 parts of waterborne epoxy resin, 15 to 25 parts of water, 10 to 20 parts of curing agents, and 1 to 5 parts of coupling agents. The cold-regeneration quick repairing material disclosed by the invention has high early strength, can be opened to traffic after repairing for 1 day to greatly reduce the traffic closing time, has excellent resistance to water damage and further both has good high-temperature stability and low-temperature crack resistance, thereby being capable of carrying out quick cold-regeneration repair for pavement diseases, especially in a humid environment.

Owner:GUIZHOU TRANSPORTATION PLANNING SURVEY & DESIGN ACADEME

Asphalt mastic macadam mixture and preparation method thereof

InactiveCN109231890AImprove low temperature performanceImprove temperature sensitivityCrack resistanceRoad engineering

The invention discloses an asphalt mastic macadam mixture and a preparation method thereof and belongs to the field of road engineering materials. The asphalt mastic macadam mixture contains the following raw materials in parts by weight: 100 parts of aggregate, 5-7 parts of SBS (Styrene-Butadiene-Styrene) modified asphalt, 8-12 parts of mineral powder, 0.2-0.6 part of a fiber stabilizer, 2-7 parts of carbon black, 5-8 parts of phenolic resins and 2-3 parts of a curing agent. The asphalt mastic macadam mixture is capable of improving the strength and durability of the pavement, and can achievethe effects of enabling the pavement to achieve excellent cracking resistance and wear resistance and reducing risk of rut diseases on the asphalt pavement.

Owner:平湖市中建沥青混凝土工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com