Patents

Literature

73results about How to "Good environmental protection function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

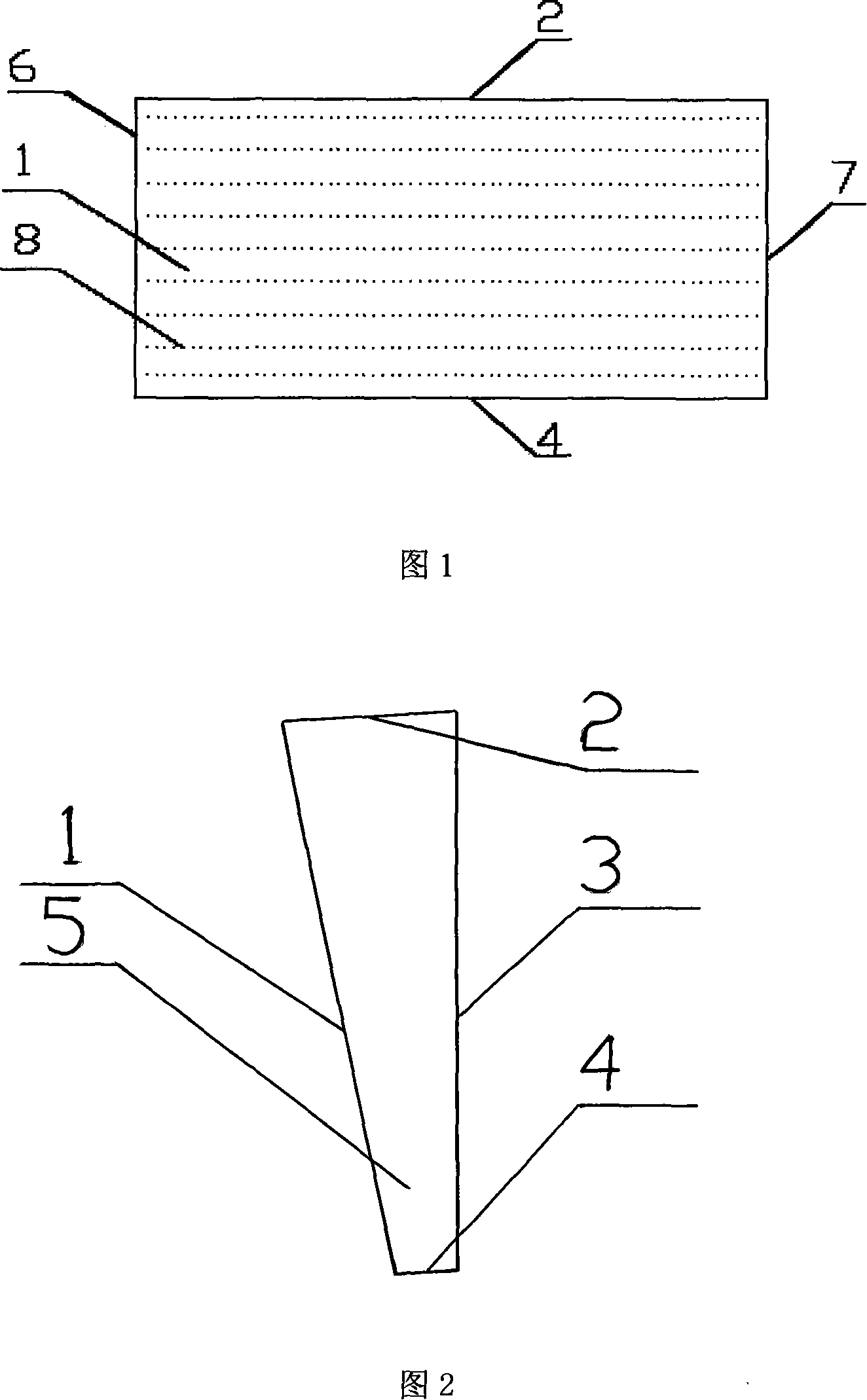

Double-layer composite micropunch sound absorption method and sound absorption panel

InactiveCN102760430AGuaranteed StrengthGood light transmissionSound producing devicesBi layerWeather resistance

The invention provides a double-layer composite micropunch sound absorption method and a sound absorption panel. The panel in the thickness of 0.5-2mm is adopted to serve as a protective panel, holes are evenly arranged on the panel with the hole diameter of 0.5-1mm, punching rate is 1-10%, a second layer is a punching thin film with the thickness of about 0.1-0.3mm, the hole diameter is 0.1-0.2mm, and the punching rate is about 1-2%. A cavity is arranged between two layers, the thickness of the cavity is within 5cm, the two layers are matched to use to form double resonance effects, and a sound absorption frequency belt of a structure is effectively increased. The double-layer composite micropunch sound absorption method and the sound absorption panel solves the problem that base plate micropunch manufacture is difficult, and strength of thin film micropunch manufacture is insufficient though the thin film micropunch manufacture is simple. Simultaneously, the device is simple, simple and convenient to manufacture, light in thin shape, wide in application face, easy to wash and resisting to high temperature and has excellent weather fastness and environmental protection function.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

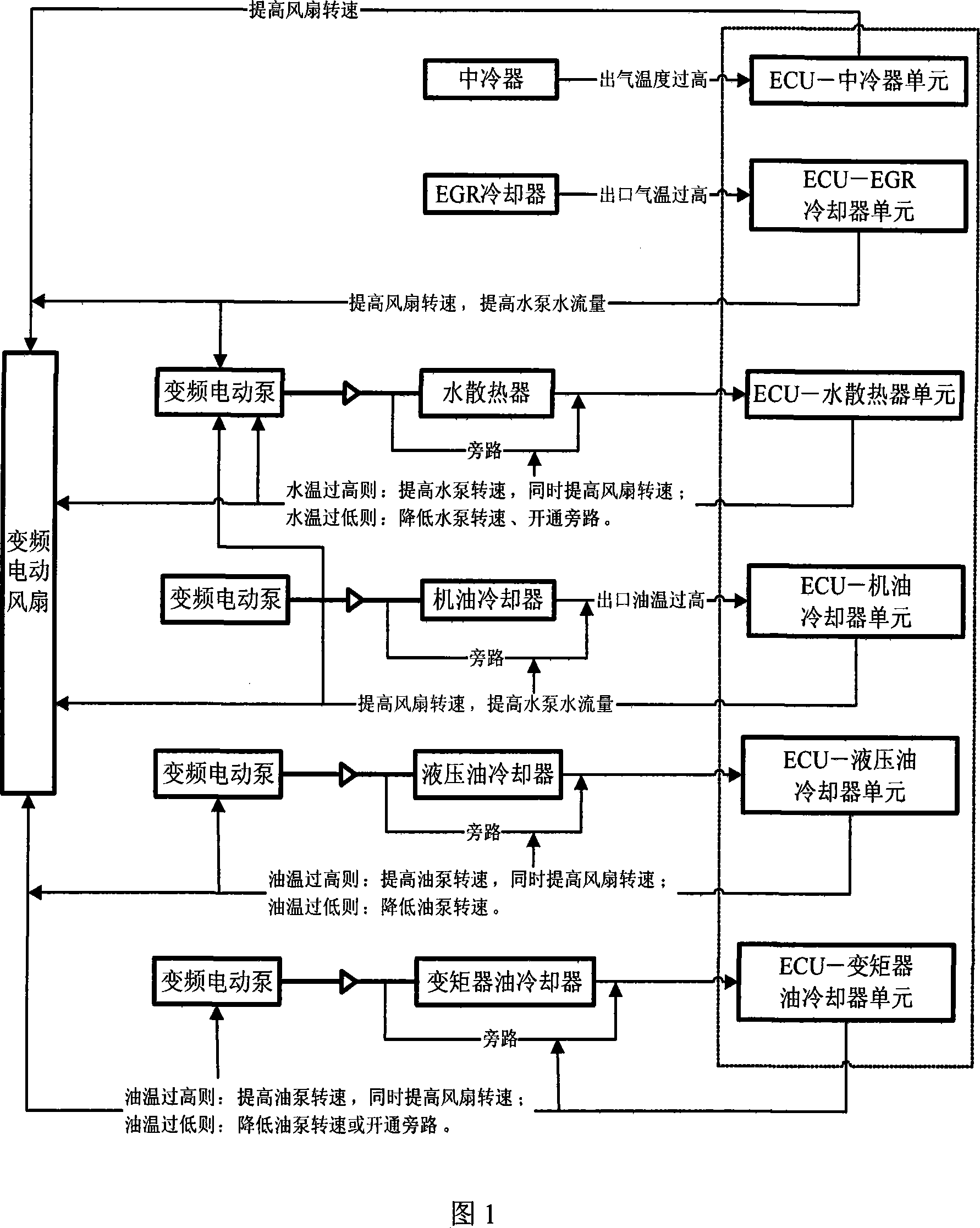

Intelligentized heat management system of propulsion plant

InactiveCN101109310ABest working condition rangeEmission reductionCoolant flow controlPositive displacement pump componentsHeat managementPollutant emissions

The invention discloses an intelligent heat management system for a power equipment, which comprises a plurality of cooling units, an electronic control unit ECU, a fan and a motorized pump, and is characterized in that the ECU can make judgment depending upon the feedback signal of the temperature of the cooling media, adjust the speed of the fan and the motorized pump, so as to control the operation temperature of the thermal media of each cooling unit to be optimal. The invention realizes the most economic oil consumption by the ECU, guarantees that the engine is always under the optimal operation state under different environments. The advantages with the invention are: 1. The invention can guarantee that the engine is always under the optimal operation condition. 2. The invention can save energy, reduce emission of pollutant, is environmental friendly. 3. Each heat exchanging unit can cool as necessary, no overhot or over cold condition will happen. 4. The intelligent heat management system for power equipments is realized completely depending upon the feedback temperature signal by the ECU.

Owner:ZHEJIANG YINLUN MACHINERY

Polyurethane material and its prepn

The present invention provides one kind of polyurethane material and its preparation process. The polyurethane material is prepared through inorganic acid catalyzed liquefacation and foamation on the mixture of natural plant powder material and composite liquefier at 100-150 deg.c under the action of microwave of 2450 MHz frequency. The composite liquefier consists of PEG400 60-80 wt%, glycerin 10-25 wt% and water 10-30 wt%. The polyurethane material may be used in making product with high mechanical strength, low density, high heat insulation, good damping performance, biodegradability advantages, and may be used to replace petrochemical material foaming polyurethane material.

Owner:李剑飞

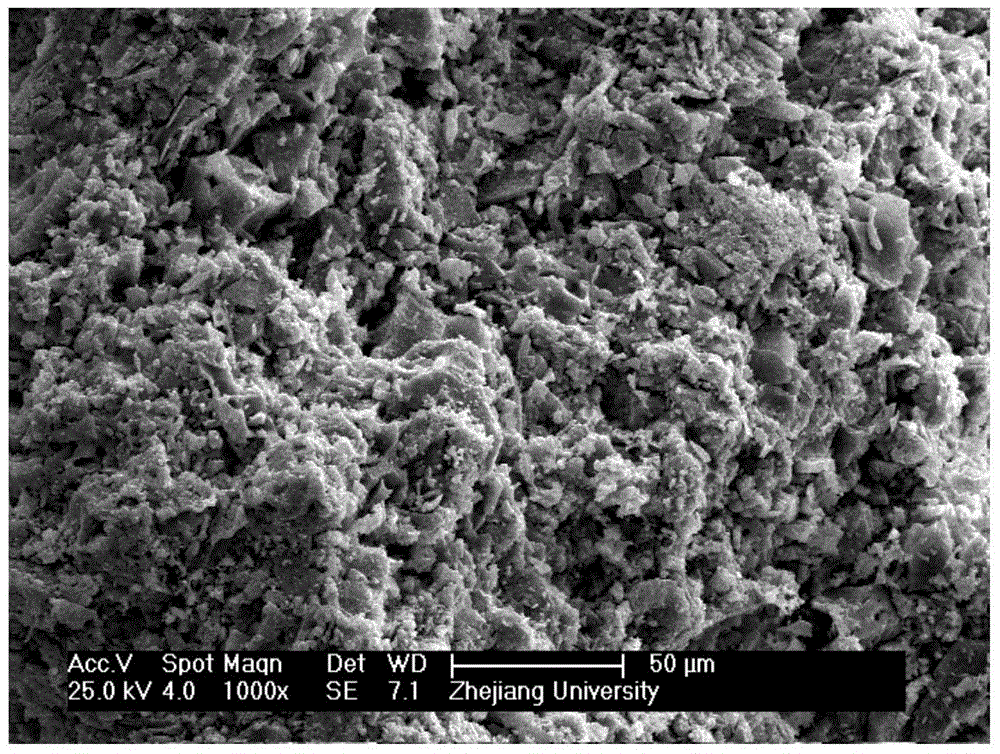

Biomass carbonization molding material and preparation method thereof

ActiveCN104610988AIncrease stomataImprove water absorptionOther chemical processesDispersed particle separationBiomassWater quality

The invention discloses a preparation method of a biomass carbonization molding material. The preparation method successively comprises the following steps: 1) crushing natural biomass materials so as to obtain powder of which the sieving rate is equal to or larger than 100 meshes; 2) adding clay to the powder, uniformly mixing the clay and the powder so as to obtain a mixed material, wherein the powder accounts for 10-45% of the total weight of the mixed material, and the clay accounts for 55-90% of the total weight of the mixed material, adding water accounting for 5-30% of total weight of the mixed material to the mixed material, and mixing and stirring the mixed material with the water; 3) injecting the obtained mixture in a mold to perform compression molding, after demolding, drying the demolded object until the moisture content is equal to or smaller than 8%, performing smoldering treatment under 800-1300 DEG C and the anoxic condition of sealing for 0.5-10 hours so as to obtain the biomass carbonization molding material. The carbonization molding material prepared by adopting the preparation method disclosed by the invention not only has good mechanical strength, but also has the characteristics of being green and environment-friendly, capable of purifying air / water quality and the like, and adsorbing harmful substances in the air / water.

Owner:LISHUI GREEN ROCK IND DESIGN

Biomass carbon matrix environment-friendly brick and making method

InactiveCN107324773AGood environmental protection functionIncrease profitCeramic materials productionClaywaresBiomass carbonToxic gas

The invention discloses a biomass carbon matrix environment-friendly brick and a making method. The biomass carbon matrix environment-friendly brick is characterized by comprising the following components (in percentage by weight): 35-45% of biological black carbon, 55-65% of an earth material and 1-3% of molding aids, wherein the brick is made by treating the earth material, mixing with the biological black carbon, molding, drying and roasting; the biological black carbon is biological black carbon granules or powder ash made of biomasses via high-temperature carbonization; the earth material comprises 15-35% of clay, 15-25% of shale powder ash, 15-25% of coal gangue powder ash and 15-25% of coal ash; the 1-3% of molding aids comprise bentonite, fulvic acid powder and tapioca flour. The making method comprises the following steps: performing high-temperature carbonization on various types of biomass straw so as to obtain biological black carbon granules or powder ash; grinding shale, coal gangue and coal residues into a powder material; uniformly mixing with the clay and the molding aids; making bricks by using a brick making machine, drying, and sintering. Due to adoption of a biomass black carbon material, the biomass carbon matrix environment-friendly brick is capable of adsorbing toxic gases as a whole for a long time, is light and environmentally friendly, and is capable of purifying indoor polluted air and lowering cost.

Owner:湖北金日生态能源股份有限公司

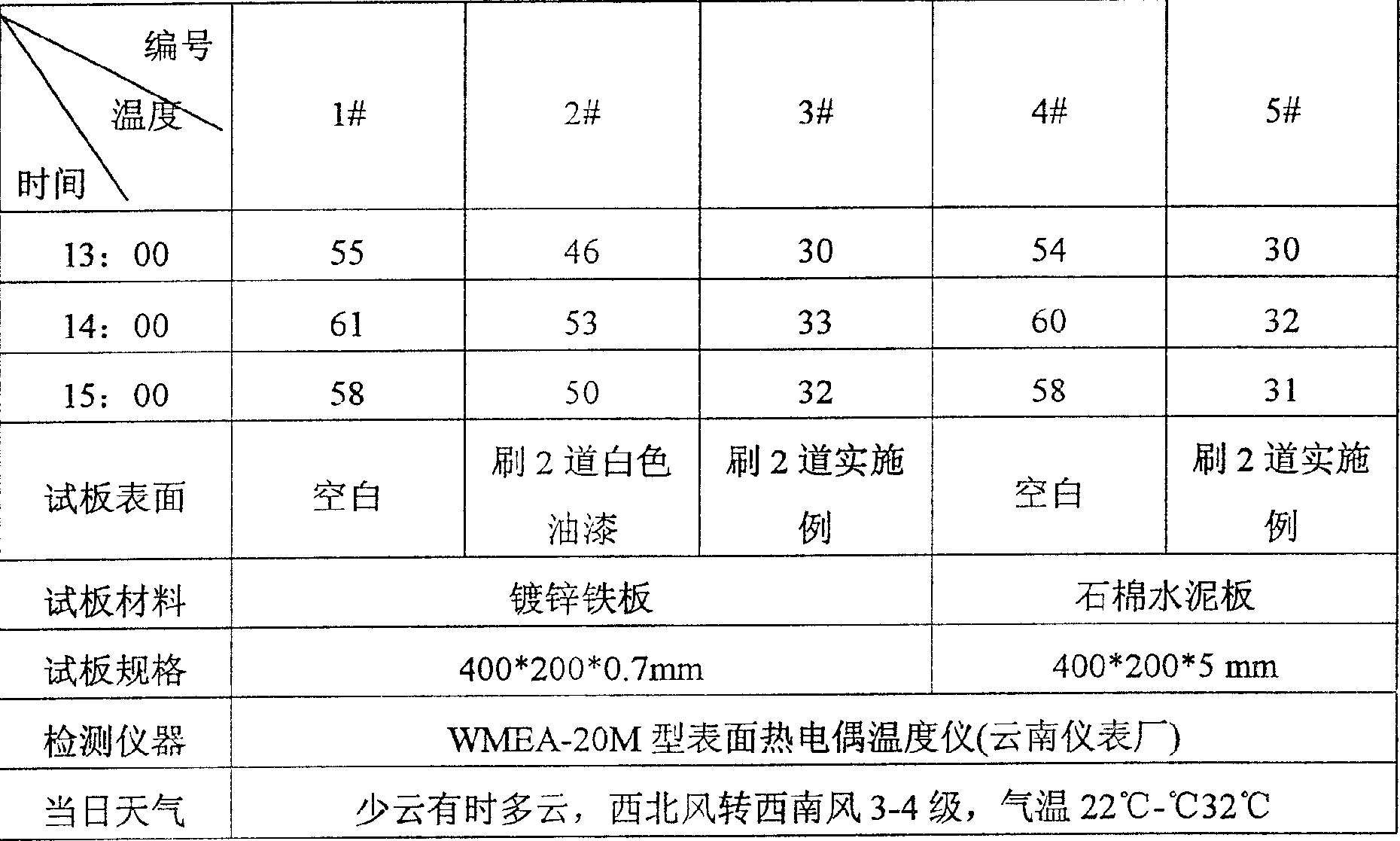

Multifunctional energy-saving coating for building

InactiveCN1706899AReduce the temperatureReduce running timeCoatingsConservation energySynthetic resin

The present invention is multifunctional energy-saving coating for building, and relates to chemical material for building and heat insulating, building protecting, energy saving, environment protection and other technology. The present invention is paint prepared with synthetic resin as filming material, heat insulating material, pigment, stuffing, assistant, pH regulator, water and other components, and through grinding, dispersing, blending, filtering and other steps. The paint has the features of being non-inflammable, non-toxic and pollution-less, and can form film on the outside of building for decoration, protection, heat insulating, saving energy and protecting environment.

Owner:孙成勋

Viscose filament yarn of feather keratin and bamboo fiber and method for producing same

ActiveCN102877158ANo pollution in the processGood environmental protection functionArtificial filament physical treatmentConjugated cellulose/protein artificial filamentsEngineeringViscosity

The invention relates to a viscose filament yarn of feather keratin and bamboo fiber and a method for producing the viscose filament yarn and belongs to the field of materials in textile industry. The invention aims to solve the problem that the conventional technology is not suitable for producing viscose filament yarns of feather keratin and bamboo fiber and provide viscose filament yarn of feather keratin and bamboo fiber and a process method for producing the same. The viscose filament yarn is produced by mixing 1 to 30 weight percent of feather keratin fluid and 70 to 99 weight percent of a bamboo fiber solution, and performing static co-mixing, spinning, solidification and post-treatment; and an aid is added for initiation, so the viscosity of bamboo is lowered, and the viscosity requirement on spinning is met by uniformly mixing the keratin fluid and the viscose.

Owner:YIBIN SPARK NEW FIBER CO LTD

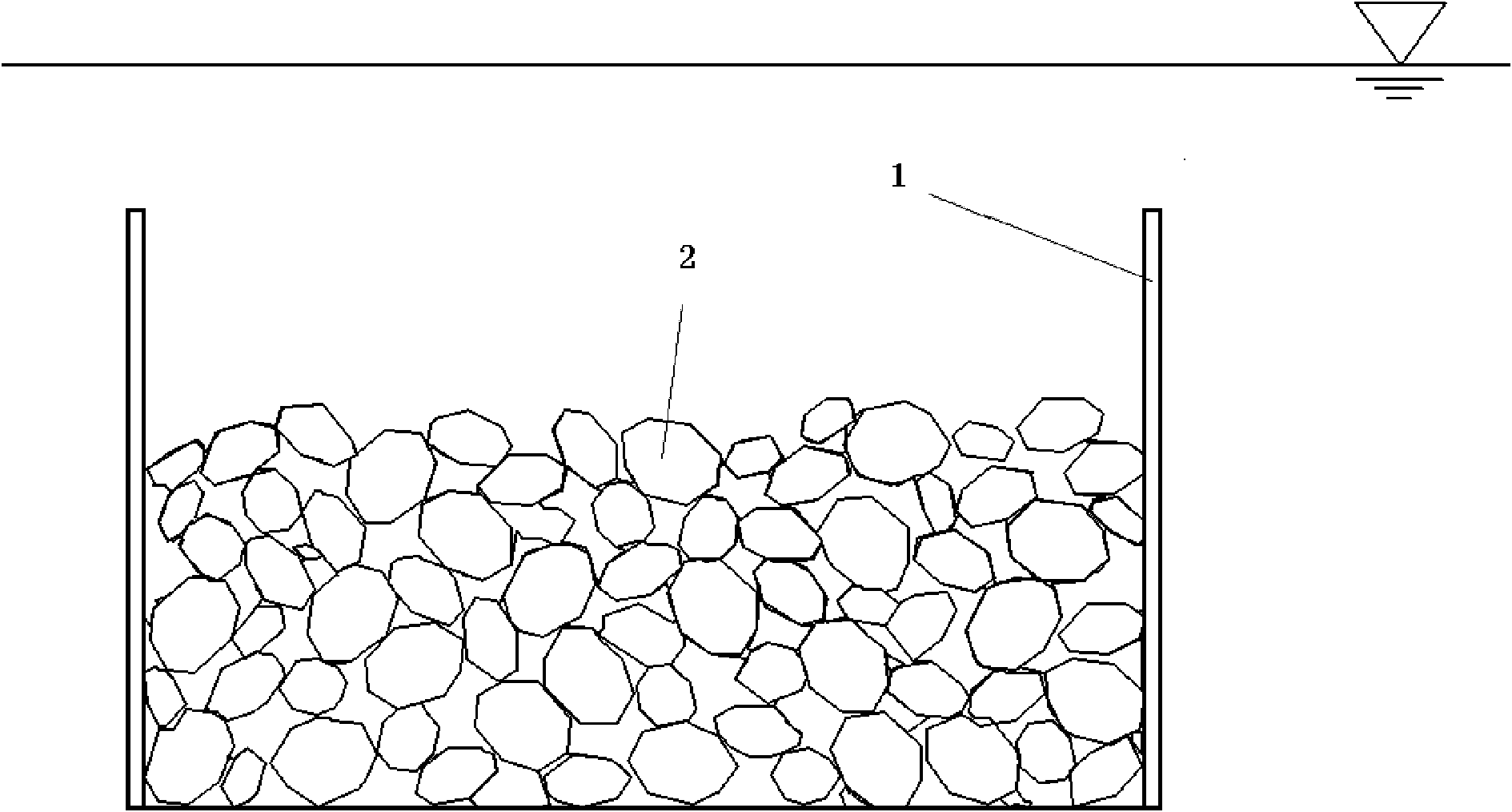

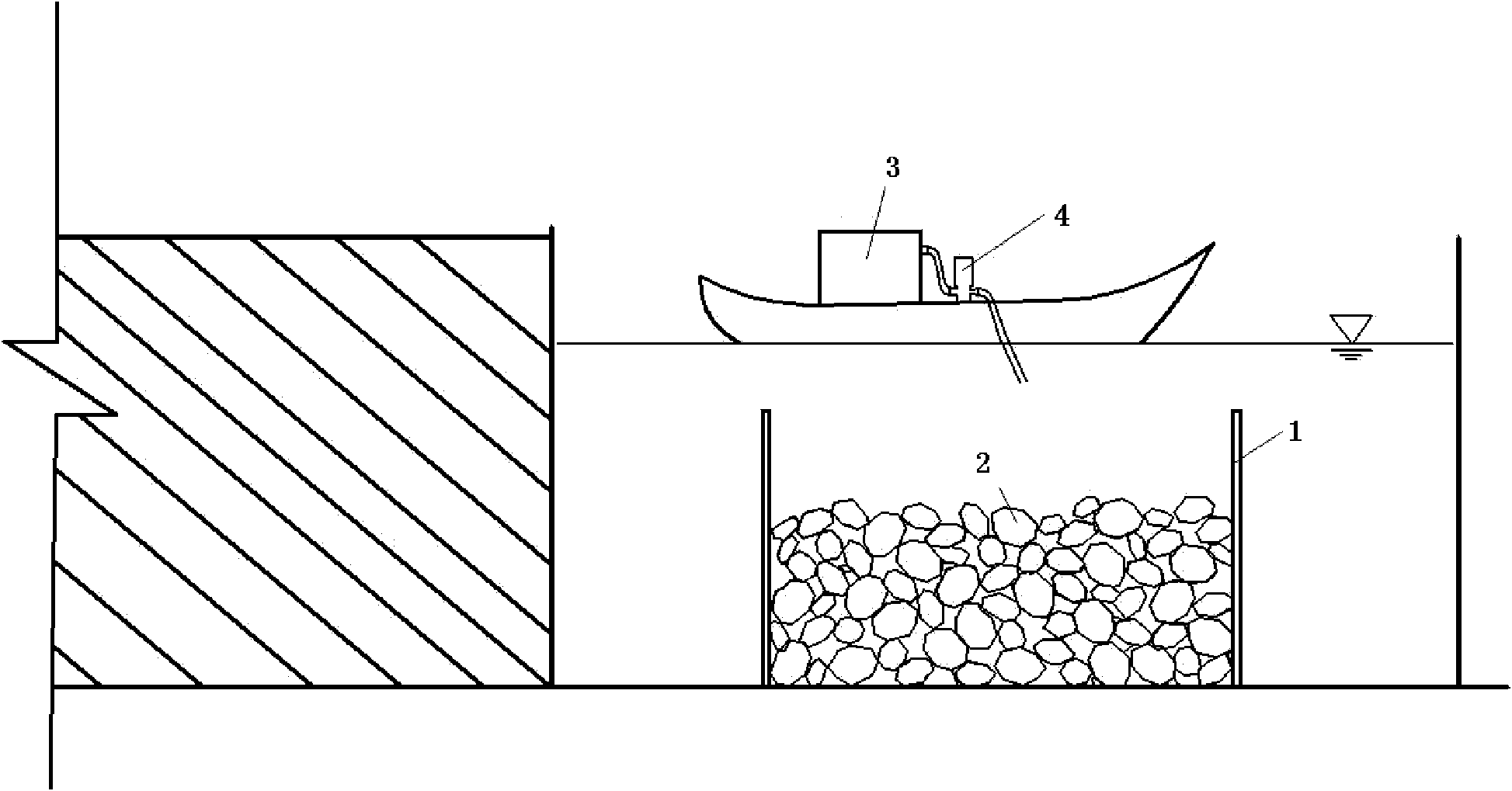

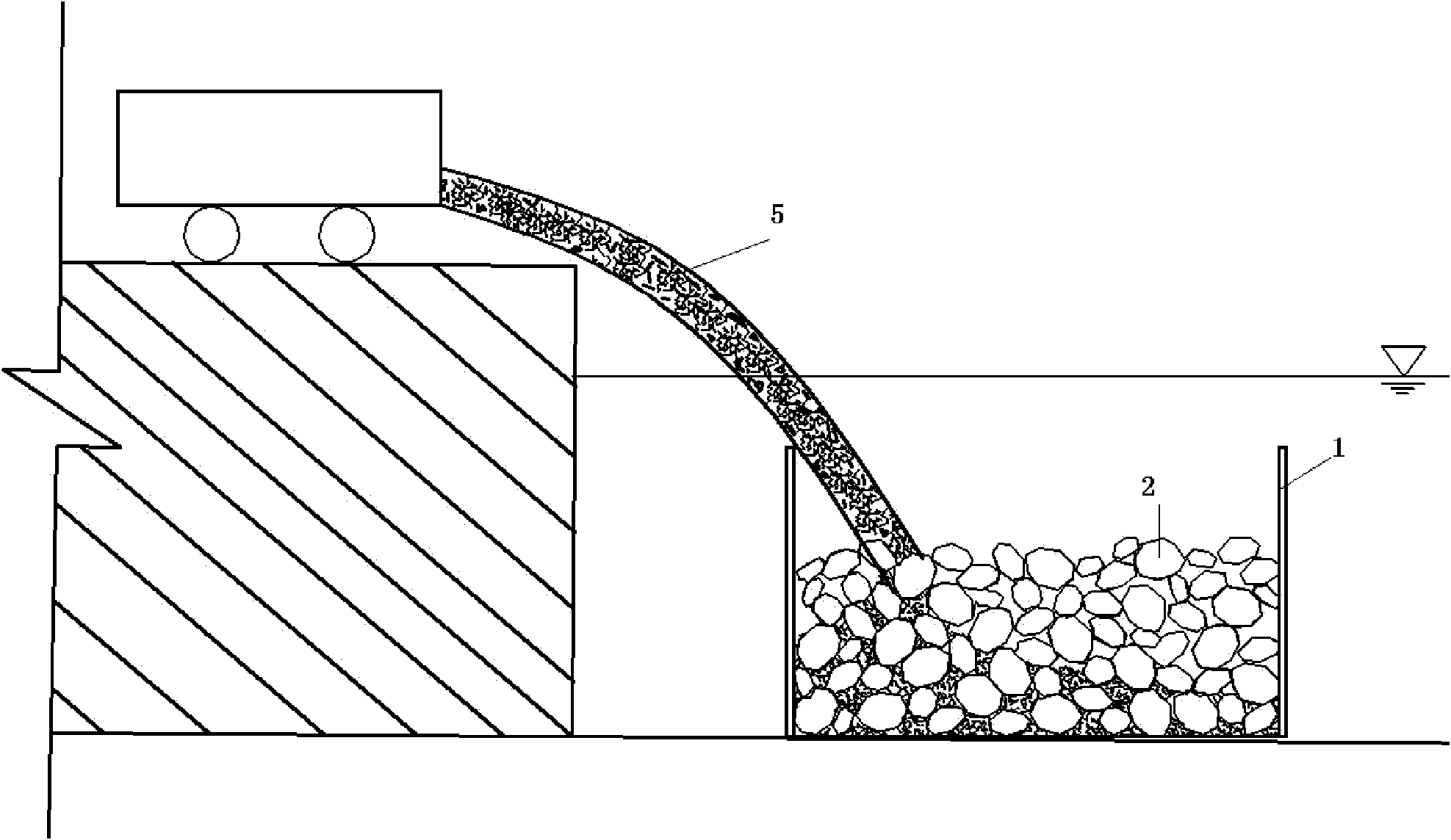

Construction method of underwater rockfill concrete

InactiveCN102277873AReduce usageExcellent dispersion resistanceFoundation engineeringUnderwaterUltimate tensile strength

The invention discloses an underwater rockfill concrete construction method, which belongs to the technical field of building construction. The present invention adopts block stones or pebbles with a particle size of more than 15cm, transports them to the surface of the underwater warehouse for natural accumulation by using ordinary transportation tools, and then puts a protective agent to protect the integrity of the underwater self-compacting concrete into the water, and uses the concrete that meets the requirements. The underwater special self-compacting concrete is poured naturally from the surface of the rockfill body with the help of a conduit, and the underwater special self-compacting concrete is used to fill the rockfill gap by its own weight, forming a dense and high-strength underwater rockfill concrete. The method is easy to construct, and has remarkable effects in improving construction efficiency and saving construction cost. The formed underwater rockfill concrete has less cement consumption, low hydration temperature rise, and has the advantages of energy saving and environmental protection.

Owner:TSINGHUA UNIV

Environment-friendly, sun-resistant and wear-proof water-based ink and preparation method thereof

InactiveCN105482549ASolve the problem of foamingGood environmental protection functionInksPolymer scienceSunscreen agents

The invention discloses environment-friendly, sun-resistant and wear-proof water-based ink and a preparation method thereof. The ink comprises raw materials in percentage by weight as follows: 25%-30% of a waterborne acrylic emulsion, 18%-20% of deionized water, 0.2%-0.5% of a dispersing agent, 0.2%-0.5% of dimethylethanolamine, 0.2%-0.4% of a wetting agent, 1.5%-2% of a slow drying agent, 5%-10% of an anti-wear agent, 10%-15% of an uvioresistant sun-screening agent, 0.2%-0.4% of a leveling agent and 30%-35% of organic pigment. The problems of poor adhesion of water-based ink and foaming of the ink in the printing use process are solved, and the water-based ink has the characteristics of high adhesion, wear resistance and sun screening.

Owner:JIANGXI TONGBAILI COLOR PRINTING PACKAGING

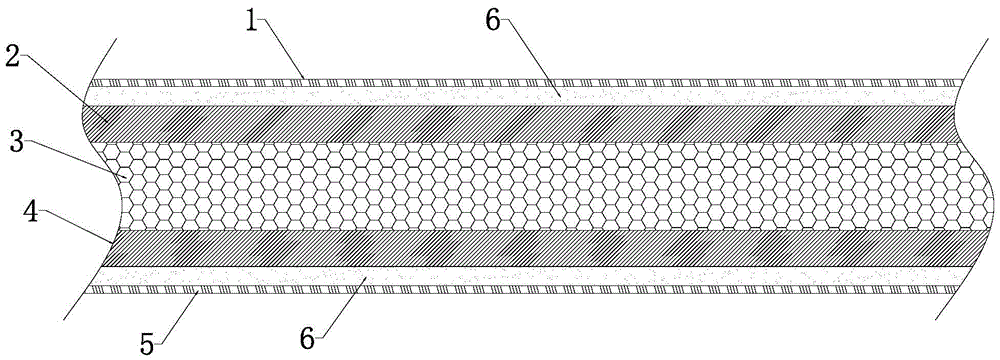

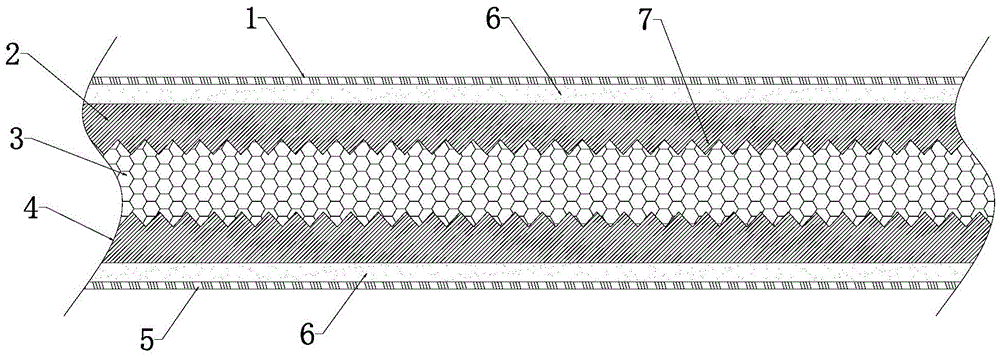

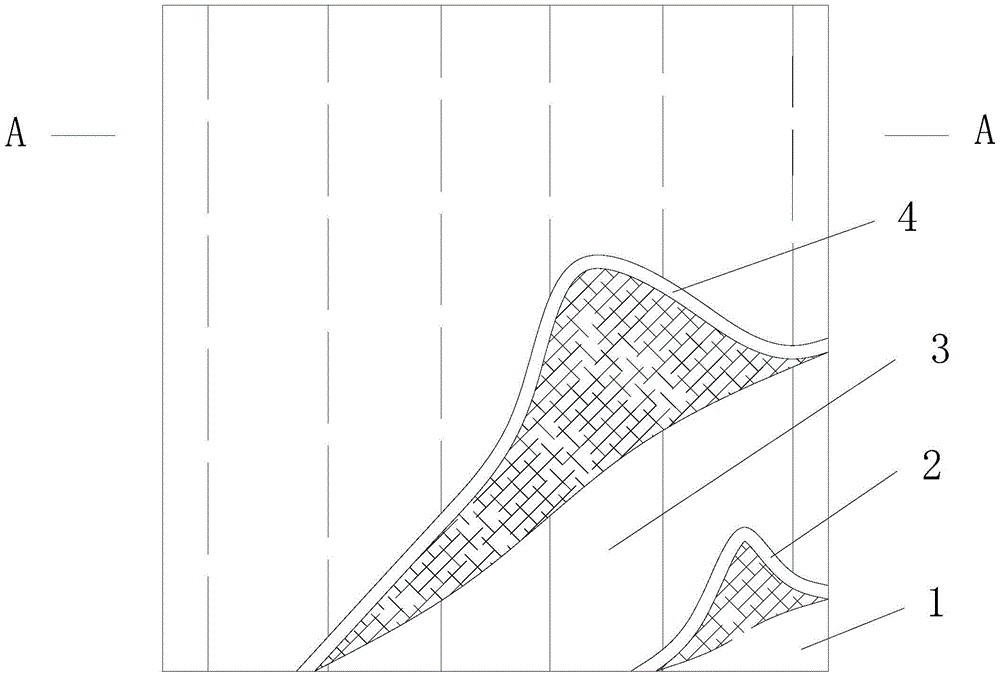

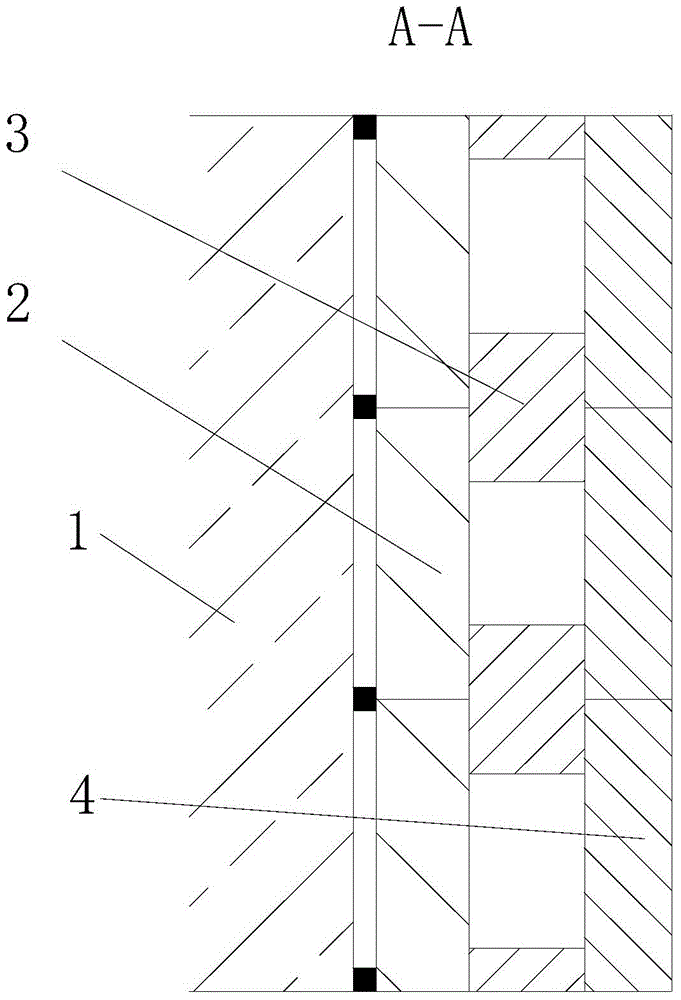

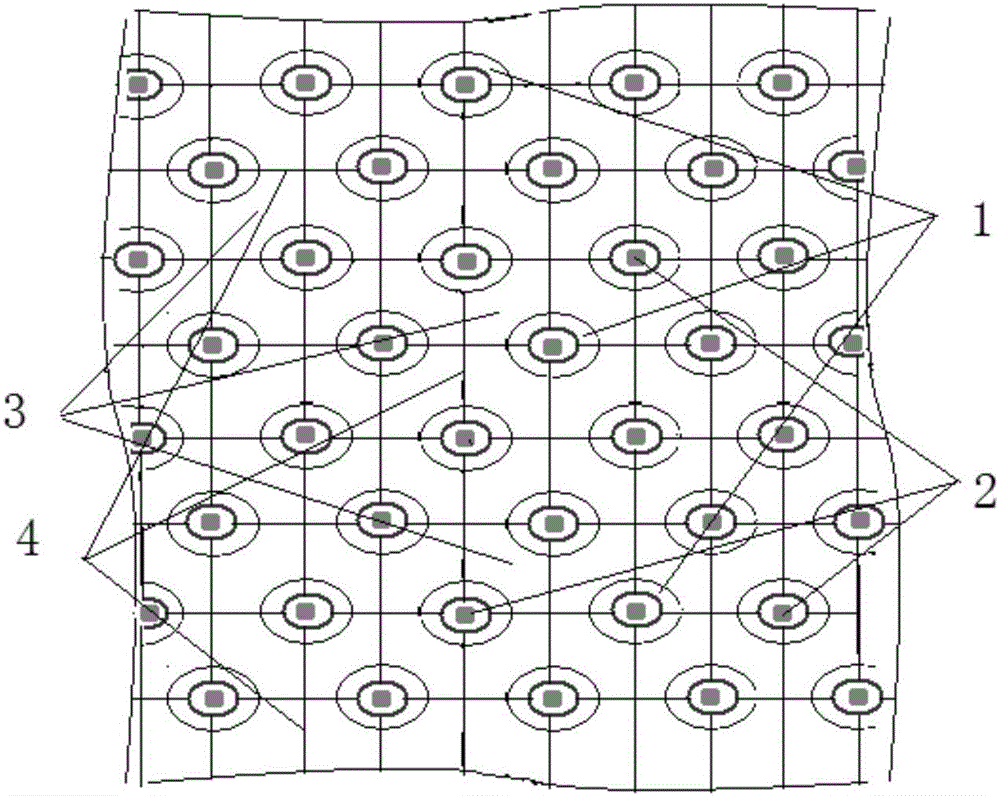

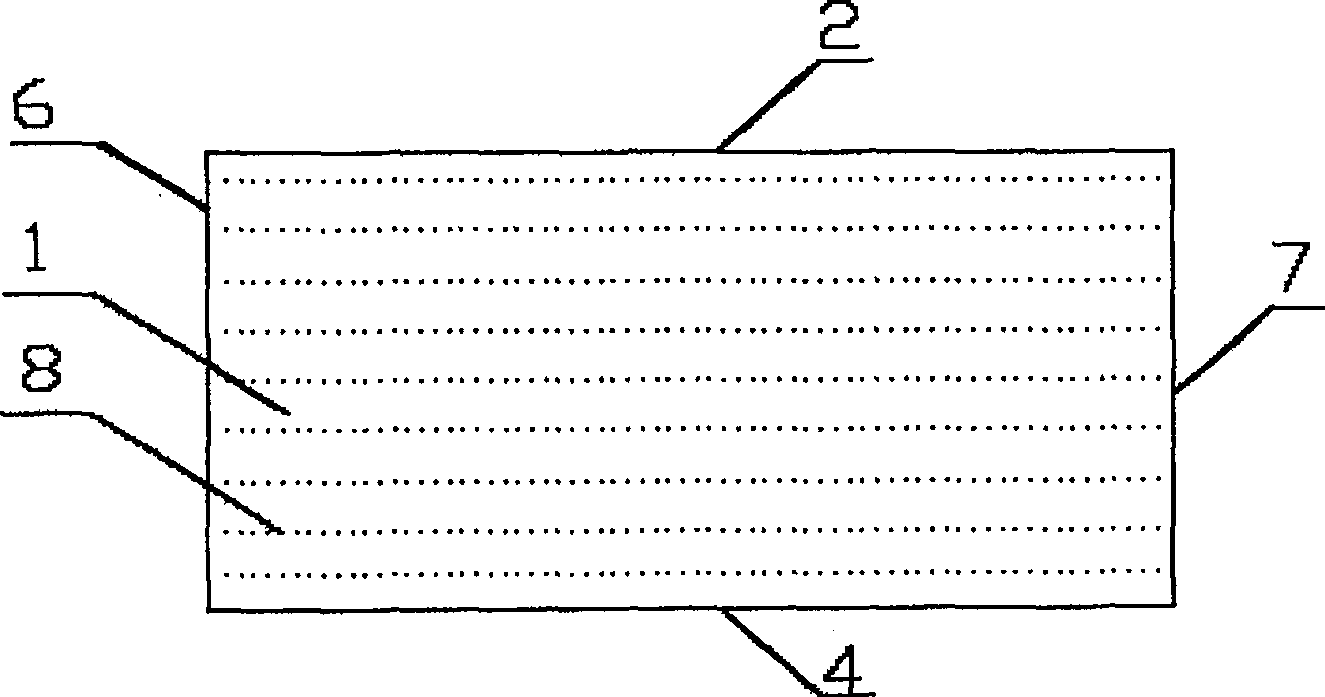

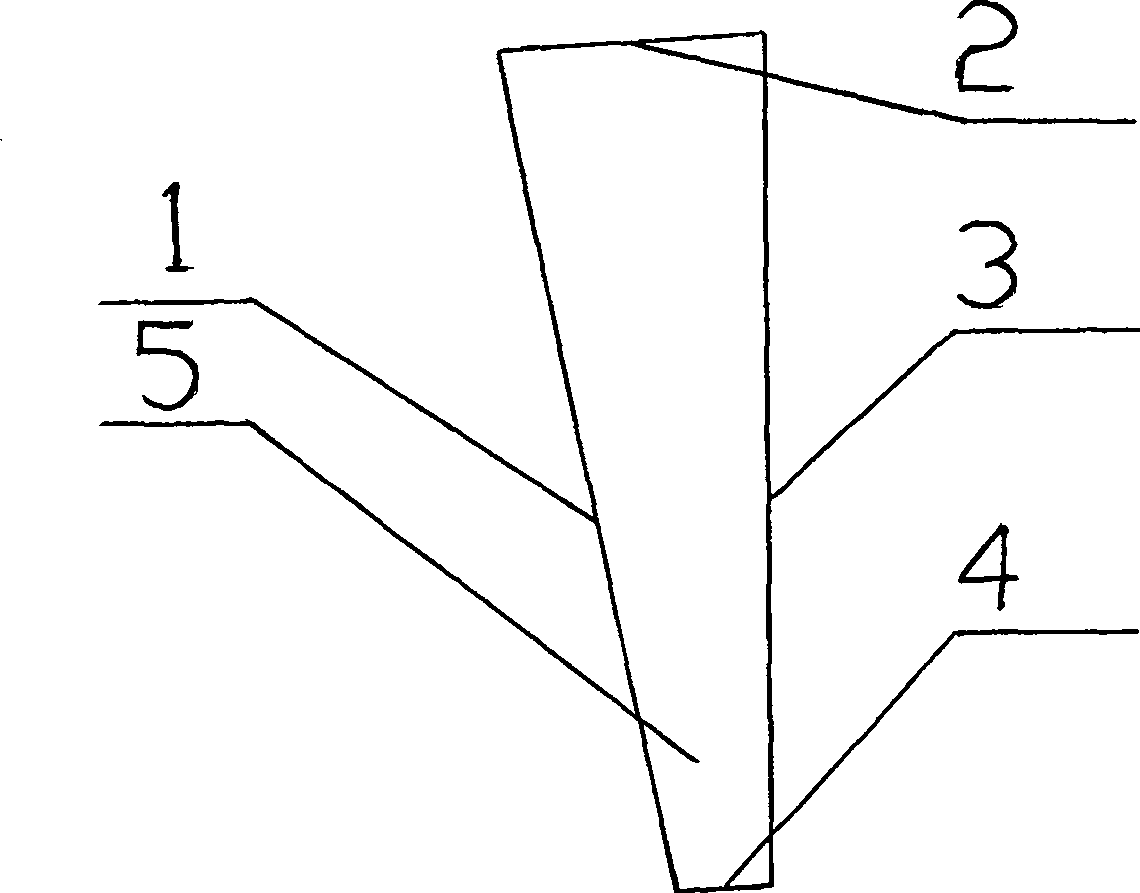

Gradual-change cavity microperforated broad band sound absorption type sound barrier

ActiveCN101139822AImprove the sound absorption coefficientSound absorption frequency bandwidthNoise reduction constructionSound barrierAbsorption factor

The invention belongs to the acoustical technical field and relates in specific to a novel non-fiber type and micropunched sound absorption type sound barrier body with transition cavity. The invention comprises a micropunched panel, a top face, a bottom face, a left end face, a right end face and a back plate; the micropunched panel, the top face, the bottom face, the left end face, the right end face and the back plate are connected to form a closed cavity; the cavity depth appears in a linear transition; the maximum depth is 2.5 to 3.5 times as the minimum depth. The micropunched panel is arranged with micropores with total occupied area of 0.5 percent to 3 percent of the panel area; the micropore aperture is 0.6 to 1.2mm. In actual use, it is only necessary to mount the invented device into a sound barrier vertical column or other places for sound absorption process. The invented device is characterized in being simple, easy and convenient manufacturing, thin shape and being light and having perfect sound absorption performances. Sound absorption band width with sound absorption factor higher than 0.4 exceeds 2 octaves. Therefore, the invention has advantages of broad application scope, easy purging, high-temperature resistance, and superior weather ability. Besides, the invented device can be completely recycled for use to thoroughly avoid the problem of secondary pollution, for which the invention has superior environmental protection function.

Owner:SHAZC GRP CORP LTD

Degradable waterproof oilproof coating on food packaging paper

ActiveCN110777566AImprove efficiencyGood environmental protection functionFlexible coversWrappersPolymer scienceMontmorillonite

The invention discloses a degradable waterproof oilproof coating on food packaging paper. The coating is composed of modified chitosan, montmorillonite and a fluorine-silicon organic matter, wherein the modified chitosan is carboxymethyl chitosan; the montmorillonite and the fluorine-silicon organic matter are combined to form a hydrophobic surface layer; and a weight ratio of the modified chitosan to the montmorillonite to the fluorine-silicon organic matter is (5-10): (5-10): 1. Because the coating does not contain a laminating film, time and energy are not consumed for treating the laminating film in the recycling process, so benefits are greatly improved; and the food packaging paper formed by coating base paper with the coating has more excellent characteristics in the aspect of an environmental protection function.

Owner:广东天银实业有限公司

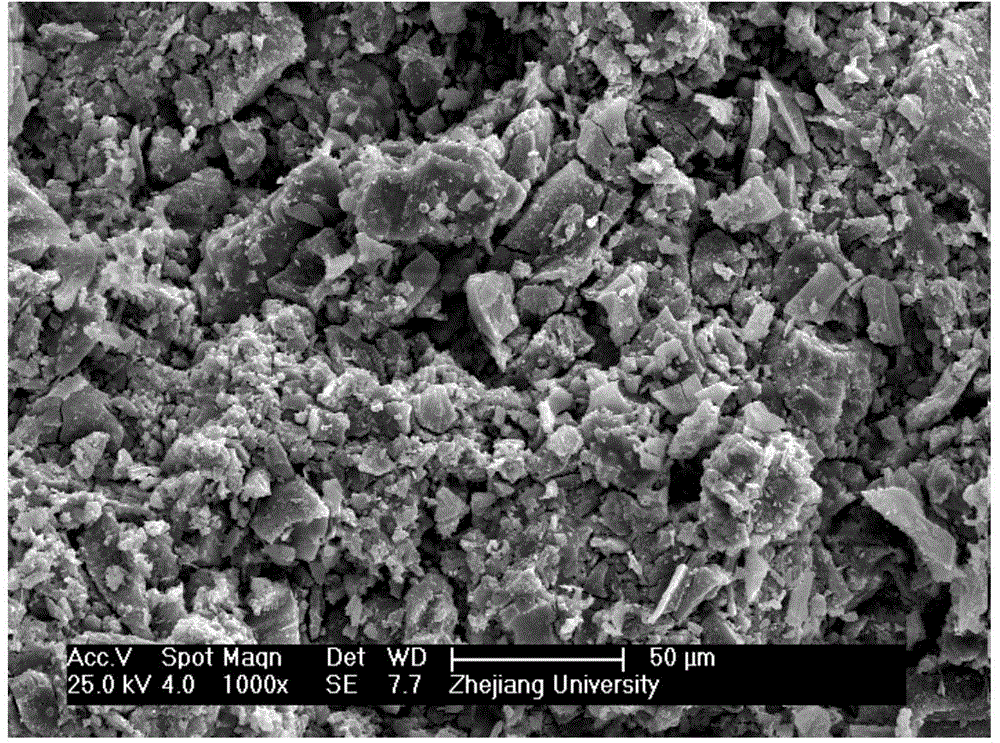

Application of zeolite powder in wall coating

InactiveCN101054488AGood environmental protection functionLow costEmulsion paintsUltimate tensile strengthAir humidity

The invention relates to an application of zeolite powder in the wall dopes. The zeolite powder is used as the inorganic filler in the wall dopes and the obtained dopes have good environmental protection effect. The dopes can effectively absorb the toxic and hazardous gases in the environment and adjust the air humidity after being cured into paint membrane. The invention also has the effects of good continuity of the paint membrane, high strength, reinforced washing and brushing resistance and improved adhesion between the paint membrane and the wall.

Owner:翟翠明

Crack-resistant plasterboard

The invention discloses a crack-resistant plasterboard. The crack-resistant plasterboard comprises, by weight, 12 parts of ore tailings, 42 parts of quicklime, 3 parts of iron oxide powder, 4 parts of fly ash, 14 parts of alumina silicate fibers, 10 parts of a silicon filling material, 4 parts of slag, 6 parts of a polymer emulsion, 6 parts of a calcium oxide expanding agent and 95 parts of water. The crack-resistant plasterboard avoids plasterboard cracking, does not contain formaldehyde, has no pollution, guarantees plasterboard strength and hardness and has good environmental protection functions.

Owner:平邑县富华石膏制品有限公司

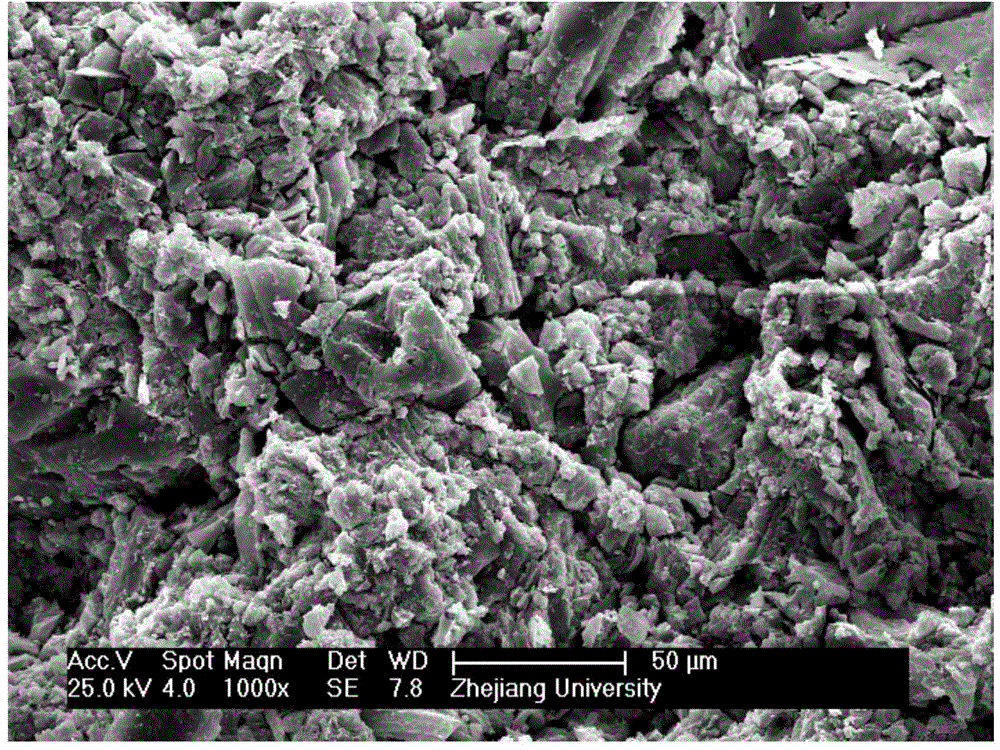

Preparation method of aqueous paint for degradation of formaldehyde gas and toluene gas

ActiveCN103275543AEfficient degradationActive removalPhysical/chemical process catalystsDispersed particle separationHydrolysisRaw material

A preparation method of an aqueous paint for degradation of a formaldehyde gas and a toluene gas is provided, and comprises: using a natural micropore nonmetal mineral as raw material; purifying the mineral by means of scrubbing, acid leaching, calcining and the like; using the purified micropore nonmetal mineral as a carrier, using an inorganic titanium salt as a precursor, and preparing a nano titanium dioxide composite photocatalytic material by neutralization, hydrolysis and precipitation at a low temperature; and using the prepared nano titanium dioxide composite photocatalytic material as a filler, and preparing the aqueous paint for degradation of the formaldehyde gas and the toluene gas. Harmful substances such as volatile organic compounds, formaldehyde, toluene and the like are not contained in the paint, and the formaldehyde gas and the toluene gas can be effectively degraded, with the formaldehyde degradation rate of up to 80% or more and the toluene degradation rate of up to 35% or more.

Owner:LUOYANG INST OF SCI & TECH

Preparation method of gypsum board

InactiveCN110386803AHigh compressive strengthHigh tensile strengthCeramicwareEnvironmental resistancePhosphogypsum

The invention belongs to the technical field of gypsum board preparation processes, and particularly relates to a preparation method of a gypsum board. The preparation method of the gypsum board comprises the following steps: a prepared oxidized desulfurization gypsum and a pretreated phosphogypsum are adopted and put into a ball mill for ball milling with a speed of 200-300 r / min and a ball milling time of 1.5-2.5 h, then transferred to a homogenization bin for homogenization, and then transferred to a disc mixer, then 15-18 parts of modified starch, 10-15 parts of modified glass fiber, 15-20parts of a coagulant, 2-8 parts of glass powder, 2-5 parts of a foaming agent, and 0.06-0.12 part of sodium dodecyl sulfate are added, and uniform mixing is carried out to obtain a mixed material; and the mixed material is poured into a flat forming machine pressed with a face protective paper, then a layer of the face protective paper is attached on the surface, hot pressing is carried out at conditions of a temperature of 180-210 DEG C and a pressure of 20-25 MPa, and solidification, cutting, drying and edge sawing are carried out to obtain the environment-friendly, lightweight and high-strength gypsum board. The preparation method of the gypsum board has the advantages of simple operation, no formaldehyde release in the process, safety and environmental protection, and good environmental protection function.

Owner:阜新泰山石膏建材有限公司

Method for simultaneously separating secondary cannabidiol and cannabigerol

ActiveCN110590511ANo pollution in the processLarge amount of preparationOrganic chemistryOrganic compound preparationCountercurrent chromatographyCannabigerol

The invention relates to a method for simultaneously separating secondary cannabidiol and cannabigerol. The method comprises the following steps: sufficiently oscillating a solvent system, allowing the solvent system to stand, and separately collecting an upper phase and a lower phaser; dissolving an industrial hemp full-spectrum essential oil sold in the market into the upper phase, performing separation by using high-speed countercurrent chromatography by taking the upper phase as an immobile phase and the lower phase as a mobile phase so as to respectively obtain a mixed liquid of secondarycannabidiol and the mobile phase and a mixed liquid of cannabigerol and the mobile phase, and removing the mobile phase, so as to obtain the secondary cannabidiol and the cannabigerol. By adopting the method, a high-speed countercurrent chromatography technique is adopted for a first time to simultaneously separate and purify secondary cannabidiol (CBDV) of which the purity is greater than 98% and cannabigerol of which the purity is greater than 97% from the industrial hemp full-spectrum essential oil.

Owner:SHANGHAI TAUTO BIOTECH CO LTD

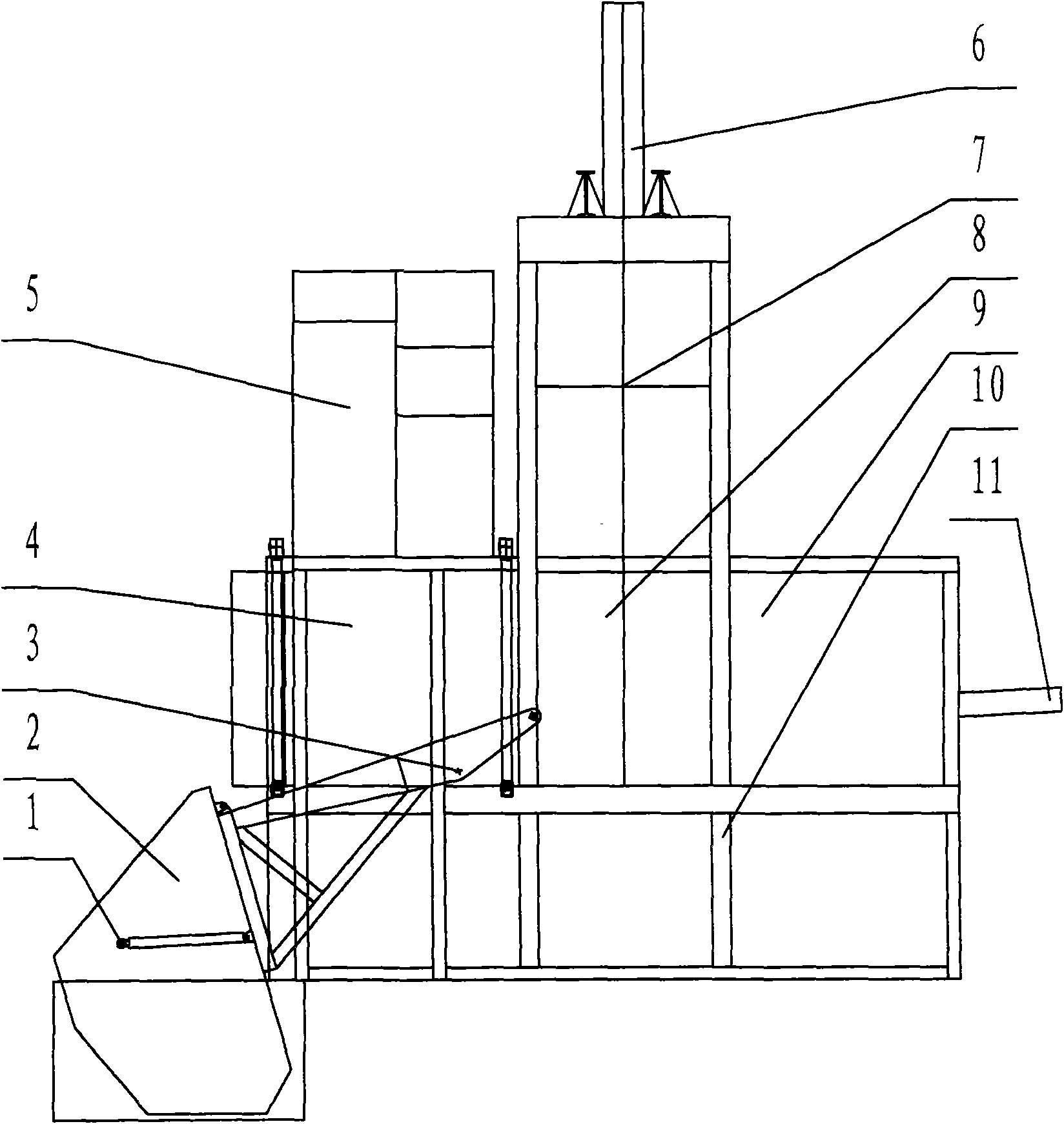

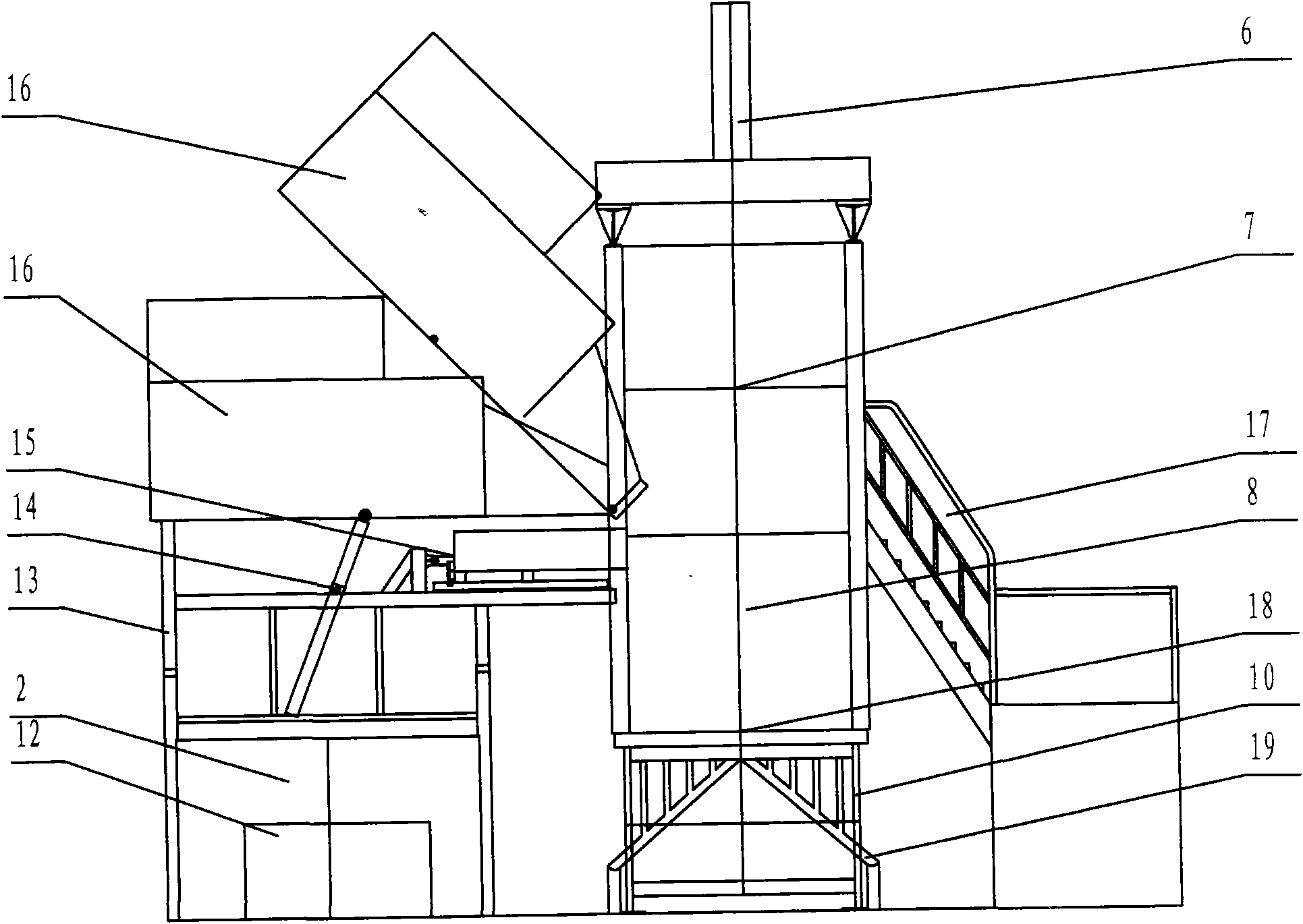

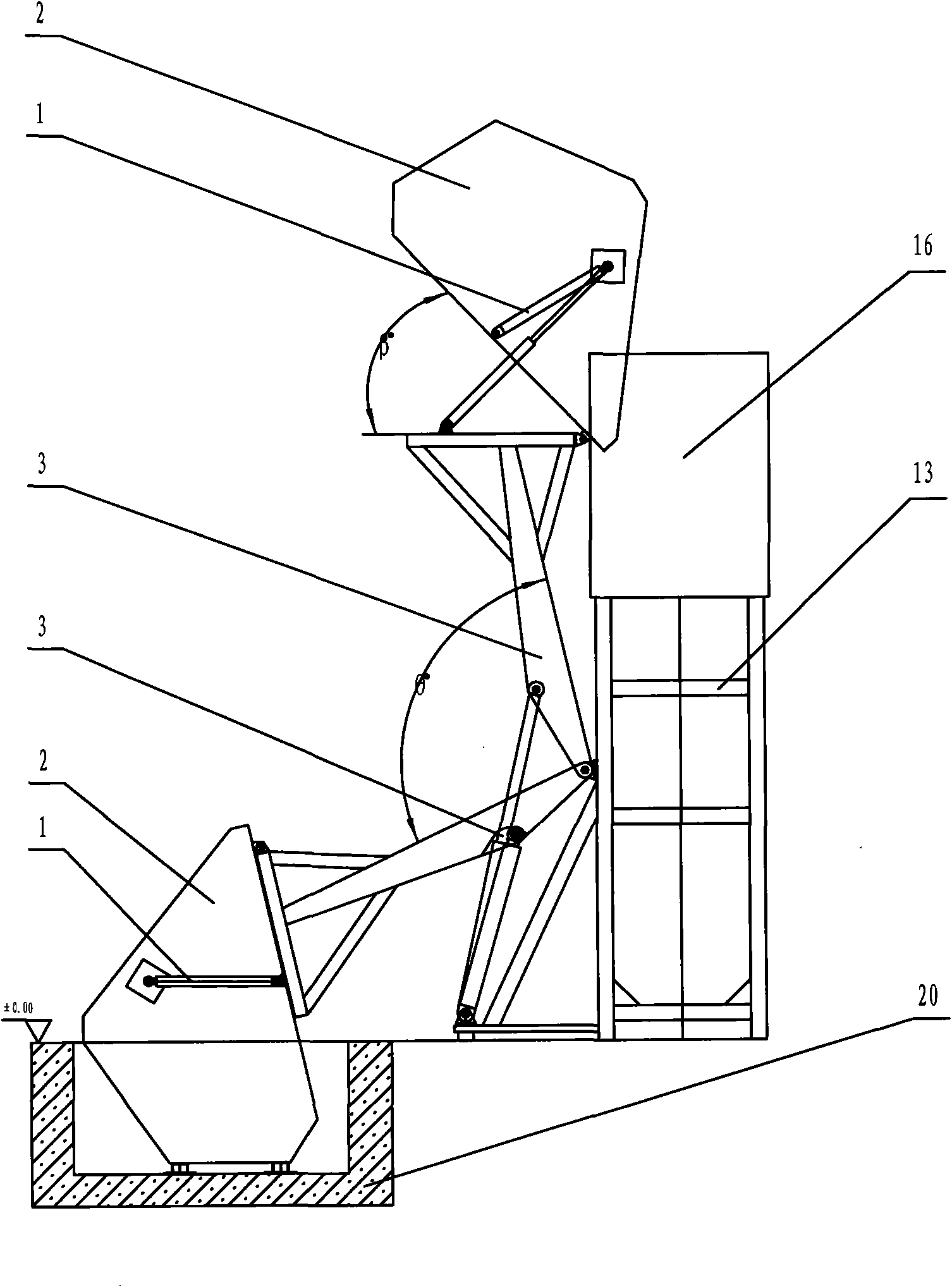

Integrated vertical garbage compressor

ActiveCN101817439AIncrease productivityImprove transport efficiencyRefuse transferringLoading/unloadingAbove groundGas compressor

The invention discloses an integrated vertical garbage compressor, which comprises a box body, a compact garbage transferring mechanism (11) and a garbage compressing mechanism (7), wherein the box body integrates a garbage compressing bin (8), a compact garbage block storage bin (4) and a compact garbage block transferring mechanism installation bin (9); and the compressor is characterized by also comprising garbage receiving mechanism, a garbage storage mechanism, a garbage heap shape processing mechanism (15) and a compressing bin sewage potential energy discharging mechanism (19); and the mounting height of the box body requires meeting truck loading height of a high compact compressing block during loading for outward transportation. The garbage compressor can simultaneously execute the working procedures of the storage, the delivery and the compression of loose garbage, thereby improving garbage transferring efficiency; and when the compact garbage block is loaded, the compressing bin is not required to be lifted, which not only reduces operating failures of equipment, but also changing kinetic energy sewage discharging into potential sewage discharging by improving a sewage discharging surface from below ground to above ground, thereby the invention saves energy, discharges completely and greatly improves working environment.

Owner:FUJIAN BAIJIE SANITATION MACHINERY CO LTD

Wear-resistant anti-cracking environment-friendly plasterboard and preparation method thereof

The invention discloses a wear-resistant anti-cracking environment-friendly plasterboard which is prepared from the following raw materials in parts by weight: polyvinyl alcohol 8-14 parts, pulverized fuel ash 7-9 parts, old plasterboard powder 35-45 parts, gypsum powder 25-35 parts, anti-cracking fiber 10-14 parts, an initiator 1-3 parts, an antifoamer 1-1.4 parts, a dispersant 2-4 parts, crystalline flake graphite 10-14 parts, starch 5-10 parts, and deionized water 50-70 parts. The plasterboard of the invention has the advantages of high and compression strength, static bending strength, large screw holding capability and breaking resistant elasticity modulus, low heat conductivity coefficient, and has the characteristics of good antibacterial property, mechanical property, anti-electromagnetic radiation property and anti-friction property. Meanwhile, the raw materials of the wear-resistant anti-cracking environment-friendly plasterboard are safe and reliable, environment-friendly and easily-accessible, the cost is low, the process is simple and is easy to operate and realize industrial production, and the process has high practical value and good application prospects.

Owner:合肥市淑芹美装饰工程有限公司

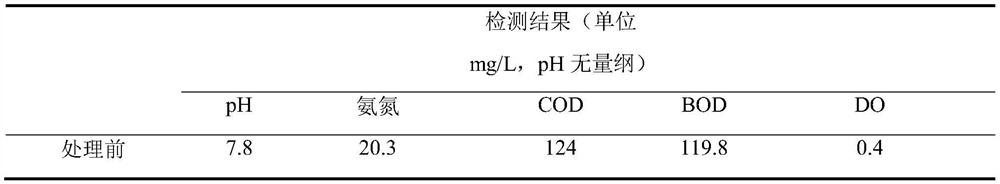

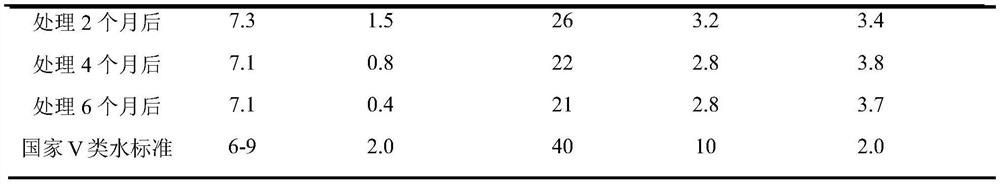

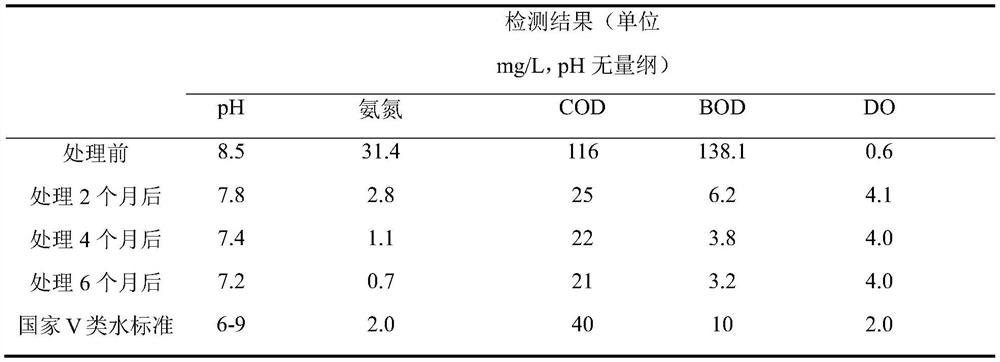

Ecological restoration method for black and odorous river channel

PendingCN113264633AStrong maneuverabilityThorough governanceWater resource protectionWater treatment parameter controlTreatments waterEcosystem

The invention provides an ecological restoration method for a black and odorous river channel, and belongs to the technical field of sewage treatment. According to the method, ecological restoration is carried out on the black and odorous river channel from five aspects of source control and sewage interception, bottom mud treatment, water body purification, ecological restoration and maintenance management, and the method is high in operability, thorough in treatment and high in treatment efficiency; through reconstruction of a riverway ecological system, the self-cleaning capacity of the water body is gradually restored, the peculiar smell and chroma of the black and odorous water body are gradually eliminated, finally ecological balance of the water body is achieved, the water quality is improved, the water body ecological system can be healthily and stably developed for a long time, and good environment-friendly and ecological functions are achieved.

Owner:SCI RES ACADEMY OF GUANGXI ENVIRONMENTAL PROTECTION

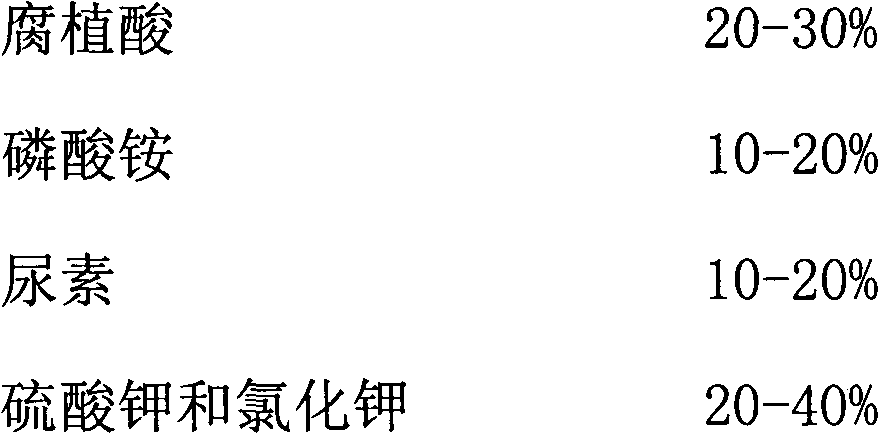

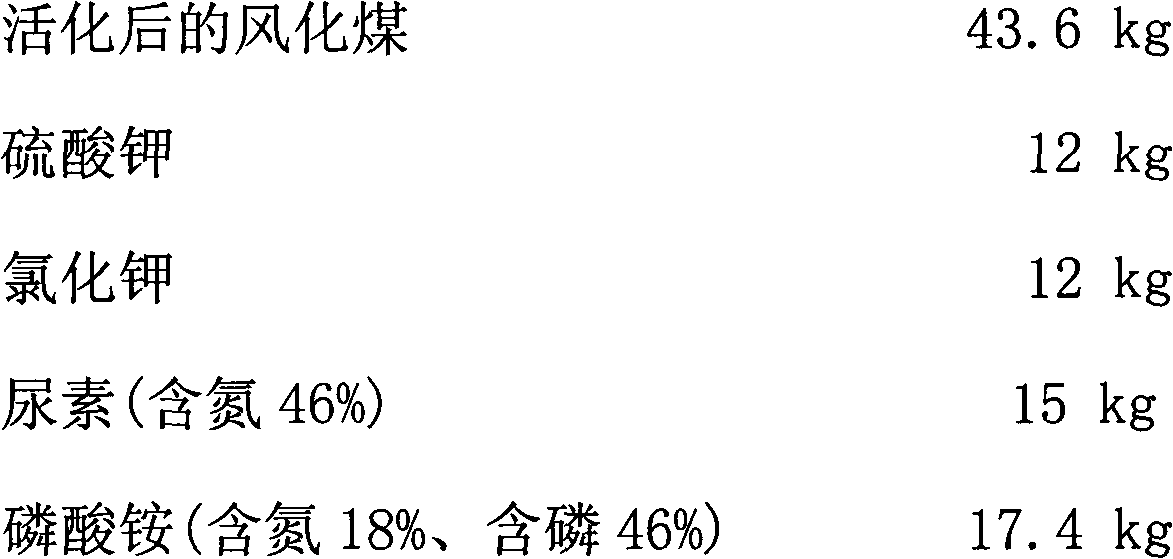

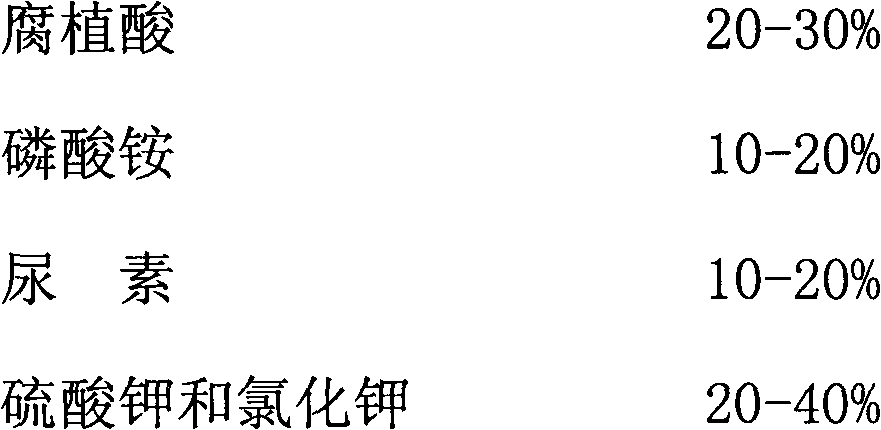

Production method of humic-acid compound fertilizer

The invention relates to a production method of a humic-acid compound fertilizer, wherein the formula of the humic-acid compound fertilizer comprises the following components: 20-30 percent of humic acid, 10-20 percent of ammonium phosphate, 10-20 percent of urea and 20-40 percent of potassium sulfate and potassium chloride, wherein the final combining proportion of all components after a product is finished should be 100 percent. The production method has the advantages of wide raw-material source, low price, reasonable and simple process flow and lower equipment cost, and the produced fertilizer has the advantages of low cost, good fertilizer efficiency, outstanding environment-friendly function and good use value and market prospect.

Owner:张静

Fiberglass online cutting machine with dust collecting device

InactiveCN104118000AReduce labor intensitySave work spaceDirt cleaningMetal working apparatusEngineeringCentrifugal fan

The invention discloses a fiberglass online cutting machine with a dust collecting device. The fiberglass online cutting machine comprises a fixed support, a movable support, a walking cutting machine body and the dust collecting device. The movable support is arranged on the upper portion of the fixed support. The walking cutting machine body is arranged on the upper portion of the movable support. The dust collecting device comprises a dust collecting cover, a dust collecting pipeline, a centrifugal fan and a dust collector, wherein the dust collecting cover is arranged on the upper portion of the walking cutting machine body, the dust collecting pipeline is arranged between the centrifugal fan and the dust collecting cover, and the dust collector is connected with an outlet of the centrifugal fan. By means of the mode, the fiberglass online cutting machine with the dust collecting device can cut fiberglass online, one-time machining of fiberglass is finished, the procedure that the fiberglass is transported again to a cutting occasion to be cut is omitted, working space is effectively saved, production efficiency of products is improved, the labor intensity of workers is relieved, ad the fiberglass online cutting machine has a good environmental friendliness function.

Owner:JIANGSU HAODA

Environmental-friendly gypsum board

InactiveCN104355593ARealize resource reuseGuaranteed StrengthSolid waste managementSlagUltimate tensile strength

The invention discloses an environmental-friendly gypsum board. The environmental-friendly gypsum board comprises the following raw materials in parts by weight: 20-25 parts of blast furnace slag with the particle size of 80-100 microns, 30-45 parts of flue gas desulfurization gypsum, 8-10 parts of plant ash, 12-15 parts of slag wool, 9-11 parts of water glass, 3-5 parts a water reducer and 40-50 parts of water with the Ph value of 9-11. The environmental-friendly gypsum board uses the blast furnace slag, the plant ash and the slag wool as the raw materials, is formaldehyde-free and pollution-free during production, meanwhile, realizes recycling of gypsum resources, and has an excellent environmental-friendly function while ensuring the strength and the hardness of the gypsum board.

Owner:合肥向荣环保科技有限公司

Method for completely separating oleic acid and linoleic acid

ActiveCN110590545ANo pollution in the processLarge amount of preparationCarboxylic compound separation/purificationReverse connectionLinoleic acid

The invention relates to a method for completely separating oleic acid and linoleic acid. The method comprises the following steps: fully shaking a solvent system, carrying out standing for separatingphases, and separately collecting the upper phase and the lower phase; dissolving 70-80% high-purity oleic acid in the upper phase, and carrying out separating by adopting high-speed counter-currentchromatography. Starting from sample feeding, firstly, forward connection and forward rotation are carried out, wherein the upper phase is a fixed phase, the lower phase is a mobile phase, and a mixedsolution of linoleic acid and the lower phase is obtained; then reverse connection and forward rotation are carried out, wherein the lower phase is a fixed phase, the upper phase is a mobile phase, and a mixed solution of oleic acid and the upper phase is obtained; and the lower phase and the upper phase are removed to separately obtain linoleic acid and oleic acid. According to the method, the oleic acid with purity of more than 99% is obtained by separating and purifying 70-80% high-purity oleic acid by using a high-speed counter-current chromatography technology for the first time, reagents of the solvent system can be recycled, and in theory, 100% of oleic acid can be recycled.

Owner:SHANGHAI TAUTO BIOTECH CO LTD

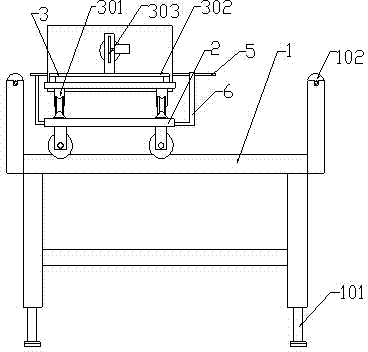

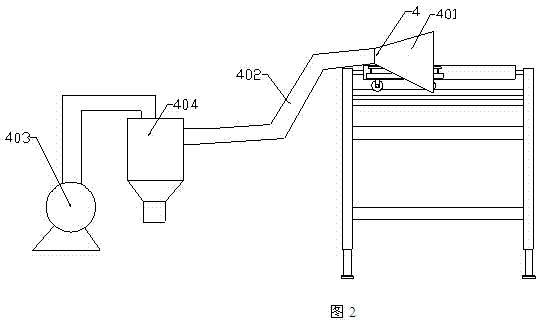

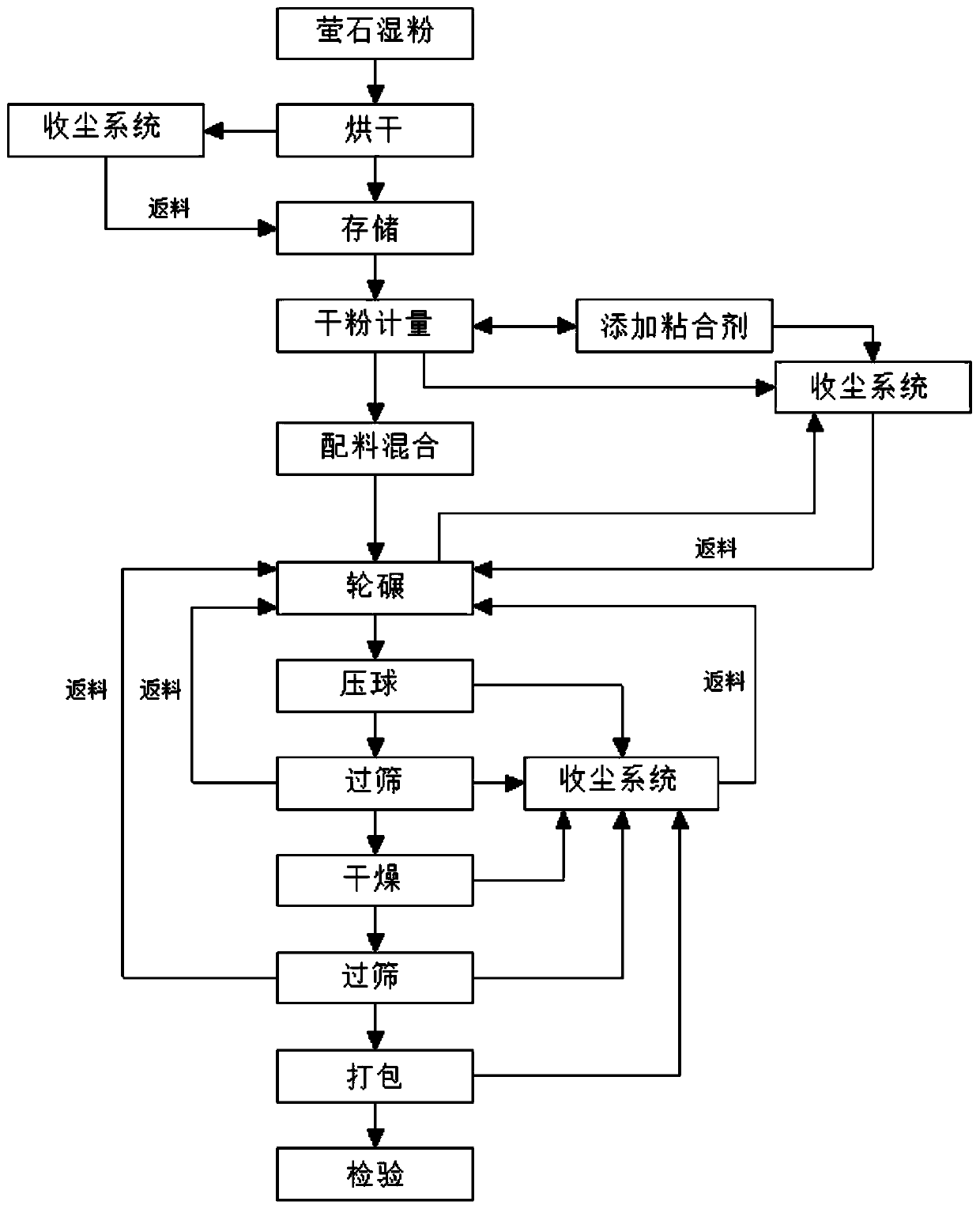

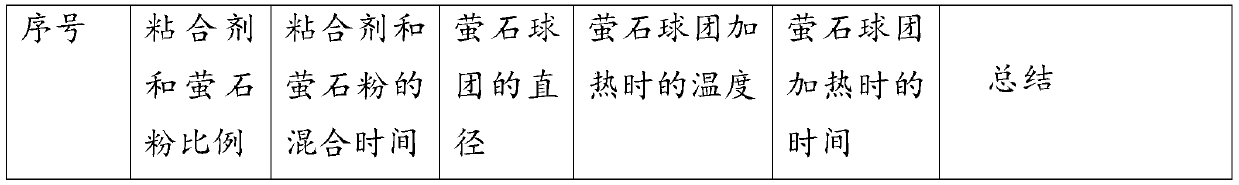

Fluorite pellet production method

The invention provides a fluorite pellet production method. The fluorite pellet production method comprises the following steps that S1, wet fluorite powder is prepared; S2, the prepared wet fluoritepowder is poured into a rotary kiln, and the wet fluorite powder is dried through the rotary kiln; S3, a storage container is prepared, the fluorite powder dried in the rotary kiln in the step S2 is discharged into the storage container, and dust generated during drying in the step S2 is collected through a dust collection system and discharged into the storage container; S4, the fluorite powder in the storage container in the step S3 is poured into a dry powder weighing machine. By means of the fluorite pellet production method, fluorite pellets can be quickly produced, no harmful gas is discharged, a good environment protection function is achieved, operation is simple, the practicability is high, time and labor are saved, method steps are reduced, the production cost of a company is reduced, requirements of different factories are met, and the using effect of the fluorite pellets is improved.

Owner:湖南有色郴州萤石球团有限公司

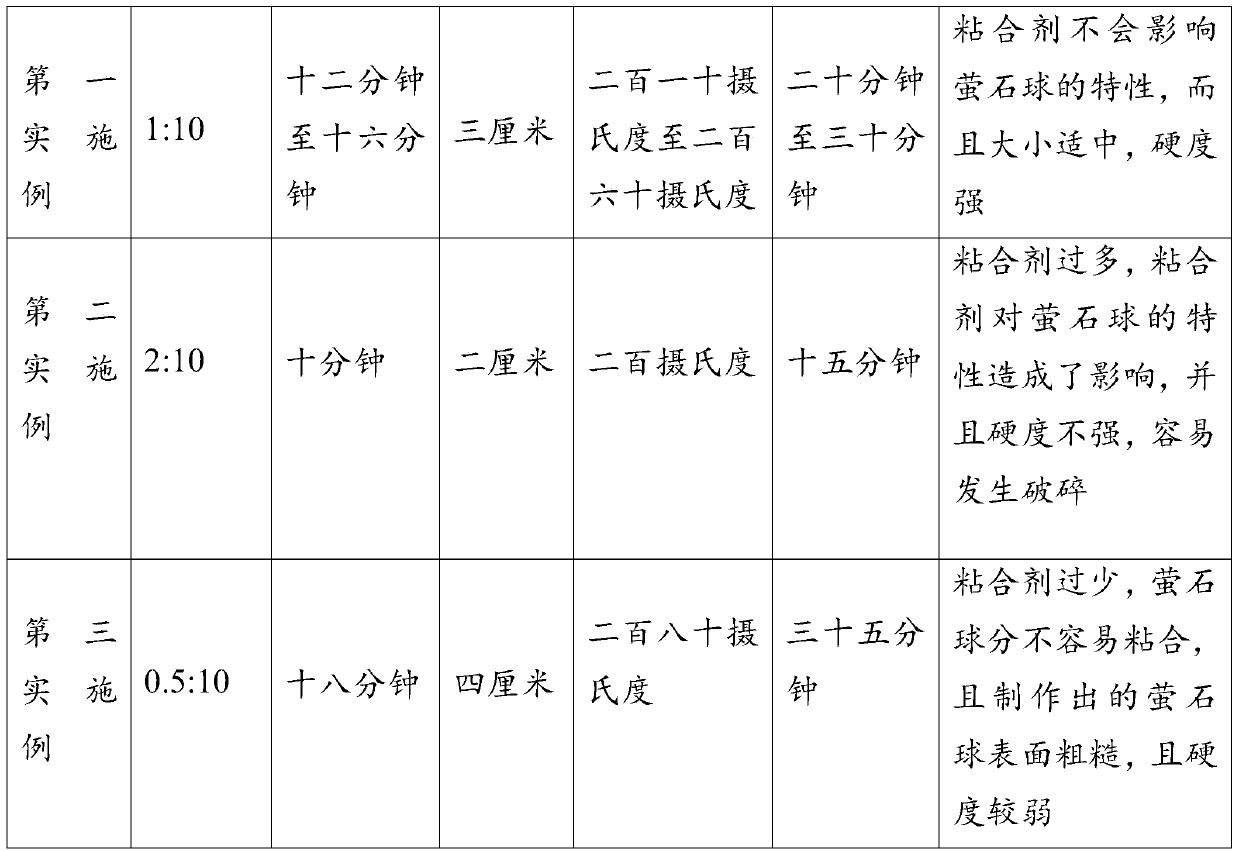

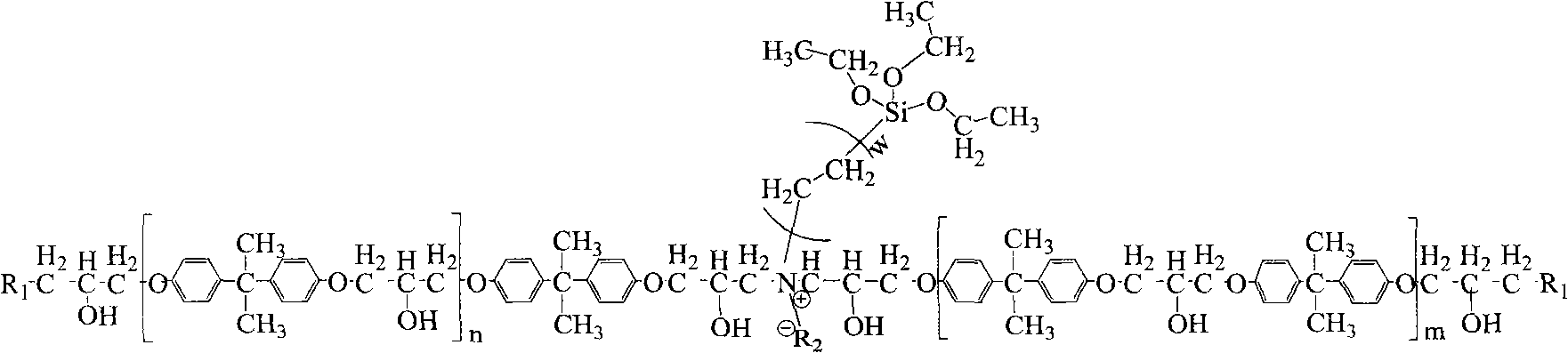

Ultraviolet light-moisture-heat triple curable automobile aqueous intermediate coat and preparation method thereof

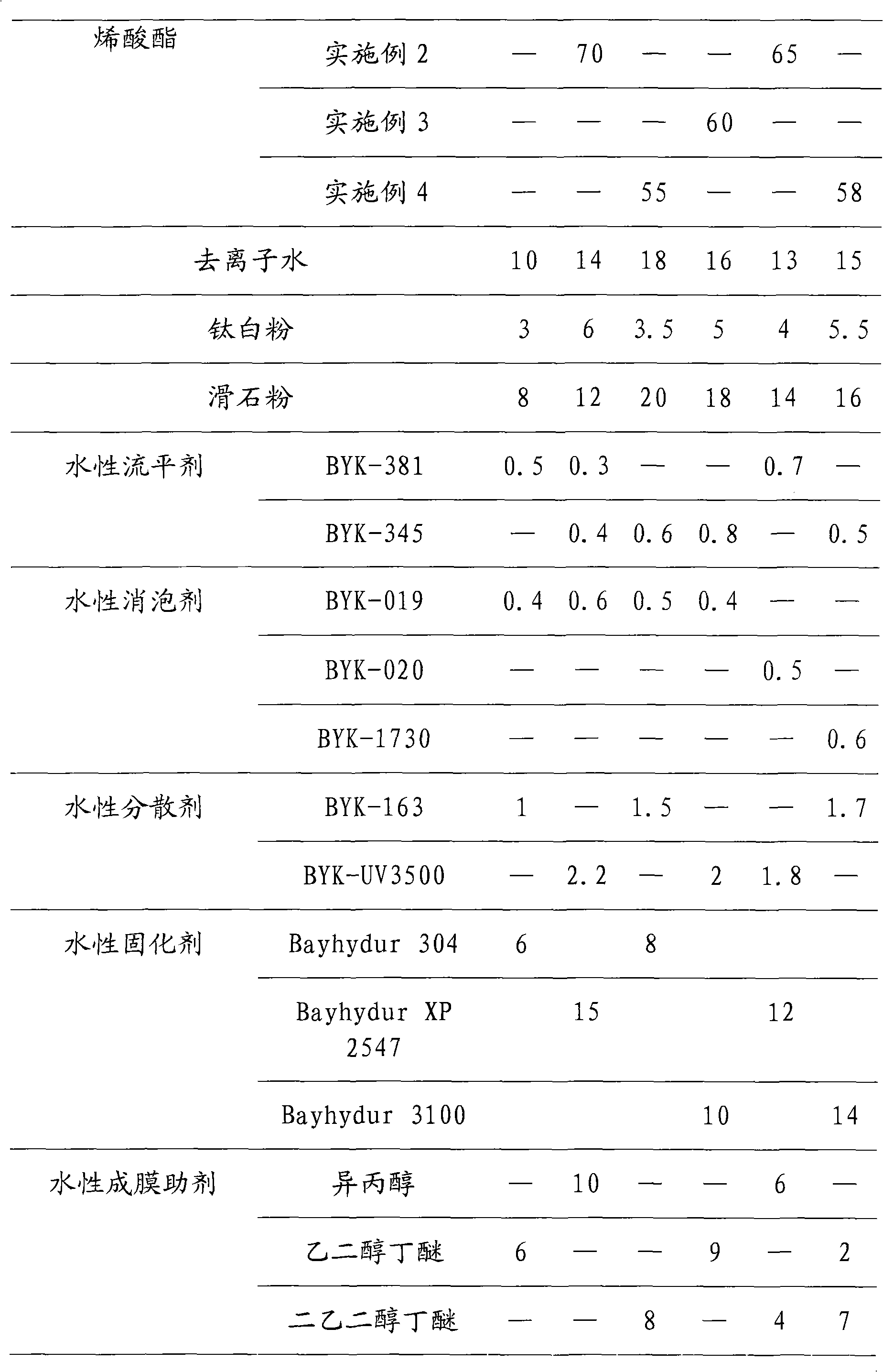

ActiveCN103387658AImprove mechanical propertiesImprove impact resistanceGroup 4/14 element organic compoundsPolyurea/polyurethane coatingsUltraviolet lightsSolvent

The invention provides a compound with a structure represented by a formula (I). R1 is acrylic group or methacrylic group. R2 is protonic acid group. w, m, and n are degrees of polymerization, where w=1-50, m=1-50, and n=1-50. The invention also provides an ultraviolet light-moisture-heat triple curable automobile aqueous intermediate coat comprising, by weight, 50-70 parts of modified aqueous epoxy acrylate with a structure represented by the formula (I), 6-15 parts of an aqueous curing agent, 10-18 parts of water, 6-10 parts of an aqueous film-forming cosolvent, 1-2.2 parts of an aqueous dispersing agent, 0.4-0.6 parts of an aqueous defoaming agent, 0.5-0.8 parts of an aqueous leveling agent, 8-20 parts of talcum powder, 3-6 parts of titanium dioxide, and 4-5 parts of a photoinitiator. The automobile aqueous intermediate coat is environment-friendly and energy-saving, and has excellent impact resistance and good grinding performance.

Owner:华涂化工(吉林)有限公司

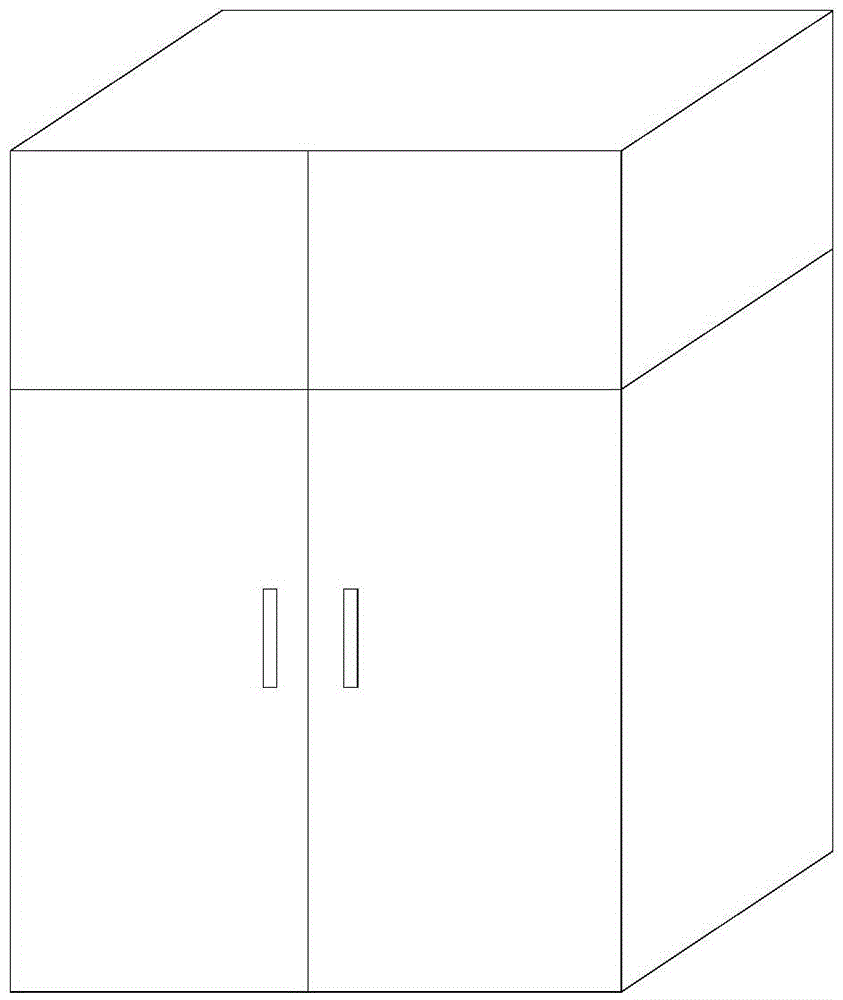

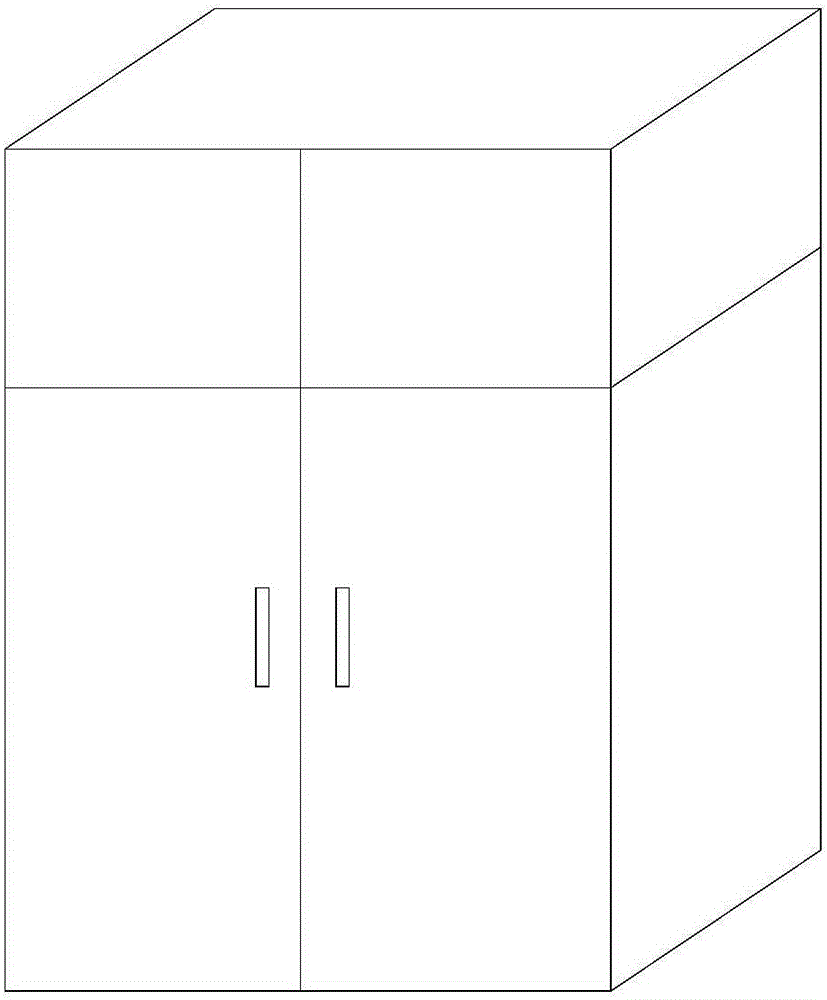

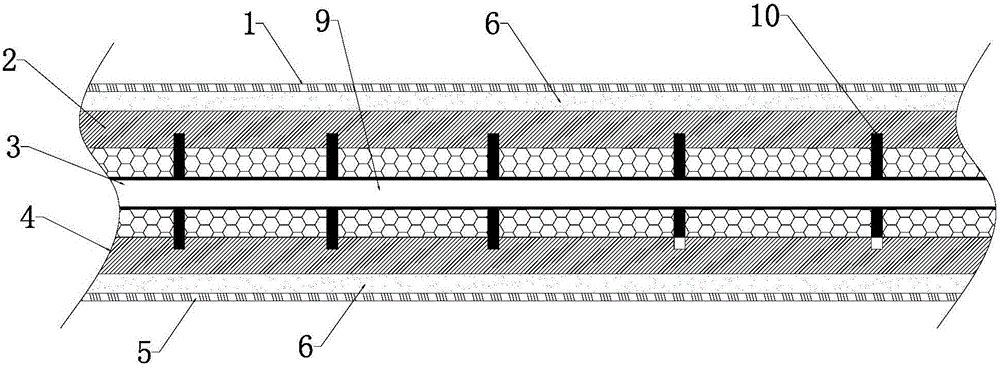

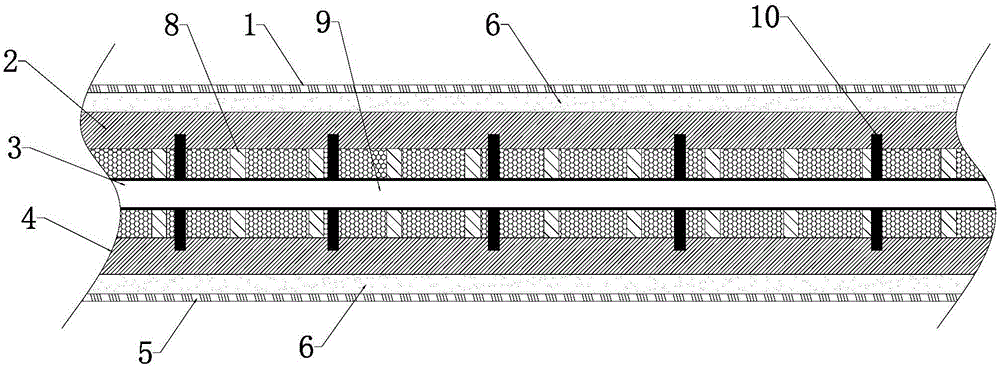

Novel cabinet

InactiveCN105619907AAchieve productionDifferent interior effectsSynthetic resin layered productsPaper/cardboard layered productsActivated carbonEngineering

The invention provides a novel cabinet which is formed by splicing a plurality of side panels and a door plank, and the side panels or / and the door plank are made of composite plates composed of multiple layers of materials. Each composite panel comprises an upper panel layer, an upper compressive layer, a heat preservation layer, a lower compressive layer and a lower panel layer from top to bottom in sequence, the position between each upper panel layer and the corresponding upper compressive layer or / and the position between each lower panel layer and the corresponding lower compressive layer is / are filled with adsorbent, the upper panel layer or / and the lower panel layer is / are densely provided with micropores communicated with the adsorbent on the inner side(s) of the upper panel layer or / and the lower panel layer, activated carbon is adopted as the adsorbent, the thickness of the upper panel layer and the thickness of the lower panel layer range from 1 mm to 10 mm, the thickness of the upper compressive layer is the same as that of the lower compressive layer, the thickness of the upper compressive layer is one time and above larger than that of the upper panel layer, the thickness of the heat preservation layer is one time and above larger than that of the upper compressive layer, and the inner side face of the upper compressive layer or / and the inner side face of the lower compressive layer is / and provided with reinforcing ribs which are parallel to one another or intersect with one another. The novel cabinet has the functions of heat preservation, shock resistance, sound insulation and the like.

Owner:长沙中瞿新材料科技有限公司 +1

Double-layer empty-sticking decorative structure for wall surface

ActiveCN105696767AThe door width is optionalSimple structureCovering/liningsEnvironmental resistanceComposite structure

The invention discloses a double-layer empty-sticking decorative structure for the wall surface. The double-layer empty-sticking decorative structure for the wall surface comprises a wallpaper layer and further comprises a bonding layer and a strut layer. The bonding layer, the strut layer and the wallpaper layer are sequentially arranged from the wall surface to the outside so as to form a three-layer composite structure. The bonding layer is transversely arranged, the strut layer is vertically arranged, and the wallpaper layer is transversely or vertically arranged; and the bonding layer and the wall surface are arranged in an empty-sticking manner, and the wallpaper layer and the bonding layer are arranged in an empty-sticking manner, so that the double-layer empty-sticking structure is formed and is the main characteristic, and the double-layer empty-sticking decorative structure for the wall surface has the beneficial effects that the structure is simple, the decorative process is simple, the decorative work efficiency is high, decorative cost is low, multiple kinds of strip-shaped decorative materials of different width specifications can be adopted at the same time for construction, and the environmental protection function is good.

Owner:CHANGHZHOU LONGCHENG HANREE WALL COATING

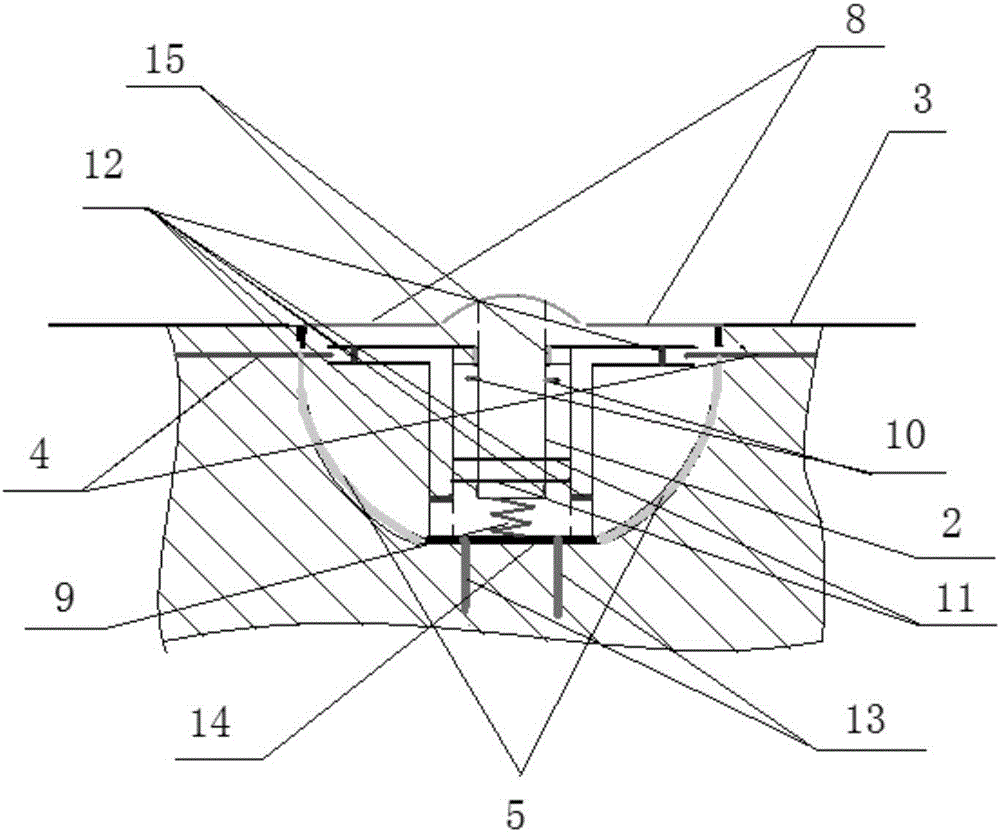

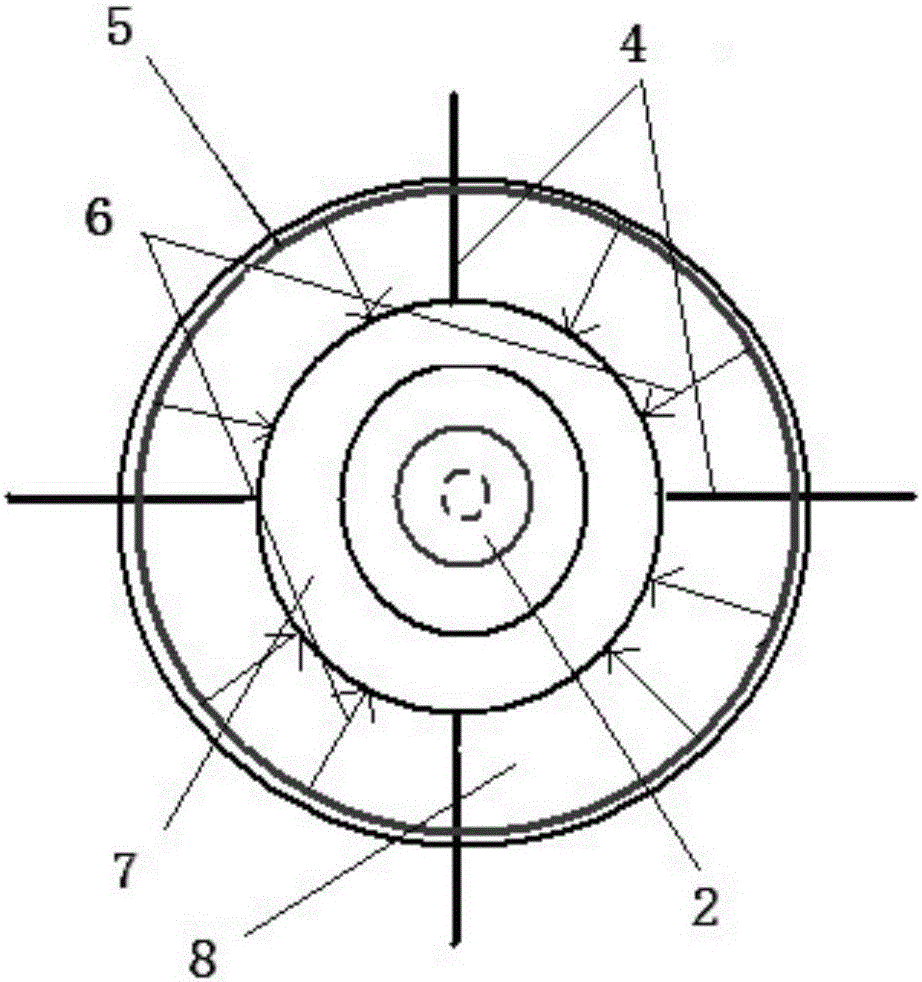

Self-deicing device and anti-icing road system

ActiveCN106592383AFull do-it-yourself performanceAll-weather performancePaving detailsAir compressionSnow removal

The invention relates to the technical field of ice and snow removal and especially relates to a self-deicing device and an anti-icing road system. The self-deicing device comprises multiple energy gathering / releasing honeycombs embedded below a surface of a subgrade and heat radiation conduits connected to the honeycombs, the inner surface of a honeycomb casing of the honeycomb is provided with a parabolic mirror, an air compression releaser is an individual component detachably connected to the honeycomb casing, a compression movable joint is resiliently connected to the bottom, the housing of the air compression releaser forms a central focal column, the central focal column has a central passage and a circumferential passage provided around the central passage, the lower end of the central passage is in communication with the lower end of the circumferential passage, a transparent glass ring cover is packaged at an opening at the upper end of the honeycomb casing, one end of the compression movable join is movably inserted into the central passage of the central focal column, and the one or more heat radiation conduits are connected to the upper opening of the circumferential passage of the central focal column. The self-deicing device has a clever design and is conducive to promotion and application.

Owner:央青卓玛

Cabinet body

InactiveCN105768643AIncrease production capacityEnvironmentally friendlyFurniture partsActivated carbonInsulation layer

The invention discloses a cabinet body.The cabinet body is formed by splicing multiple side plates and a door plate, the side places and / or the door plate are all made of composite plates formed by compositing multiple layers of materials, each composite plate comprises an upper surface plate layer, an upper compression resistant layer, a heat insulation layer, a lower compression resistant layer and a lower surface plate layer in sequence from top to bottom, the space between each upper surface plate layer and the corresponding upper compression resistant layer and / or the space between the lower compression resistant layer and the lower surface plate layer are / is filled with adsorbent, and micropores are densely formed in each upper surface plate layer or / and each lower surface plate layer, wherein the micropores are communicated with the adsorbent at the inner side / sides of each upper surface plate layer or / and each lower surface plate layer; activated carbon is adopted as the adsorbent, a wiring tube is prefabricated in each plate body, each wiring tube is arranged in the corresponding heat insulation layer in a penetrating mode, the outer wall of each wiring tube is provided with protruding blocks extending toward the corresponding upper compression resistant layer and the corresponding lower compression resistant layer at the two sides of the wire tube, and clamping grooves are formed in the corresponding positions of each upper compression resistant layer and the corresponding lower compression resistant layer.The cabinet body has the traditional containing function and furthermore has the functions of air purification, heat insulation, shock absorption, sound insulation and the like.

Owner:长沙中瞿新材料科技有限公司 +1

Gradual-change cavity microperforated broad band sound absorption type sound barrier

ActiveCN100523385CThin and lightweightImprove sound absorptionNoise reduction constructionSound barrierFiber

The invention belongs to the technical field of acoustics, and in particular relates to a non-fiber novel gradually changing cavity micro-perforated sound-absorbing sound barrier body. It is composed of micro-perforated panel, upper end surface, lower end surface, left end surface, right end surface and back plate. The micro-perforated panel, upper end surface, lower end surface, left end surface, right end surface and back plate are connected to form a closed cavity, and the depth of the cavity is linear Gradient, the maximum depth is 2.5-3.5 times the minimum depth. The microperforated panel is distributed with micropores occupying an area of 0.5% to 3% of the panel area, and the diameter of the micropores is 0.6 to 1.2mm. When in use, it only needs to install the present invention in the column of the sound barrier or other places requiring sound absorption treatment. The invention has the advantages of simple device, easy processing, thin shape and light weight, excellent sound absorption performance, the sound absorption frequency band width of which the sound absorption coefficient is greater than 0.4 exceeds 2 octaves, wide application, easy cleaning, high temperature resistance, and excellent weather resistance , can be completely recycled, completely avoiding the problem of secondary pollution, and has excellent environmental protection functions.

Owner:SHAZC GRP CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com