Construction method of underwater rockfill concrete

A technology of rockfill concrete and construction method, applied in the direction of infrastructure engineering, construction, etc., can solve the problems of high unit cost, large hydration temperature rise, high cement consumption, and achieve the goal of reducing usage, improving construction efficiency, and shortening construction period. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The construction method of underwater rockfill concrete, the specific implementation steps are as follows:

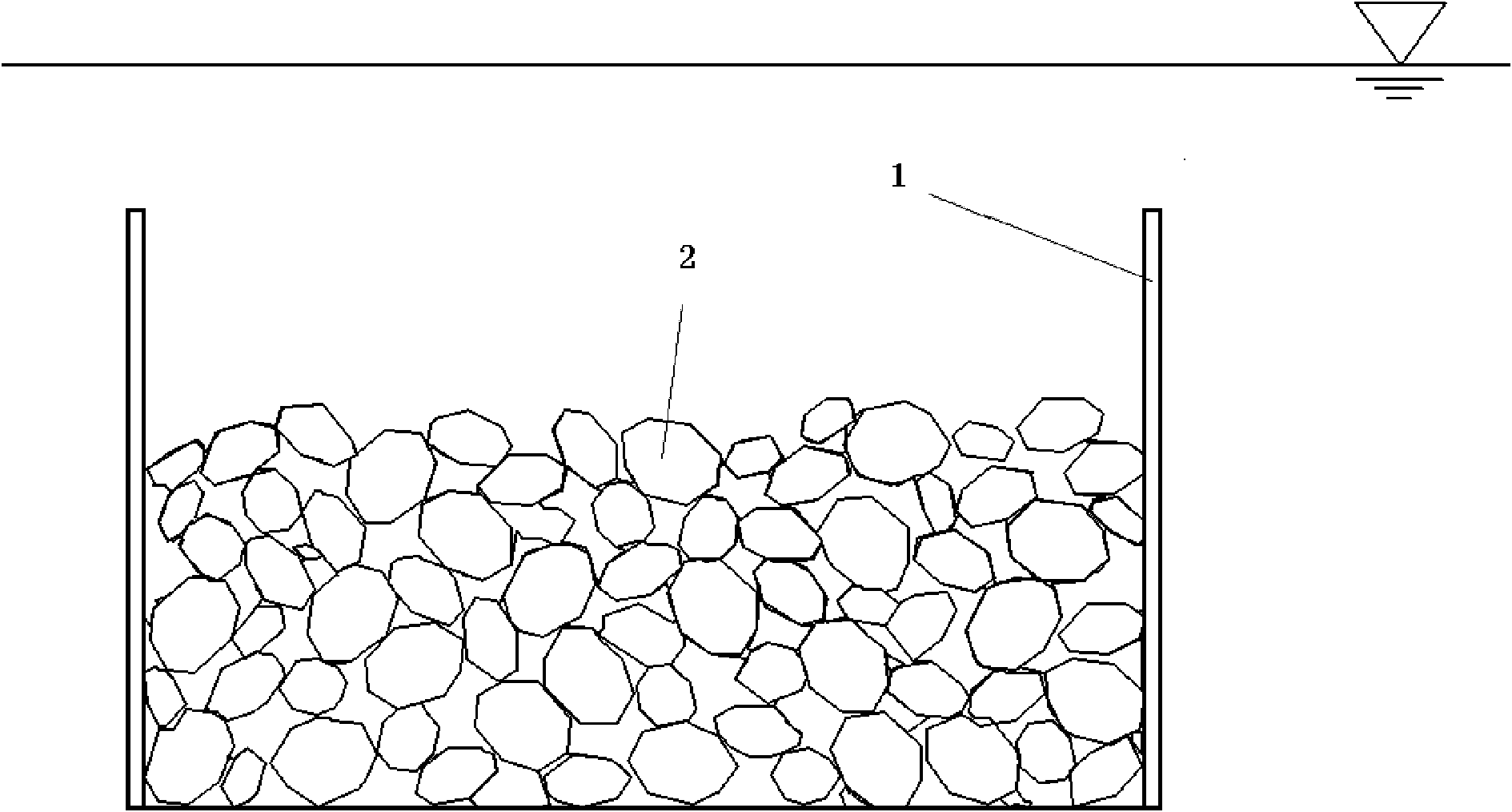

[0021] (1) Set up templates for the warehouse surface of the underwater rockfill concrete to be poured (such as figure 1 As shown), there is no need to set a template for the warehouse surface with natural barriers;

[0022] (2) Use stones or pebbles with a particle size of 30-80cm to accumulate naturally to fill the surface of the warehouse to be poured, and the thickness of the surface of the warehouse is 1.0m;

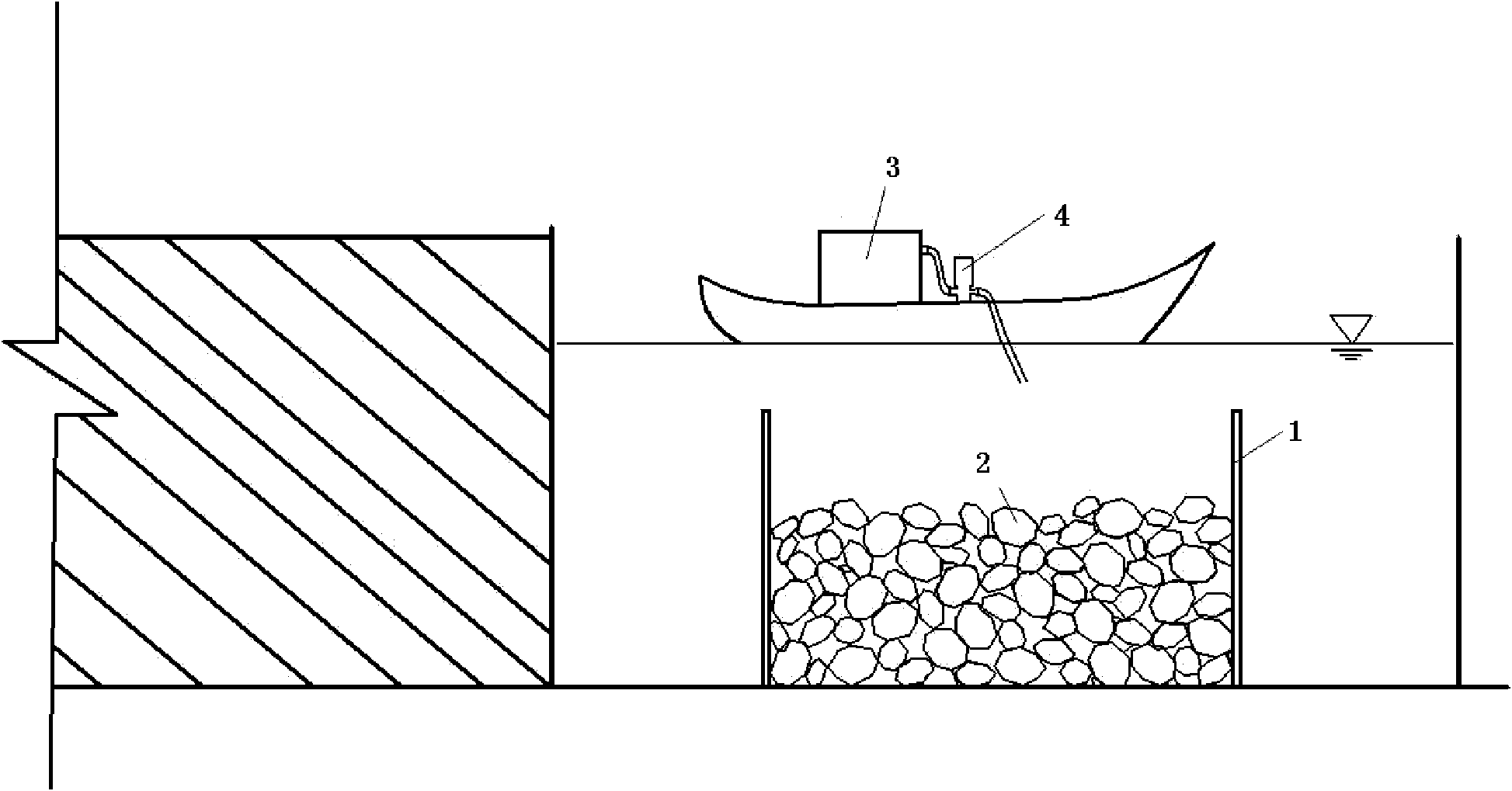

[0023] (3) Use a small boat with a water pump (such as figure 2 As shown) put a certain amount of protective agent to protect the integrity of underwater self-compacting concrete into the water body area where underwater rockfill concrete needs to be poured;

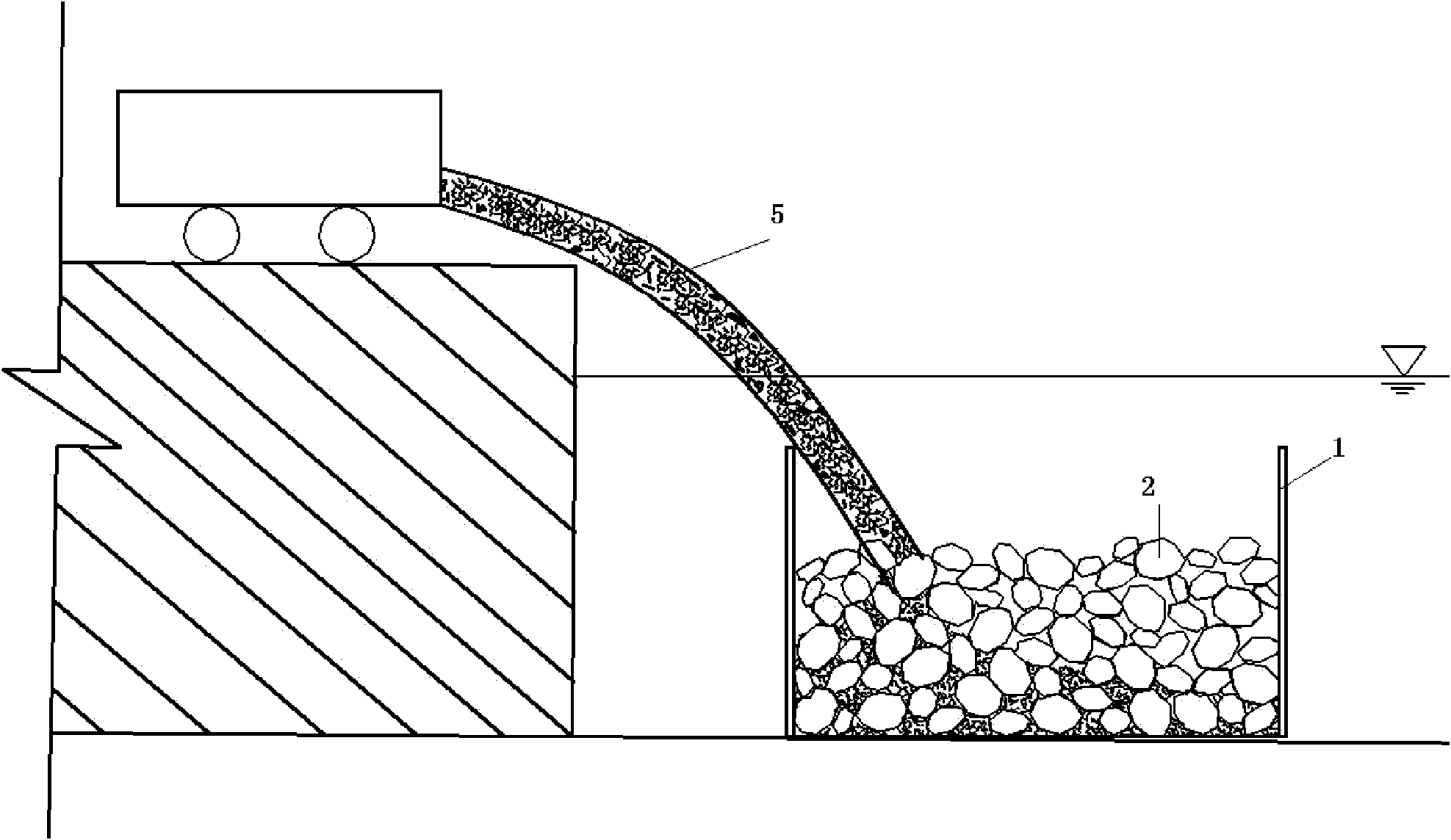

[0024] (4) Transport the underwater self-compacting concrete to the surface of the rockfill through the conduit (such as image 3 shown), pour underwater self-compacting concrete from the upp...

Embodiment 2

[0027] The construction method of underwater rockfill concrete, the specific implementation steps are as follows:

[0028] (1) Set formwork for the warehouse surface of the underwater rockfill concrete to be poured, and there is no need to set the formwork for the warehouse surface with natural barriers;

[0029] (2) Use stones or pebbles with a particle size of 80-120cm to accumulate naturally to fill the surface of the warehouse to be poured, and the thickness of the surface of the warehouse is 2.0m;

[0030] (3) Use a boat with a water pump to inject a certain amount of protective agent to protect the integrity of the underwater self-compacting concrete into the water area where the underwater rockfill concrete needs to be poured;

[0031] (4) The underwater self-compacting concrete is transported to the surface of the rockfill body through the conduit, and the underwater self-compacting concrete is poured from the upper surface of the rockfill body until it completely fill...

Embodiment 3

[0034] The construction method of underwater rockfill concrete, the specific implementation steps are as follows:

[0035] (1) Set formwork for the warehouse surface of the underwater rockfill concrete to be poured, and there is no need to set the formwork for the warehouse surface with natural barriers;

[0036] (2) Use stones or pebbles with a particle size of 120-150cm to accumulate naturally to fill the surface of the warehouse to be poured, and the thickness of the surface of the warehouse is 3.0m;

[0037] (3) Use a water pump to inject a certain amount of protective agent to protect the integrity of the underwater self-compacting concrete into the water body area where the underwater rockfill concrete needs to be poured;

[0038] (4) The underwater self-compacting concrete is transported to the surface of the rockfill body through self-burying pipes, and the underwater self-compacting concrete is poured from the upper surface of the rockfill body until it completely fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com