Patents

Literature

44results about How to "Excellent dispersion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

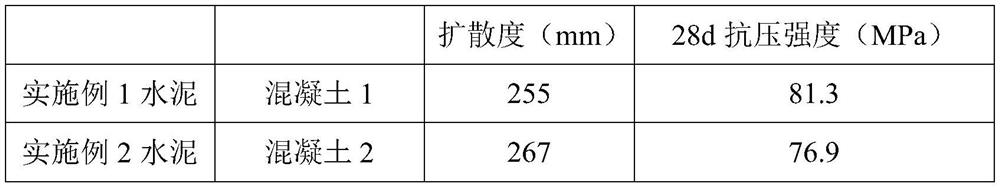

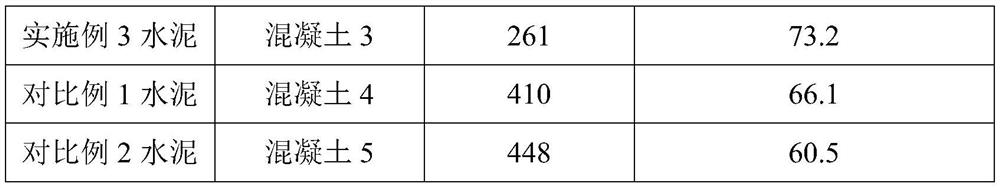

Manufactured sand underwater dispersion resistant concrete and preparation method thereof

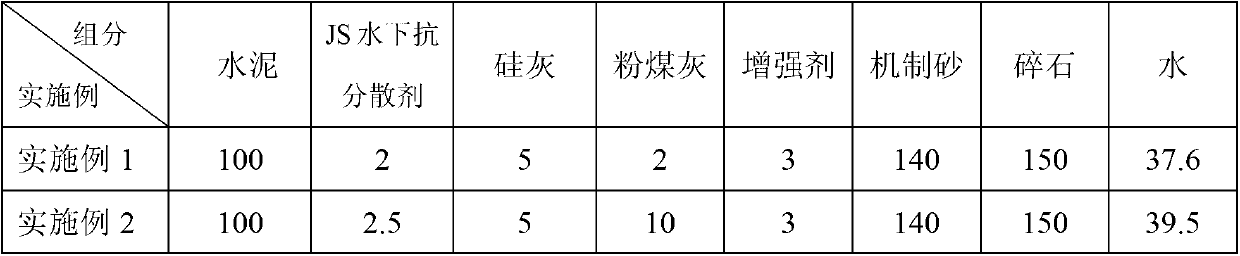

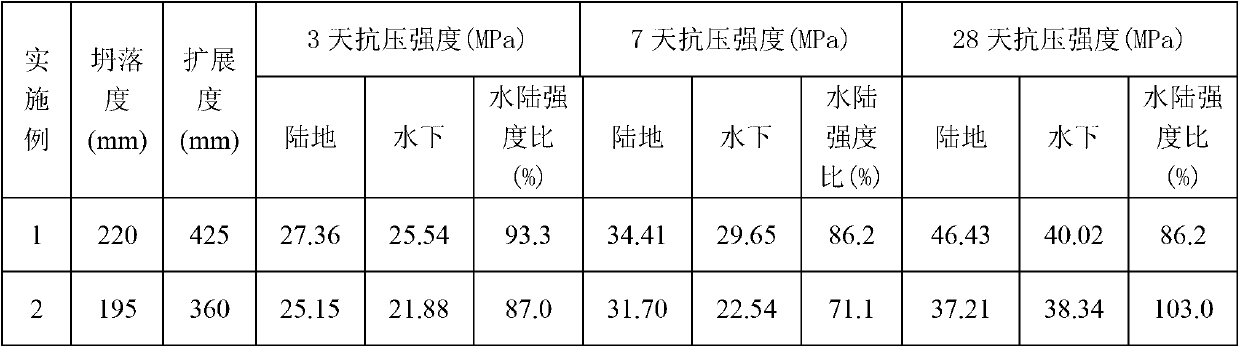

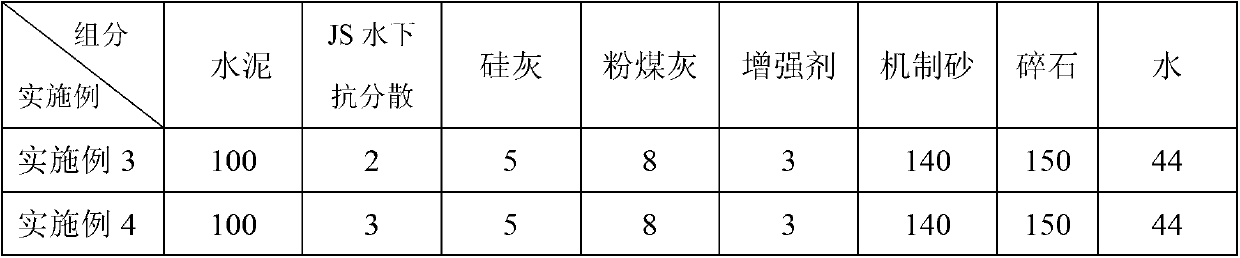

The invention relates to a manufactured sand underwater dispersion resistant concrete, which comprises the following components in parts by weight: 100 parts of cement, 1-5 parts of underwater dispersion resistant additive, 2-20 parts of silica fume, 1-20 parts of coal ash, 1-10 parts of an enhancer, 140-200 parts of manufactured sand, 140-200 parts of macadam, and 30-50 parts of water. The preparation method comprises the following steps of firstly putting the manufactured sand, the macadam aggregate, the cement, the enhancer, the coal ash and the silica fume into an agitator, blending through dry mixing, then adding the underwater dispersion resistant additive to further blend through dry mixing, adding water into the material blended through dry mixing previously, stirring for 5-8 minutes, then preparing the manufactured sand underwater dispersion resistant concrete. The manufactured sand underwater dispersion resistant concrete has strong construction mobility, so that the problem of contradiction of mobility and dispersion resistance of the underwater dispersion resistant concrete is better solved, and therefore, the manufactured sand underwater dispersion resistant concrete not only has good dispersion resistance, but also has self-leveling and self-compaction construction mobility.

Owner:江西万年青水泥股份有限公司

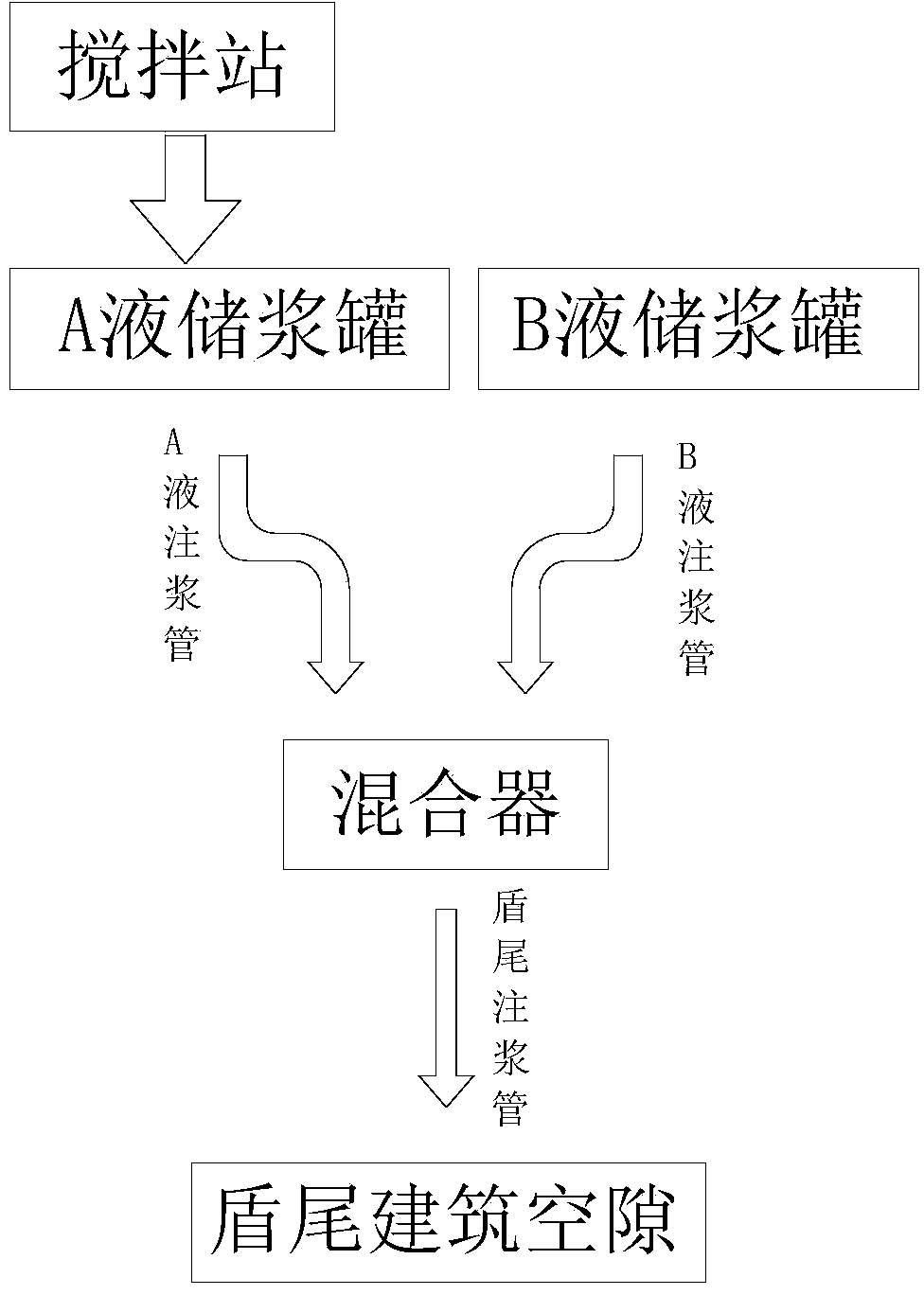

Shield synchronous grouting construction method and construction material

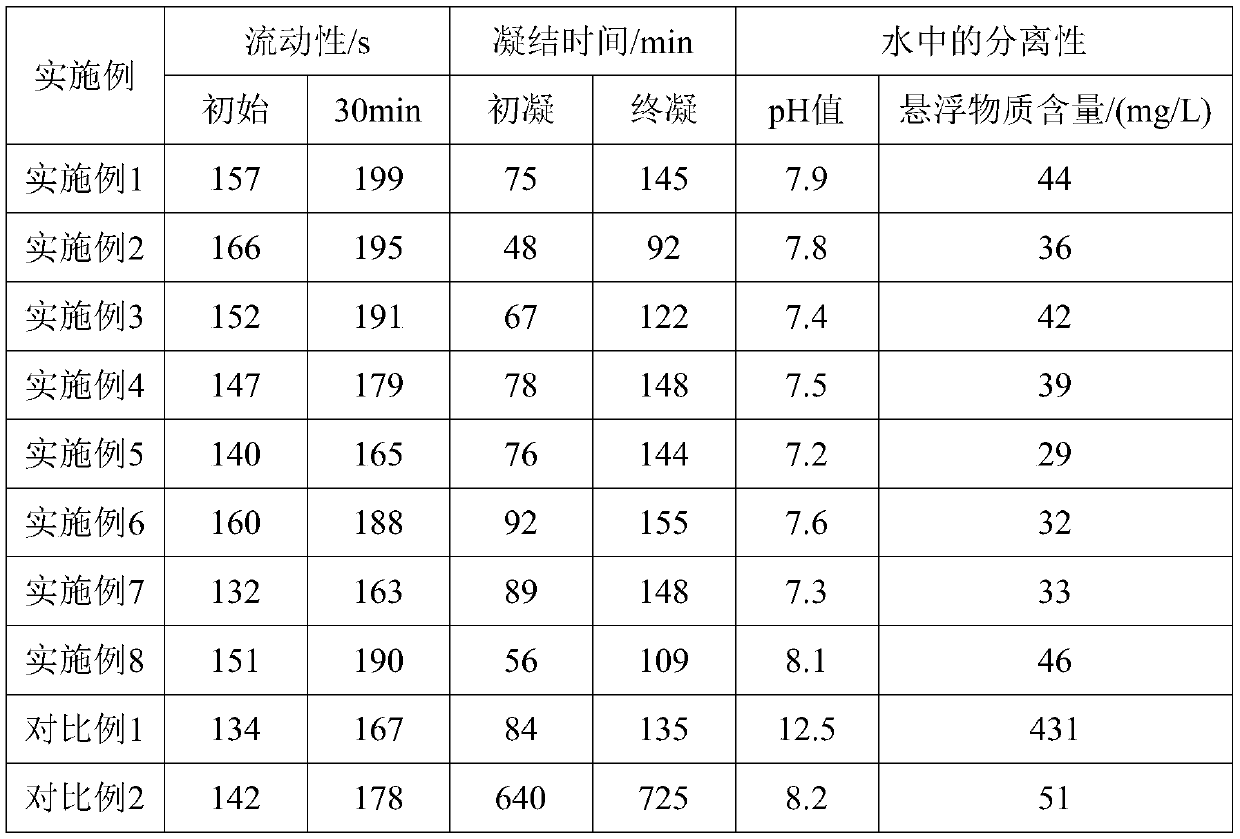

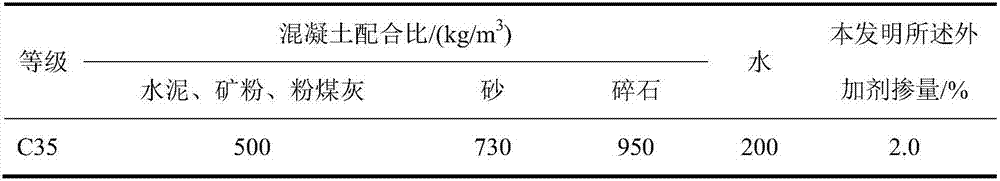

ActiveCN104074530AImprove stabilityShort entry into initial setting timeUnderground chambersTunnel liningSlurryMaterials science

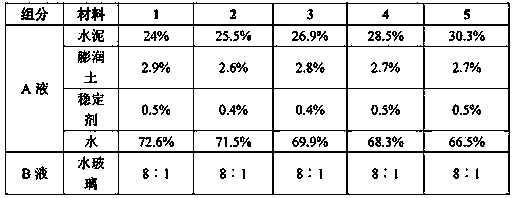

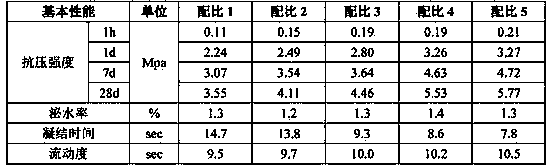

The invention discloses a shield synchronous grouting construction method and a construction material. The construction material comprises liquid A and liquid B, wherein the liquid A comprises 25.5 weight percent of cement, 2.6 weight percent of bentonite, 0.4 weight percent of stabilizing agents and 71.5 weight percent of water; the liquid B is water glass; and the volume ratio of the liquid A to the liquid B is 8:1-15:1. During synchronous grouting construction, the liquid A is prepared in a mixing station, and the liquid A and the liquid B are respectively conveyed into a liquid A slurry storage tank and a liquid B slurry storage tank which are arranged on a shield machine; the liquid A and the liquid B are respectively conveyed into a mixer positioned at the shield tail part of the shield machine through a liquid A slurry injection pipe and a liquid B slurry injection pipe; and the liquid A and / or the liquid B in the mixer are / is synchronously injected into a shield tail building gap through a shield tail slurry injection pipe. The shield synchronous grouting construction method solves various problems in subsequent grouting, synchronous single slurry injection, in-time grouting and secondary grouting in the prior art through utilizing good performance of the liquid A and the liquid B before and after the mixing of the liquid A and the liquid B and combining a primary synchronous grouting process.

Owner:CHINA RAILWAY 15TH CONSTR BUREAU GRP

Shield synchronous grouting construction material

ActiveCN106946522AControl the compressive strengthControl bleeding rateSodium BentonitePortland cement

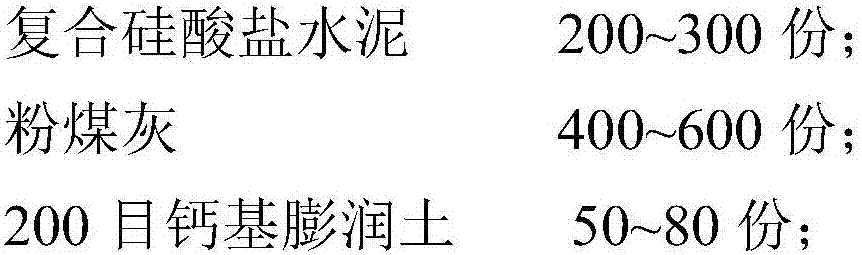

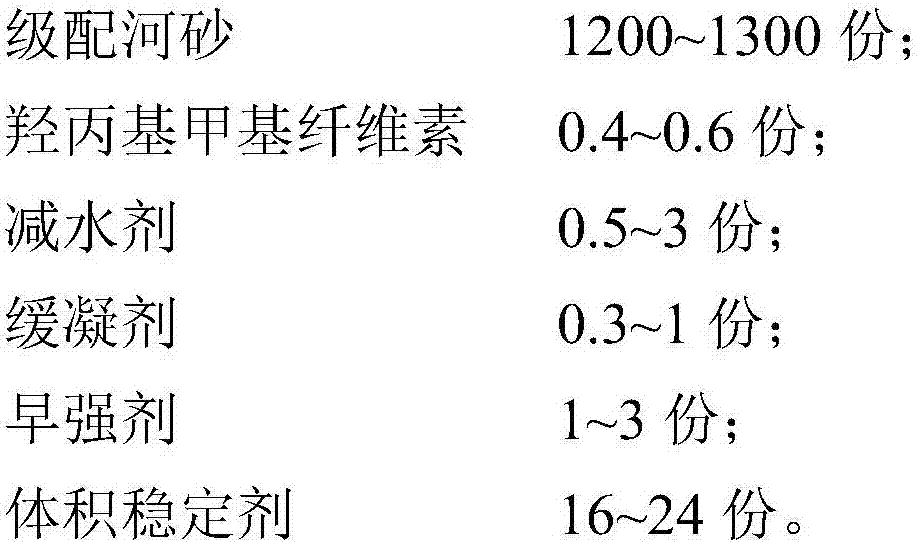

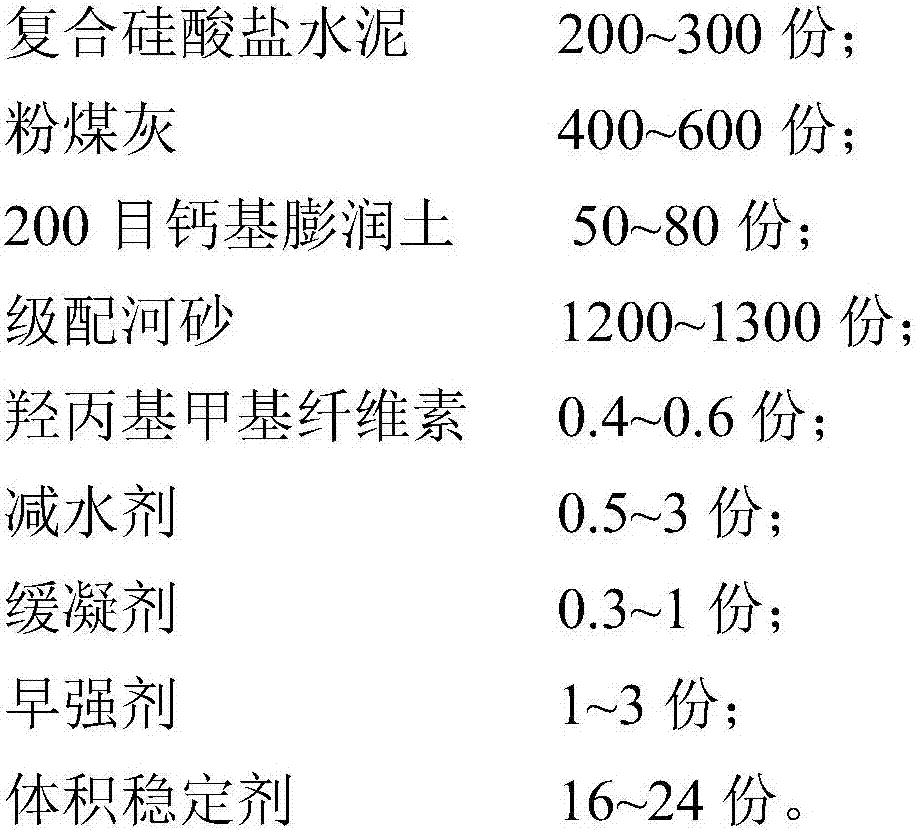

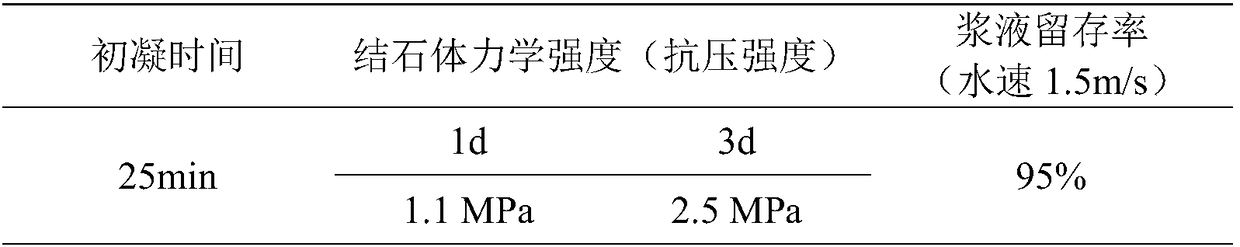

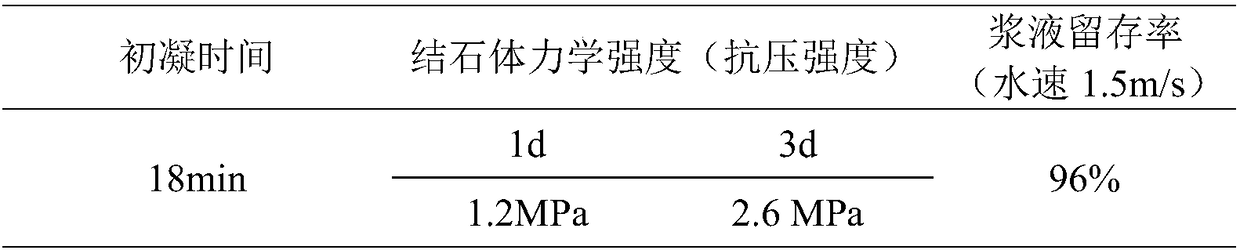

The invention discloses a shield synchronous grouting construction material including, by weight, 200-300 parts of composite Portland cement, 400-600 parts of fly ash, 50-80 parts of 200-mesh calcium based bentonite, 1200-1300 parts of grading river sand, 0.4-0.6 parts of hydroxypropylmethyl cellulose, 0.5-3 parts of a water reducer, 0.3-1 part of a retarder, 1-3 parts of an early strength agent and 16-24 parts of a volume stabilizing agent. Through reasonable adjustment of composition and content of the components, the compressive strength, bleeding ratio, setting time and flowability of the construction material are controlled, so that the construction material has long initial setting time, is quick in early strength development, is not liable to dissociation, has good volume stability, can effectively fill in gaps in buildings and prevent floatation and deformation of tunnel segments, has good flowability and anti-dispersing property, and is easy to transport and to store for a long period.

Owner:北京艺高世纪科技股份有限公司

Flowing water dispersion resistant blocking material and preparation method thereof

ActiveCN108484058AControllable clotting timeEfficient governanceProtective foundationMarine site engineeringPolyolWater soluble

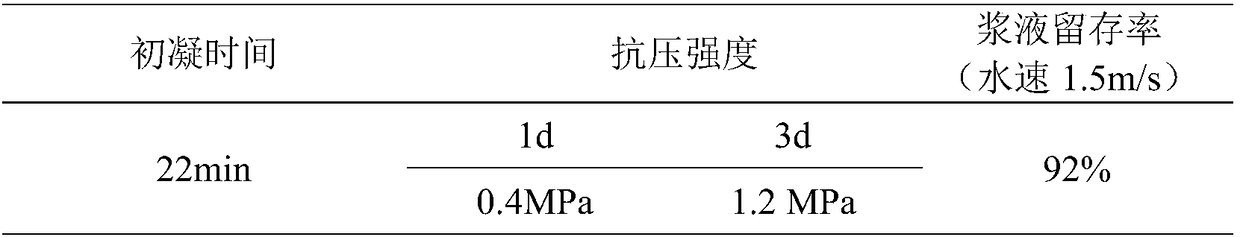

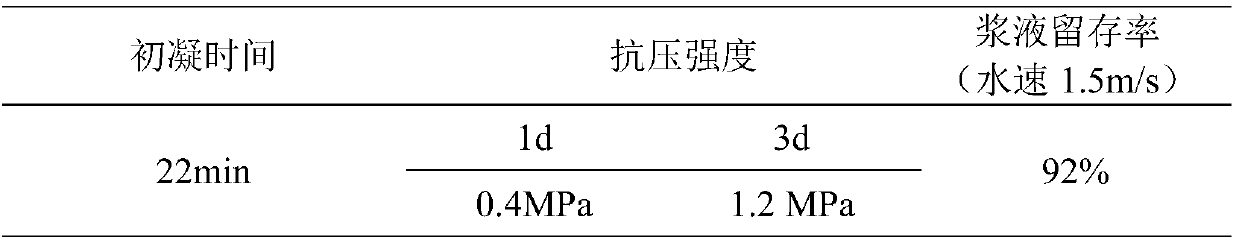

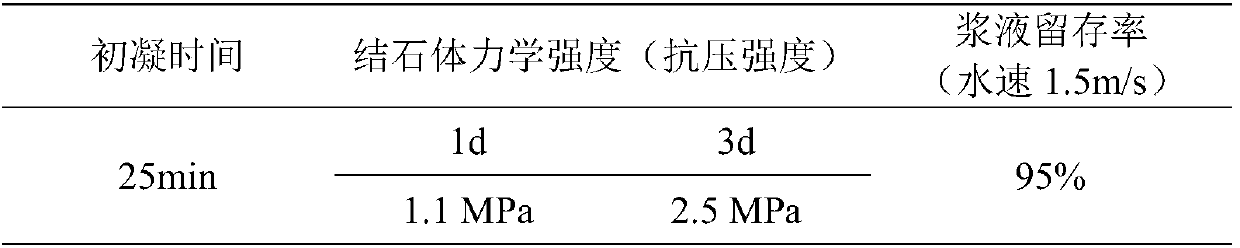

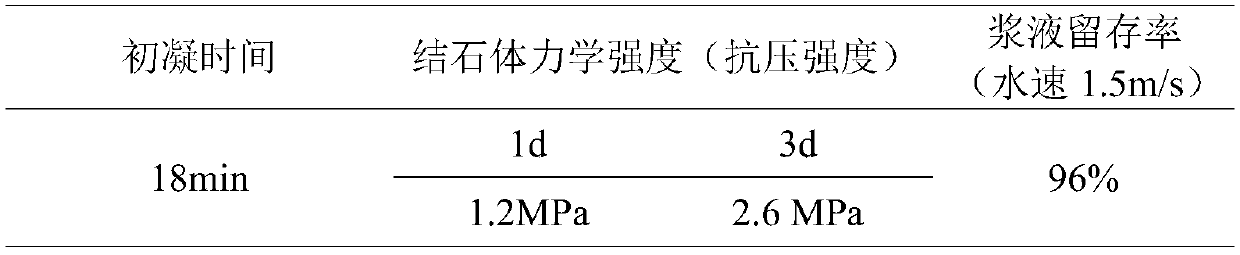

The invention discloses a flowing water dispersion resistant blocking material and belongs to the technical field of preparation of injecting paste materials. The blocking material is composed of components A and B, wherein the component A comprises a hydraulic cementing material and water, and a water-binder ratio is 0.6-1 to 1; the component B comprises the following components in percentage byweight: 0.3-1.2% of water-soluble vegetable glue, 0.2-1% of polymer polyol, 0.2-1.5% of alcohol polysaccharide, 10-44% of sodium silicate and 52.3-86.3% of water. The blocking material disclosed by the invention has the advantages of being low in cost, adjustable in setting time, high in dispersion resistance, high in slurry retention rate and excellent in consolidating mechanical property, beingsafe and non-toxic, and the like. Due to tests, the slurry retention rate reaches 90% or higher within 30 minutes at water velocity of 1.5m / s, the highest slurry retention rate can reach 97%, and excellent effects are achieved.

Owner:SHANDONG UNIV

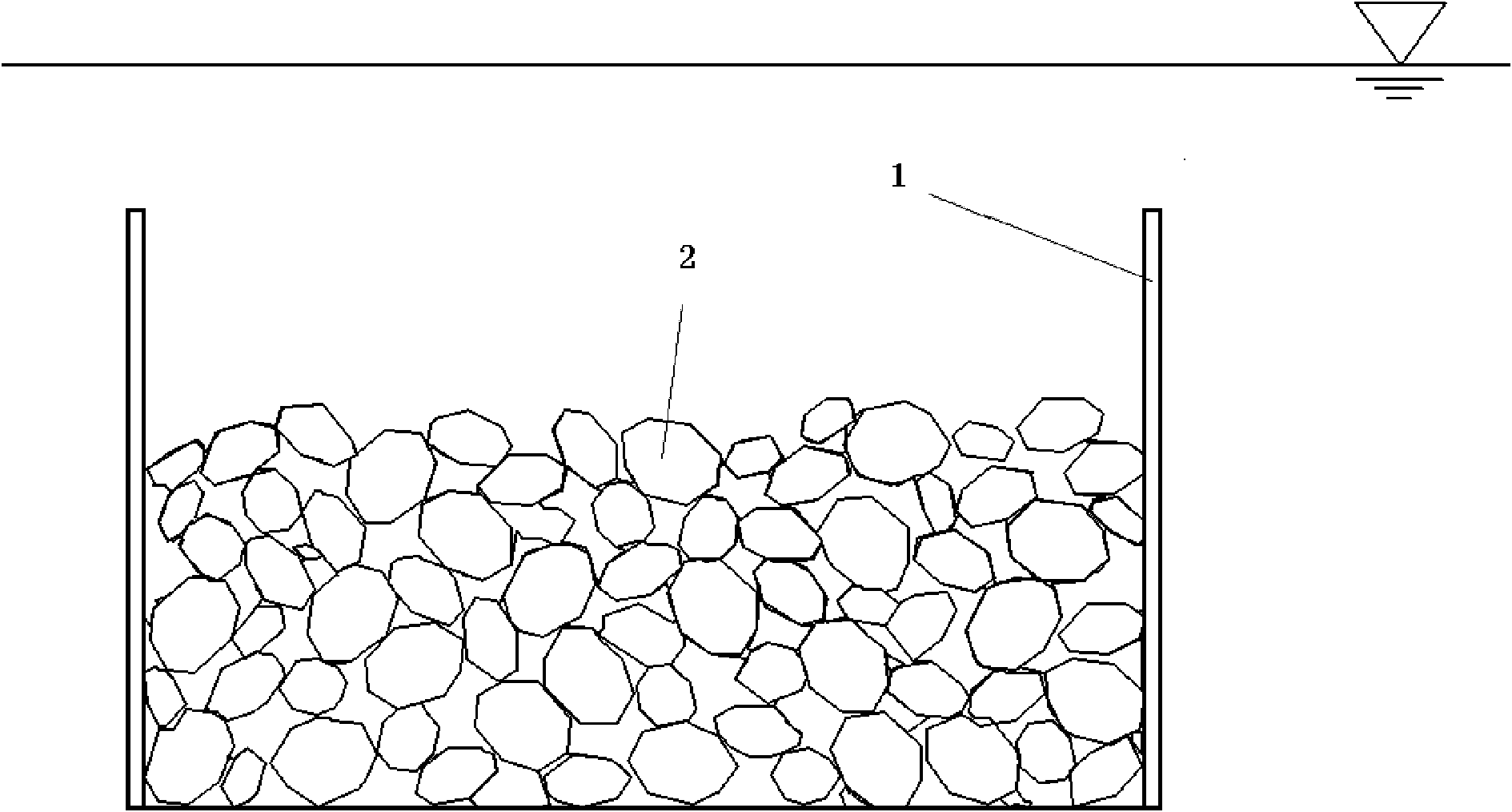

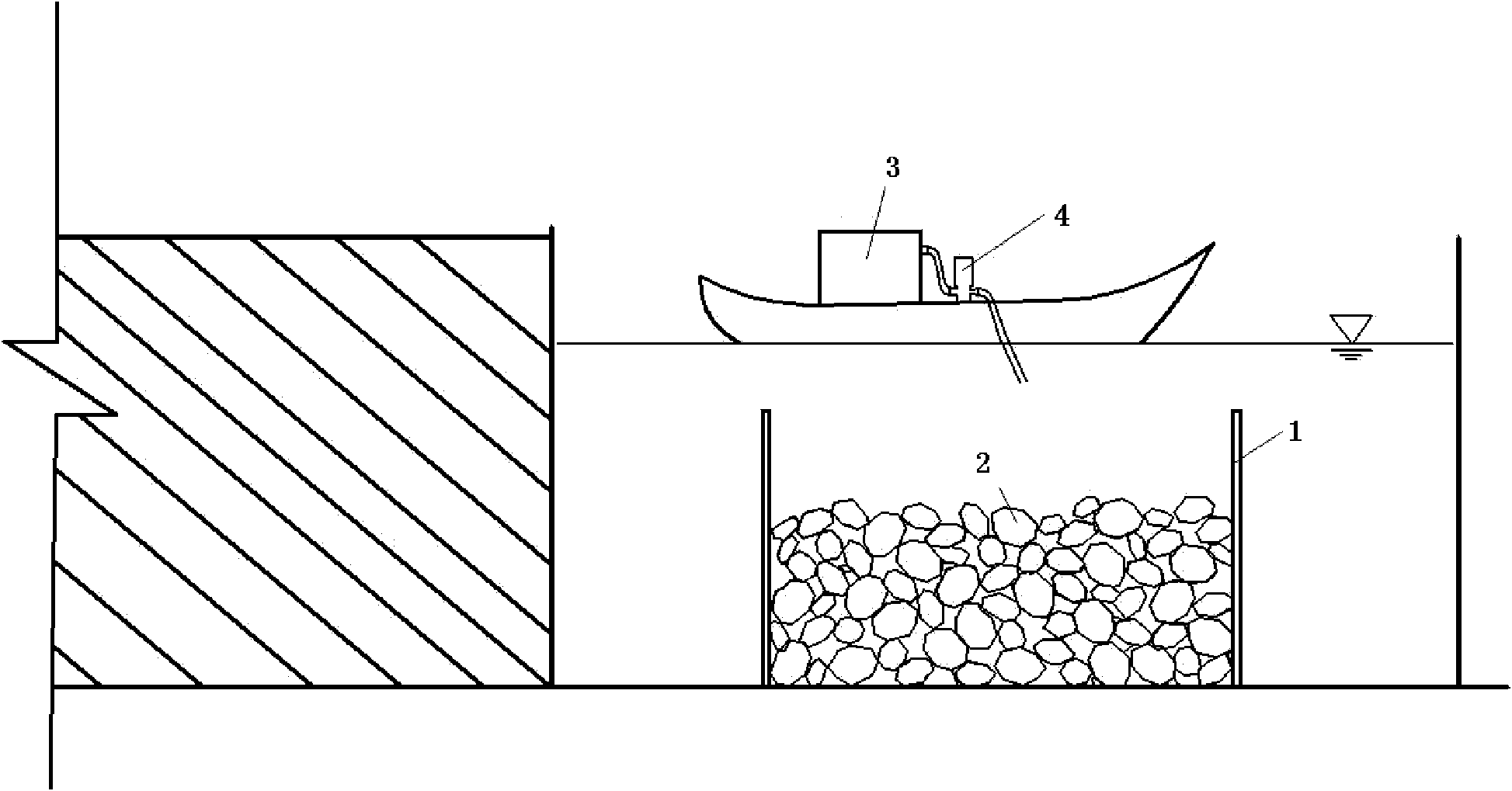

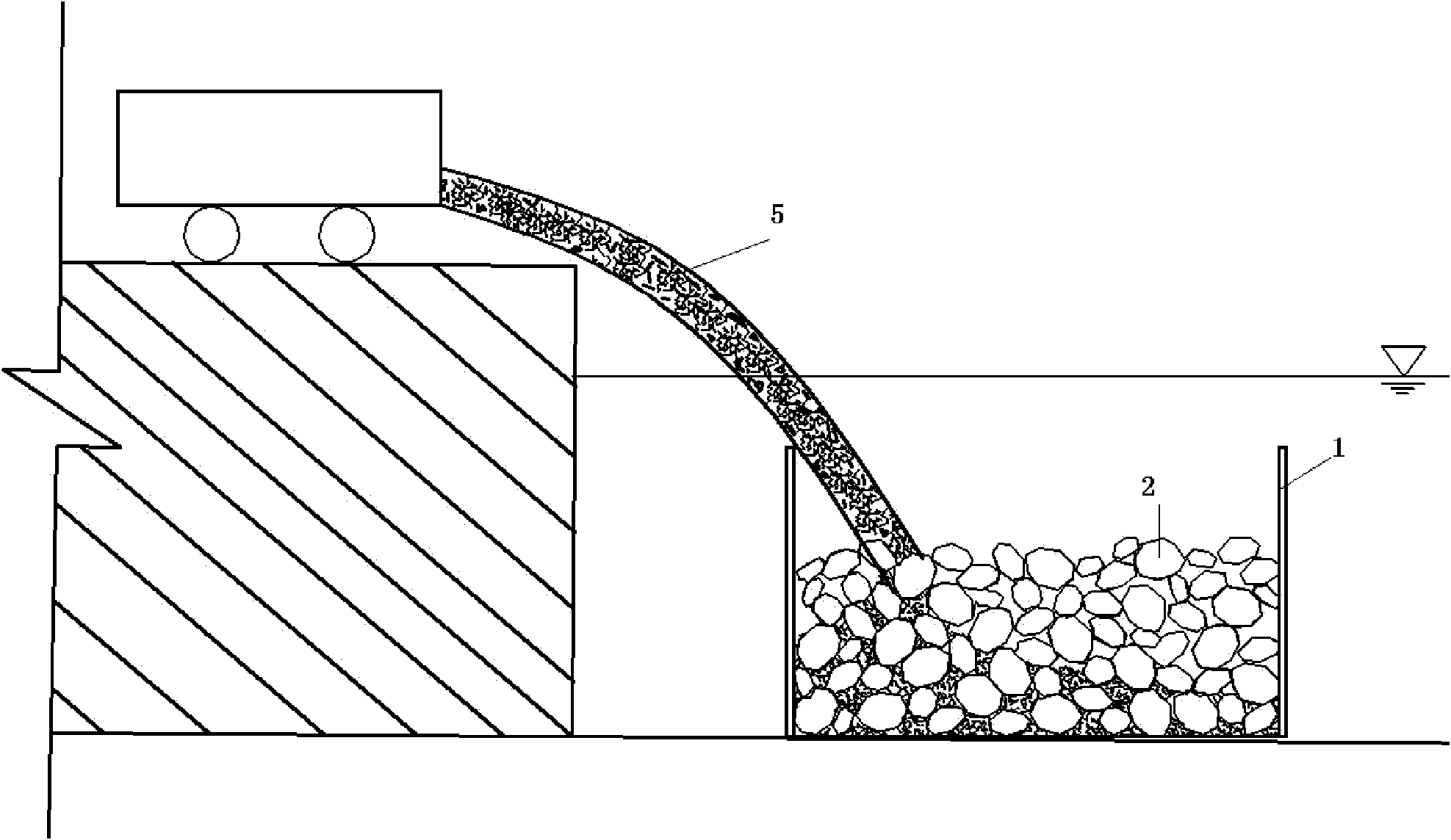

Construction method of underwater rockfill concrete

InactiveCN102277873AReduce usageExcellent dispersion resistanceFoundation engineeringUnderwaterUltimate tensile strength

The invention discloses an underwater rockfill concrete construction method, which belongs to the technical field of building construction. The present invention adopts block stones or pebbles with a particle size of more than 15cm, transports them to the surface of the underwater warehouse for natural accumulation by using ordinary transportation tools, and then puts a protective agent to protect the integrity of the underwater self-compacting concrete into the water, and uses the concrete that meets the requirements. The underwater special self-compacting concrete is poured naturally from the surface of the rockfill body with the help of a conduit, and the underwater special self-compacting concrete is used to fill the rockfill gap by its own weight, forming a dense and high-strength underwater rockfill concrete. The method is easy to construct, and has remarkable effects in improving construction efficiency and saving construction cost. The formed underwater rockfill concrete has less cement consumption, low hydration temperature rise, and has the advantages of energy saving and environmental protection.

Owner:TSINGHUA UNIV

Anti-dispersion intensifier for underwater cast-in-place pile concrete and using method thereof

ActiveCN101830665AGood flocculation effectExcellent dispersion resistanceSolid waste managementFiberSlag

The invention discloses an anti-dispersion intensifier for underwater cast-in-place pile concrete, which comprises a polycarboxylic acid water reducer, hydroxyethyl methyl cellulose ether, starch ether, polyvinyl alcohol fiber, superfine ground slag, sodium tripolyphosphate, sulphoaluminate cement clinker and desulfurized gypsum. According to the technical scheme, when the product of the invention is added in underwater cast-in-place pile concrete during the preparation of the underwater cast-in-place pile concrete, the flocculability of the concrete is increased, the anti-dispersion performance is improved in a concrete casting process, the increase effect of the post strength of the concrete is obvious, the concrete has certain expansibility, the friction between the pile body and the soil is increased, and the bearing capacity of the pile body is improved.

Owner:珠海市振业混凝土有限公司 +1

Injecting paste material for plugging water in tunnel of high-pressure karst area rich in water and preparation method of injecting paste material

InactiveCN103274650AImprove water stabilityGood flow controllabilitySolid waste managementSoil scienceCoal

The invention discloses an injecting paste material for plugging water in a tunnel of a high-pressure karst area rich in water and a preparation method of the injecting paste material. The injecting paste material comprises components in parts by weight as follows: 15-25 parts of coal ash, 5-12 parts of a water reducing accelerator, 100 parts of Portland cement and 60-100 parts of water. The preparation method of the injecting paste material comprises the steps as follows: 1), the coal ash and the Portland cement are mixed and fully stirred, a Portland cement-coal ash mixture is obtained; 2), the Portland cement-coal ash mixture is added into water and fully stirred, and a water solution of the Portland cement-coal ash mixture is obtained; and 3), the water reducing accelerator is added into the water solution of the Portland cement-coal ash mixture and fully stirred, so that the injecting paste material for plugging water in the tunnel of the high-pressure karst area rich in water is obtained. According to the injecting paste material and the preparation method, the coagulation time of the injecting paste material is controllable, the dispersion resistance is good, the strength is high, the durability and the stability are good, and the preparation method is simple, easy to implement and environment-friendly.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

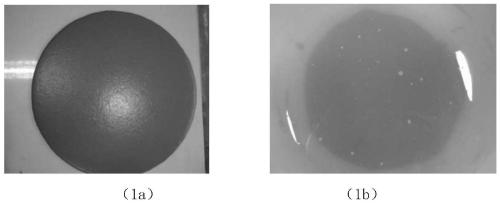

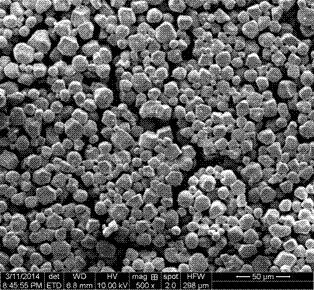

Nano modified cement-based underwater non-dispersible material and preparation method thereof

The invention belongs to the fields of water conservancy engineering, buildings, bridges, sea bank revetments, and the like, and particularly relates to a nano modified cement-based underwater non-dispersible material and a preparation method thereof. The material is prepared from cement, mineral powder, silica fume, a superplasticizer, a defoamer and other materials, a certain amount of nano-SiO2or CaCO3 and a preferred flocculant are added, the materials are mixed evenly through a mixer, and then quartz sand is added to obtain the nano modified cement-based non-dispersible material. According to the nano modified cement-based underwater non-dispersible material, the fluidity reaches 260 cm, the underwater self-leveling can be realized, good dispersion resistance is achieved while high fluidity is achieved, the content of suspended matter is lower than 80 mg / L, 1d strength is nearly 20 MPa, and 28 d strength is greater than 50 MPa, and the micro expansion effect is achieved. The nanomodified cement-based underwater non-dispersible material can be in the forms of dry powder, wet mixed mortar or concrete, and the like, can be made into dry powder materials, and can be directly used for underwater construction by being mixed with water added on site, large-scale production and application are achieved easily, and the application requirements of the fields of the water conservancy engineering, the buildings, the bridges, the sea bank revetments can be met.

Owner:闰镁科技(深圳)有限公司

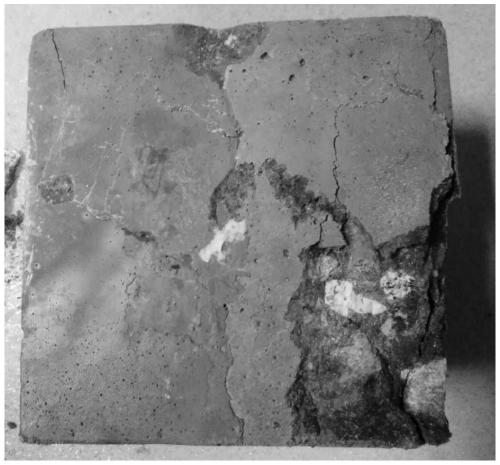

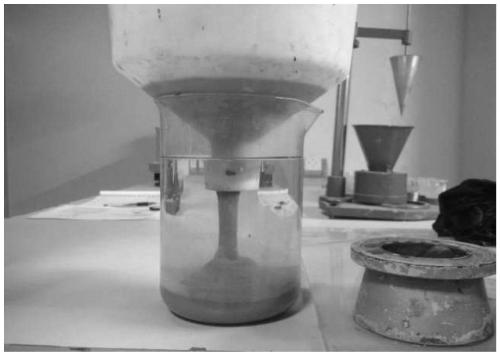

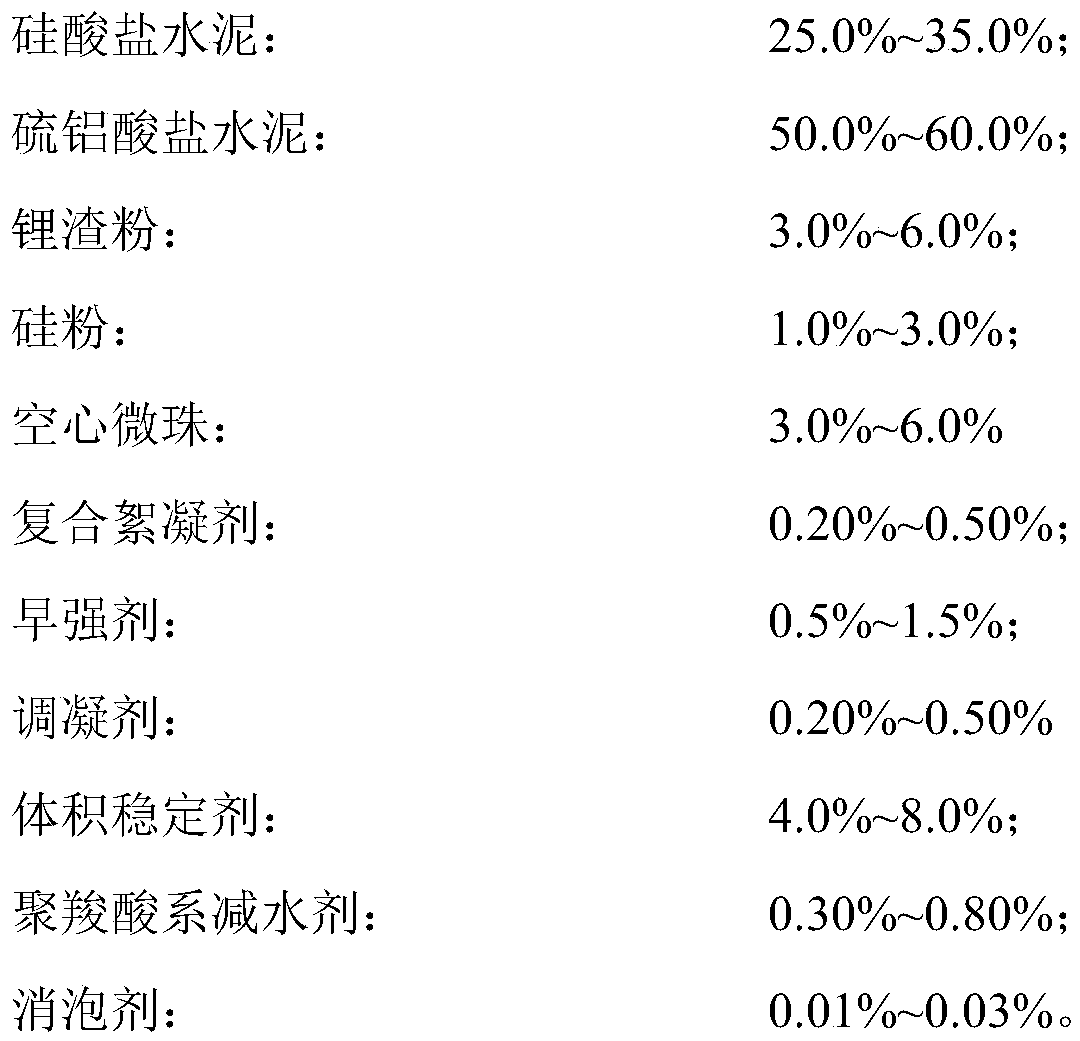

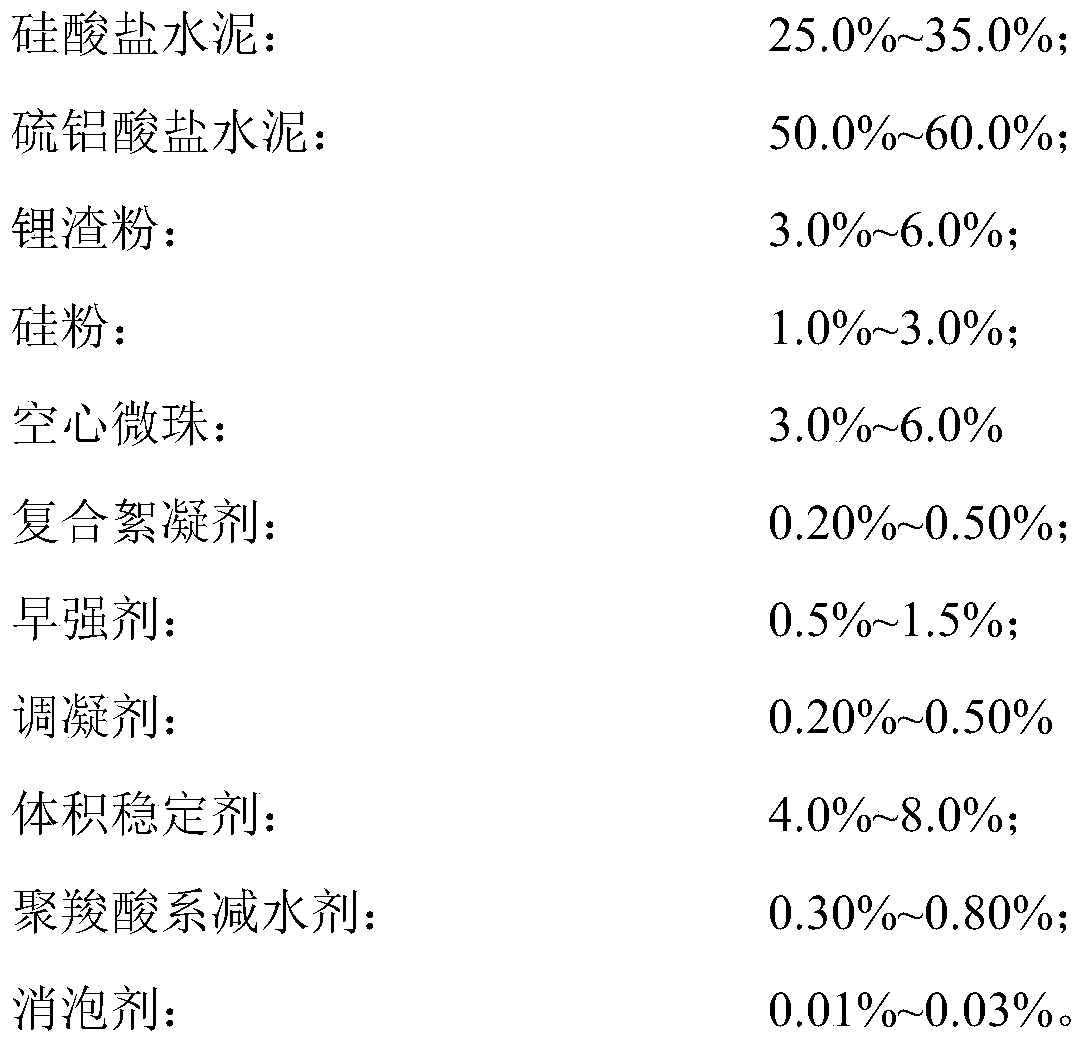

Super early strong cement base underwater non-dispersible repairing material and preparation method

The invention provides a super early strong cement base underwater non-dispersible repairing material. The material is prepared from the following components in percentage by weight: 25.0%-35.0% of portland cement, 50.0%-60.0% of sulphoaluminate cement, 3.0%-6.0% of lithium slag powder, 1.0%-3.0% of ganister sand, 3.0%-6.0% of hollow microbeads, 0.20%-0.50% of a compound flocculant, 0.5%-1.5% of an early strong agent, 0.20%-0.50% of a retarding agent, 4.0%-8.0% of a volume stabilizing agent, 0.30%-0.80% of a polycarboxylate based superplasticizer and 0.01%-0.03% of a deformer. The super earlystrong cement base underwater non-dispersible repairing material provided by the invention has the characteristics of rapid hardening, early strong performance, high underwater anti-dispersing performance, good bonding, super large flowability, stable volume, simple construction methods, and no toxicity, and is especially suitable for urgent underwater projects such as damp and poor-quality sections, large flow areas and areas waiting to be urgent operation.

Owner:安徽瑞和新材料有限公司 +1

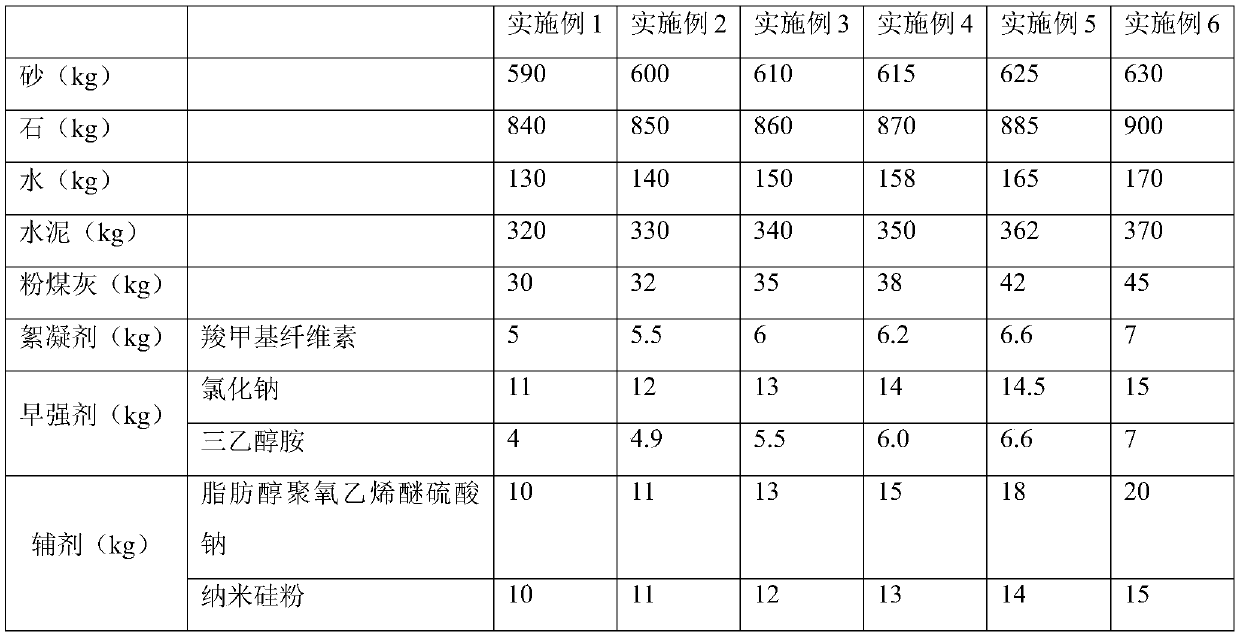

Road disease controlling grouting reinforcement material and preparation method thereof

The invention discloses a road disease controlling grouting reinforcement material. The road disease controlling grouting reinforcement material is formed by mixing a component A and a component B ata volume ratio of 2:1, wherein the component A is prepared from, by weight part, 20-120 parts of ground slag, 10-110 parts of coal ash, 12-44 parts of cement, 12-110 parts of fine sand, 0.15-0.5 partof fiber, 1.2-4.5 parts of water reducer, 2-6 parts of hardening accelerator, 1-4 parts of retarder and 50-130 parts of water; the component B is prepared from alkaline activator and flocculant at a ratio of 100:1-6. By adding the flocculant into the alkaline activator, slurries can achieve good dispersion resistance inside water-enriched gapped base layers and weak subgrades and can be rapidly coagulated to form reinforcement, so that the shortcoming that traditional slurries are prone to dispersion and low in reinforcement forming in a water-enriched environment can be overcome; by adding the fine sand into the road disease controlling grouting reinforcement material, under the condition of extensive water-enriched gapping, the flocculation effects of the flocculant can be improved, andcoagulation and reinforcement forming of the slurries can be accelerated; by adding a small mount of the hard cement into the road disease controlling grouting reinforcement material, coagulation of the mixed slurries can be further accelerated, and early strength can be improved.

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD

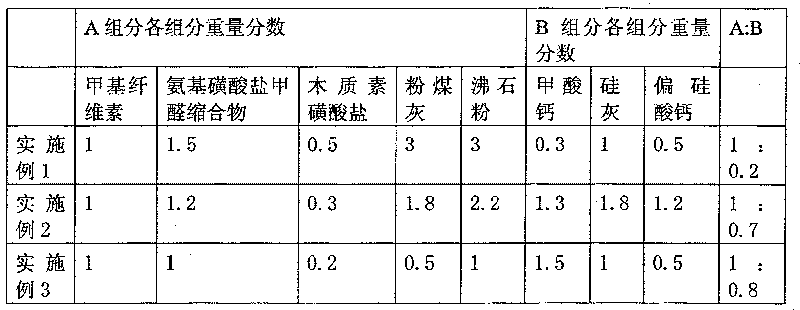

Modified methyl cellulose flocculant for underwater grouting and its manufacturing method

The present invention relates to one kind of modified methyl cellulose flocculant for underwater grouting mortar, cement slurry and concrete. The modified methyl cellulose flocculant is methyl cellulose-acrylamide copolymer prepared through polymerizing methyl cellulose and acrylamide while introducing nitrogen and adding potassium persulfate, ferrous chloride or ammonium persulfate. The modified methyl cellulose flocculant may have amido sulfate-formaldehyde condensate, polycarboxyl acid sulfidizer and melamine-formaldehyde condensate added. The modified methyl cellulose flocculant makes the underwater grouted mixture possess excellent antidispersivity and result in less water pollution and less strength loss.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Grouting material, preparation method and application thereof in seepage-proofing and water-plugging construction

PendingCN111892374AImprove permeabilityHigh strengthUnderground chambersDrilling compositionSoil scienceWater flow

The invention provides a grouting material and a preparation method thereof, and belongs to the technical field of underground engineering materials. The grouting material provided by the invention comprises the following raw materials: 760-800 parts of clay, 80-120 parts of cement, 30-70 parts of bentonite, 700-800 parts of water, 5-15 parts of water glass and 1-5 parts of a water reducing agent.According to the invention, bentonite is used for improving the clay basic slurry, and complex reaction with a cement hydration product is carried out, so that the water flushing release resistance,strength and permeation resistance of the slurry are improved, and the product has excellent economical efficiency; the water glass accelerates the gelling time of the material and generates relatively stable micelles with the clay cement slurry; the water reducing agent reduces the porosity of the material and improves the strength and impermeability of the material. The initial setting time of the grouting material is 75min, the final setting time of the grouting material is 135min, and the slurry retention rate reaches 93.82% when the water flow speed is 0.5m / s after grouting.

Owner:CENT SOUTH UNIV

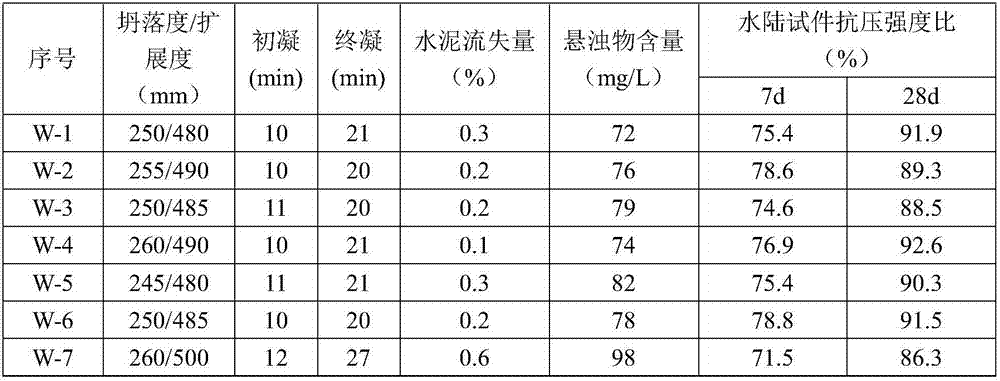

Non-dispersible underwater concrete additive, preparation method, and application thereof

ActiveCN106946492AImprove work performanceExcellent dispersion resistanceReducing agentMaterials science

The invention discloses a non-dispersible underwater concrete additive, which mainly includes a modified flocculating agent solution, a polycarboxylate water reducing agent A, a polycarboxylate water reducing agent B, a defoamer and an air entraining agent according to the following ratio, by mass, 75-93% of the modified flocculating agent solution, 5-12% of the polycarboxylate water reducing agent A, 2-10% of the polycarboxylate water reducing agent B, 0.02-0.6% of the defoamer, and 0.01-0.5% of the air entraining agent. The additive can effectively improve cohesiveness of the underwater concrete, guarantees strength of the concrete in an underwater environment, and effectively improve workability of the concrete.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD

Preparation method of underwater anti-dispersive concrete

InactiveCN108203278AExcellent anti-dispersion performanceExcellent dispersion resistancePortland cementMaterials science

The invention relates to a preparation method of underwater anti-dispersive concrete, and belongs to the field of concrete. The preparation method comprises the following steps: (1) weighing 3-6 partsby weight of Portland cement, 1 part by weight of fly ash, 2-4 parts by weight of stones I with a particle size of 9-10 mm, 2-4 parts by weight of stones II with a particle size of 7-8 mm, 4-6 partsby weight of stones III with a particle size of 5-6 mm, 2-4 parts by weight of sand I with a particle size of 3.5-4.5 mm, 2-4 parts by weight of sand II with a particle size of 1.5-2.5 mm, 0.1-0.2 part by weight of a flocculating agent and 2-4 parts by weight of water; (2) adding the cement, the fly ash, the stones I, the stones II, the stones III, the sand I, the sand II and the flocculating agent which are weighed in the step (1) into the water and carrying out uniform stirring; (3) carrying out molding on the product obtained in the step (2); and (4) curing the product obtained in the step(3) to obtain the underwater anti-dispersive concrete. The underwater concrete prepared by the preparation method has excellent anti-dispersive performance.

Owner:DALIAN UNIV OF TECH

Glucose high-polymer marine concrete anti-dispersion agent and preparation method thereof

InactiveCN104193216AImprove water retentionExcellent dispersion resistanceGlucose highChloroacetic acids

The invention discloses a marine concrete anti-dispersion agent which adopts cassava starch with a wide source as a raw material, and is prepared by reacting water, ethanol, chloroacetic acid and sodium hydroxide. The marine concrete anti-dispersion agent disclosed by the invention can be applied to underwater mortar and concrete engineering such as fresh water, sea water and the like, ensures that a mixture has anti-dispersion, anti-impact and self-advection properties, can be used for improving the hardening strength, is wide in raw material source without geographical limitation, is cheap in price, and is beneficial for bulk application.

Owner:UNIV OF JINAN

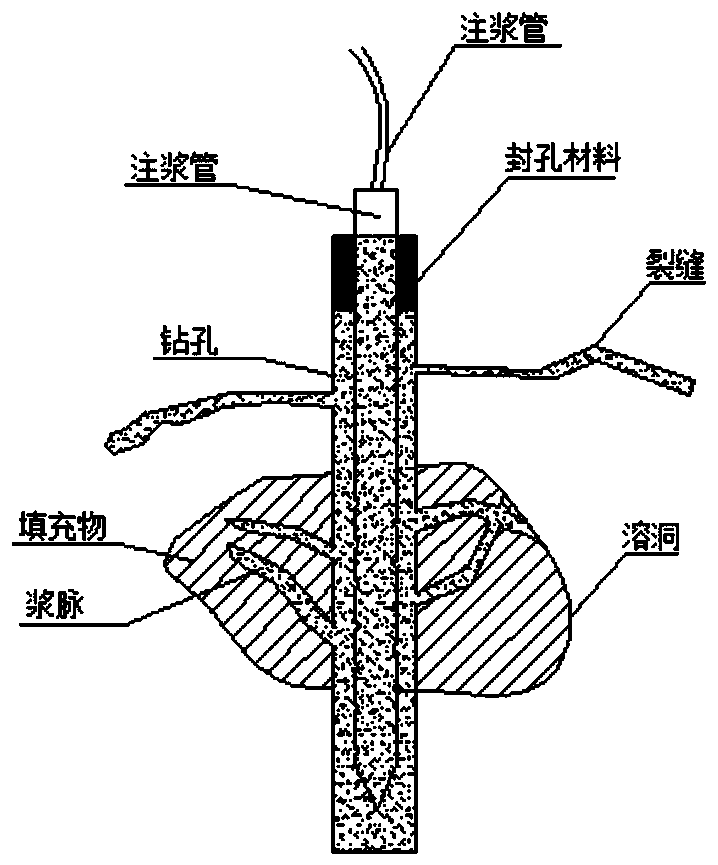

Hole sealing material for karst water inflow and preparation method and hole sealing method thereof

ActiveCN107892543AIncrease stickinessGuaranteed coagulation timeUnderground chambersDrilling compositionCarboxymethyl celluloseKarst

The invention provides a hole sealing material for karst water inflow and further correspondingly provides a preparation method and hole sealing method thereof. The hole sealing material comprises, byweight, 70-90 parts of portland cement, 10-15 parts of coal ash, 10-20 parts of bentonite, 0.05-0.16 part of sodium carboxymethyl cellulose, 15-40 parts of water, 3-5 parts of water glass and 1-2 parts of hemp thread. The hole sealing material is sufficiently kneaded, can be quickly solidified, has the advantages of good water stability, dispersion resistance, durability, high strength and the like, helps to lower the cost, improve the construction quality and make water plugging construction more convenient, achieves the aim of efficient hole sealing, and is suitable for hole sealing operation in a high-pressure water-rich karst area. The preparation method and hole sealing method of the hole sealing material are easy to operate, less in equipment input and low in cost, cause no pollution to the environment, and can guarantee the hole sealing effect and improve the hole sealing efficiency.

Owner:CENT SOUTH UNIV

Underwater non-dispersible concrete and its preparation method

Owner:天津市滨涛混凝土有限公司

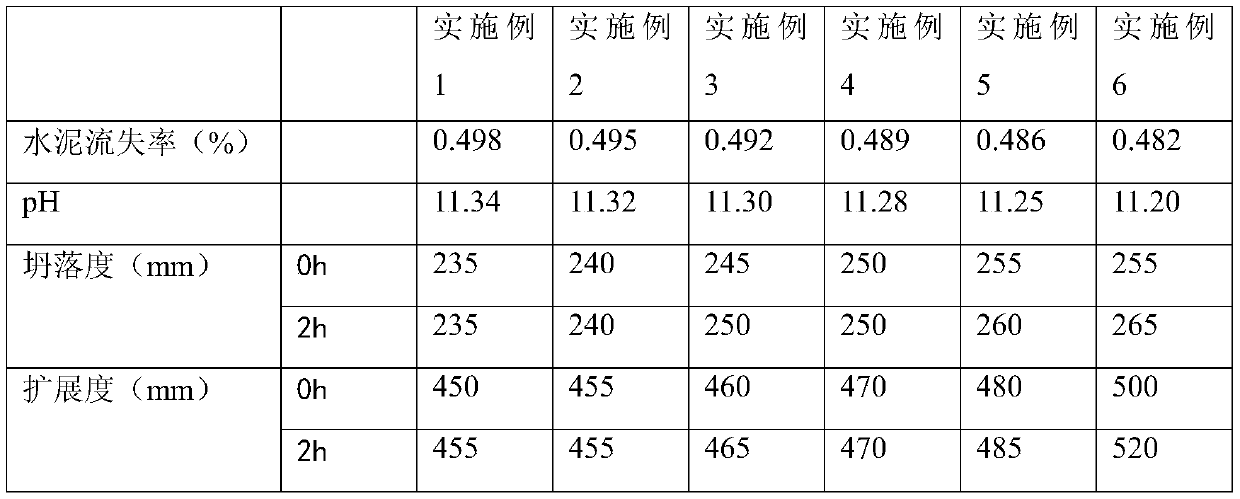

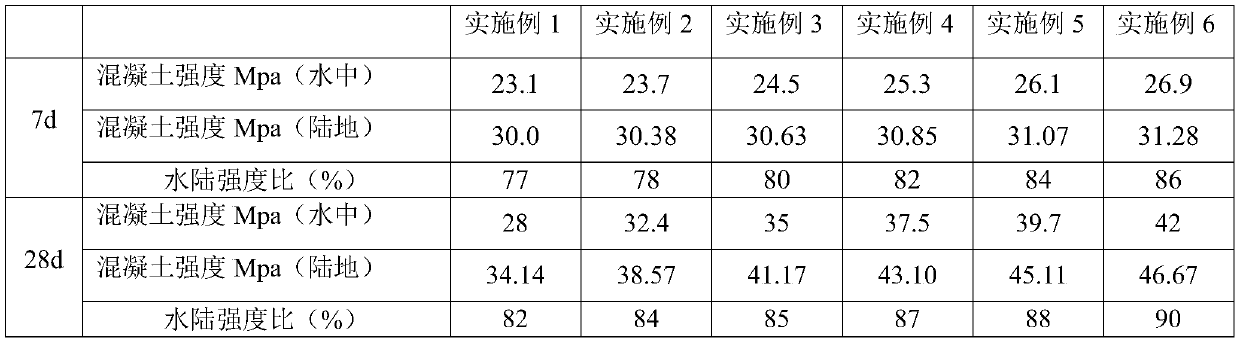

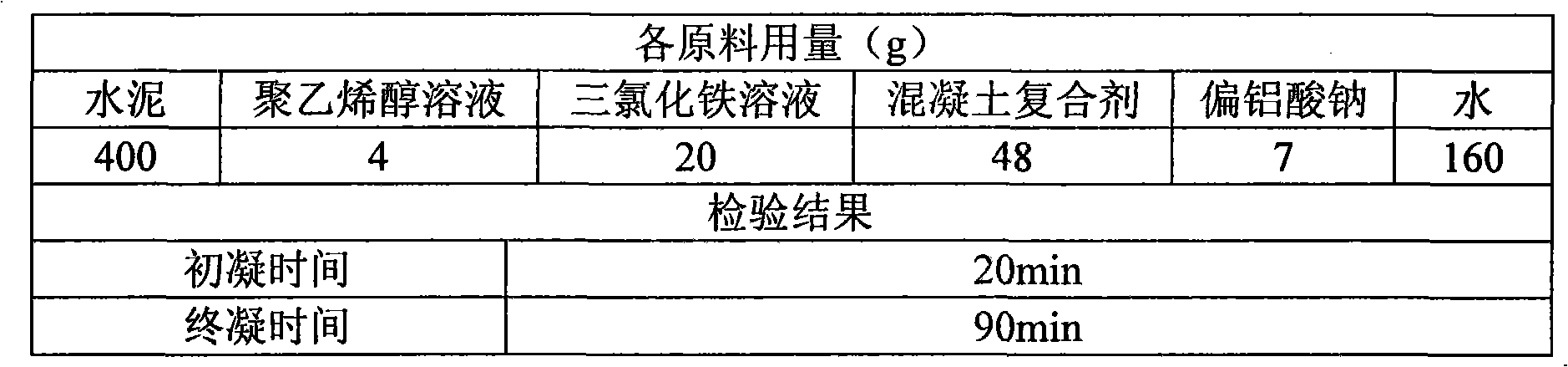

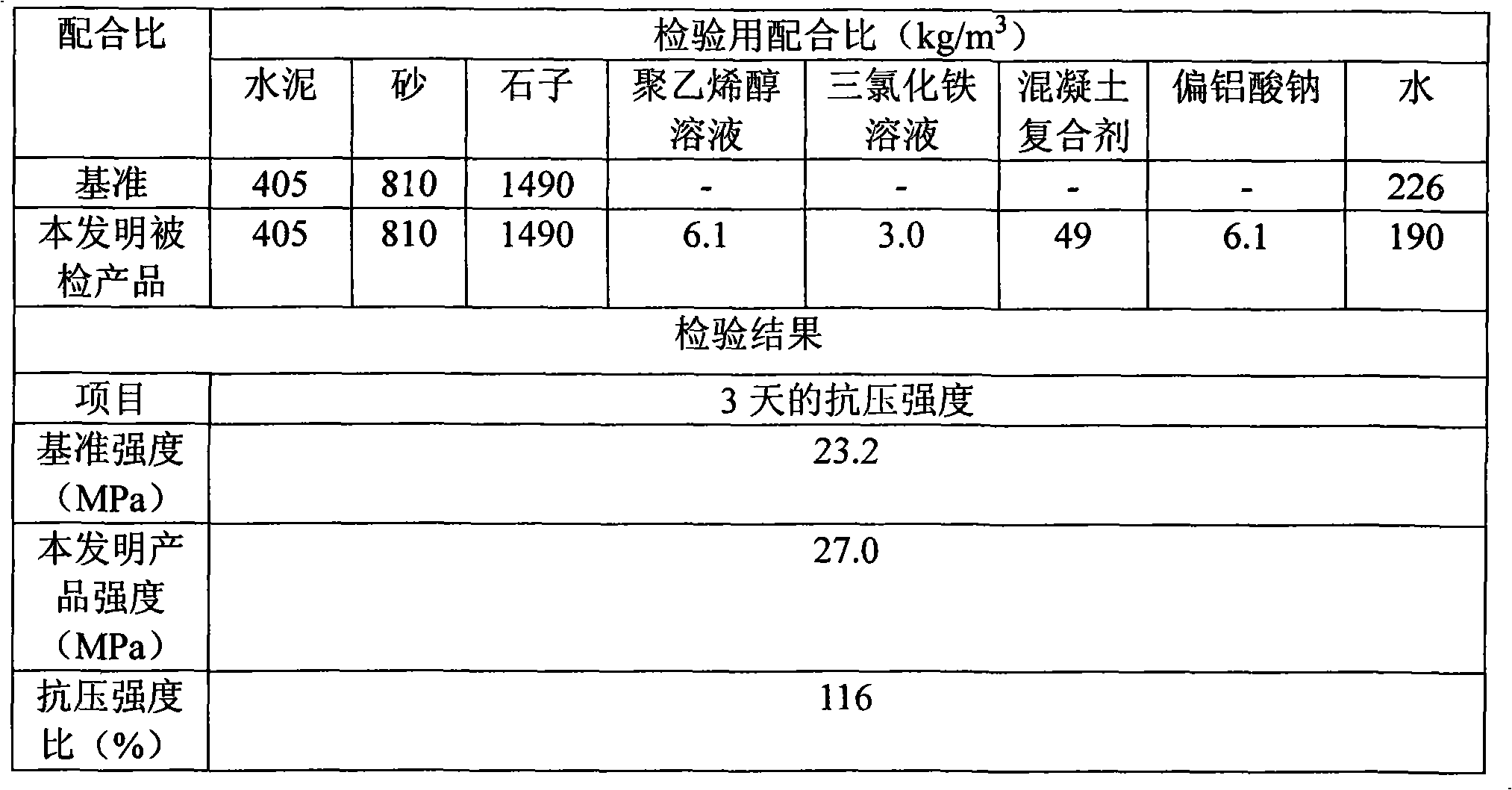

Coagulant for concrete depositing in water

The invention relates to the field of improving the curing time of the concrete in the water, in particular to a curing agent for the underwater cast concrete. The invention solves the problems of the existing underwater concrete cast that the construction technique is complicate, the manufacturing cost is high and the concrete intensity is poor and so on; counted by 100 parts of cement mass in the concrete, the curing agent consists of 0.8-2 parts of 1% of polyvinyl alcohol solution, 1-5 parts of 2% of ferric chloride solution, 1.5-2 parts of sodium metalluminate and 12 parts of concrete complexing agent; the concrete complexing agent is composed of silica, fluorite, hexadecyl sodium benzenesulfonate, hydroxycarboxylic acid and fatty group hydroxy sulphonate high efficiency water reducing agent; the underwater cast concrete has dispersibility resistance, viscidity, high plasticity and bleeding property, which leads the concrete mixture not to isolate and keep together during the falling process and can keep the uniformity of the mixture; the addition of the concrete complexing agent can improve the compression resistance rating, the sodium metalluminate and so on can ensure that the concrete is cured in the water; the invention is simple in technique, low in construction cost and reliable in engineering quality.

Owner:王衡

A kind of dynamic water anti-dispersion plugging material and its preparation method

ActiveCN108484058BControllable clotting timeEfficient governanceProtective foundationMarine site engineeringPolyolWater soluble

The invention discloses a flowing water dispersion resistant blocking material and belongs to the technical field of preparation of injecting paste materials. The blocking material is composed of components A and B, wherein the component A comprises a hydraulic cementing material and water, and a water-binder ratio is 0.6-1 to 1; the component B comprises the following components in percentage byweight: 0.3-1.2% of water-soluble vegetable glue, 0.2-1% of polymer polyol, 0.2-1.5% of alcohol polysaccharide, 10-44% of sodium silicate and 52.3-86.3% of water. The blocking material disclosed by the invention has the advantages of being low in cost, adjustable in setting time, high in dispersion resistance, high in slurry retention rate and excellent in consolidating mechanical property, beingsafe and non-toxic, and the like. Due to tests, the slurry retention rate reaches 90% or higher within 30 minutes at water velocity of 1.5m / s, the highest slurry retention rate can reach 97%, and excellent effects are achieved.

Owner:SHANDONG UNIV

Polyester grouting material and preparation method thereof

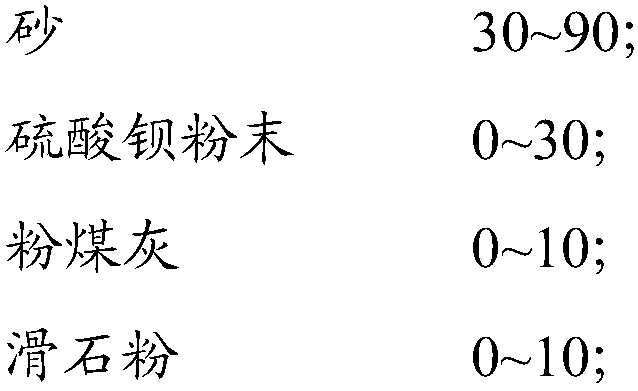

The invention relates to a polyester grouting material and a preparation method thereof. The polyester grouting material comprises the following raw materials and components in parts by weight: 5 to 15 parts of a first mixed component, 5 to 15 parts of a second mixed component and 50 to 90 parts of a third mixed component, wherein the first mixed component comprises the following components in parts by weight: 60 to 90 parts of epoxy resin, 0.5 to 5 parts of a coupling agent and 1 to 30 parts of a reactive diluent; the second mixed component comprises the following components in parts by weight: 10 to 50 parts of a curing accelerator and 50 to 90 parts of an epoxy hardener; the third mixed component comprises the following components in parts by weight: 30 to 90 parts of sand, 0 to 30 parts of a barium sulfate powder, 0 to 10 parts of coal ash and 0 to 10 parts of a talcum powder; the sand comprises the following components in parts by weight: 0 to 5 parts of first sand (5 to 10 meshes), 10 to 30 parts of second sand (10 to 30 meshes), 30 to 40 parts of third sand (30 to 40 meshes), 15 to 30 parts of fourth sand (40 to 40 meshes) and 5 to 10 parts of fifth sand (60 to 100 meshes).The raw materials of the polyester grouting material are cooperatively used with one another, so that the shrinking percentage and the integral cost can be reduced, and the polyester grouting materialis beneficial for wide application.

Owner:ZHANGJIAGANG YINGHUA MATERIAL TECH CO LTD

C30 underwater self-compacting concrete and preparation method thereof

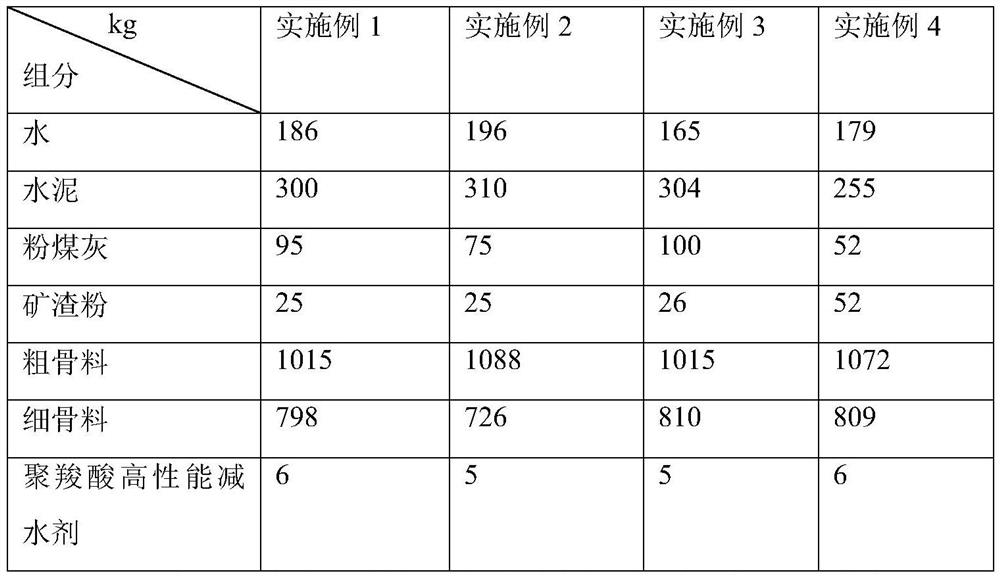

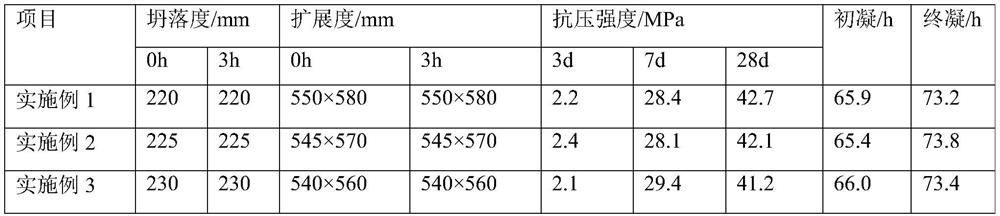

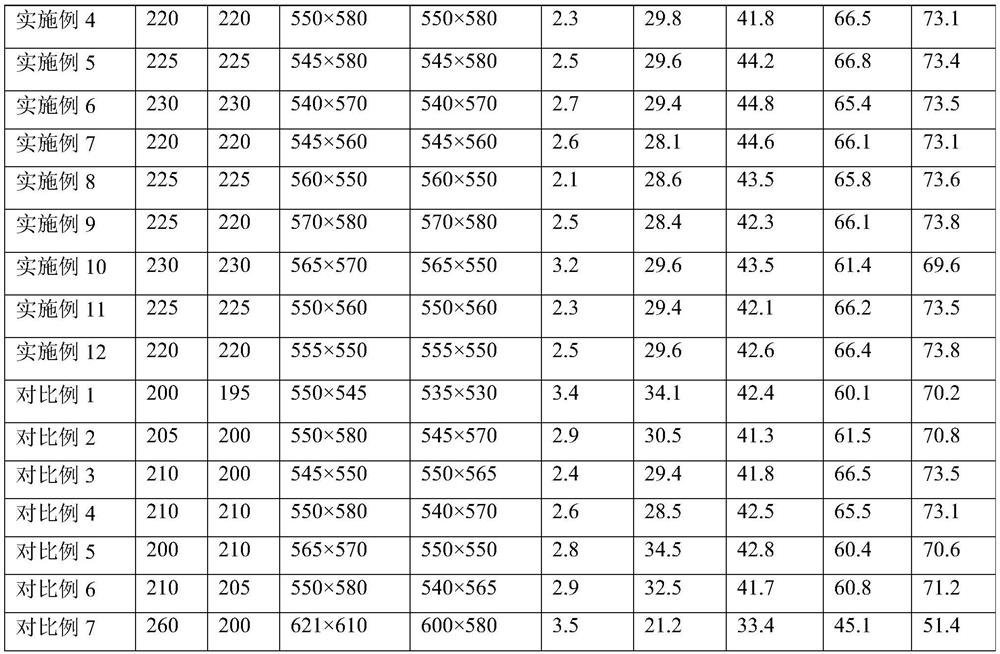

ActiveCN113387660AReduce bleedingShorten the setting timeSolid waste managementEnvironmental engineeringCarboxylic acid

The invention relates to the technical field of building materials, and particularly discloses C30 underwater self-compacting concrete and a preparation method thereof. The C30 underwater self-compacting concrete is prepared from the following components in parts by weight: 255 to 310 parts of cement, 52 to 100 parts of fly ash, 25 to 52 parts of slag powder, 1015 to 1088 parts of coarse aggregate, 726 to 810 parts of fine aggregate, 5 to 6 parts of polycarboxylic acid high-performance water reducing agent and 165 to 196 parts of water. The preparation method comprises the following steps: S1, uniformly mixing the cement, the fly ash, the slag powder, the coarse aggregate and the fine aggregate to obtain a mixture; and S2, uniformly mixing a polycarboxylic acid high-performance water reducing agent with water, adding the mixture into the mixture, and uniformly mixing to obtain the C30 underwater self-compacting concrete. The C30 underwater self-compacting concrete has the advantages of good water-retaining property, good workability, long setting time, strong underwater dispersion resistance, excellent moss growth prevention effect and long-lasting placement.

Owner:四川佰汇混凝土工程有限公司

Underwater anti-scouring environment-friendly composite material as well as preparation method and construction process thereof

ActiveCN114538855AStrong erosion resistanceImprove impermeabilitySolid waste managementFoundation engineeringAdhesiveSludge

The invention discloses an underwater anti-scouring environment-friendly composite material as well as a preparation method and a construction process thereof, and relates to the technical field of underwater pile foundations. The adhesive comprises a component A and a component B. The component A comprises the following raw materials by weight: 70-80% of an inorganic gel component; 0.5%-1% of an organic gel component; 5-10% of an anti-dispersing agent component; 2-4% of a nanometer filling component; 7-10% of fly ash; and the component B is marine sludge. According to the composite material, the waste high-water-content sludge is fully utilized, the scouring and strength indexes are guaranteed, the environment-friendly purpose is achieved, and the problem that an underwater platform foundation is eroded and corroded by wave flow is solved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Underwater concrete mechanical construction method

InactiveCN103526762ARapid development of strengthExcellent dispersion resistanceFoundation engineeringBase planeMechanical construction

The invention belongs to the technical field of underwater concrete mechanical construction and particularly relates to a full-mechanic underwater concrete construction method. According to the method, high-performance underwater concrete, a concrete mixer, a concrete conveying pump and an underwater guide pipe are included. The mechanic construction system effectively solves the technical problem of underwater construction with the high-performance underwater concrete. The method includes the following steps that the concrete mixer stirs the high-performance underwater concrete with strong force, and then guided into the concrete conveying pump and pumped to a pouring base plane through the underwater guide pipe to finish a pouring process of the underwater concrete. According to the method, mechanical work is adopted, the construction efficiency is greatly improved and the construction period is shortened.

Owner:汪峻峰

Concrete for cast-in-place pile, and preparation method thereof

ActiveCN110981306AImprove anti-corrosion performanceExcellent dispersion resistanceCelluloseWater reducer

The invention discloses a concrete for a cast-in-place pile, and a preparation method thereof. The concrete comprises cement, sands, pebbles, an anticorrosion and antirust agent, a flocculating agent,a water reducing agent and water. The preparation method comprises the following steps: (1) mixing hydroxymethyl cellulose, polyacrylamide, chitosan, calcium nitrite, fly ash, calcium oxide, cyclodextrine and the water reducing agent with diatomite, grinding the obtained mixture to obtain a premixed powder, and mixing sodium silicate with water to prepare an aqueous sodium silicate solution; (2)mixing 1 / 3 to 2 / 3 of the premixed powder obtained in step (1) with the cement, sands and pebbles, and mixing with the remaining water to obtain a mixture I; and (3) adding 1 / 3 to 2 / 3 of the premixed powder obtained in step (1) and the aqueous sodium silicate solution into the mixture I obtained in step (2), and continuously stirring to obtain the concrete for the cast-in-place pile. The concrete for the cast-in-place pile has the advantages of good workability, good corrosion resistance, good dispersion resistance, high strength, and suitableness for underwater cast-in-place construction.

Owner:THE GUANGDONG NO 3 WATER CONSERVANCY & HYDRO ELECTRIC ENG BOARD CO LTD

Grouting reinforcement material for treating road diseases and preparation method thereof

The invention discloses a grouting reinforcement material for treating road diseases, which is formed by mixing component A and component B at a volume ratio of 2:1: component A consists of 20-120 parts of slag powder, fly ash 12~110 parts, cement 12~44 parts, fine sand 12~110 parts, fiber 0.15~0.5 parts, water reducing agent 1.2~4.5 parts, early strength agent 2~6 parts, retarder 1~4 parts, water 50 parts ~130 parts are prepared; component B is prepared by alkaline activator and flocculant at a ratio of 100:1~6. The present invention adds a flocculant to the alkali activator, so that the slurry has good anti-dispersion performance in the water-rich empty base and weak roadbed, and can quickly coagulate and form strength. Insufficient strength formation is slow; adding fine sand to the grouting material will help improve the flocculation effect of the flocculant, accelerate the coagulation of the grout and form strength; adding a small amount of fast sand to the grouting material Hard cement can further accelerate the setting of the mixed slurry and improve the early strength.

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD

A kind of cement for underwater engineering

ActiveCN108558242BExcellent dispersion resistanceReduce churnCellulose acetateUltimate tensile strength

The invention relates to the technical field of building materials, in particular to cement for underwater engineering. The cement is prepared from, by weight, 100-150 parts of cement, 1-3 parts of polyacrylamide and 0.1-1 part of modified cellulose acetate. The cement for the underwater engineering has excellent dispersing resistance performance, during the underwater construction, the cement forthe underwater engineering can be used for reducing cement loss, thereby ensuring strength of cement concrete after construction.

Owner:XINGNING LONGJIANG BUILDING MATERIAL IND CO LTD

Quick coagulation flocculant for anti-washout concrete under water

InactiveCN101289291BAdjustable clotting timeImprove anti-scourabilitySolid waste managementCalcium silicateCalcium formate

Owner:CNPC RES INST OF ENG TECH

Method for manufacturing flocculant of modified polyacrylamide for concrete keeping together underwater

InactiveCN1191287CExcellent dispersion resistanceIncrease viscosityWater/sewage treatment by flocculation/precipitationSulfateWater quality

Owner:BC P INC CHINA NAT PETROLEUM CORP

Novel island reef rapid repair concrete

The invention discloses novel island reef rapid repair concrete, belongs to the technical field of adding additives into concrete, and is realized on the basis of sulphoaluminate cement with rapid solidification performance and anti-dispersing agent xanthan gum. The concrete is prepared from coral reef sand powder with the particle size of 1-3mm, coral aggregate with the particle size of 10-15mm,a superplasticizer and sulphoaluminate cement. The concrete disclosed by the invention has the characteristic of rapid solidification, has excellent underwater dispersion resistance, and is low in relative cost which cannot be achieved by other underwater concrete in island construction.

Owner:XIANGTAN UNIV

Concrete for cast-in-situ pile and preparation method thereof

ActiveCN110981306BImprove anti-corrosion performanceExcellent dispersion resistanceCelluloseWater reducer

The invention discloses a concrete for a cast-in-place pile, and a preparation method thereof. The concrete comprises cement, sands, pebbles, an anticorrosion and antirust agent, a flocculating agent,a water reducing agent and water. The preparation method comprises the following steps: (1) mixing hydroxymethyl cellulose, polyacrylamide, chitosan, calcium nitrite, fly ash, calcium oxide, cyclodextrine and the water reducing agent with diatomite, grinding the obtained mixture to obtain a premixed powder, and mixing sodium silicate with water to prepare an aqueous sodium silicate solution; (2)mixing 1 / 3 to 2 / 3 of the premixed powder obtained in step (1) with the cement, sands and pebbles, and mixing with the remaining water to obtain a mixture I; and (3) adding 1 / 3 to 2 / 3 of the premixed powder obtained in step (1) and the aqueous sodium silicate solution into the mixture I obtained in step (2), and continuously stirring to obtain the concrete for the cast-in-place pile. The concrete for the cast-in-place pile has the advantages of good workability, good corrosion resistance, good dispersion resistance, high strength, and suitableness for underwater cast-in-place construction.

Owner:THE GUANGDONG NO 3 WATER CONSERVANCY & HYDRO ELECTRIC ENG BOARD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com