Flowing water dispersion resistant blocking material and preparation method thereof

A plugging material and anti-dispersion technology, used in earthwork drilling, water conservancy engineering, sealing/isolation, etc., can solve the problems of easy aging of the consolidated body, low plugging efficiency, long setting time, etc., and achieve excellent anti-dispersion. The effect of high capacity, high impact force and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] A method for plugging dynamic water, comprising the steps of:

[0087] (1) Weigh 100g of Portland cement with a strength grade of 42.5, dissolve it in 100g of water, stir fully, make slurry A, and set aside;

[0088] (2) The total mass of raw materials is 100g, by weight percentage, xanthomonas polysaccharide 0.3%, polyethylene glycol-20000.2%, sodium alginate 0.2%, water glass 10% (mol number 3.0), and the balance is water, First, dissolve Xanthomonas polysaccharide, polyethylene glycol-2000, and sodium alginate in water in proportion, and then add water glass to it after completely dissolving, and stir thoroughly to make slurry B, which is set aside;

[0089] (3) Mix the A and B grouts prepared in steps (1) and (2) with a volume ratio of 3:1 for grouting, then test the setting time of the grout, the retention rate of the grout and the mechanical strength of the stone body, the results are shown in Table 1 Show.

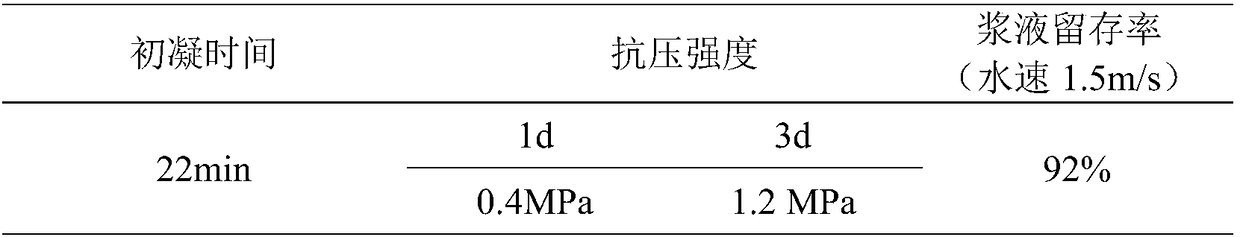

[0090] Table 1

[0091]

Embodiment 2

[0093] A method for plugging dynamic water, comprising the steps of:

[0094] (1) Weigh 100g of Portland cement with a strength grade of 42.5, dissolve 0.5g of sodium sulfate in 100g of water, stir fully, make slurry A, and set aside;

[0095](2) The total mass of raw materials is 100g, by weight percentage, xanthomonas polysaccharide 1.2%, polyethylene glycol-2000 1%, sodium alginate 1.5%, water glass 10% (mol number 3.0), and the balance is water , first dissolving xanthomonas polysaccharide, polyethylene glycol-2000, and sodium alginate in water in proportion, after being completely dissolved, adding water glass to it, stirring fully, to make slurry B, and set aside;

[0096] (3) The A and B grouts prepared in steps (1) and (2) are mixed and grouted in a volume ratio of 3:1, and then the setting time of the grout, the retention rate of the grout and the mechanical strength of the stone body are tested, and the results are shown in Table 2 Show.

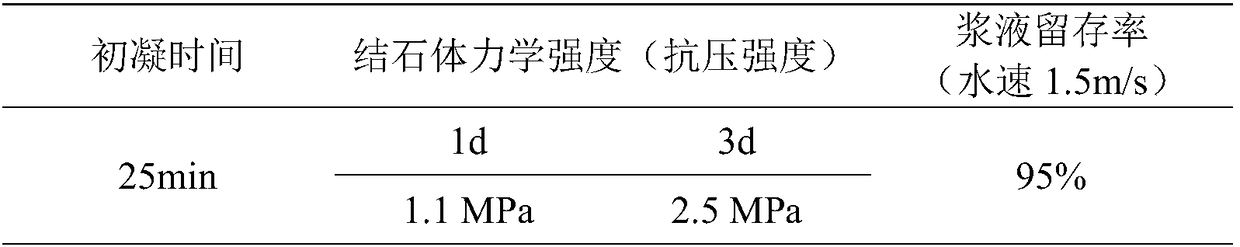

[0097] Table 2

[0098] ...

Embodiment 3

[0100] A method for plugging dynamic water, comprising the steps of:

[0101] (1) Weigh 100g of Portland cement with a strength grade of 42.5, 0.5g of sodium sulfate, and 0.5g of polycarboxylate superplasticizer, dissolve it in 90g of water, stir fully, and prepare slurry A for later use;

[0102] (2) The total mass of raw materials is 100g, by weight percentage, xanthomonas polysaccharide 1.2%, polyethylene glycol-2000 1%, sodium alginate 1.5%, water glass 10% (mol number 3.0), and the balance is water , first dissolving xanthan polysaccharide, polyethylene glycol-2000, and sodium alginate in water, after being completely dissolved, adding water glass to it, stirring fully, to make slurry B, and set aside;

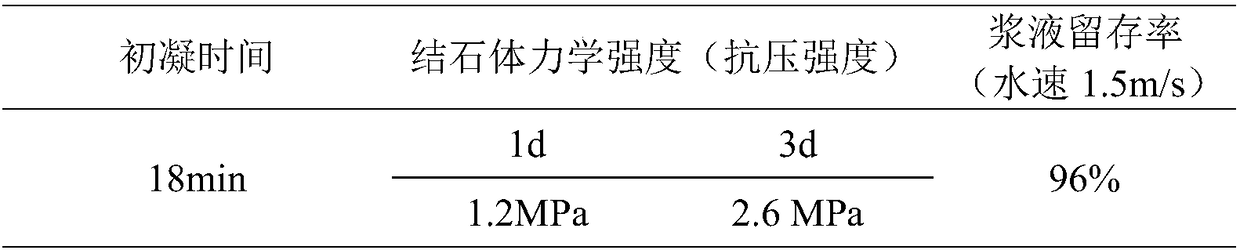

[0103] (3) Mix the A and B grouts prepared in steps (1) and (2) with a volume ratio of 3:1 for grouting, then test the setting time of the grout, the retention rate of the grout and the mechanical strength of the stone body, the results are shown in Table 3 Show.

[010...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com