Super-retarding concrete and preparation method thereof

A concrete and ultra-retarding technology, applied in the field of building materials, can solve the problems of short retardation time, low early strength, and prolong the setting time of concrete, and achieve the effect of prolonging the setting time and reducing the gap.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

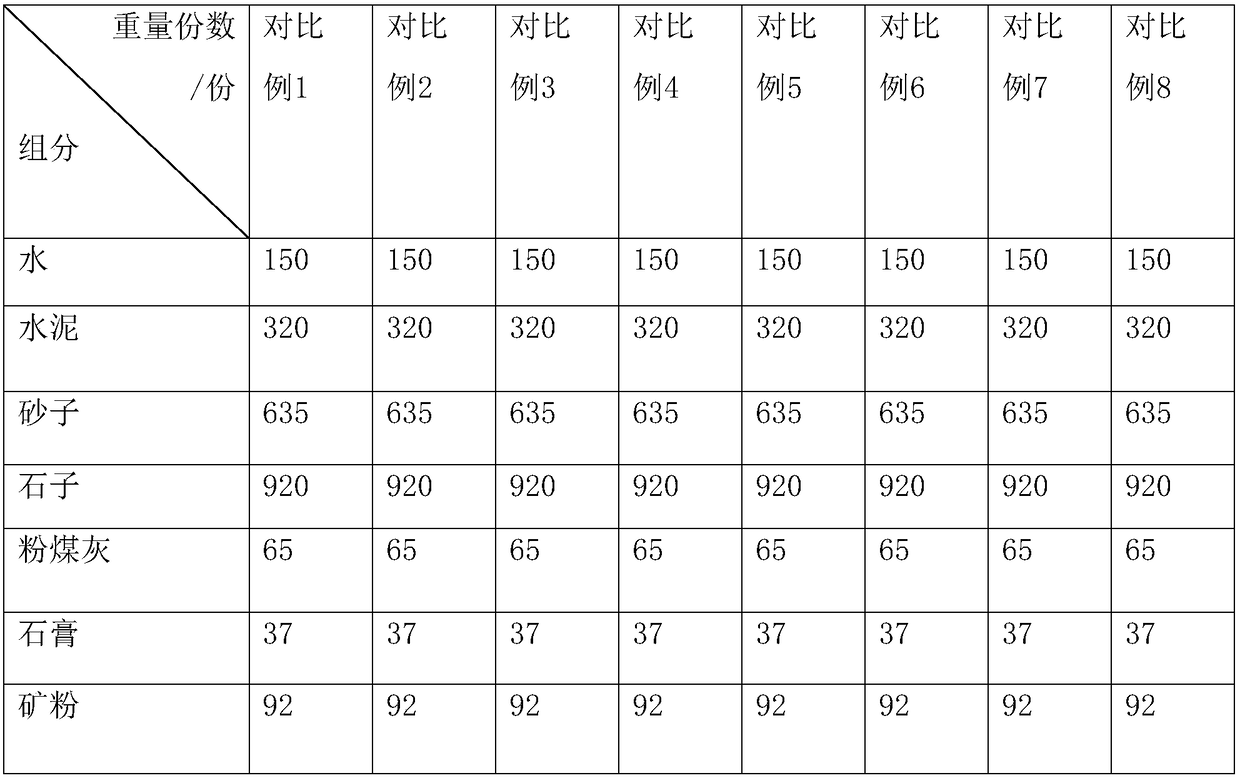

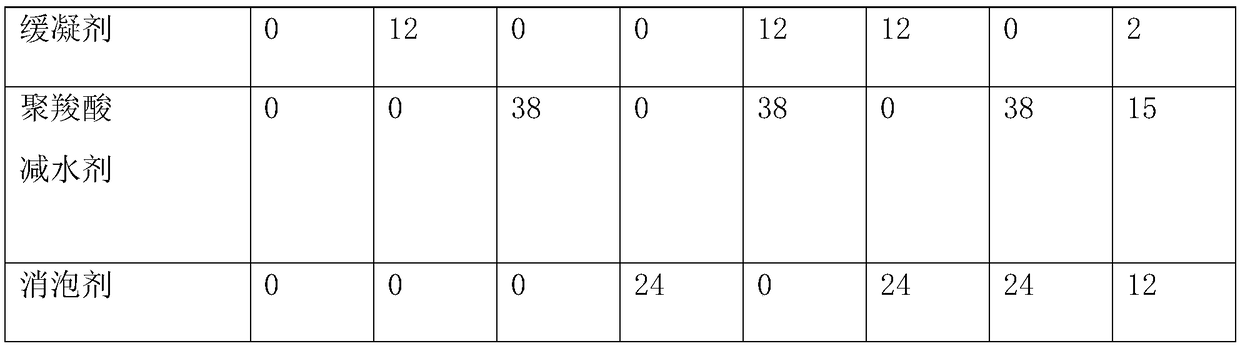

[0033] Embodiment 1: a kind of ultra-retarded concrete, is characterized in that: comprise following component expressed in parts by weight: 150 parts of water, 320 parts of cement, 635 parts of sand, 920 parts of stone, 65 parts of external admixture A, external admixture 92 parts of material B, 5.5 parts of admixture, 24 parts of defoamer, 37 parts of gypsum, 17 parts of montan wax particles;

[0034] Wherein the admixture comprises the following components expressed in parts by weight: 12 parts of retarder, 38 parts of polycarboxylate superplasticizer; external admixture A comprises fly ash, and external admixture B comprises mineral powder;

[0035] The retarder is composed of sodium thiosulfate, glycerol and sodium tripolyphosphate with a mass ratio of 1:2.4:2.3;

[0036] The polycarboxylate water reducer comprises the following components expressed in parts by weight: 92g isopentenol polyoxyethylene ether, 5.5g mass fraction is 5% hydrogen peroxide, 9g acrylic acid, 0.07...

Embodiment 2-8

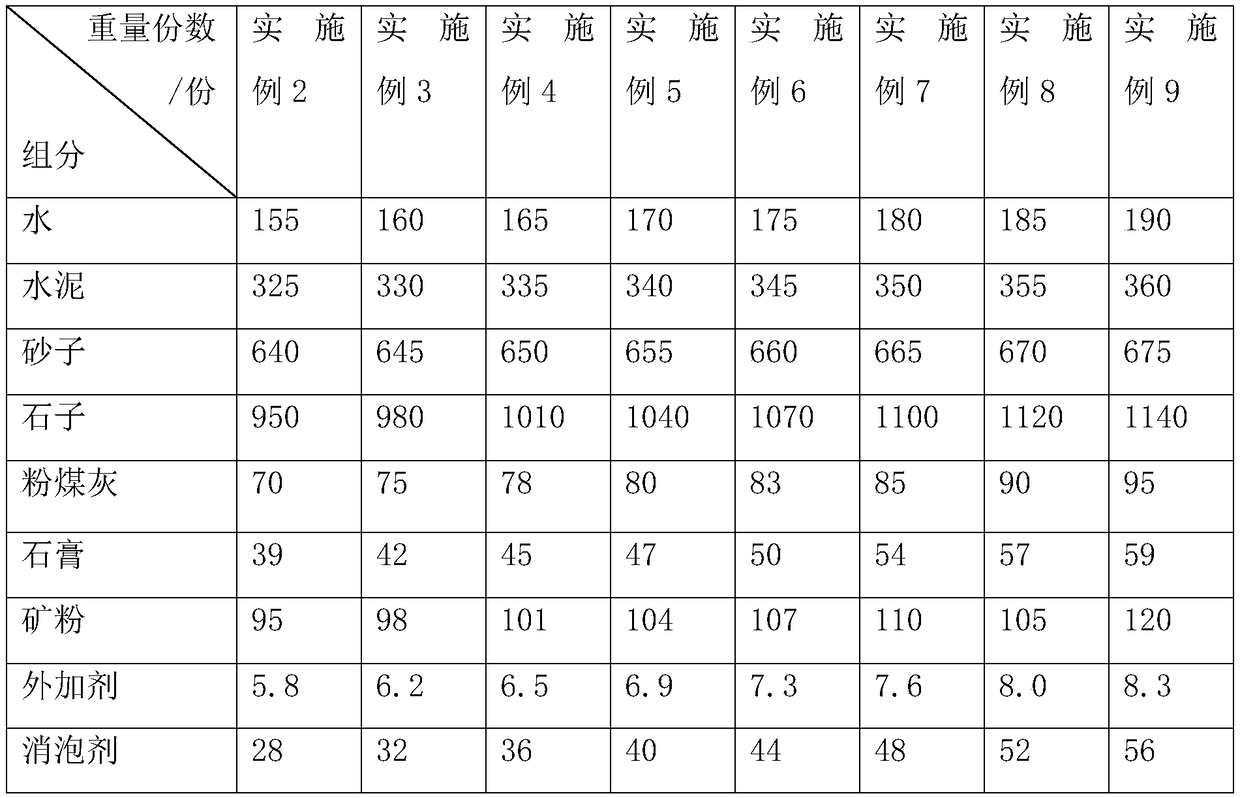

[0043] Embodiment 2-8: a kind of super-retarded concrete, the difference from embodiment 1 is that the components included and the corresponding parts by weight are shown in Table 1.

[0044] Components and corresponding parts by weight thereof included in Table 1 embodiment 2-8

[0045]

Embodiment 10

[0046] Embodiment 10: a kind of super-retarded concrete, the difference from embodiment 1 is that the parts by weight of the retarder are 14 parts, and the parts by weight of the polycarboxylate superplasticizer are 45 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com