Patents

Literature

70results about How to "Maintain slump" patented technology

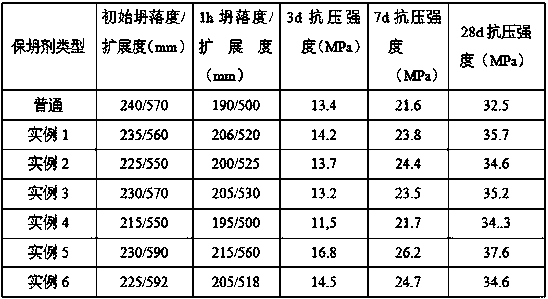

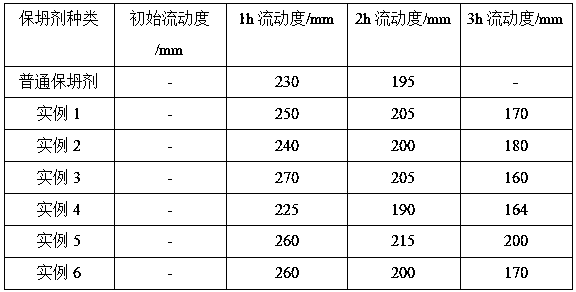

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for high-slump-retention polycarboxylate water reducer

InactiveCN103450411AIncreased steric hindranceSolve problems such as difficult pumpingMeth-Ptru catalyst

The invention discloses a preparation method for a high-slump-retention polycarboxylate water reducer. The preparation method comprises the following steps of: esterifying methoxylpolyethylene glycol monomethyl ethers with different molecular weights with methacrylic acid and a mixed polymerization inhibitor for a period of time under the action of a catalyst and at a certain temperature, then adding allyl alcohol in one time, further esterifying in the same conditions to obtain an esterified macromonomer MP containing crosslinking monomer allyl methacrylate; then performing aqueous solution polymerization on the MP, unsaturated sulfonate, (meth)acrylate unsaturated monomers and a chain transfer agent in a low-temperature condition and within a redox initiation system; and finally adding caustic soda liquid to neutralize, so as to obtain the polycarboxylate water reducer with a certain concentration. The high-slump-retention polycarboxylate water reducer prepared by the preparation method disclosed by the invention is a high-performance water reducer which is prepared at a low temperature by virtue of a molecular structure design, as well as is high in slump retention, excellent in dispersing performance, good in adaptability, simple in process, pollution-free, low in energy consumption, and easy to realize industrialized production.

Owner:KZJ NEW MATERIALS GROUP CO LTD

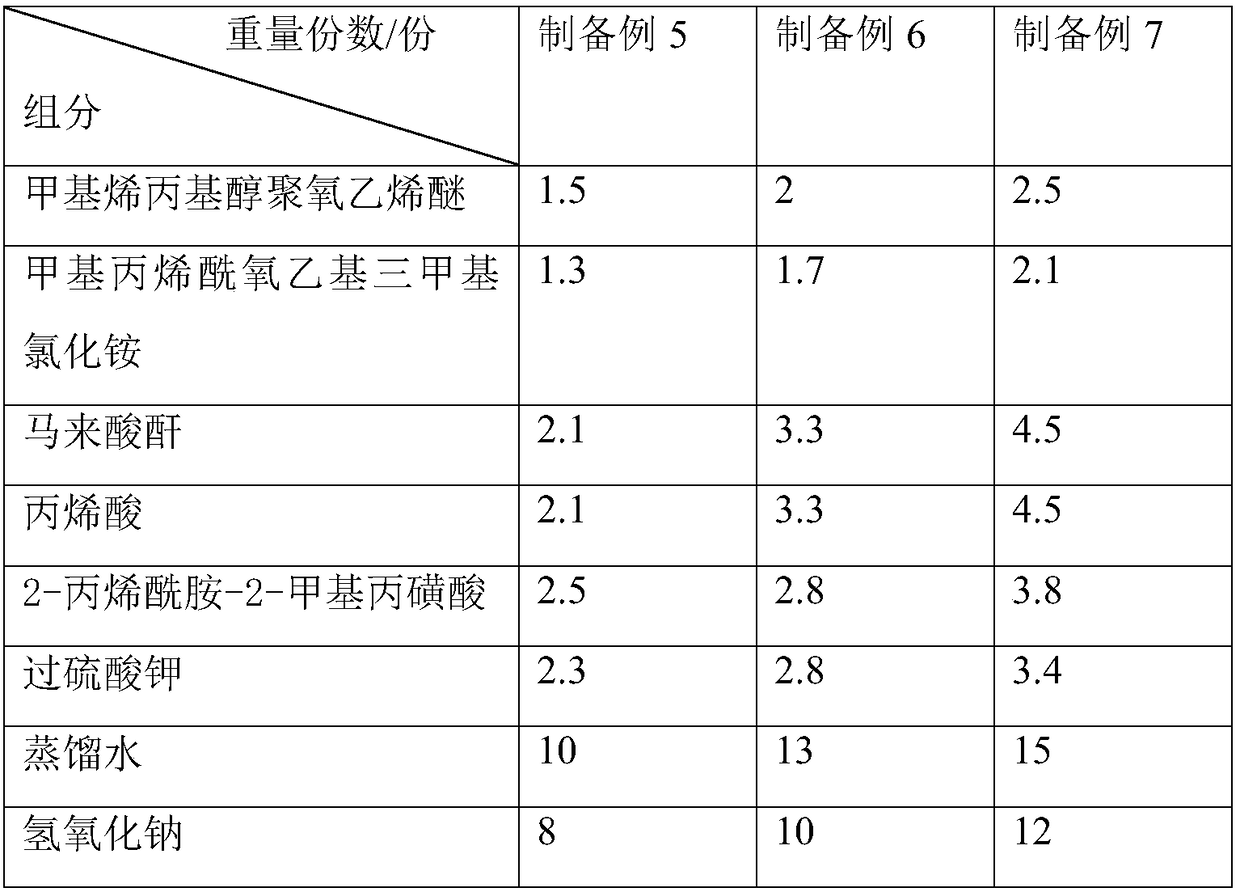

Preparation method of special slump retaining agent for cross-linked polycarboxylic acid and slump retaining agent prepared through method

ActiveCN103833939ADifficult to self-assembleEasy esterification reactionBulk polymerizationComposite material

The invention discloses a preparation method of a special slump retaining agent for cross-linked polycarboxylic acid. The preparation method comprises the following steps of step I, preparing a difunctional macromonomer: partially esterifying unsaturated polyether and unsaturated anhydride to generate a mixture A of the difunctional macromonomer, the unsaturated polyether and the unsaturated anhydride; step II, copolymerizing: polymerizing the mixture and unsaturated acid or unsaturated hydride small monomer B in the presence of a body polymerization initiator, adding sulfonic acid small monomer C and copolymerization adjusting agent to have the aqueous solution polymerization in the presence of an aqueous solution initiator to obtain a copolymerization product with mass concentration of 40 to 80 percent; step III, neutralizing: adjusting the pH value of the copolymerization product to be 6 to 7 to obtain special slump retaining agent for polycarboxylic acid. The invention also discloses a slump retaining agent prepared through the preparation method of the slump retaining agent for the cross-linked polycarboxylic acid. By introducing the difunctional macromonomer, an effect for preventing the slump loss can be realized.

Owner:KZJ NEW MATERIALS GROUP CO LTD

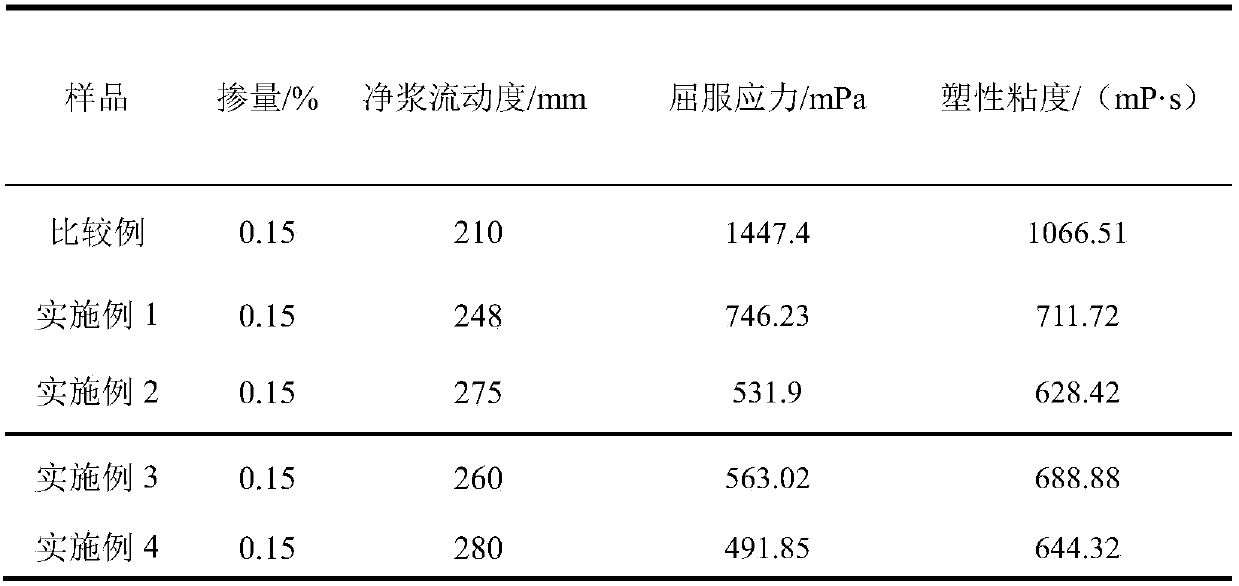

Preparation method of ester type viscosity reduction type polycarboxylate superplasticizer

ActiveCN106380554AImprove adsorption capacityIncrease electrostatic repulsionFunctional monomerSludge

The invention discloses a preparation method of an ester type viscosity reduction type polycarboxylate superplasticizer. The method comprises the following steps: (1) preparing an esterified monomer; (2) conducting the copolymerization reaction; (3) conducting the neutralization reaction. According to the technical scheme of the preparation method, methyl methacrylate and dimethylaminoethanol, remaining after the preparation of the esterified monomer, are subjected to ester exchange in the same condition of preparing the esterified monomer so as to obtain dimethylaminoethyl methacrylate as a functional monomer. Therefore, the preparation method is cost-saving and simple in operation. In addition, the functional monomer is directly introduced into the copolymerization reaction to react with other cationic monomers. During the polymerization process, anions, cations and tertiary amine groups are attached to polycarboxylic acid molecular chains, so that the surface adsorbability of cement particles can be improved. The electrostatic repulsion effect between cement particles is improved. Not only the ester type viscosity reduction type polycarboxylate superplasticizer is good in anti-sludge effect for sand and gravel materials high in cement content, but also the ester type viscosity reduction type polycarboxylate superplasticizer is good in dispersibility and viscosity-reducing effect.

Owner:KZJ NEW MATERIALS GROUP CO LTD

Still-free PHC tubular pile and production process thereof

ActiveCN102179875AEasy mixing timeMaintain slumpCeramic shaping apparatusCrushed stoneStructural engineering

The invention provides a still-free petroleum hydrocarbon (PHC) tubular pile. Compared with the prior art, the tubular pile consists of the following components by weight: 340 to 420kg of cement, 100 to 160kg of mineral powder, 700 to 900kg of yellow sand, 1,030 to 1,260kg of broken stone, 2.0 to 6.0kg of water reducing agent and 60 to 130kg of water, wherein the particle size of the broken stone is 5 to 25mm. The invention also provides a production process condition and a production process parameter of the tubular pile, so that the tubular pile can still meet the requirement of a national regulation without high-pressure steam curing; the strength of concrete can reach 80MPa within 3 to 5 days, and the strength of the concrete is higher than the design strength of the concrete within 28 days; Rn is more than or equal to 1.15R which meets evaluation requirements according to a mathematical statistical method; and the problems that a pile body is cracked, a pile top is broken, and the like when the knocking frequency of a pile sinking hammer is more than 2,000 are solved.

Owner:中交三航局第三工程有限公司

Preparation method of ether viscosity reduction type polycarboxylate superplasticizer

The invention discloses a preparation method of an ether viscosity reduction type polycarboxylate superplasticizer, which comprises the following steps: (1) copolymerization reaction; and (2) neutralization reaction. According to the preparation method disclosed by the invention, amide groups are connected to superplasticizer molecules, and then a polycarboxylate molecular chain has anion and cation groups, so that adsorbability on the surfaces of cement particles can be increased, the electrostatic repulsion effect between the cement particles can be increased, and a better viscosity reduction effect on concrete is achieved. Moreover, the amide groups are hydrolyzed under alkaline conditions so as to release potential carboxyl groups again, thereby being favorable for improving the dispersibility and slump retentivity of the superplasticizer and realizing high adaptability to cement of different varieties.

Owner:KZJ NEW MATERIALS GROUP CO LTD

Preparation method of high-solid-content ester polycarboxylic acid water reducing agent

The invention discloses a preparation method of a high-solid-content ester polycarboxylic acid water reducing agent, which comprises the following steps: (1) mixing polyethyleneglycol monomethyl ether, amino-terminated polyoxypropylene ether, methacrylic acid, a catalyst and a mixed polymerization inhibitor to react to obtain a first mixture; (2) adding unsaturated carboxylate, a cationic monomer and a chain-transfer agent into 70-75 parts of the first mixture, and uniformly mixing to obtain a second mixture; mixing an initiator and acrylic acid to obtain a third mixture; dropwisely adding the third mixture and second mixture into 80-85 parts of the 45-80-DEG C first mixture within 1.5-2 hours, keeping the temperature at 45-80 DEG C to react for 1-1.5 hours, and after the reaction finishes, adding water to regulate the concentration of the system to 80-85%; and (3) adding sodium hydroxide into the material obtained in the step (2) for neutralization to obtain the high-solid-content ester polycarboxylic acid water reducing agent. The method has the advantages of high production efficiency and environment friendliness. The prepared product has excellent properties, and is convenient for storage and line haul.

Owner:KZJ NEW MATERIALS GROUP CO LTD

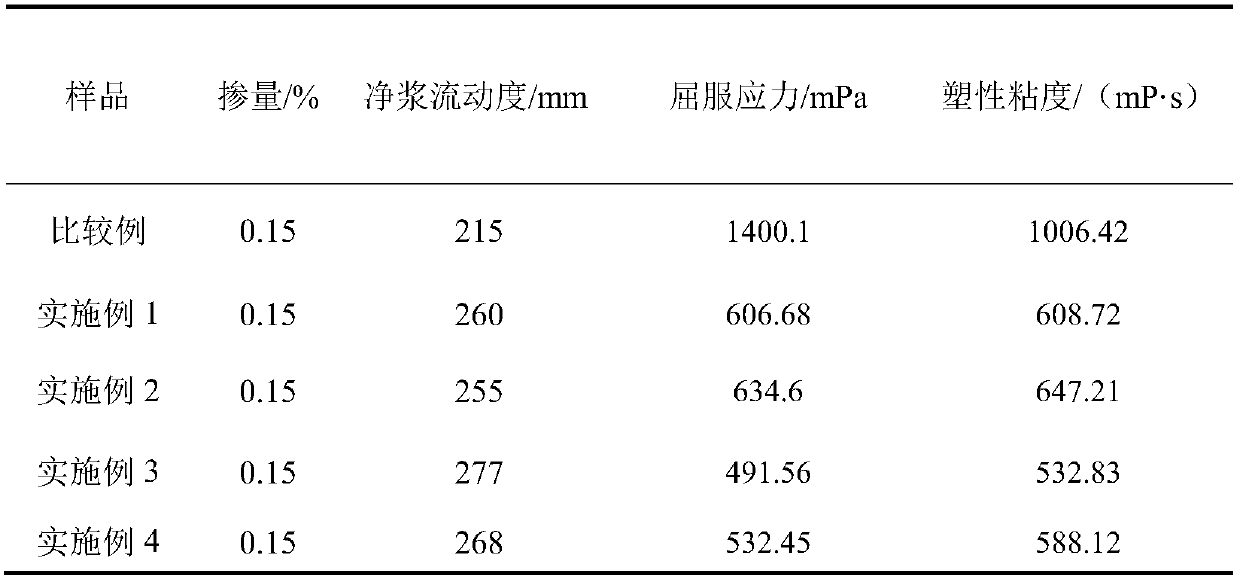

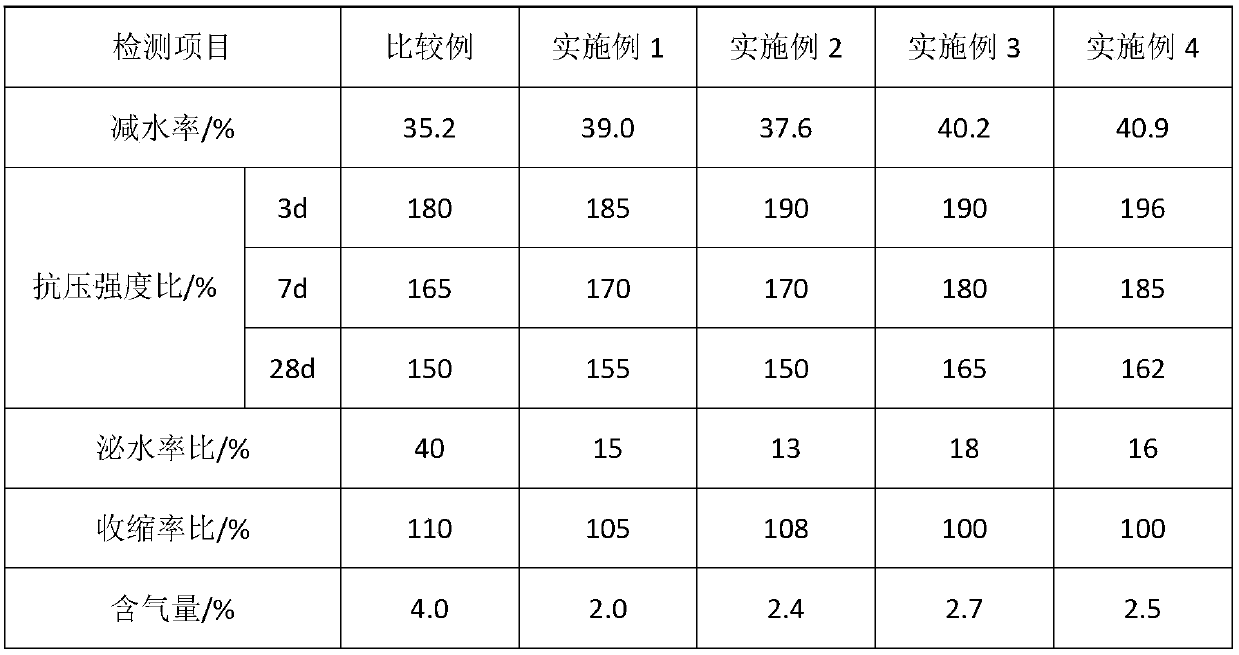

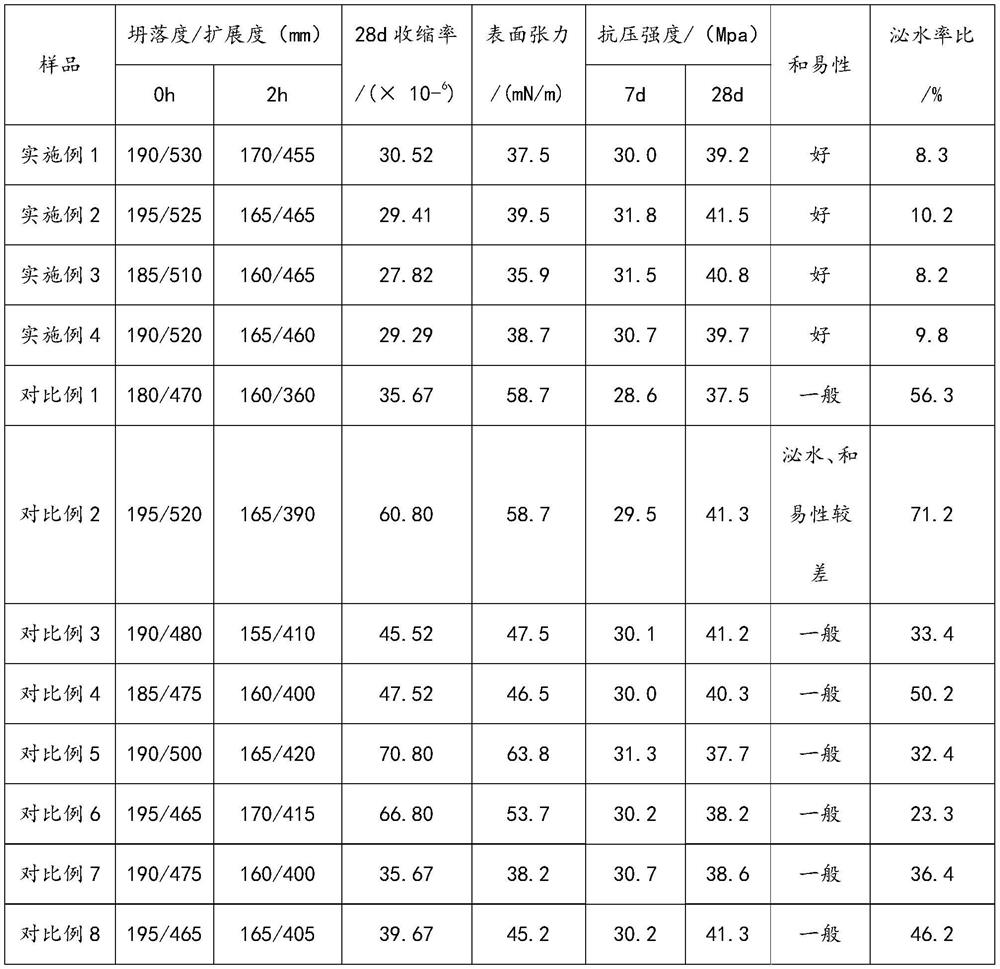

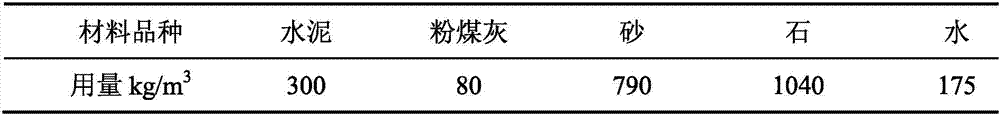

Concrete anti-bleeding inhibitor with water reducing function and preparation method thereof

The invention discloses a concrete anti-bleeding inhibitor with a water reducing function and a preparation method thereof. The anti-bleeding inhibitor is mainly prepared by subjecting polyether largemonomer, unsaturated carboxylic acid, unsaturated amide, unsaturated sulfonic acid or sulfonate, a cross-linking agent, an oxidizing agent, a reducing agent, a chain transfer agent and deionized water to free radical polymerization at 15-30 DEG C through an aqueous solution, adding a sodium hydroxide solution to adjust a pH value and then supplementing water. According to the preparation method,production is conducted at normal temperature, no heat sources are needed, the equipment is simple, no pollution is generated, the production efficiency is high, and the anti-bleeding inhibitor can effectively solve the problems that existing polycarboxylic acid water reducers are poor in water retention and water absorption performance and workability, and bleeding and bottom holding are easy tooccur; the inhibitor has excellent thickening and water retention performance, and the degree of construction difficulty can be greatly reduced.

Owner:SICHUAN TONGZHOU CHEM TECH

Super-retarding concrete and preparation method thereof

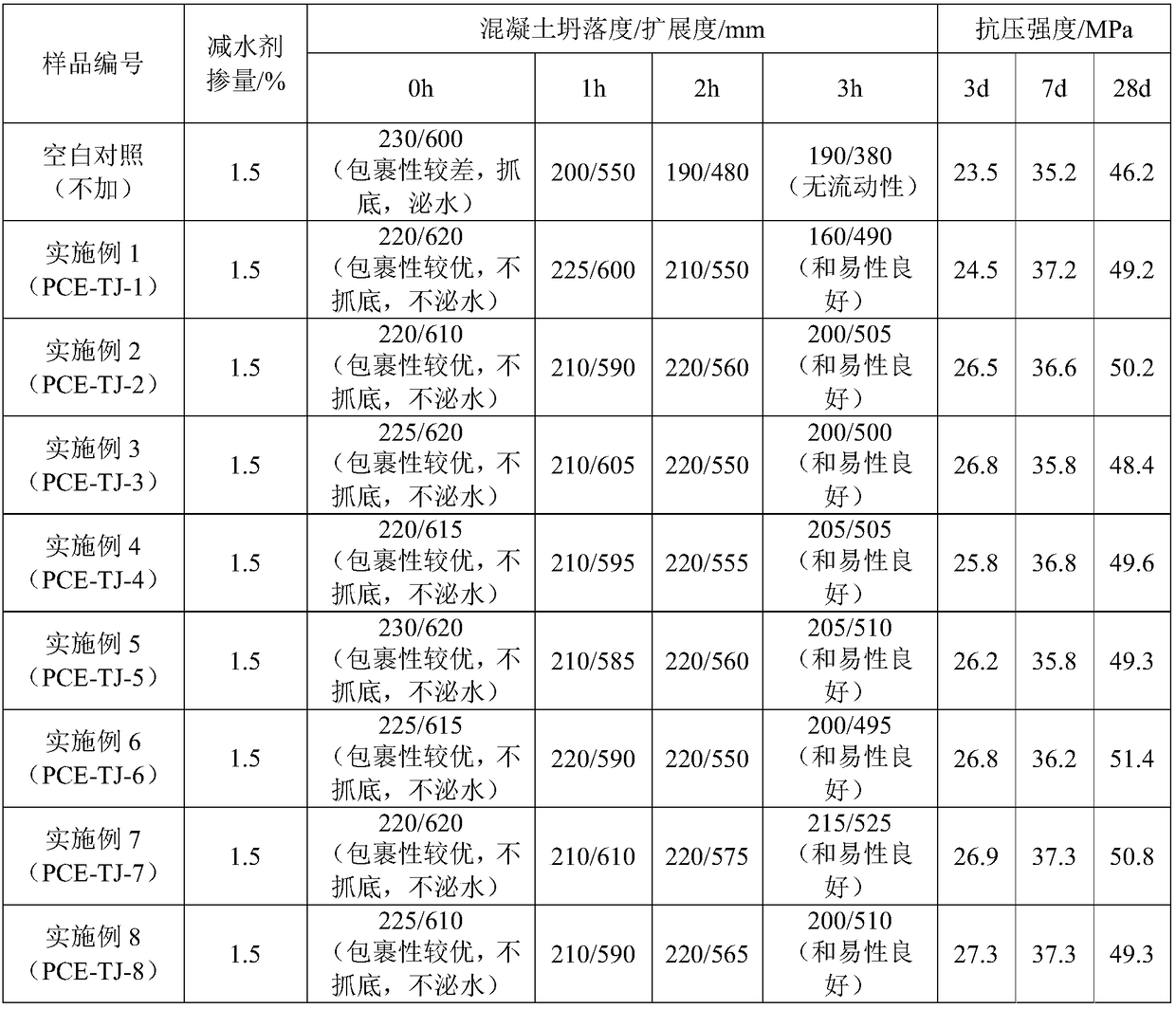

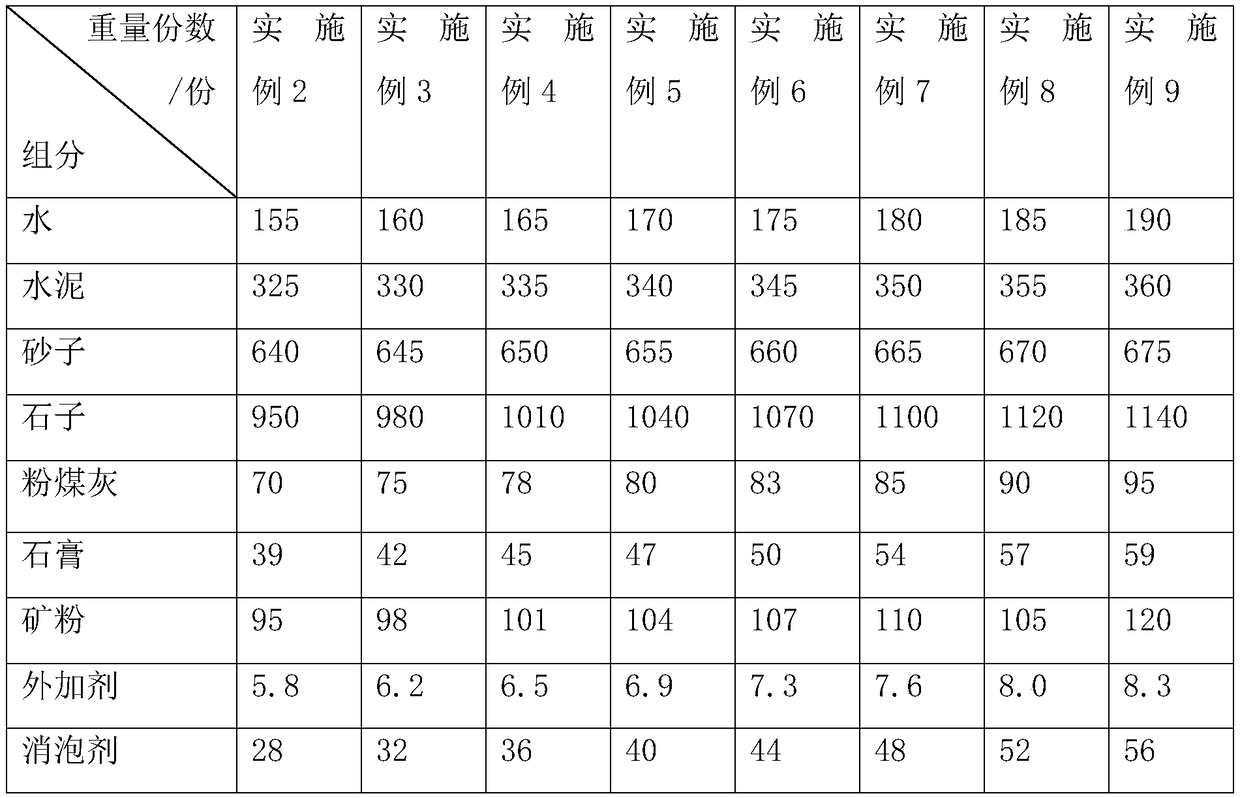

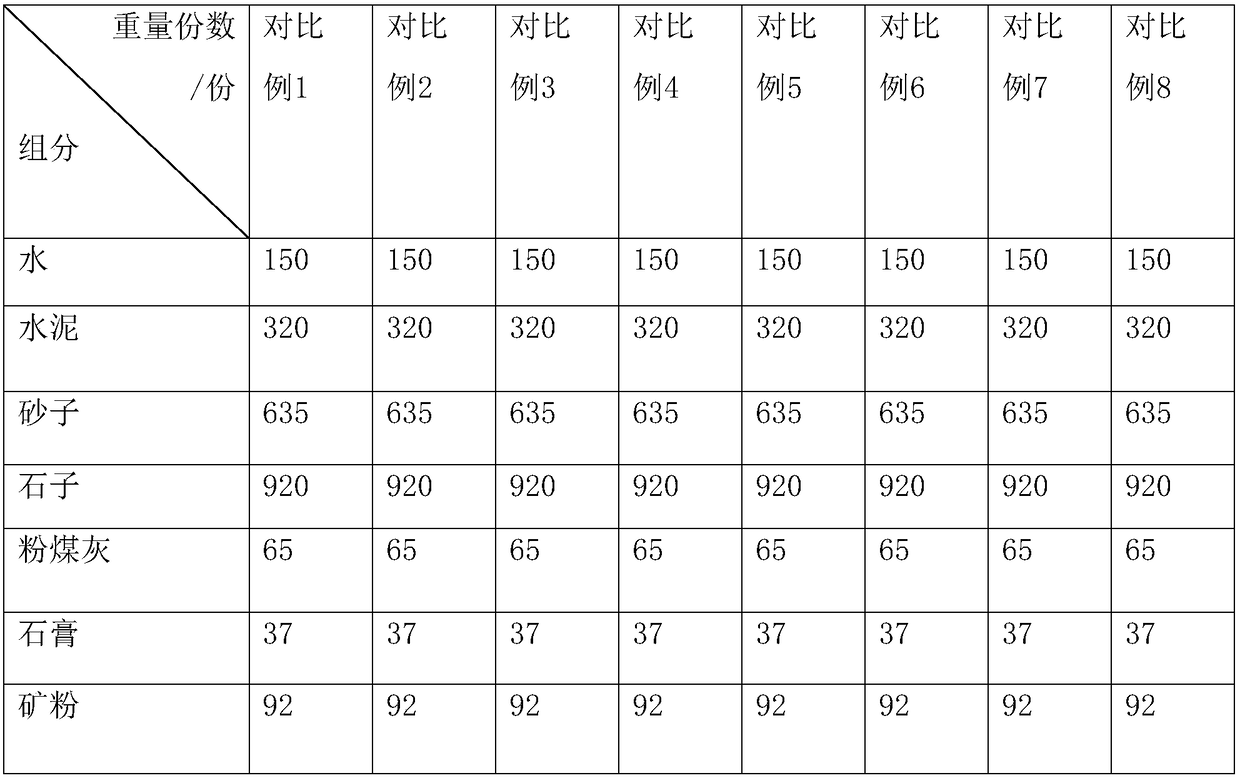

The invention discloses super-retarding concrete and relates to the technical field of building materials. According to the key pint of the technical scheme, the super-retarding concrete comprises thefollowing ingredients (by weight): 150-190 parts of water, 320-360 parts of cement, 635-675 parts of sand, 920-1140 parts of cobblestone, 65-95 parts of an admixture A, 92-120 parts of an admixture B, 37-59 parts of gypsum, and 5.5-8.3 parts of an additive. The additive comprises the following ingredients (by weight): 12-16 parts of a retarder and 38-52 parts of a polycarboxylate superplasticizer. The admixture A comprises fly ash, and the admixture B comprises mineral powder. The retarder is composed of sodium thiosulfate, glycerol and sodium tripolyphosphate according to the mass ratio of 1-3: 2.4-3.5: 2.3-3.2. The problem that concrete's short setting time and low long-term strength are hard to meet the requirement of prolonging the setting time of concrete and guaranteeing long-term strength is solved. By using the retarder and the polycarboxylate superplasticizer cooperatively, the setting time of concrete can be prolonged, and the concrete can have high long-term strength.

Owner:上海石化安东混凝土有限公司

Preparation method of novel polyether-synthesis slow-release-type polycarboxylic acid water reducer

The invention discloses a preparation method of a novel polyether-synthesis slow-release-type polycarboxylic acid water reducer. The method comprises the following steps that S1, a polyether macromonomer and deionized water are added into a reaction kettle, stirred at the normal temperature and dissolved, and a small unsaturated acid or anhydride monomer and a small unsaturation esters monomer aremixed in water to obtain an A solution; a reduction agent, a chain transfer agent and water are sufficiently mixed to obtain a B solution for use; S2, a certain amount of A solution is added to a macromonomer aqueous solution obtained in the step S1, and even stirring is conducted; S3, an oxidizing agent is added to the mixture obtained in the step S2 in advance, then the B solution is dropwise added, the A solution is dropwise added after the B solution is dropwise added for 2-10 min, and after drip addition is completed, heat preservation is conducted for 0.5 h; S4, after a reaction is completed, an alkaline solution is added for neutralization, the product is poured out, and the slow-release-type polycarboxylic acid water reducer is obtained. The obtained slow-release-type polycarboxylic acid water reducer has the advantages that the slow release time is long, the slump degree can be maintained for a long time, and the slump result is excellent.

Owner:SHANXI SUNWAY INTION TRADE CO LTD

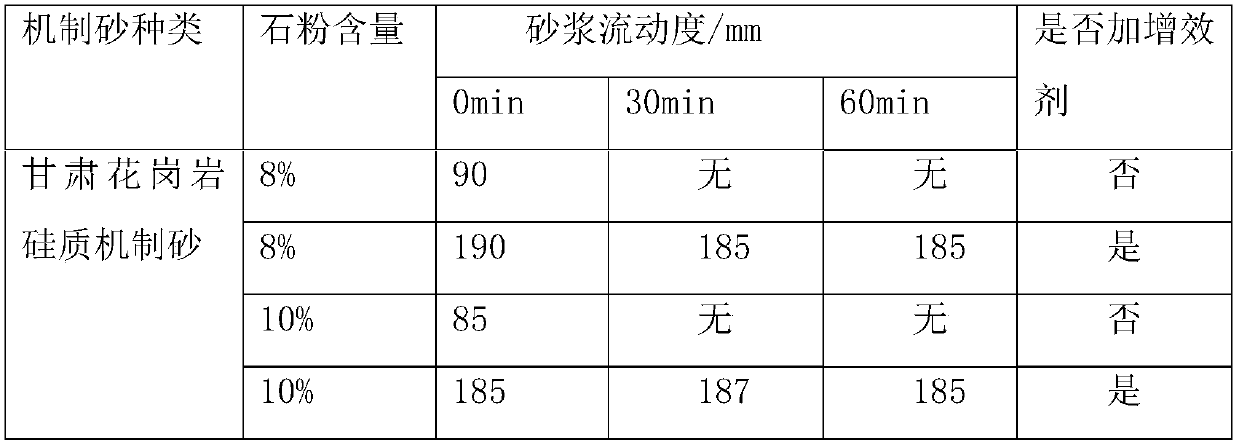

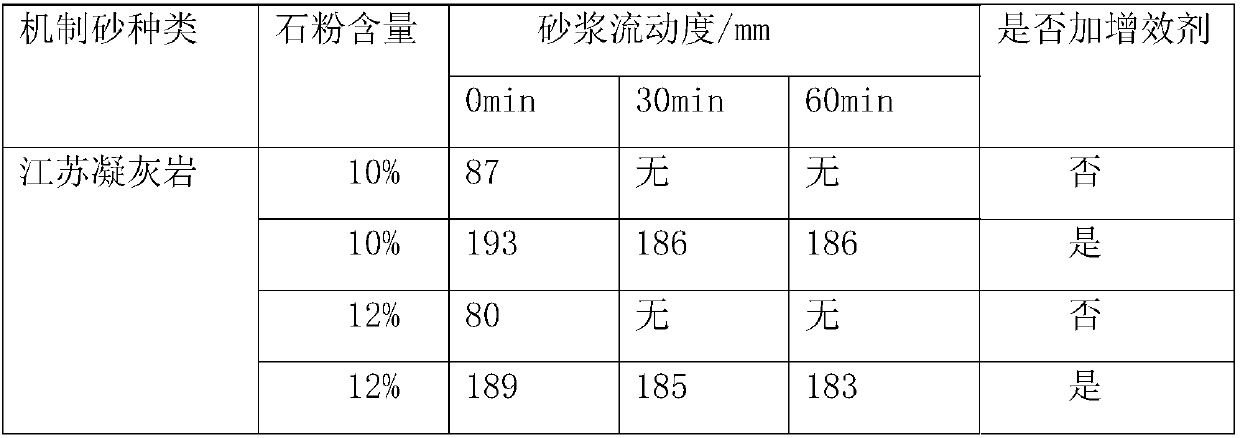

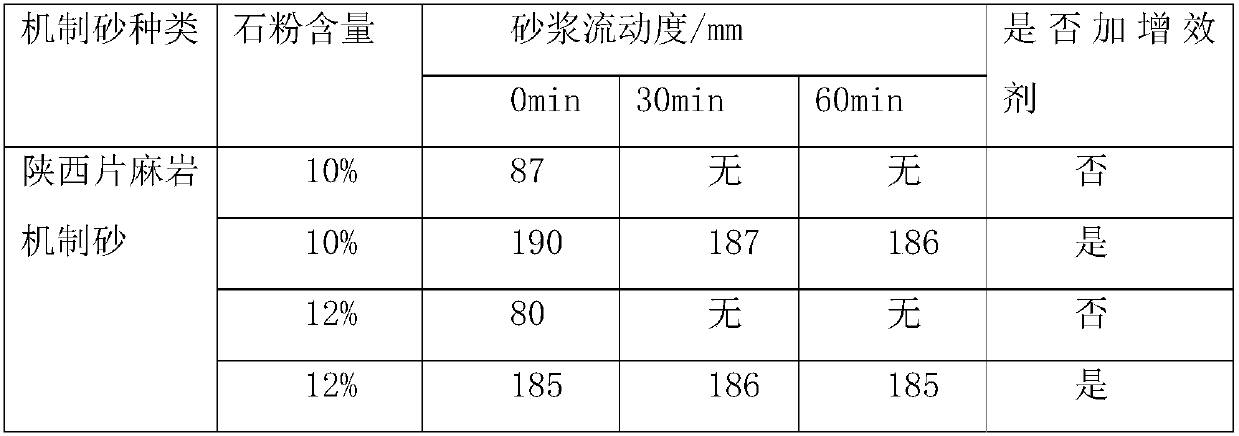

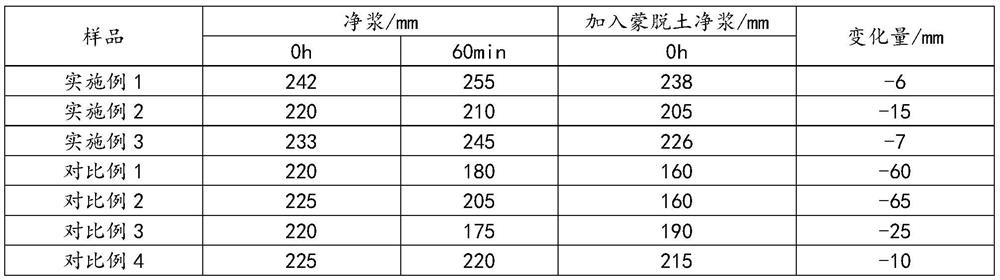

Synergist for reducing stone powder adsorption performance in siliceous machine-made sand and preparation method thereof

The invention provides a synergist for reducing the stone powder adsorption performance in siliceous machine-made sand and a preparation method thereof, and belongs to the field of machine-made sand concrete preparation. The synergist comprises, by weight, the following raw materials: 50-60 parts of a adsorption and dispersion component, 20-25 parts of an adsorption and chelating component; 0-30 parts of a retarding component; 0-10 parts of other performance improving components; the adsorption and dispersion component is one or a combination of a plurality of air-entraining surfactants; and the adsorption chelating component is one or a combination of two of an organophosphorus compound and inorganic phosphorus compound. The synergist for reducing the stone powder adsorption performance in the siliceous machine-made sand can improve the workability and strength of concrete, maintain the slump of the concrete, has low mixing amount and low cost, and has a better effect on the machine-made sand with high content of the stone powder.

Owner:UNIV OF SCI & TECH BEIJING

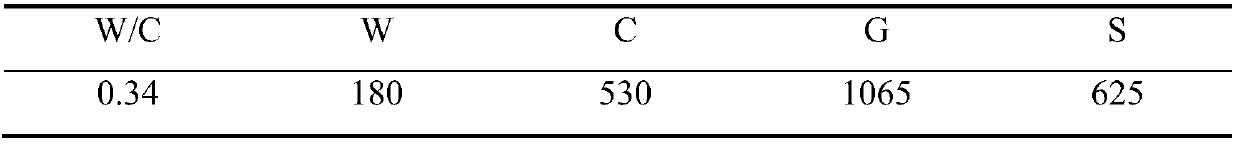

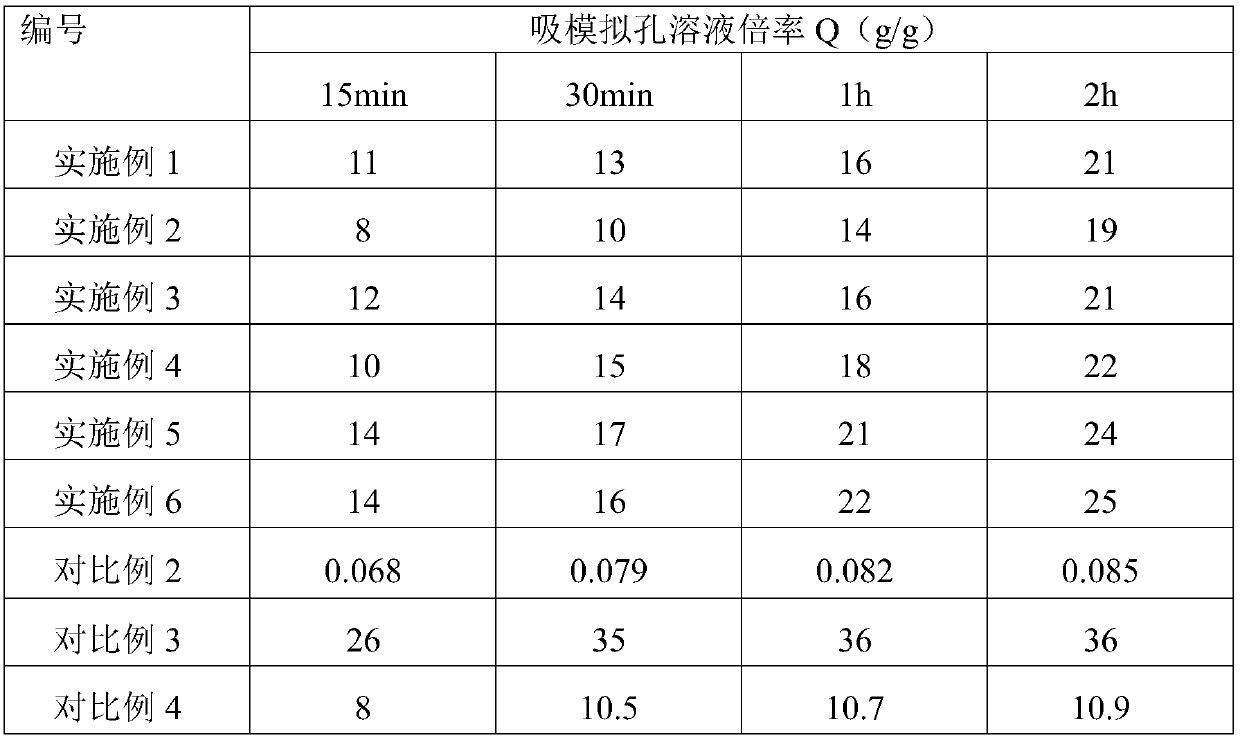

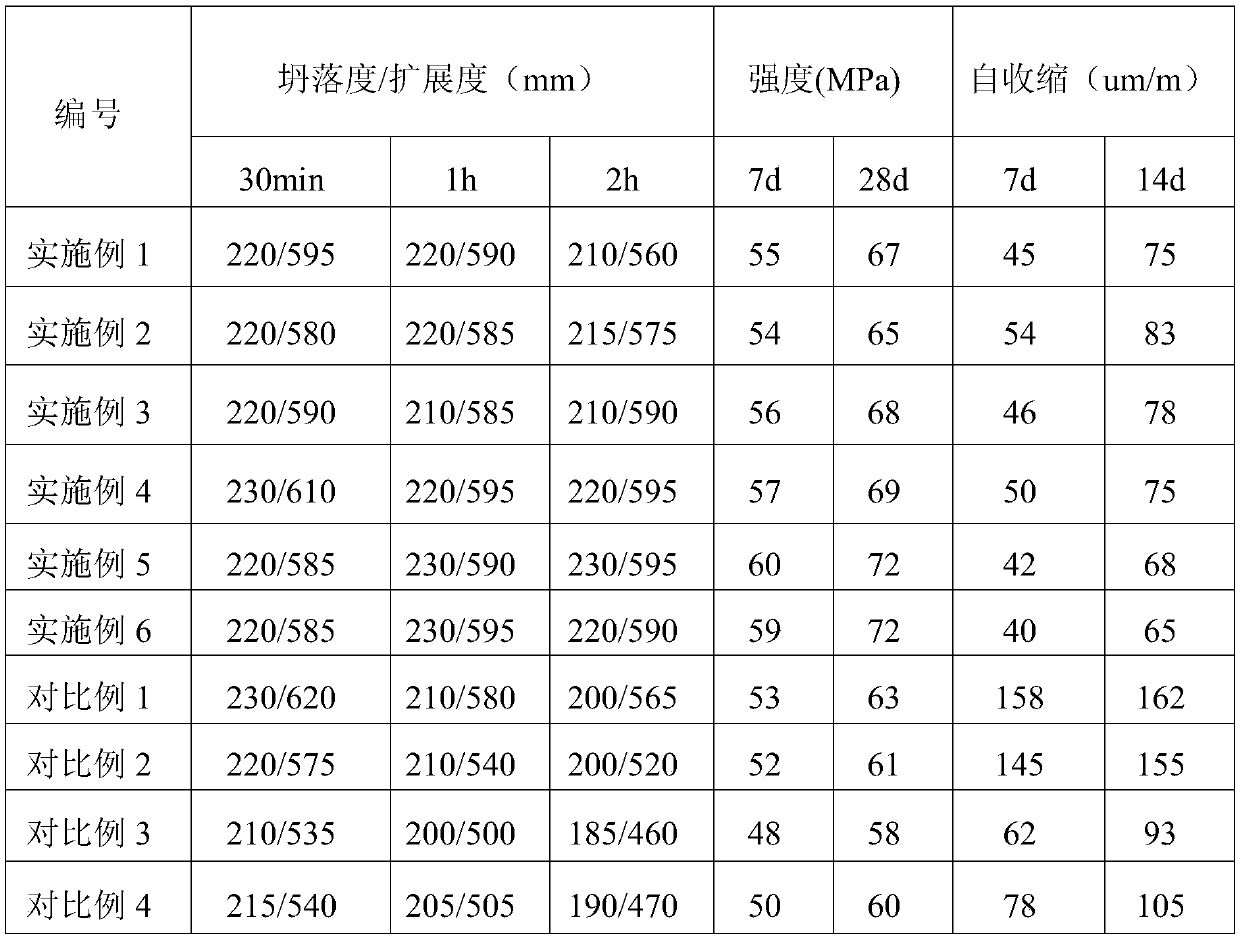

Curing agent in ceramsite carrier concrete and preparation method thereof

ActiveCN109516714AImprove water absorptionEasy to cause loss of work performanceExpanded clay aggregateAbsorption rate

The invention discloses a curing agent in ceramsite carrier concrete. A preparation method of the curing agent comprises the following steps that an acrylic acid solution, 2-acrylamide-2-methacrylic acid, initiators and crosslinking agents are uniformly mixed to prepare a reaction solution a; an etherificated sodium alginate solution, an acrylamide solution, initiators and crosslinking agents areuniformly mixed to prepare a reaction solution b; ceramsite is sequentially soaked in the reaction solution a and the reaction solution b, and is sequentially subjected to microwave treatment. Firstly, the ceramsite is used as a carrier; the polymerization of water absorption resin is performed inside and outside the ceramsite; meanwhile, a hole-inside hole-outside two-step method is used; the building of polymers with different water absorption rates inside and outside holes is realized; the prepared curing agent in the ceramsite carrier concrete can greatly improve the humidity inside the concrete; the early-period reduction and shrinkage effect of the concrete is obvious; meanwhile, the curing agent in the ceramsite carrier concrete has the advantages that the water absorption and waterrelease rate is slow; the use performance such as concrete strength is favorably guaranteed; important application and promotion values are realized.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD

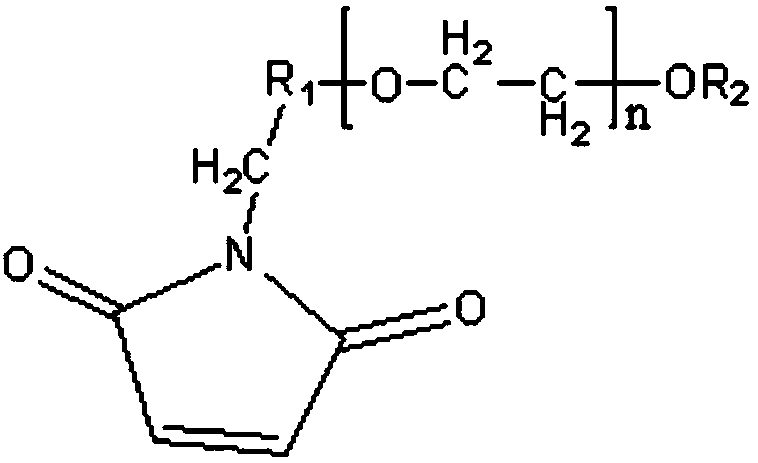

Preparation method of ether ester copolymerization type polycarboxylic acid water reducing agent capable of improving rheological behavior

The invention discloses a preparation method of an ether ester copolymerization type polycarboxylic acid water reducing agent for improving a rheological behavior. The water reducing agent is preparedthrough a copolymerization reaction of a first mixture, unsaturated polyether with the molecular weight of 4000-6000, unsaturated acid, a compound A, an initiator, a molecular weight regulator and deionized water, wherein the first mixture is prepared through an ester exchange reaction of methoxypolyethylene glycol with the molecular weight of 1000-4000, alkylphenol polyoxyethylene ether, unsaturated carboxylic ester and a polymerization inhibitor. According to the invention, a benzene ring and an imide structure are introduced, and the introduction of the benzene ring structure can effectively improve the adsorption efficiency and the thickness of an adsorption layer of polymer molecules on the surface of cement particles, so that the space stability effect of the water reducing agent ismore obvious; by means of introducing the imide structure, the adsorbability on the surface of the cement particles, the electrostatic repulsion effect among the cement particles, and the stability and the fluidity of the cement paste can be improved.

Owner:KZJ NEW MATERIALS GROUP CO LTD +1

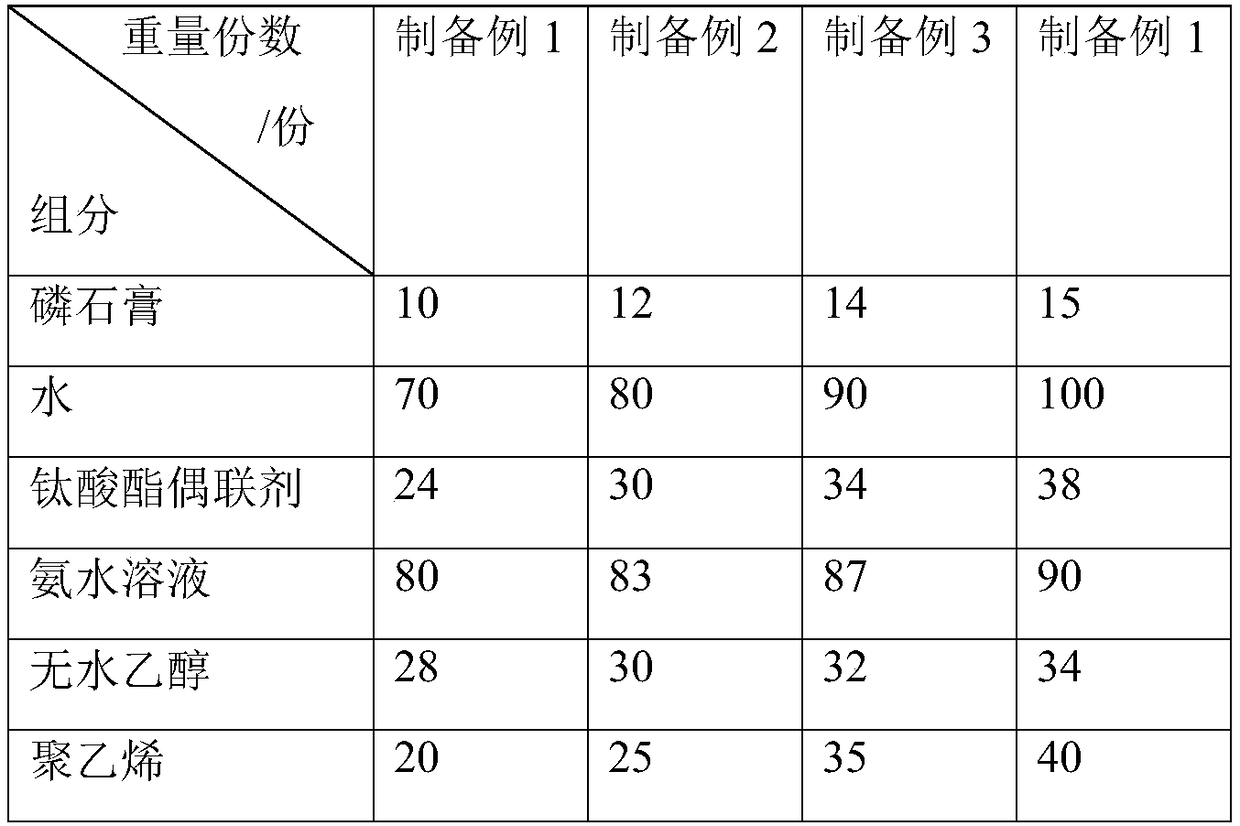

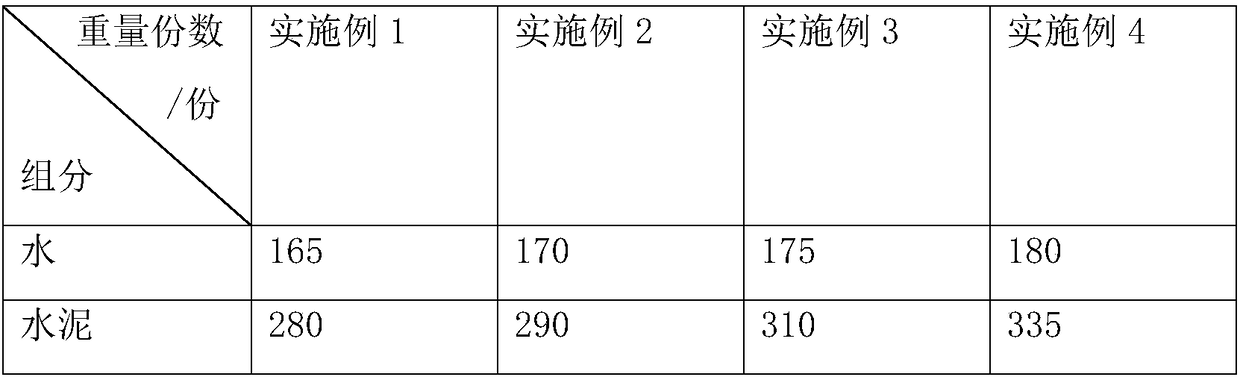

Super-retarded concrete and preparation method thereof

The invention discloses super-retarded concrete and a preparation method thereof. The super-retarded concrete is prepared from the following raw materials in parts by weight: 165-180 parts of water, 280-335 parts of cement, 565-620 parts of sand, 990-1200 parts of stone, 70-85 parts of flyash, 85-110 parts of mineral powder and 7.8-9.4 parts of an additive, wherein the additive is prepared from aretarder and a water reducer according to a mass ratio of 1 to (3.5-4.1). The retarder is prepared from the following components in parts by weight: 10-15 parts of phosphogypsum, 70-100 parts of water, 26-38 parts of a titanate coupling agent, 80-90 parts of an ammonium hydroxide solution with a mass fraction of 15-20%, 28-34 parts of absolute ethyl alcohol with a mass fraction of 20-35% and 20-40parts of polypropylene. The preparation method of the super-retarded concrete comprises the following steps: S1, adding the water reducer and a defoamer into water and fully mixing to obtain a firstmixture; S2, fully mixing corresponding parts by weigh of cement, stone, sand, flyash and mineral powder to form a second mixture; and S3, adding the first mixture into the second mixture, uniformly stirring, then adding the retarder and fully mixing to form the super-retarded concrete. The super-retarded concrete has the advantages of long setting time and high later-stage strength.

Owner:青岛康兴混凝土有限公司

Polycarboxylic acid water reducing agent for improving rheological behavior of cement pastes and preparation method thereof

ActiveCN109627397ASignificant steric stabilization effectIncreasing the thickness(Hydroxyethyl)methacrylatePhosphate

The invention discloses a polycarboxylic acid water reducing agent for improving a rheological behavior of cement pastes. The polycarboxylic acid water reducing agent is prepared by a copolymerizationreaction of a first mixture, unsaturated polyether, hydroxyethyl methacrylate phosphate, unsaturated acid, a compound A, an initiator, a molecular weight regulator and water. The invention also discloses a preparation method of the polycarboxylic acid water reducing agent for improving the rheological behavior of cement pastes. The method comprises the following steps that an esterification product with a benzene ring is obtained by carrying out the ester exchange reaction between alkylphenol polyoxyethylene ether and unsaturated carboxylic ester; the esterification product is copolymerized with the unsaturated polyether, compound A and hydroxyethyl methacrylate phosphate to introduce a benzene ring, a phosphate group and an imide structure into branched chains of the polycarboxylic acidwater reducing agent, so that the rheological behavior of the concrete, and the stability, the fluidity and the like of the slurry can be improved.

Owner:KZJ NEW MATERIALS GROUP CO LTD +1

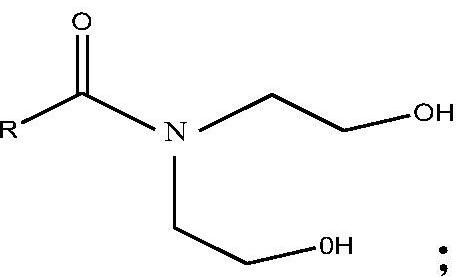

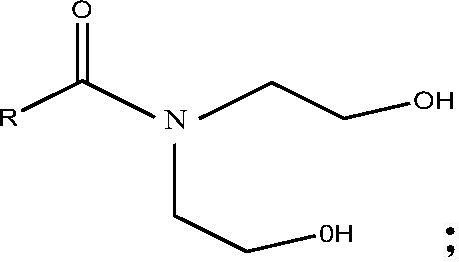

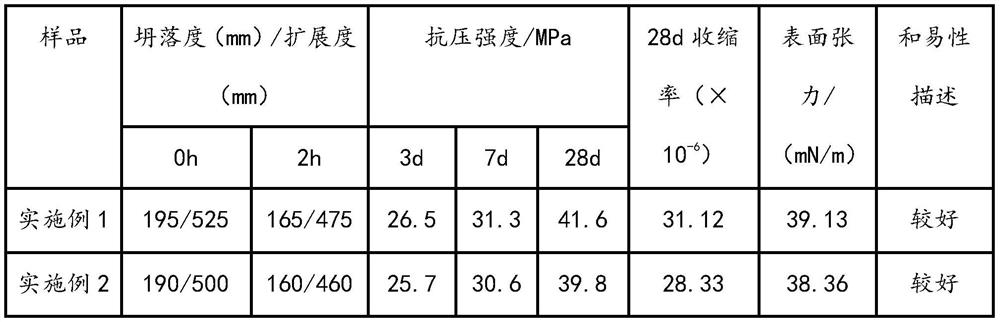

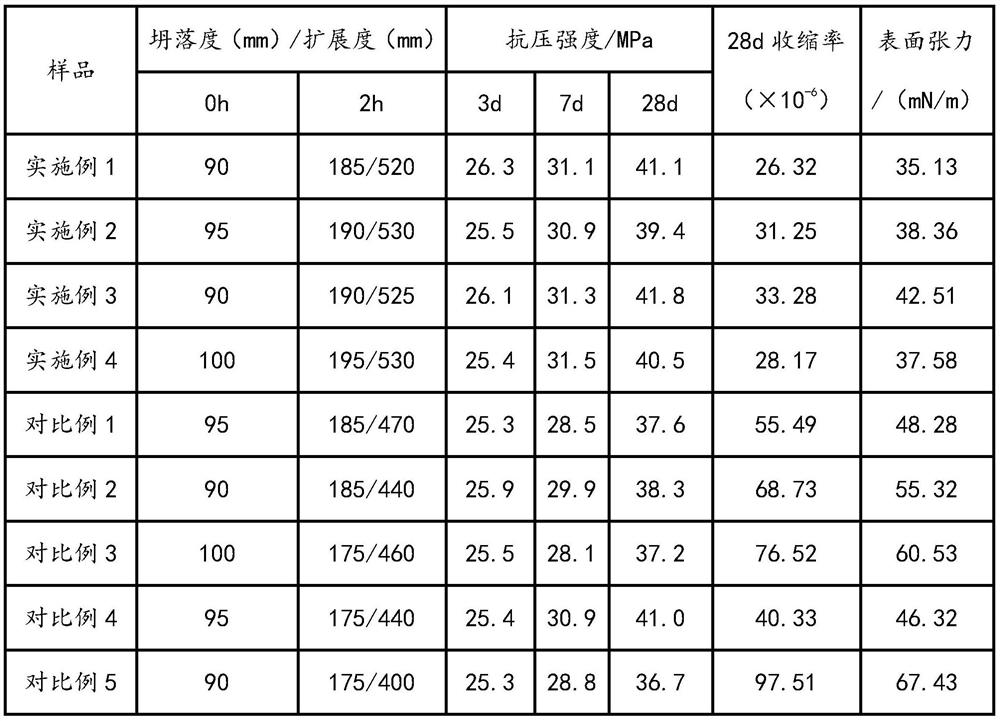

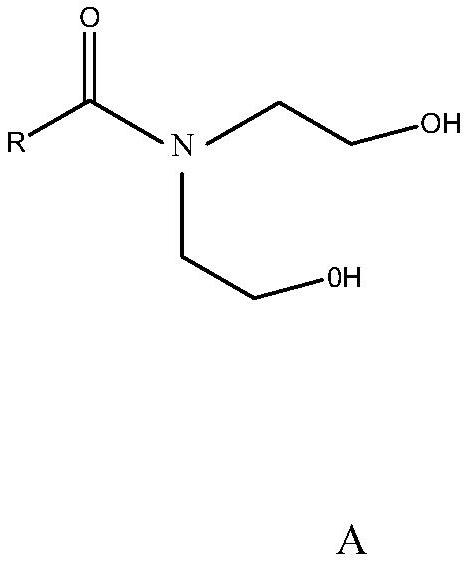

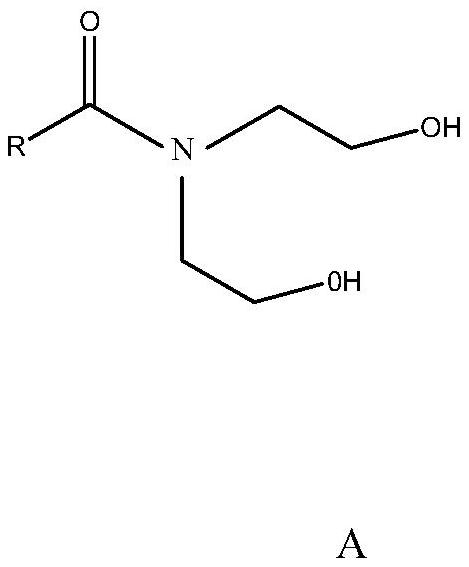

Shrinkage-reducing polycarboxylate superplasticizer and preparation method thereof

The invention relates to the technical field of building additives, in particular to a shrinkage-reducing polycarboxylate superplasticizer and a preparation method thereof. The shrinkage-reducing polycarboxylate superplasticizer comprises an esterification product, unsaturated polyoxyethylene ether, an emulsifier, an initiator solution, a chain transfer agent solution, an ester macromonomer, acrylic acid, a shrinkage-reducing functional monomer and an unsaturated sulfonate mixed solution. The preparation method comprises the following steps: preparing an esterification product; performing copolymerization reaction; and performing neutralization reaction. The esterification product is prepared by esterification of coconut diethanolamide and unsaturated acid and has the advantages of low cost and simplicity and convenience in operation, and the prepared esterification product and the shrinkage-reducing functional monomer are subjected to copolymerization reaction, so that a main chain of the polycarboxylate superplasticizer has hydrophilic groups such as amide and shrinkage-reducing groups; and the prepared polycarboxylate superplasticizer has low surface tension, effectively reduces the drying shrinkage of concrete, effectively improves the internal mechanical properties and strength of concrete, and has significant application value.

Owner:KZJ NEW MATERIALS GROUP CO LTD

Concrete cement-reducing agent and preparation method thereof

The invention discloses a concrete cement-reducing agent and a preparation method thereof, and relates to the technical field of concrete additives. The concrete cement-reducing agent comprises, by weight, 32 to 34 parts of an OXST-807 polyether monomer, 0.5 to 2 parts of modified diethanol amine, 2.5 to 3 parts of organic carboxylic acid, 0.18 to 0.31 parts of an oxidation-reduction initiator and0.05 to 0.1 parts of a chain transfer agent. According to the free radical synthesis principle, under the action of the oxidation-reduction initiator, organic carboxylic acid, modified diethanol amine and OXST-807 undergo a polymerization reaction, the polymerization degree of the polymer is controlled through the chain transfer agent, and synthesis of the concrete glue reducing agent is achieved. The concrete glue reducing agent provided by the invention is stable in performance, and the cement consumption can be reduced by 10% at most under the condition of ensuring the same concrete strength grade.

Owner:武汉奥克化学有限公司

Polycarboxylate concrete water reducing agent adapted to machine-made sand and preparation method of polycarboxylate concrete water reducing agent

The invention provides a polycarboxylate concrete water reducing agent adapted to machine-made sand and a preparation method of the polycarboxylate concrete water reducing agent. The method comprisesthe steps that after macromonomer methylallyl alcohol polyoxyethylene ether, water and an initiator sodium hydrogen sulfite are stirred to be completely dissolved, heating is performed to increase thetemperature to 55-70 DEG C, then crylic acid, an aqueous solution of high surface active monomer 2-acrylamidedodecylsulfonic acid and an aqueous solution of the initiator sodium persulfate are addeddropwise, and adding dropwise is performed for 2-3 h; heat preservation is performed for 2-3 h after adding dropwise is completed, after cooling is performed to the indoor temperature, organic alkaliis used for neutralizing and adjusting the pH value to 6-7, and the polycarboxylate concrete water reducing agent adapted to the machine-made sand is obtained. The novel polycarboxylate concrete waterreducing agent has wettability to the machine-made sand, can also obviously improve the air entrainment effect, workability, wrapping and early strength of concrete, and has a good application prospect.

Owner:SHAANXI UNIV OF SCI & TECH

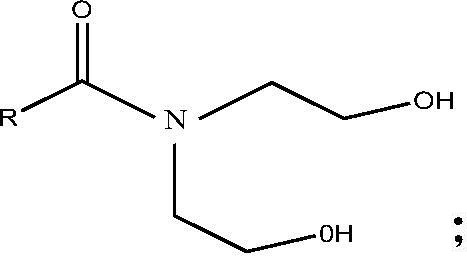

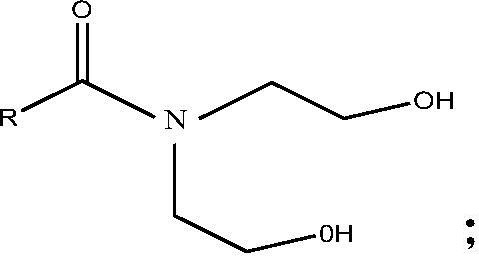

Super-slowly-released polycarboxylic acid slump inhibitor and preparation method thereof

The invention discloses a super-slowly-released polycarboxylic acid slump inhibitor and a preparation method thereof. The preparation method includes the steps: (1) esterification: performing reactionon methacrylic acid, saturated acid and 3-bi(2-ethoxyl) amino-2-hydroxypropyl sulfonic acid under the action of a catalyst to prepare an unsaturated esterification micro-monomer; (2) placing unsaturated polyether, unsaturated phosphate and unsaturated monocarboxylic acid into a backing material, and dripping a photo-initiator (solution A) dissolved in deionized water, a chain transfer agent, theunsaturated monocarboxylic acid, the unsaturated esterification micro-monomer and unsaturated carboxylic ester into the backing material to perform reaction polymerization; (3) adding pH (potential ofhydrogen) conditioning solution after heat preservation to neutralize mixture to obtain the slump inhibitor. The prepared slump inhibitor has good slump retention ability at high temperature for a long time.

Owner:GUANGDONG KEZHIJIE NEW MATERIALS +1

Highly-adaptive ultra-slow-release type polycarboxylate slump retaining admixture and preparation method thereof

A highly-adaptive ultra-slow-release type polycarboxylate slump retaining admixture and a preparation method thereof are disclosed. The method includes an esterification step, namely a step of reacting methacrylic acid, a saturated acid and 3-bis(2-hydroxyethyl)amino-2-hydroxy propanesulfonic acid under the existence of a catalyst to obtain an unsaturated esterified small monomer; (2) subjecting 4-butanediol vinyl ether polyoxyethylene ether as a macromonomer to copolymerization under the action of a composite photoinitiator; and (3) neutralizing the obtained copolymerization product with a sodium hydroxide solution to obtain the slump retaining admixture. The prepared slump retaining admixture has good slump retaining capability at high temperature for long time, has certain anti-mud effects and has good adaptability to mud-containing ground materials.

Owner:GUANGDONG KEZHIJIE NEW MATERIALS +1

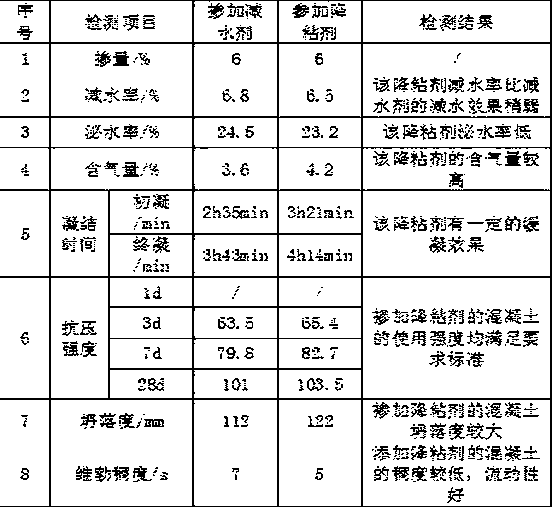

Concrete viscosity reducer and preparation method thereof

The invention provides a concrete viscosity reducer, relates to an external additive applied to ultrahigh-strength and ultra-large concrete, in particular to a viscosity reducer applied to the ultrahigh-strength and ultra-large concrete. The viscosity reducer is mainly prepared from coal ash, microbeads-POZZ, polycarboxylic acid, polysiloxane resin, sodium dodecyl benzene sulfonate, sodium phosphate, sodium sulfate, dihydrate gypsum and sodium gluconate. The viscosity reducer is designed by adding a lubricating component, a water reducer, an air entraining agent, a surfactant and a certain enhancing component, and the viscosity reducer can effectively reduce the viscosity of the concrete and avoid influence on various use properties of the concrete. The viscosity reducer is subjected to actual detection and is widely applied.

Owner:云南森博混凝土外加剂有限公司

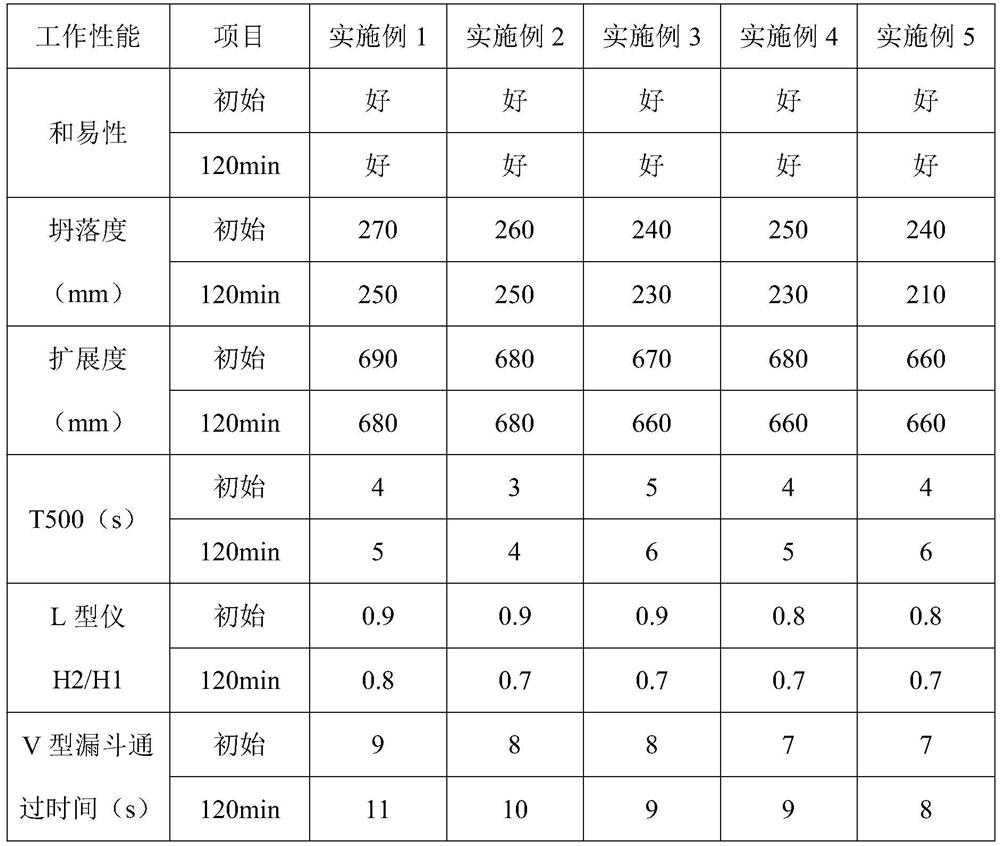

Self-compacting concrete for pumping

The invention discloses self-compacting concrete for pumping, which comprises a pumping base concrete component and a mineral admixture mixed with the pumping base concrete, the mineral admixture accounts for 3-10% of the total weight, the mineral admixture comprises a mixture of oxide at least containing Si, Al, Fe, Ca and S and inorganic acid salt, and the mineral admixture also comprises an additive accounting for not more than 0.5% of the total weight. The mineral admixture is combined into different oxides or inorganic acid salts, different activities, surface effects, filling effects orvolcanic ash effects are achieved, and when the mineral admixture is mixed into the self-compacting concrete, the slump, work-ability, cohesiveness, segregation resistance and later strength of the self-compacting concrete can be improved; the concrete has better flow-ability, compactness and homogeneity, and the production requirement of a solid square pile is met; the curing speed and the strength increasing speed of the concrete are increased, the curing time of the concrete is shortened, and the effect of rapid curing in the autoclaving-free process is achieved.

Owner:周兆弟

Solid anti-mud ultra-slow release polycarboxylate slump retention agent and preparation method thereof

The invention discloses a solid anti-mud ultra-slow release polycarboxylate slump retention agent and a preparation method of the slump retention agent. The preparation method comprises the followingsteps of: (1) esterification: allowing methacrylic acid, saturated acid and 3-di(2-ethoxyl) amino-2-hydroxyl propanesulfonate to react to prepare an unsaturated esterification micromonomer by the action of a catalyst, (2) melt polymerization: adding unsaturated polyether and 4-hydroxybutyl vinyl polyoxyethylene ether into a reaction kettle for polymerization reaction in a molten state, and (3) solidification and slicing: after the reaction, performing vacuumizing through a mechanical pump to remove an organic solvent, and then performing slicing through a condensation slicer to form the whiteflaky solid polycarboxylate slump retention agent. The prepared slump retention agent has a good anti-mud effect and good slump retention ability for a long time.

Owner:重庆建研科之杰新材料有限公司 +1

Low solid-content accelerator and preparation method thereof

The invention relates to a low solid-content accelerator and a preparation method thereof, which relate to a concrete additive, and especially relates to the low solid-content accelerator. The invention also relates to the preparation method of the accelerator. The low solid-content accelerator takes active aluminium hydroxide, aluminum sulfate, sodium silicate, sodium carbonate, sodium hydroxide,deionized water, and triisopropanolamine as raw materials for a reaction, and the above raw materials are subjected to a reaction to prepare mother liquor of the low solid-content accelerator; thickening agents such as sodium polyacrylate and maltodextrin as well as a stabilizing agent cellulose ether MF4 are added as a reaction auxiliary agent during usage of the mother liquor, the solid contentof the accelerator through complex formulation is 35%, an application amount of the low solid-content accelerator is reduced during usage, production usage cost can be greatly reduced, and the earlystage intensity of the concrete and the usage intensity at a later stage cannot be influenced.

Owner:云南森博混凝土外加剂有限公司

Solid flaky polycarboxylate slump retaining agent prepared by surfactant-free emulsion polymerization and method

InactiveCN110951008AImprove performanceHigh water reduction ratePolymer scienceEmulsion polymerization

The invention provides a solid flaky polycarboxylate slump retaining agent prepared by surfactant-free emulsion polymerization and a method. The solid flaky polycarboxylate slump retaining agent is prepared from the following components in parts by weight: 18-27 parts of a surfactant-free emulsion ester-based hydrophobic monomer, 0.48-0.72 parts of an initiator a, 9-18 parts of a surfactant-free hydrophilic small monomer, 0.41-0.69 parts of a chain transfer agent a, 765-810 parts of a polyether macromonomer, 32-68 parts of unsaturated dicarboxylic acid, 12-28 parts of an unsaturated sulfonic small monomer, 50-74 parts of alkyl acrylate, 2.3-3.8 parts of a chain transfer agent b, 3.2-5.9 parts of an initiator b, 2.6-4.6 parts of an initiator c, 3.2-4.7 parts of a chain transfer agent c, and7.7-11.5 parts of a pH regulator. The method comprises the following operation steps: (1) preparing a surfactant-free polymer; (2) preparing solutions A, B and C; (3) dropwise adding the solutions A,B and C; and (4) preparing the solid flaky polycarboxylate slump retaining agent. The slump retaining agent can effectively slow down cement hydration, effectively keep concrete slump for a long time, slow down the time-dependent loss of the concrete slump and keep the fluidity and workability of concrete, and the properties in all aspects are more stable.

Owner:HUBEI UNIV OF TECH

Esterification product for preparing water reducing agent, preparation method of esterification product, shrinkage-reducing ether polycarboxylate water reducing agent and preparation method of shrinkage-reducing ether polycarboxylate water reducing agent

ActiveCN112708041AReduce surface tensionReduce drying shrinkageFunctional monomerCoconut diethanolamide

The invention relates to the technical field of building additives, in particular to an esterification product for preparing a water reducing agent, a preparation method thereof, a shrinkage-reducing ether polycarboxylate water reducing agent and a preparation method of the shrinkage-reducing ether polycarboxylate water reducing agent. The esterification product comprises a monomer with amide and dihydroxy and an unsaturated acid esterification product. According to the shrinkage-reducing ether polycarboxylate superplasticizer prepared from the esterification product, the esterification product is prepared by esterification of coconut diethanolamide and unsaturated acid and has the advantages of low cost and simplicity and convenience in operation, and the prepared esterification product and a shrinkage-reducing functional monomer are subjected to copolymerization reaction, so that the polycarboxylate water reducing agent main chain is provided with amide and other hydrophilic groups and shrinkage reducing groups, the prepared polycarboxylate water reducing agent has lower surface tension, the drying shrinkage of concrete is effectively reduced, the concrete has better dispersity and dispersity retention performance, the internal mechanical property and strength of the concrete are effectively improved, and remarkable effect is achieved.

Owner:科之杰新材料集团四川有限公司

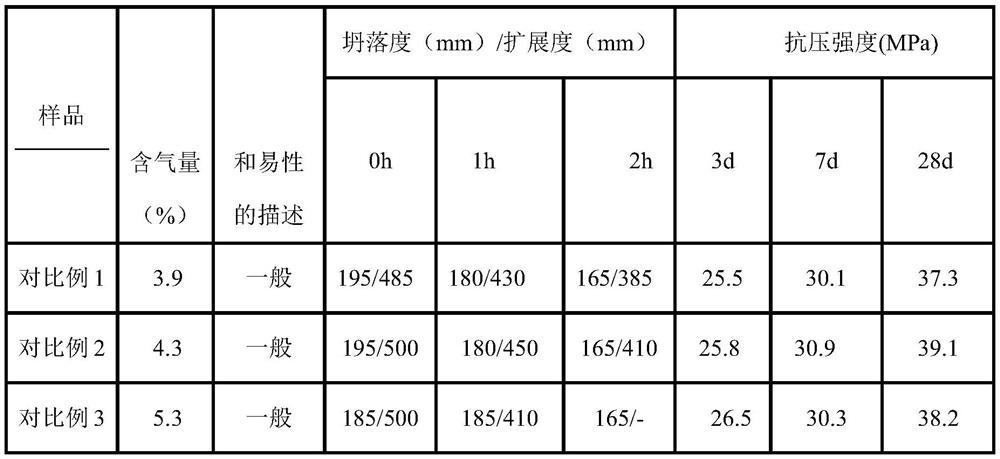

Preparation method of air-entraining ether polycarboxylate superplasticizer

The invention discloses a preparation method of an air-entraining ether polycarboxylate superplasticizer. The preparation method comprises the following steps: (1) preparing an esterification product; (2) copolymerization reaction; and (3) neutralization reaction. According to the preparation method, the esterification product is prepared by esterification of coco fatty acid diethanolamide and unsaturated acid, the preparation method has the advantages of low cost and simplicity and convenience in operation, and the prepared esterification product participates in the next copolymerization reaction, so that a main chain of the polycarboxylate superplasticizer has hydrophilic groups such as amide and the like; the prepared polycarboxylate superplasticizer has good air entraining and foam stabilizing properties, and the workability and the strength of concrete are improved.

Owner:KZJ NEW MATERIALS GROUP CO LTD +1

Ester polycarboxylate superplasticizer with rust inhibition function and preparation method thereof

ActiveCN112708069AIncreasing the thicknessGood corrosion inhibition effectElectrochemical responsePolymer science

The invention relates to the technical field of concrete admixtures, in particular to an ester polycarboxylate superplasticizer with a rust inhibition function and a preparation method thereof. The ester polycarboxylate superplasticizer is prepared from an esterification product, an ester macromonomer, acrylic acid, an unsaturated polyhydroxy monomer and a rust inhibition functional monomer B with double bonds, amino groups and sulfur bonds through copolymerization. The esterification product is prepared from a rust inhibition functional monomer A with benzene rings and hydroxyl groups and unsaturated acid through esterification reaction. According to the ester polycarboxylate superplasticizer with a rust inhibition function, provided by the invention, the rust inhibition functional monomer A containing benzene rings and hydroxyl groups and the unsaturated acid are esterified to prepare an esterification product which participates in a next-step copolymerization reaction, so that the molecules of the polycarboxylate superplasticizer have groups such as the benzene rings, the amino groups and the hydroxyl groups, nitrogen atoms in the amino groups and the hydroxyl groups can improve the adsorption capacity with the surface of a steel bar and inhibit the electrochemical reaction process of the surface of the steel bar, meanwhile, the amino groups can be combined with H<+> on the cathode surface, the cathode reaction rate is reduced, and the corrosion inhibition effect of the steel bar is enhanced.

Owner:KZJ NEW MATERIALS GROUP CO LTD +1

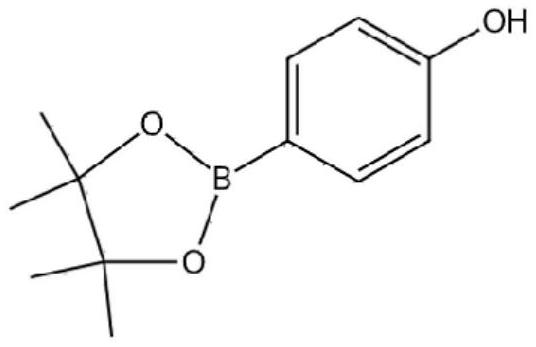

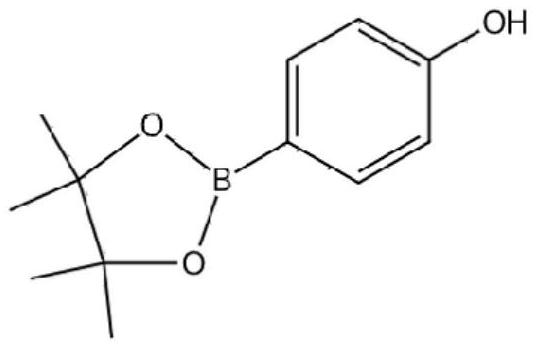

Reduction type ether polycarboxylic acid water reducer and preparation method thereof

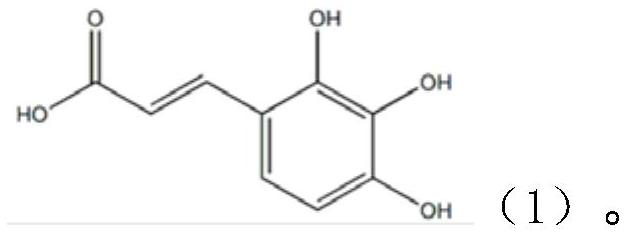

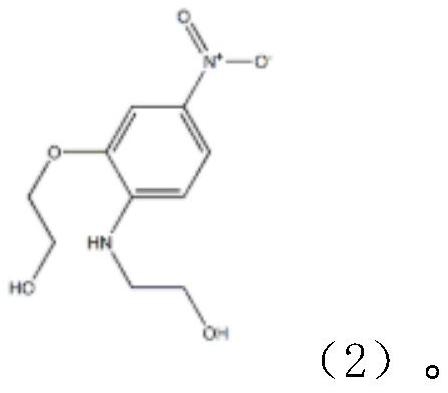

ActiveCN114230727ALow costImprove adsorption capacitySolid waste managementFunctional monomerBoronic acid

The invention relates to the field of concrete admixtures, in particular to a shrinkage-reducing ether polycarboxylic acid water reducer and a preparation method thereof. The reduction type ether polycarboxylic acid water reducer is characterized by comprising an esterification product, an ether macromonomer, acrylic acid, an unsaturated ester monomer and a functional monomer B, the esterification product is mainly obtained by performing esterification reaction on a functional monomer A and unsaturated acid; the functional monomer A is a monomer with a benzene ring, borate and hydroxyl; the functional monomer B is a monomer with a double bond, a benzene ring, a borate radical and a fluorocarbon bond. The shrinkage-reducing ether polycarboxylic acid water reducer provided by the invention can effectively reduce the surface tension of concrete, has better dispersing capacity, and can obviously improve the shrinkage-reducing effect of the concrete. Meanwhile, the hydration speed of the concrete can be further delayed, shrinkage cracking caused by temperature is prevented, and good application prospects and popularization value are achieved.

Owner:KZJ NEW MATERIALS GROUP CO LTD

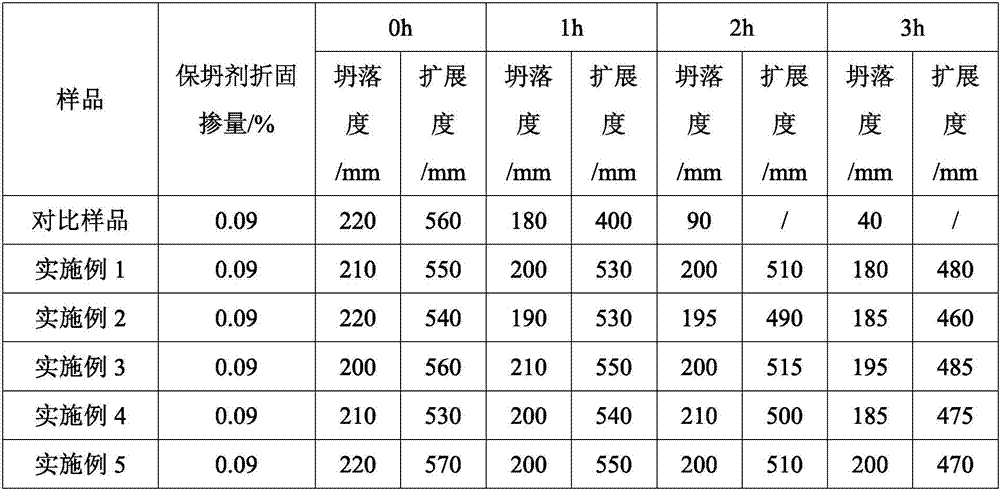

Preparation method of micro-crosslinking long-acting slump retaining agent

The invention discloses a preparation method of a micro-crosslinking long-acting slump retaining agent. The preparation method comprises the following steps: firstly, preparation of an unsaturated crosslinked small monomer; secondly, copolymerization reaction; thirdly, neutralization reaction. According to the preparation method disclosed by the invention, by self-preparation of the unsaturated small monomer and introduction of the unsaturated small monomer into the synthetic reaction, a polymer is slightly crosslinked, and a slump retaining agent molecule is relatively big in size and has greater steric hindrance; a crosslinked structure has a better intercalating-resisting effect and a good mud-resisting property.

Owner:KZJ NEW MATERIALS GROUP CO LTD

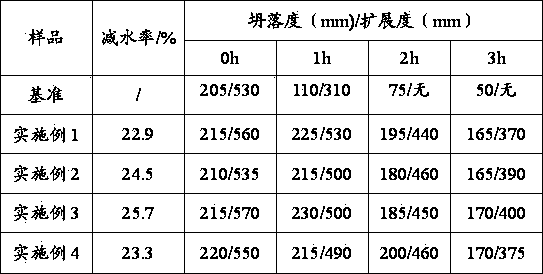

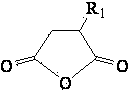

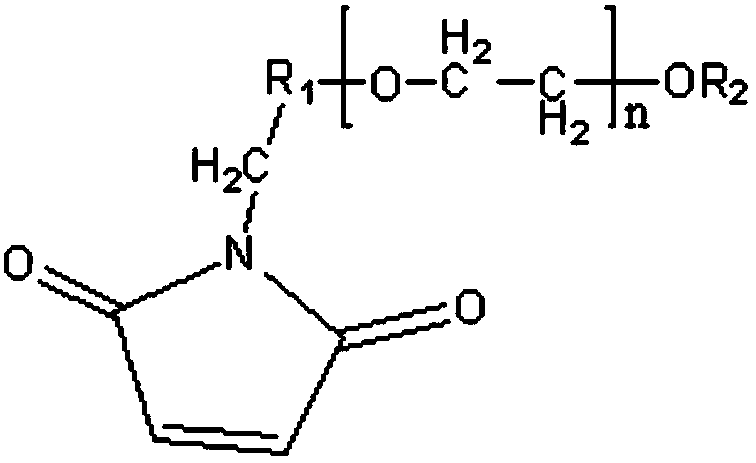

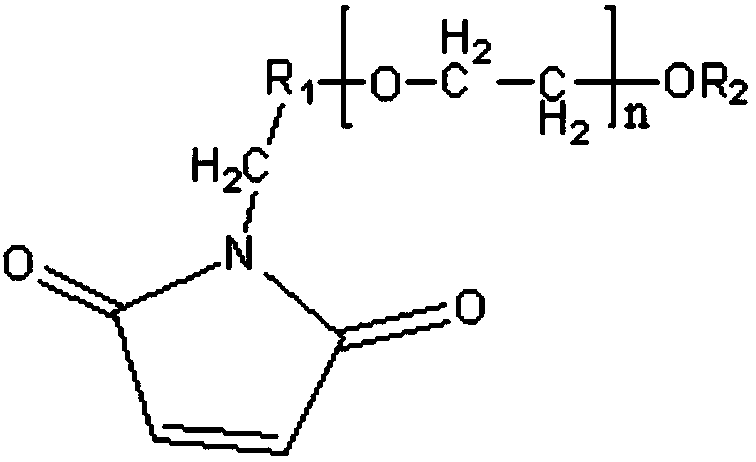

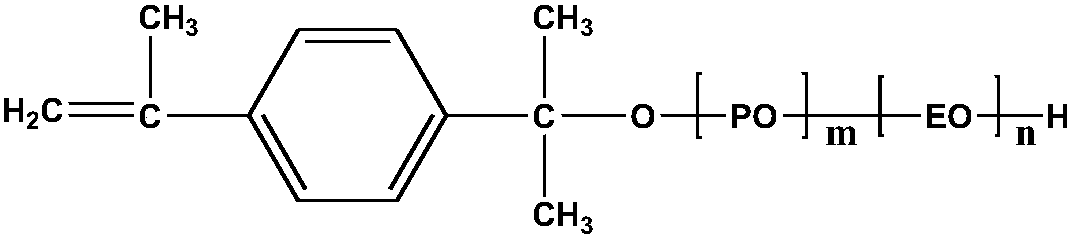

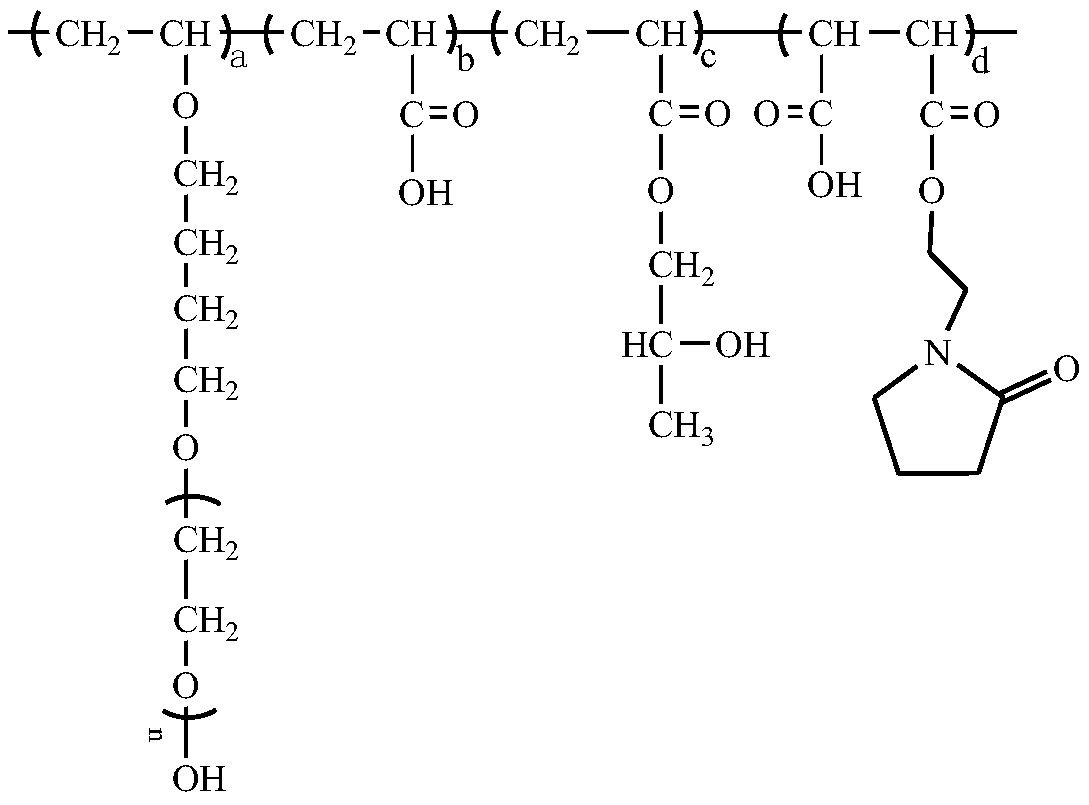

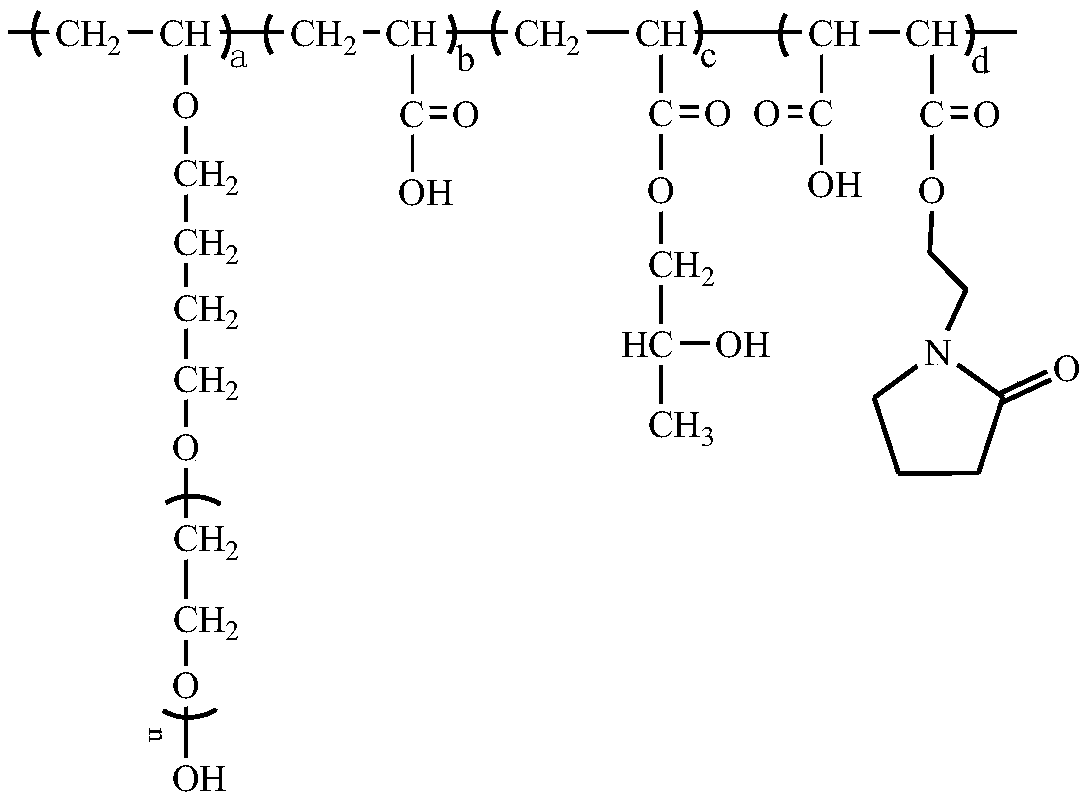

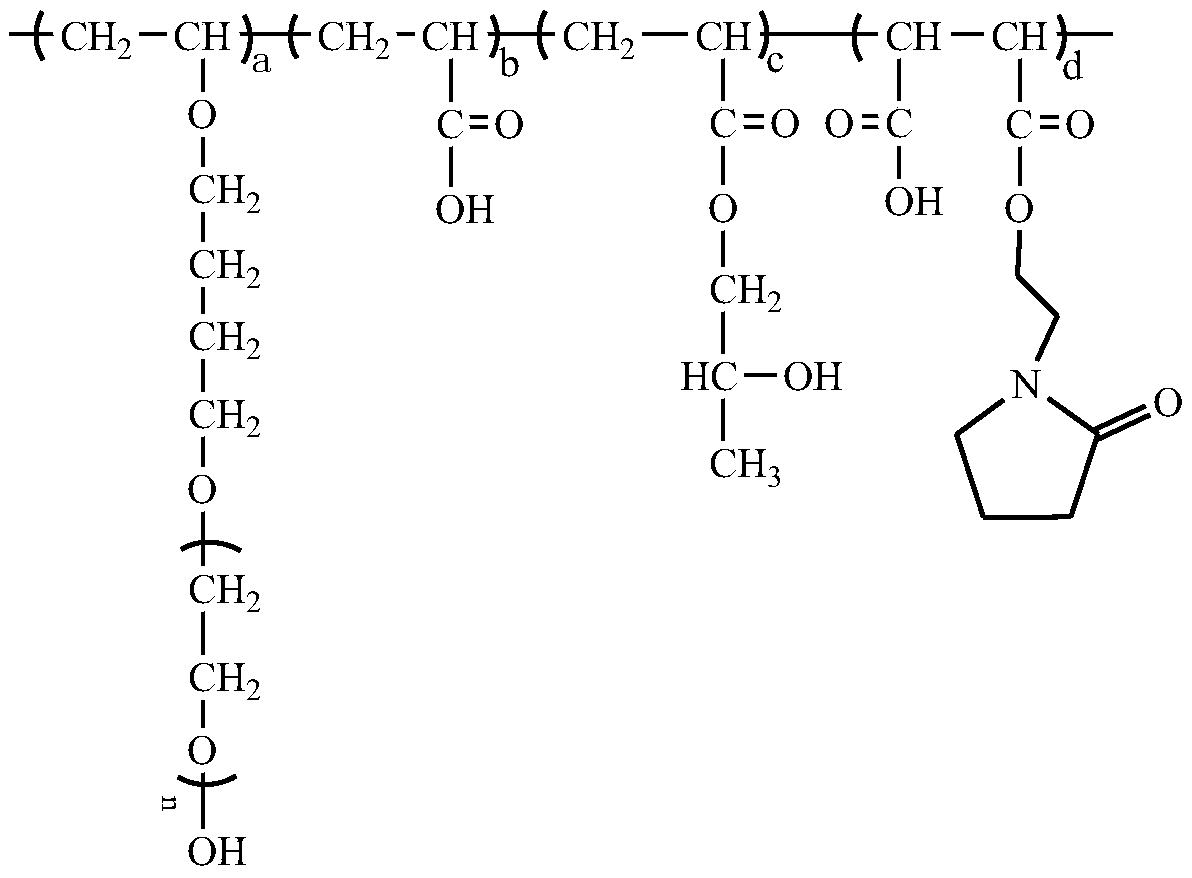

Ultra-long sustained release polycarboxylic acid slump inhibitor and preparation method thereof

ActiveCN110746549AEasy to prepareConditions are easy to controlSuperplasticizerCombinatorial chemistry

The invention discloses an ultra-long sustained release polycarboxylic acid slump inhibitor and a preparation method thereof. The molecular formula of the inhibitor is shown in the description, in theformula, a, b, c, d and n are polymerization degrees and all are positive integers, a=12-18, b=18-45, c=12-27, d=30-54, and n=50-90. The polycarboxylic acid slump inhibitor disclosed by the inventioncan be continuously hydrolyzed for a long time in an alkaline environment of concrete, continuously releases polycarboxylic acid superplasticizer molecules, supplements the consumption of cement hydration on the superplasticizer, achieves sustained maintenance of ultra-long slump, and also has a certain early strength promotion effect on concrete, and the inhibitor is simple in preparation process, easy in condition control and high in operability when being prepared.

Owner:CCCC SHEC WUHAN PORT NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com