Preparation method of novel polyether-synthesis slow-release-type polycarboxylic acid water reducer

A slow-release polycarboxylic acid and water-reducing agent technology, applied in the field of concrete admixtures, can solve the problems of unfavorable industrial production, large energy consumption, complex production process, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

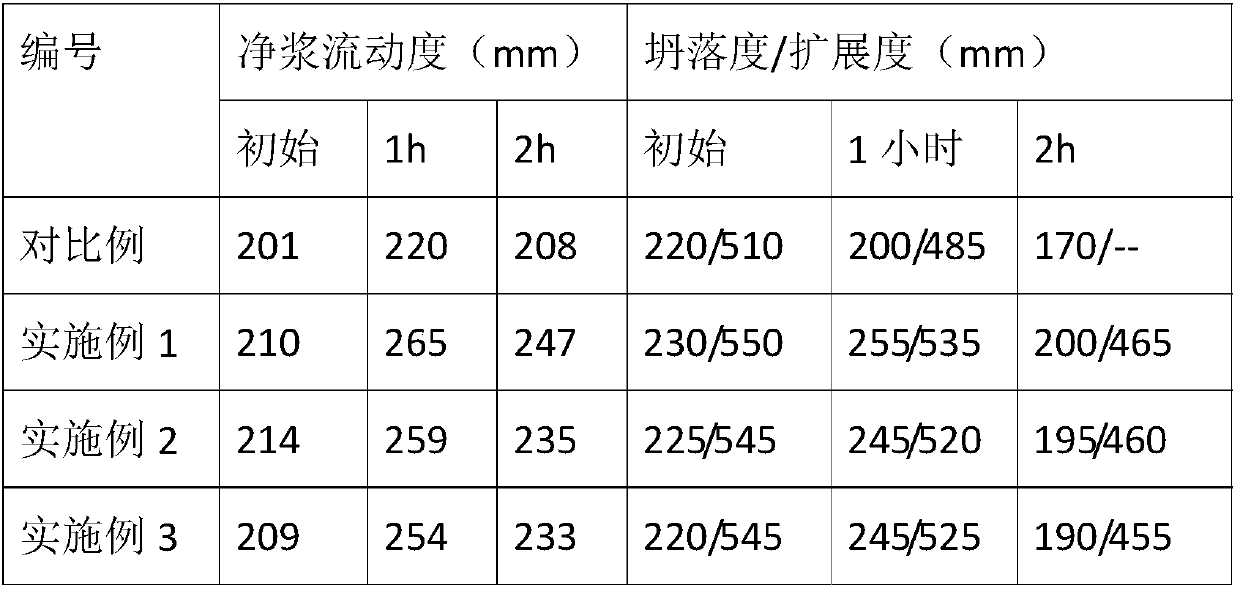

Examples

Embodiment 1

[0025] Add 300g of polyether macromonomer and 220g of deionized water into the reaction kettle, stir at room temperature to dissolve, mix 35g of acrylic acid, 101g of hydroxyethyl acrylate, and 25g of deionized water to prepare liquid A. Mix 2g of mercaptopropionic acid, 4g of vitamin C, and 35g of water to prepare liquid B. Add 32g of liquid A to the macromonomer aqueous solution obtained in S1, stir evenly, add 4g of hydrogen peroxide, start to add liquid B dropwise after 2 minutes, and add liquid A dropwise after 2-10 minutes, and the time for adding liquid A is 30 minutes , B liquid dropwise adding time is 40min. After 20 minutes of heat preservation, 13g of lye was added for neutralization, and a new type of slow-release polycarboxylate superplasticizer was obtained.

Embodiment 2

[0027] Add 300g of polyether macromonomer and 220g of deionized water into the reaction kettle, stir at room temperature to make it melt, 50g of acrylic acid, 15.5g of 2-acrylamide-2-methylpropanesulfonic acid, 101g of hydroxyethyl acrylate, Mix 25g of deionized water evenly to make liquid A. Mix 2g of mercaptopropionic acid, 4g of vitamin C, and 35g of water to prepare liquid B. Add 35g of liquid A to the macromonomer aqueous solution obtained in S1, stir evenly, add 4g of hydrogen peroxide, start to add liquid B dropwise after 2 minutes, and add liquid A dropwise after 2-10 minutes, and the time for adding liquid A is 30 minutes , B liquid dropwise adding time is 40min. After 20 minutes of heat preservation, 13g of lye was added for neutralization, and a new type of slow-release polycarboxylate superplasticizer was obtained.

Embodiment 3

[0029] Add 300g of polyether macromonomer and 220g of deionized water into the reaction kettle, stir at room temperature to melt, mix 35g of acrylic acid, 80g of hydroxyethyl acrylate, and 24g of methyl methacrylate with 25g of deionized water to form a Liquid A. Mix 2g of mercaptopropionic acid, 4g of vitamin C, and 35g of water to prepare liquid B. Add 34g of liquid A to the macromonomer aqueous solution obtained in S1, stir evenly, add 4g of hydrogen peroxide, start to add liquid B dropwise after 2 minutes, and add liquid A dropwise after 2-10 minutes, and the time for adding liquid A is 30 minutes , B liquid dropwise adding time is 40min. After 20 minutes of heat preservation, 13g of lye was added for neutralization, and a new type of slow-release polycarboxylate superplasticizer was obtained.

[0030] Commercially available room temperature synthetic liquid ultra-high water-reducing polycarboxylate superplasticizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com