Preparation method of water-soluble polyaniline nano particles serving as corrosion inhibitor

A technology of nano-particles and polyaniline, applied in the field of metal anti-corrosion, can solve the problems of hidden dangers to the health of workers, chromate pollution of the environment, etc., and achieve the effects of simple use, easy cleaning, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of water-soluble polyaniline nano particle corrosion inhibitor of the present invention specifically comprises the following steps:

[0030] First, add deionized water to the template agent PVP, and use an ultrasonic cleaner to completely dissolve the template agent; then add aniline to the completely dissolved template agent, and stir evenly at room temperature to obtain solution 1; add oxidant to solution 1, oxidant It is a mixture of ammonium sulfate and hydrochloric acid. Aniline undergoes oxidative polymerization reaction under the action of an oxidant. The reaction temperature is 2°C. After the reaction, centrifuge for 30 minutes in a centrifuge, remove the supernatant, and then neutralize it with dilute ammonia solution. Excess hydrochloric acid in the oxidizing agent, absolute ethanol and deionized water were washed until the solution was neutral, and vacuum-dried at 60° C. to obtain polyaniline nanoparticles as the final product.

[0031]...

Embodiment 1

[0035] The present invention, the preparation method of water-soluble polyaniline nanoparticle, comprises the following steps:

[0036] Step 1. Add 4.06g of polyvinylpyrrolidone and 60mL of deionized water into a 250mL three-neck flask equipped with a stirring paddle, use an ultrasonic cleaner to sonicate until completely dissolved, add 2mL of aniline, and stir at room temperature for 1 hour to obtain solution 1;

[0037] Step 2. Weigh 2.04g of ammonium persulfate and 40mL of 1mol / L hydrochloric acid solution to prepare an oxidant solution, slowly add it dropwise to solution 1, and stir at 2°C for 5h. The reaction formula is shown in formula (1);

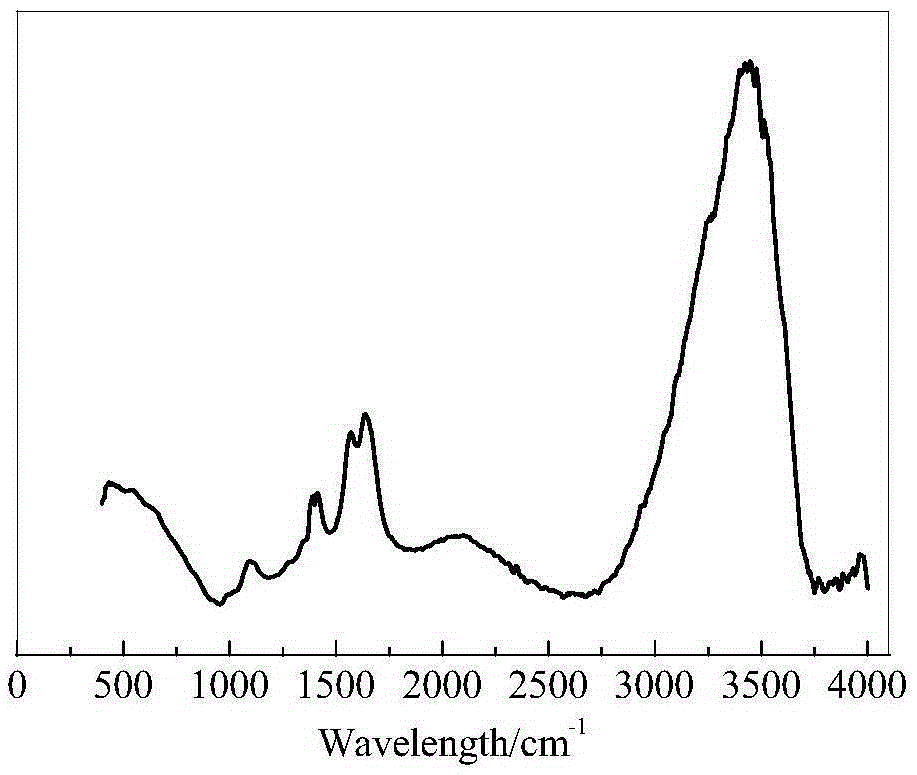

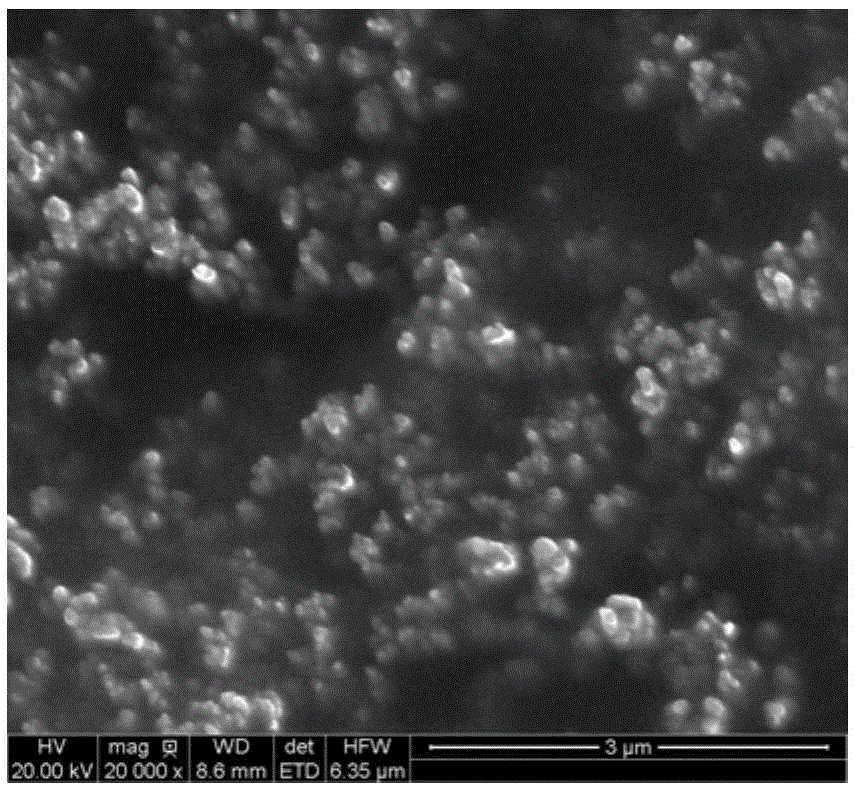

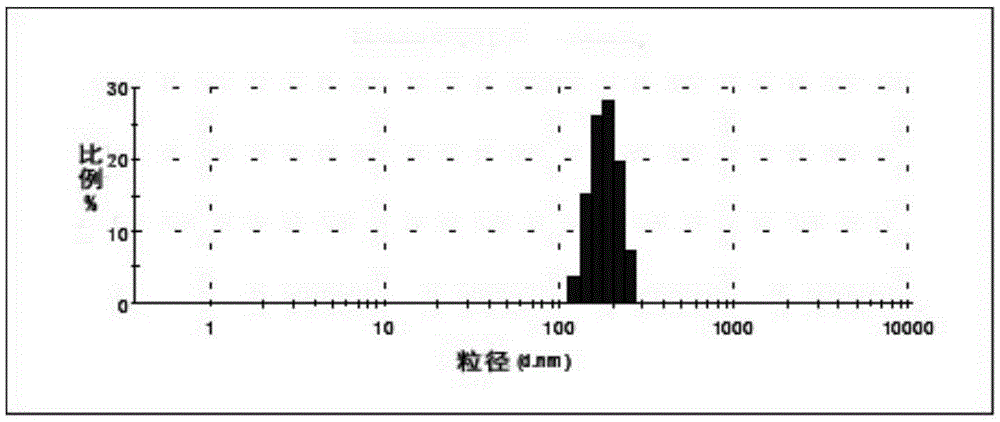

[0038] Step 3. After the reaction is over, centrifuge for 30 minutes on a centrifuge (AXTG16G), remove the supernatant, then neutralize the excess hydrochloric acid with dilute ammonia solution, wash with absolute ethanol and deionized water until the solution is neutral. Vacuum drying, take a small amount of polyaniline powder and ...

Embodiment 2

[0040] The present invention, the preparation method of water-soluble polyaniline nanoparticle, comprises the following steps:

[0041] Step 1: Weigh 3.89g of polyvinylpyrrolidone and 50mL of deionized water into a 250mL three-necked flask, use an ultrasonic cleaner to sonicate until completely dissolved, add 2mL of aniline, and stir at room temperature for 1 hour to obtain solution 1;

[0042] Step 2. Weigh 3.21g of ammonium persulfate and 40mL of 1mol / L phosphoric acid solution to prepare an oxidant solution, slowly add it dropwise to solution 1, and stir at 0°C for 4h;

[0043] Step 3, after the reaction is finished, after neutralization with sodium bicarbonate solution, after centrifugal cleaning, the concentration of the corrosion inhibitor is prepared into a hydrochloric acid washing solution with a concentration of 0.5g / L, and the slow release efficiency to carbon steel after 2h is as high as 95.6%. , polarization curve (see Figure 4 ).

[0044] Parts not mentioned i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com