Preparation method of micro-crosslinking long-acting slump retaining agent

A slump-retaining agent and micro-crosslinking technology, applied in the field of construction admixtures, can solve problems such as difficulty in meeting slump-retaining requirements, excessive slump loss, and impact on engineering construction and quality, achieving large steric hindrance and improving dispersion Ability, the effect of good collapse ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

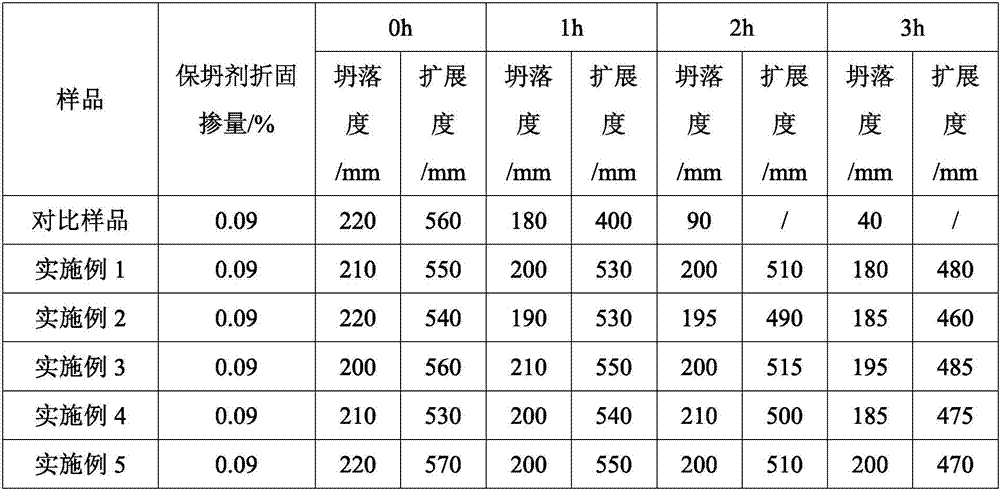

Examples

Embodiment 1

[0023] (1) Preparation of unsaturated cross-linked small monomers:

[0024] In a four-necked flask equipped with a reflux condenser, add 100 parts by weight of 1,2 dichloroethane, start the mixer to stir, heat up to 46°C, slowly add 1 part by weight of concentrated hydrochloric acid as a catalyst, and then add 20 parts by weight of formaldehyde And 0.05 parts by weight of copper sulfate, followed by adding 26 parts by weight of acrylamide, reacted for 0.5h.

[0025] Raise the temperature to 60°C, add 14 parts by weight of acrylamide, and react for 0.5h.

[0026] The temperature was raised to 75° C., and 14 parts by weight of acrylamide was added to react for 1 hour.

[0027] After the reaction is completed, lower the temperature to 45°C, adjust the pH value to 6 with ammonia water, keep the temperature for 2 hours, cool and crystallize, wash and dry to obtain the unsaturated cross-linked small monomer.

[0028] (2) Copolymerization reaction:

[0029] Dissolve 100 parts of p...

Embodiment 2

[0035] (1) Preparation of unsaturated cross-linked small monomers:

[0036] In a four-necked flask equipped with a reflux condenser, add 100 parts by weight of cyclohexane, start the stirrer to stir, heat up to 48 ° C, slowly add 3 parts by weight of concentrated sulfuric acid as a catalyst, and then add 22 parts by weight of paraformaldehyde and 0.1 Parts by weight of hydroquinone, followed by adding 22 parts by weight of acrylamide, and reacting for 1 hour.

[0037] Raise the temperature to 65°C, add 11 parts by weight of acrylamide, and react for 1 hour.

[0038] The temperature was raised to 73° C., and 11 parts by weight of acrylamide was added to react for 2 hours.

[0039] After the reaction is completed, lower the temperature to 50°C, adjust the pH value to 7 with ammonia water, keep the temperature for 1 hour, cool and crystallize, wash and dry to obtain the unsaturated cross-linked small monomer.

[0040] (2) Copolymerization reaction:

[0041] Dissolve 100 parts ...

Embodiment 3

[0047] (1) Preparation of unsaturated cross-linked small monomers:

[0048]In a four-necked flask equipped with a reflux condenser, add 100 parts by weight of methyl ethyl ketone, start the mixer to stir, raise the temperature to 50 ° C, slowly add 2 parts by weight of concentrated hydrochloric acid as a catalyst, and then add 24 parts by weight of formaldehyde and 0.15 parts by weight of p-Hydroxyanisole, followed by adding 24 parts by weight of acrylamide, and reacted for 0.5h.

[0049] Raise the temperature to 63°C, add 12 parts by weight of acrylamide, and react for 0.5h.

[0050] Raise the temperature to 72°C, then add 12 parts by weight of acrylamide, and react for 1.5 hours.

[0051] After the reaction, the temperature was lowered to 48°C, the pH value was adjusted to 6 with ammonia water, and then kept for 2 hours, cooled to crystallize, washed, and dried to obtain unsaturated cross-linked small monomers.

[0052] (2) Copolymerization reaction:

[0053] Dissolve 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com