Synergist for reducing stone powder adsorption performance in siliceous machine-made sand and preparation method thereof

A technology of stone powder and adsorption performance in sand is applied in the field of synergist for reducing the adsorption performance of stone powder in siliceous manufactured sand and its preparation field, which can solve problems such as poor concrete performance, achieve small slump loss, fast movement speed, Slump loss reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

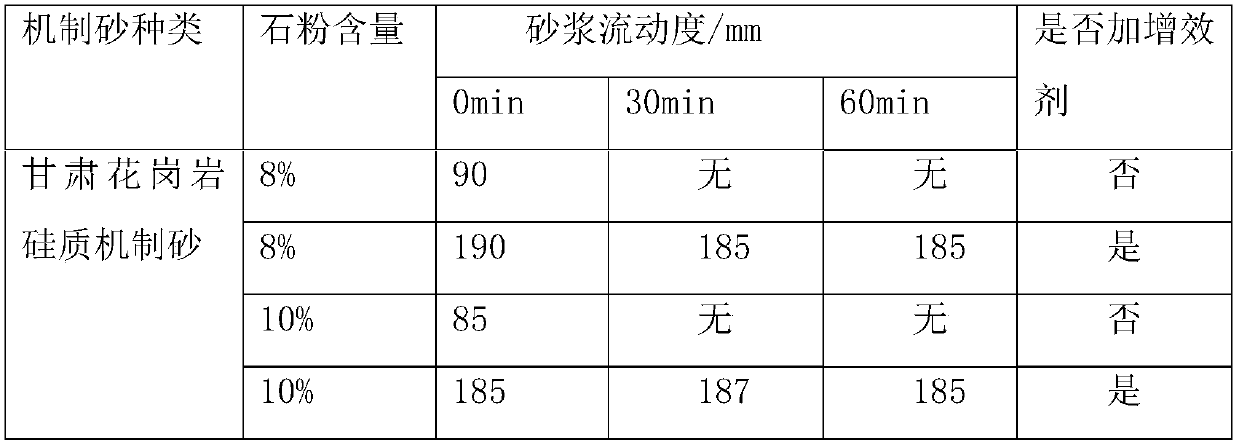

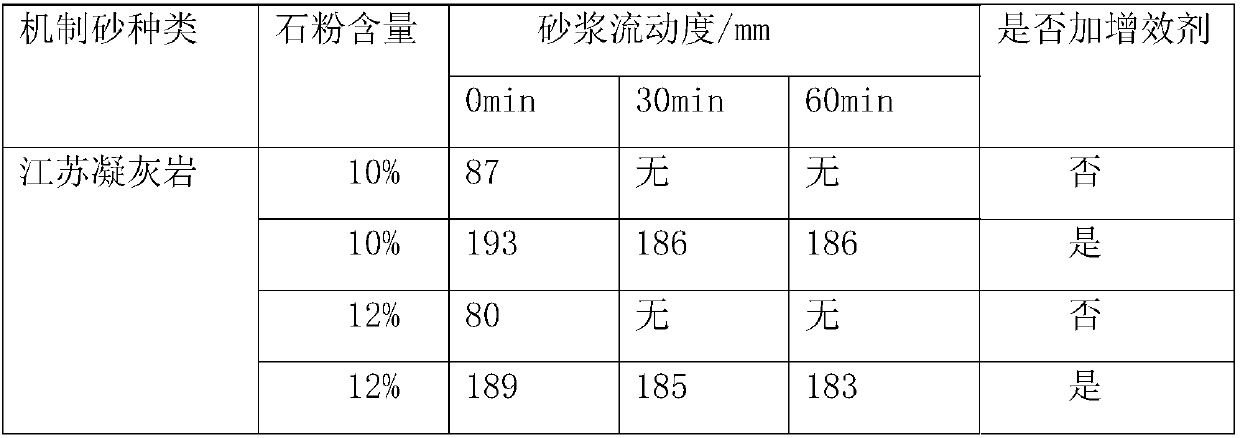

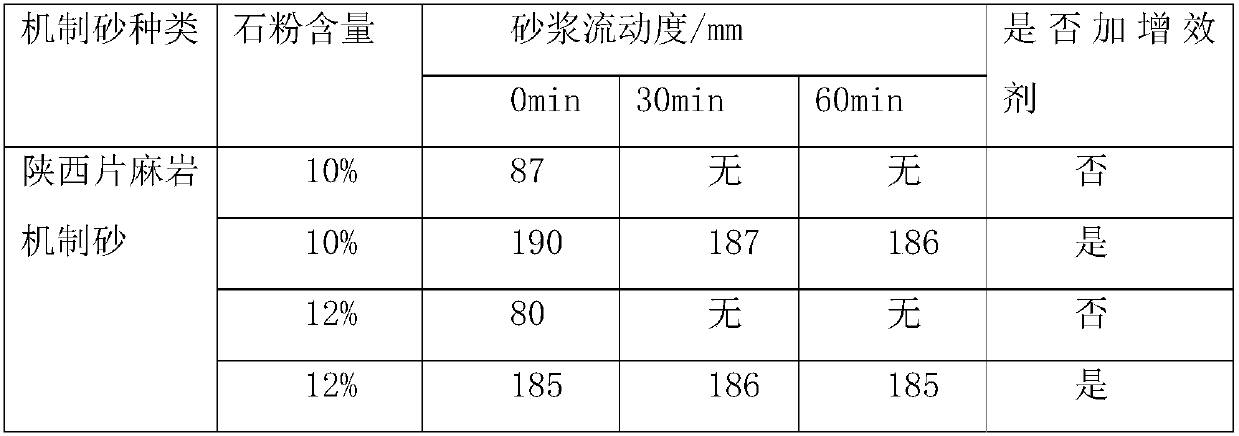

Examples

Embodiment 1

[0028] The modified synergist for the adsorption performance of stone powder in siliceous machine-made sand provided by the present invention comprises the following raw materials in parts by weight: 50-60 parts of adsorption and dispersing components; 20-25 parts of adsorption and chelation components; retarding 0-30 parts of components, 0-10 parts of other performance-improving components, the adsorption and dispersion components are one or more of the air-entraining surfactants of alcohol amines; the adsorption and chelation components are organic One or both of phosphine and inorganic phosphorus compounds.

[0029] Due to the fine particle size and large specific surface area of siliceous stone powder, it can absorb a large amount of polycarboxylate water reducer, resulting in poor workability. In addition, due to the reduction of effective polycarboxylate water reducer, siliceous stone powder cannot be effectively dispersed, resulting in some A large amount of stone pow...

Embodiment 2

[0036] In the synergist for reducing the adsorption performance of stone powder in siliceous machine-made sand provided by the present invention, the adsorption and dispersion component is triisopropanolamine, 60 parts; the adsorption and chelation component is diethylene triaminepentamethylene phosphoric acid, 25 parts .

Embodiment 3

[0038] Among synergists, air-entraining surfactants include triisopropanolamine and diethylenetriamine, 50 parts, in a ratio of 1:2; the adsorption and chelation components are all organophosphorus compounds, including diethylenetriaminepenta Fork phosphoric acid and tetrasodium hydroxyethylene diphosphate, 20 parts, the ratio is 1:1; the retarding component is glucose, 5 parts; other performance improving components are sodium polyacrylate 2 parts; the early strength component is calcium formate , 1 serving.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com