Preparation method of ester type viscosity reduction type polycarboxylate superplasticizer

A viscous polycarboxylic acid and water reducing agent technology, applied in the field of building materials, can solve the problems of the adverse effect of high-strength concrete strength, reduce the frictional resistance between aggregate particles, and the limited viscosity-reducing effect of air-entraining agents, so as to increase the space potential. resistance effect, good anti-mud effect, improve the effect of electrostatic repulsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

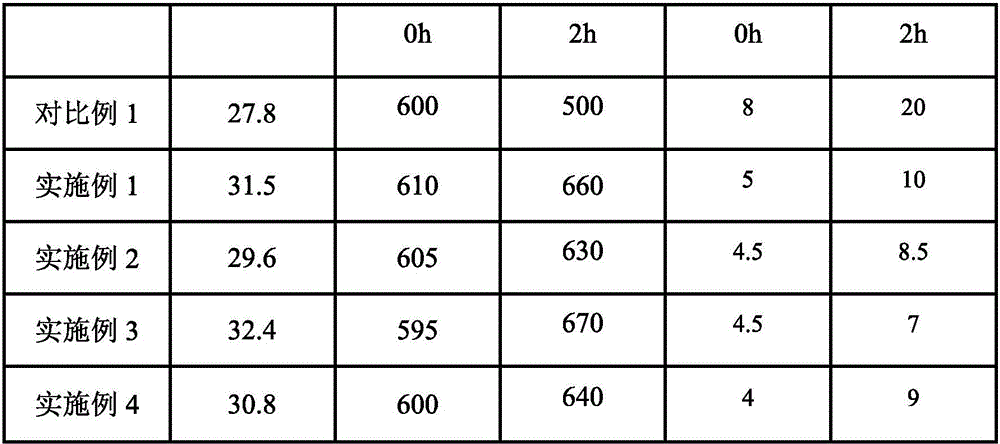

Embodiment 1

[0027] (1) Preparation of esterified monomers: in parts by weight, 100 parts of polyethylene glycol monomethyl ether with a molecular weight of 3000 are mixed with 15 parts of methyl methacrylate, 0.5 parts of 4-dimethylaminopyridine and 0.8 parts Add the polymerization inhibitor to the first reaction device equipped with a condensing device, under the protection of nitrogen, keep the temperature at 40°C for 4 hours, then add 3.5 parts of dimethylaminoethanol at one time, and continue the esterification for 1.5 hours under the reaction conditions , after the reaction, add 29.83 parts of water to adjust the concentration of the solution to be 80%, to obtain a poly(ethylene glycol monomethyl ether) methacrylate, functional monomer dimethylaminoethyl methacrylate and methyl methacrylate Esterified monomers of the mixture;

[0028] (2) Copolymerization reaction: by weight, 100 parts of esterified monomers, 3 parts of 3-allyloxy-2-hydroxyl-1-propanesulfonate, 2 parts of ethylenedim...

Embodiment 2

[0031] (1) Preparation of esterification monomer: in parts by weight, 100 parts of polyethylene glycol monomethyl ether with a molecular weight of 3000 and 19 parts of methyl methacrylate, 0.8 part of dibutyltin diacetate and 0.5 part of mixed polymerization inhibitor The agent is added to the first reaction device equipped with a condensing device, and under the protection of nitrogen, the temperature is kept at 90°C for 6 hours, and then 4.5 parts of dimethylaminoethanol is added at one time, and the esterification is continued for 1.5 hours under the reaction conditions, and the reaction After the end, add 31 parts of water to adjust the concentration of the solution to be 80%, to obtain a mixture containing polyethylene glycol monomethyl ether methacrylate, functional monomer dimethylaminoethyl methacrylate and methyl methacrylate. Esterified monomers;

[0032](2) Copolymerization reaction: by weight, first 100 parts of esterified monomers, 5 parts of 3-prop-2-acryloyloxyp...

Embodiment 3

[0035] (1) Preparation of esterified monomers: in parts by weight, 100 parts of polyethylene glycol monomethyl ether with a molecular weight of 5000, 15 parts of methyl methacrylate, 1.2 parts of isopropyl titanate and 1.0 parts of mixed resist The polymerization agent was added to the first reaction device equipped with a condensing device, and under the protection of nitrogen, the temperature was kept at 70°C for 5 hours, and then 3.5 parts of dimethylaminoethanol was added at one time, and the esterification was continued for 1.5 hours under the reaction conditions. After the reaction, add 29.88 parts of water to adjust the concentration of the solution to be 80%, to obtain a mixture containing polyethylene glycol monomethyl ether methacrylate, functional monomer dimethylaminoethyl methacrylate and methyl methacrylate. Esterified monomers;

[0036] (2) Copolymerization reaction: by weight, first 100 parts of esterified monomers, 4 parts of 2-acrylamide-2-methylpropanesulfon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com