Polycarboxylate concrete water reducing agent adapted to machine-made sand and preparation method of polycarboxylate concrete water reducing agent

A concrete water reducing agent and polycarboxylate technology, which is applied in the field of construction engineering materials, can solve the problem that the water reducing agent cannot well improve the encapsulation and wettability of sand and gravel, the wettability and early strength improvement are limited, Concrete is easy to pump segregation and other problems, to achieve the effect of improving wrapping, significant wettability, and maintaining slump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

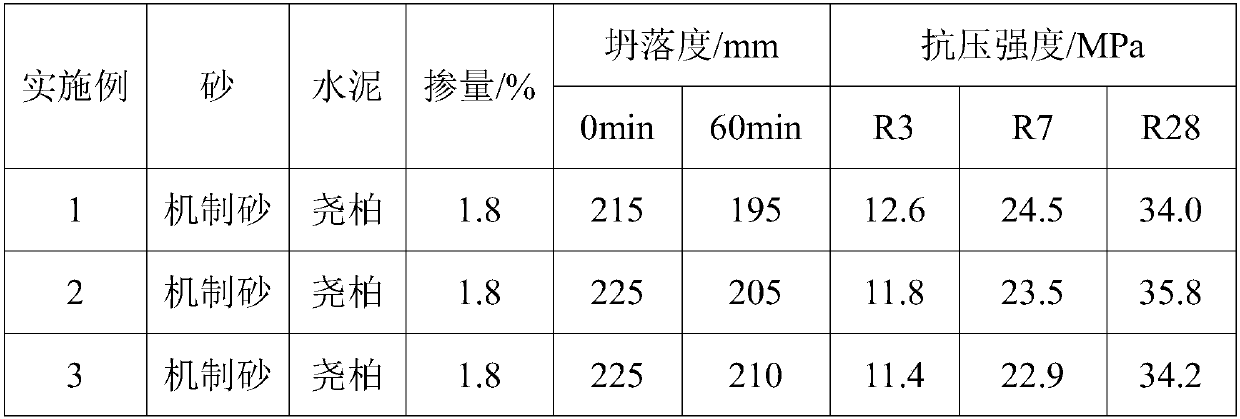

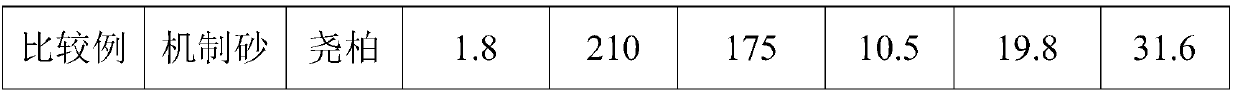

Embodiment 1

[0026] Add 24g of isobutylene alcohol polyoxyethylene ether (2400) to the reaction vessel equipped with a stirrer, add 24g of distilled water, stir to dissolve it, then dissolve 0.58g of sodium bisulfite, wait until the temperature rises to 55°C, and start adding dropwise Component 1 (formed by dissolving 1.85 g of acrylic acid and 0.4 g of 2-acrylamido dodecyl sulfonic acid successively in 6 g of distilled water) and component 2 (formed by dissolving 0.58 g of initiator sodium persulfate in 6 g of distilled water) into); dropwise for 2.0 hours, keep warm for 3 hours, wait for the reactant to cool to room temperature, adjust the pH value to between 6 and 7 with monoethanolamine, and obtain a polycarboxylate water reducer suitable for machine-made sand.

Embodiment 2

[0028] Add 24g of isobutylene alcohol polyoxyethylene ether (2400) to the reaction vessel equipped with a stirrer, add 24g of distilled water, stir to dissolve it, then dissolve 1.15g of sodium bisulfite, wait until the temperature rises to 70°C, start adding dropwise Component 1 (formed by successively dissolving 3.25 g of acrylic acid and 0.60 g of 2-acrylamido dodecyl sulfonic acid in 6 g of distilled water) and component 2 (formed by dissolving 1.15 g of initiator ammonium persulfate in 6 g of distilled water) into); dropwise for 3.0 hours, keep warm for 2.0 hours, wait for the reactant to cool to room temperature, adjust the pH value to between 6 and 7 with diethanolamine, and obtain a polycarboxylate water reducer suitable for machine-made sand.

Embodiment 3

[0030] Add 24g of isobutylene alcohol polyoxyethylene ether (2400) to the reaction vessel equipped with a stirrer, add 24g of distilled water, stir to make it dissolve, then dissolve 0.85g of sodium bisulfite, wait until the temperature rises to 60°C, start adding dropwise Component 1 (formed by successively dissolving 2.25 g of acrylic acid and 1.0 g of 2-acrylamido dodecylsulfonic acid in 6 g of distilled water) and component 2 (formed by dissolving 0.85 g of initiator potassium persulfate in 6 g of distilled water) into); add dropwise for 2.5 hours, keep warm at 60°C for 2 hours, wait for the reactant to cool to room temperature, adjust the pH value to between 6 and 7 with monoethanolamine, and obtain a polycarboxylate water reducer suitable for machine-made sand.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com